Page 1

Sliding Door Operator

Entrematic PSL Retrofit Kit

Installation Manual

Original instructions

1018482-EMen-2.0 – Issue 2019-07-13

Page 2

© All rights in and to this material are the sole property of Entrematic Group AB. Copying, scanning, alterations or modifications are

expressly forbidden without the prior written consent of Entrematic Group AB. Rights reserved for changes without prior notice.

Backtrack information: folder:Workspace Main, version:a546, Date:2019-07-13 time:03:00:15, state: Frozen

Page 3

CONTENTS - Original instructions

51 Tools required ..........................................................................................................................................................................

62 Mechanical installation ........................................................................................................................................................

62.1 Entrematic PSL Retrofit Kit for universal bracket solutions ............................................................................................

62.1.1 Check the components and kits ..............................................................................................................................

142.1.2 I/O board and the battery installation (option) .................................................................................................

142.1.3 Fix the brackets to the backbone assembly .........................................................................................................

182.1.4 Fix the brackets to the tension wheel ....................................................................................................................

182.1.5 Fix the brackets to the belt lock (option) .............................................................................................................

192.1.6 Fix the transmission bracket to the connecting bracket .................................................................................

192.1.7 Attachment of slack reducer ....................................................................................................................................

202.1.8 General rules of the installation ..............................................................................................................................

212.1.9 List of the adapted door types .................................................................................................................................

232.1.10 Adapted door types .....................................................................................................................................................

232.1.10.1 ATS CLIXMASTER .......................................................................................................................................

242.1.10.2 ATS TSF 2100 ..............................................................................................................................................

252.1.10.3 Baumgartner Al-Profil .............................................................................................................................

262.1.10.4 Baumgartner steel ...................................................................................................................................

272.1.10.5 DORMA ES 50 ............................................................................................................................................

282.1.10.6 DORMA ES 55/60 ......................................................................................................................................

292.1.10.7 DORMA ES 70 ............................................................................................................................................

302.1.10.8 DORMA ES 90/100 ...................................................................................................................................

312.1.10.9 DORMA ES 200 ..........................................................................................................................................

322.1.10.10 ELDEBE GSX ................................................................................................................................................

332.1.10.11 EMD ...............................................................................................................................................................

342.1.10.12 EMC ...............................................................................................................................................................

352.1.10.13 Faiveley 6 .....................................................................................................................................................

362.1.10.14 Faiveley 12 ..................................................................................................................................................

372.1.10.15 Faiveley 17 ..................................................................................................................................................

382.1.10.16 GEZE ECdrive ..............................................................................................................................................

392.1.10.17 GEZE TSA 340 .............................................................................................................................................

402.1.10.18 GEZE TSA 350 N/350 W ..........................................................................................................................

412.1.10.19 GEZE TSA 360 .............................................................................................................................................

422.1.10.20 GEZE TSA 450 .............................................................................................................................................

432.1.10.21 Gilgen SLK/SLG ..........................................................................................................................................

442.1.10.22 Gilgen SLM/SLP ..........................................................................................................................................

452.1.10.23 HORTON Series 2001 ..............................................................................................................................

462.1.10.24 Manusa PA 80 ............................................................................................................................................

472.1.10.25 Manusa STK ................................................................................................................................................

482.1.10.26 Manusa Visio ..............................................................................................................................................

492.1.10.27 Portalp 2000B ............................................................................................................................................

502.1.10.28 Porte Automatiche GTS-L/-P .................................................................................................................

512.1.10.29 Porte Automatiche GTV .........................................................................................................................

522.1.10.30 Record STA7 ...............................................................................................................................................

532.1.10.31 Record STA8 ...............................................................................................................................................

542.1.10.32 Record STA9/STA10 .................................................................................................................................

552.1.10.33 Record STA11 ............................................................................................................................................

562.1.10.34 Record STA12/STA14 Steel ....................................................................................................................

572.1.10.35 Record STA12/STA14 AL .........................................................................................................................

582.1.10.36 Record STA13 ............................................................................................................................................

592.1.10.37 Record STA15 ............................................................................................................................................

602.1.10.38 Record STA16/17 ......................................................................................................................................

612.1.10.39 Record STA19 ............................................................................................................................................

622.1.10.40 Record STA20 ............................................................................................................................................

632.1.10.41 Record STA21 ............................................................................................................................................

642.1.10.42 Tormax TMP ................................................................................................................................................

652.1.10.43 Tormax TX/TM/TMX .................................................................................................................................

662.1.10.44 Tormax TEP/TXP ........................................................................................................................................

672.1.10.45 Waldoor EC .................................................................................................................................................

682.1.10.46 Waldoor UC ................................................................................................................................................

692.1.10.47 Waldoor UWS 800 ...................................................................................................................................

702.1.10.48 Waldoor UWS 2400 .................................................................................................................................

3Issue 2019-07-131018482-EMen-2.0

Page 4

712.1.10.49 Ditec VALOR (escape route) .................................................................................................................

722.1.10.50 Ditec Bis O ..................................................................................................................................................

732.1.10.51 Ditec Bis V ...................................................................................................................................................

742.2 Entrematic PSL Retrofit Kit for TORMAX iMotion 2202 ...................................................................................................

742.2.1 Check the components ..............................................................................................................................................

752.2.2 Preparing .........................................................................................................................................................................

762.2.3 I/O board and the battery installation (option) .................................................................................................

772.2.4 Fix the nuts and screws on the drive unit kit and the main control assembly .........................................

812.2.5 Fix the drive unit kit and the main control assembly .......................................................................................

822.2.6 Fix the tension wheel assembly ...............................................................................................................................

832.2.7 Fix the transmission brackets ...................................................................................................................................

842.2.8 Placement of the transmission brackets ...............................................................................................................

852.2.9 Attachment of the tooth belt ...................................................................................................................................

862.2.10 Checking and adjusting the belt tension ..............................................................................................................

872.2.11 Bi-parting operators ....................................................................................................................................................

872.2.12 Attachment of slack reducer ....................................................................................................................................

882.2.13 Install the belt lock (option) .....................................................................................................................................

892.3 Entrematic PSL Retrofit Kit for GEZE Slimdrive ...................................................................................................................

892.3.1 Check the components ..............................................................................................................................................

902.3.2 Preparing .........................................................................................................................................................................

912.3.3 Exchange the extension beams ...............................................................................................................................

922.3.4 Fix the PSU (power supply unit) and drive unit kit ............................................................................................

952.3.5 Fix the mounting plate and MCU (control unit) ................................................................................................

962.3.6 I/O board and the battery installation (option) .................................................................................................

972.3.7 Fix the tension wheel assembly ...............................................................................................................................

982.3.8 Fix the transmission brackets ...................................................................................................................................

992.3.9 Placement of the transmission brackets ...............................................................................................................

1002.3.10 Attachment of the tooth belt ...................................................................................................................................

1012.3.11 Checking and adjusting the belt tension ..............................................................................................................

1022.3.12 Bi-parting operators ....................................................................................................................................................

1022.3.13 Attachment of slack reducer ....................................................................................................................................

1032.3.14 Install the belt lock (option) .....................................................................................................................................

1042.3.15 Fix the cable bracket ....................................................................................................................................................

1052.4 Entrematic PSL Retrofit Kit for Entrematic EMSL .................................................................................................................

1052.4.1 Check the components ..............................................................................................................................................

1062.4.2 Preparing .........................................................................................................................................................................

1072.4.3 Fix the backbone assembly ........................................................................................................................................

1082.4.4 Fix the I/O board and the battery (option) ..........................................................................................................

1102.4.5 Fix the tension wheel assembly ...............................................................................................................................

1112.4.6 Fix the connector brackets ........................................................................................................................................

1122.4.7 Placement of the transmission brackets ...............................................................................................................

1132.4.8 Attachment of the tooth belt ...................................................................................................................................

1142.4.9 Checking and adjusting the belt tension ..............................................................................................................

1152.4.10 Bi-parting operators ....................................................................................................................................................

1152.4.11 Attachment of slack reducer ....................................................................................................................................

1162.5 Entrematic PSL Retrofit Kit for Entrematic EMSL-T .............................................................................................................

1162.5.1 Check the components ..............................................................................................................................................

1172.5.2 Preparing .........................................................................................................................................................................

1182.5.3 Fix the backbone assembly ........................................................................................................................................

1192.5.4 Fix the I/O board and the battery (option) ..........................................................................................................

1202.5.5 Fix the tension wheel assembly ...............................................................................................................................

1212.5.6 Fix the connector brackets (for fast door leaves) ..............................................................................................

1222.5.7 Placement of the transmission brackets (for fast door leaves) .....................................................................

1232.5.8 Attachment of the tooth belt (for fast door leaves) .........................................................................................

1242.5.9 Checking and adjusting the belt tension (for fast door leaves) ....................................................................

1252.5.10 Bi-parting operators (for fast door leaves) ..........................................................................................................

1252.5.11 Attachment of slack reducer ....................................................................................................................................

1018482-EMen-2.0Issue 2019-07-134

Page 5

1 Tools required

• Allen key 6 mm with spherical tip

• Torx (T10 and T20)

• Phillips screw driver

• Multi/Wire cutter

• Spanner 10mm

• Tape measuring tool

1 Tools required

5Issue 2019-07-131018482-EMen-2.0

Page 6

2 Mechanical installation

2 Mechanical installation

2.1 Entrematic PSL Retrofit Kit for universal bracket solutions

Note! Following are the common steps for connecting components, please refer to cross-view for

each adapted door type.

2.1.1 Check the components and kits

Check the components (Universal)

Screw: ISO 14583 (MRT-TT) M6x10 FZB 8.84

Screw: DIN 6921 (M6SF) M6x8 FZB 8.811

Backbone assembly12

Slack reducer (Not needed if belt lock

13

equipped)

