Page 1

Swing Door Operator

EM EMSW EMO

ILL-01780

Installation and Service Manual

Original instructions

1005088-EMEI-16.0 – Issue 2016-10-24

Page 2

© All rights in and to this material are the sole property of Entrematic Nordic AB. Copying, scanning, alterations or modifications are

expressly forbidden without the prior written consent of Entrematic Nordic AB. Rights reserved for changes without prior notice.

Backtrack information: folder:Workspace Main, version:a356, Date:2016-10-24 time:10:35:20, state: Frozen

Page 3

CONTENTS - Original instructions

51 Revision .....................................................................................................................................................................................

62 Instructions for safe operation ...........................................................................................................................................

73 Important information .........................................................................................................................................................

73.1 Intended use ....................................................................................................................................................................................

73.2 Safety precautions .........................................................................................................................................................................

73.3 Electronic equipment reception interference .....................................................................................................................

83.4 Environmental requirements .....................................................................................................................................................

94 Technical specifications ........................................................................................................................................................

104.1 Permitted door weight and door width ................................................................................................................................

115 How the EM EMSW EMO works .........................................................................................................................................

115.1 Opening ............................................................................................................................................................................................

115.2 Closing ...............................................................................................................................................................................................

115.3 Functions on the basic control unit CU-ESD .........................................................................................................................

115.3.1 Power failure ..................................................................................................................................................................

115.3.2 Spring force ....................................................................................................................................................................

115.3.3 Extended closing force/torque (CLTQ) ..................................................................................................................

115.3.4 Power assist (POAS) .....................................................................................................................................................

115.3.5 Push and go (PAG) ........................................................................................................................................................

115.3.6 Overhead presence detector (OPD), frame mounted .....................................................................................

125.3.7 Mat ....................................................................................................................................................................................

125.4 Functions on the extension unit EXU-SI .................................................................................................................................

125.4.1 KILL function ..................................................................................................................................................................

125.4.2 Function of locks ...........................................................................................................................................................

125.4.3 Program selector ..........................................................................................................................................................

125.4.4 Impulses ..........................................................................................................................................................................

135.4.5 OPEN/CLOSE impulse ..................................................................................................................................................

135.4.6 Power failure mode (backup batteries are installed) – optional ..................................................................

135.4.7 Nurse and bed functionality .....................................................................................................................................

135.5 Functions on the extension unit EXU-SA – optional ...........................................................................................................

135.5.1 Presence impulse approach, door mounted .......................................................................................................

145.5.2 Presence detection swingpath, door mounted ..................................................................................................

145.5.3 Monitored safety sensors ...........................................................................................................................................

145.5.4 Open door indication ..................................................................................................................................................

145.5.5 Error indication .............................................................................................................................................................

156 Models ........................................................................................................................................................................................

156.1 EM EMSW EMO, standard cover (wall mounted) ................................................................................................................

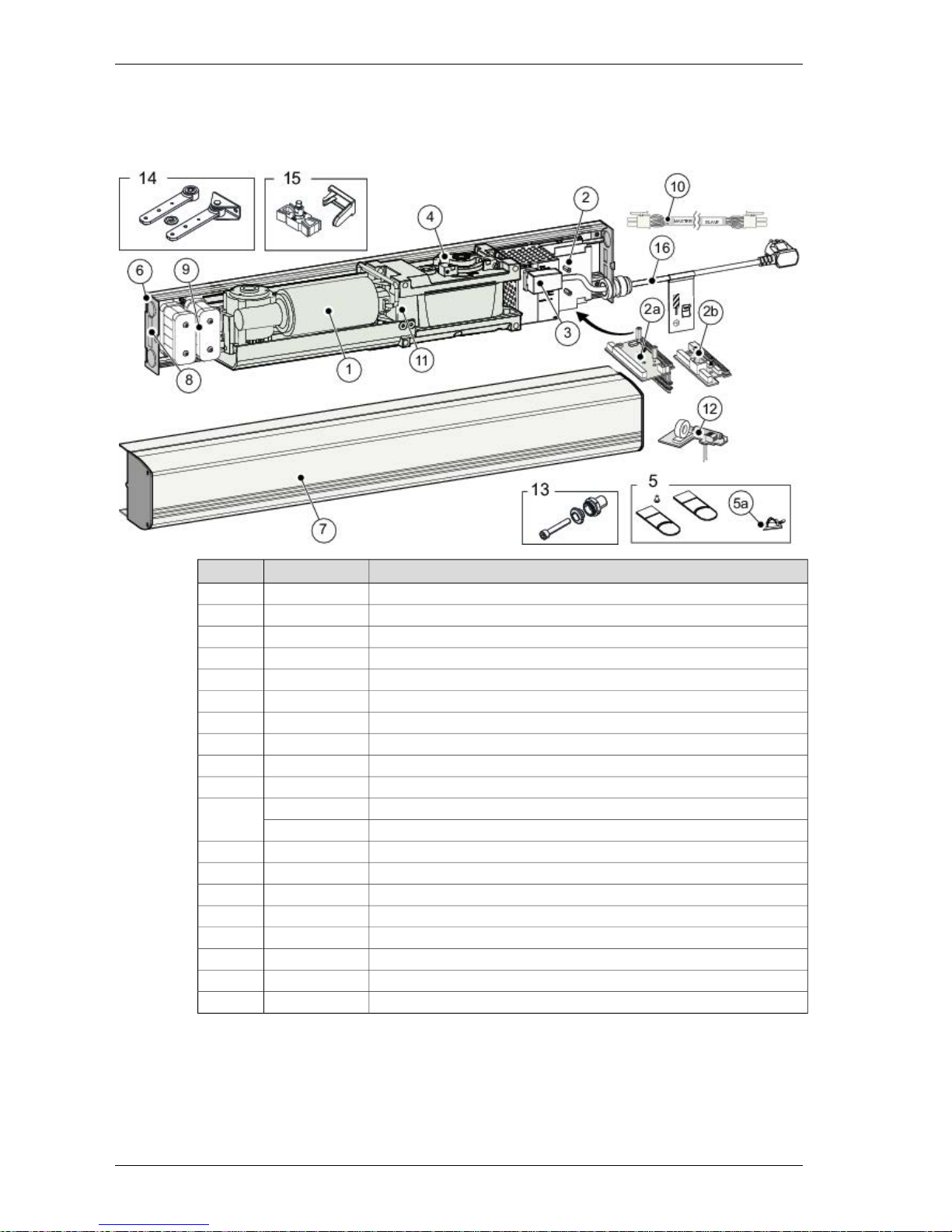

167 Part identification & Accessories ......................................................................................................................................

177.1 Arm system, PUSH .........................................................................................................................................................................

177.1.1 PUSH-arm extensions .................................................................................................................................................

177.2 Arm system, PUSH-335 ................................................................................................................................................................

177.3 Arm system, PULL ...........................................................................................................................................................................

187.4 Arm system, PULL-220 .................................................................................................................................................................

187.5 Arm system, ST-V / ST-H ...............................................................................................................................................................

187.5.1 Options for ST-V / ST-H ................................................................................................................................................

187.6 Reveal spacer: PULL / PULL-220 .................................................................................................................................................

197.7 20 mm extension ...........................................................................................................................................................................

197.8 Drive shaft extension kits ............................................................................................................................................................

207.9 Control switches ............................................................................................................................................................................

207.9.1 Power ON/OFF switch .................................................................................................................................................

207.9.2 ON/OFF/HOLD open switch (will not operate electric lock) ..........................................................................

207.9.3 4-position switch PS-4C (operates the electric lock) .......................................................................................

217.10 Sync cable for double doors (synchronizing of 2 operators) ..........................................................................................

237.11 Extension units ................................................................................................................................................................................

237.12 Battery backup unit .......................................................................................................................................................................

247.13 Cover piece kit ................................................................................................................................................................................

247.13.1 Middle piece kit .............................................................................................................................................................

247.14 Labels .................................................................................................................................................................................................

3Issue 2016-10-241005088-EMEI-16.0

Page 4

258 Pre-installation ........................................................................................................................................................................

258.1 General tips/Safety concerns .....................................................................................................................................................

258.2 Operator/Door handing ...............................................................................................................................................................

268.3 Installation examples ....................................................................................................................................................................

268.4 Fastening requirements (but not included) .........................................................................................................................

278.5 Tools required .................................................................................................................................................................................

278.6 Installation on double doors ......................................................................................................................................................

289 Mechanical installation ........................................................................................................................................................

289.1 Operator with PUSH arm system ..............................................................................................................................................

349.2 Operator with PULL arm system ...............................................................................................................................................

409.3 Installation of operator with arm system ST .........................................................................................................................

4910 Electrical connection .............................................................................................................................................................

4910.1 Mains connection ..........................................................................................................................................................................

5010.2 Control units ....................................................................................................................................................................................

5010.2.1 CU-ESD .............................................................................................................................................................................

5010.2.2 Arm system selection ..................................................................................................................................................

5110.2.3 Extension units EXU-SI / EXU-SA ..............................................................................................................................

5210.2.4 Extension unit EXU-SI ..................................................................................................................................................

5310.2.5 Extension unit EXU-SA ................................................................................................................................................

5410.3 Sensor cable inlet ...........................................................................................................................................................................

5511 Start-up ......................................................................................................................................................................................

5511.1 Adjusting the door stop ...............................................................................................................................................................

5711.2 Auto-learn – automatically sets back and latch check (recommended) .....................................................................

5711.2.1 One push / two pushes on the LEARN BUTTON (LRN) .....................................................................................

5711.2.2 Double doors .................................................................................................................................................................

5811.3 General adjustment ......................................................................................................................................................................

5911.4 Connection of activation units and accessories ..................................................................................................................

6012 Cover ..........................................................................................................................................................................................

6012.1 Fitting and removing the cover .................................................................................................................................................

6112.2 Middle piece cover ........................................................................................................................................................................

6213 Signage .......................................................................................................................................................................................

6314 Advanced settings ..................................................................................................................................................................

6314.1 Learn with advanced setting of “back- and latch-check” ..................................................................................................

6314.2 Revert to default values for “back- and latch-check" (Level 1) .......................................................................................

6414.3 Changing group of parameters (Level 2) ...............................................................................................................................

6514.4 Classification (Level 3) ..................................................................................................................................................................

6614.5 Overhead Presence Detection (OPD) Monitoring (Level 4) ............................................................................................

6714.6 Lock kick (Level 5) ..........................................................................................................................................................................

6714.7 Lock unlocked status (Level 6) ..................................................................................................................................................

6815 Reducing / Increasing the “Spring pre-tension” (SPTE) .............................................................................................

6916 Installation and adjustments ..............................................................................................................................................

6916.1 Complementary Safety Devices Swing Doors ......................................................................................................................

6916.2 Swing Doors Opening and Closing Time ................................................................................................................................

6916.2.1 How to find the correct opening and closing time ...........................................................................................

7016.3 Diagrams for Door weight ..........................................................................................................................................................

7016.3.1 Aluminium frame with glass .....................................................................................................................................

7117 Troubleshooting .....................................................................................................................................................................

7217.1 Error indication ...............................................................................................................................................................................

7318 Service / Maintenance ...........................................................................................................................................................

1005088-EMEI-16.0Issue 2016-10-244

Page 5

1 Revision

The following pages have been revised:

Revision 15.0 → 16.0Page

Updated.53

Added this new section.54

5Issue 2016-10-241005088-EMEI-16.0

1 Revision

Page 6

2 Instructions for safe operation

• Failure to observe the information in this manual may result in

personal injury or damage to equipment.

• Toreduce the risk of injury to persons - use this operator with single

or double pedestrian swinging or folding doors only.

• Do not use the equipment if repair or adjustment is necessary.

• Disconnect supply when cleaning or other maintenance is to be

carried out.

