Page 1

Commercial HVLS Fans

This manual applies to fans

manufactured beginning

November 2016 with the serial

number C61174800 and higher.

Do not install, operate or service this product unless you

have read and understand the Safety Practices, Warnings,

and Installation and Operating Instructions contained in

this User’s Manual. Failure to do so could result in death

or serious injury.

User’s Manual

Installation, Operations,

Maintenance and Parts

Part No. 6020031A

Page 2

TABLE OF CONTENTS

Introduction .................................................................2

Safety Signal Words ..................................................2

Safety Practices..........................................................3

Owner’s Responsibilities ............................................4

Fan Kit ........................................................................5

Hardware ....................................................................6

Installation Considerations .........................................7

Fan Mount ..................................................................9

Components .............................................................12

Installation ................................................................13

Operating Instructions ..............................................20

Planned Maintenance ...............................................21

Troubleshooting ........................................................22

Fire Control System Fan Shutdown..........................24

Parts List...................................................................25

Warranty ...................................................................27

Distributor Information ..............................................28

INTRODUCTION

Welcome and thank you for choosing this commercial fan from Entrematic

This User's Manual contains basic information that you need to safely install and operate your fan. Please

read and keep this User's Manual before using your new fan. For more information, please consult website at

www.entrematicfans.com.

SAFETY SIGNAL WORDS

You may nd safety signal words such as DANGER, WARNING, CAUTION or NOTICE throughout this User’s

Manual. Their use is explained below:

This is the safety alert symbol. It is used

to alert you to potential personal injury

hazards. Obey all safety messages that

follow this symbol to avoid possible death or injury.

Indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

2 6020031A — Commercial HVLS Fans November 2016

© Entrematic Group AB 2015

Indicates a potentially hazardous situation which, if

not avoided may result in minor or moderate injury.

Notice is used to address practices not related to

personal injury.

Page 3

READ AND SAVE THESE INSTRUCTIONS.

READ THESE SAFETY PRACTICES BEFORE

INSTALLING, OPERATING OR SERVICING THE FAN.

Failure to follow these safety practices could result in

death or serious injury.

READ AND FOLLOW THE OPERATING INSTRUCTIONS

IN THIS MANUAL BEFORE OPERATING THE FAN. If you

do not understand the instructions, ask your supervisor

to teach you how to use the fan.

To reduce the risk of electric shock, do not expose to

water or rain.

Support directly from building structure.

SAFETY PRACTICES

Do not use this commercial fan until you have received proper

training. Improper use could result in property damage,

bodily injury and/or death. Read and follow the complete

OPERATING INSTRUCTIONS on page 20 before use. If

you do not understand the instructions, ask your supervisor

to explain them to you or call your local distributor.

DO NOT USE THE FAN IF IT APPEARS DAMAGED OR

DOES NOT OPERATE PROPERLY. Inform your supervisor

immediately.

Do not operate the fan until all personnel, building structure

and moveable equipment are clear of all moving parts. Install

guards as required.

Do not install the fan unit onto structure of insufcient

strength. Consult a professional engineer or registered

architect. Improper installation of the fan could result in

death or serious injury.

To reduce the risk of re, electric shock and injury to

persons, HVLS fan motor assemblies must be installed

with the blade assemblies that are marked on their

cartons to indicate the suitability with this model. Other

blade assemblies cannot be substituted.

To reduce the risk of re or electric shock, do not use

this fan with any solid-state speed control device

Be certain to follow the instructions in this manual.

If you do not understand the instructions, ask your

supervisor to explain them to you or call your authorized

local distributor.

To reduce the risk of injury to persons, install fan so that

the blade is at least 3.05m (10') above the oor.

INSTALLATION AND OPERATION:

Installation of the equipment must comply with local and

national electrical codes and must be in accordance with

ANSI/NFPA 70 clauses 400.7 and 400.8.

For fans that will be subjected to high cross winds (open

bay doors or air conditioning diffuser ducts) the fan must be

at least one fan diameter (as measured from the end of the

winglet) from open bays or A/C ducts mounted below the

blade plane or there must be at least one fan diameter (as

measured from the end of the winglet) for A/C ducts mounted

at or above the blade plane.

MAINTENANCE AND SERVICE:

Before service, inspection, or cleaning make certain

that the power is disconnected and properly locked off.

If the fan does not operate properly using the procedures

in this manual, BE CERTAIN TO REMOVE POWER FROM

THE UNIT AND LOCK-OUT THE DISCONNECT ON THE

POWER CIRCUIT. Call your local distributor for service.

Keep your body clear of moving parts at all times.

All electrical troubleshooting and repair must be done by a

qualied technician and meet all applicable codes.

November 2016 6020031A — Commercial HVLS Fans 3

© Entrematic Group AB 2015

Page 4

OWNER’S RESPONSIBILITIES

The owner’s responsibilities include the following:

The owner should recognize the inherent danger of the

interface between the commercial fan and shop worker. The

owner should, therefore, train and instruct operators in the

safe use of the commercial fan.

Nameplates, cautions, instructions and posted warnings shall

not be obscured from the view of operating or maintenance

personnel for whom such warnings are intended. Warnings

which are worn or non-legible should be replaced.

Manufacturer’s recommended periodic maintenance and

inspection procedures in effect at date of shipment shall be

followed, and written records of the performance of these

procedures should be kept.

Commercial fans that are structurally damaged or have

experienced impacts from external sources, shall be removed

from service, inspected by the manufacturer’s authorized

representative, and repaired as needed before being placed

back in service.

The owner shall see that all nameplates and caution and

instruction markings or labels are in place and that the

appropriate operating and maintenance manuals are provided

to users.

Modications or alterations of commercial fans shall be made

only with written permission of the original manufacturer.