Washer: ISO 7089 (BRB) 6.4x12x1.5 FZB14

Tension wheel assembly15

Tooth belt18

Belt clamp20

Connecting bracket24

Transmission bracket26

Mounting bracket28

1018482-EMen-2.0Issue 2019-07-136

Page 7

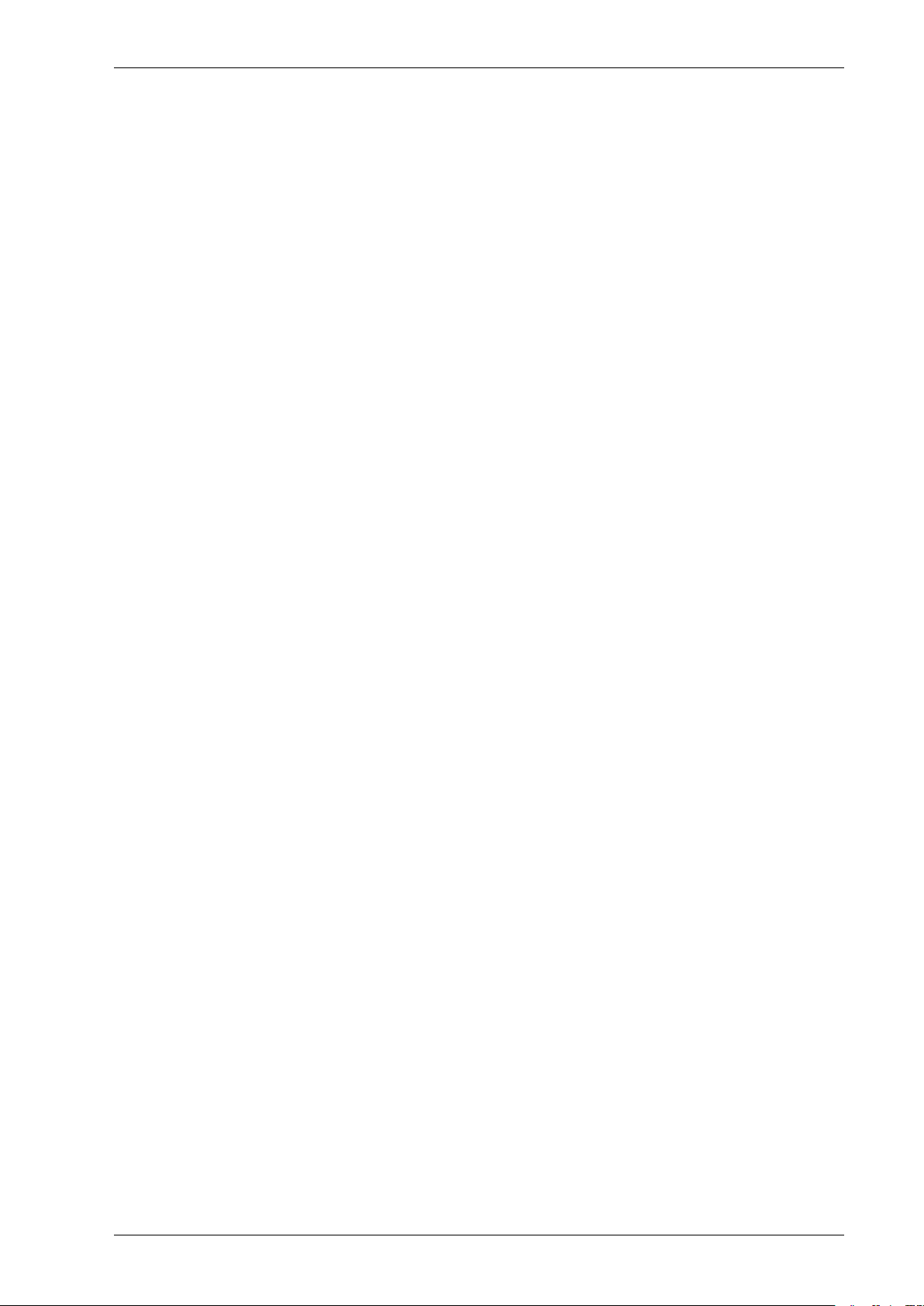

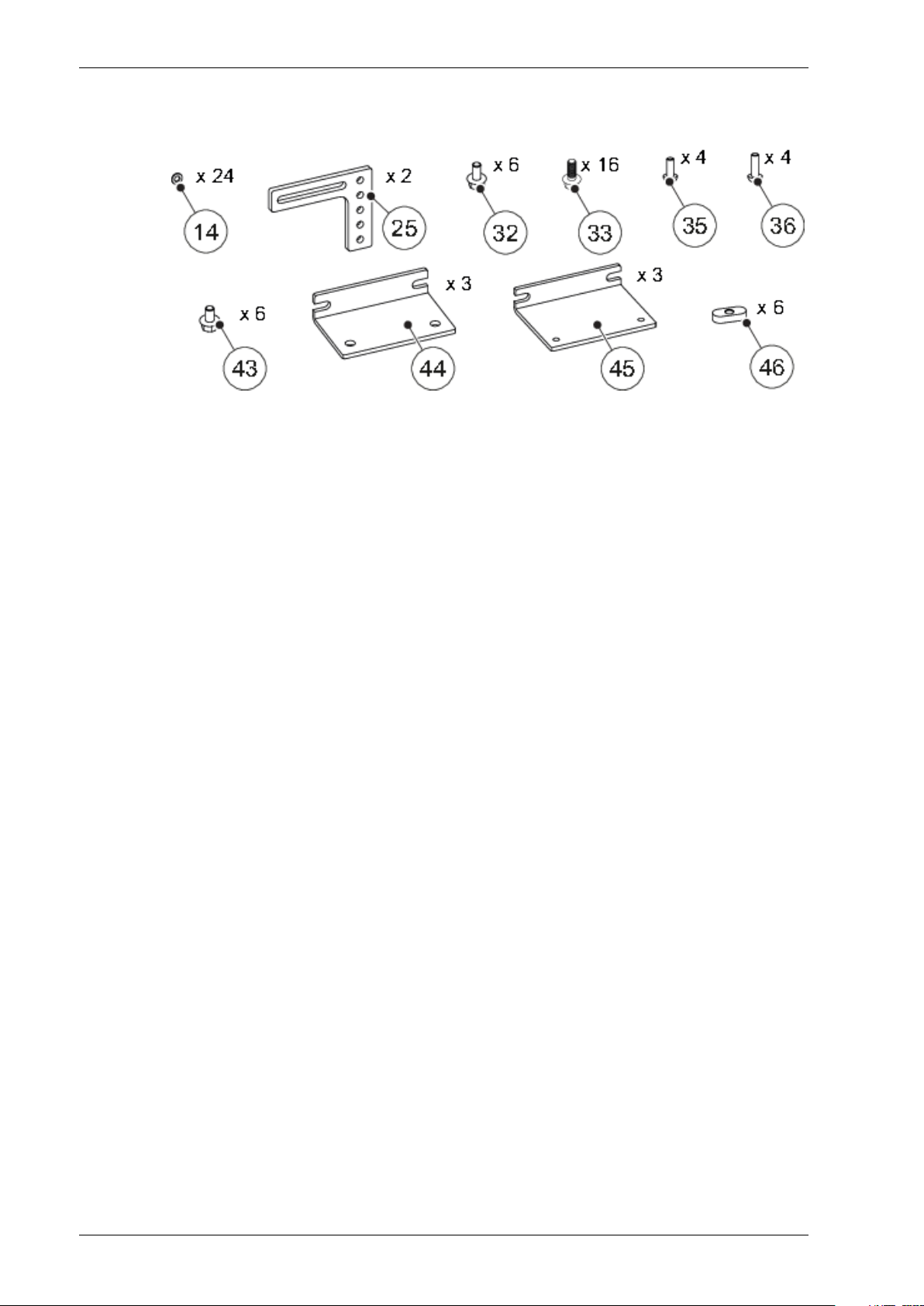

Check B1 kit

2 Mechanical installation

Washer: ISO 7089 (BRB) 6.4x12x1.5 FZB14

Bracket 125

Mounting plate27

Square nut: M629

Nut: M630

Nut: ISO 4035 (ML6M) M6 FZB31

Screw: DIN 6921 (M6SF) M6x12 FZB 8.832

Screw: DIN 6921 (M6SF) M6x14 FZB 8.833

Screw: DIN 6921 (M6SF) M6x16 FZB 8.834

Screw: ISO 14583 (MRT-TT) M6x16 FZB 8.835

Screw: ISO 14583 (MRT-TT) M6x20 FZB 8.836

Screw: ISO 14583 (MRT-TT) M6x25 FZB 8.837

Screw: ISO 14583 (MRT-TT) M6x35 FZB 8.838

7Issue 2019-07-131018482-EMen-2.0

Page 8

2 Mechanical installation

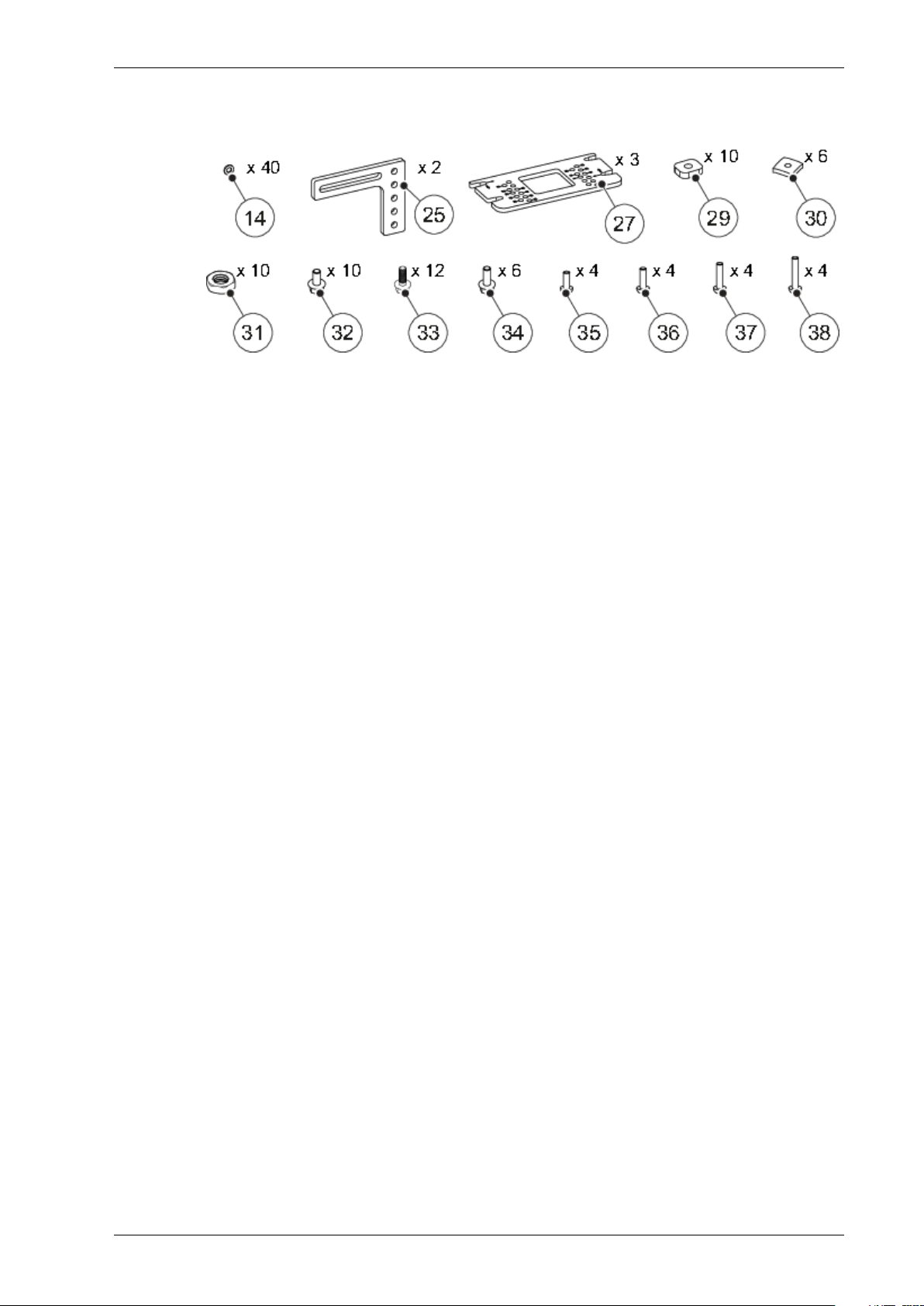

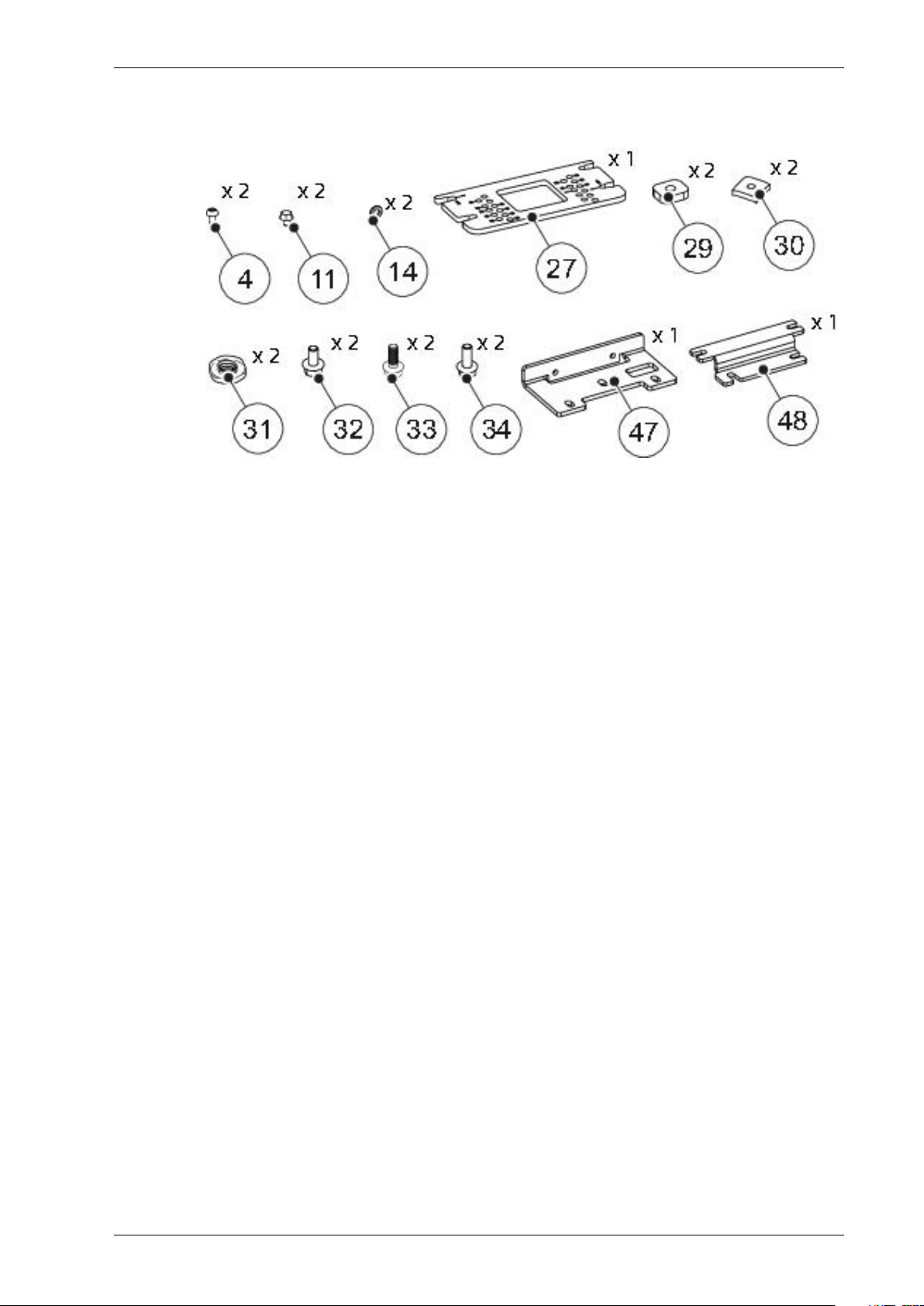

Check B2 kit

Washer: ISO 7089 (BRB) 6.4x12x1.5 FZB14

Bracket 125

Mounting plate27

Screw: DIN 6921 (M6SF) M6x12 FZB 8.832

Screw: DIN 6921 (M6SF) M6x14 FZB 8.833

Screw: DIN 6921 (M6SF) M6x16 FZB 8.834

Screw: ISO 14583 (MRT-TT) M6x16 FZB 8.835

Bracket 240

1018482-EMen-2.0Issue 2019-07-138

Page 9

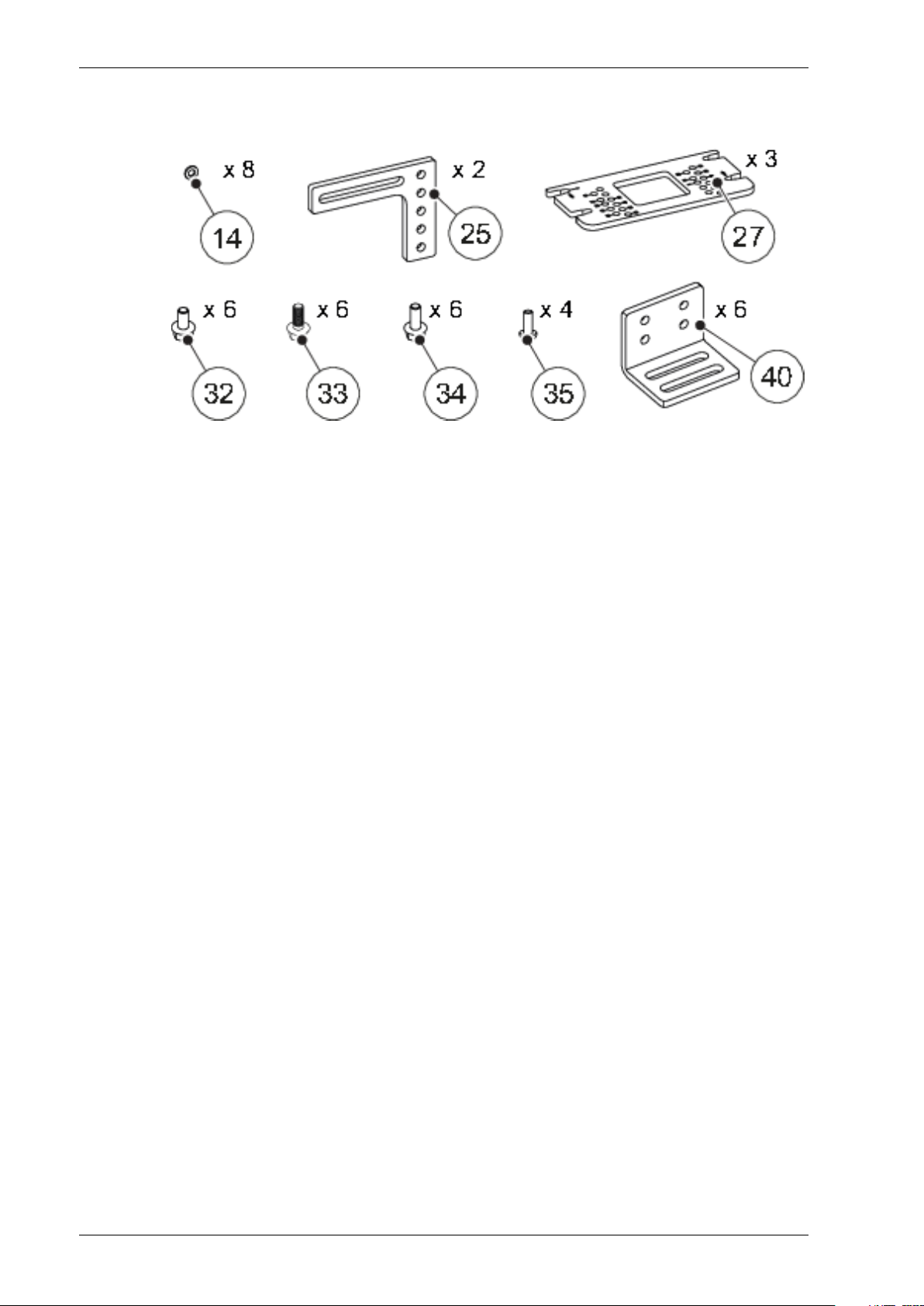

Check B3 kit

2 Mechanical installation

Washer: ISO 7089 (BRB) 6.4x12x1.5 FZB14

Mounting plate27

Square nut: M629

Screw: DIN 6921 (M6SF) M6x14 FZB 8.833

Screw: ISO 14583 (MRT-TT) M6x16 FZB 8.835

Screw: ISO 14583 (MRT-TT) M6x35 FZB 8.838

Bracket 341

Spacer block42

Screw: DIN 6921 (M6SF) M6x10 FZB 8.843

9Issue 2019-07-131018482-EMen-2.0

Page 10

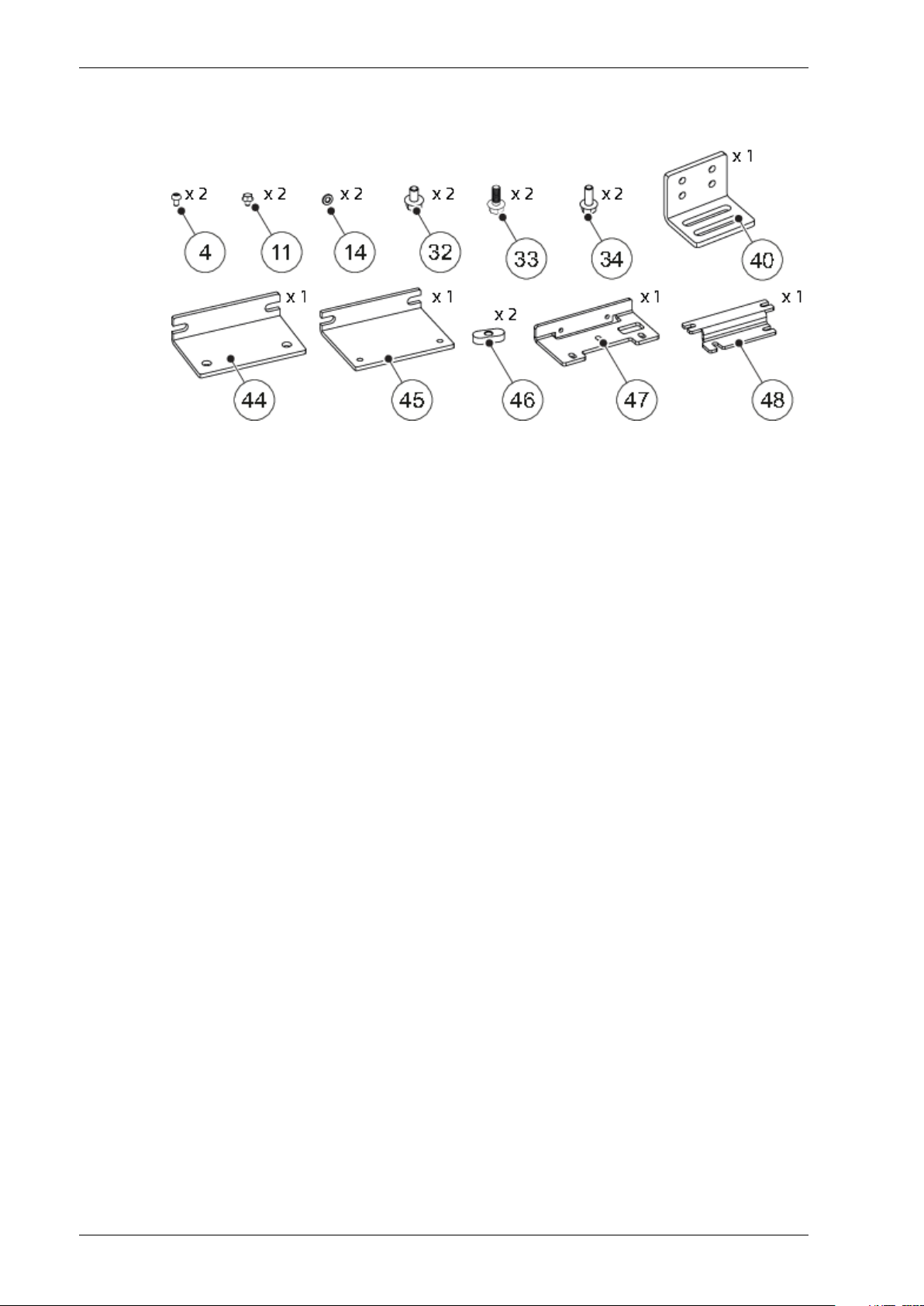

2 Mechanical installation

Check B4 kit

Washer: ISO 7089 (BRB) 6.4x12x1.5 FZB14

Bracket 125

Screw: DIN 6921 (M6SF) M6x12 FZB 8.832

Screw: DIN 6921 (M6SF) M6x14 FZB 8.833

Screw: ISO 14583 (MRT-TT) M6x16 FZB 8.835