• The operator can be used by children age 8 and above, and persons

with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, if they have been given supervision or instruction by a person responsible for their safety concerning safe

operator use and the possible hazards involved.

This does not however prevent those persons to use the door where

the operator is installed.

• Cleaning and user maintenance shall not be made by children

without supervision.

• Do not let children climb on or play with the door or the fixed/remote controls.

• Risk of battery explosion if wrong type of battery is used.

• In all instances, where work is being done, the area is to be secured

from pedestrian traffic, and the power removed to prevent injury.

• The doorset can be operated automatically by sensors or manually

by activators. It can also be used manually as a door closer.

1005088-EMEI-16.0Issue 2016-10-246

2 Instructions for safe operation

Page 7

3 Important information

3.1 Intended use

The door is designed to offer continuous use, a high degree of safety and maximum lifetime. The

system is self-adjusting to the effects caused by normal variations in the weather conditions and

to minor friction changes caused by e.g. dust and dirt.

For escape in emergency situations the doorset is opened manually.

This manual contains the necessary details and instructions for the installation, maintenance and

service of the Swing Door Operator EM EMSW EMO.

The EM EMSW EMO is an automatic swing door operator developed to facilitate entrances to

buildings and within buildings through swing doors. The EM EMSW EMO is a low-energy operator

using a DC motor and a gear-reduction system to drive an arm system, which opens the door. It is

to be installed indoors where it is suitable for almost all types of external and internal swing doors.

This widely-used operatorcanbe found on applications ranging from handicapped-access in private

homes to high-traffic retail operations.

The motor and gear system are combined into a compact unit mounted alongside the control unit

within the cover. The operator is connected to the door leaf with different arm systems.

For use see User manual 1005099.

Save these instructions for future reference.

3.2 Safety precautions

Be sure to complete a risk assessment and site acceptance test before taking the door into operation.

To avoid bodily injury,material damage and malfunction of the product, the instructions contained

in this manual must be strictly observed during installation, adjustment, repairs and service etc.

Training is needed to carry out these tasks safely.Only Entrematic Nordic-trained technicians should

be allowed to carry out these operations.

3.3 Electronic equipment reception interference

The equipment complies with the European EMC directive (US market FCC Part 15), provided installed according to Installation and Service manual.

The equipment may generate and use radio frequency energy and if not installed and used properly,

it may cause interference to radio, television reception or other radio frequency type systems.

If other equipment does not fully comply with immunity requirements interference may occur.

There is no guarantee that interference will not occur in a particular installation. If this equipment

does cause interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of

the following measures:

• Re-orient the receiving antenna.

• Relocate the receiver with respect to the equipment.

• Move the receiver away from the equipment.

• Plug the receiver into a different outlet so that equipment and receiver are on different branch

circuits.

• Check that protective earth (PE) is connected.

If necessary, the user should consult the dealer or an experienced electronics technician for additional suggestions.

7Issue 2016-10-241005088-EMEI-16.0

3 Important information

Page 8

3.4 Environmental requirements

Entrematic Nordic products are equipped with electronics and may also be equipped with batteries

containing materials which are hazardous to the environment. Disconnect power before removing

electronics and battery and make sure it is disposed of properly according to local regulations (how

and where) as was done with the packaging material.

1005088-EMEI-16.0Issue 2016-10-248

3 Important information

Page 9

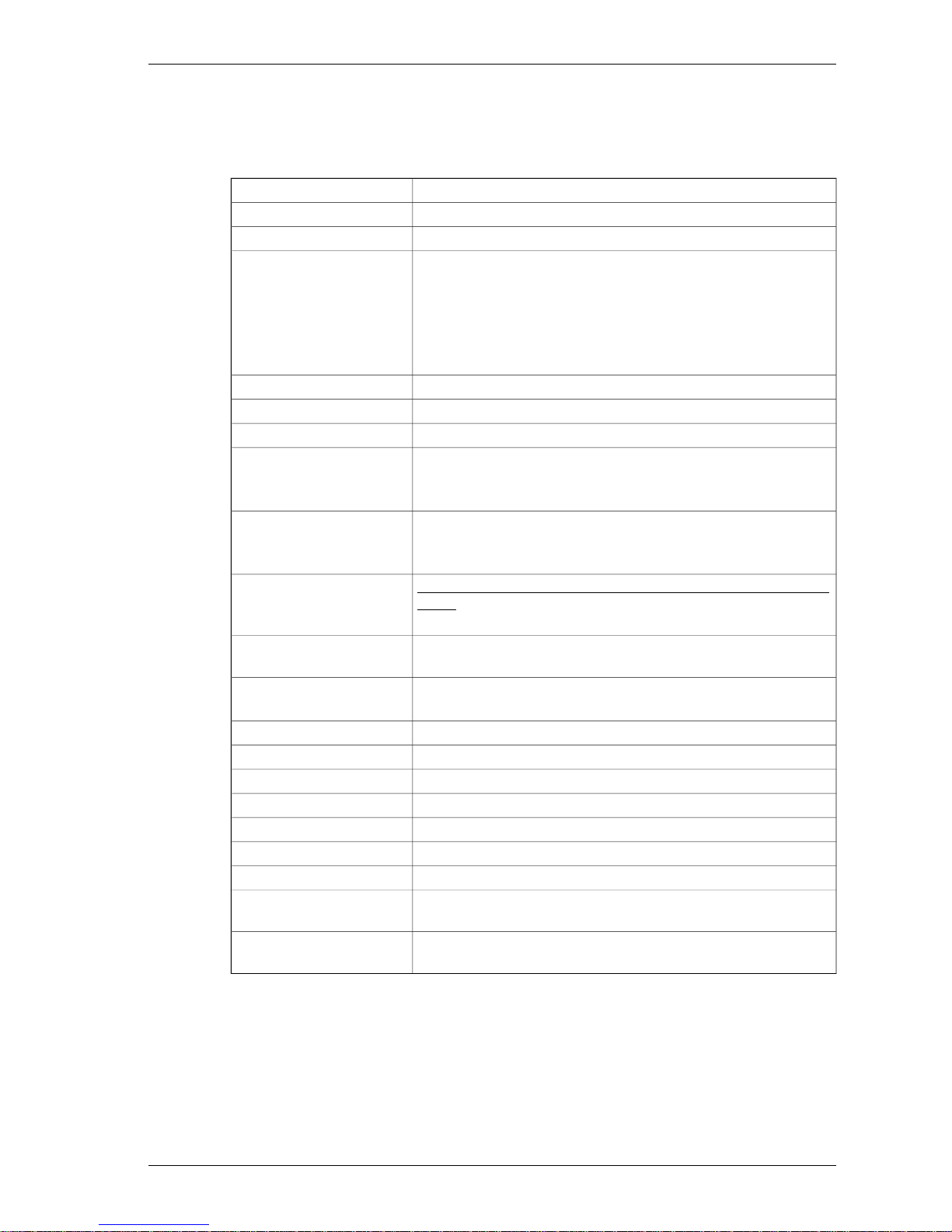

4 Technical specifications

Ensure that the door operator with technical specification below is suitable for the installation.

Entrematic Nordic ABManufacturer:

Lodjursgatan 10, SE-261 44 Landskrona, SwedenAddress:

EM EMSW EMOType:

100-240 V AC +10/-15%, 50/60 Hz, mains fuse max 10A (building

installation)

Mains supply:

Note! The mains supply shall be installed with protection and an

all-pole mains switch with isolating capability of Category III, at least

3 mm between contacts, shall be installed according to local regulations. These articles are not provided with the door.

Max. 75 WPower consumption:

24 V DC, max. 400 mAAuxiliary voltage:

2 x T 6,3 AH/250 VMains fuse F1, F2:

PUSH arm system; size 4Door size:

PULL arm system; size 1

ST-V/H arm system; size 3

For PUSH = 45 kgm

2

Max. Inertia J:

For PULL = 16 kgm

2

Inertia = Door weight x (Door width)2/ 3

The EM EMSW EMO complies with the door weights/widths stated

in the:

Controlled door closing, EN 1154 Table I, size 4

Selectable: 12V DC, max. 500 mA or 24 V DC, max. 250 mAElectro-mechanical locking

device:

PUSH arm: 80° - 110°, with reveal 0 - 305 mmDoor opening angle:

PULL arm: 80° - 110°, with reveal -20 - 130 mm

Variable between 3 - 6 secondsOpening time (0° - 80°):

Variable between 3 - 6 secondsClosing time (90° - 10°):

1.5 - 30 secondsHOLD open time:

-20 °C to +45 °CAmbient temperature:

Max. 85%Relative humidity:

7.1 kgDrive unit weight:

IP20Class of protection:

IP54Degree of protection, con-

trol actuators:

Third party approvals from established certification organizations

valid for safety in use, see Declaration of Incorporation.

Approvals:

9Issue 2016-10-241005088-EMEI-16.0

4 Technical specifications

Page 10

This product is to be installed internally.

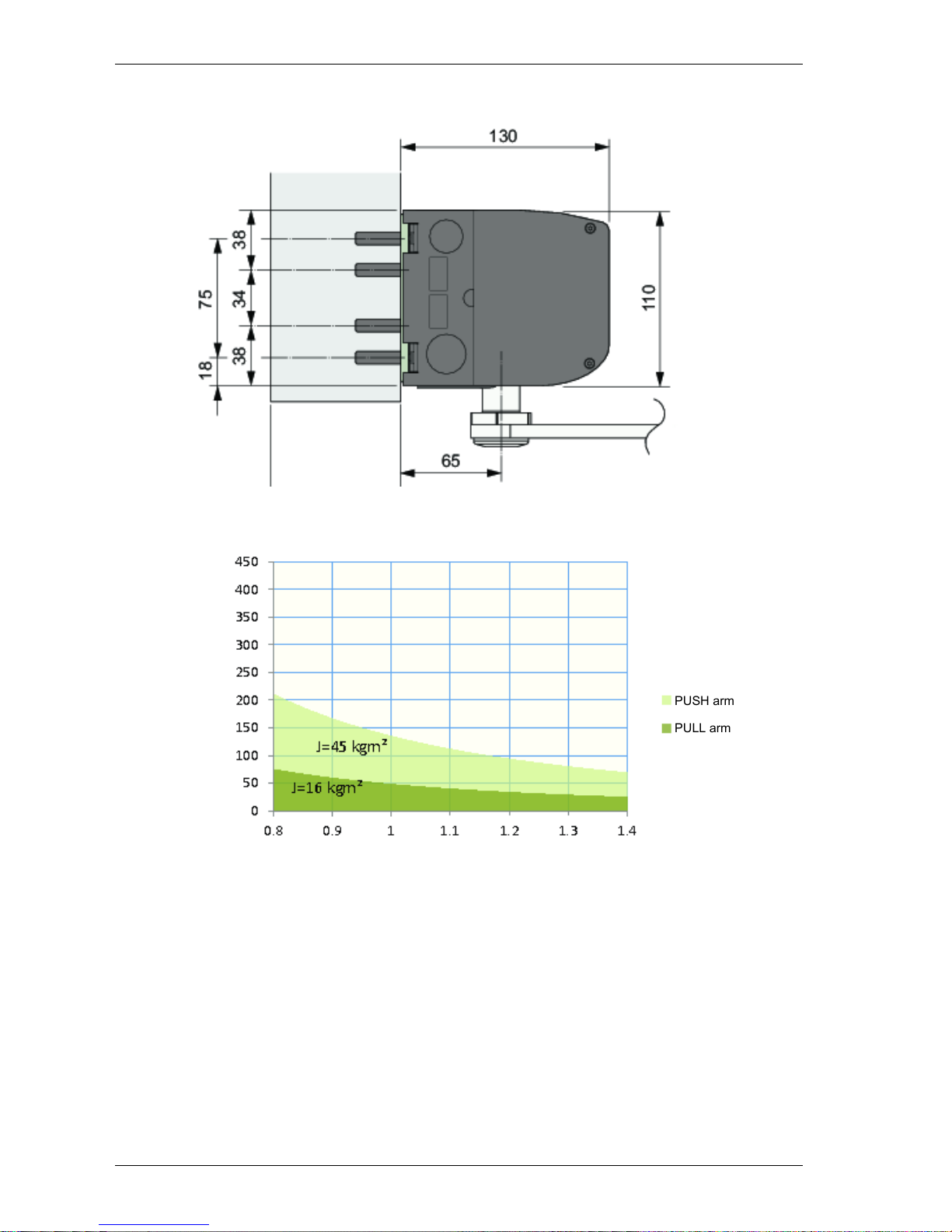

4.1 Permitted door weight and door width

PUSH arm

PULL arm

Door weight (kg)

Door width (m)

1005088-EMEI-16.0Issue 2016-10-2410

4 Technical specifications

Page 11

5 How the EM EMSW EMO works

The swing door operator EM EMSW EMO uses a DC motor and a gear-reduction system to drive an

arm system, which opens the door. Closing power is provided by a motor and a clock spring. An

electronic control unit uses a motor encoder and a microprocessor to control the door’s movement.