4 6020031A — Commercial HVLS Fans November 2016

© Entrematic Group AB 2015

Page 5

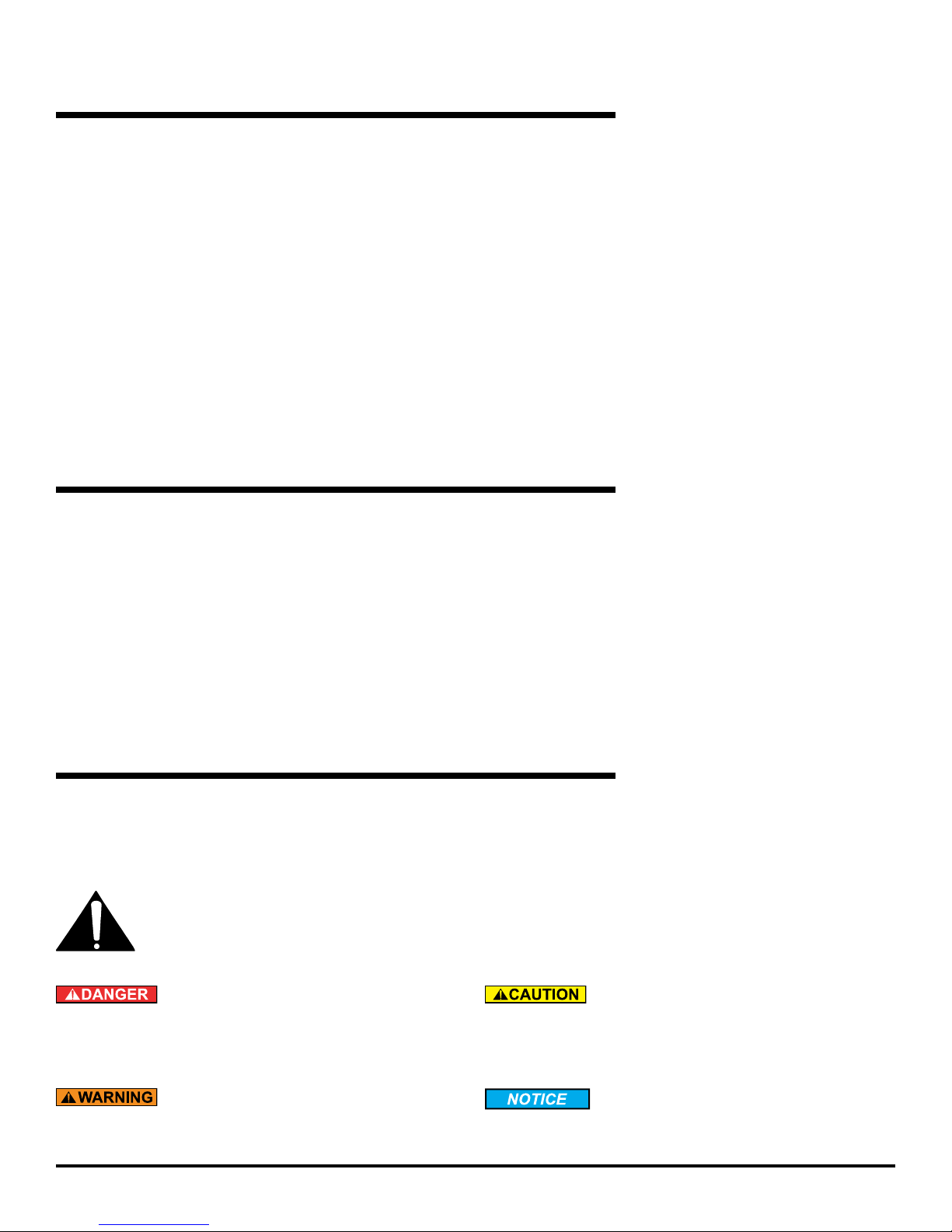

FAN KIT

PACKING KIT

1. Blade Box – 5 blades

2. Fan Motor Box

a. Motor assembly with cover.

b. Remote control.

c. Controller box.

d. Mounting hardware.

e. Power and communication cables.

REQUIRED TOOLS

• Wrenches: 9/16

• Sockets: 1/2, 9/16

• Spirit level, short

• Torque wrench: 15-60 Ft-lbs (for use with sockets)

• Tape measure

• T-15 Torx (included)

• T-40 Torx (included)

PRIOR TO FAN INSTALLATION:

1. Ensure blade length matches fan model size.

Fig. 1

Power and

communication cables

Remote control

Mounting

hardware

Down

tube

Blade assemblies

Bottom cover

Controller box

Motor assembly

with cover

3. Ensure all mounting hardware is present.

NATIONAL FIRE PROTECTION ASSOCIATION STANDARD

In accordance with NFPA 13 Standard from the National Fire

Prevention Association as referenced in sections 12.1.4 and

11.1.7: High Volume Low Speed (HVLS) Fans: The installation

of HVLS fans in buildings equipped with sprinklers, including

ESFR sprinklers, shall comply with the following:

• The maximum fan diameter shall be 14 feet (4.3 m).

• The fan shall be approximately centered between four

adjacent sprinklers.

• The vertical clearance from the fan to sprinkler deector

shall be a minimum of 3 feet (0.9 m).

• All fans shall be interlocked to shut down immediately

upon receiving a water ow signal from the alarm system

in accordance with the requirements of NFPA 72- National

Fire Alarm and Signaling Code.

