Page 1

Electronic Multi-Zone Environmental Alarm System

Installation/Owner’s Manual

D-011-0152

Page 2

Limitations of the Alarm System or Device

While your alarm system or device is reliable and sophisticated, it does not offer guaranteed protection against

burglary, fire or other emergency. Any security product, whether commercial or residential, is subject to

compromise or failure-to-warn for a variety of reasons. These include:

• Individuals may gain access through unprotected openings or have the technical sophistication to

bypass an alarm sensor or disconnect an alarm warning device.

• Monitoring devices will not operate without power. Devices powered by AC will not work if their AC

power supply is off for any reason. If system has battery backup, batteries that are not maintained can

fail to provide the necessary power for devices to function properly.

• Alarm warning devices such as sirens, bells, and horns may not alert people or awaken sleepers if they

are located on the other side of closed or partly closed doors. If warning devices are on a different level

of the residence from the bedrooms, they are less likely to awaken or alert people inside the bedrooms.

• Telephone lines needed to transmit alarm signals from a premises to a central monitoring station may

be out of service, and are subject to compromise by sophisticated means of attack.

• Signals sent by wireless transmitters may be blocked or reflected by metal before they reach the alarm

receiver. Even if the signal path has been recently checked during a weekly test, blockage can occur if

a metal object is moved into the path.

• Even if the system responds to the emergency as intended and is a monitored alarm system, the

authorities may not respond appropriately.

• This equipment, like other electrical devices, is subject to component failure.

• The most common cause of an alarm system not functioning properly is due to inadequate

maintenance. Your alarm system should be tested weekly to make sure all detection devices are

operating properly. Your control panel and keypads should be tested as well.

Installing an alarm system may make you eligible for lower insurance rates, but an alarm system is not a substitute

for insurance. Homeowners, property owners, and renters should continue to insure their lives and property.

Page 3

Table of Contents

General Information............................................................................................................................... 1

Overview ............................................................................................................................................ 1

How to Use This Manual.................................................................................................................... 2

Block Diagrams.................................................................................................................................. 3

Symbols on the Product or Manual Labeling ..................................................................................... 4

Monitoring Screens............................................................................................................................ 5

Keys ................................................................................................................................................... 6

Base Unit Connections ...................................................................................................................... 7

Access Control and Passwords ......................................................................................................... 8

System Configuration Parameters ..................................................................................................... 9

Sensors............................................................................................................................................ 10

Temperature Sensors ................................................................................................................ 10

Humidity Sensors....................................................................................................................... 11

4-20mA Sensors ........................................................................................................................ 11

Theory of Operation ....................................................................................................... 11

Power Supply / Sensor Voltage Selection...................................................................... 12

Water Sensors ........................................................................................................................... 13

Multi-Function Sensors .............................................................................................................. 13

Contact Closure Sensors ........................................................................................................... 13

Sensor Parameter Descriptions ................................................................................................. 14

Relay Operation ............................................................................................................................... 15

Preparation........................................................................................................................................... 17

Installation............................................................................................................................................ 21

Tools and Supplies Required........................................................................................................... 21

Power Requirements ....................................................................................................................... 21

Mounting the EA800 Rear Plate ...................................................................................................... 21

Install the Wired Sensors................................................................................................................. 22

EA800 Base Unit Power Connections ............................................................................................. 22

Install the Wireless Sensors............................................................................................................. 22

Connecting Wired Temperature, Contact Closure, and Water Bug Sensors................................... 24

Connecting Wired HA-III+ Humidity Sensors................................................................................... 25

Connecting Wired 4-20mA Sensors................................................................................................. 26

Connecting the EA800 Alarm Outputs............................................................................................. 27

Programming ................................................................................................................................... 27

Accessing the MAIN MENU for Programming ........................................................................... 28

Configuring System Parameter Settings.................................................................................... 28

Setting the Current Date ............................................................................................................ 31

Setting the Time......................................................................................................................... 32

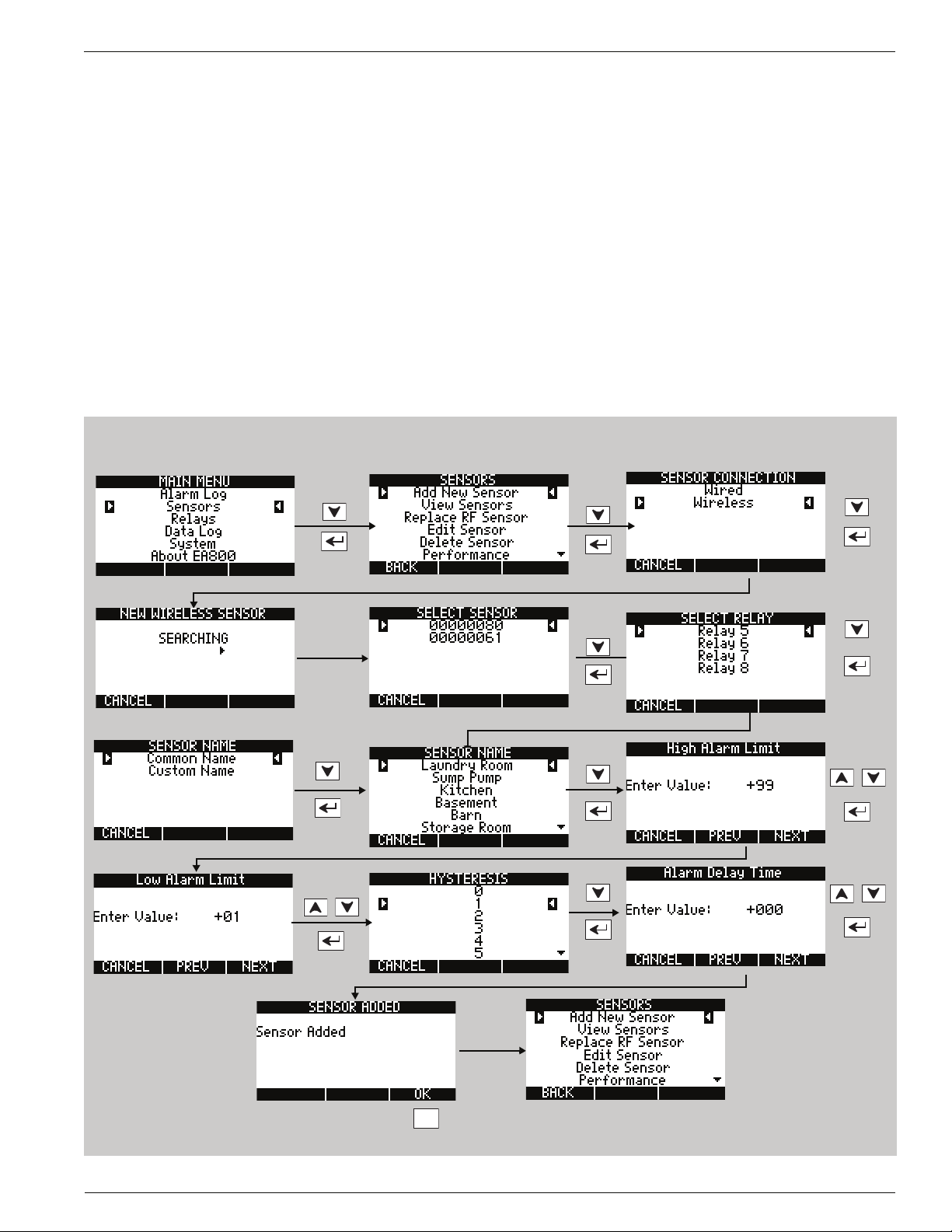

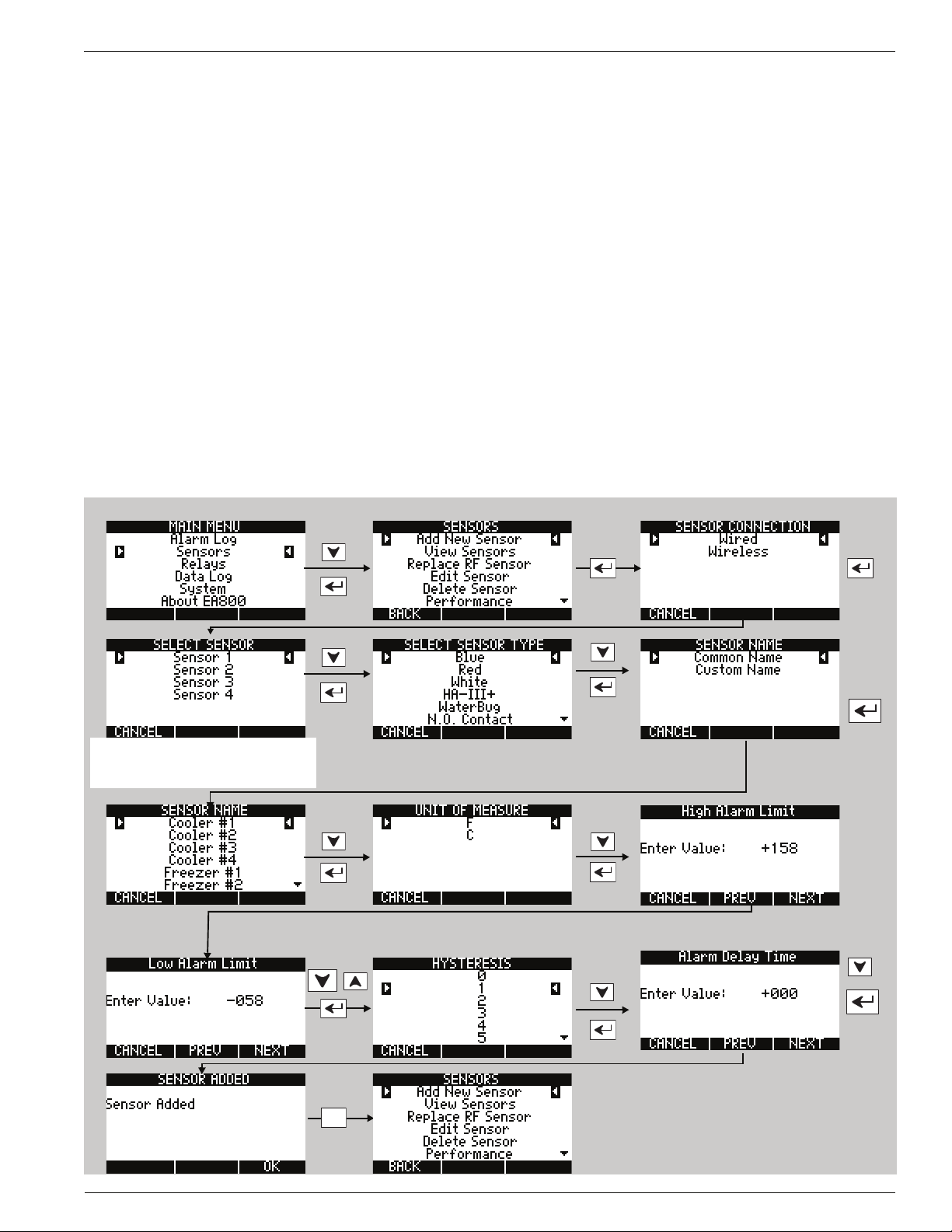

Adding Wireless Sensors................................................................................................................. 33

Adding a Wireless Temperature Sensor .................................................................................... 33

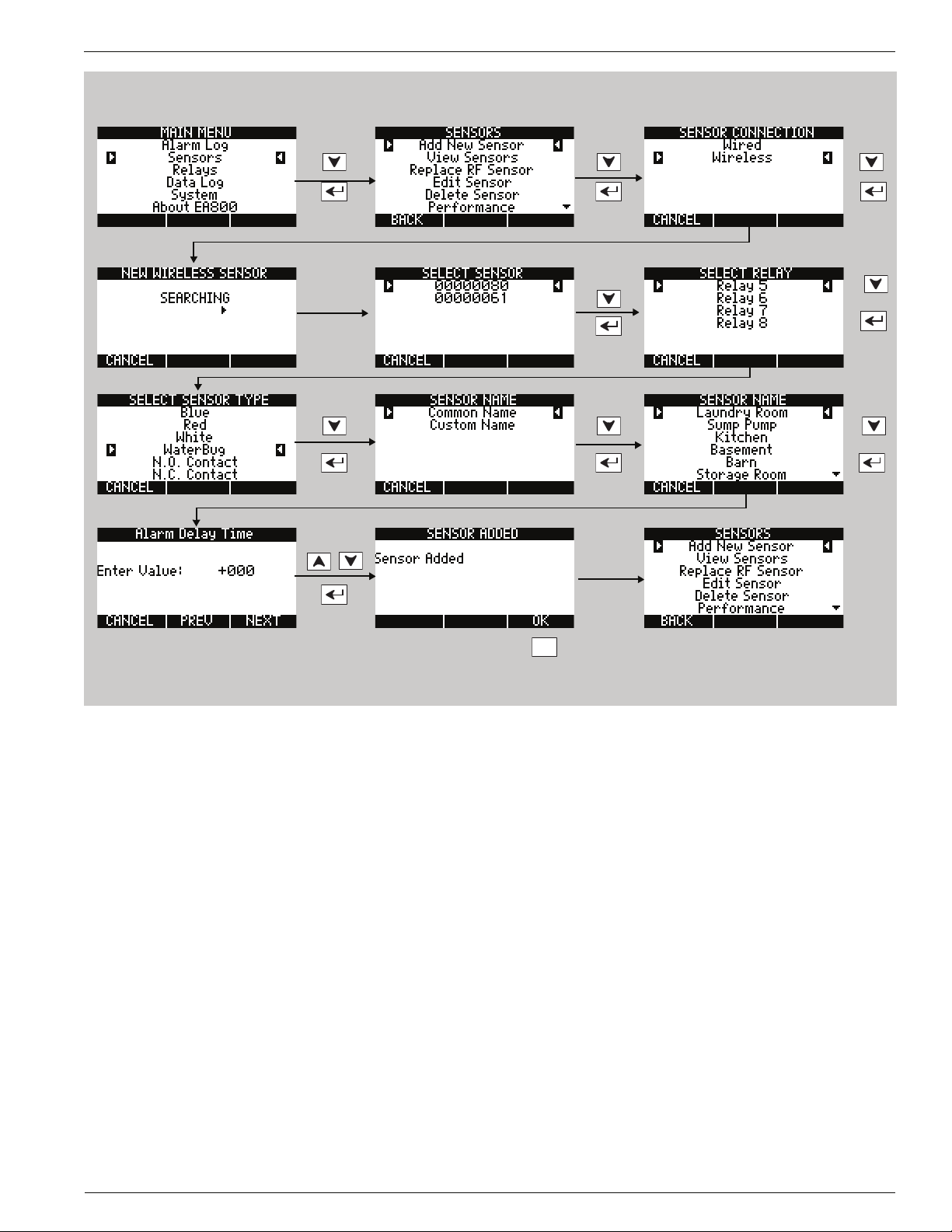

Adding a Wireless Multi-Function Sensor Using a Wired Temperature Sensor ........................ 35

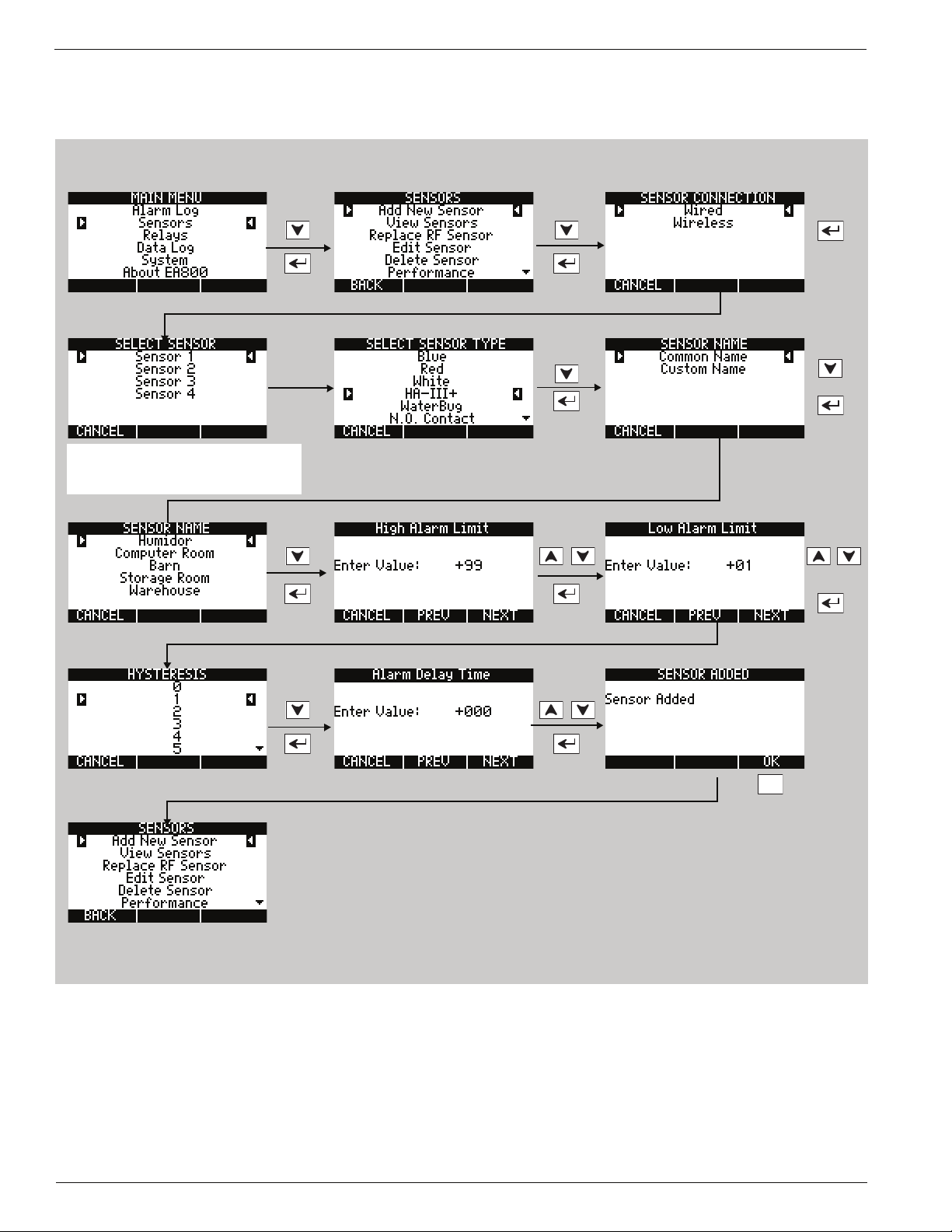

Adding a Wireless Humidity Sensor........................................................................................... 37

Adding a Wireless Multi-Function Sensor Using a Wired WaterBug Sensor............................. 38

Adding a Wireless Multi-Function Sensor Using a Wired Contact Closure Sensor ................... 40

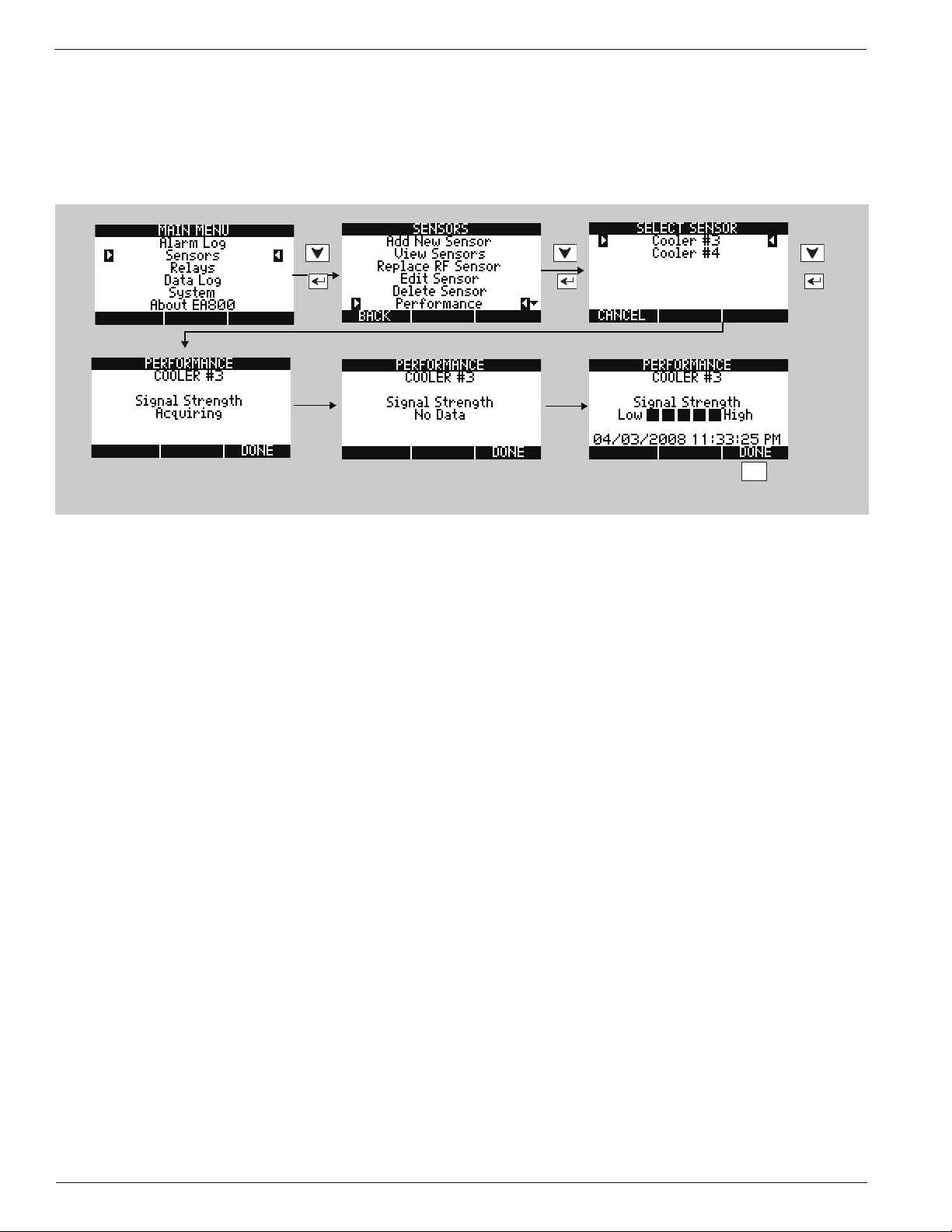

Verify Wireless Signal Strength ................................................................................................. 42

Adding Wired Sensors ..................................................................................................................... 43

Adding a Wired Temperature Sensor ........................................................................................ 43

Adding a Wired HA-III+ Humidity Sensor................................................................................... 44

Adding a Wired WaterBug Sensor ............................................................................................. 45

Adding a Wired Contact Closure Sensor ................................................................................... 46

Adding a 4-20mA Sensor ........................................................................................................... 47

Configuring the Relays..................................................................................................................... 48

-

-

Page 4

Operation .............................................................................................................................................. 49

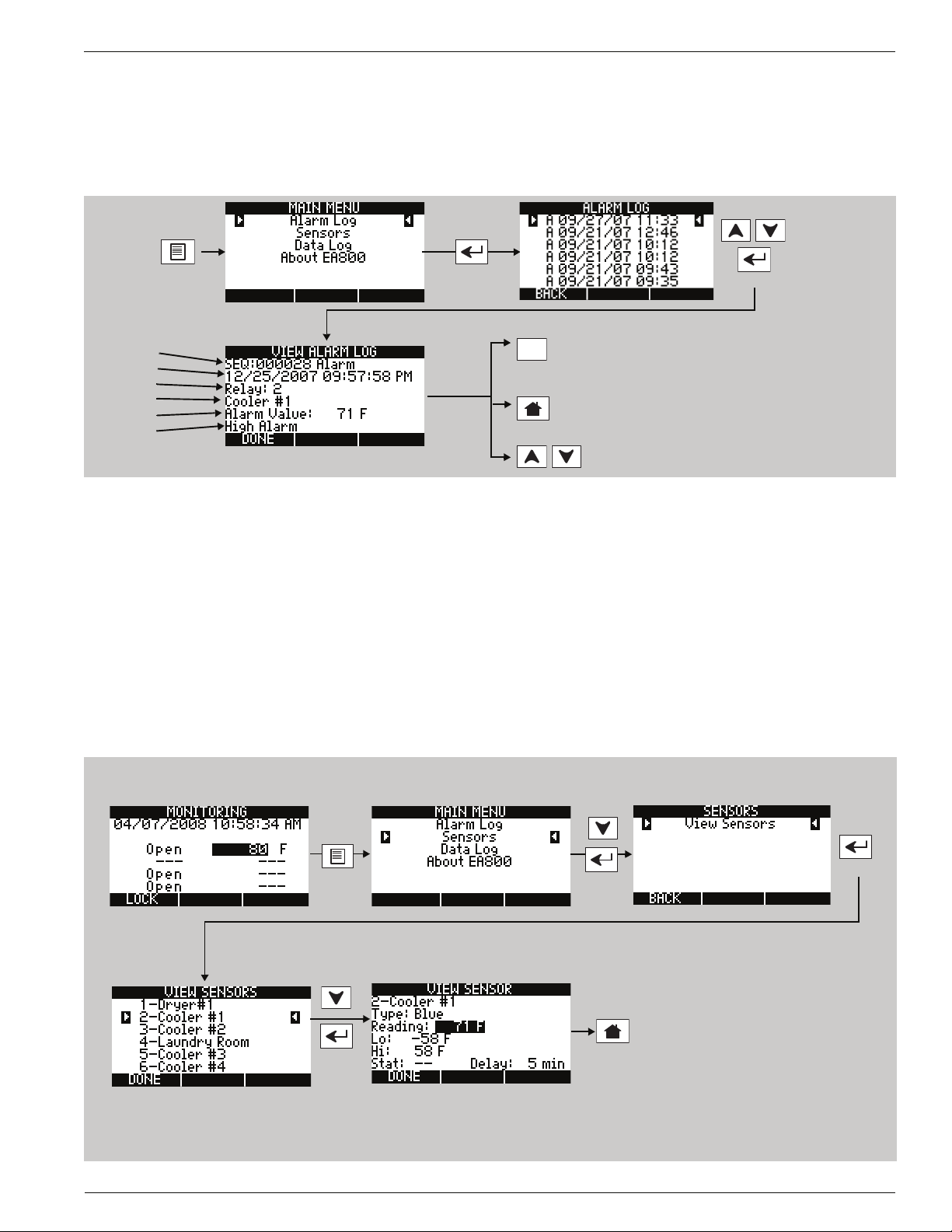

Monitoring Environmental Conditions .............................................................................................. 49

