Page 1

Operation Manual

AutoBlock Serial Number: ________________________

Electrical Box Serial Number: ______________________

490 Wando Park Blvd., Mt. Pleasant, South Carolina 29464

800-343-5319 or 843-881-6560 / Fax 843-881-3964

ENVEXP.COM

5528COVER rev3 9/10/09

Page 2

TABLE OF CONTENTS

page

Introduction

4 What’s Included

4 Uncrating

4 Unpacking

Installation

5 Preparing the AutoBlock lll

5 Space & Weight Requirements

5 Ventilation

6 Front Door Installation

6 Pump Compartment Door Installation

6 Install Reagent Line

7 Reagent Line Assembly

7 Placement of Reagent Rack

7 AutoBlock Reagent Port

8 Install Drain Line & Carboy

8 Electrical Box Installation

System Overview

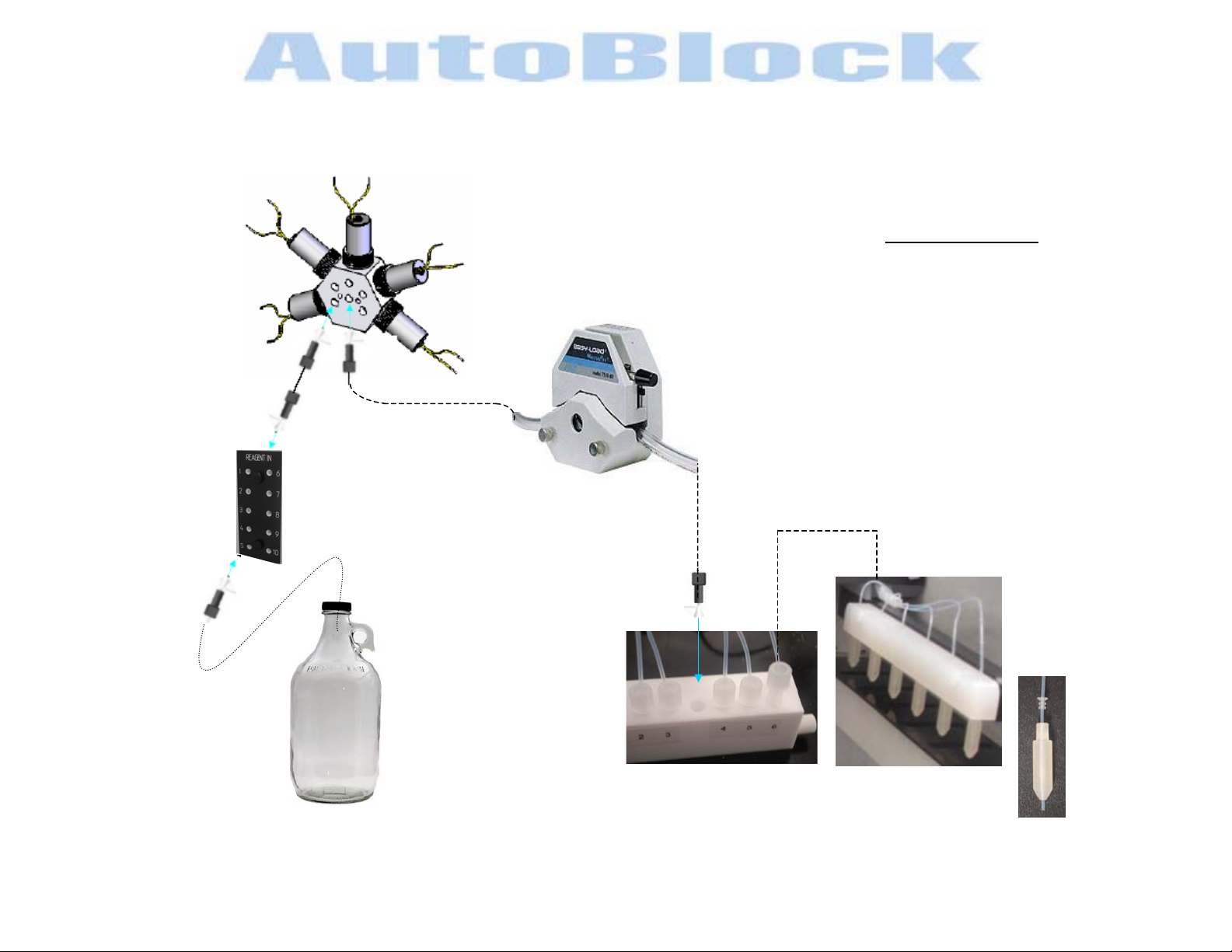

9 Reagent Flow Path

10 General Cleaning

Touch Screen Controller

11 Main Screen Functions

11 Sensor Indicators

12 Abort

12 Temperature Readouts

13 On Board Keyboard

Start Up Instructions

14 Power Switch & Load Software

14 Test Injection System

15 Sample Injection Tubing / Pump Calibration

15 Maintenance

15 Sensor Validation

Manual Mode

16 Rack Movement

17 Home

17 Fan

17 Graphite

18 Arm

18 Inject

ENVIRONMENTAL EXPRESS

For technical support call 800-745-8218 or send email to INFO@ENVEXP.COM

5528INDEX rev 3 2 9/10/09

Page 3

TABLE OF CONTENTS

page

Run Mode

19 Rack A / Rack B / Rack C

20 Pause Button

20 Main Screen Abort Button

Program Mode

21 Heat

21 Inject

22 Wait

22 Cool

22 Pause

22 Delete

23 Open

23 Save

23 New

23 Edit

24 Import / Export Method

24 Export Log

25 Syntax Errors

Service Mode

26 Setup Reagents

27 Calibrate Temp

27 Calibrate Pump

30 Maintenance

30 Options

31 Supplies

32 Supplies List

33 Exit

Warranty

34 90-day Warranty

34 9-month Warranty

34 Warranty Disclaimer

34 Charges Not Covered by Warranty

34 How the Warranty Works

Repair

35 Repair Approval

35 In-Lab Troubleshooting & Repairs

35 Repair by Manufacturer

35 Return Packing & Shipping

35 Inspection upon Receipt

35 Additional Information & Help

ENVIRONMENTAL EXPRESS

For technical support call 800-745-8218 or send email to INFO@ENVEXP.COM

5528INDEX rev 3 3 9/10/09

Page 4

INTRODUCTION

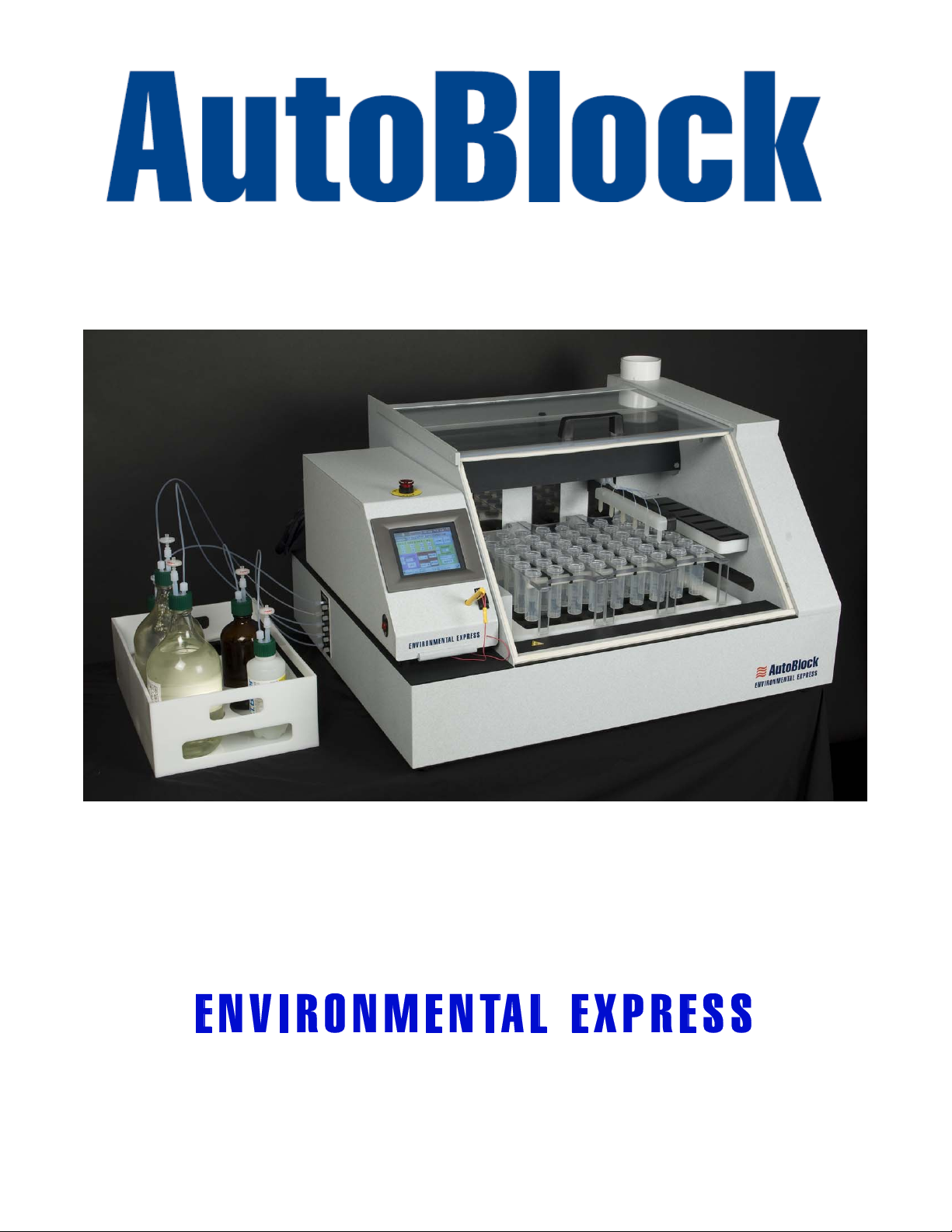

The AutoBlock has been designed specifically for your laboratory by providing safe,

clean and efficient digestions. It is capable of digesting water, wastewater, soils, and

other materials typically digested using hotplate chemistry.

