Page 1

WARRANTY REGISTRATION

enviro.com/warranty

Q2L

D I REC T VE N T F I R E PL ACE - N OVA

OWNER’S MANUAL

WARNING: If the information in this manual is not followed exactly, a

re or explosion may result causing property damage, personal injury

or loss of life. Installation and service must be performed by a qualied

4001609

Version Française: www.enviro.com/fr.html

installer, service agency or the gas supplier.

50-3054

Page 2

Safety Precautions

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in serious

injury, death, or property damage.

- Do not store or use gasoline or other ammable vapors and

liquids in the vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your

building.

• Leave the building immediately.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the re

department.

- Installation and service must be performed by a qualied

installer, service agency or the gas supplier.

INSTALLER:

Leave this manual with the appliance.

CONSUMER:

Retain this manual for future reference.

This appliance may be installed in an after-market permanently located,

manufactured (mobile) home, where not prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. This

appliance is not convertible for use with other gases, unless a certied kit is used.

Massachusetts installations (Warning): This product must be installed by a licensed plumber or

gas tter when installed within the Commonwealth of Massachusetts. Other Massachusetts code

requirements: Flexible connector must not be longer than 36in., a shut off valve must be installed;

only direct vent sealed combustion products are approved for bedrooms/bathrooms. A carbon

monoxide detector is required in all rooms containing gas red direct vent appliances. The replace

damper must be removed or welded in the open position prior to installation of a replace insert.

Page 2

Page 3

Safety Precautions

FOR SAFE INSTALLATION AND OPERATION OF YOUR “ENVIRO” HEATER,

PLEASE CAREFULLY READ THE FOLLOWING INFORMATION:

• All ENVIRO gas-red appliances must be installed in

accordance with their instructions. Carefully read all the

instructions in this manual rst. Consult the building

authority having jurisdiction to determine the need for a

permit prior to commencing the installation.

• NOTE: Failure to follow these instructions could cause

a malfunction of the replace, which could result in death,

serious bodily injury, and/or property damage.

• Failure to follow these instructions may also void your

re insurance and/or warranty.

GENERAL

• Installation and repair should be done by a qualied

service person. The appliance should be inspected before

the rst use and, at least, annually by a qualied service

person. More frequent cleaning may be required due to

excessive lint from carpeting, bedding material, etc. It

is imperative the control compartments, burners and

circulating air passageways of the appliance be kept

clean.

• Due to high temperatures, the appliance should be

located out of high trafc areas and away from furniture

and draperies.

Children and adults should be alerted to the

hazards of high surface temperatures and should

stay away to avoid burn or clothing ignition.

• Young children should be carefully supervised when

in the same room as the appliance. Toddlers, young

children and others may be susceptible to accidental

contact burns. A physical barrier is recommended if there

are at risk individuals in the house. To restrict access to a

replace or stove install an adjustable safety gate to keep

toddlers, young children and other at risk individuals

out of the room and away from hot surfaces. Any safety

screen or guard removed for servicing an appliance must

be replaced prior to operating the appliance.

• Clothing or other ammable materials should not be

placed on or near the appliance.

FOR YOUR SAFETY

• Installation and service must be performed by a qualied

installer, service agency or gas supplier.

• This installation must conform to local codes or, in the

absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1/NFPA 54, or the Natural Gas and Propane

Installation Code, CSA B149.1.

• To prevent injury, do not allow anyone who is unfamiliar

with the stove to operate it.

• To prevent injury, if the pilot or pilot and burners

have gone out on their own, open the glass door and

wait 5 minutes to air out before attempting to relight the stove.

• Always keep the area around these appliances clear of

combustible material, gasoline and other ammable liquids

and vapours.

• These appliances should not be used as a drying rack for

clothing or for hanging Christmas stockings/decorations.

• Due to the paint curing on the stove, a faint odor and slight

smoking will likely be noticed when the stove is rst used.

Open a window until the smoking stops.

Always connect this gas stove to a vent system and vent to

the outside of the building envelope. Never vent to another

room or inside the building. Make sure the specied vent

pipe is used, properly sized and of adequate height to

provide sufcient draft. Inspect the venting system annually

for blockage and signs of deterioration.

WARNING: Failure to position the parts in accordance

with the diagrams in this booklet, or failure to use only

parts specically approved with this appliance, may result in

property damage or personal injury.

WARNING: Do not operate with the glass front removed,

cracked or broken. Replacement of the glass should be done

by a licensed or qualied service person.

• Never use solid fuels such as wood, paper, cardboard, coal,

or any ammable liquids, etc., in this appliance.

• Do not use this appliance if any part has been under water.

Immediately call a qualied service technician to inspect the

appliance and to replace any part of the control system or

any gas control which has been under water.

• Do not abuse the glass by striking it or slamming the door

shut.

• If the Q2L unit is pulled out of its installation, and the vent-

air intake system is disconnected for any reason, ensure that

the vent-air intake pipes are reconnected and re-sealed in

accordance to the instructions noted in

- DIrect Vent

InItIal InstallatIon

Page 3

Page 4

Safety Precautions........................................................................................................2

Table of Contents.........................................................................................................4

Codes And Approvals....................................................................................................5

Specications.............................................................................................................6

Dimensions.....................................................................................................6

Rating Label Location.........................................................................................6

Operating Instructions..................................................................................................7

Lighting and Turning Off Instructions...................................................................7

Pilot Light.........................................................................................................8

Air Shutter (Venturi)...........................................................................................8

Remote Controls................................................................................................8

Burner Lighting.................................................................................................9

Blower Speed (Optional) ....................................................................................9

Normal Sounds During Operation........................................................................9

Maintenance And Service..............................................................................................10

Routine Maintenance........................................................................................10

Cleaning The Glass............................................................................................10

Cleaning The Firebox........................................................................................10

Replacing the Glass...........................................................................................10

Cleaning Decorative Surfaces............................................................................11

Glass Door Removal.........................................................................................11

Burner Removal...............................................................................................12

Access Door.....................................................................................................12

Gas Conversion Kit Installation..........................................................................13

Initial Installation.......................................................................................................15

Introduction.................................................................................................15

Placement and Framing....................................................................................15

Rear Vent Conversion.......................................................................................16

Corner Installation...........................................................................................17

Mantle and Non-Combustible Clearances............................................................18

Direct Vent......................................................................................................19

Vent Termination Restrictions............................................................................20

Venting Clearances..........................................................................................21

Approved Venting Parts.....................................................................................21

Horizontal Termination - Rear Vent w/ No Rise.................................................23

Allowable Co-Axial Vent Congurations..............................................................24

Horizontal Termination.....................................................................................25

Vertical Termination ........................................................................................26

Gas Line Connection and Testing.......................................................................29

Electrical Requirements ...................................................................................30

Secondary Installation................................................................................................32

Fan Kit Installation (Optional)............................................................................32

Safety Screen Installation.................................................................................33

Cabinet Extensions...........................................................................................34

Liner Installation (Optional)..............................................................................35

Fire Grate and Log Set Installation....................................................................36

Trouble Shooting.............................................................................................38

Parts List.........................................................................................................39

Parts Diagram..................................................................................................40

Notes......................................................................................................41

Warranty.......................................................................................................43

Installation Data Sheet.....................................................................................44

Page 4

Table of Contents

Page 5

Codes And Approvals

DIRECT VENT ONLY: This type is identied by the sufx DV. This appliance draws all of its air for

combustion from outside the dwelling, through a specially designed vent pipe system.

This appliance has been tested and approved for installations from 0 feet to 4500 feet (1372 m) above

sea level.

In the USA: The appliance may be installed at higher altitudes. Please refer to your American Gas

Association guidelines which state: the sea level rated input of Gas Designed Appliances installed at

elevations above 2000 (610 m) feet is to be reduced 4% for each 1000 feet (305 m) above sea level.

Refer also to local authorities or codes which have jurisdiction in your area regarding the de-rate

guidelines.

In Canada: When the appliance is installed at elevations above 4500 feet (1372 m), the certied high

altitude rating shall be reduced at the rate of 4% for each additional 1000 feet (305 m).

• This appliance has been tested by INTERTEK and found to comply with the established VENTED

GAS FIREPLACE HEATER standards in CANADA and the USA as follows:

VENTED GAS FIREPLACE HEATER (Q2L; NATURAL GAS, PROPANE GAS)

TESTED TO: ANSI Z21.88a-2014/CSA 2.33a-2014 VENTED GAS FIREPLACE HEATERS

CAN/CGA 2.17-M91 (R2014) GAS FIRED APPLIANCES FOR HIGH ALTITUDES

CSA P.4.1-02 TESTING METHOD FOR MEASURING ANNUAL FIREPLACE EFFICIENCY

This ENVIRO Q2L Fireplace:

• Has been certied for use with either natural gas or propane (see rating label).

• Is not for use with solid fuels.

• Is approved for bedroom or bed sitting room. (IN CANADA: must be installed with a listed wall

thermostat. IN USA: see current ANSI Z223.1 for installation instructions.)

