Entron EN7000-TS, EN7000 Technical Manual

EN7000 Technical Manual

Welding control for 50/60 Hz spot, projection, roll-spot, seam and multi-welding applications

EN7000 Technical Manual

2

EN7000 Technical Manual

Copyright © 2019 BF ENTRON Ltd. and/or its affiliates. All rights reserved.

The information in this manual is subject to change.

BF ENTRON assumes no responsibility for any errors that may appear in this manual.

BF ENTRON assumes no responsibility for any injury, loss or damage caused by improper installation,

use or application of the EN7000 welding control

The reproduction, transmission or use of this document or contents is not permitted without express

authority from BF ENTRON

BF ENTRON's trademarks and trade dress may not be used in connection with any product or service

that is not BF ENTRON's, in any manner that is likely to cause confusion among customers or in any

manner that disparages or discredits BF ENTRON. All other trademarks not owned by BF ENTRON are

the property of their respective owners, who may or may not be affiliated with, connected to, or

sponsored by BF ENTRON.

BF ENTRON Ltd.

Building 80 Bay 1

First Avenue

The Pensnett Estate

Kingswinford

West Midlands DY6 7FQ

Phone +44 (0)1384 455401 • Fax +44 (0)1384 455551

www.entroncontrols.com

Issue

Date

Comment

1.00

27/02/17

Added parameter descriptions and % conduction parameter.

1.02

23/05/17

Increased weld programs from 128 to 256. New options for SCR select and CT calibration.

New options for valves. New tutorial (resetting faults). Issue number corresponds to

EN7000 firmware.

1.04

26/09/17

Updated issue number.

1.05

30/11/17

Added seam welding features.

1.07

09/04/18

Models 5 and 6 discontinued. Seam welding features added to Models 3 and 4.

1.08

12/09/18

Added note to reset stepper/counter inputs. Updated status codes.

1.09

15/01/19

Revised description of force control.

1.10

12/02/19

Data log contains 6000 records

1.11

27/02/19

Models 1 and 2 discontinued. Model 3 is referred to as EN7000 and model 4 as EN7000TS. EN7000 and EN7000-TS can emulate the functionality of Models 1 and 2.

EN7000 Technical Manual

3

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THE EN7000

WARNING

DO NOT DISASSEMBLE, REPAIR, OR MODIFY THE EN7000. These actions can cause electric shock and fire.

Use only as described in this manual. Use only BF ENTRON recommended accessories and

replacement parts.

Stop operation if any problems occur. If the equipment is not working as it should, has been dropped,

damaged, left outdoors, or been in contact with water, contact BF ENTRON.

Only apply the specified power. Application of a voltage or current beyond the specified range can

cause electric shock or fire.

Do not use damaged plugs or connecting cables.

Keep water and water containers away from the EN7000. Water ingress can cause a short circuit,

electric shock, or fire.

Do not insert objects into openings. Do not use with any opening blocked; keep free of dust and debris.

Do not install the EN7000 in any of the following environments

o damp environments where humidity is 90% or higher.

o dusty environments.

o environments where chemicals are handled.

o environments near a high-frequency noise source.

o hot or cold environments where temperatures are above 40°C or below 0°C, or environments

where water will condense.

EN7000 Technical Manual

4

Contents

Section 1

Introduction…………………………………………………………………………………………...…5

Section 2

Mounting…………………………………………………………………………………..………………15

Section 3

Inputs and outputs…………………….…....……………………………………………………17

Section 4

Discrete i/o……………………………..…….…………………………………………………….……19

Section 5

MODBUS i/o…………………..…….………………………………………………………….….…...24

Section 6

Weld control…………………..…….………………………………………………………………....30

Section 7

Electrode management…………………..…….…………………………………….………38

Section 8

Status information…………………………………………………………………….………….44

Section 9

History log…………………..…….…………………………………………………………………..…47

Section 10

Multiwelding…………………..…….……………………………………………………..…………..48

Section 11

Seam welding………………..…….……………………………………………………..…………..52

Section 12

Configuration…………………..…….……………………………………………….………………59

Section 13

Programming…………………..…….………………………………………………………….……61

Section 14

Tutorials…………………..…….………………………………………………………………………...80

Section 15

Appendix…………………..…….……………………………………………………………….…….…91

Section 16

Terminology……………..…….…………………………………………………………………….…95

Section 1 Introduction

5

Introduction

The EN7000 is a SINGLE PHASE AC and 3-PHASE DC constant current and proportional force

controller for 50/60 Hz spot, projection and seam welding applications..

The controller is available in two formats:

EN7000: core welding control with single air-valve, electrode manager and expansion port.

Pre-heat and main heat intervals. Extended features include post-heat interval, force

profile, multi-gun, multi-air valve, multi electrode manager and seam welding. Gear-plate

mounted.

EN7000-TS: as EN7000, plus built-in touch screen display. Front panel mounted.

EN7000

EN7000-TS

Multiple communication and control options are supported by a number of programming methods. The

Ethernet port supports simultaneous programming and control connection via a single physical cable.

Short-circuit proof outputs and a guided-contact pilot relay provides enhanced safety. Connection to the

power system is via a single ribbon cable. Analog inputs and outputs can be used to drive a proportional

air regulator valve for force control.

Operation in Standard mode provides a basic set of features for simple applications. Extended mode

adds advanced features for more demanding applications. Choose between Standard or Extended

features (Section 12 Configuration). EN7000 must be restarted after changing this setting.

Section 1 Introduction

6

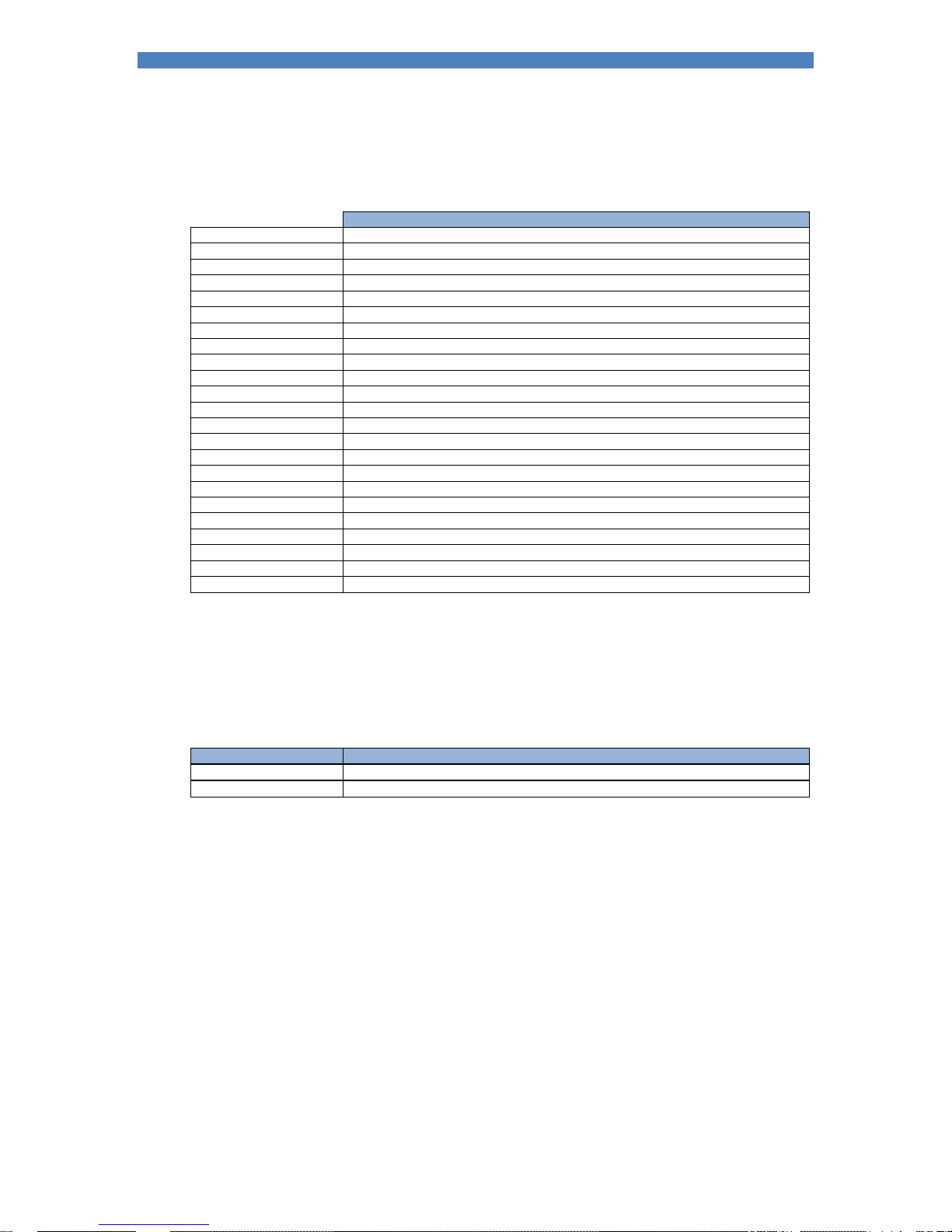

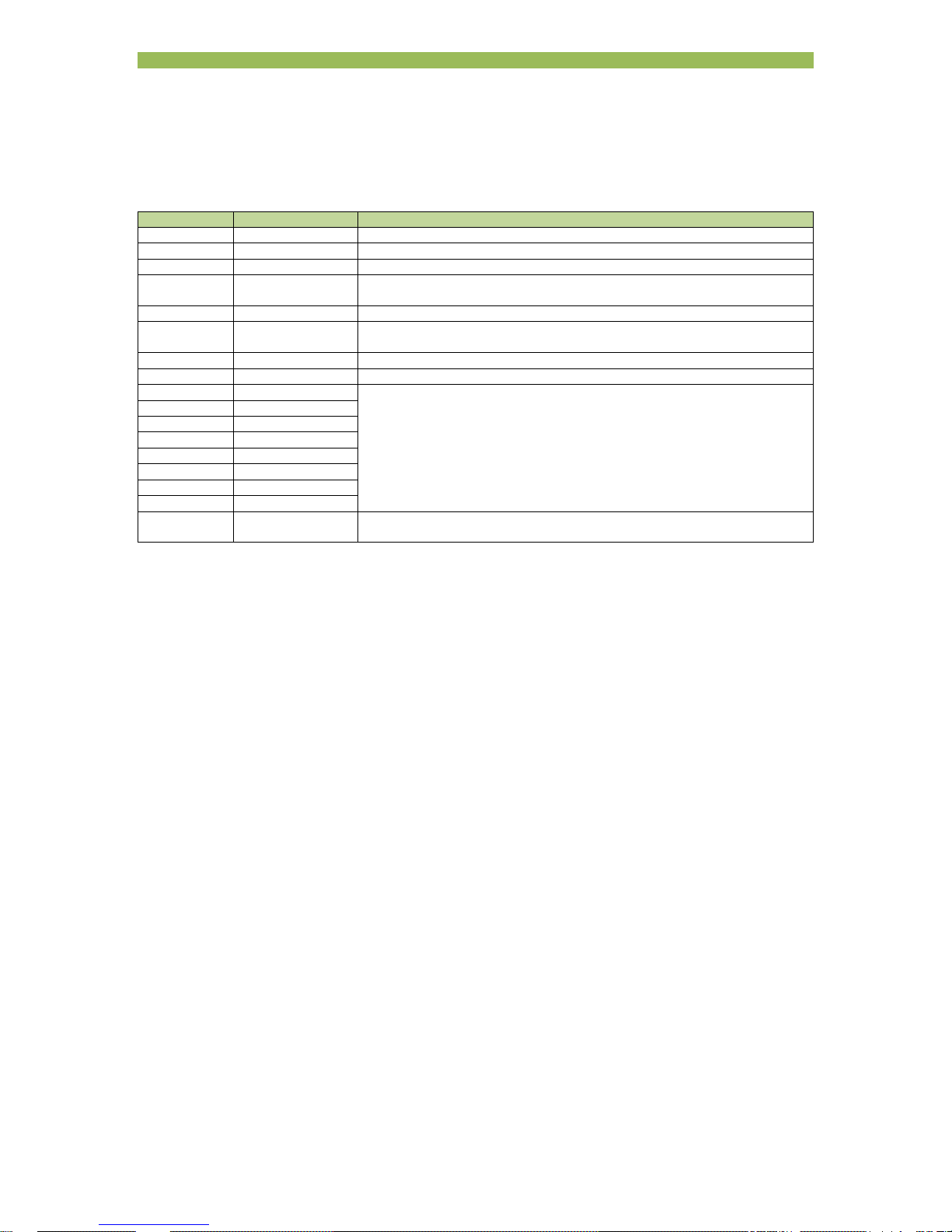

Features

Model

EN7000

EN7000-TS

Netflash programming

WSP3 programming

Built-in programmer 1

Panel mounting

Gear-plate mounting

Ethernet 2

RS232

RS485

MODBUS TCP/IP

MODBUS RTU

Analogue inputs 3 1 1

Analogue outputs 3 1 1

Discrete inputs

16

16

Discrete outputs 4

16

16

Weld programmes

256

256

Pre-heat

Main heat

Post-heat 5

Slope

Constant current

Power factor adjust

Cascade/Mux 5 8 8

Multi air valve

5, 6

8 8

Aux valves

7

7

Force profile 5

Electrodes/SCRs 5 8 8

Real-time clock

Data log (spot welds)