What’s included

SINGLE UNIT

1

1 AutoBlock Unit

1 AutoBlock Electrical Unit

1 Power Cord

3 Racks

6’ ½”ID Drain Tube

1 10L Carboy

1 ½” Barb Fitting

5 Flangeless Nut

5+2 extra Flangeless Ferrules

25’ 1/16”ID Reagent Tubing

DUAL UNIT

1

1 AutoBlock Unit

1 AutoBlock Electrical Unit

1 Power Cord

3 Racks

6’ ½”ID Drain Tube

1 10L Carboy

1 ½” Barb Fitting

10 Flangeless Nut

10+2 extra Flangeless Ferrules

50’ 1/16”ID Reagent Tubing

AutoBlock Manual

AutoBlock Manual

Unpacking

Retain all packaging material for a

minimum period of 90-days.

See Warranty for complete details.

Your AutoBlock has been packaged in a custom crate

for shipping purposes. Spend adequate time reading

this instruction manual before unpacking your

AutoBlock. While unpacking keep in mind there are

many fragile components. A quality control sheet from

the factory has been included. Use this list to inventory

components, as they are unpacked.

Note:

Residual water may be found in the internal plumbing of

your AutoBlock. This includes the pump, reagent and

drain lines. This water is non-hazardous, and was used

for system check during quality control inspection.

Uncrating Instructions

• Cut banding from crate, use standard safety precautio ns.

• Lift the entire cover from the crate.

Carefully remove

•

Foam Filler

Inner Box from the side. This box contains the electrical box, power cord & manual

Front Door that is secured to the back of the cabinet

• Remove the 10L carboy, 3-racks, reagent tubing & start up kit. There are several pieces of

packaging material in place for protection. All material must be removed.

• Remove the protective tape from the sample probe cap, reagent entry plate, JC connectors,

pump compartment door & touch screen.

• The unit will need to be cleaned from residue during shipment. Using compressed air, clean the

inside of the AutoBlock.

The AutoBlock unit is now ready to be installed. Please read installation instructions

.

5528INTRO rev 3 4 9/10/09

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

ENVIRONMENTAL EXPRESS

Page 5

INSTALLATION

on/o

Preparing the AutoBlock

Follow the instructions for uncrating from the quality control sheet supplied with the unit or introduction

section of this manual. Follow the installation procedure step by step to insure proper function of the unit.

Note:

reagent injection lines and drain lines. This water is non-hazardous, and was used for system check

during quality control inspection.

Residual water may be found in the internal plumbing of your AutoBlock. This includes the pump,

Space & Weight Requirements

Lift the AutoBlock from the bottom only. The unit weights approximately 200-lbs. carefully place the unit

on a sturdy counter with the following minimum requirements:

• Counter must be able to support a minimum 300-lb loa d.

• Space requirements: 38”W x 32”L x 26”H these are the minimum requirements. Additional space will

be needed for reagents & a carboy placed under the unit.

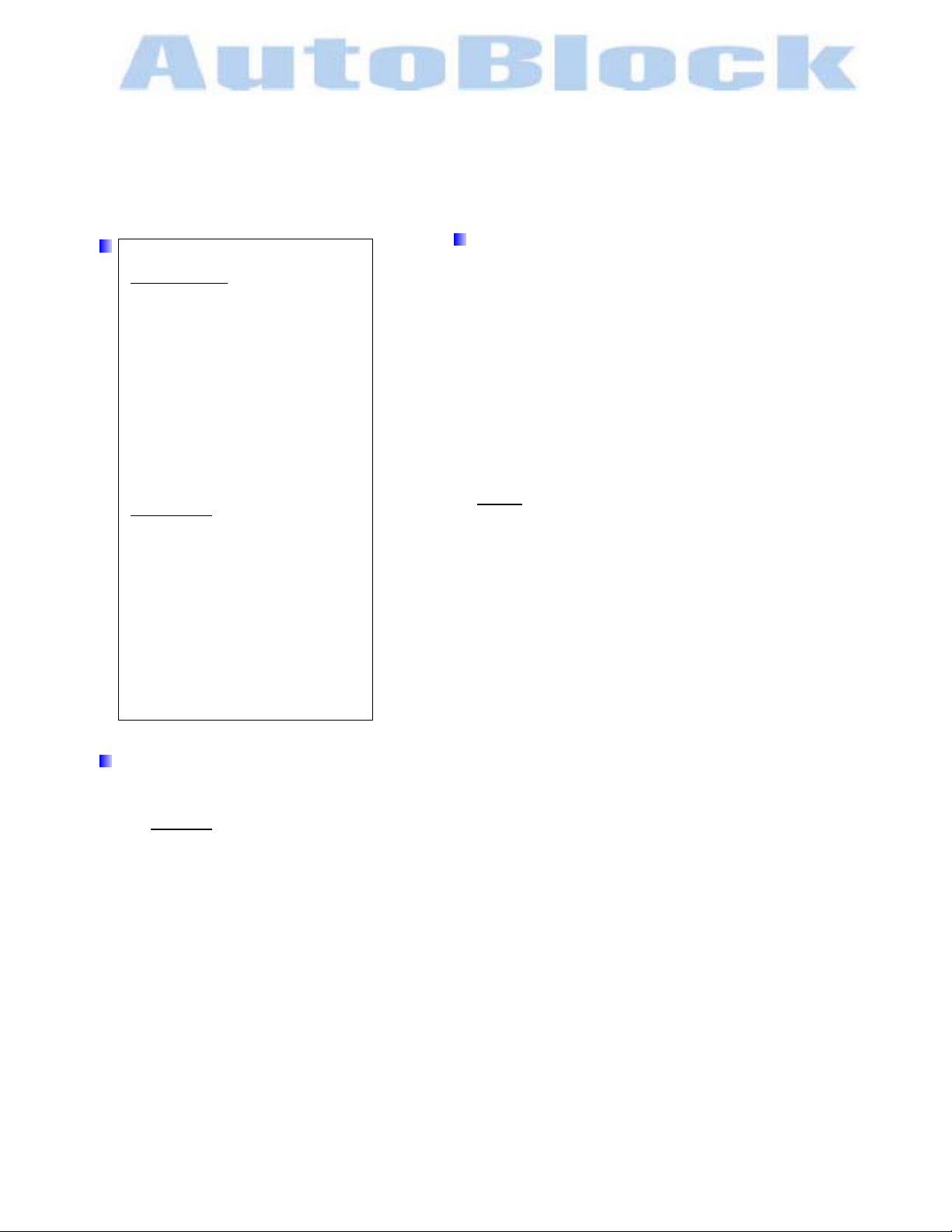

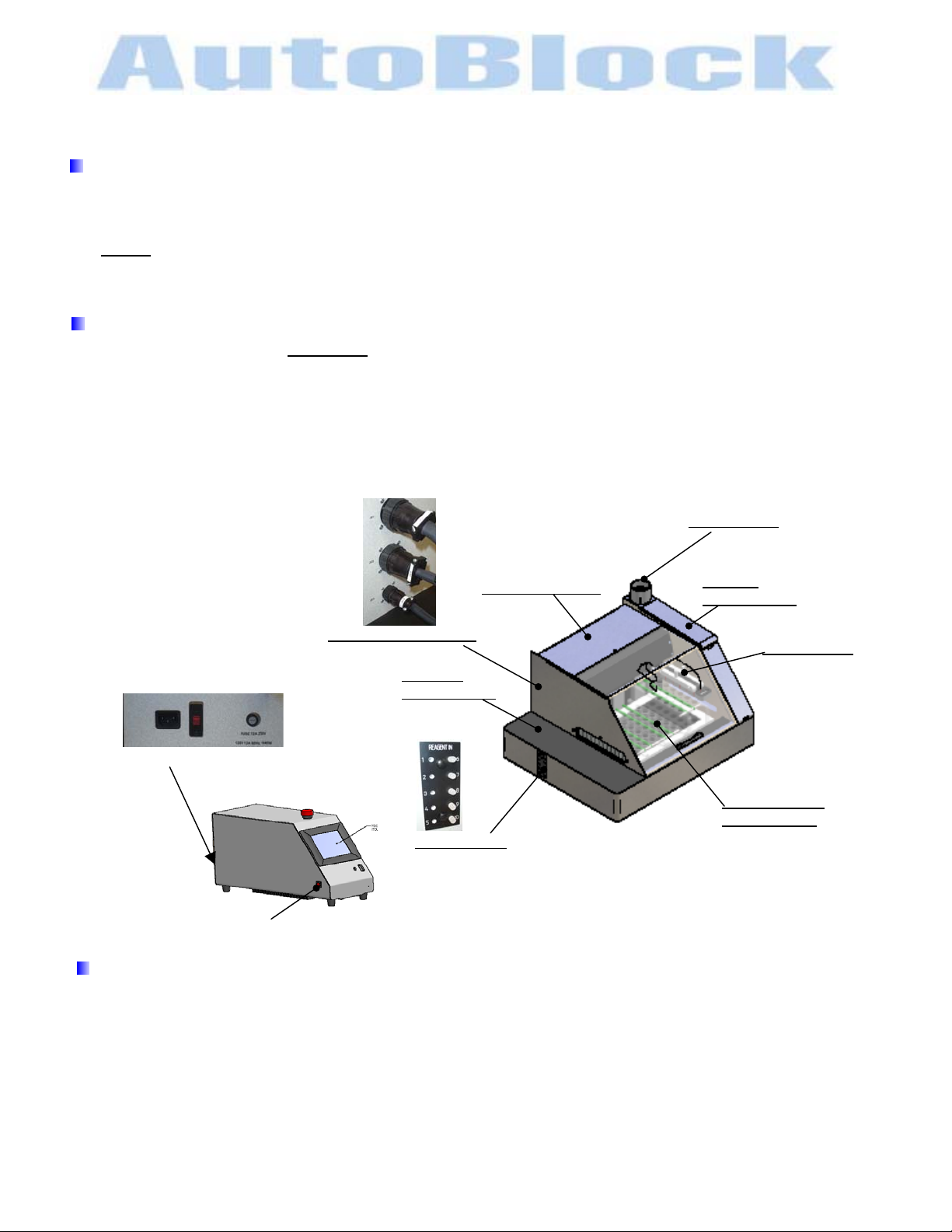

JC1

JC2

JC3

Lift Compartment

Exhaust vent

Exhaust

Compartment

electrical connections

Pumping

Compartment

Injection Arm

Power module/ Voltage / Fuse

Graphite Block

reagent ports

Compartment

ABP164

ff switch

Ventilation

The AutoBlock exhaust is located on the top right portion of the unit. Install a 4” diameter acid-resistant

