Page 1

HORIZONTAL, LOW PROFILE FAN COILS

B Y JOHNSON C O NTROL S

InstallatIon, operatIon & MaIntenance

MODELS HLF / HLP / HLE

New Release

Form ET115.24-NOM5 (908)

LD13884

Page 2

ForM Et115.24-noM5 (908)

TABLE OF CONTENTS

TABLE OF CONTENTS ..........................................................................................................................2

SAFETY SYMBOLS ...............................................................................................................................3

SAFETY CONSIDERATIONS .................................................................................................................3

SECTION ONE - RECEIPT & INITIAL INSTALLATION ................................................................4

HL SERIES FEATURES..........................................................................................................................4

PREFACE ................................................................................................................................................4

UNPACKING & INSPECTION ................................................................................................................5

HANDLING & INSTALLATION ...............................................................................................................5

Drain Pan ...........................................................................................................................................6

Coils ...................................................................................................................................................6

HL SERIES DIMENSIONAL DATA .........................................................................................................9

ARI STANDARD RATINGS...................................................................................................................10

COOLING/HEATING MEDIUM CONNECTIONS ..................................................................................10

AUXILIARY DRAIN PANS .................................................................................................................... 11

HEATING CAPACITY ............................................................................................................................11

Condensate Trap ............................................................................................................................12

DUCTWORK CONNECTIONS ..............................................................................................................12

ELECTRICAL CONNECTIONS ............................................................................................................12

Electrical Enclosure .......................................................................................................................13

TELESCOPING BOTTOM PANEL .......................................................................................................13

MODEL HLP HORIZONTAL FAN COIL OPTIONAL TELESCOPING BOTTOM

PANEL ASSEMBLY, TYPICAL INSTALLATION INSTRUCTIONS ......................................................14

MODEL HLP HORIZONTAL FAN COIL OPTIONAL TELESCOPING BOTTOM

PANEL ASSEMBLY ..............................................................................................................................15

SECTION TWO - START-UP .......................................................................................................16

GENERAL .............................................................................................................................................16

COOLING/HEATING SYSTEM .............................................................................................................16

AIR SYSTEM BALANCING ..................................................................................................................16

WATER SYSTEM BALANCING ...........................................................................................................17

CONTROLS OPERATION ....................................................................................................................17

MOTOR AND FAN DATA ......................................................................................................................17

SECTION THREE - NORMAL OPERATION & PERIODIC MAINTENANCE ..............................18

GENERAL .............................................................................................................................................18

MOTOR/BLOWER ASSEMBLY ............................................................................................................18

Fan Deck .........................................................................................................................................18

COIL ......................................................................................................................................................18

ELECTRIC RESISTANCE HEATER ASSEMBLY .................................................................................18

ELECTRICAL WIRING & CONTROLS .................................................................................................19

VALVES & PIPING ................................................................................................................................19

FILTERS, THROWAWAY ......................................................................................................................19

UNIT WEIGHT DATA (LBS.) .................................................................................................................20

DRAIN ...................................................................................................................................................20

REPLACEMENT PARTS ......................................................................................................................20

EXAMPLE WIRING DIAGRAMS ..........................................................................................................21

SECTION FOUR - INSPECTION & START-UP CHECKLIST .....................................................23

2

Johnson Controls

Page 3

FORM ET115.24-NOM5 (908)

SAFETY SYMBOLS

The following symbols are used in this document to alert the reader to areas of potential hazard:

DANGER indicates an imminently

hazardous situation which, if not

avoided, will result in death or serious

injury.

WARNING indicates a potentially

hazardous situation which, if not

avoided, could result in death or serious injury.

SAFETY CONSIDERATIONS

The equipment covered by this manual is designed for

safe and reliable operation when installed and operated

within its design specication limits. To avoid personal

injury or damage to equipment or property while

installing or operating this equipment, it is essential

that qualied, experienced personnel perform these

functions using good judgment and safe practices. See

the following cautionary statements.

ELECTRICAL SHOCK HAZARDS.

All power must be disconnected prior

to installation and serving this equipment. More than one source of power

may be present. Disconnect all power

sources to avoid electrocution or shock

injuries.

MOVING PARTS HAZARDS. Motor and Blower must be disconnected

prior to opening access panels. Motors

can start automatically, disconnect

all power and control circuits prior to

servicing to avoid serious crushing or

dismemberment injuries.

CAUTION identies a hazard which

could lead to damage to the machine,

damage to other equipment and/or

environmental pollution. Usually an

instruction will be given, together with

a brief explanation.

NOTE is used to highlight additional

information which may be helpful to

you.

Check that the unit assembly and component weights can be safely supported

by rigging and lifting equipment.

All assemblies must be adequately

secured during lifting and rigging by

temporary supports and restraints until equipment is permanently fastened

and set in its nal location.

All unit temporary and permanent

supports must be capable of safely

supporting the equipment’s weight and

any additional live or dead loads that

may be encountered. All supports must

be designed to meet applicable local

codes and ordinances.

All fastening devices must be designed

to mechanically lock the assembly in

place without the capability of loosening or breaking away due to system

operation and vibration.

HOT PARTS HAZARD. Electric Resistance heating elements must be disconnected prior to servicing. Electric

Heaters may start automatically, disconnect all power and control circuits

prior to servicing to avoid burns.

JOHNSON CONTROLS

Protect adjacent ammable materials

when brazing, Use ame and heat protection barriers where needed. Have

re extinguisher available and ready

for immediate use.

3

Page 4

ForM Et115.24-noM5 (908)

Motor

(not shown)

Right or left hand

coil and drain pan

connections, same

or opposite end

Electric Heat

Controls

(Bottom access)

Coils

Drain Pan

Supply Air

Filter

Access

(not

shown)

Blower

Return Air

Plenum

(Model HLP)

SECTION ONE - RECEIPT & INITIAL INSTALLATION

HL SERIES FEATURES

PREFACE

ENVIRO-TEC® fan coils represent a prudent investment

which can, with proper installation, operation, and

regular maintenance, give trouble-free operation and

long service.

Your equipment is initially protected under the

manufacturer’s standard warranty; however, this

warranty is provided under the condition that the steps

outlined in this manual for initial inspection, proper

installation, regular periodic maintenance, and everyday

operation of the equipment be followed in detail. This

manual should be fully reviewed in advance of any

actual work being done on the equipment. Should

any questions arise, please contact your local Sales

Representative or the factory BEFORE proceeding.

The equipment covered by this manual is available with

a vast variety of options and accessories. Consult the

approved unit submittal, order acknowledgement, and

other manuals for details on the options and accessories

provided with the equipment on each project.

lD13881

No attempt should be made to handle,

install, or service any unit without

following safe practices regarding

mechanical equipment.

All power must be disconnected before

any installation or service should be attempted. More than one power source

may be supplied to a unit. Power to

remote mounted control devices may

not be supplied through the unit. Never

wear bulky or loose tting clothing

when working on any mechanical

equipment. Gloves should only be

worn when required for proper protection from heat or other possible injury. Safety glasses or goggles should

always be worn when drilling, cutting,

or working with chemicals such as

refrigerants or lubricants.

4

Johnson Controls

Page 5

FORM ET115.24-NOM5 (908)

Never pressurize any equipment beyond specied operating pressures.

Always pressure test with some inert

uid or gas such as clear water or dry

nitrogen to avoid possible damage or

injury in the event of a leak or component failure during testing.

Always protect adjacent ammable

material when welding or soldering.

Use suitable heat shield material to

contain sparks or drops of solder.

Have re extinguisher available for

use when welding or brazing.

The manufacturer assumes no responsibility for personal

injury or property damage resulting from improper

or unsafe practices during the handling, installation,

service, or operation of any equipment.

UNPACKING & INSPECTION

All units are carefully inspected at the factory throughout

the manufacturing process under a strict detailed quality

assurance program, and where possible, all major

components and subassemblies are carefully tested for

proper operation and veried to be in full compliance

with the factory manufacturing documents. Customer

furnished components such as control valves, switches

and DDC controls are not factory tested.

