Page 1

SHERWOOD INDUSTRIES IS AN ENVIRONMENTALLY RESPONSIBLE COMPANY

THIS MANUAL IS PRINTED ON RECYCLED PAPER

EG 28 Direct Vent

By SHERWOOD INDUSTRIES

OWNERS MANUAL

WHAT TO DO IF YOU SMELL GAS

• Open windows

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire

If the information in this manual

is not followed exactly, a fire or

explosion may result causing

property damage, personal

injury or loss of life. Installation

and service must be performed

by a qualified installer, service

agency or the gas supplier.

WARNING

department.

FOR YOUR SAFETY

Do not store or use gasoline or other Flammable vapors and liquids in the vicinity of

this or any other appliance.

Page 2

SAFETY PRECAUTIONS

FOR SAFE INSTALLATION AND OPERATION OF YOUR "ENVIROGAS" STOVE, PLEASE,

CAREFULLY READ THE FOLLOWING INFORMATION:

GENERAL

• Installation and repair should be done by a

qualified service person. The appliance should

be inspected before use and at least annually

by a qualified service person. More frequent

cleaning may be required due to excessive lint

from carpeting, bedding material, etc. It is

imperative that control compartments, burners

and circulating air passageways of the

appliance be kept clean.

• Due to high temperatures the appliance

should be located out of high traffic areas and

away from furniture and draperies.

Children and adults should be alerted to

hazards of high surface temperatures and

should stay away to avoid burns or clothing

ignition.

• Young children should be carefully

supervised when they are in the same room as

the appliance.

• Clothing or other flammable material should

not be placed on or near the appliance.

• All "ENVIROGAS" gas-fired appliances must be

installed in accordance with these instructions.

Carefully read all the instructions in this manual first.

Consult the building authority having jurisdiction to

determine the need for a permit prior to commencing

the installation.

• NOTE Failure to follow these instructions could

cause a malfunction of the fireplace, which could

result in death, serious bodily injury, and/or property

damage.

• Failure to follow these instructions may also void

your fire insurance and/or warranty.

FOR YOUR SAFETY:

• Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

• Installation must conform to local codes or, in

the absence of local codes with the current CAN 1-B

149 installation code in Canada or the current

National Fuel Gas Code ANSI Z223.1 in the USA.

• To prevent injuries do not allow anyone who is

unfamiliar with the operation to use the stove.

Always keep the appliance area clear

•

and free of combustible materials, gasoline

and other flammable vapors and

• These appliances should not be used as a

drying rack for clothing or for hanging Christmas

stockings or decorations.

• Due to the paint curing on the stove a faint odor

and slight smoking will likely be noticed when the

stove is first used. Open a window until the slight

smoking stops. Always connect this gas stove to a

chimney and vent to the outside of the building

envelope. Never vent to another room or inside a

building. Make sure you use the vent pipe that is

specified. Make sure that the vent is properly sized

and is of adequate height to provide the proper draft.

Inspect the venting system annually for blockage

and any signs of deterioration.

liquids.

WARNING: Do not operate with

cracked or broken glass. Under no

circumstances should this appliance be

modified. Parts that have to be removed

for servicing must be replaced prior to

operating this appliance. Only parts

supplied by Envirogas should be used in

this appliance and replacement should

only be performed by a licensed or

qualified service person.

• Never use solid fuels such as wood, paper,

cardboard, coal, or any other flammable liquids etc.,

in this appliance.

• Do not use this heater if any part has been

under water. Immediately call a qualified service

technician to inspect the heater and to replace any

part of the control system and any gas control, which

has been under water.

• Do not abuse glass

shut.

by striking or slamming door

2

Page 3

TABLE OF CONTENTS

Safety Precautions 2

Code Approvals 3

Deciding where to locate your stove 4

Planning your installation 6

Installation of Log Sets and Embers 14

Operating Instructions 15

Maintenance and Technical 16

Trouble Shooting 17

Gas Line Connection 18

Electrical 19

Parts and Accessories 20

Fuel Conversion 21

Warranty 22

Parts List 23

Exploded Views 24-25

Installation Data Sheet 26

Mobile Home Information 3,13,19,21

CODE APPROVALS

• This Direct Vent appliance draws all of its combustion air from outside of the dwelling through specially

designed vent pipe.

These appliances have been tested by INTERTEK TESTING SERVICES (WH) and found to comply with the

established standards for a DIRECT VENT GAS FIREPLACE in CANADA and the USA as follows:

LISTED GAS FIRED GRAVITY DIRECT VENT WALL FURNACE (EG 28 DV. Nat. & LPG. )

TESTED TO: ANSI Z21.88-1998 CSA 2.33-M98 VENTED GAS FIREPLACE HEATER. UL307B-1995 GAS

BURNING HEATING APPLIANCES FOR MANUFACTURED HOMES. CGA 2.17-M91 GAS FIRED

APPLIANCES FOR USE AT HIGH ALTITUDE

SPECS:

ENVIROGAS EG 28 DIRECT VENT UNITS;

• have all been certified for use with either natural or propane gases. (see control panel and rating label.)

• are not for use with solid fuels.

• must not be connected to a chimney flue serving a separate solid-fuel burning appliance.

• are approved for bedroom or bedsitting room.

(IN CANADA: must be installed with a listed wall thermostat)

(IN USA: see current ANSI Z223.1 for installation instructions.)

• must be installed in accordance with local codes if any. If none exist use current installation code CAN/CGA

b149 in Canada or ANSI Z223.1 / NFPA 54 in the USA.

• must be properly connected to an approved venting system.

• Manufactured (mobile) home installation must be in accordance with the Manufactured Home Construction

and Safety Standard, UL 307B, Title 24 CFR, Part 3280 and/or The Standard for Manufactured Home

Installations, ANSI A225.1/NFPA 501A. The unit must be bolted to the floor of the mobile home and must be

electrically grounded to the steel chassis.

• are approved for installation on combustible materials.

• are not approved for closet or recessed installations.

ASSEMBLY INSTRUCTIONS

PREPARATION FOR INSTALLATION

• Remove the packaging from the appliance, and check to make sure there is no damage. If damage is found,

please report it to both the carrier and your dealer as soon as possible.

• Before beginning, carefully check the glass door and the log set

3

Page 4

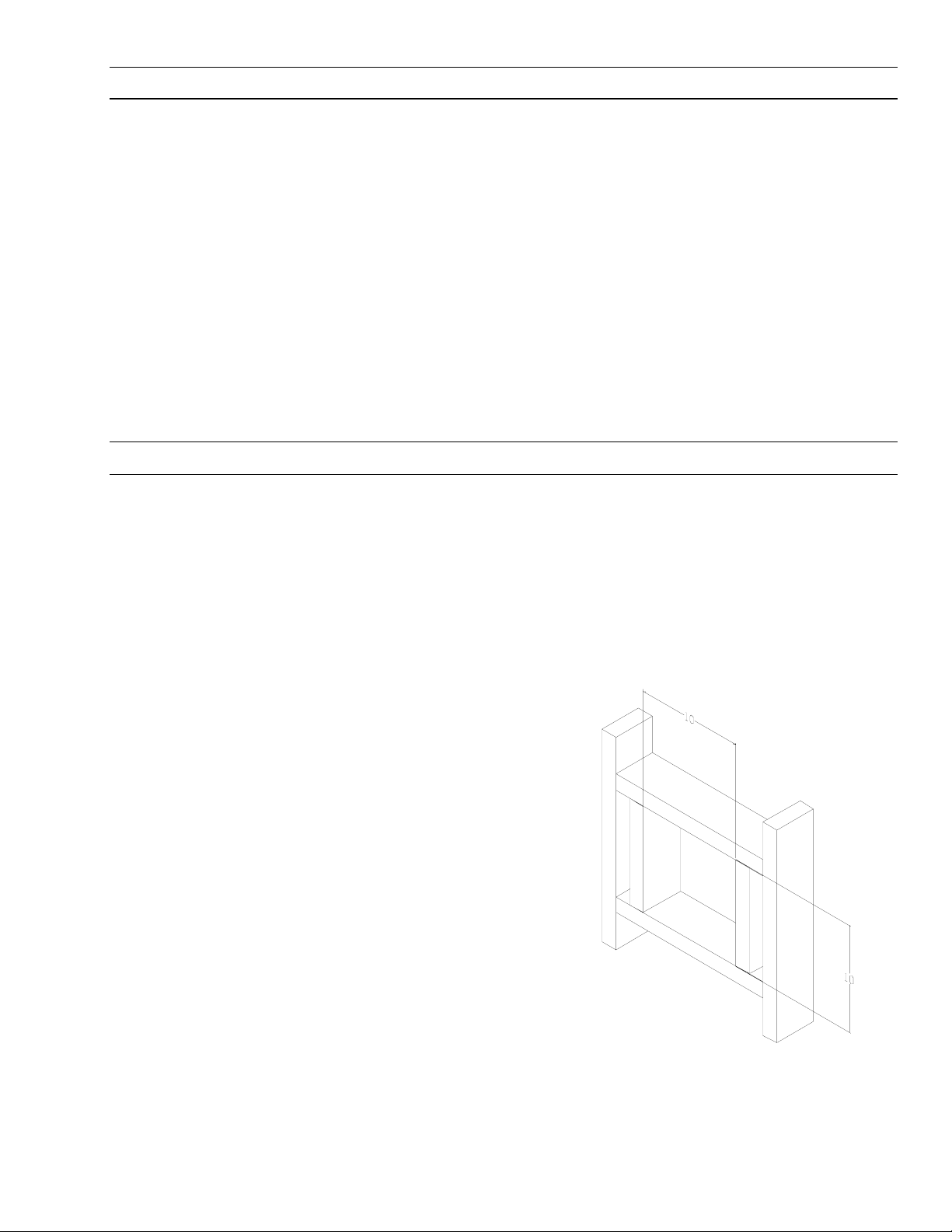

DECIDING WHERE TO LOCATE YOUR STOVE

DIMENSIONS:

Front Width: 22"/ 56 cm

Rear Width: 22"/ 56 cm

Height: 27-1/2"/ 70 cm*

Depth 19"/ 48 cm

(*not including vent coupling)

Shipping Weight: 210 lbs/95 kg

CLEARANCES:

A. Side wall to stove 10"/ 25 cm

B. Rear wall to stove 4"/ 10 cm

C. Combustible to stove Top 22”/ 56 cm

D. Floor to stove 0"/ 0 cm

E. Corner clearance 2"/ 5 cm

F. Alcove depth 48"/ 122 cm

Maintain sufficient clearances

for service and maintenance

• The stove should be located out of traffic and away from furniture and draperies.

• The stove should have sufficient access for its safe operation and maintenance.

• Locate a position where the flue system of the stove can be properly installed without damaging the integrity

of the building. e.g. cutting a wall or ceiling joist.

• The stove can be installed on any standard flooring materials i.e. Wood, carpet or linoleum.

• Check stove and flue system clearance requirements.

• Locate the stove where it can be accessed by a gas supply line.

• Locate the stove in a large and open room that is centrally located in the house. This will optimize heat

circulation and comfort.

• As the stove is equipped with a convection fan, ensure that an electrical outlet is within 6ft. (1.8m) of the

stove.

• These stoves can be installed in bedrooms.

(IN CANADA: must be installed with a listed wall thermostat)

(IN USA: see current ANSI Z223.1 for installation instructions.)

• The

flow of combustion and ventilation air must not be obstructed.