6000

6000

Expansion

Seam weld sequence 5

1

Colour touch-screen display

2

Two simultaneous connections

3

0 to 10 V

4

24 V dc, short-circuit proof, monitored

5

Extended feature

6

Guided contact safety relay, monitored

The extended features can be enabled for greater flexibility or more demanding applications.

Section 1 Introduction

7

Weld parameters

EN7000/EN7000-TS

Presqueeze

Squeeze

Pre-heat

Cool1

Upslope

Main heat

Cool2

Downslope

Pulses

Post-heat 1

Hold

Off WAV selection 1

Aux valve control

Retract/Hi-lift

Electrode selection 1

Force profile 1

SCR selection 1

Current monitor

Force monitor

Spot weld

Roll-spot weld 1

Seam weld 1

1

Extended feature

Part numbers

Model

Part number

EN7000

01-07-03

EN7000-TS

01-07-04

Section 1 Introduction

8

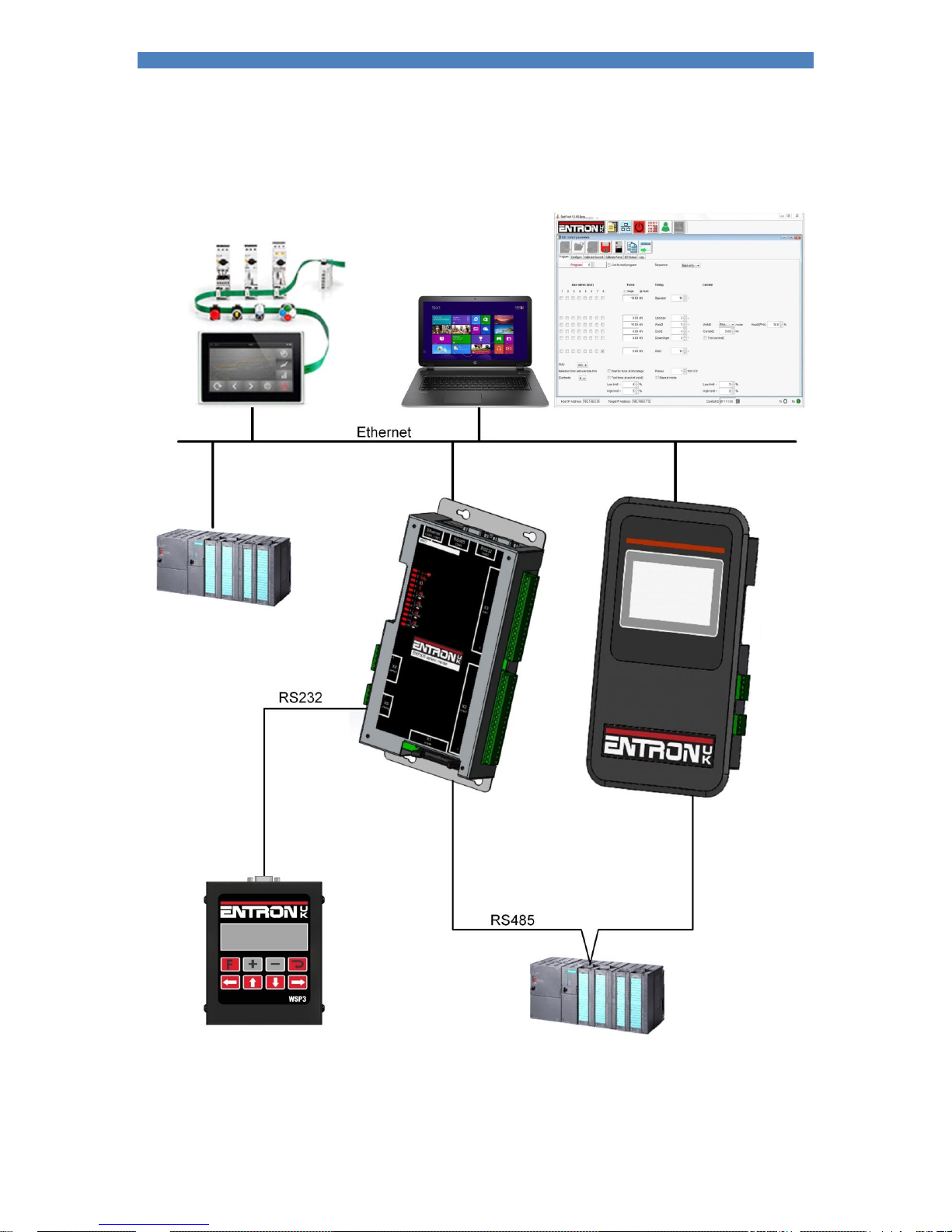

Programming options

NetFlash

This PC-compatible program displays and allows editing of all

welding parameters and status information.

In addition to programming, NetFlash provides backup/restore

functions for control data, live data logging to a file and a utility for

updating the firmware in the EN7000.

WSP3 Pendant

EN7000s work with the same WSP3 pendant that is used with

iPAK and WS2003. Access to all parameters is provided, plus

diagnostic indication.

MODBUS

A PLC or HMI MODBUS master can be used to program, control

and monitor EN7000s. All parameters are directly mapped to

MODBUS registers for easy access. Both MODBUS-TCP/IP

(Ethernet) and MODBUS-RTU (RS485) protocols are supported.

Built-in touch screen

EN7000-TS has a touch screen panel which provides easy

access to all parameters and indications.

Section 1 Introduction

9

Communications

Section 1 Introduction

10

Applications

Standard machines, portable/manual guns, robot guns, multi-welders and seam welders.

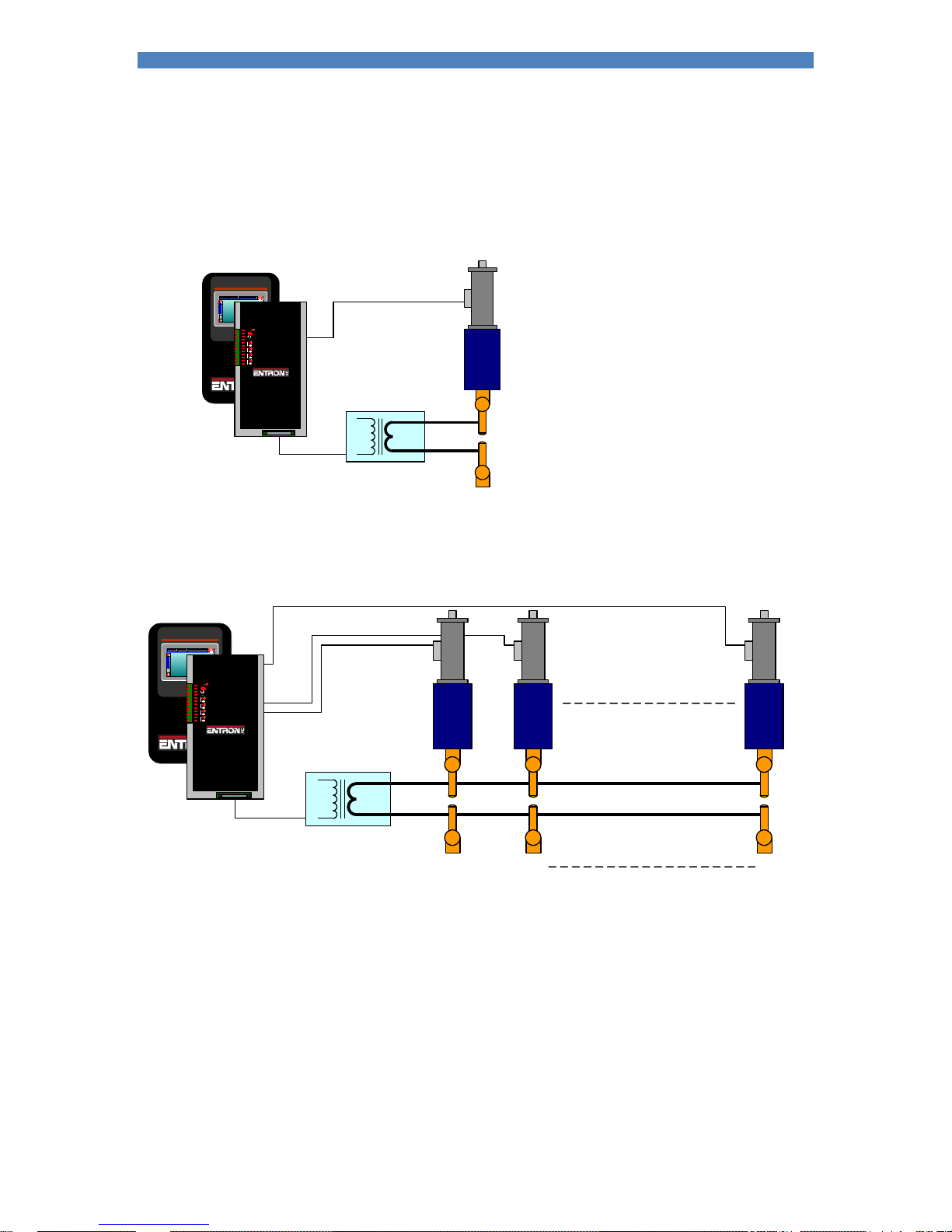

Standard machine.

Multi-head machine. Up to eight cylinders. Cascade or independent firing.