November 2016 6020031A — Commercial HVLS Fans 5

© Entrematic Group AB 2015

Page 6

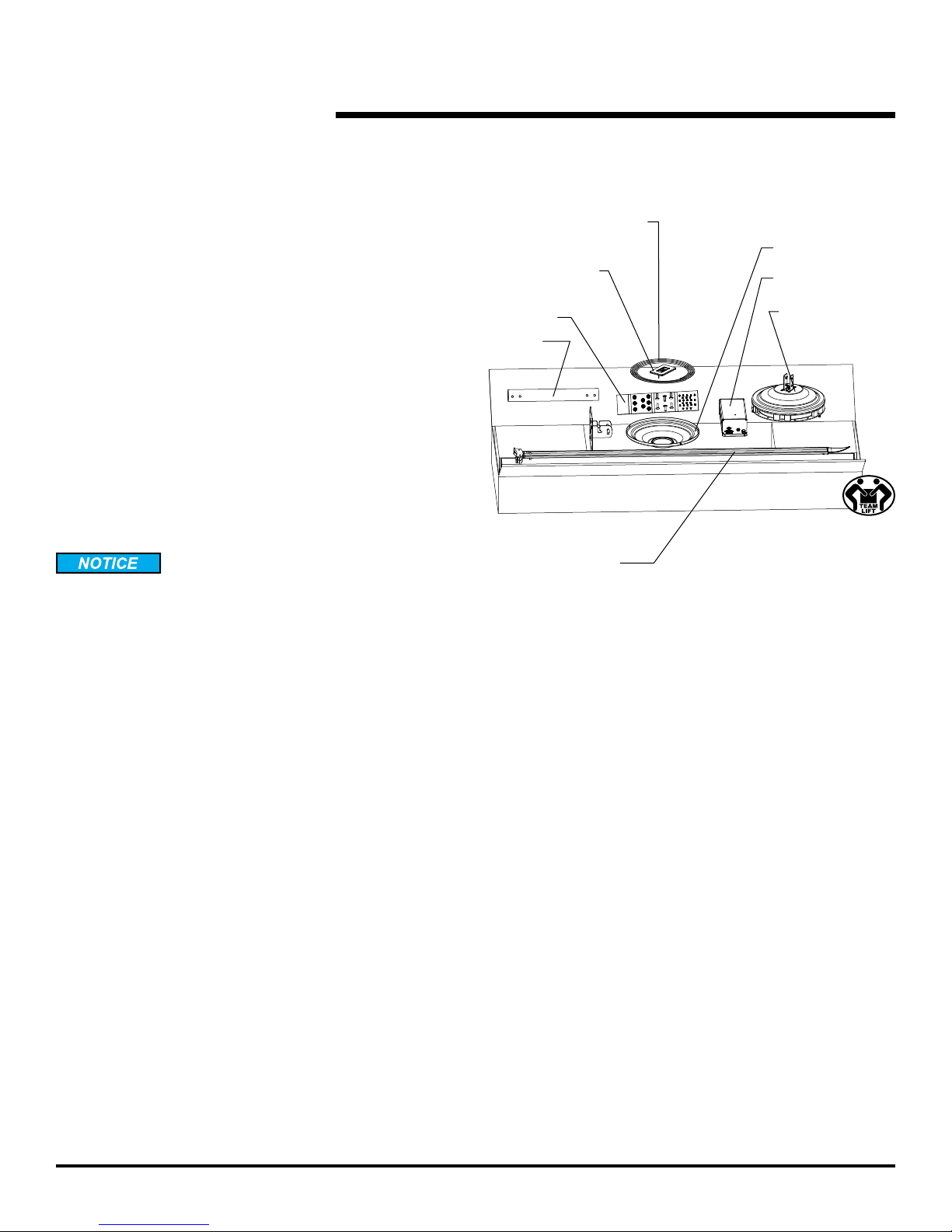

HARDWARE

Fan mount

6017852 (x4)

Clamp plate

Fan mount

6017873 (x4)

3/8-16UNC x 2-1/2" hex bolt

grade 5

serrated head

6015118 (x4)

3/8-16UNC hex nut

grade 5

serrated head

Motor mount hardware

6017838 (x4)

5/16" lock washer

6017835(x4)

5/16-18UNC x 3/4" Torx screw

grade 5

6017872 (x1)

T40 Torx wrench

Down tube mount

6017748 (x2)

3/8-16UNC x 3-1/4" hex bolt

grade 5

serrated head

6015118 (x2)

3/8-16UNC hex nut

grade 5

serrated head

Blade hardware

6017837 (x10)

5/16-18UNC x 1-3/4" hex bolt

6 6020031A — Commercial HVLS Fans November 2016

© Entrematic Group AB 2015

grade 5

serrated head

Bottom cover hardware

6017870 (x3)

8-32UNC x 1/4" Torx screw

6017871 (x1)

T15 Torx wrench

Page 7

INSTALLATION CONSIDERATIONS

Do not mount directly under or within exclusion zone or

in line with HVAC supply discharge vent.

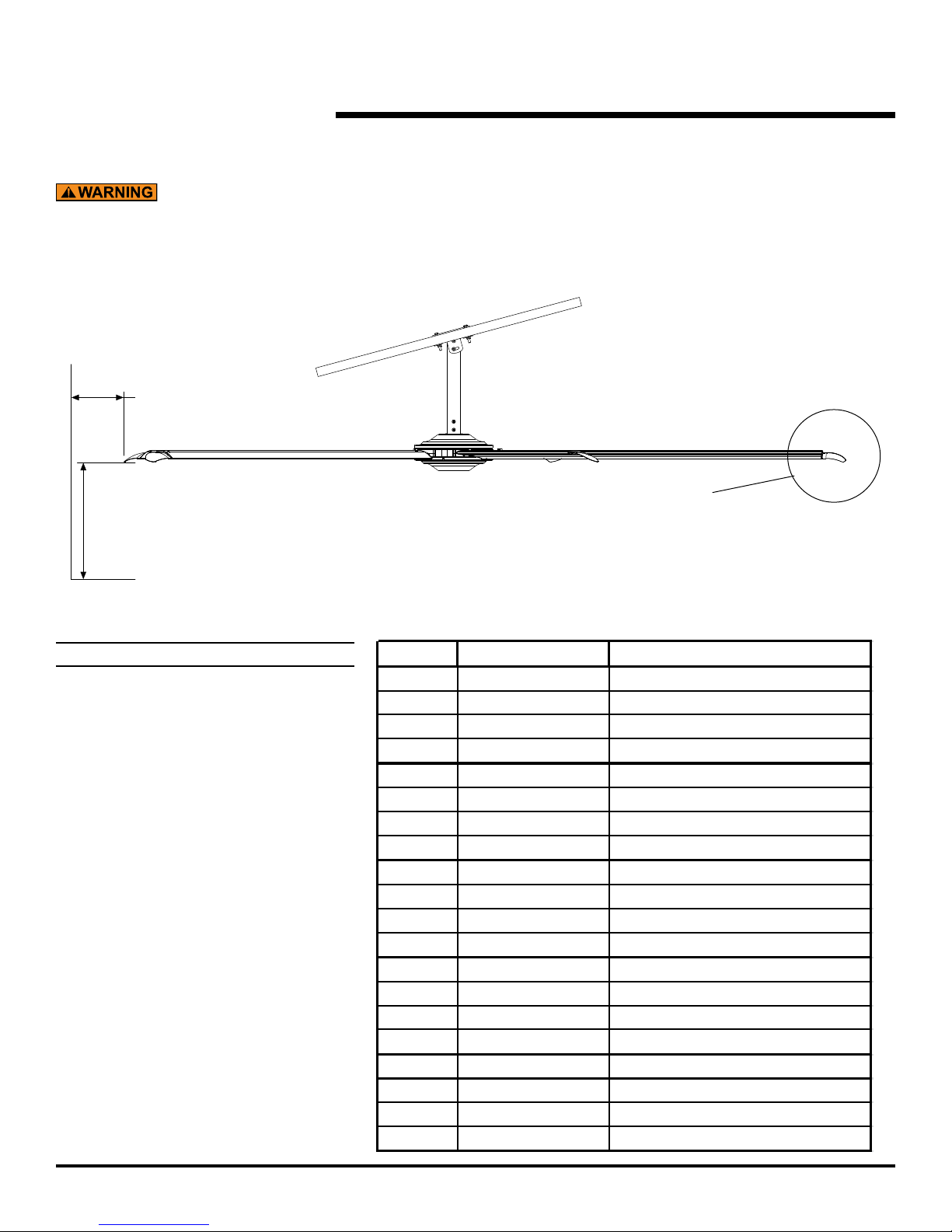

Fig. 2

36" min.

