Page 1

Ditec PWR25H/35H

Automation for hinged

gates

(translation of the original instructions)

www.entrematic.com

IP2250EN

Technical Manual

Page 2

26

IP2250EN - 2016-12-02

Contents

Key

Subject Page

1. General safety precautions 27

2. Declaration of incorporation of partly completed machinery 28

2.1 Machinery Directive 28

3. Technical specifications 29

4. Standard installation 31

5. Gearmotor dimensions and references 32

6. Installation 33

6.1 Preliminary checks 33

6.2 Bracket fastening 34

6.3 Positioning usage 35

6.4 Gearmotor installation 36

6.5 Adjusting the mechanical end stops 37

6.6 Electrical connections 38

6.7 Magnetic limit switches adjustment (PWR35H only) 39

7. Routine maintenance plan 40

8. Troubleshooting 41

9. Disposal 41

Operating instructions 43

Manual release instructions 44

i

This symbol indicates instructions or notes regarding safety, to which special attention must be paid.

This symbol indicates useful information for the correct functioning of the product.

Page 3

27

IP2250EN - 2016-12-02

This installation manual is intended for qualified personnel only.

Installation, electrical connections and adjustments must be performed in accordance

with Good Working Methods and in compliance with the present standards.

Read the instructions carefully before installing the product.

Incorrect installation could be dangerous.

Before installing the product, make sure it is in perfect condition.

Before installing the motorisation device, make all the necessary structural modifications to create safety clearance and to guard or isolate all the crushing, shearing,

trapping and general hazardous areas.

Make sure the existing structure is up to standard in terms of strength and stability.

The motorisation device manufacturer is not responsible for failure to observe Good

Working Methods when building the frames to be motorised, or for any deformations

during use.

The safety devices (photocells, safety edges, emergency stops, etc.) must be installed

taking into account the applicable laws and directives, Good Working Methods, installation premises, system operating logic and the forces developed by the motorized gate.

The safety devices must protect the crushing, shearing, trapping and general hazardous

areas of the motorised door.

Display the signs required by law to identify hazardous areas.

Each installation must bear a visible indication of the data identifying the motor-

ized gate.

When requested, connect the motorized gate to an effective earthing system that

complies with current safety standards.

During installation, maintenance and repair operations, cut off the power supply before

opening the cover to access the electrical parts.

The automation protection casing must be removed by qualified personnel only.

The manufacturer of the motorisation device declines all responsibilit y if compo-

nent parts not compatible with safe and correct operation are fitted.

Only use original spare parts when repairing or replacing products.

The installer must supply all information on the automatic, manual and emergency operation of the motorised gate, and must provide the user with the operating instructions

.

1. General safety precautions

Failure to respect the information given in this manual

may cause personal injury or damage to the device.

Keep these instructions for future reference

Page 4

28

IP2250EN - 2016-12-02

2. Declaration of incorporation of partly completed machinery

(Directive 2006/42/EC, Annex II-B)

The manufacturer Entrematic Group AB, with headquarters in Lodjursgatan 10, SE-261 44

Landskrona, Sweden, declares that the Ditec PWR25H / PWR35H automation for swing gates:

- is designed to be installed on a manual gate to form a machine pursuant to Directive 2006/42/

EC. The manufacturer of the motorised gate must declare conformity with Directive 2006/42/

EC (annex II-A) prior to initial machine start-up;

- complies with the applicable essential safety requirements indicated in Annex I, Chapter 1 of

the Directive 2006/42/EC;

- complies with the Electromagnetic Compatibility Directive 2014/30/EU;

- complies with the RED Directive 2014/53/EU;

- the technical documentation complies with Annex VII-B of the Directive 2006/42/EC;

- the technical documentation is managed by the Technical Office of Entrematic Italy (with

headquarters in Largo U. Boccioni 1 – 21040 Origgio (VA) – ITALY) and is available upon request,

sending an e-mail to ditec@entrematic.com ;

- a copy of the technical documentation will be given to competent national authorities, following

a suitably justified request.

