Page 1

CE870 Card Personalization System

Installation and User Guide

November 2011

Part No. 539977-001 Rev. B

Printer Firmware: D3.1.41-0

Embosser Firmware: Rev. A.6

Front Panel Revision: 1.1.2.34

Page 2

Notice

Please do not attempt to operate or repair this equipment without adequate training. Any

use, operation, or repair you perform that is not in accordance with the information

contained in this documentation is at your own risk.

Proprietary Notice

All drawings and information herein are the property of DataCard Corporation. All

unauthorized use and reproduction is prohibited.

Trademark Acknowledgments

Datacard is a registered trademark and service mark of DataCard Corporation in the

United States and other countries.

Windows is a registered trademark of Microsoft Corporation.

All other product names are the property of their respective owners.

Datacard Group

11111 Bren Road West

Minnetonka, MN 55343-9015

Phone: 952-933-1223

Fax: 952-933-7971

www.datacard.com

© 2011 DataCard Corporation. All rights reserved.

Printed in the United States of America.

ii

Page 3

Contents

Chapter 1: Welcome to the Card Personalization System_____________________________ 1

The CE870 Card Personalization System _________________________________________ 1

About the System ______________________________________________________________ 2

System Components ___________________________________________________________ 3

The Printer Component (Top, Front and Right Side) ___________________________ 3

Printer Multi-Card Hopper _______________________________________________ 4

Printer Connections (Left Side)___________________________________________ 5

The Touch Screen Component (Optional) ___________________________________ 6

The Embosser Component (Top, Front and Right Side) ________________________ 7

Inside the Embosser _____________________________________________________ 8

Embosser Connections (Back and Left Side)______________________________ 9

System Labels_________________________________ ________________________________ 10

Printer Configuration Label___ ______________________________________________ 10

Embosser Configuration Label ____ ___ ___ ____ ___ ____ ___ ____ ___ _______ ___ ____ _ 11

How To Topics_________________________________________________________________ 12

Chapter 2: Installation Requirements_______________________________________________ 13

PC Requirements______________________________________________________________ 13

Site Requirements _____________________________________________________________ 14

Electrical Requirements _________________________________ ______________________ 15

Chapter 3: Install the System ____________ __________________________________________ 17

Secure the System _____________________ _______________________________________ 18

Assemble the Printer and Embosser ____________________________________________ 19

Load Supplies_________________________________________________________________ 20

Load Indent Ribbon Cartridge _____________________________________________ 20

Load Topping Foil Cartridge________________________________________________ 21

Load Cleaning Sleeve _______ ____ ___ ___ ____ ___ ____ ___ ____ ___ ___ ____ ___ _____ 22

Load Cards in Hopper _____________________________________________________ 24

Connect Cables ________________________________________ ____ __________________ 25

Connect Data Cables _____________________________________________________ 25

Connect Power Cables____________________________________________________ 26

Power on the System ______________________________________________________ 27

Run Test Card ____________________________________________________________ _____ 28

Chapter 4: Using the System_______________________________________________________ 29

Process Cards ________________________________________________________________ 29

How the Card Travels ______________________________________________________ 30

About Secure Encryption __________________________________________________ 31

Use the Touch Screen _________________________________________________________ 31

Use the Front Panel__________________________________________ ___ _______________ 32

Power Button______________________________________________________________ 32

LCD Panel ________________________________________________________________ 32

User Button and Light ______________________________________________________ 33

Down Arrow, Up Arrow, and Enter Keys _____________________________________ 33

iii

Page 4

Ribbon Light ______________________________________________________________ 34

Card Light ________________________________________________________________ 34

Use the LCD Menus_______________________________ _____________________________ 35

LCD Menus________________________________________________________________ 36

Pause the System__________________________________________________________ 37

Change the LCD Backlight Brightness_______________________________________ 38

View the Printer Serial Number from the LCD Menu __________________________ 40

View Card Counts from the LCD Menu _____________________________________ 42

View the Network IP Address from the LCD Menu____________________________ 45

Set Magnetic Stripe Coercivity from the LCD Menu __________________________ 48

Use the Printer Manager ________________________________________ _______________ 50

Chapter 5: Card Design __________________________________________________________ _ 53

Basic Card Design ___________________________________ _________________________ 53

Magnetic Stripe Design___ _____________________________________________ ________ 53

About Magnetic Stripes____________________________________________________ 53

Magnetic Stripe Formats ___________________________________________________ 54

Three-Track Option_________________ ____ ___ ____ _______ ___ ___ ____ ___ ____ _ 54

Single-Track JIS Option _________________________________________________ 55

Smart Card Design ____________________________________________________________ 56

About Smart Cards ________________________________________________________ 56

Embossing and Indenting Design_______________________________________________ 57

Settings for Card Design in Printer Manager _____________________________________ 57

Chapter 6: System Maintenance___________________________________________________ 59

Clean the Printer ______________________________________________________________ 59

Clean the Embosser______________________________ _____________________________ 59

Run a Cleaning Card__________________________________________________________ 60

Chapter 7: Troubleshooting________________________________________________________ 63

Tools for Troubleshooting ______________________________________________________ 63

Locating the Issue_____________________________________________________________ 64

Installation Troubleshooting____________________________________________________ 65

Card Appearance ____________________________________________________________ 65

Indent Troubleshooting ___ _________________________________________________ 65

Topping Foil Troubleshooting _______________________________________________ 65

Magnetic Stripe_____________________ __________________________________________ 66

Card Jam_____________________________________________________________________ 68

Printer Card Jam __________________________________________________________ 68

Embosser Card Jam ________________ ___ ____ ___ ____ ___ ____ ______ ____ ___ ____ _ 69

Messages and Conditions _____________________________________________________ 70

Messages on the Printer____________________________________________________ 70

Front Panel Conditions During Messages ________________________________ 70

Messages on the Printer Manager __________________________________________ 71

Respond to Messages _________________________________________________________ 72

Printer Component Messages (100-124)_____________________________________ 72

100: Request not supported ____________________________________________ 72

101: Job could not complete____________________________ _______________ 72

iv

Page 5

102: Card not in position________________________________________________ 73

103: Printer problem____________________________________________________ 73

104: Critical problem ___________________________________________________ 73

105: Magstripe data error ______________________________________________ 73

106: Magstripe data not found _________________________________________ 74

107: Magstripe read data error _________________________________________ 74

108: Magstripe read no data ___________________________________________ 74

111: Card not picked __________________________________________________ 75

112: Hopper Empty_____________________________________________________ 75

113: Close cover to continue ___________________________________________ 75

114: Cover opened during job__________________________________________ 75

116: Magstripe not available ___________________________________________ 75

117: Reader not available ______________________________________________ 75

120: User paused the printer ____________________________________________ 76

122: Magnetic stripe format problem____________________________________ 76

123: Insert new card then continue _____________________________________ 76

124: Insert same card then continue ____________________________________ 76

Embosser Component Messages (125-151)__________________________________ 77

125: Emboss critical issue _______________________________________________ 77

126: Emboss format issue _______________________________________________ 77

127: Emboss transport error _____________________________________________ 77

128: Embosser card jam ________________________________________________ 77

129: Embosser topper jam ______________________________________________ 78

130: Embosser card entry jam___________________________________________ 78

131: Embosser card exit jam ____________________________________________ 78

132: Embosser card stack full ___________________________________________ 79

133: Embosser card reject full___________________________________________ 79

135: Indent ribbon supplies out _________________________________________ 79

136: Indent ribbon break _______________________________________________ 80

137: Embosser wheel error ______________________________________________ 80

138: Embosser indent error______________________________________________ 80

139: Lost card, open emboss cover _____________________________________ 81

140: Embosser not available ____________________________________________ 81

141: Close emboss cover _______________________________________________ 81

142: Emboss cover error ________________________________________________ 81

143: Topper ribbon problem ____________________________________________ 82

144: Topper ribbon out _________________________________________________ 82

145: Topper ribbon type problem _______________________________________ 82

146: Topper ribbon support err. _________________________________________ 82

147: Topper ribbon no tag found________________________________________ 82

149: Option not installed________________________________________________ 83

Chapter 8: Supplies and Parts _____________________________________________________ 85

Supplies ______________________________________________________________________ 85

Indent Ribbon_____________________________________________________________ 85

Topping Foil ________________________________________________ _______________ 85

v

Page 6

Supply Storage Guidelines _________________________________________________ 86

Cards ________________________________________________________________________ 86

Card Size _________________________________________________________________ 86

Card Material _____________________________________________________________ 87

Card Surface______________________________________________________________ 87

Card Handling ____________________________________________________________ 87

Card Storage _____________________________________________________________ 87

Replacement Parts____________________________________________________________ 88

Print Ribbon Cartridge _____________________________________________________ 88

Indent Ribbon Cartridge ___________________________________________________ 88

Topping Foil Cartridge _____________________________________________________ 88

Cleaning Supplies _________________________________________________________ 88

Cleaning Roller Spindle ____________________________________________________ 88

Security Lock Option_______________________________________________________ 88

Printer Power Supply ______________________________________________________ 89

Printer Power Cable _______________________________________________________ 89

Embosser Power Supply__________________________________ ___ ___ ____ ___ ____ _ 89

Embosser Power Cable ____________________________________________________ 89

Network Cable____________________________________________________________ 89

Chapter 9: Legal Notices________________________________________ __________________ 91

Regulatory Compliance _______________________________________________ ___ _____ 91

Liability Statement_____________________________ ________________________________ 93

Safety ________________________________________________________________________ 93

Trademarks___________________________________________________________________ 94

Disclaimer ____________________________________________________________________ 94

Proprietary Notice_____________________________________________________________ 94

vi

Page 7

Revision Log

Datacard CE870 Card Personalization System

Installation and User Guide

Revision Date Description of Changes

A September 2011 First release of this document

B November 2011 Update of the document with numerous additions.

vii

Page 8

viii

Page 9

Chapter 1: Welcome to the

Card Personalization System

This chapter introduces the CE870 Card

Personalization System and its components.

This section describes:

• The CE870 Card Personalization System

• About the System

• System Components

• System Labels

• How To Topics

The CE870 Card Personalization System

This manual describes the CE870 Card

Personalization System and how to use it.

Before you use the system, it must be set up and

installed. In most cases, the installation will be

performed by your systems administrator or

service provider.

Please read this manual thoroughly before you

use the system. It will help you learn about the

features of the system and how to process cards

successfully and efficiently.

Each card program has specific features that are important for you to understand.

Talk with your supervisor, system administrator, or other person to learn about

the features of your card program.

This guide provides operator information and describes how to install the system,

use the various components, and perform routine tasks.

An additional Solution Guide is available for use by Administrators or by

professionals designing a new system for card production.

CE870 Card Personalization System Installation and User Guide 1

Page 10

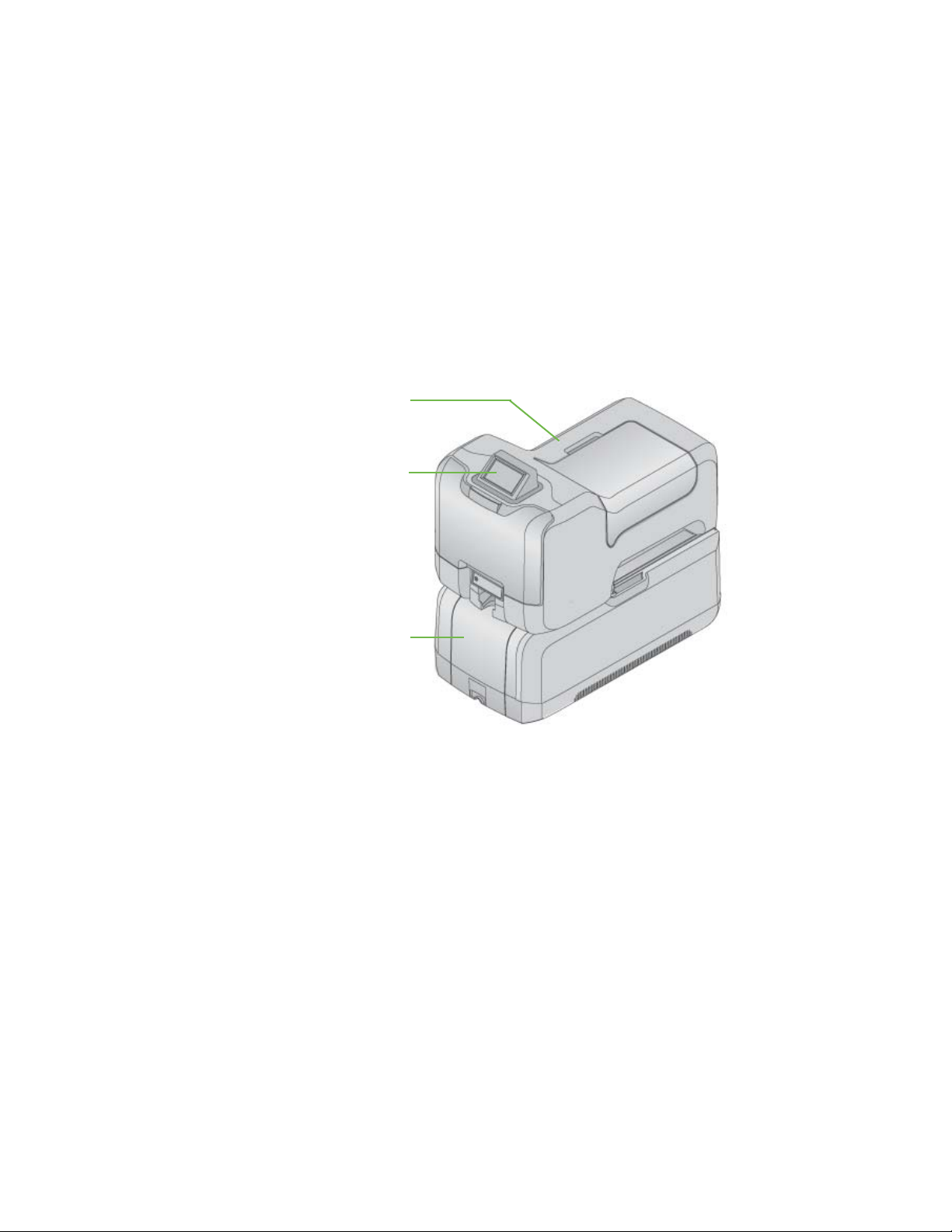

Printer Component

Embosser Component

Touch Screen

Component (Optional)

About the System

The CE870 Card Personalization System is used to produce on-site financial and

debit cards. Personalization includes processing magnetic stripe data, reading or

programming smart cards, embossing, and indenting financial data. The system

is designed to issue cards where the user is (called on-demand or instant

issuance).

The system receives data from a PC or other computer, personalizes the card

using that data, and presents a finished card. The system is a multi-component

system consisting of the following:

2 Welcome to the Card Personalization System

Printer Component

Touch Screen

Component

(Optional)

Embosser Component

Provides print and encoding features. Processes magnetic

stripe data and programs smart card chips using secure

encryption.

Provides the interface for user authentication and card

production.

Produces the raised characters and numbers on the front

of the card; an optional indenter can produce the indented

characters on the back or the front of the card.

Page 11

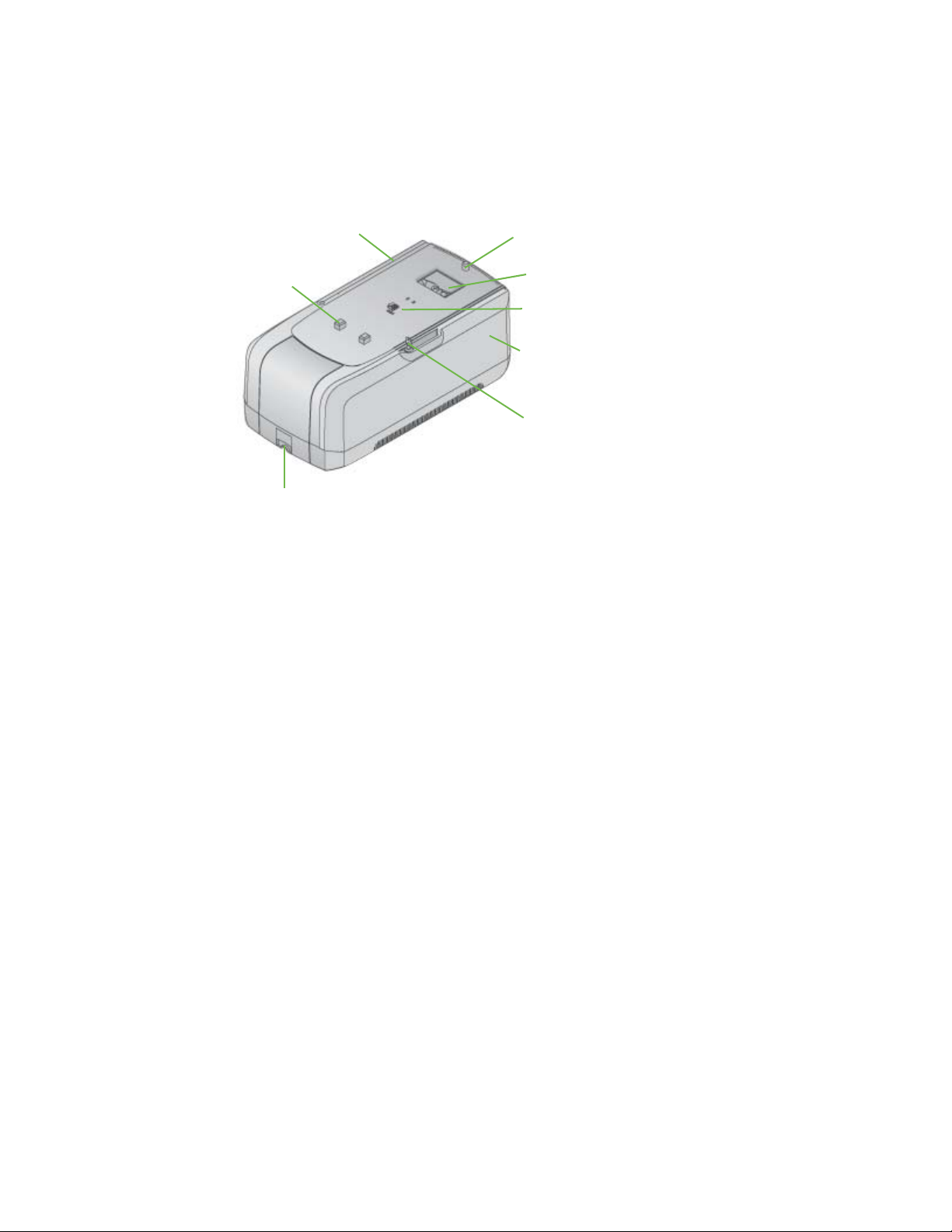

Printer

Front Panel

Printer Supplies Access Door

System Components

The Printer Component (Top, Front and Right Side)

Printer Processes magnetic stripe data and programs smart cards

using secure encryption.

