Page 1

User’s Guide

Entrust Datacard™ CR805™ Retransfer Card Printer

March 2019

Part No. 527691-001, Rev. E

Page 2

Notice

Please do not attempt to operate or repair this equipment without adequate training.

Any use, operation or repair you perform that is not in accordance with the information

contained in this documentation is at your own risk.

Trademark Acknowledgments

Datacard is a registered trademark and service mark of Entrust Datacard Corporation in

the United States and other countries.

Entrust is a registered trademark and service mark in the United States and other

countries.

MasterCard is a registered trademark of MasterCard International Incorporated.

Visa is a registered trademark of Visa International Service Association.

All other product names are the property of their respective owners.

Proprietary Notice

The design and information contained in these materials are protected by US and

international copyright laws.

All drawings and information herein are the property of Entrust Datacard Corporation. All

unauthorized use and reproduction is prohibited.

Entrust Datacard

1187 Park Place

Shakopee, MN 55379

Phone: 952-933-1223

Fax: 952-933-7971

www.entrustdatacard.com

Copyright © 2016–2019 Entrust Datacard Corporation. All rights reserved.

ii

Page 3

Compliance Statements

Liability

The WARNING and CAUTION labels have been placed on the equipment for your safety. Please do

not attempt to operate or repair this equipment without adequate training. Any use, operation,

or repair in contravention of this document is at your own risk.

Safety

The following basic safety tips are given to ensure safe installation, operation, and maintenance

of Entrust Datacard™ equipment.

• Connect equipment to a grounded power source. Do not defeat or bypass the ground lead.

• Place the equipment on a stable surface (table) and ensure floors in the work area are dry and

non-slip.

• Know the location of equipment branch circuit interrupters or circuit breakers and how to turn

them on and off in case of emergency.

• Know the location of fire extinguishers and how to use them. ABC type extinguishers may be

used on electrical fires.

• Know local procedures for first aid and emergency assistance at the customer facility.

• Use adequate lighting at the equipment location.

• Maintain the recommended temperature and humidity range in the equipment area.

iii

Page 4

Regulatory Compliance

EMC Compliance Notice

To ensure compliance of the model RX10 retransfer printer to the radiated emissions

requirements for class “A” Information Technology Equipment, be sure to use a shielded Ethernet

cable when connecting to your network

Notice for USA (FCC Notice)

This equipment has been tested and found to comply with the limits for Class A computing

devices, pursuant to Part 15 of FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy. If this

equipment is not installed and used in accordance with this instruction manual, it may cause

harmful interference to radio communications. Operation of this equipment in a residential area

is likely to cause harmful interference in which case the user will be required to correct the

interference at their own expense. Changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

Notice for Canada

Industry Canada

This digital apparatus does not exceed the Class A limits for radio noise for digital apparatus set

out in the Radio Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n'émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de la classe A prescrites dans le Règlement sur le brouillage

radioélectrique édicté par le ministère des Communications du Canada.

RSS-Gen, Issue 3, December 2010, Section 7.1.3 User Manual Notice

This Device complies with Industry Canada License-exempt RSS standard(s). Operation is subject

to the following two conditions: 1) this device may not cause interference, and 2) this device

must accept any interference, including interference that may cause undesired operation of the

device.

Cet appareil est conforme avec Industrie Canada RSS standard exemptes de licence(s). Son

fonctionnement est soumis aux deux conditions suivantes: 1) ce dispositif ne peut causer des

interférences, et 2) cet appareil doit accepter toute interférence, y compris les interférences qui

peuvent causer un mauvais fonctionnement du dispositif.

iv

Page 5

Notice for Europe

The EU Declaration of Conformity can be found on EntrustDatacard.com under product

compliance.

WARNING: This is a class A product. This equipment is compliant with class A of either CISPR32 or

CISPR22. In a domestic/residential environment this equipment may cause radio interference, in

which case the user may be required to take adequate measures.

WEEE: The model RX10 retransfer printer uses a lithium coin cell battery. Refer to the service

manual for battery removal instructions.

Simplified EU Declaration of Conformity

Entrust Datacard Corporation declares that the following radio equipment: MXD, MX6000,

MX6100, PB6500, MX2000, MX2100, SP55k, SP35, SP55, CP40, CP60, CP80, SP75, FP65, SR200,

SR300, PX10, PX30, EX30, MPR3800, CR500f, MX1100, RX10, and PB1000 is in compliance with

the Directive 2014/53/EU.

The full text of the EU declaration of conformity is available at the following Internet address,

https://www.datacard.com/productcompliance.