• Must be installed in accordance with local codes. If none exist, use current

installation code CAN/CGA B149 in Canada or ANSI Z223.1/NFPA 54 in the

USA.

• Must be properly connected to an approved venting system and not connected

to a chimney ue serving a separate solid-fuel burning appliance.

IMPORTANT NOTICE (Regarding rst re up): When the unit is turned

on for the rst time, it should be turned onto high without the fan on (if

equipped) for the rst 4 hours. This will cure the paint, logs, gasket material

and other products used in the manufacturing process. It is advisable to

open a window or door, as the unit will start to smoke and can irritate

some people. After the unit has gone through the rst burn, turn the unit

off including the pilot, let the unit get cold then remove the glass door

and clean it with a good gas replace glass cleaner, available at your local

ENVIRO dealer.

Page 5

Page 6

Dimensions:

Gas

Line

Specications

Figure 1. Q2L Dimensions - Top Vent

Rating LabeL & Lighting instRuctions Location:

To access the rating label and lighting instructions ip down the control cover. The plates are attached

to a length of chain and are never to be tampered with or removed. All important information for your

replace is on this label as well of the model specic serial number which you will need for warrenty

information.

Page 6

Figure 2. Q2L Dimensions - Rear Vent

Page 7

Operating Instructions

For Your Safety, Read Safety Precautions And

Lighting Instructions Before Operating

WARNING: IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY A FIRE OR EXPLOSION MAY

RESULT, CAUSING PROPERTY DAMAGE, PERSONAL INJURY OF LOSS OF LIFE.

Lighting anD tuRning off instRuctions:

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING:If you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life

A. This appliance has a pilot which must be lighted by hand. When

lighting the pilot, follow these instructions exactly.

B. BEFORE LIGHTING smell all around the appliance area for gas.

Be sure to smell next to the floor because some gas is heavier

than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance. Do not touch any electrical switch; do

not use any phone in your building. Immediately call your gas supplier

from a neighbor's phone. Follow the gas supplier’s instructions. If you

cannot reach your gas supplier, call the fire department.

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information above on this label.

2. Set the thermostat to the lowest setting.

3. Turn off all electric power to this appliance.

4. Open the front control panel.

5. Turn off the gas control knob clockwise to the “OFF” position.

6. Open door. Wait fIve (5) minutes to clear out any gas. Close door.

Then smell for gas, including near the floor. If you smell gas, STOP!

Follow “B” in the saftey information above on this label. If you don’t

smell gas, go to the next step.

7. Find pilot-located near the center rear of the firebox. Turn the gas

control knob counter-clockwise to “PILOT”. Push the gas

control in fully and hold, keep knob depressed for about 30 seconds

after the pilot is lit. Release knob. If pilot goes out, repeat steps 4

through 5.

C. Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by hand,

don’t try to repair it. Call a qualified service technician. Force or

attempted repair may result in a fire or explosion.

D. Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and any

gas control which has been under water.

WARNING: This gas valve has a lockout device, which will not allow the

pilot burner to be relit until the thermocouple has cooled.

-If the knob does not pop up when released, stop and immediately call your

service technician or gas supplier.

-If the pilot will not stay lit after several tries, turn the gas control knob

clockwise

8. Turn the gas control knob counter clockwise to the “ON” position.

Flip the burner switch to “ON” then turn the “HI/LOW” knob to the

desired setting.

9. Close the front control panel.

10. Turn on all electric power to the appliance.

11. Set thermostat to desired setting.

to “OFF” and call your service technician or gas supplier.

1. Set the thermostat to the lowest setting.

2. Turn off all electric power to the appliance if service is to be performed.

3. Open the front control panel and flip burner switch to “OFF”

TO TURN OFF GAS TO APPLIANCE

4. Turn the gas control knob clockwise to the “OFF” position.

5. Close the front control panel.

C-12454

Figure 3. Lighting Instruction Label

Page 7

Page 8

Operating Instructions

PiLot Light:

1. Turn off the gas to the replace. If not recently done, remove the glass and let the unit air out

for at least ve (5) minutes to clear out any gas. Turn on gas to the heater. Leak test all joints

with soapy water. NEVER USE OPEN FLAME FOR LEAK TESTING.

2. Start the pilot by pressing the gas control knob and turning it to PILOT.

While holding the gas control knob in, press the piezo ignitor several

times until the pilot light starts. Hold the gas control knob in for 30

seconds. Check that the pilot has fully engulfed the thermocouple

assembly (see Figure 4).

3. Start the main burner by turning the gas control knob to ON and then

turn the rocker switch to ON. Check that all burner ports have ame.

Thermopile

Thermocouple

4. Leak test all gas joints again.

Figure 4. Pilot Flame

aiR shutteR (VentuRi):

The air shutter adjustment lever is underneath the rebox (see Figure 5).

The air shutter allows the amount of air mixing with the incoming gas to be adjusted in order to

accommodate different climates and venting arrangements. Start the pilot and then the burner. Make

sure the pilot ame is burning normally and none of the burner ports are plugged. Let the replace burn

for roughly fteen minutes and then examine the ames for impingement or soot build up.

The ideal ame will be blue at the base and light orange above. The ames should be of medium height.

If the ames look like this, no venturi adjustment is needed. If the ames are fairly short and mostly

blue, the replace is getting too much

air. Therefore, the air shutter should

Note: Use the door tool to adjust

the venturi lever

More Primary Air

Less Primary Air

be closed (pushed it) slightly until the

correct ames are achieved. Flames

that are very orange, with tall, dark,

stringy tips, are not getting enough air.

Open the venturi until the ames clean

up. If the venturi is opened, or closed all

the way, and the correct ames cannot

be attained, turn off the gas and contact

the dealer.

Figure 5. Air shutter adjustment lever

Remote contRoLs (oPtionaL):

This replace can use an optional remote control or an optional cordless wall thermostat. If either of

these are to be used to control the replace for the majority of the time, leave the ON/OFF switch (on the

control panel) in the remote/thermostat position. Consult the instructions included with the remote/wall

thermostat for operation guidelines.

Page 8

Warning: Incorrect venturi adjustment

may lead to improper combustion, which

is a safety hazard. Contact the dealer if

there is any concern about the venturi

adjustment.

Page 9

Operating Instructions

For Your Safety, Read Safety Precautions And

Lighting Instructions Before Operating

buRneR Lighting:

A) Make sure the pilot is lit.

B) Turn gas control knob COUNTER CLOCKWISE to ON.

C) Flip the burner switch to ON.

D) Turn HI/LO knob to the desired ame height.

NOTE: Check that all burner holes are lit.

TO TURN GAS FIREPLACE OFF:

Flip switch to OFF to turn off burners only

and turn the gas control knob to off to

extinguish the pilot ame. Keep the pilot

ame OFF when not in use. If the replace

is to be serviced, turn the gas shut off

valve to OFF (DO NOT FORCE IT) and

disconnect all electrical power sources.

See Figure 6 for control panel layout.

Fan Control

(Optional)

Piezo Ignitor

Alternate Burner

Switch Location

Gas Control

Figure 6. Control Panel

HI/LO

Control

Shut Off Valve

NOTE: When the unit is turned on for the rst time, it should be turned onto high, with the fan OFF

(if equipped), for the rst two to four hours. This will cure the paint, logs, gasket material, and other

products used in the manufacturing process. It is advised that a door or window be opened as the unit

will start to smoke, which can irritate some people. After the unit has gone through the rst burn, turn

the unit OFF, including the pilot, and let the unit get completely cold. Then remove the glass and clean

it with a good gas replace glass cleaner, available at your local Enviro dealer. See “

MaIntenance anD

serVIce; Glass Door reMoVal” and “MaIntenance anD serVIce; cleanInG the Glass.”

bLoweR sPeeD (oPtionaL):

The blower will come on only when the replace is up to temperature

(approximately 15 minutes). The speed of the fan can be changed by turning

the fan control knob. The blower will continue to operate automatically after the

unit has been shut off (approximately 25 minutes).To turn the blower off, turn

the knob COUNTER CLOCKWISE until it “clicks” off (Figure 7).

It is advisable not to operate the blower below

the windings of the blower and running the blower at lower speeds could also

1

/3 speed as it puts a strain on

Figure 7. Fan Control

cause premature fan failure.

noRmaL sounDs DuRing oPeRation:

Table 1: Normal Sounds

Component Normal Sound Description

Q2 & Surround Panels Creaking when heating up or cooling down caused by thermal expansion

Burner Light pop or poof when turned off

Temperature Sensor Clinking when it senses to turn the blower on or off

Pilot Flame Quiet whisper while the pilot ame in on

Blower / Fan Air movement that increase and decreases with the speed of the blower

Gas Control Valve Dull click when turning on or off, this is the valve opening and closing

Page 9

Page 10

Maintenance And Service

Routine maintenance:

At least once a year, run through the following procedures to ensure the system is clean and working

properly. Check the burner to see if all the ports are clear and clean. Check the pilot to make sure it is not

blocked by anything. The pilot ame should be blue with little or no yellow on the tips.