Printer Supplies Access

Door

Front Panel Includes the User button, status lights, power button, and

Unlock and open the embosser supplies access door to

access printer components.

LCD panel with navigation keys.

CE870 Card Personalization System Installation and User Guide 3

Page 12

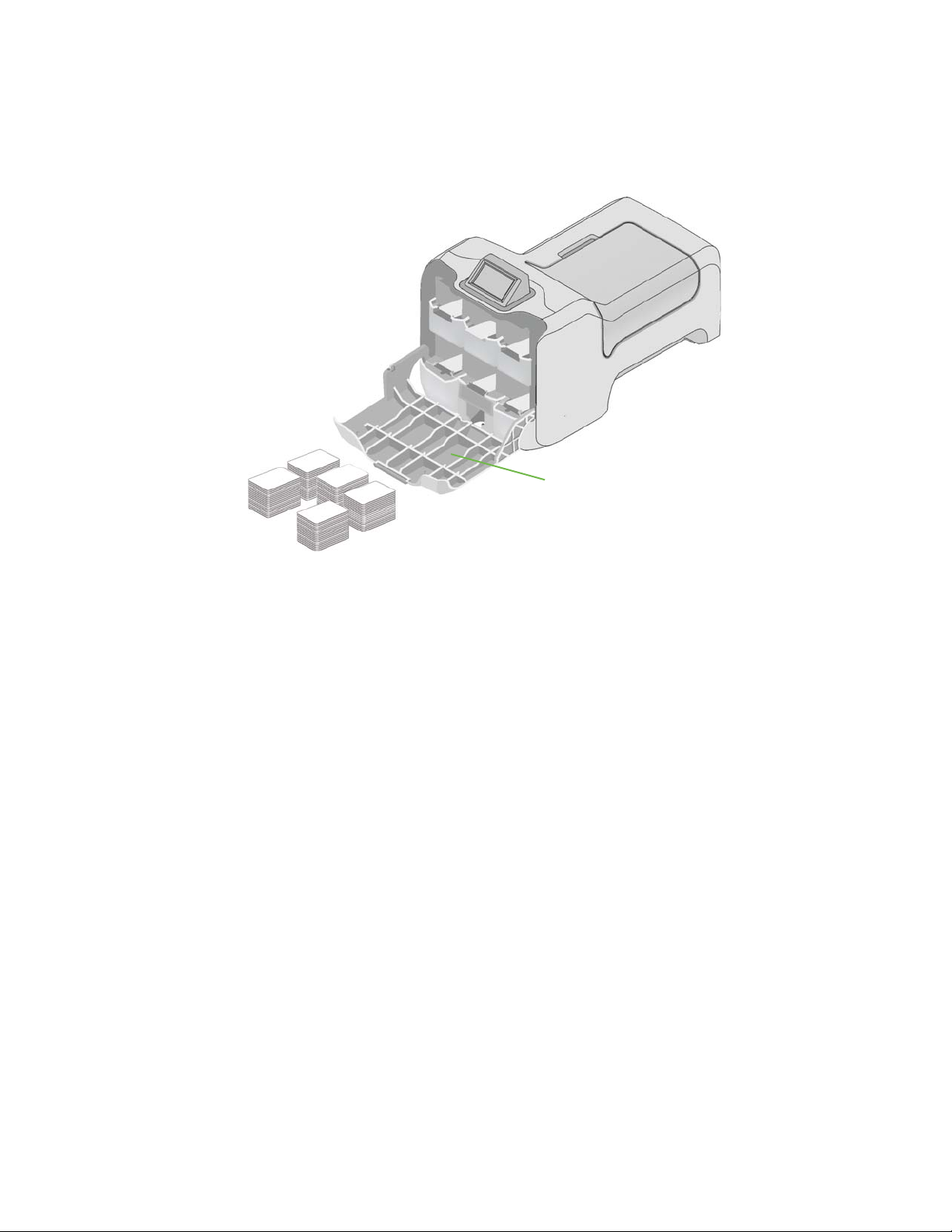

H1

H2

H3

H4

H5

H6

H2

Multi-card Hopper Cover

Printer Multi-Card Hopper

H1 and H3 to H6 Card

Hoppers

H2 Exception Card

Hopper

Multi-Card Hopper

Cover

The H1 and H3 to H6 hoppers contain standard card

designs.

The H2 hopper is a manual card hopper that contains a

manual slot and a storage area in which to store a supply

of cards that are different from standard card designs.

Store and feed cards manually into the H2 hopper.

Unlock and open the access cover to load card stock.

4 Welcome to the Card Personalization System

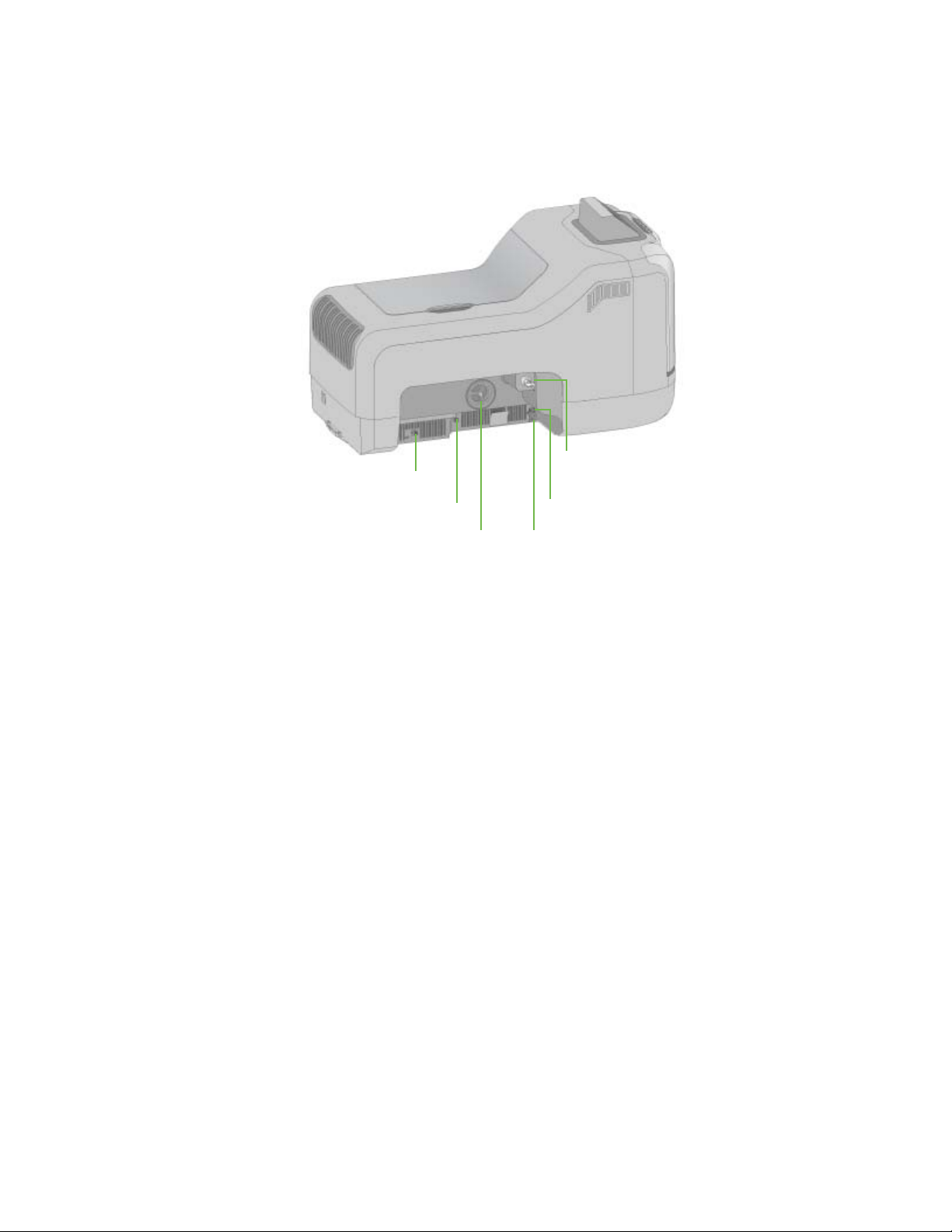

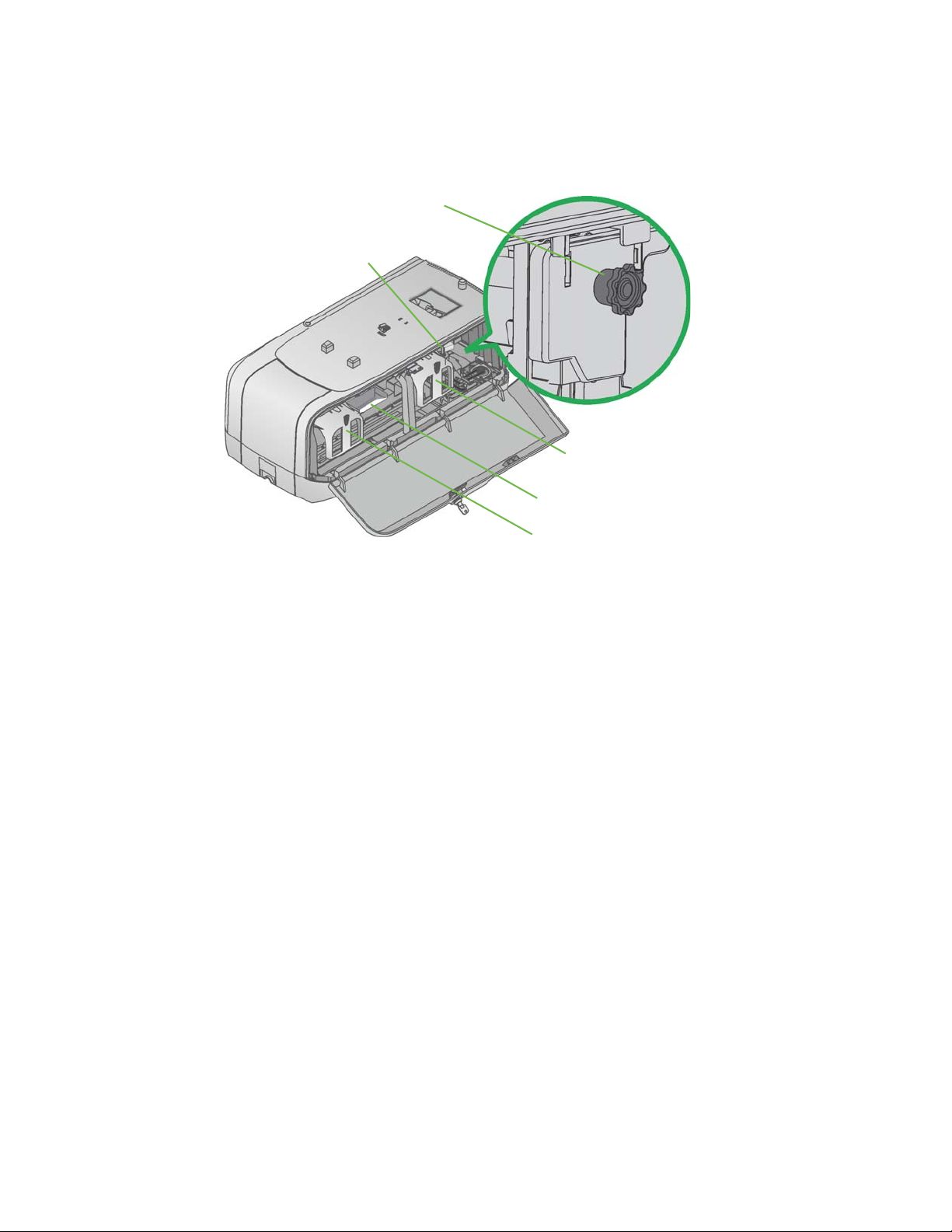

Page 13

Manual Advance Knob

Printer Access

Power Connection

Alarm Terminal

Cover Lock

Network Connection

Embosser Connection

Printer Connections (Left Side)

Alarm Terminal Connect alarm system provided by others.

Power Connection Plug in power supply.

Manual Advance Knob Use the manual advance knob to clear a card jam and

move the card in the card track.

Printer Access Cover

Provides secure access to the printer.

Lock

Network Connection Ethernet connection to network.

Embosser Connection Connect the printer to the embosser using cable from

embosser.

CE870 Card Personalization System Installation and User Guide 5

Page 14

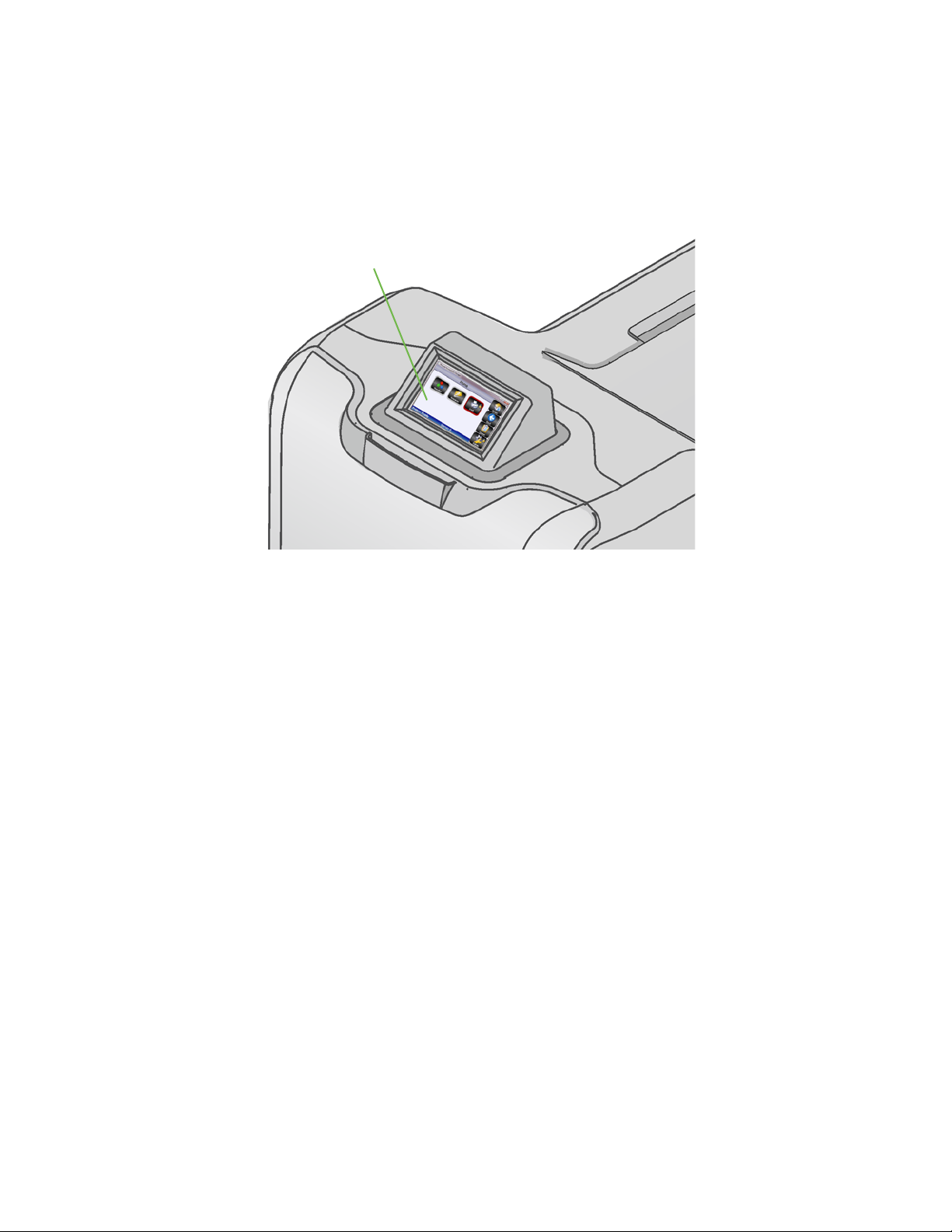

Touch Screen

The Touch Screen Component (Optional)

Touch Screen Standards Buttons with a red background require a PIN to access.

Buttons with a black background are active and can be

selected.

Buttons with a gray background are inactive and cannot

be selected.

Card Hopper Levels View the card type and number of cards remaining in

each of the hoppers inside the multi-card hopper.

Supply Levels View the amount of indent ribbon and topping foil

supplies remaining.

Printer Information View system information including:

• Model

• Serial number

• Firmware version

• IP address

• E-mail alert address

• Flash memory free space

• Printer options

For more information about the Touch Screen, see the Touch Screen User Guide.

6 Welcome to the Card Personalization System

Page 15

Printer Mounting Pins

Printer Mounting Lock

Embosser Supplies Access Door

Card Transfer Area

Embosser Access Door Lock

Printer

Mounting Pins

Cable Guide

Card Output Hopper

The Embosser Component (Top, Front and Right Side)

Cable Guide The cable guide keeps data cables between the printer and

embosser organized and hidden.

Printer Mounting Pins Aligns the printer to the embosser.

Card Transfer Area Receives the card from the printer component and places

it in position for embossing and indenting.

Printer Mounting Lock Secures the printer to the embosser.

Embosser Supplies

Access Door

Embosser Access Door

Unlock and open the embosser supplies access door to

load indent ribbon and topping foil.

