Page 1

FOR INSTALLERS AND SERVICE TECHNICIANS ONLY

GAS

FIREPLACE

SERVICE

MANUAL

Sherwood Industries Ltd. Duplication of this document is prohibited. All rights reserved.

August 2003 C-10100

Page 2

This is a service guide designed by SHERWOOD INDUSTRIES LTD.

We hope this manual will assist you to identify and correct operational concerns you might

experience in all ENVIROGAS appliances.

This service guide is designed for TRAINED SERVICE TECHNICIANS AND INSTALLERS.

This guide is NOT to be used by the homeowner.

If after reading this guide and following our recommendations and the problem still excists,

please do-not hesitate to call our technical department.

Technical Division

SHERWOOD INDUSTRIES LTD.

TABLE OF CONTENTS PAGE

1)

PILOT WILL NOT STAY LIGHT

A) IGNITION SYSTEM………………………………………………………. 1

B) IGNITION SYSTEM OK BUT PILOT WILL NOT LIGHT……………... 3

2) PILOT WILL NOT STAY LIT……………………………………………………… 7

3) MAIN BURNERS WILL NOT LIGHT…………………………………………….. 9

4) MAIN BURNERS WILL NOT STAY LIT…………………………………………. 11

5) SOOTING (ALL MODELS)…………………………………………………….…. 15

6) FLAME LIFTING

A) B-VENTED………………………………………………………………... 17

B) DIRECT VENTED………………………………………………………... 18

7) BLOWER OPERATION ………………………………………………………….. 19

8) ORIFICE SIZING CHART………………………………………………………… 20

9) STEP BY STEP SERVICE INSTRUCTIONS…………………………………… 21

10) GLOSSARY………………………………………………………………………. 23

SUGGESTED TOOLS LIST FOR SERVICING

GAS LEAK DETECTOR

MANOMETER

MULTIMETER

CORDLESS DRILL

WIRE STRIPPER/CRIMPER

WRENCHES, STANDARD AND METRIC

SCREWDRIVERS (TORX T20)

METAL SNIPS

JUMPER WIRES

NUMBERED DRILLS ((DMS))

Sherwood Industries Ltd. ENVIRO 2003

Page 3

Make sure that wires are not

broken, frayed and that all

connections are tight at both

the piezo ignitor and

electrode.

1(PILOT WILL NOT LIGHT

NO SPARK

A) IGNITION SYSTEM

Replace with only

manufactures parts

Make sure that ceramic on the

electrode is not broken.

Carefully try to spin the

porcelain.

