EN7000 Technical Manual

Welding control for 50/60 Hz spot, projection, roll-spot, seam and multi-welding applications

EN7000 Technical Manual

2

EN7000 Technical Manual

Copyright © 2019 BF ENTRON Ltd. and/or its affiliates. All rights reserved.

The information in this manual is subject to change.

BF ENTRON assumes no responsibility for any errors that may appear in this manual.

BF ENTRON assumes no responsibility for any injury, loss or damage caused by improper installation,

use or application of the EN7000 welding control

The reproduction, transmission or use of this document or contents is not permitted without express

authority from BF ENTRON

BF ENTRON's trademarks and trade dress may not be used in connection with any product or service

that is not BF ENTRON's, in any manner that is likely to cause confusion among customers or in any

manner that disparages or discredits BF ENTRON. All other trademarks not owned by BF ENTRON are

the property of their respective owners, who may or may not be affiliated with, connected to, or

sponsored by BF ENTRON.

BF ENTRON Ltd.

Building 80 Bay 1

First Avenue

The Pensnett Estate

Kingswinford

West Midlands DY6 7FQ

Phone +44 (0)1384 455401 • Fax +44 (0)1384 455551

www.entroncontrols.com

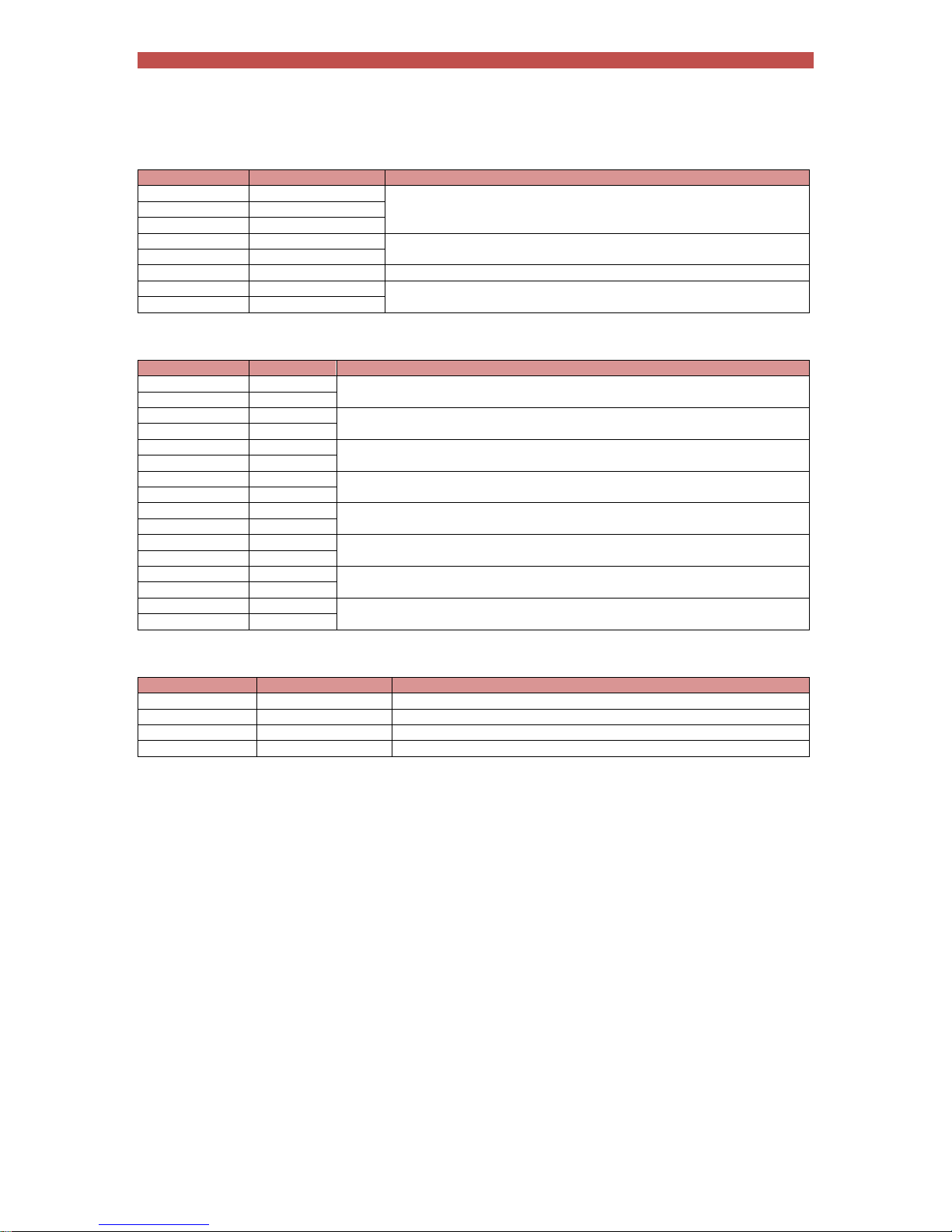

Issue

Date

Comment

1.00

27/02/17

Added parameter descriptions and % conduction parameter.

1.02

23/05/17

Increased weld programs from 128 to 256. New options for SCR select and CT calibration.

New options for valves. New tutorial (resetting faults). Issue number corresponds to

EN7000 firmware.

1.04

26/09/17

Updated issue number.

1.05

30/11/17

Added seam welding features.

1.07

09/04/18

Models 5 and 6 discontinued. Seam welding features added to Models 3 and 4.

1.08

12/09/18

Added note to reset stepper/counter inputs. Updated status codes.

1.09

15/01/19

Revised description of force control.

1.10

12/02/19

Data log contains 6000 records

1.11

27/02/19

Models 1 and 2 discontinued. Model 3 is referred to as EN7000 and model 4 as EN7000TS. EN7000 and EN7000-TS can emulate the functionality of Models 1 and 2.

EN7000 Technical Manual

3

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THE EN7000

WARNING

DO NOT DISASSEMBLE, REPAIR, OR MODIFY THE EN7000. These actions can cause electric shock and fire.

Use only as described in this manual. Use only BF ENTRON recommended accessories and

replacement parts.

Stop operation if any problems occur. If the equipment is not working as it should, has been dropped,

damaged, left outdoors, or been in contact with water, contact BF ENTRON.

Only apply the specified power. Application of a voltage or current beyond the specified range can

cause electric shock or fire.

Do not use damaged plugs or connecting cables.

Keep water and water containers away from the EN7000. Water ingress can cause a short circuit,

electric shock, or fire.

Do not insert objects into openings. Do not use with any opening blocked; keep free of dust and debris.

Do not install the EN7000 in any of the following environments

o damp environments where humidity is 90% or higher.

o dusty environments.

o environments where chemicals are handled.

o environments near a high-frequency noise source.

o hot or cold environments where temperatures are above 40°C or below 0°C, or environments

where water will condense.

EN7000 Technical Manual

4

Contents

Section 1

Introduction…………………………………………………………………………………………...…5

Section 2

Mounting…………………………………………………………………………………..………………15

Section 3

Inputs and outputs…………………….…....……………………………………………………17

Section 4

Discrete i/o……………………………..…….…………………………………………………….……19

Section 5

MODBUS i/o…………………..…….………………………………………………………….….…...24

Section 6

Weld control…………………..…….………………………………………………………………....30

Section 7

Electrode management…………………..…….…………………………………….………38

Section 8

Status information…………………………………………………………………….………….44

Section 9

History log…………………..…….…………………………………………………………………..…47

Section 10

Multiwelding…………………..…….……………………………………………………..…………..48

Section 11

Seam welding………………..…….……………………………………………………..…………..52

Section 12

Configuration…………………..…….……………………………………………….………………59

Section 13

Programming…………………..…….………………………………………………………….……61

Section 14

Tutorials…………………..…….………………………………………………………………………...80

Section 15

Appendix…………………..…….……………………………………………………………….…….…91

Section 16

Terminology……………..…….…………………………………………………………………….…95

Section 1 Introduction

5

Introduction

The EN7000 is a SINGLE PHASE AC and 3-PHASE DC constant current and proportional force

controller for 50/60 Hz spot, projection and seam welding applications..

The controller is available in two formats:

EN7000: core welding control with single air-valve, electrode manager and expansion port.

Pre-heat and main heat intervals. Extended features include post-heat interval, force

profile, multi-gun, multi-air valve, multi electrode manager and seam welding. Gear-plate

mounted.

EN7000-TS: as EN7000, plus built-in touch screen display. Front panel mounted.

EN7000

EN7000-TS

Multiple communication and control options are supported by a number of programming methods. The

Ethernet port supports simultaneous programming and control connection via a single physical cable.

Short-circuit proof outputs and a guided-contact pilot relay provides enhanced safety. Connection to the

power system is via a single ribbon cable. Analog inputs and outputs can be used to drive a proportional

air regulator valve for force control.

Operation in Standard mode provides a basic set of features for simple applications. Extended mode

adds advanced features for more demanding applications. Choose between Standard or Extended

features (Section 12 Configuration). EN7000 must be restarted after changing this setting.

Section 1 Introduction

6

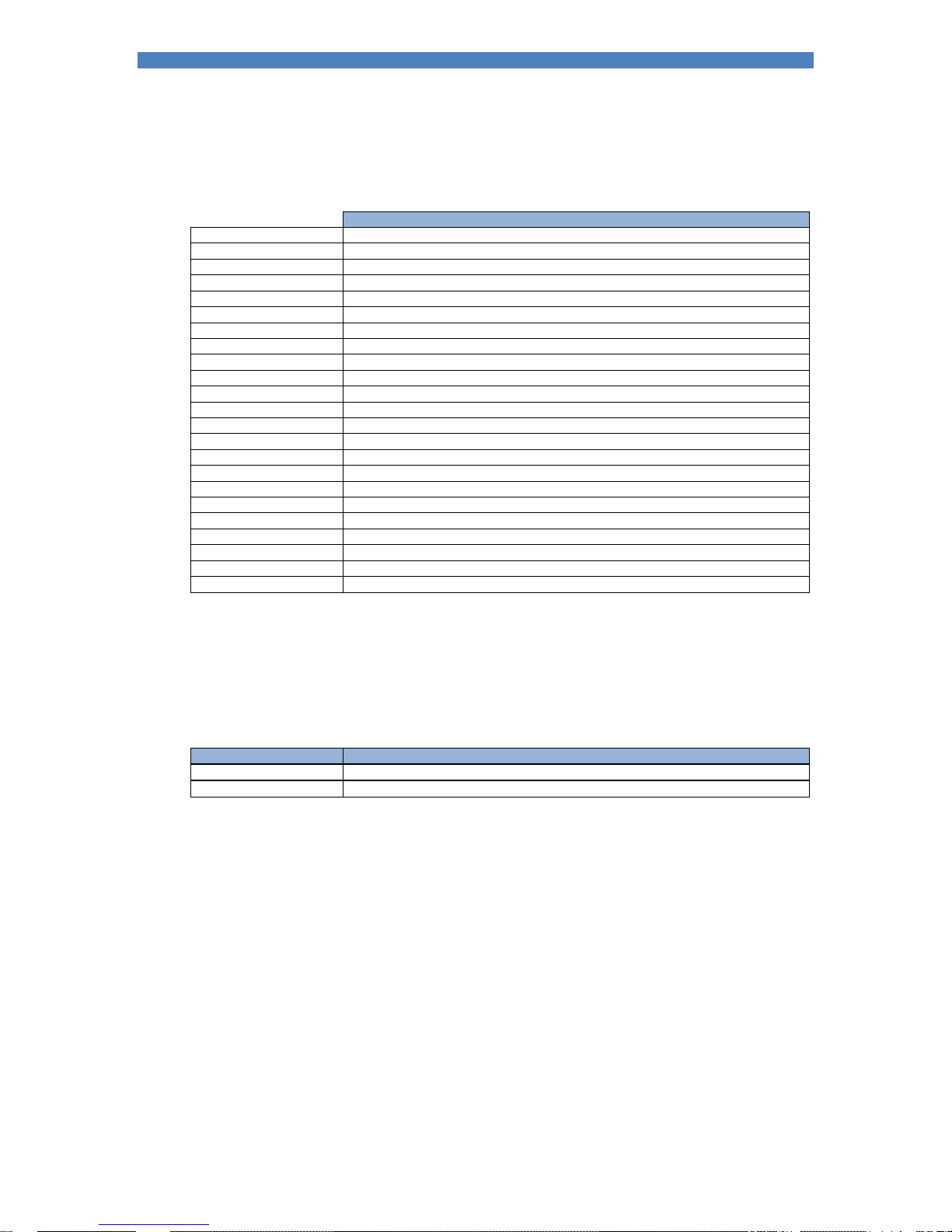

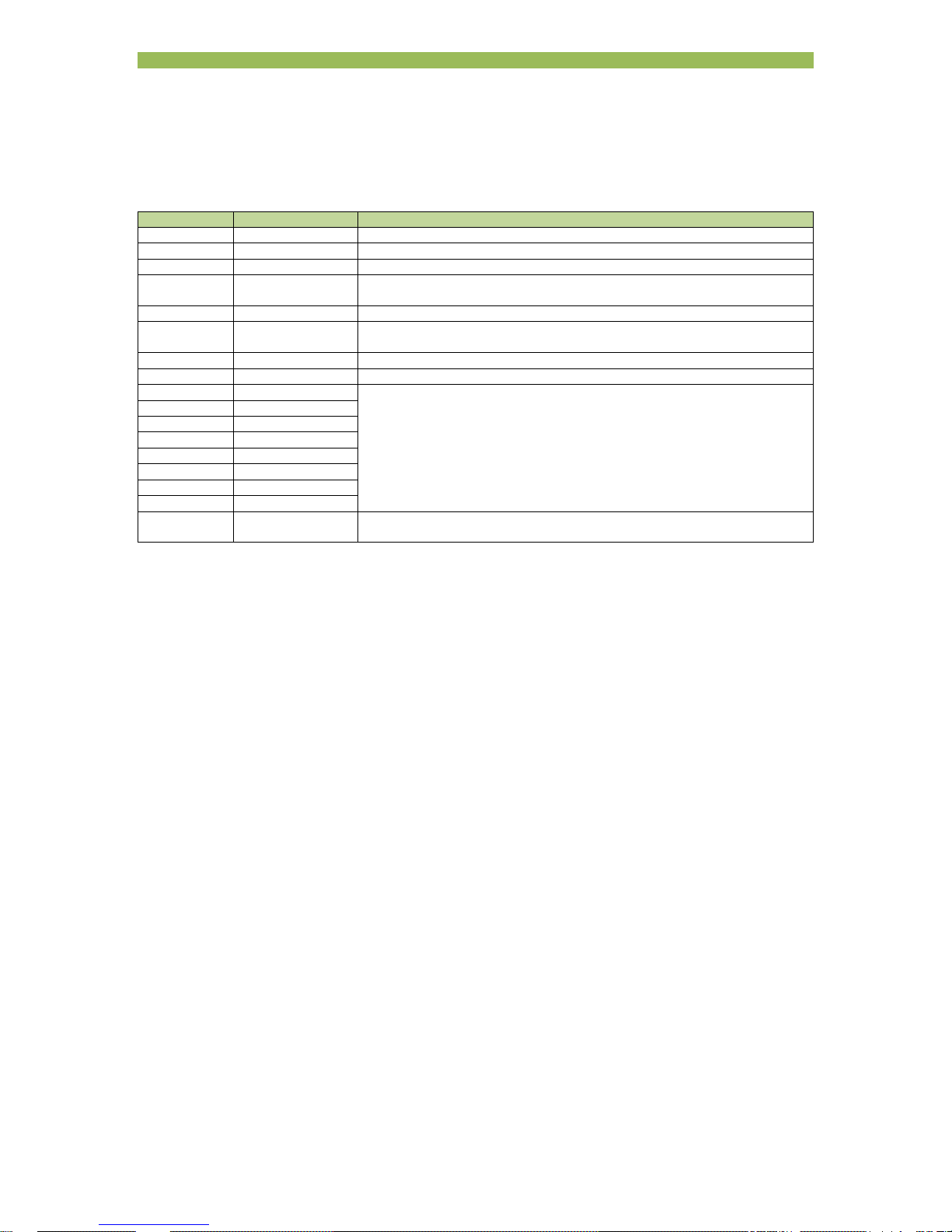

Features

Model

EN7000

EN7000-TS

Netflash programming

WSP3 programming

Built-in programmer 1

Panel mounting

Gear-plate mounting

Ethernet 2

RS232

RS485

MODBUS TCP/IP

MODBUS RTU

Analogue inputs 3 1 1

Analogue outputs 3 1 1

Discrete inputs

16

16

Discrete outputs 4

16

16

Weld programmes

256

256

Pre-heat

Main heat

Post-heat 5

Slope

Constant current

Power factor adjust

Cascade/Mux 5 8 8

Multi air valve

5, 6

8 8

Aux valves

7

7

Force profile 5

Electrodes/SCRs 5 8 8

Real-time clock

Data log (spot welds)

6000

6000

Expansion

Seam weld sequence 5

1

Colour touch-screen display

2

Two simultaneous connections

3

0 to 10 V

4

24 V dc, short-circuit proof, monitored

5

Extended feature

6

Guided contact safety relay, monitored

The extended features can be enabled for greater flexibility or more demanding applications.