Provides secure access to the embosser supplies.

Lock

Card Output Hopper Concealed output hopper holds up to ten completed

cards.

CE870 Card Personalization System Installation and User Guide 7

Page 16

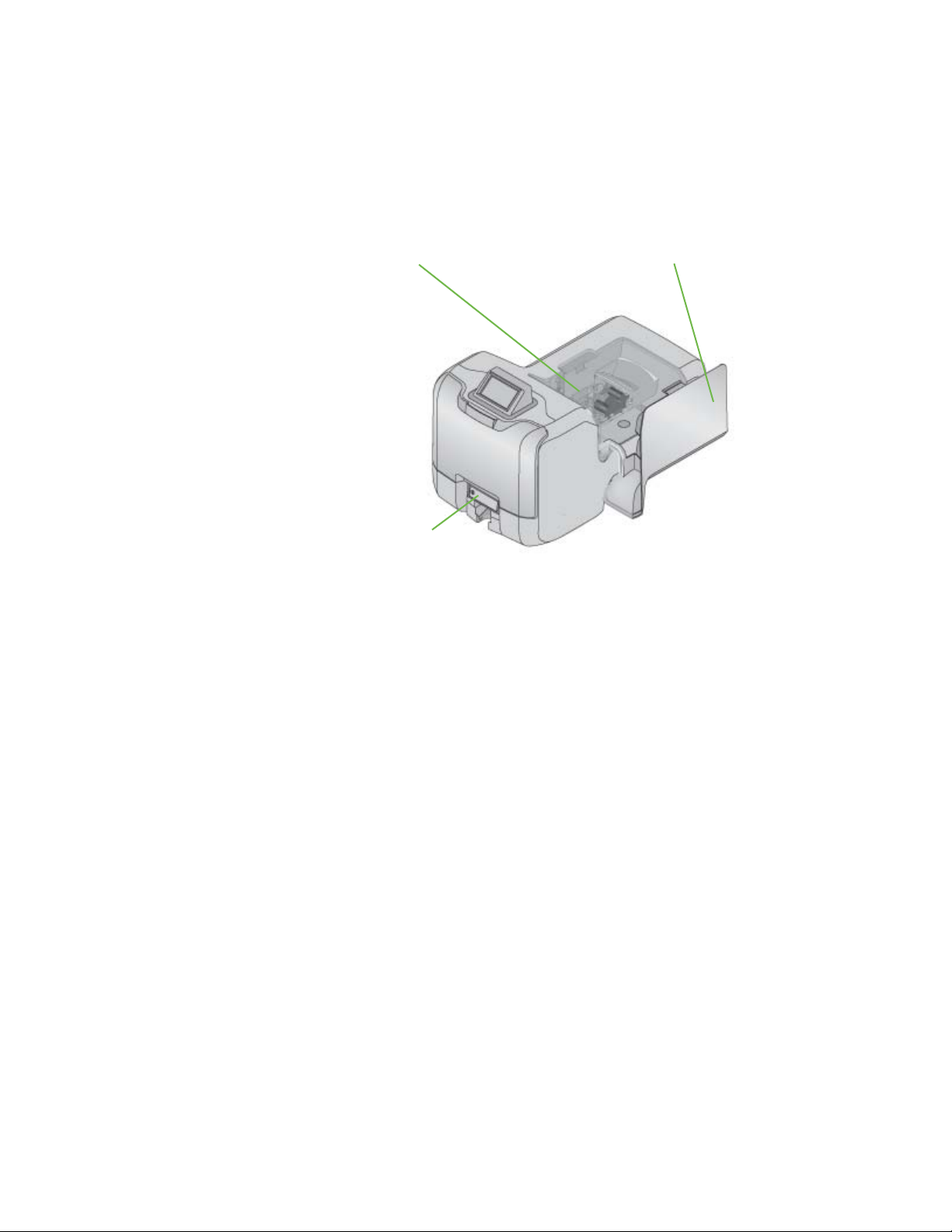

Printer Lock Lever

Indent Ribbon Cartridge

Reject Card Tray

Topping Foil Cartridge

Manual Advance Knob

Inside the Embosser

Printer Lock Lever Push the lever in to lock the printer to the embosser.

Manual Advance Knob Use the manual advance knob to clear a card jam and

move the card in the card track.

Indent Ribbon Cartridge Indent ribbon cartridge holds the indent ribbon supply.

Reject Card Tray Unfinished cards or cards not properly processed exit the

system to the reject card tray.

Topping Foil Cartridge Topping foil cartridge holds the topping foil supply.

8 Welcome to the Card Personalization System

Page 17

Power Connection

Alarm terminal

Security Lock Option

Embosser Connections (Back and Left Side)

Security Lock Option Receptacle for a cable style lock, such as a Kensington

lock.

Alarm Terminal Connect alarm system provided by others.

Power Connection Plug for the embosser power supply.

CE870 Card Personalization System Installation and User Guide 9

Page 18

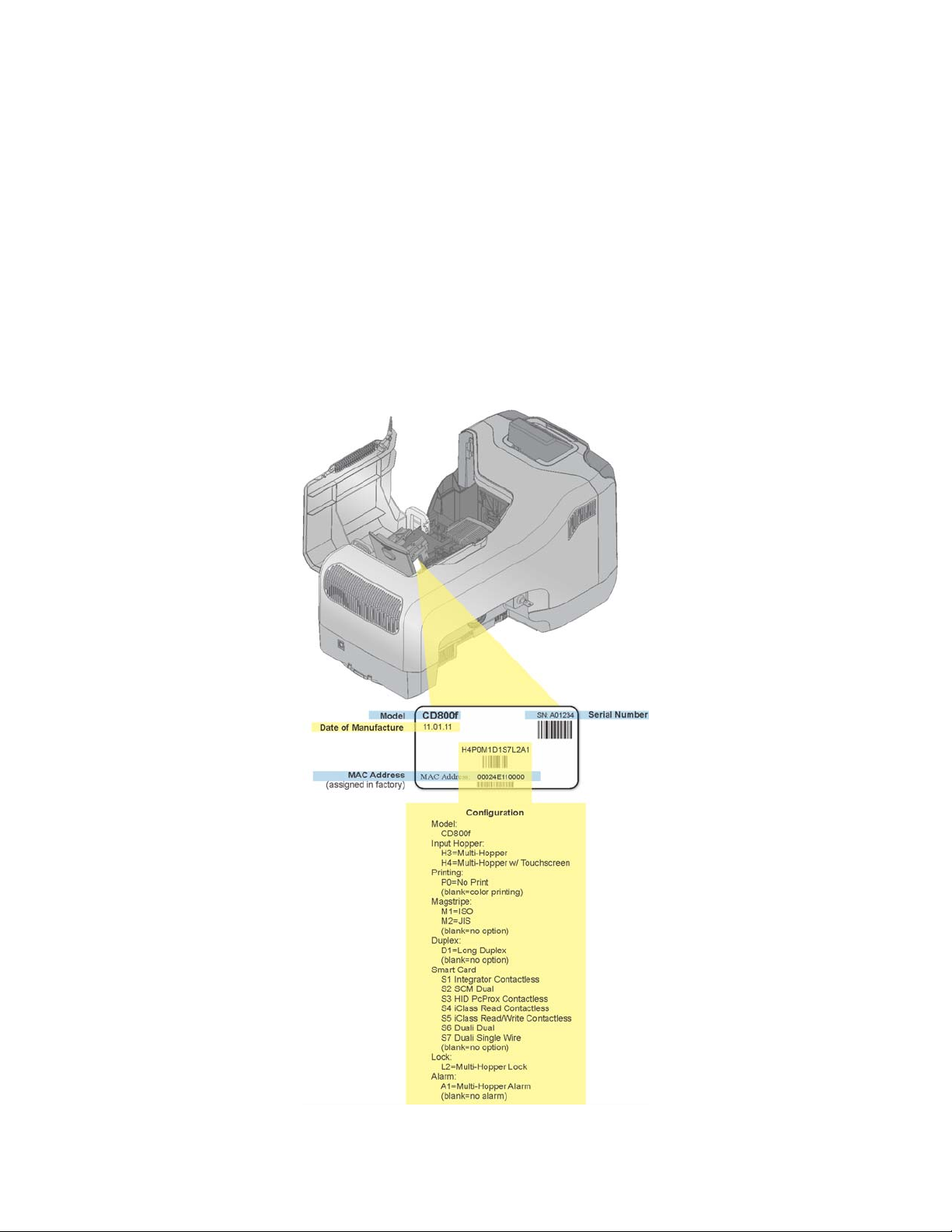

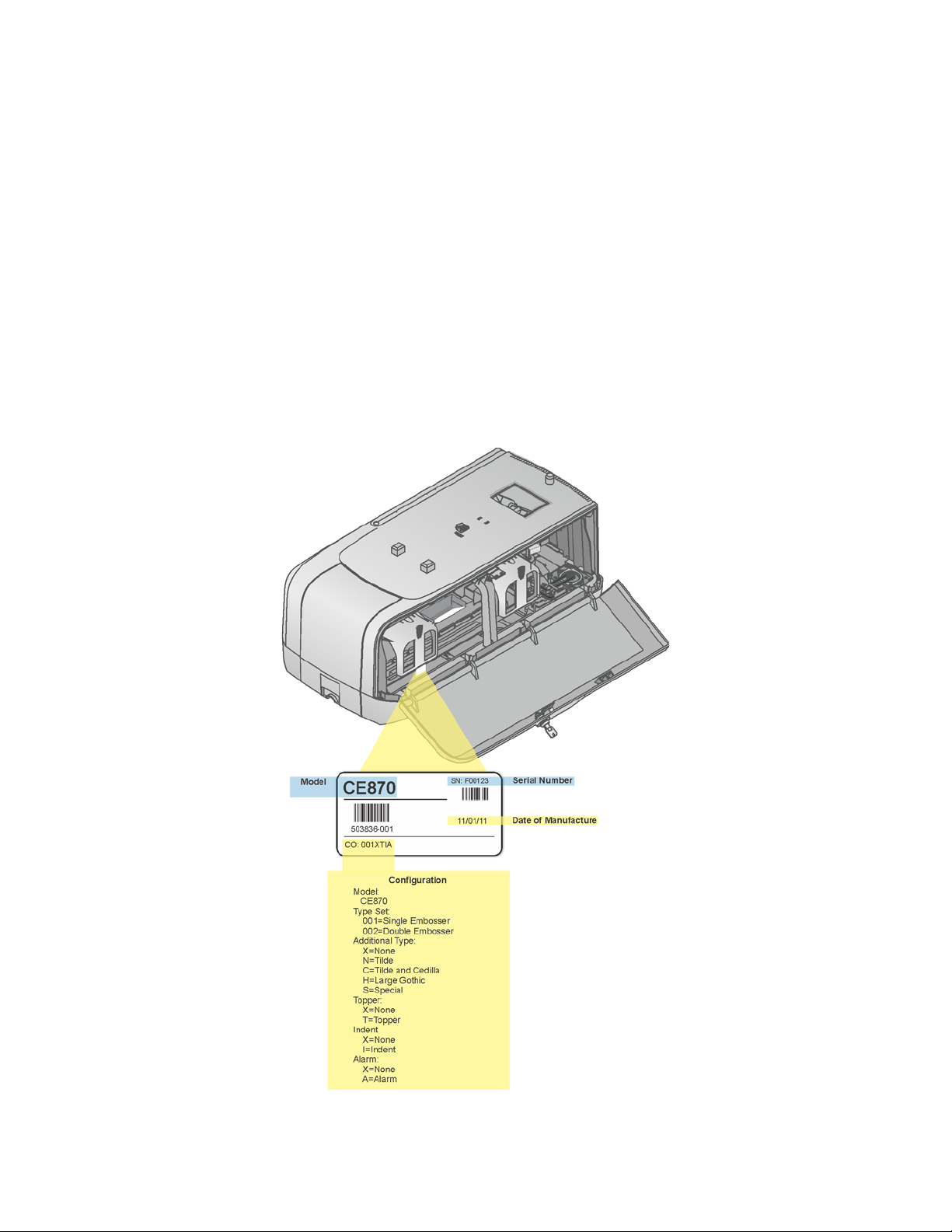

System Labels

There are two labels on the system, the printer configuration label and the

embosser configuration label. The following section describes the labels, where to

find them, and how to read them.

Printer Configuration Label

The printer configuration label is located under the printer supplies access door

on the left-hand side of the printer swingarm. To view the label, unlock and open

the printer supplies access door and press the silver button on top of the printer.

The swingarm is spring-loaded and will open when the button is released.

10 Welcome to the Card Personalization System

Page 19

The printer configuration label shows the printer name, configuration, date and

country of assembly and the MAC address to use when the printer is connected

using an Ethernet network.

The printer configuration label provides information that is useful when

requesting service. It can also help you know which components are installed. If

components are installed by the dealer or sales group, the information for those

items should be on the label.

Embosser Configuration Label

The embosser configuration label is located inside the embosser on the lower

enclosure. To view the label, unlock and open the embosser supplies access door

and locate the label inside.

CE870 Card Personalization System Installation and User Guide 11

Page 20

The embosser configuration label shows the embosser name, configuration, date

and country of assembly.

The embosser configuration label provides information that is useful when

requesting service. It can also help you know which components are installed. If

components are installed by the dealer or sales group, the information for those

items should be on the label.

How To Topics

Select a link from the topics below to quickly access common user topics on how

to use the CE870 Card Personalization System.

• Select Use the Touch Screen for information on how to open printer

manager.

• Select LCD Panel for information on how to view and use the printer LCD

menus.

• Select Respond to Messages for information on how to respond to messages

that appear on the printer LCD display.

• Select Run Test Card for information on how to print a test card and verify

system operation.

• Select Run a Cleaning Card for information on how to run a cleaning card as

recommended after every 500 cards are produced.

• Select Load Cards in Hopper for information on how to load cards into the

multi-card hopper.

• Select Load Indent Ribbon Cartridge for information on how to replace

indent ribbon inside the embosser.

• Select Load Topping Foil Cartridge for information on how to replace

topping foil inside the embosser.

12 Welcome to the Card Personalization System

Page 21

Chapter 2: Installation

Requirements

This chapter describes the PC requirements, site requirements, and

electrical requirements for the equipment.

Your company may have additional requirements for a card

production environment. Talk to your system administrator to

determine the optimum location for card production.

This section describes:

• PC Requirements

• Site Requirements

• Electrical Requirements

PC Requirements

The following network components are required:

• An Ethernet network that uses the TCP/IP protocol and can run at 100

megabits per second, also called 100base-T.

• An Ethernet cable to connect the system to the network. No Ethernet cable is

supplied with the system.

• A PC that meets the requirements listed above and is connected to and

communicating with the network.

CE870 Card Personalization System Installation and User Guide 13

Page 22

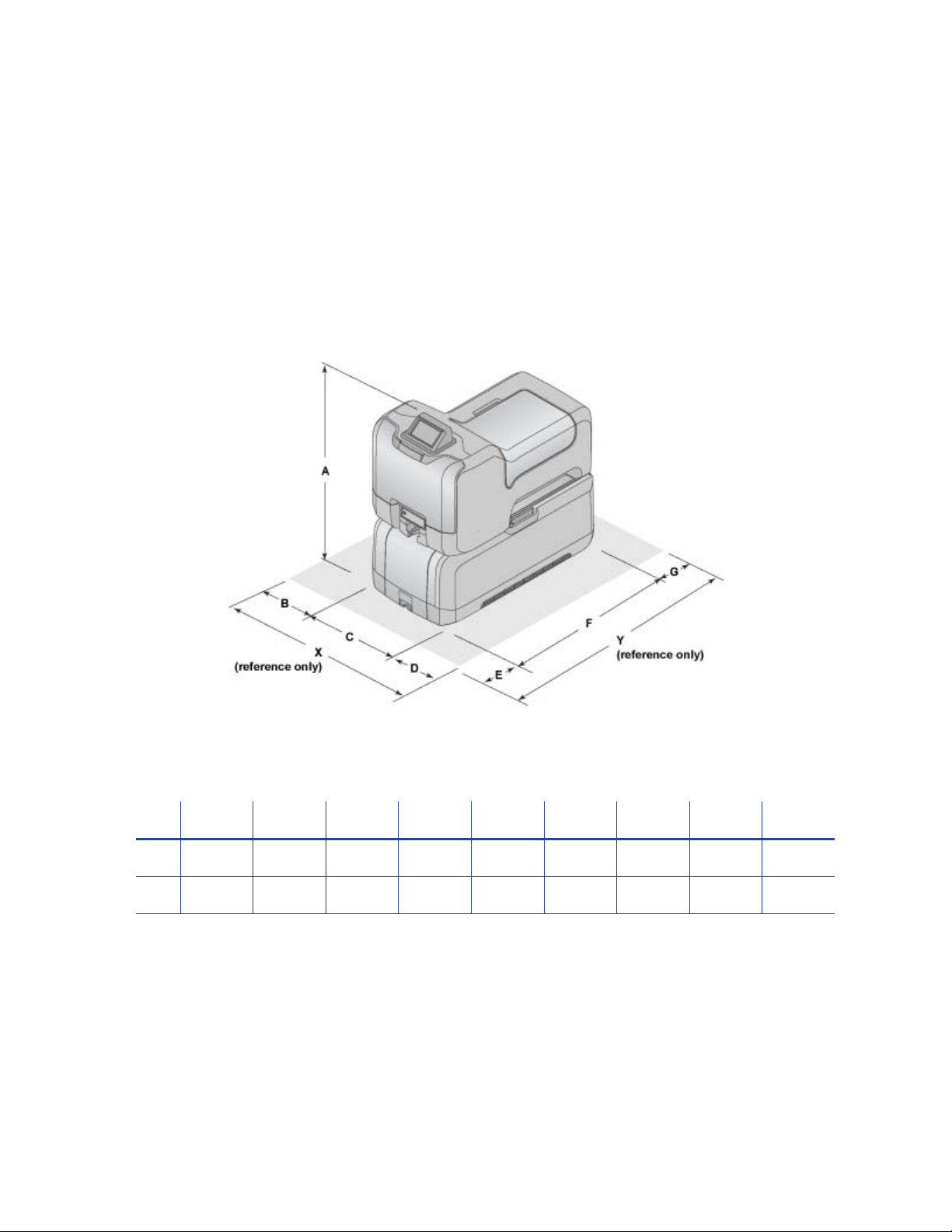

Site Requirements

Set up and use the system in an environment that meets the following

requirements.