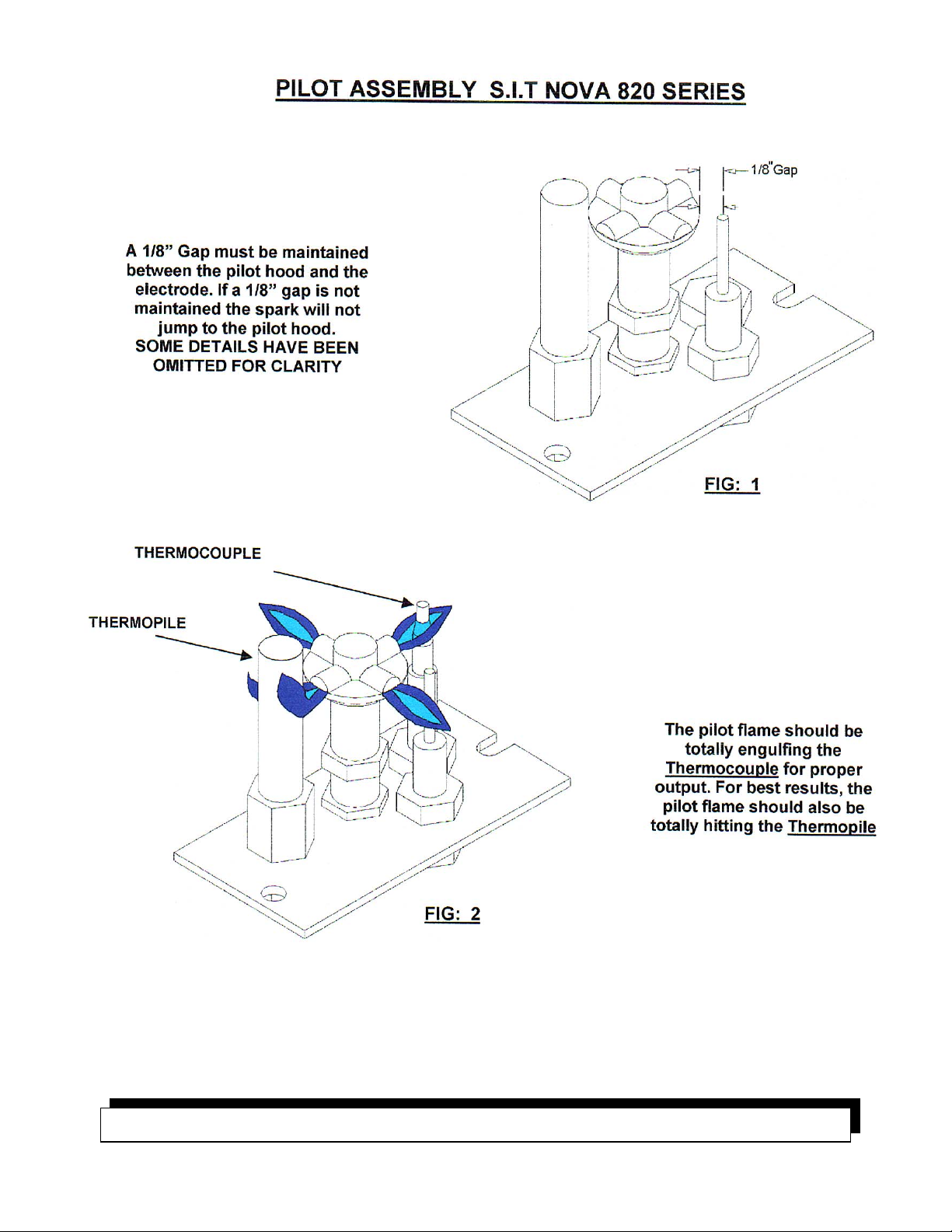

Make sure a 1/8” (3.175mm)

gap is maintained between

electrode and pilot hood.

SEE PAGE 2 FIGURE 1.

Make sure the piezo ignitor is

not loose.

Make sure piezo ignitor is

working properly. Place a

screwdriver next to ignitor,

and press ignitor. If it sparks,

OK.

IF IT DOES, replace

electrode.

Replace electrode.

Retighten hex nut on back

of the ignitor and make

sure bracket is secure on

the valve.

IF IT FAILS, replace piezo

ignitor.

Sherwood Industries Ltd. ENVIRO PAGE 1

Page 4

3.175mm

Sherwood Industries Ltd. ENVIRO PAGE 2

Page 5

B) PIEZO IGNITOR OK BUT PILOT WILL STILL NOT LIGHT

Make sure all gas lines have

been connected with no

leaks.

Make sure that the gas is

“ON” (NG) Natural gas and

(LP) Propane tanks are full.

Make sure the appliance

service valve is in the “ON”

position.

