Page 1

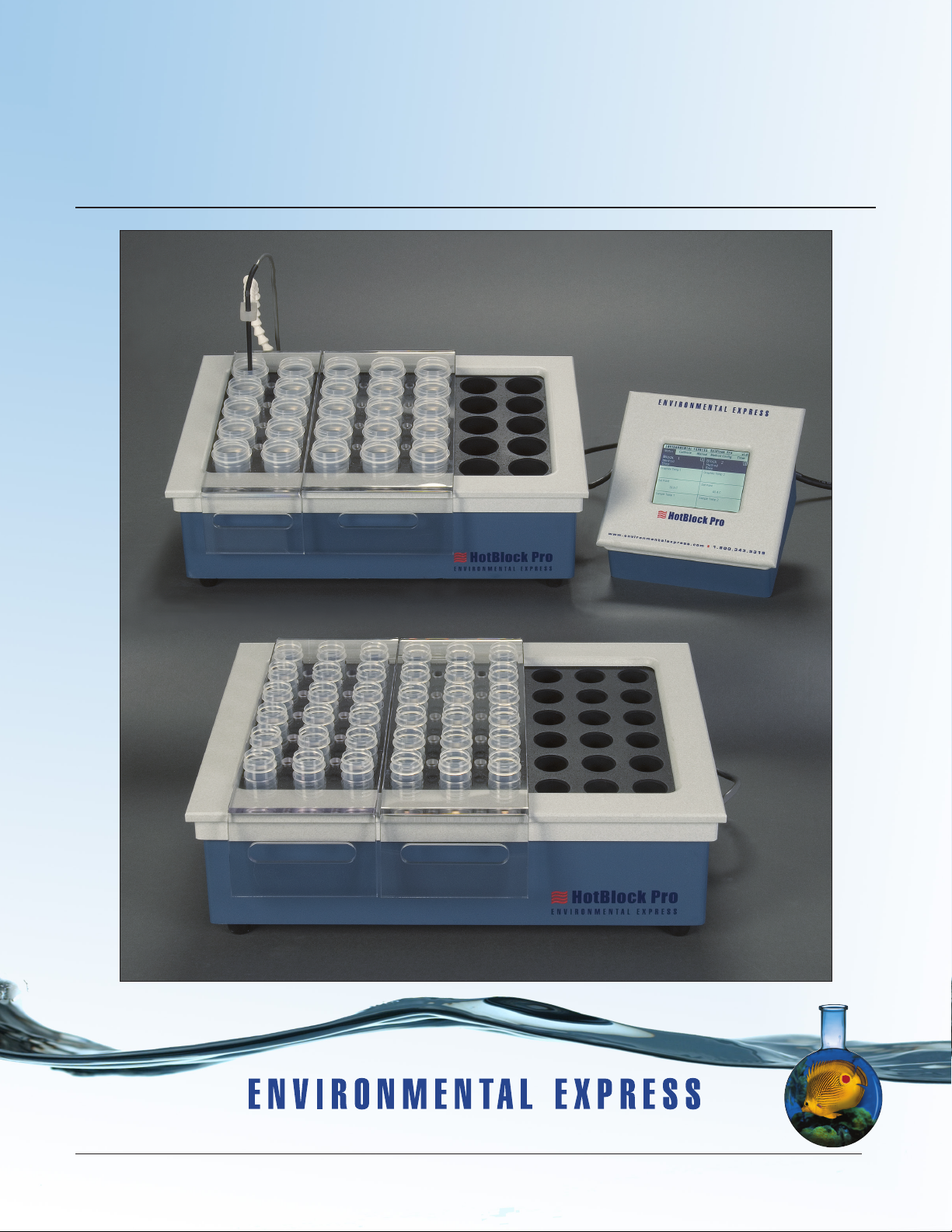

HotBlock™ Pro™ Digestion System

Operation & Instruction Manual

Call 800.343.5319 or 843.881.6560 • www.environmentalexpress.com

Copyright Environmental Express, Inc, August 2012

Page 2

HotBlock™ Pro™: Operation and Instruction Manual Contents

Dear Valued Customer,

Thank you for purchasing a

HotBlock™ Pro™ Digestion System from

Environmental Express.

We pride ourselves on

providing innovative

products designed

to improve accuracy,

efciency, and safety

in your laboratory. Please take some

time to read your product manual

before using your HotBlock™ Pro™.

As always, our Technical Sales

and Technical Support Teams are

available to assist with any questions

you have regarding our products.

Best Regards,

Al Jurgela

Chief Executive Ofcer

Environmental Express, Inc.

Contents

General Information

Warranty and Repair Policy 1

Declaration of Conformity 2

About Your HotBlock™ Pro™

Part Numbers / Model Information / Specications 4

Getting Started

Installation / Safety / Maintenance 5-6

Operation Using the HotBlock™ Pro™ Controller 8-12

HotBlock™ Pro™ Parts and Supplies

HotBlock™ Pro™ Accessories 13

Sample Filtration Supplies 14

AirLite HEPA-Filtered Enclosure 15

GhostWipes for Surface Sampling 16

Adaptation of EPA Methods for Use with Your HotBlock

TM

EPA Approval Letter 17

Method 200.2 18

Method 200.7 19

Method 200.8 20-21

Methods 245.1, 7470, and 7471 for Mercury Digestions 22

Method 365.2 for Phosphorus 23

Method 3050B 24

NIOSH Method 7303 25

Sample Preparation for Lead Analysis Using the Ghost Wipe 26

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express

Page 3

HotBlock™ Pro™: Operation and Instruction Manual Warranty

Limited Warranty

The HotBlock™ Pro™ blocks and controller are warranted against defects in materials and workmanship when used in

accordance with applicable instructions, for a period of one year from the date of shipment. This warranty extends to parts,

labor, and any approved transportation charges. This warranty applies only to damage or failure caused by normal laboratory

use. The warranty is limited to product repair. If Environmental Express, Inc. is unable to repair the HotBlock™ Pro™, the

customer may, at his or her option, receive a replacement unit or a full refund. Operating the HotBlock™ Pro™ at temperatures

higher than 180°C will void the warranty.

Environmental Express makes no other warranty, expressed or implied for this product with respect to merchantability,

tness for a particular use or any other matter. Environmental Express is not liable for any consequential or compensatory

damages arising from use of, or in conjunction with this product. The maximum liability shall be the invoice price of this

product.

Repair Policies

Under Warranty Repair:

If the HotBlock™ Pro™ should fail to operate within the warranty period (one year from date of shipment) Environmental

Express will repair it and ship it back to the customer at our expense. The remainder of the warranty period will be honored

from the original ship date. Environmental Express will bear the cost of ground transportation both to and from the

customer’s location, and bear the cost of any parts, labor and cleanup required. However, if it is determined that the damage

to the HotBlock™ Pro™ was caused by negligence or improper use, this warranty will not apply. The warranty is also void if

the system is used beyond its intended purpose or in the event of any unauthorized repair. In such cases, reasonable and

customary repair charges will apply. Repair charges will be quoted prior to work being done.

Out of Warranty Repair:

If the HotBlock™ Pro™ fails after the warranty period has lapsed, the repair procedure is as follows:

First, notify an Environmental Express customer service representative of product’s failure and place an order for repair.

Whenever possible, our customer service technician will walk you through possible troubleshooting scenarios which may

enable you to repair your block on site.

If on-site repair is not possible, the customer may return the non-working unit to Environmental Express using

A manually operated HotBlockTM loaner MAY be available during the repair period. There are only a limited

number of these units. A reasonable charge for “cleanup” will be charged if a loaner is issued. The customer will be

responsible for all shipping charges associated with a loaner unit.

Call 800.343.5319 or 843.881.6560 • www.environmentalexpress.com

2345 A Charleston Regional Pkwy • Charleston, SC 29492

Product Information:

Item # Date of Purchase

HotBlock™ Pro™ Serial #

Please record the serial # of your HotBlock™ Pro™ here for easy reference. Your serial # is located on the back of your HotBlock™ Pro™.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 1

Page 4

HotBlock™ Pro™: Operation and Instruction Manual Declaration of Conformity

The manufacturer ,Environmental Express, 2345A Charleston Regional Parkway,

Charleston, SC 29492 declares that the following products, AutoBlock™, HotBlock™

and HotBlock™ Pro™ Model Numbers SC810, SC812, SC196, SC154, SC150,

SC151, SC100, SC180, SC181 and SC182, conform to the requirements of the

directives73/23/EEC & 89/336/EEC.