5.1 Opening

When an opening signal is received by the control unit, the door is opened at the operator-adjusted

opening speed. Before the door is fully open at back check, it slows automatically to low speed.

The motor stops when the selected door opening angle has been reached. The open position is

held by the motor.

If the door is obstructed while opening, it will either stall or stop which can be selected with a DIPswitch (SOS). Stop on stall is always active in program selector Mode Off.

• Continue on stall - the door will continue to try to open during the hold open time.

• Stop on stall - the door will, even if hold open time has not expired, close after 2 seconds.

5.2 Closing

When the hold open time has elapsed, the operator will close the door automatically, using spring

force and motor. The door will slow to low speed at latch check before it reaches the fully closed

position. The door is kept closed by spring power or combined with extended closing torque by

the motor.

5.3 Functions on the basic control unit CU-ESD

Also see page 50 for more information.

5.3.1 Power failure

During power failure the operator acts as a door closer with controlled closing speed.

5.3.2 Spring force

The operator is delivered with spring pre-tension factory set to 210°. If necessary, the spring tension

can be electronically adjusted with a potentiometer to required closing force.

5.3.3 Extended closing force/torque (CLTQ)

If the potentiometer CLTQ is set to 0°, the door will close with normal spring power. If the potentiometer is turned clockwise, the motor will increase the closing force/torque.

5.3.4 Power assist (POAS)

If the potentiometer POAS is set to 0°, the door gives no power assist. If the potentiometer is turned

clockwise, the motor will give/increase power assist when the door is opened manually.

5.3.5 Push and go (PAG)

DIP-switch to select PUSH and GO, ON or OFF. PUSH and GO is available from any door position.

PUSH and GO is not active in programme selector setting OFF.

5.3.6 Overhead presence detector (OPD), frame mounted

When an OPD sensor is mounted on the frame or operator cover just above the swing side of the

door, it will–when activated–either keep the door open or closed. The sensor is not active during

opening and closing. Lock-out signal must be connected for proper function.

• a closed door will not open, if the OPD detects activity in the field

11Issue 2016-10-241005088-EMEI-16.0

5 How the EM EMSW EMO works

Page 12

• an open door will not close, if the OPD detects activity in the field

• during opening, the door will continue to open, even if the OPD detects activity in the field

• during closing, the door will continue to close, even if the OPD detects activity in the field

• the OPD is not active in program mode OFF, manually opened door or during battery operation

(Power Save Mode).

5.3.7 Mat

Mat safety means that:

• a closed door will not open, if someone steps on the mat

• an open door will not close, if someone steps on the mat

• during opening, the door will continue to open, even if someone steps on the mat

• during closing, the door will continue to close, even if someone steps on the mat

• opening impulses are prevented during closing, if someone steps on the mat

• the mat is not active in program mode OFF, manually opened door or during battery operation

(Power Save Mode).

5.4 Functions on the extension unit EXU-SI

Also see page 52 for more information.

5.4.1 KILL function

• If KILL circuit is closed, the control will ignore all signals and close door(s) at normal speed.

• When KILL is no longer active, operator will resume normal operation.

• If KILL function must have manual reset, jumper must be removed and reset button connected

to terminal No. 8 and Ground.

• The lock will lock when KILL is active regardless of program selector setting.

• The function of the lock can be changed during KILL (see page 64).

• In a double door application, KILL is only connected to the master operator.

5.4.2 Function of locks

• The lock output is short circuit proof and can source a lock with 12 V DC, max. 500 mA or 24 V

DC, max 250 mA. Lock function is active in programme selection EXIT and OFF

• DIP-switch to select 12 or 24 V DC

• DIP-switch to select locked with or without power

• DIP-switch for lock release and potentiometer for opening delay

• DIP-switch for lock kick if door is not fully closed, to overcome binding in the locking device

during closing

• Input to unlock signal from lock. Potentiometer for opening delay is to be set to max. As soon

as unlock signal is received the door will start to open. The output signal shall be active low.

5.4.3 Program selector

• Input for OPEN, EXIT and OFF (if no program selector, AUTO is default).

5.4.4 Impulses

• Input for OUTER impulse, KEY impulse and OPEN/CLOSE impulse.

1005088-EMEI-16.0Issue 2016-10-2412

5 How the EM EMSW EMO works

Page 13

5.4.5 OPEN/CLOSE impulse

The impulse will open the door and the door will stay open until a new impulse is given. If no impulse

is given the door will close after 15 minutes. This can be made infinite by changing group of parameters, see page 64.

OPEN/CLOSE impulse works only in program selection ON.

5.4.6 Power failure mode (backup batteries are installed) – optional

• In case of power failure, normal operation can be carried out with impulses from the KEY SWITCH.

• Two contacts are available for connection of 2 x 12 V batteries (NiMH).

• DIP-switch for monitoring of batteries is also available. Faulty battery will be indicated by the

LED on the CU-ESD. If selected the relay on EXU-SA can give a contact information. An audible

warning signal can be achieved by using the accessory board AIU. It is connected to the 24 VDC

and plugged into the EXU-SA relay output terminal.

• During POWER FAILURE the operator will finish the actual operating cycle and then switch of

the battery supply.The battery powered operator can be reactivated to achieve a new operating

cycle by an impulse on the KEY input.

• The operating mode during battery power can be changed from POWER SAVE to CONVENIENCE,

see page 64. During CONVENIENCE MODE the operator will work as normal until the batteries

are discharged. The batteries are rechargeable and will be charged by the control unit in the

operator. New, fully charged batteries can typically open and close a door max. 300 times in

convenience mode. In power save mode the operator can stand-by in up to 1 week, waiting for

KEY impulse.

The following sensors are not active during battery operation POWER SAVE mode.

- Mat

- Overhead presence detector (OPD/OPS), frame mounted

- Presence impulse approach, door mounted

- Presence detection swingpath, door mounted

Note! All sensors works normally in CONVENIENCE MODE.

5.4.7 Nurse and bed functionality

To make it possible to open the master door only in a double door, connect a 0/1 switch to the

slave operator EXU-SI board Kill impulse terminal 7 and 3.

5.5 Functions on the extension unit EXU-SA – optional

Also see page 53 for more information.

5.5.1 Presence impulse approach, door mounted

The presence impulse is active during fully open and closing. The sensor is mounted to the approach

side of the door. Once the door is closed, the sensor is ignored and will not be active until the next

impulse is received.

Note! When installed as a pair of doors, the presence impulse signal will re-open both doors. The

sensor is not active in program mode OFF, manually opened door or during battery operation

(Power Failure Mode).

13Issue 2016-10-241005088-EMEI-16.0

5 How the EM EMSW EMO works

Page 14

5.5.2 Presence detection swingpath, door mounted

When a sensor that is mounted on the swing side of a door detects an object, it will send a command

to the control unit to stall the door. If the control unit has received a short signal from the sensor

and there is still hold open time left on the control unit, the door will continue on its way open if

the object has cleared.

The inhibit/blanking potentiometer can be adjusted so that the sensor will avoid detecting a wall

or object near the full open position. Presence detection has a higher priority than presence impulse.

Note! When installed as a pair of doors the presence detection signal will stop both doors, except

for double egress doors. The behavior for double egress doors can be changed (see page 64). The

sensor is not active in program mode OFF, manually opened door or during battery operation.

5.5.3 Monitored safety sensors

Both presence impulse and presence detection can be monitored. If a sensor becomes defective,

the operator will not accept any impulses and will then work as a manual door closer.

5.5.4 Open door indication

A relay output is used to indicate an opening cycle or a specific position of the door. The indication

position is set by adjusting the inhibit/blanking potentiometer.

5.5.5 Error indication

A potential free contact COM/NO/NC for external error indication, see page 72.

1005088-EMEI-16.0Issue 2016-10-2414

5 How the EM EMSW EMO works

Page 15

6 Models

One main model with standard cover is available of the EM EMSW EMO.

The operator are non-handed and not dependent on the hinges. The operator suits both pushing

and pulling arm systems.

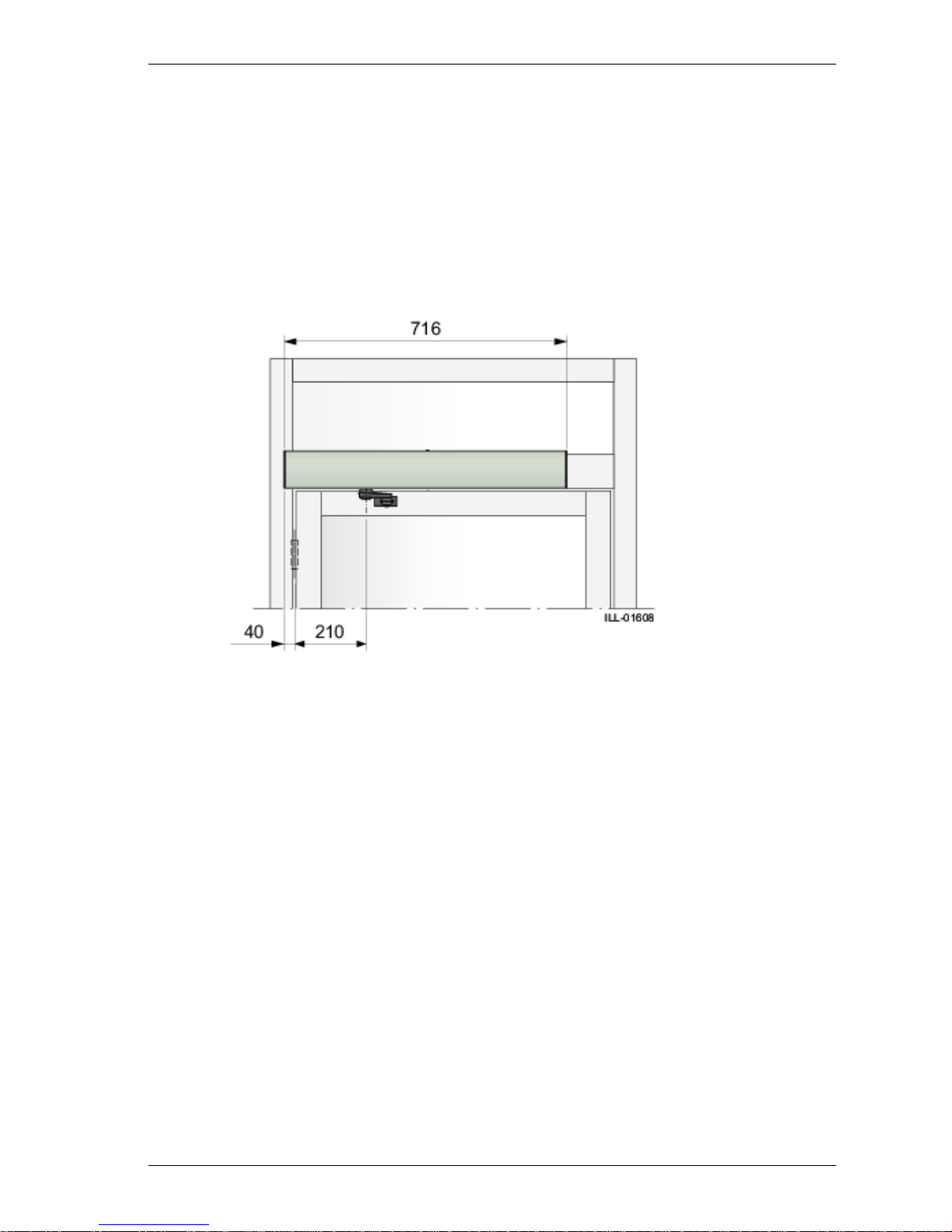

6.1 EM EMSW EMO, standard cover (wall mounted)

EM EMSW EMO is the standard operator. Pushing arm system shown. Measurement from hinge

centerline to outgoing shaft is always 210 mm regardless if butt or pivot hinged systems.