Landskrona, 01-07-2016 Matteo Fino

(Chairman)

2.1 Machinery Directive

Pursuant to the Machinery Directive (2006/42/EC), the installer who motorises a door or gate has

the same obligations as the manufacturer of machinery and as such must:

- prepare the technical data sheet which must contain the documents indicated in Annex V of the

Machinery Directive;

(the technical data sheet must be kept and placed at the disposal of competent national author-

ities for at least ten years from the date of manufacture of the motorised door or gate);

- draw up the EC Declaration of Conformity in accordance with Annex II-A of the Machinery

Directive and deliver it to the customer;

- affix the EC marking on the motorised door or gate, in accordance with point 1.7.3 of Annex I of

the Machinery Directive.

Page 5

29

IP2250EN - 2016-12-02

3. Technical specifications

PWR25H PWR35H

Power 24V

Maximum

power

5A 5.5A

Absorbed power 55W nom. / 120W max 65W nom. / 132W max

Maximum thrust 2000 N 3000 N

Maximum stroke 350mm 450mm

Opening time 10÷60 s/90° 14÷80 s/90°

Intermittence

80 cycles/day [max]

30 consecutive cycles at 20°C

max 150 cycles/day [max]

50 consecutive cycles at 20°C

Duration

From 90,000 to 150,000 cycles based on

the conditions indicated in table 3.1 (see

the durability graphs of the product)

From 120,000 to 300,000 cycles based on

the conditions indicated in table 3.1 (see

the durability graphs of the product)

Operating temperature -20°C / +55°C (-35°C + 55°C with NIO active)