Program 1

I1 = 17.0kA H1 = 23.5% PHA

PSQ = 0 ~ SQZ = 10 ~

W1 = 12 ~ C1 = 0 ~

W2 = 12 ~ C2 = 0 ~

HLD = 10 ~

Edit Program

12.5 kA Prog 01 Low cu rrent W2

BF701 V1.01

Program 1

I1 = 17.0kA H1 = 23 .5% PHA

PSQ = 0 ~ SQZ = 10 ~

W1 = 12 ~ C1 = 0 ~

W2 = 12 ~ C2 = 0 ~

HLD = 10 ~

Edit Program

12.5 kA Prog 01 Low current W2

BF701 V1.01

1 2 8

Section 1 Introduction

11

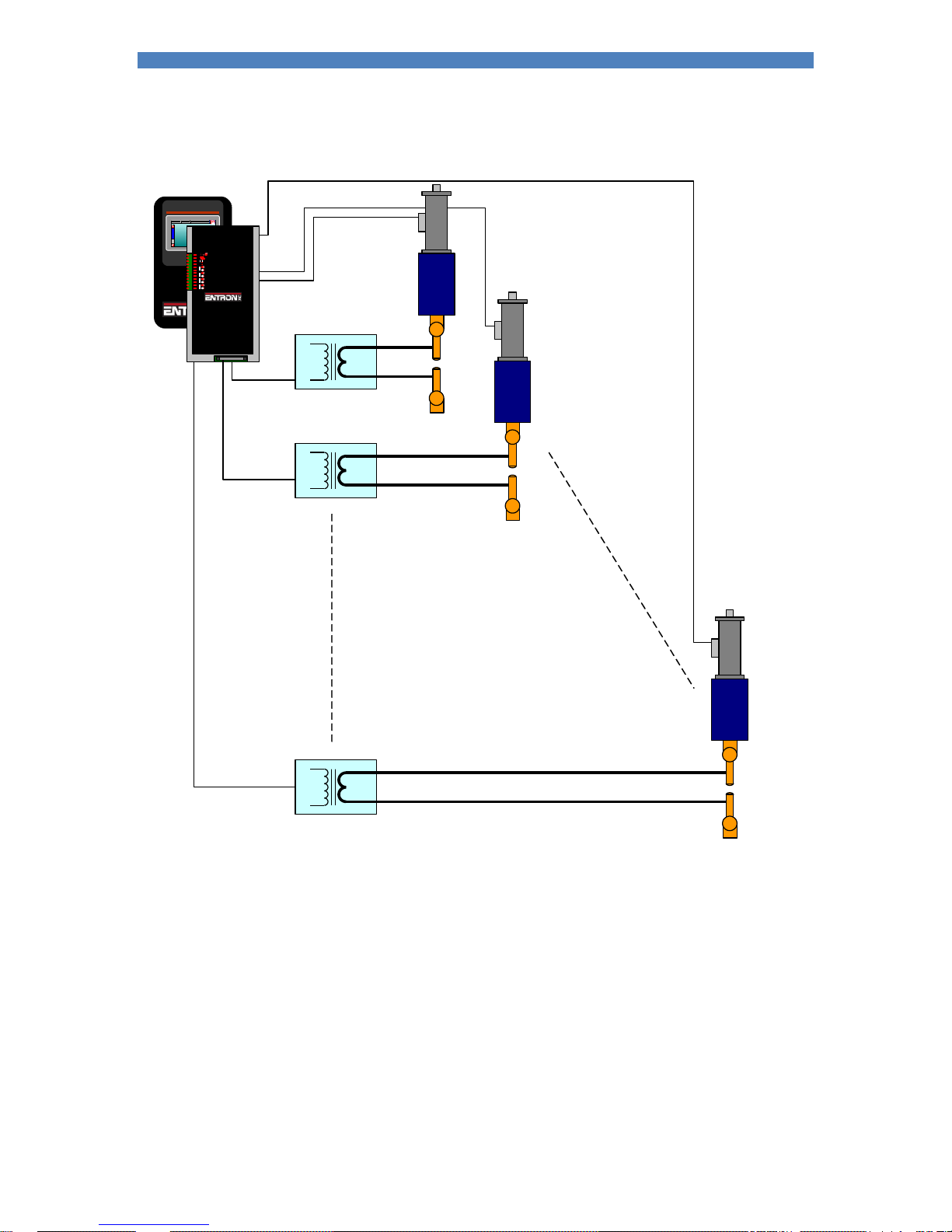

Multi-welder. Up to 8 transformers and cylinders. Cascade or independent firing.

Program 1

I1 = 17.0kA H1 = 23. 5% PHA

PSQ = 0 ~ SQZ = 10 ~

W1 = 12 ~ C1 = 0 ~

W2 = 12 ~ C2 = 0 ~

HLD = 10 ~

Edit Program

12.5 kA Prog 01 Low current W2

BF701 V1.01

1

2

8

8

2

1

Section 1 Introduction

12

Program 1

I1 = 17.0 kA H1 = 23.5% PHA

PSQ = 0 ~ SQZ = 10 ~

W1 = 12 ~ C1 = 0 ~

W2 = 12 ~ C2 = 0 ~

HLD = 10 ~

Edit Program

12.5 kA Prog 01 Low current W2

BF701 V1.01

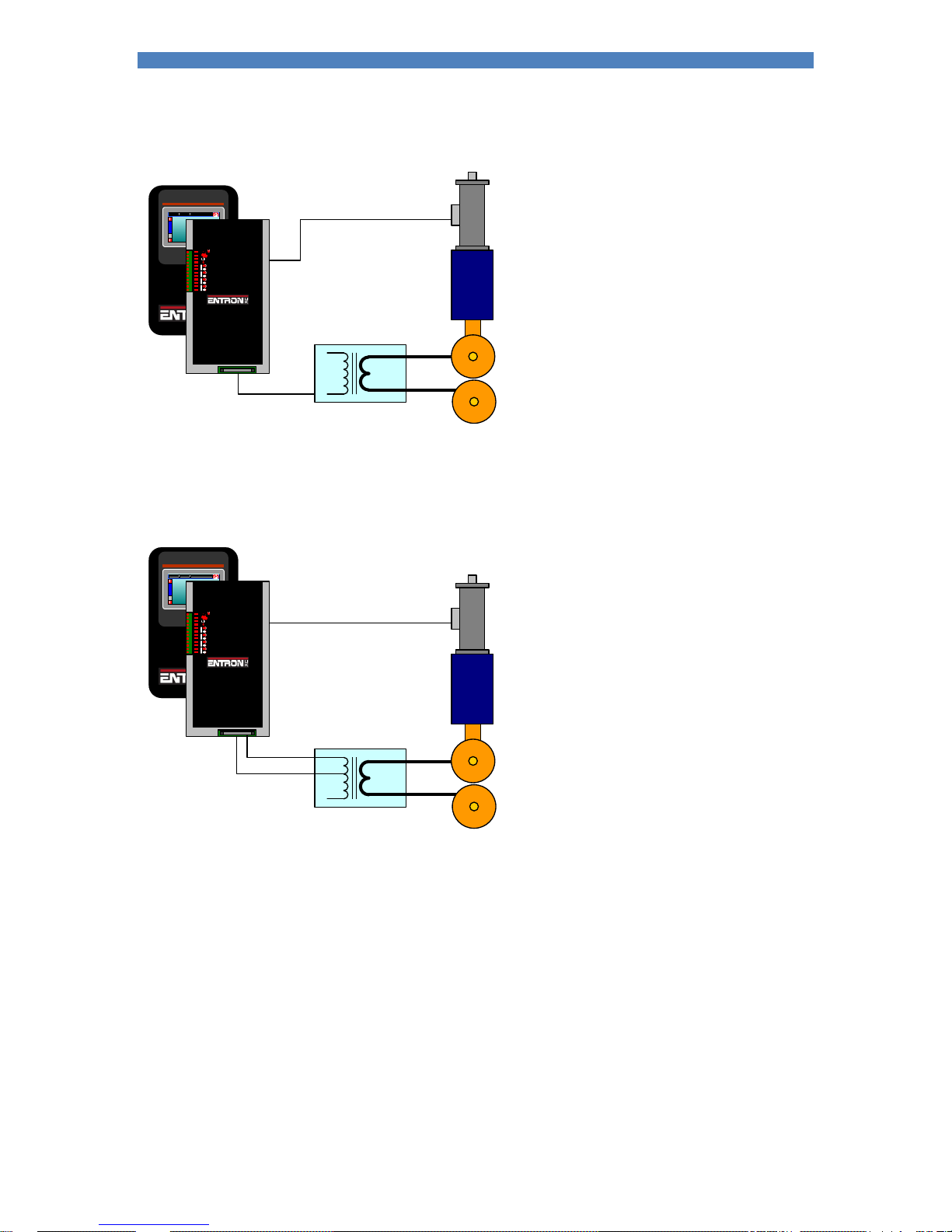

Seam welder with one transformer.

Program 1

I1 = 17.0 kA H1 = 23.5% PHA

PSQ = 0 ~ SQZ = 10 ~

W1 = 12 ~ C1 = 0 ~

W2 = 12 ~ C2 = 0 ~

HLD = 10 ~

Edit Program

12.5 kA Prog 01 Low current W 2

BF701 V1.01

Seam welder with a multi-tap transformer.

Section 1 Introduction

13

Getting started

Section 2 Mounting: Ensure the EN7000 is securely mounted.

Section 3 Inputs and outputs: connect the essential services and inputs/outputs depending on

the application.

Make sure that you have sufficient air pressure and cooling water where necessary.

Section 13 Programming: switch on then use the ‘Initialise all data’ function to clear the

EN7000’s memory.

Section 12 Configuration: set the Configuration parameters appropriately for the application.

Section 7 Electrode management: edit the calibration file.

Section 13 Programming: edit program 0 to set up a basic weld sequence e.g. Squeeze = 10,

Main heat = 10, Hold = 10, Pulses=1, and Main mode = PHA.

Section 13 Programming: a welding operation should be possible at this stage. Begin by using

the gun short-circuit. The EN7000 should report the measured current on the diagnostic

display.

Section 7 Electrode management: perform the calibration operation for the toroid sensitivity.

Observe the current with an external meter. Set the program heat to give a typical value of

welding current on the meter. Adjust the sensor sensitivity until the EN7000 measurement

corresponds with the meter.

Make any other adjustments which may be required and set up other programmes for welding.

Section 1 Introduction

14

This page intentionally left blank

Section 2 Mounting

15

Mounting

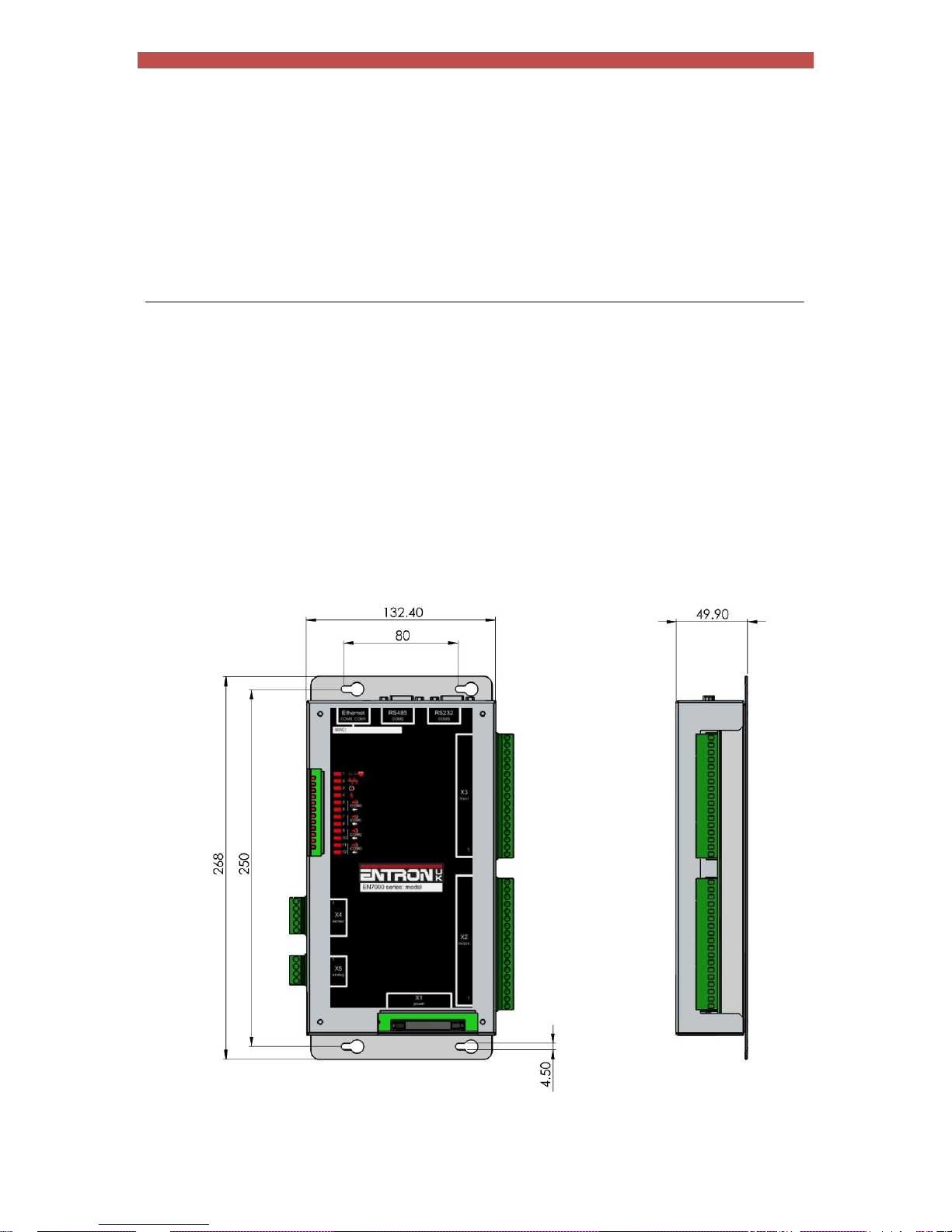

EN7000 is gear-plate mounted and EN7000-TS is front panel mounted.