Warning: Clearances must be sufcient to allow access for maintenance and service

Warning: Failure to position the parts in accordance with this manual, or failure to use only parts

specically approved with this appliance may result in property damage or personal injury.

The venting system must be periodically examined; it is recommended the examination is done by a

qualied agency.

cLeaning the gLass:

When the replace has cooled, remove the face of the replace along with the glass. See MaIntenance

anD serVIce - Glass Door reMoVal. Check the gasket material on the back of the glass, making sure that

it is attached and intact.

During a cold start up, condensation will sometimes form on the glass. This is a normal condition with all

replaces. However, this condensation can allow dust and lint to cling to the glass surface. Initial paint

curing of the appliance can leave a slight lm behind the glass, a temporary problem. The glass will need

cleaning about two weeks after installation. Use a mild glass cleaner and a soft cloth. Abrasive

cleaners will damage the glass and painted surfaces. Depending on the amount of use, the glass

should require cleaning no more than two or three times a season. Do not clean the glass when it is

hot.

cLeaning the fiRebox:

Remove the logs carefully, as they are very fragile. Gently remove all the coals and place on a paper

towel. Vacuum the bottom of the rebox thoroughly. Carefully clean any dust off the logs and remove

any lint from the burner and pilot. At this time, inspect the burner tube for cracking or severe warping.

If a problem is suspected, contact the dealer. Check the logs for deterioration or large amounts of soot;

a small amount on the bottom side of the logs is normal. Replace the logs and coals as in the seconDary

InstallatIon - FIre Grate anD loG set InstallatIon section. If new/more coals are required, contact your

nearest ENVIRO dealer.

RePLacing the gLass:

The glass in the replace is a high temperature ceramic. If the glass is damaged in any way, a factory

replacement is required (see Parts lIst). Wear gloves when handling damaged glass door assembly

to prevent personal injury. Do not operate with the glass front removed, cracked or broken. Removal

and replacement of the glass from the door must be done by a licensed or qualied service person.

The glass must be purchased from an ENVIRO dealer. No substitute materials are allowed.

Remove the door (see page 11). The replacement glass will come with a new gasket installed. Remove

any silicone remnants from the door. Apply high temperature silicone to the two vertical faces of the

door and install the new piece of glass with gasket (be sure to maintain edge clearances). Apply even

pressure to the glass to allow the silicone to adhere to the gasket material.

Page 10

Page 11

Maintenance And Service

cLeaning DecoRatiVe suRfaces:

Painted and porcelain faces should be wiped with a damp cloth periodically. If a plated face has been

purchased, it should be unpacked/unwrapped carefully to avoid getting anything on the surface of the

nish, including cleaners, polish and nger prints. It is important to note that ngerprints and other

marks can leave a permanent stain on plated nishes. To avoid this, give the face a quick wipe with

denatured alcohol on a soft cloth BEFORE lighting the replace. Never clean the face when it is

hot. Do not use other cleaners as they may leave a residue, which can become permanently etched into

the surface.

gLass DooR RemoVaL:

The door needs to be removed for

sceduled cleaning and to install the

glass media and other options.

To remove the glass door use your

two index ngers to pull the spring

latches up over the two door tabs.

Once release pivot the door to out

and pull it out of the bottom door

retainers. The door must be angled

in order for it to pull out.

Figure 8. Upper Door Latch

To replace the glass door, simply

reverse the above procedure.

Warning: Do not touch or attempt

to remove the glass door if the

replace is not completely cold.

WARNING: Never operate the

replace with the glass door

removed.

Figure 9. Bottom Door Retainers

Page 11

Page 12

Maintenance And Service

buRneR RemoVaL:

The burner may need to be removed for a few reasons, including cleaning under the burner or to be

replaced all together. Proceed only when the unit has completely cooled down.

Step 1: Remove the glass door as shown in

the MaIntenance anD serVIce - Glass Door

reMoVal.

Step 2: Remove the log set and re grate

as shown in SeconDary InstallatIon - FIre

Grate anD loG set InstallaIon

Step 3: Pull the burner out of the venturi box

and out.

To re-install the burner follow steps 1-3

in reverse. When placing the burner back

in the unit be sure not to move the air

shutter. Insure the front and rear lengths

of the burner tube are parallel as it may

have distorted with heat over time. The

ideal placement for the burner tube

is keeping it forward up against the

burner stand stops.

Figure 10. Removing Burner

access DooR:

There is an access door in the bottom on the rebox that is used for servicing components after the unit is

installed in a construction enclosure. Proceed only when the unit has completely cooled down.

Step 1: Remove the burner as

shown in the MaIntenance anD

serVIce - Burner reMoVal.

Step 2: Remove the Upper Air

Diverter by removing (2) T-20

bolts. Remove the Lower Air

Diverter.

Step 3: Remove the right and

left burner stands by removing

(4) T-20 bolts.

Step 4: Remove the (16) T-20

bolts retaining the access door

as shown in Figure 11.

Step 5: After serviving assemble

in the reverse order and be

sure the gasket is still intact.

Replace if necessary.

Figure 11. Removing Access Door

Page 12

Page 13

Maintenance And Service

Loosen

Tighten

Conversion Kit Installation:

1. Turn control knob on the gas valve to the “OFF” position and shut the gas supply off at the shut-off

valve upstream of the unit. CAUTION: The gas supply must be shut off prior to disconnecting the

electrical power and before proceeding with the conversion. Allow the valve and unit to cool down

to room temperature.

2. Remove the glass door as shown in the MaIntenance anD serVIce - Glass Door reMoVal.

3. Carefully remove the ceramic log set.

4. Remove the burner as shown in the MaIntenance anD serVIce - Burner reMoVal.

5. Convert the burner orice(s):

a) Remove the main burner orice with a ½ inch deep socket.

b) Put a bead of pipe-thread sealant or approved Teon tape on the orice threads before installing

into the brass elbow.

c) Install the new orice(s) from the kit into the brass elbow.

6. Convert the pilot injector:

a) Pull the pilot hood straight up to access the pilot injector.

b) Using a

5

/32” or 4 mm Allen key, remove the pilot injector.

c) Install the new pilot injector supplied with this conversion kit. Simply

screw the new injector inside the pilot hood using the Allen key,

d) Reinstall the hood by placing the hood on the assembly, line up the key

way, and snap into place.

7. Convert the SIT gas valve:

a) Remove the black protection cap from the HI/LO knob by hand shown in

Figure A.

b) Insert a

5

/32” or 4 mm Allen wrench into the

hexagonal key-way of the screw (see Figure B),

rotate it counter-clockwise until it is free and

extract it.

c) Check that the screw is clean and if necessary

remove dirt.

d) Flip the screw (refer to Figure C).

e) Using the Allen wrench as shown in Figure B,

rotate the screw clockwise until a torque of 9

inch lbs. WARNING! Do not over tighten the

screw. It is recommended that you grip the

wrench by the short side.

f) Verify that if the conversion is from NG to LPG,

the screw must be re-assembled with the red

o-ring visible (refer to Figure D). If the conversion

Figure B. Removing valve

screw.

is from LPG to NG, the red o-ring of the screw

must be not visible.

Figure A. Removing

valve cap.

Figure C. Flip valve

screw.

Page 13

Page 14

Maintenance And Service

Red o-ring

is not visible

Red o-ring

is visible

LPG Configuration

g) Re-attach the black protection

cap that was removed in step

a (Figure A`).

Figure D. O-ring on valve screw.

8. Reinstall the air diverters, burner tube, grate, and the ceramic log set as indicated in this manual.

9. Reconnect the main gas line if it was disconnected and open the shut-off valve at the gas line to the

unit.

10. Use a small brush to apply a warm soapy water solution to all gas connections (use a half dish soap

and half warm water). If a gas leak is present, bubbling will occur. Gas leaks can be repaired by

using an approved pipe thread sealant or approved Teon tape. NEVER USE AN OPEN FLAME WHEN

TESTING FOR LEAKS.

11. Reconnect the electrical power to the unit.

12. Relight the pilot and conrm the ame properly covers both the thermocouple and thermopile (see

Figure 4, page 8). Should the pilot require adjustment, turn the adjustment screw (gure 30, page

29) clockwise to decrease or counterclockwise to increase until the correct ame is achieved.

13. Relight the main burner in both the “HI” and “LO” positions to verify proper burner ignition, operation

and proper ame appearance. Conrm the inlet and manifold pressures are within the acceptable

ranges as directed in section

IntIal IntallatIon - Gas lIne connectIon anD testInG. If the Q2 has

been installed at an altitude higher than 2000ft (610m) it is required to de-rate the unit accordingly:

In the USA: The appliance may be installed at higher altitudes. Please refer to your American Gas

Association guidelines which state: the sea level rated input of Gas Designed Appliances installed at

elevations above 2000 (610 m) feet is to be reduced 4% for each 1000 feet (305 m) above sea level.

Refer also to local authorities or codes which have jurisdiction in your area regarding the de-rate

guidelines.