Section 1 Introduction

7

Weld parameters

EN7000/EN7000-TS

Presqueeze

Squeeze

Pre-heat

Cool1

Upslope

Main heat

Cool2

Downslope

Pulses

Post-heat 1

Hold

Off WAV selection 1

Aux valve control

Retract/Hi-lift

Electrode selection 1

Force profile 1

SCR selection 1

Current monitor

Force monitor

Spot weld

Roll-spot weld 1

Seam weld 1

1

Extended feature

Part numbers

Model

Part number

EN7000

01-07-03

EN7000-TS

01-07-04

Section 1 Introduction

8

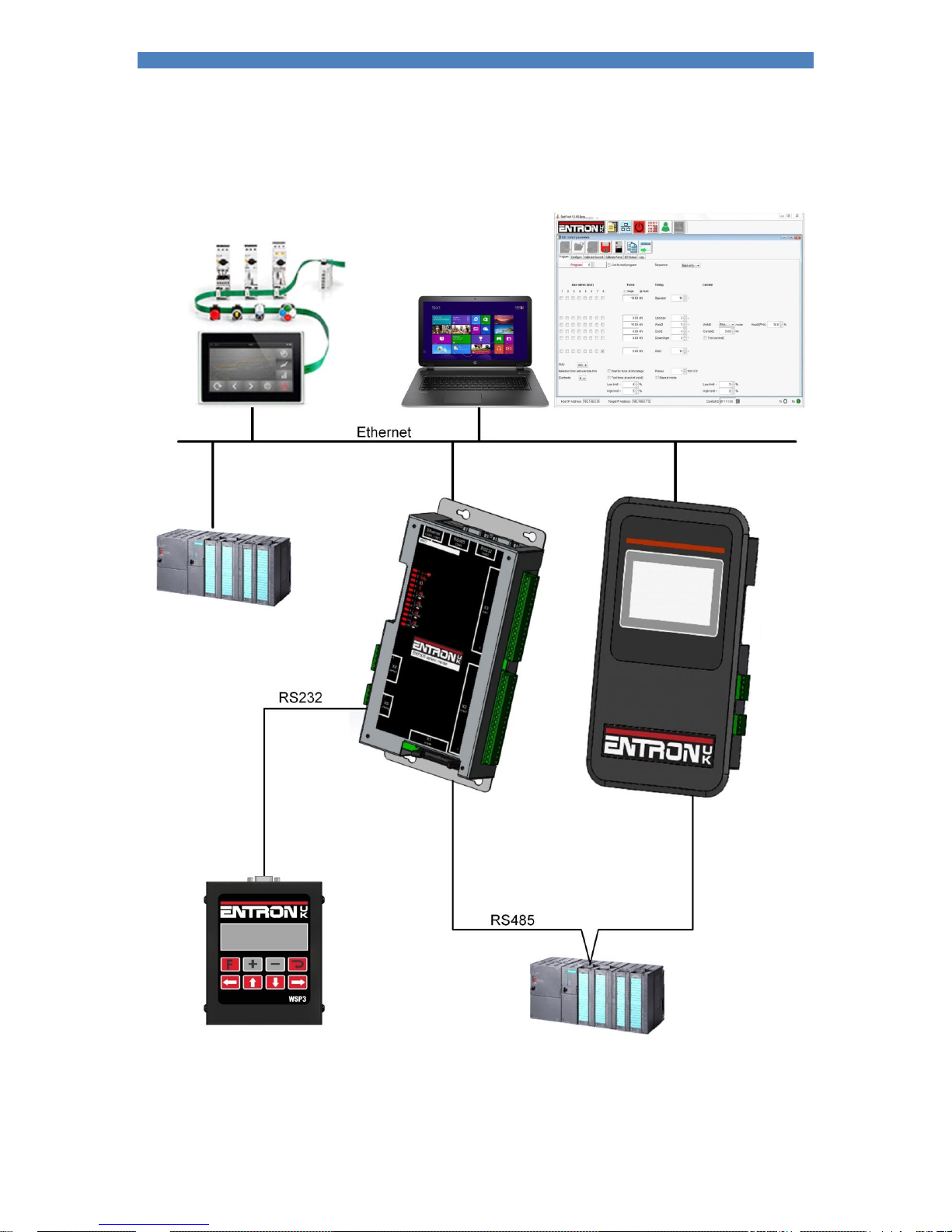

Programming options

NetFlash

This PC-compatible program displays and allows editing of all

welding parameters and status information.

In addition to programming, NetFlash provides backup/restore

functions for control data, live data logging to a file and a utility for

updating the firmware in the EN7000.

WSP3 Pendant

EN7000s work with the same WSP3 pendant that is used with

iPAK and WS2003. Access to all parameters is provided, plus

diagnostic indication.

MODBUS

A PLC or HMI MODBUS master can be used to program, control

and monitor EN7000s. All parameters are directly mapped to

MODBUS registers for easy access. Both MODBUS-TCP/IP

(Ethernet) and MODBUS-RTU (RS485) protocols are supported.

Built-in touch screen

EN7000-TS has a touch screen panel which provides easy

access to all parameters and indications.

Section 1 Introduction

9

Communications

Section 1 Introduction

10

Applications

Standard machines, portable/manual guns, robot guns, multi-welders and seam welders.

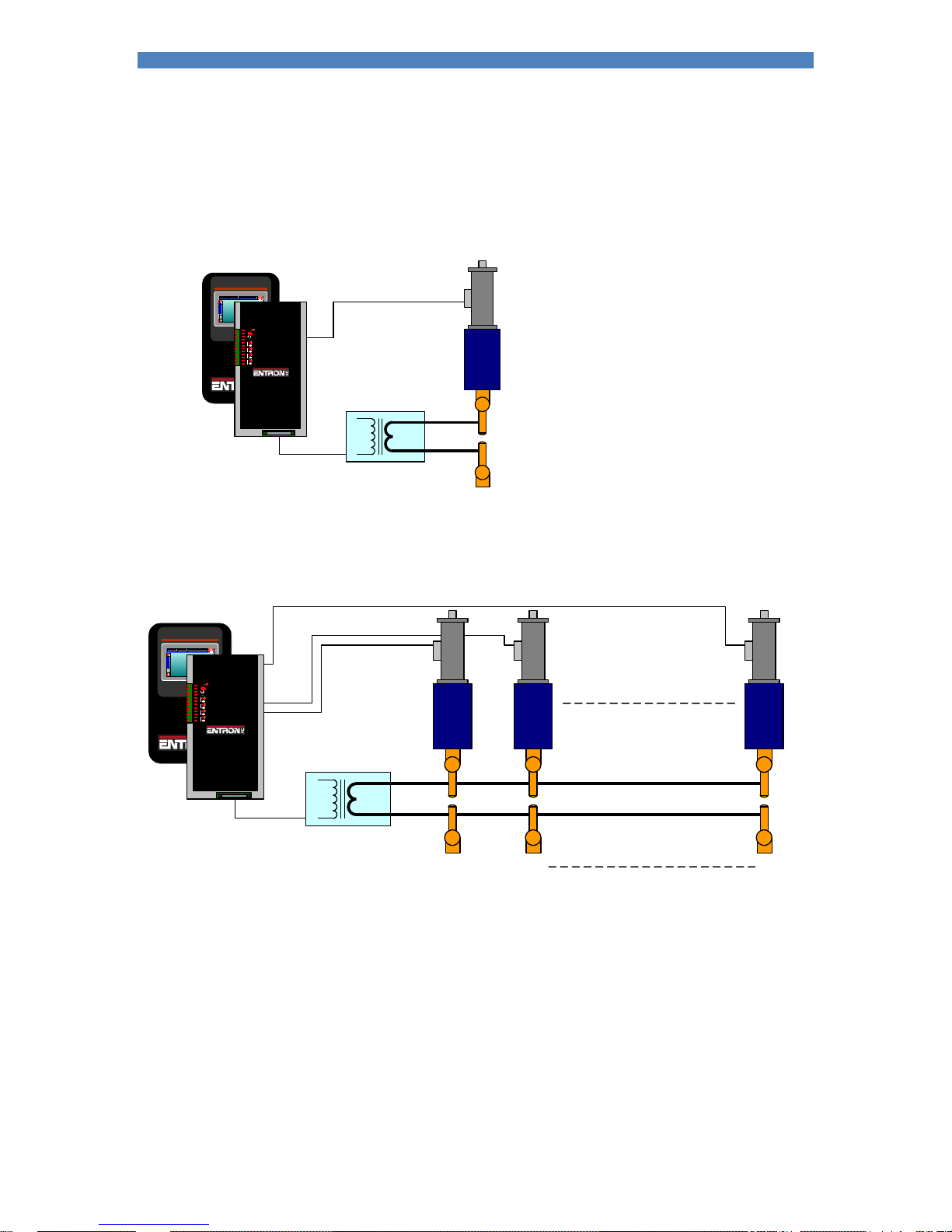

Standard machine.

Multi-head machine. Up to eight cylinders. Cascade or independent firing.

Program 1

I1 = 17.0kA H1 = 23.5% PHA

PSQ = 0 ~ SQZ = 10 ~

W1 = 12 ~ C1 = 0 ~

W2 = 12 ~ C2 = 0 ~

HLD = 10 ~

Edit Program

12.5 kA Prog 01 Low cu rrent W2

BF701 V1.01

Program 1

I1 = 17.0kA H1 = 23 .5% PHA

PSQ = 0 ~ SQZ = 10 ~

W1 = 12 ~ C1 = 0 ~

W2 = 12 ~ C2 = 0 ~

HLD = 10 ~

Edit Program

12.5 kA Prog 01 Low current W2

BF701 V1.01

1 2 8

Section 1 Introduction

11

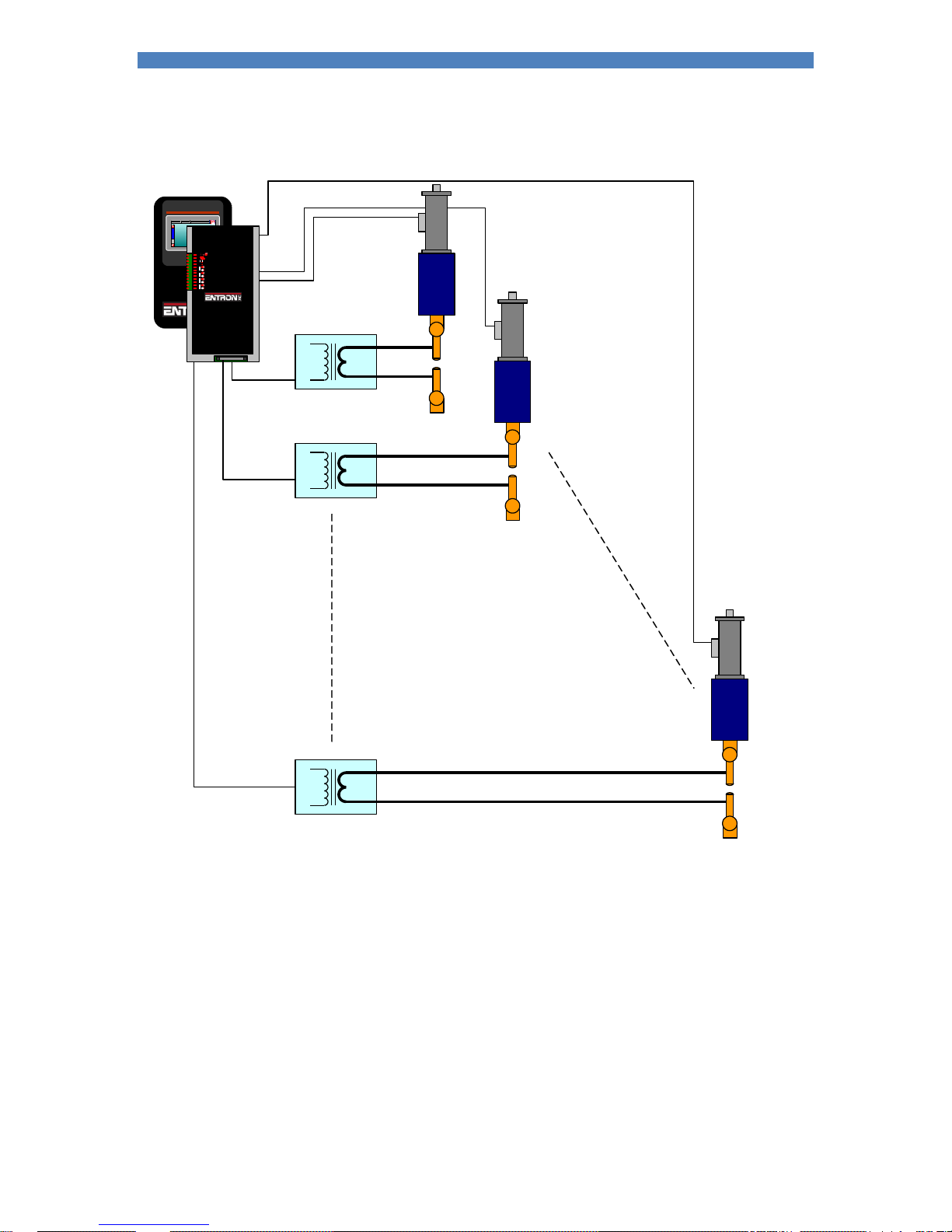

Multi-welder. Up to 8 transformers and cylinders. Cascade or independent firing.