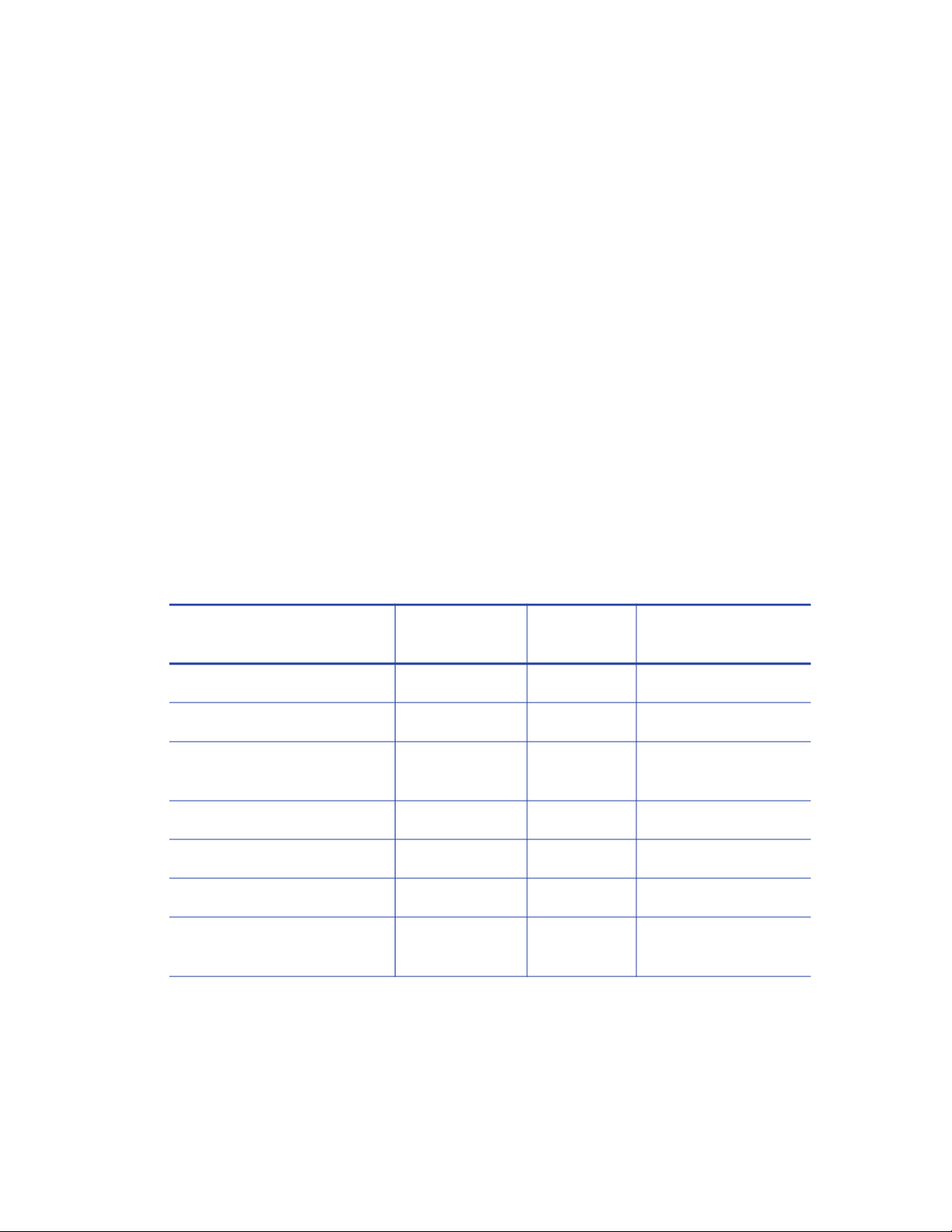

Intentional Radiator Information

Effective Radiated

Description/Model Number FCC ID Frequency

PX10 Supplies RFID GDI-Q20010 13.56MHz 9.16E-06

PX30 Supplies RFID GDI-Q30030 13.56MHz 9.16E-06

Central Issuance Supplies

RFID

LX30, RX10 Supplies RFID GDI-506241001 13.56MHz 3.03E-05

EX30 Supplies RFID GDI-Q30130 13.56MHz 9.16E-06

FP65 Supplies RFID GDI-Q10055 13.56MHz 3.65E-05

Central Issuance Smartcard

Coupler

GDI-SID004 13.56MHz 1.96E-07

GDI-50543001 13.56MHz 1.45E-05

Power (ERP) mW

EMC Compliance Notice:

For model RX10/Multi-hopper configurations, to ensure compliance with Conducted Immunity

standard EN61000-4-6, use USB cables no longer than three meters in length.

v

Page 6

Notice for Australia

This is a Class A product. In a domestic environment this product may cause radio interference, in

which case the user may be required to take adequate measures.

Notice for China (Simplified Chinese)

警告

此为 A 级产品,在生活环境中,

该产品可能会造成无线电干扰。

在这种情况下,可能需要用户

对干扰采取切实可行的措施。

Notice for Taiwan (Traditional Chinese)

Notice for Japan

Japanese Voluntary Control Council for Interference (VCCI) class A statement

Korea Communications Commission (KCC) statement

vi

Page 7

California Proposition 65 Compliance

WARNING: This product contains chemicals, including lead, known to the State of California to

cause cancer, and birth defects or other reproductive harm. Wash hands after handling.

WARNING: This product can expose you to chemicals including Di(2-ethylhexyl)phthalate

(DEHP), which is known to the State of California to cause cancer, and Di(2-ethylhexyl)phthalate

(DEHP) and Butyl benzyl phthalate (BBP), which are known to the State of California to cause

birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov

and www.datacard.com/CalifPropWarning.

California Lithium Perchlorate Warning

Perchlorate Material - special handling may apply. See www.dtsc.ca.gov/hazardouswaste/

perchlorate.

This notice is required by California Code of Regulations, Title 22, Division 4.5, Chapter 33: Best

Management Practices for Perchlorate Materials. This product/part includes a battery that

contains Perchlorate material.

Battery Precaution

CAUTION: Risk of explosion if battery is replaced by an incorrect type. Dispose of used

batteries according to the instructions.

ATTENTION: Risque d’explosion si la batterie est remplacée par un type de batterie incorrect.

Jetez les piles usagées selon les instructions.

vii

Page 8

viii

Page 9

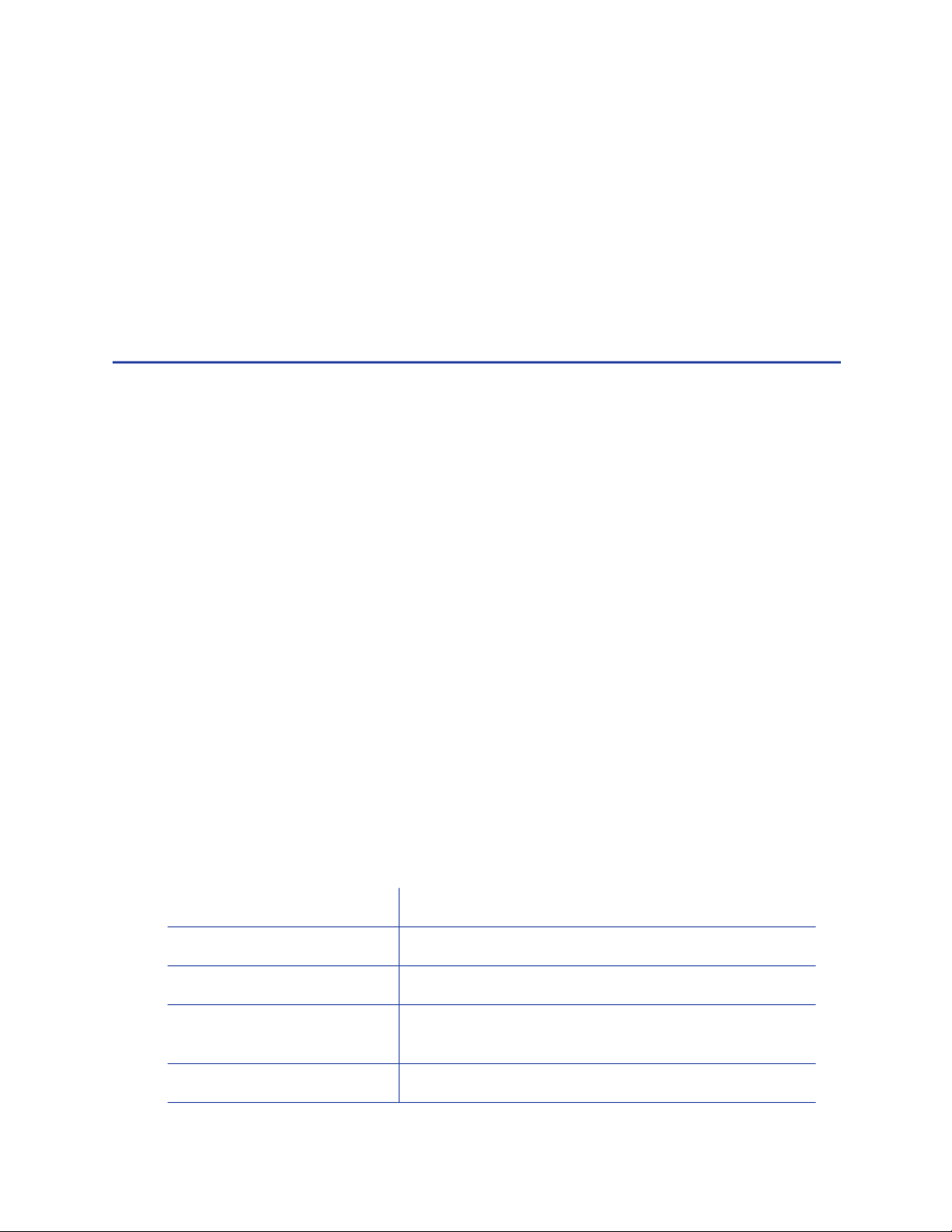

Revision Log

CR805 Retransfer Card Printer User’s Guide

Revision Date Description of Changes

01 May 2016 Beta release of this document.

A November 2016 First release of this document.