Standards to which conformity is declared:

Safety: EN 61010-1

Safety requirements for electrical equipment for

measurement, control and laboratory use,

Part 1: General requirements.

EN 61010-2-10

Safety requirements for electrical equipment for

measurement, control and laboratory use,

Part 2: Particular requirements for laboratory

4000040

EMC: EN 50082-1: 1997

Electromagnetic Compatibility – Generic immunity

standard, Part 1: Residential, commercial and light

industry. C22.2.61010.2.01

Environmental Express, Inc. declares that all HotBlocks

conform with the essential requirements of the

applicable EC directives.

equipment for the heating of materials (with

Amendments).

Signed: ________________________________________

Al Jurgela, Chief Executive Ofcer

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 2

Page 5

HotBlock™: Operation and Instruction Manual General Information

HotBlock™ Pro™ SC181

HotBlockProTM Controller SC180

External Thermocouple SC183

Above, the 54-well HotBlock™ Pro™ for 50mL samples is shown with the external controller.

The optional external thermocouple (shown left, in a specially designed holder) can be used

to monitor and record sample temperatures.

The separate controller is designed to work with one or two blocks. See individual block

specications. For digestion vessels and accessories, see pages 13-16.

Specications for SC181:

Block Footprint: 21.5”w x 15”d x 6.5”h

Block Weight: 58 lb.

Sample Capacity/Sample Size: SC181 - 54 sample, 50mL

Electrical: 110V, 9A per block

Block Temperature Range: Ambient to 180°C

Block Temperature Resolution: 0.1°C

Block Temperature Uniformity: ± 0.2°C (measured across block)

Controller Dimensions: 12”w x 10.5”d x 8”h

Controller Weight: 13 lb.

Internal Thermocouple: Type K

External Thermocouple: Records sample temperature

Part Number SC183

3 • Environmental Express www.environmentalexpress.com / 800.745.8218 / 843.576.1147

Page 6

HotBlock™ Pro™: Operation and Instruction Manual Part Numbers / Model Information / Specications

HotBlock™ Pro™ SC182

HotBlock™ Pro™ Controller SC180

Above, the 35-well HotBlock™ Pro™ for 100mL samples is shown with the external

controller. The separate controller is designed to work with one or two blocks. See

individual block specications. For digestion vessels and accessories, see pages 13-16.

Specications for SC182:

Block Footprint: 21.5”w x 15”d x 6.5”h

Block Weight: 54 lb.

Sample Capacity/Sample Size: SC182 - 35 sample, 50mL

Electrical: 110V*, 9A per block

Block Temperature Range: Ambient to 180°C

Block Temperature Resolution: 0.1°C

Block Temperature Uniformity: ± 0.2°C (measured across block)

Controller Dimensions: 12”w x 10.5”d x 8”h

Controller Weight: 13 lb.

Internal Thermocouple: Type K

External Thermocouple: Records sample temperature

Part Number SC183

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 4

Page 7

HotBlock™ Pro™: Operation and Instruction Manual Installation, Safety & Maintenance

Environmental Express HotBlockTM Pro Series

Environmental Express HotBlock™ Pro™ Series provides an efcient method of digesting and storing water, wastewater,

soil and sludge samples for metals analysis. These innovative digestion systems allow samples to be digested in a corrosionfree environment using an external touch screen controller. Samples are handled in a small area with minimal radiant

heat loss. Users should be aware of potential dangers from heating certain types of compounds. Such hazards may include

explosion or the release of toxic or ammable gases.

Denitions/Markings

Each HotBlockTM Pro displays certain markings and symbols. All personnel working with the HotBlock™ Pro™s should

have an understanding of the following symbols and denitions:

• V = voltage

• ~ = alternating current

• Hz = frequency

• A = amperes

This symbol means Caution

Hot Surface. The surface of the

HotBlock

safely touch with bare hands.

TM

may be too hot to

This symbol means Read

and become familiar with

instructions before operation of

instrument.

Installation of your HotBlockTM Pro:

1. Plug the controller into an appropriate outlet. The HotBlockTM Pro must be plugged into a 20AMP receptacle.

2. The cord running from Block 1 plugs into the corresponding receptacle on the back of the controller. If using two

blocks, attach the cord from Block 2 to the controller in the appropriate receptacle.

If external thermocouple probes (optional) are NOT being used insert the two plugs included into the RTD1 and

RTD2 receptacles on the back of the controller.

If external thermocouple probes ARE to be used insert your probe plugs into these receptacles. RTD1 receptacle

corresponds to Block 1.

3. The HotBlockTM or blocks should be located in a vented enclosure while the controller must remain outside the

enclosure for ease of operation and to keep the controller removed from the corrosive digestion environment. (See

installation requirements, page 6).

Failure to locate your HotBlock

TM

controller outside the fume hood will void your product warranty.

Installation Requirements

Locate the HotBlockTM Pro under a fume hood with a minimum face velocity of 100fpm, and allow a minimum of 2” of

space on all sides. The following environmental conditions should be observed:

• Ambient temperature range: 5-45°C

• Ambient relative humidity: 0-100%RH

• Altitude: sea level to 2500 meters

HotBlockTM Pros are rated as Pollution Degree 2 and Installation Category 2.

The HotBlockTM Pro Controller MUST be located outside the fume hood. Failure to do so will void your product warranty.

5 • Environmental Express www.environmentalexpress.com / 800.745.8218 / 843.576.1147

Page 8

HotBlock™ Pro™: Operation and Instruction Manual Installation, Safety & Maintenance

Electrical Requirements

Required Voltage: 120 volts, ~60Hz,

Current: 9A per block

(all HotBlockTM Pros are also available in 240V with CE mark)

The HotBlockTM Pro controller is supplied with a 20A male electrical plug. This safety feature requires that the unit is

connected to a 20A receptacle.

Power should not vary greater than±10%. Connecting to the power supply must be done with the supplied heat-resistant

power cord or equivalent.

For safety reasons, a separate power receptacle should be provided for HotBlockTM Pro system. Do not use extension cords

or outlet adaptors. Make certain that power outlets are earth-grounded at the grounding pin.

Potential Hazards:

The HotBlockTM Pro should only be operated by properly trained personnel using standard laboratory safety practices.

Use extreme caution when operating the HotBlockTM Pro digestion blocks. Plastic and graphite surfaces of the blocks may

be too hot to safely touch with bare hands.

The HotBlockTM Pro components contain electrical circuits and devices and compounds operating at dangerous voltages.

Contact with these circuits, devices and components can cause serious injury or painful electric shock.

Proper grounding is essential to avoid a potentially serious electric shock hazard. Ensure that there is an internal ground

connection between the metal base of the system and the 3-pin earth-grounded receptacle.

For safety reasons a separate power outlet receptacle should be provided for each HotBlockTM Pro system. Do not use

extension cords or outlet adaptors. Make certain each power outlet is earth-grounded at the grounding pin.

See individual block specications for power requirements, pages 3-4.

Application of the wrong supply voltage can create a re hazard and a potentially serious shock hazard, and could

seriously damage the HotBlockTM Pro system. See specications for individual components.

Users should be aware of potential dangers from heating certain types of compounds. Such dangers may include the

release of toxic or ammable gases or explosion.

Maintenance:

Any service inquiries should be directed to Environmental Express Inc. Technical Service Department.

After each use, clean exterior surfaces with a damp sponge to remove acid residue.

For acid spills, sponge with a diluted solution of sodium bicarbonate followed by distilled water. Acid that is spilled

directly into the digestion wells should be neutralized and removed.

Before using any cleaning or decontamination methods except those recommended, check with Environmental Express to

conrm the proposed method will not damage your HotBlockTM Pro.

Avoid excessive spills, as liquid allowed to overow into the HotBlockTM Pro casing can seriously damage electronic

components.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 6

Page 9

HotBlock™ Pro™: Operation and Instruction Manual Installation, General Information

HotBlockTM Temperature Settings:

The pre-set factory “set point” temperature of your HotBlockTM is 106°C. Factory tests have shown that this temperature is

“sea level safe.” Liquids in uncovered polypropylene tubes should not boil at this setting. Please note that the set point of the

block is not the same as the temperature of the liquids being digested. The block temperature should be optimized for the

specic digestion. The temperature of liquid contents of the digestion cup will vary according to:

• The material being digested

• The number of samples being digested

• The air movement of the digestion area

• The addition of a watch glass or reux cap

If watch glasses are being used, the control point temperature should be

lowered approximately 10°C to avoid boiling.

Note The maximum sample temperature tolerance for our polypropylene digestion

vessels (SC475) is 130°C.