Program 1

I1 = 17.0kA H1 = 23. 5% PHA

PSQ = 0 ~ SQZ = 10 ~

W1 = 12 ~ C1 = 0 ~

W2 = 12 ~ C2 = 0 ~

HLD = 10 ~

Edit Program

12.5 kA Prog 01 Low current W2

BF701 V1.01

1

2

8

8

2

1

Section 1 Introduction

12

Program 1

I1 = 17.0 kA H1 = 23.5% PHA

PSQ = 0 ~ SQZ = 10 ~

W1 = 12 ~ C1 = 0 ~

W2 = 12 ~ C2 = 0 ~

HLD = 10 ~

Edit Program

12.5 kA Prog 01 Low current W2

BF701 V1.01

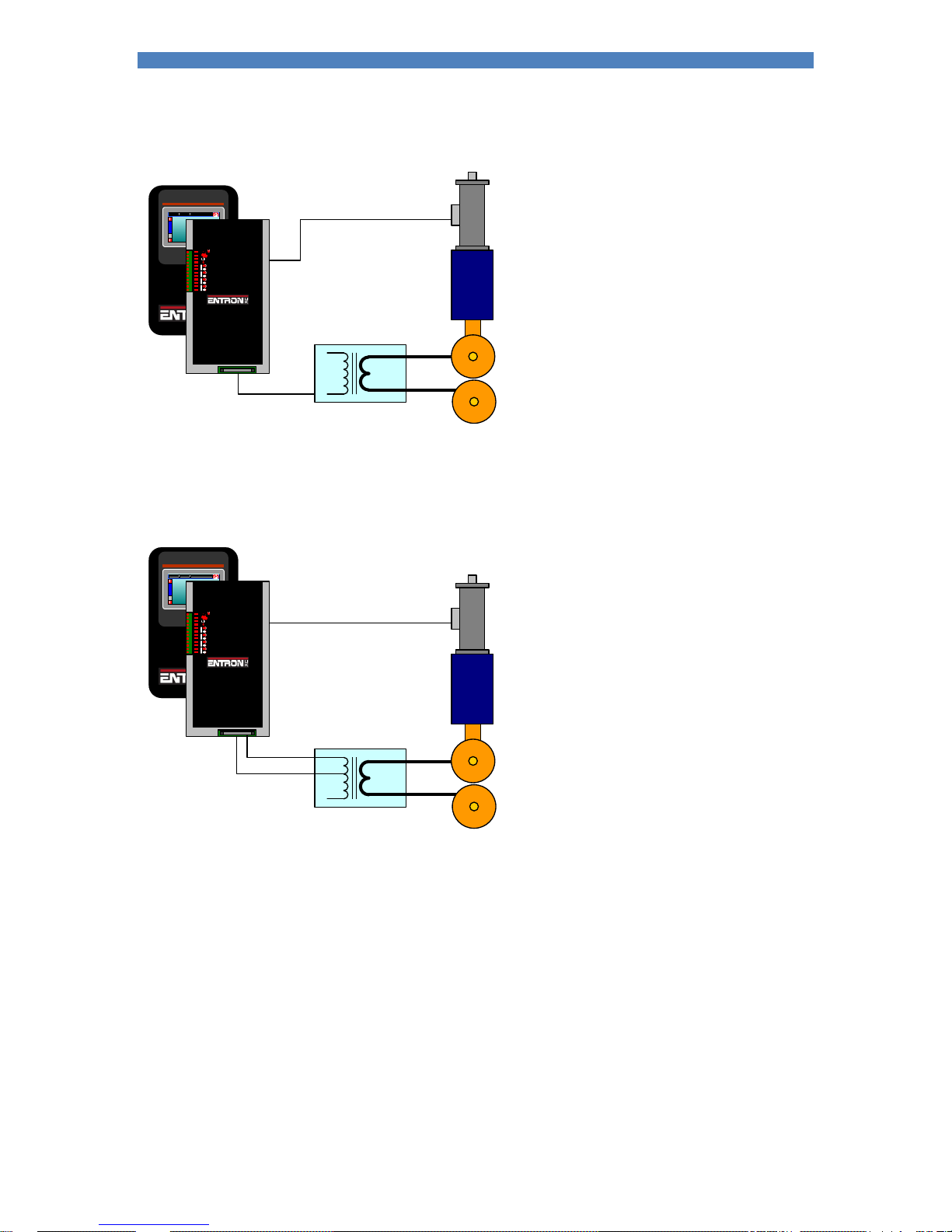

Seam welder with one transformer.

Program 1

I1 = 17.0 kA H1 = 23.5% PHA

PSQ = 0 ~ SQZ = 10 ~

W1 = 12 ~ C1 = 0 ~

W2 = 12 ~ C2 = 0 ~

HLD = 10 ~

Edit Program

12.5 kA Prog 01 Low current W 2

BF701 V1.01

Seam welder with a multi-tap transformer.

Section 1 Introduction

13

Getting started

Section 2 Mounting: Ensure the EN7000 is securely mounted.

Section 3 Inputs and outputs: connect the essential services and inputs/outputs depending on

the application.

Make sure that you have sufficient air pressure and cooling water where necessary.

Section 13 Programming: switch on then use the ‘Initialise all data’ function to clear the

EN7000’s memory.

Section 12 Configuration: set the Configuration parameters appropriately for the application.

Section 7 Electrode management: edit the calibration file.

Section 13 Programming: edit program 0 to set up a basic weld sequence e.g. Squeeze = 10,

Main heat = 10, Hold = 10, Pulses=1, and Main mode = PHA.

Section 13 Programming: a welding operation should be possible at this stage. Begin by using

the gun short-circuit. The EN7000 should report the measured current on the diagnostic

display.

Section 7 Electrode management: perform the calibration operation for the toroid sensitivity.

Observe the current with an external meter. Set the program heat to give a typical value of

welding current on the meter. Adjust the sensor sensitivity until the EN7000 measurement

corresponds with the meter.

Make any other adjustments which may be required and set up other programmes for welding.

Section 1 Introduction

14

This page intentionally left blank

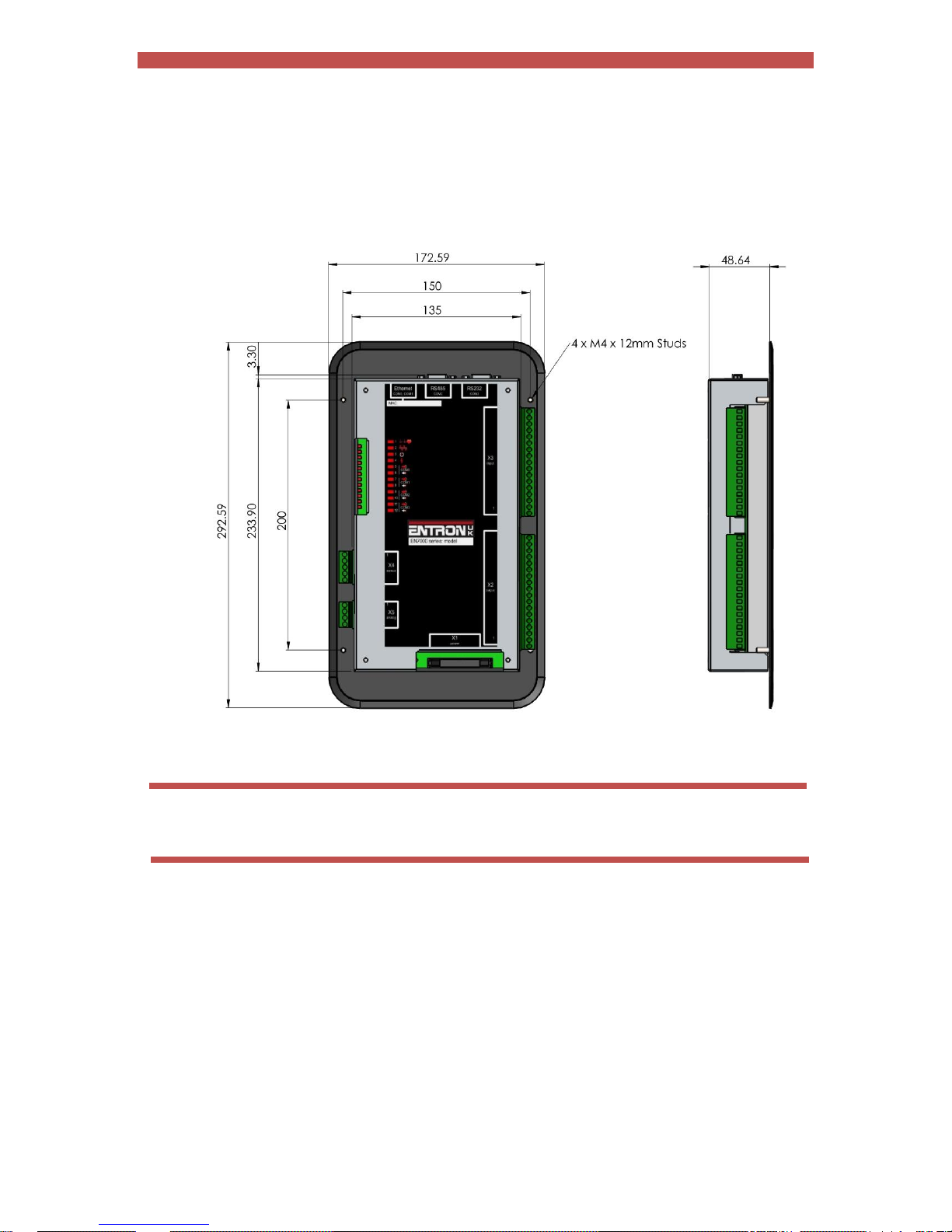

Section 2 Mounting

15

Mounting

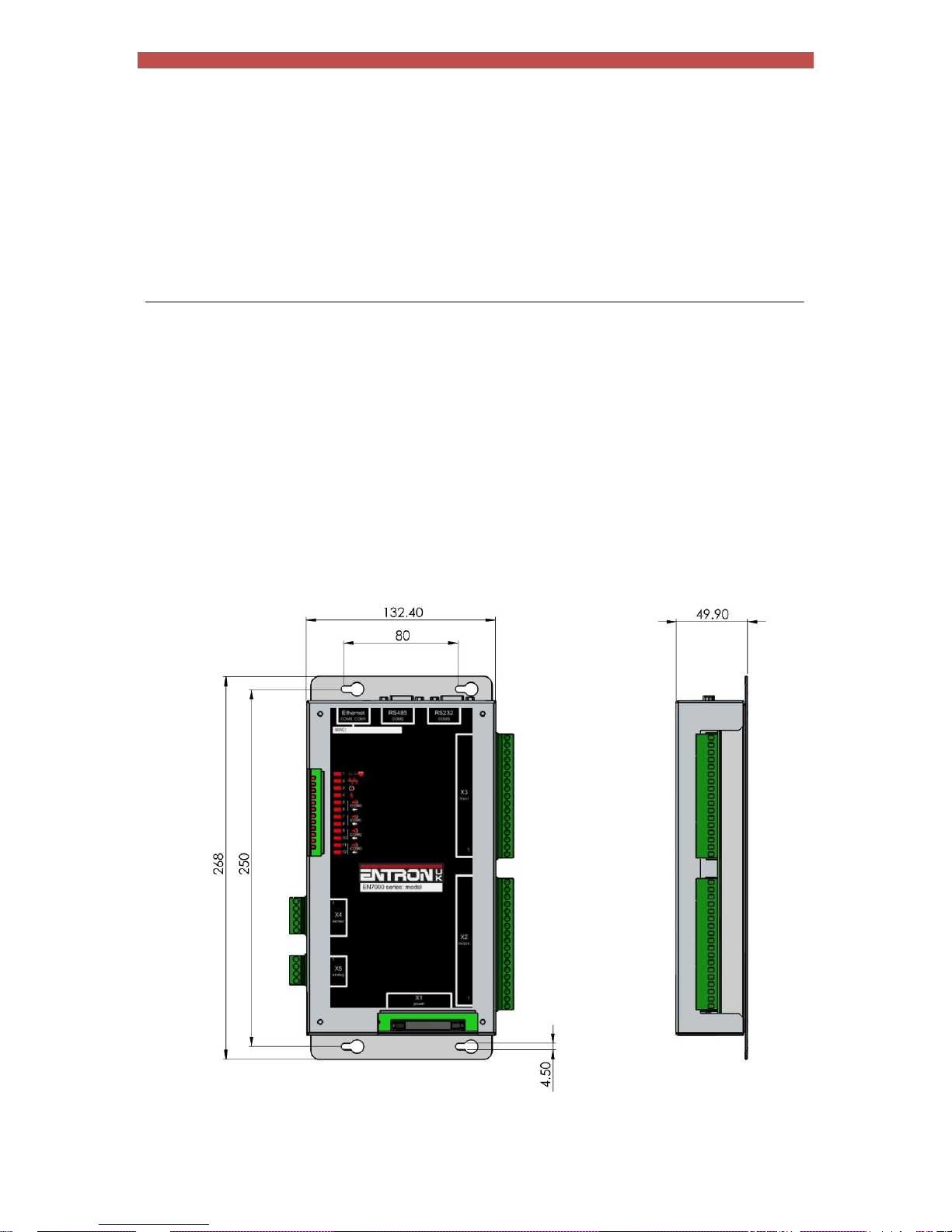

EN7000 is gear-plate mounted and EN7000-TS is front panel mounted.

If you have purchased a complete system the EN7000 will already be mounted in the case. If you have

purchased a timer only kit you will need to mount the EN7000 to the rest of your equipment.

Gear plate mounting

The mounting arrangements for EN7000 are shown below. All dimensions are in mm.

Section 2 Mounting

16

Front panel mounting

The mounting arrangements for EN7000-TS are shown below. All dimensions are in mm.

Allow space for the connectors when mounting EN7000 or EN7000-TS

Section 3 Inputs and outputs

17

Inputs and outputs

EN7000 uses a number of inputs and outputs to control and monitor the weld sequence.

Inputs

Input

AWS designation

Description

Start

FS1

When this input is activated a weld sequence begins. If the input is

removed during the Squeeze interval the sequence is aborted. If the input

is maintained through the Squeeze interval but switched off subsequently,

the sequence terminates normally.

Weld on

NW1

This input enables the weld current. If this input is inactive a weld

sequence will not produce any current.

Stop

ES1

Sequencing is inhibited or aborted if this input is not active.

Thermal

TT1

This input is usually connected to a normally closed thermal contact

attached to the weld transformer. Sequencing is inhibited if this input is not

active.

2nd stage

PS1

If enabled, EN7000 checks that the 2nd Stage signal is present before

proceeding to weld. The checking is programmable to take place either

before or after the Squeeze interval. If the signal is not present EN7000

waits for the signal before it proceeds. If the Start signal is removed while

waiting, the sequence is aborted.

Retract

RT1

This input is used to control the Retract function.

Reset fault

FR1

This input resets the Fault output and clears the status messages. Only

momentary application is required (minimum time 40ms).

Reset

counter/tip

dress

acknowledge1

Used to reset the counter(s) or acknowledge a tip dress request.

Reset

stepper2

SR1

Used to reset the stepper(s).

P1

BP1

Program select inputs. Weld program selection is made by applying the

binary code for the required program. Programs 0 to 127 can be selected

(programs 128 to 255 can be selected internally or via the fieldbus).

P2

BP2

P4

BP4

P8

BP8

P16

BP16

P32

BP32

P64

BP64

CT Input for the current transformer.

Toroid

Input for the toroid.

Analog

0 to 10 V analog input. Can be used to monitor a proportional air regulator

valve output or other sensor for force control and monitoring.

Section 3 Inputs and outputs

18

Outputs

Output

AWS designation

Description

EOS

EH1

This output switches on to indicate the end of the weld sequence.

HAV

RV1

Used in conjunction with the Retract input to control the welding head.

Fault

FT1

This output indicates a fault condition.

Ready

This output is active if EN7000 is ready to weld. The output switches off

under some fault conditions.

Contactor

MC1

This output can be used to control an isolation contactor.

Counter/tip

dress request

This output indicates that the counter has reached its limit or that a tip

dressing operation is required.

Stepper

This output indicates that the stepper has reached its limit.

Pre-warn

This output indicates that the stepper is close to its limit.

AV1

Additional outputs that can be used during the weld sequence.

AV2

AV3 AV4 AV5 AV6

AV7

AV8

Analog

0 to 10 V analog output. Can be used to drive a proportional air regulator

valve for force control

1

Momentary operation will reset all expired counters. If maintained for more than 5 seconds all counters will be

reset, regardless of status.

2

Momentary operation will reset all expired steppers. If maintained for more than 5 seconds all steppers will be

reset, regardless of status.