Degree of protection IP44 IP44

Dimensions (mm) 820 x 100 x 107 h 970 x 100 x 107 h

Weight (Kg) 7.8 9

Tab. 3.0

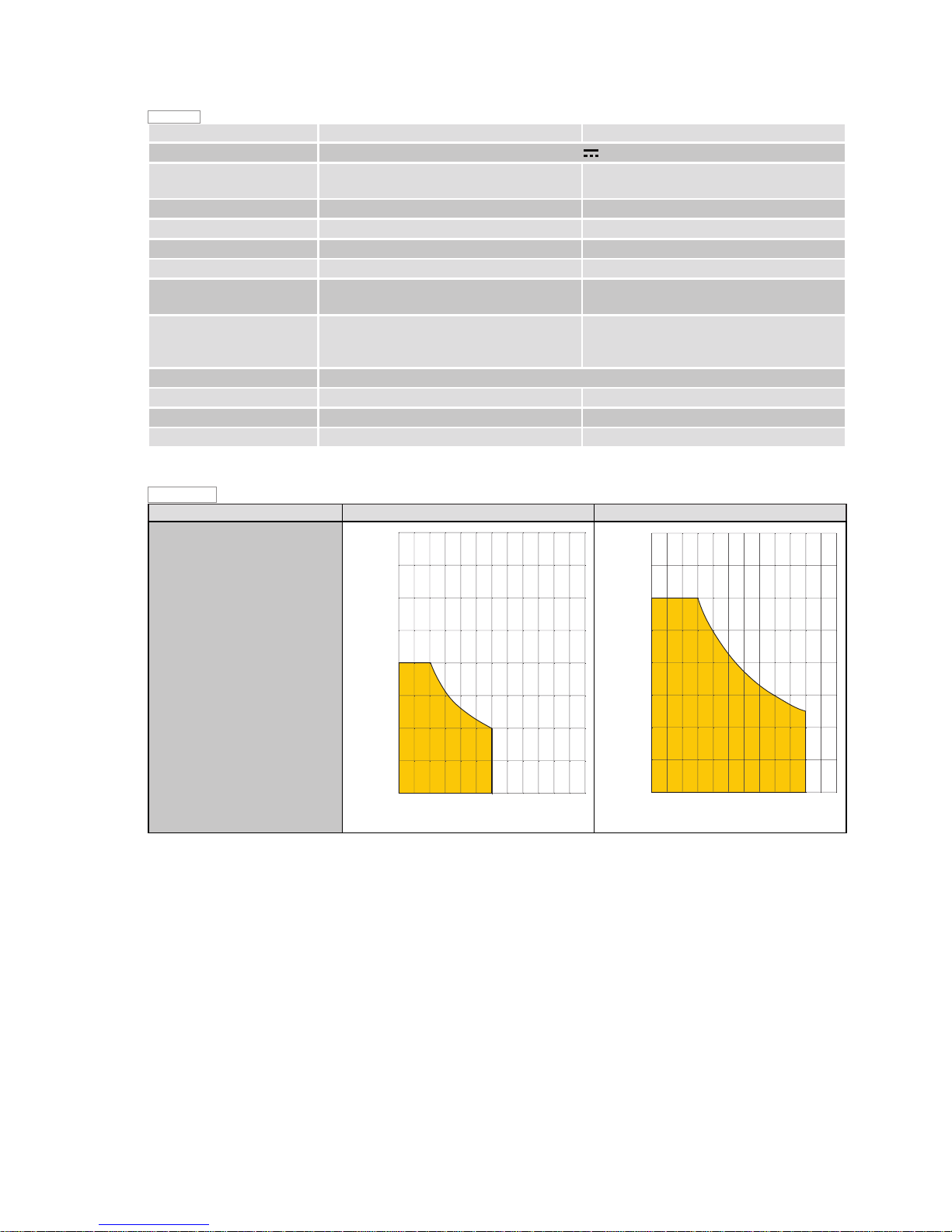

Graph 3.0

WARNING: To prevent burglary, the use of an electric lock is recommended with wings longer

than 2.3m.

PWR25H PWR35H

Usage limits

(gate wing weight and length)

0

1

100

200

300

400

500

600

700

800

23

(m)

(Kg)

4

1

0

100

200

300

400

500

600

700

800

23

(m)

(Kg)