In Canada: When the appliance is installed at elevations above 4500 feet (1372 m), the certied high

altitude rating shall be reduced at the rate of 4% for each additional 1000 feet (305 m).

14. MAKE SURE that the conversion label is installed on or close to the rating label to signify that the

unit has been converted to a different fuel type.

Page 14

Page 15

Initial Installation

37 7/8"

(962mm)

36¼"

(921mm)

3 5/8"

(93mm)

13

1

/4"

(337mm)

5 5/8"

(143mm)

Gas

Inlet

A

d

j

ac

e

n

t

w

a

l

l

1" min

(25mm)

QUALIFIED INSTALLERS ONLY

intRoDuction:

This section of the owner’s manual is for the use of qualied technicians only. Fireplace placement,

hearths, facing, mantels, and venting terminations will be covered, as well as the gas and electric

systems. There are several installation safety guidelines that must be adhered to. Please carefully read

the safety precautions at the front of this manual.

NOTE: The Q2L comes as a top vent unit but can be converted to a rear vent.

Warning: Clearances must be sufcient to allow access for maintenance and service.

PLacement anD fRaming:

Table 2. Framing Dimensions.

Firebox Framing

7/8

Depth 15

Width 34

Height - Rear Vent 40” 1016mm

Height - Top Vent *48”+ 1219mm

Gas Inlet (Distance

From Back)

Gas Inlet (Height) 1

* + vertical vent rise (not including elbow)

” 403mm

9/16

” 878mm

7/16

” 113mm

4

9/16

” 40mm

The location for the replace can be

along a wall, raised, at oor level, or

in a corner. There are specic framing

measurements for each situation.

The basic opening should have the

”

7/16

4

(113mm)

34 9/16”

(878mm)

dimensions shown in Figure 12.

The replace must have a strong and

level surface to be placed on. The

40”

(1016mm)

14”

7/8

15

”

(356mm)

(403mm)

1 9/16”

(40mm)

surface should be made of wood or a

non-combustible material, not carpet.

The gas line, 3/8” JIC tting, should

be brought to the right side of the

Figure 12. Dimensions for Framing the Firebox

replace. The location should be

chosen so the replace will be at least

36 inches (91.4 cm) from drapes, doors and other combustibles. The framed opening should also

be a minimum of 4 5/8” (11.7 cm) from the nearest perpendicular wall (sidewall to the edge of the

opening).

Page 15

Page 16

Initial Installation

QUALIFIED INSTALLERS ONLY

ReaR Vent conVeRsion:

For smaller openings the Q2L can be converted from a top vent to a rear vent unit.

DV Adaptor

Must use 1/4”

8-32 Bolts

Figure 13. Vent Conversion - Step 1

Step 2: Switch the removed parts

around as shown in Figure 16 and

re-install all 12 screws. Be sure not

to damage any gaskets - If damage

occurs fully remove the gasket

and use high temp silicone as a

replacement.

Exhaust Tube

Cover Plate

Must use 1/4”

8-32 Bolts

Figure 14. Upper Mounting Holes

Step 1: Using a T-20 screwdriver

remove the DV Adaptor, Exhaust

Tube, and cover plate (12 screws

total) as shown in Figure 13.

Note: The DV adaptor and Cover

Plate use the T20 1/4” bolts.

Use lower set of

holes

Figure 15. Lower Mounting Holes

Page 16

Figure 16. Vent Conversion - Step 2

Page 17

Initial Installation

QUALIFIED INSTALLERS ONLY

coRneR instaLLation:

The dimensions for installing a replace in the corner of a room are given in Figures 17 and 18. Refer to

“InItIal InstallatIon - allowaBle co-axIal Vent conFIGuratIons” for allowable pipe lengths.

Do not interfere with the structural integrity of the walls.

D

A

16 1/4

B

C

Figure 17. Dimensions for a corner installation

Rear Vent (no cabinet extensions)

Dimension A = 41 5/16

Dimension B = 29 3/16

Dimension C = 11 29/32

Dimension D = 8 1/4

34 9/16

Rear Vent (with cabinet extensions)

Dimension A = 43 15/16

Dimension B = 31 1/16

Dimension C = 13 3/4

Dimension D = 8 1/4

Top Vent (no cabinet extensions)

Dimension A = 41 5/16

Dimension B = 29 3/16

Dimension C = 11 29/32

Dimension D = 14 1/16

Top Vent (with cabinet extensions)

Dimension A = 43 15/16

Dimension B = 31 1/16

Dimension C = 13 3/4

Dimension D = 14 1/16

Page 17

Page 18

Initial Installation

QUALIFIED INSTALLERS ONLY

mantLe & non-combustibLe cLeaRances:

When installing the Q2L as a zero clearance replace the correct clearances and materials must be used:

aboVe unit: A minimum 10” of non-combustible facing material, with a R-Value no less than 0.26, must

be used above the unit (in front of the included steel framing plate).

in fRont of unit: The Q2L can be placed on the oor if desired although it is recommended that it be

raised aleast an inch or higher for more heat sensetive materials such as carpet or linoleum.

aDjacent/siDewaLL: There must be a minimum distance of 4 5/8” (417mm) from the side of the Q2L

cabinet to an adjacent wall composed of combustible material (see Figure 18).

mantLe: It is not necessary to install a mantle, but if one is desired the guidelines as shown in Figure 19.

12" (305mm)

Mantle

2" (51mm)

Mantle

5

"

(417mm)

4

8

Distance from a side wall

42"

(1067mm)

49"

(1245mm)

Page 18

Unit can be placed on the floor

Figure 18. Non-Combustible Clearances

Page 19

Initial Installation

49”

48”

47”

46”

45”

44”

43”

42”

1 2 3 4 5 6 7 8 9 10 11 12

M A N T L E H E I G H T

M A N T L E D E P T H

Minimum Mantle Clearances

12” MANTLE

2” MANTLE

QUALIFIED INSTALLERS ONLY

Note: Mantle height dimensions are based from the bottom of the appliance.

Figure 19. Mantle Clearances

DiRect Vent:

WARNING: This appliance has been designed to draw room air for proper heat circulation

from the bottom of the unit, and out the top front. Blocking or modifying these openings in

any way can create hazardous situations.

The vent length for the Q2L must be between 6” (150 mm) and 40’ (12.2 m). This model is vented

with co-axial 4” intake, 6 5/8” exhaust aluminum or stainless steel approved rigid vent leading into a

vertical or horizontal termination cap. This model can also be used with aluminum or stainless steel ex

venting. The ue collar of this model will t inside of a standard 4” x 6 5/8” vent and must be either

correctly interlocked or fastened, with three screws directly to the vent collar.

Check periodically that the vents are unrestricted. Also ensure that all direct vent pipes have been

properly sealed and installed after routine inspection or cleaning. The air intake and exhaust pipes must

be installed in the correct locations on the top of the Q2L.

Page 19

Page 20

Initial Installation

QUALIFIED INSTALLERS ONLY

Vent teRmination RestRictions:

N

O

D

E

C

B

L

F

Fixed

Closed

Openable

B

B

Openable

Fixed

Closed

H

G

G

M

B

A

J

I

Termination Cap

Figure 20. Vent Termination Restrictions, refer to Table 3

Letter Canadian Installation

A 12 in (30 cm) Clearance above grade, verandah, porch, deck, or balcony.

B 12 in (30 cm) 9 in (23 cm) Clearance from window or door that may be opened.

C 12 in (30 cm)* Clearance from permanently closed window (to prevent

D 24 in (60 cm)* Vertical clearance to ventilated soft located above the

E 18 in (45 cm)* Clearance to unventilated soft.

F 12 in (30 cm)* Clearance to outside corner.

G 12 in (30 cm)* Clearance to inside corner.

H 3 ft (91 cm) within a height of

15 ft (4.5 m) above the meter/

regulator assembly

I 3 ft (91 cm) 3 ft (91 cm)* Radial clearance around service regulator vent outlet.

J 12 in (30 cm) 9 in (23 cm) Clearance to non-mechanical air supply inlet to building, or

K 6 ft (1.83 m) 3 ft (91 cm) above if within 10

L 7 ft (2.13 m

M 12 in / 30 cm

N 12 in (30 cm)* Clearance horizontally to any surface (such as an exterior

O 12 in (30 cm) Clearance above roof line for vertical terminations.

1

)t

+

Air Supply Inlet

Gas MeterG

Restriction Zone

(Termination not allowed)

Table 3: Vent Termination Clearances

US Installation

3 ft (91 cm) within a height of

15 ft (4.5 m) above the meter/

regulator assembly*

ft (3 m) horizontally

7 ft (2.13 m)

12 in / 30 cm*

2

condensation).

terminal, within a horizontal distance of 2 ft (60 cm) from

center line of terminal.

Clearance to each side of center line extended above

meter/regulator assembly.

the combustion air inlet to any other appliance.

Clearance to mechanical air supply inlet.

*t

+

Clearance above paved sidewalk or paved driveway located

on public property.