FIG. 1

FIG. 2

4

Page 5

VENT TERMINAL CLEARANCES

A= Clearance above grade, verandah, porch, deck, or

balcony [*12 inches (30 cm) minimum]

B= Clearance to window or door that may be opened

[*12 inches (30 cm) minimum]

C= Clearance to permanently closed window

[minimum 12 inches (30 cm) recommended to prevent

condensation on window]

D= Vertical clearance to ventilated soffit located above the

terminal within a horizontal distance of 2 feet (60 cm)

from the center-line of the terminal (24 inches (60 cm)

minimum)

E= Clearance to unventilated soffit

[18 inches (45 cm) minimum]

F= Clearance to outside corner [12 inches minimum]

G= Clearance to inside corner [`12 inches minimum]

*** A vent shall not terminate directly above a sidewalk or paved driveway, which is located between two single family dwellings

and serves both dwelling

** Only permitted if verandah. Porch, deck, or balcony is fully open on a minimum of 2 sides beneath the floor

As specified in CGA B149 Installation Codes (1991) Note: Local Codes or Regulation

Installations over 15 feet

(4.5m) vertical require the

use of a vent restrictor

WHEN VENTING THIS APPLIANCE YOU MUST STAY WITHIN THE

SHADED AREA (see venting chart provided) FOR ALL VENTING

APPLICATIONS.

VENT RESTRICTOR RING: A vent restrictor ring is supplied with each

direct vent fireplace. This restrictor ring is to be installed when the vertical

chimney installation is over 15’ (4.57 M). Before the chimney is placed onto

the stove, place this vent restrictor ring into the 4” (10.16 CM) flue pipe(as

shown), once the vent restrictor ring has been installed, the vertical sections

of chimney can be installed.

H= *Not to be installed above a meter/regulator assembly

within 3 feet (90 cm) horizontally from the center-line of

the regulator

I= Clearance to service regulator vent outlet

[*6 feet (1.8m) minimum]

J= Clearance to non-mechanical air supply inlet to building

or the combustion air inlet to any other appliance

[12 inches (30 cm) minimum]

K= Clearance to a mechanical air supply inlet

[*6 feet (1.8m) minimum]

L=*** Clearance above paved side-walk or paved driveway

located on public property

[*7 feet (2.1m) minimum]

M= Clearance under verandah, porch, deck, or balcony

[*24 inches (60 cm) minimum **]

5

Page 6

These models have been tested and certified for use with SIMPSON DURAVENT DIRECT VENT TYPE "GS" PIPE FOR GAS

STOVES. SECURITY VENTING SYSTEMS (SECURE VENT) Kits are available for vertical venting or horizontal venting. It is

recommended that a bead of RTV High Temperature Silicone be applied to each outer vent joint and milpac to each inner joint

before installation.

This model has also been tested for horizontal venting installations when using SHERWOOD INDUSTRIES LTD. horizontal

venting kit PART # EG 40-500

SHERWOOD INDUSTRIES LTD PARTS:

1 Horizontal direct vent termination cap

1 Flue collar adapter 5” tall (4 T20 Torx)

1 Wall thimble

1 Inside finish trim collar

1 5’ length of 4” double walled flex pipe

2 24” sections 6 5/8’ straight pipe

1 6 5/8” 90° elbow

A MINIMUM VERTICAL LENGTH OF 24" TO THE FIRST 90 DEGREE ELBOW IS REQUIRED. WITH THIS MINIMUM

VERTICAL RISE, HORIZONTAL RUNS OF FROM ONE TO FOUR FEET ARE PERMITTED TO REACH THE OUTSIDE VENT

TERMINATION.

BEFORE BEGINNING THE INSTALLATION TAKE CARE TO ENSURE AN APPROPRIATE OUTSIDE LOCATION FOR THE

VENT TERMINATION CAN BE ACCOMMODATED. FOLLOW THE VENT LENGTH DIAGRAM PRECISELY.

VENTING TERMINALS CANNOT BE RECESSED INTO A WALL OR SIDING.

If extra elbows are being used, overall allowable length will be reduced by 3 ft. per additional elbow

4 Spring spacers

3 Decorative brass rings

1 4oz tube RTV silicone

1 4oz can charcoal gray spray paint

20 9/16” tech screw

8 1 1/2” wood screws

1 Vinyl siding deflector

Simpson Duravent Parts

Number Description Number Description 908B 6" Pipe Length, Black

907B 9" Pipe Length, Black

906 (B) 12" Pipe Length, (Black)

904 (B) 24" Pipe Length, (Black)

903 (B) 36" Pipe Length, (Black)

902 (B) 48" Pipe Length, (Black)

911 (B) 11" to 14-5/8" Pipe , Adjustable, Black

945 (B) 45° Elbow, (Black)

990 (B) 90° Elbow, (Black)

940 Round Support / Wall Thimble Cover

941 Cathedral Ceiling Support Box

943 Flashing, 0/12 to 6/12 Roof Pitch

Add suffix (B) for optional black parts as listed.

943S Flashing, 7/12 to 12/12 Roof Pitch

953 Storm Collar

963 Ceiling Firestop

988 Wall Strap

984 Horizontal Square Termination

985 High Wind Horizontal Termination

980 Vertical Termination

991 High Wind Vertical Termination

950 Vinyl Siding Standoff

942 Wall Thimble

971 Horizontal Termination Kit A

PLANNING YOUR INSTALLATION

There are two basic types of Direct Vent System installations. The two types of installations are:

Vertical Termination Horizontal Termination

6

Page 7

When planning your installation, it will be necessary to select the proper length of vent pipe for your particular requirements. It

is important to note when passing through a wall, the maximum allowable wall thickness is 10-inches (254mm), 1 ½ inches

clearance to combustibles must be maintained. Select the amount of vertical rise desired for “vertical-to-horizontal” type

installations. To determine the length of vent pipe required for vertical installations, measure the distance from the appliance

flue outlet to the ceiling, the ceiling thickness, the vertical rise through the attic or second story, and allow for sufficient vent

height above the roofline. For two story applications, A firestop is required at each floor level. If an offset is needed in the attic,

additional pipe and elbows will be required. To connect the venting system to the appliance flue outlet, a twist-lock adapter is

built into the appliance at the factory.

HORIZONTAL INSTALLATION

STEP 1. Set the appliance in the desired location. Check to determine if wall studs or roof rafters are in the way when the

venting system is attached. If this is the case, you may want to adjust the location of the appliance.

STEP 2. Direct vent pipe and fittings are designed with special twist-lock connections. Assemble the desired combination of

black pipe and elbows to the appliance adapter with pipe seams oriented towards the wall or floor, as much out of

view as possible.

Place a bead of Mil-Pac on the outer edge of the inner exhaust pipe (non-flared end). Place a bead of high temperature

silicone on the male edge of the outer pipe. Push the pipe sections completely together, then twist-lock one section clockwise

approximately one-quarter turn, until the two sections are fully locked. The female locking lugs will not be visible from the

outside, on black pipe. They may be located by examining the inside of the female ends as shown in FIG-10.

NOTE:

(1) Twist-lock procedure: four indentations, located on the female

end of the pipes and fittings, are designed to slide straight onto

the male ends of adjacent pipes and fittings, by orienting the

four pipe indentations so they match and slide into the four

entry slots on the male end.

(2) Horizontal runs of vent pipe must be supported every three

feet. Wall straps are available for this purpose.

FIG. 10

FIG.10

STEP 3. With the pipe attached to the stove into the correct location, mark the wall for a 10 inch x 10 inch square hole. The

center of the square hole should match the centerline of the horizontal pipe. Cut and frame the 10-inch x 10-inch

hole in the exterior wall where the vent will be terminated. If the wall being penetrated is constructed of noncombustible material i.e. masonry or concrete, a 7-inch hole is acceptable.

STEP 4. Position the horizontal vent termination in the center of the 10-inch square hole, and attach to the exterior wall with

the four screws provided. Before attaching the Vent Termination to the exterior wall, run a bead of non-hardening

mastic around the edges, so as to make a seal between the termination and the wall. The arrow on the vent

termination should be pointing up, insure that the proper clearances to combustible materials are maintained.

STEP 5. Before connecting the horizontal run of the vent pipe to the vent termination, slide the black decorative wall thimble

cover over the vent pipe.

STEP 6

. Slide the appliance and vent assembly towards the wall, carefully inserting the vent pipe into the cap assembly. It is

important that the vent pipe extend into the vent cap a sufficient distance with a minimum of 1 ¼inch overlap. Secure

the connection between the vent cap pipe and the vent cap by attaching the two sheet metal straps extending from

the vent cap assembly into the outer wall of the vent pipe. Use the two sheet metal screws provided to connect the

straps to the vent pipe. Bend any remaining portion of the sheet metal straps back towards the vent cap, so the

decorative wall thimble FIG-13 will conceal it.

7

Page 8

STEP 7. Slide the decorative wall thimble up to the wall surface and attach with the screws provided. Apply decorative brass

or chrome trim if desired. FIG-14.

NOTES

NOTES:

: (1) The four wood screws provided should be replaced with the appropriate fasteners for stucco, brick, concrete, or

other types of siding.

(2) For buildings with vinyl siding, a vinyl siding standoff (950), should be installed between the vent cap and the

exterior wall FIG-12. Attach the vinyl siding standoff to the horizontal termination. The vinyl siding standoff prevents

excessive heat from possibly melting the vinyl siding material. Note that the horizontal vent termination bolts onto the

flat portion of the vinyl siding standoff. (shaded area in FIG-12), so that an air space will exist between the wall and

the vent termination.

(1) The horizontal run of vent pipe must be level and should have a ¼ inch rise for every one foot of run towards

the termination. Never allow the vent to run downward. This could cause high temperature and may present the

possibility of a fire

(2) The location of the horizontal vent termination on the exterior wall must not be easily blocked or obstructed.

Termination clearances are as follows:

(3) When installing a vent pipe in chase the minimum clearance to combustibles is 4” inches (100 mm).

FIG. 11 FIG. 12

FIG-13 FIG-14

8

Page 9

VERTICAL INSTALLATION

STEP 1. Check the instructions for required clearances (air spaces) to combustibles when passing through ceilings, walls,

roofs, enclosures, attic rafters , or other nearby combustible surfaces. Do not pack air spaces with insulation.

STEP 2. Set the gas appliance in the desired location. Drop a plumb bob down from the ceiling to the position of the appliance

flue exit, and mark the location where the vent will penetrate the ceiling. Drill a small hole at this point. Next, drop a

plumb bob from the roof to the hole previously drilled in the ceiling, mark the spot where the vent will penetrate the

roof. Determine if ceiling joists, roof rafters, or other framing will obstruct the venting system. You may wish to

relocate the appliance, or to offset, to avoid cutting load bearing members.

STEP 3. To install the Round Support Box/Wall Thimble in a flat ceiling, cut a 10- inch square hole in the ceiling, centered in

the hole drilled in Step 2. Frame the hole as shown in FIG-16.

STEP 4. Assemble the desired lengths of black pipe and elbows necessary to reach from the appliance adapter up through

the Round Support Box. Insure that all pipe and elbow connections are in their fully twist-locked position.

STEP 5. Cut hole in the roof centered on the small hole placed in the roof from Step 2. The hole should be of sufficient size to

meet minimum requirements for Clearance to Combustibles, as specified. Continue to assemble lengths of pipe and

elbows necessary to reach from the ceiling Support Box up through the roofline. Galvanized pipe and elbows may be

utilized in the attic, as well as above the roofline. The galvanized finish is desirable above the roofline, due to the

higher corrosion resistance.

STEP 6. Once the pipe sections have been joined, and run up through the hole in he roof, slip an elbow strap (Part-989) over

the exposed sections, bend the support straps outwards, and push the Elbow Strap down to the roof level, as shown

in FIG 17. Tighten the clamp around the Pipe section. Use a level to make sure the pipe is truly vertical. With roofing

nails, secure the support straps to the roof. Seal the nails holes heads with non-hardening mastic. Trim the excess

length of the support straps that extend out beyond the edge of the flashing.

STEP 7. Slip the flashing over the pipe section protruding through the roof. Secure the base of the flashing to the roof with

roofing nails. Use a non-hardening sealant between the uphill edge of the flashing and the roof. Insure the roofing

material overlaps the top edge of the flashing as shown in FIG 17. Verify that you have at least the minimum

clearance to combustibles at the roofline.