duct and clamp to the exhaust outlet. Vent using state & federal guidelines. When connecting ductwork,

verify zero to negative pressure to prevent backflow. The length of the duct should not exceed 25’. Vent

the duct to the outside of the laboratory building or plumb into the existing ductwork.

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528INSTALL rev 3 5 9/15/09

Page 6

INSTALLATION

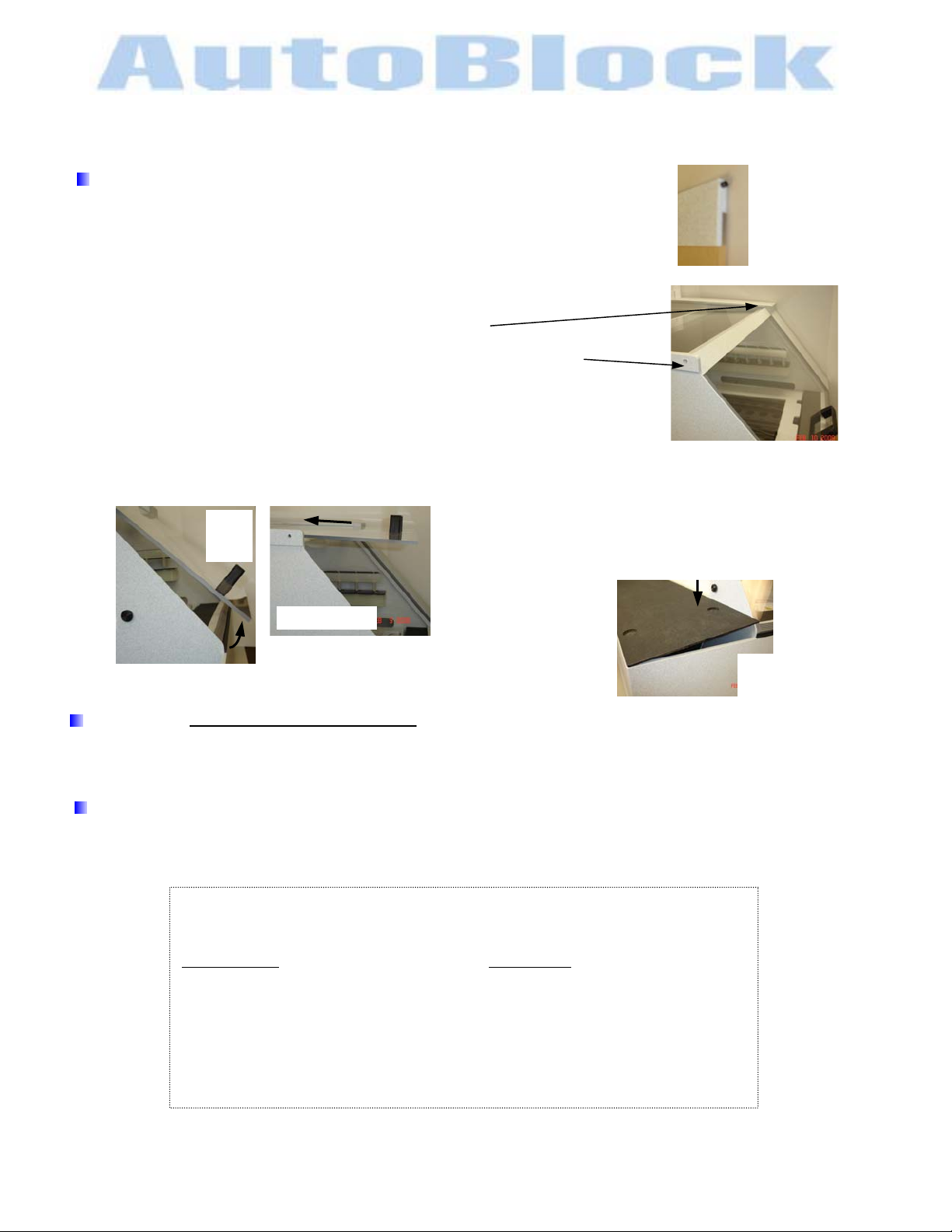

Front Door Installation

Unpack the front door assembly using caution not to scratch the acrylic.

Both hinge pins have been inserted into the door assembly

Remove the hinge pin from the left side using a hex wrench.

Place door in cabinet opening,

sliding the right side hinge pin into the cabinet location.

Align the left side hinge pin location & screw in the second hinge pin.

Hand tighten the hinge pin.

Lift the door & close it. It will be a snug fit. Lift the door up & slide back.

After the installation of the front door, Environmental Express does not warranty

breakage due to operator handling.

as shown.

Closing the

Insert edge first along the outside of the cabinet. Tilt the other edge at 10

the cabinet. Push down to close.

lift

door

up

slide door back

Pump Compartment Door

push down

on this edge

angle

pump compartment

door as shown

0

angle along the filter side of

Install Reagent Line

The following steps will connect 2.5 liter or standard 38mm top, reagent bottles to AutoBlock. These are

standard 2.5L acid bottles. For the DI water ports, 1 & 6, use a clean acid bottle filled with H

SINGLE UNIT DUAL UNIT

5 Flangeless Nuts 10 Flangeless Nuts

5 + 2 extra Flangeless Ferrules 10 + 2 extra Flangeless Ferrules

25’ Reagent Lines 1/16”ID 50’ Reagent Lines 1/16”ID

Vented Reagent Caps (optional)

Reagent Bottom of the Bottle Filter (optional)

Uptake Reagent Components

Components are supplied in a start up kit

2

O.

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528INSTALL rev 3 6 9/15/09

Page 7

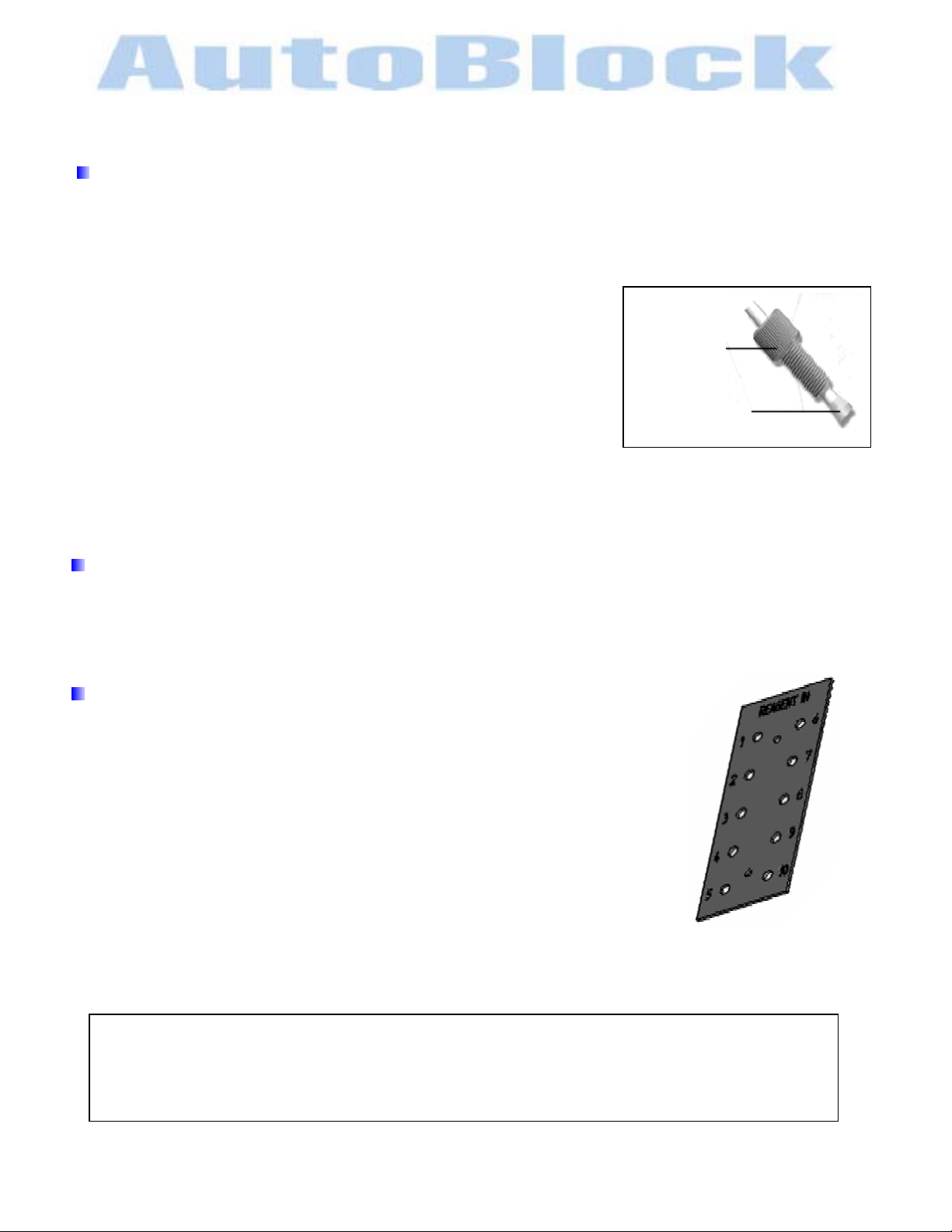

Reagent Line Assembly

1. Cut appropriate lengths of 1/16”ID Teflon tubing, not to exceed 5’ lengths. The ends need to be a

square-cut face.