Clearance under verandah, porch, deck, or balcony.

wall) for vertical terminations.

Description

K

A

1

In accordance with the current CSA B149, Natural Gas and Propane Installation Code.

2

In accordance with the current ANSI Z223.1 NFPA 54, National Fuel Gas Code.

* These numbers are only estimates.

t

A vent shall not terminate directly above a side walk or paved driveway that is located between two single family dwellings

and it serves both dwellings.

+

Permitted only if verandah, porch, deck, or balcony is fully open on a minimum of two sides beneath the oor.

Clearances are in accordance with local installation codes and the requirements of the gas supplier.

NOTE: Venting terminals shall not be recessed into walls or siding.

Page 20

Page 21

Initial Installation

Framing

Joists/Studs

10”

10”

QUALIFIED INSTALLERS ONLY

Venting cLeaRances:

A 1” (25 mm) clearance to combustibles must be maintained around any vertical vent pipe. Around a

horizontal vent pipe, the clearance to combustibles should be 2” (51 mm) above and 1½” (38 mm)

on the sides and bottom. When combustible materials are directly above a 90° elbow, 3” (76 mm) of

clearance are necessary.

Table 4. Vent Pipe Minimum Clearances

Vertical Pipe to

the Side Walls

Hard

Pipe

1”

(25.4 mm)

A 10” (254 mm) x 10” (254 mm) frame (see Figure 21) will assure the proper support and spacing for

the vent pipe as it passes through the wall. Installations in Canada require that a wall thimble be used for

passing through walls and ceilings. All sealing and vapour barriers must comply with local building codes.

The conguration of the venting pipes depends on the locations

of walls, ceilings, and studs. However, the pipes cannot be of

arbitrary length and arrangement. Because the length of the

vertical and horizontal sections dramatically affects the burning

efciency of the replace, certain guidelines have been set in

InItIal InstallatIon - allowaBle co-axIal Vent conFIGuratIons.

Venting terminals can not be recessed into a wall or siding.

Horizontal Pipe to

the Sides & Bottom

1½”

(38.1 mm)

Above an Elbow

Above the Unit

3”

(76.2 mm)

Above an Elbow

Not Above the Unit

3”

(76.2 mm)

Above Horizontal

Vent Pipe

2”

(51 mm)

Wall Frame 8”

(203mm) or less

10”x10”

(25x25cm)

WARNING: This gas appliance must not be connected

to a chimney ue serving a separate solid-burning

appliances.

Figure 21. Vent Framing For Wall or Ceiling

aPPRoVeD Venting PaRts:

Table 5: Approved Vent Manufacturers

Manufacturer Trade Name Nominal Sizes

American Metal Products AmeriVent Direct 4” - 6 5/8”

ICC EXCELDirect 4” - 6 5/8”

Security Chimneys International LTD Secure Vent 4” - 6 5/8”

Selkirk Metalbestos Direct-Temp 4” - 6 5/8”

Simpson Dura-Vent Direct Vent GS 4” - 6 5/8”

The Q2L replace has been tested and certied for use with AMERICAN METAL PRODUCTS “AMERIVENT

DIRECT”, SIMPSON DURAVENT TYPE GS PIPE FOR GAS STOVES. SECURITY CHIMNEY’S “SECURE VENT

DIRECT VENT SYSTEM” and SELKIRK “DIRECT-TEMP VENT SYSTEM” kits are available for horizontal and

vertical venting. When using Simpson Duravent, it is recommended that, before installation, a bead of

RTV High Temperature Silicone should be applied to each outer vent joint, and Mil-Pac to each inner

joint. When planning an installation, it will be necessary to select the proper length of vent pipe for the

particular requirements.

WARNING: Do not mix parts from different vent manufacturers’ systems.

Page 21

Page 22

Initial Installation

QUALIFIED INSTALLERS ONLY

EXCEPTION TO WARNING: This product has been evaluated by Intertek for using a Direct Vent GS

starting collar in conjunction with Secure Vent, Direct-Temp, AmeriVent Direct, and EXCELDirect venting

systems. Use of these systems with the Direct Vent GS starting collar is deemed acceptable and does

not affect the Intertek WH listing of the appliance.

Table 6: Vent part numbers (Must state if galvanized or black wanted, PART NUMBERS)

Direct Vent GS Direct-Temp Secure Vent Ameri Vent Direct Description

908 4DT-6 SV4L6 6” pipe length

4D7 7” pipe length

907 4DT-9 9” pipe length

906 4DT-12 SV4L12 4D12 12” pipe length

904 4DT-24 SV4L24 4D2 24” pipe length

903 4DT-36 SV4L36 4D3 36” pipe length

902 4DT-48 SV4L48 4D4 48” pipe length

945 4DT-EL45 SV4EBR45 4D45B 45° elbow, black

990 4DT-EL90 SV4EBR90 4D90B 90° elbow, black

950 4DT-VS SV4VS Vinyl siding standoff/sheild

942 4DT-WT SV4RSN 4DWT Wall thimble

953 4DT-SC SV4FC 4DSC Storm collar

963 4DT-FS SV4BF 4DFSP Fire stop

988 4DT-WS/B SV4BM 4DWS Wall strap/support/band

970 4DT-HKA SV0SHK 4DHTK1

911 11” to 14 ⅝” pipe, adjustable

4DT-AJ 4D12A 4” to 10” pipe , adjustable

SV4LA12 1½” to 12” pipe , adjustable

943 4DT-AF6 4DF Flashing, 0/12 to 6/12 roof pitch

943S 4DT-AF12 4DF12 Flashing, 7/12 to 12/12 roof pitch

SV4FA Flashing, 1/12 to 7/12 roof pitch

SV4FB Flashing, 8/12 to 12/12 roof pitch

943F SV4F Flat ashing

991 4DT-HVC High wind vertical termination

985 4DT-HHC High wind horizontal termination

Horizontal termination kit (SD: Basic Kit,

SEL: Kit A, SC: Standard Kit)

978 4DT-VKC SV0FAK 4DVTK Vertical termination kit

971 4DT-HKB SV0SHK2 4DHTK2

Page 22

Horizontal termination kit

(SD: Kit A, SEL: Kit B, SC: Kit)

Page 23

Initial Installation

QUALIFIED INSTALLERS ONLY

hoRizontaL teRmination - ReaR Vent:

The Q2L can be installed in rear vent applications with no vertical rise within the parameters as shown in

Figures 22 and 23. If any vertical rise is required a top vent conguration should be used.

Approved horizontal termination

12” (31 cm) Max. vent length

Approved through wall thimble

Figure 22. Corner Rear Vent

Note: For every 12” (305mm)

of horizontal venting travel there

should be at least 1/4: (6.4mm) of

vertical travel.

Max. 1 x 45˚ Elbow

6” (15 cm) Min. vent length

18” (46 cm) Max. vent length

Approved horizontal termination

Figure 23. Flat to Wall Rear Vent

Approved through wall thimble

Page 23

Page 24

40’

Initial Installation

QUALIFIED INSTALLERS ONLY

aLLowabLe co-axiaL Vent configuRations:

Figures 24 shows the range of venting options for top vented congurations only using either vertical

or horizontal terminations; any layout that remains within the shaded area is acceptable. Having the

fewest number of elbows is ideal as they tend to disrupt air movement. Using 45˚ elbows is preferable to

using 90˚ elbows. Also, a shorter vent system will perform better than a longer one. The total length of

horizontal vent pipe can not exceed 20 feet (6.1m) and the total vent length can not exceed 40ft (12.2m).

Any combination of rise and run can be

(12.2m)

35’

(10.7m)

30’

(9.14m)

Vent

Position

used as long as it lays within the shaded

area (a total of two (2) 90˚ elbows or four

(4) 45˚ elbows can be used. In addition

to what is shown, if a 90˚ elbow is used

in the horizontal plane, 3 feet (91.4cm)

must be subtracted from the allowable

horizontal run (for each 45˚ elbow, 1½

feet must be subtracted).

25’

(7.62m)

20’

(6.1m)

15’

(1.52m)

10’

(3.05m)

5’

(1.52m)

0’

(0m)

0’

(0m)

Page 24

5’

(1.52m)

(3.05m)

10’

15’

(4.57m)

20’

(6.1m)

Figure 24. Possible Vent Congurations

for Top Vent Only. Vertical and Horizontal

Terminations

Page 25

Initial Installation

QUALIFIED INSTALLERS ONLY

hoRizontaL teRmination:

NOTES:

1. Horizontal pipes must not be level. For every 12” (305 mm) of horizontal travel (away

from the stove), there should be at least ¼” (6.4 mm) of vertical travel. Never allow

the vent to run downward, as this could cause high temperatures or even present the

possibility of a re.

2. The exterior of the horizontal

vent termination must not be

blocked or obstructed.

3. If the vent termination is not

being attached to wood, the

four wood screws provided

should be replaced with

material appropriate fasteners.

4. For buildings with vinyl siding,

a vinyl standoff should be

installed between the vent cap

and the exterior wall. Attach

the vinyl siding standoff to

the horizontal termination.