STEP 8. Continue to add pipe sections until the height of the vent cap meets the minimum code requirements. FIG 22. Note

that for steep roof pitches, the vent height must be increased. In high wind conditions, nearby trees, adjoining roof

lines, steep pitched roofs, and other similar factors can result in poor draft, or down drafting. In these cases,

increasing the vent height may solve the problem.

STEP 9. Slip the Storm Collar over the pipe, and push it down to the top of the roof flashing as shown in FIG 17. Use the non-

hardening sealant around the joint between the pipe and the Storm Collar.

STEP 10. Twist lock the vent cap.

FIG-16 FIG-17

9

Page 10

NOTES:

(1) If an offset is necessary in the attic to avoid obstructions, it is important to support the vent pipe every 3 feet, to avoid

(2) When ever possible, use 45° degree elbows instead of 90° degree elbows. The 45° degree elbow offers less

NOTES:

(1) For multi story installations. A ceiling firestop (part 963) is required at the second floor, and any subsequent floors.

(2) Any occupied areas above the first floor, including closets and storage spaces, which the vertical vent passes

excessive stress on the elbows, and possible separation. Wall straps are available for this purpose. FIG-18

restriction to the flow of flue gases and intake air.

FIG-19. The opening should be framed to 10-inch x 10-inch inside dimensions, in the same manner as shown in FIG-

16.

through, must be enclosed. The enclosure may be framed and sheetrocked with standard building materials. However

consult the appliance manufactures installation instructions for the minimum allowable clearance between the outside

of the vent pipe, and the combustible surfaces of the enclosure. Do not fill any required air spaces with insulation.

FIG. 18 FIG.19

FIG.20

FIG. 20

FIG-21 FIG-22

10

Page 11

CATHEDRAL CEILING INSTALLATION

STEP 1. Follow installation steps 1 and 2 under Vertical Termination.

STEP 2. Using the plumb bob, mark the centerline of the venting system on the ceiling and drill a small hole through the ceiling

and roof at this point. From the roof, locate the drill hole and mark the outline of the “Cathedral Ceiling Support Box”.

STEP 3. Remove shingles or other roof coverings as necessary to cut the rectangular hole for the “Support Box”. Cut the hole

1/8” larger than the “Support Box” outline.

STEP 4. Lower the “Support Box” through the hole in the roof until the bottom of the “Support Box” protrudes at least 2-inches

below the ceiling.(FIG-20), align the “Support Box“ both vertically and horizontally with a level. Temporarily tack the

“Support Box” in the place through the inside walls and into the roof sheathing.

STEP 5. Using tin snips, cut the “Support Box” from the top corners down to the roofline, and fold the resulting flaps over the

roof sheathing.(FIG-21). Before nailing it in to the roof, run a bead of non-hardening mastic around the top edges of

the “Support Box”, to make a seal between the box and the roof. Clean out any combustible material from the inside

of the “Support Box”.

STEP 6. Complete the cathedral ceiling installation by following the same procedures outlined in Steps 4 through 9 for “Vertical

Termination”.

SHERWOOD INDUSTRIES LTD VENTING KITS

Inspect this kit to ensure this kit is complete and there is no damage to any of the components. If damage is present contact

your dealer or your courier company. If some components are missing or damaged do not attempt the installation.

Decide on a location for the unit that will meet any or all, local code requirements. Refer to sections in this manual. Deciding

Were To Locate Your Stove, and Planning Your Installation.

Set the appliance in the desired location. Check to determine if any wall studs, electrical wiring or plumbing pipes are in the

way of the venting system as it passes through the wall. If obstructions are found in the wall it may be required to adjust the

location of the appliance.

Set the appliance in the desired location. Temporarily place the 24” section of pipe (without the crimped end) on the unit and

install the 90° elbow pointing in the direction that the vent will exit the structure. Project a level line from the center point of the

elbow. Using this center point, scribe a 10” hole or square on the wall. Cut the hole out on both the interior and exterior wall

surfaces. Install the wall thimble and secure this thimble on both the inner

and outer wall surfaces.

With the appliance still in place install the 24” horizontal section on the

elbow and let this section of pipe protrude through the exterior wall. Mark

this pipe so that it is flush with the exterior surface and cut this section of

pipe.

Dismantle the outer pipe sections.

Remove the 4” flue collar from the unit and remove any lose sealant, install

the new 4” diameter x 5” high flue collar provided in this kit.

Attach the flexible liner to the vent termination cap by placing a small bead

of high temperature silicone on the vent terminal and slide the flex liner

onto the vent terminal and secure with 3 sheet metal screws evenly

spaced.

Dress the flex liner through the wall thimble and attach the vent terminal to

the outside of the house using 4 wood screws provided. (The use of nonhardening mastic should be used around the vent to ensure a watertight

seal.)

11

Page 12

Install 2 spring spacers around the flex pipe. Slide the horizontal section of pipe

over the flexible liner and install through the wall thimble, ensure that this

portion of pipe slides onto the vent termination cap. Slide the inside finished

collar over the horizontal section of pipe and secure to wall using the screws

provided. Slide the 90° elbow over the flex pipe. Stretch the flex liner to a

length long enough to ensure the flex liner can be easily connected to the flue

outlet of the appliance. Install the remaining spring spacers over the flexible

liner and install the vertical section of pipe.(DO NOT SLIP THESE SECTIONS

OF PIPE TOGETHER, YOU WILL REQUIRE SOME MOVEMENT IN THESE

PIPE SECTIONS IN ORDER TO SECURE THE FLEX PIPE TO THE FLUE

OUTLET ON THE APPLIANCE.)

Place a bead of high temperature silicone on the flue pipe and slide flex liner

over collar, secure the flex liner with 3 sheet metal screws evenly spaced.

Align all straight sections of pipe, slipping all joints together and installing 3

sheet metal screws evenly spaced.

A small can of touch up paint has been supplied with this kit. Lightly touch up

any scratches that might have accord during the installation process.

Install brass decorative rings around each joint making sure this decorative ring

covers the sheet metal screws which secure each section of pipe together and

secure to vent pipe in the slotted tab on the backside of the pipe so that the

fastener would not be easily seen.

Secure the horizontal section of pipe to the inside finished collar by installing a

screw in the tab on the inside finished collar. (THIS WILL PREVENT THE PIPE FROM BEING DISCONNECTED AT THE

VENT TERMINAL.)

Light the appliance and ensure proper operation.

WALL THIMBLE

FIRE STOP

SPRING

SPACERS

HORIZONTAL WALL

TERMINATION

DECORATIVE

BRASS RINGS

EXHAUST

4” FLEX

PIPE

WALL

FRAMING

INSIDE

FINISHED

COLLAR

COMBUSTION

AIR

6 5/8” OUTER

PIPE

12

Page 13

VENTING INTO CLASS “A” CHIMNEYS

This model is also certified and tested to vent into

CLASS “A” wood.

stove chimneys

Place the freestanding direct vent appliance in the

desired location.

Using Simpson Dura Vent conversion kit #s 931-932933, depend on the ID diameter of the CLASS “A”

chimney that this appliance is to be vented into.

Place a bead of high temperature silicone or mil pac at

each connection to ensure a tight seal.

NOTE: A 4” flex liner must be used in the application.

NOTE: Use Simpson Dura Vent from the top of the

appliance until this vent reaches the CLASS “A”

chimney. Install the retro adapter to the top section of

GS direct vent pipe and install the flex liner to the retro

adapter.

Fully liner the CLASS “A” chimney with a minimum 4”

flex liner to the top of the CLASS “A” chimney.

Placing a bead of high temperature silicone to the

Simpson Cap adapter and securely attach the flex liner

to the adapter.

Secure the cap adapter to the CLASS “A” chimney

ensuring an air tight seal.

Install the vertical termination cap.

Light the unit and ensure proper operation.

THE USE OF ANY EXISTING CHIMNEY AS AN AIR

INTAKE IS NOT COVERED UNDER THE ANSI

Z21.88-1999 CSA 2.33-M99 TEST METHODS AND

THE RESULTING ITS/WHI PRODUCT

CERTIFICATION. THE CODE AUTHORITY HAVING

JURISDICTION MUST BE CONSULTED PRIOR TO

PROCEEDING WITH THIS INSTALLATION METHOD.

Simpson GS Dura

vent cap

Cap Adapter

Class “a Chimney

Roof Flashing

4” flex liner inside

Class “A” chimney

Ceiling rafters

Retro adapter

GS Simpson Dura

Vent pipe 4” x 6 5/8”

Mobile Home

• When the unit is installed in a Mobile Home it must be

grounded to the steel chassis or connected to a

grounding rod.

• In a Mobile Home installation the unit must be bolted

securely to the floor using the holes provided.

• Manufactured (mobile) home installation must be in accordance

with the Manufactured Home Construction and Safety Standard,

UL 307B, Title 24 CFR, Part 3280 and/or The Standard for

Manufactured Home Installations, ANSI A225.1/NFPA 501A

Holes for unit hold

down screws

13

Page 14

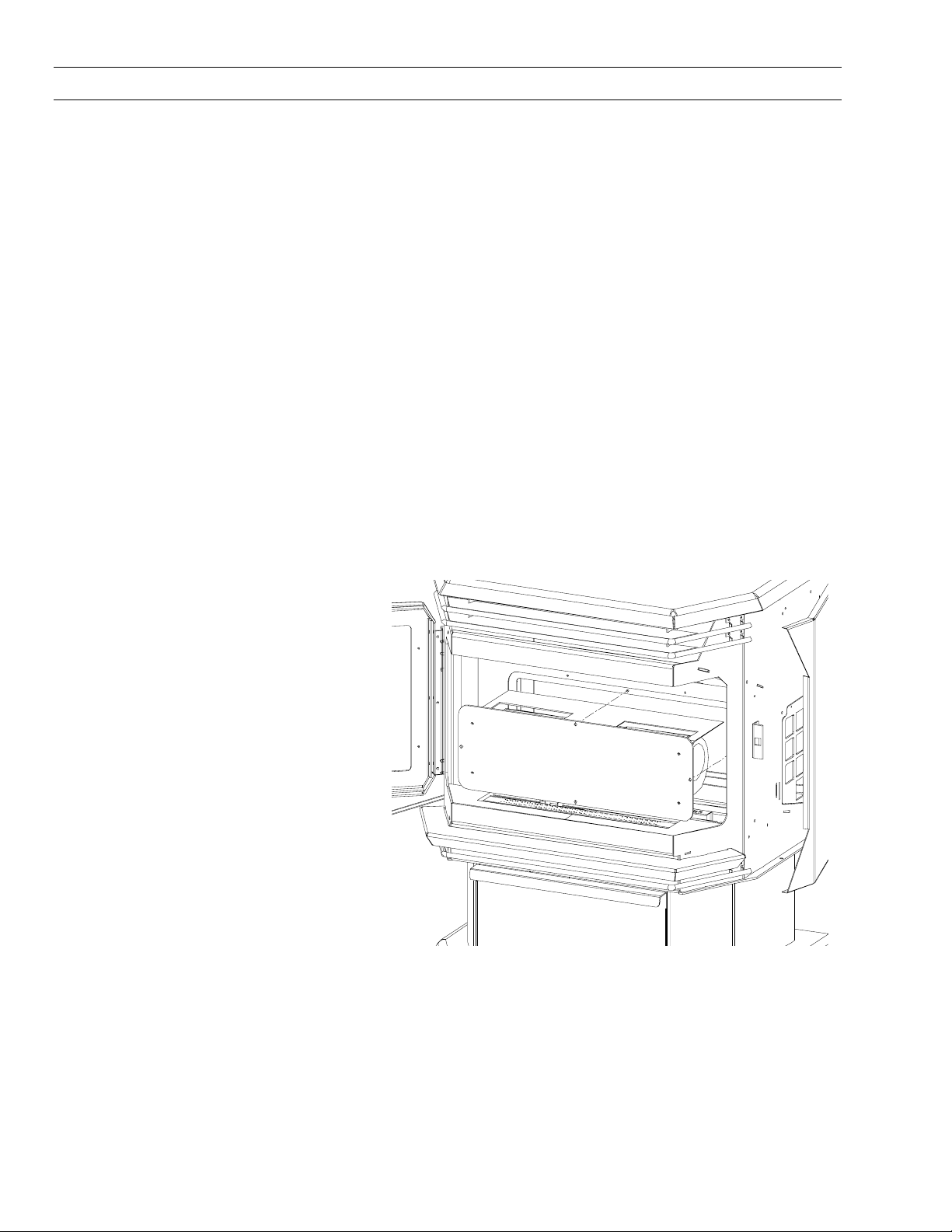

INSTALLATION OF LOGSET and EMBERS INSTALLATION OF LOGSET and EMBERS

INSTALLING THE GLOWING EMBERS INSTALLING THE GLOWING EMBERS

A bag of Rock Wool embers is provided for use on the burner. A bag of Rock Wool embers is provided for use on the burner.