(to wall)

10' min.

(to floor)

36" exclusion zone

(18" radius)

[both sides]

NOTE:

Angle mount has 45° of motion. The

extension lengths shown are minimum

recommendations only, based solely of roof

pitch and fan diameter. Other considerations

must be evaluated when determining

extension requirements, such as placement

of lights, sprinkler systems, HVAC systems,

etc. In addition, OSHA requirements state

that fan blades must be a minimum of 10'

above the oor.

Fan Size Extension size (Ft) Max Roof Angle Allowable (degrees)

6Ft 1.5 17

6Ft 2 20

6Ft 3 35

6Ft 4 40

8Ft 1.5 10

8Ft 2 15

8Ft 3 25

8Ft 4 32

10Ft 1.5 10

10Ft 2 12

10Ft 3 19

10Ft 4 28

12Ft 1.5 8

12Ft 2 10

12Ft 3 17

12Ft 4 25

14Ft 1.5 6

14Ft 2 8

14Ft 3 15

14Ft 4 21

November 2016 6020031A — Commercial HVLS Fans 7

© Entrematic Group AB 2015

Page 8

INSTALLATION CONSIDERATIONS, continued

PLACEMENT AND SPACING

Consult your local distributor to help you plan the most

efcient installation of your fans.

Ensure fan placement is such that the fans blades are a

minimum of 10' from any manned working suface (oor or

mezzanine)

Ensure fan blade does not extend into exclusion zone.

Extensions are available if required. See Fig. 2.

Avoid mounting fans directly under lights or skylights to

avoid visual strobing affect.

NOTE:

If the fan is part of a networked system, ensure placement is

in accordance with the building layout.

NOTE:

Be certain to comply with all local and national codes during

installation.

For fans that will be subjected to high cross winds (open

bay doors, outdoor applications or air conditioning

diffuser ducts) the fan must be at least one fan diameter

(as measured from the end of the winglet) from open

bays or A/C ducts mounted below the blade plane or

there must be at least one fan diameter (as measured

from the end of the winglet) for A/C ducts mounted at or

above the blade plane.

In addition, all outdoor mounted fans must be protected

from exposure from the elements. Consult your local

distributor for outdoor patio applications.

8 6020031A — Commercial HVLS Fans November 2016

© Entrematic Group AB 2015

Page 9

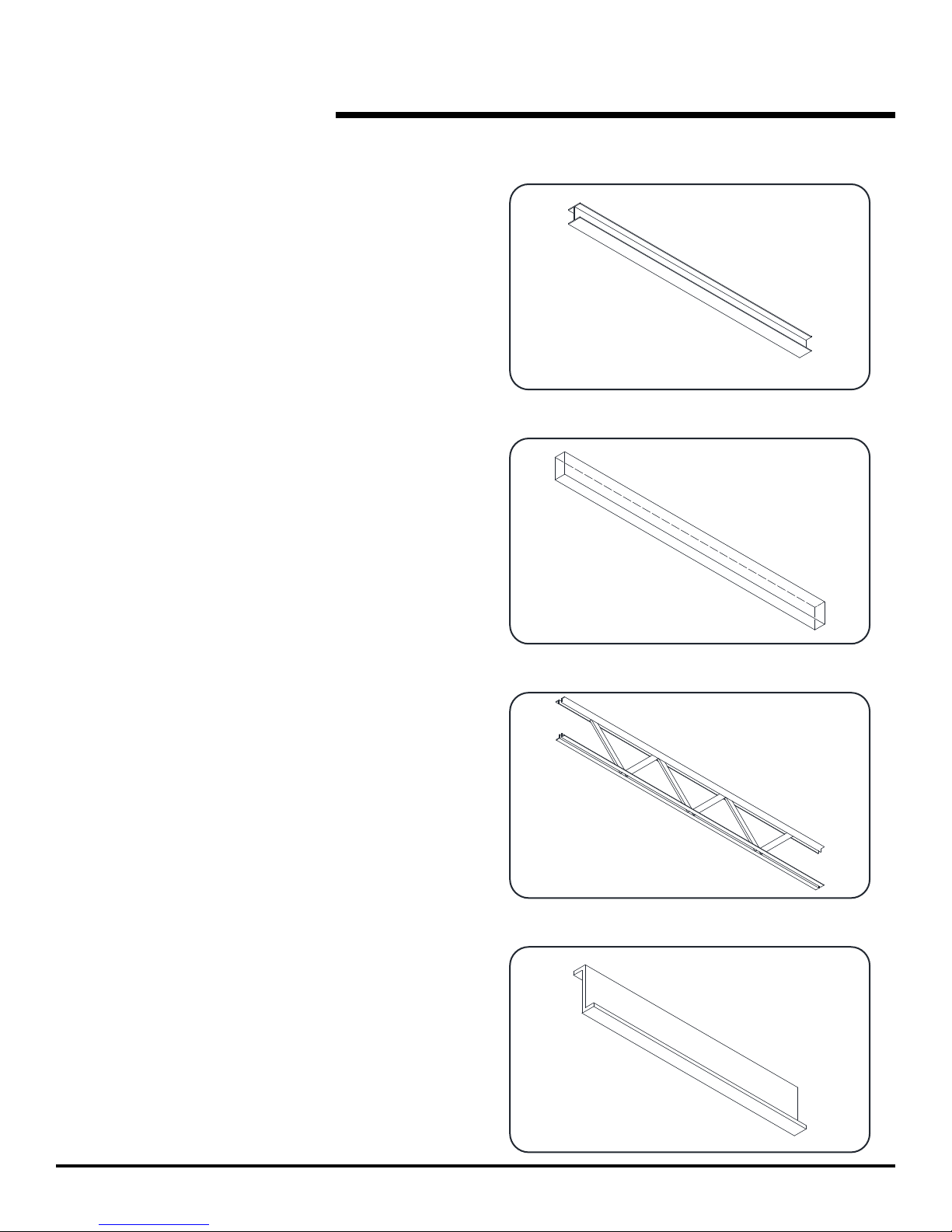

FAN MOUNT (TYPICAL MOUNTING TYPES)

I-BEAM MOUNTED

See page 9 for I-beam mounting instructions.

SOLID BEAM MOUNTED

See page 9 for solid beam mounting instructions.

I-beam

TRUSS MOUNTED

See page 10 for truss mounting instructions.