Section 4 Discrete i/o

19

Discrete i/o

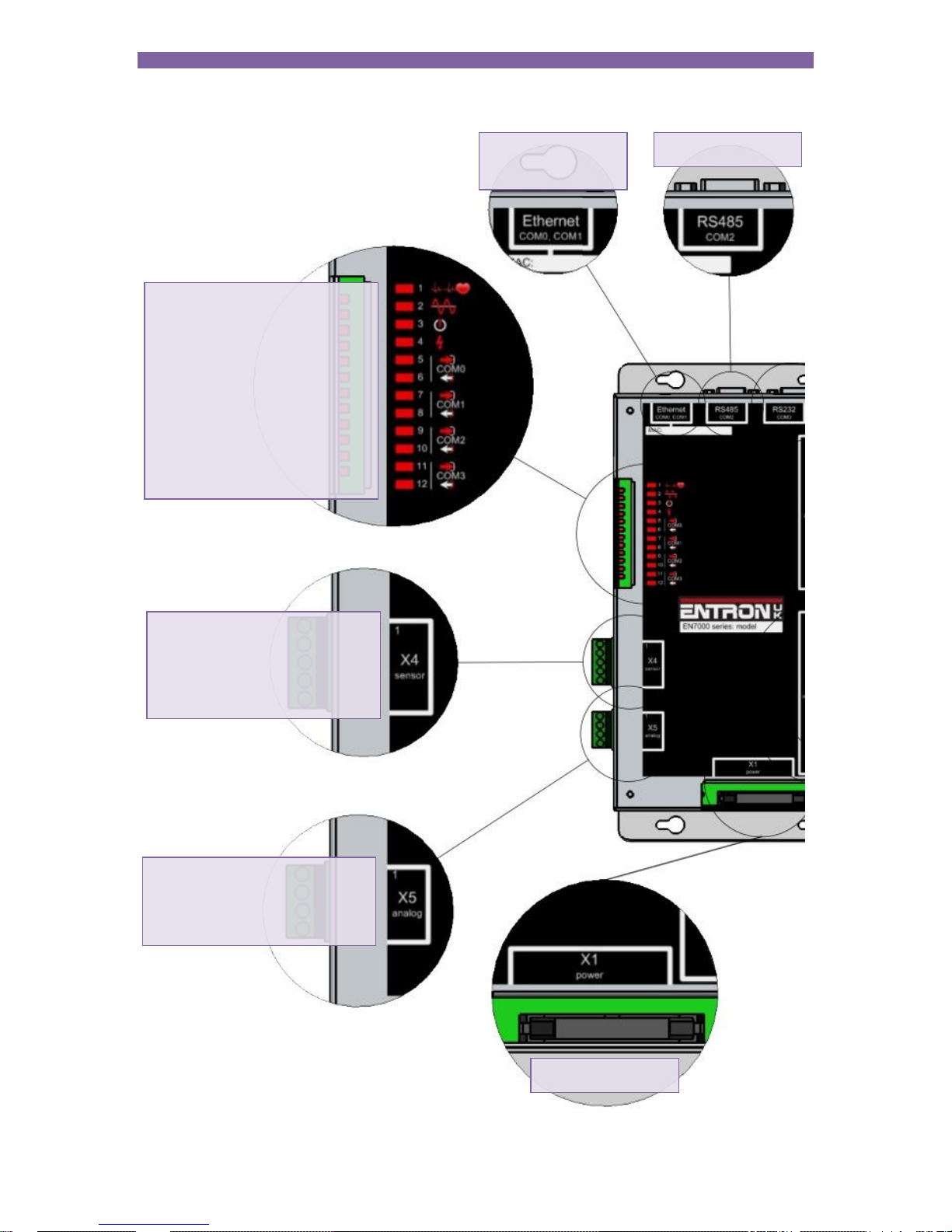

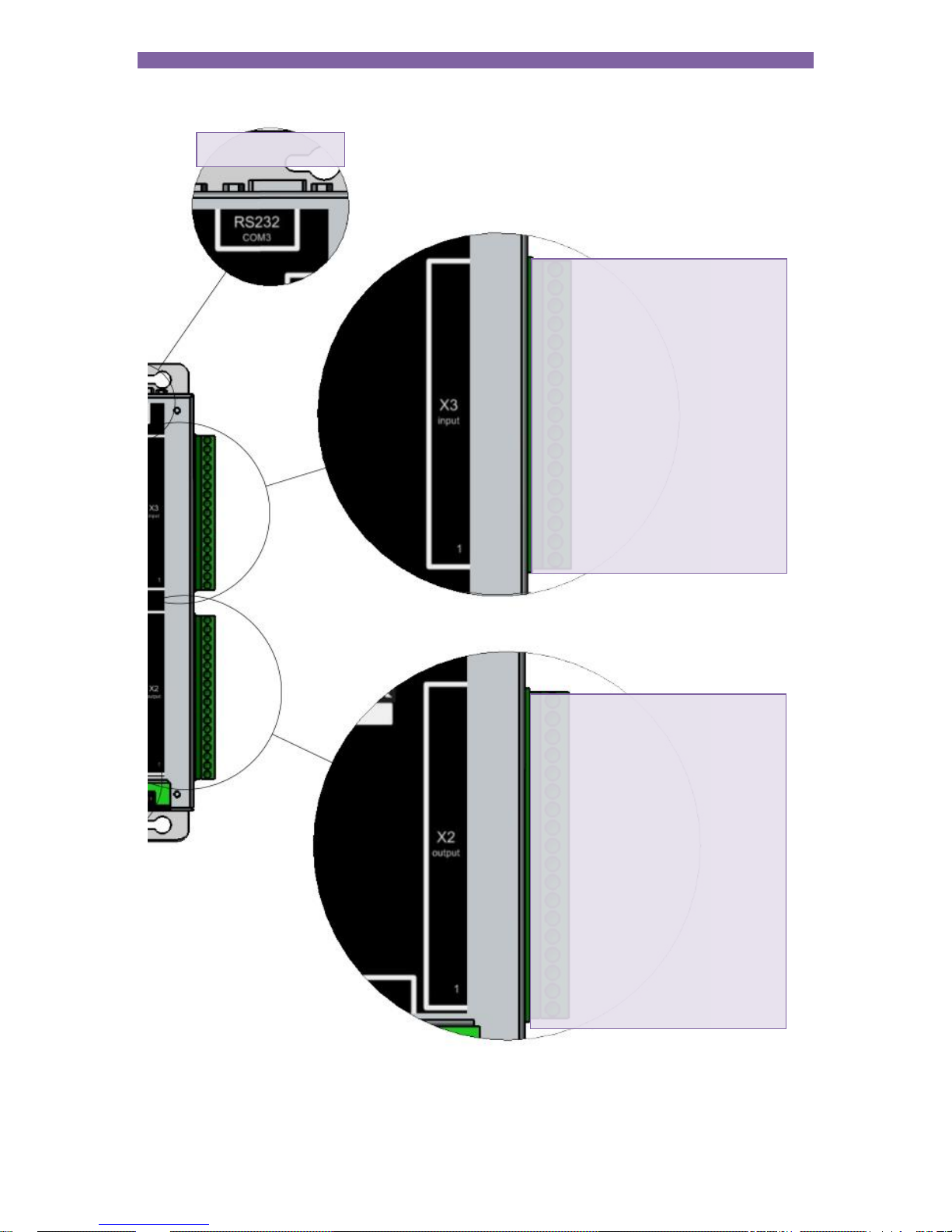

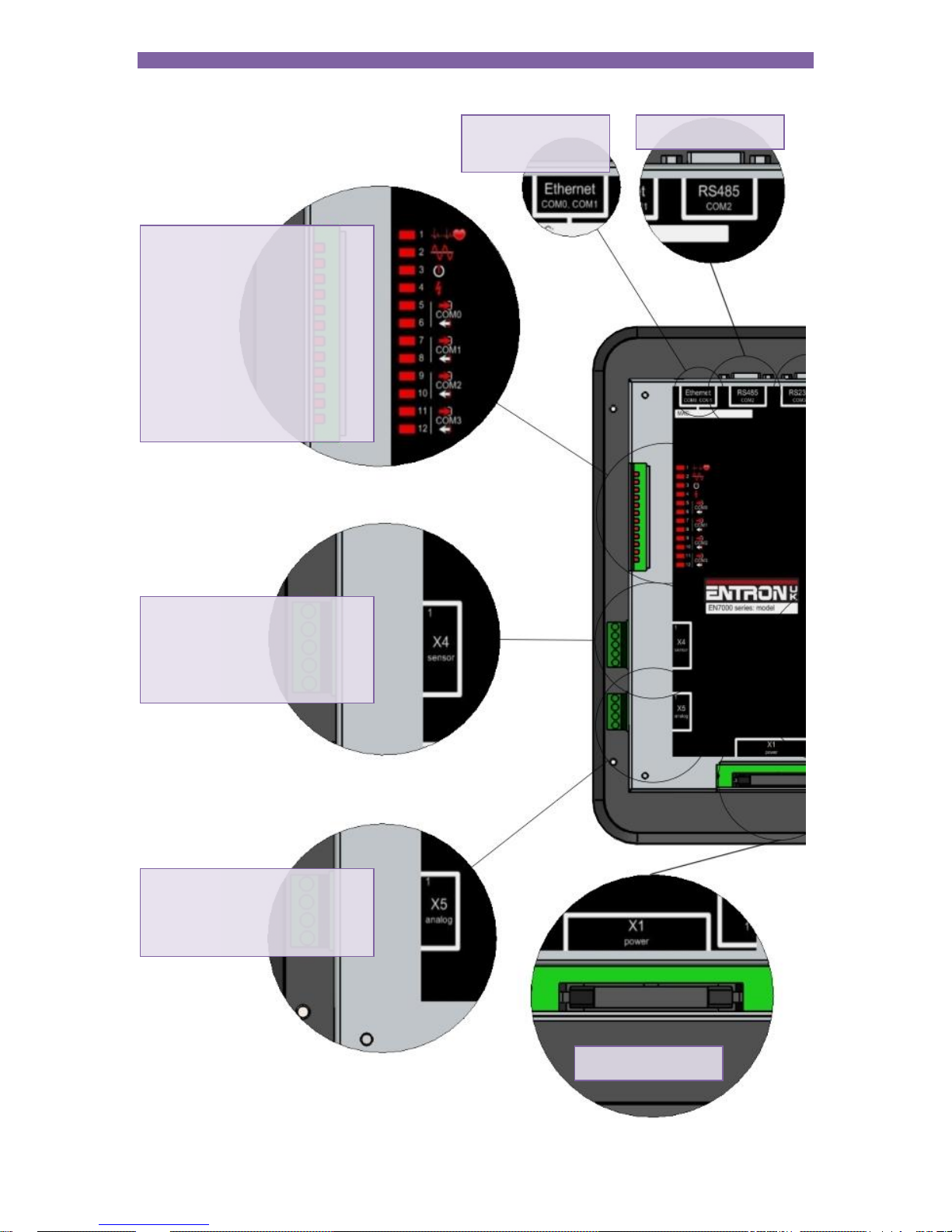

The inputs and outputs are accessible via connectors X2, X3, X4 and X5. The connectors are two-part

terminals for use with wires up to 1 mm

2

If the EN7000 is supplied fitted into a case some connections will have been pre-wired by BF ENTRON.

See the case wiring diagram for details.

Section 4 Discrete i/o

20

EN7000

Outputs are rated 500 mA @24 V dc

AWS designations in parenthesis

1

inputs must be linked if not required

1. Heartbeat

2. Synchronised to ac mains

3. Sequence initiated

4. Weld current

5. Data receive COM0

6. Data send COM0

7. Data receive COM1

8. Data send COM1

9. Data receive COM2

10. Data send COM2

11. Data receive COM3

12. Data send COM3

1. CT input

2. CT input

3. Toroid input

4. Toroid input

5. Gnd

1. 0 V

2. Output (0 to 10 V)

3. Input (0 to 10 V)

4. Gnd

MODBUS-RTU

NetFlash

MODBUS-TCP/IP

Power

Section 4 Discrete i/o

21

i/o bit

17. 24 V (24 VDC) 1

16. 15 P64 (BP64)

15. 14 P32 (BP32)

14. 13 P16 (BP16)

13. 12 P8 (BP8)

12. 11 P4 (BP4)

11. 10 P2 (BP2)

10. 9 P1 (BP1)

9. 8 Reset stepper (SR1)

8. 7 Reset counter/tip dress ack

7. 6 Reset fault (FR1)

6. 5 Retract (RT1)

5. 4 2nd stage (PS1)

4. 3 Transformer thermal (TT1) 1

3. 2 Stop (ES1) 1

2. 1 Weld on (NW1) 1

1. 0 Start (FS1)

i/o bit

18. 0 V (SVC)

17. Do not connect

16. 15 AV1 (SV1)

15. 14 AV2 (SV2)

14. 13 AV3 (SV3)

13. 12 AV4 (SV4)

12. 11 AV5 (SV5)

11. 10 AV6 (SV6)

10. 9 AV7 (SV7)

9. 8 AV8 (SV8)

8. 7 Prewarn

7. 6 Stepper

6. 5 Counter/Tip dress request

5. 4 Contactor (MC1)

4. 3 Ready

3. 2 Fault (FT1)

2. 1 HAV (RV1)

1. 0 EOS (EH1)

WSP3

Section 4 Discrete i/o

22

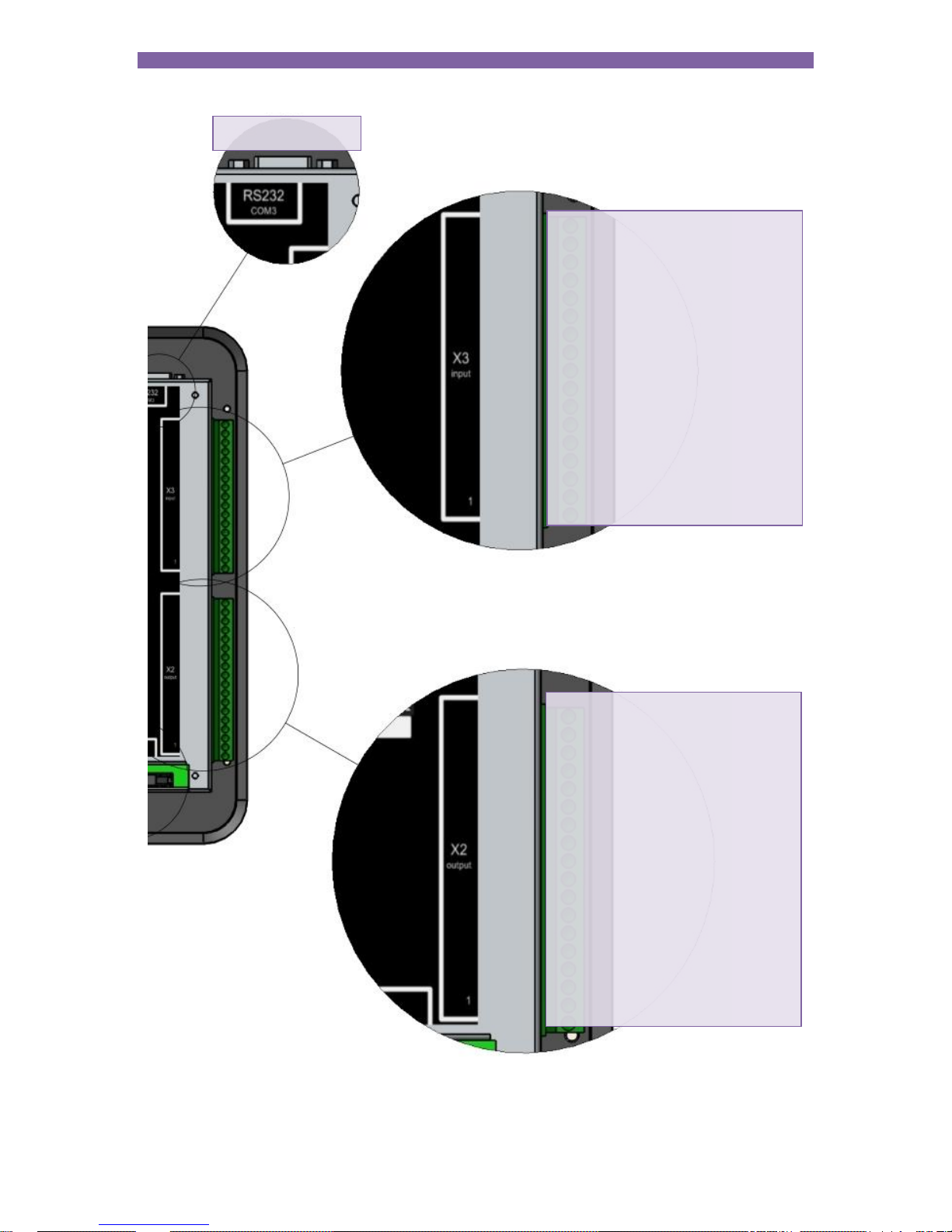

EN7000-TS

Outputs are rated 500 mA @24 V dc

AWS designations in parenthesis

1

inputs must be linked if not required

1. Heartbeat

2. Synchronised to ac mains

3. Sequence initiated

4. Weld current

5. Data receive COM0

6. Data send COM0

7. Data receive COM1

8. Data send COM1

9. Data receive COM2

10. Data send COM2

11. Data receive COM3

12. Data send COM3

1. CT input

2. CT input

3. Toroid input

4. Toroid input

5. Gnd

1. 0 V

2. Output (0 to 10 V)

3. Input (0 to 10 V)

4. Gnd

NetFlash

MODBUS-TCP/IP

MODBUS-RTU

Power

Section 4 Discrete i/o

23

i/o bit

17. 24 V DC out 1

16. 15 P64 (BP64)

15. 14 P32 (BP32)

14. 13 P16 (BP16)

13. 12 P8 (BP8)

12. 11 P4 (BP4)

11. 10 P2 (BP2)

10. 9 P1 (BP1)

9. 8 Reset stepper (SR1)

8. 7 Reset counter/tip-dress ack

7. 6 Reset fault (FR1)

6. 5 Retract (RT1)

5. 4 2nd stage (PS1)

4. 3 Transformer thermal(TT1) 1

3. 2 Stop (ES1) 1

2. 1 Weld on (NW1) 1

1. 0 Start (FS1)

i/o bit

18. 0 V (SVC)

17. do not connect

16. 15 AV1 (SV1)

15. 14 AV2 (SV2)

14. 13 AV3 (SV3)

13. 12 AV4 (SV4)

12. 11 AV5 (SV5)

11. 10 AV6 (SV6)

10. 9 AV7 (SV7)

9. 8 AV8 (SV8)

8. 7 Prewarn

7. 6 Stepper

6. 5 Counter/tip-dress request

5. 4 Contactor (MC1)

4. 3 Ready

3. 2 Fault (FT1)

2. 1 HAV (RV1)

1. 0 EOS (EH1)

WSP3

Section 5 MODBUS i/o

24

MODBUS i/o

EN7000 can be operated via MODBUS instead of using the discrete inputs and outputs.