Remember that the temperature display (current block temperature) is not the

temperature of the sample. Sample temperature will usually be 5-15° less than

the display temperature.

Adjusting the Temperature of Your HotBlockTM:

1. Plug the HotBlockTM into an approved receptacle. Turn the HotBlockTM on by pressing the button on the back of the unit.

Wait until the display shows the current block temperature (in red) and the set point temperature (in green).

2. Press and hold or tap the or key. The display will show the set point temperature on the right in blue. The

adjustment is from ambient to 150°C in increments of 0.1°C. There is no need to press the green (advance) or ∞ button.

Safe-Sample™ Temperature Protection:

Your HotBlockTM is protected from runaway temperatures by a fail-safe alarm system. In the unlikely event that the heating

system fails to respond to the controller, the Safe-Sample™ system will automatically shut the system off and sound an audible

alarm.

This alarm sequence occurs if the actual temperature of the block reaches a temperature that is fteen degrees higher

than the set point temperature. If this should occur, the HotBlock

HotBlockTM must be turned off, then turned back on to reset the alarm.

If the alarm sounds, see the troubleshooting section of this manual, page 11-13.

TM

will stop heating, preventing the loss of samples. The

7 • Environmental Express www.environmentalexpress.com / 800.745.8218 / 843.576.1147

Page 10

HotBlock™: Operation and Instruction Manual Operation

Easy, Intuitive Operation Using the HotBlock™ Pro™ Controller

The HotBlockTM Pro controller, catalog # SC180, provides operational control of either one or two HotBlock™ Pro™

digestion blocks simultaneously. The two blocks controlled may be either the SC181 for 50mL samples, the SC182 for 100mL

samples or any combination of the two styles. The SC180 controller also works with just one digestion block and does not have

to have two digestion blocks connected. The controller continually measures block temperature throughout the digestion

process. The optional external thermocouple (SC183) may be used to measure sample temperature. These temperatures are

continually displayed on the full color screen in the STATUS mode.

The full color, touch screen is easy to navigate. To move from screen to screen simply touch the name of the desired

screen at the top of the touch pad with your nger (see screen illustrations below).

The color touch pad controller has four operating screens. They are the Status screen, Calibrate screen, Method screen and

Timer screen.

Following are descriptions and illustrations of these screens and their functions.

The Status Screen Continually Displays Current Operating Conditions.

The rst screen to appear will give you the option

of choosing BLOCK 1 or BLOCK 2. Choose the appropriate

Block.

• Next, the STATUS screen will appear. When operating two

blocks you can toggle between the two by pressing the strip at

the top of the screen. BLOCK 1 STATUS is shown in the sample

screen pictured bottom right. To view the status of two blocks

simultaneously, press the STATUS key in the lower right corner

of your screen. The STATUS screen continually displays current

operating conditions of each digestion block throughout the

digestion process. This screen allows the analyst easy access to

essential information including the method in progress, block

temperature, set point temperature and sample temperature.

The top of the STATUS screen displays the method number

and the step number of the method being performed for

each block. Individual blocks may perform different methods

simultaneously.

• The STATUS screen continually displays the actual temperature

of each graphite block in operation as well as the set point

temperature of each block. When an external thermocouple

is used, the STATUS screen displays the sample temperature.

When the external thermo-couple is NOT in use, the Sample

Temp eld displays ***.*.

• Please note that the HotBlock™ Pro™ does not control the

sample temperature directly, only the block temperature. The

relation of the sample temperature to the block temperature

is affected by variables including sample type, environmental

conditions and use of watch glasses or similar devices.

• If there is a programmed SOAK time, the STATUS screen

displays the time remaining in the SOAK period. The SOAK

cycle will not begin until the temperature is within 3°C of

SET POINT temperature. The ashing green light (bottom left)

signals that the SOAK cycle has begun.

The rst screen to appear when you turn on your block gives you the option

of choosing Block 1 or Block 2. Choosing either block will take you to the

STATUS screen.

When you choose the Block you want to monitor, The STATUS screen will

appear. You have the option of monitoring either Block 1 or Block 2 or both

Blocks simultaneously.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 8

Page 11

HotBlock™: Operation and Instruction Manual Operation

The Calibrate Screen Allows the Operator to Calibrate Block and Sample Temperatures.

• To calibrate the Graphite Block

Temperature, run a method (see

page 10) to achieve an appropriate temperature. For most labs

90°C should work. Allow the block

temperature to stabilize. This may

take 20-30 minutes.

Measure the temperature of the

block at several points with a

surface thermometer or IR thermometer and take an average of

the readings. If wells are lled

with DI water please note that the

temperature cannot be higher than

100°C. Do not use cups for this

calibration.

Once an average and stable tem-

perature is achieved, press Offset

Adj (Graphite Temp 1). A keypad

will pop up prompting you to enter

the appropriate temperature in

degrees. Use your set point and

your average measured temperature to calculate your Offset Adj. To decrease the temperature press (-). When you have

correctly entered the appropriate temperature, press ENTER. You will automatically return to your CALIBRATION screen.

Example: Set Point = 90°C

Measured Temperature (Actual) = 91.2

Offset Adj = (-) 1.2

Calibration of blocks and samples in fast and easy using the CALIBRATE function of your controller.

• To calibrate the External Thermocouple, the use of a NIST traceable thermometer is recommended. First ll several digestion vessels

with a representative sample or a reagent blank and place them in random wells in your block. Insert both the external

thermocouple and the NIST thermometer in each sample. Calculate an average of these sample temperatures. Once an average

and stable temperature is achieved, press Offset Adj (Sample Temp 1). A keypad will pop up prompting you to enter the appropriate

temperature in degrees. Use your set point and your average measured temperature to calculate your Offset Adj.To decrease the

temperature press (-). When you have correctly entered the appropriate temperature, press ENTER. You will automatically return to

your CALIBRATION screen.

Example: Set Point = 90°C

Measured Temperature (Actual) = 91.2

Offset Adj = (-) 1.2

Note: Each external thermocouple-to-block connection is unique. An external thermocouple can only be calibrated to one port of one controller at

a time. If the external temperature controller is used in a different port, then the calibration procedure must be repeated.

9 • Environmental Express www.environmentalexpress.com / 800.745.8218 / 843.576.1147

Page 12

HotBlock™ Pro™: Operation and Instruction Manual Operation

Digestion Methods Can Be Created and Stored

Using the Method Conguration Screen.

Individual digestion methods can be created and stored by

the HotBlock™ Pro™. Each method can have up to six steps. Each

step is a combination of temperature, ramp rate and soak time.

The HotBlock™ Pro™ can store as many as 15 individual methods.

Methods can be saved by number for future use.

• To program a method, select the METHODS tab on the

controller. Select the Method Number you wish to program,

then select View/Edit (Figure 1).

• This takes you to the screen (shown right, Figure 2) which

displays six steps and programmable parameters for each

step. Program each parameter individually from this screen.

• To program your rst step, select (Y) STEP ONE (see Figure

2). Program each parameter of Step one. As you press each

parameter, a keypad will appear prompting you to enter the

appropriate data.

For example, press the TEMP eld, type the appropriate

temperature in the pop-up box (range 20-180°C) and

press ENTER.

Follow this procedure for RAMP (maximum ramp is

3.0°C/min).

Select SOAK and type in the hours HH (99 maximum)

followed by the minutes MM (59 maximum).

If no (0:00) SOAK TIME is set, the step is automatically

inactive and the controller will skip to the next step in the

method. If all subsequent steps have no SOAK TIME, the

program is ended and the block will stop heating.

• After entering all your parameters for Step 1, proceed to

Step 2 of your method. Continue programming up to six

steps for each method.

• If an automatic PAUSE is necessary before continuing to

the next step, program the pause by changing NO to YES

in the PAUSE column (see Figure 2). At the appropriate

time in the method, the sequence will PAUSE. A pop-up

box will show you that the method is paused. Press

CONTINUE to continue to the next step.

Figure 1. Selecting Method from the main menu will take you to the screen shown above

(Figure 1). Click on the Method Number you wish to program.

Figure 2. From this screen you will program each step of your method. Select Step 1, select

the parameter you wish to set. Enter the appropriate data in the pop-up keypad and press

ENTER. Continue to the next parameter.

A pop up box will show you that your method has PAUSED as programmed.

Press CONTINUE to continue to the next step in your method.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 10

Page 13

HotBlock™: Operation and Instruction Manual Getting Started

Easily Name Your Programmed Methods.