Screw: ISO 14583 (MRT-TT) M6x20 FZB 8.836

Screw: DIN 6921 (M6SF) M6x10 FZB 8.843

Bracket 444

Bracket 545

Nut: M646

1018482-EMen-2.0Issue 2019-07-1310

Page 11

Check belt lock fixing bracket kit 1

2 Mechanical installation

Screw: ISO 14583 (MRT-TT) M6x10 FZB 8.84

Screw: DIN 6921 (M6SF) M6x8 FZB 8.811

Washer: ISO 7089 (BRB) 6.4x12x1.5 FZB14

Mounting plate27

Square nut: M629

Nut30

Nut: ISO 4035 (ML6M) M6 FZB31

Screw: DIN 6921 (M6SF) M6x12 FZB 8.832

Screw: DIN 6921 (M6SF) M6x14 FZB 8.833

Screw: DIN 6921 (M6SF) M6x16 FZB 8.834

Fixing bracket47

Mounting bracket48

11Issue 2019-07-131018482-EMen-2.0

Page 12

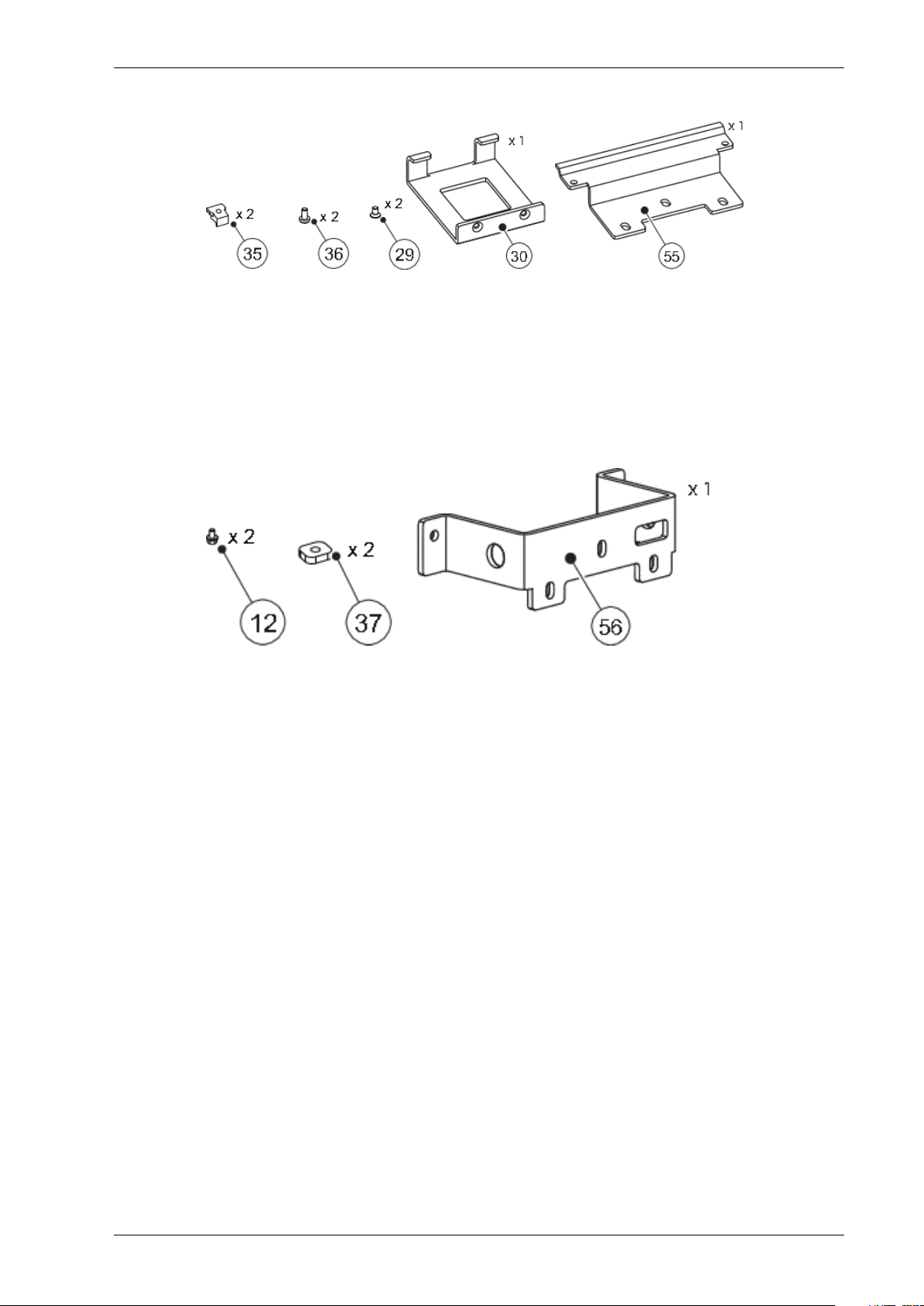

2 Mechanical installation

Check belt lock fixing bracket kit 2

Screw: ISO 14583 (MRT-TT) M6x10 FZB 8.84

Screw: DIN 6921 (M6SF) M6x8 FZB 8.811

Washer: ISO 7089 (BRB) 6.4x12x1.5 FZB14

Screw: DIN 6921 (M6SF) M6x14 FZB 8.833

Screw: DIN 6921 (M6SF) M6x16 FZB 8.834

Bracket 240

Screw: DIN 6921 (M6SF) M6x10 FZB 8.843

Bracket 444

Bracket 545

Nut: M646

Fixing bracket47

Mounting bracket48

1018482-EMen-2.0Issue 2019-07-1312

Page 13

2 Mechanical installation

Nut: M535

Screw: ISO 14583 (MRT) M5x10 FZB 8.836

Screw: ISO 7046 (MFTS) M3x5 FZB 8.829

Belt guide30

Fixing bracket (belt lock) TORMAX iMotion

55

2202

Screw: DIN 6921 (M6SF) M6x10 FZB 8.812

Square nut: M637

Fixing bracket (belt lock) GEZE Slimdrive56

13Issue 2019-07-131018482-EMen-2.0

Page 14

2 Mechanical installation

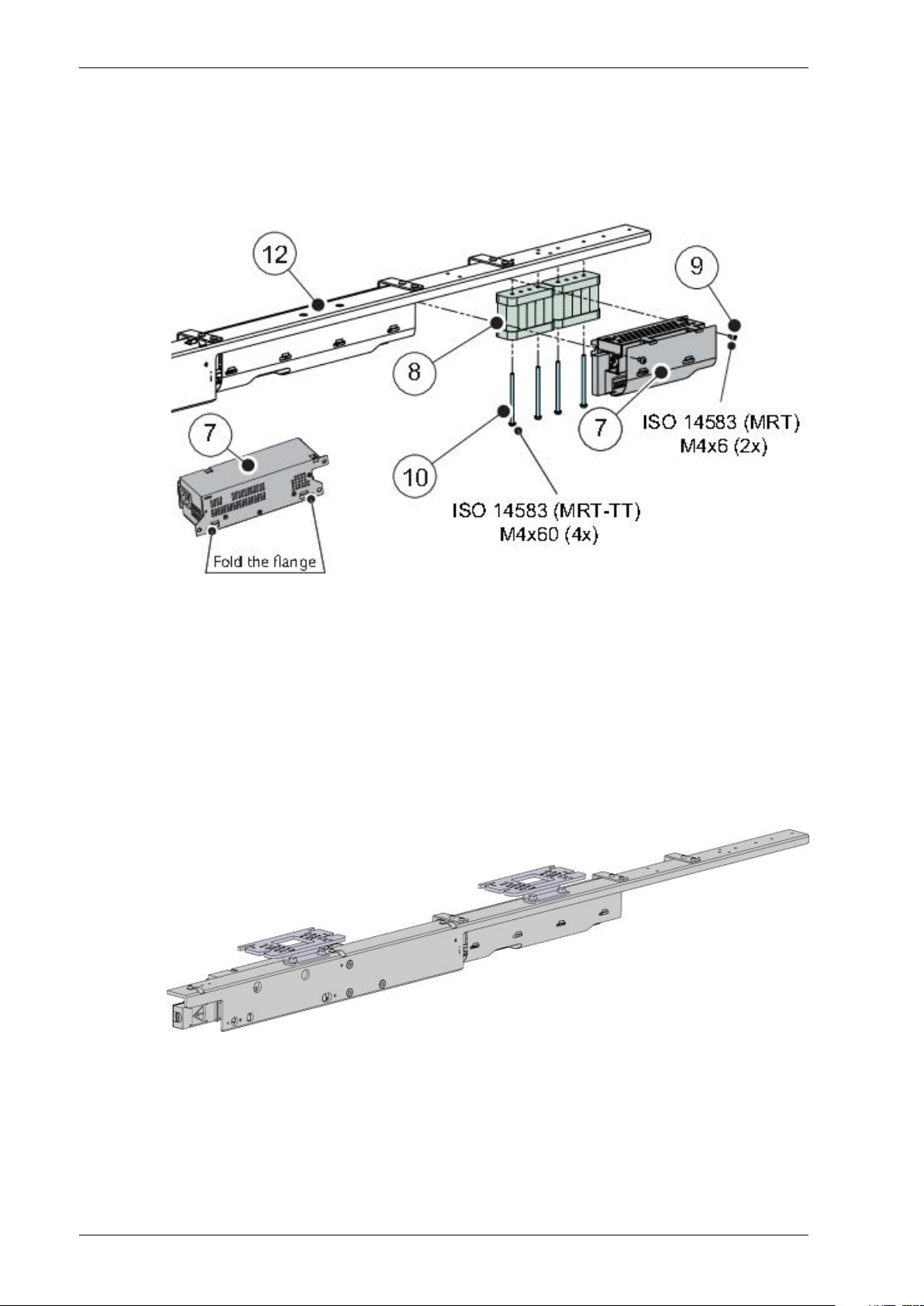

2.1.2 I/O board and the battery installation (option)

Note! I/O board must be selected when bi-stable.

Fix the I/O board (7) and the battery (8) to the backbone assembly (12) with the screws (9) and

(10).

2.1.3 Fix the brackets to the backbone assembly

Note! The brackets in the picture is only an example, please choose the suitable brackets for the

specified operator that shall be upgraded.