Each unit is carefully packaged for shipment to avoid

damage during normal transport and handling. The

equipment should always be stored in a dry place in the

proper orientation as marked on the carton.

All shipments are made F.O.B. factory and it is the

responsibility of the receiving party to inspect the

equipment upon arrival. Any obvious damage to the

carton and/or its contents should be recorded on the bill

of lading and a claim should be led with the freight

carrier.

After determining the condition of the carton exterior,

carefully remove each unit from the carton and inspect

for hidden damage. At this time check to make sure that

“furnished only” items such as switches, thermostats,

etc. are accounted for. Any hidden damage should be

recorded and immediately reported to the carrier and a

claim led as before. In the event a claim for shipping

damage is led, the unit, shipping carton, and all packing

must be retained for physical inspection by the freight

carrier. All equipment should be stored in the factory-

shipping carton with internal packing in place until

installation.

At the time of receipt, the equipment type and

arrangement should be verified against the order

documents. Should any discrepancy be found, the local

Sales Representative should be notied immediately

so that the proper action may be instituted. Should

any question arise concerning warranty repairs, the

factory must be notified BEFORE any corrective

action is taken. Where local repairs or alterations can

be accomplished, the factory must be fully informed as

to the extent and expected cost of those repairs before

work is begun. Where factory operations are required,

the factory must be contacted for authorization to return

equipment and a Return Authorization Number will be

issued. Unauthorized return shipments of equipment

and shipments not marked with an authorization number

will be refused. In addition, the manufacturer will not

accept any claims for unauthorized expenses.

HANDLING & INSTALLATION

While all equipment is designed for durability and

fabricated for sturdy construction and may present a

rugged appearance, great care must be taken to assure

that no force or pressure be applied to the coil, piping

or drain stub-outs during handling. Also, depending

on the options and accessories, some units could

contain delicate components that may be damaged by

improper handling. Wherever possible, all units should

be maintained in an upright position and handled by

the chassis as close as possible to the mounting point

locations.

In the case of a full cabinet unit, the unit must obviously

be handled by the exterior casing. This is acceptable

providing the unit is again maintained in an upright

position and no impact forces are applied that may

damage internal components, access panels, or painted

surfaces. The equipment covered in this manual IS NOT

suitable for outdoor installations. The equipment should

never be stored or installed where it may be subjected

to a hostile environment such as rain, snow, or extreme

temperatures.

JOHNSON CONTROLS

5

Page 6

ForM Et115.24-noM5 (908)

During and after installation, special care must be taken

to prevent foreign material such as paint, plaster, and

drywall dust from being deposited in the drain pan or

on the motor or blower wheels. Failure to do so may

have serious adverse effects on unit operation and in

the case of the motor and blower assembly, may result

in immediate or premature failure. All manufacturers’

warranties are void if foreign material is allowed to be

deposited on the motor or blower wheels of any unit.

Some units and/or job conditions may require some form

of temporary covering during construction.

While the manufacturer does not become involved

in the design and selection of support methods and

components, it should be noted that unacceptable

system operating characteristics and/or performance

might result from improper or inadequate unit structural

support. In addition, adequate clearance must be

provided for service and removal of the equipment and

its accessory components. Anchoring the equipment in

place is accomplished by using the mounting points

provided and positioning the unit to maintain the unit

on a LEVEL plane. The drain pan is internally sloped

toward the outlet connection. Care must be taken to

insure that the unit drain pan does not slope away from

the outlet connection. All units are supplied with hanger

brackets with rubber grommet isolators and brass inserts

for use with 3/8” all thread hanger rod.

Drain Pan

lD13882

Standard drain pans are externally insulated, single wall

galvanized steel and can be equipped with a secondary

drain connection. The HL drain pan is easily removable

for cleaning or reversing connections. Auxiliary drip

pan to catch condensed moisture from valves and piping

must be sloped toward the drain pan.

Coils

All fan coils are available in 2 or 4 pipe congurations.

Heating coils are available in reheat or preheat position.

Heating and cooling coils are available with right, left

or opposite side connections.

The unit’s drain pan is factory sloped

toward the drain connection when the

unit is installed level and plumb.

Verify that the proper types of service are actually

provided to the unit. On units with steam heating

coils, the maximum steam pressure applied to the unit

should never exceed 15 PSIG. The drain piping and

steam trap should be sized and routed to allow for

proper condensate ow. The electrical service to the

unit should be compared to the unit nameplate to verify

compatibility. The routing and sizing of all piping, and

the type and sizing of all wiring and other electrical

components such as circuit breakers, disconnect

switches, etc. should be determined by the individual

job requirements and should not be based on the size

and/or type of connection provided on the equipment.

All installations should be made in compliance with all

governing codes and ordinances. Compliance with all

codes is the responsibility of the installing contractor.

6

Johnson Controls

Page 7

ForM Et115.24-noM5 (908)

HL SERIES DIMENSIONAL DATA

Drawings are subject to change without notice. Refer to www.enviro-tec.com for current submittal drawings.

Model HLF (Free Return)

Johnson Controls

lD13885

7

Page 8

FORM ET115.24-NOM5 (908)

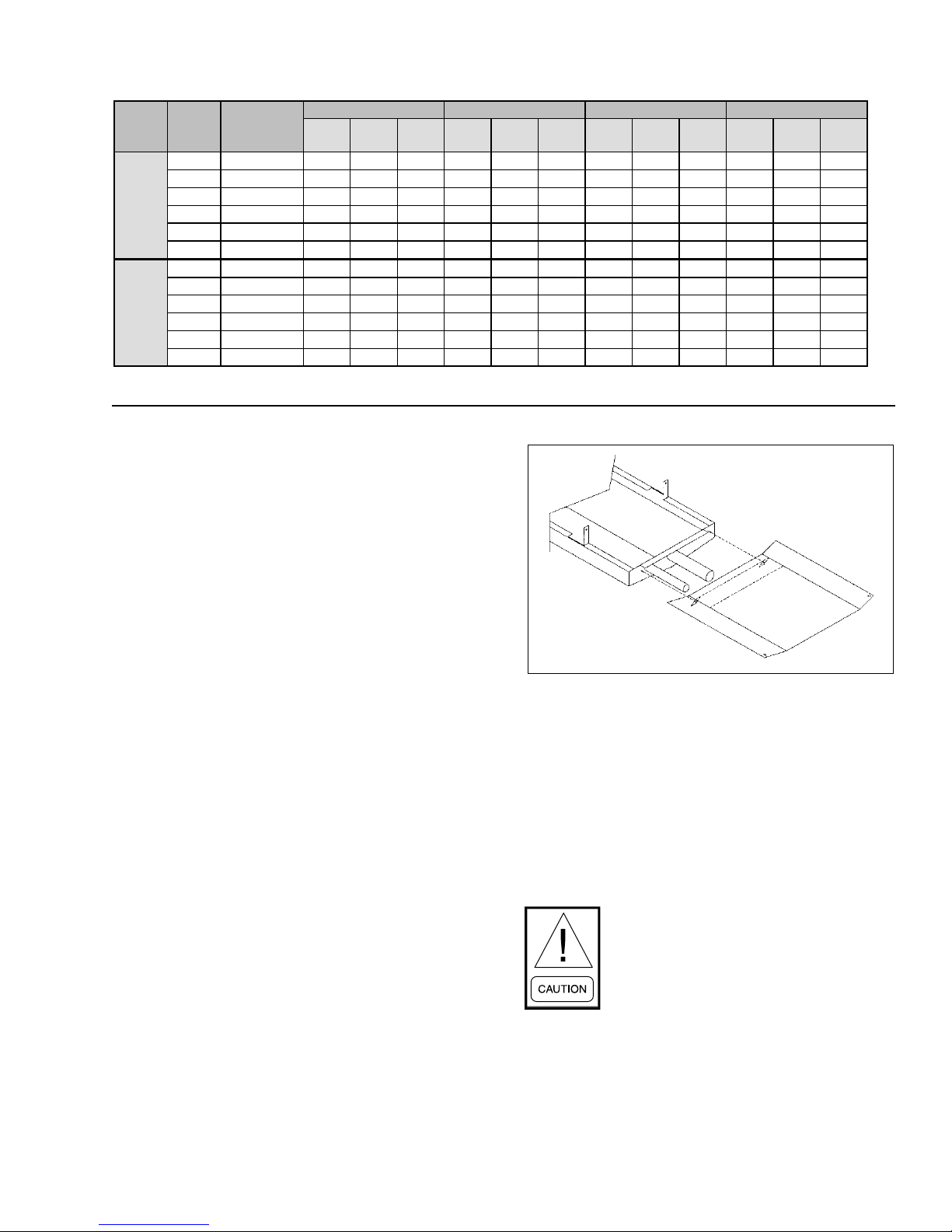

HL SERIES DIMENSIONAL DATA

Drawings are subject to change without notice. Refer to www.enviro-tec.com for current submittal drawings.