• It is recommended that the system be placed on a table that is no taller than 32

inches (81 cm) in height to allow easy user access and viewing of components.

• Provide space for the system and for clearance around the system. The system

dimensions and recommended clearance area are shown in the table below.

Dimensions (in/cm)

ABCDEFGXY

in 27.6 2 16.3 8.5 10 28.1 2 26.8 40.1

cm 70.1 5.1 41.4 21.6 25.4 71.4 5.1 68.1 101.9

• Choose a location in an environment with temperatures ranging from

60° to 95° F (15° to 35° C).

• Use single phase, 3-wire, grounded receptacles.

• Keep all dust, dirt, food, and liquids away from the system.

• Place the system and its supplies in a clean office environment, keeping paper

and foreign materials off the equipment.

14 Installation Requirements

Page 23

• Place the system on a sturdy, level surface.

• Place the system and its supplies away from direct sunlight.

• Do not place the system near heating ducts, fans, or other air vents.

• Do not use the system for purposes other than the intended use.

Electrical Requirements

The power supply is rated as follows:

System Component Electrical Requirements

Printer 110-240V ~ 1.5 Amp, 50-60Hz

Embosser 110-240V ~ 3.5 Amp, 50-60Hz

The power supply detects the input voltage, and works within the range stated.

CE870 Card Personalization System Installation and User Guide 15

Page 24

16 Installation Requirements

Page 25

Chapter 3: Install the System

This section provides information about installing

the CE870 Card Personalization System. Installation

includes system setup, connecting cables, and

installing supplies.

The setup procedure is

described in this section. The

components are shipped in

several containers. Make

sure that you have all

components, including those

not supplied, before you

start the installation. Items

not supplied in the shipping

cartons include Ethernet

cable(s) and bolt-down supplies.

The system is often installed by a systems administrator or service provider.

This section describes how to:

• Secure the System

• Assemble the Printer and Embosser

• Load Supplies

• Connect Cables

• Run Test Card

CE870 Card Personalization System Installation and User Guide 17

Page 26

Indent Ribbon

Cartridge

Topping Foil

Cartridge

Embosser Supplies

Access Door

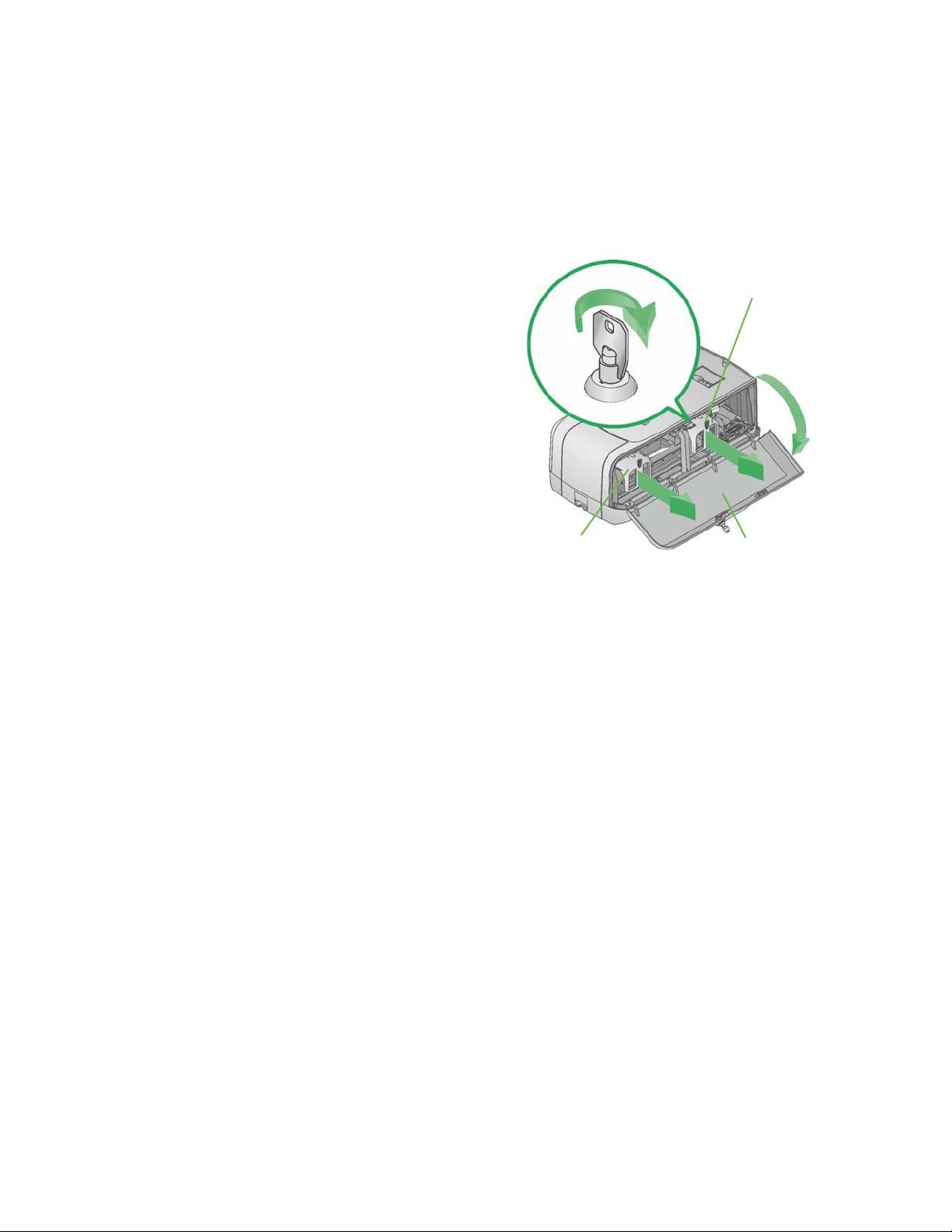

Secure the System

The embosser includes bolt-down openings for securing the system to its

mounting surface. Choose a location in which to install the system following the

requirements shown in Site Requirements.

1. Unlock and open the embosser

supplies access door.

2. Remove the topping foil and

optional indent ribbon cartridges

and set aside.

3. Bolt the embosser to the work

surface.

You need the following supplies:

• Embosser Bolt-Down

Specification Sheet (Part No.

539999-001).

• Two 1/4 inch Bolts.

The length of the bolts depends on the thickness of the mounting surface.

Bolt length minimum of surface thickness + ¾ inch. Bolt length maximum

of surface thickness +1¼ inch.

• Two 5/8 inch outer diameter Washers.

• Two 1/4 inch Nuts.

Plastic locking nuts are recommended.

A. Drill mounting holes in the mounting surface following the dimensions

and requirements shown on the Embosser Bolt-Down Specification Sheet.

B. Insert the bolts.

i. Place a flat washer on each of the bolts.

ii. Insert the bolts into the mounting holes inside the embosser.

iii. Align the bolts with the holes in the embosser.

C. Secure the embosser using washers and nuts on the inside of the

embosser.

4. Replace the topping foil and indent ribbon cartridges.

5. Close and lock the embosser supplies access door.

18 Install the System

Page 27

Printer

Locking

Lever

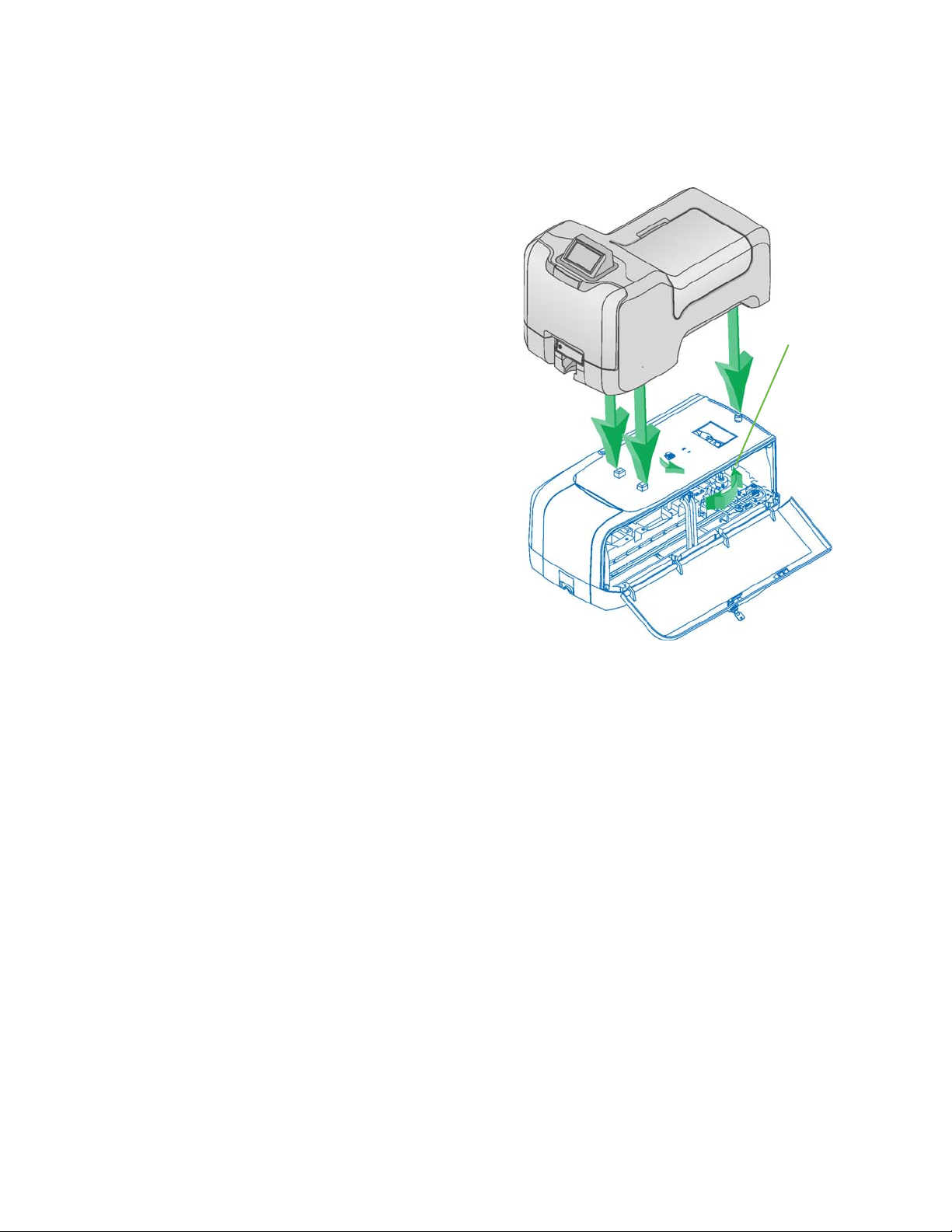

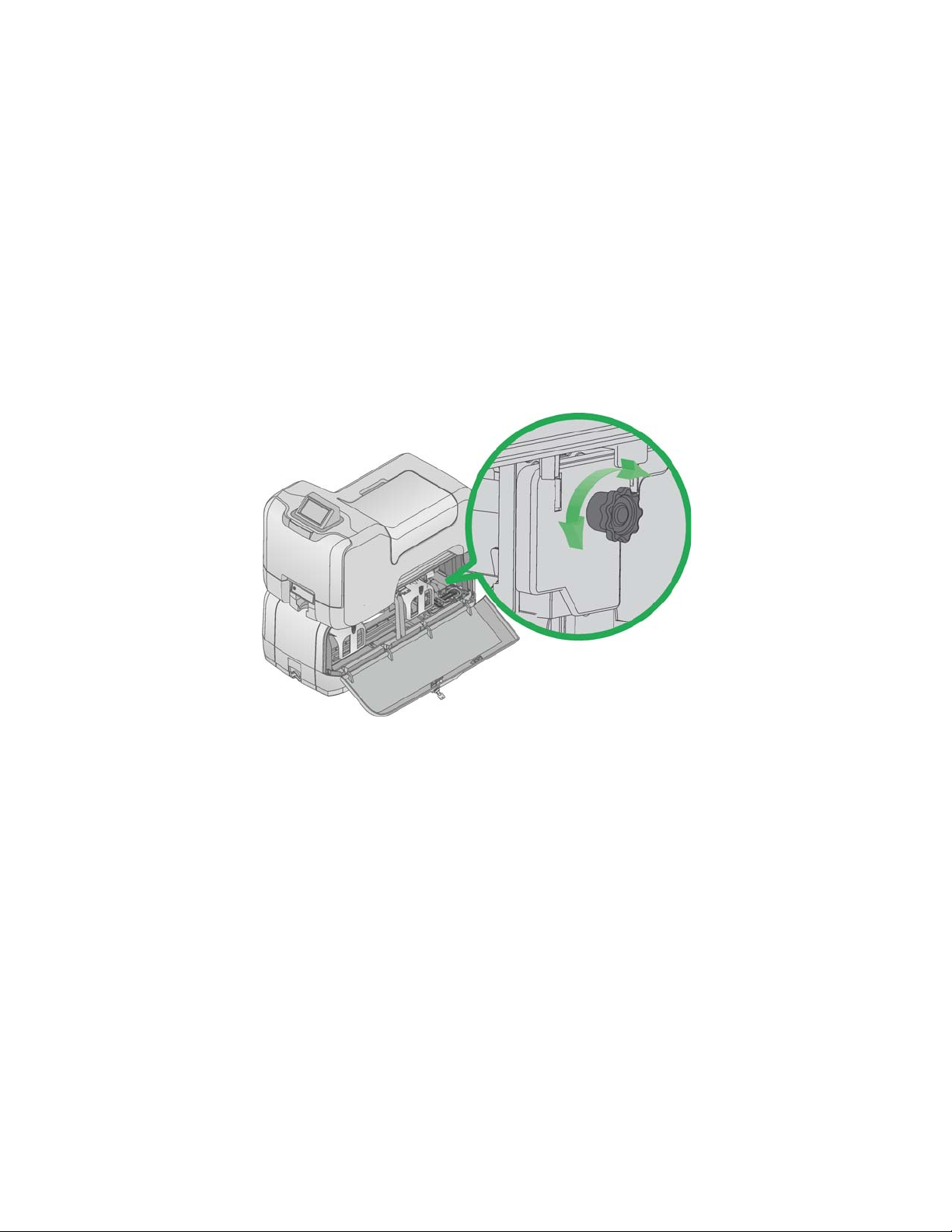

Assemble the Printer and Embosser

1. Unlock and open the embosser

supplies access door.

2. Slide the printer locking lever to

the left to position the mounting

lock in the unlocked state.

3. Lift the printer over the embosser

and align the pins on the

embosser with the holes on the

underside of the printer.

4. Press down gently, but firmly on

the printer component and push

the printer locking lever to the

right to lock the printer to the

embosser.

5. Check that the printer is securely

locked to the embosser.

6. Close and lock the embosser

supplies access door.

CE870 Card Personalization System Installation and User Guide 19

Page 28

Load Supplies

Embossing supplies include topping foil and indent ribbon. The topping foil is

applied to the embossed characters and can be applied to up to five lines of

characters. The indent ribbon is used to apply black (or white) color to a single

line of indented characters. The printer supplies include a cleaning sleeve.

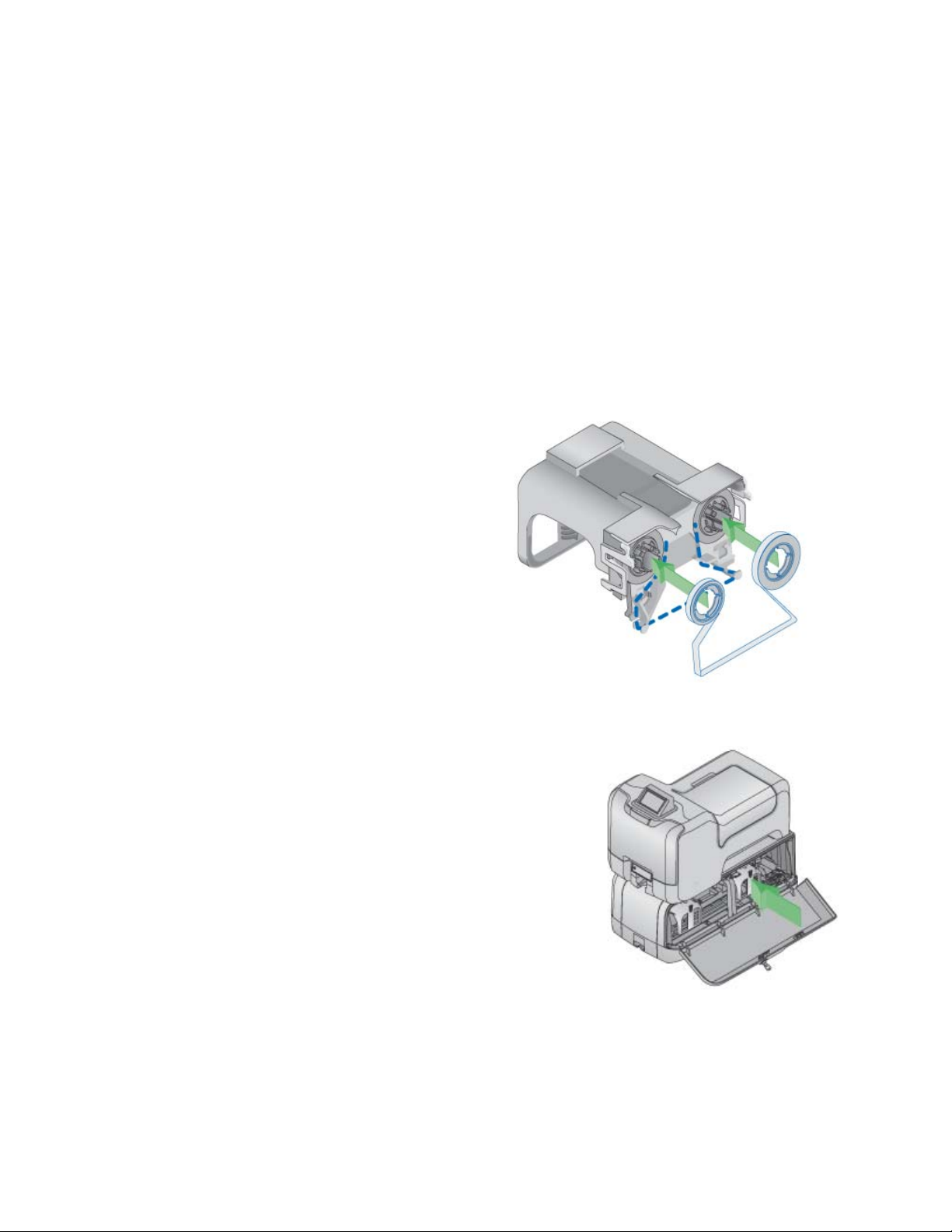

Load Indent Ribbon Cartridge

1. Unlock and open the embosser supplies access door and remove the cartridge

from the embosser. The indent ribbon cartridge is on the right. See Inside the

Embosser for more information.