Note that the termination

bolts onto the at portion of

the standoff, providing an air

space between the wall and

the vent termination. The air

gap prevents excessive heat

from possibly melting the vinyl

siding.

5. Horizontal pipes must be

supported every 3’ (914 mm).

Plumber’s all round strap will sufce.

Elbow

Wall thimble

fire stop

Exhaust

pipe

Combustion air

outer pipe

Figure 25. Horizontal Vent Termination

Horizontal wall

termination

Wall framing

6. When running horizontal pipe, clearances to combustibles must be maintained 1½ inches (38 mm)

sides, 1½ inches (38 mm) bottom, and 2” (51 mm) top.

Step 1.

Set the replace in the desired location. Check to determine if wall studs will be in the way when

the venting system is attached. If this is the case, the location of the replace may have to be

adjusted or the venting may have to be offset.

Step 2. Direct vent pipe sections are designed with special twist-lock connections. Dry t the desired

combination of pipe and elbows to the appliance adaptor.

Step 3. With the pipe in the correct position and attached to the replace, mark the wall for a 10”

(25.4 cm) x 10” (25.4 cm) square hole (see Figure 25). The center of the hole should match

the center line of the horizontal pipe. Cut and frame the hole in the exterior wall where the

vent will be terminated. If the wall being penetrated is made of a non-combustible material (i.e.

masonry or concrete) a 7” (17.8 cm) hole is acceptable.

Page 25

Page 26

Initial Installation

QUALIFIED INSTALLERS ONLY

NOTE: For Simpson Duravent only, place a bead of Mil-Pac or Rutland No 78 Stove and Gasket Cement

on the outer edge of the inner exhaust pipe (non-ared end). Push the pipe sections together, then twist

about ¼ turn, making sure the two sections are fully locked. Wrap all seams with foil ducting tape.

Step 4.

With the hole now framed, the wall thimble installed, and the pipe extending into the wall,

proceed to the outside. Attach the termination to the pipe using RTV and Mil-Pac or Rutland No

78 Stove and Gasket Cement to seal joints. The vent pipe must extend into the vent cap at least

1¼ inches (3.2 cm). Secure the connection between the vent cap and the pipe by attaching

the two (2) sheet metal straps, which extend from the vent cap assembly to the outer wall of

the vent pipe. Bend any remaining portion of the strap back towards the vent cap. Security

Secure Vent uses a twist lock cap.

Step 5.

Position the horizontal vent termination in the center of the 10” (25.4 cm) square hole and

attach to the exterior wall with the four screws provided. The arrow on the vent termination

should be pointing up. Run a bead of non-hardening mastic around the edges of the vent

cap, to make a seal with the wall. Ensure the proper clearances to combustibles have been

maintained.

VeRticaL teRmination:

Step 1. Check the instructions for required clearances (air spaces) to combustibles when passing

through ceilings, walls, roofs, enclosures, attic rafters, or other nearby combustible surfaces.

Do not pack air spaces with insulation.

Step 2. Set the gas appliance in the desired location. Drop a plumb bob down from the ceiling to

the position of the appliance ue exit, and mark the location where the vent will penetrate

the ceiling. Drill a small hole at this point. Next, drop a plumb bob from the roof to the hole

previously drilled in the ceiling, mark the spot where the vent will penetrate the roof. Determine

if ceiling joists, roof rafters, or other framing will obstruct the venting system. You may wish to

relocate the appliance, or to offset, to avoid cutting load bearing members.

Step 3. To install the Round

Support Box/Wall Thimble

in a at ceiling, cut a 10

“ (25.4 cm) square hole

in the ceiling, centered in

the hole drilled in Step 2.

Frame the hole as shown

in Figure 26.

Step 4.

Assemble the desired

lengths of black pipe

and elbows necessary to

reach from the appliance

adapter up through the

Round Support Box.

Insure that all pipe and

elbow connections are

in their fully twist-locked

position.

Elbow Strap

Figure 26. Vertical Vent Termination

Vertical

Termination

Storm Collar

Flashing

Roofing nails

Page 26

Page 27

Initial Installation

H

Dimension ‘H’ obtained

from table below.

QUALIFIED INSTALLERS ONLY

Step 5. Cut hole in the roof centered on the small hole placed in the roof from Step 2. The hole should

be of sufcient size to meet minimum requirements for Clearance to Combustibles, as specied.

Continue to assemble lengths of pipe and elbows necessary to reach from the ceiling support

box up through the roof line. Galvanized pipe and elbows may be utilized in the attic, as well

as above the roof line. The galvanized nish is desirable above the roof line, due to the higher

corrosion resistance.

Step 6.

Once the pipe sections have been joined, and run up through the hole in the roof, slip an elbow

strap over the exposed sections, bend the support straps outwards, and push the elbow strap

down to the roof level, as shown in Figure 26. Tighten the clamp around the pipe section. Use

a level to make sure the pipe is truly vertical. With roong nails, secure the support straps to

the roof. Seal the nails holes heads with non-hardening mastic. Trim the excess length of the

support straps that extend out beyond the edge of the ashing.

Step 7.

Slip the ashing over the pipe section protruding through the roof. Secure the base of the

ashing to the roof with roong nails. Use a non-hardening sealant between the uphill edge

of the ashing and the roof. Insure the roong material overlaps the top edge of the ashing.

Verify that you have at least the minimum clearance to combustibles at the roof line.

Step 8.

Continue to add pipe sections until the height of the vent cap meets the minimum code

requirements. Refer to Figure 27 and Table 7. Note that for steep roof pitches, the vent height

must be increased. In high wind conditions, nearby trees, adjoining roof lines, steep pitched

roofs, and other similar factors can result in poor draft, or down drafting. In these cases,

increasing the vent height may solve the problem.

Step 9.

Slip the storm collar over the pipe, and push it down to the top of the roof ashing as shown

in Figure 27. Use the non-hardening sealant around the joint between the pipe and the storm

collar.

Step 10. Twist-lock the vent cap.

Table 7: Minimum ‘H’ for Figure 27.

Roof Pitch Minimum Height (H)

Figure 27: Height of Vertical Termination;

Reference Table 7

Feet Meters

Flat to 7/12 1 0.3

Over 7/12 to 8/12 1.5 0.46

Over 8/12 to 9/12 2 0.61

Over 9/12 to 10/12 2.5 0.76

Over 10/12 to 11/12 3.25 0.99

Over 11/12 to 12/12 4 1.22

Over 12/12 to 14/12 5 1.52

Over 14/12 to 16/12 6 1.83

Over 16/12 to 18/12 7 2.13

Over 18/12 to 20/12 7.5 2.29

Over 20/12 to 21/12 8 2.44

Page 27

Page 28

plumber’s tape

connected to

wall strap

Wall strap

45° elbows (x2)

Initial Installation

QUALIFIED INSTALLERS ONLY

NOTES:

(1)

If an offset is necessary in the attic to avoid

obstructions, it is important to support the vent

pipe every 3’ (914 mm), to avoid excessive stress

on the elbows, and possible separation. Wall straps

are available for this purpose (see Figure 28).

(2) When ever possible, use 45° degree elbows instead

of 90° degree elbows. The 45° degree elbow offers

less restriction to the ow of ue gases and intake

air.

(3)

For multi story installations; a ceiling restop is

required at the second oor, and any subsequent

oors (see Figure 29). The opening should be

framed to 10” (254 mm) x 10” (254 mm) inside

dimensions, in the same manner as shown in Figure

21.

(4) Any occupied areas above the rst oor,

Figure 28: Use of Wall Straps.

including closets and storage spaces,

which the vertical vent passes through,

must be enclosed. The enclosure may be

framed and sheet-rocked with standard

building materials. However consult

the appliance manufactures installation

instructions for the minimum allowable

clearance between the outside of the vent

pipe, and the combustible surfaces of

the enclosure. Do not ll any required air

spaces with insulation.

Figure 29: Multi-Story Vent Pipe Installation

Page 28

Page 29

Initial Installation

QUALIFIED INSTALLERS ONLY

gas Line connection anD testing:

WARNING: Only persons licensed to work with gas piping may make the necessary gas connections to

this appliance.

GAS LINE CONNECTION

• This stove is equipped with a certied exible pipe located on the right side of the unit terminating

in a 3/8” female JIC tting. Consult your local authorities codes or the CAN/CGA B 149 (1 or 2)

installation code in Canada, or in the USA gas installations follow either local codes or the current

edition of the National Fuel Gas Code ANSI Z223.1.

• The efciency rating of this appliance is a product thermal efciency rating determined under

continuous operating conditions and was determined independently of any installed system.

The appliance and its shutoff valves must be

disconnected from the gas supply piping system

Gas Control

Knob

Pilot Adjustment

Screw

during any pressure testing where the pressure

exceeds ½ PSIG (3.45 KPa) or damage will occur

to the valve.

The appliance must be isolated from the gas supply

piping system by closing its individual manual

N

O

T

O

L

I

P

F

O

F

shutoff valve during any pressure testing of the gas

supply piping system at test pressures equal to or

less than ½ psig (3.45 KPa).