Model HLP (Plenum)

8

LD13886

JOHNSON CONTROLS

Page 9

Drawings are subject to change without notice. Refer to www.enviro-tec.com for current submittal drawings.

(TYPICAL EACH SIDE)

PARTIAL REAR VIEW

FRONT VIEW

TOP VIEW

SIDE VIEW

DIMENSIONS - In [mm]

ordinances.

Provide sufficient clearance to access electrical

controls and comply with applicable codes and

field to match individual job requirements.

8. Field piping casing penetrations must be cut in the

7. Internal insulation of field piping may be required.

optional electrical enclosure, coil, and drain pan.

6. Fixed bottom panel is removable for access to

access to filter and fan assembly.

5. Louvered bottom panel is hinged and removable for

indicated to provide proper drain slope.

4. Drain piping should be routed through casing opening

optional features.

3. Electrical enclosure size and location may vary with

2. Left hand unit shown, right hand unit opposite.

conversion.

dimensions ±1/4" [6mm]. Metric values are soft

1. All dimensions are Inches [millimeters]. All

NOTES:

DRAIN TUBE EXIT

1-1/8 K.O. FOR

ELECTRICAL ENTRY

TWO 7/8 K.O. FOR

RESILIENT GROMMET

ROD HOLES WITH

3/8 [10] DIA HANGER

3-1/2 [89]

1-5/8 [41]

[76]

3

[94]

3-11/16

[137]

5-3/8

RETURN GRILLE

STAMPED STEEL

SUPPLY GRILLE

STAMPED STEEL

[838]

33

[57]

2-1/4

[210]

8-1/4

[32]

1-1/4

[305]

12

[165]

6-1/2

F

E

[38]

1-1/2

[762]

30

[38]

1-1/2

D

C B

A

5-1/435-1/2

43

6-1/4

46

23-1/2

25

6-1/4

6-1/4

5-1/4

67-1/2

27-1/2

39-1/2

47-1/2

59-1/2

6-1/4

5-1/4

F

6-1/4

6-1/4

7-1/4

80

70

B C ED

47

57

7-1/4

77

67

37

6-1/4

A

UNIT

SIZE

27-1/2

39-1/2

40

47-1/2

59-1/2

50

60

20

30

40

50

60

19-1/2

[133][902][1092][159][597][1168]

[159]

[159]

[133]

[1715]

[699]

[1207]

[1511]

[1003] [133]

[159]

[159]

[159]

[184][1778]

[2032]

[940]

[1448]

[1194]

[159]

[184]

[1702]

[1956]

[1016]

[1270]

[1524]

[1511]

[495]

[1003]

[1207]

[699]

HL SERIES DIMENSIONAL DATA

Model HLE Horizontal Exposed Fan Coil

Front Stamped Supply Grille, Bottom Stamped Return Grille

ForM Et115.24-noM5 (908)

Johnson Controls

lD13883

9

Page 10

COOLING/HEATING MEDIUM CONNECTIONS

AIRFLOW POWER

CFM QT QS Flow Rate WPD INPUT

(DRY FLOW) (BTUH) (BTUH) GPM ft-wg (WATTS)

HLF 20 3 10 330 7800 6100 1.8 1.6 81

HLF 25 3 10 450 11500 8500 2.6 3.4 138

HLF 30 3 10 640 13900 11000 3.2 7.6 152

HLF 40 3 10 800 18500 14300 4.2 3.7 263

HLF 50 3 10 1140 24000 19300 5.4 7.4 402

HLF 60 3 10 1590 34000 26500 7.6 14.6 489

HLF 20 4 10 320 8500 6000 1.8 3.1 77

HLF 25 4 10 430 11600 8600 2.6 6.6 135

HLF 30 4 10 610 16900 12600 3.9 10.9 151

HLF 40 4 10 780 21900 16400 4.9 7.2 261

HLF 50 4 10 1040 28500 225

00 6.4 12.9 380

HLF 60 4 10 1510 41400 31300 9.2 27.1 466

HLP 20 3 10 270 6900 5300 1.6 1.2 81

HLP 25 3 10 420 10900 8100 2.5 3.1 132

HLP 30 3 10 540 12600 9800 2.8 6.1 152

HLP 40 3 10 770 18100 13900 4.1 3.5 263

HLP 50 3 10 1010 22300 18200 5.0 7.1 372

HLP 60 3 10 1460 32300 25600 7.2 13.3 489

HLP 20 4 10 260 7400 5200 1.6 2.5 77

HLP 25 4 10 410 10900 8100 2.5 6.0 130

HLP 30 4 10 520 15600 11500 3.5 10.0 151

HLP 40 4 10 740 21300 15900 4.8 6.9 261

HLP 50 4 10 970 27200 21400 6.1 11.9 361

HLP 60 4 10 1370 38600

29700 8.6 23.8 466

HLE 20 3 10 240 6300 4800 1.5 1.1 75

HLE 25 3 10 310 8900 6500 2.0 2.2 127

HLE 30 3 10 450 11100 8600 2.5 4.9 135

HLE 40 3 10 650 16300 12400 3.7 2.9 245

HLE 50 3 10 820 19500 15700 4.4 5.6 337

HLE 60 3 10 1130 27500 21500 6.1 10.0 402

HLE 20 4 10 240 6300 4700 1.5 2.1 65

HLE 25 4 10 300 8700 6300 2.0 4.0 125

HLE 30 4 10 440 13600 10000 3.1 7.9 130

HLE 40 4 10 630 18900 14000 4.2 5.5 235

HLE 50 4 10 780 23400 18300 5.3 9.1 321

HLE 60 4 10 1040 31900 24200 7.1 16.8 383

COIL COOLING CAPACITY

WATER

MODEL /

SIZE Rows FPI

NOTE: Based on 80°F DB

and 67°F WB EAT, 45°F

EWT, 10°F temperature

ris e, hig h fan speed.

Motor type is PSC and

motor voltage is 115/1/60.

Airflow under dry coil conditions. Model HLE tested

at 0.0" external static pressure. Models HLF and HLP

tested at 0.05" external

static pressure.

Toxic residues and loose particles resulting from manufacturing and eld piping techniques

such as joint compounds, soldering ux, and metal shavings may be present in the unit and

the piping system. Special consideration must be given to system cleanliness when connecting

to solar, domestic or potable water systems.