I/O board7

Battery8

Screw: ISO 14583 (MRT) M4x69

Screw: ISO 14583 (MRT-TT) M4x6010

Backbone assembly12

1018482-EMen-2.0Issue 2019-07-1314

Page 15

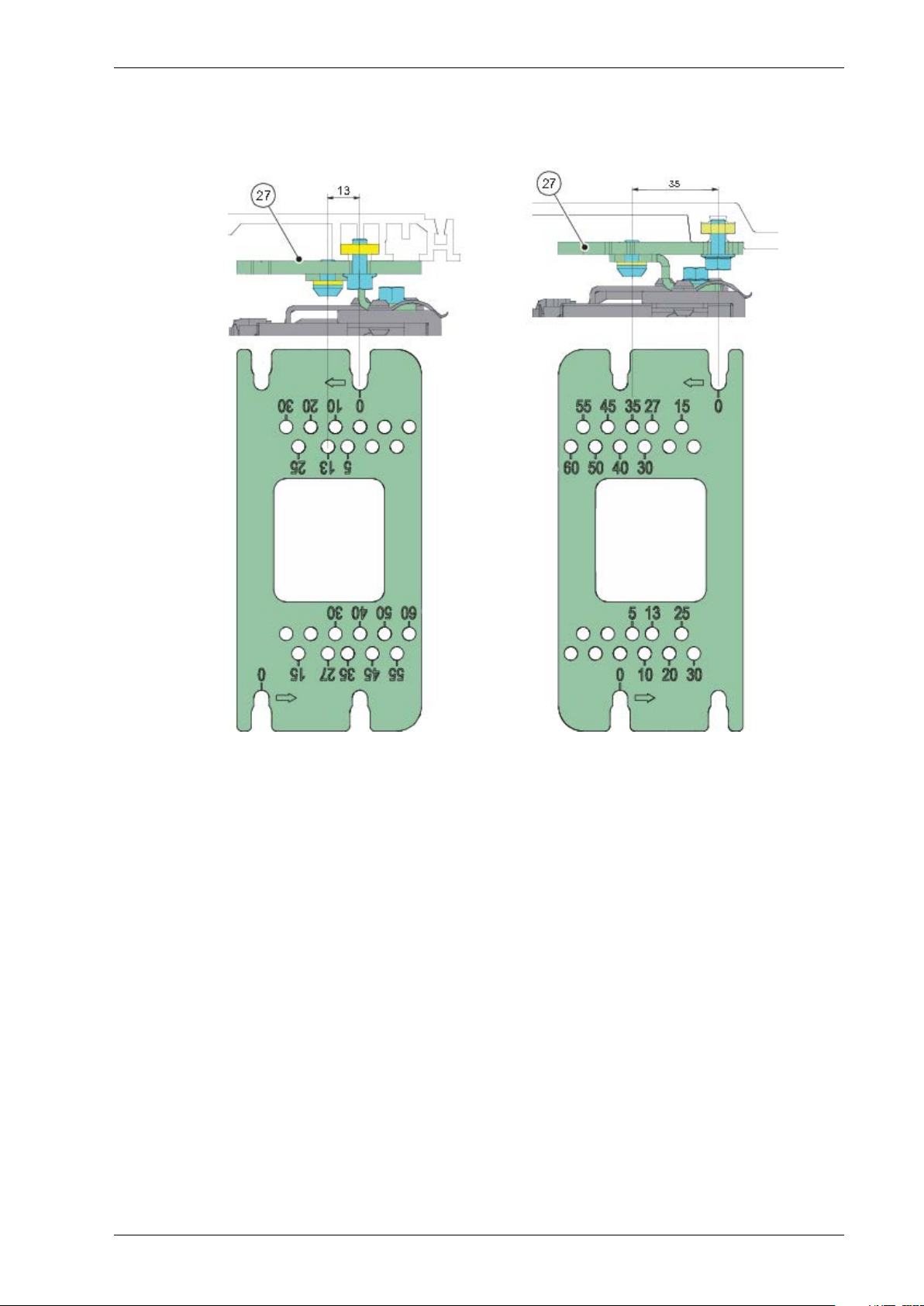

2 Mechanical installation

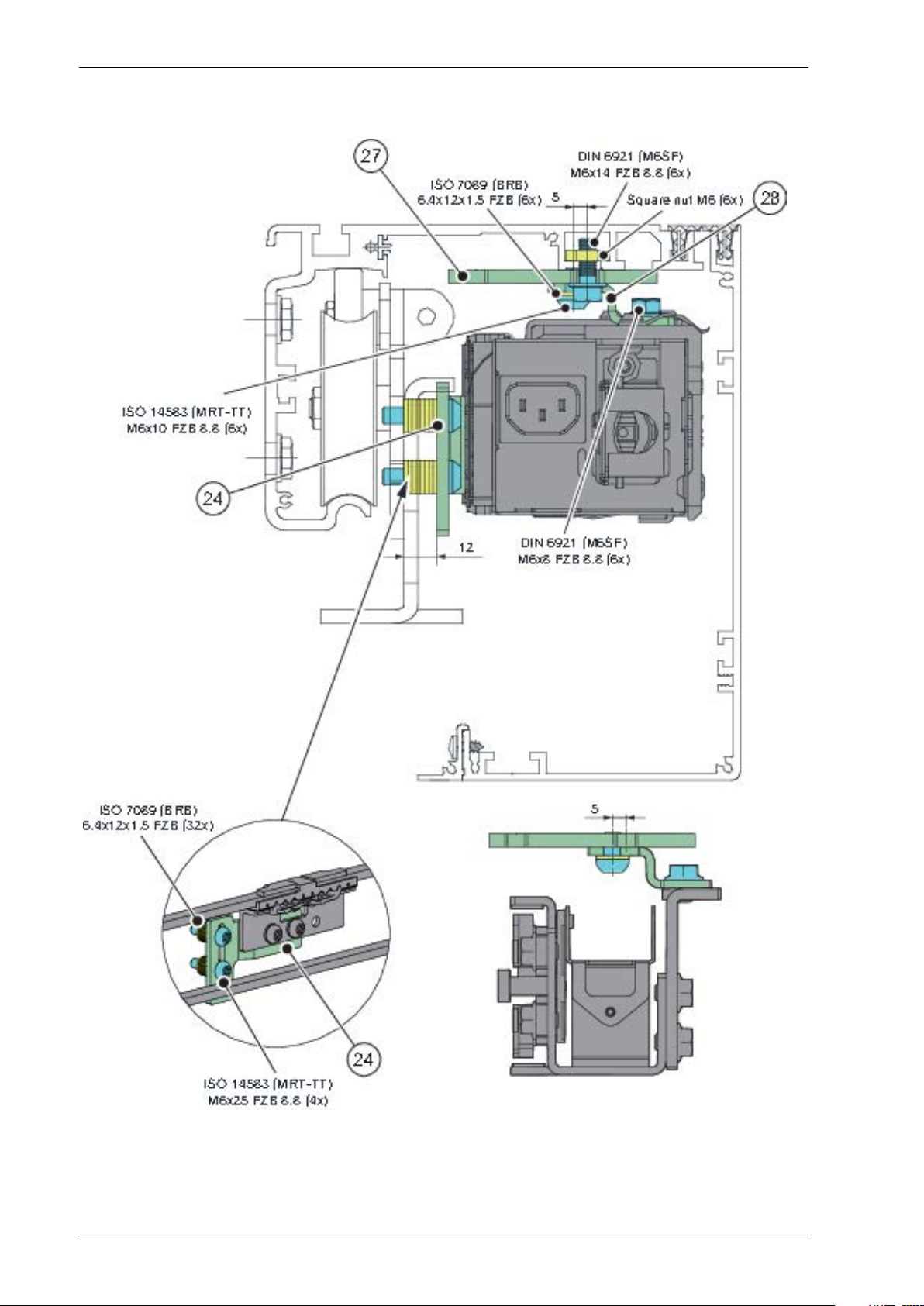

a How to install the mounting plate. Please refer to the dimension on the surface of plate (27)

firstly.

Mounting plate27

15Issue 2019-07-131018482-EMen-2.0

Page 16

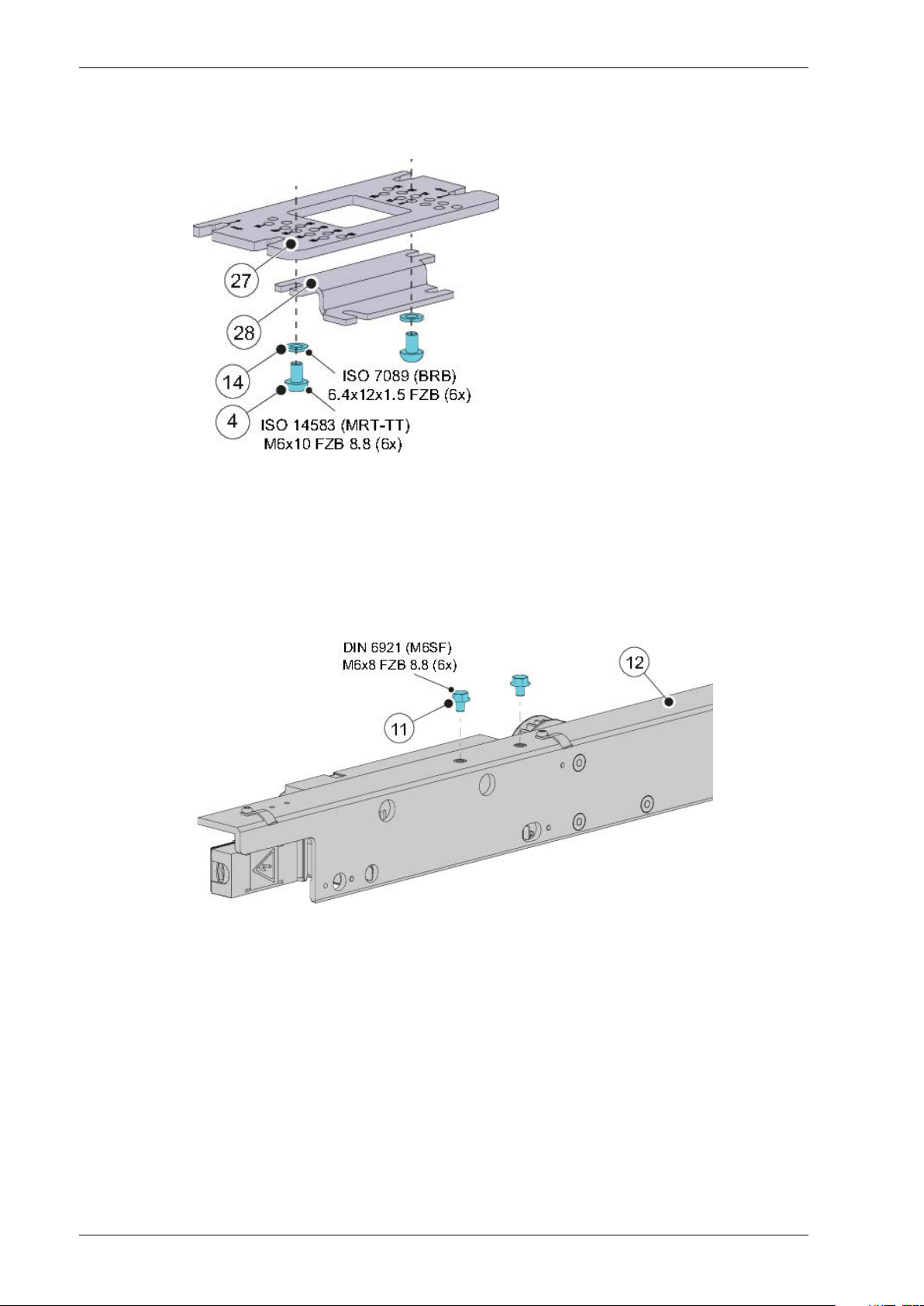

2 Mechanical installation

b Assemble themountingplate (27) and mounting bracket (28) with the washers (14) and screws

(4).

Screw: ISO 14583 (MRT-TT) M6x10 FZB 8.84

Washer: ISO 7089 (BRB) 6.4x12x1.5 FZB14

Mounting plate27

Mounting bracket28

c Fix two screws (11) to the backbone assembly (12), don't tighten the screws (11).

Screw: DIN 6921 (M6SF) M6x8 FZB 8.811

Backbone assembly12

1018482-EMen-2.0Issue 2019-07-1316

Page 17

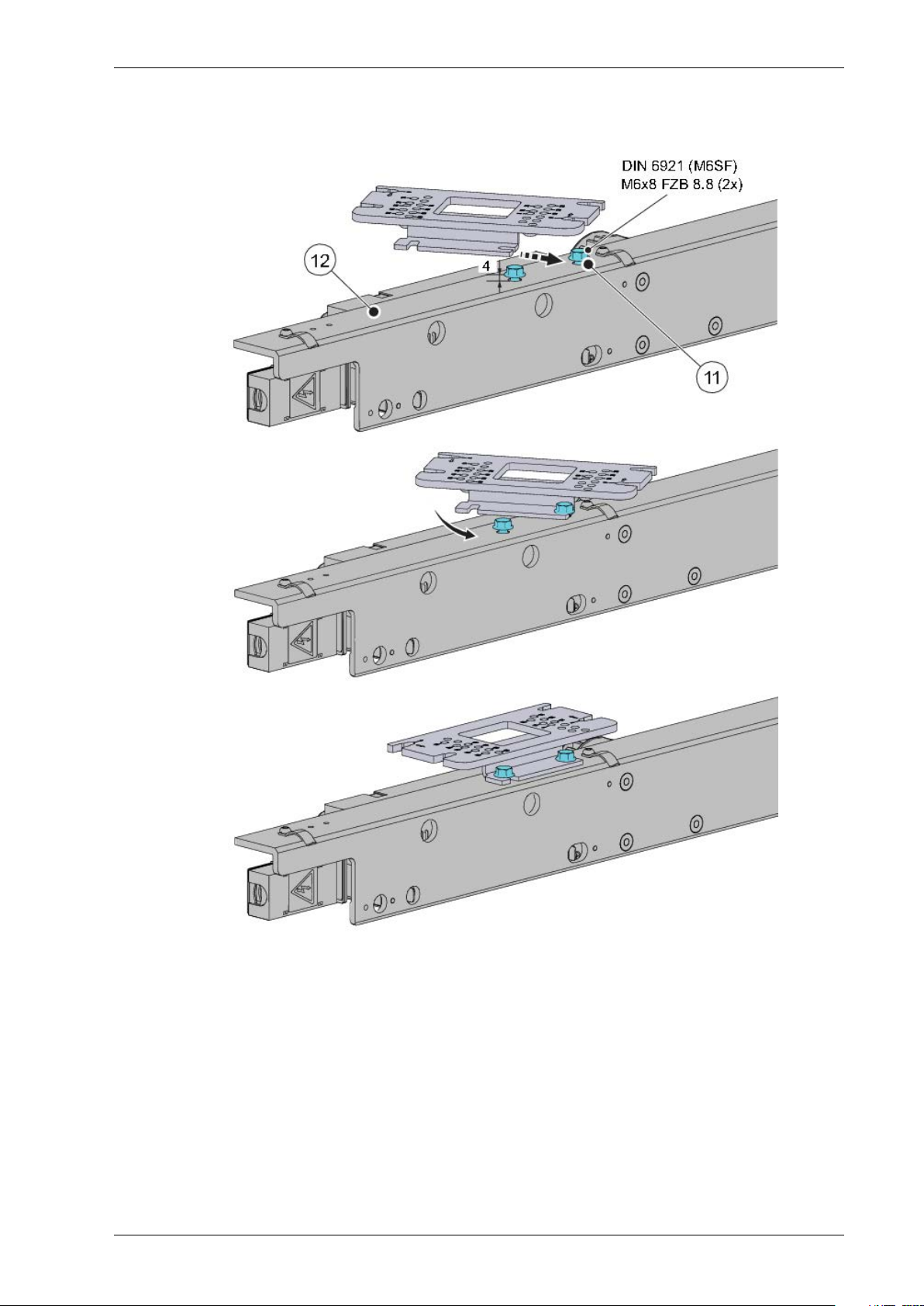

2 Mechanical installation

d Fix the brackets to the backbone assembly (12), then tighten the screws (11) with a torque of

8 - 10 Nm.

Screw: DIN 6921 (M6SF) M6x8 FZB 8.811

Backbone assembly12

17Issue 2019-07-131018482-EMen-2.0

Page 18

2 Mechanical installation

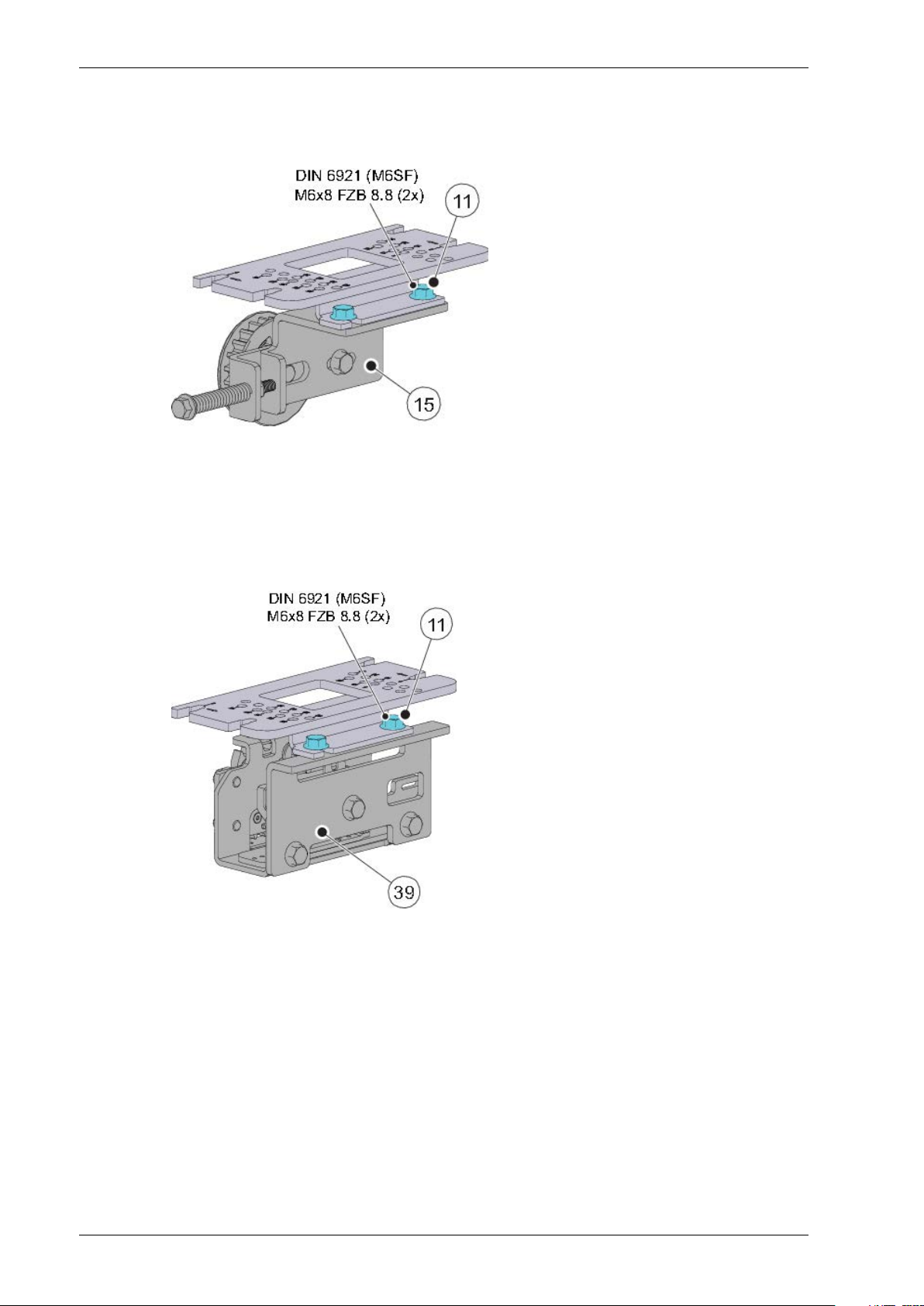

2.1.4 Fix the brackets to the tension wheel

Fix the brackets to the tension wheel assembly (15) in the same way as 2.1.3 .

Screw: DIN 6921 (M6SF) M6x8 FZB 8.811

Tension wheel assembly15

2.1.5 Fix the brackets to the belt lock (option)

Fix the brackets to the belt lock (39) in the same way as 2.1.3.