If you have purchased a complete system the EN7000 will already be mounted in the case. If you have

purchased a timer only kit you will need to mount the EN7000 to the rest of your equipment.

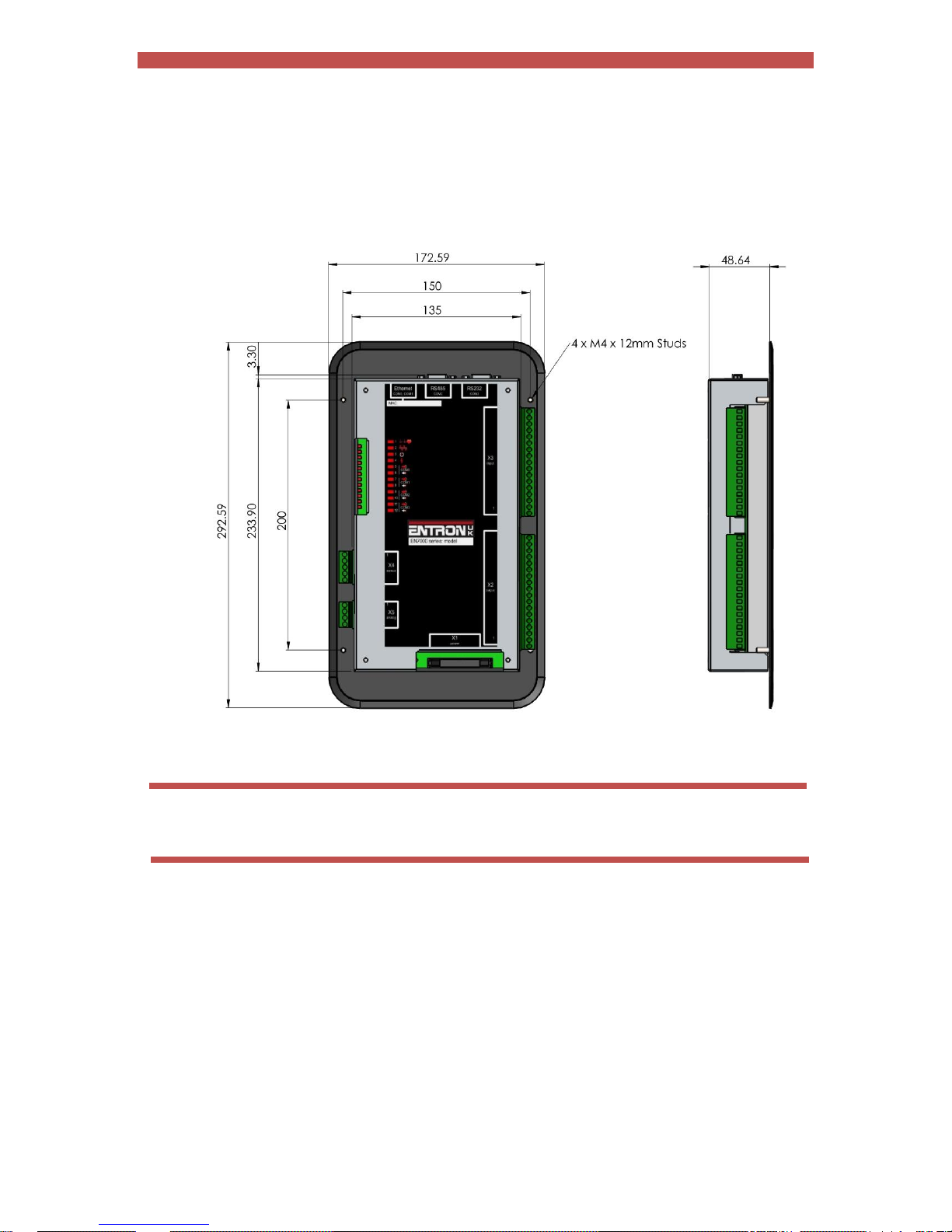

Gear plate mounting

The mounting arrangements for EN7000 are shown below. All dimensions are in mm.

Section 2 Mounting

16

Front panel mounting

The mounting arrangements for EN7000-TS are shown below. All dimensions are in mm.

Allow space for the connectors when mounting EN7000 or EN7000-TS

Section 3 Inputs and outputs

17

Inputs and outputs

EN7000 uses a number of inputs and outputs to control and monitor the weld sequence.

Inputs

Input

AWS designation

Description

Start

FS1

When this input is activated a weld sequence begins. If the input is

removed during the Squeeze interval the sequence is aborted. If the input

is maintained through the Squeeze interval but switched off subsequently,

the sequence terminates normally.

Weld on

NW1

This input enables the weld current. If this input is inactive a weld

sequence will not produce any current.

Stop

ES1

Sequencing is inhibited or aborted if this input is not active.

Thermal

TT1

This input is usually connected to a normally closed thermal contact

attached to the weld transformer. Sequencing is inhibited if this input is not

active.

2nd stage

PS1

If enabled, EN7000 checks that the 2nd Stage signal is present before

proceeding to weld. The checking is programmable to take place either

before or after the Squeeze interval. If the signal is not present EN7000

waits for the signal before it proceeds. If the Start signal is removed while

waiting, the sequence is aborted.

Retract

RT1

This input is used to control the Retract function.

Reset fault

FR1

This input resets the Fault output and clears the status messages. Only

momentary application is required (minimum time 40ms).

Reset

counter/tip

dress

acknowledge1

Used to reset the counter(s) or acknowledge a tip dress request.

Reset

stepper2

SR1

Used to reset the stepper(s).

P1

BP1

Program select inputs. Weld program selection is made by applying the

binary code for the required program. Programs 0 to 127 can be selected

(programs 128 to 255 can be selected internally or via the fieldbus).

P2

BP2

P4

BP4

P8

BP8

P16

BP16

P32

BP32

P64

BP64

CT Input for the current transformer.

Toroid

Input for the toroid.

Analog

0 to 10 V analog input. Can be used to monitor a proportional air regulator

valve output or other sensor for force control and monitoring.

Section 3 Inputs and outputs

18

Outputs

Output

AWS designation

Description

EOS

EH1

This output switches on to indicate the end of the weld sequence.

HAV

RV1

Used in conjunction with the Retract input to control the welding head.

Fault

FT1

This output indicates a fault condition.

Ready

This output is active if EN7000 is ready to weld. The output switches off

under some fault conditions.

Contactor

MC1

This output can be used to control an isolation contactor.

Counter/tip

dress request

This output indicates that the counter has reached its limit or that a tip

dressing operation is required.

Stepper

This output indicates that the stepper has reached its limit.

Pre-warn

This output indicates that the stepper is close to its limit.

AV1

Additional outputs that can be used during the weld sequence.

AV2

AV3 AV4 AV5 AV6

AV7

AV8

Analog

0 to 10 V analog output. Can be used to drive a proportional air regulator

valve for force control

1

Momentary operation will reset all expired counters. If maintained for more than 5 seconds all counters will be

reset, regardless of status.

2

Momentary operation will reset all expired steppers. If maintained for more than 5 seconds all steppers will be

reset, regardless of status.