B August 2017 Added new cleaning procedures and laminator support.

C September 2017 Added multi-hopper support.

D July 2018 Added modular single hopper support and general updates.

E March 2019 Updated the printer cleaning instructions.

ix

Page 10

x

Page 11

Contents

Chapter 1: Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Chapter 2: About the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

About the CR805 Retransfer Card Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

The Front and Right Side of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Single-Hopper Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Multi-Hopper Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Multi-Hopper Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

The Left Side of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

The Back of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Inside the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Printer Configuration Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Multi-Hopper Configuration Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Single Hopper Configuration Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 3: Using the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Printer Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Tasks and Users. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Secure Encryption. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Use the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Power Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Down Arrow, Up Arrow, and Enter Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

User Button and Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Ribbon Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Card Light. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Use the LCD Panel Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Retrieve the Printer’s Network IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Retrieve an IPv4 Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Retrieve an IPv6 Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Print a Test Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Select a Card Stock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Select a Color Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Load and Replace Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Load Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Single-Hopper Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Use the Exception Slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Multi-Hopper Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Use the Multi-Hopper Exception Slide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

xi

Page 12

Replace the Ink Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Replace the Cleaning Sleeve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Replace the Retransfer Film . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Chapter 4: Print Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Print Cards from ID Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Print Cards from Other Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Chapter 5: System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Maintain the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Printer Cleaning Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Clean the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Use the Isopropanol Cleaning Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Single-Hopper Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Multi-Hopper Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Run the Isopropanol Cleaning Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Use the Adhesive Cleaning Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Single-Hopper Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Multi-Hopper Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Run the Adhesive Cleaning Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Prepare the Printer for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Clean the Printhead Cam Rollers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Clean the Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Use a Cleaning Swab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Use a Lapping Stick . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Empty the Printer Reject Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Chapter 6: Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Locate a Problem Within the Card Production System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Locate a Problem with Basic Printer Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Installation Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

USB Installation Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Network Installation Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Card Printer Driver Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

The Card Printer Driver does not detect the network-connected printer. . . . . . . . . . . . . 67

The Card Printer Driver does not detect the USB-connected printer . . . . . . . . . . . . . . . . 67

Driver status or Windows print queue does not provide expected data . . . . . . . . . . . . . 68

Printer Messages do not display on the PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Card Appearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Tools for Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Something did not print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Printing includes unexpected data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Print quality concerns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Magnetic Stripe Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

xii

Page 13

Laminator Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Advanced Troubleshooting Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Printer Card Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Clear a Card Jam in the K1 Horizontal Transport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Single-Hopper Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Multi-Hopper Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Clear a Card Jam in the K2 Vertical Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Clear a Card Jam in the Flipper Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Repair a Broken Ink Ribbon or Retransfer Film . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Messages and Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Messages on the Printer LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Printer Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Laminator Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Messages from the Card Printer Driver on the PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Messages from Printer Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Other Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Respond to Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Printer Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Close and lock doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

100: Request not supported. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

103: Printer problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

104: Critical problem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

105: Magstripe data error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

106: Magstripe data not found . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

107: Magstripe read data error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

108: Magstripe read no data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

111: Card not picked . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

112: Card hopper empty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

113: Close cover to continue. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

114: Cover opened during job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

116: Magstripe not available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

117: Reader not available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

120: User paused the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

122: Magstripe format problem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

149: Option not installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

150: Print while unlocked . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

151: Failed to lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

152: Insert new card side 2 up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

153: Insert same card side 2 up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

166: C2 supply out or missing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

167: C2 supply not identified . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

168: C2 supply not supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

170: Insert new card side 1 up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

171: Insert same card side 1 up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

172: Insert cleaning card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

xiii

Page 14

173: Improper shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

175: C2 supply error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

176: C2 supply type error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

228: C1 printhead error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

229: C2 heat sensor error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

230: C2 heater error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

231: C2 heated roller motion error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

232: Retransfer debow error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

233: Smart card contact fail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

234: K1 transport card jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

235: K2 transport card jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

236: Flipper module rotate error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

237: C1 supply out or missing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

238: C1 supply not identified . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

239: C1 supply not supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

240: C1 supply error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

241: C1 supply type error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

242: RT1 reject tray full. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

243: Card lost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

245: Configuration error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

275: Multi-hopper error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

276: Multi-hopper card jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

277: Multi-hopper pick error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

278: Insert cleaning card in H2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Laminator Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

177: Laminator not available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

196: Laminator error critical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

197: Laminator entry card problem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

198: L1 area card problem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

199: L2 area card problem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

200: Laminator exit card problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

201: L1 supply problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

202: L1 supply out or missing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

203: L1 supply type problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

204: L1 supply not supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

205: L1 supply not identified . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

206: L2 supply problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

207: L2 supply out or missing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

208: L2 supply type problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

209: L2 supply not supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

210: L2 supply not identified . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

211: L1 heater problem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

212: L2 heater problem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

213: L1 heater sensor problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

214: L2 heater sensor problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

xiv

Page 15

215: L1 heater roller problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

216: L2 heater roller problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

217: Debow problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

218: Impresser problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

219: Impresser sensor problem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

220: Impresser heater problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

221: Bar code scanner problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

222: Firmware version mismatch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

223: Laminator system mismatch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Driver-Only Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

500: The printer is not available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

501: The printer connection was lost. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

502: The card data is missing or is not usable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

504: The card data is missing or is not usable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

505: USB communication issue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

506: A card is currently processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

507: The printer is unlocked . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

508: The printer is shutting down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

509: The printer is offline or suspended. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

510: The printer is unlocked . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Driver SDK Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

511: Cannot lock or unlock the printer. Locks are not installed. . . . . . . . . . . . . . . . . 112

512: Cannot lock or unlock the printer. The password is incorrect or invalid. . . . . . 112

513: Cannot lock or unlock the printer. The printer is busy. . . . . . . . . . . . . . . . . . . . . 112

514: Cannot lock or unlock the printer. The cover is open. . . . . . . . . . . . . . . . . . . . . 112

515: Failed to lock or unlock the printer. The locks did not function. . . . . . . . . . . . . 112

516: Timeout expired before bar code could be read. . . . . . . . . . . . . . . . . . . . . . . . 112

517: Wrong printer job ID.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Appendix A: CR805 Card Printer with Inline Lamination . . . . . . . . . . . . . . . . . . . . . . . A-1

About the Laminator System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Outside the Laminator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Laminator Back and Left Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Laminator Status Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Laminator Front and Right Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Inside the Laminator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Laminator Configuration Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Laminator Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Laminator Overlay Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Load Laminator Overlay Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Card Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Verify Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Empty the Laminator Reject Tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

Clear a Laminator Card Jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

Clean the Laminator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

xv

Page 16

xvi

Page 17

Chapter 1: Introduction

About This Manual

This manual provides user information for the Entrust Datacard™ CR805™ Retransfer Card

Printer. The manual includes:

An overview of printer components and options, and a description of the system label.