Always check for gas leaks with a soap

and water solution after completing the

required pressure test.

Inlet

PressureTap

IN OUT

Manifold

PressureTap

Figure 30: Fully Labeled Gas Valve.

TO TEST VALVE PRESSURES

The pressure taps are located on the top right of the valve shown in Figure 30.

•Turn set screw 1 turn counter clockwise to loosen,

•Place

5

/16” (8 mm) I.D. hose over pressure tap system.

•Check pressures using a manometer.

•When nished, release pressure, remove hose & tighten set screw.

O

L

T

I

P

I

H

L

O

TP TH TP TH

Hi/Low

Knob

*Gas Valve will be

mounted upside down on

some models

Main Orice #40 DMS #55 DMS

Manifold Pressure 3.5” W.C. (0.87 KPa) 10.0” W.C. (2.49 KPa)

Min. Manifold Pressure 1.6” W.C. (0.40 KPa) 6.4” W.C. (1.59 KPa)

Max Supply Pressure 7.0” W.C. (1.74 KPa) 11.0” W.C. (2.74KPa)

Min. Supply Pressure 4.5” W.C. (1.12 KPa) 10.4” W.C. (2.59 KPa)

Max BTU/hr Input 24,000 BTU/hr (7.03 KW) 20,000 BTU/hr (5.86 KW)

Min. BTU/hr Input 17,000 BTU/hr (1.12 KW) 16,000 BTU/hr (4.69 KW)

NEVER USE AN OPEN FLAME FOR LEAK TESTING.

Table 8: Pressure and BTU Information

Natural Gas Propane Gas

Page 29

Page 30

Initial Installation

TP

TP/TH

TH

Blue

Grey

Blue

Place Thermostat

Wires Here.

On/Off/Thermostat

Switch

QUALIFIED INSTALLERS ONLY

eLectRicaL RequiRements:

This Q2 will operate without external electrical power. This model has a Millivolt gas control which uses the

pilot ame to generate enough electricity to operate the main burner. This appliance when equipped with

a blower, must be electrically connected and grounded in accordance with local codes or in the absence of

local codes, with the current CSA C22.1 CANADIAN ELECTRICAL CODE Part 1, SAFETY STANDARDS FOR

ELECTRICAL INSTALLATIONS, OR THE NATIONAL ELECTRICAL CODE ANSI / NFPA 70 in the U.S.

CAUTION: Label all wires prior to disconnection when servicing controls. Wiring errors can cause

improper and dangerous operation. Verify proper operation after servicing.

Table 9: Recommended Thermostat

Wire Size

Wire Size Max. Length

14 gauge 100 ft (30.48 m)

16 gauge 60 ft (18.29 m)

18 gauge 40 ft (12.00 m)

20 gauge 25 ft (7.62 m)

22 gauge 18 ft (5.49 m)

70 ° F

N

O

F

F

O

70 ° F

UP

DOWN

COOL / HEAT

PROGRAM

Optional

Thermostat

Figure 31: Q2 Wiring Diagram

Optional

Remote

Control

Blue

Blue

BV Only

o

120°F (49°C)

180

F (82oC)

Temperature

Sensor

Optional

Wall Switch

Figure 32: Accessory Wiring

ON/OFF/REMOTE

Thermostat Switch

Grey

Thermopile

Manifold

Pressure

Tap

Gas

Control

Valve

Blue

Pilot

Adjustment

Screw

Thermocouple

Inlet

Pressure

Tap

The Q2 comes from the

manufacture with an on/

off switch mounted to

the control panel. If you

would like to install a

wall mounted switch or

thermostat then use the

diagram to assist you

in wiring the accessory

into the unit. Disconnect

the connection behind

the switch in the control

panel as tap into the (2)

terminals as shown in

gure 32

Optional Thermostat (50-583)

Optional Wall Switch (50-559)

Page 30

Page 31

Initial Installation

QUALIFIED INSTALLERS ONLY

eLectRicaL RequiRements:

Optional Fan Kit (50-2981): The fan will not operate if the appliance is cold. Once the unit is lit and the

fan is set to the desired level, the fan will automatically turn on upon reaching operating temperature.

The fan will automatically turn off after the appliance has cooled down.

The replace must be electrically connected and grounded in accordance with local codes or, in the

absence of local codes, with the current CSA C22.1 Canadian Electrical Code Part 1, Safety Standards For

Electrical Installations, or The National Electrical Code ANSI / NFPA 70 in the US..

(Building Wiring)

Electrical

Junction

Box

Figure 33: Fan wiring diagram

CAUTION: When servicing controls, label all wires prior to disconnection. Wiring errors can cause

improper and dangerous operation. Verify proper operation after servicing. If any of the original wire

supplied with the appliance must be replaced, it must be replaced with 18 AWG wire with a temperature

rating of 105°C.

Page 31

Page 32

Secondary Installation

Q2

fan Kit instaLLation (oPtionaL 50-2981):

Optional Fan Kit 50-2981

This appliance when installed, must be electrically connected and grounded in accordance with local codes

or in the absence of local codes, with the current CSA C22.1 CANADIAN ELECTRICAL CODE. Part 1, SAFETY

STANDARDS FOR ELECTRICAL INSTALLATIONS, or THE NATIONAL ELECTRICAL CODE ANSI / NFPA 70 in the

USA.

CAUTION: Label all wires prior to disconnection when servicing controls. Wiring errors can

cause improper and dangerous operation. Verify proper operation after servicing.

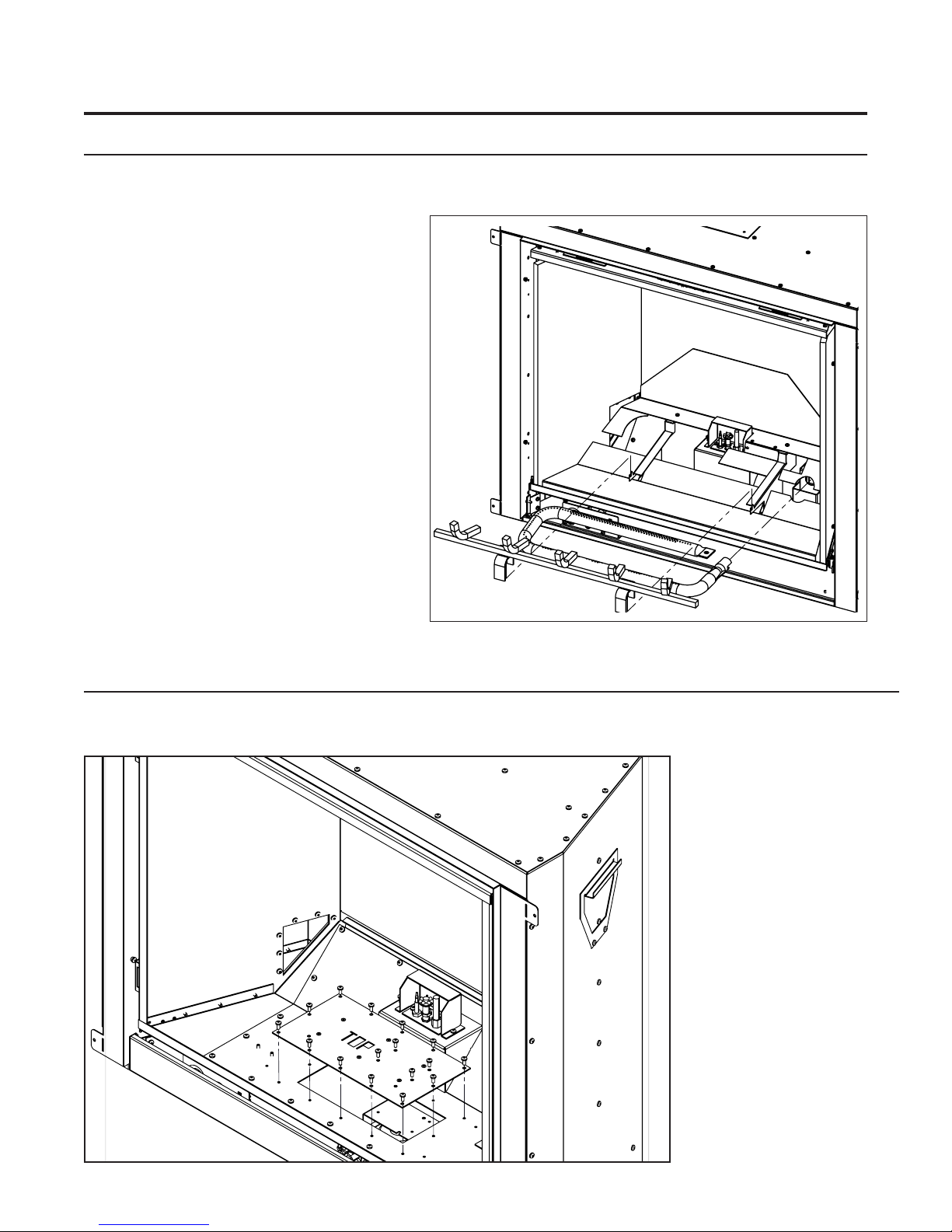

Installation of Fan Kit:

1. Remove the contents from the box and inspect for any damage to the fan assembly. If damage is noticed call your dealer,

distributor or courier company and have components replaced (see Figure 1).