Section 4 Discrete i/o

19

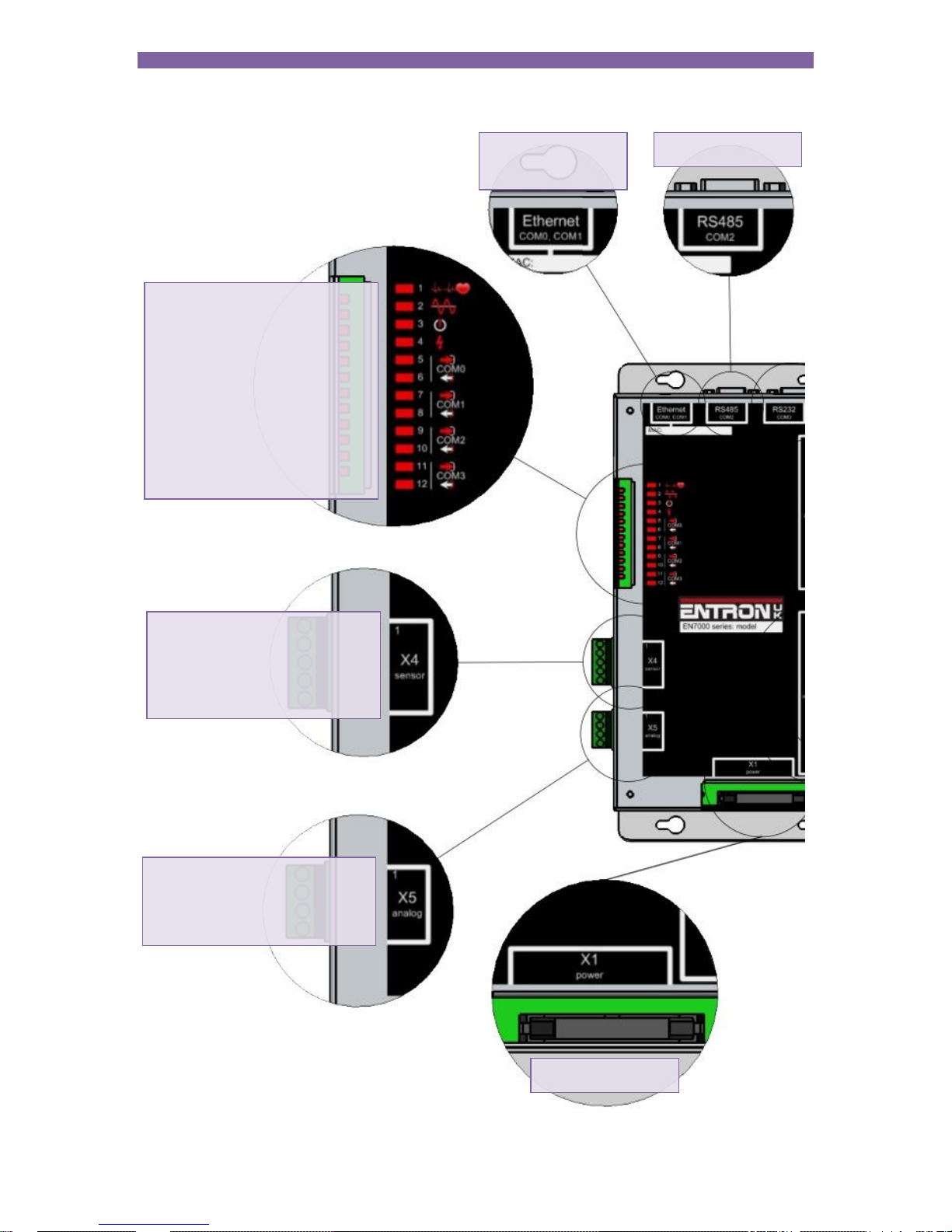

Discrete i/o

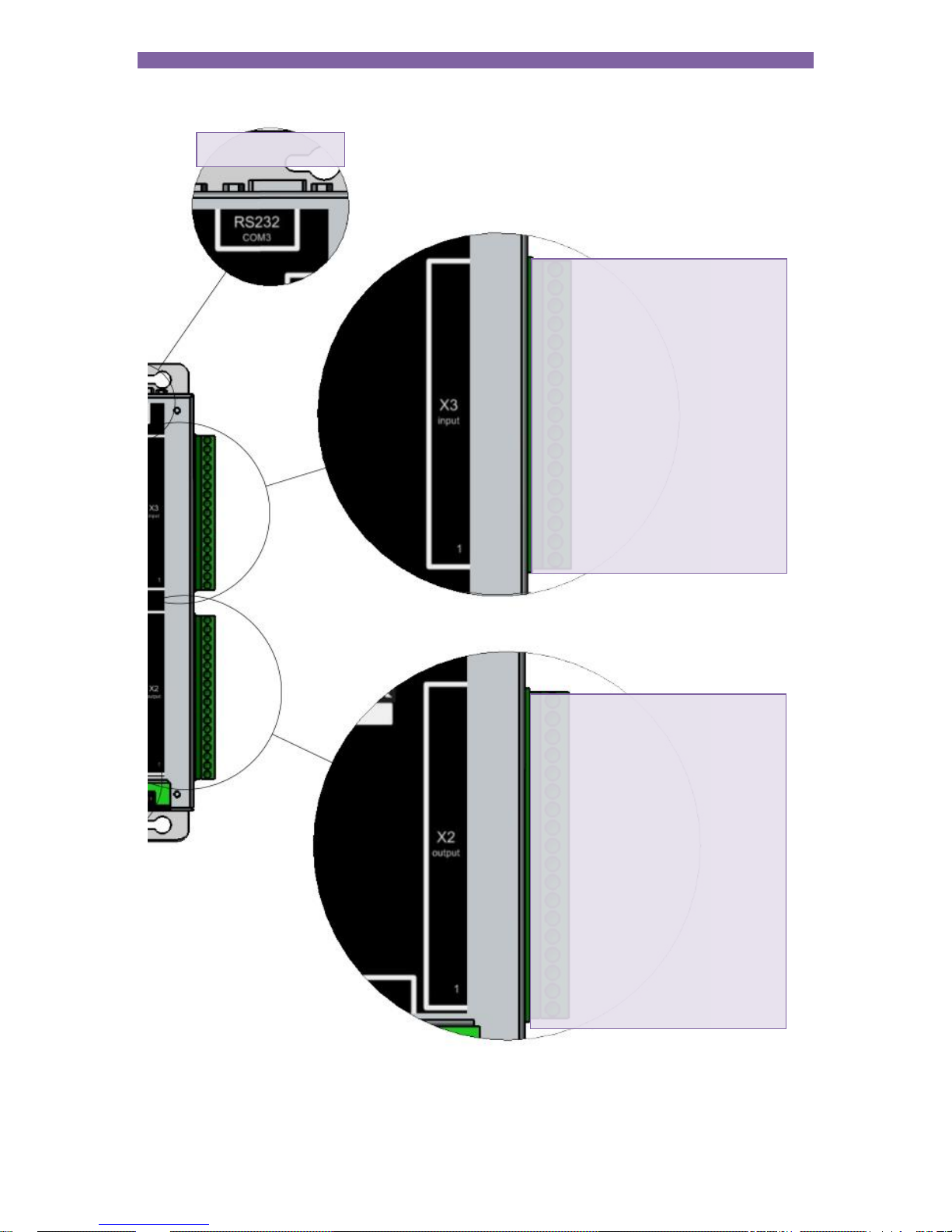

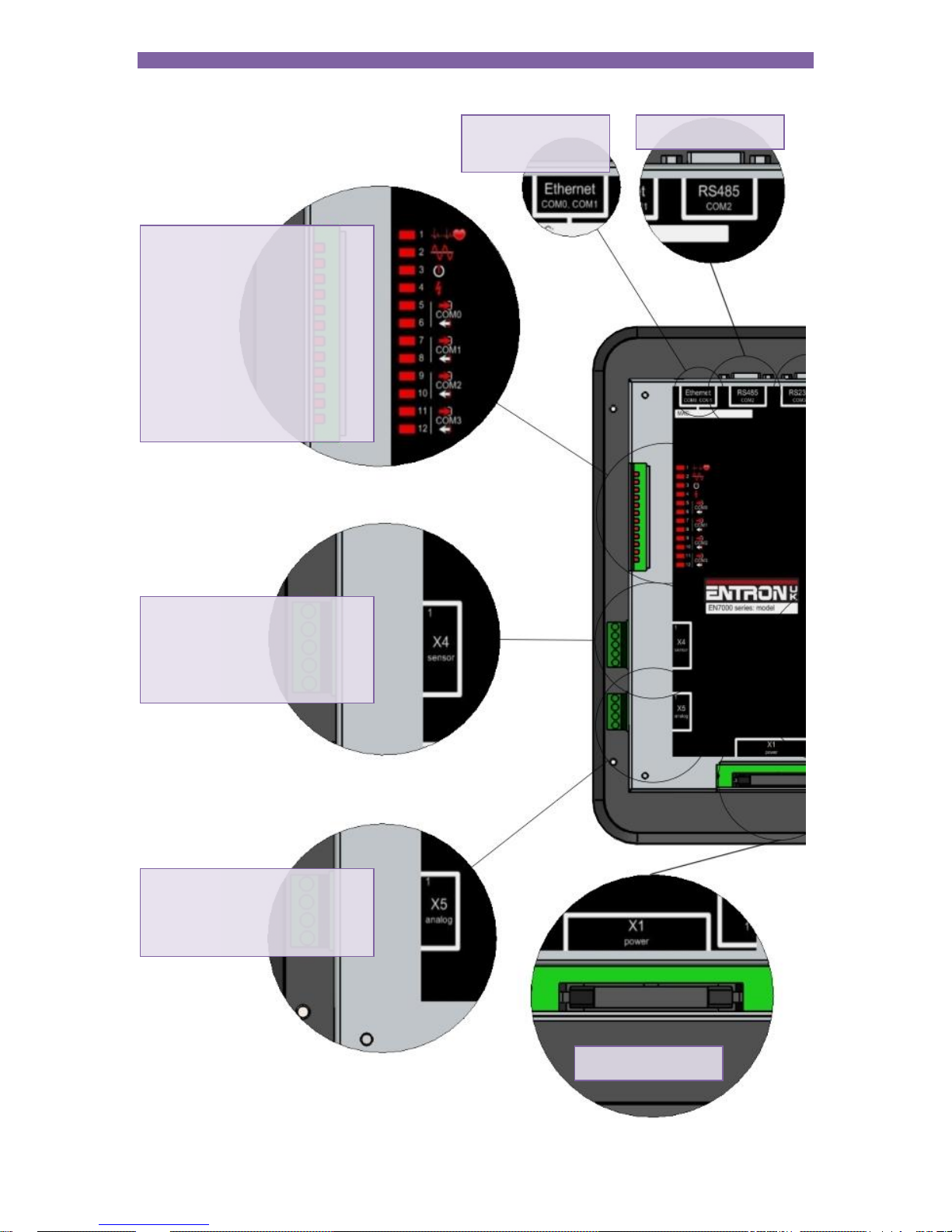

The inputs and outputs are accessible via connectors X2, X3, X4 and X5. The connectors are two-part

terminals for use with wires up to 1 mm

2

If the EN7000 is supplied fitted into a case some connections will have been pre-wired by BF ENTRON.

See the case wiring diagram for details.

Section 4 Discrete i/o

20

EN7000

Outputs are rated 500 mA @24 V dc

AWS designations in parenthesis

1

inputs must be linked if not required

1. Heartbeat

2. Synchronised to ac mains

3. Sequence initiated

4. Weld current

5. Data receive COM0

6. Data send COM0

7. Data receive COM1

8. Data send COM1

9. Data receive COM2

10. Data send COM2

11. Data receive COM3

12. Data send COM3

1. CT input

2. CT input

3. Toroid input

4. Toroid input

5. Gnd

1. 0 V

2. Output (0 to 10 V)

3. Input (0 to 10 V)

4. Gnd

MODBUS-RTU

NetFlash

MODBUS-TCP/IP

Power

Section 4 Discrete i/o

21

i/o bit

17. 24 V (24 VDC) 1

16. 15 P64 (BP64)

15. 14 P32 (BP32)

14. 13 P16 (BP16)

13. 12 P8 (BP8)

12. 11 P4 (BP4)

11. 10 P2 (BP2)

10. 9 P1 (BP1)

9. 8 Reset stepper (SR1)

8. 7 Reset counter/tip dress ack

7. 6 Reset fault (FR1)

6. 5 Retract (RT1)

5. 4 2nd stage (PS1)

4. 3 Transformer thermal (TT1) 1

3. 2 Stop (ES1) 1

2. 1 Weld on (NW1) 1

1. 0 Start (FS1)

i/o bit

18. 0 V (SVC)

17. Do not connect

16. 15 AV1 (SV1)

15. 14 AV2 (SV2)

14. 13 AV3 (SV3)

13. 12 AV4 (SV4)

12. 11 AV5 (SV5)

11. 10 AV6 (SV6)

10. 9 AV7 (SV7)

9. 8 AV8 (SV8)

8. 7 Prewarn

7. 6 Stepper

6. 5 Counter/Tip dress request

5. 4 Contactor (MC1)

4. 3 Ready

3. 2 Fault (FT1)

2. 1 HAV (RV1)

1. 0 EOS (EH1)

