Page 1

Swing Door Operator

EM EMSW

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

12 3 4

TB2

TB2

0 V DC

24 V DC

0 V DC

Kill

Key Impulse

Lock 24 V DC

Kill jumper

MVI N.O. / N.C.

MVI Open Lock / Door

Lock w. / w.o. power

Lock time 1.5 s / until closing

Slave delay off / on

Master / Slave

Push & Go

Outer Impulse

MVI Impulse

1003870

ALL TB1 AND TB2,

CLASS 2 SUPPLY

MAX. 24 V

0 V DC

24 V DC

Motor control

"Slave"

ON

123

4

5678

H.O.T

Opening Delay

MVI H.O.T

1

2

3

4

S

W

5

6

7

8

9

10

11

13

12

14

Installation and Service Manual

Original instructions

1004291-EMEI-10.0 – Issue 2016-01-27

Page 2

© All rights in and to this material are the sole property of Entrematic Group AB. Copying, scanning, alterations or modifications are

expressly forbidden without the prior written consent of Entrematic Group AB. Rights reserved for changes without prior notice.

Backtrack information: folder:Workspace Main, version:a289, Date:2016-01-27 time:06:49:12, state: Frozen

Page 3

CONTENTS - Original instructions

51 Revision .....................................................................................................................................................................................

62 Instructions for safe operation ...........................................................................................................................................

73 Important information .........................................................................................................................................................

73.1 Intended use ....................................................................................................................................................................................

73.2 Safety precautions .........................................................................................................................................................................

83.3 Electronic equipment reception interference .....................................................................................................................

83.4 Environmental requirements .....................................................................................................................................................

94 Technical specification ..........................................................................................................................................................

114.1 Permitted door weight and door width .................................................................................................................................

125 How the EM EMSW works ....................................................................................................................................................

125.1 Opening ............................................................................................................................................................................................

125.2 Closing ...............................................................................................................................................................................................

125.3 Functions on the Control Unit CSDB .......................................................................................................................................

125.3.1 Key Impulse ....................................................................................................................................................................

125.3.2 Outer Impulse ................................................................................................................................................................

135.3.3 Multi Voltage Input (MVI) ..........................................................................................................................................

145.3.4 Kill Input ..........................................................................................................................................................................

145.3.5 Limit Switch Open ........................................................................................................................................................

145.3.6 Home Switch (optional) ............................................................................................................................................

145.3.7 Lock output ....................................................................................................................................................................

155.3.8 Double Door ..................................................................................................................................................................

155.3.9 Push to Go .......................................................................................................................................................................

155.3.10 Error Messages ...............................................................................................................................................................

155.3.11 Programme Selector ...................................................................................................................................................

155.4 Functions on the Extension Unit EXB ......................................................................................................................................

155.4.1 Inner impulse .................................................................................................................................................................

155.4.2 Low Pass Filter (automatic cycle delay) ................................................................................................................

165.4.3 Presence Impulse ..........................................................................................................................................................

165.4.4 Presence Detection ......................................................................................................................................................

165.4.5 Sensor Monitoring .......................................................................................................................................................

165.4.6 Overhead Presence Detection (OPD) ....................................................................................................................

165.4.7 Mat Safety .......................................................................................................................................................................

165.4.8 LockOut ...........................................................................................................................................................................

175.4.9 Programme selector ....................................................................................................................................................

186 Models ........................................................................................................................................................................................

186.1 EM EMSW, standard cover (wall or door leaf mounted) ...................................................................................................

197 Part identification & Accessories ......................................................................................................................................

197.1 Arm systems, PUSH ......................................................................................................................................................................

197.2 Arm systems, PUSH-335 .............................................................................................................................................................

207.3 Arm system, PULL ...........................................................................................................................................................................

207.4 Arm system, PULL-220 .................................................................................................................................................................

207.5 Arm system, ST-V / ST-H ...............................................................................................................................................................

207.5.1 Options for ST-V / ST-H ................................................................................................................................................

217.6 Further accessories ........................................................................................................................................................................

237.7 Labels .................................................................................................................................................................................................

248 Pre-Installation ........................................................................................................................................................................