ARI STANDARD RATINGS

FORM ET115.24-NOM5 (908)

10

LD13887

JOHNSON CONTROLS

Page 11

QS

(MBH

)

QS

(MBH

)

QS

(MBH

)

QS

(MBH

)

GPM WPD GPM WPD GPM WPD GPM WPD

20 250 8.6 0.4 0.2 15. 7 0.8 0.9 19.7 1.0 0.3 22.9 1.2 0.5

25 400 15.0 0.6 0.6 21.0 1.1 3.1 30.0 1.5 1.1 28.3 1.4 1.8

HLP 30 500 16.1 0.8 0.6 29.2 1.5 3.2 38.3 2.0 1.2 43.4 2.2 0.7

HLF 40 750 23.6 1.2 1.5 40.5 2.1 1.6 55.2 2.8 1.1 64.9 3.3 1.8

50 1000 28.7 1.5 0.7 53.7 2.7 2.9 73.7 3.8 2.0 86.5 4.4 3.4

60 1400 36.1 1.9 1.1 66.9 3.4 4.7 92.4 4.7 3.4 108.3 5.5 5.6

20 250 7.9 0.4 0.3 14. 0 0.8 1.5 19.2 1.0 0.5 17.4 0.9 0.8

25 350 10.8 0.6 0.5 19.3 1.0 2.6

27.2 1.4 0.9 25.4 1.3 1.5

30 450 13.5 0.7 0.9 24.0 1.3 4.8 30.7 1.6 1.7 34.4 1.8 1.0

40 650 20.4 1.1 2.0 34.0 1.8 1.7 46.0 2.4 1.2 49.6 2.6 1.9

50 850 22.5 1.2 0.7 40.7 2.1 3.1 53.0 2.8 2.1 59.4 3.0 3.3

60 1200 30.9 1.6 1.2 55.4 2.9 5.5 72.6 3.8 3.9 80.0 4.1 6.0

2 ROW 3 ROW 4 ROW

HLE

UNIT

TYPE

UNIT

SIZE

NOM INAL

CFM

1 ROW

NOTE: Based on 70°F DB EAT, 180°F EWT, 40°F temperature drop, high

fan speed.

HEATING CAPACITY

FORM ET115.24-NOM5 (908)

LD13888

Submittals and Product Catalogs detailing unit operation,

AUXILIARY DRAIN PANS

controls, and connections should be thoroughly

reviewed BEFORE beginning the connection of the

various cooling and/or heating mediums to the unit.

All accessory valve packages should be installed as

required, and all service valves should be checked for

proper operation.

If coil and valve package connections are to be made

with “sweat” or solder joint, care should be taken to

assure that no components in the valve package are

subjected to a high temperature which may damage seals

or other materials. Many two-position electric control

valves, depending on valve operation, are provided with

a manual-opening lever. This lever should be placed

in the “open” position during all soldering or brazing

operations. Valve bodies should be wrapped with a wet

Mounted directly to the unit drain pan, AUXILIARY

DRAIN PANS may also be secured by the mounting

holes to eld supports or to the unit coil utilizing pipe

hanger wire, plastic ties, or metal strapping.

rag to help dissipate heat encountered during brazing.

After the connections are completed, the system should

If the valve package connection at the coil is made with

a union, the coil side of the union must be prevented

from twisting (“backed up”) during tightening to prevent

then be tested for leaks. Since some components are not

designed to hold pressure with a gas, hydronic systems

should be tested with water.

damage to the coil tubing. Over-tightening must be

avoided to prevent distorting the union seal surface and

and piping, the chilled water valve cluster (or expansion

valve on DX units) should be installed in such a way that

any dripping or sweating is contained in the auxiliary

drain pan or other device. Valves and TXV’s should be

secured or supported to avoid damage to coil headers

or distributor tubes.

JOHNSON CONTROLS

destroying the union. In the case of eld installed valves

Refrigerant systems should be tested with dry nitrogen

rather than air to prevent the introduction of moisture

into the system. In the event that leaking or defective

components are discovered, the Sales Representative

must be notied BEFORE any repairs are attempted.

All leaks should be repaired before proceeding with

the installation.

All water coils must be protected from

freezing after initial lling with water.

Even if the system is drained, unit coils

may still hold enough water to cause

damage when exposed to temperatures

below freezing.

LD13889

11

Page 12

FORM ET115.24-NOM5 (908)

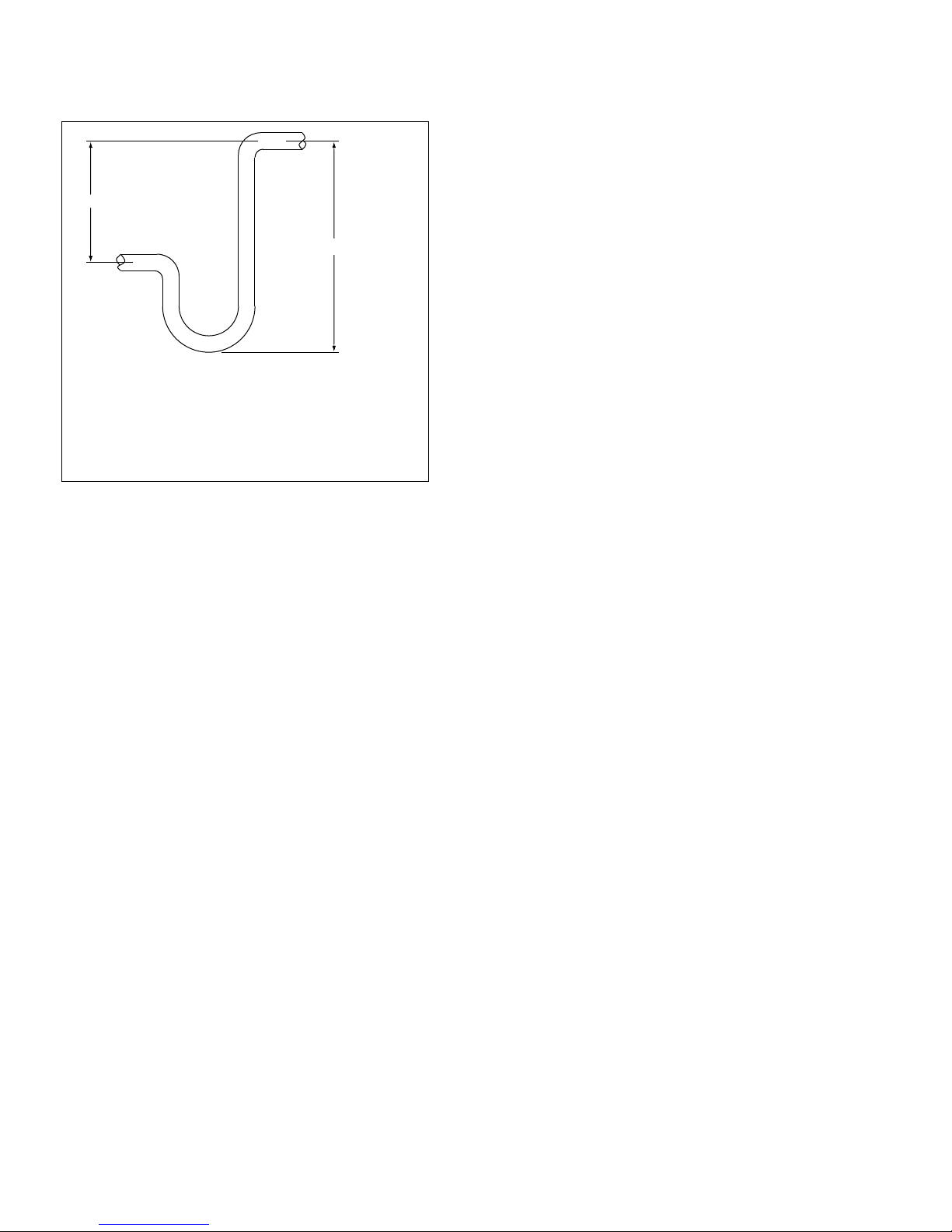

NOTE:

"A" DIMENSION (IN.) DEPTH MUST BE EQUAL TO OR

GREATER THAN UNIT'S NEGATIVE FAN PRESSURE AT

CONDENSATE PAN (INWC).

"B" DIMENSION MUST BE EQUAL TO (A x 1.5) + ID OF

DRAIN LINE.

A

B

Condensate Trap

LD13891

After system integrity has been established the piping

should be insulated in accordance with the project

specications. ALL chilled water piping and valves or

refrigerant suction piping not located over drain pans

must be insulated to prevent damage from sweating.

This includes factory and eld piping inside the unit

cabinet.