Both MODBUS TCP/IP (Ethernet) and MODBUS RTU (RS485) protocols are supported.

Write the inputs using MODBUS function 16

Read the outputs using MODBUS function 3

MODBUS access types

Write inputs

Type

Value

Description

Function code

UINT

16

Write multiple registers

Read offset

UINT

0

Read length

UINT

0

Write offset

UINT

16#8000 (= 32768)

Write length

UINT

2

Read outputs

Type

Value

Description

Function code

UINT

3

Read holding registers

Read offset

UINT

16#9000 (= 36864)

Read length

UINT

24 Write offset

UINT

0 Write length

UINT

0

Section 5 MODBUS i/o

25

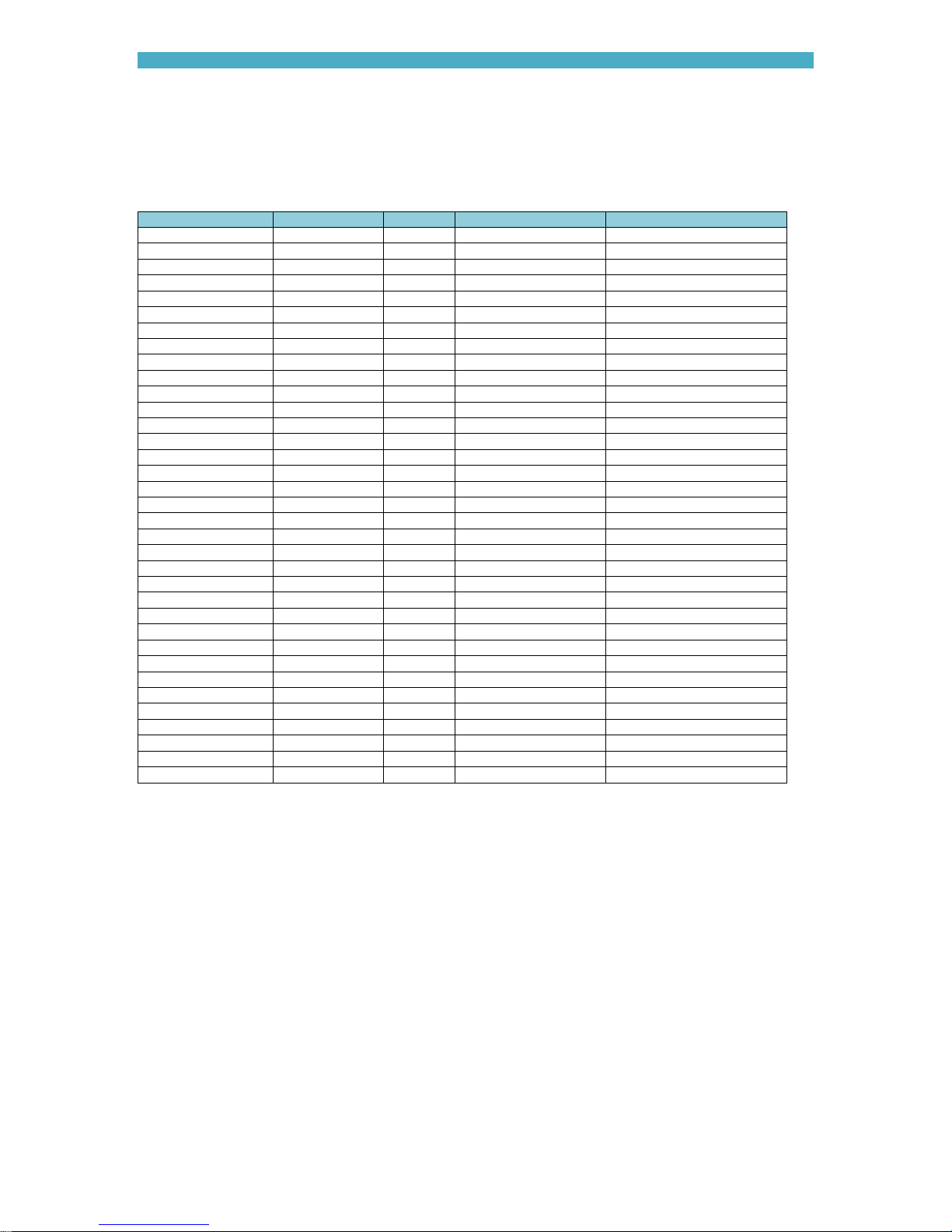

MODBUS mapping (inputs to EN7000)

Variable

Channel

Address

Type

Description

Write inputs

%QW0

WORD ARRAY [0..1]

Write multiple registers

Write inputs [0]

%QW0

WORD

WRITE 16#8000 (= 32768)

Start

Bit 0

%QX0.0

BOOL

Weld on

Bit 1

%QX0.1

BOOL

Stop

Bit 2

%QX0.2

BOOL

Transformer t’stat

Bit 3

%QX0.3

BOOL

2nd stage

Bit 4

%QX0.4

BOOL

Retract

Bit 5

%QX0.5

BOOL

Reset fault

Bit 6

%QX0.6

BOOL

Reset counter

Bit 7

%QX0.7

BOOL

Reset stepper

Bit 8

%QX1.0

BOOL

Reserved

Bit 9

%QX1.1

BOOL

Reserved

Bit 10

%QX1.2

BOOL

Reserved

Bit 11

%QX1.3

BOOL

Reserved

Bit 12

%QX1.4

BOOL

Reserved

Bit 13

%QX1.5

BOOL

Reserved

Bit 14

%QX1.6

BOOL

Reserved

Bit 15

%QX1.7

BOOL

Write inputs [1]

%QW2

WORD

WRITE 16#8001 (= 32769)

P1

Bit 0

%QX2.0

BOOL

P2

Bit 1

%QX2.1

BOOL

P4

Bit 2

%QX2.2

BOOL

P8

Bit 3

%QX2.3

BOOL

P16

Bit 4

%QX2.4

BOOL

P32

Bit 5

%QX2.5

BOOL

P64

Bit 6

%QX2.6

BOOL

P128

Bit 7

%QX2.7

BOOL

Reserved

Bit 8

%QX3.0

BOOL

Reserved

Bit 9

%QX3.1

BOOL

Reserved

Bit 10

%QX3.2

BOOL

Reserved

Bit 11

%QX3.3

BOOL

Reserved

Bit 12

%QX3.4

BOOL

Reserved

Bit 13

%QX3.5

BOOL

Reserved

Bit 14

%QX3.6

BOOL

Reserved

Bit 15

%QX3.7

BOOL

Section 5 MODBUS i/o

26

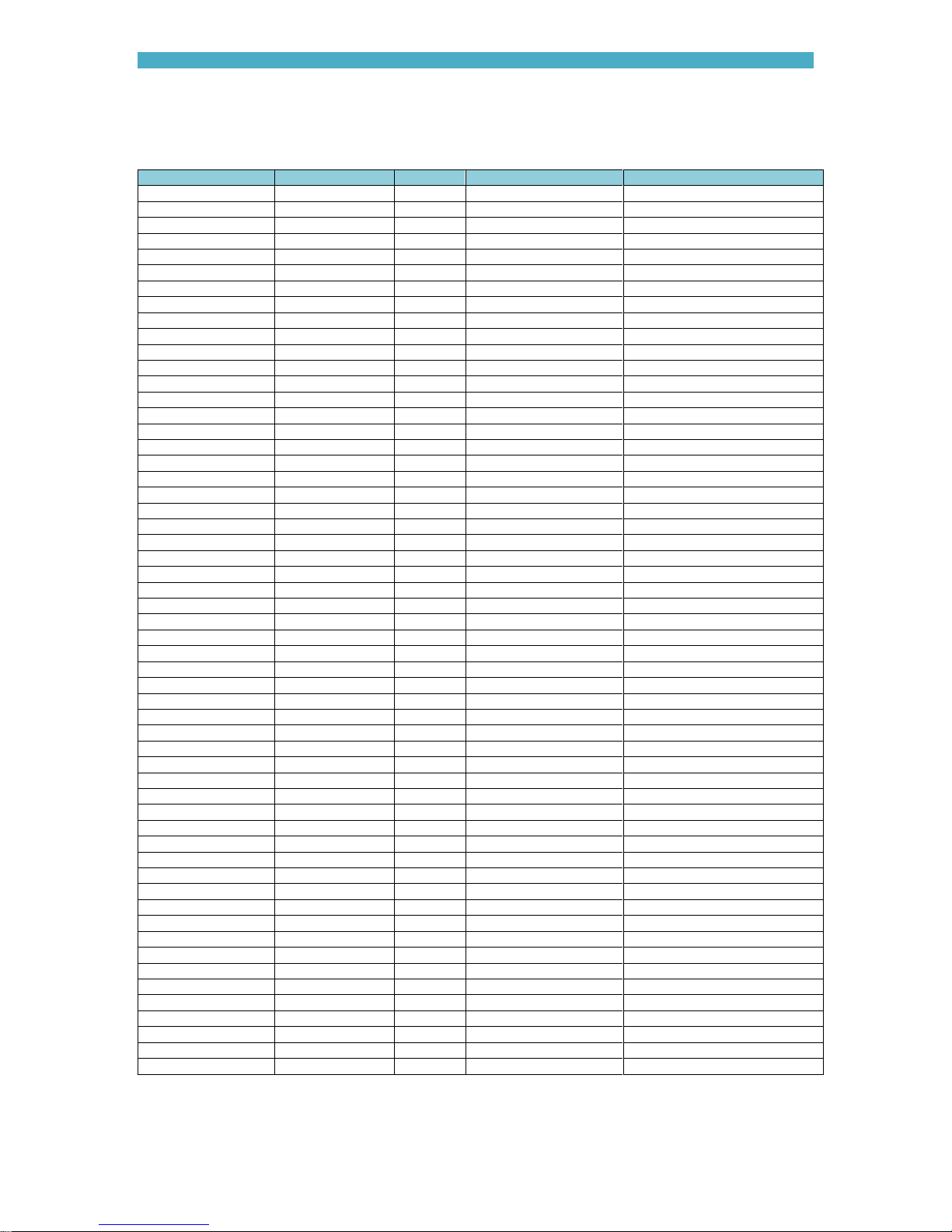

MODBUS mapping (outputs from EN7000)

Variable

Channel

Address

Type

Description

Read outputs

%IW0

WORD ARRAY [0..23]

Read holding registers

Read outputs [0]

%IW0

WORD

READ 16#9000 (= 36864)

EOS

Bit 0

%IX0.0

BOOL

HAV

Bit 1

%IX0.1

BOOL

Fault

Bit 2

%IX0.2

BOOL

Ready

Bit 3

%IX0.3

BOOL

Contactor

Bit 4

%IX0.4

BOOL

Counter

Bit 5

%IX0.5

BOOL

Stepper

Bit 6

%IX0.6

BOOL

Pre-warn

Bit 7

%IX0.7

BOOL

AV8

Bit 8

%IX1.0

BOOL

AV7

Bit 9

%IX1.1

BOOL

AV6

Bit 10

%IX1.2

BOOL

AV5

Bit 11

%IX1.3

BOOL

AV4

Bit 12

%IX1.4

BOOL

AV3

Bit 13

%IX1.5

BOOL

AV2

Bit 14

%IX1.6

BOOL

AV1

Bit 15

%IX1.7

BOOL

Read outputs [1]

%IW2

WORD

READ 16#9001 (= 36865)

Start

Bit 0

%IX2.0

BOOL

≘ %QX0.0

Weld on

Bit 1

%IX2.1

BOOL

≘ %QX0.1

Stop

Bit 2

%IX2.2

BOOL

≘ %QX0.2

Transformer t’stat

Bit 3

%IX2.3

BOOL

≘%QX0.3

2nd stage

Bit 4

%IX2.4

BOOL

≘ %QX0.4

Retract

Bit 5

%IX2.5

BOOL

≘ %QX0.5

Reset fault

Bit 6

%IX2.6

BOOL

≘ %QX0.6

Reset counter

Bit 7

%IX2.7

BOOL

≘ %QX0.7

Reset stepper

Bit 8

%IX3.0

BOOL

≘ %QX1.0

P1

Bit 9

%IX3.1

BOOL

≘ discrete input P1

P2

Bit 10

%IX3.2

BOOL

≘ discrete input P2

P4

Bit 11

%IX3.3

BOOL

≘ discrete input P4

P8

Bit 12

%IX3.4

BOOL

≘ discrete input P8

P16

Bit 13

%IX3.5

BOOL

≘ discrete input P16

P32

Bit 14

%IX3.6

BOOL

≘ discrete input P32

P64

Bit 15

%IX3.7

BOOL

≘ discrete input P64

Read outputs [2]

%IW4

WORD

READ 16#9002 (= 36866)