Name your method AFTER programming all your steps and

parameters as described on page 10. To name a method, go to the

METHOD tab. Select the method number you wish to name, then click

on VIEW/EDIT. This will take you to the screen shown here (Figure

1). Click on the GRAY BAR (indicated in gure 1 by the red arrow) at

the top of the screen under the TABS. When you click on this bar, a

pop-up keypad will allow you to type in the method name. Then press

ENTER. When you choose the METHOD NUMBER you wish to run, the

METHOD NAME will appear in the BLUE BOX at the bottom of the

METHOD screen (see METHOD screen, Figure 2).

Method Screen, Figure 1. When you click on the gray bar, a pop-up keypad will enable you

to type in the method name.

Easily Initiate a Stored Method.

To start a stored method go to the METHOD screen. Press the

METHOD button you wish to use, Then press RUN ON BLOCK 1 or

RUN ON BLOCK 2 accordingly.

Please note that the SOAK timer will not appear on the STATUS screen or

start counting down until the block temperature is within 3°C of

SET POINT temperature.

Method Screen, Figure 2. To initiate a stored method go to the METHOD screen

and select the number of the method you wish to run. The method name will

appear in the blue box at the bottom of the screen.

11 • Environmental Express www.environmentalexpress.com / 800.745.8218 / 843.576.1147

Page 14

HotBlock™ Pro™: Operation and Instruction Manual Operation

A Method Can Be Aborted at Any Time During the Digestion Process.

If you need to abort a digestion procedure during the program,

press the STOP button on the STATUS screen.

Abort a method at any time from the STATUS screen.

The Timer Screen Can Be Used to Time Manual Digestions or Other Laboratory Functions.

The timer screen is an independent countdown timer that can be

used to time manual digestions or other laboratory functions. Press the

TIMER box, then press TIME. Program the time in minutes using the

pop-up keypad and press ENTER. To start the timer press START. To cancel,

press STOP. There is no pause function on the timer. A pop-up box will

appear when the timed cycle is complete. TIME REMAINING continually

shows progress of the timed cycle.

Monitor progress of a timed method on the TIMER screen. A pop up box

alerts you when the timed cycle is complete.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 12

Page 15

HotBlock™ Pro™: Operation and Instruction Manual Parts & Supplies

SC475 — Polypropylene Screw Cap Digestion Vessels for

Use With HotBlock™ Pro™ SC181

These carefully engineered digestion vessels provide premium performance in your

HotBlock™ Pro™. Molded of claried homopolymer polypropylene, these vessels provide a

higher working temperature and greater chemical resistance than commonly used copolymer polypropylene. Each vessel is graduated to 50mL and has a total capacity of 68mL.

Molded-in graduations are extremely accurate, allowing analysts to easily reproduce volumes

to within 0.5%. Using the graduated vessels for sample measurement reduces the need for

graduated cylinders and volumetric asks and eliminates sample transfers. The result is a

“one-cup” system that greatly reduces labor and costs associated with metals preparation.

The 33mm threaded cap is lined with a 0.040” polyethylene faced foam liner for a leak-proof

seal. Only the metals-free polyethylene liner comes into contact with the sample. SC475

vessels come in cases of 500 and are packaged to ship as a standard size UPS package,

keeping shipping costs at a minimum. Vessels come standard with green caps. White caps

are also available (SC480-W).

• Certied for low metals background • Compact packaging reduces shipping costs

• Lined closure system ensures leak-free • Accurate graduations eliminate the need

performance with no contamination for graduated cylinders

SC505 — Ribbed Watch Glasses

44mm ribbed watch glasses t all 50mL digestion vessels. Polypropylene construction is naturally free of

contaminant’s. Ribbed design allows partial reux during digestion. Watch glass has a center stem to aid in

handling. Pack of 1,000.

SC506 — Reux Caps

Special cap has a 0.5” hole in its center to allow the addition of reagents while cap

remains in place on the SC475 digestion vessel. The reux cap does not have to be removed

during the digestion process. The cap is not ribbed, but ts over the top of the SC475 digestion vessel to maintain a centered position. Tests have shown equal reux between SC506

reux cap and SC505 watch glass. Pack of 1000.

SC200 — Polycarbonate Transfer Racks

Each sample transfer rack for the HotBlock™ is designed to hold and handle eighteen SC475 50mL digestion

vessels. Racks are made of polycarbonate for heat and acid

resistance and t over the HotBlock™ to facilitate handling

of samples and improve temperature and evaporation

uniformity.

SC446 — Plastic Storage Racks (not pictured)

24 cup capacity plastic racks neatly hold the SC475

digestion cup. Made of polypropylene, racks accommodate

any tube up to 30mm and are stackable for efcient storage.

13 • Environmental Express www.environmentalexpress.com / 800.745.8218 / 843.576.1147

Page 16

HotBlock™ Pro™: Operation and Instruction Manual Parts & Supplies

SC446 — Urethane Foam Storage Racks (not pictured)

Low cost storage system uses high density urethane foam for semi-permanent storage of digested samples. Each rack holds

25 capped SC475 digestion cups. Racks with cups may be stacked to save space. Overall size of rack is 10” x 10” x 1”. Pack of 5.

Accessories for SC182 HotBlock™ Pro™

SC490 — Polypropylene Screw Cap Digestion Vessels for use with SC182 HotBlock™

This 125mL, wide-mouth digestion vessel is supplied with a 48mm screw cap. The cap is lined with coextruded

polyethylenefoam for leak-proof performance. Made of homopolymer polypropylene, the SC490 digestion vessel is designed

for use in the SC182 HotBlock™. Vessels are graduated at 10mL, 25mL and 50mL, 75mL and 100mL and are packaged in cases

of 200.

SC225 — Polycarbonate Racks for SC182 HotBlock™

This set of two polycarbonate racks was designed to t the SC150 Hot Block (see photo page 4). A 15-place rack

paired with a 10-place rack give you 25 sample capacity. Racks t the SC150 HotBlock™ securely for safe accurate digestions.

SC 7150 — Wire Storage Rack for SC490s

Powder coated wire rack shown above is for storing SC490 cups. Rack has an 18 cup capacity.

SC610 — Ribbed Watch Glass

52mm ribbed watch glass is designed for use with SC490, 125mL digestion vessel. Polypropylene watch glass has

a stem in its center to aid in handling.

FilterMateTM Filtration Systems For Use With SC475 Digestion Vessels

Dirty or particulate-laden samples may require that the digested sample be ltered

prior to analysis. This is especially true with sludge, wastewater and soil samples.

FilterMate™ Systems provide a convenient and inexpensive method of ltration that

requires no transfer steps. The FilterMate™ ts directly into the digestion cup and is pushed

through the liquid being ltered to the bottom of the cup with a detachable plunger. After

the ltration is complete, the plunger is removed and discarded while the lter assembly

remains in the bottom of the cup. This arrangement does not interfere with storage or use

of the cup in an autosampler.

FilterMates are available with different choices of lters:

SC0401 — Standard 2μm PTFE-faced Polypropylene Filter

The popular SC0401 has the highest dirt holding capacity. This is the

most popular and is suitable for most laboratory applications.

SC0408 — Certied 2μm PTFE Filter

The SC0408 FilterMate™ utilizes a pure expanded ber PTFE lter. This

high dirt trapping FilterMate™ is especially suitable for trace level analysis

and is supplied with lot certication for trace metals by ICP/MS.

SC0407 — 0.45μm PTFE Membrane Filter

The SC0407 FilterMate™ uses a PTFE prelter in addition to a 0.45μm nal lter.

This model is not recommended for particulate laden samples.

SC0404 — 0.7μm Glass Fiber FilterMate™ for TCLP

For ltering small volumes of TCLP extract, we offer the SC0404 FilterMate™ with acid-washed glass ber lter material

suitable for TCLP ltrations. The 0.7μm lter is supported by a porous polyethylene frit.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 14

Page 17

HotBlock™: Operation and Instruction Manual Parts & Supplies

Use FilterMate™ for Field Filtrations

If your method requires ltration in the eld prior to analysis, the FilterMate™ offers an easy and inexpensive alternative to cumbersome pumps and devices commonly used for this procedure. With just two SC475 digestion cups and one SC0407 FilterMate™, you can

meet the requirements of eld ltrations. Simply take your sample in one SC475 cup, lter with a SC0407 FilterMate™, pour the ltrate into

another cup and cap.

SC0510 — Holder for FilterMate™ Filtrations

This machined HDPE xture adds stability when

performing FilterMate™ ltrations. Digestion cup is placed

into center hole of FilterMate™ Holder prior to beginning

ltration. The holder secures the digestion cup as the FilterMate™ is depressed through the liquid sample.