15Issue 2016-10-241005088-EMEI-16.0

6 Models

Page 16

7 Part identification & Accessories

DescriptionArt. No.Item No.

Transmission unit3310034981

Control unit CU-ESD3310035322

EXU-SI (Kit to extend the security functions) - optional3310035542a

EXU-SA (Kit to extend the safety functions) - optional3310035572b

Mains contact3317006073

Door stop body3300002304

Mounting kit3310117975

Cable holder (50 pcs)3310035785a

Bottom end plate331003543BK/SI6

Cover3310049987

Power ON/OFF switch3310035818

ON/OFF/HOLD open switch - optional331003582

Battery backup unit - optional3310035679

Sync cable - optional33100358310

Encoder cable33000023311

MUL33100573612

Adaptor kit330000484BK/SI13

PUSH arm service kit330000485BK/SI14

PULL arm service kit330000486BK/SI15

Cable kit100634016

1005088-EMEI-16.0Issue 2016-10-2416

7 Part identification & Accessories

Page 17

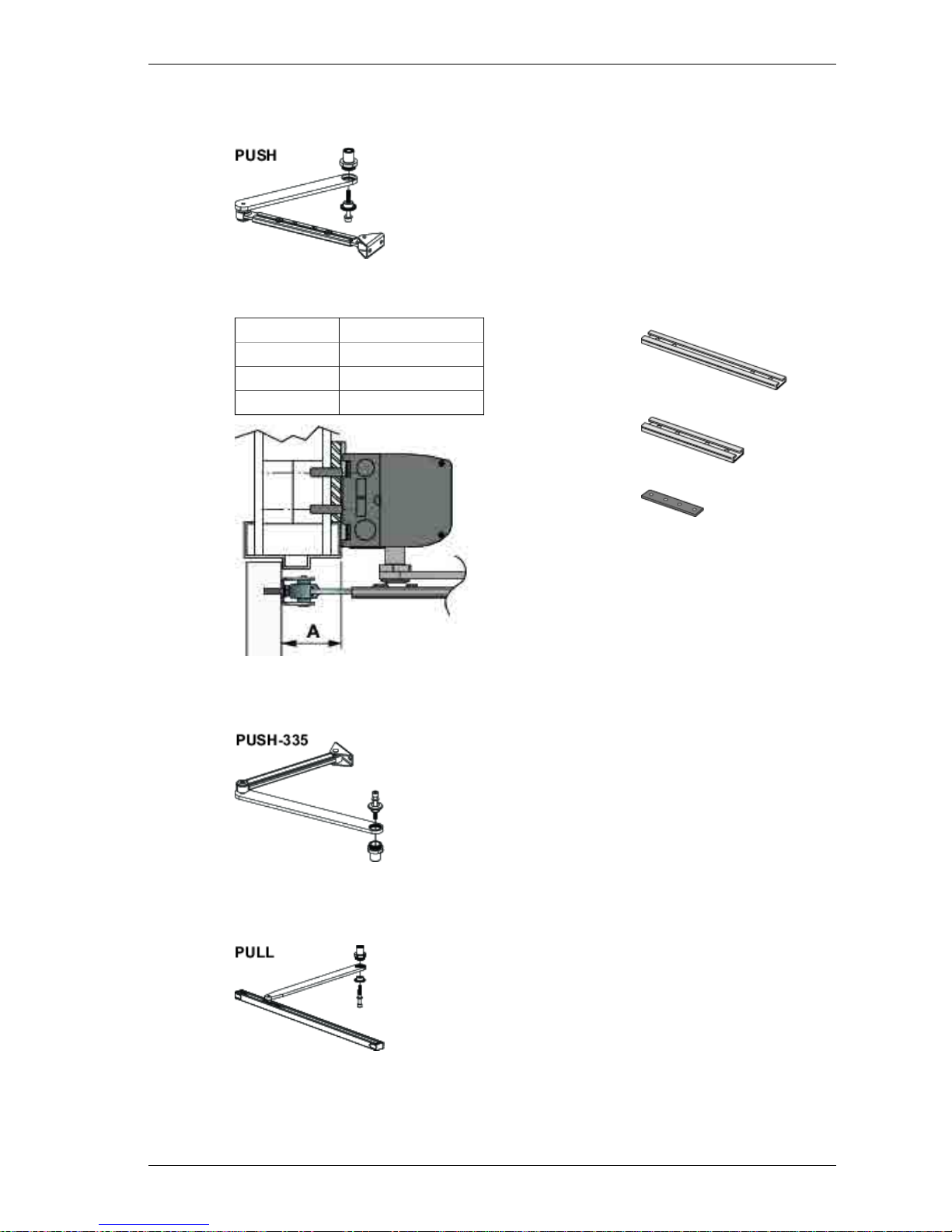

7.1 Arm system, PUSH

Art. No. 1014113BK/SI

It is used if the operator is installed on the wall on the opposite side of

the door swing and approved for fire applications.

7.1.1 PUSH-arm extensions

345 mm extension

Art. No. 173005BK/SI

ExtensionReveal = A

None (standard arm)0-100 mm

345 mm100-215 mm

230 mm + Joint part215-305 mm

230 mm extension

Art. No. 173004BK/SI

Joint part

Art. No. 173191

7.2 Arm system, PUSH-335

Art. No. 1011706BK/SI

It is used if the operator is installed on the door leaf hinge side.

7.3 Arm system, PULL

Art. No. 1011707BK/SI

It is used if the operator is installed on the wall on the same side as the

door swing.

17Issue 2016-10-241005088-EMEI-16.0

7 Part identification & Accessories

Page 18

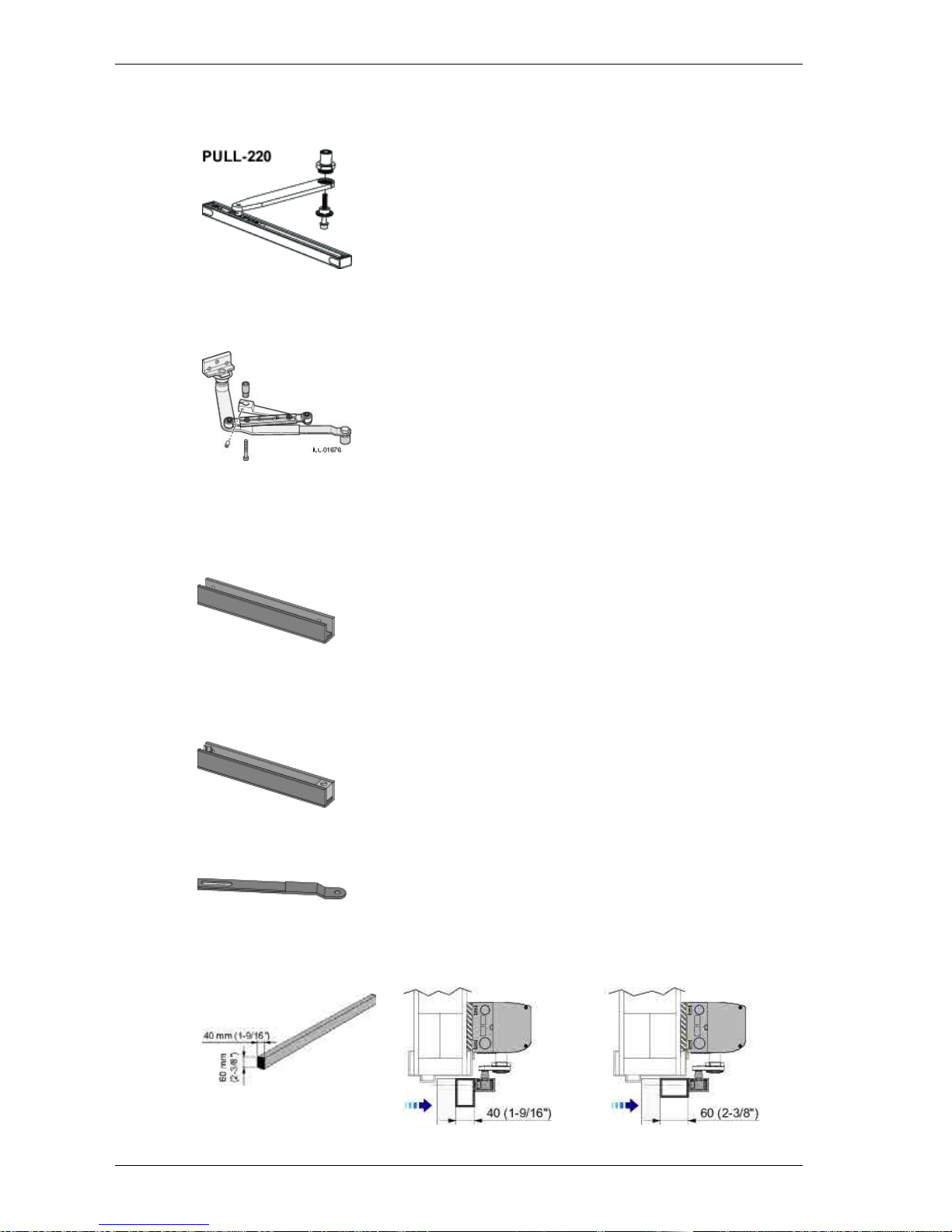

7.4 Arm system, PULL-220

Art. No. 1014114BK/SI

It is used if the operator is installed on the wall on the same side as the

door swing and when the door is 450-700 mm wide.

7.5 Arm system, ST-V / ST-H

ST-V, Art. No. 172312SI, 172313BK

ST-H, Art. No. 172314SI, 172315BK

Note! Door fitting not included.

It is used if the operator is installed on the wall on the same side

as the door swing and break-out unit is required.