2. Slide the flangeless nut over the tubing, with the nut threads facing the tubing end.

3. Slide the flangeless ferrule over the tubing, with the tapered portion of

the ferrule facing towards the nut. The large diameter of the ferrule

should be pushed to the end of the tubing.

4. AutoBlock reagent ports are located on the left side of AutoBlock

labeled #’s 1-10.

5. Insert the tubing with the flangeless ferrule into the receiving port

until it bottoms. While holding the tubing, tighten the Flangeless nut

finger tight. The tubing should not be able to move in the port.

Repeat for all ports available.

INSTALLATION

Flangeless nut

Flangeless Ferrule

reference diagram for placement

Placement of Reagent Rack

Position the six-bottle reagent rack (optional) on the left side of AutoBlock.

For dual systems, there may be two six-bottle reagent racks (optional).

AutoBlock Reagent Port

AutoBlock reagent ports are located on the left side of AutoBlock, labeled #’s 1-10.

The reagents have been set up in the following manner:

Single System Dual System**

If these reagents do not suit your application, you may change them. Changing the reagents and ports

numbers are addressed in the SERVICE TAB – SETUP REAGENT section.

*Port #1 H20(1) *Port #6 H20(6)

Port #2 HNO3(2) Port #7 KMnO4(7)

Port #3 HCL(3) Port #8 PERSULF(8)

Port #4 H2O2(4) Port #9 NH2OH(9)

Port #5 H2SO4(5) Port #10 H20(10)

*Ports #1 & #6 must remain H

**In a single system ports #6-10 have been plugged.

0

2

reagent plate

Vented Reagent Caps and Bottom of the Bottle Filter (optional)

Loosen the nut on the top of a vented reagent cap. Insert one end of reagent tubing through the nut until

it reaches the bottom of the 2.5L bottle. Hand tighten the nut.

A bottom of the bottle filter may be used to filer the reagent. Attach this to the end of the tubing before

inserting it into the 2.5L bottle.

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528INSTALL rev 3 7 9/15/09

Page 8

Install Drain Line & Carboy

• Remove the ½” barb fitting from the

bag of parts supplied

• Remove the nut from the fitting

• Remove the cap from the carboy

• Place the fitting into the cap. The treaded portion

of the fitting needs to be on the inside of the cap.

• Place the washer & then nut onto the fitting & tighten.

• Place the cap back onto the carboy.

• The drain line is located on the right side towards the back of the unit. Place the supplied ½” tubing

onto the barb fitting and the other end to the carboy.

direction the entire length.

The system is designed for downward gravity flow throughout the entire length to the carboy.

Place the carboy under the AutoBlock.

Electrical Box Installation

• Position the on/off switch to the off position.

• A 10’ power cord has been supplied.

Power requirements are standard 115VAC 12A US and Canada

Power requirements are standard 220VAC 6A International

Plug the power cord into the power module located in the back of the electrical box and into a

standard AC outlet

• Place the electronic box on the platform of the AutoBlock, left hand side of the unit. The mounting feet

will rest in the recessed holes.

• Connect the three cables from the electrical box to the AutoBlock system on the left side. JC1, JC2

and JC3 have been marked on the cable connector & on the AutoBlock.

INSTALLATION

carboy cap & bulkhead fitting

Insure the tubing goes in a DOWNWARD

ON

OFF

on/off switch

Congratulations

You have finished physically setting up the AutoBlock and are ready to move

onto a systems check and calibration. A systems check and calibration set up

must be done before any methods run.

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528INSTALL rev 3 8 9/15/09

Page 9

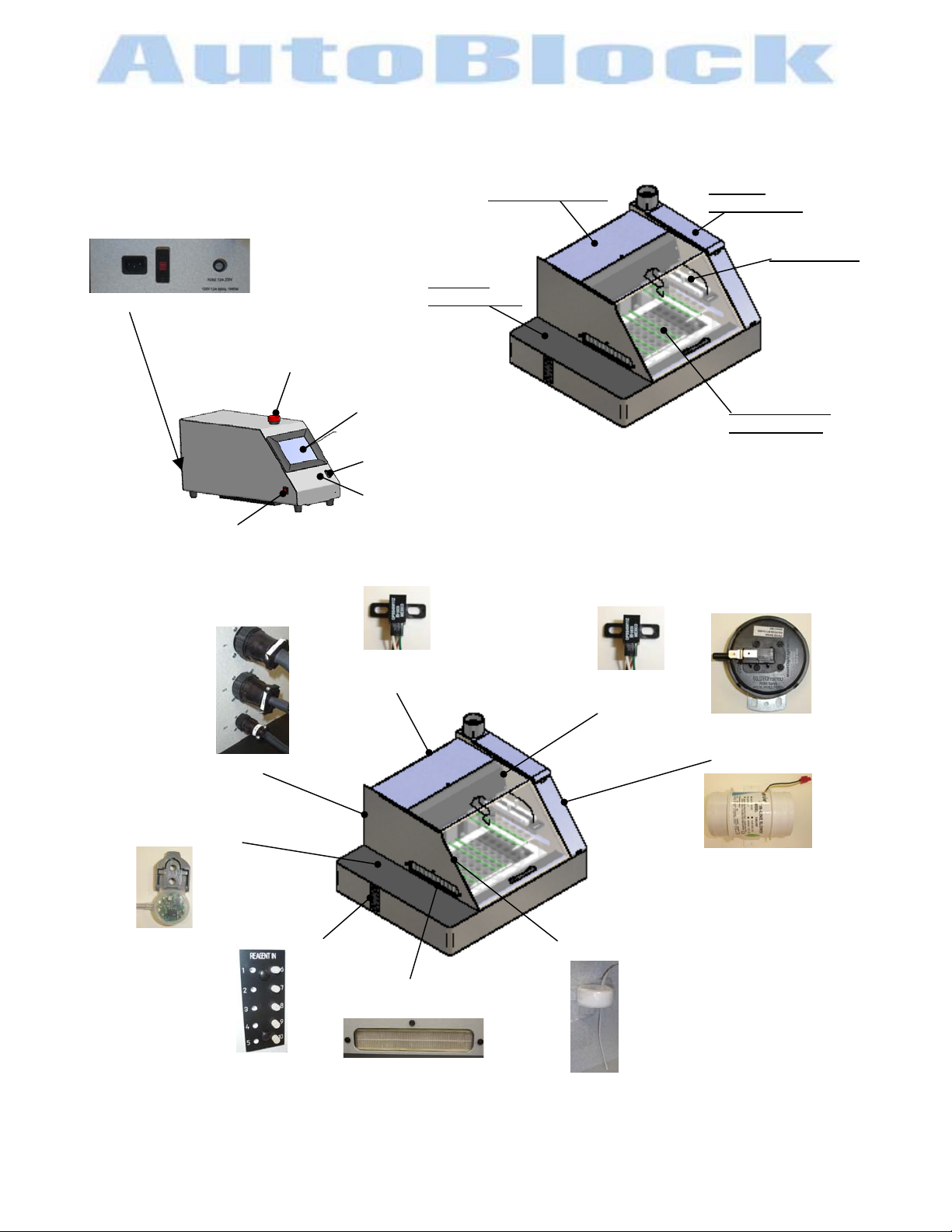

System Overview

g

y

on/o

(3)

9

Component Layout

Power module/ Voltage / Fuse

Emer

ABP164

ff switch

ency Stop Assembl

Touch Screen

USB

Stylus

Pumping

Compartment

Lift Compartment

Exhaust

Compartment

Injection Arm

Graphite Block

Compartment

JC1

JC2

JC3

electrical connections

ABP125

lift sensors

ABP125

Inj arm sensor

ABP152

pressure sensor

ABP127

leak detector sensor

ABP128

exhaust fan assembly

reagent ports

ABP151

HEPA filter

RTD -Sample Assembly

ABP130

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528OVERVIEW rev3 9 9/10/0

Page 10

y

g

p

System Overview

Reagent Flow Path

ABP122

5-Valve Assembl

Reagent-Valve

Tubing Kit -single

Reagent Ports/Cabinet

Teflon Tubin

ABP140

Uptake

1/8” Flangeless Nut

1/8” Flangeless Ferrule

for

General Cleaning

Wipe clean with mild cleaner or isopropyl.

ABP154

Pum

Head

Keep debris from inside of graphite block

wells.

ABP143

ABP144

Pump Tubing Kit

1/16” Flangeless Nut

1/16” Flangeless Ferrule

ABP108

Manifold

ottleReagent B

W/Plug

Sample Injection Kit

Injection arm with splitter

ABP159

Injection Guide

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528OVERVIEW rev 3 10 9/10/09

Page 11

TOUCH SCREEN CONTROLLER

The touch screen controller is specifically designed for use with the AutoBlock. Once the system is

turned on, the AutoBlock software will automatically load. Pressing the screen tabs or input boxes with

the attached stylus activates the touch screen. It is not necessary to push very hard, this may damage

the screen.