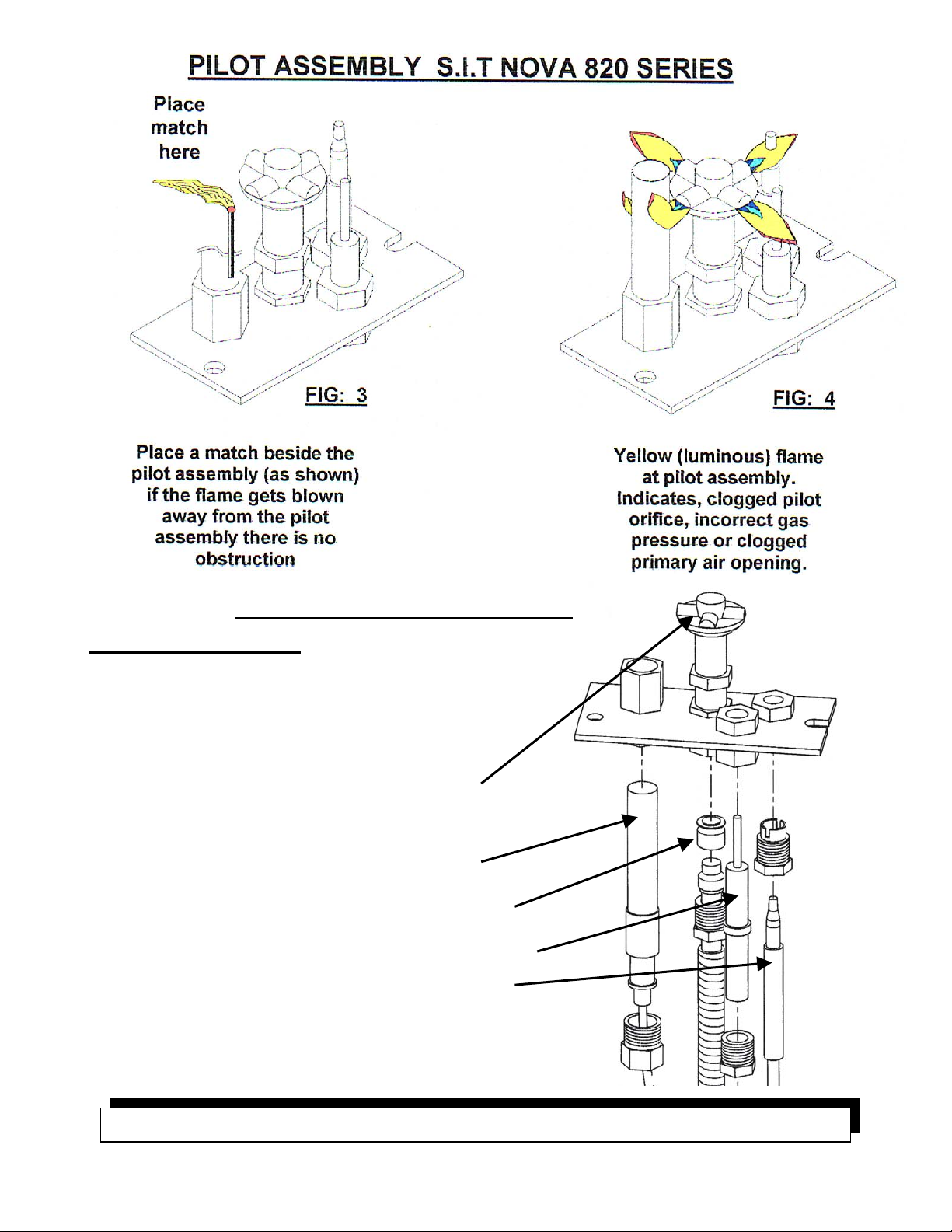

SEE PAGE 4 FIGURE 3.

Test to make sure there is no

air in the gas line.

SEE PAGE 4 FIGURE 3.

Correct if necessary, test

for gas leaks in an

approved manner.

Correct if necessary.

Turn service valve to the

“ON” position.

Use a match to see if air or

gas comes from the pilot

assembly.

Make sure that the valve has

not reset itself.

(All valves have an interlock

safety device.)

Make sure pilot injector is

not clogged.

Sherwood Industries Ltd. ENVIRO PAGE 3

Wait 60 seconds for the

safety to reset itself.

Clean the pilot injector if

necessary.

Page 6

EXPLODED VIEW S.I.T PILOT ASSEMBLY

To remove pilot injector:

Remove the two screws that hold

the pilot assembly to the burner

control assembly.

Lift the assembly straight up being

careful not to damage any

components.

Using a 10 mm wrench undo the

securing nut on pilot tubing and pull

tubing down to access injector.

Being careful not to damage the

ceramic spark electrode.

Replace the injector and reinstall

the pilot tubing, always to perform a

gas leak test before lighting the

pilot assembly.

The number on the side of the

injector will determine the size. This

number is in millimeters.