7.5.1 Options for ST-V / ST-H

Door fitting standard

Art. No. 172071

Door fitting Break-out (pivot doors)

Art. No. 172325, right, reveal A = 0-60 mm or left when A > 60-100 mm

Art. No. 172327, right, reveal A > 60-100 mm or left when A = 0-60 mm

Arm extension

Art. No. 172320 required when the reveal A >60-100 mm

7.6 Reveal spacer: PULL / PULL-220

Art. No. PULL 1014667BK/SI

1005088-EMEI-16.0Issue 2016-10-2418

7 Part identification & Accessories

Page 19

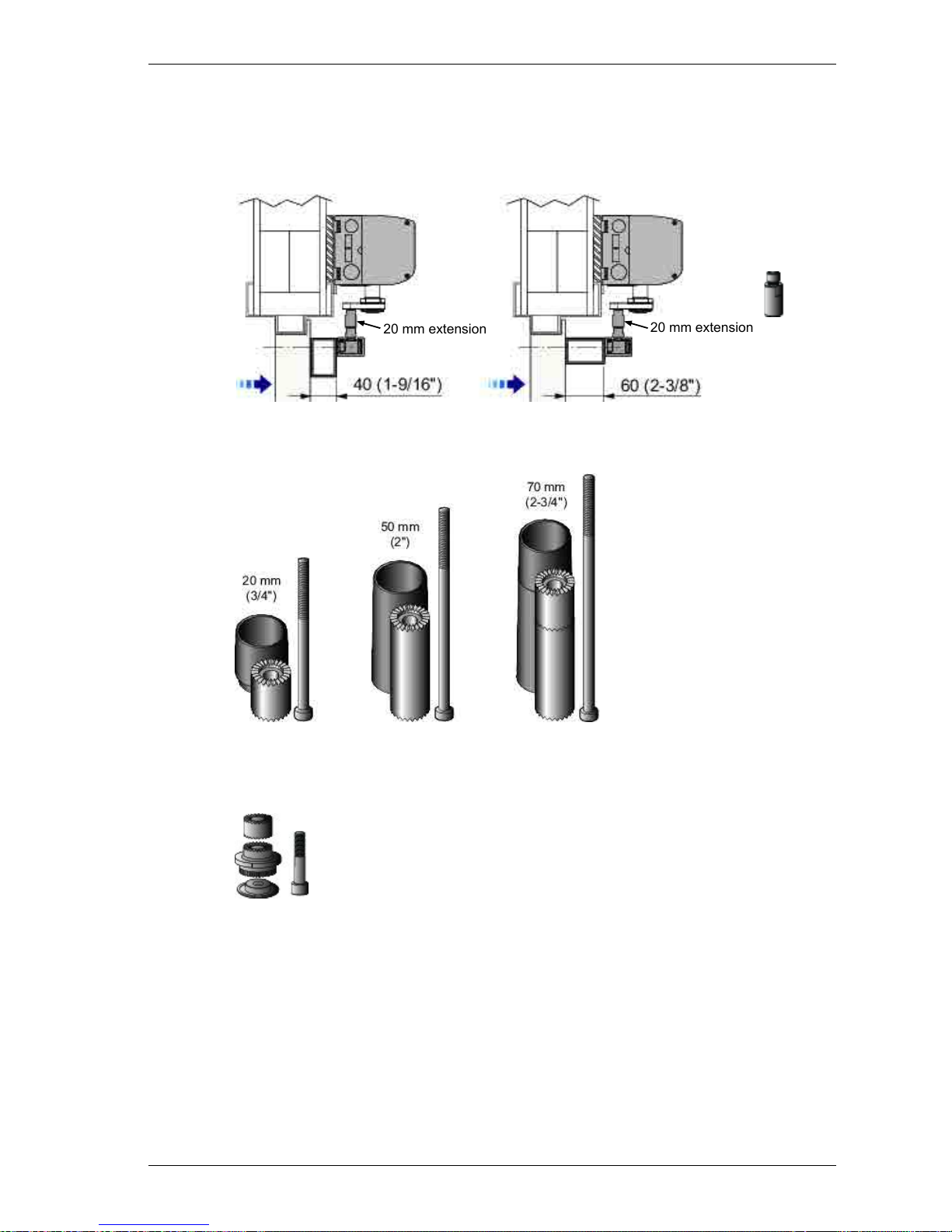

7.7 20 mm extension

Extension 20 mm for PULL/PAS and lower mounting of slide track profile.

Art. No.: 1011205

20 mm extension

20 mm extension

7.8 Drive shaft extension kits

Art. No.

173109BK/173109SI

Art. No.

173108BK/173108SI

Art. No.

173107BK/173107SI

Lower adapter M8, used for 20 mm lower installation height.

Art. No.

1007618

19Issue 2016-10-241005088-EMEI-16.0

7 Part identification & Accessories

Page 20

7.9 Control switches

7.9.1 Power ON/OFF switch

White

Brown

Art. No. 1003581

7.9.2 ON/OFF/HOLD open switch (will not operate electric lock)

White

Brown

Green

Art. No. 1003582

ProgramFunction

Impulses from activation units connected to XIMP are forwarded into inner impulse

(see page 50).

ON

Impulses from activation units connected to XIMP are not forwarded into inner impulse.

These units cannot open the door.

OFF

The door is held permanently open.HOLD

7.9.3 4-position switch PS-4C (operates the electric lock)

FunctionPosition

Art. No

655845

The door is closed. The door cannot be opened with inner and

outer activation units. The door is locked if an electromechanical

locking device has been fitted. The door can be opened with a key

switch (if fitted).

OFF

Passage from inside only. The door is normally locked if an electromechanical locking device has been fitted. The door can only

be opened with the inner activation unit and with a key switch (if

fitted).

EXIT

The door can be opened with the inner and outer manual and/or

automatic activators. The electric strike, if fitted, is open.

AUTO

Normal pos-

ition

The door is held permanently open by the motor.OPEN

1005088-EMEI-16.0Issue 2016-10-2420

7 Part identification & Accessories

Page 21

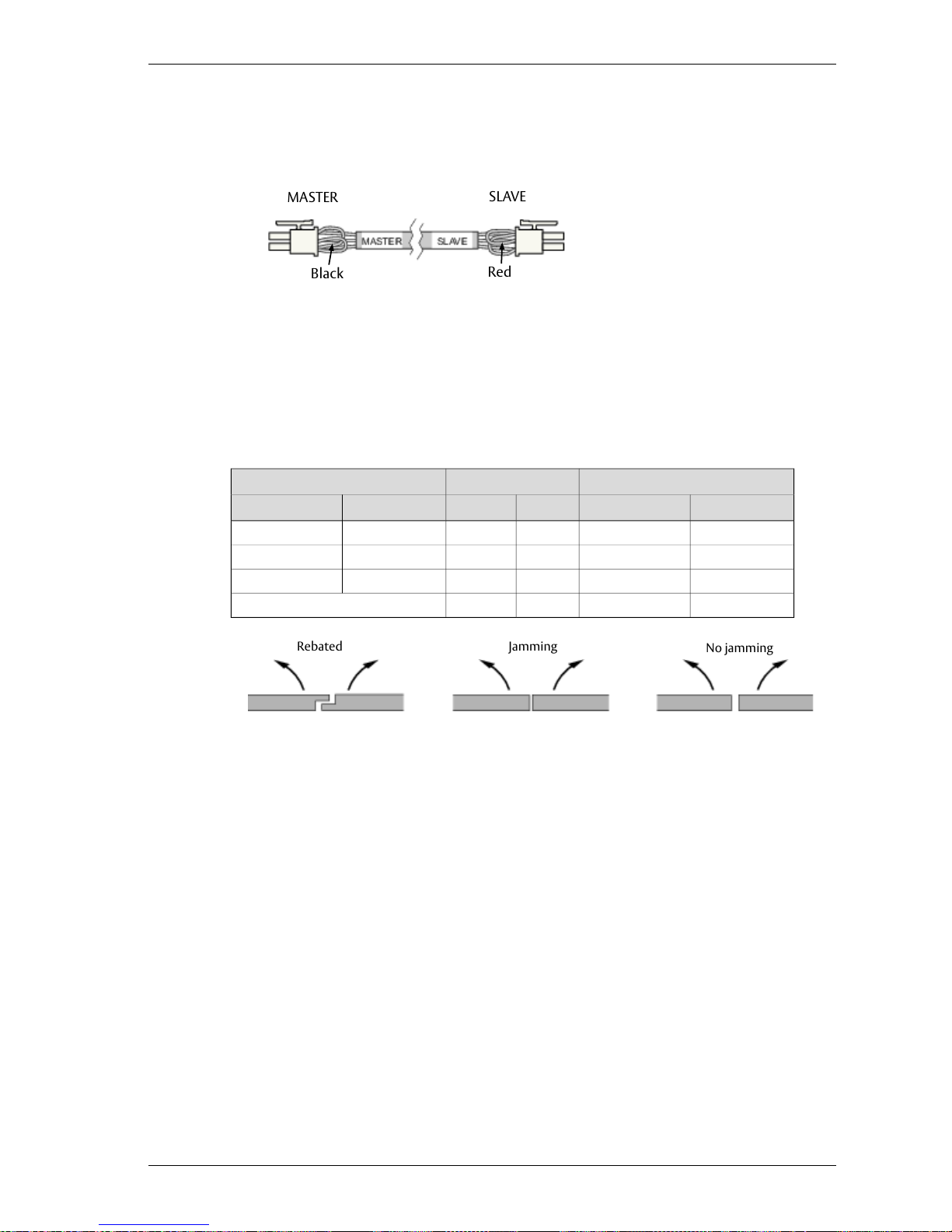

7.10 Sync cable for double doors (synchronizing of 2 operators)

Note! Connect a cable between Master CU and Slave CU.

Red

Black

SLAVE

MASTER

Note! The connection/marking of the sync cable determines which of the operators is the MASTER

and SLAVE.

For a Rebated door;