2. Push the full roll of indent

ribbon onto the spindle on

the right until it snaps

securely into place.

3. Route the ribbon around the

ribbon guides as shown.

4. Push the empty take-up

spool onto the spindle on the

left until it snaps securely

into place.

5. Turn the take-up spool one

full turn counterclockwise to

take up ribbon slack.

6. Replace the indent ribbon cartridge.

The emboss and indent ribbon cartridges

are not interchangeable; they fit only into

the designated cartridge area.

A. Hold the cartridge by its handle.

B. Align the cartridge with the guides

inside the embosser.

C. Slide the cartridge in until it stops.

7. Close and lock the embosser supplies

access door.

20 Install the System

Page 29

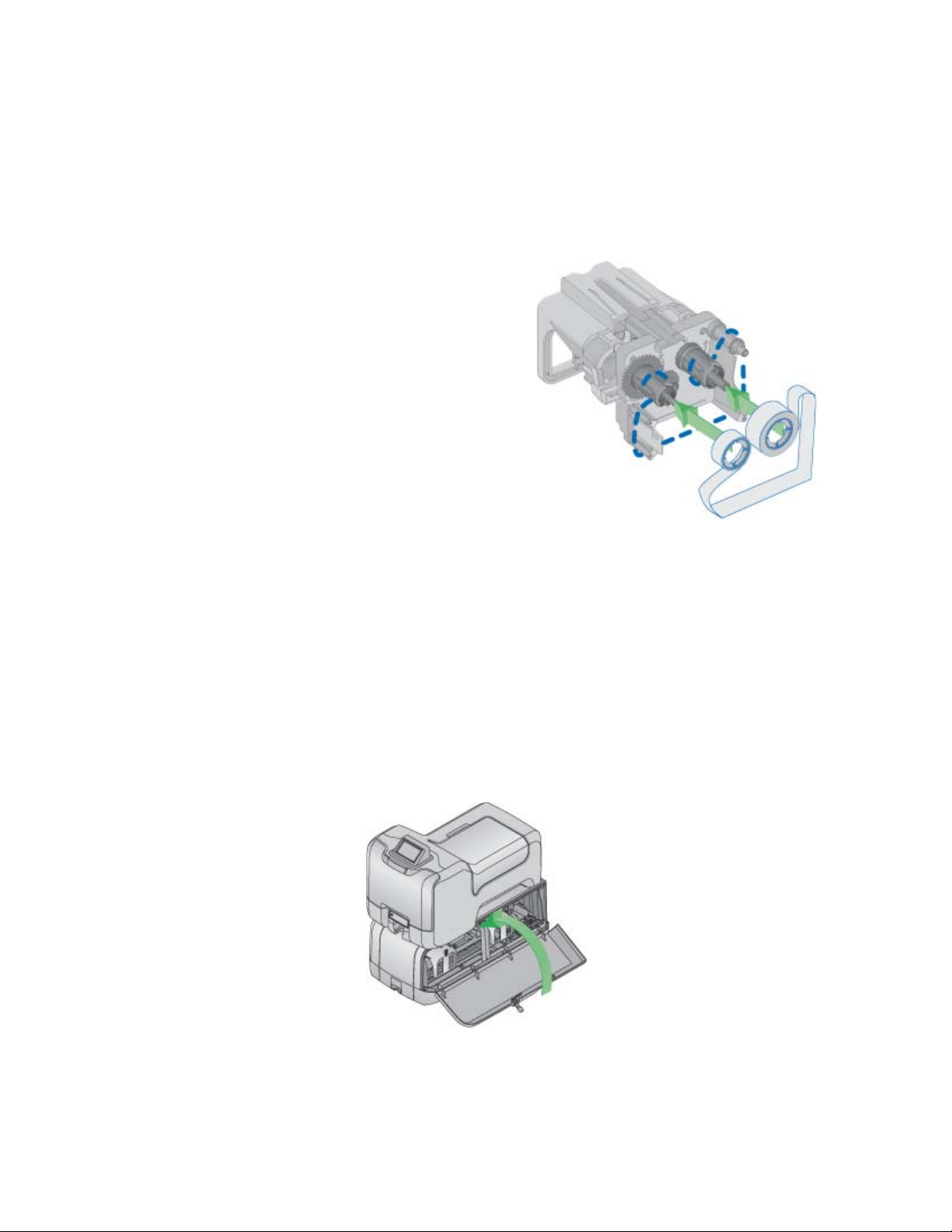

Load Topping Foil Cartridge

1. Unlock and open the embosser supplies access door and remove the topping

foil cartridge. The topping foil cartridge is on the left. See Inside the

Embosser for more information.

2. Push the full roll of ribbon onto the

spindle on the right until it snaps

securely into place.

3. Route the ribbon around the

ribbon guides as shown.

4. Push the empty take-up spool onto

the spindle on the left (spindle

with the black gear) until it snaps

securely into place.

5. Turn the take-up spool one full

turn counterclockwise to take up

ribbon slack.

6. Replace the topping foil cartridge.

The emboss and indent ribbon cartridges are not interchangeable; they fit

only into the designated cartridge area.

A. Hold the cartridge by its handle.

B. Align the top of the cartridge with the guides inside the embosser.

C. Slide the cartridge in until it stops.

7. Close and lock the embosser supplies access door.

CE870 Card Personalization System Installation and User Guide 21

Page 30

Printer

Supplies

Access Door

Unlock

Silver

Button

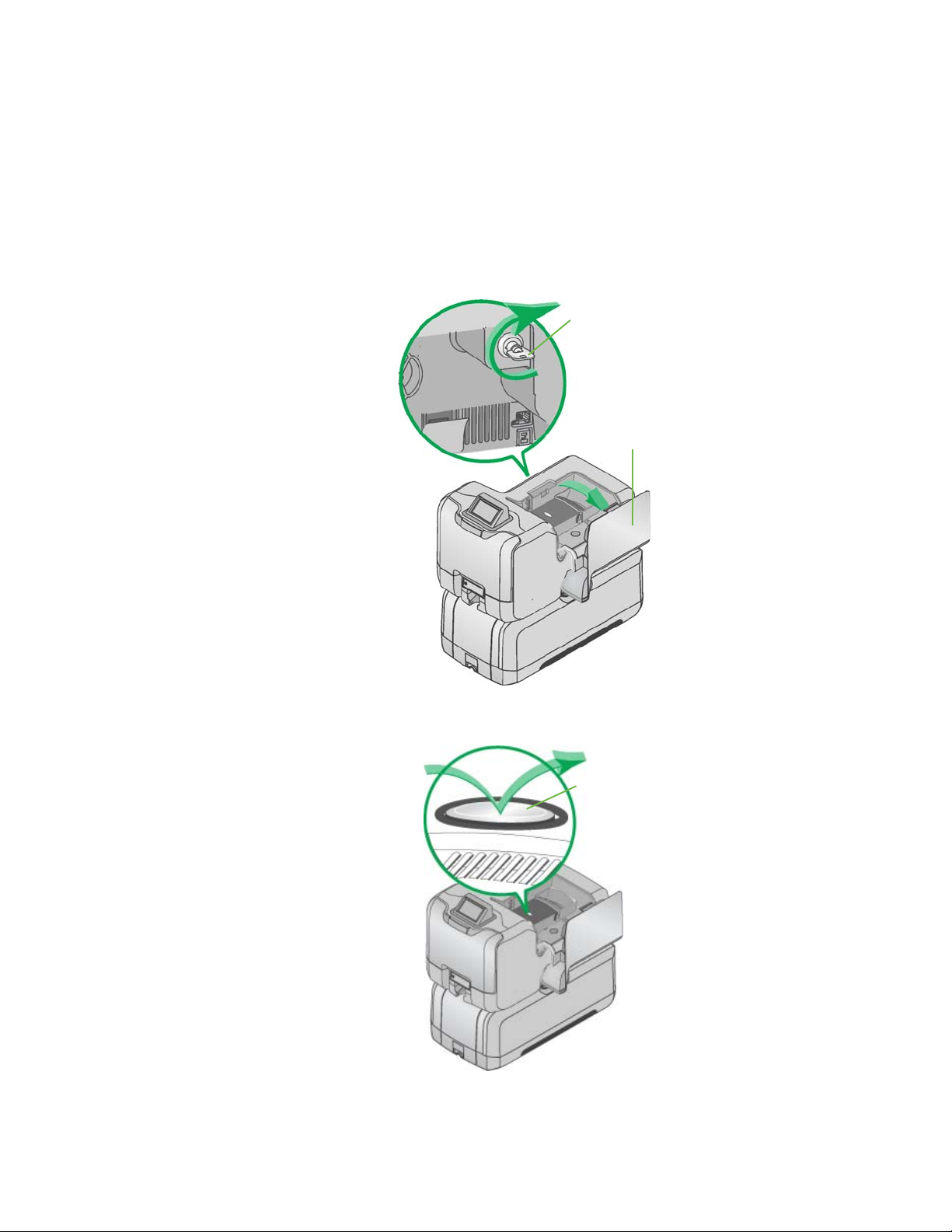

Load Cleaning Sleeve

The printer component uses a replaceable cleaning sleeve to clean dust or lint

from the surface of the card stock before processing data. Each cleaning sleeve is

effective for approximately 500 cards.

1. Unlock the printer and open the printer supplies access door.

2. Press the silver button and open the printer swingarm.

22 Install the System

Page 31

Print

Ribbon

Cartridge

Protective

Ribbon

Cleaning

Roller

Spindle

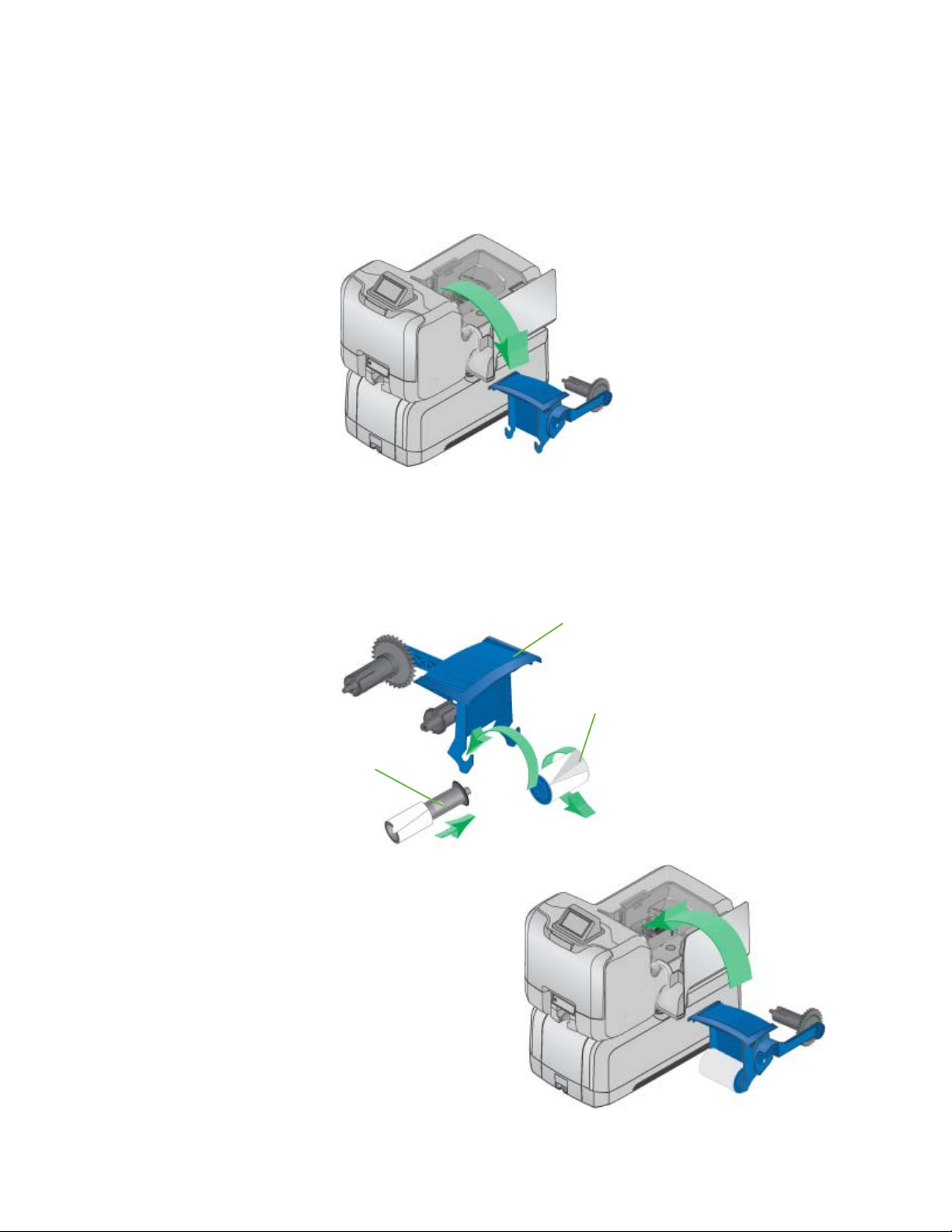

3. Prepare the print ribbon cartridge.

A. Remove the print ribbon cartridge. The printer ships with the cleaning

roller spindle installed on the print ribbon cartridge.

B. Remove the cleaning roller spindle from the cartridge and slide the

continuous cleaning sleeve onto the spindle. Place the spindle with

cleaning sleeve back onto the ribbon cartridge.

C. Remove the protective wrapper from the cleaning sleeve.

4. Reinstall the ribbon cartridge and

close the printer swing arm.

5. Leave the printer access door

open and unlocked to load cards

into the multi-card hopper. The

printer lock secures both the

printer access and multi-card

hopper doors.

CE870 Card Personalization System Installation and User Guide 23

Page 32

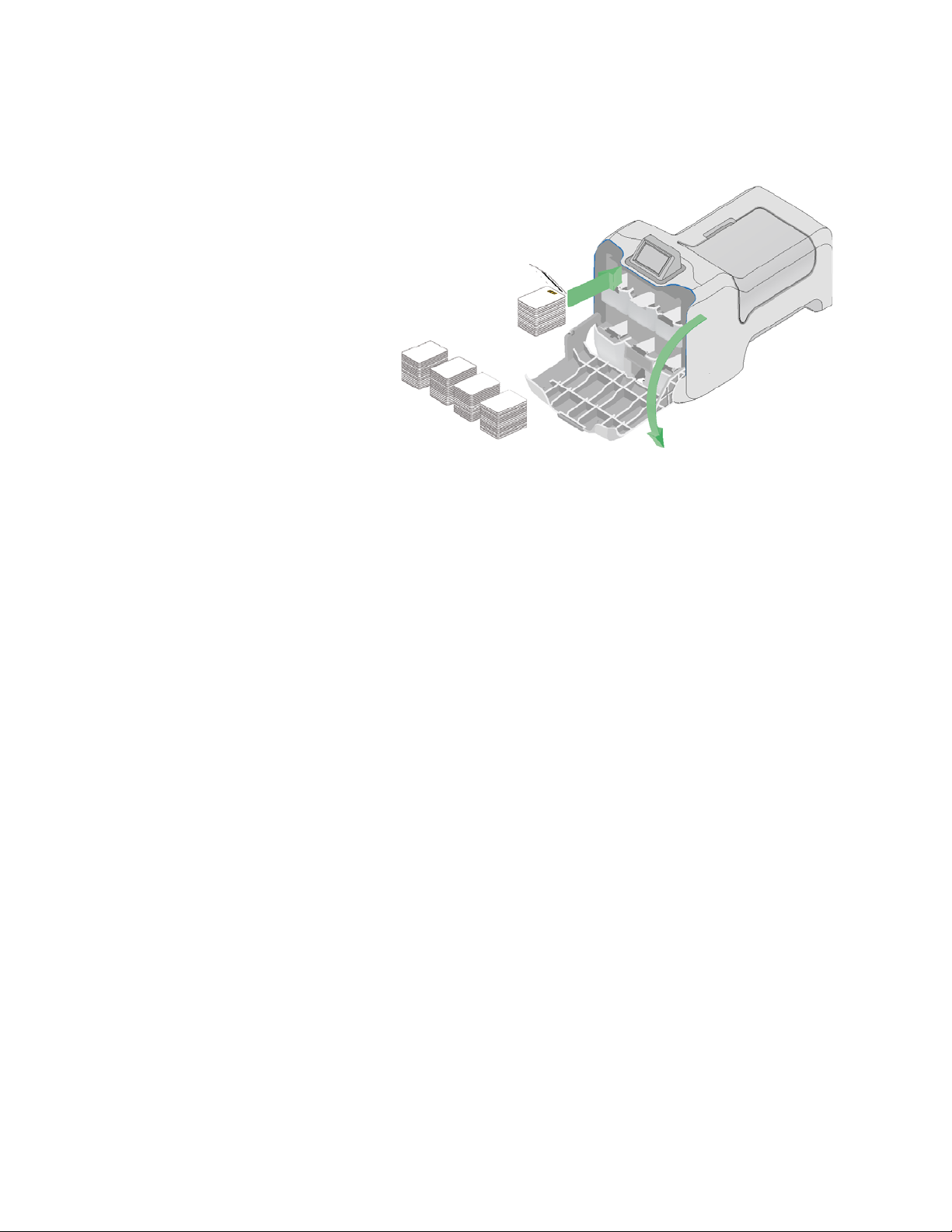

Load Cards in Hopper

1. Open the multi-

card hopper.