Viewing Sensor Settings .................................................................................................................. 50

Viewing Active Alarms ..................................................................................................................... 50

Viewing the Alarm Log ..................................................................................................................... 51

Viewing Pending Alarm Information................................................................................................. 51

Viewing Limit Settings ...................................................................................................................... 52

Viewing the Event Log ..................................................................................................................... 52

Viewing the Sensor Log ................................................................................................................... 53

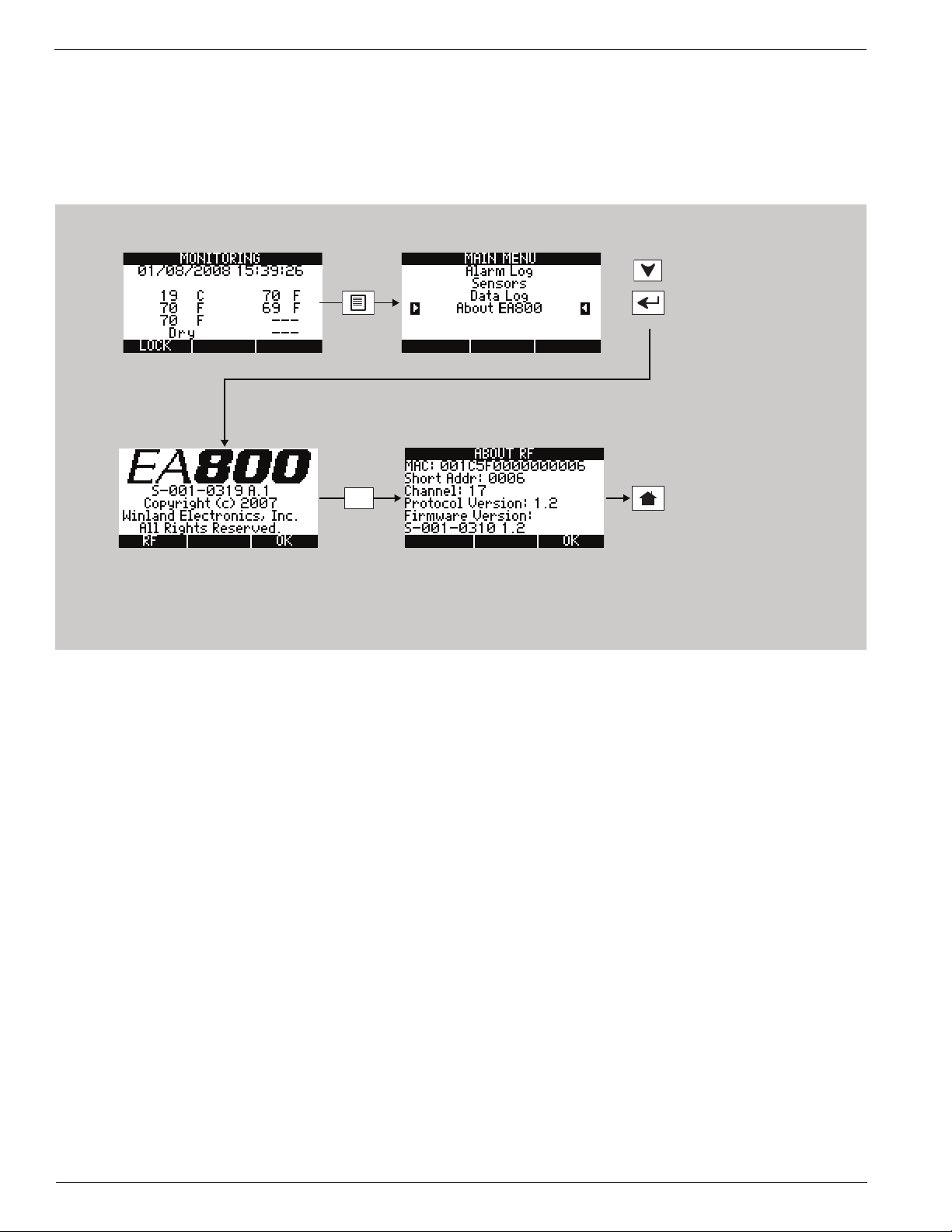

Viewing Firmware Information ......................................................................................................... 53

Viewing RF Information.................................................................................................................... 54

Maintenance ......................................................................................................................................... 55

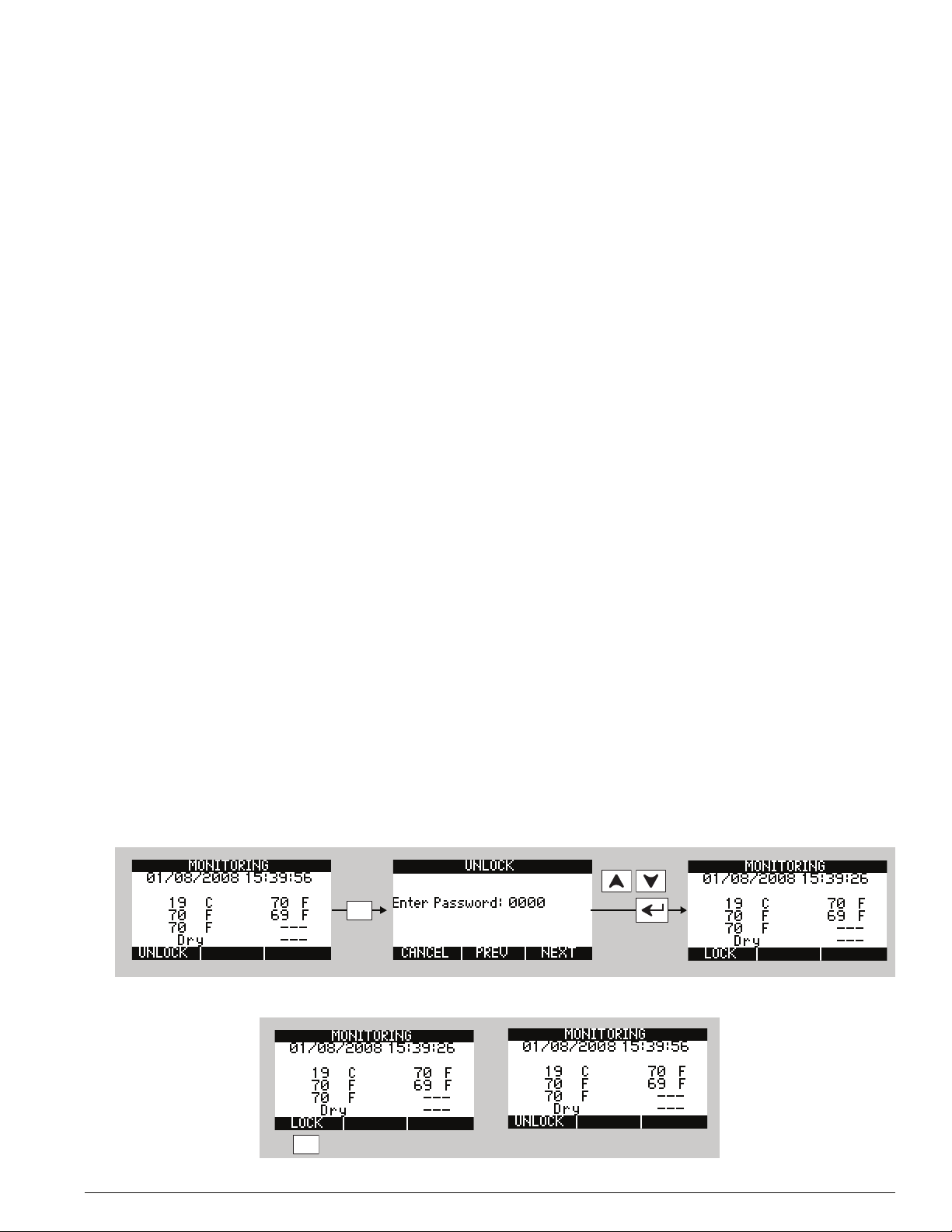

Locking and Unlocking the EA800................................................................................................... 55

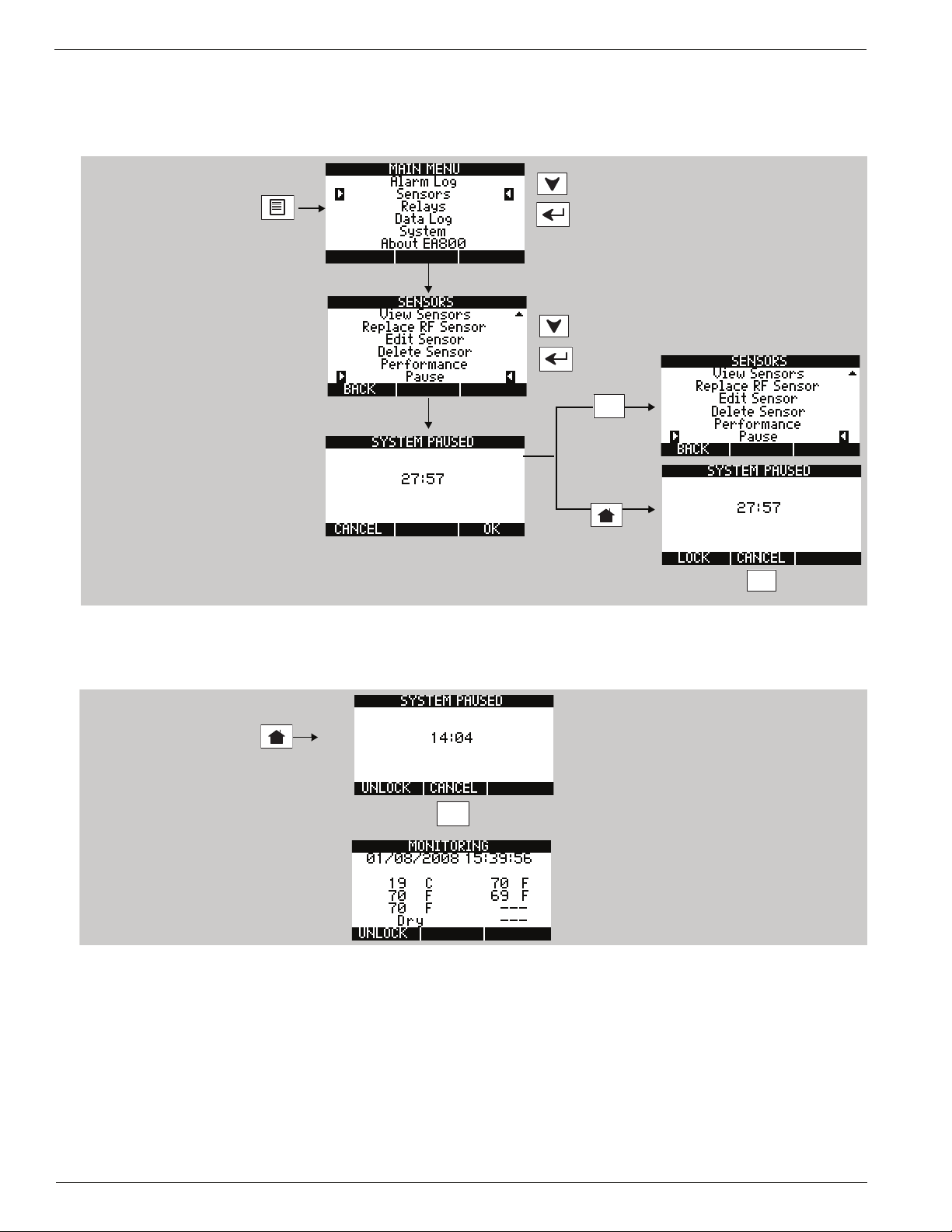

Pausing Monitoring and Cancelling Pause ...................................................................................... 56

Adding a Sensor .............................................................................................................................. 57

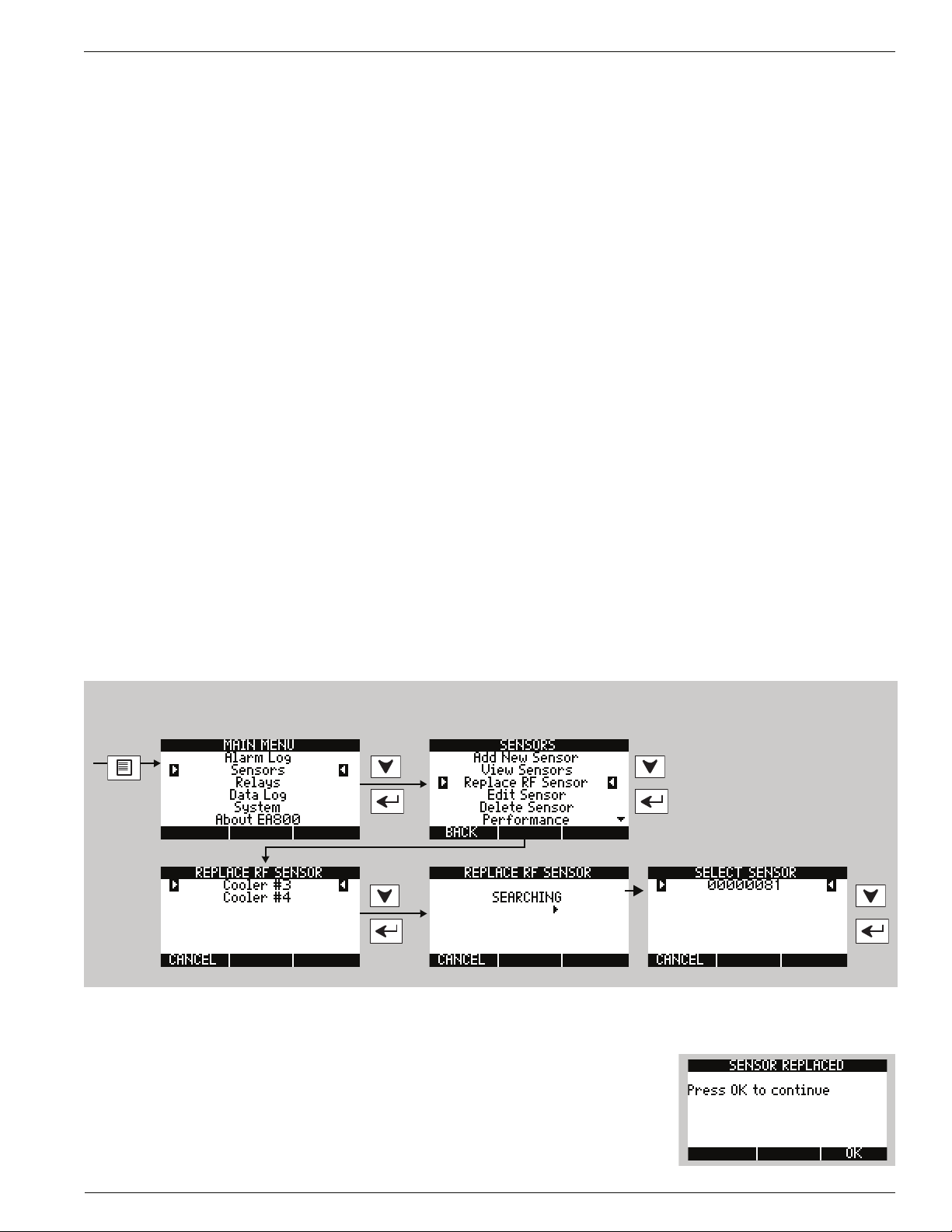

Replacing a Sensor.......................................................................................................................... 57

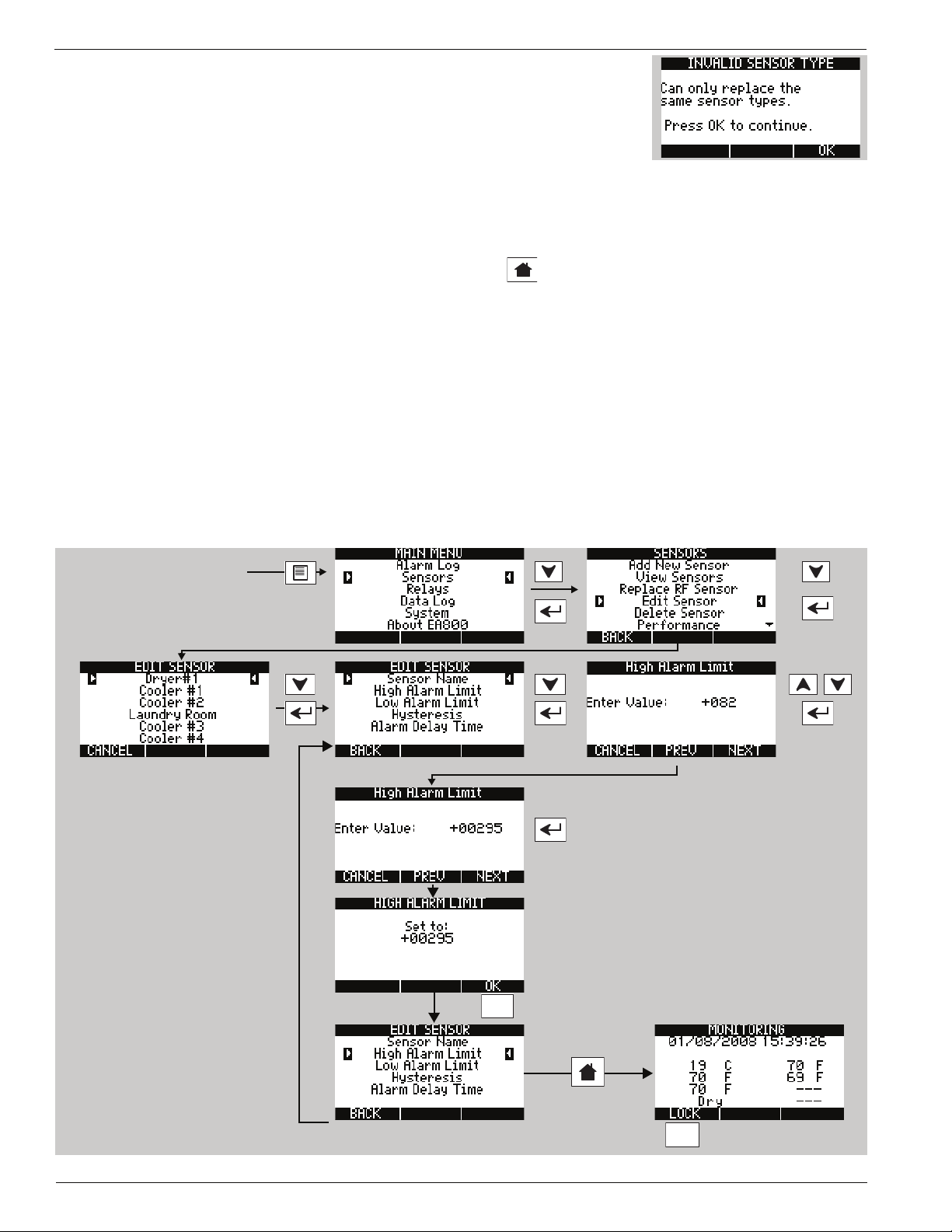

Editing Sensor Parameters .............................................................................................................. 58

Reprogramming a Relay .................................................................................................................. 59

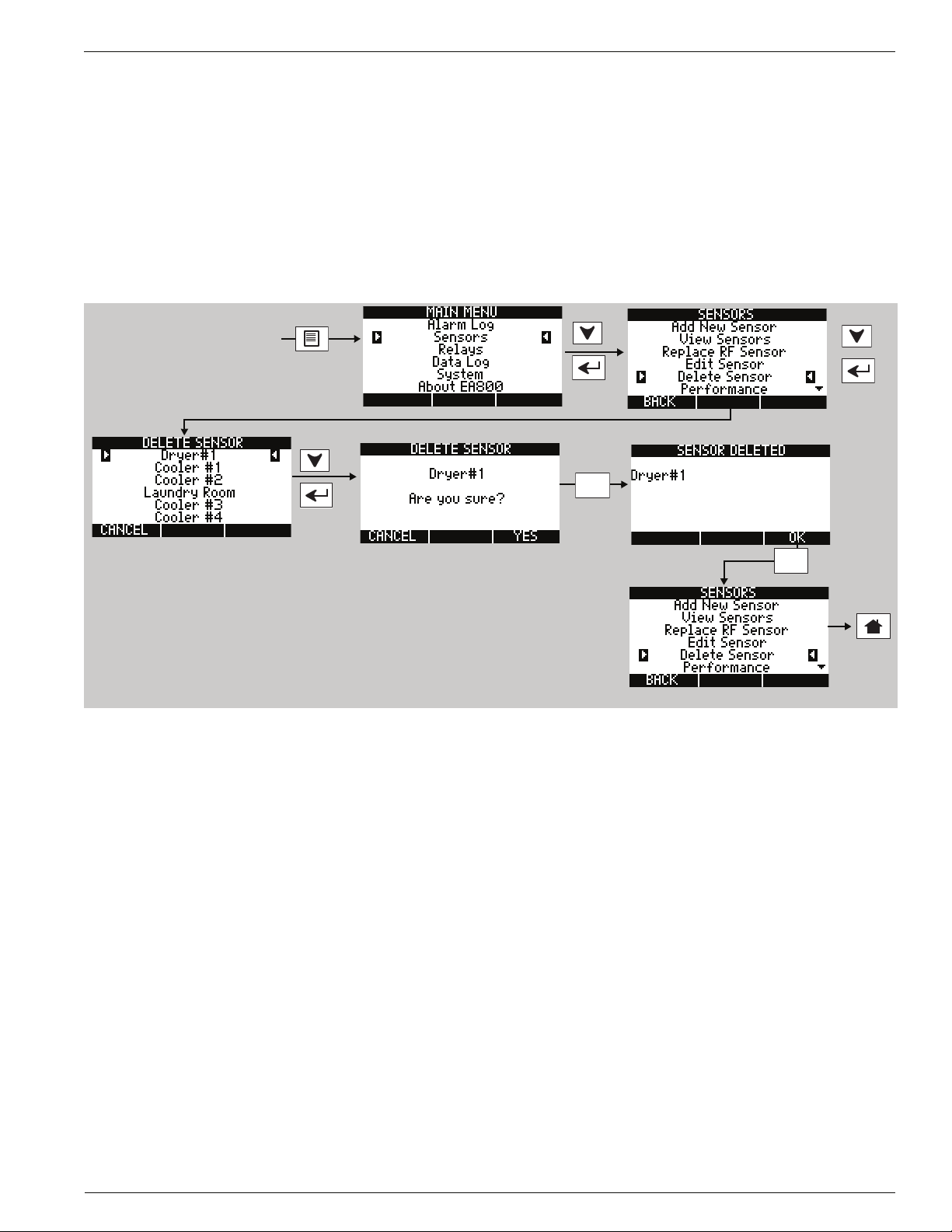

Deleting a Sensor ............................................................................................................................ 59

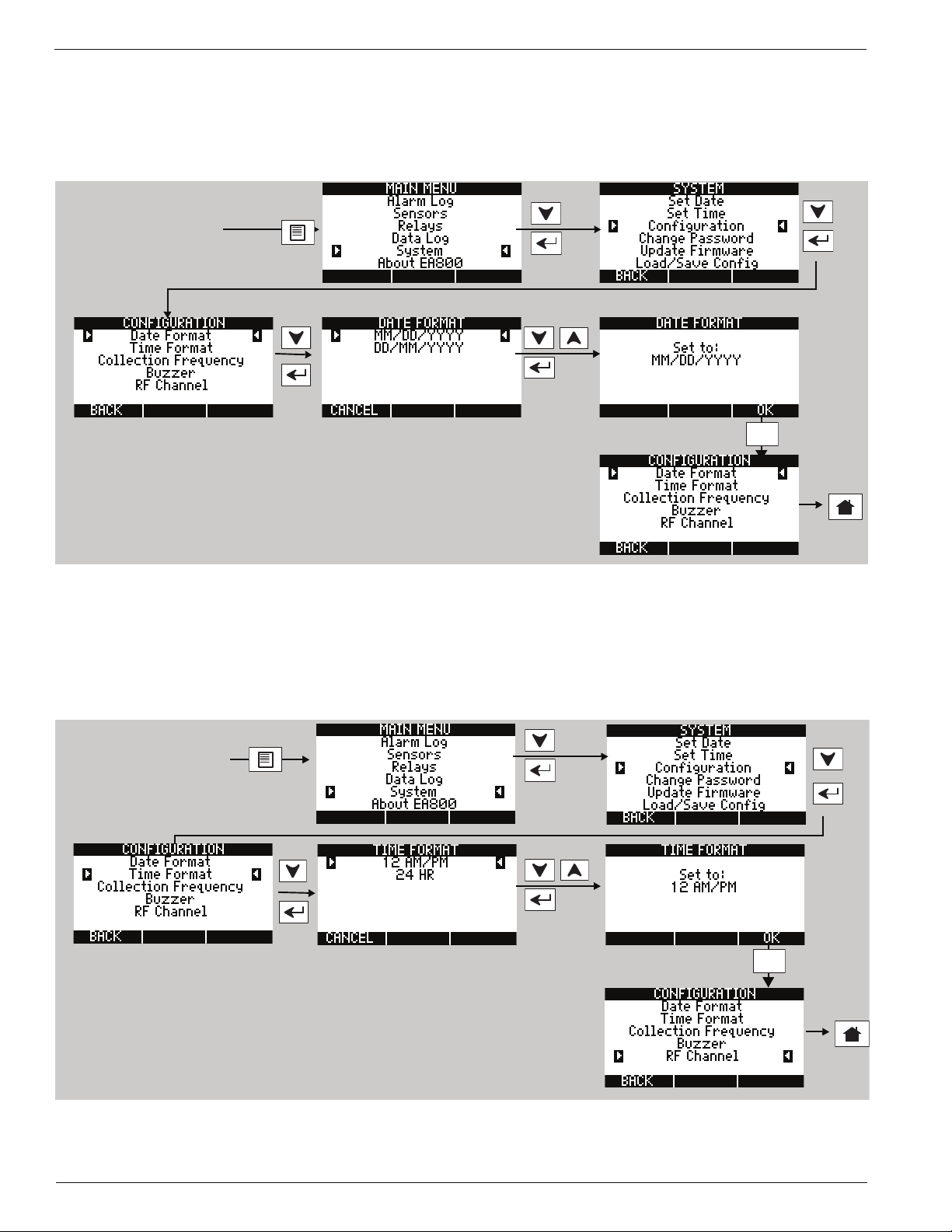

Changing the Date Format............................................................................................................... 60