Screw: DIN 6921 (M6SF) M6x8 FZB 8.811

Belt lock39

1018482-EMen-2.0Issue 2019-07-1318

Page 19

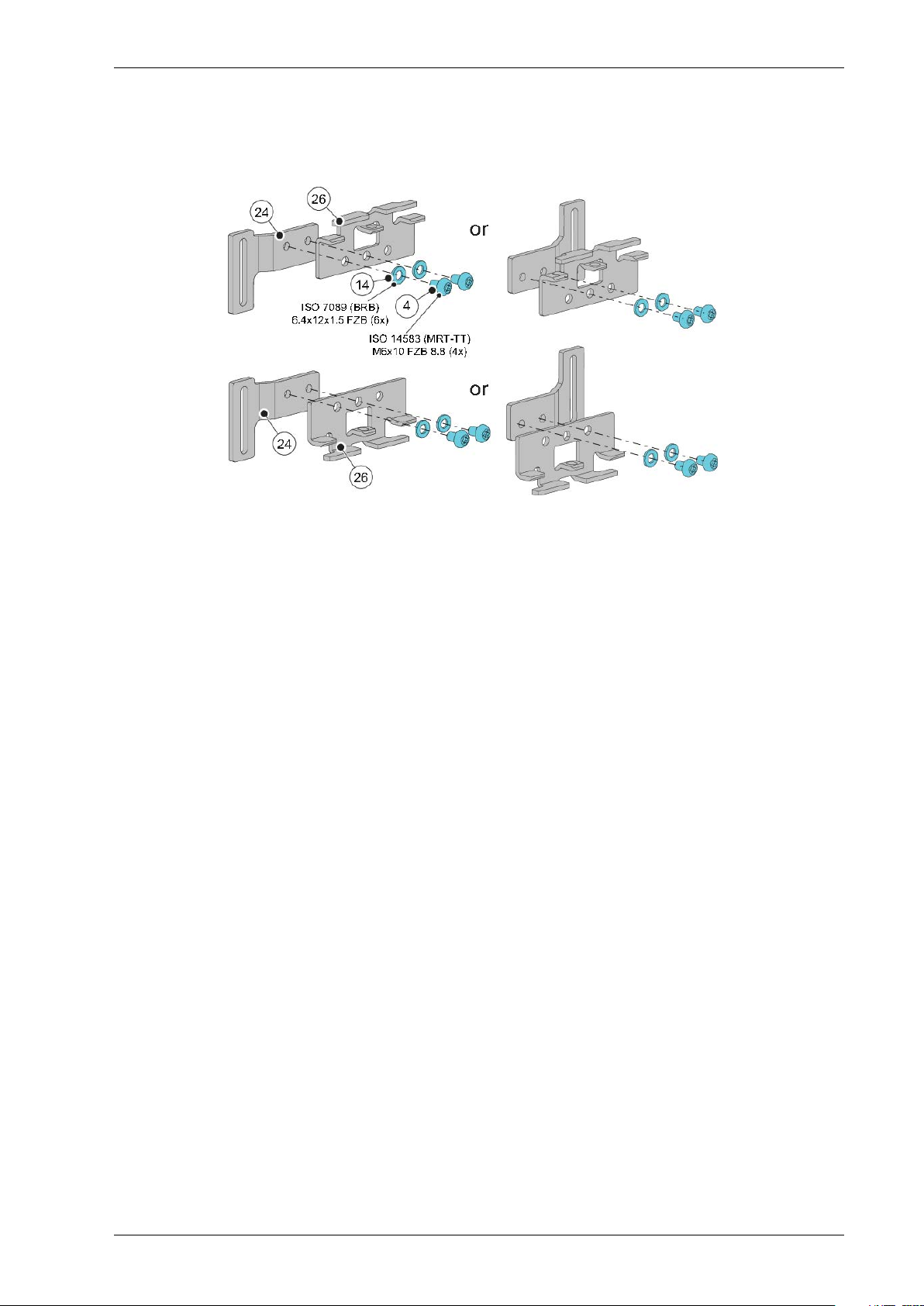

2.1.6 Fix the transmission bracket to the connecting bracket

a Fix the transmission bracket (26) to the connecting bracket (24) with the screws (4) and

washers (14).

2 Mechanical installation

2.1.7 Attachment of slack reducer

Please refer to PSL150 Installation and Service Manual (1016248).

Screw: ISO 14583 (MRT-TT) M6x10 FZB 8.84

Washer: ISO 7089 (BRB) 6.4x12x1.5 FZB14

Connecting bracket24

Transmission bracket26

19Issue 2019-07-131018482-EMen-2.0

Page 20

2 Mechanical installation

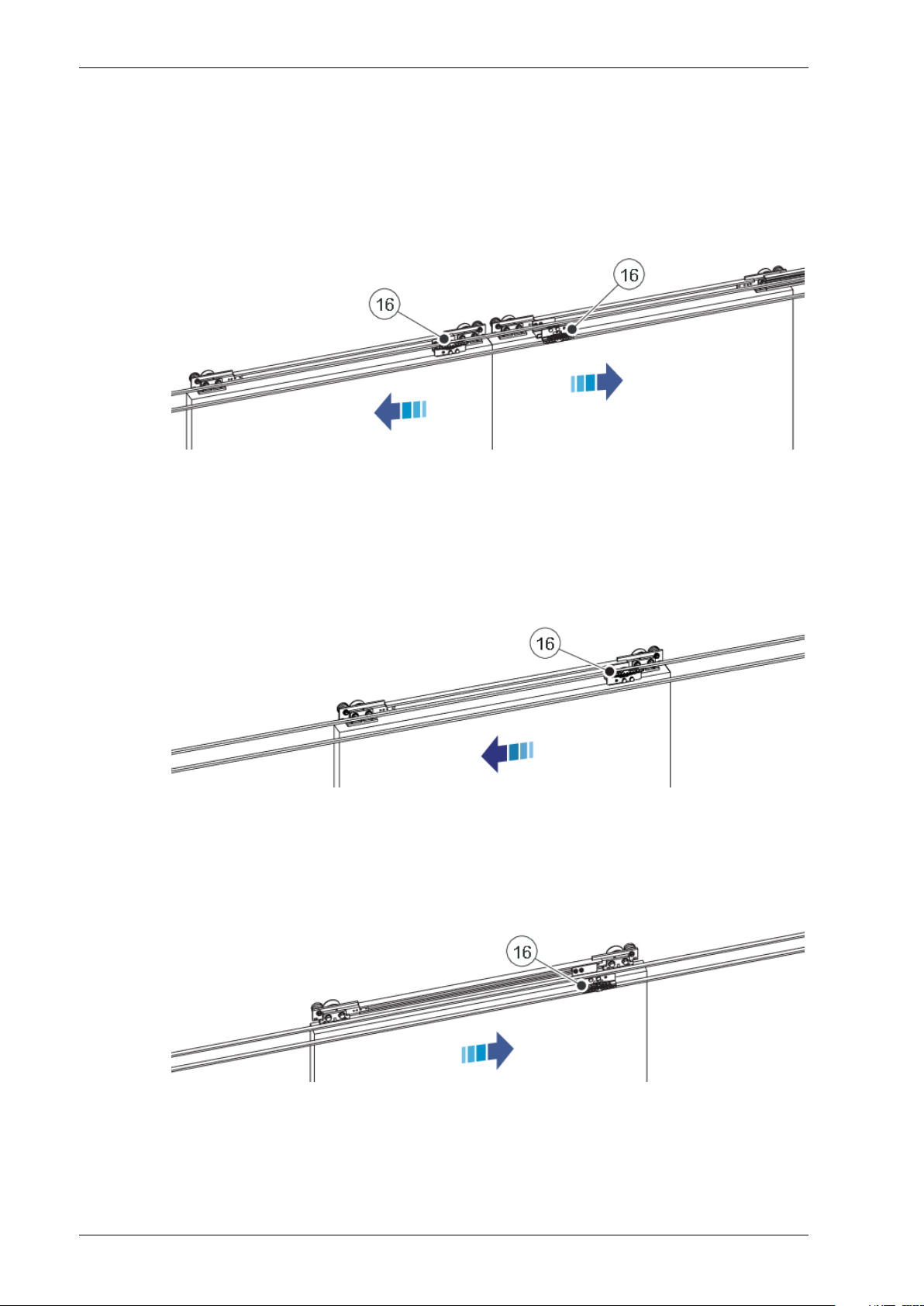

2.1.8 General rules of the installation

Position of the belt connecting to the transmission brackets.

Bi-parting opening

The transmission bracket (16) on the left door leaf shall be connected to the upper belt.

The transmission bracket (16) on the right door leaf shall be connected to the lower belt.

Transmission bracket16

Single left opening

The transmission bracket (16) shall be connected to the upper belt.

Transmission bracket16

Single right opening

The transmission bracket (16) shall be connected to the lower belt.