CAUTION: Use only the type of ember material supplied with this appliance. Due to the amount of ember material

CAUTION: Use only the type of ember material supplied with this appliance. Due to the amount of ember material

there may be more than required.

there may be more than required.

If over time, through cleaning and servicing, these embers require replacement, contact your nearest

If over time, through cleaning and servicing, these embers require replacement, contact your nearest

ENVIROGAS dealer for replacement embers.

ENVIROGAS dealer for replacement embers.

Remove the ember material from the

Remove the ember material from the

plastic bag.

plastic bag.

Cover the shaded areas in the

Cover the shaded areas in the

diagram shown beside.

diagram shown beside.

Totally fill these areas with glowing

Totally fill these areas with glowing

ember material.

ember material.

DO NOT PACK DOWN. LEAVE

DO NOT PACK DOWN. LEAVE

EMBER MATERIAL LOOSE.

EMBER MATERIAL LOOSE.

CAUTION: NEVER OPERATE THIS APPLIANCE WITH THE DOOR REMOVED CAUTION: NEVER OPERATE THIS APPLIANCE WITH THE DOOR REMOVED

INSTALLING THE LOGSET INSTALLING THE LOGSET

Carefully remove log from box. Check to ensure there is no damage. It is very important to install this log in its

Carefully remove log from box. Check to ensure there is no damage. It is very important to install this log in its

proper position to insure safe, optimum operating conditions.

proper position to insure safe, optimum operating conditions.

• Open the front door. • Open the front door.

• Place each piece of the log set into the

• Place each piece of the log set into the

firebox resting on the pins provided.

firebox resting on the pins provided.

Ensure that the holes in logs line up.

Ensure that the holes in logs line up.

• Close the door and tighten securely. • Close the door and tighten securely.

Upon the first light up, watch for ignition to all

Upon the first light up, watch for ignition to all

burner ports. If a long delay is noted:

burner ports. If a long delay is noted:

• First, wait for the appliance to cool down • First, wait for the appliance to cool down

• Open the front door of the appliance. • Open the front door of the appliance.

• Check to carefully re-position the embers making sure that burner ports are not plugged solid or blocked. • Check to carefully re-position the embers making sure that burner ports are not plugged solid or blocked.

(See adjusting the venturi section to adjust air for proper flame). (See adjusting the venturi section to adjust air for proper flame).

14

14

Page 15

OPERATING INSTRUCTIONS

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING: IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR EXPLOSION

MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

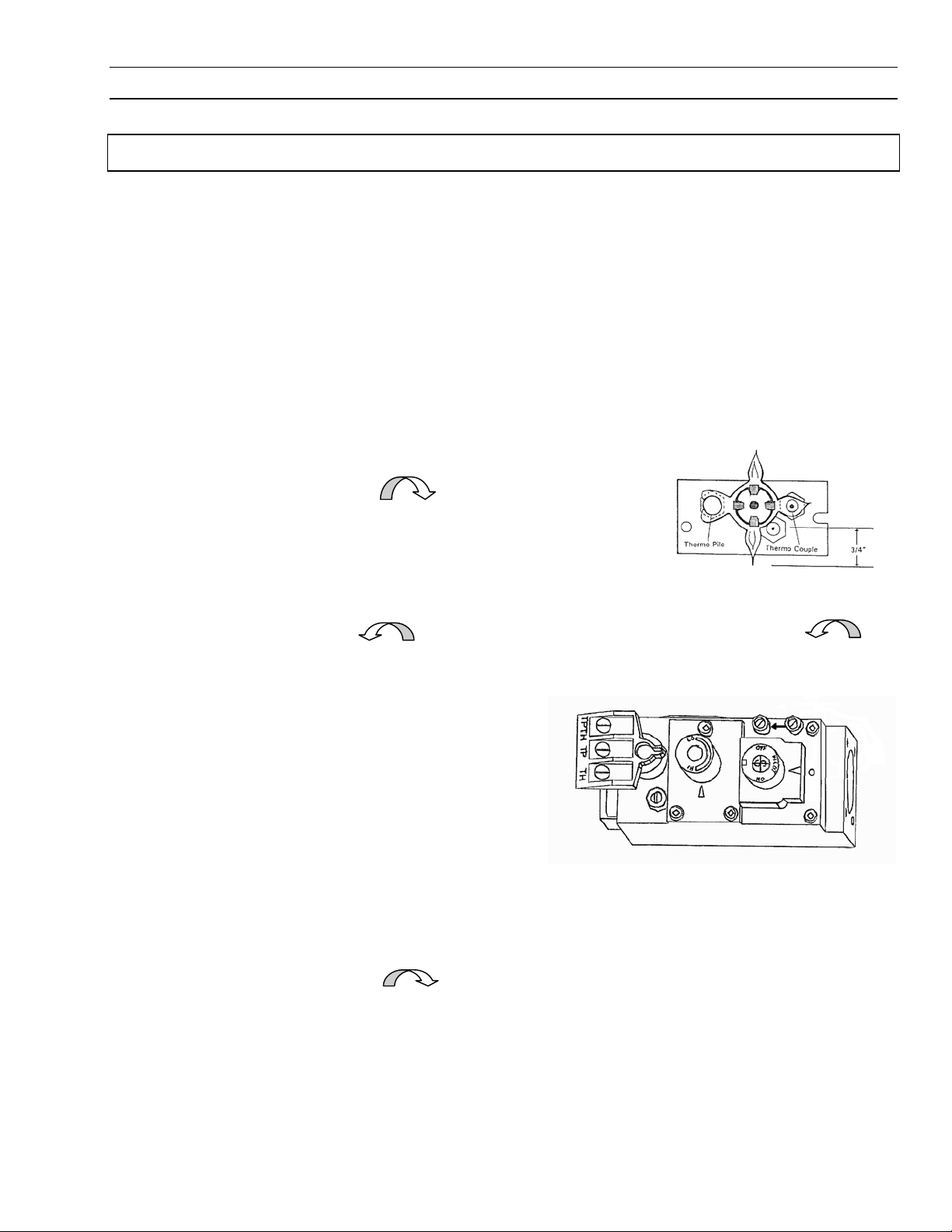

A) This appliance is equipped with a pilot, which must be lit by

hand by following these instructions exactly.

B) BEFORE LIGHTING smell all around the appliance area

for gas, and next to the floor because some gas is heavier

than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information above.

2. Turn off all electrical power to the

appliance.

3. Turn the gas control knob clockwise to

the “off’ position.

4. Open door. Wait five (5) minutes to clear out any gas.

Close door. If you smell gas including near the floor,

STOP! Follow “B” in the above safety information.

If you don’t smell gas go to next step.

5. Find the pilot located to the right between the front and

rear burner.

6. Turn gas control knob counterclockwise to “PILOT”.

7. Push the gas control knob in fully and hold. Immediately

light the pilot by pushing the piezo spark igniter. Keep

knob depressed for about 30 seconds after pilot is lit.

Release knob. If pilot goes out, repeat steps 4 through 6.

WARNING The gas valve has a lockout device, which

will not allow the pilot burner to be re-lit until the

thermocouple, has cooled.

If the knob does not pop up when released, stop and

immediately call your service technician or gas supplier.

NOTE: Check to be sure the pilot flame engulfs the

thermocouple and that the burners light completely.

TO TURN OFF GAS TO APPLIANCE

1. Turn the gas control knob clockwise to

“OFF” DO NOT FORCE

• If you cannot reach your gas supplier, call the fire

department.

C) Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or turn

by hand, do not try to repair it . Call a qualified service

technician. Force or attempted repair may result in a fire

or explosion.

D) Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the

control system and any gas control which has been under

water

If the pilot will not

stay lit after

several tries, turn

the gas control

knob to “OFF"

and call you

service

technician or gas

supplier.

8. Turn gas control knob counter-clockwise

to the “ON” position.

Flip burner switch to “ON” then turn “HI / LO” knob to the

desired setting.

HI \ LO knob Control knob

on all electrical power to the unit

2. Turn off all electrical power to the appliance if service is to

be performed.

3. Flip burner switch to off.

9. Turn

15

Page 16

MAINTENANCE AND TECHNICAL

Periodically check to ensure that your "Direct Vent"

system is clear.

Periodically check the pilot and burner. Check to see

that all the burner ports are clean and clear. Check

the pilot head for blockage. Check to ensure the pilot

flame is blue with small yellow tips.

OPENING THE DOOR

Caution door is hot when in operation.

1. Open the right hand hinged side flap, which will

expose a door fastener. Using a 1/2" wrench, loosen

the fastener.

2. Due to the shape of the bay window door. You

must also open the left-hand side flap before

attempting to open the door.

CLEANING OF GLASS

Do not clean glass when hot

It will be necessary to clean the ceramic glass

periodically. During a cold start up, condensation will

sometimes form on the glass, this is a normal

condition with all gas fireplaces and stoves. However,

this condensation can allow dust and lint to cling to the

glass surface. Initial paint curing of the appliance can

leave behind a slight film on the glass. This is a

temporary problem. It is therefore recommended that

the glass be cleaned initially after about the first two

weeks of use.

After that, depending upon the amount of use,

cleaning should be required no more than two or three

times per season.

To clean the door, use a mild glass cleaner and a soft

cloth. Abrasive cleaners will damage the glass and

gold surfaces. Close door tightly.

TO REPLACE DOOR AND GLASS ASSEMBLY

The glass in this appliance is an integral part of the

door assembly. If the glass is damaged or broken a

replacement door assembly including glass must be

fitted.

To Replace:

• open door fully

• Lift door vertically so that hinge pins lift out of

hinge receivers.

• Return the door assembly to dealer.

Door and glass assembly must be replaced as a

complete unit by your ENVIROGAS Dealer.

No substitute materials are allowed.

FOR CLEANING THE INSIDE OF THE FIREBOX

Remove the log carefully from the firebox. Gently

remove the embers and place on a piece of paper

towel, until ready to replace.

Vacuum the firebox thoroughly. Carefully clean off

any dust on the logs and remove any lint from the

main burner and pilot burner.

After carefully replacing the log and embers in their

correct positions, and the door has been resealed, relight the pilot, following the instructions on the attached

label.