PILOT HEAD

THERMOPILE

PILOT INJECTOR

SPARK ELECTRODE

THERMOCOUPLE

Sherwood Industries Ltd. ENVIRO PAGE 4

Page 7

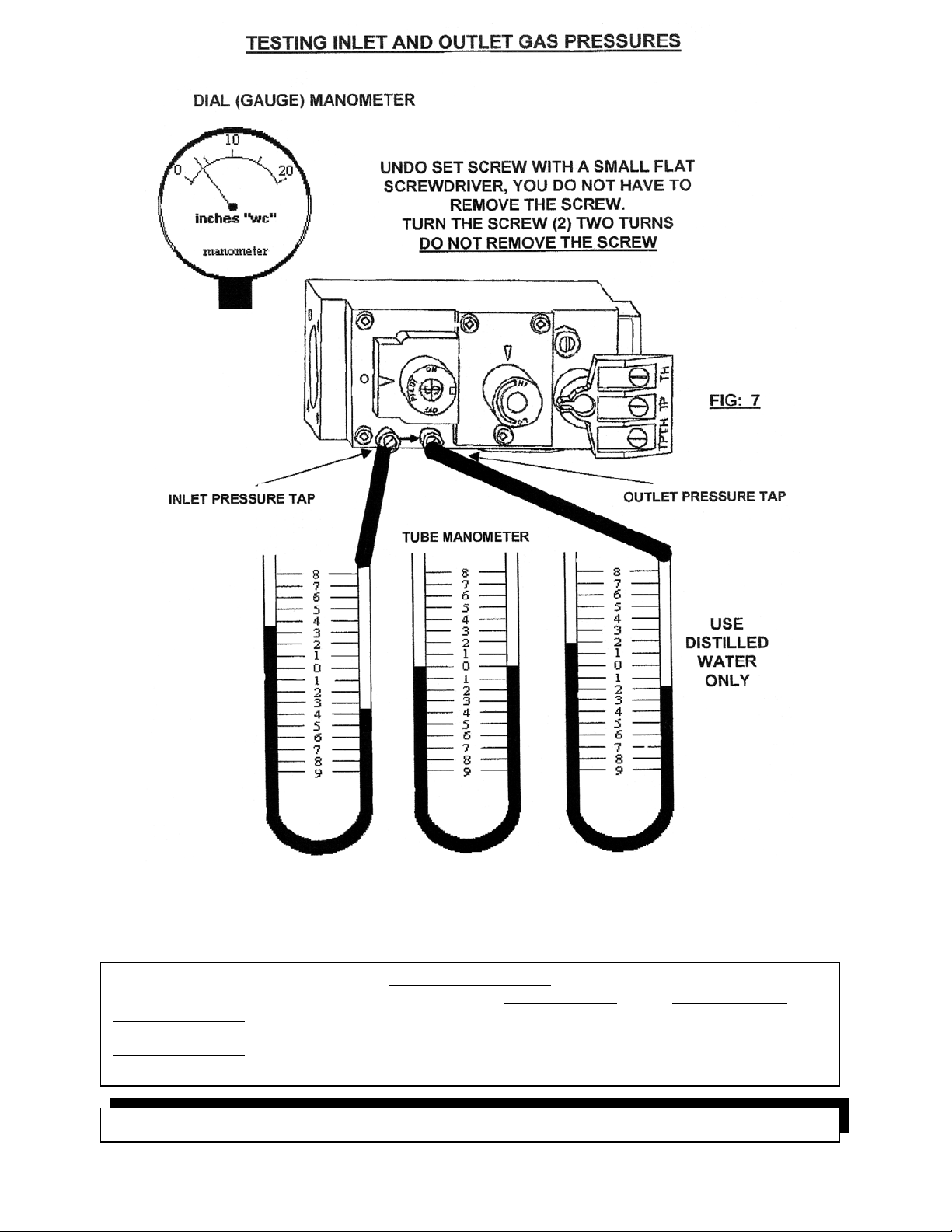

3.5” wc BELOW 0

3.5” wc ABOVE 0

INLET GAS PRESSURE

7” wc (NG) NATURAL

GAS

NO PRESSURE

1.75” wc BELOW 0

1.75” wc ABOVE 0

OUTLET GAS PRESSURE

3.5 “ wc (NG) NATURAL

GAS

SUPPLY PRESSURES

NATURAL GAS

PROPANE GAS

50% TURN DOWN MAX SUPPLY PRESSURE 7” wc 12” wc

MIN SUPPLY PRESSURE 5” wc 11.5” wc

33% TURN DOWN MAX SUPPLY PRESSURE 7” wc 13” wc

MIN SUPPLY PRESSURE 4.5” wc 10.5” wc

Sherwood Industries Ltd. ENVIRO PAGE 5

Page 8

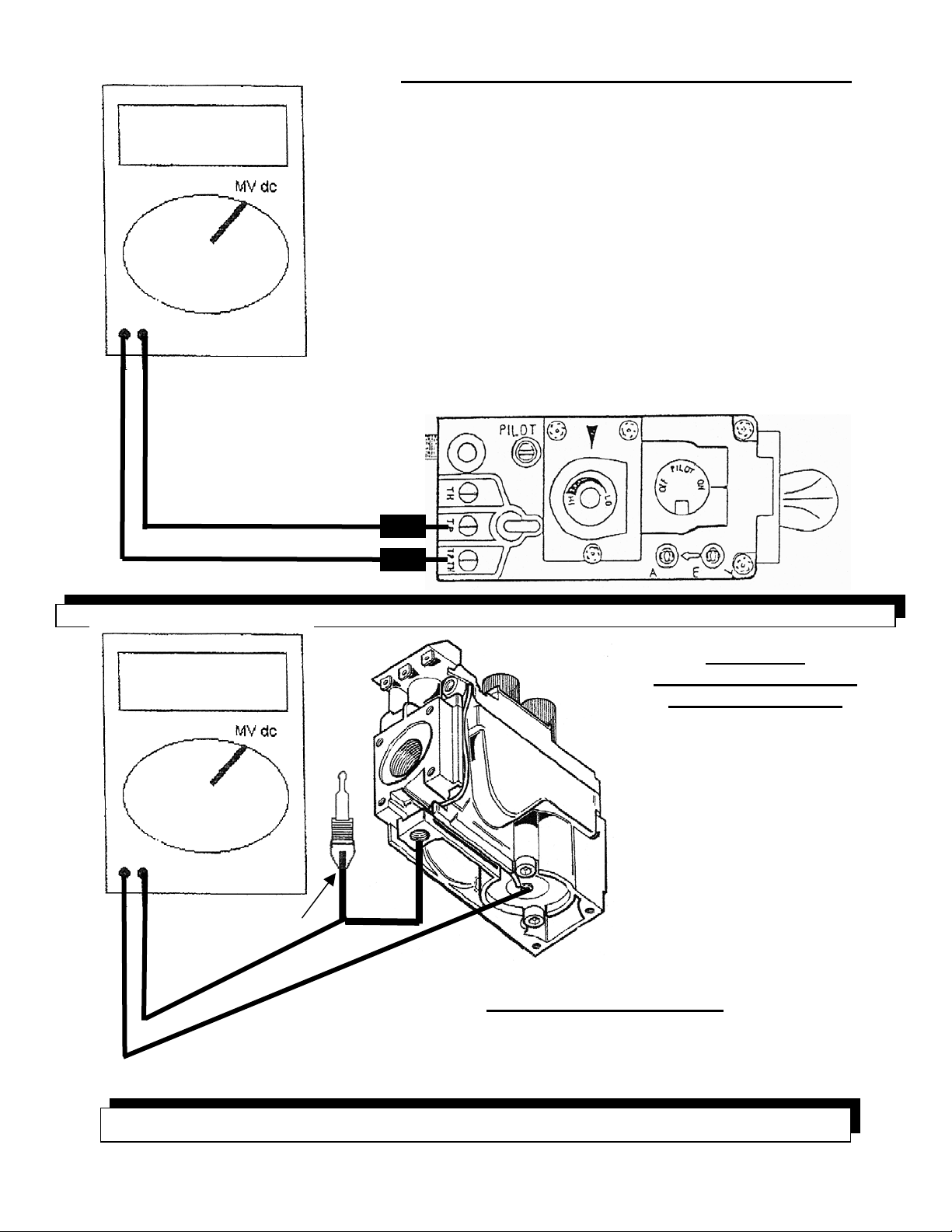

190 mv DC

CHECKING THERMOPILE FOR PROPER VOLTAGE

Place the leads of the multimeter on the TP/TH and TP

terminals on the valve as shown.

With the switch in the “ON” position, the readings should

be approximately 190mV DC (this an average reading) or

greater for proper Thermopile operation.

The main burners may not come ON if the readings are

less than 145mV DC.

If a thermostat has been installed. Place the

ON/OFF/THERMO switch in the THERMO position; place

the leads of the multimeter on the TP/TH and TH terminals

on the valve or on the connections at the thermostat.

MV reading should be higher than 190 mV DC for proper

valve operation.

THESE READINGS SHOULD BE CONSTANT WITH NO

FLUCTUATION.

2 to 6mv DC

CHECKING

THERMOCOUPLE FOR

PROPER VOLTAGE

Place one lead from the

multimeter on the

thermocouple lead, and the

other lead from the

multimeter on the back of

the valve where the blue

wire is soldered to the valve.

These readings should be

between 8 and 16mV DC.

If these readings are 2 to 6

mV DC, the Thermocouple

should be replaced

When using a S.I.T EUROSIT 630 SERIES gas valve, place

one lead from the multimeter on the thermocouple lead and

the other lead into the adapter located on the back of the