Main Screen Functions

There are several operations that appear permanently on the touch screen.

There are FIVE tabs of operation located at the top of the touch screen:

The MANUAL screen will appear at start up.

-A pop up message will appear: “READY TO HOME MOTORS?” Press the Continue button.

-Motors will activate to initialize in their home positioning.

-A pop up message will appear: “MOTORS ARE HOMED” Press the Continue button.

To switch between tabs, press the appropriate tab with the stylus. Each tab will be described in this

manual to allow the analysts to fully operate the AutoBlock.

The main screen will go into sleep mode when left unattended. Touch the top of the screen with the

stylus to awaken.

Sensor Indicators

Alarm sensors are located in the upper left portion of the screen and when triggered change color. These

sensors may take a few moments to change its status, it is not instantaneous.

P

Located in the Exhaust Compartm ent. Detection if a pressure drop has occurred.

Green light will indicate a positive operating state

Red light will indicate the sensor has been activated & needs attention.

L

Located in the Pumping Compartment. It will detect if there is a leak present.

Green light will indicate a positive operating state

Red light will indicate the sensor has been activated, immediate attention should be given to this

MANUAL RUN PROGRAM SERVICE EXIT

Pressure Sensor

Leak Detector Sensor

situation. The AutoBlock will not operate until the leak has been resolved. Reference Start Up

Instructions–Sensor Validation section of this manual for addition information.

Manual Tab

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528TOUCHCREEN Rev 2 11 9/10/09

Page 12

TOUCH SCREEN CONTROLLER

ABORT

If you need an emergency stop depress the

Activate the ABORT

By selecting the abort button, the abort operation will seize all communications to the control board.

The temperature will not read correctly and will not heat. All motion is stopped. The ABORT button will turn

green.

-A pop up message will appear: “DO YOU WANT TO ABORT”

Pressing the Cancel button will bring you back to the main screen and the abort command will not be activate.

Press the Abort button to activate the abort command, a pop up message will appear

“CONTINUE TO TURN ON FAN”

“CANCEL TO TURN OFF FAN”

Press the Continue button to turn the fan on.

If fumes are present or the block is greater than 40

Pressing the Cancel button to leave fan off.

Deactivate the ABORT

After selecting to turn on the fan or leave off

-A pop up message will appear: “READY TO HOME MOTORS?”, Press the Continue button.

-Motors will activate to initialize in their home positioning.

-A pop up message will appear: “MOTORS ARE HOMED”. Press the Continue button.

The ABORT command will then be deactivated and the ABORT button will turn red.

Abort Button

E-STOP immediately.

0

C, it is recommended to keep the fan on

Emergency Stop

Temperature Readouts

Actual temperature readings for samples & block are displayed in the upper right portion of the screen.

SX

G

Sample Temperature

Place the external thermocouple, located inside the front compartment, into a sample for accurate reading.

Temperature that has been set to the graphite block ,

Displayed in the upper left portion of the screen.

Reference the Manual Tab for setting the block temperature.

Manual Tab

Graphite Block Temperature, 0C

Sample Temperature, 0C

0

C

Manual Tab

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528TOUCHCREEN Rev 2 12 9/10/09

Page 13

On Board Keyboard

To activate this feature, select the icon on the task bar with the stylus.

Typing

-keyboard acts as any standard keyboard

-press the SHIFT button to change the top row symbols/numbers

-press the CAPS button to change from low/capital letters

Move keyboard

- Touch the keyboard and drag across the screen to new location.

To deactivate the keyboards,

- select the icon on the task bar

- or the icon on the keyboard located on the bottom row next to the control button

- or the X in the upper right-hand corner

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528TOUCHCREEN Rev 2 13 9/10/09

Page 14

START UP INSTRUCTIONS

These start up instructions are to aid in optimizing the performance of AutoBlock. You system has gone

through a quality control check during manufacturing. These parameters need to be checked at setup to

ensure the system is in operable condition and the parameters meet your laboratory specificat ions. All

parameters can be changed to meet your laboratory specifications.

If you need assistance during this set up instructions, please feel free to call Environmental Express

during normal business hours. Contact information is listed at the bottom of each page.

ON

Power switch & load software

The touch screen controller is specifically designed for use with the AutoBlock.

Once the system is turned on, WindowsXP will start up and the AutoBlock software will start to load.

This will take about 30-seconds

It is not necessary to push very hard, this may damage the screen.

Pressing the screen tabs or input boxes with the attached stylus activates the touch screen.

One the screen has initialized the onboard keyboard with pop up.

Disable the keyboard by depressing the DISABLE button located next to the control button

There are several options to start the AutoBlock software:

-Double Click the ABIII icon on the main Desktop

-Select the START button on the task bar and select the ABIII icon

-Select the START button on the task bar and select All Programs and then select the ABIII icon

The MANUAL screen will appear at start up.

-A pop up message will appear: “READY TO HOME MOTORS?” Press the Continue button.

-Motors will activate to initialize in their home positioning.

-A pop up message will appear: “MOTORS ARE HOMED.” Press the Continue button.

There are FIVE tabs of operation located at the top of the touch screen:

MANUAL RUN PROGRAM SERVICE EXIT

on/off switch

OFF

Testing Injection System

In Manual tab, prime the line with H

For initial injection test, H

1. Remove the pumping compartment cover, placing the electrical box off to the side of the AutoBlock unit.

2. Place 3-racks with vessels onto the lift arm.

The racks should be in the up position. Press the in the ALL button in the yellow section of the screen.

3. Inject each reagent line with 10ml of H2O. Inspect tubing for any air bubbles.

Refer to MANUAL TAB on instructions for injection

If air bubbles are present, inspect all connections & repeat by injecting 10ml of reagent for re-inspection.

Air bubbles may be caused from improper face-to-face connections.

4. Repeat for each port #1-5 (single unit) and #1-10 (dual unit)

O should be used on all ports.

2

O as follows.

2

Manual Tab

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528STARTUP rev 3 14 9/10/09

Page 15

START UP INSTRUCTIONS

Sample Injection Tubing / Pump Calibration

Follow the steps to Calibrate Sample Injection Tubing and Calibrate Pump under the Service Tab in this

manual.

The Sample Injection Tubing and Pump(s) has been tested and calibrated during manufacturing.

It is best to calibrate the system again to ensure accuracy.

Maintenance

Review and set up the Maintenance portion under the Service Tab in this manual.

The maintenance schedule has been set during manufacturing. There will be popup alerts on the touch

screen to remind the operator to inspect & maintain the AutoBlock.

Sensor Validation

Change of status may take a few moments. It is not an instant response.

If these sensors indicators do not change status please review the System Overview section of this

manual for setting them to a positive operating condition.

1. From the Manual Mode, turn the fan on by pressing the FAN button.

The Pressure Sensor indicator

front door must be closed.

2. Close the front door and the pressure sensor indicator

3. Press the FAN button to turn the fan off. The pressure sensor indicator

The Leak Detector Sensor indicator

P

on the touch screen, will turn green when operating correctly. The

P

will turn red

P

will turn red.

L

on the touch screen will be green when no leak is detected.

Manual Tab

You are now ready to successfully run digestion methods in your new AutoBlock.

Reference Program Tab for creating and editing methods.

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528STARTUP rev 3 15 9/10/09

Page 16

MANUAL TAB

The manual mode is just what it implies. In this mode, digestion functions (raising/lowering racks,

heating, cooling, injection, etc…) are performed individually by the analyst. The manual tab is used in

method development, troubleshooting and on going inspections, and other situations where hands-on

control of operations are required.

Manual tab screen with dual system

Rack Movement

The (3) 18-position rack have been designed to hold 50ml vessels for a 54-well block.

Each rack can be moved up or down individual from one another.

By pressing the will raise the rack will lower the rack

Rack A

Rack B

Rack C

All

After selecting

-A pop up message will appear: “RACK UP?”, Press Continue or Cancel button.

Cancel

A pop up message will appear: “CANCELLED?”, Press Continue button

You have canceled the command & return to the manual tab

Continue

The selected rack will move in the selected direction

A pop up message will appear: “RACK IS UP.”, Press Continue button

located on the left, columns 1-2-3

center location, columns 4-5-6

located on the right, columns 7-8-9

will raise or lower all three racks one at a time

(yellow section)

COLUMN & RACK DESIGNATION

or

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528MANUAL rev3 16 9/10/09

Page 17

HOME

This operation will home the three lift motors and the injection arm motor.

The three lift motors will go to the down position and the injection arm will position itself over the drain.

Press the Home button

-A pop up message will appear: “HOME MOTOR?” Press Continue or Cancel button.

Cancel

You have canceled the command & return to the manual tab

Continue

The lift &injection arm motors will activate

A pop up message will appear: “RACKS ARE DOWN AND ARM IS LOCATED OVER THE

FAN

By pressing this button the fan will turn on or off.

A confirmation message fan is on/off. Press the OK button.

The fan will automatically turn on when the block is over 40

Graphite

Set the temperature to the graphite block with the or

The temperature is set in

After selecting a temperature press the

- A pop up message will appear: “THE BLOCK TEMPERATURE HAS BE SET” Press Continue button

The change will also reflect the readout on the upper right corner of the screen

NOTE:

The temperature of the graphite block will not be the temperature of the external thermocouple (sample

probe).

Test the sample temperature to achieve proper graphite temperature.

Heat the graphite block to 115

The use of the reflux cap (SC506) will raise the sample temperature 10

(blue section)

DRAIN.”, Press Continue button

(blue section)

(pink section) Range: 150C-1500C

0

C, inc/dec by 0.10C

MANUAL TAB

0

C, and cannot be turned off below 400C

buttons, or by using the keyboard.