CLEARANCES MUST BE SUFFICIENT TO ALLOW

ACCESS FOR MAINTENANCE AND SERVICE

16

Page 17

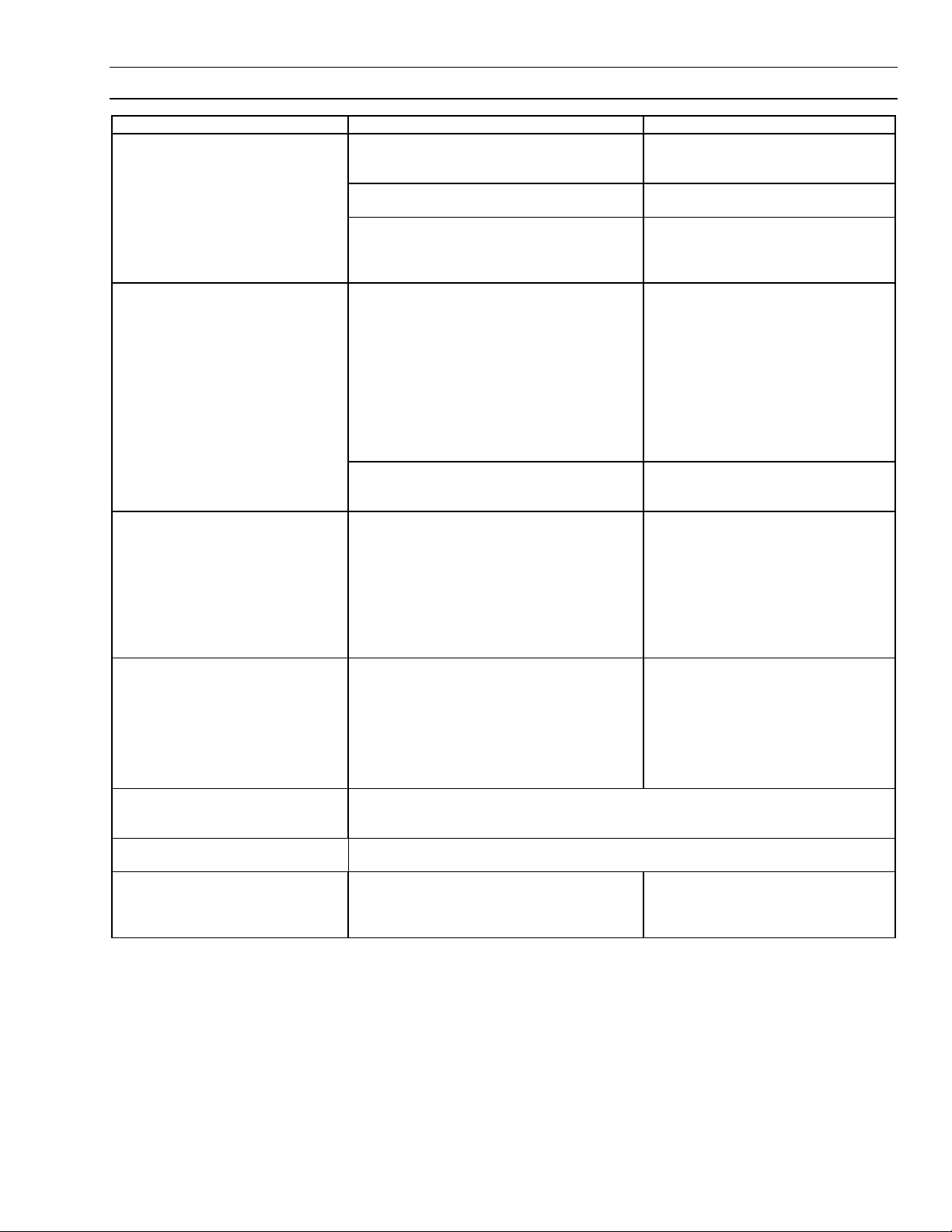

TROUBLE SHOOTING

Problem Possible Cause Solution

Spark will not light the pilot after

repeated pressing of spark igniter

Broken spark electrode -Check for broken ceramic insulation

Miss-aligned spark electrode -If spark is not arcing from the

Pilot will not remain lit Problem with thermocouple circuit -Check for proper connection of

Air in gas line - (Pilot flame dies while knob

Burners will not remain lit Problem with thermopile circuit -Check gas line pressure.

Flame lifting Leak in vent pipe

Glass fogs up Normal conditions - after the appliance warms up glass will clear

Blue flames

Flames are burning “dirty” or

Sooting

Defective piezo igniter Check connections to igniter

-If igniter connections are good but

there is no spark-replace igniter

replace, electrode if broken

electrode to pilot- adjust by loosening

screws on pilot base. Adjust and retighten

thermocouple to rear of valve. If

loose, tighten lightly

-Check pilot for full flame

impingement around thermocouple.

If the pilot is to small - Check gas

pressure, adjust pilot rate screw,

check pilot head for blockage.

-Check thermocouple voltage at

valve- must be greater than 5 mV. If

low, replace thermocouple.

-Bleed line.

is depressed.)

Improper vent configuration

Terminal may be recirculating flue gases

** Due to additives in gas, glass may get hazy during normal use**

Clean when needed.

Normal during start - flame will yellow as the

appliance heats up.

Flame impingement -Check log position

-Check gas line pressure.

-Contact dealer.

-Check for flame impingement on

thermopile, if low see “Pilot will not

stay lit”

-Check thermopile for a Minimum of

300 mV when burner switched

on.

-Check wiring to thermostat for

breaks.

-Check for leaks in vent connections

-Check vent configuration with

manual

-Check to see if terminal is on

correctly

-May need to install high wind

termination cap

-Contact dealer.

-Increase primary air by opening

venturi shutters

See also “Burners will not stay lit”

17

Page 18

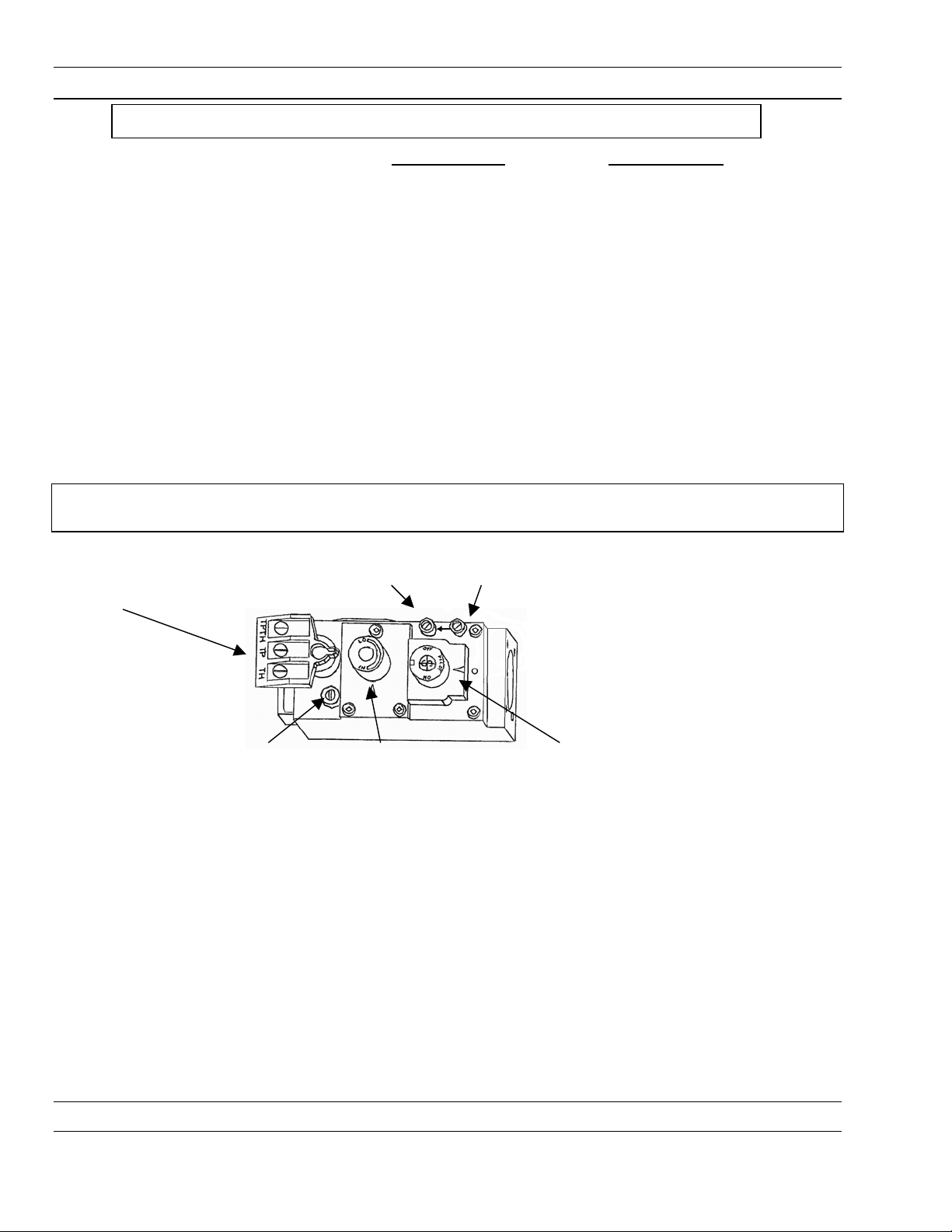

GAS LINE CONNECTION

Main Orifice #42 dms #53 dms

Manifold pressure. 3.8” wc (0.95 kPa) 11” wc (2.74 kPa)

Min. Manifold pressure. 1.1” wc (0.27 kPa) 2.7” wc (0.67 kPa)

Supply Pressure. 7.0” wc (1.74 kPa) 12” wc (2.98 kPa)

Min. Supply pressure. 5” wc (1.25 kPa) 11.5” wc (2.86 kPa)

Max. BTUH Input. 26,500 Btu/h(7.87 kW) 26,500 Btu/h(7.87 kW)

Min. BTUH Input. 13,500 Btu/h(3.9 kW) 13,500 Btu/h(3.9 kW)

Output fan off 21,000 Btu/h(6.15 kW) 21,500 Btu/h(6.3 kW)

Output fan on 21,500 Btu/h(6.3 kW) 22,000 Btu/h(6.45 kW)

High Altitude Canada 0-4500 ft. (1372m), in the USA follow ANSI Z223.1

WARNING:

NOTE: The gas line connection may be made using 3/8" rigid tubing or an approved flex connector. Since some municipalities

have additional local codes it is always best to consult your local authorities and the CAN/CGA-B149 (1 or 2) Installation Code.

For USA gas installations follow either local codes or the current edition of the National Fuel Gas Code ANSI.Z223.1.

Only persons licensed to work with gas piping may make the necessary gas connections to this appliance.

UPON CONNECTION, MARK APPROPRIATE FUEL TYPE ON RATING LABEL LOCATED

Manifold Pressure Tap. Inlet Pressure Tap.

Millivolt Terminals

ORIFICE SIZES, PRESSURE AND BTU’S

NATURAL GAS PROPANE GAS

ON THE INSIDE OF THE RIGHT HAND SIDE PANEL.

Pilot Adjustment screw. "HI-LOW" Burner Gas Knob. Pilot "ON-OFF" Gas Knob.

The appliance and its shutoff valves must be disconnected

from the gas supply piping system during any pressure

testing where the pressure exceeds 1/2 PSIG (3.45 kPa)

or damage will occur to the valve.

The appliance must be isolated from the gas supply piping

system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psig (3.5

kPa).

When using copper or flex connectors use only fittings

approved for gas connections.

NEVER USE AN OPEN FLAME FOR LEAK TESTING

ELECTRICAL

TO TEST

The pressure taps are located in the top right corner on

the valve face (right - inlet, left - manifold pressure).

• Turn setscrew counter clockwise to loosen, 2 turns.

• Place 5/16" hose over pressure tap system.

• When finished, release pressure, remove hose &

tighten setscrew.

Always check for gas leaks with a soap and water solution

after completing the required pressure test.

18

Page 19

The ENVIROGAS EG 28.FS.DV. will operate with no external power supply. These models have a Millivolt gas

control which uses the pilot flame to generate enough electricity to operate the main burner.