WSP3

Section 4 Discrete i/o

22

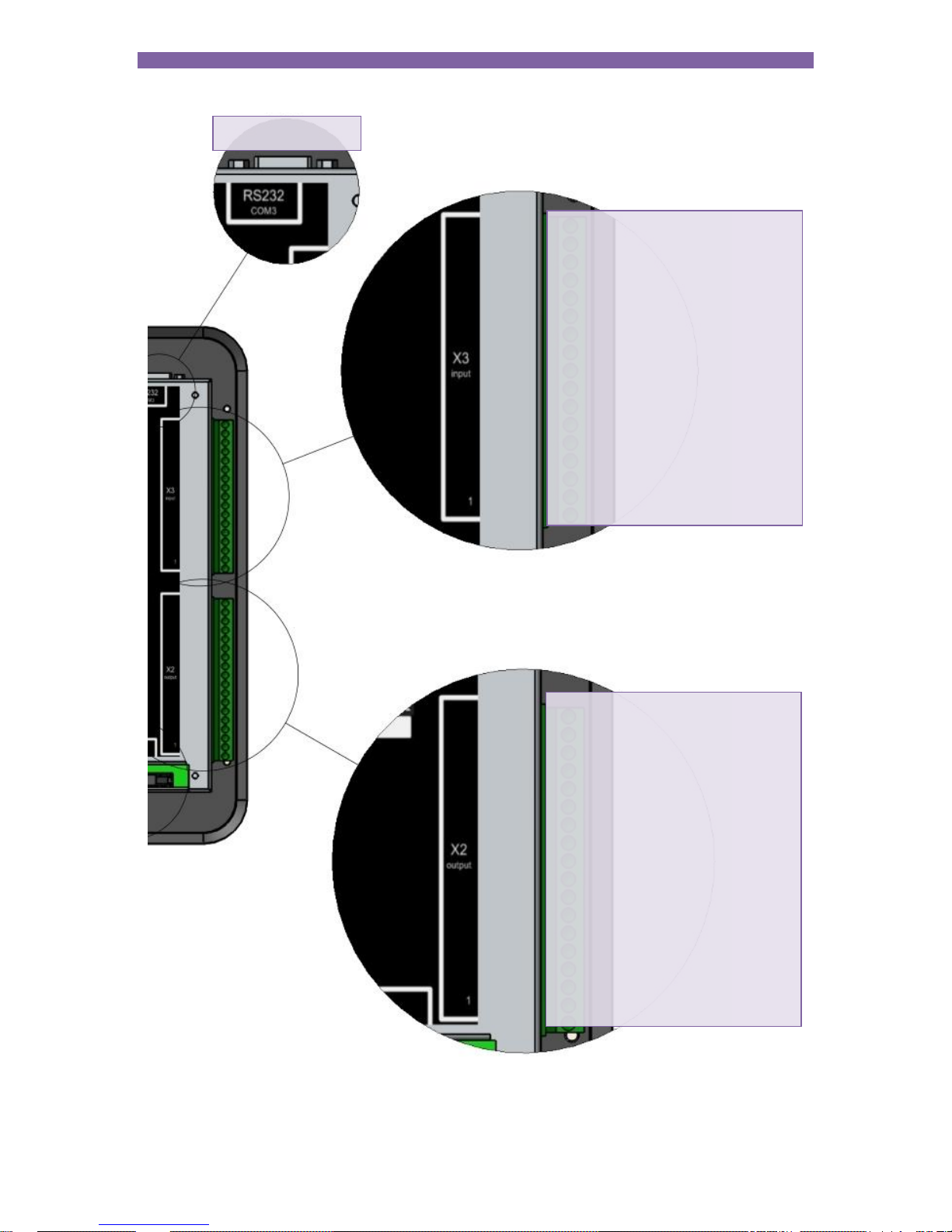

EN7000-TS

Outputs are rated 500 mA @24 V dc

AWS designations in parenthesis

1

inputs must be linked if not required

1. Heartbeat

2. Synchronised to ac mains

3. Sequence initiated

4. Weld current

5. Data receive COM0

6. Data send COM0

7. Data receive COM1

8. Data send COM1

9. Data receive COM2

10. Data send COM2

11. Data receive COM3

12. Data send COM3

1. CT input

2. CT input

3. Toroid input

4. Toroid input

5. Gnd

1. 0 V

2. Output (0 to 10 V)

3. Input (0 to 10 V)

4. Gnd

NetFlash

MODBUS-TCP/IP

MODBUS-RTU

Power

Section 4 Discrete i/o

23

i/o bit

17. 24 V DC out 1

16. 15 P64 (BP64)

15. 14 P32 (BP32)

14. 13 P16 (BP16)

13. 12 P8 (BP8)

12. 11 P4 (BP4)

11. 10 P2 (BP2)

10. 9 P1 (BP1)

9. 8 Reset stepper (SR1)

8. 7 Reset counter/tip-dress ack

7. 6 Reset fault (FR1)

6. 5 Retract (RT1)

5. 4 2nd stage (PS1)

4. 3 Transformer thermal(TT1) 1

3. 2 Stop (ES1) 1

2. 1 Weld on (NW1) 1

1. 0 Start (FS1)

i/o bit

18. 0 V (SVC)

17. do not connect

16. 15 AV1 (SV1)

15. 14 AV2 (SV2)

14. 13 AV3 (SV3)

13. 12 AV4 (SV4)

12. 11 AV5 (SV5)

11. 10 AV6 (SV6)

10. 9 AV7 (SV7)

9. 8 AV8 (SV8)

8. 7 Prewarn

7. 6 Stepper

6. 5 Counter/tip-dress request

5. 4 Contactor (MC1)

4. 3 Ready

3. 2 Fault (FT1)

2. 1 HAV (RV1)

1. 0 EOS (EH1)

WSP3

Section 5 MODBUS i/o

24

MODBUS i/o

EN7000 can be operated via MODBUS instead of using the discrete inputs and outputs.

Both MODBUS TCP/IP (Ethernet) and MODBUS RTU (RS485) protocols are supported.

Write the inputs using MODBUS function 16

Read the outputs using MODBUS function 3

MODBUS access types

Write inputs

Type

Value

Description

Function code

UINT

16

Write multiple registers

Read offset

UINT

0

Read length

UINT

0

Write offset

UINT

16#8000 (= 32768)

Write length

UINT

2

Read outputs

Type

Value

Description

Function code

UINT

3

Read holding registers

Read offset

UINT

16#9000 (= 36864)

Read length

UINT

24 Write offset

UINT

0 Write length

UINT

0

Section 5 MODBUS i/o

25

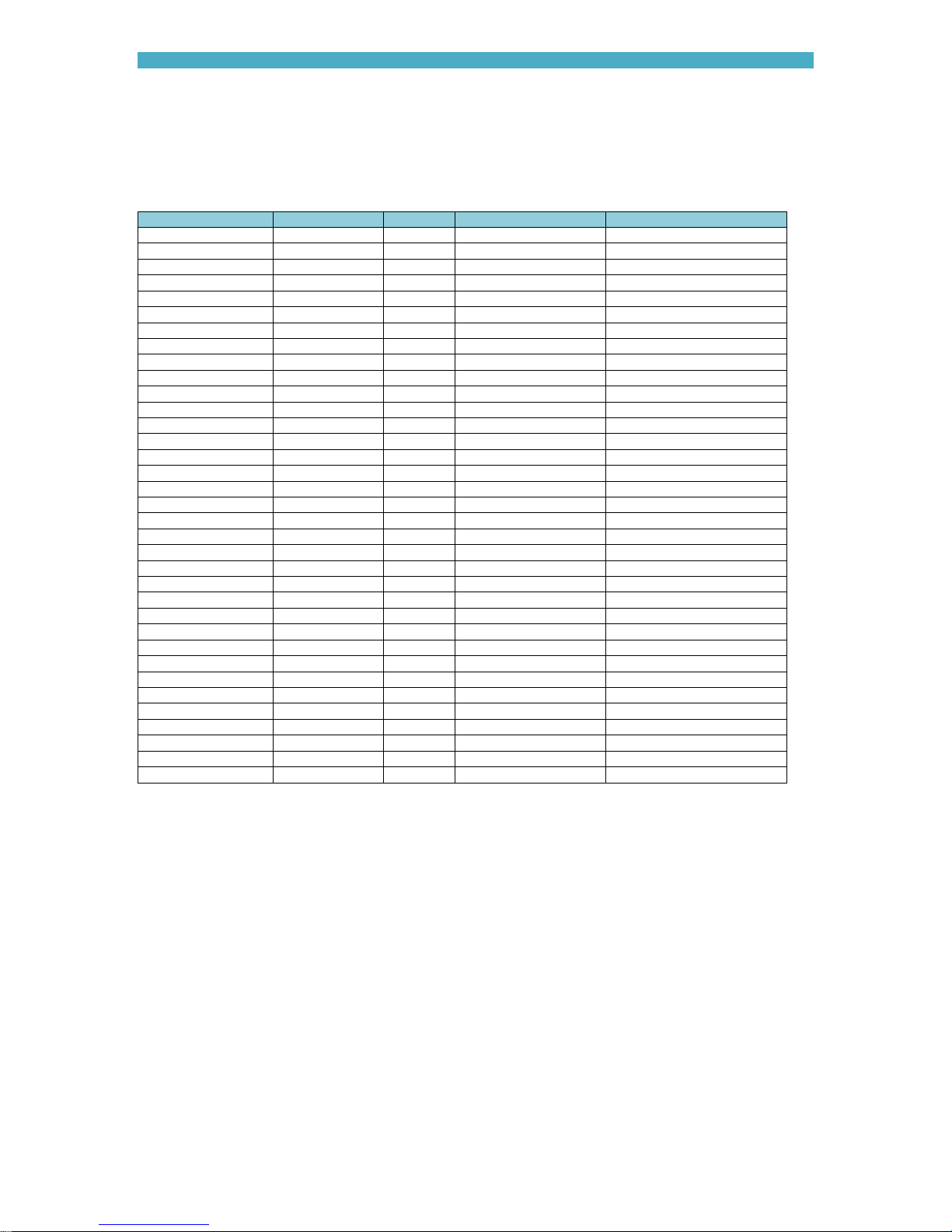

MODBUS mapping (inputs to EN7000)

Variable

Channel

Address

Type

Description

Write inputs

%QW0

WORD ARRAY [0..1]

Write multiple registers

Write inputs [0]

%QW0

WORD

WRITE 16#8000 (= 32768)

Start

Bit 0

%QX0.0

BOOL

Weld on

Bit 1

%QX0.1

BOOL

Stop

Bit 2

%QX0.2

BOOL

Transformer t’stat

Bit 3

%QX0.3

BOOL

2nd stage

Bit 4

%QX0.4

BOOL

Retract

Bit 5

%QX0.5

BOOL

Reset fault

Bit 6

%QX0.6

BOOL

Reset counter

Bit 7

%QX0.7

BOOL

Reset stepper

Bit 8

%QX1.0

BOOL

Reserved

Bit 9

%QX1.1

BOOL

Reserved

Bit 10

%QX1.2

BOOL

Reserved

Bit 11

%QX1.3

BOOL

Reserved

Bit 12

%QX1.4

BOOL

Reserved

Bit 13

%QX1.5

BOOL

Reserved

Bit 14

%QX1.6

BOOL

Reserved

Bit 15

%QX1.7

BOOL

Write inputs [1]

%QW2

WORD

WRITE 16#8001 (= 32769)