SET

button.

0

C, the sample probe should read 950C

0

C

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528MANUAL rev3 17 9/10/09

Page 18

p

MANUALTAB

Arm

Select which column you would like a reagent injected to by the pull down menu

-Select DRAIN, 9,8,7,….1

-Press the MOVE button

-A pop up message will appear: “MOVE INJECTION ARM?”,

Press Continue or Cancel button.

Cancel

You have canceled the command & return to the manual tab

Continue

The injection arm will move to the selected column

A pop up message will appear: “INJECTION ARM MOVE COMPLETE.”

Press Continue button

NOTE:

There will be a left & a right splitter.

ARM (1-5) will inject thru the left splitter

ARM (6-10) will inject thru the right splitter

(red section)

**Dual System**

single unit system shown

dual unit has two s

litters

Inject

Select which column to be injected thru the ARM-section and move injection arm before proceeding.

The Inject command does not automatically purge or prep. Bring the injection arm to he drain and inject

6ml H20(1) to purge and 6ml of reagent to prep.

Amount

Select the amount of reagent to be injected with the

The volume is set in ml. inc/dec by 0.1ml

Reagent

Select the Reagent to be injected from the drop-down menu. Reagents have been pre-installed.

Reference the SERVICE TAB-REAGENT SETUP for port configuration and to make changes

EXAMPLE: H20(1) Reagent H20 is connected to port (1) on the AutoBlock unit

-Select REAGENT(PORT)

After selecting a reagent press the

-A pop up message will appear: “INJECT REAGENT?” Press Continue or Cancel button.

Cancel

You have canceled the command & return to the manual tab

Continue

The reagent will inject the specified amount

A pop up message will appear: “REAGENT INJECTED.” Press Continue button

NOTE:

REAGENTS (1-5) will inject thru the left splitter

REAGENTS (6-10) will inject thru the right splitter

(green section) Range: 0.1ml-50.0ml

INJECT

**Dual System**

button

or buttons or by using the keyboard.

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528MANUAL rev3 18 9/10/09

Page 19

RUN TAB

The RUN TAB determines what methods will be selected and to what racks/columns they will be run.

Rack A / Rack B / Rack C

After determining which rack(s) are going to be used, select the method you want to run.

Some methods have been pre-programmed. Reference Program tab in the manual for adding/editing

methods

Load racks onto the lift arms in the down position

NOTE:

For proper airflow, all racks should be filled with empty cups. No need to run reagents in those columns.

Each column must contain 6 cups. Polypropylene cups can only be used to 130

Selecting Methods

A default program will appear in all three racks. Select method to be used from the pull down menu.

When selecting a method start with

Protocol for running different methods at the same time

The same temperature and the same reagents must be used for each method.

This will allow you to run 1, 2 or 3 different methods at once.

Activating Selecting Columns

If running all three racks, select column 9

If running racks A & B, select column 6

If running Rack A only, select column 3

-A pop up message will appear: “COLUMNS X-X ARE ACTIVE.” Press Continue button.

the active column indicator will turn green

Deactivating Selecting Columns

Select the column to deactivate

The de-active column indicator will turn black

Run Methods

Press the RUN METHODS button to begin.

The AutoBlock software will check for syntax errors in methods before starting

-A pop up message will appear: “CONTINUE WITH METHOD?”, Press Continue or Cancel button.

Cancel

A pop up message will appear: “METHODS CANCELED?”, Press Continue button

You have canceled the command & return to the run tab

Rack A. then proceed to Rack B then Rack C.

Run Tab

0

C

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528RUN rev 3 19 9/10/09

Page 20

RUN TAB

Run Methods continued

Continue

The racks and the injection arm will home and the method will begin.

If syntax terror occurs

The AutoBlock software will check for syntax errors in methods before starting

-A pop up message will appear: “SYNTAX ERROR XX –method command line appears”

-Look up syntax error in the PROGRAM TAB section of this manual.

-Press Continue button

-A pop up message will appear: “SYNTAX ERROR. METHOD CANNOT START. PLEASE FIX ERRORS.”

- Press Continue button

-Return to the PROGRAM TAB to edit the method. Saving the edited method before running.

If incompatible methods occurs

The AutoBlock software will check for syntax errors in methods before starting

-A pop up message will appear: “HEAT TEPERATURES MUST BE TH SAME FOR ALL THREE METHODS”

-Press Continue button

-A pop up message will appear: “SYNTAX ERROR. METHOD CANNOT START. PLEASE FIX ERRORS.”

-Press Continue button

-Select compatible methods to run or run at different times

Under the rack/method/column section, the screen will show which current command is being executed

in the method.

Pause Button

You may select this at any point. AutoBlock will finish the current step and then pause.

-A pop up message will appear: “METHODS WILL PAUSE AS SOON AS CURRENT COMMAND IS

COMPLETE” Press Continue button.

Continue

The method will now resume from it’s last executed command.

Main Screen Abort Button

You may select this at any point. By selecting the abort button the abort operation will seize all

communications to the control board. The temperature will not read correctly and will not heat.

All motion is stopped. Reference TOUCH SCREEN CONTOLLER section of this manual

If you need an emergency stop depress the E-STOP.

5528RUN rev 3 20 9/10/09

A pop up message will appear: “METHODS PAUSED. TO RESUME METHODS CLICK

CONTINUE ?”, Press Continue button

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

Page 21

PROGRAM TAB

g

Methods are stored and can be edited. Custom methods can be programmed into the AutoBlock.

Below depicts the Program Tab. Each command will be described in detail to ensure operator

understandin

.

program mode –heat screen

HEAT

Set the block temperature in 0C. Range: 150C to 1500C

This is not

Polypropylene cups can only be used to 130

Command Sequence:

1. Select HEAT command from the main menu

2. Select the block temperature by up or down buttons or by keyboard. (

3. Added User Notes. With the keyboard activated, press comment area with stylus and type

example note: heat samples for 2 hours

NOTE: Racks will not lower into graphite until within 5 degrees of set point.

sample temperature.

Program Tab

0

C

0

C)

INJECT

This command adds reagents. Range: 0.1 - 50 ml

The injection arm will move over the drain, raise the racks, prep the lines with

6ml of reagent, inject the specified amount of reagent into selected columns,

move the injection arm to the drain & purge lines with 6ml of water. Racks are

left in the up position.

The lines will prep & purge unless specified by the no prep or no purge command. This can be done by

using the ADD command.

If the reagent is not listed in the drop down menu, go to the SERVICE TAB –Setup Reagents,

to add them in.

Command Sequence:

1. Select INJECT command from the main menu

2. Select the reagent from the drop down menu

3. Select amount to inject by arrow buttons or by keyboard (ml)

4. Added User Notes. With the keyboard activated, press comment area with stylus and type.

Proceed to the continue button

program mode –inject screen

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528MANUAL-program Rev 3 21 9/15/09

Page 22

PROGRAM TAB

WAIT

Sets the amount of time the samples will be heated during a step.

Range: 1-999 minutes.

The method will wait for the set graphite temperature to be reached,

0

C degrees, rack are then lowered. The method will then wait for the

±5

specified number of minutes.

Command Sequence:

1. Select WAIT command from the main menu

2. Select the wait time by up or down buttons or by keyboard. (minutes)

3. Added User Notes. With the keyboard activated, press comment area with stylus and type.

Proceed to the continue button

COOL

Set the amount of time the samples will be cooled. Range: 1-999 minutes

The racks will be raised out of the graphite block and cool for the specified

number of minutes. The fan will automatically increase to its maximum for

efficient sample cooling.

Command Sequence:

1. Select COOL command from the main menu

2. Select range by up or down buttons or by keyboard. (minutes)

3. Added User Notes. With the keyboard activated, press comment area with stylus and type.

Proceed to the continue button

program mode –wait screen

program mode –cool screen

PAUSE

An operator will receive a pop up message. The method will not execute

the next command until the analysts responds.

Command Sequence:

1. Select PAUSE command from the main menu

2. Add message with the keyboard activated, press comment area

Example message: Insure volume level is correct

Proceed to the continue button

DELETE

Directly deletes last command from the method screen.

Command Sequence:

Proceed to the continue button

with stylus and type.

1. Select PAUSE command from the main menu

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

program mode –pause screen

program mode –sample program

5528MANUAL-program Rev 3 22 9/15/09

Page 23

EVERY METHOD

At the end of each method the following two commands need to be added

With the keyboard activated, press command area and type in the command string as follows:

Press the CONTINUE button and SAVE the method

enter: COLUMN DRAIN

enter: DISPENSE H2O(1) 10

PROGRAM TAB

OPEN

Opens directory where previous methods were saved MyComputer\LocalDisk(C)\HardDisk\Methods\

Select the OPEN button

Select a method from the directory

Press the OK button

SAVE

Save a new or edited method.

Select the Save button and activate keyboard

Type method name in FILE NAME area, Press OK button

Methods are stored in this directory MyComputer\LocalDisk(C)\HardDisk\Methods\

NEW

Clears the method command area enables operator to program command s to a new method

Select the NEW button

The methods field clears

EDIT

Allows the operator to modify current methods.

Method command area must have commands programmed on the screen

Select the EDIT button

Highlight the command to edit, activate the keyboard to make changes.