SC801 — AirLiteTM HEPA-Filtered Enclosure

This bench-top enclosure for the HotBlock Pro™

provides HEPA-ltered air for cleaner, more uniform

digestions. The AirLite uses a quiet, 117 CFM internal PVC

coated fan that is easily accessible by the technician. The

cabinet of the AirLite is constructed from PET-G for

exceptional clarity. The door of the hood opens a full 180°

to allow unrestricted access to the chamber. The body of the

enclosure rests in a thermoformed Kydex® bottom that traps

spills and can easily be removed for cleaning. The AirLite is

designed to enhance the use of the HotBlock Pro™and can

reduce sample contamination during the digestion process.

The HEPA lter can be changed in minutes. The AirLite can

be used anywhere a clean environment is required. It can

be exhausted with standard 4” exible duct to the outside or

into existing ductwork. Spare 117CFM fan included.

Specications —

Size: 25.5” h X 32” w X 24” d

Door Opening Size: 32” W X 17” h

Materials: Acrylic walls and door, Kydex® top and

bottom plates

Fan: 117CFM, PVC Coated

Electrical: 120VAC, 1 amp, 3-Prong plug

15 • Environmental Express www.environmentalexpress.com / 800.745.8218 / 843.576.1147

Page 18

HotBlock™: Operation and Instruction Manual Parts & Supplies

Ghost WipeTM For Surface Sampling

Including Lead and Beryllium Testing This revolutionary product eases sample

preparation and analysis of surface lead or surface dust. The Ghost Wipe is a sturdy wiping

material moistened with DI water that holds together even on the roughest wiping surfaces.

In the lab, the Ghost Wipe readily and completely dissolves during the digestion process.

This feature provides more complete dispersion of analytes and more uniform recoveries.

In addition, there is no messy brous material to clog sample uptake capillary or

nebulizer. Ghost Wipes meet all ASTM Designation E1792 specications for sampling

materials for lead in surface dust. Wipes are 15cm x 15cm and are supplied in individual

sealed packets.

SC4210 —Case of 500 Ghost Wipes

SC4250 —Case of 1,000 Ghost Wipes

C1010 — Dust Sampling Template, 10cm x 10cm, pack of 250

C1012 — Dust Sampling Template, 12” x 12”, pack of 100

Meets ASTM E1792

Requirements

Take a sample with Ghost Wipe. Digest as usual in acid solution.

Ghost wipes totally dissolve during

digestion for easy analysis.

Lead Wipe Standard in Screw-Cap, Rigid-walled Cup (SC475)

The lead wipe standard is a Ghost Wipe spiked with in-situ dust. Using an NIST traceable solid sample, known amounts of lead are

placed on a wipe and each sample is individually labeled with the exact amount of lead the wipe contains. Each spike sample contains

175-250 micrograms of lead per wipe and come with a certicate of analysis showing the Sample ID# and the starting concentration

of the dust.

Catalog #SC4252 Box of 10

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 16

Page 19

HotBlock™: Operation and Instruction Manual EPA Approval Letter

17 • Environmental Express www.environmentalexpress.com / 800.745.8218 / 843.576.1147

Page 20

HotBlock™: Operation and Instruction Manual EPA Method 200.2

Adaptation for EPA Method 200.2, Revision 2.8

for use with the Environmental Express HotBlock™ Digestion System

Revised 05.05

Scope and Application:

The following procedures have been written as an aid to EPA digestion procedure 200.2 for use with the Environmental Express

HotBlock. EPA Method 200.2 is for the determination of total recoverable analytes in groundwater, surface water, drinking water, wastewater

and (with the exception of silica ) in solid samples such as sediment, sludge and soil. Use EPA Method 200.2 for reference while following the

sample preparation steps outlined below. A complete list of elements appropriate for analysis is included in EPA Method 200.2. Analysis can

be performed by ame atomic absorption, GF/AA, ICP and ICP-MS.

Apparatus and Materials:

1. HotBlock for Metals Digestions — Model Number SC100, SC150* or SC154

2. Polypropylene Digestion Vessels — Part Number SC475 (or SC490 for use with HotBlock SC150)

3. Ribbed Watch Glasses, Part Number SC505 or Reux Caps, Part Number SC506

(for use with SC490 vials for HotBlock SC150, use Ribbed Watch Glasses, Part Number SC610 )

4. FilterMateTM — Part Number SC0401 (or appropriate FilterMate) for sample ltration if necessary

*Note: For all procedures, when using the SC150 block with the SC490 digestion vials with a 100mL sample, double the volume of all reagents and

acids added.

Procedure, Aqueous Sample Preparation:

1. Mix sample thoroughly to achieve homogeneity. For each digestion procedure, transfer a 50mL sample (or appropriate volume for

your lab) into the SC475 polypropylene vessel. For best results, weigh the sample directly in the vessel on a tared balance.

2. Add 1mL (1:1) HNO3 and 1mL (1:1) HCl, then swirl. Heat the sample in the HotBlock at 95°C for 2.5 hours without boiling. Place a

ribbed watch glass (SC505) on top of the digestion vessel.

Note: When using a watch glass, adjust the control point temperature of the HotBlock so that a 50mL, 5% acid solution is heated to 85°C BEFORE placing

the watch glass over the sample. Laboratory tests have proven that the addition of the ribbed watch glass will add approximately 10°C to the sample temperature, bringing the sample temperature up to 95°C. Refer to page 7 of the operations manual for instructions on HotBlock temperature adjustment.

3. Using the polycarbonate transfer racks, remove samples from the HotBlock and allow them to cool.

4. After cooling, dilute samples to 50mL with DI Water.

5. If necessary, lter with SC0401 (or appropriate FilterMate) to remove insoluble material.

The ltration step should be performed slowly with little pressure placed on the plunger. If excessive backpressure occurs, stop ltration

and allow sediments to “settle out”. Applying pressure to the plunger may cause sample “blow through” allowing sediment to pass through

the lter into the digestate.

Procedure, Solids Sample Preparation:

1. Sieve a dried sample using a 5-mesh polypropylene sieve and grind in a mortar and pestle. Weigh a representative

sample of 0.5 ±0.01g into a digestion vessel.

2. Add 2mL of (1+1) HNO3 and 5mL of (1+4) HCl+DI. Cover with a ribbed watch glass (SC505) or reux cap (SC506), and place in the HotBlock at 95°C. Refer to page 7 of the operations manual for instructions on HotBlock temperature adjustment.

3. Heat sample for 30 minutes.

4. (Optional) Although step 3 is the nal heating step for EPA Method 200.2, if the sample is suspected of having a high concentration of

organic compounds, it is recommend to complete this step: Add 2mL of 30% H2O2 to the well-cooled sample. Allow the exothermic reaction to occur (approximately 10 minutes) and place the sample back in the HotBlock at a temperature of 10° less than the original set

point for an additional 30 minutes. The reaction with the H2O2 raises the sample temperature. Boiling should not occur if the temperature of the HotBlock is lowered.

Note: H2O2 helps aid in the breakdown of high organic compounds in the sample thus creating a more complete digestion.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 18

Page 21

HotBlock™: Operation and Instruction Manual EPA Method 200.7

5. Using the polycarbonate transfer racks, remove samples from the HotBlock™ and allow them to cool completely.

6. Bring sample volume to 50mL with DI water.

7. If necessary, lter with SC0401 (or appropriate FilterMate™) to remove insoluble material.

Note: The ltration step should be performed slowly with little pressure placed on the plunger. If excessive backpressure

occurs, stop ltration and allow sediments to “settle out”. Applying pressure to the plunger may cause sample “blow through”

allowing sediment to pass through the lter into the digestate.

All QC samples, concentration limitations, elemental lists and reagent specications are addressed in depth in EPA Method 200.2.

Safety concerns are also part of the full method. Follow the instructions listed in EPA Method 200.2. These steps should only be used as a

guide to help improve the performance of your HotBlock™.

Adaptation of EPA Method 200.7, Revision 4.4

for use with the Environmental Express HotBlock™ Digestion System

Revised 05.05

Scope and Application:

The following procedures have been written as an aid to EPA digestion procedure 200.7 for use with the Environmental

Express HotBlock™. EPA Method 200.7 is for the determination of total recoverable analytes in groundwater, surface water,

drinking water, wastewater, and (with the exception of silica) in solid samples such as sediment, sludge and soil. Use EPA

Method 200.7 for reference while following the sample preparation steps outlined below. A complete list of elements

appropriate for analysis is included in EPA Method 200.7. Analysis can be performed by ICP.