valve, there are two blue wire a inserted into this adapter.

Sherwood Industries Ltd. ENVIRO PAGE 6

Page 9

2) PILOT WILL NOT STAY

LIT

Make sure the gas pressure is

correct for type of fuel you are

using.

SEE PAGE 5 FIGURE 7.

Make sure pilot flame is

engulfing the top 3/8” of the

thermocouple.

SEE PAGE 2 FIGURE 2.

Make sure thermocouple

connections on valve are

tight.

DO NOT OVER TIGHTEN!!!

Use a manometer on the inlet

side of the valve to measure

gas pressure. Adjust inlet

pressure or contact your gas

supplier.

Thermocouple should be the

same height as the pilot hood.

Adjust pilot as required.

Check for clogged pilot

injector.

Thermocouple connections

should be hand tight plu1/4

turn.

Make sure the thermocouple

line has no kinks and is clean

on both ends. Also check the

thermocouple for damage.

Make sure the thermocouple

has proper voltage (DC

VOLTAGE).

Sherwood Industries Ltd. ENVIRO PAGE 7

Clean thermocouple ends

with Emery cloth or an

abrasive sponge.

DO NOT USE A METAL FILE.

Replace if damaged.

Using a multimeter, insert

adapter between valve and

thermocouple, if the readings

are less than 2 TO 6 mV DC,

replace thermocouple.

SEE PAGE 6 FIGURE 8.

Page 10

S.I.T EUROSIT MODULATING 630 SERIES

Sherwood Industries Ltd. ENVIRO PAGE 8

Page 11

3) MAIN BURNERS WILL

NOT LIGHT

Make sure gas valve knob is

in the “ON” position.

SEE PAGE 8 FIGURE 6.

Make sure that the “ON-OFF

THERMO” switch is in the

“ON” position.

Make sure that the

thermostat is “NOT” in the

lowest position.

Make sure that all control

wires are not damaged,

broken or frayed and that all

wire connections are tight.

Correct if necessary.

Turn valve to the “ON”

position.

Turn switch “ON”.

Turn thermostat “UP”.

Replace damaged wires as

necessary. Gently squeeze

connectors with a pair of

pliers and reinstall wires.

Make sure that the

thermopile connections are

tight on the valve.