Changing the Time Format .............................................................................................................. 60

Changing the Date or Time Setting.................................................................................................. 61

Changing Sensor Data Collection Frequency.................................................................................. 61

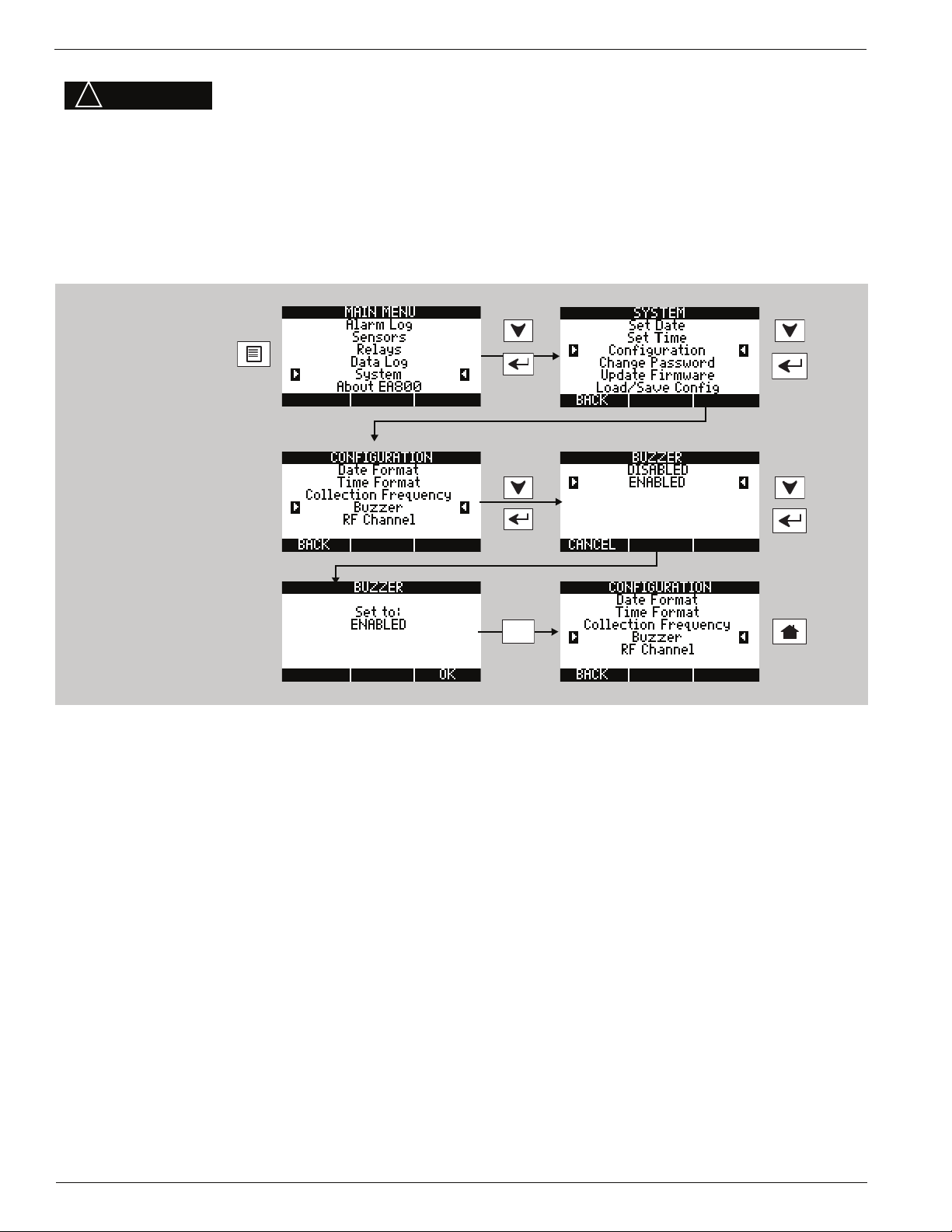

Changing the Buzzer Setting ........................................................................................................... 62

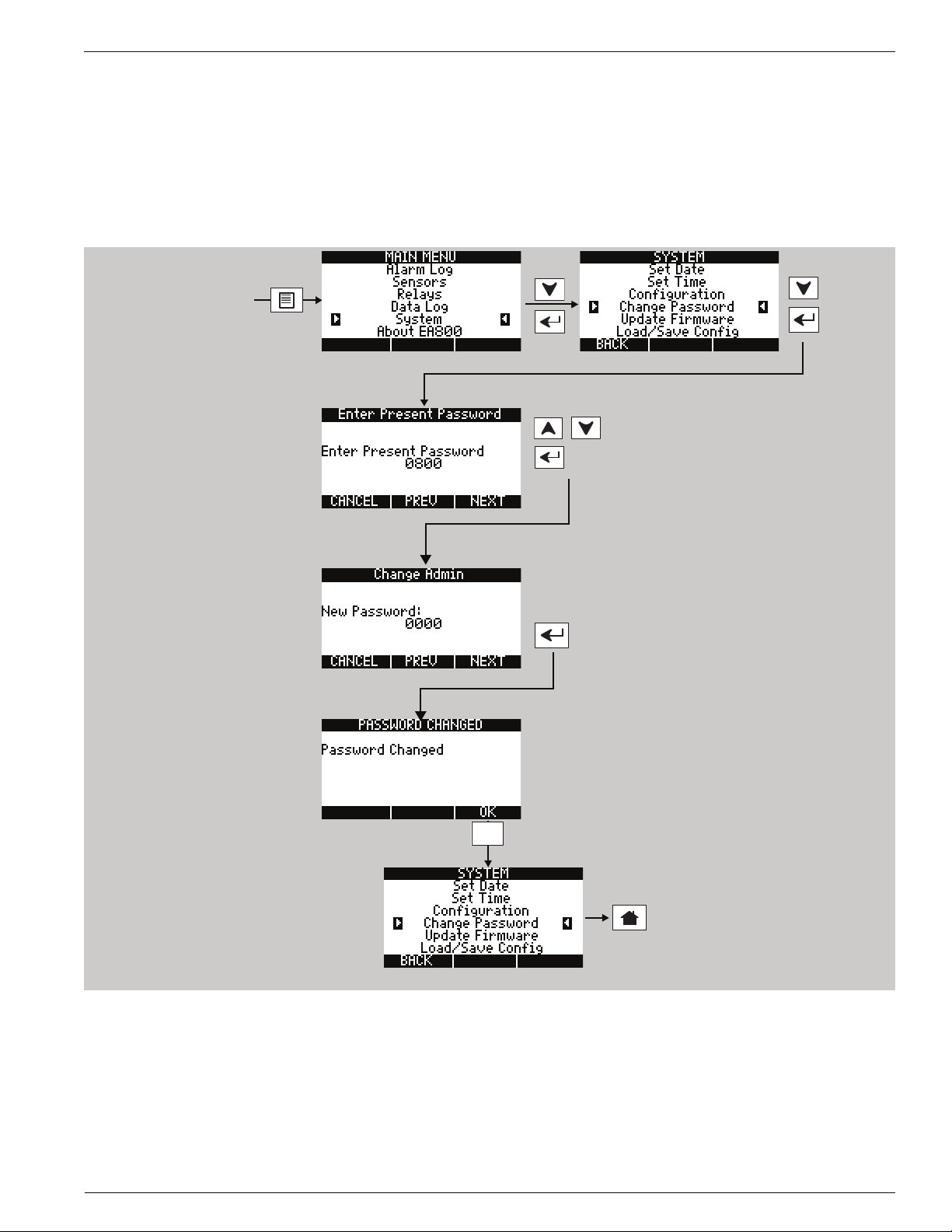

Changing the Password................................................................................................................... 63

Clearing the Alarm Log .................................................................................................................... 64

Clearing the Sensor Log .................................................................................................................. 64

Updating the Firmware..................................................................................................................... 65

Saving Configuration Settings.......................................................................................................... 66

Loading Configuration Settings........................................................................................................ 67

Exporting the Stored Logs ............................................................................................................... 68

Exported Alarm Data.................................................................................................................. 68

Exported Event Data .................................................................................................................. 69

Exported Sensor Data................................................................................................................ 69

Troubleshooting................................................................................................................................... 71

Verifying RF Signal Strength............................................................................................................ 72

Viewing Signal Strength for a Wireless Sensor.......................................................................... 72

Specifications....................................................................................................................................... 73

Base Unit and Sensor Specifications............................................................................................... 73

Accessories...................................................................................................................................... 74

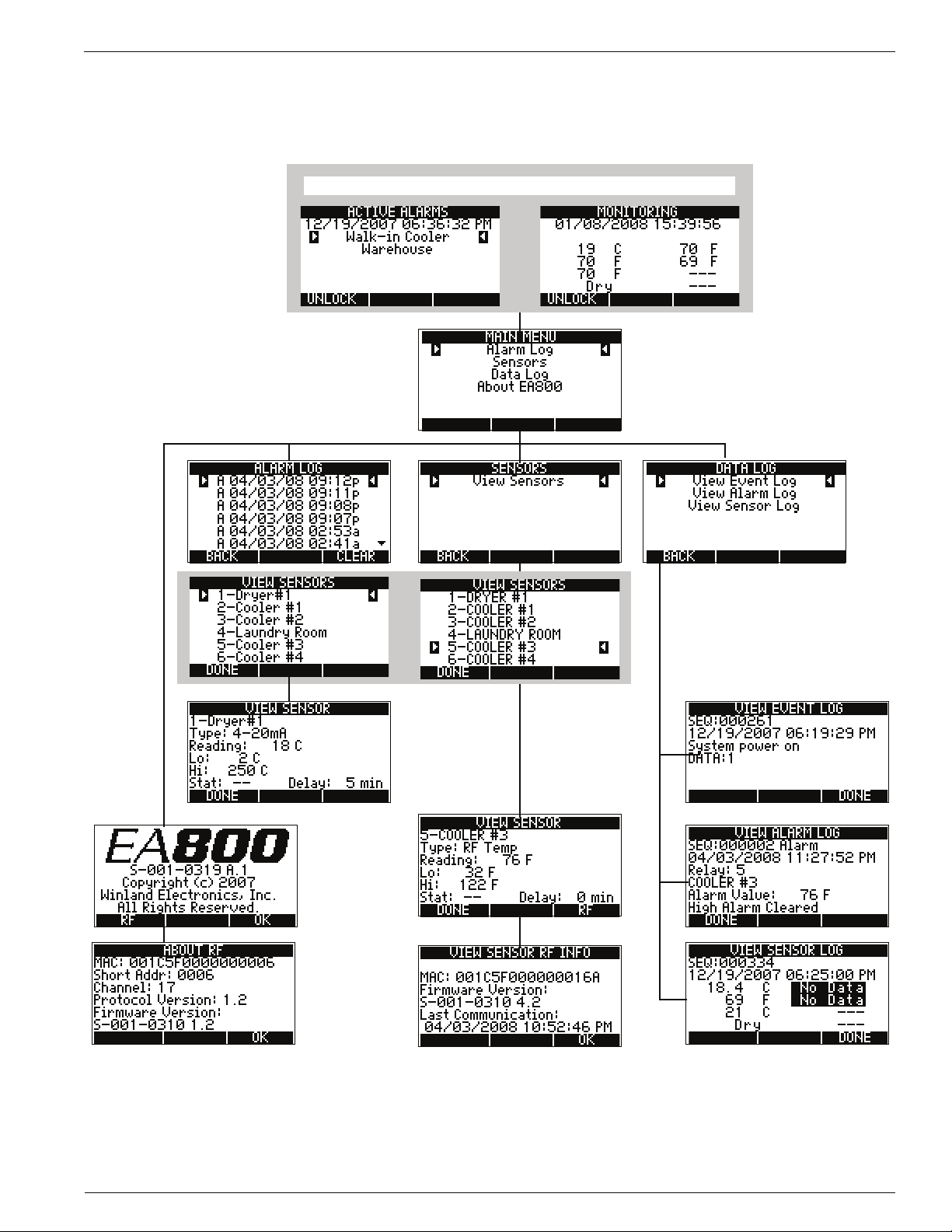

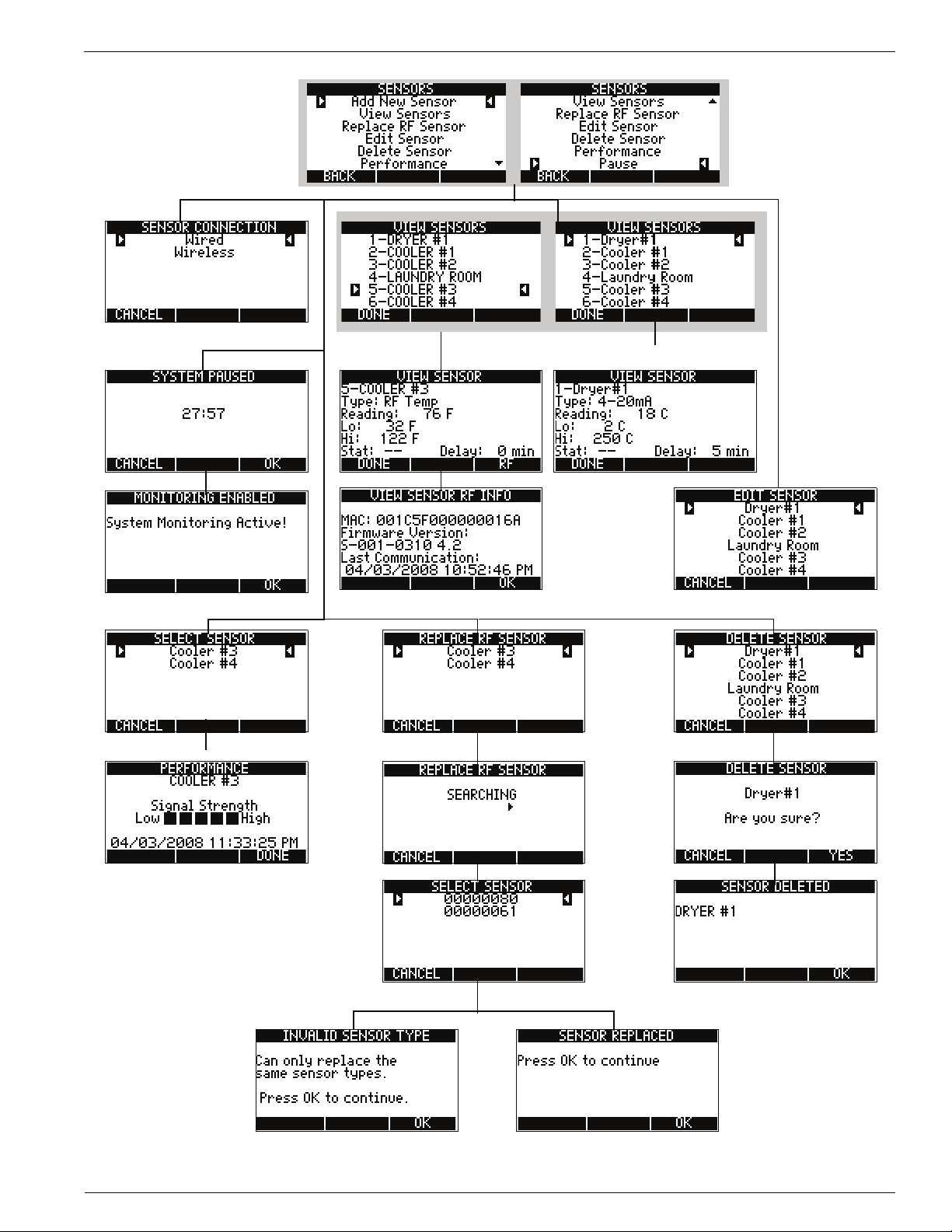

Appendix A: Screen Maps................................................................................................................... 75

Appendix B: Planning Worksheet ...................................................................................................... 83

Appendix C: Wiring Diagram .............................................................................................................. 85

Appendix D: System Configuration Record ...................................................................................... 87

Warranty and Service Information ..................................................................................................... 93

ii D-011-0152

Page 5

General Information

Overview

The EnviroAlert® EA800 Multi-Zone Environmental Alarm System monitors the environmental conditions detected

by the sensors connected to the base unit, and provides alarm signals when monitored conditions at any of the

sensors exceed the user-programmable HIGH LIMIT or LOW LIMIT set points. The alarm signals are provided via

relay outputs that can operate with process controls, security systems, or other similar automated equipment. The

EA800 Alarm System can be configured with wired or optional wireless sensors (sold separately). The EA800

allows connection of up to 4 wired and 4 wireless sensors.

Setup and programming is done using the front panel keys and the liquid crystal display (LCD) on the base unit.

The display assists the user during setup, and shows measured conditions for the monitored environment during

operation.

The EA800 can monitor multiple critical environments using multiple sensor inputs. Each sensor input/alarm

channel is designated a “Relay”.

Using the appropriate accessory sensors (sold separately), the EA800 Alarm System monitors and provides

alarms for the following conditions:

■ Normally open/normally closed contacts

■ Temperature: from -80° C to 150° C (-112° F to 302° F)

■ Humidity: from 5% to 95% RH (non-condensing)

■ Presence of water

■ Any sensor with a 4-20mA interface

The EA800 base unit may be mounted directly to a 3-gang electrical enclosure or to walls. The wireless sensors

are easily mounted to the wall. Figure 1 shows the base unit and a wireless sensor.

Figure 1 EnviroAlert EA800 Base Unit and Optional Wireless Sensor

-

-

Page 6

How to Use This Manual

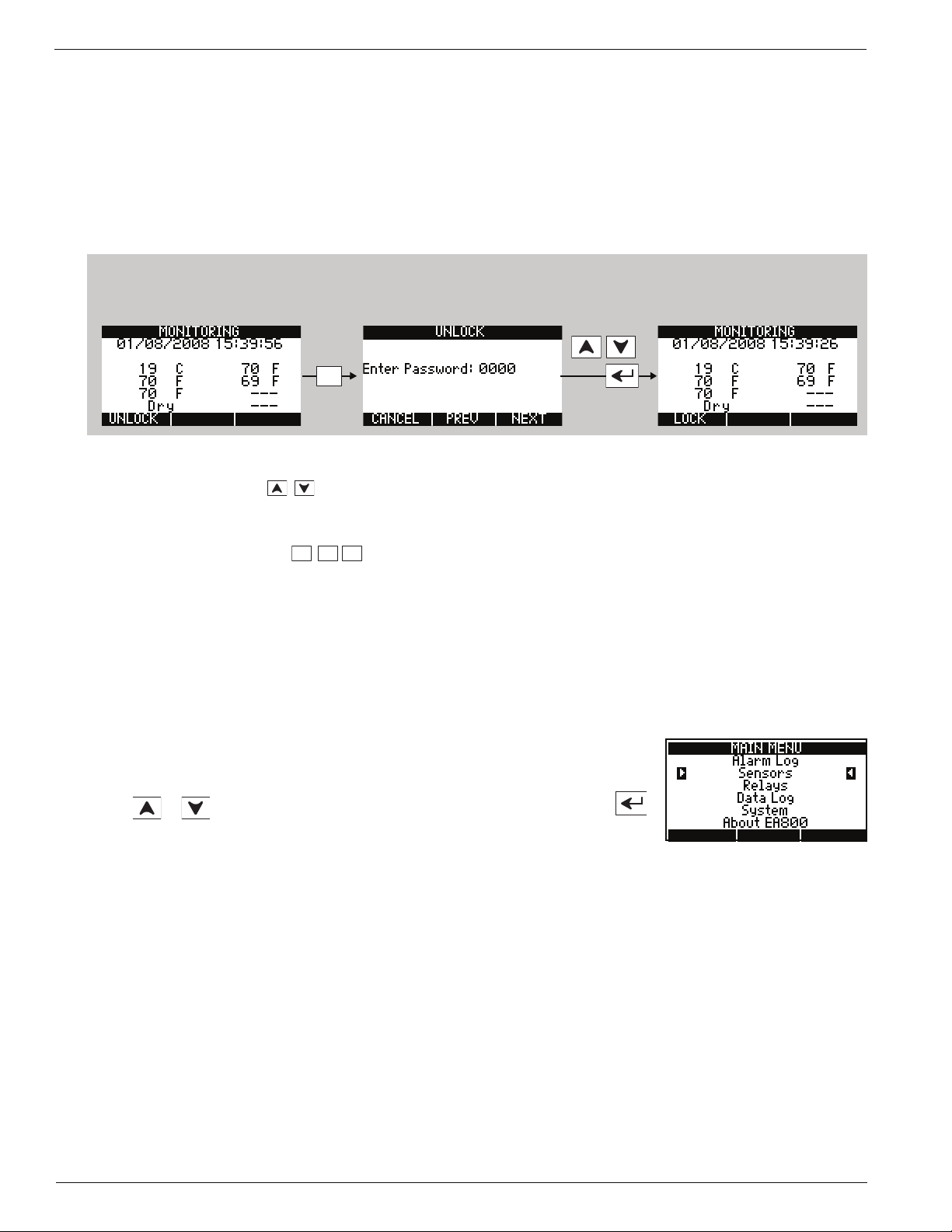

Enter:

0800

F1

Step 1: Press the

F1 soft key.

Step 2: The

UNLOCK screen

is displayed. Enter your

password using the arrow

keys.

Step 3: Press the

ENTER key

F1 can be pressed at this time

to lock the unit.

How to Use This Manual

This manual is organized into sections that guide you through the installation process, then describe how to use the

EA800 and change its programmed settings if necessary. Some troubleshooting guidelines are provided, and the

appendices contain forms for you to photocopy and use to record the programmed settings of the EA800 and the

monitoring system setup.

The manual presents EA800 programming procedures by showing you the sequence of menus and screens you

will see as you perform the procedure, and the keys to press to advance to the next screen. The example below is

the procedure for unlocking the EA800 base unit to allow programming.

The arrows on the drawing indicate the direction of procedure flow.

In all procedures, use the keys to select menu options and to increase/decrease alphanumeric values for

programming options. Use the PREV and NEXT soft keys (F2 and F3) to move the cursor to the next digit when

entering numeric data.

The functions of the soft keys change and are defined on the screen in the area above each key. If no

F1 F2 F3

text is shown above a soft key, it means the key performs no function on the current screen.

“Keys” on page 6 describes the functions of each key on the base unit.

Note: For convenient reference, “Appendix A: Screen Maps” on page 75 contains maps of all menus and

screens.

Throughout the manual, text that appears on the EA800 base unit screens is shown like this: MONITORING

Key names are shown in text like this: F1

The current menu selection is highlighted on the screen by arrows on either side of the

selection, as shown in the example at right. On this MAIN MENU screen, the current selection

is Sensors.

Use the or keys to move the highlight to the desired menu item, then press

to make the selection.