Apparatus and Materials:

1. HotBlock™ for Metals Digestions — Model Number SC100, SC150*, or SC154

2. Polypropylene Digestion Vessels — Part Number SC475 (or SC490 for use with HotBlock™ SC150)

3. Ribbed Watch Glasses, Part Number SC505 or Reux Caps, Part Number SC506

(for use with SC490 vials for HotBlock™ SC150, use Ribbed Watch Glasses, Part Number SC610 )

4. FilterMateTM — Part Number SC0401 (or appropriate FilterMate™) for sample ltration if necessary

*Note: For all procedures, when using the SC150 block with the SC490 digestion vials with a 100mL sample, double the

volume of all reagents and acids added.

Procedure, Total Recoverable Elements, Aqueous Sample (EPA Method 200.7, Paragraph 11.2):

1. Mix sample thoroughly to achieve homogeneity. For each digestion procedure, transfer a 50mL sample (or appropriate volume for

your lab) into the SC475 polypropylene vessel. For best results, weigh the sample directly in the vessel on a tared balance.

2. Add 1.5mL concentrated HNO3 and swirl. Heat in the HotBlock™ at a sample temperature of 95°C and evaporate to near

dryness (5mL) taking care that the cup does not go dry. This will take approximately four hours.

3. Using the polycarbonate transfer racks, remove samples from the HotBlock™ and allow them to cool.

4. Add an additional 2.5mL of concentrated HNO3. Cover with a disposable watch glass (catalog number SC505) and

reux until digestion is complete.

Note: When using a watch glass, adjust the set point temperature of the HotBlock™ so that a 50mL, 5% acid solution is heated to

85°C BEFORE placing the watch glass over the sample. Laboratory tests have proven that the addition of the ribbed watch glass will

add approximately 10°C to the sample temperature, bringing the sample temperature up to 95°C. Refer to page 7 of the operations

manual for instructions on HotBlock™ temperature adjustment.

4. Reduce volume to 5mL and cool.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 19

Page 22

HotBlock™: Operation and Instruction Manual EPA Method 200.8

5. After cooling, add 0.5 mL of (1:1) HCl and 7mL of DI Water and warm gently in the HotBlock™ for 15 minutes. Dilute to 50mL with

DI Water.

6. If necessary, lter with SC0401 (or appropriate FilterMate™) to remove insoluble material.

Note: The ltration step should be performed slowly with little pressure placed on the plunger. If excessive backpressure occurs stop

ltration and allow sediments to “settle out”. Applying pressure to the plunger may cause sample “blow through” allowing sediment

to pass through the lter into the digestate.

Procedure, Total Recoverable Elements, Solids Sample

(EPA Method 200.7, Paragraph 11.3):

1. Use 50mL of well-mixed, acid-preserved sample and transfer to a SC475 digestion cup.

2. Add 1mL of (1:1) HNO3 and 0.5mL of 1:1 HCl and heat in the block at a sample temperature of 95°C.

3. Reduce volume to 25mL. This will take approximately two hours and 15 minutes.

4. Using the polycarbonate transfer racks, remove samples from the HotBlock™ and allow them to cool.

5. Adjust volume to 50mL with DI water.

6. Use the FilterMate™ ltration device to remove insoluble material that can clog nebulizers.

Note: The ltration step should be performed slowly with little pressure placed on the plunger. If excessive backpressure occurs

stop ltration and allow sediments to “settle out”. Applying pressure to the plunger may cause sample “blow through” allowing

sediment to pass through the lter into the digestate. All QC samples, concentration limitations, elemental lists and reagent

specications are addressed in depth in EPA Method 200.7. Safety concerns are also part of the full method. Follow the

instructions listed in EPA Method 200.7. These steps should only be used as a guide to help improve the performance of

your HotBlockTM.

Adaptation of EPA Method 200.8

for use with the Environmental Express HotBlock™ Digestion System

Revised 05.05

Scope and Application:

The following procedures have been written as an aid to EPA digestion procedure 200.8 for use with the Environmental Express

HotBlock™. EPA Method 200.8 is for the determination of total recoverable analytes in groundwater, surface water,drinking water, wastewater, and (with the exception of silica) in solid samples such as sediment, sludge and soil. Use EPA Method 200.8 for reference while following

the sample preparation steps outlined below. A complete list of elements appropriate for analysis is included in EPA Method 200.8. Analysis

can be performed by ICP-MS.

Apparatus and Materials:

1. HotBlock™ for Metals Digestions — Model Numbers SC100, SC150*, or SC154

2. Polypropylene Digestion Vessels — Part Number SC475 (or SC490 for use with HotBlock™ SC150)

3. Ribbed Watch Glasses, Part Number SC505 or Reux Caps, Part Number SC506

(for use with SC490 vials for HotBlock™ SC150, use Ribbed Watch Glasses, Part Number SC610 )

4. FilterMateTM — Part Number SC0401 (or appropriate FilterMate™) for sample ltration if necessary

*Note: For all procedures, when using the SC150 block with the SC490 digestion vials with a 100mL sample, double the volume of all

reagents and acids added.

20 • Environmental Express www.environmentalexpress.com / 800.745.8218 / 843.576.1147

Page 23

HotBlock™: Operation and Instruction Manual EPA Method 200.8

Procedure, Aqueous Sample Preparation — Dissolved Analytes (EPA Method 200.8, Paragraph 11.1):

1. For the determination of dissolved analytes in ground and surface waters, pipet a 20mL or greater aliquot of ltered,

acid-preserved sample into the SC475 digestion vessel.

2. Add an appropriate volume of (1+1) HNO3 to adjust the acid concentration of the aliquot to approximate a 1% (v/v) nitric acid

solution. If the direct addition procedure is being used, add internal standards, cap and mix.

Note: If a precipitate is formed during acidication, transport or storage the sample aliquot must be treated using procedures for

Total Recoverable Analytes.

Procedure, Aqueous Sample Preparation—Total Recoverable Analytes

(EPA Method 200.8, Paragraph 11.2):

Note: This section applies to water samples containing turbidity of greater than 1 NTU.

1. For each digestion procedure, transfer 50mL of well-mixed, unltered, acid-preserved sample into the SC475 polypropylene vessel.

2. Add 1.0mL (1+1) HNO3 and 0.5mL of (1+1) HCl and swirl. Heat in the HotBlock™ at a sample temperature of 95°C. The HotBlock™

set temperature should be approximately 115°C. The temperature of a reference blank should be tested to ensure

correct temperature.

3. Reduce the volume of the sample aliquot to about 20mL at this temperature. This should take about 2.5 hours.

4. Place a ribbed watch glass (SC505) over the digestion vessel to reduce additional evaporation.

Note: When using a watch glass, adjust the set point temperature of the HotBlock™ so that a 50mL, 5% acid solution is heated to

85°C BEFORE placing the watch glass over the sample. Laboratory tests have proven that the addition of the ribbed watch glass

will add approximately 10°C to the sample temperature, bringing the sample temperature up to 95°C. Refer to page 7 of the

operations manual for instructions on HotBlock™ temperature adjustment.

5. Gently reux the sample for 30 minutes.

6. Using the polycarbonate transfer racks, remove samples from the HotBlock™ and allow them to cool.

7. Add reagent water to bring the sample to the 50mL mark on the digestion vessel. Cap and mix.

8. If necessary, lter with SC0401 (or appropriate FilterMate™) to remove insoluble material.

Note: The ltration step should be performed slowly with little pressure placed on the plunger. If excessive back pressure occurs,

stop ltration and allow sediments to “settle out.” Applying pressure to the plunger may cause sample “blow through” allowing

sediment to pass through the lter into the digestate.

9. Prior to analysis, adjust the chloride concentration by pipetting 20mL of the prepared solution into another SC475 digestion vessel

and bring up to 50mL volume with reagent water. If the dissolved solids in this solution are >0.2%, additional dilution may be

necessary to prevent clogging of the extraction and/or skimmer cones. Note the dilution factor for concentration calculations. If

the direct addition procedure is being used, add internal standards, cap and mix.