• the Master door must open before the Slave door

• the Slave door must close before the Master door

How to cut the jumper for double doors

Cut the jumper with colorDoor designFunction

SLAVE sideMASTER sideJammingRebatedClosingOpening

No cuttingNo cuttingNoNoSynchronousSynchronous

No cuttingCut blackNoYesAsynchronousSynchronous

Cut redNo cuttingYesYesAsynchronousAsynchronous

Cut redCut black——Double egress

Rebated

Jamming

No jamming

21Issue 2016-10-241005088-EMEI-16.0

7 Part identification & Accessories

Page 22

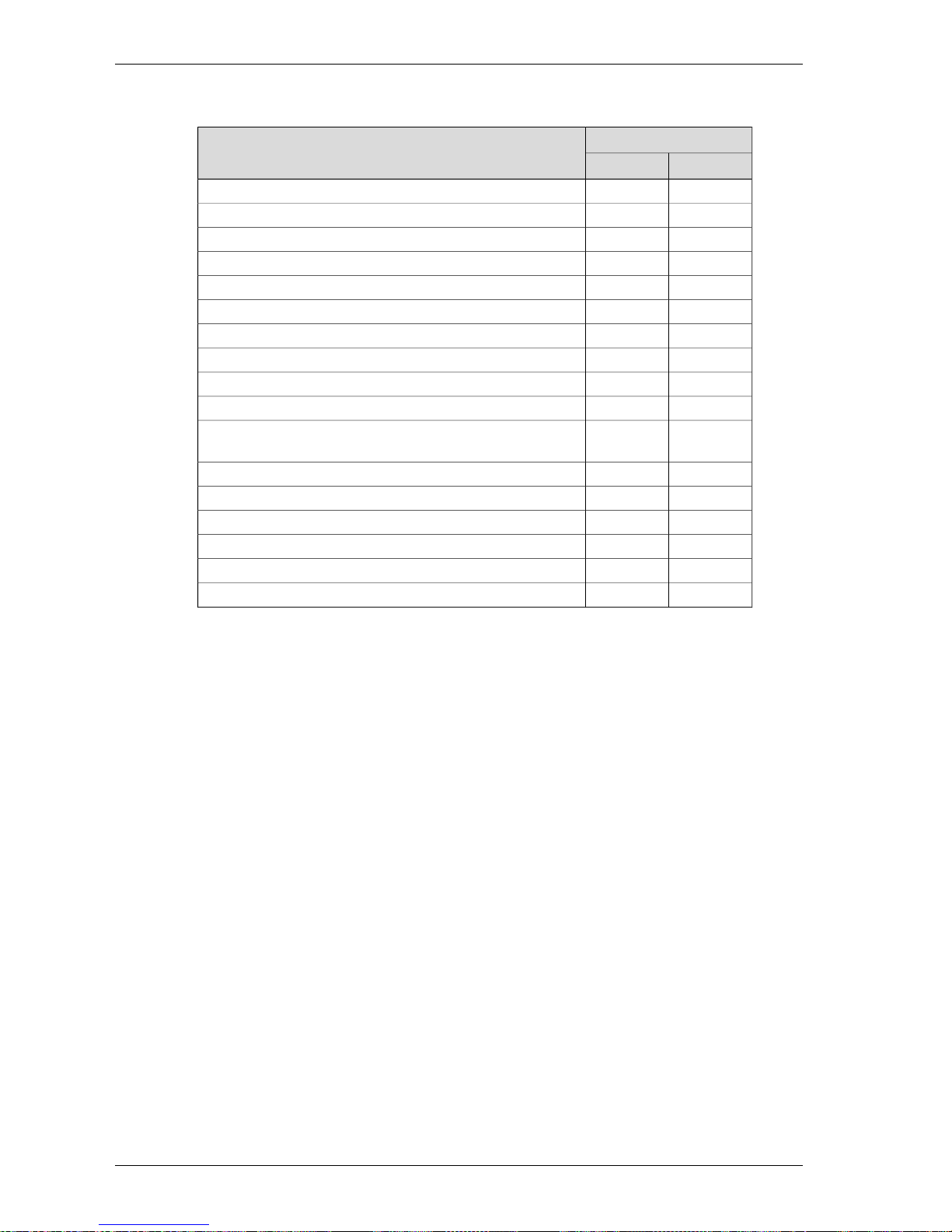

Settings for double doors

Settings on the

Function

SLAVEMASTER

Common

XProgram selection

XOpening time

XClosing time

XHold open time

XClose / Continue to open when the door is obstructed

XPAG On/Off

(X)*XLevel of Power assist

(X)*XExtended closing force

XOPD Impulse or Mat Logic Impulse

XSelection of operating mode during operation on battery

power

Individual

XXLock/Unlock signal voltage

XXLocked without/with power

XXLock release Enable/Disable

XXOpen Delay Time

XXLock kick Enable/Disable

* For “Double egress doors”, these functions must be set separately for MASTER and SLAVE as the

arm systems as well as the air pressure may be different.

Note!

• Locks on the MASTER and SLAVE doors must be connected to the control unit (CU) on the corresponding operator.

• Inner and outer impulses can be connected to either MASTER or SLAVE CU or both.

• The OPD is to be connected to the MASTER CU except for “Double egress”, where each OPD

must be connected to corresponding CU.

• Door leaf mounted sensors must always be connected to corresponding CU.

• The slave door can be prevented to open, if kill is activated on the SLAVE control unit.

1005088-EMEI-16.0Issue 2016-10-2422

7 Part identification & Accessories

Page 23

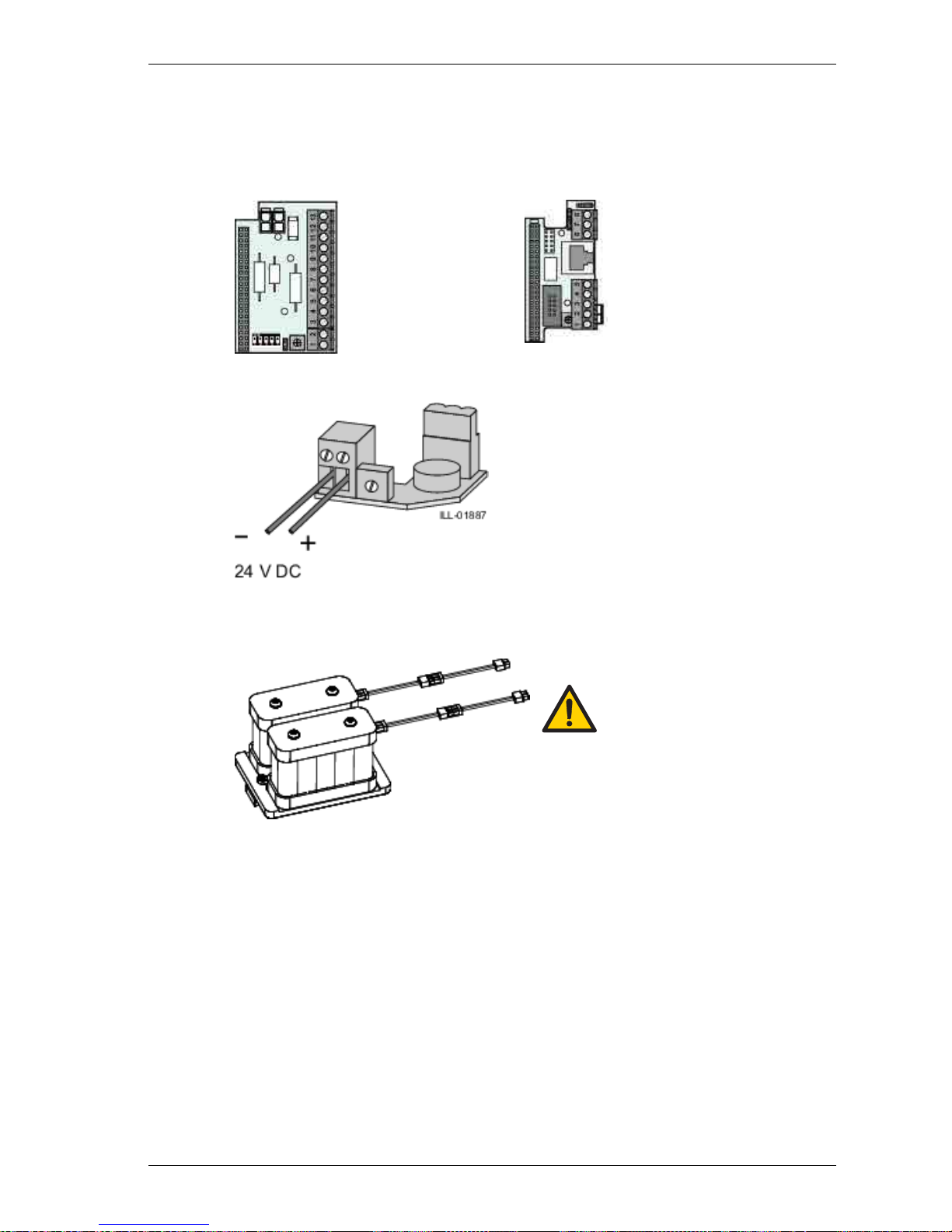

7.11 Extension units

For installation see page 51.

EXU-SA (kit for safety functions)

Art. No. 1003557

EXU-SI (kit for security functions)

Art. No. 1003554

AIU (Audible warning signal)

Art. No. 656083

7.12 Battery backup unit

Note! Disconnectmains when replacing battery.

Risk of explosion if wrong type of battery is used.

Art. No. 1003567

23Issue 2016-10-241005088-EMEI-16.0

7 Part identification & Accessories

Page 24

7.13 Cover piece kit

7.13.1 Middle piece kit

Art. no 1008383

7.14 Labels

Label kit - including all below

Art. No. 1005227

Emergency break-out, DIN right door

Art. No. 1001785

Emergency break-out, DIN left door

Art. No. 1001786

Activation by disabled people

Art. No. 1003963

Operator designed for disabled people

Art. No. 1003964

Supervision of child

Art. No. 1001695

1005088-EMEI-16.0Issue 2016-10-2424

7 Part identification & Accessories

Page 25

8 Pre-installation

8.1 General tips/Safety concerns

In all instances, where work is being done, the area is to be secured from pedestrian traffic, and the power removed to prevent injury.

• If there are sharp edges after drilling the cable outlets, chamfer the edges to avoid damage to

the cables.

• For enhanced security and vandalism protection, always mount the operator access in the interior of a building whenever possible.

• Make sure the ambient temperature is in the range specified in section Technical specification.

• Make sure that the power is off before installing.

• Make sure that the door leaf and the wall are properly reinforced at the installation points.

• Unpack the operator and make sure that all parts are delivered in accordance with the packing

note and that the operator is in good mechanical condition.

• Ensure proper material is being used for the door leaves and that there are no sharp edges.

Projecting parts shall not create any potential hazards. If glass is used bare glass edges shall not

come in contact with other glass. Toughened or laminated glass are suitable glasses.

• Ensure that entrapment between the driven part and the surrounding fixed parts due to the

opening movement of the driven part is avoided. The following distances are considered sufficient

to avoid entrapments for the parts of the body identified;

- for fingers, a distance greater than 25 mm or less than 8 mm

- for heads, a distance greater than 200 mm

- for feet, a distance greater than 50 mm

- and for the whole body, a distance greater than 500 mm

• Danger points shall be safe guarded up to a height of 2.5 m from the floor level.

• The operator shall not be used with a doorset incorporating a wicket door.

8.2 Operator/Door handing

Operator/Door handing (DIN Right or DIN Left) is determined by which side the hinges are mounted

seen from the swing side.

DIN Left

DIN Right

25Issue 2016-10-241005088-EMEI-16.0

8 Pre-installation

Page 26

8.3 Installation examples

Non combustible

material in fire ap-

plication

Non combustible

material in fire

application

Steel reinforcement or rivnutA

Wood reinforcementB

Expansion-shell bolt (for brick wall min. M6x85,

UPAT PSEA B10/25)

C

Aluminium profile system1

Plasterboard wall2

Reinforced concrete wall and brick wall3

Plasterboard wall4

8.4 Fastening requirements (but not included)

Minimum requirements of wall profile*Base material

5 mm**Steel

6 mm**Aluminium

min. 50 mm from the undersideReinforced concrete

50 mmWood

Expansion-shell bolt, min. M6x85, UPAT PSEA B10/25, min. 50 mm from

the underside

Brick wall

* Entrematic Nordic minimum recommended requirements. Building Codes may give different

specifications.

** Thinner wall profiles must be reinforced with rivnuts.

1005088-EMEI-16.0Issue 2016-10-2426

8 Pre-installation

Page 27

8.5 Tools required

• Torx T10

• Metric Allen wrenches 2,5; 3; 4 and 6 mm

• Flatblade screwdriver (potentiometer and terminal size)

• Screwdriver (Philips size 2)

• Nut driver, 5 mm

• Carpenter’s level

• Tape rule

• Power drill and set of drill bits

• Center punch

• Wire stripper

• Silicone sealant

• Installation and Service Manual (this manual)

8.6 Installation on double doors

If the operators are to be mounted at the same height with pushing and pulling arm systems, the

height is determined by the pulling arm system, PULL. The pushing arm system PUSH must always

have a shaft extension, minimum 50 mm, maximum 70 mm to match the mounting heights visually.

Example: if PULL has a 20 mm extension, the PUSH must have a 70 mm extension. If PULL has 0 mm

extension, the PUSH must have a 50 mm extension.

27Issue 2016-10-241005088-EMEI-16.0

8 Pre-installation

Page 28

9 Mechanical installation

Note! Consider all power wire entry locations and signaling wires before preparing back plate.

9.1 Operator with PUSH arm system

0 - 100 (305)

1005088-EMEI-16.0Issue 2016-10-2428

9 Mechanical installation

Page 29

Cont. "Operator with PUSH arm system"

DIN Right

Cable inlet

29Issue 2016-10-241005088-EMEI-16.0

9 Mechanical installation

Page 30

Cont."Operator with PUSH arm system"

Operator should be attached using the

top/centered bolt first, then follow pattern

1005088-EMEI-16.0Issue 2016-10-2430

9 Mechanical installation

Page 31

Cont."Operator with PUSH arm system"

DIN Left

31Issue 2016-10-241005088-EMEI-16.0

9 Mechanical installation

Page 32

Cont."Operator with PUSH arm system"

Operator should be attached using

the top/centered bolt first, then fol-

low pattern

1005088-EMEI-16.0Issue 2016-10-2432

9 Mechanical installation

Page 33

Cont."Operator with PUSH arm system"

33Issue 2016-10-241005088-EMEI-16.0

9 Mechanical installation

Page 34

9.2 Operator with PULL arm system

Note! Measurement Z must be reduced by 20 mm if lower adapter from

kit 1007618 is used.