2. Fan cards before

placing them into

the input hopper.

• Insert

magnetic

stripe cards

with the

stripe down

and toward

the right side

of the input

hopper.

• Insert smart cards (contacted or contactless) with the smart card chip on

top toward the back of the hopper.

3. The input hoppers are labeled H1 through H6. Load up to 100 cards (0.030-in

/ 0.762mm thickness) into hoppers H1, H3, H4, H5, and H6.

4. The hopper labeled H2 is the manual hopper and manual slot. Load special

card stock on the optional shelf located in the hopper for manual printing.

5. Close the multi-card hopper when finished loading cards.

24 Install the System

Page 33

Printer

Supplies

Access Door

Printer

Swingarm

Lock

Data

Cable

Ethernet

Cable

6. Close and lock the printer swingarm and supplies access door.

Connect Cables

Connect Data Cables

This section provides information about connecting the printer to the embosser

and connecting the system to the network. Connect the cables in the order below.

1. Connect the data cable from the

embosser to the bottom data

port on the printer.

2. Connect the system to a network

connection using an Ethernet

cable. This cable is not supplied

with the system.

3. Plug one end of the Ethernet

cable into the top port on the

printer, and the other end into

your network port.

CE870 Card Personalization System Installation and User Guide 25

Page 34

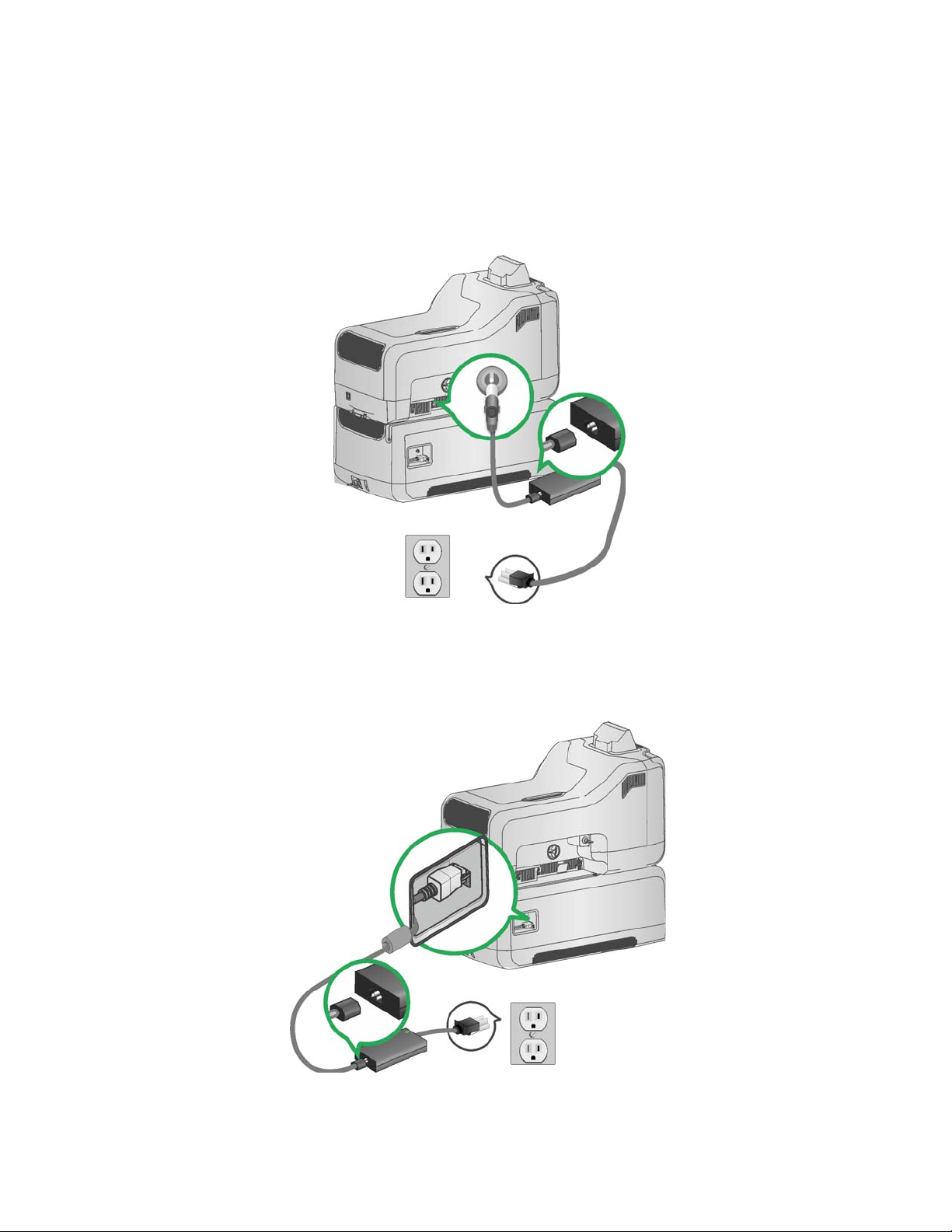

Connect Power Cables

1. Connect the printer power cable into the printer and into the power supply.

2. Connect the power supply cord into the power outlet.

3. Connect the embosser power cable into the embosser and into the power

supply.

4. Connect the power supply cord into the power outlet.

26 Install the System

Page 35

Power on the System

1. Power on the system by

pressing the power button on

the Front Panel.

2. Wait until the system has

powered on and Ready

displays on the LCD screen.

3. See Power Button for more

information.

CE870 Card Personalization System Installation and User Guide 27

Page 36

Run Test Card

Process a test card to verify that the

system has been set up correctly and is

working.

Run a test card using the Printer

Manager. For more information about

the Printer Manager, see the Solutions

Guide (Part No. 539998).

28 Install the System

Page 37

Chapter 4: Using the System

This section details information about how the card travels

through the system, how the data is received and processed, and

how to use the features of the system such as the optional Touch

Screen and the printer’s Front Panel.

This section describes how to:

• Process Cards

• Use the Touch Screen

• Use the Front Panel

• Use the LCD Menus

• Use the Printer Manager

Process Cards

The software used to enter card data is called a server-based print director. In

most cases, this is a custom application developed specifically for your

organization. The software is designed to send card data to the card

personalization system.

The data is received and the card can be accessed and produced from the system’s

optional Touch Screen. The Touch Screen uses the Datacard Personalization

Manager (DPM) to produce the card. With DPM, you can select which hopper to

pick from, and preview your print job before producing a card.

To access the features of the DPM and to produce a card, you will need to sign in

to the Touch Screen using your unique ID and authentication number.

CE870 Card Personalization System Installation and User Guide 29

Page 38

The Touch Screen requires a

The Multi-Card Hopper moves the

The card is transferred

Indent data is processed first.

to the characters.

The finished card

The card flipper turns the card over so that

The Printer

encodes magnetic stripe

data and processes smart

card information.

card from the selected hopper and

transfers it into the printer component.

username and authentication code

to access the print queue, status,

check supplies, and select the

hopper from which to print.

into the embosser

component through a

series of flippers.

characters can be embossed on the front

of the card.

1. Letters and numbers are embossed.

2. Topping foil is applied to the characters.

exits the system

through the card

output hopper.

1. Characters are indented.

2. Indent ribbon is applied

3. Optionally, the front may also be indented.

How the Card Travels

Card processing is a two-step process. The first step is sending the card to print

from the PC. The second step processes the card through the Touch Screen. After

the card has been verified and sent to print, the multi-card hopper pick

mechanism moves to the selected hopper, picks a card, and moves the card into

the printer component for processing.

The card moves to the magnetic stripe encode area or to the smart card park

station depending on the type of card selected. The encrypted data is decrypted

and written to the card. When magnetic stripe and smart card functions are

complete, the card is transferred to the embosser component.

If the card design includes indent data and the embossing wheel includes

optional indent characters, the system processes the indent data first. Upon

entering the embosser, the card is flipped to indent characters and apply ribbon

to the characters on the back of the card. If the card design includes indent

characters on the front of the card, the card is automatically turned and moved

back to the indent module to indent and apply ribbon to the characters on the

front of the card.

30 Using the System

Page 39

The system then processes the emboss data. The emboss function is a two-step

process. First the characters are embossed and then topping foil is applied to

those characters.

About Secure Encryption

Secure encryption on the CE870 Card Personalization System means that the

magnetic stripe or smart card data entered is converted into a secure form of code

before it is sent to the system. The system receives the encrypted data through the

Touch Screen. Datacard Personalization Manager (DPM) passes the encrypted

data to the printer component. The printer decrypts the code and sends the data

to the magnetic stripe or smart card chip on the card.

The printer contains both SSL (Secure Sockets Layer) and AES-128 (Advanced

Encryption Standard) encryption methods. The default setting is SSL. To change

the default encryption method, see your systems administrator or contact your

service provider.

The printer does not accept magnetic stripe or smart card data that is not

encrypted. If non-encrypted data is sent to the printer, a message displays on the

printer’s LCD panel and the card is rejected.

Use the Touch Screen

The optional Touch Screen allows users to interact with the card production

system. From the Touch Screen you can view or enter the print queue, view

supplies and card stock, or make any changes to the system or user authentication

codes.

The Home screen is the base for all Touch

Screen activity. From here you can view the

printer queue and status, check supplies and

designate the hopper from which to print. You

can also unlock the system from the Touch

Screen.

For more information about the Touch Screen

and how to use it, see the Touch Screen User

Guide (Part No. 527228-001).

CE870 Card Personalization System Installation and User Guide 31

Page 40

Use the Front Panel

The front panel of the printer provides the controls you need to operate the

system. It includes the following:

Power Button

Use this button to power the system off

and on. All lights show steady amber

while the system powers on.

To power on the system, press the

button for 1 to 2 seconds until the

system powers on.

To power off the system, press the

button for 1 to 2 seconds until the

system powers off.

If the system is processing cards, you can press the button for 2 or more seconds

to power the system off immediately. You hear the power-down tone. Cards in

process are not completed and are sent to the reject card tray.

LCD Panel

• The LCD panel indicates the system status.

• The panel includes a menu system. See Use the LCD Menus for details.

• The panel displays printer and embosser messages. See Respond to

Messages for details.

32 Using the System

Page 41

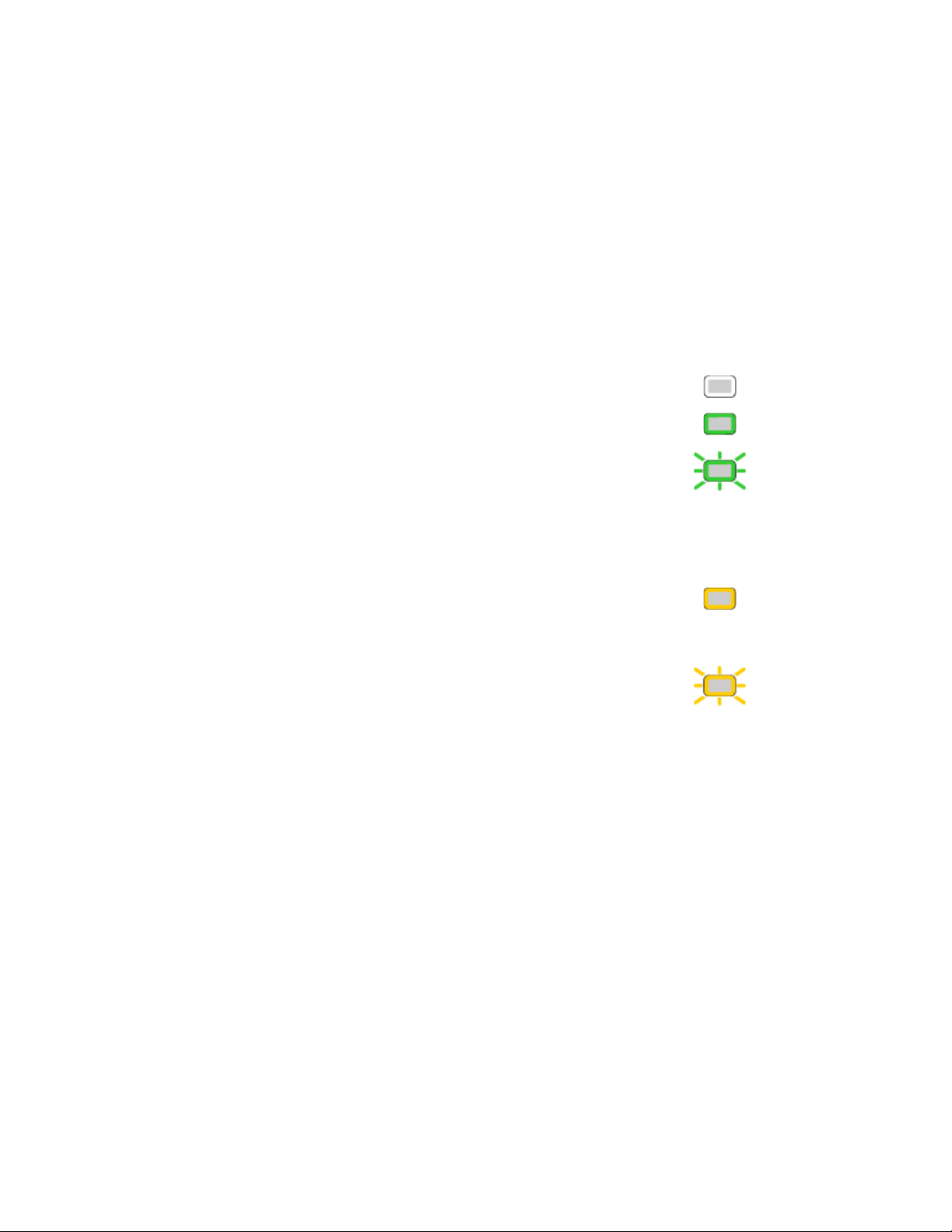

User Button and Light

The printer has a USER button with a boarder of light that indicates the system

status.

• Press the U

• Press the U

SER button to suspend the printer when it displays Ready.

SER button to clear a message.

• Press the USER button for 2 seconds or more to clear all messages.

• The U

Off System is off.

Green System is ready or suspended.

Flashing green System is busy. The light flashes slowly

Amber The system is not ready.

Flashing Amber The system has a problem. The light

SER light indicates whether the system is ready, busy, or not ready.

(every 2 seconds).

or

The system has a hardware error

concerning the embosser. The light

flashes quickly (every 1/2 second).

The P

OWER button was pressed to turn

the printer off.

flashes at a medium rate (every second).

or

The system has a hardware error

concerning the printer. The light flashes

quickly (every 1/2 second).

Down Arrow, Up Arrow, and Enter Keys

Use the arrow keys to move through the LCD menu system and the ENTER key to

make a selection. See Use the LCD Menus for details.

CE870 Card Personalization System Installation and User Guide 33

Page 42

Ribbon Light

The ribbon flashes green when the indent ribbon or topping foil levels are low,

out or there is an problem concerning supplies.

• There is no message displayed on the LCD panel when the card light is

• A message is displayed on the LCD panel with details of the problem when

flashing slowly (every 2 seconds). This condition indicates that supplies are

low.

the card light is flashing quickly (every 1/2 second).

Off Ribbon is okay.

Flashing Green The ribbon is low. The light flashes

Card Light

The card light flashes green when the system has a card problem in the embosser

component and flashes amber when the system has a card problem in the printer

component.

• There will be a message displayed on the LCD panel with details of the

Off Cards are okay.

Flashing Green There is a problem with the cards

Flashing Amber There is a problem with the cards

slowly (every 2 seconds).

or

The ribbon is out or there is a

problem with supplies. The light

flashes quickly (every 1/2 second).

problem when the card light is flashing quickly (every 1/2 second).

related to the embosser component.

The light flashes quickly (every 1/2

second).

related to the printer component.

The light flashes quickly (every 1/2

second).

34 Using the System

Page 43

Use the LCD Menus

The front panel of the printer component includes an LCD display with

navigation keys. When the system is not actively processing cards, the LCD menu

system is available. See Use the Front Panel for more information about other

features of the front panel.

Use the LCD menu for tasks including:

• Pause the system when cards are in the print queue. See Pause the System.

• Changing the backlight of the LCD panel. See Change the LCD Backlight

Brightness.

• Viewing the serial number of the printer. See View the Printer Serial

Number from the LCD Menu.

• Retrieving card counts. See View Card Counts from the LCD Menu.

• Viewing the network IP Address. See View the Network IP Address from

the LCD Menu.

• Setting the Magstripe Coercivity. See Set Magnetic Stripe Coercivity from

the LCD Menu.

CE870 Card Personalization System Installation and User Guide 35

Page 44

LCD Menus

The menu system has four major

branches:

• Use the Maintenance menu

• Use the Status menu to see

• Use the Configuration menu

• Use the Activate menu to

to run a cleaning card.

settings and data about the

printer.

to change settings.

enable and disable secure

features of the printer. This

menu is used only during

installation or removal of the

system.

HINTS & TIPS

• The menu system can be used

when Ready is displayed on

Line 1 of the LCD panel.

• The printer returns to the

Ready status after two

minutes of no activity.

Changes not applied will be

lost.

• To leave a selection without

changing the value, press the

up or down arrow key to

scroll to Exit and then press

the E

NTER key.

36 Using the System

Page 45

Pause the System

The system can be paused to prevent additional cards from being processed. A

paused system will complete an active print job and suspend any additional jobs

from printing until unpaused.

1. Pause the system by pressing and holding the U

SER button while Ready or

Busy is displayed on line 1 of the LCD panel.

Suspended is displayed on line 1 of the LCD panel. An active print job (if any)

will continue until completed. Any additional card production will be

paused.