Z-PURLIN MOUNTED

See page 10 for z-purlin mounting instructions.

Solid beam

Truss

November 2016 6020031A — Commercial HVLS Fans 9

Z-purlin

© Entrematic Group AB 2015

Page 10

FAN MOUNT (TYPICAL MOUNTING TYPES), continued

Fig. 3

If building support beam is not level, ensure proper fan

clearance using the mounting information shown on

page 6 or add mounting extensions as required to ensure

clearance. See Fig 2.

I-BEAM MOUNTING

1. Locate fan centered square to the bottom ange of the

I-beam.

2. Locate and secure the clamp plates (6017852) using the

provided 3/8-16UNC hex serrated ange nuts and 3/816UNC X 2 1/2" long bolts. See Fig. 3.

NOTE:

Ensure that the clamp plates overlap the I-beam ange by

at least 30%.

3. Torque the nuts to 20-28 ft-lbs.

SOLID BEAM MOUNTING

(6018175 — CONCRETE; 6018026 — WOOD)

1. Locate the beam bracket (6018108). Ensure that the

bottom ange of the bracket is below the bottom of the

beam and square to the beam.

NOTE:

The vertical ange of the beam bracket must be square with

respect to the oor. Shim as required.

2. Using the holes in the beam bracket as a template, mark

and drill at least four (4) 9/16" dia. holes through the beam.

Space the holes as widely as practical. See Fig. 4.

3. Locate both beam brackets with respect to the holes and

fasten using 3/8" dia. grade 5 bolts (not provided). Torque

to 20-28 ft-lbs. Locking hardware (nuts and washers)

required.

Do not use lag bolt style fasteners to secure the solid

beam bracket.

Fig. 4

10 6020031A — Commercial HVLS Fans November 2016

© Entrematic Group AB 2015

Page 11

FAN MOUNT (TYPICAL MOUNTING TYPES), continued

TRUSS MOUNT INSTALLATION

NOTE:

The recommended additional structural material for truss

mounting is 1-5/8" x 1-5/8" strut channel beams and hardware.

Other structural materials may be used but consult factory

prior to use.

1. Size the strut channel beams to ensure at least 3" of

overlap at each end on adjoining building truss members.

2. Locate the mount bracket at the desired location (center

preferred) on the strut channel beams and fasten using

the provided 6017873 and 6015118 3/8" dia. grade 5

hardware. Use 6017852 clamp plates as required. Torque

to 20-28 ft-lbs.

3. Locate beam/mount assembly on building truss system.

See Fig. 5. (top mounting preferred)

4. Fasten strut channel beams to building truss system using

3.8" dia., grade 5 hardware (not provided). DO NOT use

spring loaded strut channel beam hardware. Locking

hardware (nuts and washers) required.

Fig. 5

Fig. 6

Z-PURLIN MOUNT INSTALLATION – (OPTIONAL KIT 6017945)

1. The z-purlin mounting kit is available from Entrematic.

Consult a structural engineer prior to installation.

2. Using the z-purlin backer plate as a template, locate and

mark the holes in the z-purlins for both opposing mounts.

3. Attach the z-purlin brackets to the z-purlins. Torque to

20-28 ft-lbs. See Fig. 6.

4. Cut angle irons to required length and install, spanning

the z-purlin mounts using the supplied hardware. Torque

to 20-28 ft-lbs. See Fig. 6.

5. Using the fan mount as a template, mark and drill four

7/16" dia. holes into the spanned angle irons.

6. Mount bracket to the angle irons using the supplied 3/8"

x 1" grade 5 screws and nuts. Torque to 20-28 ft-lbs. See

Fig 6.

November 2016 6020031A — Commercial HVLS Fans 11

© Entrematic Group AB 2015

Page 12

COMPONENTS

Controller box

Blade assembly

Bottom cover

Fig. 7

Fan mount

Down tube

Guy wires

(if required

see page 18)

Power/

communication

cables

Motor assembly

Remote control

12 6020031A — Commercial HVLS Fans November 2016

© Entrematic Group AB 2015

Page 13

INSTALLATION

Downtube

Downtube

DOWN TUBE ASSEMBLY

1. Route the power and communication cables through the

down tube.

2. With the down tube located next to the motor assembly,

install the cable connections to the top of the motor

assembly. See Fig 8. Use the support materials contained

in the shipping package to support motor assembly to

prevent damage.

3. Install the ground cable connector to the terminal located

on the top of the motor assembly. Ensure that the cable

is oriented to prevent interference with the down tube.

See Fig 8.

Ensure proper connection of the power and communication

cables. Failure to properly connect the cables can lead

to operating issues.

4. Slide the down tube over the motor assembly mount bracket

ensuring that the cables are not pinched or placed into a

bind. Align the down tube so that the holes in the down

tube align with the holes in the motor assembly mount

bracket.

Fig. 8

fasteners

Ensure downtube

cables are firmly

engaged

Motor

assembly

5. Attach the down tube to the motor assembly mount bracket

using the 6017838 5/16" dia. Torx screws and 6017838

washers supplied. Tighten the Torx screws using the

provided 6017872 Torx wrench.

Route ground wire

to avoid plug

Motor ground

fastener

November 2016 6020031A — Commercial HVLS Fans 13

© Entrematic Group AB 2015

Page 14

INSTALLATION, continued

communication cables

HANG THE MOTOR

1. In the top hole of the down tube, install a supplied 6017448

3/8" dia. x 3-1/4" bolt and 6015118 nut loosely. Ensure

that the screw does not pinch or bind the power and

communication cables. See Fig 9.

2. Using the bolt installed in the previous step, hang the motor

and down tube assembly on the fan mount. Ensure that

the power and communication cables are free of binding

or pinching. See Fig 10.

3. Loosely install the second 6017448 3/8" dia. x 3-1/4" bolt

and nut in the bottom hole at the top of the down tube.

Ensure that the bolt does not pinch or bind the power and

communication cables. See Fig 11.

4. Using a spirit level, ensure that the down tube is plumb.

5. Tighten the 3/8" dia x 3-1/4" bolts to 20-28 ft-lbs.

Fig. 9

Top hole

Down tube

Fig. 10

Hang down tube

from fan mount

Fig. 11

Power and

(to controller box)

Bottom hole

14 6020031A — Commercial HVLS Fans November 2016

© Entrematic Group AB 2015

Page 15

are firmly engaged.

(to building power)

CONTROLLER INSTALLATION

Building power

(from controller box)

INSTALLATION, continued

Fig. 12

Before doing any electrical work, make certain the power

is disconnected and properly tagged or locked off. All

electrical work must be done by a qualied technician

and meet all applicable codes. USE EXTREME CAUTION.