1005088-EMEI-16.0Issue 2016-10-2434

9 Mechanical installation

Page 35

Cont. "Operator with PULL arm system"

DIN Left

35Issue 2016-10-241005088-EMEI-16.0

9 Mechanical installation

Page 36

Cont. "Operator with PULL arm system"

Operator should be attached using

the top/centered bolt first, then follow

pattern

1005088-EMEI-16.0Issue 2016-10-2436

9 Mechanical installation

Page 37

Cont. "Operator with PULL arm system"

DIN Right

37Issue 2016-10-241005088-EMEI-16.0

9 Mechanical installation

Page 38

Cont. "Operator with PULL arm system"

Operator should be attached using

the top/centered bolt first, then follow

pattern

1005088-EMEI-16.0Issue 2016-10-2438

9 Mechanical installation

Page 39

Cont. "Operator with PULL arm system"

DIN Right

DIN Left

39Issue 2016-10-241005088-EMEI-16.0

9 Mechanical installation

Page 40

9.3 Installation of operator with arm system ST

1005088-EMEI-16.0Issue 2016-10-2440

9 Mechanical installation

Page 41

Cont. "Installation of operator with arm system ST"

Outside open door

DIN Left

41Issue 2016-10-241005088-EMEI-16.0

9 Mechanical installation

Page 42

Cont. "Installation of operator with arm system ST"

Operator should be attached

using the top/centered bolt

first, then follow pattern

Operator should be attached using

the top/centered bolt first, then fol-

low pattern

1005088-EMEI-16.0Issue 2016-10-2442

9 Mechanical installation

Page 43

Cont. "Installation of operator with arm system ST"

Outside open door

DIN Right

43Issue 2016-10-241005088-EMEI-16.0

9 Mechanical installation

Page 44

Cont. "Installation of operator with arm system ST"

Operator should be attached us-

ing the top/centered bolt first, then

follow pattern

1005088-EMEI-16.0Issue 2016-10-2444

9 Mechanical installation

Page 45

Cont. "Installation of operator with arm system ST"

Note, the way of mounting the arm!

45Issue 2016-10-241005088-EMEI-16.0

9 Mechanical installation

Page 46

Cont. "Installation of operator with arm system ST"

1005088-EMEI-16.0Issue 2016-10-2446

9 Mechanical installation

Page 47

Cont. "Installation of operator with arm system ST"

47Issue 2016-10-241005088-EMEI-16.0

9 Mechanical installation

Page 48

Cont. "Installation of operator with arm system ST"

Cut out for arm bracket

DIN Right

DIN Left

1005088-EMEI-16.0Issue 2016-10-2448

9 Mechanical installation

Page 49

10 Electrical connection

Note! During any work with the electrical connections the mains must be disconnected.

• Place the electric switch easily accessible from the operator. If a plug contact is used in the installation the wall socket shall be placed easily accessible from the operator.

• If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualified persons in order to avoid a hazard.

10.1 Mains connection

a Switch off the mains.

b Assemble the bottom end plates and tighten the two screws firmly.

c Connect the plug contact to the wall socket or connect to the mains switch.

Note! The mains switch must be connected according to national regulation.

d Connect the mains to the operator.

Mains:100-240 V AC – 50/60 Hz

Alt. 1

Mains

Alt. 2

Symbol shown to ensure that the manual is read before the installation starts.

PE = Yellow/Green

L = Brown

N = Blue

Mains

49Issue 2016-10-241005088-EMEI-16.0

10 Electrical connection

Page 50

10.2 Control units

10.2.1 CU-ESD

The CU-ESD can be equipped with extension units, EXU-SI and/or EXU-SA, depending on the functions

required. See page 12 or 13.

Power ON/OFF switch

Encoder

Motor

Synchronizing of double doors

ON/OFF/HOLD open switch

Lock-out for OPD (–)

Overhead presence detection/Mat safety

Inner impulse

Ground

Overhead presence detection (incl. 24 V, LOUT and

Safety Impulse)

= ERROR

Hold open time

DIP-switches shown in

OFF position

Closing torque

Power assist

Closing speed

Opening speed

Spring tension

PAG

MAT

SOS

PUSH & GO

Safety mat

Stop on stall

ARM 1/2 Arm system setting

LEARN BUTTON

Inner impulse controlled by

10.2.2 Arm system selection

Factory set arm configuration is PUSH, if PULL or ST is required:

a Switch power OFF

b Select arm configuration

c Switch power ON

1005088-EMEI-16.0Issue 2016-10-2450

10 Electrical connection

Page 51

10.2.3 Extension units EXU-SI / EXU-SA

Installation

To extend the functions, the extension units can be mounted on top of the control unit CU-ESD,

separately or combined.

5 mm nut driver

Torx T10

Mains

Tag strip

long 2 pcs EXU

short 1 pc EXU

51Issue 2016-10-241005088-EMEI-16.0

10 Electrical connection

Page 52

10.2.4 Extension unit EXU-SI

Functions

This extension unit has inputs for electro-mechanical lock, program selector, batteries, KILL function, OPEN/CLOSE,

KEY opening and outer impulse.

Program selector

Unlocked signal from lock

KILL reset (see jumper below)

KILL impulse

KEY impluse (5 s)

OPEN / CLOSE impulse (latching relay)

Outer Impulse

Ground

Electro-mechanical locking device (12V DC max. 500 mA /

24 V DC max 250 mA, see DIP-switch No. 1 below)

Potentiometer for opening delay

2)

Manual kill reset (jumper off)

Automatic kill reset (jumper on)

Battery monitoring

Lock kick

1)

Lock release

2)

Locked without power (OFF) / with power (ON)

Lock 12 V (OFF) / 24 V (ON)

DIP-switches

shown in OFF

position

Battery backup unit

Position OFF: Smooth closing, to be used on doors without lock.

Position ON: More powerful closing, to be used on doors with lock, to overcome binding in the locking device.

1)

If the switch is set to ON, the LOCK RELEASE is active during the opening delay time set by the potentiometer.

For PAIR OF DOORS installations, the LOCK RELEASE works in sequence: First the MASTER then the SLAVE.

2)

Note! Lock only functions when Program Selector is in OFF or EXIT.

1005088-EMEI-16.0Issue 2016-10-2452

10 Electrical connection

Page 53

10.2.5 Extension unit EXU-SA

This extension unit has inputs for door mounted sensors, which can give presence impulse on approach side

and/or presence detection on swing path side. Relay output for error indication, KILL output, Lock output or

door indication is also integrated. When the jumper for the relay is set to ‘Open/Closed door indication’, its activation will follow the Blanking LED.

Functions

Monitoring of presence detection/DMPS.SS

Monitoring of presence impulse/DMPS.NS

No monitoring (both jumpers on)

Monitoring of presence detection and presence impulse

External error indication

Opened door indication

Relay output (“External error indication” or“Open

door indication”, see above) 24 V, 1 A

Ground

Remove strapping when connecting to terminals 2

and/or 3

Blanking potentiometer

(Adjust the potentiometer to avoid presence detection sensor to detect

the wall. Range 45 - 90 degrees.)

Blanking LED

Door mounted sensors

2)

DMPS:

Relay 1: Presence impulse (NC)

Relay 2: Presence detection (NC)

(-) 0 VDC Ground

(+) 24 VDC

QTST = Sensor monitoring

PDET = Presence detection (NC)

1)

PIMP = Presence impulse (NC)

1)

1)

If not used strap to “Ground”.

2)

Remove strapping from terminals 2 and/or 3.

53Issue 2016-10-241005088-EMEI-16.0

10 Electrical connection

Page 54

10.3 Sensor cable inlet

Art. No.: 1007567

Alt. 1

Alt. 2

Art. No.: 1015369BK/SI

1005088-EMEI-16.0Issue 2016-10-2454

10 Electrical connection

Page 55

11 Start-up

The spring pre-tension is factory set to 210° and is normally not necessary to adjust. If adjustment

has to be carried out, see page 68.

11.1 Adjusting the door stop

a Close the door.

b Turn the potentiometer SPTE to 0° (if not already on 0°).

c Switch on the mains (the operator will find its closed position).

d Open the door to required open position, plus approx. 5/8” (15 mm), by turning the poten-

tiometer SPTE on the CU-ESD, clockwise.

55Issue 2016-10-241005088-EMEI-16.0

11 Start-up

Page 56

e Loosen the door stop arm.

f Mount the door stop arm on the splines a), as close as possible to the stop block b). Fine-adjust

if necessary with the screw on the stop block c).

g Close the door by turning the potentiometer SPTE to 0° and let the door close.

Note! Impulses are not accepted if SPTE is more than 0°.

Door stop arm1

Fixing screw2

Stop block3

Fine-adjustment screw4

1005088-EMEI-16.0Issue 2016-10-2456

11 Start-up

Page 57

11.2 Auto-learn – automatically sets back and latch check (recommended)

This learning is performed by pushing the LEARN BUTTON (LRN).

• Before the learning procedure starts, make sure that the door has been properly closed i.e., not

by force.

• If any of the parameters SPRING PRE-TENSION, CLOSING TORQUE (CLTQ) and LOCK RELEASE

(DIP-switch No. 3 on EXU-SI) are changed after performing a learn, a new learn must be carried

out.

• Learn can be carried out with activation units and locks connected.

• The back-check will be automatically adjusted to 10° and 1 second before open position. The

latch-check will be automatically adjusted to 10° and 1.5 seconds before closed position.

Back-check

Latch-check

11.2.1 One push / two pushes on the LEARN BUTTON (LRN)

Note! Remain clear of swing path of door, as door may close rapidly. The door has no safety during

auto-learn cycle.

One push (delayed opening)

Push the button once. The door will open after 2 seconds and adjust the back-check and latchcheck automatically.

Two pushes (direct opening)

Push the button twice. As above, but the door starts to move directly.

11.2.2 Double doors

For double doors, the MASTER door must be learned first and thereafter the SLAVE door. When the

SLAVE door is learned, the MASTER door will open up to fully open position during the learning

phase of the SLAVE door.

The doors can also be learned separately before connecting the sync cable. In case of astragal doors

and separate learning, the MASTER door must be held open before the SLAVEdoor learn is carried

out.

57Issue 2016-10-241005088-EMEI-16.0

11 Start-up

Page 58

11.3 General adjustment

a Set the hold open time with the potentiometer on the control unit.

b Adjust the opening speed (OPSP). Turning clockwise increases the speed.

c Adjust the closing speed (CLSP). Turning counter-clockwise decreases the speed.

d Connect the required activation units.

e Check that the installation complies with Installation and adjustments on page 69.

1005088-EMEI-16.0Issue 2016-10-2458

11 Start-up

Page 59

11.4 Connection of activation units and accessories

See sensor manuals for mounting and adjustments. Protective device shall comply with EN 12978.

Door mounted

When sensors are used in order to avoid contact with the door leaf it is required that the presence

detect sensor and the presence impulse sensor fulfills Performance Level = d according to EN ISO

13849-1. These sensors shall also be monitored (tested) by EM EMSW EMO door operator.

Configue sensor EMSP33-M:

DIP A7 to ON (for Master sensor)

DIP B4 to ON for Presence impulse

DIP B4 to OFF for presence detection

** Note! When using the quick connector, opening

and closing side will be reversed.