Transmission bracket16

1018482-EMen-2.0Issue 2019-07-1320

Page 21

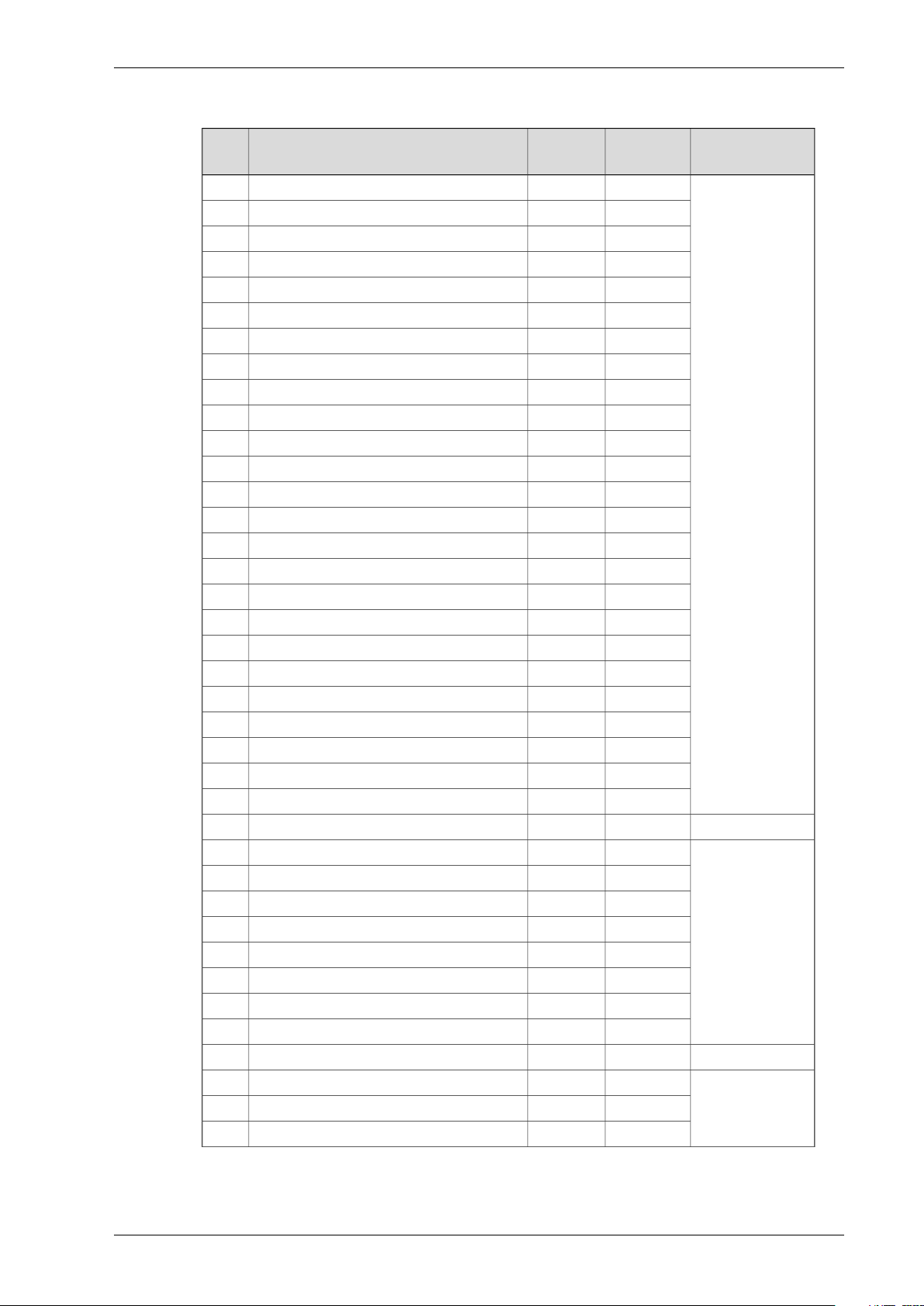

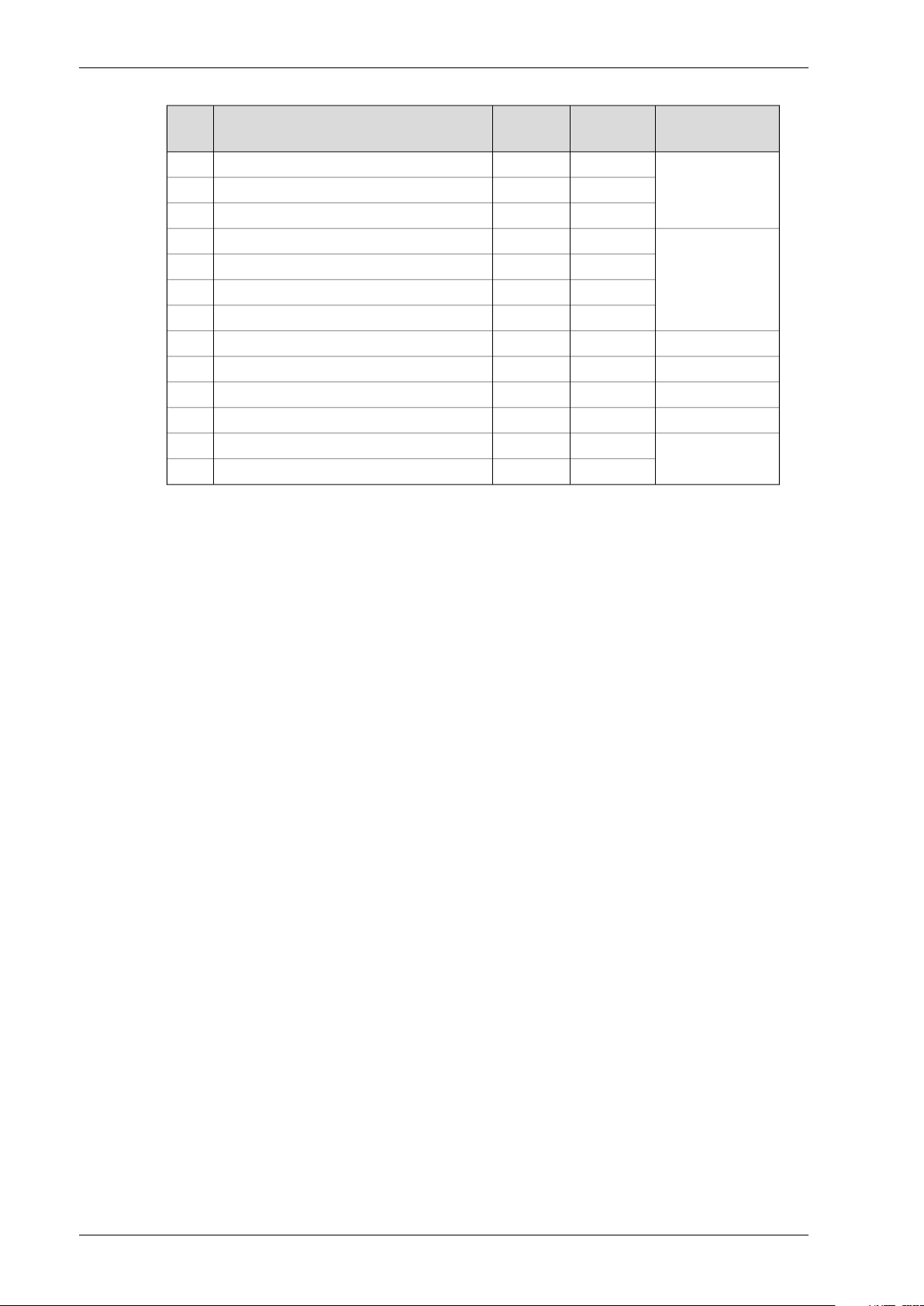

2.1.9 List of the adapted door types

2 Mechanical installation

Bracket kitPageOperator Brand&TypeItem

Belt lock fixing

bracket kit

B123ATS CLIXMASTER1

B124ATS TSF 21002

B125Baumgartner Al-Profil3

B226Baumgartner steel4

B127DORMA ES 505

B128DORMA ES 55/606

B129DORMA ES 707

B130DORMA ES 90/1008

B331DORMA ES 2009

B132ELDEBE GSX10

B133EMD11

B134EMC12

B135Faiveley 613

1019396

B136Faiveley 1214

B137Faiveley 1715

B338GEZE ECdrive16

B139GEZE TSA 34017

B140GEZE TSA 350 N/350 W18

B141GEZE TSA 36019

B142GEZE TSA 45020

B143Gilgen SLK/SLG21

B144Gilgen SLM/SLP22

B145HORTON Series 200123

B146Manusa PA 8024

B147Manusa STK25

1019399B448Manusa Visio26

B249Portalp 2000B27

B150Porte Automatiche GTS-L/-P28

B151Porte Automatiche GTV29

B252Record STA730

1019396

B253Record STA831

B154Record STA9/STA1032

B155Record STA1133

B156Record STA12/STA14 Steel34

1019399B457Record STA12/STA14 AL35

B158Record STA1336

B159Record STA1537

1019396

B160Record STA16/1738

21Issue 2019-07-131018482-EMen-2.0

Page 22

2 Mechanical installation

Bracket kitPageOperator Brand&TypeItem

Belt lock fixing

bracket kit

B461Record STA1939

B462Record STA2040

1019399

B463Record STA2141

B164Tormax TMP42

B165Tormax TX/TM/TMX43

1019396

B166Tormax TEP/TXP44

B167Waldoor EC45

1019399B268Waldoor UC46

1019396B169Waldoor UWS 80047

1019399B470Waldoor UWS 240048

1019396B171Ditec VALOR (escape route)49

B272Ditec Bis O50

1019396

B273Ditec Bis V51

1018482-EMen-2.0Issue 2019-07-1322

Page 23

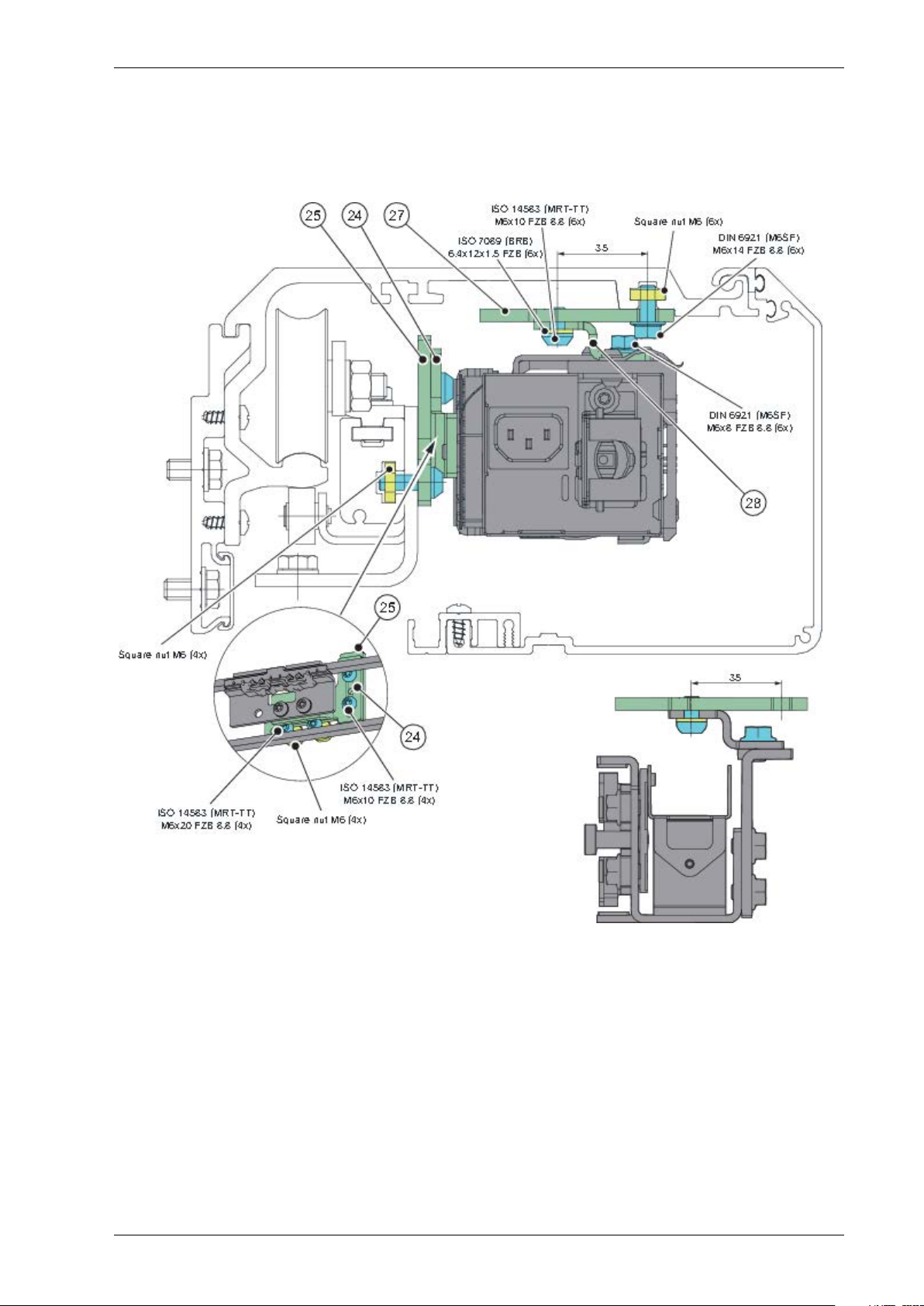

2.1.10 Adapted door types

Note! Original nuts and bolts can be reused.