Touching wires could result in electrical shock, death or

serious injury.

On 120V fan, never allow more than 130 volts incoming

power to be connected to the controller box. Damage to

the fan and serious personal injury or death may result.

NOTE:

The controller box should be located outside of the blade arc

where possible and oriented such that the connections at

either end are accessible.

1. Install the controller box to building structure such that the

box is secure against movement. Fasteners not included.

2. Route the power and communication cables from the fan

mounting location to the controller box. Ensure that the

cables are routed clear of the fan blades and supported

throughout their run.

3. Connect the power and communication cables from the

fan to the controller box. See Fig. 12.

From fan

Ensure

cable connectors

Power cord

Fig. 13

Line

Ground

Neutral

Ensure proper connection of the power and communication

cables. Do not alter factory supplied cables. Failure to

properly connect the cables can lead to operating issues.

4. Connect controller box power cord to building power. See

Fig. 13.

NOTE:

If re alarm option is not being used, ensure re alarm jumper

is in place to ensure proper operation. See page 24.

November 2016 6020031A — Commercial HVLS Fans 15

Power cord

Fig. 14

Fire alarm jumper

© Entrematic Group AB 2015

Page 16

INSTALLATION, continued

12-17 ft-lbs.

Tang Blade pocket

INSTALL BLADES

1. Position mounting end of blade assembly in an open

blade pocket on the motor assembly rim as shown.

Angle the blade approximately 45° downward and rotated

approximately 15° forward. See Fig 15. This will position

the forward tang of the blade mount between the two steel

mount rings on the motor assembly.

2. Rotate the blade backward and upward to allow the mount

end of the blade to slide into the blade pocket on the motor

assembly rim. Position the forward tang of the mount in

the forward end of the blade pocket.

3. Rotate in the same plane as the hub to seat the blade

mount into the blade pocket.

4. Insert two 6017837 5/16" dia x 1-3/4" long fasteners

from below through the hub mount ring and blade mount.

Tighten enough to hold the blade in place but do not fully

tighten at this time.

5. Repeat installation steps 1 through 4 for each of the

remaining blades.

Fig. 15

Insert blade

tab at an angle.

6. Fully torque the blade mount fasteners to 12-17 ft-lbs.

Slide tab in

and to left.

Rotate until

blade tab

clicks in

place.

Install bolts

through

bottom of

hub and

tighten with

1/2" socket.

Torque to

16 6020031A — Commercial HVLS Fans November 2016

© Entrematic Group AB 2015

Page 17

Bottom cover

INSTALL BOTTOM COVER

1. Align the mounting holes on the bottom cover with the

mounting holes on the motor assembly. Install the three

6017870 #8 dia Torx fasteners supplied. Firmly tighten

the fasteners using the 6017871 Torx tool provided. See

Fig 16.

INSTALLATION, continued

Fig. 16

November 2016 6020031A — Commercial HVLS Fans 17

© Entrematic Group AB 2015

Page 18

thin rod provided into

the end of the clamp.

cable end.

INSTALLATION, continued

OPTIONAL GUY WIRE KIT (6016307)

NOTE:

Guy wires are required on all fan installations where the down

tube is greater than 4' in length. Guy wires are designed to

constrain lateral movement of the fan while in operation.

This movement may be due to impacts on the fan or winds

impinging on the blades that would cause the fan to sway.

Failure to attach guy wires may result in loss of warranty.

Ensure that the proper guy wire length is accompanying

the extension used. Ensure that the angle formed by the

guy wire with the roof structure is less than 45 degrees.

See Fig 17. Avoid any sharp edges or corners to reduce

fatiguing and fraying of the guy wires. Failure to attach

guy wires may result in severe injury or death.

1. Remove parts from package and inventory. Package

contents include: 4 cables, 4 gripple cable clamps, 2

5/16-18 x 1" serrated anged hex nuts, 2 guywire clamp

brackets and 1 Gripple release tool.

Fig. 17

45°

2. Locate the down tube clamp bracket on the down tube. The

clamp bracket should be located approximately halfway

between the mounting bracket and the motor assembly.

3. Fasten the halves of the down tube clamp bracket with

the 5/16" dia x 1" carriage bolts supplied. Torque to 12-17

ft-lbs.

4. Attach each cable to the building structure by either looping

the cable through the cable eyelet and around a beam/

truss or other secure building structure (preferred method)

or by using 3/8" dia. grade 5 fasteners and lock-washers

(not provided) to secure to structure. Tighten fasteners

to 20-28 ft-lbs.

5. On each cable assembly, slide one Gripple cable clamp

approximately 12" on the cable. See Fig 17.

6. Loop one cable assembly through each lug on the down

tube clamp bracket using the free end of the cable.

7. Thread the free end of each cable assembly back through

the Gripple cable clamp. Leave loose.

45°

To loosen, insert the

While gripping the

clamp and pressing

the rod into the

clamp, pull on the

18 6020031A — Commercial HVLS Fans November 2016

© Entrematic Group AB 2015

Page 19

INSTALLATION, continued

8. Using a spirit level on the down tube, tighten the cable

assemblies by pulling the cable through the Gripple

cable clamp as required to achieve a taut cable set while

maintaining the down tube plumb. Either secure the loose

cable ends or trim.

INSTALLING THE REMOTE

1. The fan remote may be mounted directly into a standard

wall junction box or directly to a wall surface using mounting

tape. Locate the remote within 50' of the fan. See Fig 18.

NOTE:

A clear sight line between the fan and the remote is preferred

in order to maximize the remote's effective distance.

Fig. 18

‘snap’

Wallplate

adapter

Wallplate

November 2016 6020031A — Commercial HVLS Fans 19

© Entrematic Group AB 2015

Page 20

OPERATING INSTRUCTIONS

and status light

Decrease speed

Before operating the fan, read and follow the Safety Practices,

Warnings and Operating Instructions in this manual. Use by

untrained personnel could result in death or serious injury.

VERIFY PRIOR TO OPERATION

1. Power supplied to fan.

2. Obstruction clearance.

3. Safety cables (optional) properly installed.

4. All fasteners are properly torqued.

Fig. 19

Green LED

Power on

STARTING THE FAN

NOTE:

Pressing the POWER ON button once, while the fan is running

will set fan to full speed.

Visually inspect the fan to ensure that there are no obstructions

or personnel in the movement area.

1. Press the FAVORITE button. The fan will start and spin

up to approximately 2/3 full speed.

2.