PS-4C

Eye-Tech

Activation

sensor

BrownAInner impulse

YellowBOuter Impulse

PinkCKey Impulse

VioletDPresence impulse

WhiteEPresence detection

BlueFOff

RedGKill impulse NO

GreenHStandard*

BlackI

59Issue 2016-10-241005088-EMEI-16.0

11 Start-up

Page 60

12 Cover

The cover and back plate are manufactured in clear anodized aluminium. The end plates are made

of black painted steel sheet.

12.1 Fitting and removing the cover

The cover is slid over flanges in the back plate so that the ridges fit in the grooves.

Break off and snap on the fill cover into the back plate for output shaft. Snap on the other fill cover

for the second slot. Secure cover with the screw.

When properly installed and adjusted, attach the product label, which includes the CE mark on the

right side of the lower part of the operator cover (see illustration).

Apply the EM logotype to the cover – see illustration.

Only for SE: Apply the SITAC label next to the product label - see illustration.

Disconnect from

supply before

servicing

1005088-EMEI-16.0Issue 2016-10-2460

12 Cover

Page 61

12.2 Middle piece cover

61Issue 2016-10-241005088-EMEI-16.0

12 Cover

Page 62

13 Signage

Check that all required signage is applied and intact. Mandatory indicates that the signage is required

by European directives and equivalent national legislation outside the European Union.

Product label: Mandatory

Emergency break-out: Mandatory, if approved for escape route.

Entrematic Nordic door sticker: Mandatory, if applicable to highlight the presence of the glass (applied to all glass sections

that are moving).

Supervision of child: Mandatory, if applicable (applied to both sides of the door). To be placed on entrances where the risk

analysis shows use by children, elderly and disabled.

Operator designed for disabled people:

Recommended, if applicable (applied to both sides of the door).

Activation by disabled people: Recommended, if applicable.

SITAC label: Mandatory in SE

No entry, identifying one-way traffic: Mandatory in GB and US, if applicable, not included in the product.

1005088-EMEI-16.0Issue 2016-10-2462

13 Signage

Page 63

14 Advanced settings

14.1 Learn with advanced setting of “back- and latch-check”

See the prerequisites for performing a “learn” under the heading Auto-learn – automatically sets

back and latch check (recommended) on page 57.

a Push the button once or twice as for auto-setting.

b Stop the door at required back-check.

c The door reverts towards closed position.

d Remove the stop.

e Stop the door at required latch-check.

f The door reverts to learn the fully open position.

g Remove the stop.

h The door reverts to closed position.

14.2 Revert to default values for “back- and latch-check" (Level 1)

a Disconnect batteries if any.

b Disconnect the mains.

c Press the LEARN BUTTON (LRN) and keep it depressed.

d Connect the mains.

e Watch the ERROR LED.

f Release the LEARN BUTTON after 1 flash (LED is out).

g The BACK CHECK, LATCH CHECK and OPEN POSITION have now reverted to default values.

h Disconnect the mains.

i Next time the mains is connected, a new learn is needed to be run, and the operator will use

the default values.

63Issue 2016-10-241005088-EMEI-16.0

14 Advanced settings

Page 64

14.3 Changing group of parameters (Level 2)

a Disconnect batteries if any.

b Disconnect the mains.

c Press the LEARN BUTTON (LRN) and keep it depressed.

d Connect the mains.

e Watch the ERROR LED.

f Release the LEARN BUTTON after 2 flashes (LED is out).

The ERROR LED flashes a number of short flashes that corresponds to the parameter group

number (see table). After a short pause the LED will repeat the group number, and so on.

g Pushing the LEARN BUTTON once, increases the parameter group number. When the highest

parameter group number is reached it will start with number 1 (default) again.

h Pushthe button until you get the requested parameter group. Ensure that the requested group

of parameters has been selected by counting the number of flashes.

i Disconnect the mains.

j Next time the mains is connected, the operator will use the new group of parameters.

10987654321 (default)Parameter/ Group

15 minutes15 minutes15 minutes15 minutes15minutes15 minutes15 minutes15 minutesInfinite15 minutesOPEN/CLOSE

HOLD OPENTIME

ConveniencePower SavePower SavePower SavePower SavePower SavePower SaveConveniencePower SavePower SaveBATTERY mode

Locked during KILL

Lock follows

program selector during

KILL

Locked during KILL

Locked during KILL

Locked during KILL

Locked during KILL

Lock follows

program selector during

KILL

Locked during

KILL

Locked during KILL

Locked during KILL

KILL mode

Reverses

when obstructed

Door closerDoor closerDoor closerDoor closerReverses

when obstructed

Door closerDoor closerDoor closerDoor closerOBSTRUCTION

mode

1)

Separate

presence detection

Separate pres-

ence detec-

tion

Separate

presence detection

Separate

presence detection

Common

presence detection

Separate

presence detection

Separate

presence detection

Separate presence detection

Separate

presence detection

Separate

presence detection

DOUBLE EGRESS

mode

OnOnOnOffOnOnOnOnOnOnLOCK RETRY

In AUTO

mode

In AUTO

mode

In OFF, EXIT

and AUTO

mode

In AUTO

mode

In AUTO

mode

In AUTO

mode

In AUTO

mode

In AUTO

mode

In AUTO

mode

In AUTO

mode

OPEN/CLOSE impulse

Normally

Open

Normally

Closed

Normally

Open

Normally

Open

Normally

Open

Normally

Open

Normally

Open

Normally

Open

Normally

Open

Normally

Open

KILL Impulse

Configuration

1)

If set to REVERSES WHEN OBSTRUCTED, the operator re-opens when obstructed, similar to a presence impulse.

As default the operator tries to close two times extra in automatic operation, OFF or EXIT mode and one time in manual operation, OFF or

EXIT mode if there is a problem with binding striking plates. This function can be switched off (see LOCK RETRY above).

Note! When changing group of parameters, normally only the master control must be configured in a double door application. When

changing from or to group seven, both MASTER and SLAVE must be configured.

1005088-EMEI-16.0Issue 2016-10-2464

14 Advanced settings

Page 65

14.4 Classification (Level 3)

a Disconnect batteries if any.

b Disconnect the mains.

c Press the LEARN BUTTON (LRN) and keep it depressed.

d Connect the mains.

e Watch the ERROR LED.

f Release the LEARN BUTTON after 3 flashes (LED is out).

g Identify the current classification

The ERROR LED flashes an amount of short flashes that correspond to the classification number.

After a short pause the LED will repeat the classification number and so on.

h Changing the classification

If you push the LEARN BUTTON once, the classification number will increase. When you have

reached the highest classification number it will start at number one again.

• Push the button until you get the requested classification

• Disconnect the mains

Next time the mains is connected, the operator will use the new classification.

i Classification table

21Classification

Low energyFull power(Default)

EN 16005Standard

Automatic limitation 1.69 J3 - 6 sOpening speed

Automatic limitation 1.69 J3 - 6 sClosing speed

The fastest setting of Opening Speed and Closing Speed are automatically limited to the value

in the table, and can only be reduced.

If classification 2, Low energy,is used the operator will automatically follow the speed limitation

in EN 16005.

The learn procedure must be carried out after a change of the classification setting.

Speed settings for Low energy mode

The table shows minimum opening time to back check or to 80° open or minimum closing

time from 90° to 10° open.

Door mass (kg)Width of door leaf (mm)

9080706050

Time (s) min

3,53,33,23,23,0750

3,63,43,23,13,1850

4,24,03,73,43,21000

5,14,84,54,23,81200

65Issue 2016-10-241005088-EMEI-16.0

14 Advanced settings

Page 66

14.5 Overhead Presence Detection (OPD) Monitoring (Level 4)

a Disconnect batteries if any.

b Disconnect the mains.

c Press the LEARN BUTTON (LRN) and keep it depressed.

d Connect the mains.

e Watch the ERROR LED.

f Release the LEARN BUTTON after 4 flashes (LED is out).

g Identify the current monitoring

The ERROR LED flashes an amount of short flashes that correspond to the status number.

After a short pause the LED will repeat the status number and so on.

h Changing the status

If you push the LEARN BUTTON once, the status number will increase. When you have reached

the highest status number it will start at number one again.

• Push the button until you get the requested monitoring status, 1 = OFF (default), 2 = ON

• Disconnect the mains

Next time you connect the mains the operator will use the new status setting.

i Recommended settings for sensor SP34-M

Sensor dip switch settings

Dip 1 = ON

Dip 2-8 = OFF

Interface dip switch settings

Dip 1, 4 and 7 = OFF

Dip 2, 3, 5, 6 and 8 = ON

1005088-EMEI-16.0Issue 2016-10-2466

14 Advanced settings

Page 67

14.6 Lock kick (Level 5)

a Disconnect batteries if any.

b Disconnect the mains.

c Press the LEARN BUTTON (LRN) and keep it depressed.

d Connect the mains.

e Watch the ERROR LED.

f Release the LEARN BUTTON after 5 flashes (LED is out).

g Identify the current lock kick status

The ERROR LED flashes an amount of short flashes that correspond to the status number.

After a short pause the LED will repeat the status number and so on.

h Changing the status

If you push the LEARN BUTTON once, the status number will increase. When you have reached

the highest status number it will start at number one again.

• Push the button until you get the requested lock kick status, 1 = Basic (default), 2 = Enhanced

• Disconnect the mains

Next time the mains is connected, the operator will use the new status setting.

14.7 Lock unlocked status (Level 6)

a Disconnect batteries if any.

b Disconnect the mains.

c Press the LEARN BUTTON (LRN) and keep it depressed.

d Connect the mains.

e Watch the ERROR LED.

f Release the LEARN BUTTON after 6 flashes (LED is out).

g Identify the current lock unlocked status

The ERROR LED flashes an amount of short flashes that correspond to the status number.

After a short pause the LED will repeat the status number and so on.

h Changing the status

If you push the LEARN BUTTON once, the status number will increase. When you have reached

the highest status number it will start at number one again.

• Push the button until you get the requested status, Lock is unlocked at

1= Lock is unlocked when door is not closed

2= Lock is unlocked when door is 0-10 degrees from closed position, during opening

• Disconnect the mains

Next time the mains is connected, the operator will use the new status setting.

67Issue 2016-10-241005088-EMEI-16.0

14 Advanced settings

Page 68

15 Reducing / Increasing the “Spring pre-tension” (SPTE)

The spring pre-tension is factory set to 210° and is normally not necessary to adjust. If adjustment

has to be carried out see below.

a Loosen the door stop arm. Remove if fitted on the topside, slide down if fitted on the bottom.

b Turn the potentiometer for spring pre-tension (SPTE) clockwise until the door opens to 45°.

c Loosen the drive arm fixing screw.

d Moving the door towards open position, reduces the tension, or:

Moving the door towards closed position, increases the tension.

e Tighten the drive arm.

f Turn the potentiometer SPTE to 0°.

g Open the door to required open position, plus approx. 15 mm, by turning the potentiometer

SPTE clockwise.

h Mount the door stop arm as close as possible to the open door stop block, fine- adjust with the

screw if necessary.

i Turn the potentiometer SPTE to 0°.

j Push the LEARN BUTTON.

k Let the door do the learn cycle without touching it.

Note! Max. allowable spring pre-tension is 210°. Over-tension may damage the spring or overheat

the motor.

1005088-EMEI-16.0Issue 2016-10-2468

15 Reducing / Increasing the “Spring pre-tension” (SPTE)

Page 69

16 Installation and adjustments

16.1 Complementary Safety Devices Swing Doors

If there is any risk for finger jam, add finger protection strip at the hinge side for internal doors,

article No. 833334 or add finger protection roll for external doors, article No. 833333.

16.2 Swing Doors Opening and Closing Time

Adjust, as a minimum, the operator's opening and closing time according to the diagram below.

16.2.1 How to find the correct opening and closing time

• Measure the door width.