4

Page 6

30

IP2250EN - 2016-12-02

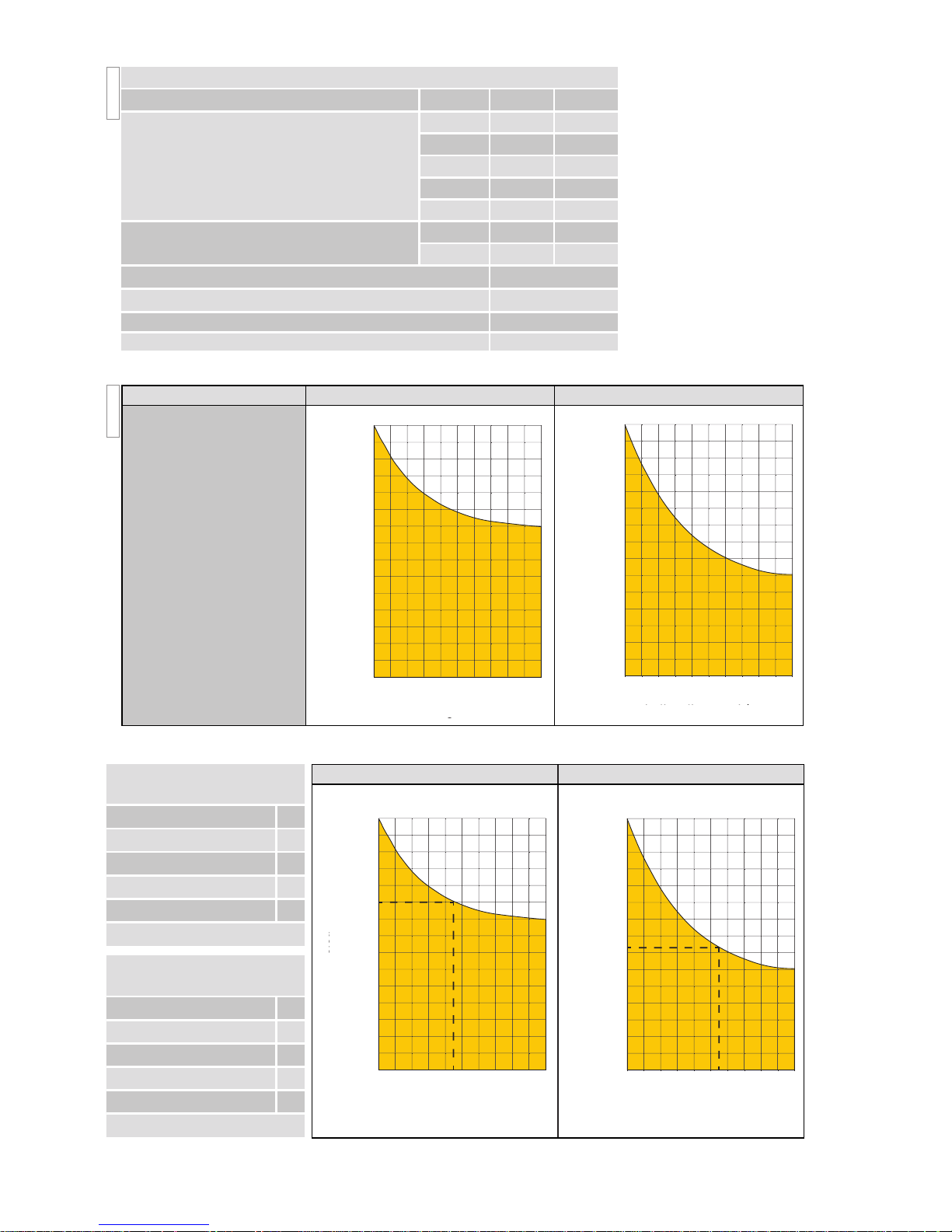

PWR25H PWR35H

Durability of the product

0

102030

405060

70

80

90

100

0

10.000

indice di gravosità

20.000

30.000

40.000

50.000

60.000

70.000

80.000

90.000

100.000

110.000

120.000

130.000

140.000

150.000

cicli

0

102030

405060

70

80

90

100

0

20.000

indice di gravosità

40.000

60.000

80.000

100.000

120.000

140.000

160.000

180.000

200.000

220.000

240.000

260.000

280.000

300.000

cicli

PWR25H PWR35H

0

102030

405060

70

80

90

100

0

10.000

indice di gravosità

20.000

30.000

40.000

50.000

60.000

70.000

80.000

90.000

100.000

110.000

120.000

130.000

140.000

150.000

cicli

0

102030

405060

70

80

90

100

0

20.000

indice di gravosità

40.000

60.000

80.000

100.000

120.000

140.000

160.000

180.000

200.000

220.000

240.000

260.000

280.000

300.000

cicli

Severity index

PWR25H PWR35H

Wing weight

>150Kg 10 >200Kg 20 >300Kg 30 10

>400Kg - 20

>500Kg - 30

Wing width

>2m 20 10

>3m - 20

Solid wing 15

Windy area 15

Speed setting VA/VC/PO/PC over the default values 10

Force setting R1/R2 over the default values 10

Tab. 3.1Tab. 3.2

Two examples of the operator durability calculation are shown below:

The durability of the

product is influenced by

the severity index:

with reference to Tab. 3.1,

according to the type of

piston, the weight and

the width of the wing

and the use conditions,

different corrective factors were estimated, the

sum of which influence

the operator durability

(see Tab. 3.2).