P1

Bit 0

%QX2.0

BOOL

P2

Bit 1

%QX2.1

BOOL

P4

Bit 2

%QX2.2

BOOL

P8

Bit 3

%QX2.3

BOOL

P16

Bit 4

%QX2.4

BOOL

P32

Bit 5

%QX2.5

BOOL

P64

Bit 6

%QX2.6

BOOL

P128

Bit 7

%QX2.7

BOOL

Reserved

Bit 8

%QX3.0

BOOL

Reserved

Bit 9

%QX3.1

BOOL

Reserved

Bit 10

%QX3.2

BOOL

Reserved

Bit 11

%QX3.3

BOOL

Reserved

Bit 12

%QX3.4

BOOL

Reserved

Bit 13

%QX3.5

BOOL

Reserved

Bit 14

%QX3.6

BOOL

Reserved

Bit 15

%QX3.7

BOOL

Section 5 MODBUS i/o

26

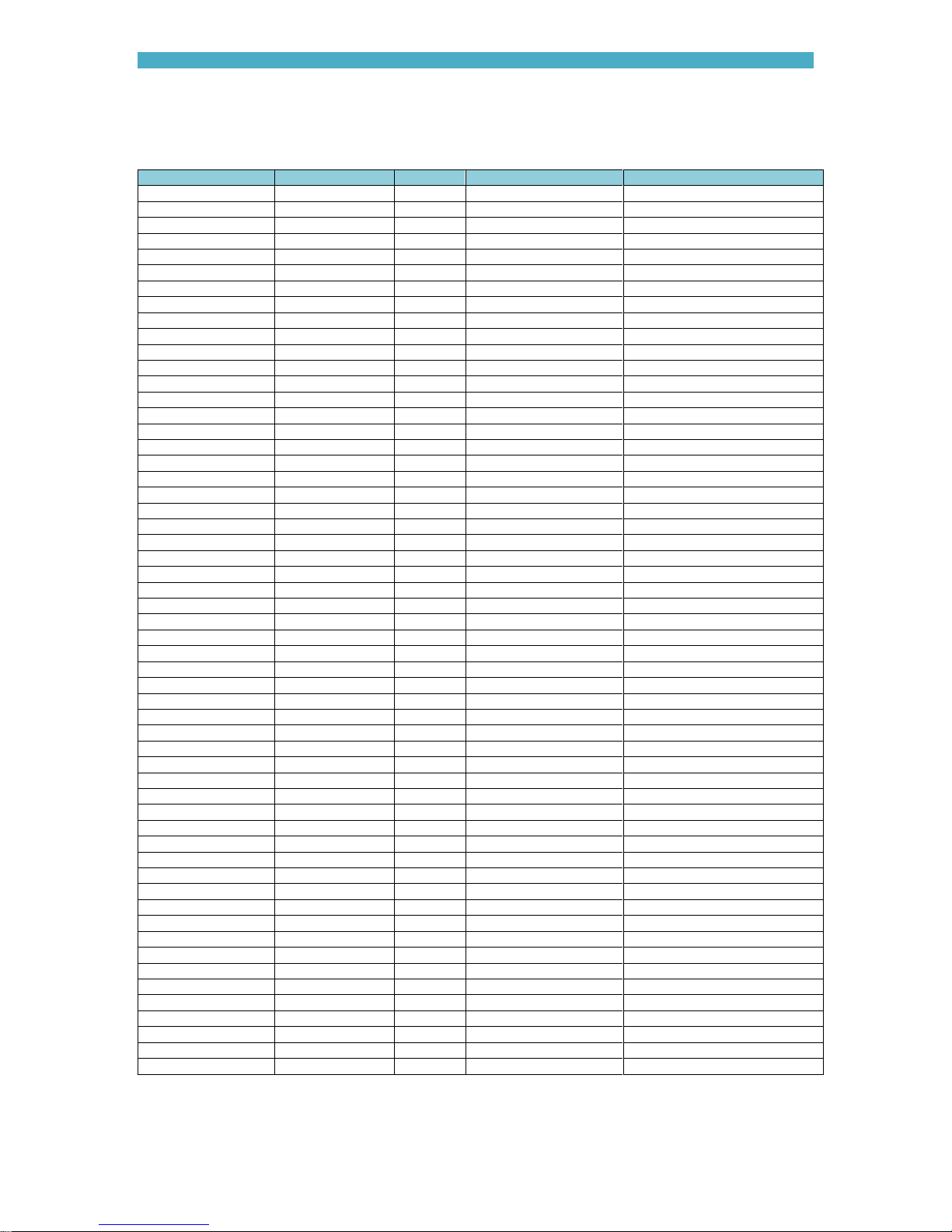

MODBUS mapping (outputs from EN7000)

Variable

Channel

Address

Type

Description

Read outputs

%IW0

WORD ARRAY [0..23]

Read holding registers

Read outputs [0]

%IW0

WORD

READ 16#9000 (= 36864)

EOS

Bit 0

%IX0.0

BOOL

HAV

Bit 1

%IX0.1

BOOL

Fault

Bit 2

%IX0.2

BOOL

Ready

Bit 3

%IX0.3

BOOL

Contactor

Bit 4

%IX0.4

BOOL

Counter

Bit 5

%IX0.5

BOOL

Stepper

Bit 6

%IX0.6

BOOL

Pre-warn

Bit 7

%IX0.7

BOOL

AV8

Bit 8

%IX1.0

BOOL

AV7

Bit 9

%IX1.1

BOOL

AV6

Bit 10

%IX1.2

BOOL

AV5

Bit 11

%IX1.3

BOOL

AV4

Bit 12

%IX1.4

BOOL

AV3

Bit 13

%IX1.5

BOOL

AV2

Bit 14

%IX1.6

BOOL

AV1

Bit 15

%IX1.7

BOOL

Read outputs [1]

%IW2

WORD

READ 16#9001 (= 36865)

Start

Bit 0

%IX2.0

BOOL

≘ %QX0.0

Weld on

Bit 1

%IX2.1

BOOL

≘ %QX0.1

Stop

Bit 2

%IX2.2

BOOL

≘ %QX0.2

Transformer t’stat

Bit 3

%IX2.3

BOOL

≘%QX0.3

2nd stage

Bit 4

%IX2.4

BOOL

≘ %QX0.4

Retract

Bit 5

%IX2.5

BOOL

≘ %QX0.5

Reset fault

Bit 6

%IX2.6

BOOL

≘ %QX0.6

Reset counter

Bit 7

%IX2.7

BOOL

≘ %QX0.7

Reset stepper

Bit 8

%IX3.0

BOOL

≘ %QX1.0

P1

Bit 9

%IX3.1

BOOL

≘ discrete input P1

P2

Bit 10

%IX3.2

BOOL

≘ discrete input P2

P4

Bit 11

%IX3.3

BOOL

≘ discrete input P4

P8

Bit 12

%IX3.4

BOOL

≘ discrete input P8

P16

Bit 13

%IX3.5

BOOL

≘ discrete input P16

P32

Bit 14

%IX3.6

BOOL

≘ discrete input P32

P64

Bit 15

%IX3.7

BOOL

≘ discrete input P64

Read outputs [2]

%IW4

WORD

READ 16#9002 (= 36866)

Start

Bit 0

%IX4.0

BOOL

≘ discrete input Start

Weld on

Bit 1

%IX4.1

BOOL

≘ discrete input Weld on

Stop

Bit 2

%IX4.2

BOOL

≘ discrete input Stop

Thermal

Bit 3

%IX4.3

BOOL

≘ discrete input Thermal

2nd stage

Bit 4

%IX4.4

BOOL

≘ discrete input 2nd stage

Retract

Bit 5

%IX4.5

BOOL

≘ discrete input Retract

Reset fault

Bit 6

%IX4.6

BOOL

≘ discrete input Reset fault

Reset counter

Bit 7

%IX4.7

BOOL

≘ discrete input Reset counter

Reset stepper

Bit 8

%IX5.0

BOOL

≘ discrete input Reset stepper

P1

Bit 9

%IX5.1

BOOL

≘ discrete input P1

P2

Bit 10

%IX5.2

BOOL

≘ discrete input P2

P4

Bit 11

%IX5.3

BOOL

≘ discrete input P4

P8

Bit 12

%IX5.4

BOOL

≘ discrete input P8

P16

Bit 13

%IX5.5

BOOL

≘ discrete input P16

P32

Bit 14

%IX5.6

BOOL

≘ discrete input P32

P64

Bit 15

%IX5.7

BOOL

≘ discrete input P64

Section 5 MODBUS i/o

27

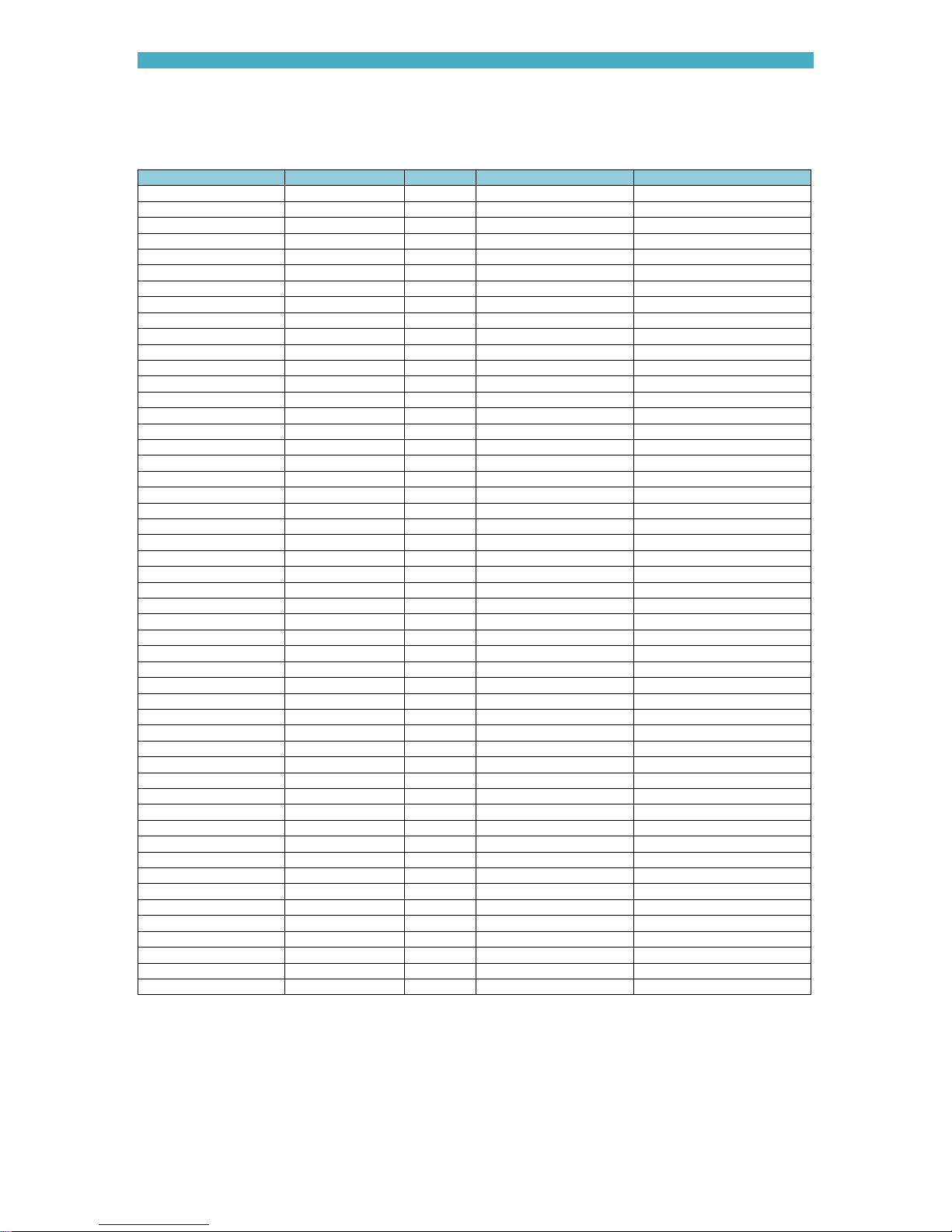

Variable

Channel

Address

Type

Description

Analog input (mV)

Read outputs [3]

%IW6

WORD

READ 16#9003 (= 36867)

Analog output (mV)

Read outputs [4]

%IW8

WORD

READ 16#9004 (= 36868)

% conduction

Read outputs [5]

%IW10

WORD

READ 16#9005 (= 36869)

Reserved

Read outputs [6]

%IW12

WORD

READ 16#9006 (= 36870)

Reserved

Read outputs [7]

%IW14

WORD

READ 16#9007 (= 36871)

Status register 0

Read outputs [8]

%IW16

WORD

READ 16#9008 (= 36872)

Stop

Bit 0

%IX16.0

BOOL

Bit 0

Sync. error

Bit 1

%IX16.1

BOOL

Bit 1

Retract not ready

Bit 2

%IX16.2

BOOL

Bit 2

SCR hot

Bit 3

%IX16.3

BOOL

Bit 3

Transformer hot

Bit 4

%IX16.4

BOOL

Bit 4

Pilot fault

Bit 5

%IX16.5

BOOL

Bit 5

Restart required

Bit 6

%IX16.6

BOOL

Bit 6

Reserved

Bit 7

%IX16.7

BOOL

Reserved

Bit 8

%IX17.0

BOOL

Reserved

Bit 9

%IX17.1

BOOL

Reserved

Bit 10

%IX17.2

BOOL

Reserved

Bit 11

%IX17.3

BOOL

Reserved

Bit 12

%IX17.4

BOOL

Reserved

Bit 13

%IX17.5

BOOL

Reserved

Bit 14

%IX17.6

BOOL

Reserved

Bit 15

%IX17.7

BOOL

Status register 1

Read outputs [9]

%IW18

WORD

READ 16#9009 (= 36873)