Start

Bit 0

%IX4.0

BOOL

≘ discrete input Start

Weld on

Bit 1

%IX4.1

BOOL

≘ discrete input Weld on

Stop

Bit 2

%IX4.2

BOOL

≘ discrete input Stop

Thermal

Bit 3

%IX4.3

BOOL

≘ discrete input Thermal

2nd stage

Bit 4

%IX4.4

BOOL

≘ discrete input 2nd stage

Retract

Bit 5

%IX4.5

BOOL

≘ discrete input Retract

Reset fault

Bit 6

%IX4.6

BOOL

≘ discrete input Reset fault

Reset counter

Bit 7

%IX4.7

BOOL

≘ discrete input Reset counter

Reset stepper

Bit 8

%IX5.0

BOOL

≘ discrete input Reset stepper

P1

Bit 9

%IX5.1

BOOL

≘ discrete input P1

P2

Bit 10

%IX5.2

BOOL

≘ discrete input P2

P4

Bit 11

%IX5.3

BOOL

≘ discrete input P4

P8

Bit 12

%IX5.4

BOOL

≘ discrete input P8

P16

Bit 13

%IX5.5

BOOL

≘ discrete input P16

P32

Bit 14

%IX5.6

BOOL

≘ discrete input P32

P64

Bit 15

%IX5.7

BOOL

≘ discrete input P64

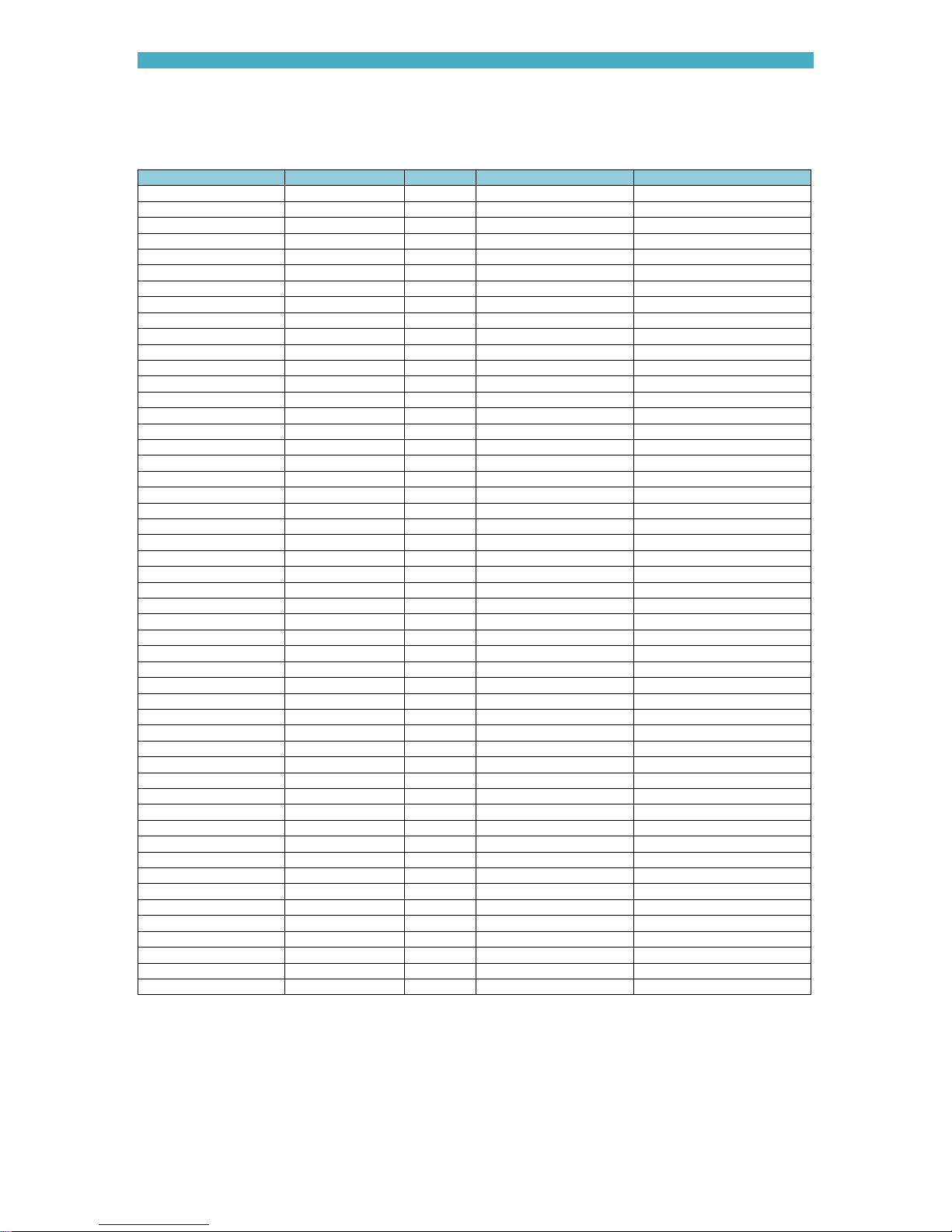

Section 5 MODBUS i/o

27

Variable

Channel

Address

Type

Description

Analog input (mV)

Read outputs [3]

%IW6

WORD

READ 16#9003 (= 36867)

Analog output (mV)

Read outputs [4]

%IW8

WORD

READ 16#9004 (= 36868)

% conduction

Read outputs [5]

%IW10

WORD

READ 16#9005 (= 36869)

Reserved

Read outputs [6]

%IW12

WORD

READ 16#9006 (= 36870)

Reserved

Read outputs [7]

%IW14

WORD

READ 16#9007 (= 36871)

Status register 0

Read outputs [8]

%IW16

WORD

READ 16#9008 (= 36872)

Stop

Bit 0

%IX16.0

BOOL

Bit 0

Sync. error

Bit 1

%IX16.1

BOOL

Bit 1

Retract not ready

Bit 2

%IX16.2

BOOL

Bit 2

SCR hot

Bit 3

%IX16.3

BOOL

Bit 3

Transformer hot

Bit 4

%IX16.4

BOOL

Bit 4

Pilot fault

Bit 5

%IX16.5

BOOL

Bit 5

Restart required

Bit 6

%IX16.6

BOOL

Bit 6

Reserved

Bit 7

%IX16.7

BOOL

Reserved

Bit 8

%IX17.0

BOOL

Reserved

Bit 9

%IX17.1

BOOL

Reserved

Bit 10

%IX17.2

BOOL

Reserved

Bit 11

%IX17.3

BOOL

Reserved

Bit 12

%IX17.4

BOOL

Reserved

Bit 13

%IX17.5

BOOL

Reserved

Bit 14

%IX17.6

BOOL

Reserved

Bit 15

%IX17.7

BOOL

Status register 1

Read outputs [9]

%IW18

WORD

READ 16#9009 (= 36873)

Start on

Bit 0

%IX18.0

BOOL

Bit 16

Weld off

Bit 1

%IX18.1

BOOL

Bit 17

No 2nd stage

Bit 2

%IX18.2

BOOL

Bit 18

Output fault

Bit 3

%IX18.3

BOOL

Bit 19

No force

Bit 4

%IX18.4

BOOL

Bit 20

Too many links

Bit 5

%IX18.5

BOOL

Bit 21

Bad link

Bit 6

%IX18.6

BOOL

Bit 22

Reserved

Bit 7

%IX18.7

BOOL

Reserved

Bit 8

%IX19.0

BOOL

Reserved

Bit 9

%IX19.1

BOOL

Reserved

Bit 10

%IX19.2

BOOL

Reserved

Bit 11

%IX19.3

BOOL

Reserved

Bit 12

%IX19.4

BOOL

Reserved

Bit 13

%IX19.5

BOOL

Reserved

Bit 14

%IX19.6

BOOL

Reserved

Bit 15

%IX19.7

BOOL

Status register 2

Read outputs [10]

%IW20

WORD

READ 16#900A (= 36874)

Low force

Bit 0

%IX20.0

BOOL

Bit 32

High force

Bit 1

%IX20.1

BOOL

Bit 33

Low pre-current

Bit 2

%IX20.2

BOOL

Bit 34

High pre-current

Bit 3

%IX20.3

BOOL

Bit 35

Low main current

Bit 4

%IX20.4

BOOL

Bit 36

High main current

Bit 5

%IX20.5

BOOL

Bit 37

Low post-current

Bit 6

%IX20.6

BOOL

Bit 38

High post-current

Bit 7

%IX20.7

BOOL

Bit 39

Reserved

Bit 8

%IX21.0

BOOL

Reserved

Bit 9

%IX21.1

BOOL

Reserved

Bit 10

%IX21.2

BOOL

Reserved

Bit 11

%IX21.3

BOOL

Reserved

Bit 12

%IX21.4

BOOL

Reserved

Bit 13

%IX21.5

BOOL

Reserved

Bit 14

%IX21.6

BOOL

Reserved

Bit 15

%IX21.7

BOOL

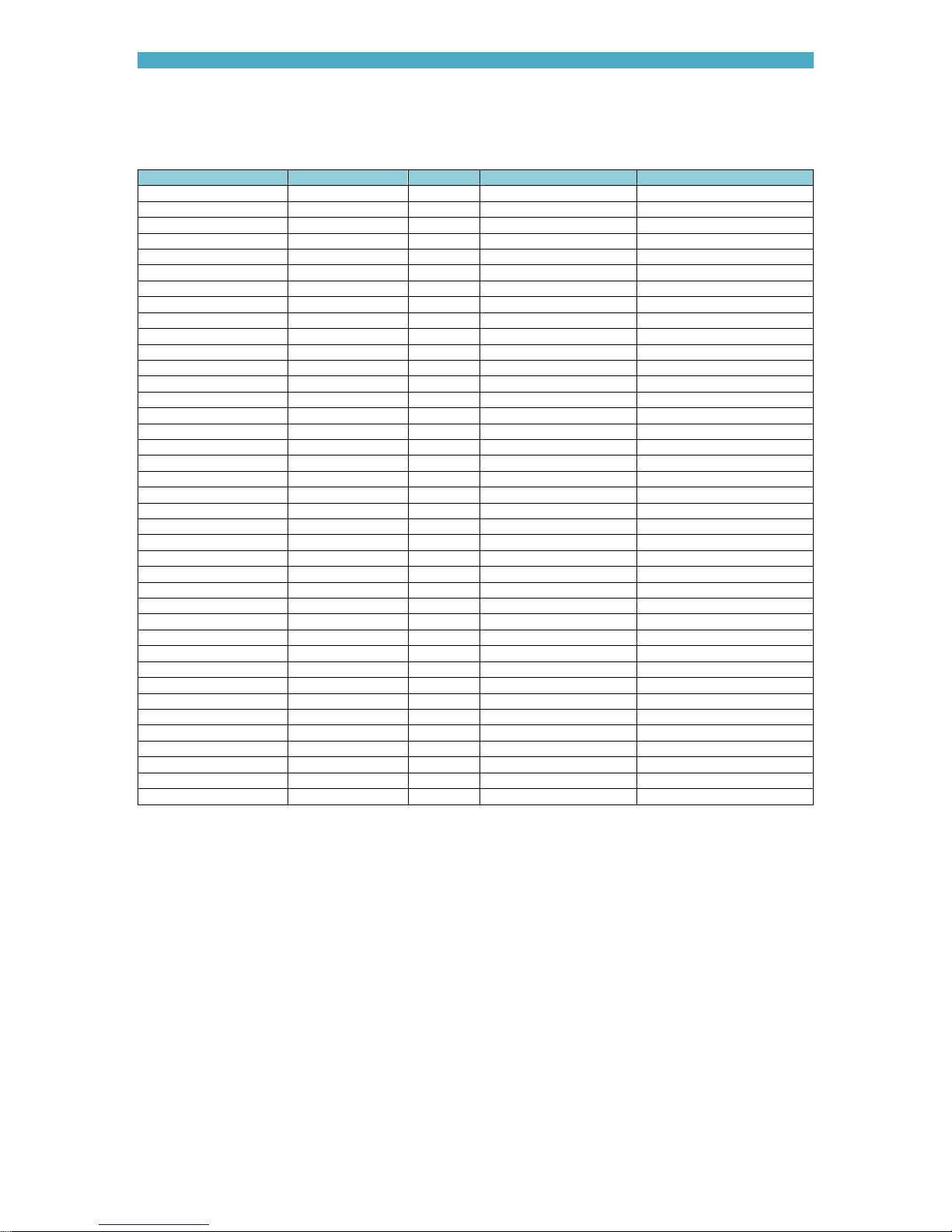

Section 5 MODBUS i/o

28

Variable

Channel

Address

Type

Description

Status register 3

Read outputs [11]

%IW22

WORD

READ 16#900B (= 36875)

End of count 0

Bit 0

%IX22.0

BOOL

Bit 48

End of count 1

Bit 1

%IX22.1

BOOL

Bit 49

End of count 2

Bit 2

%IX22.2

BOOL

Bit 50

End of count 3

Bit 3

%IX22.3

BOOL

Bit 51

End of count 4

Bit 4

%IX22.4

BOOL

Bit 52

End of count 5

Bit 5

%IX22.5

BOOL

Bit 53

End of count 6

Bit 6

%IX22.6

BOOL

Bit 54

End of count 7

Bit 7

%IX22.7

BOOL

Bit 55

Reserved

Bit 8

%IX23.0

BOOL

Reserved

Bit 9

%IX23.1

BOOL

Reserved

Bit 10

%IX23.2

BOOL

Reserved

Bit 11

%IX23.3

BOOL

Reserved

Bit 12

%IX23.4

BOOL

Reserved

Bit 13

%IX23.5

BOOL

Reserved

Bit 14

%IX23.6

BOOL

Reserved

Bit 15

%IX23.7

BOOL

Status register 4

Read outputs [12]

%IW24

WORD

READ 16#900C (= 36876)

End of electrode 0

Bit 0

%IX24.0

BOOL

Bit 64

End of electrode 1

Bit 1

%IX24.1

BOOL

Bit 65

End of electrode 2

Bit 2

%IX24.2

BOOL

Bit 66

End of electrode 3

Bit 3

%IX24.3

BOOL

Bit 67

End of electrode 4

Bit 4

%IX24.4

BOOL

Bit 68

End of electrode 5

Bit 5

%IX24.5

BOOL

Bit 69

End of electrode 6

Bit 6

%IX24.6

BOOL

Bit 70

End of electrode 7

Bit 7

%IX24.7

BOOL

Bit 71

Reserved

Bit 8

%IX25.0

BOOL

Reserved

Bit 9

%IX25.1

BOOL

Reserved

Bit 10

%IX25.2

BOOL

Reserved

Bit 11

%IX25.3

BOOL

Reserved

Bit 12

%IX25.4

BOOL

Reserved

Bit 13

%IX25.5

BOOL

Reserved

Bit 14

%IX25.6

BOOL

Reserved

Bit 15

%IX25.7

BOOL

Status register 5

Read outputs [13]

%IW26

WORD

READ 16#900D (= 36877)

Tip dress 0

Bit 0

%IX26.0

BOOL

Bit 80

Tip dress 1

Bit 1

%IX26.1

BOOL

Bit 81

Tip dress 2

Bit 2

%IX26.2

BOOL

Bit 82

Tip dress 3

Bit 3

%IX26.3

BOOL

Bit 83

Tip dress 4

Bit 4

%IX26.4

BOOL

Bit 84

Tip dress 5

Bit 5

%IX26.5

BOOL

Bit 85

Tip dress 6

Bit 6

%IX26.6

BOOL

Bit 86

Tip dress 7

Bit 7

%IX26.7

BOOL

Bit 87

Reserved

Bit 8

%IX27.0

BOOL

Reserved

Bit 9

%IX27.1

BOOL

Reserved

Bit 10

%IX27.2

BOOL

Reserved

Bit 11

%IX27.3

BOOL

Reserved

Bit 12

%IX27.4

BOOL

Reserved

Bit 13

%IX27.5

BOOL

Reserved

Bit 14

%IX27.6

BOOL

Reserved

Bit 15

%IX27.7

BOOL

Section 5 MODBUS i/o

29

Variable

Channel

Address

Type

Description

Status register 6

Read outputs [14]

%IW28

WORD

READ 16#900E (= 36878)

Prewarn 0

Bit 0

%IX28.0

BOOL

Bit 96

Prewarn 1

Bit 1

%IX28.1

BOOL

Bit 97

Prewarn 2

Bit 2

%IX28.2

BOOL

Bit 98

Prewarn 3

Bit 3

%IX28.3

BOOL

Bit 99

Prewarn 4

Bit 4

%IX28.4

BOOL

Bit 100

Prewarn 5

Bit 5

%IX28.5

BOOL

Bit 101

Prewarn 6

Bit 6

%IX28.6

BOOL

Bit 102

Prewarn 7

Bit 7

%IX28.7

BOOL

Bit 103

Reserved

Bit 8

%IX29.0

BOOL

Reserved

Bit 9

%IX29.1

BOOL

Reserved

Bit 10

%IX29.2

BOOL

Reserved

Bit 11

%IX29.3

BOOL

Reserved

Bit 12

%IX29.4

BOOL

Reserved

Bit 13

%IX29.5

BOOL

Reserved

Bit 14

%IX29.6

BOOL

Reserved

Bit 15

%IX29.7

BOOL

Status register 7

Read outputs [15]

%IW30

WORD

READ 16#900F (= 36879)

Reserved

Bit 0

%IX30.0

BOOL

Reserved

Bit 1

%IX30.1

BOOL

Reserved

Bit 2

%IX30.2

BOOL

Reserved

Bit 3

%IX30.3

BOOL

Reserved

Bit 4

%IX30.4

BOOL

Reserved

Bit 5

%IX30.5

BOOL

Reserved

Bit 6

%IX30.6

BOOL

Reserved

Bit 7

%IX30.7

BOOL

Reserved

Bit 8

%IX31.0

BOOL

Reserved

Bit 9

%IX31.1

BOOL

Reserved

Bit 10

%IX31.2

BOOL

Reserved

Bit 11

%IX31.3

BOOL

Reserved

Bit 12

%IX31.4

BOOL

Reserved

Bit 13

%IX31.5

BOOL

Reserved

Bit 14

%IX31.6

BOOL

Reserved

Bit 15

%IX31.7

BOOL

Pre-heat current (A)

Read outputs [16]

%IW32

DWORD

READ 16#9010 (= 36880)

Main current (A)

Read outputs [18]

%IW36

DWORD

READ 16#9012 (= 36882)

Post-heat current (A)

Read outputs [20]

%IW40

DWORD

READ 16#9014 (= 36884)

Program number

Read outputs [22]

%IW44

WORD

READ 16#9016 (= 36886)

Force1

Read outputs [23]

%IW46

WORD

READ 16#9017 (= 36887)

1

value is multiplied by the scale factor (898.88 for kN or 4 for lbf)

Section 6 Weld control

30

Weld control

EN7000 controls the weld sequence by using the i/o in conjunction with the welding parameters. The parameters

are stored in programs so that different materials and machine sequences can be used. There are 256 weld

programs.