Example of the duration

calculation for PWR25H

Wing weight >150 Kg 10

Wing width >2m 20

R1/R2>default 0

Windy area 15

Total severity index 45

Estimated duration 100,000 cycles

Example of the duration

calculation for PWR35H

Wing weight >300 Kg 10

Wing width >3m 20

R1/R2>default 10

Windy area 15

Total severity index 55

Estimated duration 148,000 cycles

Severity index

Severity index

cycles

cycles

Severity index Severity index

cycles

cycles

Page 7

31

IP2250EN - 2016-12-02

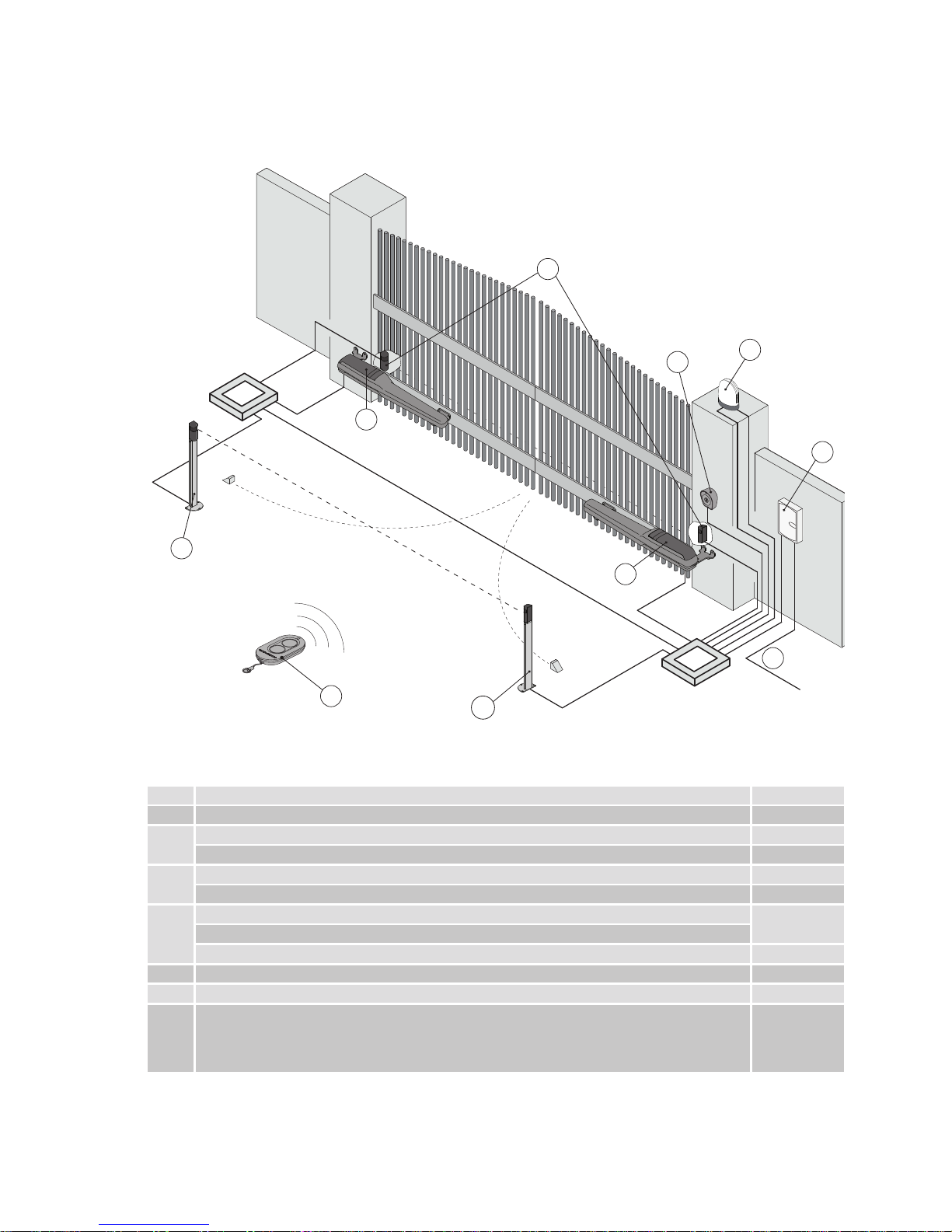

4. Standard installation

Ref. Description Cable

1 Transmitter /

2

Flashing light 2 x 1 mm²

Antenna (integrated into the flashing light) coaxial 58 Ω

3

Key selector switch 4 x 0.5 mm²

Digital combination wireless keypad /

4

Actuator PWR25H

2 x 1.5 mm²

Actuator PWR35H

Actuator PWR35H with magnetic limit switches 3 x 1.5 mm²

5 Photocells 4 x 0.5 mm²

6 Control panel 3G x 1.5 mm²

A

Connect the power supply to a type-approved omnipolar switch, with a contact opening

distance of at least 3mm (not supplied).

The connection to the mains must follow an independent path, separate from the

connections to the control and safety devices.

1

4

6

A

3

2

5

5

4

5

Page 8

32

IP2250EN - 2016-12-02

5. Gearmotor dimensions and references

Ref. Description

7 Rear cover

8 Release lock hatch

9 Cover fastening screw

10 Release key

11 Release pin

12 Front cover

107100

LT

R

8

11

9

10

7

8

12

11

7

9

10

Model L R

PWR25H 820 350

PWR35H 970 450

PWR25H

PWR35H

Fig. 5.1

Fig. 5.2

Page 9

33

IP2250EN - 2016-12-02

6.1 Preliminary checks

6. Installation

The declared operating and performance features can only be guaranteed with the use of ENTREMATIC accessories and safety devices.