How to use the printer, including how to power the printer on and off, how to use the front

panel and LCD menus, how to print a test card, how to load and replace supplies, and the

basics of card processing.

1

How to perform routine maintenance and troubleshooting tasks.

An additional Installation and Administrator’s Guide is available for use by administrators or other

professionals responsible for setting up the printer. Refer to the Owner’s Library CD.

Intended Audience

The manual is intended for the printer operator who is responsible for printing cards, loading and

replacing supplies, maintaining the printer, and troubleshooting error conditions.

Technical Support

Use the following to contact Entrust Datacard Technical Support.

US Phone Number 1-800-328-3996

North America Email: north.america.cust.serv@entrustdatacard.com

Latin America and Caribbean Email: americas@entrustdatacard.com

Europe, Middle East, and

Africa

Email: emea.customer.service@entrustdatacard.com

Asia Pacific Email: dcap.admin@entrustdatacard.com

CR805 Retransfer Card Printer User’s Guide 1

Page 18

2 Introduction

Page 19

Chapter 2: About the Printer

This chapter describes how to identify and access the components of the

CR805 Retransfer Card Printer.

About the CR805 Retransfer Card Printer

The CR805 Retransfer Card Printer uses retransfer technology to produce high-quality, over-theedge printing on a variety of PVC and non-PVC card materials. The retransfer process provides a

reliable print quality on card surfaces that have minor variations, such as those due to smart chips

or RFID antennas embedded in the card.

The retransfer printing process uses two types of supply: a color pigment ink ribbon and a

retransfer film. Heat from a thermal printhead causes the ink pigment to release from the ribbon

and adhere to the retransfer material. The film is then bonded to the card using a heat and

pressure process that also applies the film to the edges of the card. The printer also has the ability

to apply two layers of the retransfer film on the front side or on both sides of a card, for added

durability.

2

The printer supports several types of color ink ribbon. The ribbon typically contains the following

panels: cyan, magenta, yellow, black, and primer (CMYKP). Ink ribbons also may include an

inhibitor panel that prevents any ink or retransfer material from being applied to areas of the card

that have a magnetic stripe or signature panel, or an ultraviolet fluorescent (F) panel. Refer to the

printer’s Installation and Administrator’s Guide for a list of ink ribbons available for the printer.

The printer prints at a resolution of 600 x 600 dpi. It can print on one side or both sides of the

card. It also can encode data on a magnetic stripe or a smart card chip. Magnetic stripe and

contact or contactless smart card capabilities are optional.

A 125-card input and 25-card output hopper are standard on non-locking CR805 card printers.

CR805 card printers with locks are manufactured without an input hopper, which allows you to

install either a 125-card single hopper, or a multi-hopper with six input hoppers, each with a 125card capacity. An optional 125-card output hopper also is available and can be installed without

tools on single-hopper printers. In addition, an optional upgrade kit allows you to install a Wi-Fi

Dongle in the printer.

An optional laminator also is available when you purchase your printer, or as a field upgrade

(refer to Appendix A: "CR805 Card Printer with Inline Lamination”).

Refer to “Printer Configuration Label” on page 12 for more information about identifying the

factory-installed options in the printer.

CR805 Retransfer Card Printer User’s Guide 3

Page 20

The Front and Right Side of the Printer

Use the following sections to become familiar with the printer.

Single-Hopper Printer

Input

Hopper

Printer Access

Door

Access Door

Output

Hopper

Front

Panel

Access Door

Handle

Input Hopper

Lock

Lock

Input Hopper The input hopper holds cards for printing. The hopper holds

up to 125 cards (0.030 in. or 0.762 mm thickness).

Note: the input hopper can be removed from the printer for

secure storage.

Output Hopper The output hopper holds up to 25 completed cards.

Front Panel The front panel allows you to work with the printer. It includes

OWER button, the USER button, status lights, and the LCD

the P

panel with navigation keys. Refer to “Use the Front Panel” on

page 19 for a description of the front panel items.

Input Hopper Lock The input hopper lock secures the input hopper. The lock can

be opened using a key, or by using the Card Printer Driver SDK

with your application. Refer to the Windows XPS Driver

Software Development Kit Programmer’s Reference Guide for

more information.

Sending a command to open the lock opens all locks on the

printer and on any attached component.

4 About the Printer

Page 21

Printer Access Door The access door provides access to the printer supplies and to

Access Door Handle The handle allows you to open the printer access door.

Access Door Lock Some printers also may have a lock on the access door. Unlock

Multi-Hopper Printer

the rear access door release. Open the door to replace

supplies or clear a card jam. A slot inside the door holds the

printer User Reference Guide, which contains instructions for

performing routine printer tasks.

the door to access the inside of the printer. The lock can be

opened using the key or through a command issued by an

application.

Sending a command to open the lock opens all locks on the

printer and on any attached component.

Input Hoppers 1–6

Hopper Lock

Bars

Output

Hopper

Multi-Hopper

Lock

Lock Bar Release

Button (B1)

Cartridge Release

Buttons

Exception Slide

Input Hoppers 1 – 6 Each hopper cartridge in the multi-hopper holds up to 125

cards (0.030 in. or 0.762 mm thickness).

Output Hopper The output hopper holds up to 25 completed cards.

CR805 Retransfer Card Printer User’s Guide 5

Page 22

Multi-Hopper Lock The multi-hopper lock secures all six input hoppers. The lock

can be opened using a key, or by using the Card Printer Driver

SDK with your application. Refer to the Windows XPS Driver

Software Development Kit Programmer’s Reference Guide for

more information.

Sending a command to open the lock opens all locks on the

printer and on any attached component.

Lock Bar Release

Button (B1)

The release button (B1) releases the lock bars in front of the

input hopper cartridges. Slide the button to the left to release

the bars. You must have unlocked the multi-hopper using the

key or a software command before the lock bars can be

released.

Hopper Lock Bars The lock bars rotate to the left to allow access to the hopper

cartridge doors, so that you can load cards into the cartridges.

Cartridge Release Buttons The cartridge release buttons allow you to remove the

cartridge from the multi-hopper unit. Push in the buttons,

squeeze the cartridge, and pull it out from the multi-hopper.

Notes:

You do not need to remove a hopper cartridge to load

cards.

Hopper cartridges can be removed for secure storage.

Exception Slide The exception slide allows you to insert a single card into the

printer without unlocking the multi-hopper or opening a

hopper cartridge. Refer to “Use the Multi-Hopper Exception

Slide” on page 33.

6 About the Printer

Page 23

Multi-Hopper Cartridge

The multi-hopper cartridges can be pulled out from the multi-hopper unit. You can remove the

cartridges with the cards inside and store them securely, if necessary.

Card Weight

Cartridge

Door

Label

Cartridge Door

Release Button

Cartridge Door

Release Button

The door release button allows you to open the cartridge door.

Press down on the release button.

Retainer

Cartridge Door The cartridge door swings down to provide access to the cartridge

to load cards.