Cancel

You have canceled the command & return to the main PROGRAM TAB

Continue

Saves the change and returns to the main PROGRAM TAB to continue programming

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528MANUAL-program Rev 3 23 9/15/09

Page 24

IMPORT/EXPORT METHOD

Methods are stored in this directory MyComputer\LocalDisk(C)\HardDisk\Methods\

Methods are saved by METHOD NAME.TXT file example: 200.7 WATERS 50ML.TXT

Methods can also be written using notepad or word. Save as a text file (.txt) onto a USB stick

Basic operator knowledge of Microsoft Windows is required

Insert USB stick into USB slot near the touch screen

IMPORT

There are two ways to import methods

1. From the PROGRAM TAB, press OPEN button

Select MY COMPUTER from the side icons

Select TRAVELDRIVE (D:) and press the OPEN button

Select METHODS and press the OPEN button

Select method to import and press the OK button

Save the method using the SAVE procedures on the previous page

2. Press the START tab on the task bar

Select MY COMPUTER from the side icons

Select TRAVELDRIVE (D:) and press the OPEN button

Select method

Using the EDIT, COPY TO FOLDER

Select MyComputer\LocalDisk(C)\HardDisk\Methods, press the COPY button

EXPORT

There are two ways to export methods

1. From the PROGRAM TAB, open the method to be exported

press SAVE button

Select MY COMPUTER from the side icons

Select TRAVELDRIVE (D:) and press the OPEN button

Activate the keyboard, type method name in FILE NAME area

Press OK button

2. Press the START tab on the task bar

Select MY COMPUTER from the side icons

Double click LOCAL DISK(C:)

Double click HARDDISK

Double click METHODS

Select method to export

Using the EDIT, COPY TO FOLDER

Select TRAVELDRIVE (D:), press the COPY button

PROGRAM TAB

EXPORT LOG

Logs are stored in this directory MyComputer\LocalDisk(C)\HardDisk\Data\

Using the same procedure for Exporting Methods extracting method logs from the DATa directory.

Data logs are saved by MethodName.TXT Hour_Minute Month_Day_Year. DAT file

example: 200.7 WATERS 50ML.TXT12_30_FEB_01_09.DAT

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528MANUAL-program Rev 3 24 9/15/09

Page 25

SYNTAX ERRORS

Run Tab

Select the method(s) and columns to run

Press RUN METHODS button

If there is an error in the method programming a popup will appear, note what syntax occurs

syntax error will appear with the following format:

SYNTAX ERROR# -COMMAND

The method will not continue until the syntax error is fixed in the program.

Return to the Program Tab, open the method and edit. SAVE the method before returning to the Run Tab

# definition and description

10 value out of range

20 unrecognized command

30 reagent not recognized

40 loop must execute at least 1 time

50 loop must use a stop loop command

60 elevator command must use up or down to specify location

PROGRAM TAB

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528MANUAL-program Rev 3 25 9/15/09

Page 26

SERVICE TAB

The SERVICE TAB is set up for AutoBlock to be calibrated,

maintained, and custom levels set for optimal performance.

service tab screen

Setup Reagents

Select SETUP REAGENTS button from the SERVICE TAB

Reagents are set to correspond with reagent ports. AutoBlock reagent ports are located on the

left side of AutoBlock, labeled #’s 1-10. The reagents have been set up in the following manner:

Single System Dual System**

**In a single system ports #6-10 have been plugged.

If the reagent arrangement or if other reagents are used, you may change the list.

In the following steps. Listed below are common reagents with viscosity ratings.

Reagent

H2O(1) (ports 1 & 6, cannot be changed) Low

HNO3(2) Nitric Acid Medium

HCL(3) Hydrochloric Acid Low

H2O2(4) Hydrogen Peroxide 30% Medium

H2SO4(5) Sulfuric Acid High

H2O(6) (ports 1 & 6, cannot be changed) Low

KMnO4(7) Potassium Permanganate Low

PERSUL(8) per sulfates Low

NH2OH(9) Hydroxylamine Low

H2O(10) Water Low

Viscosity ratings control the pump speed to maximize efficiency and provide volume delivery accuracy.

Low Viscosity, fast pump speed, (reagent near the viscosity of water)

High Viscosity, slow pump speed

*Port #1 H20(1) *Port #6 H20(6)

Port #2 HNO3(2) Port #7 KMnO4(7)

Port #3 HCL(3) Port #8 PERSUL(8)

Port #4 H2O2(4) Port #9 NH2OH(9)

Port #5 H2SO4(5) Port #10 H20(10)

*Ports #1 & #6 must remain H

O

2

Viscosity

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5588SERVICE rev4 26 9/15/09

Page 27

A

t

SERVICE TAB

reagent setup screen reagent new screen

Setup Reagents

•

Selecting a different reagent on a port:

fter selecting SETUP REAGENTS button from the SERVICE TAB use the pull down menu on the p

by pressing the arrow button.

-Select the reagent from the list.

• To add a reagent to the pull down menu, you are able to add your own.

Select the New button from the screen. A new screen will appear, input information needed.

Reagent

With the keyboard activated, press reagent area and type in Reagent Name(port#)

No spaces allowed

Example: HCL(3) Reagent Name:HCL used on Port #3

Viscosity

Select the pull down menu by pressing the arrow button, choose Low, Medium, High.

SAVE the input information.

-A pop up message will appear: “NEW REAGENT ADDED.” Press Continue

-Select RETURN TO SETUP PORTS button to return to the setup screen

• To deleted a reagent on the pull down menu.

Select the DEL button from the screen. A new screen will appear, input information needed.

Reagent

Select Reagent to be Deleted from the pull down menu by pressing the arrow button

Choose Reagent Name, the viscosity associated with the reagent will appear in the Viscosity

of Reagent box

DELETE the reagent information

-A pop up message will appear: “REAGENT DELETED.” Press Continue

-Select RETURN TO SETUP PORTS button to return to the setup screen

• To change a reagent information on the pull down menu. (name change or viscosity rate)

You will need to add a new reagent & delete the old reagent

Select Main Menu button to return to the SERVICE TAB. By selecting the Main Menu button, the new port

selection has been saved.

continued

or

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5588SERVICE rev4 27 9/15/09

Page 28

Calibrate Temp

The Graphite Block has been tested and calibrated during manufacturing to ensure

0

a +/-2

The graphite block temperature needs calibration if a large variation is noted.

Consult Environmental Express before calibrating.

After selecting the Calibrate Temp button

-A pop up message will appear:

“DO YOU WANT TO CALIBRATE THE GRAPHITE BLOCK? YOUR OLD CALIBRATION TEMPERATUE

WILL BE LOST.” Press Continue or Cancel button.

Cancel

You have canceled the command & return to the Calibration screen

Your current calibration temperature will show in the actual temperature box

Continue

• After the graphite Block temperature reaches 90

• Record the actual graphite block temperature with an infrared thermometer.

• Enter the

using the keyboard. (

• SAVE the input information.

Select

C variation in temperature range.

-A pop up message will appear: “THE BLOCK IS BEING SET TO 90

TEMPERATURE HAS STABILIZED, RECORD ACTUAL TEMPERATURE READING”

or by

Main Menu button to continue back to the SERVICE TAB screen.

G

readout in the Graphite Block Actual Temp. This may be done with the UP or DOWN buttons

O

C)

SERVICE TAB

0

C, let the temperature stabilize for 15 minutes.

0

C. WAIT 15MIN AFTER

calibrate temp screen

calibrate pump screen

Calibrate Pump

To

maintain an accurate injection volume and viscosity rating,

th

e pump requires calibration.

Co

ntact Environmental Express for an Excel worksheet to calibrate injection tubing.

Se t the initial length of tubing to 108”.

N ote:

Check all lines for air bubbles & clogs before calibrating

Ca

librate Injection Tubing

1.

Label each vessel 1-6. Weigh six dry, clean test tubes, record weight in chart.

2.

Place test tubes in order #1-6, from front to back into a rack.

In the MANUAL TAB, place in rack C position and raise the rack.

3. Prime the line with 6ml of H O.

INJECT field(green section)

Amount

Set the volume to 6ml, by changing the amount of reagent with the UP or DOWN

Reagent

Select the H2O(1) to be injected.

With injection arm over the drain, press the INJECT button

4. After the lines have been primed, Move the ARM(red section)

Set the position of the arm location over the test tubes, by selecting the correct column from the Column L

drop down menu

Press the MOVE button

5. Change the Amount of volume to 30ml (green section)

Press the INJECT button

2

buttons

manual tab screen

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5588SERVICE rev4 28 9/15/09

Page 29

SERVICE TAB

Calibrate Pump

6. After the reagent has injected 30ml.

After the lines have injected, Move the ARM(red section) over the drain, by selection from the Column

L drop down menu

Press the MOVE button

7. Re-weigh each test tube and record the total weight (tube +H

8. Average range is 2%

• When the average range reaches 0-2%, you are ready to calibrate the pump(s).

Reference SERVICE TAB section on pump calibration

• If the target range exceeds ±2%, refer to the Amount Trimmed column.

This is the amount of tubing that needs to be cut off to the corresponding row.

a. Pull the tubing from the nozzle.

b. Measure the amount to be cut, refer to the Amount Trimmed column

Cut each tubing with a tube cutter

8. Dry test tubes and repeat steps 3-5 until the target range reaches ±2%

9. Return to the Service Mode tab and select Calibration Pump button.

10. Under the heading, Pump1 actual ml injected, enter value by using the UP or DOWN buttons

or by using the keyboard. (ml).

This value is obtained from the Calibrate Injection Tubing worksheet. Reference the min-max-middle

values. Use the MIDDLE value for the pump1 actual ml injected.

11. SAVE the input information.

Select Main Menu button to continue back to the SERVICE MODE screen. By selecting the Main Menu

button, the new calibration has been saved.

In a dual system, the second injection arm tubing is calibrated in the same manner, except using H

and Arm(6-10).

continued

2

O)

single unit system shown

dual unit has two splitters

O(6)

2

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5588SERVICE rev4 29 9/15/09

Page 30

SERVICE TAB

A

Maintenance

This section is designed to remind the operator when it is time for

replacement of parts or calibration of processes.