Adjust the speed by pressing either the INCREASE SPEED

or DECREASE SPEED buttons. Each press of the buttons

will adjust the fan speed by approximately 5%.

STOPPING THE FAN

1. Press the POWER OFF button once to stop the fan.

PROGRAMMING THE FAVORITE BUTTON

NOTE:

The fan ships from the factory with the FAVORITE button

pre-programmed to approximately 2/3 full speed.

Increase speed

Favorite button

Power off

Fig. 20

1. With the fan running, adjust the speed of the fan using

either the INCREASE SPEED or DECREASE SPEED

button to achieve desired speed. See Fig. 19.

2. Once desired speed is achieved, press and hold the

FAVORITE button for 10 seconds. This speed now

becomes the new FAVORITE speed.

CHANGING DIRECTION

1. The fan direction control is located on the top of the motor

assembly. To reverse direction, stop the fan and press the

button. See Fig. 20.

20 6020031A — Commercial HVLS Fans November 2016

© Entrematic Group AB 2015

Fan direction control

Page 21

Before service, inspection, or cleaning make certain that

the power is disconnected and properly locked off.

Before servicing the fan, read and follow the Safety

Practices on page 3 and the Operation section in this

manual. Failure to do so could result in death or serious

injury.

To ensure the continued proper operation of your fan,

perform the following planned maintenance procedures.

Fig. 21

PLANNED MAINTENANCE

ANNUALLY

1. Inspect blade mounting hardware and tighten as required.

Torque to 20-28 ft-lbs.

2. Inspect guy wires for chafng or wear. Ensure wires are

taut. Re-tighten cables as required and ensure all cable

mounting hardware is secure. Maintain plumb attitude of

downtube. Torque to 12-17 ft-lbs.

3. Inspect fan blades and winglets. Clean fan blades as

required. Use a soft dry cloth. If necessary, use a mild

detergent to clean surfaces. Do not use harsh cleansers.

Legend

Symbol

Description

Cleaning

(Location - Frequency)

Visually Inspect

(Replace Damaged Or Worn)

Check Fasteners

(Torque to spec. if necessary)

November 2016 6020031A — Commercial HVLS Fans 21

© Entrematic Group AB 2015

Page 22

TROUBLESHOOTING

Before servicing the fan, read and follow the Safety

Practices on page 3 and the Operation section in this

manual. Failure to do so could result in death or serious

injury.

Use the Troubleshooting Guide if the fan fails to perform

properly. Find the condition that most closely matches your

situation and make the recommended adjustments.

Problem Possible Cause Solution

1. No blue light, no fan movement

a) No power to fan

b) Circuit breaker on controller

box tripped

c) Communication cable loose

d) Remote is not programmed

e) Bad remote

f) Issue inside controller box

Before service, inspection, or cleaning make certain that

the power is disconnected and properly locked off.

Before doing any electrical work, make certain the power

is disconnected and properly locked or tagged off. Failure

to do so may result in death or serious injury. All electrical

troubleshooting and repair must be done by a qualied

technician and meet all applicable codes. Failure to do so

could result in electrical shock, death or serious injury.

a) Check incoming power

b) Reset circuit breaker See Fig. 22.

c) Ensure communication cable is rmly

attached at each end.

d) Program remote. See page 23.

e) Replace and program new remote

f) Consult technical service

2.

Fast blink (approx. 2 blinks/sec.)

blue light, no fan movement

3. Fast blink blue light, fan

movement.

4. Slow blink blue light, no

movement

5. Solid blue light, sustained

shuddering movement

6. Fan runs but makes noise or

vibrates

a) Power cable loose

a) Bad communication cable

b) Encoder cable loose

c) Motor power lead loose

d) Issue inside controller box

a) Fire alarm jumper issue

a) Issue inside controller box

a) Bad motor bearing

b) Missing or damaged winglet

c) Loose or damaged blade

d) Loose or damaged guy

wires

a) Ensure power cable is rmly attached at

each end

a) Replace cable

b) Consult technical service

c) Consult technical service

d) Consult technical service

a) Ensure jumper wire is in place

a) Consult technical service

a) Check if fan rotates freely by hand

without binding

b) Check winglets

c) Ensure blades are rmly attached and

mounting fasteners are tight

d) Ensure guy wires are taut and properly

installed

22 6020031A — Commercial HVLS Fans November 2016

© Entrematic Group AB 2015

Page 23

TROUBLESHOOTING, continued

Controller box

Green LED

PROGRAMMING THE REMOTE

NOTE:

The fan ships from the factory with the remote pre-programmed

and ready to use. To program or reprogram the remote, access

to the controller box will be required. Ensure that the fan is

not running and there is power to the controller box.

1. Locate the controller box and ensure that there is access

to the top cover.

2. On the top cover, locate the remote program access hole.

See Fig 22.

3. With a small dowel or other blunt object, gently depress

the programming button for 10 seconds.

4. On the remote, press and hold the power off button for 6

seconds. Release the button when the green LED on the

remote begins to ash to show that the wireless remote

has been associated with the controller. See Fig 23.

CHANGING THE BATTERY IN THE REMOTE

Fig. 22

Fig. 23

Circuit breaker

Program

access hole

Power off

Burn hazard. To avoid the risk of re, explosion or burns, DO

NOT recharge, disassemble, crush, puncture or incinerate

the battery. DO NOT heat the battery above 212°F (100°C).

NOTE:

A dead battery must be replaced promptly in order to retain

programming.

1. Remove the wireless remote from the faceplate assembly.

2. Place a athead screwdriver into the slot at the bottom of

3. Slide the battery out, toward the top of the remote.

4. Slide a new CR 2032 battery underneath the contact strap,

5. Replace the back enclosure.

6. Ensure proper fan operation. If the remote fails to control

Fig. 24

the remote. Twist to open. DO NOT press buttons without

back enclosure on. See Fig. 24.

with the (-) terminal toward the front of the remote.

the fan, re-program the remote using the process described

above.

7. Re-install remote into faceplate as required.

November 2016 6020031A — Commercial HVLS Fans 23

© Entrematic Group AB 2015

Page 24

FIRE CONTROL SYSTEM FAN SHUTDOWN — OPTIONAL

This fan includes a re alarm jumper for a building re control

systems option that allows the fan to be shut down by the re

control system in case of a re emergency.

NOTE:

Ensure that the re alarm jumper is in place or the building

re control system is connected and jumper removed.

1. The normally closed (NC) contacts must be dry contacts.

They open in the event of an active re alarm.