Procedure, Solid Sample Preparation:

1. For each digestion procedure, transfer 0.5 g ± 0.01 g of a dried sieved sample into the SC475 polypropylene vessel.

2. Add 2.0mL (1:1) HNO3 and 5mL (1:4) HCl and swirl. Heat in the HotBlock™ at a sample temperature of 95°C.

3. Heat the sample for 30 minutes. Allow to cool and bring to 50mL volume with DI water.

4. Filter with SC0401 (or appropriate FilterMate™) to remove insoluble material.

All QC samples, concentration limitations, elemental lists and reagent specications are addressed in depth in EPA Method 200.8. Safety

concerns are also part of the full method. Follow the instructions listed in EPA Method 200.8. These steps should only be used as a guide to

help improve the performance of your HotBlock™.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 21

Page 24

HotBlock™: Operation and Instruction Manual EPA Methods for Mercury Digestions

Adaptation of EPA Methods for Mercury Digestions 245.1, 7470, 7471,

for use with the Environmental Express HotBlock™ Digestion System

Revised 05.05

Scope and Application:

The following procedures have been written as an aid to EPA Digestion Methods 245.1, 7470 and 7471 for use with the Environmental

Express HotBlock™. EPA Methods 245.1 and 7470 are for the determination of mercury in aqueous samples and TCLP extracts. EPA Method

7471 is for the determination of mercury in soil, oil and sediment. Use the full EPA Methods for reference while following the sample

preparation steps outlined below.

Apparatus and Materials:

1. HotBlock™ for Metals Digestions — Model Numbers SC100, SC150*, or SC154

2. Polypropylene Digestion Vessels — Part Number SC475 (or SC490 for use with HotBlock™ SC150)

3. Ribbed Watch Glasses, Part Number SC505 or Reux Caps, Part Number SC506 (for use with SC490 vials for HotBlock™ SC150, use

Ribbed Watch Glasses, Part Number SC610 )

*Note: For all procedures, when using the SC150 block with the SC490 digestion vials with a 100mL sample, double the volume of all

reagents and acids added.

Procedure, Aqueous Sample Preparation:

1. Add 20mL of well-mixed sample to a SC475 digestion vessel or 2mL of TCLP extract and 18mL water.

Note: This is a 10x dilution for instruments that can achieve the detection limit including the dilution, otherwise digest 20mL of

TCLP extract.

2. Add 20mL of standard solutions or appropriate amount of standard spiking solution to give desired concentration when

diluted to 20mL.

3. Add 0.5mL of concentrated HNO3.

4. Add 1.0mL of concentrated H2SO4.

5. Mix thoroughly. Add 3mL of 5% KMnO4 and let stand for 15 minutes. If sample does not maintain purple or brown color, add an

additional 3mL of KMnO4 solution to all samples, blanks and standards. If the sample still does not maintain color, discard set

and dilute the sample prior to digestion.

6. Add 1.6mL of 5% persulfate solution. Place watch glass or reux cap on top of digestion vessel to allow pressure to vent while

minimizing evaporative loss.

7. Digest the sample for 2 hours at 95°C ± 5%.

8. Remove samples and let cool to room temperature.

9. Add 1mL of 12% sodium chloride/ hydroxyl amine hydrochloride solution.

Procedure, Soil, Oil and Sediments, 7471A:

1. Add 30mL of each standard solution or appropriate amount of standard spiking solution to give desired concentration when

diluted to 30mL in a SC475 cup. The standards should be made in 3% HNO3.

2. Weigh 0.60± 0.05g of homogenized sample into a tube. For best results, weigh the sample directly in the vessel on

a tared balance.

22 • Environmental Express www.environmentalexpress.com / 800.745.8218 / 843.576.1147

Page 25

HotBlock™: Operation and Instruction Manual EPA Method 365.2

3. Add 30mL of 3% HNO3 solution.

4. To each tube add 0.5mL of concentrated HNO3 and 2.0 mL of concentrated HCl.

5. Place watch glass or reux cap on top of digestion vessel and digest at 95°C for 10 minutes.

Note: When using a watch glass, adjust the set point temperature of the HotBlock™ so that a 50mL sample is heated to 85°C BEFORE

placing the watch glass over the sample. Laboratory tests have proven that the addition of the ribbed watch glass will add 10°C to the

sample temperature, bringing the sample temperature up to 95°C. Refer to page 7 of the operations manual for instructions on HotBlock™

temperature adjustment.

6. Add 3mL of 5% KMnO4 and let stand for 15 minutes. If sample does not maintain purple or brown color, add an additional 3mL

of KMnO4 solutions to all samples, blanks and standards. If the sample still does not maintain color, discard set and dilute the

sample prior to digestion. Heat samples at 95°C for 30 minutes.

7. Let samples cool to room temperature and add 3.0mL of 12% NaCl/NH2OH solution.

8. Cap tubes and shake. If color does not dissipate, incrementally add 0.5mL of 12% NaCl/NH2OH solution until color is gone.

All QC samples, concentration limitations, elemental lists and reagent specications are addressed in depth in EPA Methods 245.1, 7470 and

7471. Safety concerns are also part of the EPA Methods. These steps should only be used as a guide to help improve the performance of your

HotBlock™.

Adaptation of EPA Method 365.2, Phosphorus ALL FORMS

Colorimetric, Ascorbic Acid, Single Reagent

for use with the Environmental Express HotBlock™ Digestion System

Revised 05.05

Scope and Application:

The following procedures have been written as an aid to EPA Method 365.2 for use with the Environmental Express HotBlock™. EPA

Method 365.2 is for the determination of phosphorous in drinking water, surface water and saline water and in domestic and industrial

wastes. Use EPA Method 365.2 for reference while following the sample preparation steps outlined below. Range is 0.01 to 0.5 mg/L.

Apparatus and Materials:

1. HotBlock™ for metals digestions — Model Numbers SC100, SC150*, or SC154

2. Polypropylene Digestion Vessels — Part Number SC475 (or SC490 for use with HotBlock™ SC150)

3. FilterMateTM — Part Number SC0401 (or appropriate FilterMate™) for sample ltration if necessary

* Note: For all procedures, when using the SC150 block with the SC490 digestion vials with a 100mL sample, double the volume of

all reagents and acids added.

Procedure, Aqueous Sample Preparation:

1. For each digestion procedure, transfer 50mL of sample (or appropriate volume for your lab) into the SC475

polypropylene vessel.

2. Add 1mL of H2SO4 solution and swirl. (11 N H2SO4— Slowly add 310mL concentrated H2SO4 to 600mL distilled water. When

cooled dilute to 1 liter.)

3. Add 0.4g of ammonium persulfate.

4. Heat the sample in the HotBlock™ at approximately 100°C for 40 minutes. The sample should slightly boil.

Note: Adjust the HotBlock™ temperature so that the sample obtains a temperature of 100°C. Please refer to page 7 of the HotBlock™

Operation Manual for temperature adjustment and principles of operation.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 23

Page 26

HotBlock™: Operation and Instruction Manual EPA Method 3050B

5. Using the polycarbonate transfer racks, remove samples from the HotBlock™ and allow them to cool.

6. After cooling, dilute to 30mL with DI Water and adjust the pH of the sample to 7.0 ± 0.2 with 1 N NaOH using a pH meter. If the

sample is not clear at this point, add 2-3 drops of acid. Bring the sample to the 50mL mark.

7. If necessary, lter with SC0401 (or appropriate FilterMate™) to remove insoluble material.

Note: The ltration step should be performed slowly with little pressure placed on the plunger. If excessive back pressure occurs,

stop ltration and allow sediments to “settle out.” Applying pressure to the plunger may cause sample “blow through” allowing

sediment to pass through the lter into the digestate. All QC samples, concentration limitations, elemental lists and reagent

specications are addressed in depth in EPA Method 365.2. Safety concerns are also part of the full method. Follow the instructions

listed in EPA Method 365.2. These steps should only be used as a guide to help improve the performance of your HotBlock™.

Adaptation of EPA Method 3050B

for use with the Environmental Express HotBlock™ Digestion System

Revised 05.05

Scope and Application:

The following procedures have been written as an aid to EPA Method 3050B for use with the Environmental Express HotBlock™. EPA

Method 3050B is for the preparation of sediment, sludge, and soil samples for analysis. Use EPA Method 3050B for reference while following

the sample preparation steps outlined below. A complete list of elements appropriate for analysis is included in EPA Method 3050B. Analysis

can be performed by ame atomic absorption, GF/AA, ICP and ICP-MS.

Apparatus and Materials:

1. HotBlock™ for Metals Digestions — Model Numbers SC100, SC150*, or SC154

2. Polypropylene Digestion Vessels — Part Number SC475 (or SC490 for use with HotBlock™ SC150)

3. Ribbed Watch Glasses, Part Number SC505 or Reux Caps, Part Number SC506 (for use with SC490 vials for HotBlock™ SC150, use

Ribbed Watch Glasses, Part Number SC610 )

4. FilterMateTM — Part Number SC0401 (or appropriate FilterMate™) for sample ltration if necessary

* Note: When using the SC150 block with the SC490 digestion vials with a 100mL sample, double the volume of all reagents and

acids added.