The drain should always be connected and piped to an

acceptable disposal point. For proper moisture carry-

off, the drain piping should be sloped away from the

unit at least 1/8” per foot. A drain trap may be required

by local codes and it is strongly recommended for odor

containment.

DUCTWORK CONNECTIONS

All ductwork and/or supply and return grilles should

be installed in accordance with the project plans and

specications. If not included on the unit or furnished

®

from the factory, ENVIRO-TEC

supply and return

grilles are available in a variety of types.

All units must be installed in non-combustible areas.

Some models are designed to be connected to duct-work

with a MINIMUM amount of external static pressure.

Consult the approved submittals and the product catalog

for unit external static pressure limitations.

Units provided with outside air for ventilation should

have some form of low temperature protection to

prevent coil freeze-up.

It should be noted that none of these methods would

adequately protect a coil in the event of power failure.

The safest method of freeze protection is to use glycol

in the proper percent solution for the coldest expected

air temperature.

The manufacturer assumes no responsibility for

undesir able sy stem op eration due to improper

design, equipment or component selection, and/or

installation of ductwork, grilles, and other eld supplied

components.

ELECTRICAL CONNECTIONS

The unit nameplate lists the unit electrical characteristics

such as the required supply voltage, fan and heater

amperage and required circuit ampacities. The unitwiring diagram shows all unit and eld wiring. Since

each project is different and each unit on a project may

be different, the installer must be familiar with the

wiring diagram and nameplate on the unit BEFORE

beginning any wiring. This unit is not acceptable for

installation in hazardous/explosive areas.

12

JOHNSON CONTROLS

Page 13

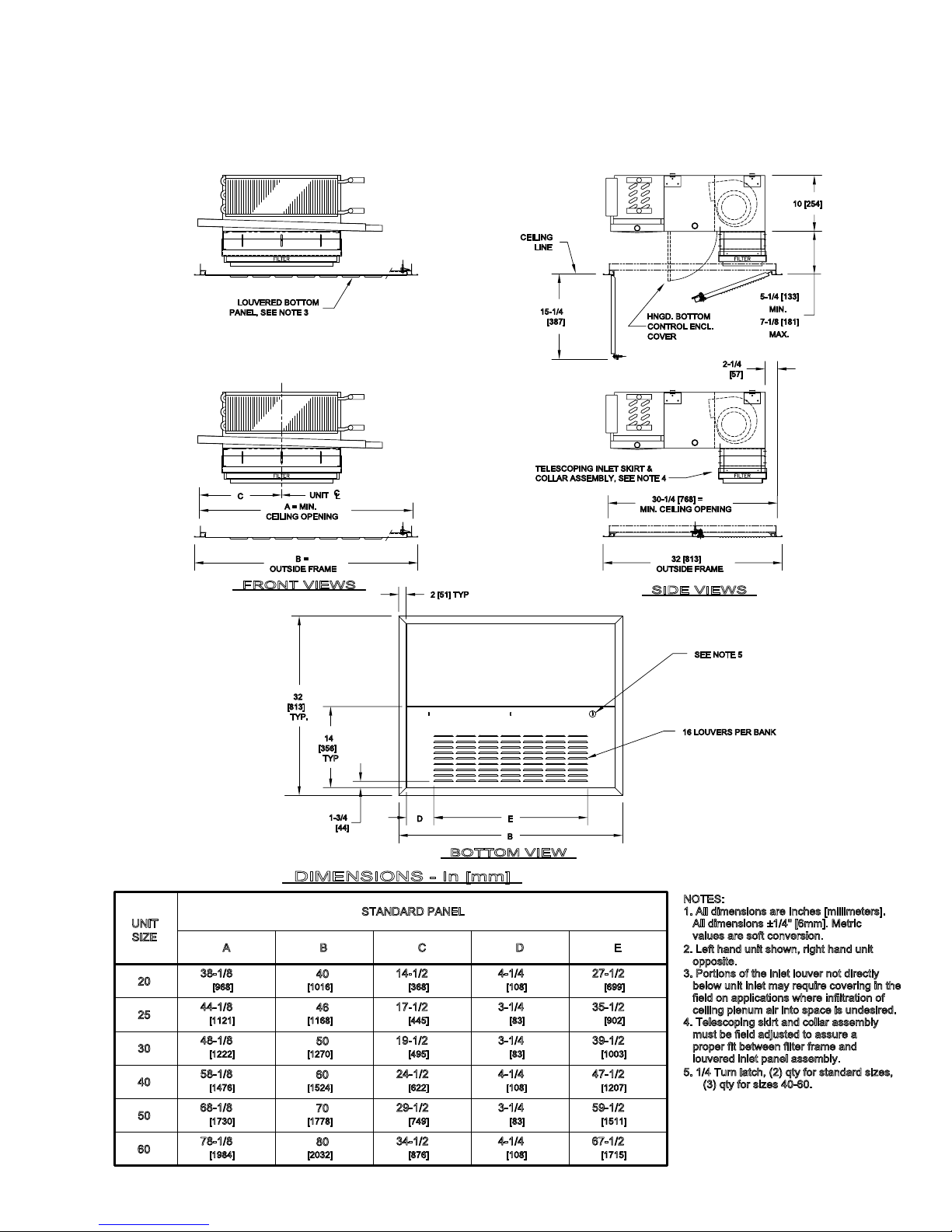

Electrical Enclosure

LD13890

The optional bottom hinged electrical enclosure

provides access to a spacious electrical compartment.

This compartment houses all electric heat and control

components. Terminal strips are furnished for simple

power and control wiring connections.

FORM ET115.24-NOM5 (908)

All eld wiring should be done in accordance with

governing codes and ordinances. Any modication of

the unit wiring without factory authorization will result

in voiding of all factory warranties and will nullify any

agency listings.

The manufacturer assumes no responsibility for any

damages and/or injuries resulting from improperly eld

installed or wired components.

TELESCOPING BOTTOM PANEL

All components furnished for eld installation, by either

the factory or the controls contractor should be located

and checked for proper function and compatibility. All

internal components should be checked for shipping

damage and all electrical connections should be

tightened to minimize problems during start-up.

Any devices such as fan switches or thermostats

that have been furnished from the factory for eld

installation must be wired in strict accordance with the

applicable wiring diagrams. Failure to do so could result

in personal injury or damage to components and will

void all manufacturers’ warranties.

The fan motor(s) should never be controlled by any

wiring or device other than the factory furnished switch

or thermostat/switch combination, without factory

authorization.

LD13892

The telescoping bottom panel allows for fully recessing

the unit while permitting service access into the ceiling

plenum. The architectural ceiling panel is nished with

a durable powder coat paint.

Portions of the inlet louver not directly

below unit inlet may require covering in the eld on applications where

inltration of ceiling plenum air into

space is undesired. Telescoping skirt

and collar assembly must be eld adjusted to assure a proper t between

lter frame and louvered inlet panel

assembly. Refer to assembly submittal

drawings for specic dimensions.

JOHNSON CONTROLS

13

Page 14

FORM ET115.24-NOM5 (908)

NOTES:INLET COLLAR INSTALLATION

STUD/DRYWALL CEILING SYSTEMSUSPENDED GRID/TILE CEILING SYSTEM

TYPICAL INSTALLATION METHODS

SIDE VIEW

infiltration of ceiling plenum air into space is undesired.

may require covering in the field on applications where

9. Portions of the inlet louver not directly below unit inlet

Filter removal direction is optional.

telescoping skirt, after final adjustment of skirt location.

8. Attach standard filter rack assembly to bottom of

assure close fit of filter rack to louvered bottom panel.

7. Telescoping skirt assembly must be field adjusted to

airflow pattern. Shim frame to support as required.

to do so may result in poor bottom panel fit and improper

6. Frame assembly must be installed flat and square. Failure

frame assembly.

5. Remove solid and louvered bottom panels before mounting

located and drilled to suit individual job requirements.

4. Mounting hardware not provided. Mounting holes must be

3. Left hand unit shown, right hand unit opposite.

2. All drawings subject to change without prior notice.

±1/4" [6mm]. Metric values are soft conversion.