Section 6 Weld control

31

Spot sequence timing

The weld programs contain the following timing parameters.

Parameter

Units

Range

Description

Squeeze

cycles

0 - 99

The time between the initial application of the electrode force and

the first application of welding current

Pre-heat1

cycles

0 - 99

The pre-heat welding current is applied

Cool11

cycles

0 - 99

The material is allowed to cool with electrode force applied

Upslope

cycles

0 - 99

Welding current is increased during this time

Main heat

cycles

0 - 99

The main welding current is applied

Cool22

cycles

0 - 99

The material is allowed to cool with electrode force applied

Downslope

cycles

0 - 99

Welding current is decreased during this time

Post-heat3

cycles

0 - 99

The post-heat welding current is applied

Hold

cycles

0 - 99

Electrode force continues after the welding current has finished

Off4

cycles

0 - 99

Electrode force is released until the next sequence begins

1

Pre-heat program option must be enabled to use this feature

2

Pulsations program option must be greater than 1 to use this feature

3

Post-heat program option must be enabled to use this extended feature

4

Repeat mode program option must be enabled to use this feature

The diagram shows how the parameters control the sequence. The Cool2 interval is not shown.

Start input

EOS output

WAV output

Force

Current

Interval

Squeeze

Pre-heat

Cool1

Upslope

Main heat

Downslope

Post heat

Hold

Off

Upslope can be used on hard, irregular shaped, oxidized and aluminium materials

Downslope can be used to reduce marking and embrittlement

Section 6 Weld control

32

Seam sequence timing (extended feature)

The weld programs contain the following timing parameters. All parameters can be adjusted during the

sequence.

Parameter

Units

Range

Description

Squeeze

cycles

0 - 99

The time between the initial application of the electrode force and

the first application of welding current

Pre-heat1

cycles

0 - 99

The pre-heat welding current is applied

Cool11

cycles

0 - 99

The material is allowed to cool with electrode force applied

Upslope

cycles

0 - 99

Welding current is increased during this time

Main heat

cycles

0 - 99

The main welding current is applied

Downslope

cycles

0 - 99

Welding current is decreased during this time

Post-heat2

cycles

0 - 99

The post-heat welding current is applied

Cool2

cycles

0 - 99

The material is allowed to cool with electrode force applied

Hold

cycles

0 - 99

Electrode force continues after the welding current has finished

1

Pre-heat program option must be enabled to use this feature

2

Post-heat program option must be enabled to use this feature

The diagram shows how the parameters control the sequence.

Start input1

EOS output

WAV output

Motor output2

Force

Current

Interval

Squeeze

Pre-heat

Cool1

Upslope

Main heat

Downslope

Post-heat

Cool2

Upslope

Main heat

Downslope

Post-heat

Cool2

Upslope

Main heat

Downslope

Post-heat

Cool2

Hold

1

The intervals from Upslope to Cool2 repeat until the Start input is removed.

2

The operation of the motor output is determined by the 2nd stage test (Section 12 Configuration).

Section 6 Weld control

33

Spot current control

The weld programs contain the following current control parameters.

Parameter

Units

Range

Description

Pre-mode1

PHA/CCR

Operating mode of the Pre-heat interval

Pre-heat1

%

0.0 – 99.9

The % heat used during the Pre-heat interval in PHA mode

Pre-current1

kA

0 – 500

The current used during the Pre-heat interval in CCR mode

Main mode

PHA/CCR

Operating mode of the Main heat interval

Main heat

%

0.0 – 99.9

The % heat used during the Main heat interval in PHA mode

Main current

kA

0 – 500

The current used during the Main heat interval in CCR mode

Post mode2

PHA/CCR

Operating mode of the Post-heat interval

Post heat2

%

0.0 – 99.9

The % heat used during the Post-heat interval in PHA mode

Post current2

kA

0 – 500

The current used during the Post-heat interval in CCR mode

Test current

on/off

Each current can be tested between limits

High limit

%

0 - 99

Current high limit

Low limit

%

0 - 99

Current low limit

3-Phase trim3

%

+/- 99

Balances the current in each phase

1

Pre-heat program option must be enabled to use this feature

2

Post-heat program option must be enabled to use this extended feature.

3

3-phase configuration must be selected to use this feature

PHA (Phase Angle) mode. The current and heat parameters are independently adjustable. No current

regulation takes place.

CCR (Constant Current) mode. The current parameter is adjustable but the heat is automatically

determined by the EN7000 to regulate the current.

The diagram shows how the parameters control the welding current. The Cool2 interval is not shown.

Start input

EOS output

WAV output

Force

Pre-heat/current

Main heat/current

Post-heat/current

Current

Interval

Squeeze

Pre-heat

Cool1

Upslope

Main heat

Downslope

Post-heat

Hold

Off

Pre-heat and Post-heat can be used on hard or heat resistant metals

Section 6 Weld control

34

Seam current control (extended feature)

The weld programs contain the following current control parameters.

Parameter

Units

Range

Description

Pre-mode1

PHA/CCR

Operating mode of the Pre-heat interval

Pre-heat1

%

0.0 – 99.9

The % heat used during the Pre-heat interval in PHA mode

Pre-current1

kA

0 – 500

The current used during the Pre-heat interval in CCR mode

Pre-monitoring1

on/off

The current can be tested between limits

Main mode

PHA/CCR

Operating mode of the Main heat interval

Main heat

%

0.0 – 99.9

The % heat used during the Main heat interval in PHA mode

Main current

kA

0 – 500

The current used during the Main heat interval in CCR mode

Main monitoring

on/off

The current can be tested between limits

Post mode2

PHA/CCR

Operating mode of the Post-heat interval

Post heat2

%

0.0 – 99.9

The % heat used during the Post-heat interval in PHA mode

Post current2

kA

0 – 500

The current used during the Post-heat interval in CCR mode

Post monitoring2

on/off

The current can be tested between limits

Low limit

%

0 - 99

Current low limit

High limit

%

0 - 99

Current high limit

Balance

%

0.0 – 10.0

Balances the current during pulsed seam welding

3-Phase trim3

%

+/- 99

Balances the current in each phase

1

Pre-heat program option must be enabled to use this feature

2

Post-heat program option must be enabled to use this feature

3

3-phase configuration must be selected to use this feature

PHA (Phase Angle) mode. The current and heat parameters are independently adjustable. No current

regulation takes place.

CCR (Constant Current) mode. The current parameter is adjustable but the heat is automatically

determined by the EN7000 to regulate the current.

The diagram shows how the parameters control the welding current.

Start input

EOS output

WAV output

Force

Pre-heat/current

Main heat/current

Post-heat/current

Current

Interval

Squeeze

Pre-heat

Cool1

Upslope

Main heat

Downslope

Post-heat

Cool2

Hold

Section 6 Weld control

35

Force control

The weld programs contain the following force control parameters.

Parameter

Units

Range

Description

Squeeze1

kN/lbf

variable

Force used from the start of the Squeeze interval

Pre-heat1

kN/lbf

variable

Force used from the start the Pre-heat interval

Cool11

kN/lbf

variable

Force used from the start the Cool1 interval

Upslope1

kN/lbf

variable

Force used from the start the Upslope interval

Main heat

kN/lbf

variable

Force used from the start of the Main heat interval

Cool2

kN/lbf

variable

Force used from the start of the Cool2 interval

Downslope1

kN/lbf

variable

Force used from the start of the Downslope interval

Post-heat1

kN/lbf

variable

Force used from the start the Post-heat interval

Hold1

kN/lbf

variable

Force used from the start the Hold interval

Wait for force2

on/off

Wait until the applied force has been reached

Test force

on/off

Test the applied force at the end of the Main interval

High limit

%

0 - 99

Force high limit

Low limit

%

0 - 99

Force low limit

1

Force profile program option must be enabled to use this extended feature. If the force profile option is

disabled the Main heat force is used for the duration of the weld.

2

Occurs at the same time as 2nd stage. If Wait for force is required without 2nd stage, select 2nd stage

Before or After Squeeze (Section 12 Configuration) and permanently assert the 2nd stage input

The diagram shows how the force profile can control the welding force. The Cool2 interval is not shown.

Start input

EOS output

WAV output

Force

Current

Interval

Squeeze

Pre-heat

Cool1

Upslope

Main heat

Downslope

Post-heat

Hold

Off

Section 6 Weld control

36

Valves

EN7000 has eight digital outputs or valves (AV1 – AV8) that can be operated independently during a

weld sequence. The valves are categorised as WAV, motor1 or AUX valves.

A WAV valve turns on at start of sequence and turns off at the end of the Hold interval.

The operation of a motor valve is determined by the 2nd stage test (Section 12 Configuration).

An AUX valve may be programmed to come on during any interval of the weld sequence,

including the Off time in repeat mode.

EN7000 features

Configuration

WAV function

Motor function

Description

Standard

All

AV1

n/a

AV1 is automatically

selected

Extended (spot)

Single electrode

AV1

n/a

AV1 is automatically

selected

Multi-electrode

AV1 – AV8

n/a

Any combination of AV1 to

AV8 may be selected

Extended (seam)

Single electrode

AV1

AV2

AV1 and AV2 are

automatically selected

Multi-electrode

AV1 – AV8

AV1 – AV8

Any combination of AV1 to

AV8 may be selected

Valves not being used for the WAV or motor function may be used as AUX valves. WAV/motor settings

always override any corresponding AUX settings.

The weld programs contain the following valve control parameters.

Parameter

Units

Range

Description

WAV

AV1 – AV8

WAV output

Motor1

AV1 – AV8

Motor output

Squeeze

AV1 – AV8

on/off

Valve states during the Squeeze interval

Pre-heat

AV1 – AV8

on/off

Valve states during the Pre-heat interval

Cool1

AV1 – AV8

on/off

Valve states during the Cool1 interval

Upslope

AV1 – AV8

on/off

Valve states during the Upslope interval

Main heat

AV1 – AV8

on/off

Valve states during the Main heat interval

Cool2

AV1 – AV8

on/off

Valve states during the Cool2 interval

Downslope

AV1 – AV8

on/off

Valve states during the Downslope interval

Post-heat

AV1 – AV8

on/off

Valve states during the Post-heat interval

Hold

AV1 – AV8

on/off

Valve states during the Hold interval

Off2

AV1 – AV8

on/off

Valve states during the Off interval

1

Seam mode only.

2

Repeat mode program option must be enabled to use this feature.

Section 6 Weld control

37

Options

Each weld program has a number of optional features.

Parameter

Range

Description

Pre-heat

on/off

Enables or disables the Pre-heat parameters

Post-heat

on/off

Enables or disables the Post-heat parameters

Pulsations

1 - 99

The number of times the Main heat – Cool2 interval is repeated

Link

on/off

The next welding program will be started automatically if the input signals

are maintained

Repeat

on/off

The welding program will be repeated if the input signals are maintained

Force profile

on/off

Use multiple force values during the weld

Pulsations can be used to temper the material, control nugget growth and reduce electrode wear.

The Start signal must be maintained for the full duration of the sequence if pulsations are set to 10 or

more, otherwise the sequence will terminate after 10 pulses.

Program selection

The program that will be used for welding can be selected in one of two ways

Section 12 Configuration: by using the Program Select inputs (external)

Section 13 Programming: by using the Use Program parameter (internal)

If the external method is used, inputs P1 – P64 correspond to the binary value of the program that will

be used. If the internal method is used, the Use Program parameter determines the weld program that

will be used. The program number may be changed during a seam weld sequence.

Multi-electrode operation

The extended features allow each welding program to be assigned an electrode.

Parameter

Units

Range

Description

Electrode

0 - 7

The electrode number

When a program is used, EN7000 will automatically trigger the correct transformer by referencing the

electrode/transformer assignment as described below. In addition, the electrode number is also used to

access the appropriate stepper, counter and calibration information

Section 7 Electrode management

38

Electrode management

Electrode management is provided via a combination of stepper and counter functions.

The stepper provides a means of gradually increasing the current to compensate for electrode wear. The counter

counts the number of welds that the electrode has done and allows the electrode to be dressed a number of

times before it is replaced. The extended features provide eight steppers and counters that can be assigned to up

to eight transformers or SCRs.

Section 7 Electrode management

39

Step 0 Step 1 Step 2 Step 3 Step 4 Step 5 Step 6 Step 7 Step 8 Step 9

Spots

Current or Heat

dH0/dI

0

dH1/dI

1

dH2/dI

2

dH3/dI

3

dH4/dI

4

dH9/dI

9

Steppers

A stepper is programmed by means of a curve which will provide values of heat and current increments

related to the number of spots done. The curve is defined by a set of 10 points.

Parameter

Units

Range

Description

Step 0 - 9

The step number

Spots

welds

0 - 9999

The number of welds in the step

+Heat

%

0.0 - 50.0

The increase in heat during the step

+Current

%

0.0 - 50.0

The increase in current during the step

Preset

1 - 5

Apply predefined values to the stepper curve

Enable stepper

on/off

Enables or disables the stepper

Stop at end

on/off

EN7000 can inhibit welding at the end of the last step

Spots done

welds

0 - 99999

The number of welds that have been done since the last reset

PHA mode will make use of both the +Heat and +Current parameters. CC mode uses only the +Current

parameters.

The Stepper output is active at the end of the last step. The Prewarn output is active during the last

step.

To get started enter the values for Step 9 then select a Preset to load the intermediate values

Section 7 Electrode management

40

Count up to

Spots

Current

or Heat

Count up to-n

Tip-dress (Counter)

output

Reset counter input

Pre-warn output

End of stepper output

Reset stepper input

@reset,stepper=n

n

0 1 2 3 4 0

Dressings done

max. dressings=4

Count up to-n Count up to-n

Count up to-n

Tip-dress Tip-dress Tip-dress Tip-dress Replace electrodes

See note 1

Counters

A counter is programmed by entering values related to the electrode maintenance and lifetime.