Card Weight The card weight maintains a downward pressure on the loaded

cards so that they enter the printer properly. Lift the card weight to

the top of the cartridge and gently pull it forward until it locks in

position. A diagram inside the cartridge shows how to position the

card weight and load cards.

Note: Do not place the cards on top of the card weight.

Label Retainer The label retainer allows you to insert a paper label inside the

cartridge door. Use a label to identify the cartridge number or the

type of cards loaded in each cartridge. Use a flathead screwdriver to

open the label retainer door.

CR805 Retransfer Card Printer User’s Guide 7

Page 24

The Left Side of the Printer

Smart Card/Bar Code

Reader USB Connection

USB

Connection

Power Connection The power connection provides a plug-in connector for the

Cable Lock

Receptacle

Power

Connection

Wi-Fi Mounting

Cover

Data Port

Network

Connection

printer power supply.

Cable Lock Receptacle The receptacle allows you to insert the security plate before

attaching the optional cable lock.

Smart Card/Bar Code Reader

USB Connection

The connection allows you to connect a loosely coupled

smart card reader and bar code reader (used by some

printers) to the computer.

Data Port The data port allows you to connect the printer to another

component, such as a laminator.

Network Connection The network connection allows you to connect the printer

to an Ethernet network.

USB Connection The USB connection allows you to connect the printer

directly to a computer.

Wi-Fi Mounting Cover The mounting cover in Wi-Fi ready system enclosures allows

you to install the optional Wi-Fi Dongle in the printer. Refer

to the Wi-Fi Upgrade Installation Instructions for complete

information.

8 About the Printer

Page 25

The Back of the Printer

Rear Access

Door

Printer Access

Door

Rear Door Fan

Rear Access Door The rear access door allows you to clear a card jam in the

vertical transport. You must open the printer access door to

reach the rear access door release (K3). Refer to “Inside the

Printer” on page 10 for information about how to open the

rear access door.

Rear Door Fan The fan provides ventilation in the printer to cool the card

after the retransfer process.

CR805 Retransfer Card Printer User’s Guide 9

Page 26

Inside the Printer

Ink Ribbon Cartridge

Release Button

Ink Ribbon

Cartridge (C1)

Retransfer Film

Cartridge (C2)

Retransfer Film Cartridge

Release Button

Vertical Transport

Area

Manual Advance

Knob (K2)

Rear Access Door

Release (K3)

Manual Advance

Knob (K1)

Ink Ribbon Cartridge (C1)

The ink ribbon cartridge (C1) holds the ink print ribbon.

(blue)

Retransfer Film Cartridge (C2)

The retransfer film cartridge (C2) holds the retransfer film.

(yellow)

Cartridge Release Buttons The ink ribbon and retransfer film cartridge release buttons

allow you to remove the cartridges from the printer for

loading or error recovery. Press the release button and pull

the cartridge out from the printer.

Vertical Transport The vertical transport area houses the magnetic stripe unit

and the smart card reader. Some CR805 printers also may

include an optional bar code reader that reads and verifies

the bar code on specialized pre-serialized cards.

10 About the Printer

Page 27

Rear Access Door Release (K3) The rear access door release (K3) opens the rear access

door in the back of the printer to clear a card jam in the

vertical transport.

Manual Advance Knob (K1)

Manual Advance Knob (K2)

The manual advance knobs allow you to move a card inside

the printer (K1) or in the vertical transport area (K2) to

clear a card jam. The K2 knob is present only if a magnetic

stripe unit or smart card reader is installed in the printer.

The following illustration shows the inside of the printer when the ink ribbon and retransfer

cartridges are removed.

Printhead

Cleaning

Spindle (C3)

Retransfer

Station

Reject Tray (RT1)

Printhead The printhead prints the card data on the retransfer film

using the ink ribbon.

Cleaning Spindle (C3) The cleaning spindle (C3) holds the replaceable cleaning

sleeve, which removes dust and other particles from cards

to maintain print quality.

CR805 Retransfer Card Printer User’s Guide 11

Page 28

Retransfer Station The retransfer station houses the heated roller that bonds

the retransfer film containing the printed image to the

surface of the card.

Reject Tray (RT1) The reject tray (RT1) holds unfinished cards or cards that

were not processed properly. Empty the reject tray

regularly. Refer to “Empty the Printer Reject Tray” on

page 59.

Note: If your system includes a laminator, the printer reject

tray is not used. Cards are placed in the laminator reject

tray. Refer to “Laminator Back and Left Side” on page A-2.

Printer Configuration Label

The printer system configuration label shows the

components installed when the printer was built.

It provides information that is useful when

requesting service. The label is located on the

inside of the printer access door, and on the

printer frame behind the retransfer film cartridge

(you must remove the cartridge to see the label).

The label shows the following information:

Printer model and serial number

Configuration, which includes the factory-

Configuration

Label

installed options in the printer

Date and country of assembly

MAC address to use when the printer is connected via an Ethernet network

Additional labels may be attached to the printer to indicate components installed by the dealer

or sales group after the printer was manufactured.

12 About the Printer

Page 29

Option Configuration Code

Input Hopper H0=No Hopper (Modular Single Hopper or Multi-Hopper Ready)

H1=125 Card Input Hopper

Duplex D0=Simplex

D1=Duplex

Magnetic Stripe M1=ISO

M2=JIS

blank=No Magnetic Stripe option

Smart Card Sx=Smart Card option, where x indicates the type of smart card

reader installed in the printer (refer to the printer’s Installation and

Administrator’s Guide for a list of smart card readers supported by

the printer and their option codes)

blank=No Smart Card option

Bar Code Scanner B2=Bar Code Scanner

blank=No Bar Code Scanner

Locks L1=H1 Lock

blank=No locks

Wi-Fi W1=Wi-Fi Dongle

blank=No Wi-Fi

CR805 Retransfer Card Printer User’s Guide 13

Page 30

Multi-Hopper Configuration Label

The multi-hopper configuration label is located on the back of the multi-hopper. After the multihopper is attached to the printer, a second label should be added on the inside of the printer

access door, next to the printer configuration label.

Multi-Hopper Configuration Label

The label shows the following information:

The name of the multi-hopper module

Serial number

Part number

Configuration code

Date and country of assembly

Printer Configuration

Label

14 About the Printer

Page 31

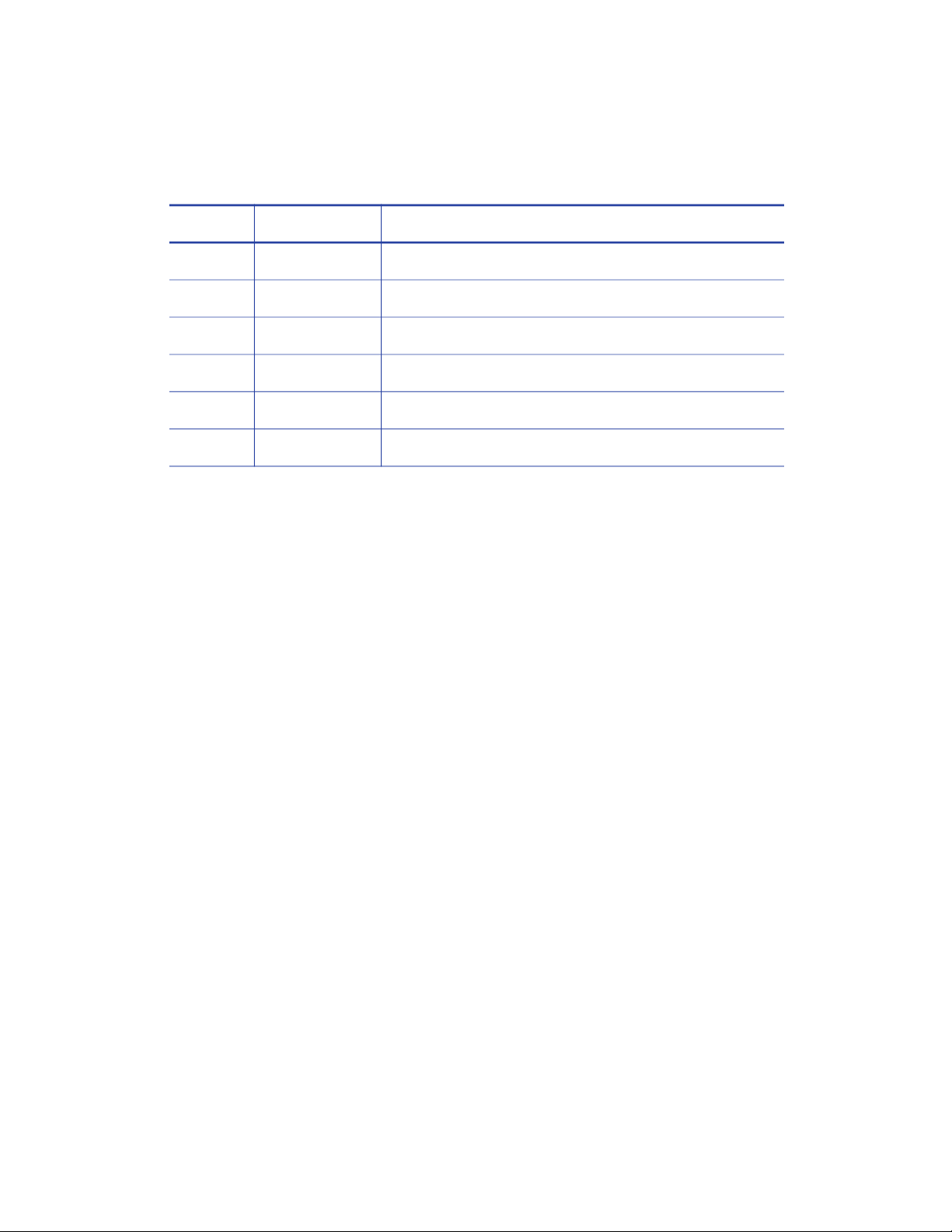

Option Configuration Code

Hopper Cassette Type C1=6 125-Card Removable Input Hoppers

Printer Type N1=CR805, CR825, or CE875

Locks L1=Multi-Hopper Lock

blank=No lock

Single Hopper Configuration Label

The single hopper configuration label is located on the back of the modular single hopper. After

the hopper is attached to the printer, a second label should be added on the inside of the printer

access door, next to the printer configuration label.

Single Hopper Configuration Label

The label shows the following information:

Serial number

Printer Configuration

Label

Part number

Configuration code

Date and country of assembly

CR805 Retransfer Card Printer User’s Guide 15

Page 32

Option Configuration Code

Hopper Cassette Type C1=125-Card Removable Input Hopper

Printer Type N1=CR805, CR825, or CE875

Locks L1=Hopper Lock

blank=No lock

16 About the Printer

Page 33

Chapter 3: Using the Printer

This chapter describes how to perform the basic tasks required to

operate the printer.

Printer Overview

The CR805 Retransfer Card Printer is used with other equipment and software to create a card

personalization system. The system produces cards for a specific purpose, and the cards must

meet defined requirements.

Equipment

The system can include:

3

A PC, with software to support the printer, such as:

The XPS Card Printer Driver for Windows.

ID software designed specifically to capture, format, and save the data for cards, such as

Datacard® TruCredential™ Suite Software.

A retail application, such as Microsoft Word.

Capture devices (optional), such as:

A digital camera connected to the PC to take photos.

A signature capture pad, fingerprint reader, or PIN pad.

The printer with supplies and a facility power source.

A data connection between the printer and PC, which can be a USB connection or a network

connection. (You cannot use both with one printer.)

CR805 Retransfer Card Printer User’s Guide 17

Page 34

Tasks and Users

Typical roles in a card personalization system include:

The operator, who makes cards, loads supplies, and handles minor problems such as card

jams.

The system administrator, who sets up the card printer and other hardware, sets up card

designs, configures card production software, and identifies the best use of the card printer

in the organization

Secure Encryption

Secure encryption means that all data entered is converted into a secure form of code by your

software application before it is sent to the system. The printer decrypts the code and sends the

data to the magnetic stripe or smart card chip on the card.

The printer uses TLS 1.2 encryption for maximum security. Refer to the printer’s Installation and

Administrator’s Guide for complete information about using secure printing.

18 Using the Printer

Page 35

Use the Front Panel

The front panel of the printer provides the controls you need to operate the system. The front

panel controls are described in detail in the following sections.

Power Button

Down

Arrow

Power Button

Press the POWER button for 1 to 2 seconds to power on the printer. All lights show steady amber

while the printer powers on.

Up

Arrow

Enter

LCD Panel

Status Lights

Ribbon

Cards

User Light &

User Button

To power off the printer, press the P

OWER button for 1 to 2 seconds until the printer begins to shut

down.

To power off the system while processing cards, press the button for 2 or more seconds. Card jobs

in the printer do not complete and are sent to the reject tray.

We recommend that you do not unplug the printer power cord to power off the

printer.

Down Arrow, Up Arrow, and Enter Key

Use the arrow keys to move through the printer menu system, and the ENTER key to make a

selection.

Press the up or down arrow key while the LCD panel displays Ready to display additional

information about the printer on line 2, including the firmware version, printer model, serial

number, IP address, and supply part numbers. If the system includes a laminator, the laminator

firmware version and laminator serial number also display. If you do not press a key for 30

seconds, the LCD panel returns to the default Ready message.

When you use the arrow keys to view the printer IP address, only the IPv4 address

displays. To see the IPv6 addresses available to the printer, you must use the LCD

Status menu. Refer to “Retrieve an IPv6 Address” on page 25.

CR805 Retransfer Card Printer User’s Guide 19

Page 36

User Button and Light

The printer’s USER button displays with a border of light that indicates the system status. Use the

SER button to:

U

Suspend the printer—press the USER button when the LCD panel displays Ready.

Clear a message (recover from an error)—press the USER button once.

Cancel all jobs and clear all pending error messages—press the USER button for two seconds

or more.

Determine whether the system is ready, busy, or not available. Indicators include the

following. Refer to “Messages and Conditions” on page 84 for a list of the LCD messages that

correspond to the U

Light Description

Off The printer is off or suspended.