2. The re control system fan shutdown option is not

enabled when shipped. To enable the re control system

fan shutdown option, remove jumper and route a pair of

conductors to a set of customer supplied N.C. contacts

in the building's re alarm panel. See Fig. 25.

3. To test the re control system fan shutdown operation

remove the wire from the NC contact at the building re

control panel. The fan should coast to a stop.

If the jumper is left installed the fan will not shut down

due to re control system contacts.

Fig. 25

Fire alarm jumper

24 6020031A — Commercial HVLS Fans November 2016

© Entrematic Group AB 2015

Page 25

PARTS LIST

Fig. 26

2

1

To ensure proper function, durability and safety of the

product, only replacement parts that do not interfere with

the safe, normal operation of the product must be used.

Incorporation of replacement parts or modications that

weaken the structural integrity of the product, or in any

way alter the product from its normal working condition

at the time of purchase from Entrematic may result in

product malfunction, breakdown, premature wear, death

or serious injury.

4

11

3

8

12

10

9

21

November 2016 6020031A — Commercial HVLS Fans 25

18

14

22

7

6

13

5

17

20

19

15

© Entrematic Group AB 2015

16

Page 26

PARTS LIST

Item Quantity Description Part Number

1 1 MOUNT, 45° 6018002

2* 1 UPPER COVER - SILVER 6016269

3* 1 LOWER COVER - SILVER 6017786

4 1 CONTROLLER CONSULT FACTORY

5 1 POWER CABLES - 132" 6016279

6 1 CONTROL CABLES - 132" 6017645

7 1 CONCRETE BEAM MOUNT — OPTIONAL 6018175

8* 1 DOWN TUBE - SILVER - 18" 6017726

9* 1 BLADE ASSEMBLY — 6FT - SILVER 6017580

BLADE ASSEMBLY — 8FT - SILVER 6017581

BLADE ASSEMBLY — 10FT - SILVER 6017582

BLADE ASSEMBLY — 12FT - SILVER 6017583

BLADE ASSEMBLY — 14FT - SILVER 6017584

10 1 REMOTE CONSULT FACTORY

11 1 MOTOR ASSEMBLY 6016280

12 1 CEILING COVER PLATE 6017848

13 1 WOOD BEAM CLAMP — OPTIONAL 6018026

14 1 EXTENSION GUY WIRE KIT, 3-5' 6016307

EXTENSION GUY WIRE KIT, 6-10' 6017765

EXTENSION GUY WIRE KIT, 11-15' 6017766

15 2 3/8-16UNC X 3 1/4", FLNG SERTD HEX BOLT, GRD-5 6017748

16 3 8-32UNC X1/4 LG FLT HD SCREW-TORX, ZP 6017870

17 10 5/16-18UNC X 1 3/4", FLGD SRTD HEX BOLT,GRD-5, ZP 6017837

18 6 3/8-16UNC HEX SERRATED FLANGE NUT 6015118

19 4 5/16-18UNC X 3/4 LG TORX SOC HD SCREW, GRD 2, ZP 6017835

20 4 5/16 INT TOOTH LOCK WASHER 6017838

21 4 CLAMP PLATE, COMM FAN 6017852

22 4 3/8-16UNC X 2 1/2", FLNG SERTD HEX BOLT, GRD-5 6017873

*Consult factory for colors other than silver.

26 6020031A — Commercial HVLS Fans November 2016

© Entrematic Group AB 2015

Page 27

WARRANTY

THIS LIMITED WARRANTY IS ENTREMATIC’S SOLE AND EXCLUSIVE WARRANTY WITH RESPECT TO THE HVLS

FAN AND IS IN LIEU OF ANY OTHER GUARANTEES OR WARRANTIES, EXPRESS OR IMPLIED. THIS LIMITED

WARRANTY APPLIES ONLY TO THE ORIGINAL PURCHASER OF THE HVLS FAN AND CANNOT BE TRANSFERRED.

ENTREMATIC warrants that this HVLS FAN will be free from aws in material and workmanship under normal use for a

period of one (1) year from the earlier of 1) 60 days after the date of initial shipment by ENTREMATIC, or 2) the date of

installation of the HVLS FAN by the original purchaser, provided that the owner maintains and operates the HVLS FAN in

accordance with this User's Manual.

In the event that this HVLS FAN proves decient in material or workmanship within the applicable Limited Warranty period,

owner shall so notify ENTREMATIC, and Entrematic will, at its option:

1. Replace the HVLS FAN, or the decient portion(s) thereof, without charge to the owner; or

2. Alter or repair the HVLS FAN, on site or elsewhere, without charge to the owner.

In addition, ENTREMATIC warrants the HVLS FAN for an additional nine (9) years for replacement parts only.

This Limited Warranty does not cover any failure caused by improper installation, abuse, improper operation,

negligence, or failure to maintain and adjust the HVLS FAN properly. Parts requiring replacement due to damage

resulting from impact, abuse, or improper operation are not covered by this warranty. ENTREMATIC DISCLAIMS ANY

RESPONSIBILITY OR LIABILITY FOR ANY LOSS OR DAMAGE OF ANY KIND (INCLUDING WITHOUT LIMITATION,

DIRECT, INDIRECT, CONSEQUENTIAL OR PUNITIVE DAMAGES, OR LOST PROFITS OR LOST PRODUCTION)

arising out of or related to the use, installation or maintenance of the HVLS FAN (including premature product

wear, product failure, property damage or bodily injury resulting from use of unauthorized replacement parts or

modication of the HVLS FAN). ENTREMATIC’s sole obligation with regard to a HVLS FAN that is claimed to be

decient in material or workmanship shall be as set forth in this Limited Warranty. This Limited

Warranty will be null and void if the original purchaser does not notify ENTREMATIC’s warranty department within

ninety (90) days after the product deciency is discovered.

THERE ARE NO WARRANTIES, EXPRESS OR IMPLIED, WHICH EXTEND BEYOND THE DESCRIPTION ON THE

FACE HEREOF, INCLUDING, BUT NOT LIMITED TO, A WARRANTY OF MERCHANTABILITY OR OF FITNESS FOR A

PARTICULAR PURPOSE, ALL OF WHICH ENTREMATIC HEREBY DISCLAIMS.

November 2016 6020031A — Commercial HVLS Fans 27

© Entrematic Group AB 2015

Page 28

Please direct questions about your fan to your local distributor.

Your local distributor is:

Corporate Head Ofce:

1612 Hutton Dr. Suite 140

Carrollton, TX. 75006

Tel. 1-972-466-0707

Fax 1-972-323-2661

Part No. 6020031A© Entrematic Group AB 2015

Loading...

Loading...