Start on

Bit 0

%IX18.0

BOOL

Bit 16

Weld off

Bit 1

%IX18.1

BOOL

Bit 17

No 2nd stage

Bit 2

%IX18.2

BOOL

Bit 18

Output fault

Bit 3

%IX18.3

BOOL

Bit 19

No force

Bit 4

%IX18.4

BOOL

Bit 20

Too many links

Bit 5

%IX18.5

BOOL

Bit 21

Bad link

Bit 6

%IX18.6

BOOL

Bit 22

Reserved

Bit 7

%IX18.7

BOOL

Reserved

Bit 8

%IX19.0

BOOL

Reserved

Bit 9

%IX19.1

BOOL

Reserved

Bit 10

%IX19.2

BOOL

Reserved

Bit 11

%IX19.3

BOOL

Reserved

Bit 12

%IX19.4

BOOL

Reserved

Bit 13

%IX19.5

BOOL

Reserved

Bit 14

%IX19.6

BOOL

Reserved

Bit 15

%IX19.7

BOOL

Status register 2

Read outputs [10]

%IW20

WORD

READ 16#900A (= 36874)

Low force

Bit 0

%IX20.0

BOOL

Bit 32

High force

Bit 1

%IX20.1

BOOL

Bit 33

Low pre-current

Bit 2

%IX20.2

BOOL

Bit 34

High pre-current

Bit 3

%IX20.3

BOOL

Bit 35

Low main current

Bit 4

%IX20.4

BOOL

Bit 36

High main current

Bit 5

%IX20.5

BOOL

Bit 37

Low post-current

Bit 6

%IX20.6

BOOL

Bit 38

High post-current

Bit 7

%IX20.7

BOOL

Bit 39

Reserved

Bit 8

%IX21.0

BOOL

Reserved

Bit 9

%IX21.1

BOOL

Reserved

Bit 10

%IX21.2

BOOL

Reserved

Bit 11

%IX21.3

BOOL

Reserved

Bit 12

%IX21.4

BOOL

Reserved

Bit 13

%IX21.5

BOOL

Reserved

Bit 14

%IX21.6

BOOL

Reserved

Bit 15

%IX21.7

BOOL

Section 5 MODBUS i/o

28

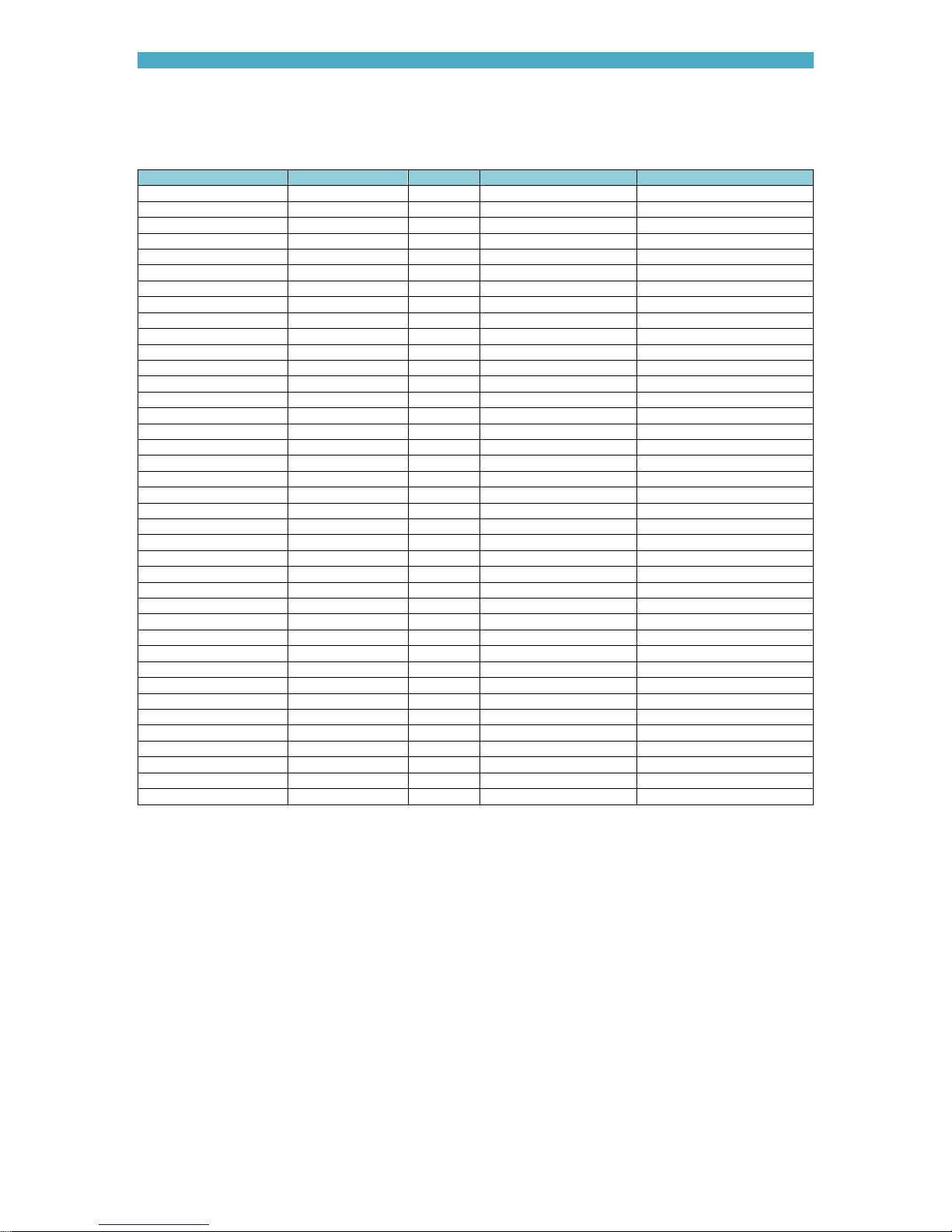

Variable

Channel

Address

Type

Description

Status register 3

Read outputs [11]

%IW22

WORD

READ 16#900B (= 36875)

End of count 0

Bit 0

%IX22.0

BOOL

Bit 48

End of count 1

Bit 1

%IX22.1

BOOL

Bit 49

End of count 2

Bit 2

%IX22.2

BOOL

Bit 50

End of count 3

Bit 3

%IX22.3

BOOL

Bit 51

End of count 4

Bit 4

%IX22.4

BOOL

Bit 52

End of count 5

Bit 5

%IX22.5

BOOL

Bit 53

End of count 6

Bit 6

%IX22.6

BOOL

Bit 54

End of count 7

Bit 7

%IX22.7

BOOL

Bit 55

Reserved

Bit 8

%IX23.0

BOOL

Reserved

Bit 9

%IX23.1

BOOL

Reserved

Bit 10

%IX23.2

BOOL

Reserved

Bit 11

%IX23.3

BOOL

Reserved

Bit 12

%IX23.4

BOOL

Reserved

Bit 13

%IX23.5

BOOL

Reserved

Bit 14

%IX23.6

BOOL

Reserved

Bit 15

%IX23.7

BOOL

Status register 4

Read outputs [12]

%IW24

WORD

READ 16#900C (= 36876)

End of electrode 0

Bit 0

%IX24.0

BOOL

Bit 64

End of electrode 1

Bit 1

%IX24.1

BOOL

Bit 65

End of electrode 2

Bit 2

%IX24.2

BOOL

Bit 66

End of electrode 3

Bit 3

%IX24.3

BOOL

Bit 67

End of electrode 4

Bit 4

%IX24.4

BOOL

Bit 68

End of electrode 5

Bit 5

%IX24.5

BOOL

Bit 69

End of electrode 6

Bit 6

%IX24.6

BOOL

Bit 70

End of electrode 7

Bit 7

%IX24.7

BOOL

Bit 71

Reserved

Bit 8

%IX25.0

BOOL

Reserved

Bit 9

%IX25.1

BOOL

Reserved

Bit 10

%IX25.2

BOOL

Reserved

Bit 11

%IX25.3

BOOL

Reserved

Bit 12

%IX25.4

BOOL

Reserved

Bit 13

%IX25.5

BOOL

Reserved

Bit 14

%IX25.6

BOOL

Reserved

Bit 15

%IX25.7

BOOL

Status register 5

Read outputs [13]

%IW26

WORD

READ 16#900D (= 36877)

Tip dress 0

Bit 0

%IX26.0

BOOL

Bit 80

Tip dress 1

Bit 1

%IX26.1

BOOL

Bit 81

Tip dress 2

Bit 2

%IX26.2

BOOL

Bit 82

Tip dress 3

Bit 3

%IX26.3

BOOL

Bit 83

Tip dress 4

Bit 4

%IX26.4

BOOL

Bit 84

Tip dress 5

Bit 5

%IX26.5

BOOL

Bit 85

Tip dress 6

Bit 6

%IX26.6

BOOL

Bit 86

Tip dress 7

Bit 7

%IX26.7

BOOL

Bit 87

Reserved

Bit 8

%IX27.0

BOOL

Reserved

Bit 9

%IX27.1

BOOL

Reserved

Bit 10

%IX27.2

BOOL

Reserved

Bit 11

%IX27.3

BOOL

Reserved

Bit 12

%IX27.4

BOOL

Reserved

Bit 13

%IX27.5

BOOL

Reserved

Bit 14

%IX27.6

BOOL

Reserved

Bit 15

%IX27.7

BOOL

Section 5 MODBUS i/o

29

Variable

Channel

Address

Type

Description

Status register 6

Read outputs [14]

%IW28

WORD

READ 16#900E (= 36878)

Prewarn 0

Bit 0

%IX28.0

BOOL

Bit 96

Prewarn 1

Bit 1

%IX28.1

BOOL

Bit 97

Prewarn 2

Bit 2

%IX28.2

BOOL

Bit 98

Prewarn 3

Bit 3

%IX28.3

BOOL

Bit 99

Prewarn 4

Bit 4

%IX28.4

BOOL

Bit 100

Prewarn 5

Bit 5

%IX28.5

BOOL

Bit 101

Prewarn 6

Bit 6

%IX28.6

BOOL

Bit 102

Prewarn 7

Bit 7

%IX28.7

BOOL

Bit 103

Reserved

Bit 8

%IX29.0

BOOL

Reserved

Bit 9

%IX29.1

BOOL

Reserved

Bit 10

%IX29.2

BOOL

Reserved

Bit 11

%IX29.3

BOOL

Reserved

Bit 12

%IX29.4

BOOL

Reserved

Bit 13

%IX29.5

BOOL

Reserved

Bit 14

%IX29.6

BOOL

Reserved

Bit 15

%IX29.7

BOOL

Status register 7

Read outputs [15]

%IW30

WORD

READ 16#900F (= 36879)

Reserved

Bit 0

%IX30.0

BOOL

Reserved

Bit 1

%IX30.1

BOOL

Reserved

Bit 2

%IX30.2

BOOL

Reserved

Bit 3

%IX30.3

BOOL

Reserved

Bit 4

%IX30.4

BOOL

Reserved

Bit 5

%IX30.5

BOOL

Reserved

Bit 6

%IX30.6

BOOL

Reserved

Bit 7

%IX30.7

BOOL

Reserved

Bit 8

%IX31.0

BOOL

Reserved

Bit 9

%IX31.1

BOOL

Reserved

Bit 10

%IX31.2

BOOL

Reserved

Bit 11

%IX31.3

BOOL

Reserved

Bit 12

%IX31.4

BOOL

Reserved

Bit 13

%IX31.5

BOOL

Reserved

Bit 14

%IX31.6

BOOL

Reserved

Bit 15

%IX31.7

BOOL

Pre-heat current (A)

Read outputs [16]

%IW32

DWORD

READ 16#9010 (= 36880)

Main current (A)

Read outputs [18]

%IW36

DWORD

READ 16#9012 (= 36882)

Post-heat current (A)

Read outputs [20]

%IW40

DWORD

READ 16#9014 (= 36884)

Program number

Read outputs [22]

%IW44

WORD

READ 16#9016 (= 36886)

Force1

Read outputs [23]

%IW46

WORD

READ 16#9017 (= 36887)

1

value is multiplied by the scale factor (898.88 for kN or 4 for lbf)

Loading...

Loading...