2 D-011-0152

Page 7

General Information

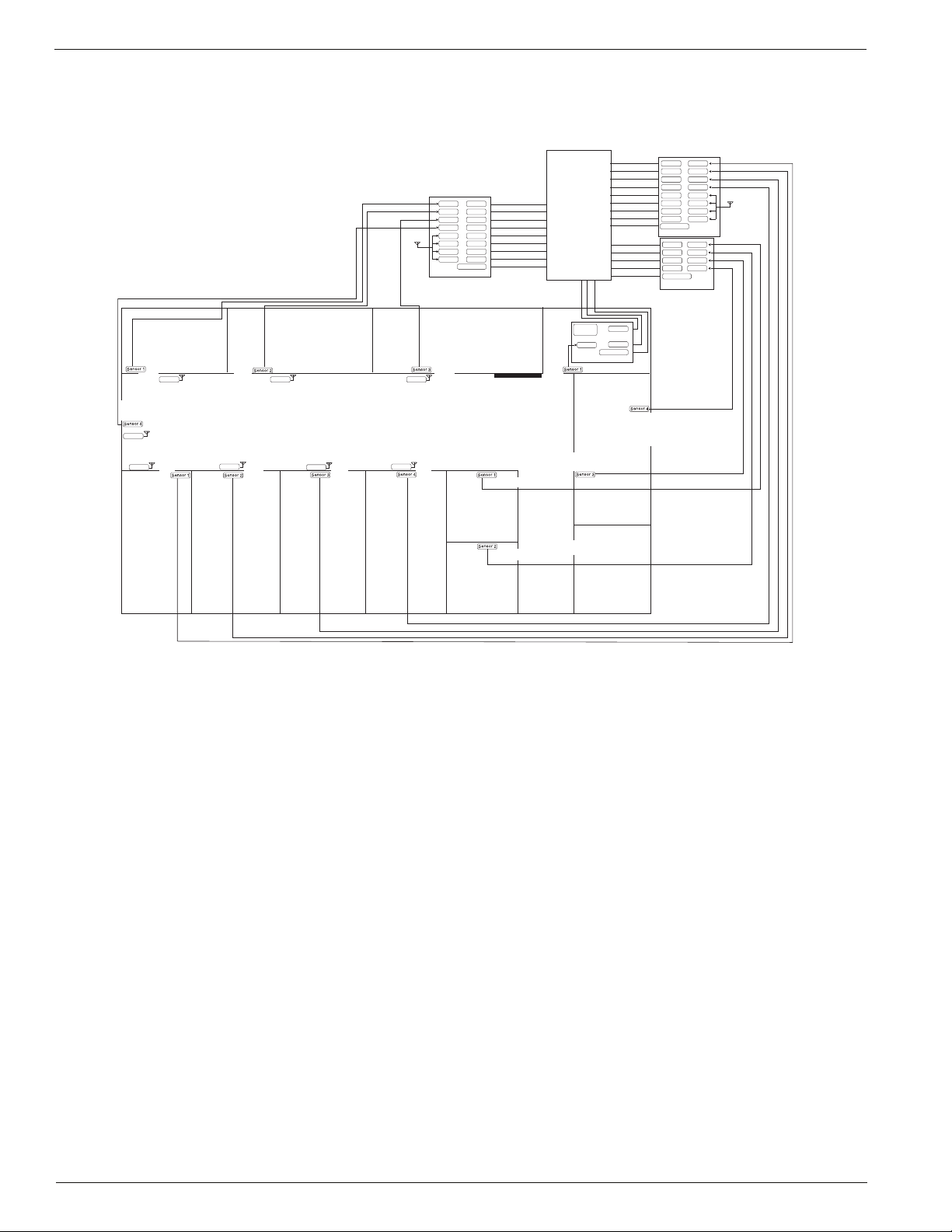

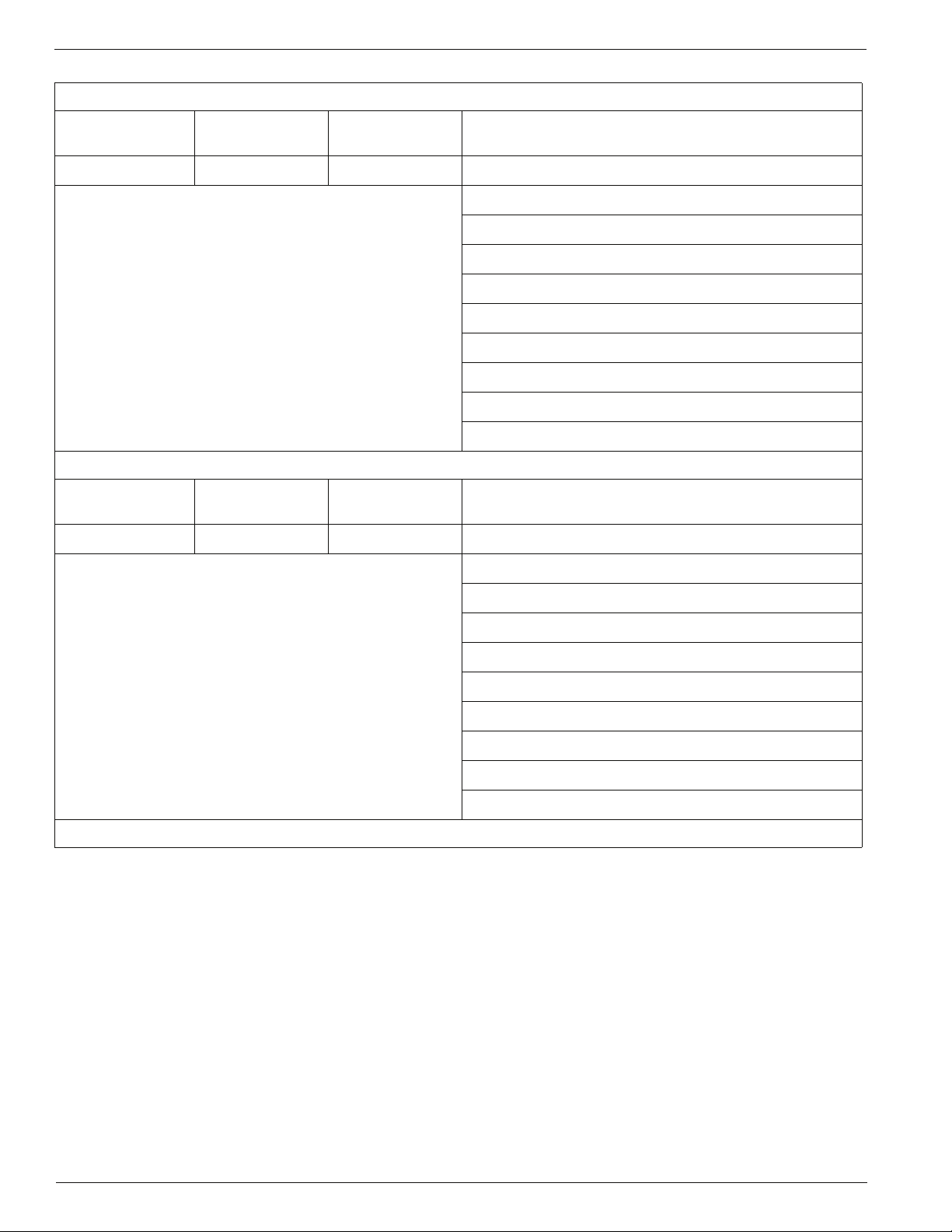

Sensor 5

Sensor 6

Sensor 7

Sensor 8

Wireless Sensors

Relay 1

Output 1

Output 2

Relay 2

Output 3

Relay 3

Output 4

Relay 4

Output 5

Relay 5

Output 6

Relay 6

Output 7

Relay 7

Output 8

Relay 8

EA800 Base Unit

Aux Output

RF Receiver

Sensor 1

Sensor 2

Sensor 3

Sensor 4

System Control

Relay 9

Relay 1 coil control logic

Relay 2 coil control logic

Relay 3 coil control logic

Relay 4 coil control logic

Relay assignment

and coil control logic

Alarm Panel

From other

EA800, EA400, and EA200

Environmental Alarm Systems

Sensor 5

Sensor 6

Sensor 7

Sensor 8

Wireless Sensors

Relay 1

Output 1

Output 2

Relay 2

Output 3

Relay 3

Output 4

Relay 4

Output 5

Relay 5

Output 6

Relay 6

Output 7

Relay 7

Output 8

Relay 8

EA800 Base Unit

Aux Output

RF Receiver

Sensor 1

Sensor 2

Sensor 3

Sensor 4

System Control

Relay 9

Relay 1 coil control logic

Relay 2 coil control logic

Relay 3 coil control logic

Relay 4 coil control logic

Relay assignment

and coil control logic

Sensor 5

Sensor 6

Sensor 7

Sensor 8

Wireless Sensors

Relay 1

Output 1

Output 2

Relay 2

Output 3

Relay 3

Output 4

Relay 4

Output 5

Relay 5

Output 6

Relay 6

Output 7

Relay 7

Output 8

Relay 8

EA800 Base Unit

Aux Output

RF Receiver

Sensor 1

Sensor 2

Sensor 3

Sensor 4

System Control

Relay 9

Relay 1 coil control logic

Relay 2 coil control logic

Relay 3 coil control logic

Relay 4 coil control logic

Relay assignment

and coil control logic

Block Diagrams

Figure 2 shows a block diagram of the base unit interfaces and functions. The EA800 provides eight relays for

indicating when a programmed alarm limit has been exceeded or a warning condition exists. An additional AUX

(Auxiliary) Output relay provides an output signal to an optional audible alarm or strobe that is activated whenever

an alarm condition exists.

Figure 2 EA800 Environmental Alarm System Block Diagram

The EA800 can be made part of a larger security system as shown in Figure 3. In a security system there may be

more than one EA800 installed along with other components such as the Winland EA200 or EA400 multi-zone

environmental alarm systems.

-

-

Figure 3 Facility Security System Block Diagram - Example

Page 8

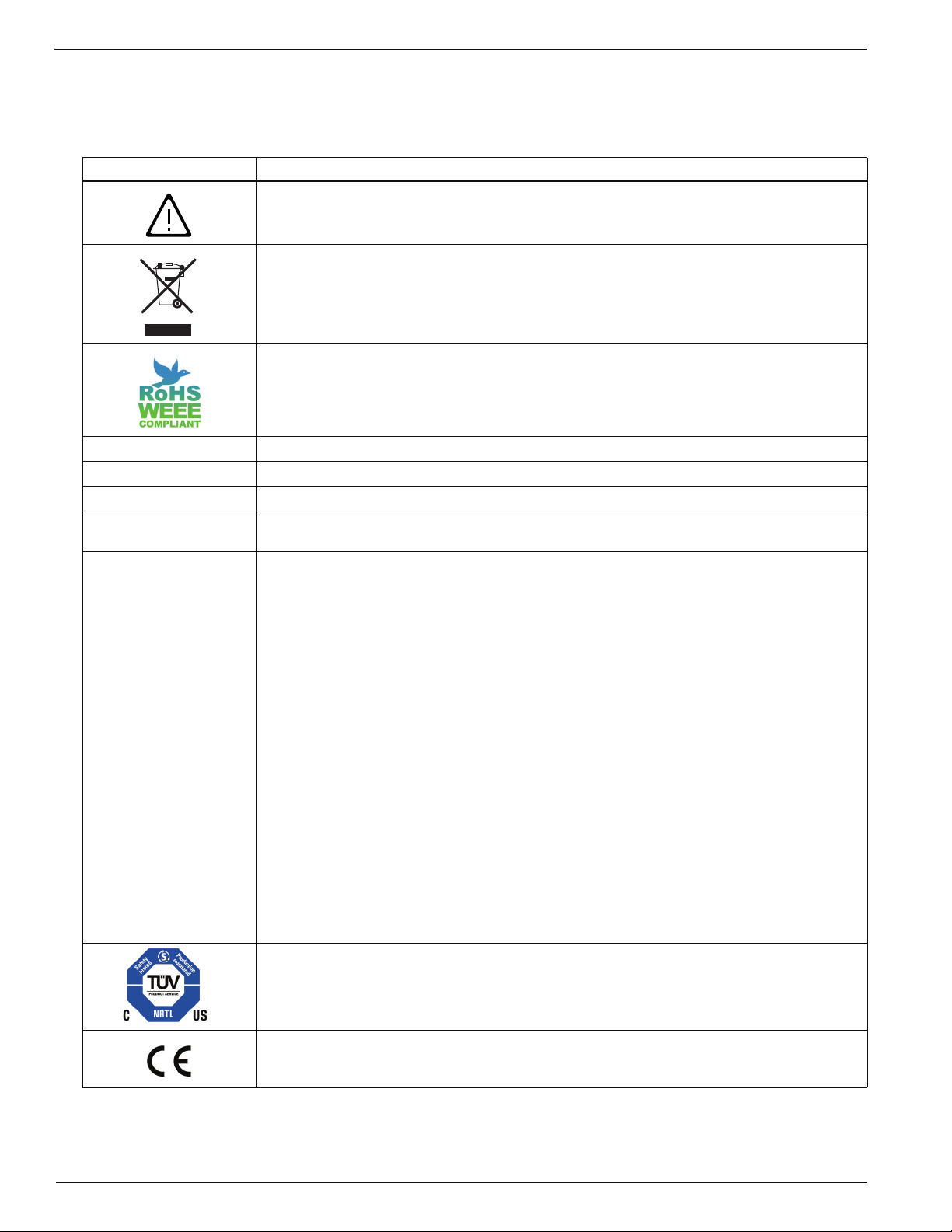

Symbols on the Product or Manual Labeling

Symbols on the Product or Manual Labeling

Symbols appearing on the product labeling, packaging, and/or in this manual are shown and described in Table 1.

Table 1 Symbols on Product or Manual

Symbol Definition

Attention, consult accompanying documents or statements.

NO Normally Open (NO) relay contact terminal

NC Normally Closed (NC) relay contact terminal

C Common relay contact terminal

AUX Combined single pole double throw (SPDT) NO relay output that activates upon an

Model: EA800

• FCC ID:

V5SEA800-031108

• IC: 7635A-EA800

Models: EA-WMFS,

EA-WTS, EA-WHS

• FCC ID:

V5SEA-WS-031108

• IC: 7635A-EAWS

For product disposal, ensure the following:

• Do not dispose of this product as unsorted municipal waste.

• Collect this product separately.

• Use collection and return systems available to you.

Indicates product complies with RoHS-WEEE directive.

alarm from any of the sensors.

This device complies with part 15 of the FCC Rules. Operation is subject to the follow-

ing two conditions: (1) This device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause

undesired operation.

Caution Statement (per CFR 15.21):

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate the equipment.

Class B Product Compliance Statement (per CFR 15.105(b)):

NOTE: This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one

or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

The TÜV certification combines electrical safety certification for Canada (SCC), United

States (NRTL), and Europe (EU Directives). This product was voluntarily tested

according to the relevant safety requirements and mentioned properties pertaining to

this certification mark.

The product is in conformity with all applicable requirements for its placing on the

European Union market.

4 D-011-0152

Page 9

General Information

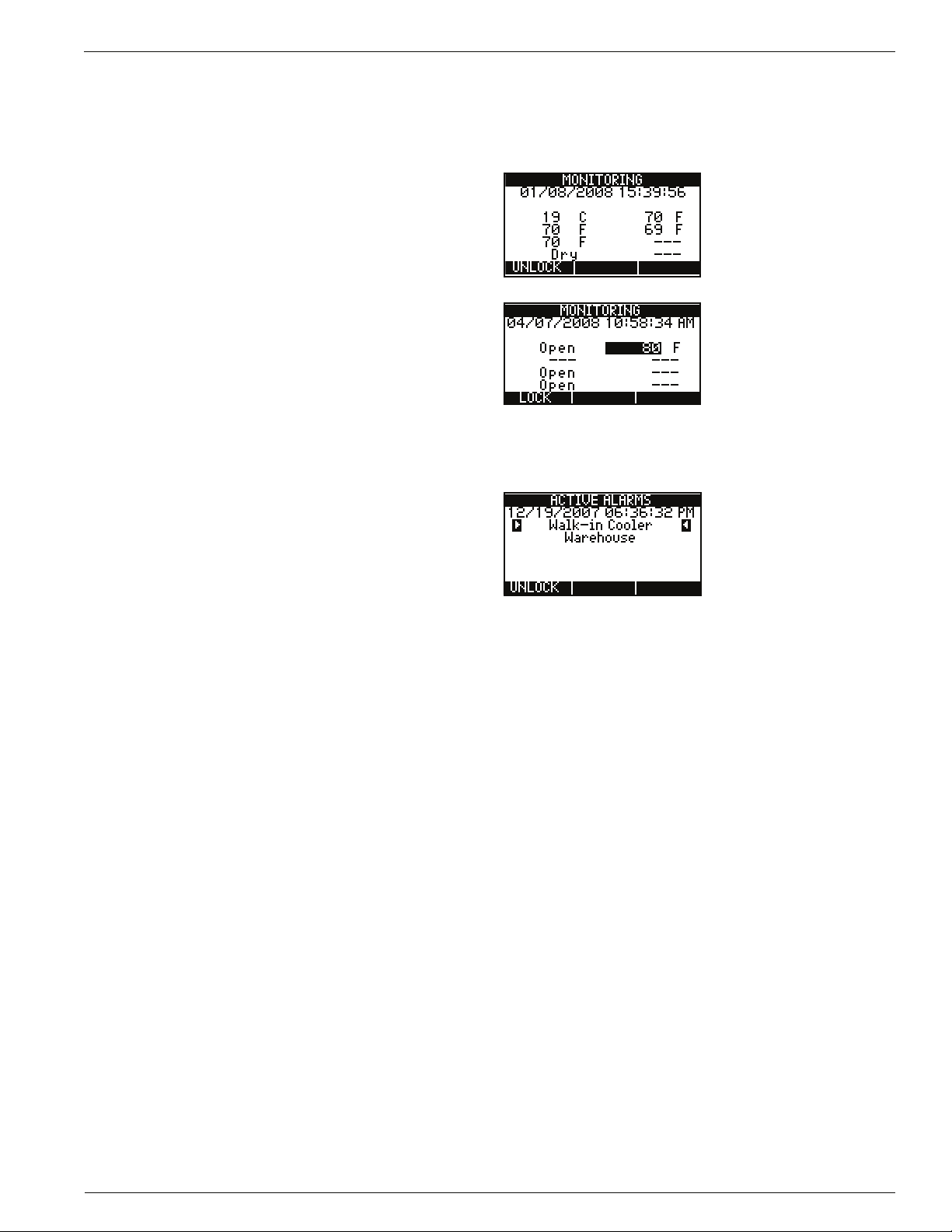

Monitoring Screens

The EA800 user interface is menu-based. During normal system monitoring, one of the following three screens is

displayed depending on the current state of the programmed sensors:

The MONITORING (home) screen is displayed

when there are no active alarms. The screen lists

all programmed sensors connected to the base

unit and their current reading or state.

The MONITORING (home) screen displays pending

alarms in reverse video as shown in the example

at right (71° exceeds the temperature limit for

Sensor 2, so it is shown as light text on black).

Pending alarms indicate that the programmed limits for the sensor have been exceeded, but the

sensor’s programmed delay time has not elapsed

yet. If the monitored conditions continue to

exceed the programmed limits for longer than the

programmed delay period, the pending alarm will

become an active alarm.

The ACTIVE ALARMS screen is shown when one or

more sensors are in an active alarm or warning

state. If more than one alarm is active, each will

be listed on the screen. In the example shown,

Walk-in Cooler and Warehouse alarms are

occurring simultaneously.

-

-

Page 10

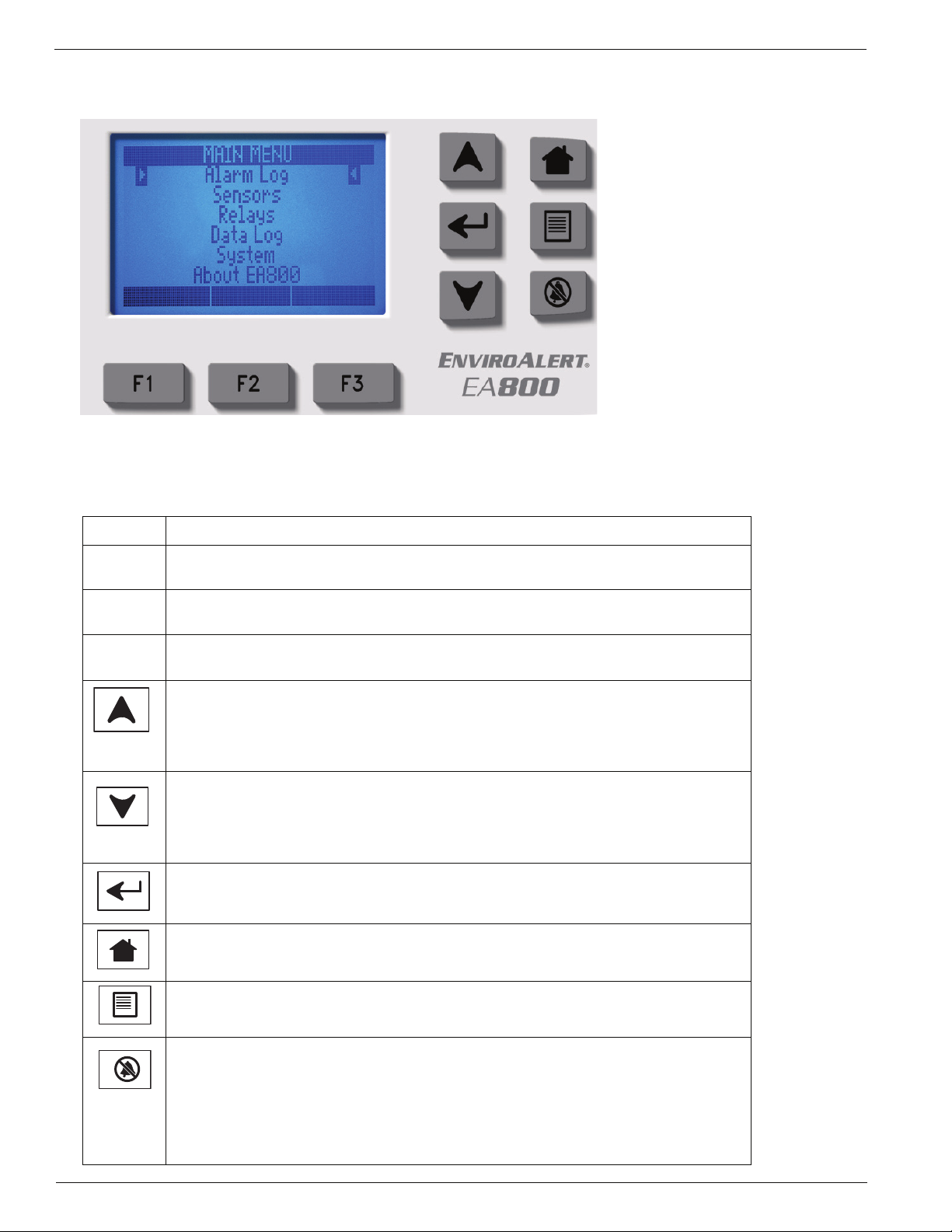

Keys

Keys

Figure 4 shows the base unit display and entry keys. The keys are described in Table 2.

Figure 4 EA800 Base Unit Keys

Table 2 Key Functions

Key Function

F1 This key's function changes as determined by the software. Its current function is

displayed immediately above the key on the display.

F2 This key's function changes as determined by the software. Its current function is

displayed immediately above the key on the display.

F3 This key's function changes as determined by the software. Its current function is

displayed immediately above the key on the display.

Up Arrow: This key provides the scroll up function. It moves the selection cursor up

a list or increments the value of alphanumeric entry fields as identified by the flashing cursor. The values provided are dependent on the currently active field. For

example, the available selections may be a + or - sign, numbers, or alphanumeric

characters and special characters.

Down Arrow: This key provides the scroll down function. It moves the selection

cursor down a list or decrements the value of alphanumeric entry fields as identified

by the flashing cursor. The values provided are dependent on the currently active

field. For example, the available selections may be a + or - sign, numbers, or alphanumeric characters and special characters.

ENTER key. This key accepts the currently entered selection when pressed. If the

selection is a menu item, the selected item is accessed. If the current selection is an

entered value, pressing the ENTER key accepts the entered value.

HOME key. This key displays the home screen (MONITORING) when pressed.

MENU key: Displays the MAIN MENU screen when pressed from any menu level or

from the home screen.

SILENCE key: Alarms cannot be cleared and will continue to recur until the moni-

tored conditions detected by the sensors are within the programmed parameters.

Pressing the SILENCE key temporarily silences the local audible alarm and deactivates the auxiliary relay for 10 minutes.

If a new alarm originating from a different sensor occurs within this 10-minute

period, the audible alarm and aux relay are reactivated, and require another key

press to silence the audible alarm.

6 D-011-0152

Page 11

General Information

CAUTION

!

CAUTION

!

Powe r

In

Aux

Powe r

Out

J6

J5

Input 1 Input 2 Input 3 Input 4

J13 J14

J2

J10J8 J9

Output 1 Output 2 Output 3 Output 4 Output 5 Output 6 Output 7 Output 8 Aux

NO COM NC NO COM NC NO COM NC NO COM NC NO COM NC NO COM NC NO COM NC NO COM NC NO COM NC

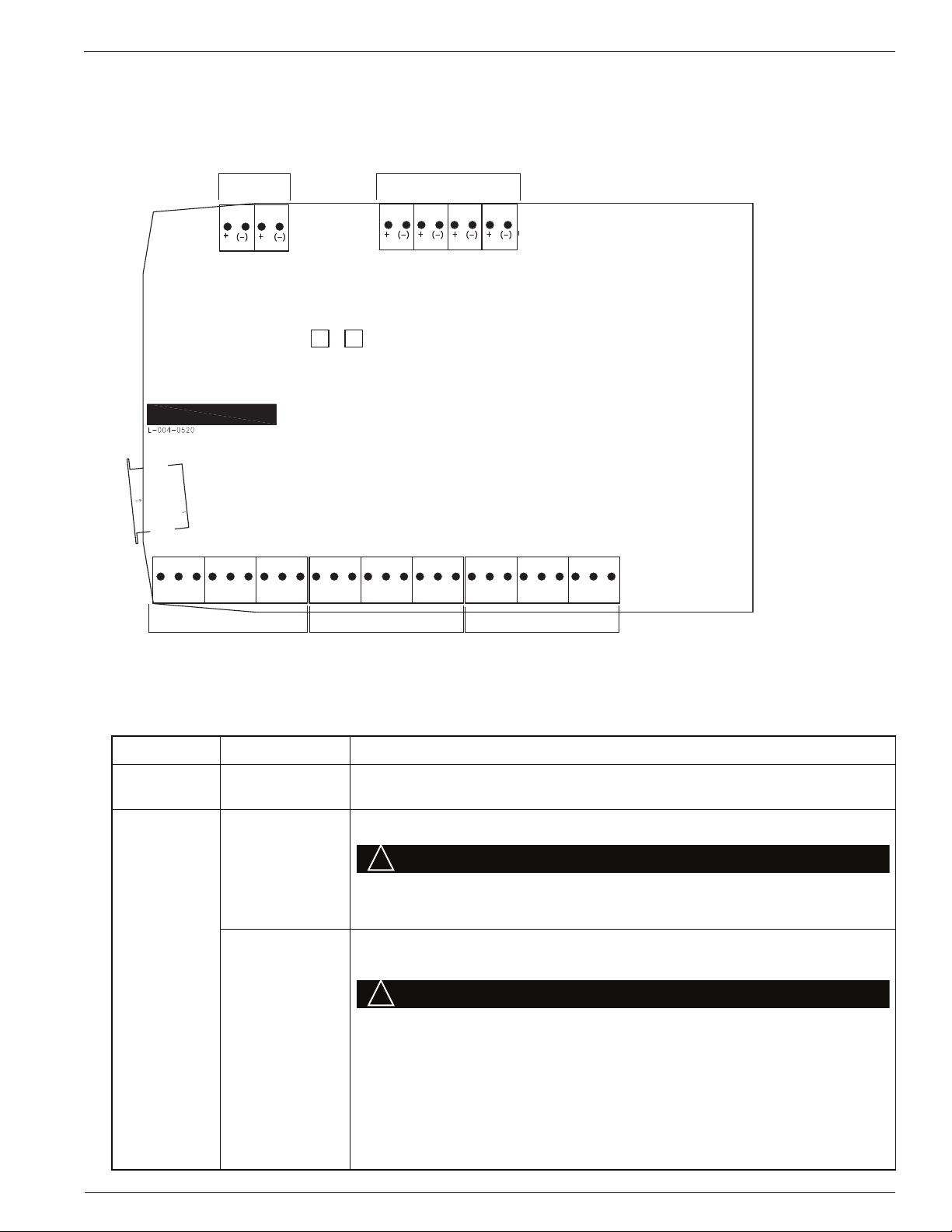

Base Unit Connections

Figure 5 shows the EA800 base unit's connections and Table 3 describes the functions of each connection.