Procedure, Aqueous Sample Preparation:

1. Mix sample thoroughly to achieve homogeneity and sieve if appropriate. For each digestion procedure, weigh to the nearest 0.01

gram and transfer a 0.5-1-gram aliquot (or appropriate amount for your lab) to the SC475 polypropylene digestion vessel. For best

results, weigh the sample directly in the vessel on a tared balance.

2. Add 5mL (1:1) HNO3 + DI Water and swirl. Cover with a ribbed watch glass or reux cap and heat the sample in the HotBlock™ at

95°C for 15 minutes without boiling.

Note: If using the watch glass, adjust the HotBlock™ temperature so that a 50mL, 5% acid solution is heated to 85°C. Laboratory

tests have proven that the addition of the ribbed watch glass will add approximately 10°C to the sample temperature. Refer to

page 6 of the operations manual for instructions on HotBlock™ temperature adjustment.

3. Allow the sample to cool, then add 5mL concentrated HNO3 and reux at 95°C for 30 minutes. Repeat this step until NO brown

fumes are given off by the sample.

4. Heat sample with the ribbed watch glass for an additional 1.5 hours. Do not allow the sample to boil or go dry. Neither of these

aspects should occur if the temperature of the HotBlock™ is adjusted correctly.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 24

Page 27

HotBlock™: Operation and Instruction Manual NIOSH Method 7303

5. Using the polycarbonate transfer racks, remove samples from the HotBlock™ and cool completely (it is very important that

samples are cooled completely).

6. Add 2-5mL DI Water and 0.5mL of 30% H2O2 slowly. Allow an exothermic reaction to occur. Wait 5-10 minutes and place samples

back in the HotBlock™ with the ribbed watch glasses in place. If effervescence starts to occur lift the samples out of the HotBlock™

and allow the reaction to continue. Do not let the samples foam out of the vessel. (Reducing the HotBlock™ display temperature

by 10°C should reduce the effervescence while maintaining the sample temperature).

6. Continue to add 0.5mL of H2O2 until the sample remains unchanged in color (no longer than 30 minutes). Continue heating for a

total of 2 hours.

7. For the analysis of samples for FLAA or ICP-AES, add 5mL concentrated HCl to each sample and cover with a ribbed watch glass

and reux at 95°C for 15 minutes. GFAA and ICP-MS digestions, skip this step.

8. After cooling, dilute to 50mL with DI Water.

All QC samples, concentration limitations, elemental lists and reagent specications are addressed in depth in EPA Method 3050B. Safety

concerns are also part of the full method. Follow the instructions listed in EPA Method 3050B. These steps should only be used as a guide to

help improve the performance of your HotBlock™.

Adaptation of NIOSH Method 7303

for use with the Environmental Express HotBlock™ Digestion System

Scope and Application:

The following procedures have been written as an aid to NIOSH Method 7303 for use with the Environmental Express HotBlock™.

Method 7303 is for the preparation of cellulose ester membrane lters commonly used in air sampling devices. Use EPA Method 7303 for

reference while following the sample preparation steps outlined below. A complete list of elements appropriate for analysis is included in

Method 7303. Analysis can be performed by ICP or AA.

Revised 05.05

Apparatus and Materials:

1. HotBlock™ for Metals Digestions — Model Numbers SC100, SC150*, or SC154

2. Polypropylene Digestion Vessels — Part Number SC475 (or SC490 for use with HotBlock™ SC150)

3. Ribbed Watch Glasses, Part Number SC505 or Reux Caps, Part Number SC506 (for use with SC490 vials for HotBlock™ SC150, use

Ribbed Watch Glasses, Part Number SC610 )

4. FilterMateTM — Part Number SC0401 (or appropriate FilterMate™) for sample ltration if necessary

* Note: When using the SC150 block with the SC490 digestion vials with a 100mL sample, double the volume of all reagents and

acids added.

Procedure, Filter Preparation:

1. Remove lter from cassette holder and fold into quarters taking care not to lose any sample.

2. Place in SC475 digestion vessel and add 1.25mL HCl.

3. Cover with plastic watch glass or reux cap. Place in HotBlock™ and heat at a sample temperature of 95°C for 15 minutes.

Note: If using the watch glass, adjust the HotBlock™ temperature so that a 50mL, 5% acid solution is heated to 85°C. Laboratory tests

have proven that the addition of the ribbed watch glass will add approximately 10°C to the sample temperature. Refer to page 6 of the

operations manual for instructions on HotBlock™ temperature adjustment.

3. Remove samples from the HotBlock™ and cool for 5 minutes.

4. Remove watch glass and add 1.25mL HNO3. Replace watch glass and return to HotBlock™ at sample temperature of

95°C for 15 minutes.

5. Remove the sample from the HotBlock™ and cool for at least 5 minutes. Discard watch glass.

6. Dilute to 25mL nal volume with distilled, deionized type II water.

All QC samples, concentration limitations, elemental lists and reagent specications are addressed in depth in Method 7303. Safety concerns

are also part of the full method. Follow the instructions listed in Method 7303. These steps should only be used as a guide to help improve

the performance of your HotBlock™.

25 • Environmental Express www.environmentalexpress.com / 800.745.8218 / 843.576.1147

Page 28

HotBlock™: Operation and Instruction Manual Ghost Wipe

Sample Preparation for Lead Analysis with the Ghost Wipe

Revised 05.05

Methodology Note:

The following procedure has been written as an aid for use with the Environmental Express HotBlockTM and strictly follows HUD

(Housing and Urban Development) guidelines for Lead in Dust Wipes Appendix A-5.0 which references NIOSH 7082.

Scope and Application:

This application deals with the preparation of samples using lead wipes, specically the Ghost Wipe from Environmental Express. The

sample is heated in the presence of Nitric and Hydrochloric acids to dissolve the wipe and all lead compounds into solution. Analysis can be

performed by ame atomic absorption (FLAA) or inductively coupled plasma technique (ICP).

Apparatus and Materials:

1. HotBlock™ for Metals Digestions — Model Numbers SC100, SC150*, or SC154

2. Ghost Wipe — Part Number SC4210 or SC4250

3. Polypropylene Digestion Vessels — Part Number SC475 (SC490 for HotBlock™ SC150)

4. Ribbed Watch Glasses, Part Number SC505 or Reux Caps, Part Number SC506

(for use with SC490 vials for HotBlock™ SC150, use Ribbed Watch Glasses, Part Number SC610 )

5. FilterMateTM — optional if sample does not completely dissolve

* Note: For all procedures, when using the SC150 block with the SC490 digestion vials with a 100mL sample, double the volume

of all reagents and acids added.

Reagents:

1. Concentrated Reagent-grade HNO3 (5mL repipet dispenser recommended)

2. Concentrated Reagent-grade HCl (5mL repipet dispenser recommended)

Procedure:

1. ransfer the wipe to the SC475 digestion cup. It is recommended that the wipe is sent to the sampling area with a cup and wipe so

no transfer steps are required. The wipe must be transported in a rigid-walled container according to the sampling procedure

ASTM E1728.

2. Add 10mL DI Water, 2mL HNO3 and 2mL HCl. Cover with a ribbed watch glass.

3. Heat the sample for 45 minutes at 95°C.

Note: When using a watch glass, adjust the set point temperature of the HotBlock™ so that a 50mL solution is heated to 85°C

BEFORE placing the watch glass over the sample. Laboratory tests have proven that the addition of the ribbed watch glass will add

approximately 10°C to the sample temperature, bringing the sample temperature up to 95°C. Refer to page 6 of the operations

manual for instructions on HotBlock™ temperature adjustment.

4. Using the polycarbonate transfer racks, remove samples from the HotBlock™ and allow them to cool for approximately 10 min

utes. Bring the sample to 50mL volume. If excess amounts of undigested material remain, lter the sample using a 2.0μm PTFE

FilterMate™.

5. Cap and mix well.

According to AIHA Policies 2001- Revision Nov. 2000, one LCS, one matrix spike and one duplicate must be run every 20 samples. “The LCS

shall be a solid matrix material with an established concentration obtained from a source independent of the instrument calibration and

traceable to NIST or other similar reference material. Liquid spikes may not be used for preparing LCSs”.

Environmental Express does offer NIST traceable spiked Ghost Wipes. The catalog number is SC4252. The range is 175-200μg Lead per wipe.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 26

Loading...

Loading...