Green The printer is ready.

Blinking green The printer is busy.

Amber The printer is not ready.

Blinking amber The printer has an error.

SER light.

OR

An attached component has an error.

OR

The P

the printer.

OWER button was pressed to turn off

Color Cycle:

Amber, Green,

Light Green, Off

The printer is not ready or a secure door on

the printer is unlocked. The colors cycle

quickly.

Close and Lock Doors displays on the LCD

panel if no other message is present.

20 Using the Printer

Page 37

Ribbon Light

The ribbon light indicates the status of a supply in the printer or in an attached component.

Indicators include the following. Refer to “Messages and Conditions” on page 84 for a list of the

LCD messages that correspond to the ribbon light.

Light Description

Off The supply levels are okay.

Blinking amber A blinking light indicates one of the

Blinking green There is a problem with a supply in an

Card Light

The card light indicates the status of cards in the printer or an attached component. Indicators

include the following. Refer to “Messages and Conditions” on page 84 for a list of the LCD

messages that correspond to the card light.

Light Description

Off The cards are okay.

following:

A problem with a printer supply.

The printer supply level is low. The light

blinks slowly (every 2 seconds).

The printer supply is out. The light blinks

quickly (every 1/2 second).

attached component.

Blinking amber A blinking light indicates either of the

following:

No card is detected for the print job.

Insert a card to continue printing.

A scheduled printer cleaning is due.

Insert a cleaning card now, or set aside

time to run a cleaning card. Refer to

“Clean the Printer” on page 47.

Blinking green There is a card problem in an attached

component.

CR805 Retransfer Card Printer User’s Guide 21

Page 38

Use the LCD Panel Menus

The LCD panel shows the printer’s menu system and displays messages and conditions.

For a list of error messages and recovery information, refer to “Respond to Messages” on

page 89.

22 Using the Printer

Page 39

When the printer is in the Ready status, the LCD displays the model number of the printer.

Press the USER button to suspend the printer. Then, press ENTER to enter the menu system. Use

the arrow keys to move through the menus, and press E

NTER to make a selection. The menu

system has four major branches:

Use the Maintenance menu to run a cleaning card, print a test card, or reset the locks on a

system with locks.

Use the Status menu to see settings and data about the printer.

Use the Configuration menu to change settings.

Use the Activate menu to enable or disable the printer.

The Activate menu is used only during installation or removal of financial systems

that require activation.

HINTS & TIPS

You can access the menu system when Ready displays on line 1 of the LCD panel.

The printer returns to the Ready status after 2 minutes of no activity. Changes that have not

been applied are lost.

To leave a selection without changing the value, press the up or down arrow key until Exit

displays, and then press E

NTER.

Retrieve the Printer’s Network IP Address

You must know the printer IP address to perform some tasks. For example, the XPS Card Printer

Driver asks you to enter the network IP address during installation. You also use the IP address

when launching Printer Manager, the printer’s web interface, from a browser window.

To display the IP address, you can do one of the following:

Press the up or down arrow key while the printer displays Ready. Refer to “Down Arrow, Up

Arrow, and Enter Key” on page 19.

Use the LCD menu system Status menu.

If the printer is configured to use a static IP address, the printer’s front panel displays

the address even when the printer is not connected to a network. In addition, the LCD

displays a “+” if the network is active, or a “-” if the network is inactive, as a prefix to

the static IP address.

CR805 Retransfer Card Printer User’s Guide 23

Page 40

The printer supports both IPv4 and IPv6 addressing. Because an IPv6 address is much longer than

an IPv4 address, the LCD displays the two types of addresses differently.

Retrieve an IPv4 Address

Do the following to display an IPv4 address using the Status menu. You also can display the

subnet mask, gateway address, and MAC address, if necessary.

Begin with the printer power connected, and the printer connected to the network.

1. Press the P

OWER button to power on the printer, if necessary.

2. Access the Status menu in the LCD menu:

a. Press the U

b. Press E

SER button to suspend the printer.

NTER to enter the menu system.

c. Press the down arrow to display Status on line 2.

d. Press E

NTER to enter the Status menu.

e. Press the down arrow until Network IPv4 displays

on line 2.

f. Press E

NTER to display the Network IPv4 menu.

3. Press the down arrow until IP Address displays on line 2.

24 Using the Printer

Page 41

4. Press E

5. Press E

NTER to display the IP address. Record the IP address.

NTER to return to the Network IPv4 menu. Subnet Mask

displays on line 2.

6. Press E

7. Press E

NTER to display the subnet mask. Record it, if necessary.

NTER to return to the Network IPv4 menu. Gateway

Address displays on line 2.

8. Press E

NTER to display the gateway address. Record it, if

necessary.

9. Press E

NTER to return to the Network IPv4 menu.

10. Press the down arrow to scroll to Exit on line 2.

11. Press E

to Ready. The U

NTER. Then, press the USER button to return the printer

SER button glows green.

Retrieve an IPv6 Address

A printer on an IPv6 network can be configured to use one or more of the following methods,

depending on how the network is set up:

Link Local IPv6 address: The printer and PC clients are restricted to the same subnet. Link

local is enabled automatically when IPv6 is enabled and offers the best security for your

network.

DHCPv6: A DHCPv6 server is externally configured to give out an IPv6 address.

Stateless Address AutoConfiguration (SLAAC): One or more routers with IPv6 enabled on the

subnet give out a subnet prefix that allows access to IP addresses.

Manual IPv6 Address: The printer has a designated IPv6 address on a specified subnet. The

address does not change without manual intervention. This is similar to an IPv4 static IP

address.

CR805 Retransfer Card Printer User’s Guide 25

Page 42

The method used is enabled or disabled using the LCD Configuration menu. Refer to the printer’s

Installation and Administrator’s Guide for more information about enabling IPv6.

To display an IPv6 address using the Status menu, do the following.

Begin with the printer power connected, and the printer connected to the network.

1. Press the P

OWER button (if needed) to power on the printer.

2. Access the Status menu in the LCD menu:

a. Press the U

b. Press E

SER button to suspend the printer.

NTER to enter the menu system.

c. Press the down arrow to display Status on line 2.

d. Press E

NTER to enter the Status menu.

e. Press the down arrow until Network IPv6 displays

on line 2.

f. Press E

26 Using the Printer

NTER to display the Network IPv6 menu.

Page 43

3. Press the down arrow until the address method used by

your network displays on line 2.

DHCP

SLAAC

Manual

Local

Press ENTER to display the IP address.

The example shows the LCD display for an IPv6 Manual address. DHCP, SLAAC,

and Local addresses behave the same, as does the gateway address for a manual

address.

An IPv6 address is represented as eight groups of four

hexadecimal digits separated by colons. The address

requires 39 characters to display. Because the LCD is limited

to 16 characters per line, the IPv6 address is spread across

three screens of the LCD. You can press either the down

arrow or the E

NTER key to display the next section of the

address. A digit at the end of line 1 indicates which section of

the address is being displayed.

A stateless (SLAAC) configuration (if enabled) can have multiple values depending

on the router setup. The LCD displays up to four SLAAC addresses. An additional

digit in line 1 indicates which address is being displayed.