Note: The base unit has four wired sensor inputs and four wireless RF sensor inputs.

Figure 5 EA800 Base Unit Connections

Table 3 EA800 Base Unit Connector Functions

Connector Designation Function

J2 USB USB Type A connection used to program firmware, export logs, and export

and import configuration files. www.winland.com lists compatible USB sticks.

J5 Power In 11-26 VDC input power connection for EA800 base unit (from accessory

power supply or alarm panel).

CAUTION

Observe (+) and (-) polarity markings screened on circuit board. EA800

can be damaged if power polarity is reversed.

Aux Power Out 11-26 VDC power out connection for EA800 accessories requiring power

(such as HA-III+ Humid Alert). This output voltage equals that of Power In and

is current-limited to a maximum of 500 mA.

CAUTION

Connect only accessories specified in this manual to the Aux Power Out

connection. Connection of unsuitable loads to this connection may

damage the power supply and EA800, or result in improper or unreliable

operation.

Note: Accuracy for the HA-III+ sensor is stated at +12VDC input.

If Aux Power Out is used to power the HA-III+ and is not

+12VDC, then the accuracy of the HA-III+ is compromised.

-

-

Page 12

Access Control and Passwords

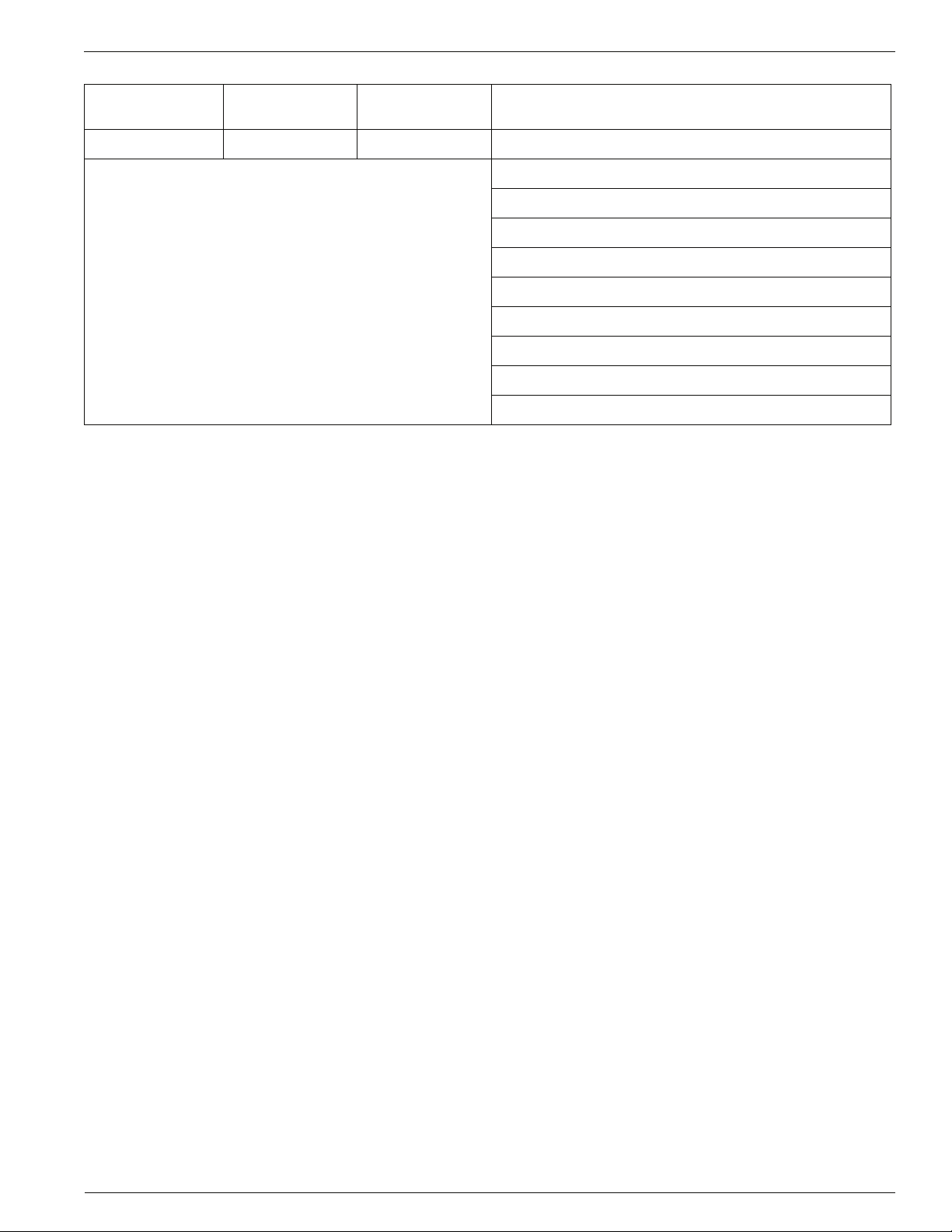

Table 3 EA800 Base Unit Connector Functions — continued

Connector Designation Function

J6 INPUT 1 Wired input for Relay 1 external temperature, water, 4-20mA, contact closure,

or humidity sensor.

INPUT 2 Wired input for Relay 2 external temperature, water, 4-20mA, contact closure,

or humidity sensor.

INPUT 3 Wired input for Relay 3 external temperature, water, 4-20mA, contact closure,

or humidity sensor.

INPUT 4 Wired input for Relay 4 external temperature, water, 4-20mA, contact closure,

or humidity sensor.

J8 OUTPUT 1 Form C relay alarm output for Relay 1.

OUTPUT 2 Form C relay alarm output for Relay 2.

OUTPUT 3 Form C relay alarm output for Relay 3.

J9 OUTPUT 4 Form C relay alarm output for Relay 4.

OUTPUT 5 Form C relay alarm output for Relay 5.

OUTPUT 6 Form C relay alarm output for Relay 6.

J10 OUTPUT 7 Form C relay alarm output for Relay 7.

OUTPUT 8 Form C relay alarm output for Relay 8.

AUX OUT Form C relay output that activates upon an alarm from any of the relays

(Relay 1 through Relay 8).

J13 Antenna RF receive and transmit

J14 Antenna RF receive and transmit

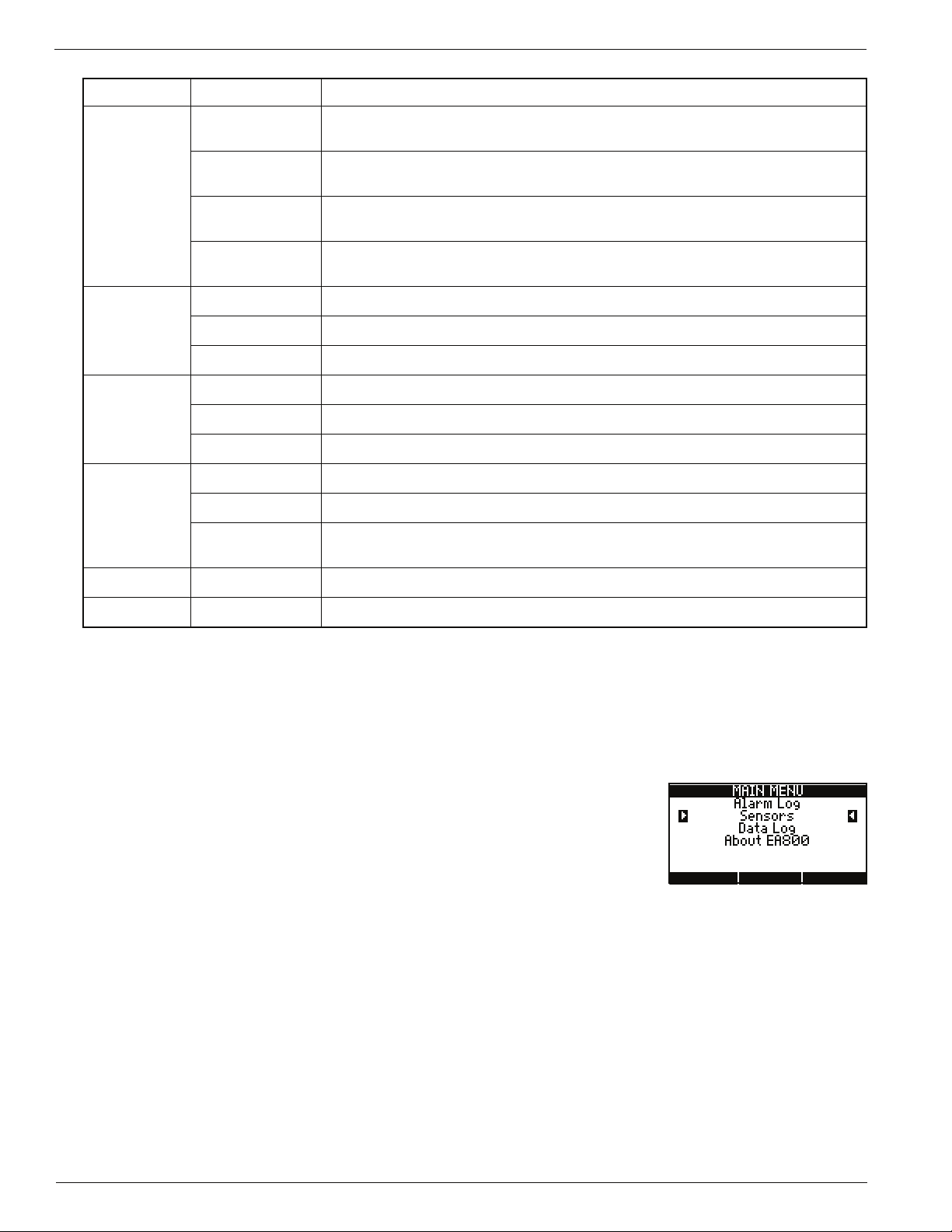

Access Control and Passwords

The EA800 base unit is normally locked to prevent unauthorized use. The currently active function of the F1 soft

key (UNLOCK or LOCK) is displayed above the key. The locked and unlocked states are described below.

Note: The base unit locks automatically after 30 minutes of inactivity if the user does not press the LOCK soft

key (F1).

■ Locked: This is the default state and limits access to the EA800 to viewing only.

UNLOCK is displayed above the F1 soft key indicates that the base unit is

currently locked. Pressing the F1 soft key prompts the user to enter a password

to unlock the base unit, permitting full access to all screens and functions. The

HOME key, MENU key, and the MAIN MENU options shown on the screen at right

are available to the user when the base unit is locked.

■ Unlocked: When the base unit is unlocked, LOCK displayed above the F1 soft key, and all information,

programming, and maintenance screens may be viewed and programming changes may be made. Pressing

the F1 soft key locks the EA800 base unit and protects it from unauthorized or unintended programming

changes, log downloads, and firmware uploads.

The base unit allows the use of two passwords for unlocking:

■ The factory default password is 0800. This password cannot be changed or deleted.

■ A second, optional password may be set by the user. To create a second user password, see “Changing the

Password” on page 63.

8 D-011-0152

Page 13

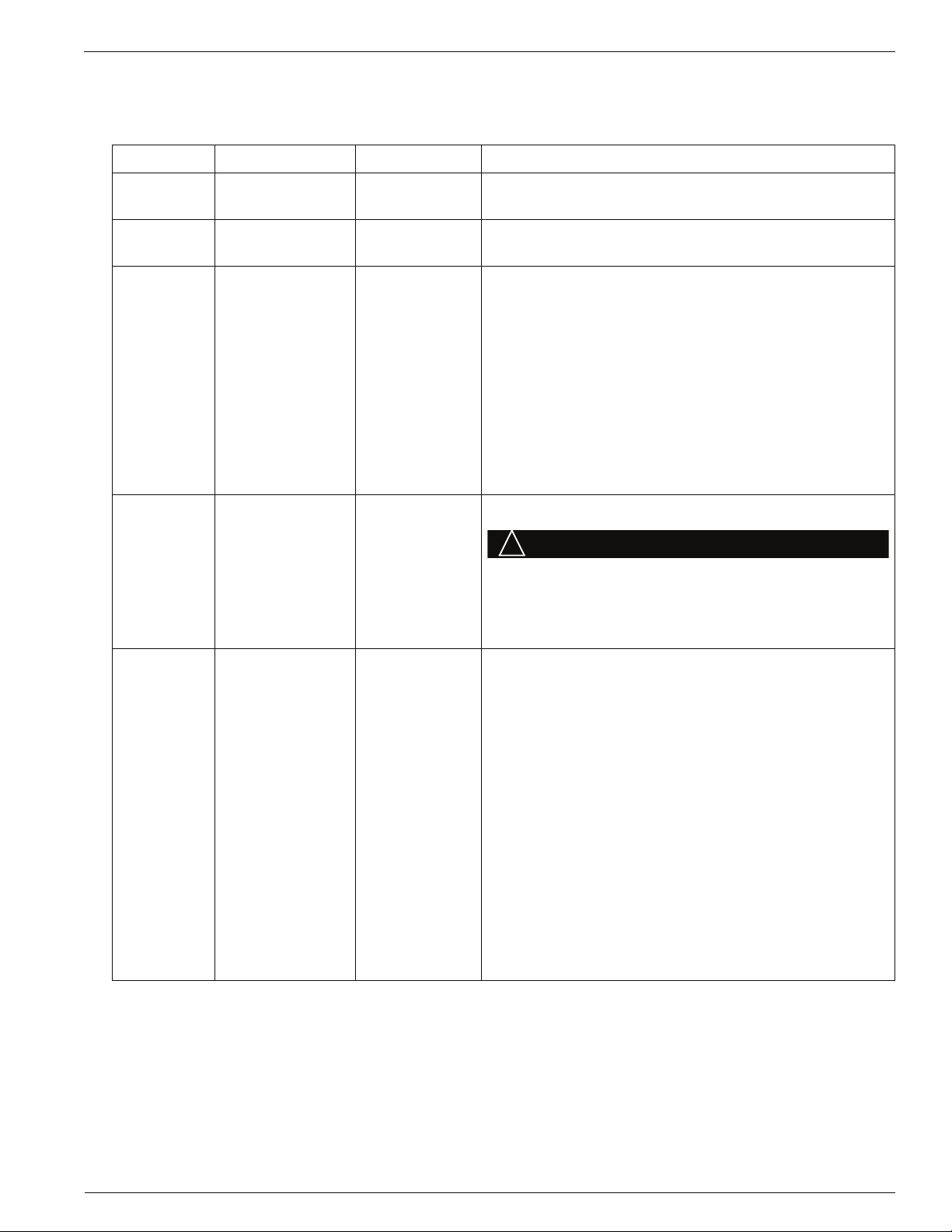

System Configuration Parameters

WARNING

!

The EA800 base unit requires certain system level information as outlined in Table 4.

Table 4 System Configuration Parameters

Parameter Selections Factory Default Description

General Information

Date Format • MM/DD/YYYY

• DD/MM/YYYY

Time Format • 12-hour

• 24-hour

Data Collection Frequency

Buzzer • Enable

• 30 seconds

• 1 minute

• 5 minutes

• 15 minutes

• 30 minutes

• 60 minutes

•Disable

MM/DD/YYYY Sets the desired date format for all event time stamps.

24-hour Sets the desired time format for all event time stamps.

5 minutes Sets the interval for collecting and recording data from the

sensors. The data collection frequency applies to all sensors.The EA800 provides approximately 10,000 data

points to be collected regardless of the frequency

selected. The estimated time duration covered for each

data collection frequency is listed below.

30 seconds = 3.5 days

1 minute = 1 week

5 minutes = 1 month

15 minutes = 3 months

30 minutes = 6 months

60 minutes = 1 year

Enabled Enables and disables the buzzer when an alarm limit has

been exceeded or a warning condition exists.

Selecting Disable for this parameter turns the audible

alarm buzzer off completely. No audible alarm tone

will sound when an alarm occurs if DISABLE is

selected.

RF Channel 11 (2405 MHz)

12 (2410 MHz)

13 (2415 MHz)

14 (2420 MHz)

15 (2425 MHz)

16 (2430 MHz)

17 (2435 MHz)

18 (2440 MHz)

19 (2445 MHz)

20 (2450 MHz)

21 (2455 MHz)

22 (2460 MHz)

23 (2465 MHz)

24 (2470 MHz)

25 (2475 MHz)

26 (2480 MHz)

channel 16 Selects the ISM band radio frequency (RF) channel for

transmission between the wireless sensors and EA800

base unit.

-

-

Page 14

Sensors

Sensors

A variety of sensors may be used with the EA800 base unit to provide environmental status and information. These

include the following:

■ Wired Sensors: Relays 1 through 4 are for use with sensors wired to the base unit. Wired sensors can be any

of the following types:

• Low temperature sensors - Blue Thermistor Probes

• High temperature sensors - Red Thermistor Probes

• Ultra Low temperature sensors - White Thermistor Probes

• HA-III+ humidity sensor

• Water Bug sensor (supervised)

• N.O. Contact

• N.C. Contact

• 4-20 mA

■ Wireless Sensors: Relays 5 through 8 are for use with wireless sensors. These sensors transmit to the EA800

base unit through RF links. Each wireless sensor is hard-coded with an address the base unit uses to identify

the sensors installed in the system. When you program the system you assign each installed wireless sensor

to a relay using its hard coded address. Wireless sensors can be any of the following types:

• Wireless Humidity Sensor (EA-WHS)

• Wireless Temperature Sensor (EA-WTS)

• Wireless Multi-Function Sensor (EA-WMFS): Any of the following wired sensors can be connected to the

wireless multi-function sensor, effectively converting the wired sensor to wireless:

• Low temperature sensors - Blue Thermistor Probes

• High temperature sensors - Red Thermistor Probes

• Ultra Low temperature sensors - White Thermistor Probes

• Water Bug sensor (supervised)

• Normally Open (NO) Contact

• Normally Closed (NC) Contact

Temperature Sensors

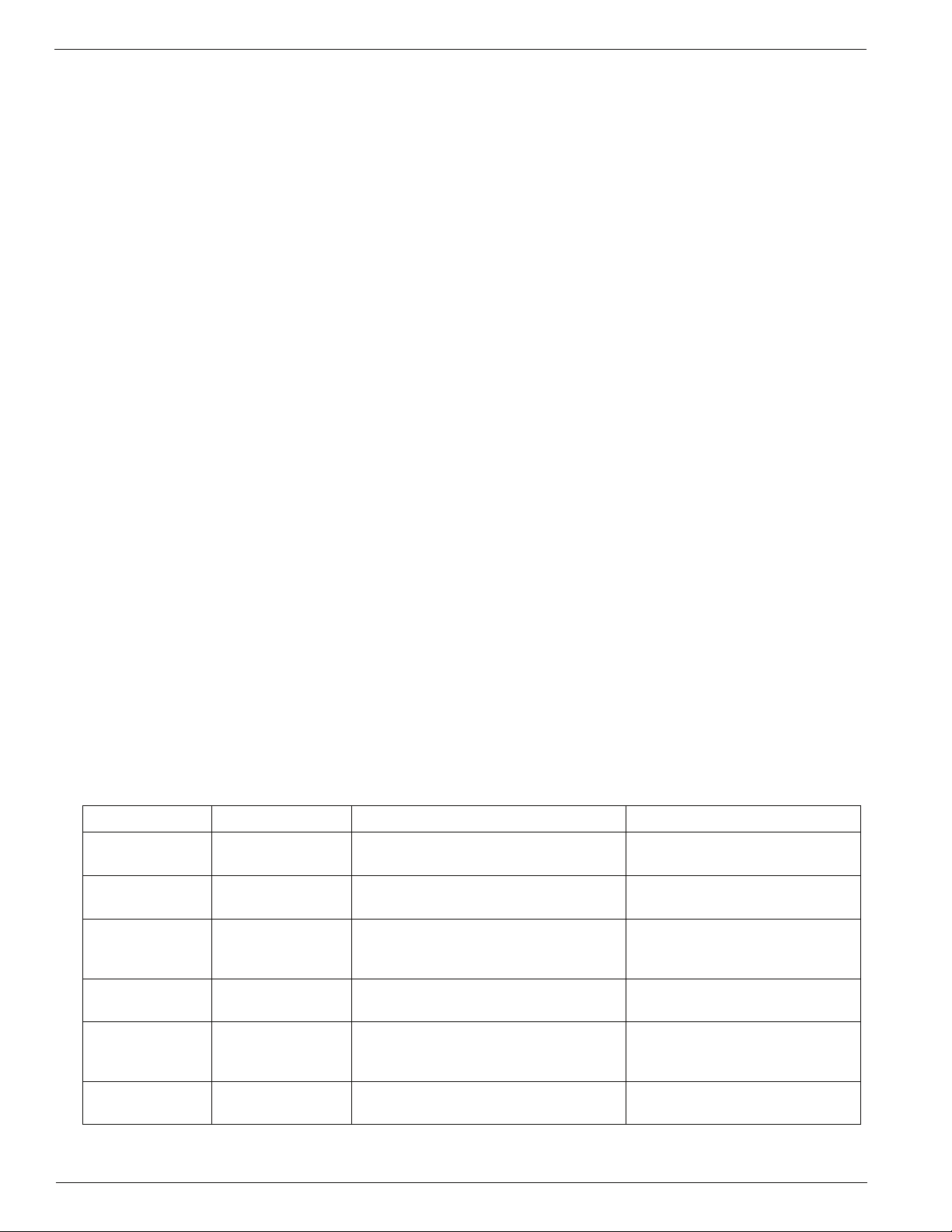

Table 5 lists the temperature sensors available for use with the EA800 Alarm System.

Table 5 EA800 Compatible Temperature Sensors

Sensor Part Number Description Operating Range/Parameters

High Temp Red,

Stainless Steel

Low Temp Blue,

Stainless Steel

Low Temp Blue,

waterproof

High Temp Red,

waterproof

Ultra Low Temp

White, Stainless

Steel

Wireless Temp PN M-001-0125 Stand alone wireless temperature

PN M-001-0081 Thermistor, Stainless Steel Probe,

High Temperature Sensor

PN M-001-0082 Thermistor, Stainless Steel Probe,

Low Temperature Sensor

PN M-001-0086 Thermistor, waterproof, low tempera-

ture sensor. For use in coolers and

freezers.

PN M-001-0087 Thermistor, waterproof, high tempera-

ture sensor

PN M-001-0111 Thermistor Stainless Steel Probe,

Ultra Low Temperature Sensor

sensor

0° C to 150° C

(32° F to 302° F)

-50° C to 70° C

(-58° F to 158° F)

-50° C to 70° C

(-58° F to 158° F)

0° C to 150° C

(32° F to 302° F)

-80° C to 0° C

(-112° F to 32° F)

0° C to 50° C

(32° F to 122° F)

10 D-011-0152

Page 15

General Information

+

DC

+

-

4.0V200O

Aux Power

J5

+

(-)

+

(-)

Input N

J6

+

-

Vsensor

4-20mA

Transmitter

EA800

Max Load of

200O includes

1000' of 22 AWG

(2 conductor)

wire connecting

the EA800 to the

4-20mA sensor

If Vsensor = 8V and Aux Power = 12V

+

DC

External

Supply

+

-

4.0V200O

Aux Power

J5

+

(-)

+

(-)

Input N

J6

+

-

Vsensor

4-20mA

Transmitter

EA800

Max Load of

200O includes

1000' of 22 AWG

(2 conductor)

wire connecting

the EA800 t o the

4-20mA sensor

If Vsensor > 8V and Aux Power = 12V

Humidity Sensors

Table 6 lists the humidity sensors available for use with the EA800 Alarm System.

Table 6 EA800 Compatible Humidity Sensors

Sensor Part Number Description Operating Range/Parameters

HA-III+ PN M-001-0091 Humidity monitoring module 5% to 95% rh

(non-condensing)

Wireless

Humidity

PN M-001-0126 Wireless humidity monitoring

module

5% to 95% rh

(non-condensing)

4-20mA Sensors

Theory of Operation

Industry standard 4-20mA sensors can be used with the EA800. However, it is important to verify that this type of

sensor will operate properly over the entire output range.