2. Disconnect the power source coming into the appliance by ipping the circuit breaker

to avoid injury or damage to the components.

3. Install the fan controller into the control panel as shown in Figure 2. Use the retainer

nut to secure the controller. Note: nut bites into controller shaft without threads.

4a. If the appliance has not yet been installed into a construction enclosure remove the

fan cover plate with the (10) screws at the rear of the unit using a 1/4” socket (see

Figure 3); slot the fan into the silicone retainers on the opposite side as shown in

Figure 4.

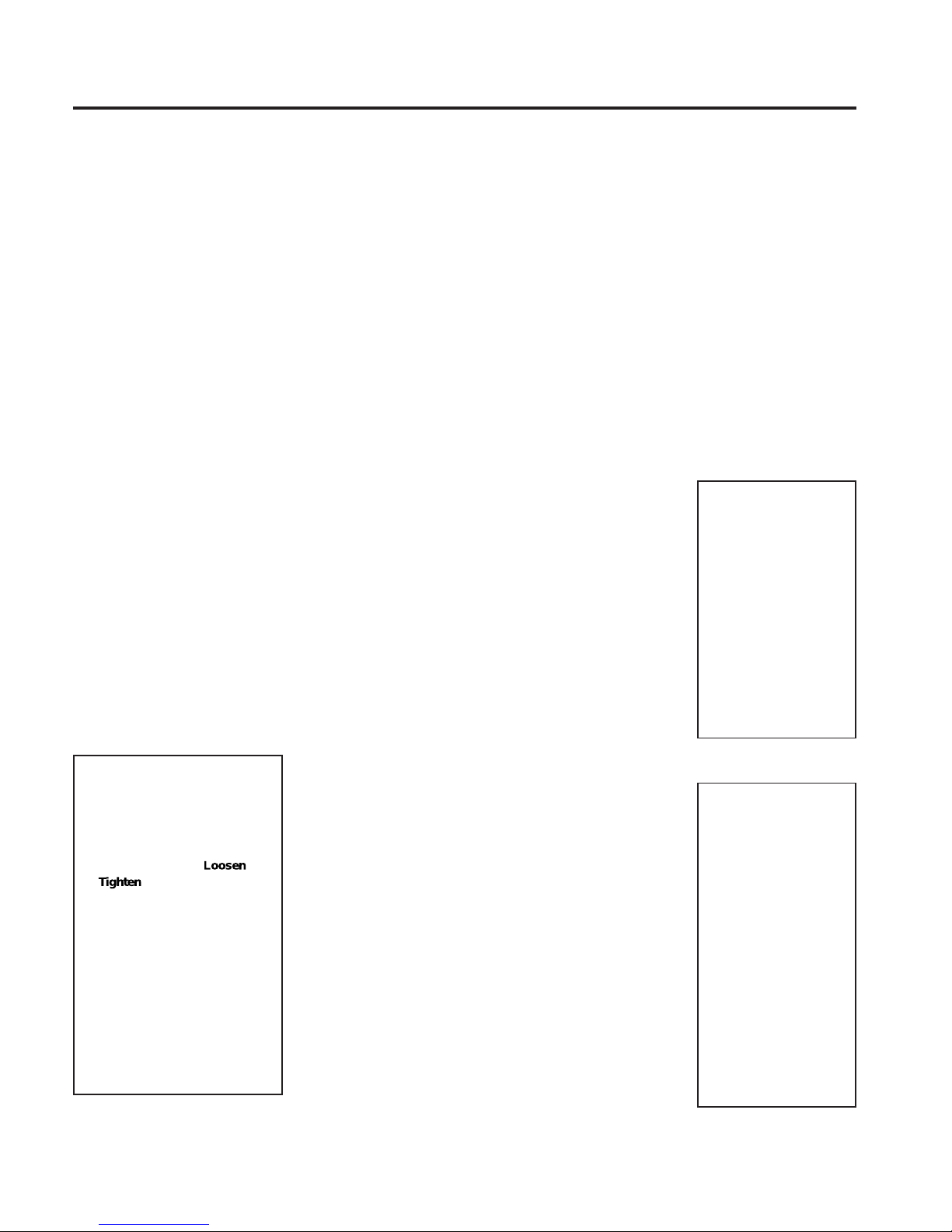

4b. If the appliance is already installed into a construction enclosure you will need to

consult your Q2 owners manual on how to remove the interior rebox components.

Once they are removed see Figure 5 on how to remove the valve tray using the (23)

T-20 screws. Be careful not to damage the sealing gasket - If gasket gets damaged

replace that section with high-temp silicone. Do not completely remove the valve tray

just lift it up enough to get the fan inside and mounted onto the silicone gromments

as shown in Figure 4.

5. Attach one short and one long black wire to the fan terminals - push the other end of

the short wire through the electrical box bushing and attach it to the black incoming

power source wire by using a supplied male wire terminal. Incoming power should

be routed through the rear of the unit into the electrical box. Ensure the incoming

ground wire is well connected to interior of the electrical box ground screw.

6. Mount the temperature sensor in the retainer already mounted to the bottom of the

rebox. Continue to wire the circuit as shown in Figure 6. Double check to be sure

all wiring is correct then install the electrical box cover that came with the appliance.

Replace all components and ip the circuit break to the on position.

7. The fan will not turn on until 120F or 49C has been reached under the replace. The

fan will continue to run even after the appliance has turned off until the temperature

has dropped below the set point (this could be up to 20 minutes after shut down).

Figure 1: Fan Kit Contents

Figure 2: Fan Controller Mounting

Figure 3: Fan Cover Removal

*parts removed

for clarity

Page 32

Figure 5: Valve Tray RemovalFigure 6: Fan Wiring

Figure 4: Fan Mounting

C-14402

Page 33

Secondary Installation

safety scReen instaLLation (50-3051):

The safety screen supplied with the

unit must be assembled rst before

it can be installed. When installed,

the screen should not extrude out

any farther than the surround if

the cabinet extensions are installed

(See Secondary InstallationCabinet Extensions).

Safety Screen Assembly

1. Attach the left, right, and end

brackets onto the safety screen

using a T20 screwdriver and

the supplied sixteen (16) #8

T20 screws (see Figure 34).

Do not over-tighten the screws

or they might strip out of the

screen frame.

2. Lift the face upright in front

of the appliance with the

four (4) hooks pointing down

towards the replace. Slide the

hooks into the corresponding

brackets on each side of the

cabinet (see Figure 36). Ensure

the hooks are secure before

releasing the safety screen.

End Cover

Left Mounting Hook

Q2 Safety Screen

Figure 34. Screen Bracket Assembly

3/8 #8-32 T-20 Screws x 16

Right Mounting Hook

End Cover

Figure 36. Safety Screen MountingFigure 35. Screen Mounting Hooks

Page 33

Page 34

Secondary Installation

cabinet extensions:

The Q2L needs to be recessed into the construction enclosure in order for the safety screen to be ush with

the surroundings to provide a more cosmetically appealing look. By assembling the cabinet extensions the

unit can be pushed further into the wall while still maintaining a construction edging for facing materials

such as tile or drywall. Assemble the parts as shown using a T20 screwdriving and the supplied hardware.

Right Edge

Top Edge

1/8" Spacer X4

Right Face

Top Face

Left Edge

Page 34

3/8" T20 Screw X34

Left Face

Figure 37. Cabinet Extension Assembly

Page 35

Secondary Installation

PaneL instaLLation (oPtionaL):

These instruction are applicable to both the Q2 brick liner set (50-2977) and the Q2 enamel porcelain

liner set (50-2978).

Step 1: Be sure the replace is cool.

Remove the door, the log set (if installed),

log grate, burner tube, and the upper

and lower air diverters. Removal of these

parts will be found in the MaIntenance

anD serVIce section of this manual. Once

all required components are removed your

appliance should resemble Figure 38.

Step 2: The panels are

delicate so please handle

with care. Remove the panels

from their packaging and insert

the rear liner rst followed by

the sides. Hold into position as

shown in Figure 39.

Figure 38. Firebox liner preperation

Step 3: Screw the (2) retainer brackets into

the existing exhaust bafe with the supplied

#8 T-20 bolts. Before tightening press the

retainer onto the panel rmly. Tighten them

once the panels seems to be in the correct

position. (See Figure 40)

Figure 40. Liner panel retainers

Figure 39. Liner panel position

Page 35

Page 36

Secondary Installation

fiRe gRate anD Log set instaLLation:

The placement of the logs is not arbitrary. If they are positioned incorrectly, the ames can be “pinched”

and will not burn correctly. All of the logs come with either a notch or ledge, which make alignment easier.