Make sure millivolt readings

from thermopile are within

manufactures

specifications. MAKE SURE

MILLIVOLT READINGS ARE

CONSTANT.

SEE PAGE 6 FIGURE 8.

Continued on next page.

Sherwood Industries Ltd. ENVIRO PAGE 9

Tighten the two screws on

valve if necessary

“TP/TP-TH” terminals on

valve.

Place leads of multimeter

on the “TP/TH-TP”

terminals on gas valve. If

the readings are less than

145mV DC, replace

thermopile

Page 12

j

MAIN BURNERS WILL NOT LIGHT CON’T.

Check spill switch operation

on B-vented models only

SEE PAGE 10 FIGURE 9.

Check the “ON-OFF” switch

and thermostat for proper

operation.

Make sure that the main

burner orifices are not

clogged or damaged.

Bypass spill switch with a

umper wire as shown. If the

unit starts, replace the spill

switch. DO NOT LEAVE BY

PASSED IN.

Use a jumper wire. If the unit

starts, replace switch if

necessary.

Remove the top tray.

Remove orifice and clean.

Replace if damaged.

Sherwood Industries Ltd. ENVIRO PAGE 10

Page 13

4) MAIN BURNERS WILL

Make sure pilot flame engulfs

the thermopile and does

“NOT” have a yellow

luminous flame.

SEE PAGE 4 FIGURE 4.

NOT STAY LIT

Adjust pilot if necessary.

Check outlet gas pressure.

Check for clogged pilot

injector or blocked air inlet.

Make sure millivolt readings

from thermopile are constant.

Make sure all wiring is not

damaged or broken and all

connections are tight.

B-VENTED MODELS

Check spill switch.

Check to make sure the vent is

drafting properly.

Make sure all venting meets

manufactures specifications

as well as local gas and

building code requirements.

Using a multimeter check

thermopile. If not constant

replace thermopile.

Correct if necessary.

By pas spill switch.

If unit starts, replace spill

switch.

Check for spillage.

SEE PAGE 12.

Correct if necessary.

Check chimney for blockage

or restriction.

Sherwood Industries Ltd. ENVIRO PAGE 11

Correct if necessary.

Page 14

Sherwood Industries Ltd. ENVIRO PAGE 12

Page 15

SAMPLE DIRECT VENT CHIMNEY INSTALLATIONS

ALL MODELS

Sherwood Industries Ltd. ENVIRO PAGE 13

Page 16

SAMPLE B-VENTED CHIMNEY INSTALLATIONS

ALL MODELS

INSERT MODELS

MUST BE FULLY

LINED AND SEALED

Sherwood Industries Ltd. ENVIRO PAGE 14

Page 17

5) SOOTING

Make sure log placement is

in the correct location.

Make sure there is sufficient

air supply.

Check air shutter on the

venturi tube for proper

primary air adjustment.

SEE PAGE 16.

Make sure orifice matches

that on the rating plate.

Correct to manufactures

specifications.

Correct if necessary.

Outside air supply may be

required on B-vented

models.

Increase primary air.

Open air shutter.

Correct if necessary.

Make sure outlet (manifold)

pressure is correct.

Make sure the unit has been

derated for high altitude

applications.

(if required)

Check to make sure that the

vent is drafting properly.

Sherwood Industries Ltd. ENVIRO PAGE 15

Use a manometer to check

the gas pressure.

SEE PAGE 5 FIGURE 7.

Correct if necessary.

Correct if necessary.

Page 18

IF THE AIR SHUTTER IS

Y

A

OPENED WIDER, THE

FLAME COULD APPEAR

ALMOST ALL BLUE

WITH FLAME LIFTING

BEING THE END RESULT

IF OPENED TOO MUCH

WITH THE AIR SHUTTER

SET PROPERLY, THE

FLAME WILL SIT ON THE

BURNER PORT AND THE

FLAME PATTERN WILL

START AT THE BOTTOM

WITH A BLUE FLAME

THEN TURNING TO A

WHITE ALMOST

ELLOW FLAME WITH A

SLIGHT ORANGE EDGE

AS THE AIR SHUTTER

IS CLOSED, THE

FLAME COULD

PPEAR TALLER WITH

A VERY LAZY BLACK

ORANGE TIPPED

FLAME PRODUCING

CARBON (SOOT)

Sherwood Industries Ltd. ENVIRO PAGE 16

Page 19

6) FLAME LIFTING

A) B-VENTED MODELS

Check air shutter on the

burner tube (venturi).

Make sure there are no

leaks in the venting system.

Improper venting

configuration.

Make sure that manifold

(outlet).

Pressure is correct.

Adjust air shutter, by

closing shutter.

DO NOT GO TOO FAR OR

THE UNIT WILL SOOT.

Seal venting if necessary.

Correct if necessary.

Use a manometer to check

gas pressure.

SEE PAGE 5 FIGURE 7.