4. Record the address.

5. Press the down arrow until Exit displays on line 2.

6. Press E

NTER. Then, press the USER button to return the printer to Ready. The USER button glows

green.

CR805 Retransfer Card Printer User’s Guide 27

Page 44

Print a Test Card

The printer includes a test card that prints without using a driver or other source of card data.

Use it to verify that the printer is printing correctly. Make sure that cards are in the input hopper

and all supplies are loaded before you begin. Refer to “Load and Replace Supplies” on page 31 for

complete information.

1. Begin with the printer Ready. The U

SER button shows steady

green.

2. Press the U

SER button to display Suspended on line 1 of the

LCD panel.

3. Press E

4. Press E

NTER to enter the menu system.

NTER to enter the Maintenance menu.

5. Press the down arrow until Test Card displays on line 2.

6. With Test Card displayed on line 2, press E

NTER to display Start

on line 2.

7. Press E

NTER to print the test card.

After the card prints, the printer returns to Ready.

28 Using the Printer

Page 45

Select a Card Stock

The printer can have up to ten different card stocks defined. For example, one card stock might be

used for a general ID card, while others are used for a retail card or a financial debit or credit card.

Refer to the Printer Manager section of the printer’s Installation and Administrator’s Guide for

more information about card stocks.

You can use the front panel menus to specify the card stock that is loaded in the input hopper or

in each multi-hopper cartridge, or the card stock that will be inserted using the exception slot.

Do the following to select the card stock loaded in the input hopper.

1. Press the U

SER button to display Suspended on line 1 of the LCD

panel.

2. Press E

NTER to enter the menu system.

3. Press the down arrow to display Configuration on line 2.

4. Press E

NTER to enter the Configuration menu.

5. Press the down arrow until Hopper displays on line 2, and then

press E

NTER to display the Hopper menu.

6. Press the down arrow until the correct hopper

displays on line 2. You can specify a card stock for

hoppers 1 through 6 in a multi-hopper printer.

7. Press E

NTER to select the card stock loaded in the

input hopper.

8. Press the down arrow until the card stock displays,

and then press E

CR805 Retransfer Card Printer User’s Guide 29

NTER to save your selection.

Page 46

Select a Color Mode

You can use the front panel menus to select the color mode that best defines the color printing

requirements for your site. The color modes are calibrated and installed in the printer during

manufacturing.

You also can select the color mode using Printer Manager. Refer to the printer’s Installation and

Administrator’s Guide for more information about the color modes available.

Do the following to select the color mode.

1. Press the U

SER button to display Suspended on line 1 of the

LCD panel.

2. Press E

NTER to enter the menu system.

3. Press the down arrow to display Configuration on line 2.

4. Press E

NTER to enter the Configuration menu.

5. Press the down arrow until Color Mode displays on line 2, and

then press E

NTER to display the Color Mode menu.

6. Press the down arrow until the color mode you want to use

displays on line 2, and then press E

NTER to save your

selection.

30 Using the Printer

Page 47

Load and Replace Supplies

To keep the printer ready to print cards, load blank card stock into the input hopper, load ink

ribbon and retransfer film on the appropriate cartridges, and load a cleaning sleeve into the

printer.

If your system includes the optional laminator, also load overlay material into the

L1 and L2 (if equipped) laminators. Refer to “Load Laminator Overlay Material” on

page A-9, for information about loading the laminator cartridges.

Load Cards

Do the following to load cards in the input hopper. If you plan to insert cards manually using the

exception slot, keep a supply of blank cards available.

Handle cards by the edges only, or wear card inspection gloves approved by Entrust Datacard.

Cards can stick together. Slide or fan the cards to separate the edges before placing them in

the input hopper.

Insert ISO magnetic stripe cards with the stripe (back side) facing down and to the right.

Insert smart cards with the smart card chip facing up and toward the back of the hopper.

A diagram inside the input hopper shows the correct orientation for each type of card.

Single-Hopper Printer

1. Unlock the input hopper lock, if present, and open the

input hopper door.

2. Load the cards into the input hopper. The hopper can

hold up to 125 cards.

3. Close and lock the input hopper, if necessary.

CR805 Retransfer Card Printer User’s Guide 31

Page 48

Use the Exception Slot

The exception slot allows you to insert a single card, such as a

different card type than those loaded in the input hopper. The

input hopper does not have to be opened to insert a card

through the exception slot.

1. Slide the card into the exception slot.

2. Push the card all the way into the input hopper. The card

slides under any cards already in the input hopper so that

it can be picked.

Multi-Hopper Printer

Do the following to load cards into a multi-hopper cartridge.

1. Unlock the multi-hopper lock.

2. Slide the lock bar release button (B1)

to the left to release the hopper lock

bars.

3. Rotate a lock bar to the left to

provide access to the multi-hopper

input cartridge that you want to load.

4. Press the cartridge release button at

the top of the cartridge and open the

cartridge door.

5. Lift the card weight to the top of the

cartridge and gently pull it forward

until it locks in position.

6. Load the cards into the input hopper

cartridge.

3

1

2

5

4

6

32 Using the Printer

Page 49

The diagrams inside the cartridge show how to

position the card weight and load cards. Do not

place the cards on top of the card weight.

You do not need to remove the cartridge from

Card Weight

the multi-hopper.

Cards

7. Close the cartridge door. This releases the card weight so that it is lowered on top of the

cards.

8. Rotate the lock bar back into position.

9. Slide the lock bar release button to the right to lock the lock bars into place.

10. Lock the multi-hopper.

Caution: The lock bars, lock bar release button, and the multi-hopper door lock all

must be in the lock position for the printer to operate. If any of the locks are left in

the unlock position, the printer issues an error. You must unlock and re-lock all locks

to clear the error and place the printer in Ready status.

Use the Multi-Hopper Exception Slide

Use the exception slide to insert a single card into the printer without unlocking the multi-hopper

or opening a hopper cartridge.

1. Pull the exception slide out from

the multi-hopper.

2. Insert the card into the exception

slide tray.

3. Push the exception slide back into

the multi-hopper.

The card is pulled into the printer to

complete the job.

CR805 Retransfer Card Printer User’s Guide 33

Page 50

Replace the Ink Ribbon

Replace the ink ribbon when the ribbon runs out.

1. Unlock the printer, if necessary, and open the

printer access door.

2. Press the ink ribbon cartridge release button and

remove the blue ink ribbon cartridge (C1).

3. Place the cartridge on a flat surface with the

spindles facing up.

4. Remove both used spools from the cartridge.

a. Press the blue latch button and slide the

used supply spool out from the cartridge.

b. Press the silver latch button and slide the

full take-up spool out from the cartridge.

c. Follow your site’s guidelines to properly

discard the used ink ribbon.

5. Clean the printer.

Each ink ribbon package contains an isopropanol

cleaning card.

a. Open the ink ribbon package and remove the

cleaning card.

b. Run the cleaning card through the printer.

Refer to “Clean the Printer” on page 47 for

complete information about the cleaning

process.

b

Ink Ribbon

a

Cleaning

Sleeve

Isopropanol

Cleaning Card

We recommend that you clean the printer after every 250 cards processed and