Failure to adhere to AutoBlock maintenance instructions and/or

requirements can void all warranties and result in damage to the

utoBlock, loss of samples and/or losses not covered by the

warranty. Please review the warranty section of this manual.

After selecting the MAINTENENCE button, there are several items to

be addressed on (3) pages. Next to each maintenance item shows:

date last serviced - service indicator - next service date

Maintenance items that need addressing are:

Graphite Calibration Teflon Tubing Pump 1 Teflon Tubing Pump 2

System Clean Pump Tubing 1 Pump Tubing 2

VICI Emitters Pump Calibration 1 Pump Calibration 2

HEPA Filter Check Waste Drum

After service has been completed double click the SERVICE button to update

the screen. This will change the button from red to green and change the service dates.

Select MAIN MENU button to continue back to the SERVICE TAB screen.

By selecting the Main Menu button, the new information has been saved

before continuing onto the next/previous page.

Options

AutoBlock comes with 2-pages of recommended

preset features. Recommended service days may be

changed by the operator to increase or decrease based

on usage and standard laboratory protocol.

Time entered is in days.

Options included:

By selecting the UP or DOWN button

each item will change its current value

Recommended service days have already been provided.

Automatic Reminders

System Clean 30

HEPA Filter 180

VICI Emitters 365

Graphite Calibration 365

Fan Speed 100%

Pump Tubing 365

Teflon Tubing 365

Pump Calibration 30

Waste Drum 30

Select MAIN MENU button to save data & continue back to the SERVICE TAB screen.

service (days)

365

365

100

manual screens

this third screen is only shown in a

options screen

dual system

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5588SERVICE rev4 30 9/15/09

Page 31

Supplies

Call Environmental Express for all your AutoBlock supplies. Have your AutoBlock serial number with you, this is

located in the back of the unit and inside the exhaust compartment.

After selecting the SUPPLIES button, Environmental Express contact information will appear.

ENVIRONMENTAL EXPRESS

490 Wando Park Blvd. Tel 800-343-5319

Mt. Pleasant, South Carolina 29464 Tel 843-881-6560

Fax 843-881-3964

Email INFO@EnvExp.Com

The current software version that is running on this AutoBlock unit will appear at the bottom of screen.

Press SPARE LIST button

A scroll down list of supplies will appear. There is also a supplies list in your manual.

SERVICE TAB

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5588SERVICE rev4 31 9/15/09

Page 32

Supplies

Call Environmental Express for all your AutoBlock supplies.

Have your

exhaust compartment.

ENVIRONMENTAL EXPRESS

490 Wando Park Blvd. Tel 800-343-5319 or

Mt. Pleasant, South Carolina 29464 Tel 843-881-6560

Fax 843-881-3964

Email INFO@ENVEXP.COM Email INFO@ENVEXP.COM

AutoBlock serial number with you; this is located in the back of the unit and inside the

P/N P/N DESCRIPTION DESCRIPTION QTY QTY

per package per package

ABP103

ABP104

ABP105

ABP106

ABP107

ABP108

ABP120 Pump Motor Assembly 1

ABP121 Heater Mat Assembly 1

ABP122 5-Valve Assembly 1

ABP123 Lift Motor Assembly 1

ABP124 Injection Arm Motor Assembly 1

ABP125 Photo Sensor Assembly 1

ABP127 Leak Detector Assembly 1

ABP128 Exhaust Fan Assembly 1

ABP129 RTD-Block Assembly 1

ABP130 RTD-Sample Assembly 1

ABP140 Reagent-Valve Tubing Kit (single) 1

ABP141 Reagent-Valve Tubing Kit (dual) 1

ABP143 Sample Injection Kit 1

ABP144 Pump Tubing Kit 1

ABP145 Insulation Kit, 9pc set 1

ABP149 10L Carboy w/Cap & Fitting 1

ABP150 Thumbs Screw 3

ABP151 HEPA Filter 1

ABP152 Pressure Sensor 1

ABP153 Drain Tubing Kit 1

ABP154 Pump Head 1

ABP159 Injection Guide 6

ABP163 54-well Rack, 18-position 3

ABP164 On/Off Switch 1

ABP171 Power Cord 1

VICI Emitter Disk 4

Pump to Motor Coupling set 2pc

Tygon Tubing for Waste Line 10’

Teflon Line for Uptake 25’

Replacement Solenoid 1

Manifold w/Plug 1

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528SUPPLY rev3 32 9/10/09

Page 33

EXIT

Closes the program, shutting down the system and saving data

Select the blue EXIT button in the center of the screen

-A popup message will appear: “SAVING DATA BEFORE EXIT. THIS WILL TAKE A FEW MINUTES.”

-Select the Continue button.

When the AutoBlock software has finished exiting the top row of the screen will change

EXIT TAB

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528EXIT rev 3 33 9/10/09

Page 34

Warranty

The Environmental Express AutoBlock is warranted to heat, hold temperature, automatically add

reagents, Warranty lift racks, cool samples with air flow and perform the stated functions of th e touch

screen controller for a period of ONE YEAR. This 1-year warranty is divided into two sections as follows:

90-Day Warranty

The 90-day warranty covers parts, shipping and labor for a period of ninety (90) days from the original

ship date, thereafter it expires. This warranty applies only in the case of damage or failure caused by

reasonable and normal laboratory use.

9-Month Warranty

The 9-month warranty begins immediately following the 90-day warranty. It covers parts and ground

shipping costs for the replacement parts only. This warranty applies only in the case of damage or failure

caused by reasonable and normal laboratory use. The 9-month warranty expires 365-days after the

original ship date.

Warranty Disclaimer

Environmental Express makes no other warranty, expressed or implied. Environmental Express shall not

be liable for consequential, incidental, specific or any other indirect damages resulting from economic

loss or property damages sustained by any customer from use of this product.

Environmental Express does not warrant the AutoBlock against damage resulting from chemical

reactions that may occur between reagents or between samples and reagents or between various liquids

and components of the AutoBlock. It is the responsibility of the laboratory to verify the compatibility of the

reagents, heat and time indexes, the compatibility of each sample matrix and other varying digestion

method conditions prior to operation.

Charges Not Covered by Warranty

• Failure to retain the original shipping crate and all other packaging materials for at least 90-days could

result in additional charges should repairs prove necessary.

• Failure to adhere to AutoBlock maintenance instructions and requirements can void all warranties and

result in damage to the AutoBlock, loss of samples, and create repair issues not covered by the

warranty. See maintenance section instructions.

How the Warranty Works

Upon receipt of the unit it is the laboratory’s responsibility to inventory all parts and immediately notify

Environmental Express of any suspected defects or missing parts. If during the first 90-days following the

original ship date the unit malfunctions, a telephone call to troubleshoot the issue must be initiated by the

laboratory. If it is deemed by the technical staff of Environmental Express that the problem cannot be

fixed by the lab, and that the failure occurred during normal and accepted laboratory operations, then a

written Return Authorization Form and Number will be issued by Environmental Express. The AutoBlock

will be returned to Environmental Express in its original shipping container.

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528WARRANTY rev 3 34 9/10/09

ENVIRONMENTAL EXPRESS

Page 35

Repair

If your system requires attention beyond basic maintenance, please follow the guidelines below. Failu re

to so could result in loss of warranty protection and increased charges.

Repair Approval

Any attempt by laboratory personnel to repair the AutoBlock without first obtaining Environmental

Express’ written consent may void all or part of the Warranty, expressed or implied. Call 800-343-5319 or

(1-843-881-6560 outside the US) to obtain approval before beginning any repair work.

In-Lab Troubleshooting & Repairs

The AutoBlock has been engineered so that mechanically minded laboratory personnel can perform most

troubleshooting, repairs and tests. Technical assistance in such circumstances is always provided over

the phone (or via email, fax, etc…) by Environmental Express, whether the AutoBlock is in or out of the

warranty periods. There is no charge for this assistance. The AutoBlock is component based, making

most repairs quick.

Repair by Manufacturer

In the unlikely event that the unit must be returned to the manufacturer, it is the lab’s responsibility to:

Obtain a

1 Coordinate shipment and insurance with Environmental Express

2 Properly pack* the AutoBlock in approved materials only*

3 Place a Purchase Order with Environmental Express for repair

These elements are critical to a successful repair experience.

Return Authorization Form and Number

Return Packing & Shipping

It is the responsibility of the laboratory to retain in good condition the original crate and other packing

material for a period no less than 90-days following the receipt of the AutoBlock. If the original shipping

container is not available, a new shipping container must be purchase from Environmental Express prior

to shipment. Shipping charges and insurance from your lab to Environmental Express, and return

shipment charges via standard trucking line will be the responsibility of the lab except for approved 90day warranty claims.

Inspection upon Receipt

Upon receipt, Environmental Express will inspect, repair and return the unit in a timely manner, and bear

associated costs covered by warranty, if any applies. However, if it is determined by Environmental

Express that the damage to the AutoBlock was caused by negligence or improper use or improper

packaging/shipment, no warranty shall apply. In such case, reasonable and customary repair charges will

apply including freight and insurance cost to and from the laboratory.

Additional Information & Help

If you have any questions or concerns do not hesitate to pick up the phone and call 800-343-5319 or

(1-843-881-6560 outside the US). Standard hours of operation are 8:30am-5:30pm EST-Monday through

Friday excluding holidays. You can email questions to INFO@ENVEXP.COM at any point. Please include

you name, company name & telephone number. A technical service representative will respond as

quickly as possible. This manual addresses issues normally seen in the field.

ENVIRONMENTAL EXPRESS

For technical support call 1-800-745-8218 or send email to INFO@ENVEXP.COM

5528WARRANTY rev 3 35 9/10/09

Loading...

Loading...