Unless otherwise specified, all measurements are expressed in mm.

Check that the structure of the gate is sturdy and that the hinges are lubricated and function smoothly.

If possible, provide an opening and closing stop, otherwise use the integrated mechanical stops

and/or the electric limit switch (optional) if available. The mechanical parts must be in accordance

with the provisions of the EN12604 standard.

The installation measurements indicated in the table allow to choose the values of [A] and [B] on

the basis of the desired opening angle and in relation to the on site spaces and overall dimensions.

Increasing measurement [A], you reduce the opening approach speed.

Reducing measurement [B], you increase the degrees of gate opening.

Measurements [A] and [B] must, however, be compatible with the effective stroke of the piston.

A

P

D

E

L

B

S

C

min 60 con apertura a 90°

ABCSDELP min

PWR25H

90 160 50 110 95°

90 700

110

110 160 50 110 100° 120

150 130 50 80 110° 160

130 150 70 80 90° 140

110 180 100 80 90° 120

100 190 110 80 90° 110

PWR35H

90 190 50 140 95°

110 850

100

130 190 50 140 100° 140

150 190 50 140 110° 160

130 180 70 110 90° 140

130 210 100 110 90° 140

110 260 150 110 90° 120

100 280 200 80 90° 110

Tab. 6.1

i

The fixing point of the automation varies depending on the space available and the gate to

be automated, therefore it is up to the installer to choose each time the best solution to

ensure the correct operation of the system.

min. 60 with 90° opening

Page 10

34

IP2250EN - 2016-12-02

After choosing the most suitable fastening point for the front bracket [14] to the gate wing, to determine the height position, proceed with the sizing, positioning and fixing of the rear bracket [13].

If necessary, shorten the rear bracket [13] following measurement (S) in Tab. 6.1.

- Once you have fastened the rear bracket [13] following the measurements indicated on page

10, fasten the front bracket [14] to the gate.

- With the gate completely closed, position the front bracket [14], in accordance with measurement (L). Check that the front bracket [13] and rear bracket [14] are properly levelled as

shown in the following figures and fasten the front bracket [13] to the gate.

NB: If necessary, the front bracket [14] can be rotated and fixed as shown in figures [B], in this

way the operator position will be higher by about 40 mm.

6.2 Bracket fastening

L

13

43

14

L

13

87

14

PWR25H

2xØ9

90

38

112

70

Ø17,2

90

50

155

72

80 (S)

110 (S)

100

140 (S)

70

3xØ9

3xØ14

A

B

i

Configuration [A] is the one recommended for a greater mechanical resistance.

Page 11

35

IP2250EN - 2016-12-02

The positioning of the brackets can be greatly simplified by using the positioning template (optional

accessory), which allows to establish with certainty the fixing positions and distances of a bracket

with respect to the other during installation. In this way positioning errors and incorrect alignment

of the fixing holes are avoided thanks to the level integrated in the template.

The installation template is compatible with all pistons of the PWR, Obbi and Luxo series.

6.3 Positioning template usage

4xØ9

49

110

132

80

47

100

Ø17,2

50

155

72

80 (S)

110 (S)

100

140 (S)

70

3xØ9

3xØ14

PWR35H

L

13

43

14

L

13

87

14

A

B

Page 12

36

IP2250EN - 2016-12-02

6.4 Gearmotor installation

• Open the release lock hatch [8], loosen the screw [9] and remove the rear cover [7].

• Release the piston by inserting the key [10] in the appropriate pin [11] and turn it counter-clock-

wise as indicated by the arrow.

• Insert the rear bushing [18] into the hole of the rear bracket [13] and lubricate the pivot points.

• Fix the piston to the rear bracket, fully tightening the M8x45 screw [19] to nut [20].

• Open the wing manually and insert the front mounting pin [15] into the hole of the front fastening

bracket [14]; block the pin in the bracket using the washer [16] and the M8x16 screw [17] supplied.

• Moving the gate manually, check that the entire stroke takes place without interference.