Figure 6 shows an example of the loop circuit for a 4-20mA sensor whose minimum operating voltage is 8V or less

when connected to an EA800 base unit that is powered with 12VDC.

Figure 7 shows an example of the loop circuit for a 4-20mA sensor whose minimum operating voltage is greater

than 8V when connected to an EA800 base unit that is powered with 12VDC.

-

-

Figure 6 I4-20mA Sensor Wiring Diagram - EA800 Aux Power Supply

Figure 7 4-20mA Sensor Wiring Diagram - External Power Supply

Page 16

Sensors

Power Supply / Sensor Voltage Selection

In order to determine the power supply voltage necessary to ensure correct full-scale operation, it is necessary to

identify all voltage drops within the current loop.

Figures 6 and 7 show an EA800 drop of 4.0 VDC. This value accounts for the voltage drop generated by

connecting the 4-20mA sensor to the EA800 using 1000 feet of 22 AWG wire.

Now it is only necessary to identify the operating voltage range of the 4-20mA sensor, more importantly the

minimum operating voltage. Once identified, the minimum operating voltage of the sensor can be added to the

4.0V voltage drop of the EA800 (+ wire) to determine the power supply voltage necessary to ensure correct

full-scale operation.

Example:

■ Assume that a 4-20mA sensor whose operating input voltage range is 10 – 30V has been selected for use.

Therefore the minimum operating voltage of the sensor is 10V (V

). When the 4.0V drop of the EA800

sensor

(and wire) is added, it can be determined that at least 14VDC is needed to power the loop.

■ If the EA800 is connected to a 12VDC power supply, use of the sensor in this example requires an external

power supply of at least 14V as shown in Figure 7.

It is important to not exceed the maximum operating voltage of the 4-20mA sensor, as specified within the sensor’s

product specification.

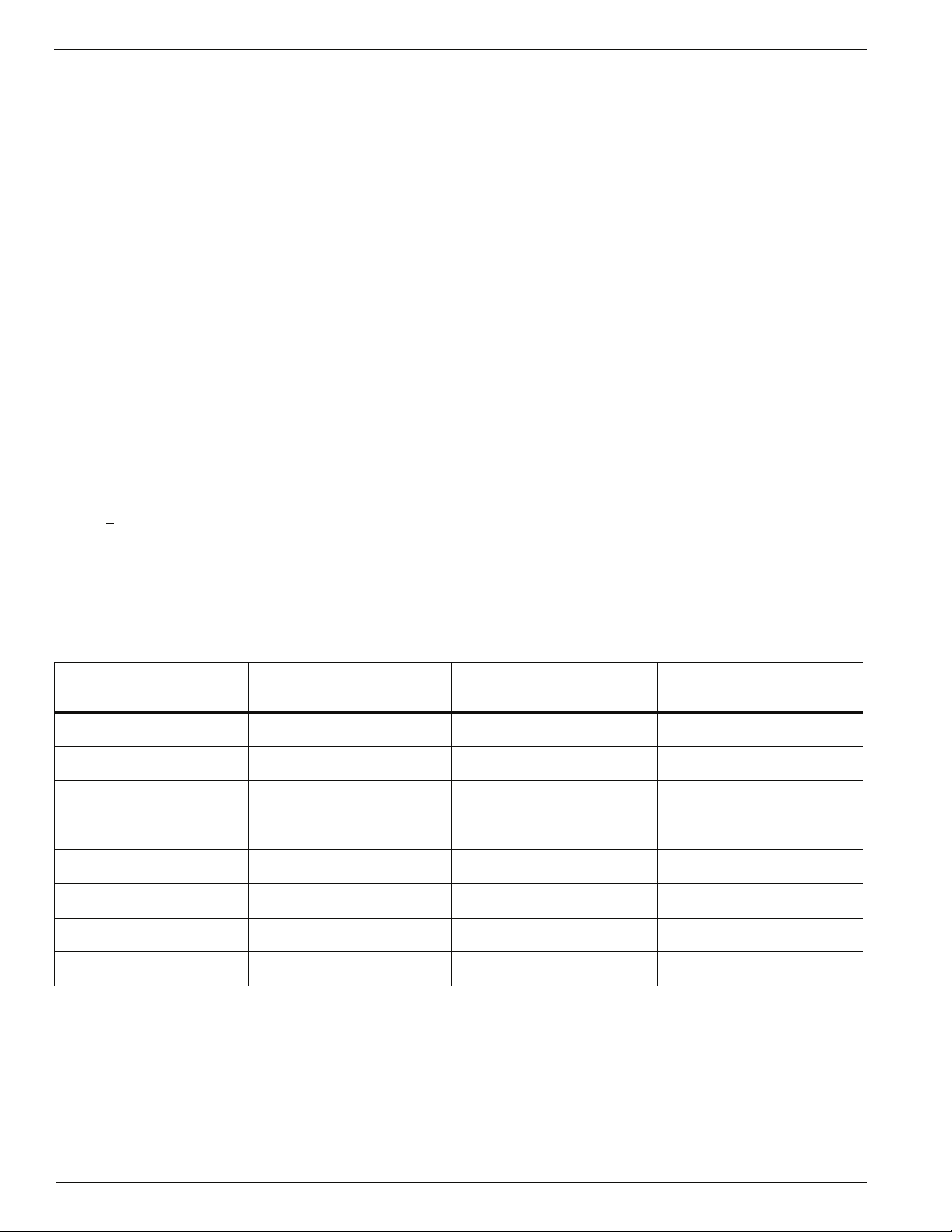

The following formula provides the basis for the selection matrix shown in Table 7. Please use Table 7 to select

either the proper sensor rating to be used with a known power supply, or select a power supply for a known sensor

rating.

R

< (Vcc – x) .023

L

where:

■ R

= Loop resistance of 200

L

■ V

= Power supplied to EA800 or Aux Power Out

cc

■ X = Sensor voltage (max)

Table 7 4-20mA Voltage Select Matrix

Power Supplied to EA800

or AUX. Power Out

V

(max.) [Maximum

sensor

sensor voltage rating]

Power Supplied to EA800 or

AUX. Power Out

V

sensor

sensor voltage rating]

11 VDC 7 VDC 19 VDC 15 VDC

12 VDC 8 VDC 20 VDC 16 VDC

13 VDC 9 VDC 21 VDC 17 VDC

14 VDC 10 VDC 22 VDC 18 VDC

15 VDC 11 VDC 23 VDC 19 VDC

16 VDC 12 VDC 24 VDC 20 VDC

17 VDC 13 VDC 25 VDC 21 VDC

18 VDC 14 VDC 26 VDC 22 VDC

(max.) [Maximum

12 D-011-0152

Page 17

General Information

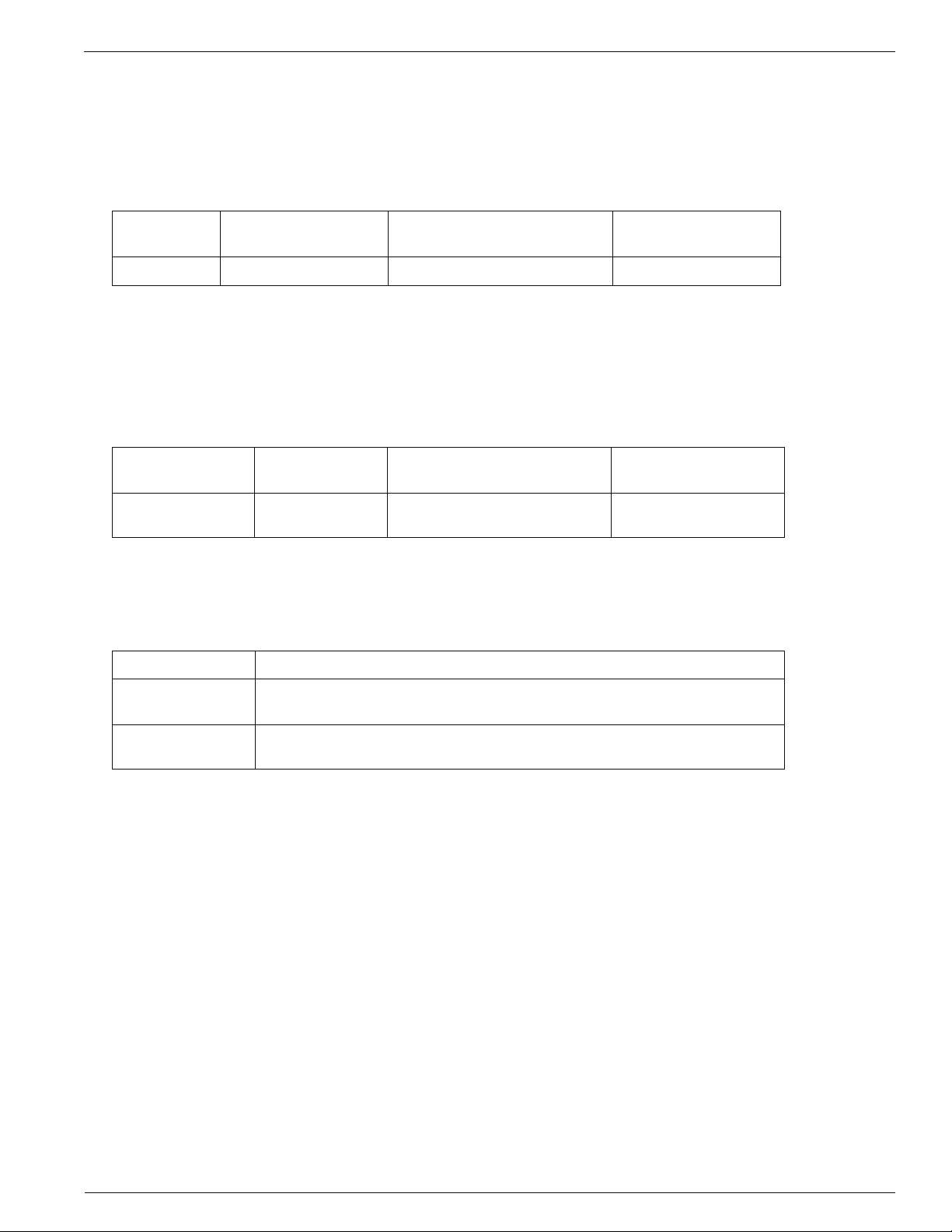

Water Sensors

Table 8 lists the water sensors available for use with the EA800 Alarm System.

Use of water sensors requires that at least one supervised water sensor be used. Up to five additional

unsupervised water sensors may be added in parallel on the same input where the supervised water sensor is

configured.

Table 8 EA800 Compatible Water Sensors

Operating

Sensor Part Number Description

Water Bug PN M-001-0094 Supervised water sensor

1

Range/Parameters

NA

1 Water sensors are not effective nor intended for use in distilled or deionized water.

Multi-Function Sensors

Multi-function wireless sensors may be connected to a wired sensor to act as a transmitter. Table 9 lists the

multi-function sensor available for use with the EA800 Alarm System.

Table 9 EA800 Compatible Multi-Function Sensors

Operating

Sensor Part Number Description

Range/Parameters

Wireless

Multi-Function

PN M-001-0127 Wireless link for sensors. See

page 16 for allowed sensors.

Dependent on sensor

connected.

Contact Closure Sensors

Table 10 lists the contact closure sensors compatible for use with the EA800 Alarm System.

Table 10 EA800 Compatible Closure Sensors

Sensor Description

NO closure Normally open contact closure such as door contacts, motion detectors,

NC closure Normally closed contact closure such as door contacts, motion detectors,

and glass break sensors

and glass break sensors

-

-

Page 18

Sensors

Sensor Parameter Descriptions

This section provides a description of each sensor parameter.

Table 11 Sensor Parameter Descriptions

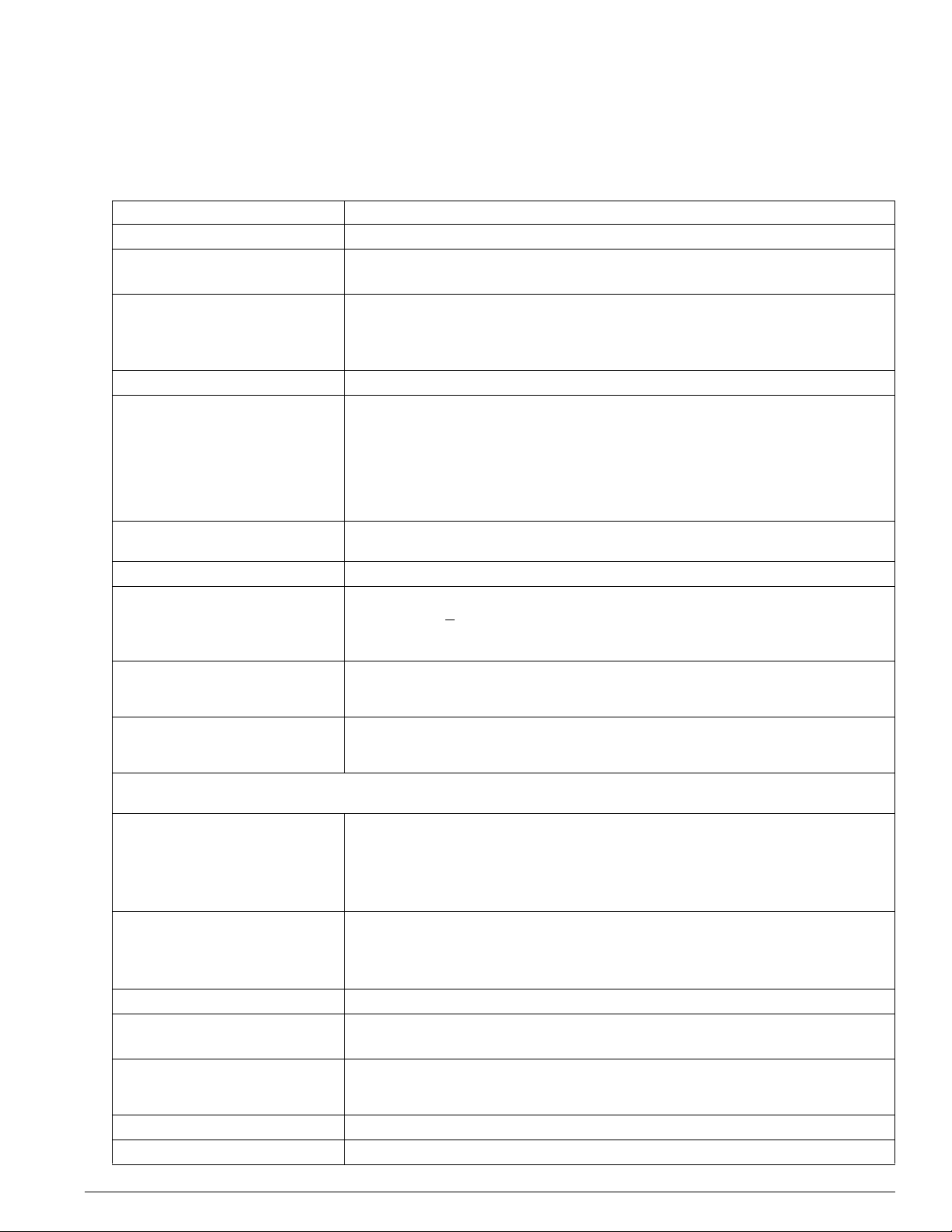

Parameter Applicable to Sensors Description

Sensor Name All A name used to identify the sensor in the alarm system. Select a name

readily identified by the viewer. The sensor name is displayed on the

Main screen during a no-alarm condition and on the Alarm screen during

an alarm condition. Two name choice types are available:

• Common Name: These are preprogrammed names.

• Custom Name: This selection allows you to enter any name if the

preprogrammed common names do not adequately identify the sensor

in the system (limited to 16 characters).

Note: Duplicate sensor names are not permitted.

Unit of

Measure

• Blue, Red and White

temperature sensors

• 4-20mA sensor

• Wireless

temperature sensors

This parameter allows you to choose the unit of measure used for sensor reading and display.

• Blue, Red and White temperature sensors: °C or °F

• 4-20mA sensors: the following Common Units of measure are

available: F (Fahrenheit), C (Centigrade), K (Kelvin), % rh (percent

relative humidity), psi (pounds per square inch), Pa (Pascals), kPa

(kiloPascals), lb (pound), kg (kilogram)

• 4-20mA sensors can also use custom units. Enter the appropriate units

for the connected 4-20mA sensor via the keypad.

Resolution 4-20mA sensor This determines the range that may be used for the 4-20mA sensor. The

full scale range is determined by the values entered in the Low Scaled

Value and the High Scaled Value. You must select the correct resolution

in order to set the true range limits for the 4-20mA sensor you are installing. The available values are as follows:

Maximum Allowed Maximum Allowed

Resolution Low Scaled Value High Scaled Value

1. -9999. +9999.

0.1 -999.9 +999.9

0.01 -99.99 +99.99

0.001 -9.999 +9.999

Low Scaled

Value

4-20mA sensor This parameter equals the environmental reading that results in a sensor

output of 4mA or its minimum valid reading. This is dependent on the

setting of the resolution as discussed above.

High Scaled

Value

4-20mA sensor This parameter equals the environmental reading that results in a sensor

output of 20mA or its maximum valid reading. This is dependent on the

setting of the resolution as discussed above.

Hysteresis • Blue, Red and White

temperature sensors

• HA-III+

• 4-20mA sensor

The Hysteresis setting helps prevent alarms from being set and reset

continually if the environment is at or near the alarm set point by providing an acceptable variance. For example, if Hysteresis is set at 2 and the

sensor High limit is set at 50, the sensor reading must decrease to 48

(50 minus 2) in order for the alarm condition to reset to a no-alarm condition.

Low Alarm

Limit

• Blue, Red and White

temperature sensors

The Low Alarm Limit sets the value that trips the low alarm when

exceeded.

• HA-III+

• 4-20mA sensor

• Wireless humidity

sensor

• Wireless

temperature sensor

14 D-011-0152

Page 19

Table 11 Sensor Parameter Descriptions — continued

NC

NO

To

alarm

panel

From

EA800

logic

Idc

C

NC

NO

To

alarm

panel

From

EA800

logic

Idc

C

NC

NO

To

alarm

panel

From

EA800

logic

Idc = 0

C

Parameter Applicable to Sensors Description

General Information

High Alarm

Limit

• Blue, Red and White

temperature sensors

The High Alarm Limit sets the value that trips the high alarm when

exceeded.

• HA-III+

• 4-20mA sensor

• Wireless humidity

sensor

•Wireless

temperature sensor

Alarm Delay

Time

All This sets the time period that an alarm condition can exist before the

alarm is triggered. This is useful for helping to prevent false alarms from

occurring in situations where normal activities cause conditions to temporarily exceed alarm thresholds. For example, the temperature in a

freezer may temporarily rise above the High alarm limit while frozen food

is being restocked and the freezer door is open, but the delay prevents

the alarm from going off unless the temperature fails to cool below the

alarm threshold within the alarm delay period.

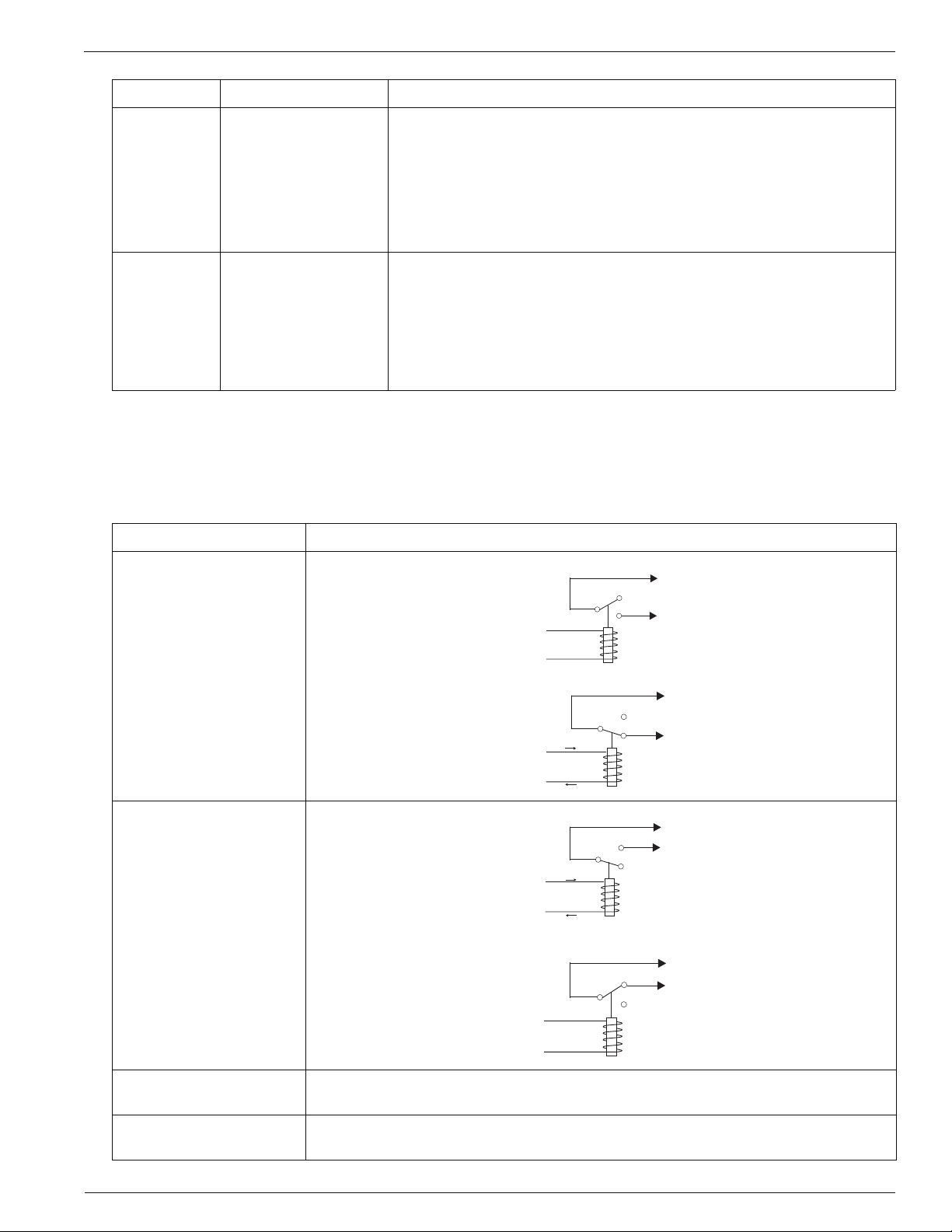

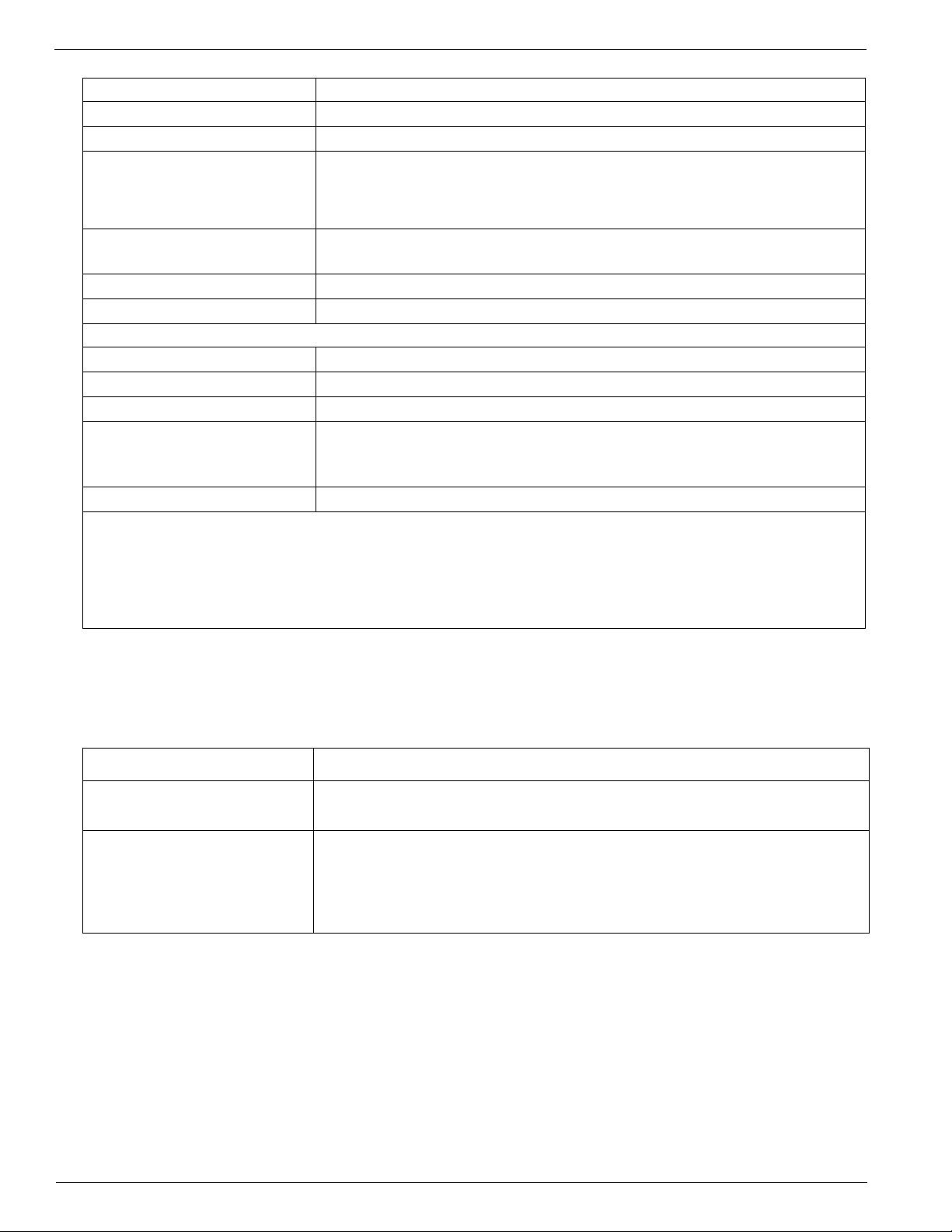

Relay Operation

This section describes the operation of the base unit's relays. The relays must be programmed correctly so that

their outputs provide the desired signaling to the alarm panel.