1. All dimensions are inches [millimeters]. All dimensions

REQUIRE INDEPENDENT SUPPORT.

BOTTOM PANEL ASSEMBLY. BOTTOM PANEL ASSEMBLY MAY

NOTE: CEILING "T" BAR GRID MAY NOT SUPPORT TELESCOPING

MAX.

7-1/8 [181]

5-1/4 [133]

MIN.

RACK, SEE NOTE 8

STANDARD FILTER

CASING

"HLP" UNIT

FAN DECK

INSTALLED TOWARD

GUIDE FLANGE

SEE NOTE 4

ON COLLAR AND UNIT CASING,

SCREWS THRU MATING FLANGES

INSTALL SELF-DRILLING SHT MTL

WITH REAR OF UNIT

ALIGN INLET COLLAR

SEE NOTES 4 & 6

SCREW AS REQUIRED,

SHT MTL OR WOOD

REQUIRED

SHIM AS

SEE NOTES 4 & 6

SCREW AS REQUIRED,

SHT MTL OR WOOD

CEILING

DRYWALL

PANEL FRAME EXTRUSION

TELESCOPING BOTTOM

BOTTOM PANEL

SOLID OR LOUVERED

REQUIRED

SHIM AS

CEILING STUD

METAL OR WOOD

BOTTOM PANEL

SOLID OR LOUVERED

PANEL FRAME EXTRUSION

TELESCOPING BOTTOM

"T" BAR

CEILING GRID

CEILING TILE

ACOUSTIC FIBRE

TPANEL FIRS

OPEN THIS

[57]

2-1/4

10 [254]

[387]

15-1/4

CEILING LINE

FINISHED

MODEL HLP HORIZONTAL FAN COIL

Optional Telescoping Bottom Panel Assembly, Typical Installation Instructions

Drawings are subject to change without notice. Refer to www.enviro-tec.com for current submittal drawings.

14

LD13893

JOHNSON CONTROLS

Page 15

FORM ET115.24-NOM5 (908)

SIDE VIEWS

FRONT VIEWS

BOTTOM VIEW

DIMENSIONS - In [mm]

5. 1/4 Turn latch, (2) qty for standard sizes,

(3) qty for sizes 40-60.

opposite.

values are soft conversion.

All dimensions ±1/4" [6mm]. Metric

NOTES:

must be field adjusted to assure a

proper fit between filter frame and

louvered inlet panel assembly.

4. Telescoping skirt and collar assembly

2. Left hand unit shown, right hand unit

3. Portions of the inlet louver not directly

1. All dimensions are Inches [millimeters].

below unit inlet may require covering in the

field on applications where infiltration of

ceiling plenum air into space is undesired.

MIN.

MAX.

5-1/4 [133]

7-1/8 [181]

E

TYP

[356]

14

D

2 [51] TYP

[44]

1-3/4

16 LOUVERS PER BANK

SEE NOTE 5

[387]

15-1/4

[57]

2-1/4

MIN. CEILING OPENING

30-1/4 [768] =

OUTSIDE FRAME

32 [813]

C

OUTSIDE FRAME

B =

CEILING OPENING

A = MIN.

B

TYP.

[813]

32

10 [254]

COVER

HNGD. BOTTOM

CONTROL ENCL.

CEILING

LINE

LOUVERED BOTTOM

PANEL, SEE NOTE 3

L

C

UNIT

E

35-1/2

39-1/2

27-1/2

59-1/2

67-1/2

47-1/2

4-1/4

3-1/4

4-1/4

3-1/4

D

3-1/4

4-1/414-1/2

40

20

38-1/8

C

19-1/2

17-1/2

B

50

46

24-1/2

34-1/2

29-1/2

60

80

70

A

UNIT

SIZE

30

25

48-1/8

44-1/8

40

50

60

68-1/8

78-1/8

58-1/8

STANDARD PANEL

[699]

[902]

[1003]

[1207]

[1511]

[1715][108]

[83]

[108]

[83]

[108]

[83]

[368][1016][968]

[445]

[495]

[1168]

[1270]

[622]

[749]

[876]

[1524]

[1778]

[2032]

[1121]

[1222]

[1730]

[1984]

[1476]

TELESCOPING INLET SKIRT &

COLLAR ASSEMBLY, SEE NOTE 4

MODEL HLP HORIZONTAL FAN COIL

Optional Telescoping Bottom Panel Assembly

Drawings are subject to change without notice. Refer to www.enviro-tec.com for current submittal drawings.

JOHNSON CONTROLS

LD13894

15

Page 16

SECTION TWO - START-UP

FORM ET115.24-NOM5 (908)

GENERAL

Before beginning any start-up operation, the startup personnel should familiarize themselves with the

unit, options and accessories, and control sequence to

understand the proper system operation. All personnel

should have a good working knowledge of general

start-up procedures and have the appropriate start-up

and balancing guides available for consultation.

The initial step in any startup operation should be a nal

visual inspection. All equipment, plenums, duct-work,

and piping should be inspected to verify that all systems

are complete and properly installed and mounted, and

that no debris or foreign articles such as paper or drink

cans are left in the units or other areas. Each unit should

be checked for loose wires, free blower wheel operation,

and loose or missing access panels or doors. Except as

required during start-up and balancing operations, no

fan coil units should be operated without all the proper

ductwork attached, supply and return grilles in place,

and all access doors and panels in place and secure.

A clean lter of the proper size and type must also be

installed. Failure to do so could result in damage to the

equipment or building and furnishings, and/or void all

manufacturers’ warranties.

COOLING/HEATING SYSTEM

Prior to the water system start-up and balancing, the

chilled/hot water systems should be ushed to clean

out dirt and debris, which may have collected in the

piping during construction. During this procedure,

all unit service valves must be in the closed position.

This prevents foreign matter from entering the unit and

clogging the valves and metering devices. Strainers

should be installed in the piping mains to prevent

this material from entering the units during normal

operation.

During system filling, air venting from the unit is

accomplished by the use of the standard manual, or

optional automatic, air vent tting installed on the coil.

In the case of the manual air vent tting, the screw

should be turned counterclockwise no more than 1-½

turns to operate the air vent. Automatic air vents may

be unscrewed one turn counterclockwise to speed initial

venting but should be screwed in for automatic venting

after start-up operations.

The air vent provided on the unit is not

intended to replace the main system air

vents and may not release air trapped

in other parts of the system. Inspect the

entire system for potential air traps and

vent those areas as required, independently. In addition, some systems may

require repeated venting over a period

of time to properly eliminate air from

the system.

AIR SYSTEM BALANCING

All duct-work must be complete and connected, and all

grilles, lters, access doors and panels must be properly

installed to establish actual system operating conditions

BEFORE beginning air balancing operations.

Each individual unit and attached duct-work is a unique

system with its own operating characteristics. For this

reason, air balancing is normally done by balance

specialists who are familiar with all procedures required

to properly establish air distribution and fan system

operating conditions. These procedures should not be

attempted by unqualied personnel.

After the proper system operation is established,

the actual unit air delivery and the actual fan motor

amperage draw for each unit should be recorded in

a convenient place for future reference such as the

inspection, installation, & start-up check sheet, a copy

of which is provided on the back of this manual. Contact

the Sales Representative or the factory for additional

copies of this sheet.

16

JOHNSON CONTROLS

Page 17

MOTOR AND FAN DATA

FORM ET115.24-NOM5 (908)

UNIT

SIZE

20

25

30

40

50

60

NOTES:

1. Motor electrical data is nameplate data. Actual data will vary with application.

2. 230 volt motor is nameplated for 208/230/1/60. Use 230 volt motor data for 208 volt applications.