ATS CLIXMASTER

2 Mechanical installation

Connecting bracket24

Bracket 125

Mounting plate27

Mounting bracket28

23Issue 2019-07-131018482-EMen-2.0

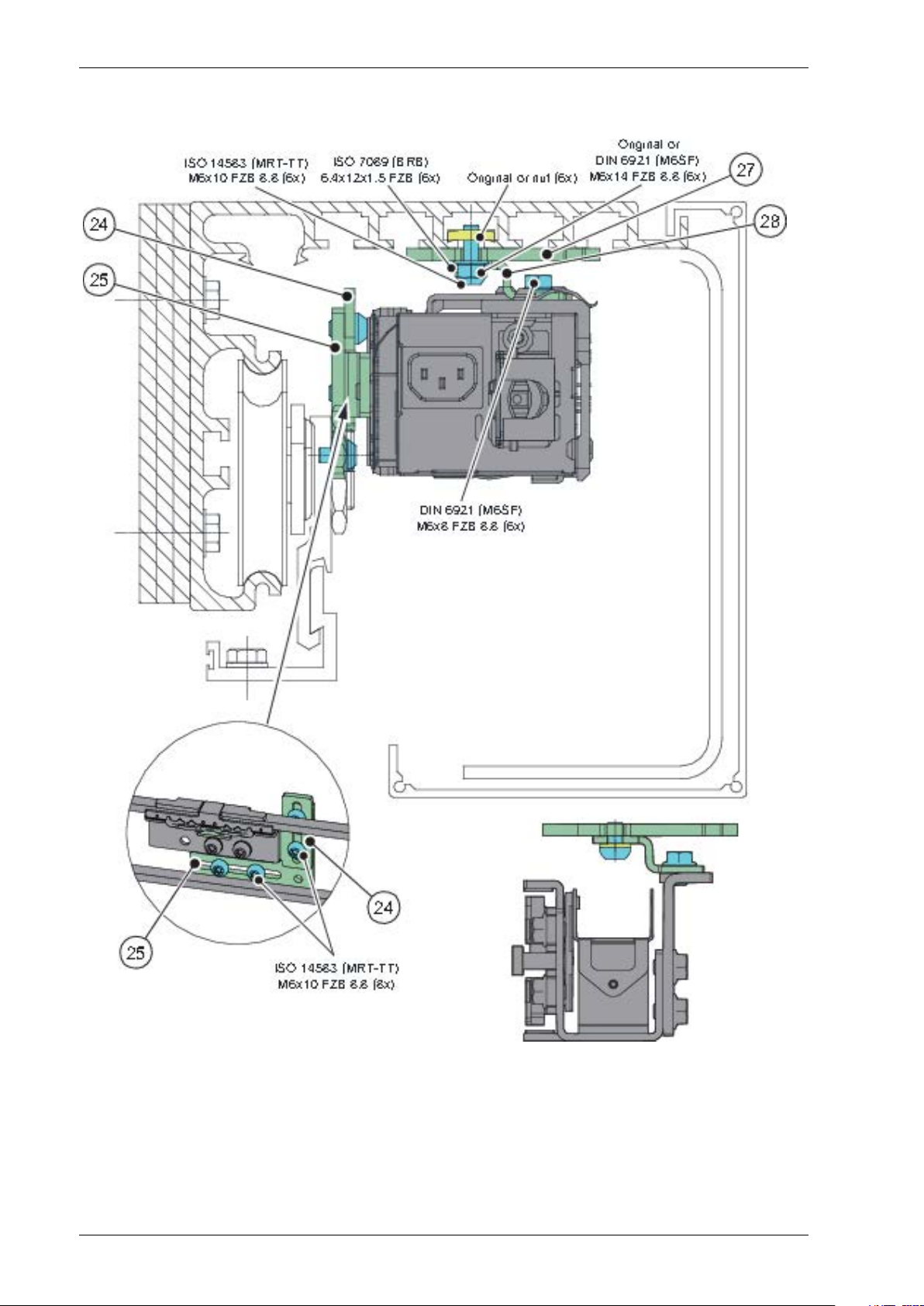

Page 24

2 Mechanical installation

ATS TSF 2100

Connecting bracket24

Bracket 125

Mounting plate27

Mounting bracket28

1018482-EMen-2.0Issue 2019-07-1324

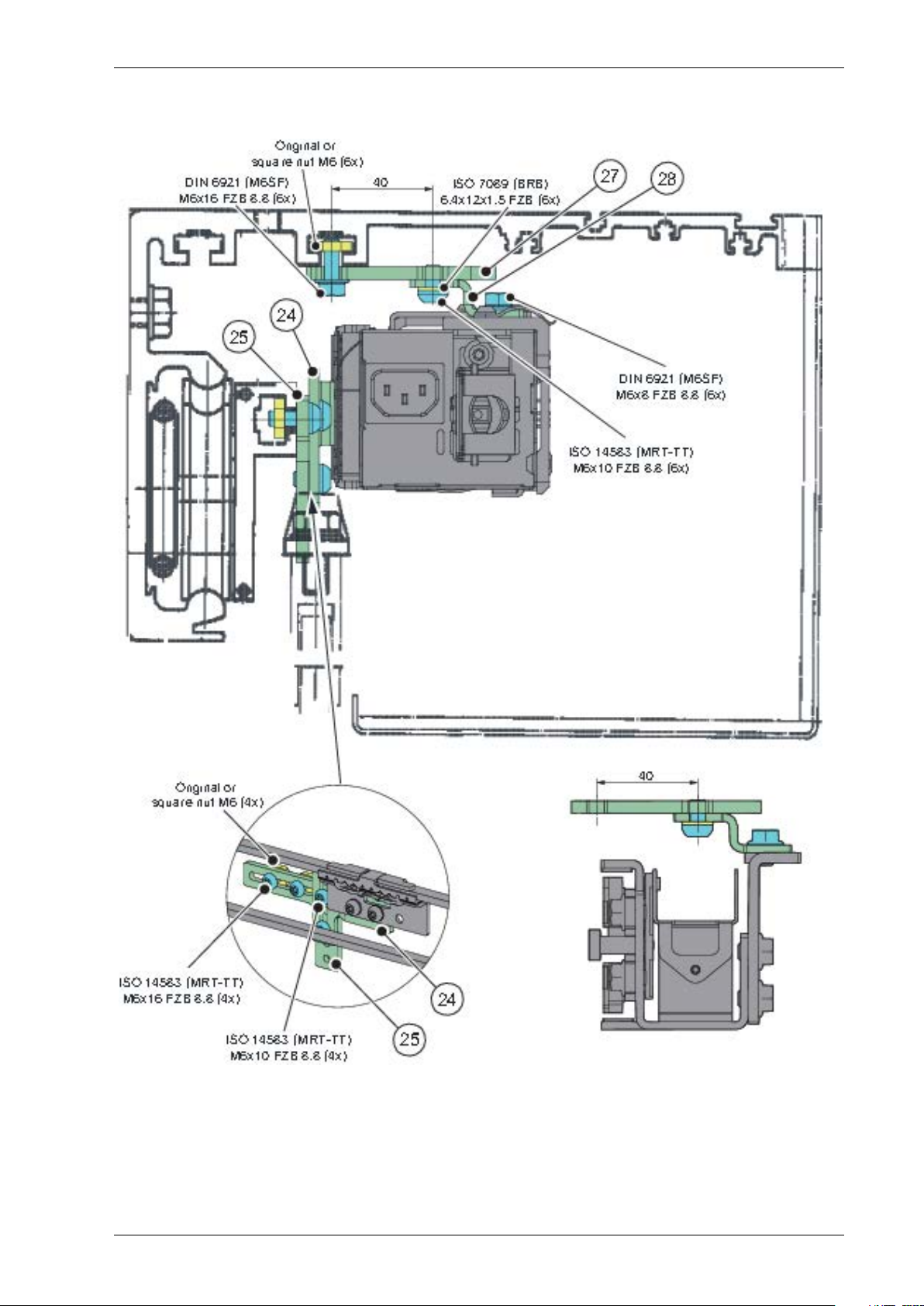

Page 25

Baumgartner Al-Profil

2 Mechanical installation

Connecting bracket24

Bracket 125

Mounting plate27

Mounting bracket28

25Issue 2019-07-131018482-EMen-2.0

Page 26

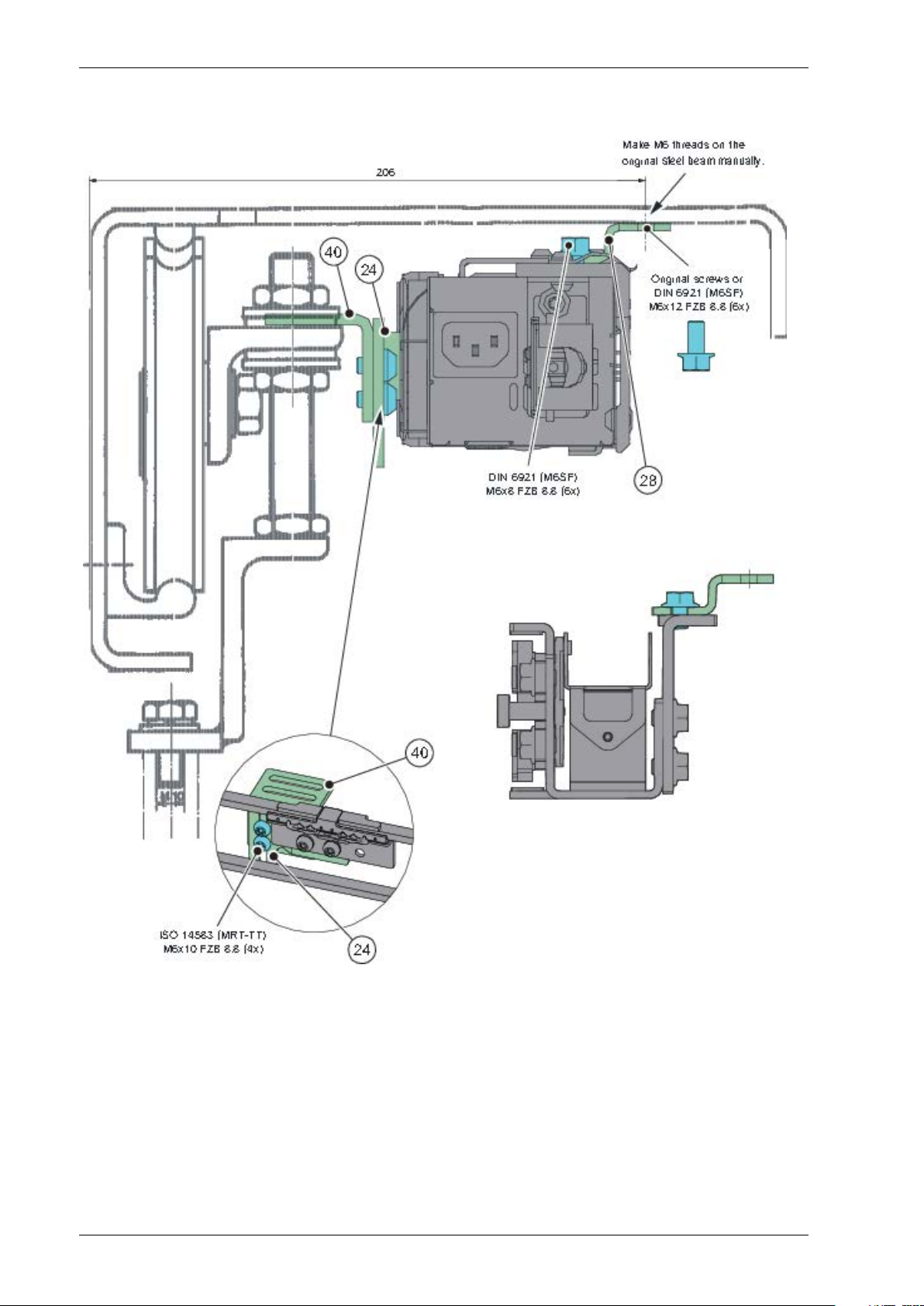

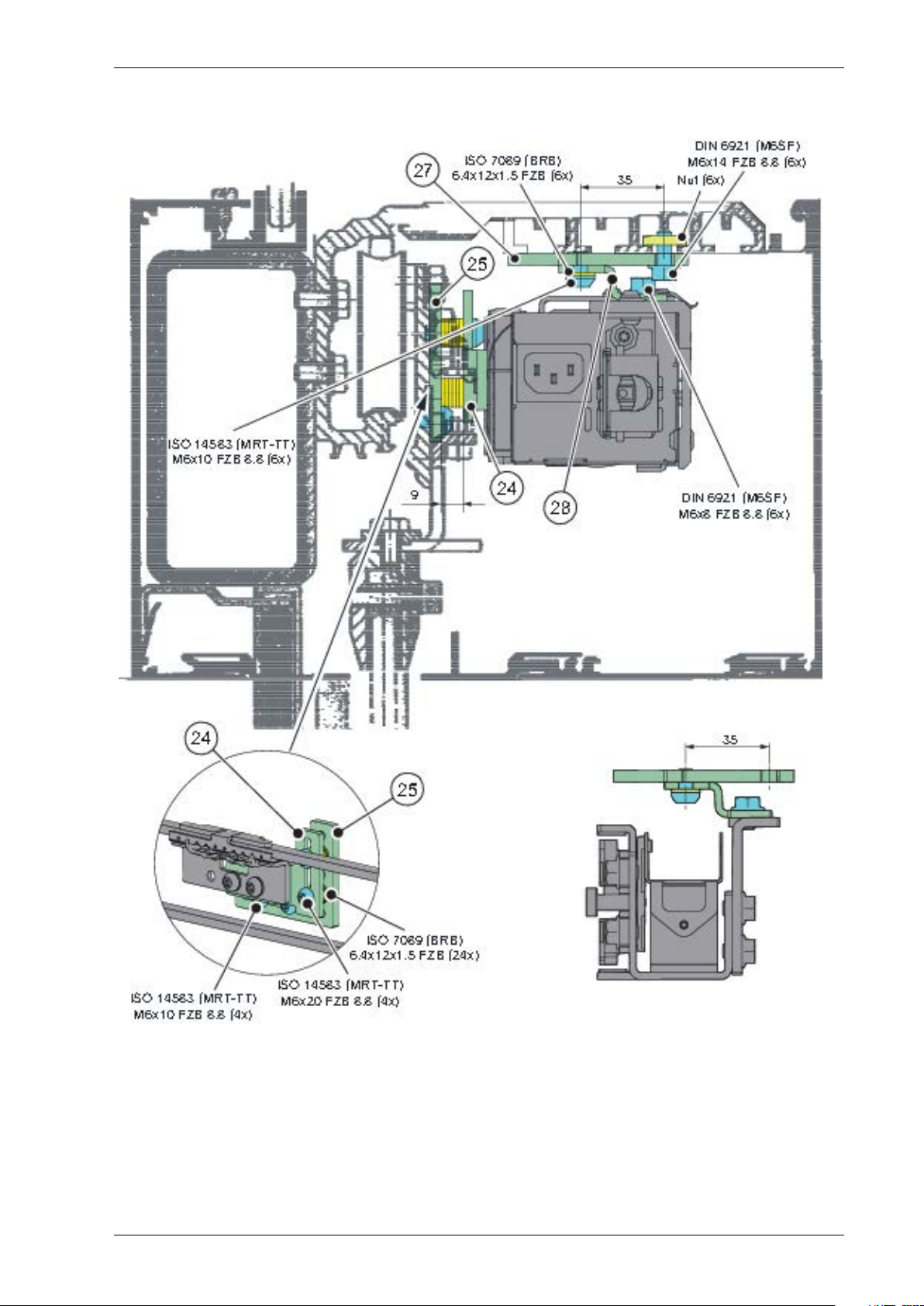

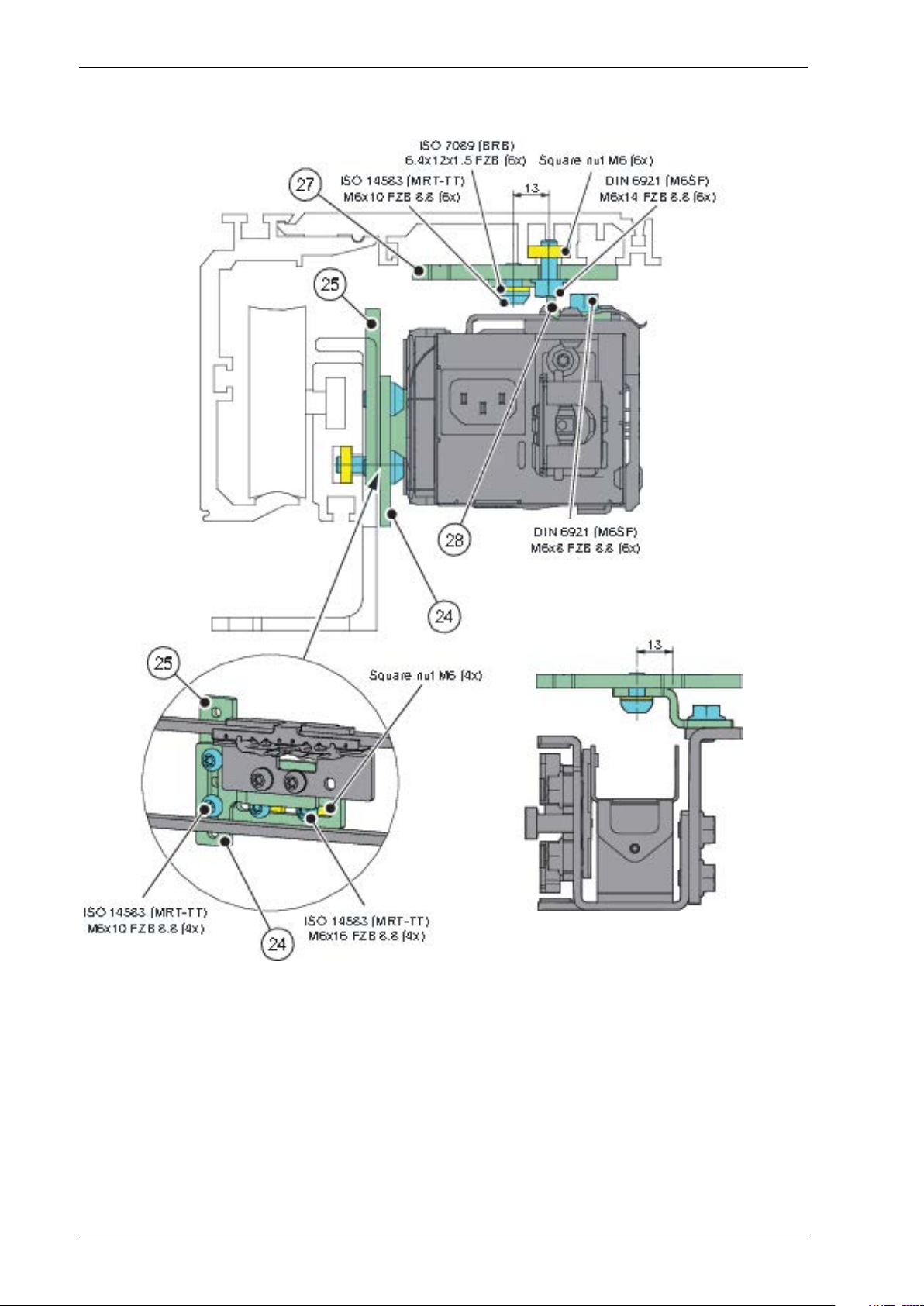

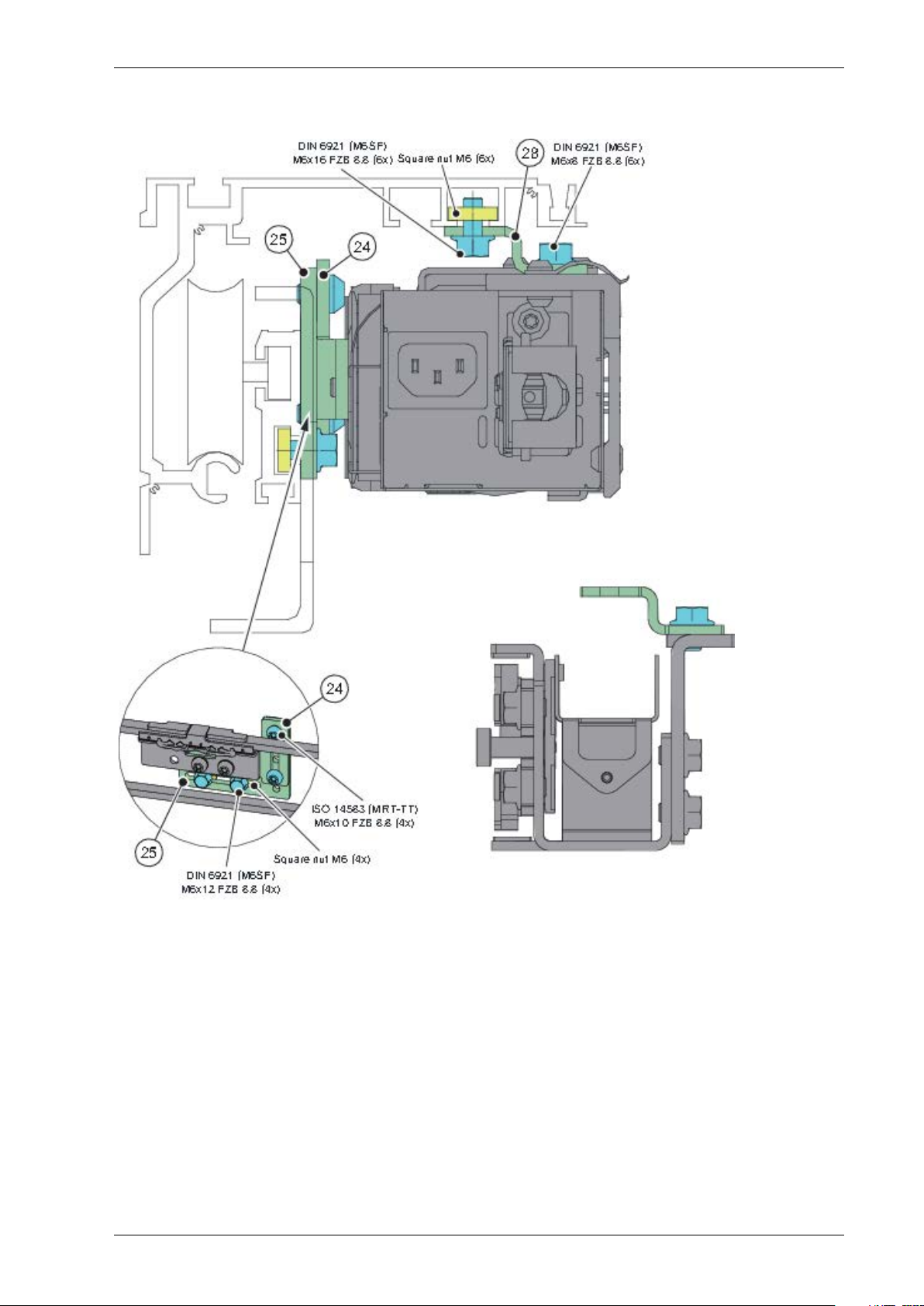

2 Mechanical installation

Baumgartner steel

Connecting bracket24

Mounting bracket28

Bracket 240

1018482-EMen-2.0Issue 2019-07-1326

Page 27

DORMA ES 50

2 Mechanical installation

Connecting bracket24

Bracket 125

Mounting plate27

Mounting bracket28

27Issue 2019-07-131018482-EMen-2.0

Page 28

2 Mechanical installation

DORMA ES 55/60

Connecting bracket24

Bracket 125

Mounting plate27

Mounting bracket28

1018482-EMen-2.0Issue 2019-07-1328

Page 29

DORMA ES 70

2 Mechanical installation

Connecting bracket24

Mounting plate27

Mounting bracket28

29Issue 2019-07-131018482-EMen-2.0

Page 30

2 Mechanical installation

DORMA ES 90/100

Connecting bracket24

Mounting plate27

Mounting bracket28

1018482-EMen-2.0Issue 2019-07-1330

Page 31

DORMA ES 200

2 Mechanical installation

Connecting bracket24

Mounting plate27

Mounting bracket28

Bracket 341

31Issue 2019-07-131018482-EMen-2.0

Page 32

2 Mechanical installation

ELDEBE GSX

Connecting bracket24

Mounting plate27

Mounting bracket28

1018482-EMen-2.0Issue 2019-07-1332

Page 33

EMD

2 Mechanical installation

Connecting bracket24

Mounting plate27

Mounting bracket28

33Issue 2019-07-131018482-EMen-2.0

Page 34

2 Mechanical installation

EMC

Connecting bracket24

Mounting plate27

Mounting bracket28

1018482-EMen-2.0Issue 2019-07-1334

Page 35

Faiveley 6

2 Mechanical installation

Connecting bracket24

Bracket 125

Mounting plate27

Mounting bracket28

35Issue 2019-07-131018482-EMen-2.0

Page 36

2 Mechanical installation

Faiveley 12

Connecting bracket24

Bracket 125

Mounting plate27

Mounting bracket28

1018482-EMen-2.0Issue 2019-07-1336

Page 37

Faiveley 17

2 Mechanical installation

Connecting bracket24

Bracket 125

Mounting plate27

Mounting bracket28

37Issue 2019-07-131018482-EMen-2.0

Page 38

2 Mechanical installation

GEZE ECdrive

Connecting bracket24

Bracket 125

Mounting bracket28

1018482-EMen-2.0Issue 2019-07-1338

Page 39

GEZE TSA 340

2 Mechanical installation

Connecting bracket24

Mounting bracket28

39Issue 2019-07-131018482-EMen-2.0

Page 40

2 Mechanical installation

GEZE TSA 350 N/350 W

Connecting bracket24

Bracket 125

Mounting bracket28

1018482-EMen-2.0Issue 2019-07-1340

Page 41

GEZE TSA 360

2 Mechanical installation

Connecting bracket24

Bracket 125

Mounting bracket28

41Issue 2019-07-131018482-EMen-2.0

Page 42

2 Mechanical installation

GEZE TSA 450

Connecting bracket24

Bracket 125

Mounting bracket28

1018482-EMen-2.0Issue 2019-07-1342

Page 43

Gilgen SLK/SLG

2 Mechanical installation

Connecting bracket24

Bracket 125

Mounting bracket28

43Issue 2019-07-131018482-EMen-2.0

Page 44

2 Mechanical installation

Gilgen SLM/SLP

Connecting bracket24

Bracket 125

Mounting bracket28

1018482-EMen-2.0Issue 2019-07-1344

Page 45

HORTON Series 2001

2 Mechanical installation

Connecting bracket24

Bracket 125

Mounting plate27

Mounting bracket28

45Issue 2019-07-131018482-EMen-2.0

Page 46

2 Mechanical installation

Manusa PA 80

Connecting bracket24

Bracket 125

Mounting plate27

Mounting bracket28

1018482-EMen-2.0Issue 2019-07-1346

Page 47

Manusa STK

2 Mechanical installation

Connecting bracket24

Bracket 125

Mounting plate27

Mounting bracket28

47Issue 2019-07-131018482-EMen-2.0

Page 48

2 Mechanical installation

Manusa Visio

Connecting bracket24

Bracket 444

1018482-EMen-2.0Issue 2019-07-1348

Page 49

Portalp 2000B

2 Mechanical installation

Bracket11

Backbone assembly12

Screw: ISO 4014 (M6S) M6x813

49Issue 2019-07-131018482-EMen-2.0

Page 50

2 Mechanical installation

Porte Automatiche GTS-L/-P

Connecting bracket24

Bracket 125

Mounting plate27

Mounting bracket28

1018482-EMen-2.0Issue 2019-07-1350

Page 51

Porte Automatiche GTV

2 Mechanical installation

Connecting bracket24

Mounting plate27

Mounting bracket28

51Issue 2019-07-131018482-EMen-2.0

Page 52

2 Mechanical installation

Record STA7

Connecting bracket24

Mounting bracket28

Bracket 240

1018482-EMen-2.0Issue 2019-07-1352

Page 53

Record STA8

2 Mechanical installation

Connecting bracket24

Bracket 125

Mounting bracket28

Bracket 240

53Issue 2019-07-131018482-EMen-2.0

Page 54

2 Mechanical installation

Record STA9/STA10

Connecting bracket24

Bracket 125

Mounting bracket28

1018482-EMen-2.0Issue 2019-07-1354

Page 55

Record STA11

2 Mechanical installation

Connecting bracket24

Bracket 125

Mounting plate27

Mounting bracket28

55Issue 2019-07-131018482-EMen-2.0

Page 56

2 Mechanical installation

Record STA12/STA14 Steel

Connecting bracket24

Bracket 125

Mounting bracket28

1018482-EMen-2.0Issue 2019-07-1356

Page 57

Record STA12/STA14 AL

2 Mechanical installation

Connecting bracket24

Bracket 125

Bracket 444

57Issue 2019-07-131018482-EMen-2.0

Page 58

2 Mechanical installation

Record STA13

Connecting bracket24

Bracket 125

Mounting bracket28

1018482-EMen-2.0Issue 2019-07-1358

Page 59

Record STA15

2 Mechanical installation

Connecting bracket24

Bracket 125

Mounting bracket28

59Issue 2019-07-131018482-EMen-2.0

Page 60

2 Mechanical installation

Record STA16/17

Note! * Cut the original component holder beam to smaller pieces.