The appliance when installed, must be electrically connected and grounded in accordance with local codes or in

the absence of local codes, with the current CSA C22.1 CANADIAN ELECTRICAL CODE. Part 1, SAFETY

STANDARDS FOR ELECTRICAL INSTALLATIONS, or THE NATIONAL ELECTRICAL CODE ANSI / NFPA 70 in

the USA.

NOTE:

• Operation of the fan increases the

efficiency and the heat output of the

appliance.

• The thermostat connects to the two

purple wires in the harness

• Control panel light uses a 7w max.

bulb

• If the unit is installed in a Mobile

Home it must be connected to a

grounding rod.

• If the unit is installed in a Mobile

Home it must be bolted securely to

the floor.

CAUTION

Label all wires

prior to

disconnection

when servicing

controls. Wiring

errors can cause

improper and

dangerous

operation. Verify

proper operation

after servicing.

WARNING: ELECTRICAL

GROUNDING INSTRUCTIONS.

This appliance is equipped with a threeprong (grounding) plug for your protection

against shock hazard and should be

plugged into a properly grounded three-prong receptacle.

DO NOT cut or remove the grounding prong from the plug.

INSTALLING REMOTE THERMOSTAT OR WALL SWITCH

RECOMMENDED WIRE SIZE for thermostat installation: 18 gauge, 2 wire solid core, Low Voltage wire. (Bell wire)

1. Install the 18 Gauge wire supplied to the two terminals on the thermostat or remote wall switch.

2. Connect the other end of the wire to the gas valve using the two outside terminals on the front of the gas valve.

Use the terminals marked (TP/TH and TH).

RECOMMENDED MAXIMUM LEAD LENGTH (TWO WIRE)

WHEN USING WALL THERMOSTAT

WIRE SIZE

14 GAUGE 100 FEET

16 GAUGE 64 FEET

18 GAUGE 40 FEET

20 GAUGE 18 FEET

MAXIMUM LENGTH

19

Page 20

PARTS AND ACCESSORIES

Service Parts available from your local Envirogas Dealer

Burner Control Assembly

Natural Gas Pilot Assembly

Propane Pilot Assembly

Door Bolt

Relief Door Gasket

Regulating Valve

Piezo Igniter

Burner Switch

B-vent Spill switch 220°

Orifice Blank

Accessories

Gold trim Package

Low Voltage Thermostat

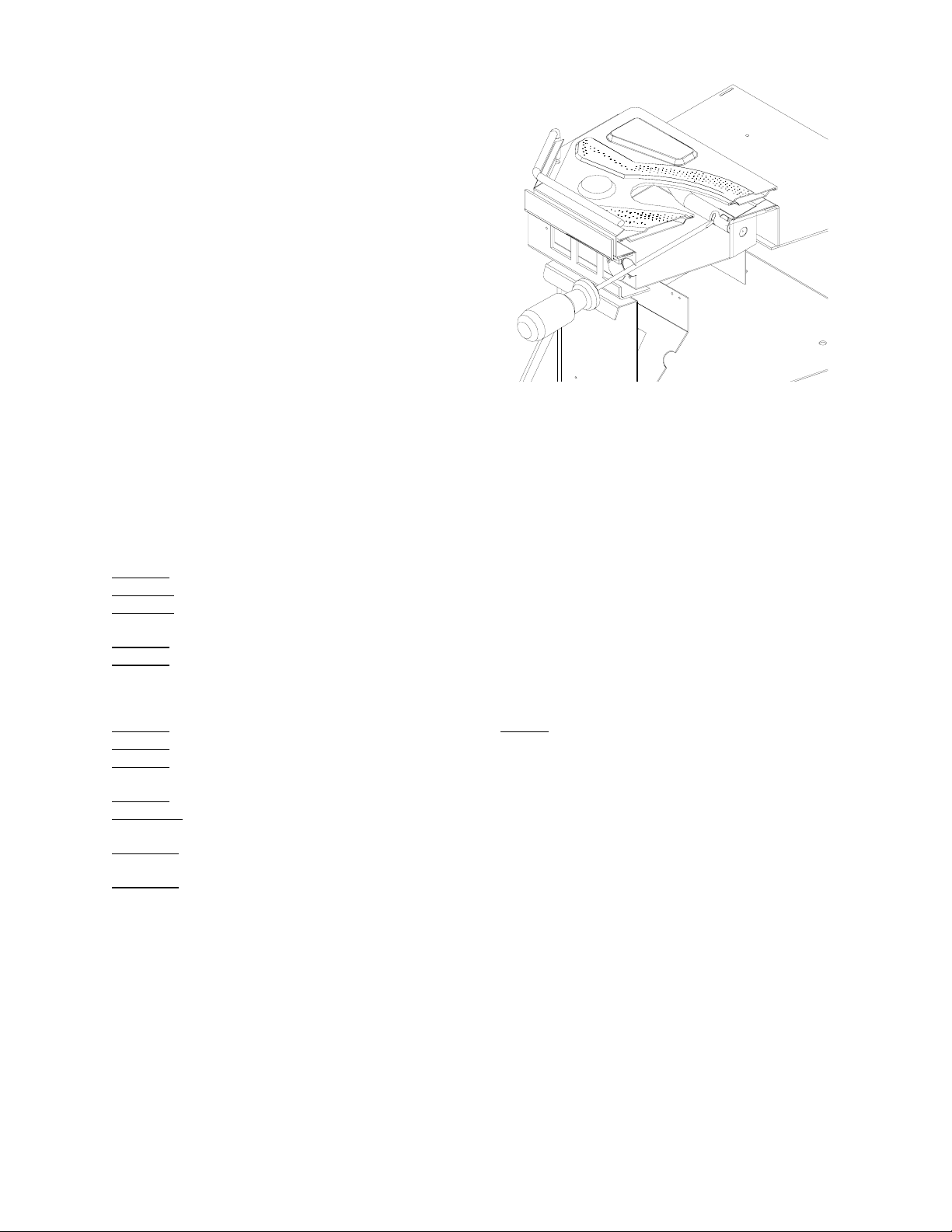

INSTALLING OR REMOVING THE BLOWER

The blower does not require lubrication.

1. Turn the unit off and remove the log set.

2. Remove the burner tray assembly by

removing the screw on either side of the

tray, between the front and rear burners.

Lift the tray out.

3. Remove the 4-5/16” bolts that hold the

blower mounting plate to the back firewall.

Use a light lubricating oil on screws before

removal.

4. Carefully pull the assembly into the firebox.

Install the blower onto the mounting

bracket (blower outlets pointing through the

two holes in the bracket) using the 4

screws provided.

5. Connect wires according to the wiring

diagram. (If removing the blower,

disconnect the blower leads from the

harness. Remove the blower.)

6. Check mounting plate gasket and reverse steps 1 through 4.

Convection Blower

Light Bulb Holder

Light Switch (momentary)

Fan Controller

Log Set (with Embers)

Thermocouple

Embers

Thermopile

Door Gasket

Convection Fan Sensor 120° (48°C)

20

Page 21

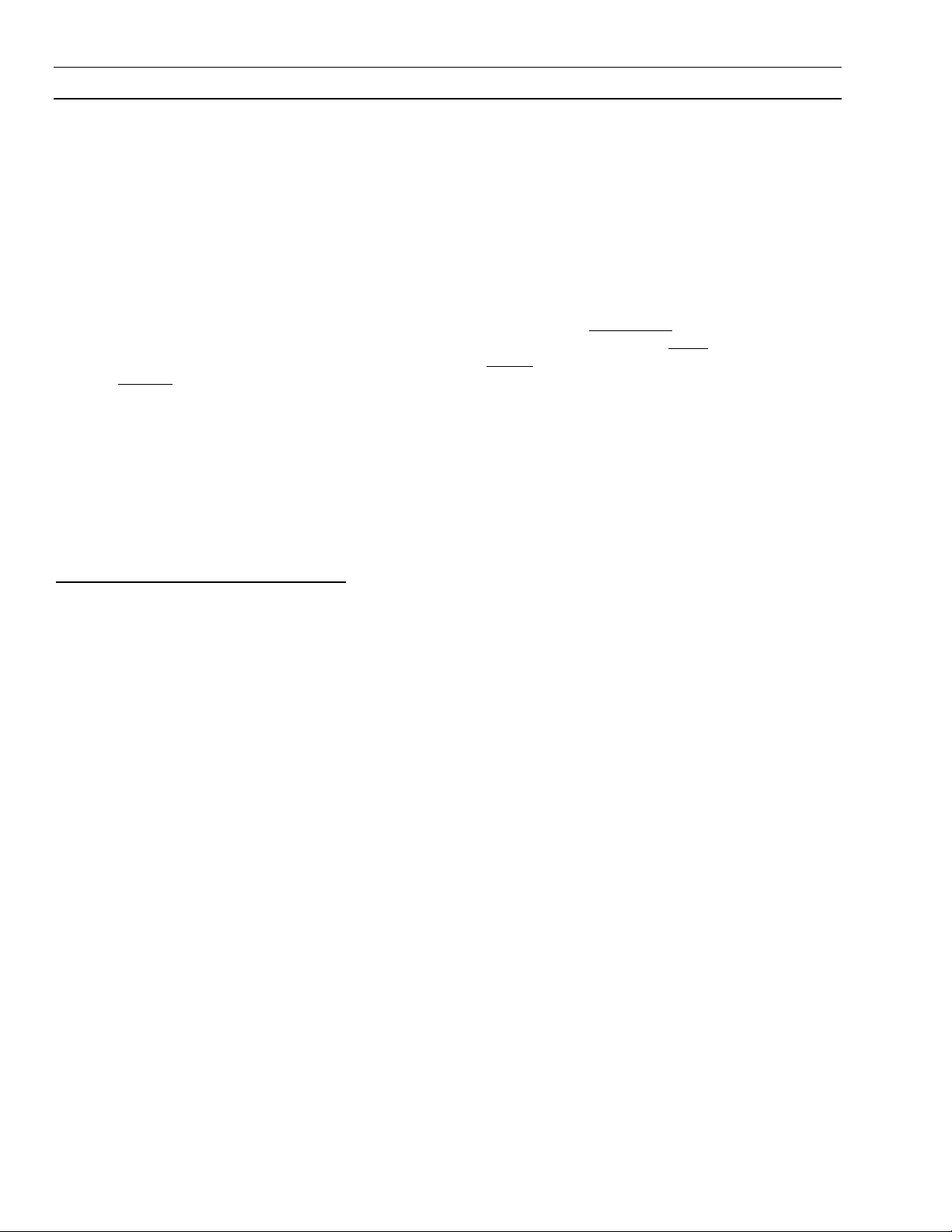

ADJUSTING THE VENTURI

• Remove the ash shelf by undoing the screw at

each end, pull shelf towards you.

• Remove one screw from the cover plate located

below the ash shelf. Loosen the other screw (do

not remove) swing the cover plate out of the way

and tighten screw down to hold it in place.

• With along screwdriver rotate spring clips to open

or close the shutter to the desired setting.

• The burner flame should be a bright

yellow/orange when hot. Excessive blue is to

lean and dark orange with soot is too rich.

FUEL CONVERSION

“Warning” This conversion kit shall be installed

by a qualified service technician in accordance

with the manufacturer’s instructions and all applicable codes and requirements of the authority having

jurisdiction. If the information in these instructions is not followed exactly, a fire, explosion or CO

poisoning may result. The qualified service agency is responsible for the proper installation of this kit.

The installation is not proper or complete until the operation of the converted appliance is checked as

specified in the owner’s conversion kit.

Please read and follow these instructions. Also please read the instruction guide lines provided by S.I.T on how to

remove and install the HI-LOW regulator.

STEP 1.

STEP 2. Shut the gas off and disconnect the main gas line from the unit.