2. Unpause the system by pressing and holding the USER button.

Ready is displayed on line 1 of the LCD panel. Cards can now continue to be

printed.

CE870 Card Personalization System Installation and User Guide 37

Page 46

Change the LCD Backlight Brightness

Begin with the printer displaying Ready. The USER button shows steady green.

1. Enter the menu system.

A. Press and hold the U

SER button.

Suspended is displayed on line 1 of the LCD panel.

B. Press the E

NTER key to enter the menu system.

2. Access the LCD backlight option.

A. Press the down arrow key until Configuration displays on line 2 of the

LCD panel.

B. Press the E

NTER key to enter the Configuration menu.

LCD backlight displays on line 2 of the LCD panel.

C. Press E

38 Using the System

NTER to select the LCD Backlight.

Page 47

3. Select LCD backlight level.

A. Press the Down arrow key to lower the light level.

Or

Press the Up arrow key to increase the light level.

B. When the light is at the desired level, press the E

NTER key.

The printer saves the settings and returns to the Configuration menu.

4. Exit the menu system.

A. Press an arrow key repeatedly to display Exit on line 2 of the LCD panel.

B. Press the E

NTER key to exit the Configuration menu.

C. Press an arrow key repeatedly until Exit on line 2 of the LCD panel.

D. Press the E

NTER key to exit the Main menu.

5. Press the USER key.

When the Ready is displayed in line 1 of the LCD panel, the printer is

ready.

CE870 Card Personalization System Installation and User Guide 39

Page 48

View the Printer Serial Number from the LCD Menu

Begin with the printer displaying Ready. The USER button shows steady green.

1. Enter the menu system.

A. Press and hold the U

SER button.

Suspended is displayed on line 1 of the LCD panel.

B. Press the E

NTER key to enter the menu system.

2. View the Serial Number.

A. Press the down arrow key until Status displays.

B. Press the E

NTER key to enter the Status menu.

C. Serial Number is the first choice on the menu. Press ENTER to display the

printer serial number.

40 Using the System

Page 49

3. Exit the menu system.

A. Press an arrow key repeatedly to display Exit on line 2 of the LCD panel.

B. Press the E

NTER key to exit the Configuration menu.

C. Press an arrow key repeatedly until Exit on line 2 of the LCD panel.

D. Press the E

NTER key to exit the Main menu.

4. Press the USER key.

When the Ready is displayed in line 1 of the LCD panel, the printer is

ready.

CE870 Card Personalization System Installation and User Guide 41

Page 50

View Card Counts from the LCD Menu

Begin with the printer displaying Ready. The USER button shows steady green.

1. Enter the menu system.

A. Press and hold the U

SER button.

Suspended is displayed on line 1 of the LCD panel.

B. Press the E

NTER key to enter the menu system.

2. Enter the Card Count menu.

A. Press the down arrow key until Status displays on line 2 of the LCD

panel.

B. Press the E

NTER key to enter the Status menu.

C. Press the down arrow until Card Counters is displayed on line 2 of the

LCD panel.

D. Press E

NTER key to enter the Card Counters menu.

E. Press the down arrow until Card Count is displayed on line 2 of the LCD

panel.

F. Press ENTER key to enter the Card Count menu.

42 Using the System

Page 51

3. View the Card Count.

A. Press the E

NTER key to view the total number of cards picked on the

system.

B. View the Completed Card count.

i. Press the E

panel. Press the E

NTER key to display Completed Card on line 2 of the LCD

NTER key again to view the Completed Card count.

ii. Press the ENTER key to display Rejected Cards on line 2 of the LCD

panel. Press the E

iii. Press the E

Press the E

NTER key to display Lost Cards on line 2 of the LCD panel.

NTER key again to view the Lost Cards count.

NTER key again to view the Rejected Cards count.

iv. Press the Enter key to display Exit on line 2 of the LCD panel. Press the

NTER key again to exit to the Card Counters menu.

E

4. Exit the menu system.

A. Press an arrow key repeatedly to display Exit on line 2 of the LCD panel.

B. Press the E

NTER key to exit the Status menu.

C. Press an arrow key repeatedly to display Exit on line 2 of the LCD panel.

D. Press the E

NTER key to exit the Main menu.

CE870 Card Personalization System Installation and User Guide 43

Page 52

5. Press the USER key.

When the Ready is displayed in line 1 of the LCD panel, the printer is

ready.

44 Using the System

Page 53

View the Network IP Address from the LCD Menu

The printer can display the IP address it uses when connected to the network. It

also displays the Subnet Mask and Gateway Address.

Begin with the printer connected to the network and displaying Ready. The U

button shows steady green. printer.

1. Enter the menu system.

A. Press and hold the U

SER button.

Suspended is displayed on line 1 of the LCD panel.

B. Press the E

NTER key to enter the menu system.

2. Enter the Network Status and IP Address menu.

A. Press the down arrow key until Status displays on line 2 of the LCD panel.

SER

B. Press the E

NTER key to enter the Status menu.

C. Press the down arrow key until Network Status displays on line 2 of the

LCD panel.

D. Press E

NTER key to enter the Network Status menu.

CE870 Card Personalization System Installation and User Guide 45

Page 54

3. View network information.

A. View IP Address.

i. Press the down arrow key until IP Address displays on line 2 of the

LCD panel.

ii. Press the E

NTER key to display the printer IP Address.

B. View Subnet Mask.

i. Press E

NTER to return to the Network Status menu. Subnet Mask is

displayed on line 2 of the LCD panel.

ii. Press the E

NTER key to display the printer Subnet Mask.

C. View Gateway Address.

i. Press ENTER to return to the Network Status menu. Gateway Address

is displayed on line 2 of the LCD panel.

ii. Press the E

NTER key to display the printer Gateway Address.

4. Exit the menu system.

A. Press an arrow key repeatedly to display Exit on line 2 of the LCD panel.

B. Press the E

46 Using the System

NTER key to exit the Network Status menu.

Page 55

C. Press an arrow key repeatedly to display Exit on line 2 of the LCD panel.

D. Press the E

NTER key to exit the Status menu.

E. Press an arrow key repeatedly to display Exit on line 2 of the LCD panel.

F. Press the E

NTER key to exit the Main menu.

5. Press the USER key.

When the Ready is displayed in line 1 of the LCD panel, the printer is

ready.

CE870 Card Personalization System Installation and User Guide 47

Page 56

Set Magnetic Stripe Coercivity from the LCD Menu

The setting for coercivity can be changed from the LCD panel, if needed. Usually,

coercivity is a system-wide decision and does not change.

1. Enter the menu system.

A. Press and hold the U

SER button.

Suspended is displayed on line 1 of the LCD panel.

B. Press the E

NTER key to enter the menu system.

C. Press the down arrow key until Configuration displays on line 2 of the

LCD panel.

D. Press E

NTER key to enter the Configuration menu.

2. Set Magnetic Stripe Coercivity.

A. Press the down arrow key until Magstripe displays on line 2 of the LCD

panel.

B. Press E

48 Using the System

NTER key to enter the Magstripe menu.

Page 57

C. Press the down arrow key until Coercivity displays on line 2 of the LCD

panel.

D. Press E

NTER key to enter the Coercivity menu.

i. Press an arrow key to display the intended coercivity.

ii. Press the ENTER key. Apply is displayed on line 2 of the LCD panel.

iii. Press the Enter key to save the value. Exit is displayed on line 2 of the

LCD panel.

Press the ENTER key to exit the Magstripe menu.

3. Exit the menu system.

A. Press an arrow key repeatedly to display Exit on line 2 of the LCD panel.

B. Press the E

CE870 Card Personalization System Installation and User Guide 49

NTER key to exit the Configuration menu.

Page 58

4. Press the USER key.

When the Ready is displayed in line 1 of the LCD panel, the printer is

ready.

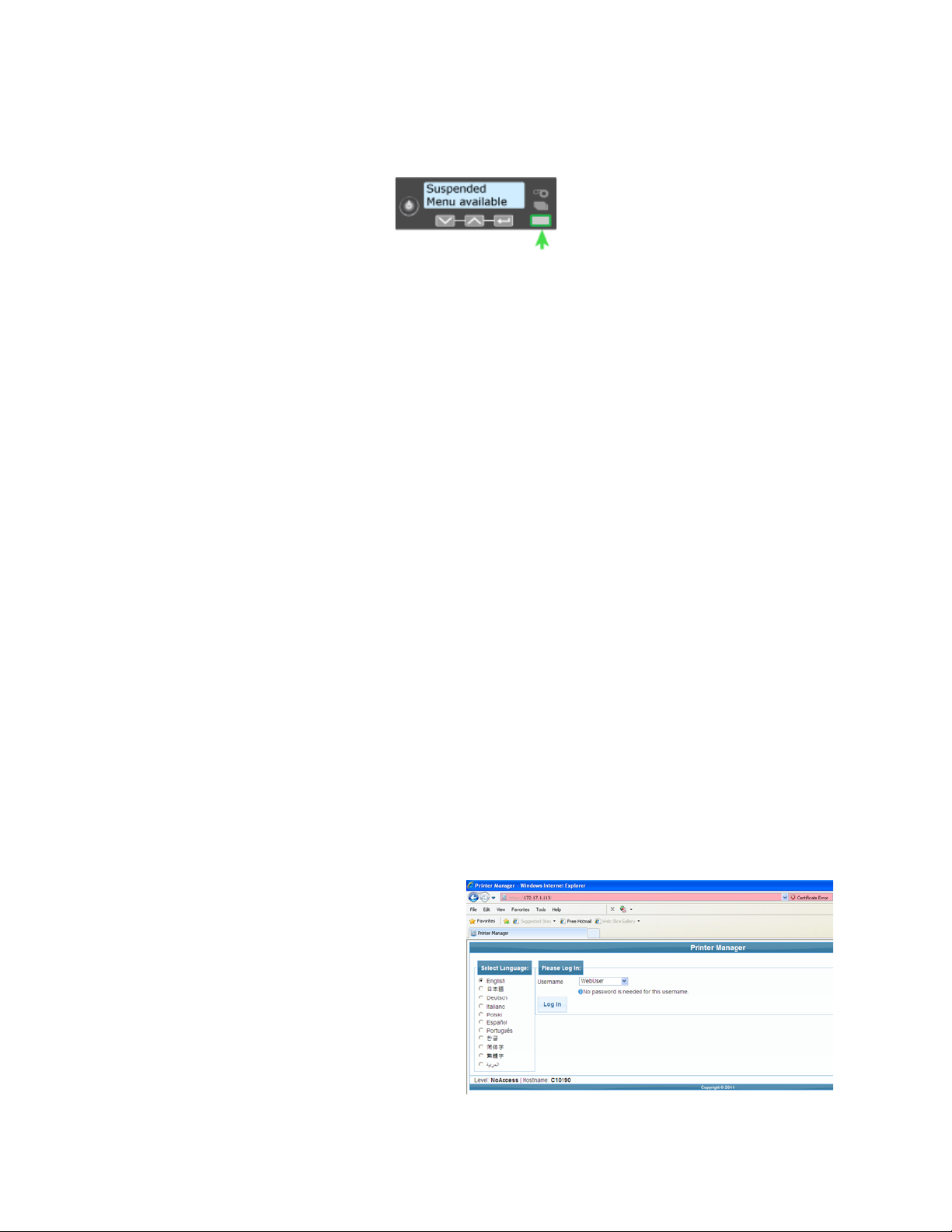

Use the Printer Manager

The system includes the Printer Manager, which displays information about the

system and card production in a Web browser window. Your administrator or

installer uses it to set up the advanced features of the system components and to

work with a service provider when troubleshooting card production issues.

For mor information about specific tasks available to the end user, see the

Solutions Guide (Part No. 539998).

1. Make sure that the LCD Panel displays Ready.

2. Obtain the printer Network IP Address or the USB IP Address and write it

down.

3. Open a Web Browser on the PC.

4. In the Address area of the browser, enter the following:

https://printer IP address

For example: https://123.1.23.123 where 123.1.23.123 is replaced by the

printer IP address.

5. Press the E

NTER key.

6. Select the language in which to display the Printer Manager session from the

left-hand column.

7. In the P

LEASE LOG IN area

select a Username and

enter a password (if

required).

A. Select a Username that

best matches your job

responsibility. Options

are:

• WebUser

50 Using the System

Page 59

• WebAdmin

• WebService

B. Enter a password (if required).

Hints & Tips

8. Click the L

9. Use the L

OG IN button.

OG OUT button in Printer Manager and close the browser after

logging out.

• If the Browser cannot connect to the printer, make sure that:

• The front panel displays Ready on the LCD panel.

• Another user does not have a Printer Manager session running.

• The Printer Manager contains a hover-text feature that shows help

information when the cursor hovers over the setting in the description

column.

For the safety, use the Log Out button in Printer Manager and close the browser

after logging out.

CE870 Card Personalization System Installation and User Guide 51

Page 60

52 Using the System

Page 61

Chapter 5: Card Design

Card design is the name given to the combined features of the

processed cards.

This section describes:

• Basic Card Design

• Magnetic Stripe Design

• Smart Card Design

• Embossing and Indenting Design

• Settings for Card Design in Printer Manager

Basic Card Design

Card design includes:

• The various types of data

such as name and account

number, emboss and indent

characters, and special

features such as magnetic

stripe or smart card chip.

• The layout of the data.

• Processes to enhance card

appearance such as adding

emboss or indent ribbon.

Magnetic Stripe Design

About Magnetic Stripes

The printer component contains a magnetic stripe module to process magnetic

stripe data. There are two options available for the CE870 printer component: ISO

and JIS. See the Printer Configuration Label to determine the type of module

installed.

CE870 Card Personalization System Installation and User Guide 53

Page 62

The module format (ISO or JIS) defines the type and

format of the information to encode. The standard ISO

format is a three-track option and the JIS format is a

single-track option. The ISO standard includes default

data settings that determine how many characters can

be encoded on each track. It also determines which

characters can be encoded. Your cards can use the

default format for each track, or can use a different

combination of tracks and data formats.

The JIS module also includes default data settings.

The printer component may require additional settings to match the coercivity of

the card. The system administrator sets these values and they remain the same for

all cards processed using the same design. The defaults are set to standard ISO

format and high-coercivity. There are five high-coercivity cards included with the

system. Use these cards to set up and test the magnetic stripe feature. See Set

Magnetic Stripe Coercivity from the LCD Menu if you need to change the

coercivity.

The type of magnetic stripe cards you use must match the type of module

installed. Purchase magnetic stripe cards to match the type of module installed.

See the card included in the package for details and specifications of the magnetic

stripe.

Magnetic Stripe Formats

Three-Track Option

The default data formats for a three-track magnetic stripe option are:

• Track 1 — IATA

• Track 2 — ABA

• Track 3 — TTS

This combination is often abbreviated IAT. This format is also called ISO format.

IATA (International Air Transport Association)

The maximum number of characters for IATA format date is 76 characters. These

characters can include spaces, upper case alphabetic characters, numeric

characters, and the following special characters:

! # $ % ' ( ) * + , - . / ; : < @ > = ^ ] \ [ " & _

54 Card Design

Page 63

ABA (American Bankers Association)

The maximum number of characters for ABA format is 37 characters. Numeric

characters and the following special characters are allowed:

: ; < = >

TTS (Thrift Third Standard)

The maximum number of characters for TTS format is 104 characters. Numeric

characters and the following special characters are allowed:

: ; < = >

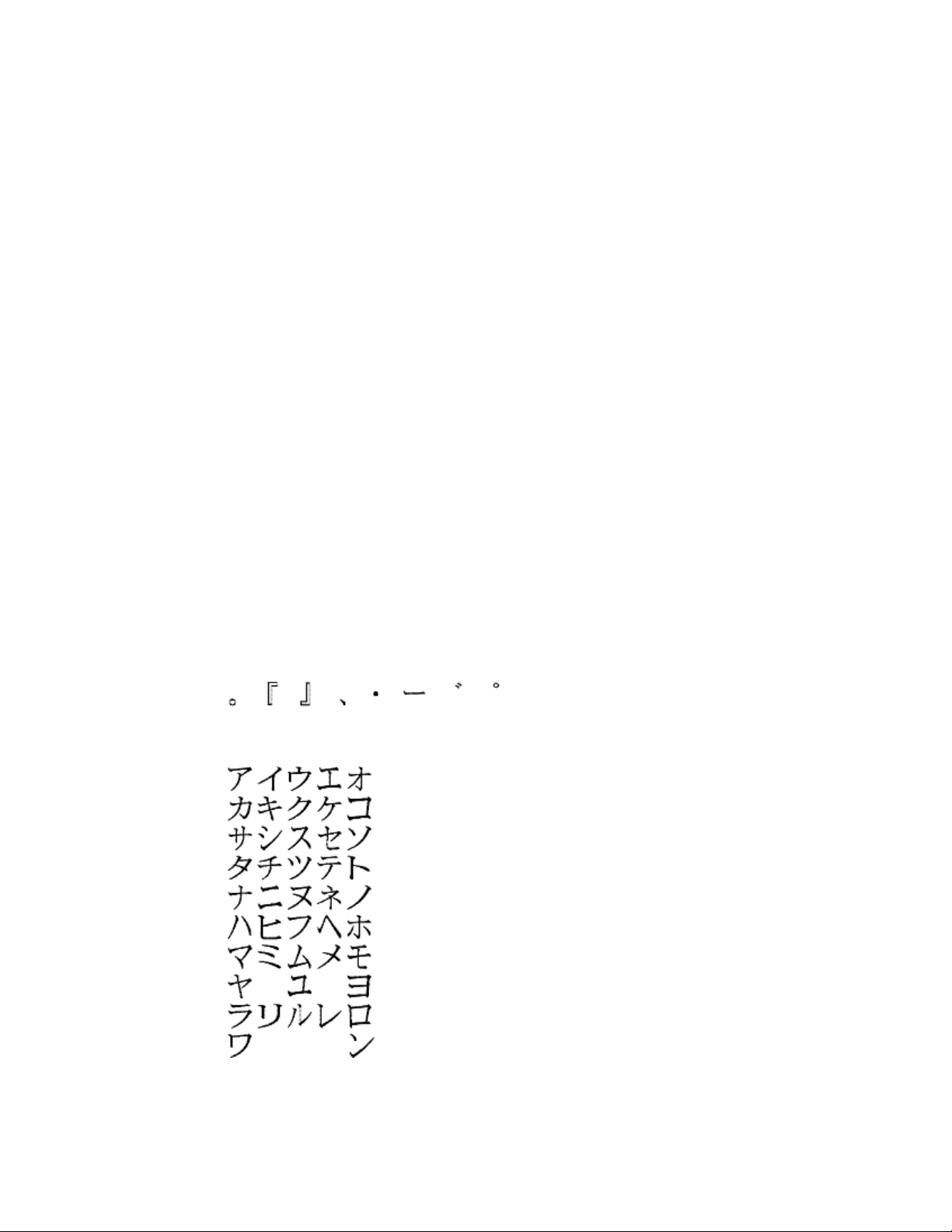

Single-Track JIS Option

The default data encoding format for a single-track magnetic stripe module is the

JIS (Japanese Industrial Standard) Type II format.