8

9

7

10

13

20

11

18

19

15

14

16

17

Page 13

37

IP2250EN - 2016-12-02

4 mm

4 mm

180°

6.5 Adjusting the mechanical end stops

The mechanical end stops are adjusted in steps of 4mm.

Example: GATE WING STOP at stroke [R] = 340 – 344 – 348mm, etc.

If the stopping point of the gate wing does not coincide with the required position, remove the

mechanical end stop and rotate it 180° before replacing it in the toothed guide (as shown in the

figure below).

In this way, the mechanical end stops are still adjusted in 4mm steps, but at points differentiated

by 2mm.

Example: GATE WING STOP at stroke [R] = 338 – 342 – 346mm, etc.

Page 14

38

IP2250EN - 2016-12-02

6.6. Electrical connections

The PWR25H and PWR35H gear-motors can be connected to control panels LCU30 and LCU40.

To connect the automation to the control panel, proceed as follows:

• Remove the rear cover [9] as shown in paragraph 6.4;

• Fit the cable gland on the automation, securing it with the nut inserted in the hole in the casting

(Fig. 6.1 and 6.2), then insert the connecting cables (Fig. 6.3);

• Connect the various wires as shown in the wiring diagram in Fig. 6.4;

• Secure the rear cover [9] to the gearmotor.

The electrical wiring and start-up of the gear-motors PWR25H and PWR35H are shown in the

installation manuals of control panels LCU30 and LCU40.

A flexible corrugated Ø16 pipe and related Ø20 fitting (not supplied) can be used to increase protection of the motor cable.

Fig. 6.1

Fig. 6.2

Fig. 6.3

LN

33 32

31

36 35

34

Alimentazione

230V

~ - 50/60 Hz

24V 24V

Motoriduttore 24V con

ritardo in apertura

33/36 32/35 31/34

Motoriduttore 24V con

Quadro elettronico

ritardo in chiusura

33/36 32/35 31/34

M2

M1

M1

M2

Fig. 6.4

24V gearmotor with

opening delay

24V gearmotor with

closing delay

Control Panel

Power

Page 15

39

IP2250EN - 2016-12-02

• Loosen the sensor support screws, adjust the opening and closing position of the sensors using

the notches as a guide, and tighten the screws.

• Secure the cables to the appropriate supports using cable straps.

See the instructions attached to the limit switch kit for additional information.

6.7 Magnetic limit switches adjustment (PWR35H only)

The front cover must be removed for the maintenance, adjustment and/or installation of the

magnetic limit switches:

• Loosen screw [11], slide the cover [12] forward and lift the front of it.

12

11

Fig. 6.5

Fig. 6.6

Page 16

40

IP2250EN - 2016-12-02

Perform the following operations and checks every 6 months or based on the intensity of use of

the automation.

Disconnect the 230 V~ power supply and batteries (if present):

- Clean and lubricate the gate's rotation pins, hinges and drive screws with neutral grease.

- Check the resistance of the fixing points.

- Check the electrical wiring is in good condition.

Reconnect the 230V~ power supply and batteries (if present):

- Check the power adjustment.

- Check that all commands and safety functions (photocells) are operating correctly.

- Check that the release system is working correctly.

- Test the batteries (in continuity) if present, disconnecting power and performing a few manoeuvres

in succession. Once performed, turn on the 230 V~ power supply again.

7 . Routine maintenance plan

7.2 Maintenance every 12 months or 20,000 cycles (PWR35H only)

- Lubrication of the reducer gears and motor worm screw:

insert lubricant using a manual greaser, connecting it to the specific filler valve (model NIP DIN

71412A-M6) inside the manual release compartment [Fig. 7.1].

Amount of grease to be inserted (5ml) = (8-10g).

- Lubrication of the drive screw and split nut / nut screw:

remove the plastic front cover [see par. 6.7] and spread the lubricant on the upper visible part of

the drive screw [Fig. 7.2].

Approx. amount of grease to be used (5ml) = (8-10g).

Fig. 7.1

Recommended grease: type EP1.

i

Fig. 7.2

7.1 Maintenance every 6 months or 10,000 cycles

Page 17

41

IP2250EN - 2016-12-02

The packaging components (cardboard, plastic, etc.) should be disposed through the

separate collection for recycling. Before proceeding however, check the local regulations

regarding disposal.