STEP 3. Open the door by unscrewing the ½” bolt on the right hand side of the stove. Lift door off the hinges mounted on

STEP 4. Change the regulator on the front of the gas valve. (Follow the instructions provided by S.I.T)

STEP 5. To change the pilot orifice: First, remove the two (2) T-20 Torx screws that hold the pilot assembly to the burner

(BE CAREFUL WHEN TIGHTENING THE PILOT FITTING, YOU COULD BREAK THE CERAMIC IGNITER ELECTRODE).

STEP 6. Re-install the pilot assembly in the reverse order of STEP 5.

STEP 7. Remove the burner orifice with a ½” deep socket.

STEP 8. Install the new orifice supplied making sure that the orifice is in the correct location. Be sure to put a bead of pipe

STEP 9. Reinstall the burner tray, log set and door.

STEP 10. Re connect the gas line to the unit. Do a leak check using a soap and water solution or an approved manner on

STEP 11. Re-light the appliance to insure proper operation and proper flame appearance. Be sure to adjust the venturi setting

STEP 12. MAKE SURE that the sticker provided by S.I.T is installed to signify that this valve has been converted to a different

A VISUAL CHECK OF THE REGULATOR KNOB IS NECESSARY TO DETERMINE WHETHER OR NOT THE

REGULATOR IS THE CORRECT PART. A 50% TURN DOWN REGULATOR WILL HAVE ONLY ONE

CORNER ON THE KNOB.

1 50% turn down HI-LOW Regulator w 3 T-20 Torx

screws

1 T-20 tamper proof Torx screwdriver bit

1 pilot injector

1 Main orifice

Carefully inspect all parts supplied with this conversion kit.

the left-hand side. Remove the burner tray top for the appliance

tray. Lift the pilot assembly from the burner tray. Using a 10mm wrench, disconnect the pilot line from the pilot

assembly and remove the pilot injector. Install the new pilot injector.

thread sealant or approved Teflon tape on the orifice before installing into the burner assembly.

the gas supply line and the pilot tubing.

to achieve an efficient flame in the fireplace.

type of fuel. Also make sure that the rating plate has a conversion label to show that this unit has been converted to

a different fuel type.

1 Pilot assembly mounting gasket

NATURAL GAS PROPANE

Pilot Orifice. .51mm .35mm

Burner Orifice. #42 dms #53dms

Venturi Settings 1/16” min ¼” min

21

Page 22

WARRANTY

Sherwood Industries Ltd. offers a *Lifetime Warranty on this gas product. The lifetime warranty covers the

appliance for a period of seven years from the date of installation. This warranty applies only to the original

owner in the original location

Covered under the lifetime warranty are Cabinet Sides, Tops, Pedestals, Surround Panels and Chassis and Heat

Exchanger. These steel components are covered against manufacturer’s defects for parts 5 years and labor for

the first year and for parts only thereafter.(A) The following exclusions apply:- over-firing due to incorrect setup or

tampering, damage caused by incorrect installation, usage or abuse. The unit must be properly installed by a

qualified technician or installer, and must meet all local and national gas and building code requirements.

We also cover against manufacture defects under our lifetime warranty. The following components,

Gold Plating, Log Set, Burners and Glass (A) The following exclusions apply: Gold plating

scratching, marring, chemicals, fingerprints, abrasive cleaners or discoloration with age. Glass- use of harsh or

abrasive cleaners, striking the glass or surface contaminates. Logset- Damage caused by incorrect handling or

misuse. Burners

Sherwood Industries Ltd. offers a 2-year warranty on all the Electrical Components and Gas Components against

manufacturing defects. Paint is covered against flaking. This offer includes parts and labor for 1 year and for

parts only thereafter.

The paint on the Metal Brick Liner may peel. This is due to the extreme conditions applied to the paint and is no

way covered under warranty.

Your dealer shall make all claims under this warranty in writing.

(A): TO A MAXIMUM OF SEVEN YEARS

- damage caused by improper or continuous operation under incorrect conditions.

WHEN FILING A WARRANTY CLAIM PLEASE COMPLETE THE FOLLOWING

INFORMATION ON AN OFFICIAL WARRANTY CLAIM FORM:

To the Dealer

• Name, address and telephone number of purchaser and date of purchase.

• Date of installation. Name of installer and dealer. Serial number of the appliance. Nature of complaint, defects

or malfunction, description and part # of any parts replaced.

To the Distributor

• Sign and verify that work and information are correct.

This warranty covers defects in materials and workmanship only if the product has been installed according to the

manual’s instructions. If the product is damaged or broken as a result of misuse or mishandling the warranty does

not apply. The warranty does not cover removal and re-installation costs.

Sherwood Industries Ltd. reserves the right to repair or to replace the defective product. The shipping costs are to

be paid by the consumer. All warranties by the manufacture are set forth herein and no claim shall be made

against the manufacturer on any oral warranty or representation.

Sherwood Industries Ltd. and its employees or representatives will not assume any damages, either directly or

indirectly caused by improper usage, operation, installation, servicing or maintenance of this appliance.

Sherwood Industries Ltd. reserves the right to make changes without notice. Please complete and mail the

warranty registration card and have the installer fill in the installation data sheet in the back of the manual for

warranty and future reference.

- Damage caused by

22

Page 23

PARTS LIST

EC-001

EC-002

EC-006 SIT NOVA 820 NG VALVE 50% EG28-116 BURNER TRAY TOP

EC-007 SIT NOVA 820 LP VALVE 50% EG28-120 FS DV OWNERS MANUAL

EC-009 THERMOCOUPLE (POST 10/00) EG28-121 FS BV OWNERS MANUAL

EC-011 SPARK ELECTRODE w/CABLE EG28-123 FS CABINET SIDE PANEL

EC-012 THERMOPILE EG28-124 FS BV STOVE TOP

EC-013 PILOT NG w/ELECTRODE EG28-125 FIREBOX BAFFLE

EC-014 PILOT LP w/ELECTRODE EG28-126 FS DV STOVE TOP

EC-015 FULLY ASSEMBLED PILOT NG EG28-129 UPPER GOLD BARS

EC-016 FULLY ASSEMBLED PILOT LP EG28-130 LOWER GOLD BAR

EC-019 PILOT ORIFICE NG EG28-131 DV TOP BAFFLE

EC-020 PILOT ORIFICE LP EG28-132 BV TOP BAFFLE

EC-021 PILOT GASKET EG28-139 WIRE CHANNEL

EC-022 ORIFICE BLANK - FRONT EG28-140 PEDESTAL WIRING PLATE

EC-022A ORIFICE BLANK - BACK EG28-141 PEDESTAL BACK

EC-023 S.I.T. PIEZO IGNITER EG28-143

EC-024

EC-025 BURNER SWITCH (FOR NOVA TRAY) EG28-150 ASH SILL

EC-029 FAN ACCESS COVER GASKET EG28-161 DOOR HINGE STRIP

EC-030 CONVECTION BLOWER EG28-162 DOOR LATCH STRIP

EC-031 MINIATURE LIGHT BULB EG28-169 BV 4” CRIMPED FLUE COLLAR

EC-032 FS LIGHT BULB HOLDER EG28-170 DV 4” FLARED FLUE COLLAR

EC-037 FS WIRING HARNESS EG28-201 LP to NG CONVERSION KIT

EC-038 FS FAN CONTROLLER EG28-203 NG to LP CONVERSION KIT

EC-040- FS FAN CONTROLLER KNOB

EC-043 IEC POWER CORD 115 V

EC-045 EMBERS

EC-048 LOG SET AND EMBERS

EC-054 1 X 1 SIDE CABINET HINGE

EC-055 FPI SIDE PANEL MAGNET

EC-057 3/8 TADPOLE GASKET

EC-059 DOOR LATCH BOLT

EC-060 SIMPSON DURA VENT ADAPTER

EC-061 FS DV VENT KIT

EC-064 FAN IMPELLER

EC-065 DOOR NUT MOUNTING BRACKET

EC-066 LIGHT SWITCH

EC-067 VENT RESTRICTOR RINGS

EG28-095 LATCH BRACKET AND NUT

EG28-097 GLASS SET w/ TAPE

EG28-099 PAINTED DOOR ASSEMBLY W GLASS

EG28-100 OUTER PAINTED DOOR (A)

EG28-101 GOLD DOOR ASSEMBLY W GLASS

EG28-102 OUTER GOLD DOOR (A)

EG28-103 INNER DOOR W GLASS

120° F CERAMIC TEMP SENSOR

220° F CERAMIC SPILL SWITCH

SS FLEX CONNECTOR WITH 3/8”