3. Unit size 30, 208/230 and 277 volt motors are 1/12 HP at high tap.

FAN

SPEED

High (1) 1/30

Medium (1) 1/50 0.4 39 0.3 49 0.3 48

Low (1) 1/60 0.3 33 0.3 43 0.3 41

High (1) 1/15

Medium (1) 1/30 0.9 90 0.3 80 0.3 80

Low (1) 1/60 0.5 60 0.2 60 0.2 60

High (1) 1/10

Medium (1) 1/30 0.8 76 0.3 75 0.5 65

Low (1) 1/60 0.5 47 0.2 54 0.4 41

High (1) 1/6

Medium (1) 1/12 1.5 162 0.5 171 0.5 152

Low (1) 1/40 0.6 75 0.4 79 0.3 74

High

Medium

Low

High (2) 1/6

Medium (2) 1/12 3.0 324 1.0 342 1.0 304

Low (2) 1/40 1.2 150 0.6 158 0.6 148

MOTOR

H.P.

(1) 1/8

(1) 1/6 2.5 257 1.4 233 1.0 255

(1) 1/15 1.3 145 0.6 109 0.5 132

(1) 1/12 1.5 156 0.5 106 0.5 151

(1) 1/40 0.8 69 0.3 63 0.3 86

(1) 1/40 0.6 75 0.4 62 0.3 84

# OF

FANS

1

1

2

2

3

4

115 VOLTS 208/230 VOLTS 277 VOLTS

AMPS WATTS AMPS WATTS AMPS WATTS

0.8 57 0.6 77 0.3 71

1.0 125 0.5 120 0.5 120

1.9 165 0.8 158 0.8 162

2.5 261 1.4 284 1.0 254

1.6 215 0.9 216 0.8 214

5.0 522 2.8 568 2.0 508

WATER SYSTEM BALANCING

A complete knowledge of the hydronic system, its

components, and controls is essential to proper water

system balancing and this procedure should not be

attempted by unqualied personnel. The system must

be complete and all components must be in operating

condition BEFORE beginning water system balancing

operations.

Each hydro nic system has d ifferent op erating

characteristics depending on the devices and controls

in the system. The actual balancing technique may vary

from one system to another.

After the proper system operation is established, the

appropriate system operating conditions such as various

water temperatures and ow rates should be recorded

in a convenient place for future reference.

Before and during water system balancing, conditions

may exist which can result in noticeable water

noise or undesired valve operation due to incorrect

system pressures. After the entire system is balanced,

these conditions will not exist on properly designed

systems.

CONTROLS OPERATION

Before proper control operation can be veried all other

systems must be in proper operation. The correct water

and air temperatures must be present for the control

function being tested. Some controls and features are

designed to not operate under certain conditions.

A wide range of controls and electrical options and

accessories may be used with the equipment covered

in this manual. Consult the approved unit submittals,

order acknowledgement, and other manuals for detailed

information regarding each individual unit and its

controls. Since controls and features may vary from

one unit to another, care should be taken to identify

the controls to be used on each unit and their proper

control sequence. Information provided by component

manufacturers regarding installation, operation, and

maintenance of their individual controls is available

upon request.

JOHNSON CONTROLS

17

Page 18

FORM ET115.24-NOM5 (908)

SECTION THREE - NORMAL OPERATION & PERIODIC MAINTENANCE

GENERAL

Each unit on a job will have its own unique operating

environmen t and conditions that may dictate a

maintenance schedule for that unit that is different

from other equipment on the job. A formal schedule of

regular maintenance and an individual unit log should

be established and maintained. This will help to achieve

the maximum performance and service life of each unit

on the job.

Information regarding safety precautions contained in the preface at the

beginning of this manual should be

followed during any service and maintenance operations.

For more detailed information concerning service

operations, consult your Sales Representative or the

Factory.

MOTOR/BLOWER ASSEMBLY

The type of fan operation is determined by the control

components and their method of wiring, and may vary

from unit to unit. Refer to the wiring diagram for each

unit for that unit’s individual operating characteristics.

Motors are permanently lubricated, PSC type and do

not require eld lubrication.

Fan Deck

LD13896

The fan assembly is easily removed from the unit

without disconnecting the ductwork for service access

to motors and blowers at, or away from the unit.

Should the assembly require more extensive service,

the motor/ blower assembly may be removed from the

unit to facilitate such operations as motor or blower

wheel/housing replacement, etc. Dirt and dust should

not be allowed to accumulate on the blower wheel or

housing. This can result in an unbalanced blower wheel

condition that can damage a blower wheel or motor.

The wheel and housing may be cleaned periodically

using a vacuum cleaner and a brush taking care not to

dislodge the factory balancing weights on the blower

wheel blades.

COIL

Coils may be cleaned in place by removing the motor/

blower assemblies and brushing the entering air face

between ns with a soft brush parallel to ns. Do not

brush perpendicular to n orientation as damage may

occur. Brushing should be followed by cleaning with a

vacuum cleaner. If a compressed air source is available,

the coil may also be cleaned by blowing air through the

coil ns from the leaving air face. Vacuuming should

again follow this. Units provided with the proper type

of air lters, replaced regularly, may require periodic

coil cleaning.

ELECTRIC RESISTANCE HEATER ASSEMBLY

Electric resistance heaters typically require no normal

periodic maintenance when unit air lters are changed

properly. Other conditions and equipment may affect the

operation and service life in the system. The two most

important operating conditions for an electric heater are

proper airow and proper supply voltage. High supply

voltage and/or poorly distributed or insufcient airow

over the element will result in element overheating. This

condition may result in the heater cycling on the high

limit thermal cutout. Open wire type heaters provided

have an automatic reset switch with a back-up high

limit thermal switch. Automatic reset switches are as

the name implies; they reset automatically after the

heater has cooled down. High limit thermal switches

must be replaced once the circuit has been broken.

The high limit thermal cutout device is a safety device

only and is not intended for continuous operation. With

proper unit application and during normal operation,

the high limit thermal cutout will not operate. This

device only operates when some problem exists and

ANY condition that causes high limit cutout MUST be

corrected immediately. High supply voltage also causes

excessive amperage draw and may result in tripping

of the circuit breaker or blowing of the fuses on the

incoming power supply.

18

JOHNSON CONTROLS

Page 19

FORM ET115.24-NOM5 (908)

UNIT

SIZE

COIL FACE

AREA

RETURN AIR

GRILLE FREE AREA

SUPPLY AIR

GRILLE FREE AREA

FILTER FACE

AREA

NOMINAL FILTER SIZES

20 1.04 [.09] 0.47 [.04] 0.40 [.04] 1.18 [.11]

20 x 8.5 x 1

[508 x 216 x 25]

25 1.35 [.13] 0.58 [.05] 0.50 [.05] 1.54 [.14]

26 x 8.5 x 1

[660 x 216 x 25]

30 1.56 [.14] 0.68 [.06] 0.56 [.05] 1.77 [.16]

30 x 8.5 x 1

[762 x 216 x 25]

40 2.08 [.19] 0.81 [.08] 0.80 [.07] 2.36 [.22]

(2) 20 x 8.5 x 1

[508 x 216 x 25]

50 2.60 [.24] 1.01 [.09] 0.96 [.09] 2.95 [.27]

(1) 20, (1) 30 x 8.5 x 1

[508, 762 x 216 x 25]

60 3.13 [.29] 1.15 [.11] 1.20 [.11] 3.54 [.33]

(2) 30 x 8.5 x 1

[762 x 216 x 25]

Face Area, Free Area and Filter Sizes

NOTES:

1. Face and free areas are in square feet

[square meters].

2. Filter sizes are in inches [millimeters].

3. Free area of ENVIRO -TEC®Model

HLE and T elescoping Bottom Panel

return grilles.

4. Free area of ENVIRO -TEC®Model

HLE supply grille and minimum free

area allowable for a supply grille

supplied by others.

ELECTRICAL WIRING & CONTROLS

The electrical operation of each unit is determined by

the components and wiring of the unit and may vary

from unit to unit. Consult the wiring diagram for the

actual type and number of controls provided on each

unit. The integrity of all electrical connections should be

veried at least twice during the rst year of operation.