Table 12 Relay Configuration Settings

Relay Setting Description

No Alarm

Relay State:

De-Energized (default)

No Alarm: Power is removed from the relay coil as shown below.

To

NC

NO

alarm

panel

From

EA800

logic

C

Idc = 0

No Alarm

Relay State: Energized

Active Condition:

Alarm Only

Active Condition:

Alarm or Warning (default)

-

-

Alarm: Power is applied to the relay coil as shown below.

No Alarm: Power is applied to the relay coil as shown below.

Alarm: Power is removed from the relay coil as shown below. This provides for a

default alarm if the EA800 loses power in addition to the sensors' alarms.

Sets the alarm to be active when an alarm condition exists.

Sets the alarm to be active when an alarm condition exists or a warning is active.

Page 20

Relay Operation

16 D-011-0152

Page 21

Preparation

CAUTION

!

CAUTION

!

CAUTION

!

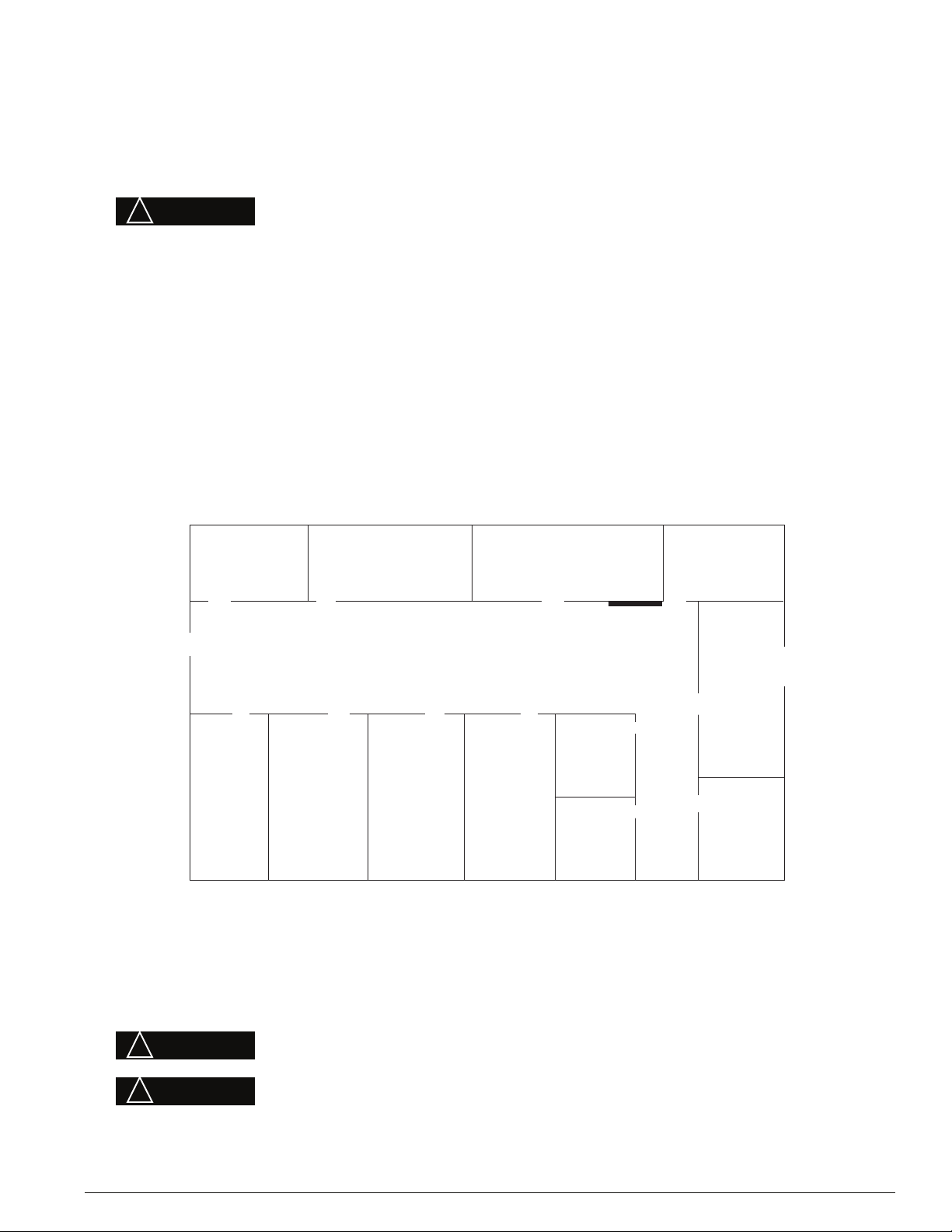

Before you begin installation, ensure that you properly plan the alarm system. During the planning phase you will

generate all the documentation you need to successfully install the EA800 base unit and sensors in the alarm

system. This is important because complete and accurate installation documentation aids in system maintenance

later.

If the EA800 base unit will be connected to a remote alarm panel, do not connect

the base unit to the alarm panel until after sensor connection and configuration

is complete. Connecting the remote alarm panel before configuring the EA800

sensors will result in false alarms at the remote panel.

The suggested preparation procedure is as follows:

1. Read and understand the entire manual. General Information provides important information required to

properly plan, install, and use the EA800. The preparation phase helps ensure that the EA800 system will

function as required.

2. Photocopy the pages of Appendix B: Planning Worksheet, Appendix C: EA800 Wiring Diagram (one for each

EA800 base unit in the system), and Appendix D: System Configuration Record to create a record of the

specific EA800 alarm system installation you are currently working on.

3. Draw a floor plan for the facility where you will install the EA800 alarm system. Identify important details such

as the coolers, doors, computer rooms, etc. An example is shown below.

Cooler1

Cooler 2

Storage Room 3 Computer

Room

Rear

Entry

Freezer 1

4.

Locate the base unit where authorized personnel can readily access it. If required, consideration should be

Freezer 2 Room 1

Figure 8 Example Floor Plan

Room 2

Women's Room

Alarm panel

installation area

Men's Room

Front

Entry

Front Desk

Conference Room

made regarding a location that discourages unauthorized access. If using wireless sensors, locate the base

unit to minimize the wireless distance. Ensure that the desired mounting locations for the EA800 base unit and

each sensor comply with the environmental specifications listed in Table 13: Specifications.

Do not install the EA800 base unit in coolers or freezers.

Use only wired sensors specified in this manual for the INPUT 1 through INPUT 4

connections. Unverified sensors may damage the EA800 or result in improper or

unreliable operation.

-

-

Page 22

5. Complete the copy of Appendix B: Planning Worksheet for the facility in which the EA800 system is to be

WARNING

!

CAUTION

!

installed. This must include all monitored areas for the total security system so that you know how many EA800

base units are needed.

6. Determine the sensors required from the Planning Worksheet you completed and the information provided for

each sensor type in “System Configuration”. Enter these in the copy of the System Configuration Record you

made.

Note: When water sensors are required, you must use at least one supervised water sensor and may add up to

five additional unsupervised water sensors, all in parallel. Thus, an alarm on any sensor will result in an

alarm with no way to determine which sensor is the source.

7. Enter the sensor information in the copy of the EA800 Wiring Diagram you made. It is a good idea to name

each sensor on this diagram and use that name in both the EA800 Wiring Diagram and the System

Configuration Record. This helps ensure proper programming of the system after you have physically installed

the system.

EA800 relay outputs are intended only for use as low-voltage, low-current

alarm connections, and not for direct switching or control of AC-mains

powered loads. Additionally, local codes may further dictate or limit the types

of loads and associated wiring to be used with the low-current Form C relay

outputs used with the EA800. Connecting AC-mains type circuits to the EA800

may result in an electric shock and/or fire hazard.

Do not connect a load to the AUX OUT or OUTPUT 1 through OUTPUT 8 relay

outputs that exceeds limitations stated in the Specifications section of this

manual. Loads exceeding the specified limitations may damage the EA800, or

result in improper or unreliable operation.

8. Using the floor plan you created, identify the specific locations for each sensor and verify that their locations

meet the specifications. See Specifications for operational parameters such as cable length.

Note: For 4-20mA sensors: See 4-20mA Sensors for a discussion of determining the constraints for your

4-20mA sensor to ensure accuracy over its rated range.

9. Determine the channel to use for the wireless sensors. If more than one EA800 is being installed on-site, it is

recommended that they be configured to use different channels.

10. The wireless sensor must be located so that the wireless signal strength is adequate as outlined in Winland

Application Note AN00101. You must verify that the wireless sensors can communicate with the base unit

before you permanently mount them.

Note: Certain environments may present conditions that intermittently cause interference with wireless sensor

to base unit communications. You should understand the environment in which the EA800 is to operate

to minimize their affects on system performance.

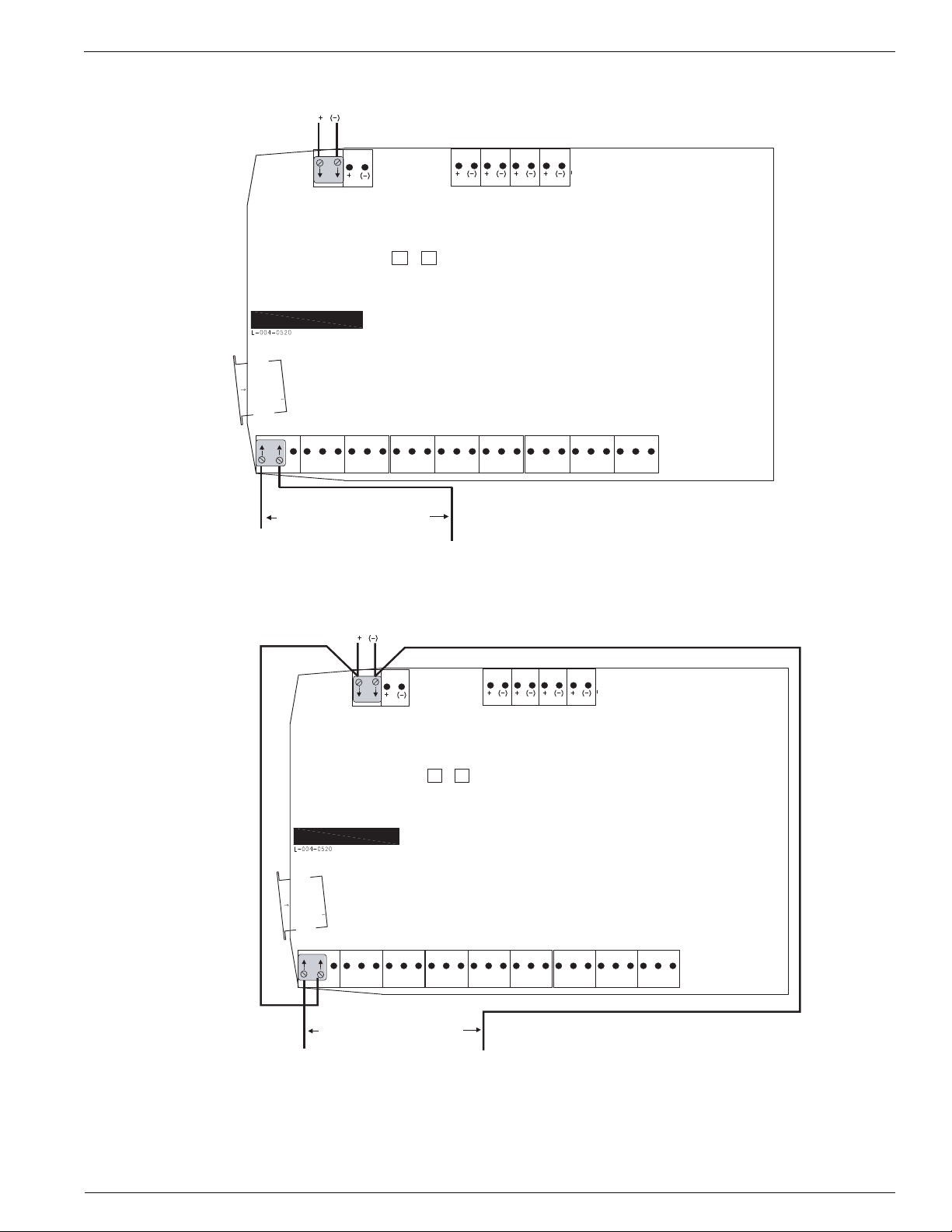

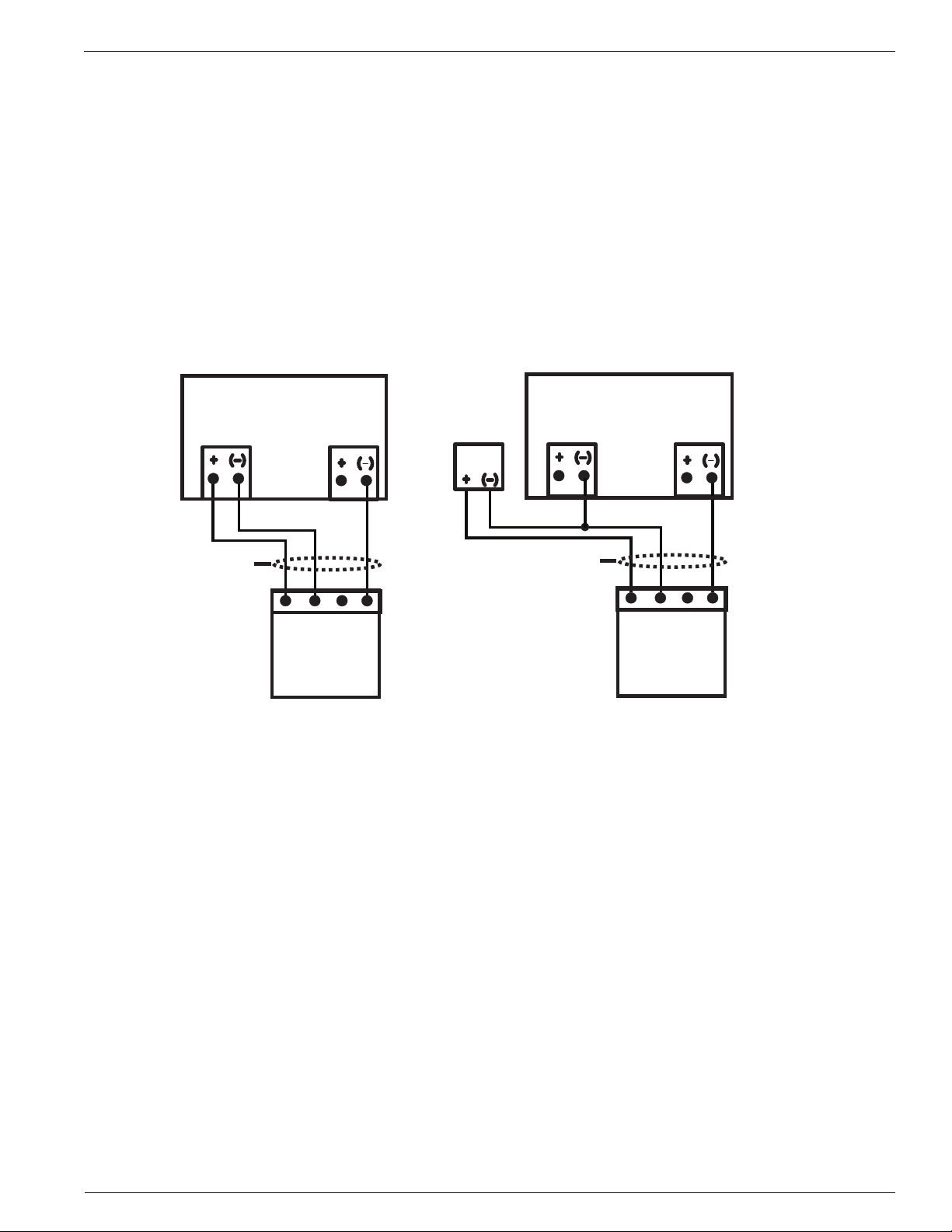

11. Decide the loop design you will use. Figure 9 shows an alarm loop where alarm power is derived from the

alarm loop. Figure 10 shows an alarm loop where alarm power is derived from the power supply feeding the

EA800.

Note: if using a self-powered loop, ensure the power supply can provide power for all loading conditions.

18 D-011-0152

Page 23

From 11-26 VDC

Power

In

Aux

Power

Out

J6

J5

Input 1 Input 2

Input 3 Input 4

J13 J14

J2

J8

Output 1 Output 2 Output 3 Output 4 Output 5 Output 6 Output 7 Output 8 Aux

NO COM NC NO COM NC NO COM NC NO COM NC NO COM NC NO COM NC NO COM NC NO COM NC NO COM NC

From 11-26VDC

power supply

To "alarm-on-closed"

loop circuit (power

supplied via EA800)

To alarm +

To alarm -

power supply

Preparation

J13 J14

J6

Input 1 Input 2

Input 3 Input 4

J5

Aux

Power

Power

In

Out

J2

J8

Output 1 Output 2 Output 3 Output 4 Output 5 Output 6 Output 7 Output 8 Aux

NO COM NC NO COM NC NO COM NC NO COM NC NO COM NC NO COM NC NO COM NC NO COM NC NO COM NC

To "alarm-on-closed"

loop circuit (power

supplied via loop)

Figure 9 Typical Alarm Loop Wiring Configuration (External Power)

Figure 10 Typical Alarm Loop Wiring Configuration (Self-Powered)

-

-

Page 24

12. Create an interconnect wiring diagram for the system. Identify the location of each sensor An example of a

Sensor 5

Sensor 7

Sensor 8

Relay 1

Output 1

Output 2

Relay 2

Output 3

Relay 3

Output 4

Relay 4

Output 5

Relay 5

Output 6

Relay 6

Output 7

Relay 7

Output 8

Relay 8

EA800 No. 1

Aux Output

Alarm Panel

Sensor 5

Sensor 6

Sensor 7

Sensor 8

Relay 1

Output 1

Output 2

Relay 2

Output 3

Relay 3

Output 4

Relay 4

Output 5

Relay 5

Output 6

Relay 6

Output 7

Relay 7

Output 8

Relay 8

EA800 No. 2

Aux Output

Computer

Room

Rear

Entry

Front

Entry

Front Desk

Men's Room

Women's Room

Conference Room

Alarm panel

installation area

Ch1

Ch2

Sensor 6

Ch1

Ch1

Ch1 Ch1

Ch2

Ch2

Ch2 Ch2

Zone 1

Output 1

Output 2

Zone 2

Output 3

Zone 3

Output 4

Zone 4

EA400

Aux Output

Internal

Sensor

Output 1

Output 2

Zone 1

EA200

Aux Output

Cooler1 Cooler 2

Storage Room 3

Freezer 1 Freezer 2

Room 1

Room 2

system map is shown in Figure 11. This example illustrates a system that includes multiple EA800 Multi-Zone

Environmental Alarm systems, a Winland EA400 Multi-Zone Environmental Alarm system, and a Winland

EA200 Multi-Zone Environmental Alarm system.

13.

Determine the cabling required to complete the installation as indicated by the loop design, the sensors you

have selected, and the system interconnect wiring diagram.

14. Complete the System Configuration section on the copy of the System Configuration Record you made. See

System Configuration for a description of each system level parameter.

When you have completed the previous steps you are ready to proceed to physically install the EA800 base unit

and its associated sensors using the documentation you have just created.

Figure 11 System Interconnect Wiring Diagram Example

20 D-011-0152

Page 25

Installation

WARNING

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

Tools and Supplies Required

Ensure that you have the following prior to starting the installation:

■ Phillips Screwdriver

■ Mounting hardware for the EA800 base unit and any optional sensor units

■ If required, a drill and the appropriate drill bits

■ Wire stripper

■ Sensors (not supplied; see “Accessories” on page 54)

■ Sensor Wiring (typically 18-22 AWG twisted-pair; not supplied)

■ Alarm Wiring (typically 18-22 AWG; see EA800 Output (Alarm) Connections)

■ Power sources

Power Requirements

All power terminals must be connected to a Class 2 power limited circuit complying with the National Electric Code

NFPA 70, Article 725. Where required, this equipment is to be isolated from the mains supply by a limited power

source as specified in EN60950.

EA800 relay outputs are intended only for use as low-voltage, low-current alarm

connections, and not for direct switching or control of AC-mains powered loads.

Additionally, local codes may further dictate or limit the types of loads and

associated wiring to be used with the low-current Form C relay outputs used with

the EA800. Connecting AC-mains type circuits to the EA800 may result in an

electric shock and/or fire hazard.

Connect only sensors specified in this manual to the wired and wireless input

connections. Using sensors not specified in this manual may damage the EA800 or

cause improper or unreliable operation.

Do not connect a load to the AUX OUT or OUTPUT 1 through OUTPUT 8 relay

outputs that exceeds limitations stated in the Specifications section of this manual.

Loads exceeding the specified limitations may damage the EA800, or result in

improper or unreliable operation.

The EA800 printed circuit board (PCB) contains electrostatic discharge (ESD)

sensitive devices. To help prevent damage caused by ESD, observe appropriate

ESD handling rules whenever the PCB in the EA800 is exposed.

Batteries shall not cause explosion or produce a fire HAZARD as a result of

excessive charge or discharge, or if a battery is installed with incorrect polarity.

If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

Mounting the EA800 Rear Plate

The base unit has a removable rear plate that may be attached to a 3-gang electrical enclosure or directly to a wall.

1. Remove the rear mounting plate from the base unit as follows:

■ Pull the rear mounting plate down and away from the EA800 main chassis. The retainer tabs on the main

chassis disengage from the holes in the rear mounting plate.

■ Completely remove the mounting plate from the base unit by disengaging the mounting plate hinges from the

mating tabs on the base unit.

-

-

Page 26

Install the Wired Sensors

CAUTION

!

CAUTION

!

CAUTION

!

2. Mount the mounting plate as follows:

■ Mounting to 3-gang enclosure: Use four (4) machine screws to secure the mounting plate to the mating holes in

the 3-gang enclosure.

■ Mounting to drywall surface: Place the mounting plate in mounting position. Mark the four mounting hole

locations. Install drywall anchors and secure the mounting plate to the anchors.

Note: If wall-mounted, prepare a wiring access hole at this time. All wiring must pass through the opening in the

center of mounting plate.

Install the Wired Sensors

Install the wired sensors in accordance with the instructions provided with the wired sensors.

1. Mount each wired sensor in its designated location.

2. Label each sensor's wires for easy identification.

3. Route the wires from the sensor to the base unit and dress the wires as required by local code. It is important

to ensure that the wires are protected along their entire length, are not stressed at any point, and are

adequately supported along their entire length.

4. Pass the wires through the mounted EA800 rear panel.

EA800 Base Unit Power Connections

Do not connect or disconnect power, sensor, or alarm wiring while power is applied.

Connecting and disconnecting the EA800 base unit with power connected may damage the

base unit or result in improper or unreliable operation.

Connection of unsuitable loads to this connection may damage the power supply and

EA800 base unit, or result in improper or unreliable operation.

Note: Do not apply power to the base unit until you are ready to begin sensor programming. The base unit has

a 30-minute timer that starts when the unit is first powered up. If at least one sensor is not added and programmed within the 30-minute time period, an alarm will occur.

1. Using a terminal block adapter, connect power supply + and - leads to POWER IN (+) and (-) on J5. Observe

proper polarity. If using a transformer, ensure that the transformer is an isolated power supply.

2. If Aux Power Out is to be used, connect + and - leads to AUX POWER OUT (+) and (-) on J5 using a terminal

block adapter.

Install the Wireless Sensors

If the EA800 base unit will be connected to a remote alarm panel, do not connect

the base unit to the alarm panel until after sensor connection and configuration

is complete. Connecting the remote alarm panel before configuring the EA800

sensors will result in false alarms at the remote panel.