ELBOW 18” LONG

EG28-108 FREESTANDING PEDESTAL

EG28-109 FS PEDESTAL DOOR

BURNER COMPLETE W/NOVA SIT

VALVE NG

EG28-145

BURNER COMPLETE W/NOVA SIT

VALVE LP

23

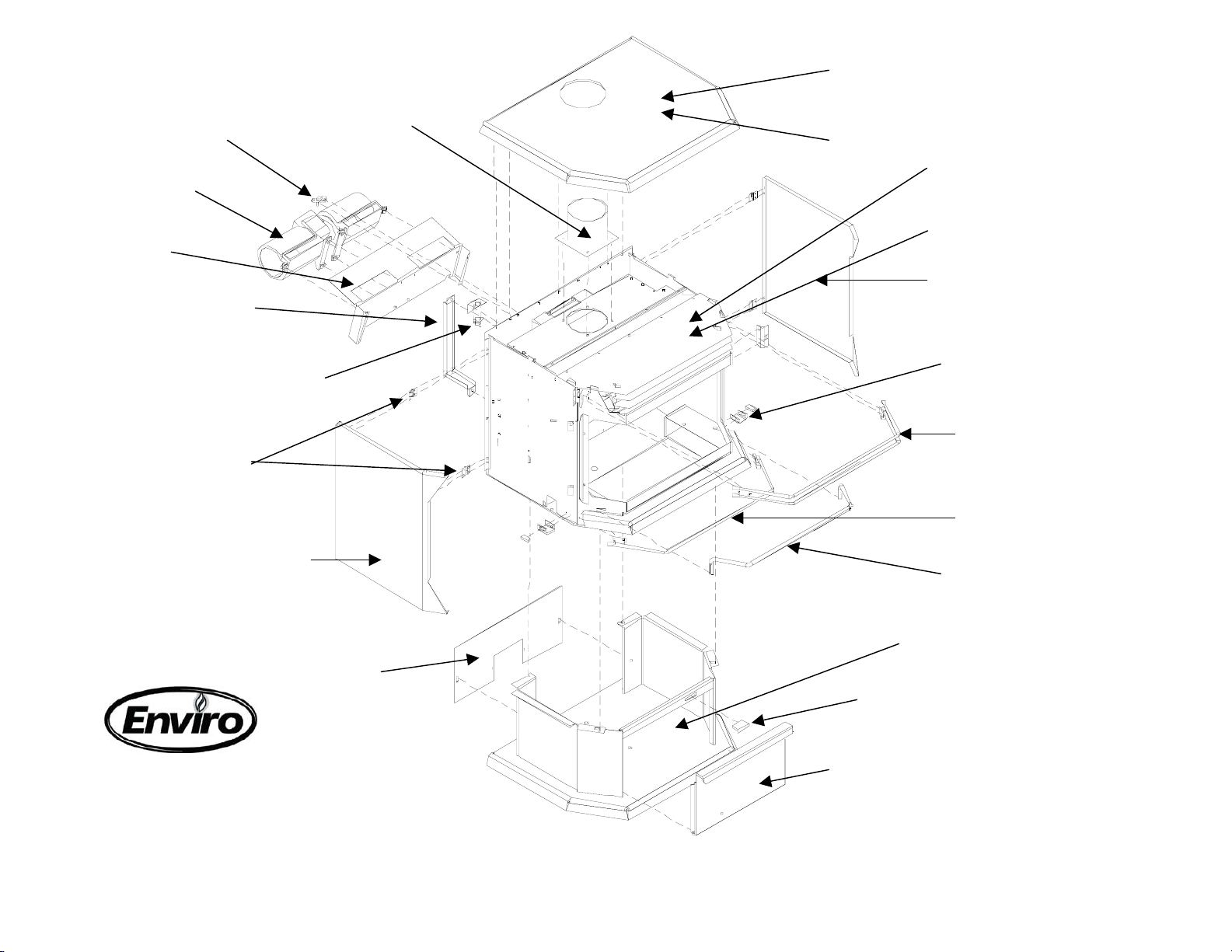

Page 24

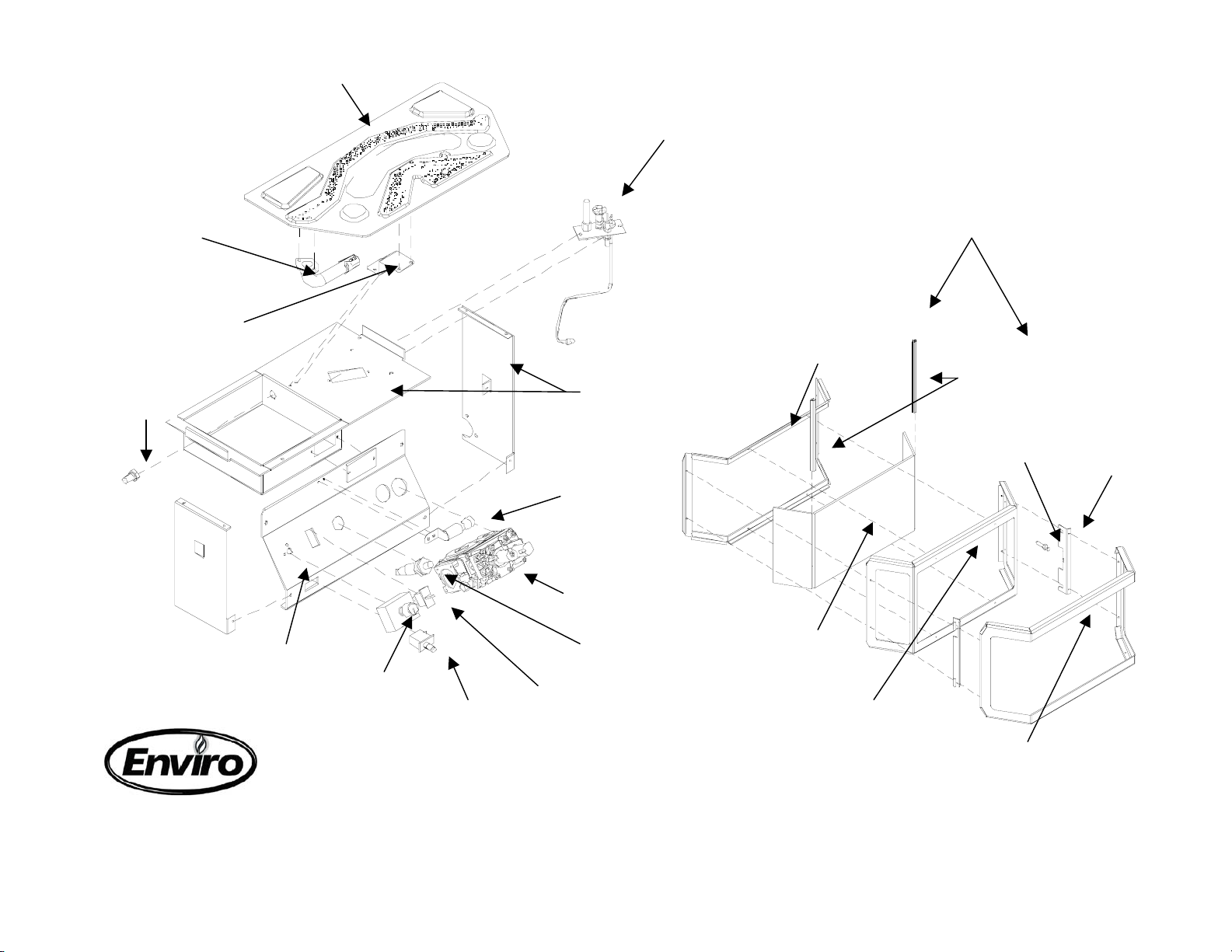

120 ° F (49° C)

CERAMIC FAN

TEMP SENSOR

CONVECTION

BLOWER

EC-030

FS FAN

MOUNTING

BRACKET

EG28-304

EC-001

WIRE

CHANNEL

EG28-139

220° F (104° C)

CERAMIC

SPILL SWITCH

1 X 1 SIDE

CABINET

HINGE

EC-054

FS CABINET

SIDE PANEL

EG28-123

EC-002

BV 4”

CRIMPED

FLUE PIPE

EG28-169

DV 4”

FLARED

FLUE PIPE

EG28-170

PEDESTAL

BACK

EG28-141

FS BV

STOVE TOP

EG28124

FS DV

STOVE TOP

EG28-126

FS PEDESTAL

DOOR MAGNET

EG28-056

BV TOP

BAFFLE

EG28-132

DV TOP

BAFFLE

EG28-131

FS CABINET

SIDE PANEL

EG28-123

DOOR MAGNET

AND BRACKET

UPPER

GOLD BARS

EG28-129

LOWER

GOLD BAR

EG28-130

FIREBOX GOLD

BAR

EG28-128

FREESTANDI

NG

PEDESTAL

EG28 FREESTANDING

EXPLODED

Page 2 of 2 JULY 2001

FS PEDESTAL DOOR

EG28-109

24

Page 25

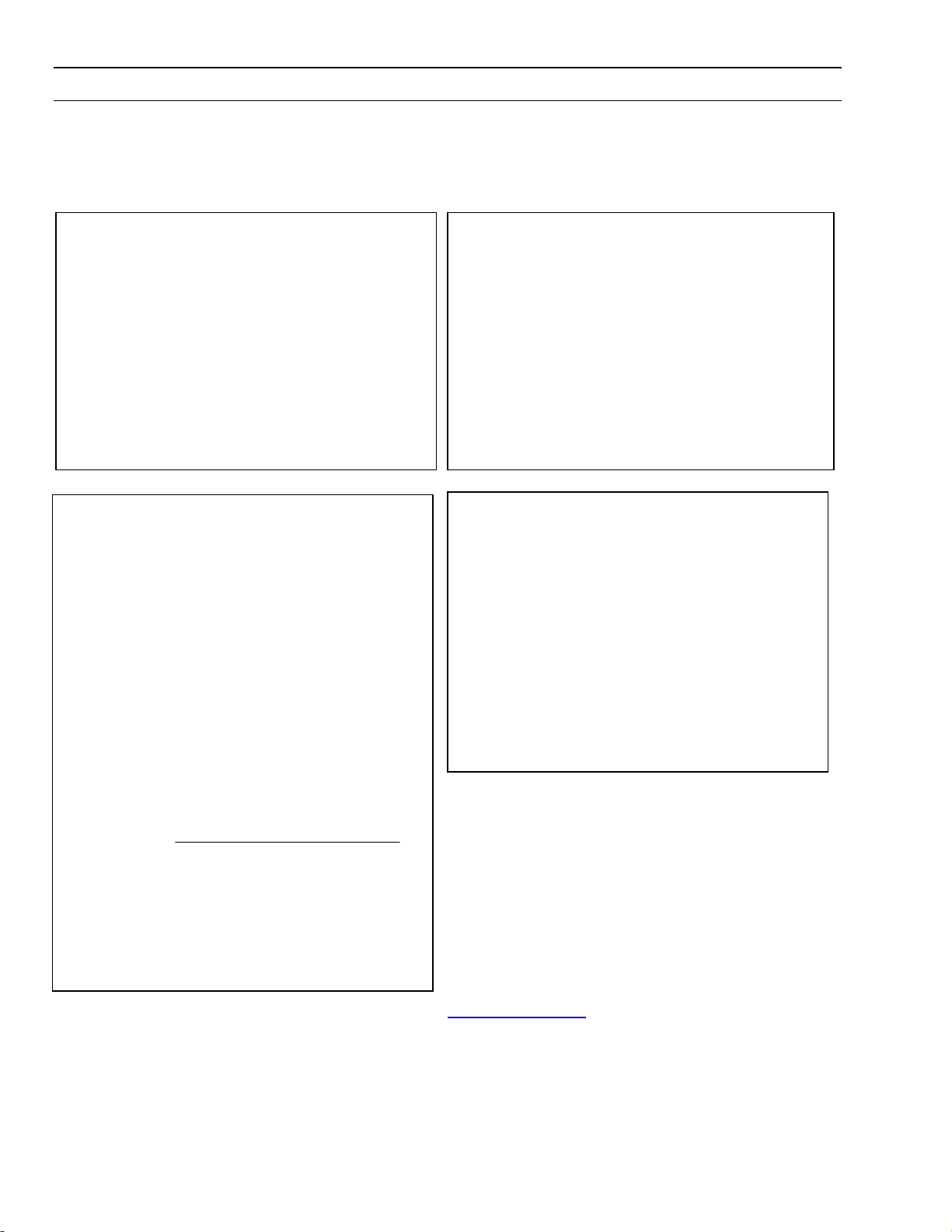

BURNER CONTROL

ASSEMBLY

COMPLETE

EG28-143 NG

EG28-145 LPG

VENTURI

TUBE

BURNER

BRACKET

ORIFIC

E

BLANK

PAN BURNER TOP

GAS TRAY TOP

AND SIDES

FS LIGHT BULB

HOLDER

EC-031

FULLY ASSEMBLED

PILOT

EC-015 NG , 016 LP

THERMOPILE

EC-012

THERMOCOUPLE

EC-009

PILOT ORIFICE

EC-019 NG, 020 LP

SPARK ELECTRODE

EC-011

RETAINER

GLASS

PAINTED DOOR ASSEMBLY

WITH GLASS (A+B)

EG28-099

GOLD DOOR ASSEMBLY

WITH GLASS (A+B)

EG28-101

GLASS

EXTRUSIONS

DOOR LATCH

BOLT

EC-059

DOOR LATCH

STRIP

EG28-162

CONTROL

PANEL

FS FAN

CONTROLLER

EC-038

LIGHT

SWITCH

EG28-038

EG28 DOOR AND GAS TRAY ASSEMBLY

EXPLODED

Page 1 of 2 JULY 2001

S.I.T NOVA 820 VALVE

EC-006 NG, 007 LP

S.I.T PIEZO

IGNITER

EC-023

BURNER

SWITCH

EC-025

25

GLASS SET

WITH TAPE

EG28-097

INNER DOOR

WITH GLASS (B)

EG28-103

OUTER DOOR

PAINTED OR

GOLD (A)

EG28-100 , 102

Page 26

INSTALLATION DATA SHEET

_

_

one

_

The installer for warranty purposes and future reference must record the following information. Please keep this information for

your records.

Model: EG 28 Direct Vent

Name of Owner:

__________________________________________

Address:

__________________________________________

__________________________________________

__________________________________________

Phone:_____________________________________

• Model :___________________________________

• Serial Number: __________________

• Date of Purchase:

__________/________/________

• Date of Installation:

Name of Dealer:

___________________________________________

Address:

___________________________________________

___________________________________________

___________________________________________

Phone: ___________________________________

Name of Installer:

___________________________________________

Address:

________________________________________

_

_________/________/________

• ____ Natural Gas (Nat.), ____ Propane (LPG)

• Inlet Gas Supply Pressure: ________ in.w.c.

If the orifices were changed by the installer.

• Main Orifice:

• Pilot Orifice # ________ or ______ in.Dia.

Installer's Signature: ________________________

E-MAIL ADDRESS ( www.envirofire.biz )

SHERWOOD INDUSTRIES, 6782 OLDFIELD ROAD., SAANICHTON, B.C., CANADA V8M 2A3

___________________________________________

___________________________________________

:

Ph

MANUFACTURED BY:

08/30/02

26

Loading...

Loading...