Sherwood Industries Ltd. ENVIRO PAGE 17

Page 20

B) DIRECT VENT MODELS

Check air shutter on the

burner tube (venturi).

Make sure there are no leaks

in the venting system.

Make sure the unit is not

recirculating flue products.

Make sure the gas pressure

is correct for fuel being used.

Adjust air shutter.

Close until flame sits onto

the burner ports.

Seal exhaust tube with high

temperature silicone.

Also make sure that

combustion air pipe is

sealed.

Check flue for blockage or

high wind situations.

Use a manometer to check

gas outlet (manifold)

pressure.

SEE PAGE 5 FIGURE 7.

Make sure the orifice size is

the same as the rating plate.

Add a vent restrictor ring.

SEE OWNERS MANUAL.

Sherwood Industries Ltd. ENVIRO PAGE 18

Correct if necessary.

Only if necessary.

Page 21

7) BLOWER DIAGNOSIS

ALL MODELS

Check to make sure that the fan is plugged in.

Make sure the fan control knob is in the “ON”

position.

Make sure the two wires are connected to the

fan temperature sensor.

Make sure that the two wires are connected to

the blower.

Make sure there are no broken, damaged or

frayed wires.

Make sure that the fan sensor is secure and that

it is not damaged.

Using a supply cord connected

to the blower, plug the blower

directly into wall outlet.

By pass the fan temperature

sensor with a jumper wire.

By pass the fan controller with

jumper wire. a

MAKE SURE THAT THE FAN SENSOR IS AT OPERATING

TEMPERATURE BEFORE TESTING THE FAN CONTROLLER.

If the blower does not work,

replace the blower.

If the blower works, replace

the fan temperature sensor

If the blower does not work,

replace the fan controller.

Sherwood Industries Ltd. ENVIRO PAGE 19

Page 22

ORIFICE SIZING

CHART

NATURAL GAS PROPANE GAS

DRILL# SIZE 3.5” 3.8” 10” 11”

70 .0280 1991 2074 5221 5476

69 .0292 2165 2256 5678 5956

68 .0310 2440 2542 6400 6713

1/32 .0313 2487 2591 6524 6843

67 .0320 2600 2709 6820 7153

66 .0330 2765 2881 7253 7607

65 .0350 3110 3240 8158 8557

64 .0360 3291 3429 8631 9053

63 .0370 3476 3622 9117 9563

62 .0380 3666 3820 9617 10087

61 .0390 3862 4024 10130 10625

60 .0400 4062 4232 10655 11176

59 .0410 4268 4447 11195 11742

58 .0420 4479 4667 11748 12322

57 .0430 4695 4892 12314 12916

56 .0465 5490 5720 14400 15104

3/64 .0469 5585 5819 14649 15365

55 .0520 6865 7153 18008 18888

54 .0550 7680 8002 20146 21131

53 .0595 8989 9366 23578 24730

1/16 .0625 9918 10334 26014 27286

52 .0635 10238 10667 26854 28167

51 .0670 11398 11876 29896 31357

50 .0700 12441 12962 32633 34228

49 .0730 13530 14097 35490 37225

48 .0760 14665 15279 38467 40347

5/64 .0781 15487 16136 40622 42608

47 .0785 15646 16302 41039 43045

46 .0810 16658 17356 43695 45831

45 .0820 17072 17787 44780 46969

44 .0860 18778 19565 49256 51663

43 .0890 20111 20954 52753 55331

42 .0935 22197 23127 58221 61067

3/32 .0938 22339 23275 58596 61460

41 .0960 23399 24379 61377 64377

40 .0980 24384 25406 63961 67087

39 .0995 25137 26190 65933 69156

38 .1015 26157 27253 68610 71964

37 .1040 27462 28613 72032 75553

36 .1065 28798 30005 75537 79229

7/64 .1094 30388 31661 79707 83603

35 .1100 30722 32009 80582 84522

34 .1110 31283 32594 82055 86066

SHERWOOD IDUSTRIES LTD. ENVIRO PAGE 20

Page 23

STEP BY STEP SERVICE INSTRUCTIONS

These appliances do require to be serviced. Our best recommendation is that the appliance be

serviced (1) once a year, maybe just before the heating season starts.

Annual service should and inspection should include:

⇒ Open the two side panels or remove the face frame from the appliance. Vacuum all areas

around the convection blower making sure there are no obstructions near the convection

blower or in the impeller fan blades.

⇒ EG-95 inserts and freestanding fireplaces convection blowers do require lubrication. Use

lightweight oil 20 SAE, 3 in 1 oil, or sewing machine oil (2 drops only). Too much oil will

contract dust and dirt, which could cause premature breakdown of the convection blower.

⇒ Check all wiring for loose connections and damage to any of the wires.

⇒ Check to make sure that the flue is connected and that the flue is not plugged and that it is

free from obstructions.