The maximum number of characters for the JIS format is 69 characters. These

characters can include spaces, numeric characters, upper case alphabetic

characters, lower case alphabetic characters, and the following special characters:

! " # $ % & ' ( ) * + , - . / : ; < = > ? @ [ ] ^ _ ~ { | } ~

From a PC running a Japanese edition of a supported operating system Japaneselanguage characters are also supported. They include the following special

characters:

45 Katakana characters:

CE870 Card Personalization System Installation and User Guide 55

Page 64

and the following 10 Katakana characters:

Each time you start using Japanese-language characters, or stop using them, a

hidden character is added. Each hidden character reduces the number of

characters you can encode by one character.

Smart Card Design

About Smart Cards

This section presents basic information about personalizing smart cards. Smart

card processing is different from other types of personalization because the

“smart card” step of personalization is controlled by an application that is

different from the rest of card personalization.

Smart card setup is usually provided by a value-added reseller or service

provider. Information about the smart card module installed and the type of

cards to use can be requested from your service provider or value-added reseller.

The following items are required when personalizing smart cards:

• Smart card reader in the printer.

• Smart cards that work with the reader in the printer.

The configuration label includes codes to identify the type and model of smart

card module installed in the printer.

If the S6 value is included in the configuration code, the printer has shipped from

the factory with a Duali dual interface smart card reader. See the Printer

Configuration Label for more information.

56 Card Design

Page 65

Embossing and Indenting Design

The CE870 Embosser is the

component of a card production

system that creates the raised

lettering and numbering that is seen

on the front of most financial or debit

cards. Inside the embosser, you will

find the embossing wheel and

topping- and indent-ribbon

cartridges. The embossing wheel can

be purchased with up to 112 punch

and die pairs. Other features of the

embossing wheel that are determined at time of purchase include multiple font

choices and a variety of special characters.

The embossing wheel can also be purchased with indent characters to produce

characters that are pressed into (indented) the front or back surface of the card.

The most common use of indent characters is to create the Card Security Code

(CSC), sometimes called the Card Verification Value (CVV) on financial credit

and debit cards. Indent ribbon is avaiable in two colors (black or white) and a

special paneld ribbon is also available (paneled black and white).

The CE870 Embosser can emboss up to five lines of text or numbers. Topping foil

is available in five colors and is heat sealed to the embossed characters.

Settings for Card Design in Printer Manager

Administrators and service providers can use the Printer Manager to perform

system setup tasks and troubleshoot the system.

The Printer Manager contains card design settings that managers and service

providers can use to set up card production. The card design settings include

magnetic stripe setup and smart card testing. The Printer Manager also contains

troubleshooting features such as a log file that can track all processes of a card job.

Service providers can use the information in the log file to troubleshoot and relay

information to service providers when troubleshooting card processing issues.

See Use the Printer Manager for more information.

CE870 Card Personalization System Installation and User Guide 57

Page 66

58 Card Design

Page 67

Chapter 6: System

Maintenance

The CE870 Card Personalization System is designed

to be easy to maintain. System operators should be

instructed in routine maintence tasks such as

running a cleaning card. The cleaning card process

removes dirt and particles from inside the system.

This section includes the following:

• Clean the Printer

• Clean the Embosser

• Run a Cleaning Card

Clean the Printer

The following steps should be followed to keep the printer component of the

system clean and in good operation.

• Run a cleaning card and replace the cleaning sleeve in the printer component

after every 500 cards processed by the print system.

• Keep the surface and area around the printer clean and free of environmental

contaminates such as dust and moisture.

• Never clean the surface of the printer with abrasive chemicals or cleansers.

• Keep the area around the printer free of obstructions that may limit

ventilation or access to components.

Clean the Embosser

These steps should be followed to keep the embosser component of the system

clean and in good operation.

• Keep the surface and area around the embosser clean and free of

environmental contaminates such as dust and moisture.

• Never clean the surface of the embosser with abrasive chemicals or cleansers.

• Keep the area around the embosser free of obstructions that may limit

ventilation or access to components.

CE870 Card Personalization System Installation and User Guide 59

Page 68

Run a Cleaning Card

Run a cleaning card to clean debris from the inside of the printer system. The

cleaning card can remove most contaminants from the print system. Run a

cleaning card after every 250 cards processed by the printer system or every 6

months.

Begin with the printer displaying Ready. The U

1. Remove the print ribbon cartridge.

A. Unlock and open the printer

supplies access door.

B. Open the printer cover and remove

the print ribbon cartridge.

C. Close the printer cover, then close

and lock the printer supplies access

door. The front panel should

display Ready and the U

SER button

shows steady green.

2. Enter the menu system.

A. Press and hold the U

SER button.

SER button shows steady green.

Suspended is displayed on line 1 of the LCD panel.

B. Press the E

NTER key to enter the menu system.

3. Enter the Cleaning Card menu.

A. Press the down arrow key until Maintenance displays on line 2 of the LCD

panel.

B. Press the E

60 System Maintenance

NTER key to enter the Maintenance menu.

Page 69

C. Press the down arrow key until Cleaning Card displays on line 2 of the

LCD panel.

D. Press the E

NTER key to enter the Cleaning Card menu.

4. Run the cleaning card.

A. Press the down arrow key until Start displays on line 2 of the LCD panel.

B. Press the ENTER key to display Insert Cleaning Card on the LCD panel.

The U

SER button and the Card light blink.

C. Open the cleaning card package,

remove card and insert the

cleaning card into the manual slot

above the front panel.

The printer moves the cleaning

card through the printer several

times and ejects it in the card

output hopper of the embosser.

D. Remove the used cleaning card.

Wait a few minutes for the rollers

to dry.

CE870 Card Personalization System Installation and User Guide 61

Page 70

5. Relpace cleaning sleve on print ribbon cartridge and return cartridge into the

printer component.

A. Replace the cleaning sleeve on

the print ribbon cartridge with a

new sleeve, and remove the

protective cover.

B. Unlock and open the printer

supplies access door and printer

cover. Return the print ribbon

cartridge into the printer

component.

C. Close the printer cover and

printer supplies access door. The

printer is ready to print cards

again.

Discard the used cleaning card

and cleaning sleeve.

6. Exit the menu system.

A. Press E

NTER repeatedly to exit the menu system.

B. The LCD panel displays Ready and the USER button glows steady green.

62 System Maintenance

Page 71

Chapter 7: Troubleshooting

This chapter details user procedures to recover

from errors that may occur with the system.

This section describes:

• Tools for Troubleshooting

• Locating the Issue

• Installation Troubleshooting

• Card Appearance

• Magnetic Stripe

• Card Jam

• Messages and Conditions

• Respond to Messages

Tools for Troubleshooting

The tools for troubleshooting a problem include the supplies and equipment you

use to print cards:

• Blank cards to print, used at several stages of troubleshooting.

• Indent ribbon and topping foil.

• Cleaning supplies, especially printer cleaning cards and a cleaning pen.

CE870 Card Personalization System Installation and User Guide 63

Page 72

Locating the Issue

The printer, embosser, and software applications work together to produce cards.

If the system is not working as you expect, follow these steps, in the order listed,

to isolate the source of the issue before contacting your service provider.

1. Check that the power cables are connected to both the printer and embosser.

2. Check that all network cables between the printer, embosser, and network are

connected.

3. Power on the printer. Make sure that Ready displays on the front panel

within 1 minute?

• If the printer powers on correctly, continue to step 4.

• If the printer powers on but does not display “Ready,” the printer is not

working properly.

• If the printer does not power on, make sure the printer is connected to a

functioning power source.

A. Remove the printer power cord from the outlet.

B. Connect another device to the same outlet to verify that the power source

functions correctly.

If the power source is functioning correctly, request service for the printer

from you system administrator.

C. Connect the printer to a functioning outlet and repeat, beginning with

step 1.

4. Print a test card. See Run Test Card for the steps to follow.

5. Make sure that the test card prints.

• If the test card prints, the printer is working correctly.

• If the test card does not print, the printer is not working correctly. Request

service for the printer from your system administrator.

64 Troubleshooting

Page 73

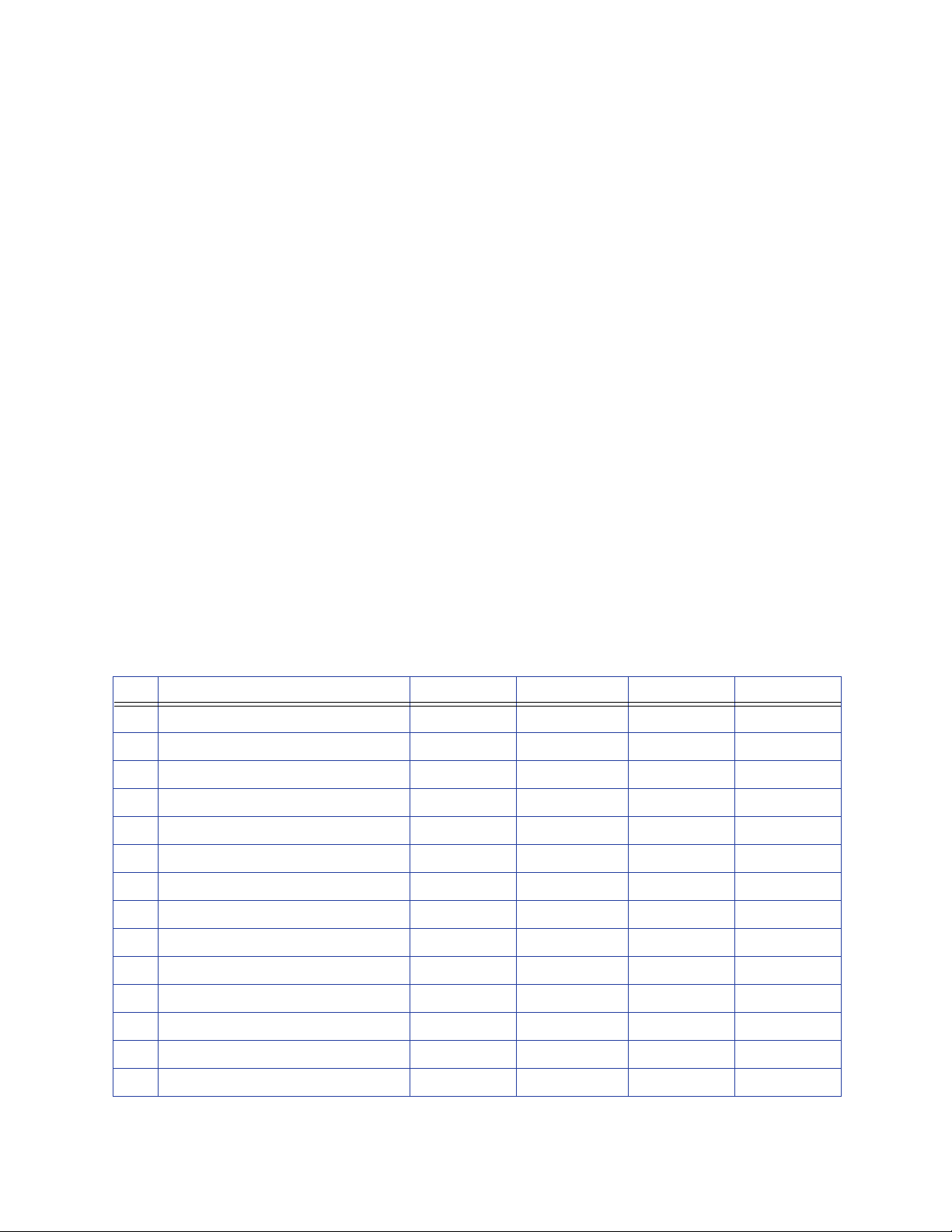

Installation Troubleshooting

This section describes issues that could prevent a successful installation and

offers recommended solutions to those issues.

Problem Solution

The system is not

connected to the

network.

Disconnect then reconnect the data cable to the

network port and the printer. Restart the system.

Card Appearance

Card appearance problems can be caused by the indent ribbon and topping foil

application.

Indent Troubleshooting

Problem Probable Cause Solution

The indent characters

are very light.

The indent ribbon is

loaded incorrectly or

not being taken up on

rollers.

Topping Foil Troubleshooting

Problem Probable Cause Solution

Load the indent ribbon correctly. See

Load Indent Ribbon Cartridge for more

information. Contact your system

administrator if the problem continues.

The topping foil is very

light.

CE870 Card Personalization System Installation and User Guide 65

The topping foil is

loaded incorrectly.

The topper

temperature is not hot

enough.

Load the topping foil correctly. See Load

Topping Foil Cartridge for more

information.

Contact your system administrator to

adjust the temperature of the topper

mechanism.

Page 74

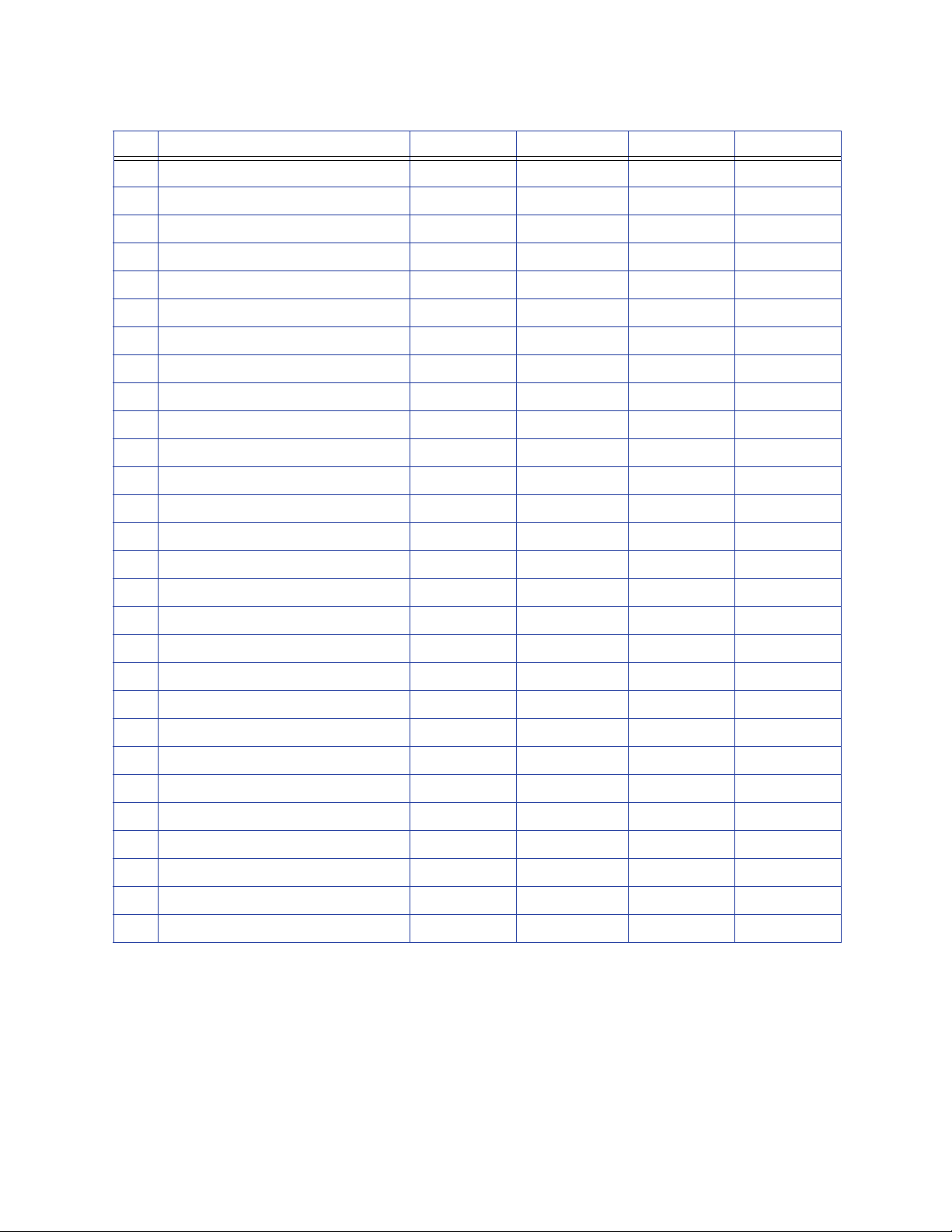

Magnetic Stripe

The printer uses the coercivity set using the LCD panel or Printer Manager and

uses the data format set using the Printer Manager.

Problem Solution

Cards are not loaded

correctly.

Cards do not have a

magnetic stripe.

The card has dirt or

damage on the

magnetic stripe.

The magnetic stripe on

the card is low

coercivity material and

the High Coercivity

setting is selected.

Message 106 is

displayed.

The magnetic stripe on

the card is high

coercivity material and

the Low Coercivity

setting is selected.

Load cards with the magnetic stripe down and

toward the right side. See Load Cards in Hopper.

Load magnetic stripe cards in the multi-card hopper.

If the cards have a magnetic stripe, check the

quality of the cards. Change card stock if needed.

Encode and print the card again. If an error message

displays again, run a cleaning card to clean the mag

stripe head.