Parameter

Units

Range

Description

Enable counter

on/off

Enables or disables the counter

Count

welds

0 - 9999

The number of welds that have been done since the last reset

End count

welds

0 - 99999

The maximum number of welds that can be done

Stop at end

on/off

EN7000 can inhibit welding until the counter is reset

Enable tip dress

on/off

Enables or disables the tip dressing feature

Dressings done

0 - 9999

The number of times the electrodes have been dressed

Max dressings

0 - 9999

The maximum number of times the electrodes can be dressed

Reset to

welds

0 - 9999

The weld count following a tip dress operation

If tip dressing is enabled EN7000 will activate the Tip Dress Request output when the Count value is

reached.

Section 7 Electrode management

41

Current calibration

The welding current can be measured by a Current Transformer (CT) or by a coil (toroid) on the primary

or secondary circuit. If the sensor is measuring the primary current EN7000 can display secondary

current when the relationship between primary and secondary current has been calibrated.

Parameter

Units

Range

Description

Power factor

Cos (Φ)

0 - 0.86

The power factor of the welding transformer1

Toroid

mV/kA

100 - 60000

The sensitivity of the toroid

CT

mV/kA

100 - 60000

The sensitivity of the CT

Point 1 (primary)

kA

0 - 32.0

The measured value of primary current at a low heat (Ip1)

Point 1 (secondary)

kA

0 - 500.0

The measured value of secondary current at a low heat (Is1)

Point 2 (primary)

kA

0 - 32.0

The measured value of primary current at a high heat (Ip2)

Point 2 (secondary)

kA

0 - 500.0

The measured value of secondary current at a high heat

(Is2)

Apply conversion

off/points/ratio

Use the conversion to display secondary current (CT only)

Turns ratio

1 - 999

The turns ratio of the welding transformer (CT only)

CCR gain2

1 - 10

The CCR gain. Set to 5 as a starting point

1

Section 14 Tutorials: Setting the power factor.

2

Seam mode only.

If using a CT the turns ratio of the transformer can be used to scale the current. Alternatively the scaling

can be determined by measuring the values of primary and secondary current at two different heat

levels.

Produce a short circuit weld at a low heat in PHA mode and measure the primary current (Ip1)

and secondary current (Is1) using an external weld current meter.

Repeat the short circuit weld at a higher heat and measure the primary current (Ip2) and

secondary current (Is2) using an external weld current meter.

.

Enter the measured values into the Point 1/Point 2 parameters. Select the appropriate conversion

method.

The current can be calibrated for each electrode

Calibration is not required if a toroid is being used for secondary feedback. In this situation only the

toroid sensitivity is required.

I

p

I

s1

I

s

I

p2

I

p1

I

s2

Section 7 Electrode management

42

Force calibration

The analog input and analog output can be used for force control in terms of kN or lbf when they have

been calibrated.

Parameter

Units

Range

Description

OUT Point 1

mV

0 - 10000

Analog output (point 1)

OUT Point 1

kN/lbf

Measured output force (point 1)

OUT Point 2

mV

0 - 10000

Analog output (point 2)

OUT Point 2

kN/lbf

Measured output force (point 2)

IN Point 1

mV

0 - 10000

Analog input (point 1)

IN Point 1

kN/lbf

Measured input force (point 1)

IN Point 2

mV

0 - 10000

Analog input (point 2)

IN Point 2

kN/lbf

Measured input force (point 2)

The relationship between the analog input and output and the electrode force can be determined by

measuring the values at two points. The values define a linear relationship between mV and kN/lbf.

The force can be calibrated for each electrode.

Section 7 Electrode management

43

Multi-electrode operation (extended feature)

This extended mode feature allows the assignment of an electrode to a transformer or SCR.

Parameter

Units

Range

Description

Electrode

0 - 7

The electrode number

Transformer/SCR

0 - 7

The transformer or SCR that the electrode is connected to

The diagram shows how the electrodes can be assigned to transformers/SCRs

Electrodes 0 and 1 are assigned to transformer/SCR 0

T0

Electrodes 2 and 3 are assigned to transformer/SCR 1

T1

Electrodes 4 and 5 are assigned to transformer/SCR 2

T2

Electrodes 6 and 7 are assigned to transformer/SCR 3

T3

The electrodes are assigned to weld programs in the same way.

E0

E1

E2

E3

E4

E5

E6

E7

Section 8 Status

44

Status information

EN7000 reports a number of conditions to assist with diagnostics, quality control and maintenance. Each

condition corresponds to a code which is accessible via MODBUS.

Code

Condition

Action

0

Normal

1

Stop

Check the Stop input

2

Sync. error

Check 27 V ac sync signal and/or the Frequency parameter in Configuration

3

Retract not ready

Operate the Retract input

4

SCR hot

Check SCR cooling

5

Transformer hot

Check weld transformer cooling

6

Pilot fault

Safety relay fault. Do not use the EN7000 and return it for service.

7

Restart required

Restart the EN7000

8

Headlocked

The welding head is locked because of a fault condition

9

Reserved

10

Reserved

11

Reserved

12

Reserved

13

Reserved

14

Reserved

15

Reserved

15

Reserved

17

Start on

The Start input is on following a weld sequence or stop/power-up condition

18

Weld off

Check the Weld On input

19

Reserved

20

Output fault

One or more outputs have failed

21

Reserved

22

Too many links

Too many weld programs are linked together

23

Bad link

A link has been made to a weld program that cannot be used

24

Reserved

25

Reserved

26

Reserved

27

Reserved

28

Reserved

29

Reserved

30

Reserved

31

Reserved

32

Reserved

33

Low force

Check the analog input and output circuits and/or adjust force parameters

34

High force

Check the analog input and output circuits and/or adjust force parameters

35

Low pre-current

Check CT/toroid feedback and/or adjust Pre-heat parameters

36

High pre-current

Check CT/toroid feedback and/or adjust Pre-heat parameters

37

Low main current

Check CT/toroid feedback and/or adjust Main heat parameters

38

High main current

Check CT/toroid feedback and/or adjust Main heat parameters

39

Low post-current

Check CT/toroid feedback and/or adjust Post-heat parameters

40

High post-current

Check CT/toroid feedback and/or adjust Post-heat parameters

41

No 2nd stage

Check the 2nd Stage input

42

No force

Check analog input circuit

Section 8 Status

45

43

Reserved

44

Reserved

45

Reserved

46

Reserved

47

Reserved

48

Reserved

49

End of count 0

Reset counter 0

50

End of count 1

Reset counter 1

51

End of count 2

Reset counter 2

52

End of count 3

Reset counter 3

53

End of count 4

Reset counter 4

54

End of count 5

Reset counter 5

55

End of count 6

Reset counter 6

56

End of count 7

Reset counter 8

57

Reserved

58

Reserved

59

Reserved

60

Reserved

61

Reserved

62

Reserved

63

Reserved

64

Reserved

65

End of electrode 0

Reset stepper 0

66

End of electrode 1

Reset stepper 1

67

End of electrode 2

Reset stepper 2

68

End of electrode 3

Reset stepper 3

69

End of electrode 4

Reset stepper 4

70

End of electrode 5

Reset stepper 5

71

End of electrode 6

Reset stepper 6

72

End of electrode 7

Reset stepper 7

73

Reserved

74

Reserved

75

Reserved

76

Reserved

77

Reserved

78

Reserved

79

Reserved

80

Reserved

81

Tip dress 0

Dress the electrodes and then reset counter 0

82

Tip dress 1

Dress the electrodes and then reset counter 1

83

Tip dress 2

Dress the electrodes and then reset counter 2

84

Tip dress 3

Dress the electrodes and then reset counter 3

85

Tip dress 4

Dress the electrodes and then reset counter 4

86

Tip dress 5

Dress the electrodes and then reset counter 5

87

Tip dress 6

Dress the electrodes and then reset counter 6

88

Tip dress 7

Dress the electrodes and then reset counter 7

89

Reserved

90

Reserved

91

Reserved

92

Reserved

93

Reserved

94

Reserved

95

Reserved

96

Reserved

97

Prewarn 0

Stepper 0 has completed its 9th step

98

Prewarn 1

Stepper 1 has completed its 9th step

99

Prewarn 2

Stepper 2 has completed its 9th step

100

Prewarn 3

Stepper 3 has completed its 9th step

101

Prewarn 4

Stepper 4 has completed its 9th step

102

Prewarn 5

Stepper 5 has completed its 9th step

103

Prewarn 6

Stepper 6 has completed its 9th step

104

Prewarn 7

Stepper 7 has completed its 9th step

105

Reserved

106

Reserved

Section 8 Status

46

107

Reserved

108

Reserved

109

Reserved

110

Reserved

111

Reserved

112

Reserved

113

Reserved

114

Reserved

115

Reserved

116

Reserved

117

Reserved

118

Reserved

119

Reserved

120

Reserved

121

Reserved

122

Reserved

123

Reserved

124

Reserved

125

Reserved

126

Reserved

127

Reserved

128

Reserved

Section 9 History log

47

History log

EN7000 stores the results of the last 6000 spot welds in a history log. Each record contains the following

information:

Parameter

Units

Range

Description

Time and date

The time and date when the entry was recorded

Program

0 - 255

The weld program used

Pre-current

kA

0 – 500

The current recorded during the Pre-heat interval

Main current

kA

0 – 500

The current recorded during the Main heat interval

Post-current

kA

0 – 500

The current recorded during the Post-heat interval

Force

kN/lbf

Variable

The force recorded during the weld

The log can be viewed or reset as required.

Section 10 Multiwelding

48

Multiwelding (extended feature)

The extended features allow up to four transformers/SCRs to be directly connected or up to eight when used with

a decoder.

Up to 8 electrodes can be assigned

to the welding transformers

The electrode number is determined by the weld program:

Parameter

Units

Range

Description

Electrode

0 - 7

The electrode number

The weld programs can be linked together.

The electrode is assigned to a transformer:

Parameter

Units

Range

Description

Electrode

0 - 7

The electrode number

SCR/Transformer

0 - 7

The transformer or SCR that the electrode is connected to

Section 10 Multiwelding

49

The diagram shows how the electrodes can be assigned to transformers/SCRs

Electrodes 0 and 1 are assigned to transformer/SCR 0

T0

Electrodes 2 and 3 are assigned to transformer/SCR 1

T1

Electrodes 4 and 5 are assigned to transformer/SCR 2

T2

Electrodes 6 and 7 are assigned to transformer/SCR 3

T3

There are two methods available for multiwelding.

Multi-gun operation allows each welding program to be triggered independently but allows for selection

of a transformer and electrode.

Multi-gun cascade operation allows up to eight welding programs to be linked together and triggered

from a single start command. The programs then ripple through with minimal time between them,

selecting transformers and electrodes on the fly. The linked programs are known as a cascade.

E2

E3

E4

E5

E6

E7

E0

E1

Section 10 Multiwelding

50

Multi-gun operation

Each welding program is started independently but different electrodes and transformers can be

selected.

The WAV output can be a separate output for each program

Start input

EOS output

WAV output

Program

select

Current

(transformer 0)

Current

(transformer 1)

Current

(transformer 2)

Current

(transformer 3)

Section 10 Multiwelding

51

Multi-gun cascade operation

Different electrodes and transformers can still be selected but the welding programs are linked together

and started by a single Start command

In multi-gun cascade operation the program select inputs select the first program in the cascade.

Start input

EOS output

WAV output

Program

First

program #

select

Current

(transformer 0)

Current

(transformer 1)

Current

(transformer 2)

Current

(transformer 3)

Section 11 Seam welding

52

Seam welding (extended feature)

EN7000 can be used for seam welding applications. The seam program parameters provide a flexible sequence

that works in conjunction with the inputs and outputs to produce many different types of seam weld e.g.

continuous seam

seam pulsation

seam modulation

seam pre-heat

roll-spot

The parameters are described in Section 6 Weld control and can be adjusted during the weld. Intervals that are

not required may be set to 0.

Section 11 Seam welding

53

Continuous seam

A continuous seam weld maintains a set current for the duration of the weld. The following example shows how

this type of sequence may be implemented.

Parameter

Setting

Description

Sequence timing

Squeeze

cycles

The time between the initial application of the electrode force and

the first application of welding current

Main heat

cycles

The main welding current is applied

Hold

cycles

Electrode force continues after the welding current has finished

Current control

Main mode

PHA/CCR

Operating mode of the Main heat interval

Main heat

%

The % heat used during the Main heat interval in PHA mode

Main current

kA

The current used during the Main heat interval in CCR mode

Main monitoring1

on/off

The current can be tested between limits

Low limit1

%

Current low limit

High limit1

%

Current high limit

Options

Pre-heat

off

Disable the Pre-heat parameters

Post-heat

off

Disable the Post-heat parameters

1

optional

Start input1

EOS output

WAV output

Force

Current

Interval

Squeeze

Man

heat

Hold

1

The Main heat interval is repeated until the Start input is removed.

Section 11 Seam welding

54

Seam pulsation

Seam pulsation can be used in applications where a continuous weld is not required. The Main heat and the

Cool2 intervals are repeated for the duration of the weld. The following example shows how this type of sequence

may be implemented.

Parameter

Setting

Description

Sequence timing

Squeeze

cycles

The time between the initial application of the electrode force and

the first application of welding current

Main heat

cycles

The main welding current is applied

Cool2

cycles

The material is allowed to cool with electrode force applied

Hold

cycles

Electrode force continues after the welding current has finished

Current control

Main mode

PHA/CCR

Operating mode of the Main heat interval

Main heat

%

The % heat used during the Main heat interval in PHA mode

Main current

kA

The current used during the Main heat interval in CCR mode

Main monitoring1

on/off

The current can be tested between limits

Low limit1

%

Current low limit

High limit1

%

Current high limit

Options

Pre-heat

off

Disable the Pre-heat parameters

Post-heat

off

Disable the Post-heat parameters

Balance

%

Allows the current to be balanced when using pulsed seam welding

1

optional

Start input1

EOS output

WAV output

Force

Current

Interval

Squeeze

Main

heat

Cool2

Main

heat

Cool2

Main

heat

Cool2

Main

heat

Cool2

Hold

1

The Main heat – Cool2 intervals are repeated until the Start input is removed.

Section 11 Seam welding

55

Seam modulation

Seam modulation can be used in applications where a change in current is required. Two Heat intervals are

repeated for the duration of the weld. The following example shows how this type of sequence may be

implemented.

Parameter

Setting

Description

Sequence timing

Squeeze

cycles

The time between the initial application of the electrode force and

the first application of welding current

Main heat

cycles

The main welding current is applied

Post-heat

cycles

The post-heat welding current is applied

Hold

cycles

Electrode force continues after the welding current has finished

Current control

Main mode

PHA/CCR

Operating mode of the Main heat interval

Main heat

%

The % heat used during the Main heat interval in PHA mode

Main current

kA

The current used during the Main heat interval in CCR mode

Main monitoring1

on/off

The current can be tested between limits

Post mode

PHA/CCR

Operating mode of the Post-heat interval

Post heat

%

The % heat used during the Post-heat interval in PHA mode

Post current

kA

The current used during the Post-heat interval in CCR mode

Post monitoring1

The current can be tested between limits

Low limit1

%

Current low limit

High limit1

%

Current high limit

Options

Pre-heat

off

Disable the Pre-Heat parameters

Post-heat

on

Enable the Post-heat parameters

1

optional

Start input1

EOS output

WAV output

Force

Current

Interval

Squeeze

Main

heat

Post-

heat

Main

heat

Post-

heat

Main

heat

Post-

heat

Main

heat

Post-

heat

Hold

1

The Main heat – Post-heat intervals are repeated until the Start input is removed.

Section 11 Seam welding

56

Seam pre-heat

Pre-heat can be used in applications where the initial current needs to be different to the main current. The

following example shows a continuous seam weld with a pre-heat.

Parameter

Setting

Description

Sequence timing

Squeeze

cycles

The time between the initial application of the electrode force and

the first application of welding current

Pre-heat

cycles

The pre-heat welding current is applied

Main heat

cycles

The main welding current is applied

Hold

cycles

Electrode force continues after the welding current has finished

Current control

Pre-mode

PHA/CCR

Operating mode of the Pre-heat interval

Pre-heat

%

The % heat used during the Pre-heat interval in PHA mode

Pre-current

kA

The current used during the Pre-heat interval in CCR mode

Pre-monitoring1

The current can be tested between limits

Main mode