⇒ Also check to make sure that the fresh air, if installed, is not clogged and that it is free from

obstructions.

⇒ Open the glass door by undoing the ½” bolt on the right hand side of the appliance, swing the

door all the way open and gently lift the door of the two pins on the left hand side of the

appliance.

⇒ Carefully remove the log set from the firebox. NOTE: The edges of the logs become brittle

with heat over time so they could be damaged when removing the logs. Remove the glowing

ember material making sure not to drop any of the ember material, which could drop into air

passages or drop on the pilot assembly.

⇒ Inspect the pilot assembly for build up on the Thermocouple and Thermopile; also make sure

that the pilot assembly has not been damaged.

⇒ Vacuum all areas inside the firebox in and around the burner tray, control panel and

surrounding areas.

⇒ Carefully replace the logs and glowing embers into the firebox making sure that the log and

ember material are in the correct location (refer to the owner and operators manual).

⇒ Inspect the door gaskets to make sure that it is not cracked broken or frayed. Place the door

assembly back on the two pins on the left side of the appliance, close the door and tighten the

½” bolt on the right hand side, make sure that the gasket is fully sealed (pay special

attention to the corners of the bay window). Visually check for a small gap, if there is a

gap, open the door and fluff the gasket up a little, reinstall the glass and re inspect the gasket

to make sure it has sealed.

⇒ Relight the appliance, before you turn the gas control knob to the “ON” position, do a millivolt

reading from the thermopile. Turn the gas control knob to the “ON” position, before the main

burners are turned “ON” do another millivolt reading at the thermopile to make sure there is no

change.

Sherwood Industries Ltd. ENVIRO PAGE 21

Page 24

⇒ Turn the switch to the “ON” position; check the millivolt readings at the thermopile make sure

that the readings meet manufacters specifications. Turn the unit “OFF”.

⇒ Install a manometer on the inlet side of the gas valve marked (E), re light the appliance make

sure that the inlet pressure meets the manufactures specifications.

⇒ Shut the unit “OFF” once again and do an outlet (manifold) pressure test. Relight the

appliance and make sure the outlet (manifold) pressure is within manufactures specifications.

⇒ FINALLY, check to make sure that the unit is venting properly by placing a match in the

dilution air outlet or in the draft tube on insert models. If the match is blown out then there is

some sort of restriction. Correct if necessary.

CLEANING THE APPLIANCE

Only use a very soft cloth an a non abrasive cleaner, DO NOT use any alcohol’s, mineral

spirits, gasoline’s or abrasive cleaners.

⇒ When cleaning the glass there could be some stubborn material left on the glass, DO NOT

use a scraper or abrasive cleaning agents on the glass because this could scratch the glass

which in turn will make he glass weak at the point of the scratch. There is a glass cleaner that

is specially designed for gas fireplaces, which can be purchased at your local dealer.

Sherwood Industries Ltd. ENVIRO PAGE 22

Page 25

10) GLOSSARY

B-VENTED SYSTEM

A venting system using only approved double wall pipe and approved B-vent components. This

system also uses room air for proper venting action through the dilution air inlet mounted on the

back of the unit.

CONTINUITY TEST

By using a multimeter set on OHMS, is determined if the circuit is complete, or continuous (no

break in the circuit).

DIRECT VENT SYSTEM

A venting system sealed from the structure for both the exhaust gases and fresh air supply.

ELECTRODE (ignition)

Receives spark from the piezo ignitor to light the pilot.

IGNITOR (piezo)

A component used to create an electrical spark to the electrode to light the pilot.

IMPINGEMENT

When flame comes in contact with physical components. Impingement can cause incomplete

combustion resulting in carbon monoxide production as well as soot.

MANOMETER

Instrument used to measure gas pressure.

MILLIVOLT

One –one thousands (1/1000) of a volt (.001mV DC)

MULTIMETER

Instrument used to measure Volts. Amps, Ohms, (Volts DC, AC)

ORIFICE

A component that controls gas flow through the burners.

PILOT INJECTOR

A component that directs gas flow through the pilot assembly.

PRESSURE REGULATOR

A device used to maintain downstream gas pressure.

RATING PLATE

A plate in the appliance which shows all certifications and what type of fuel and what the

appliance is rated for (example: BTU’s, gas type, serial#, etc.).

SOOTING

Carbon build up produced by incomplete combustion of the fuel being used.

SPILLAGE

When flue products do not properly exit the structure through the venting system.

SPILL SWITCH

A temperature sensitive switch designed to shut the appliance off in the case of improper

venting action.

THERMOCOUPLE

A device used to generate power with heat from the pilot, up to 25mV DC.

THERMOPILE

A device used to generate power with heat from the pilot, up to 750mV DC.

VENTURI

Where gas and air are mixed before entering the burner tube.

Sherwood Industries Ltd. ENVIRO PAGE 23

Loading...

Loading...