22 D-011-0152

Page 27

Installation

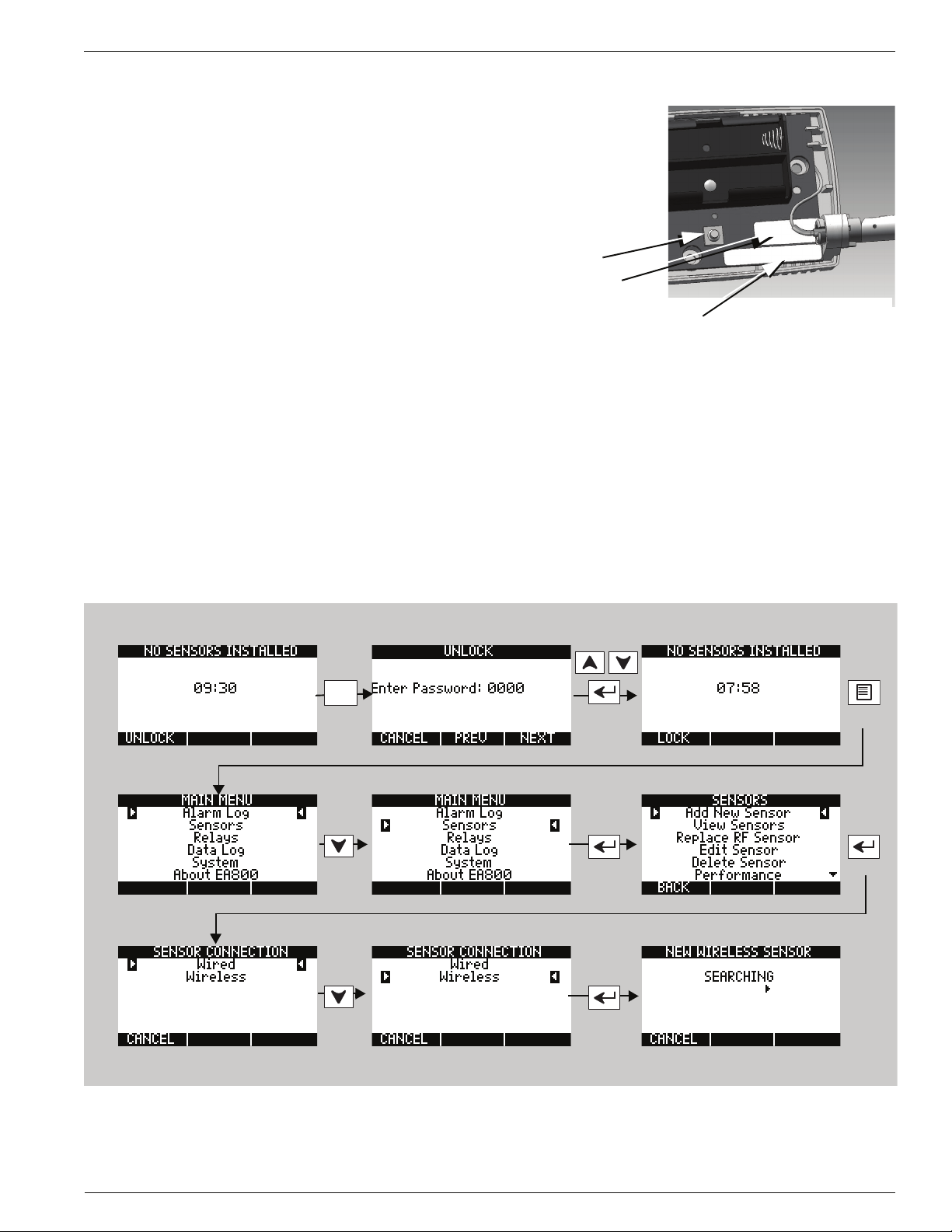

RESET BUTTON

SENSOR MODEL NO.

(Example: EA-WTS = Wireless Temperature Sensor)

MAC Address Label

Figure 12 Wireless Sensor MAC Address Location

Enter

0800

F1

Example shown, set values as

appropriate for your system.

Note: Verify that the wireless sensors can communicate with the base unit as outlined in the following proce-

dure before permanently mounting them.

1. Remove the cover from the wireless sensors and

record the MAC addresses (see Figure 12) of

each wireless sensor on the Configuration

Worksheet you completed during the preparation

phase. The MAC address is printed on a label

affixed to each wireless sensor’s printed circuit

board (PCB) and is used to identify each sensor

during programming.

2. Temporarily mount the front panel of the base

unit to the mounted rear panel.

3. Connect power to the EA800. The EA800

completes its boot process and the MONITORING

or NO SENSORS INSTALLED (if there are currently

no wireless sensors installed) screen is

displayed.

4. With the wireless sensors located near the base

unit, connect power to each wireless sensor.

5. Unlock the keypad and allow the base unit to detect the wireless sensors using the following procedure.

Note: The keypad locks automatically after 30 minutes of inactivity (no key presses). If you have not finished

the detection and programming process for a sensor and this occurs, entered values are lost and you

must start the programming procedure for the sensor from the beginning. It is recommended that you

allow the base unit to identify the wireless sensors one at a time, with the sensors unmounted and in the

same location as the base unit.

-

-

Page 28

Connecting Wired Temperature, Contact Closure, and Water Bug Sensors

RESET BUTTON

SENSOR MODEL NO.

(Example: EA-WTS = Wireless Temperature Sensor)

MAC Address Label

Figure 13 Wireless Sensor IDs and MAC Address Location

J6

Input 1 Input 2 Input 3 Input 4

+ (-) + (-) + (-)

+ (-)

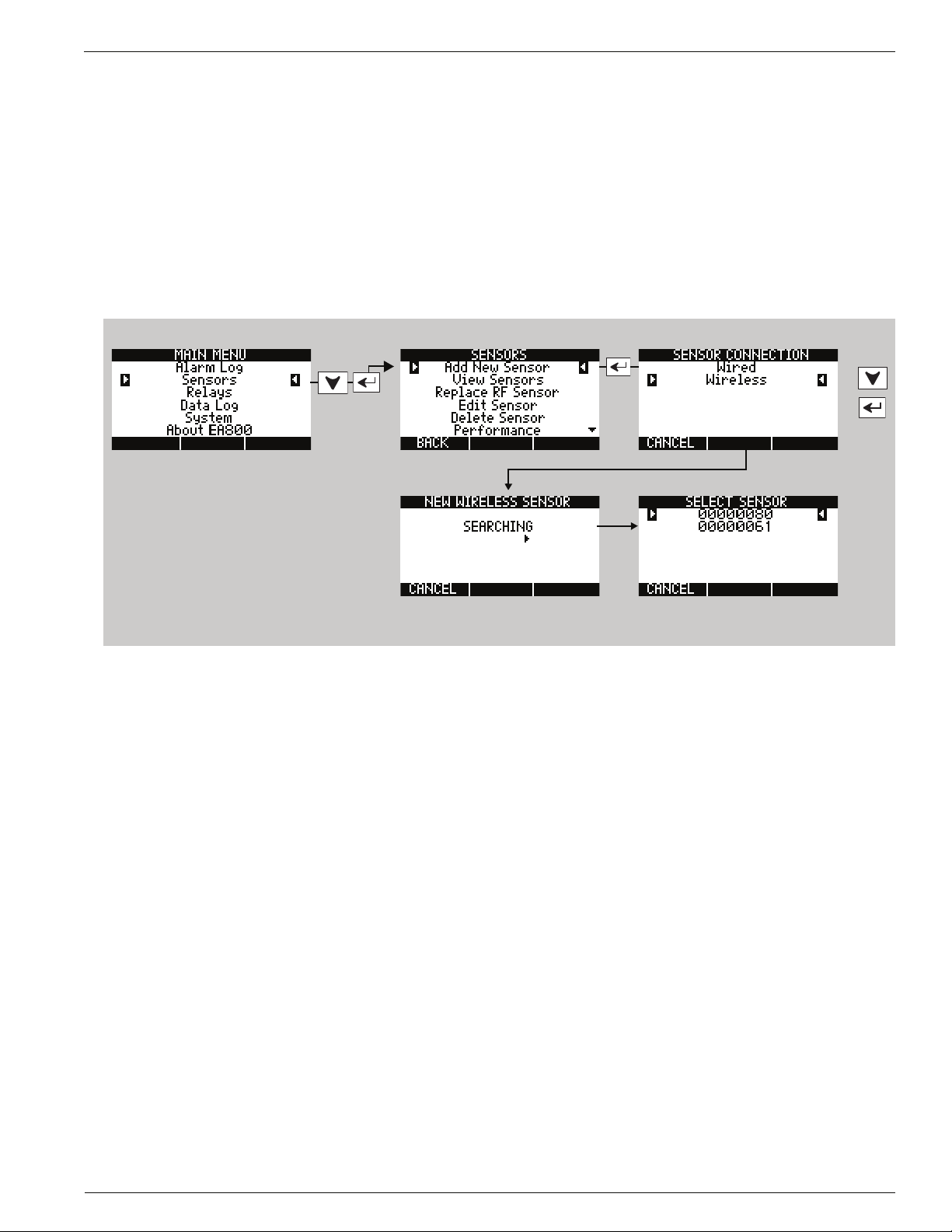

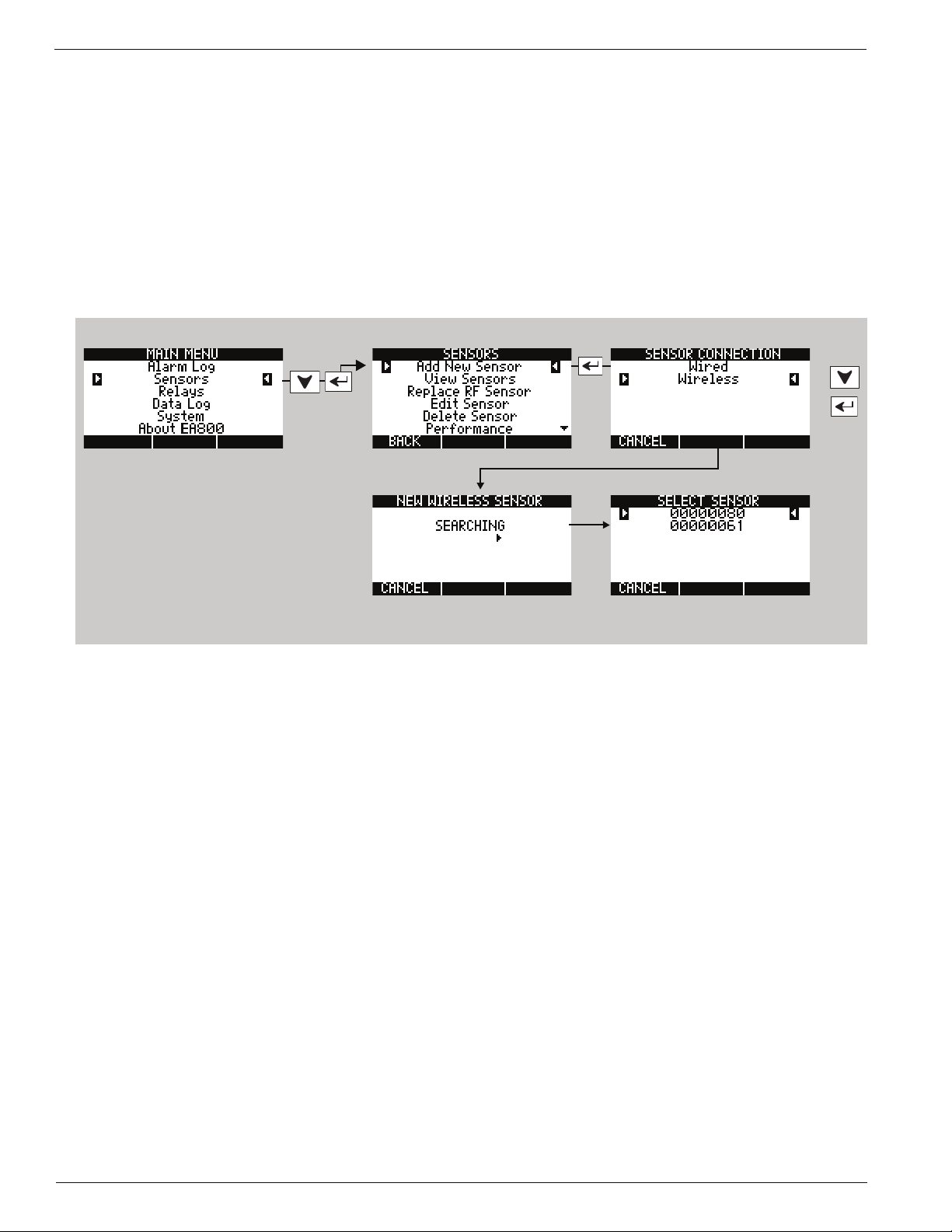

Note: It may take a few minutes for the base unit to detect the wireless sensors.

At this point the NEW WIRELESS SENSOR screen is displayed and an arrow moves from left to right indicating that the

EA800 is waiting to receive sensor ID data. When the EA800 has communicated with the reachable sensors the

SELECT SENSOR screen displays a list of wireless sensors detected.

■ When a sensor is detected, confirm that the ID

number shown matches the ID number on the

sensor’s label..

■ If the sensors can communicate with the EA800,

their IDs appear in the list as shown in the

example at right. Do not permanently install the

sensors that appear in the list until you verify

their signal strength when you program the

wireless sensors in the system later in the

installation process.

■ If the list of number(s) on the screen does not

contain the number found on the sensor's PC

board, press F1 (CANCEL) to continue the

search process.

Note: Press the Reset Button on the sensor to

restart the search process if necessary.

After the base unit has identified each wireless sensor and you have programmed it, temporarily mount it in its

desired location using tape. This allows the sensor to be relocated if necessary in order to obtain good signal

strength

Connecting Wired Temperature, Contact Closure, and Water Bug Sensors

1. Make certain the sensor's wiring is passed through the opening in the mounting plate.

2. Remove the adapter from the correct input connector header by pulling the adapter up and off of the circuit

board header connector.

3. Strip the ends of each of the sensor's wires as indicated by the gauge on adapter you just removed.

4. Insert the stripped wire ends into screw terminals of the adapter as indicated by the EA800 Wiring Diagram you

completed in the preparation phase. There is no need to observe polarity when connecting sensor wires. See

Figure 14.

Figure 14 EA800 Base Unit Wired Temperature, Contact Closure, and Water Bug Sensor Connections

5.

Secure the connections using the setscrews on the adapter. Check the connection by lightly pulling on each

connection.

6. After connecting the wire ends to the adapter, align the adapter to the correct header pins as indicated by your

EA800 Wiring Diagram, and press the adapter fully onto the header connector pins.

24 D-011-0152

Page 29

Connecting Wired HA-III+ Humidity Sensors

J6

Input N

User

supplied

cable

HA-III+

Connector

Power Input

GND

SINK

SOURCE

NC

NC

J5

Aux Power Out

EA800 Base Unit

J6

Input N

User

supplied

cable

HA-III+

Connector

Power Input

GND

SINK

SOURCE

NC

NC

J5

Aux Power Out

External

Powe r

Adapter

EA800 Base Unit

Base Unit-Powered

External Adapter-Powered

1. Make certain the sensor's wiring is passed through the opening in the mounting plate.

2. Remove the adapter from the correct input connector headers by pulling the adapter up and off of the circuit

board header connectors.

3. Strip the ends of each of the sensor's wires as indicated by the gauge on adapter you just removed.

4. Insert the stripped wire ends into screw terminals of the adapter as indicated by your EA800 Wiring Diagram

you completed in the preparation phase. Observe proper polarity. See Figure 15.

Installation

Figure 15 EA800 Base Unit Wired HA-III+ Sensor Connections

5. Secure the connections using the setscrews on the adapter. Check the connection by lightly pulling on each

connection.

6. After connecting the wire ends to the adapter, align the adapter to the correct header pins as indicated by your

EA800 Wiring Diagram, and press the adapter fully onto the header connector pins.

-

-

Page 30

Connecting Wired 4-20mA Sensors

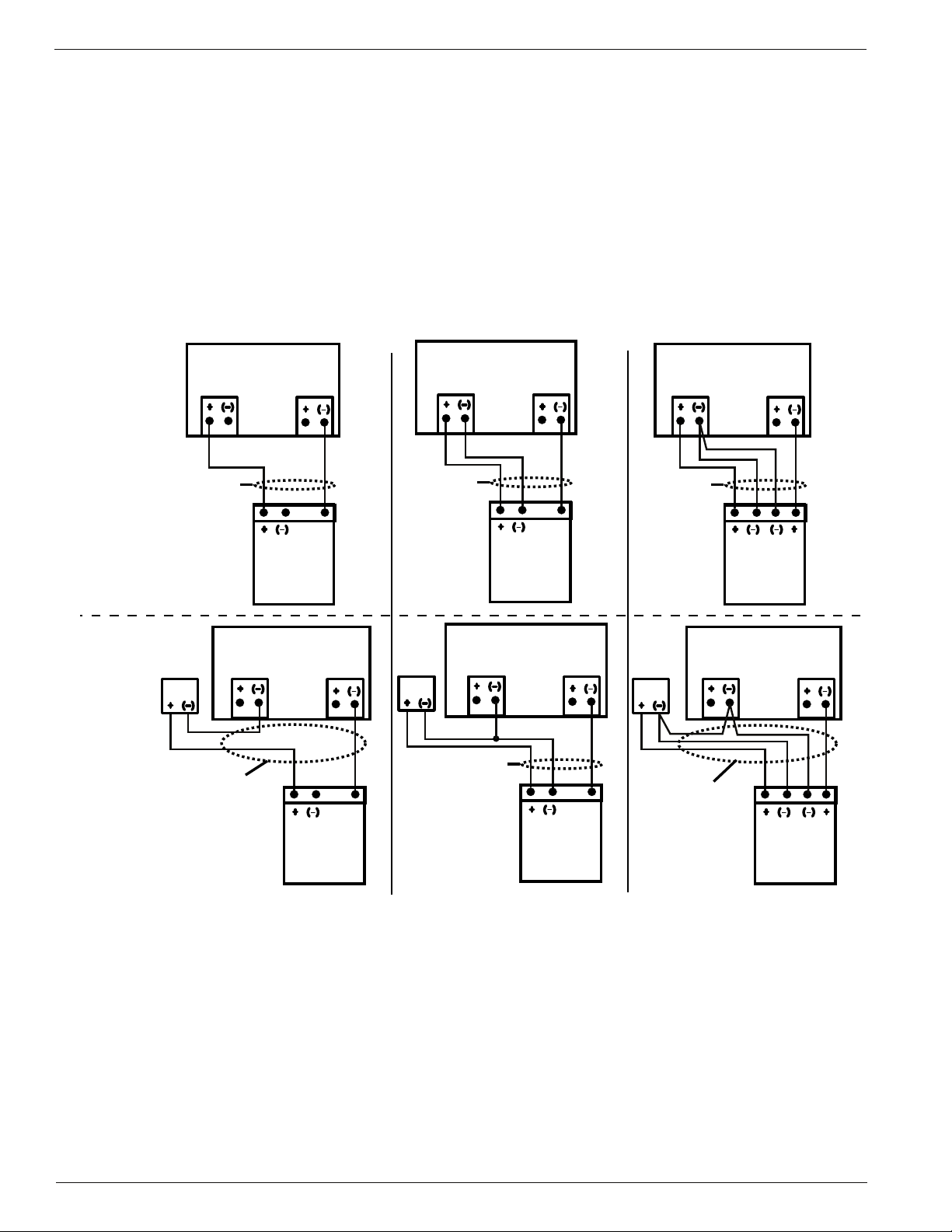

4-20mA Sensors

(3-wire)

EA800 Base

Unit Powered

External

Adapter

Powered

J6

Input N

User

supplied

cable

4-20mA

Transmitter

Connector

NC

J5

Aux Power Out

EA800 Base Unit

J6

Input N

User

supplied

cable

NC

J5

Aux Power Out

External

Powe r

Adapter

EA800 Base Unit

4-20mA

Transmitter

Connector

4-20mA

Output

4-20mA

Output

4-20mA Sensors

(2-wire)

J6

Input N

User

supplied

cable

4-20mA

Transmitter

Connector

NC

J5

Aux Power Out

EA800 Base Unit

J6

Input N

User

supplied

cable

NC

J5

Aux Power Out

External

Powe r

Adapter

EA800 Base Unit

4-20mA

Transmitter

Connector

4-20mA

Output

4-20mA

Output

4-20mA Sensors

(4-wire)

J6

Input N

User

supplied

cable

4-20mA

Transmitter

Connector

NC

J5

Aux Power Out

EA800 Base Unit

J6

Input N

User

supplied

cable

NC

J5

Aux Power Out

External

Powe r

Adapter

EA800 Base Unit

4-20mA

Transmitter

Connector

Connecting Wired 4-20mA Sensors

1. Make certain the sensor's wiring is passed through the opening in the mounting plate.

2. Remove the adapter from the correct input connector headers by pulling the adapter up and off of the circuit

board header connectors.

3. Strip the ends of each of the sensor's wires as indicated by the gauge on adapter you just removed.

4. Insert the stripped wire ends into screw terminals of the adapter as indicated by your EA800 Wiring Diagram

you completed in the preparation phase. Observe proper polarity. See Figure 15.

5.

6. After connecting the wire ends to the adapter, align the adapter to the correct header pins as indicated by your

Figure 16 EA800 Base Unit Wired 4-20mA Sensor Connections

Secure the connections using the setscrews on the adapter. Check the connection by lightly pulling on each

connection.

EA800 Wiring Diagram, and press the adapter fully onto the header connector pins.

26 D-011-0152

Page 31

Installation

CAUTION

!

CAUTION

!

Connecting the EA800 Alarm Outputs

If the EA800 base unit will be connected to a remote alarm panel, do not connect

the base unit to the alarm panel until after sensor connection and configuration

is complete. Connecting the remote alarm panel before configuring the EA800

sensors will result in false alarms at the remote panel.

1. If alarm loops will be controlled by the EA800, install all required wiring from alarm loops to the EA800

mounting location.

2. Connect the alarm loop leads to the terminal block adapter. Attach the adapter to terminals C and either NC or

NO on the appropriate circuit board header connector.

3. Repeat the previous step for each alarm loop.

4. Engage the mating tabs on the EA800 main chassis into the mounting plate upper hinges.

5. Pivot the bottom of the EA800 main chassis into closed position while aligning the retainer tabs on the main

chassis with the holes in the rear mounting plate and ensure that the wiring is not pinched, stressed, or

protruding between the chassis halves.

6. Snap the main chassis closed onto the mounting plate. When properly closed, the main chassis and mounting

plate mating surfaces are flush.

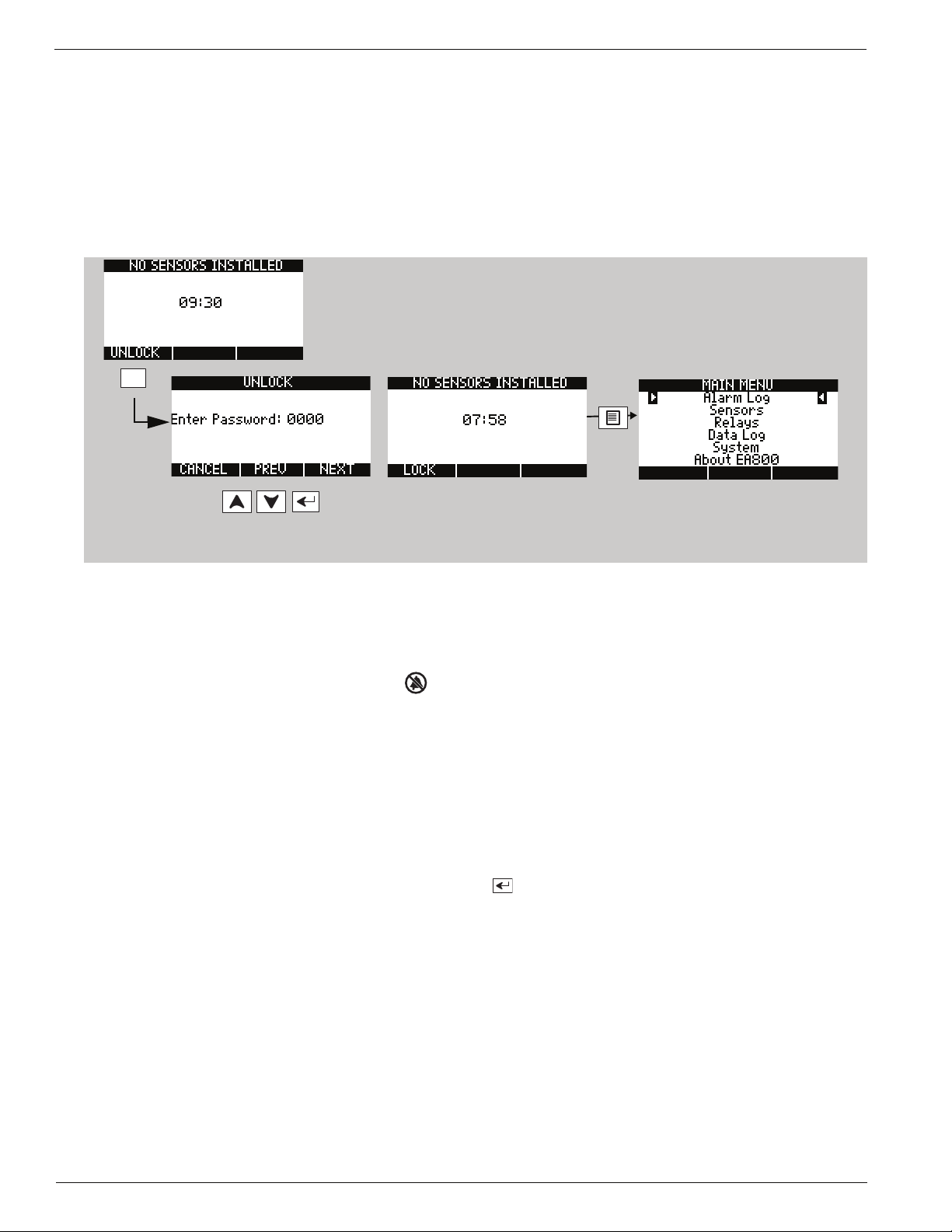

Programming

When powered-up, the EA800 is ready for programming. The following is an overview of the general process for

programming the EA800:

■ View the MAIN MENU and unlock the EA800 as described in “Accessing the MAIN MENU for Programming” on

page 28.

■ Set the system configuration as described in “Configuring System Parameter Settings” on page 28.

■ Set the current date as described in “Setting the Current Date” on page 31.

■ Set the current time as described in “Setting the Time” on page 32.

■ Add the wireless sensors. See the appropriate subsection under “Adding Wireless Sensors” on page 33.

■ Add the wired sensors. See the appropriate subsection under “Adding Wired Sensors” on page 43.

■ Verify performance of the wireless sensors. See “Verify Wireless Signal Strength” on page 42.

■ Configure the relays. See “Configuring the Relays” on page 48.

If the EA800 base unit will be connected to a remote alarm panel, do not connect

the base unit to the alarm panel until after sensor connection and configuration

is complete. Connecting the remote alarm panel before configuring the EA800

sensors will result in false alarms at the remote panel.

Note: When no sensors are programmed in the EA800 system, the EA800 base unit boots up with a 30-minute

delay before the alarm buzzer sounds. At this time the Alarm screen is displayed with a System Alarm