The packaging materials should not be discarded in the environment or left within reach of

children, as they are a potential source of danger.

To dispose of electrical and electronic equipment, batteries and storage cells correctly,

users must take the product to special "recycling centres" provided by the municipal authorities

for disposal according to the methods envisaged by current legislation.

NB: for spare parts, see the spares price list.

8 . Troubleshooting

i

Problem Possible cause Operation

The gate doesn't

open or close.

No power supply. Check that the mains power supply is

present.

Gearmotor released. See release instructions.

Photocells interrupted. Check that the photocells are clean and

operating correctly.

Permanent stop command. Check the stop command or control

panel.

Faulty selector. Check the selector or control panel.

Faulty remote control Check the condition of the batteries.

Electric lock not working Check the positioning and proper oper-

ation of the lock.

The gate opens but

doesn't close.

Photocells interrupted. Check that the photocells are clean and

operating correctly.

9 . Disposal

Page 18

42

IP2250EN - 2016-12-02

Page 19

43

IP2250EN - 2016-12-02

Operating instructions

General safety precautions

These precautions are an integral and essential part of the product and

must be supplied to the user.

Read them carefully since they contain important information on safe installation, use and maintenance.

These instructions must be kept and forwarded to all possible future users

of the system.

This product must only be used for the specific purpose for which it was

designed.

Any other use is to be considered improper and therefore dangerous. The

manufacturer cannot be held responsible for any damage caused by improper, incorrect or unreasonable use.

Avoid operating in the proximity of the hinges or moving mechanical parts.

Do not enter within the operating range of the motorised door or gate while

it is moving.

Do not obstruct the motion of the motorised door or gate, as this may cause

a dangerous situation.

The motorised door or gate may be used by children over the age of 8 and

by people with reduced physical, sensorial or mental abilities, or lack of

experience or knowledge, as long as they are properly supervised or have

been instructed in the safe use of the device and the relative hazards.

Children must be supervised to make sure they do not play with the device,

nor play/remain in the sphere of action of the motorised door or gate.

Keep remote controls and/or any other command devices out of the reach

of children, to avoid any accidental activation of the motorised door or gate.

In the event of a product fault or malfunction, turn off the power supply

switch. Do not attempt to repair or intervene directly, and contact only

qualified personnel.

Failure to comply with the above may cause a dangerous situation.

Any repairs or technical interventions must be carried out by qualified

DETACH AND DELIVER TO THE CUSTOMER

Page 20

44

IP2250EN - 2016-12-02

DETACH AND DELIVER TO THE CUSTOMER

For any problems and/or information, contact the Technical Service.

Manual release instructions

In the event of failure or lack of voltage, open the hatch (8), insert the key (10) in the pin (11) and

rotate counter-clockwise, as indicated by the arrow.

If present, release any electric lock. Manually open the gate.

Turn the key clockwise to lock the wings.

WARNING: Only lock and release the door wings when the motor is switched off.

All the rights concerning this material are the exclusive property of Entrematic Group AB.

Although the contents of this publication have been drawn up with the greatest care, Entrematic Group AB

cannot be held responsible in any way for any damage caused by mistakes or omissions. We reserve the

right to make changes without prior notice.

Copying, scanning or changing in any way is expressly forbidden unless authorised in writing by Entrematic

Group AB.

8

10

11

personnel.

Cleaning and maintenance work must not be carried out by children unless

they are supervised.

To ensure that the system works efficiently and correctly, the manufacturer’s indications must be complied with and only qualified personnel must

perform routine maintenance on the motorised door or gate. In particular,

regular checks are recommended in order to verify that the safety devices

are operating correctly.

All installation, maintenance and repair work must be documented and

made available to the user.

Only lock and release the door wings when the motor is switched off. Do not

enter within the operating range of the wing.

Page 21

45

IP2250EN - 2016-12-02

DETACH AND DELIVER TO THE CUSTOMER

Installer's stamp Operator

Date of intervention

Technician's signature

Customer's signature

Intervention performed

Page 22

IP2250EN - 2016-12-02

Entrematic Group AB

Lodjursgatan 10

SE-261 44, Landskrona

Sweden

www.entrematic.com

Loading...

Loading...