Bi-parting

2/3 of the original beam for backbone assembly.

1/6 of the original beam for tension wheel.

1/6 of the original beam for belt lock.

Left opening

2/3 of the original beam for backbone assembly.

1/3 of the original beam for tension wheel and belt lock.

Right opening

2/3 of the original beam for backbone assembly and belt lock.

1/3 of the original beam for tension wheel.

Connecting bracket24

Bracket 125

Mounting plate27

Mounting bracket28

1018482-EMen-2.0Issue 2019-07-1360

Page 61

Record STA19

2 Mechanical installation

Connecting bracket24

Mounting bracket28

61Issue 2019-07-131018482-EMen-2.0

Page 62

2 Mechanical installation

Record STA20

Connecting bracket24

Bracket 444

1018482-EMen-2.0Issue 2019-07-1362

Page 63

Record STA21

2 Mechanical installation

Connecting bracket24

Mounting bracket28

63Issue 2019-07-131018482-EMen-2.0

Page 64

2 Mechanical installation

Tormax TMP

Connecting bracket24

Bracket 125

Mounting plate27

Mounting bracket28

1018482-EMen-2.0Issue 2019-07-1364

Page 65

Tormax TX/TM/TMX

2 Mechanical installation

Connecting bracket24

Bracket 125

Mounting bracket28

65Issue 2019-07-131018482-EMen-2.0

Page 66

2 Mechanical installation

Tormax TEP/TXP

Bracket11

Backbone assembly12

Screw: ISO 4014 (M6S) M6x813

1018482-EMen-2.0Issue 2019-07-1366

Page 67

Waldoor EC

2 Mechanical installation

Connecting bracket24

Mounting bracket28

67Issue 2019-07-131018482-EMen-2.0

Page 68

2 Mechanical installation

Waldoor UC

Bracket11

Backbone assembly12

Screw: ISO 4014 (M6S) M6x813

1018482-EMen-2.0Issue 2019-07-1368

Page 69

Waldoor UWS 800

2 Mechanical installation

Connecting bracket24

Bracket 125

Mounting plate27

Mounting bracket28

69Issue 2019-07-131018482-EMen-2.0

Page 70

2 Mechanical installation

Waldoor UWS 2400

Connecting bracket24

Bracket 125

Mounting bracket28

Bracket 545

1018482-EMen-2.0Issue 2019-07-1370

Page 71

Ditec VALOR (escape route)

2 Mechanical installation

Connecting bracket24

Mounting bracket28

Bracket 545

71Issue 2019-07-131018482-EMen-2.0

Page 72

2 Mechanical installation

Ditec Bis O

Connecting bracket24

Mounting plate27

Mounting bracket28

Bracket 240

1018482-EMen-2.0Issue 2019-07-1372

Page 73

Ditec Bis V

2 Mechanical installation

Connecting bracket24

Mounting plate27

Mounting bracket28

Bracket 240

73Issue 2019-07-131018482-EMen-2.0

Page 74

2 Mechanical installation

2.2 Entrematic PSL Retrofit Kit for TORMAX iMotion 2202

2.2.1 Check the components

Check the components in the package as following.

Drive unit kit13

Main control assembly14

Tension wheel assembly15

Tooth belt18

Belt clamp20

Nut: DIN 985 M6 (M6M)25

Screw: ISO 14581 (MFT) M6x1226

Transmission bracket27

Universal transmission bracket28

Nut: M535

Screw: ISO 14583 (MRT) M5x1036

Slack reducer (Not needed, if belt lock

37

equipped)

1018482-EMen-2.0Issue 2019-07-1374

Page 75

2.2.2 Preparing

a Dismount the original drive system, following components should be retained: door carriers

(1), beam (2), cover set (3), door stops (4), cable holders (5), nuts (11) and screws (12).

Note! If there are not enough nuts (11) and screws (12), use the nuts (35) and the screws (36)

to replace.

2 Mechanical installation

Door carrier1

Beam2

Cover set3

Door stop4

Cable holder5

Nut: M511

Screw: M5x1012

Nut: M535

Screw: ISO 14583 (MRT) M5x1036

75Issue 2019-07-131018482-EMen-2.0

Page 76

2 Mechanical installation

2.2.3 I/O board and the battery installation (option)

Note! I/O board must be selected when bi-stable.

a Fix the I/O board (7) and the battery (8) to the main control assembly (14) with the screws (9)

and (10).

I/O board7

Battery8

Screw: ISO 14583 (MRT) M4x69

Screw: ISO 14583 (MRT-TT) M4x6010

Main control assembly14

1018482-EMen-2.0Issue 2019-07-1376

Page 77

2.2.4 Fix the nuts and screws on the drive unit kit and the main control assembly

a Take off the drive unit from the Backbone assembly (40), then fix it onto drive unit plate (57)

with the original screws and washeres.

2 Mechanical installation

Backbone assembly40

Drive unit plate57

77Issue 2019-07-131018482-EMen-2.0

Page 78

2 Mechanical installation

b Take off the PSU from the Backbone assembly (40), then fix it onto drive unit plate (57) with

the original screws and other components.

Backbone assembly40

Drive unit plate57

1018482-EMen-2.0Issue 2019-07-1378

Page 79

2 Mechanical installation

c Take off the MCU from the Backbone assembly (40), then fix it onto electronic mounting plate

(58) with the original screws and washeres.

Backbone assembly40

Electronic mounting plate58

79Issue 2019-07-131018482-EMen-2.0

Page 80

2 Mechanical installation

d Fix the nuts (11) to the drive unit kit (13) and main control assembly (14) with screws (12), but

do not tighten the screws (12).

Nut: M511

Screw: M5x1012

Drive unit kit (HD or DD)13

Main control assembly14

1018482-EMen-2.0Issue 2019-07-1380

Page 81

2.2.5 Fix the drive unit kit and the main control assembly

a Lift the drive unit kit (13) and main control assembly (14) to the beam (2), Then tighten the

screws (12) with a torque of 6 Nm.

2 Mechanical installation

Beam2

Nut: M511

Screw: M5x1012

Drive unit kit (HD or DD)13

Main control assembly14

81Issue 2019-07-131018482-EMen-2.0

Page 82

2 Mechanical installation

2.2.6 Fix the tension wheel assembly

a Fix the nuts (11) to the tension wheel assembly (15) with screws (12), but do not tighten the

screws (12).

Lift the tension wheel assembly (15) to the beam (2), do not tighten the screws (12) fully, so it

shall be able to slide along the beam (2).

b The position of the tension wheel assembly (15) should be as close as possible to the drive unit,

but make sure that the tension wheel assembly (15) will not interfere with the door carrier

when the door is fully opened.

Beam2

Nut: M511

Screw: M5x1012

Tension wheel assembly15

1018482-EMen-2.0Issue 2019-07-1382

Page 83

2.2.7 Fix the transmission brackets

a Unscrew the existing screws (24), fix the transmission brackets (27) and the universal transmis-

sion brackets (28) to the door carriers (1) with the screws (24) and (26).

Note! The door leaves should be holded firmly when unscrew the the existing screws (24) on

the door carriers (1).

2 Mechanical installation

Door carrier1

Existing screw: M6x1424

Nut: DIN 985 M6 (M6M)25

Screw: ISO 14581 (MFT) M6x1226

Transmission bracket27

Universal transmission bracket28

83Issue 2019-07-131018482-EMen-2.0

Page 84

2 Mechanical installation

2.2.8 Placement of the transmission brackets

Bi-parting opening

The transmission bracket (16) on the left door leaf shall be connected to the inner belt.

The transmission bracket (16) on the right door leaf shall be connected to the outer belt.

Transmission bracket16

Single left opening

The transmission bracket (16) shall be connected to the inner belt.

Transmission bracket16

Single right opening

The transmission bracket (16) shall be connected to the outer belt.

Transmission bracket16

1018482-EMen-2.0Issue 2019-07-1384

Page 85

2.2.9 Attachment of the tooth belt

a Cut the tooth belt (18) to the right length if needed. Route the tooth belt (18) around the drive

unit pulley (19) and around the tension wheel assembly (15).

b For bi-parting doors the belt ends are joined with the belt clamp (20) in the outer part of the

tooth belt (18).

c Click the belt clamp (20) into position.

Note! Do not adjust parameter P12!

2 Mechanical installation

Tension wheel assembly15

Transmission bracket16

Tooth belt18

Drive unit pulley19

Belt clamp20

85Issue 2019-07-131018482-EMen-2.0

Page 86

2 Mechanical installation

2.2.10 Checking and adjusting the belt tension

a Loosen the fixing screw (32) without removing it.

b Screw the adjustment screw (33) to its outmost position.

c Tension the tooth belt (18) by pulling the tension wheel assembly (15) by hand. Tighten the

screws (12) with a torque of 6 Nm.

d Tighten the adjustment screw (33) until there is a gap of approx. 1-2 mm between the lock nut

(34) and the bracket according to illustration below, but not further. Be sure not to overtighten,

otherwise the adjustment screw (33) might damage the tension wheel (31).

e Retighten the fixing screw (32) with a torque of 10 Nm.

Note! Do not make any adjustment on the lock nut (34).

Beam2

Screw: M5x1012

Tension wheel assembly15

Tooth belt18

Tension wheel31

Fixing screw32

Adjustment screw33

Lock nut34

1018482-EMen-2.0Issue 2019-07-1386

Page 87

2.2.11 Bi-parting operators

a Put doors in fully closed position. Make sure that the doors trailing edge is align with the side

light.

b Click the belt clamp (20) into position in the inner transmission bracket (16).

c Check door panels for proper centering in the fully closed and opened positions.

2 Mechanical installation

2.2.12 Attachment of slack reducer

Please refer to PSL150 Installation and Service Manual (1016248).

Tension wheel assembly15

Transmission bracket16

Tooth belt18

Drive unit pulley19

Belt clamp20

87Issue 2019-07-131018482-EMen-2.0

Page 88

2 Mechanical installation

2.2.13 Install the belt lock (option)

a Take down the screws (29) and the belt guide (30).

b Fix the nuts (11) to the belt lock (21) with screws (12), but do not tighten the screws (12).

Lift the tooth belt lock (21) to the beam (2), then tighten the screws (12) with a torque of 6

Nm.

c Fix the belt guide (30) to the belt lock (21) with the screws (29).

Nut: M511

Screw: M5x1012

Belt lock21

Screw: ISO 7046 (MFTS) M3x5 FZB 8.829

Belt guide30

1018482-EMen-2.0Issue 2019-07-1388

Page 89

2.3 Entrematic PSL Retrofit Kit for GEZE Slimdrive

2.3.1 Check the components

Check the components in the package as following.

2 Mechanical installation

Screw: ISO 7046 (MFX) M6x1025Screw: ISO 14583 (MRT) M4x69

MCU26Screw: ISO 4014 (M6S) M6x811

Transmission bracket27Screw: DIN 6921 (M6SF) M6x1012

Universal transmission bracket28Drive unit kit13

Cable bracket30PSU14

Screw: ISO 14585 ST 4.2x9.531Tension wheel assembly15

Screw: ISO 14581 (MFT) M6x1232Tooth belt18

Nut: M637Belt clamp20

Screw: ISO 14583 (MRT) M5x1038Mounting plate24

Slack reducer (Not needed if belt lock

39

equipped)

89Issue 2019-07-131018482-EMen-2.0

Page 90

2 Mechanical installation

2.3.2 Preparing

a Dismount the original drive system, following components should be retained: door carriers

(1), beam (2), cover set (3), square nuts (4), door stops (5) and extension beams (6).

Note! If there are not enough square nuts (4), use the nuts (37) to replace.

Door carrier1

Beam2

Cover set3

Square nut: M64

Door stop5

Extension beam6

Nut: M637

1018482-EMen-2.0Issue 2019-07-1390

Page 91

2.3.3 Exchange the extension beams

a Exchange the extension beams (6).

2 Mechanical installation

Extension beam6

91Issue 2019-07-131018482-EMen-2.0

Page 92

2 Mechanical installation

2.3.4 Fix the PSU (power supply unit) and drive unit kit

a Take off the PSU from the Backbone assembly (40), then fix it onto PSU bracket (41) with the

original screws and washeres.

Backbone assembly40

PSU bracket41

1018482-EMen-2.0Issue 2019-07-1392

Page 93

2 Mechanical installation

b Take off the drive unit from the Backbone assembly (40), then fix it onto drive motor mounting

plate (42) with the original screws, washeres and other components.

Backbone assembly40

Drive motor mounting plate42

93Issue 2019-07-131018482-EMen-2.0

Page 94

2 Mechanical installation

c Fix the PSU (14) and the drive unit kit (13) onto the extension beam (6) with screws (12). Then

tighten the screws (12) with a torque of 10 Nm.

Square nut: M64

Extension beam6

Screw: DIN 6921 (M6SF) M6x1012

Drive unit kit13

PSU14

1018482-EMen-2.0Issue 2019-07-1394

Page 95

2.3.5 Fix the mounting plate and MCU (control unit)

a Take off the MCU (26) from the Backbone assembly (40).

b Fix the mounting plate (24) to the extension beam (6) with screws (25), then fix the MCU (26)

onto the mounting plate (24) with the original screws (9) and washeres.

2 Mechanical installation

Mounting plate24Beam2

Screw: ISO 7046 (MFX) M6x1025Square nut: M64

MCU26Extension beam6

Backbone assembly40Screw: ISO 14583 (MRT) M4x69

Drive motor mounting plate42

95Issue 2019-07-131018482-EMen-2.0

Page 96

Fold the flange

2 Mechanical installation

2.3.6 I/O board and the battery installation (option)

Note! I/O board must be selected when bi-stable.

a Fix the I/O board (7) and the battery (8) to the mounting plate (24) with screws (9) and (10).

I/O board (KS902MP)7

Battery (KS902BAT2)8

Screw: ISO 14583 (MRT) M4x69

Screw: ISO 14583 (MRT-TT) M4x5510

Mounting plate24

1018482-EMen-2.0Issue 2019-07-1396

Page 97

2.3.7 Fix the tension wheel assembly

a Fix the tension wheel assembly (15) to the extension beam (6) with the screws (32), do not

tighten the screws (32) fully, so it shall be able to slide along the extension beam (6).

b The position of the tension wheel assembly (15) should be as close as possible to the drive unit,

but make sure that the tension wheel assembly (15) will not interfere with the door carrier

when the door is fully opened.

2 Mechanical installation

Square nut: M64

Extension beam6

Tension wheel assembly15

Screw: ISO 14581 (MFT) M6x1232

97Issue 2019-07-131018482-EMen-2.0

Page 98

2 Mechanical installation

2.3.8 Fix the transmission brackets

a Unscrew the existing screws (29), fix the transmission brackets (27) and the universal transmis-

sion brackets (28) to the door carriers (1) with the existing screws (29) and the screws (11).

Note! If there are not enough existing screws (29), use the screws (38) to replace.

Door carrier1

Screw: ISO 4014 (M6S) M6x811

Transmission bracket27

Universal transmission bracket28

Existing screw: M5x1029

Screw: ISO 14583 (MRT) M5x1038

1018482-EMen-2.0Issue 2019-07-1398

Page 99

2.3.9 Placement of the transmission brackets

Bi-parting opening

The transmission bracket (16) on the left door leaf shall be connected to the upper belt.

The transmission bracket (16) on the right door leaf shall be connected to the lower belt.

2 Mechanical installation

Transmission bracket16

Single left opening

The transmission bracket (16) shall be connected to the upper belt.

Transmission bracket16

Single right opening

The transmission bracket (16) shall be connected to the lower belt.

Transmission bracket16

99Issue 2019-07-131018482-EMen-2.0

Page 100

2 Mechanical installation

2.3.10 Attachment of the tooth belt

a Cut the tooth belt (18) to the right length if needed. Route the tooth belt (18) around the drive

unit pulley (19) and around the tension wheel assembly (15).

b For bi-parting doors the belt ends are joined with the belt clamp (20) in the lower part of the

tooth belt (18).

c Click the belt clamp (20) into position.

Note! Do not adjust parameter P12!

Tension wheel assembly15

Transmission bracket16

Tooth belt18

Drive unit pulley19

Belt clamp20

1018482-EMen-2.0Issue 2019-07-13100

Loading...

Loading...