Afterwards, all controls should be inspected regularly

for proper operation. Some components may experience

erratic operation or failure due to age. Wall thermostats

may also become clogged with dust and lint and should

be periodically inspected and cleaned to provide reliable

operation.

When replacing any components such as fuses,

contactors, or relays, use only the exact type, size, and

voltage component as furnished from the factory. Any

deviation without factory authorization could result

in personnel injury or damage to the unit and will

void all factory warranties. All repair work should be

done in such a manner as to maintain the equipment in

compliance with governing codes and ordinances or

testing agency listings.

More specific information regarding the use and

operating characteristics of the standard controls offered

by this manufacturer is contained in other manuals.

VALVES & PIPING

No formal maintenance is required on the valve package

components most commonly used with fan coil units

other than a visual inspection for possible leaks in the

course of other normal periodic maintenance. In the

event that a valve should need replacement, the same

precautions taken during the initial installation to protect

the valve package from excessive heat should also be

used during replacement. In some cases, the valve

actuator may fail and usually can be replaced without

removing valve body from piping.

FILTERS, THROWAWAY

The type of throwaway lter most commonly used on

fan coil units should be replaced on a regular basis.

The time interval between each replacement should be

established based on regular inspection of the lter and

should be recorded in the log for each unit. Refer to the

chart below for recommended lter size for each product

type and size. If the replacement lters are not purchased

from the factory, the lters used should be the same type

and size as that furnished from or recommended by the

factory. Pleated media or extended surface lters should

not be used since the high air pressure drops encountered

with these types of lters is not compatible with the

type of fan coil unit covered in this manual. Consult the

factory for applications using lter types other than the

factory standard or optional product.

JOHNSON CONTROLS

LD13897

19

Page 20

20 25 30 40 50 60

40 [18] 51 [23] 59 [27] 69 [ 31] 91 [41] 111 [ 50]

45 [20] 56 [25] 65 [30] 80 [ 36] 103 [ 47] 123 [ 56]

119 [ 54] 138 [ 63] 155 [70] 181 [82] 220 [ 100] 257 [117]

1 ROW - DRY 8 [4] 10 [5] 11 [5] 13 [6] 15 [7] 18 [8]

1 ROW - W ET 10 [5] 12 [5] 13 [6] 15 [7] 18 [ 8] 21 [10]

2 ROW - DRY 11 [5] 13 [6] 15 [7] 18 [8] 22 [10] 26 [12]

2 ROW - W ET 14 [6] 16 [7] 18 [8] 22 [10] 27 [12] 32 [15]

3 ROW - DRY 14 [6] 17 [8] 19 [9] 24 [11] 29 [ 13] 34 [15]

3 ROW -

WET 17 [8] 21 [10] 24 [ 11] 30 [14] 36 [16] 42 [19]

4 ROW - DRY 17 [8] 20 [9] 23 [ 10] 29 [13] 36 [16] 42 [19]

4 ROW - W ET 21 [10] 25 [11] 29 [13] 36 [16] 45 [20] 53 [24]

COIL

ROWS

COMPONENT

UNIT SIZE

HLF BASE UNIT

HLP BASE UNIT

HLE BASE UNIT

NOTE: Unit weight data is in pounds [kilograms].

UNIT WEIGHT DATA (lbs.)

DRAIN

The drain should be checked before initial start-up and

at the beginning of each cooling season to assure that

the lines are clear. If it is clogged, steps should be taken

to clear the debris so that condensate will ow easily.

Periodic checks of the drain should be made during the

cooling season to maintain a free owing condensate.

Should the growth of algae and/or bacteria be a concern,

consult an air conditioning and refrigeration supply

organization familiar with local conditions for chemicals

available to control these agents.

REPLACEMENT PARTS

Factory replacement parts should be used wherever

po ssible to maintain t he unit perfo rmance and

operating characteristics and the testing agency listings.

Replacement parts may be purchased through the local

Sales Representative.

Contact the local Sales Representative or the factory

be fore attempting any unit modifications. Any

modications not authorized by the factory could result

in personnel injury and damage to the unit and could

void all factory warranties.

20

FORM ET115.24-NOM5 (908)

When ordering parts, the following information must be

supplied to ensure proper part identication:

1. Complete unit model number

2. Unit hand connection (right or left hand) while

facing the direction of airow at the inlet

3. Complete part description including any numbers.

On warranty replacements, in addition to the information

previously listed, the project CO # that appears on the

unit nameplate, is required. Contact the factory for

authorization to return any parts such as defective parts

replaced in warranty. All shipments returned to the

factory MUST be marked with a Return Authorization

Number, which is provided by the factory.

All equipment and components sold through the Parts

Department are warranted under the same conditions

as the standard manufacturer’s warranty with the

exception that the warranty period is 12 months unless

the component is furnished as warranty replacement.

Parts furnished as warranty replacements are warranted

for the remaining term of the original unit warranties.

JOHNSON CONTROLS

LD13898

Page 21

FORM ET115.24-NOM5 (908)

EXAMPLE WIRING DIAGRAMS

"Example Wiring Diagram - Typical 24 VAC Control Drawing (Refer to unit control enclosure for actual order-specic drawing)"

JOHNSON CONTROLS

84-10-0615-REV05

21

Page 22

FORM ET115.24-NOM5 (908)

EXAMPLE WIRING DIAGRAMS (Continued)

"Example Wiring Diagram - Typical 24 VAC Control Drawing (Refer to unit control enclosure for actual order-specic drawing)"

22

84-10-0205-REV05

JOHNSON CONTROLS

Page 23

SECTION FOUR - INSPECTION & START-UP CHECKLIST

RECEIVING & INSPECTION

Unit Received Undamaged.

Unit Arrangement/Hand Correct.

HANDLING & INSTALLATION

Unit Mounted Level & Square.

Proper Electrical Service Provided.

Proper Service Switch/Disconnect Provided

Proper Chilled Water Line Size to Unit.

Proper Refrigerant Line Sizes to Unit.

Proper Steam Condensate Trap on Return Line.

All Services to Unit In Code Compliance.

COOLING/HEATING CONNECTIONS

Protect Valve Package Components From Heat.

Connect Field Piping To Unit.

Install Drain Line & Traps As Required

Install Condensate Pan under Piping as Required

FORM ET115.24-NOM5 (908)

Unit Received Complete As Ordered

Unit Structural Support Complete & Correct

Proper Access Provided For Unit & Accessories

Proper Overcurrent Protection Provided

Proper Hot Water Line To Unit

Proper Steam Line Sizes To Unit

Proper Steam Supply Pressure to Unit (15psi Max)

All Shipping Screws & Braces Removed

Mount Valve Packages

Pressure Test All Piping for Leaks

Insulate All Piping as Required

DUCTWORK CONNECTIONS

Install Ductwork, Fittings & Grilles As Required.

Control Outside Air For Freeze Protection.

ELECTRICAL CONNECTIONS

Refer To Unit Wiring Diagram.

All Field Wiring In Code Compliance.

UNIT STARTUP

General Visual Unit & System Inspection.

Record Ambient Temperature.

Close All Unit Isolation Valves.

Fill Systems With Water/Refrigerant.

All Ductwork & Grilles In Place.

Start Fans, Etc.

Check All Ductwork & Units For Air Leaks.

Record All Final Settings For Future Use.

Check All Dampers For Proper Operation.

Verify Proper Heating Operation.

Proper Supply & Return Grille Type & Size Used

Insulate All Ductwork as Required

Connect Incoming Power Service or Services

Record Electrical Supply Voltage

Check All Wiring for Secure Connections

Flush Water Systems

Vent Water Systems as Required

All Unit Panels & Filters in Place

Check for Overload Condition of All Units

Balance Air Systems As Required

Check Piping & Ductwork For Vibration

Verify Proper Cooling Operation

Reinstall All Covers & Access Panels

JOHNSON CONTROLS

23

Page 24

©2008 Johnson Controls, Inc.

P.O. Box 423, Milwaukee, WI 53203 www.johnson-

controls.com

Printed in USA ET115.24-NOM5 (908)

New Release

Loading...

Loading...