248.1 General tips/Safety concerns .....................................................................................................................................................

248.2 Fastening requirements ...............................................................................................................................................................

258.3 Tools required .................................................................................................................................................................................

258.4 Installation on double doors ......................................................................................................................................................

268.5 Installation examples for fire approved doors .....................................................................................................................

279 Mechanical installation ........................................................................................................................................................

279.1 Wall mounted operator with arm system PUSH .................................................................................................................

309.2 Door leaf mounted operator with arm system PUSH-335 ...............................................................................................

3Issue 2016-01-271004291-EMEI-10.0

Page 4

319.3 Wall mounted operator with arm system PULL, PULL-220 and ST ................................................................................

319.3.1 Changing the direction of rotation .........................................................................................................................

329.3.2 Installation of operator with arm system PULL ..................................................................................................

369.3.3 Installation of operator with arm system ST .......................................................................................................

4210 Electrical connection .............................................................................................................................................................

4210.1 Control units ....................................................................................................................................................................................

4210.1.1 CSDB .................................................................................................................................................................................

4210.1.2 CSDA-S .............................................................................................................................................................................

4210.1.3 EXB .....................................................................................................................................................................................

4210.1.4 CSDA-F ..............................................................................................................................................................................

4310.2 Connection of control unit CSDB – single doors .................................................................................................................

4410.3 Connection of control units CSDB and CSDA-S – double doors ....................................................................................

4510.4 Connection of control units CSDB/CSDB – double doors ................................................................................................

4610.5 Connection of extension unit EXB – option ..........................................................................................................................

4710.6 Sensor cable inlet ...........................................................................................................................................................................

4811 Start-Up .....................................................................................................................................................................................

4811.1 Closing torque ................................................................................................................................................................................

4911.2 Opening torque ..............................................................................................................................................................................

5011.3 Connection of activation units and accessories ..................................................................................................................

5112 Cover ..........................................................................................................................................................................................

5112.1 Fitting and removing the cover .................................................................................................................................................

5212.2 Middle piece cover ........................................................................................................................................................................

5313 Signage .......................................................................................................................................................................................

5414 Installation on fire doors ......................................................................................................................................................

5414.1 Control unit CSDA-F (option) ....................................................................................................................................................

5514.1.1 Connection of control unit CSDA-F – single door ..............................................................................................

5614.1.2 Connection of control unit CSDA-F – double door ...........................................................................................

5614.1.3 Function check ..............................................................................................................................................................

5714.2 Automation of fire doors without overriding fire detection and alarm system .......................................................

5714.2.1 General connection .....................................................................................................................................................

5714.3 Automation of fire doors with overriding fire detection and alarm system ..............................................................

5814.3.1 Connection of CSDA-F to a fire alarm system ......................................................................................................

5915 Installation and adjustments - Low Energy Operator .................................................................................................

5915.1 Complementary Safety Devices Swing Doors ......................................................................................................................

6015.2 Swing Doors Opening and Closing Time ................................................................................................................................

6015.2.1 How to find the correct opening and closing time ...........................................................................................

6015.3 Diagrams for Door weight ..........................................................................................................................................................

6115.3.1 Aluminium frame with glass .....................................................................................................................................

6115.3.2 Steel frame with glass .................................................................................................................................................

6215.3.3 Solid wood ......................................................................................................................................................................

6316 Installation instructions for Accessories .........................................................................................................................

6316.1 COOA - Coordination unit ...........................................................................................................................................................

6316.1.1 EM EMSW 2 - Push ........................................................................................................................................................

6416.1.2 EM EMSW 2 - Pull ..........................................................................................................................................................

6516.2 PAG .....................................................................................................................................................................................................

6616.3 Door stop ..........................................................................................................................................................................................

6717 Troubleshooting .....................................................................................................................................................................

6818 Service/Maintenance .............................................................................................................................................................

1004291-EMEI-10.0Issue 2016-01-274

Page 5

1 Revision

Following pages have been revised:

Revision 9.0 → 10.0Page

Updated illustration with arm.10

Added this new section.11

Updated Art. No., texts and illustration with arm.19

Added PUSH-335.19

Updated Art. No., texts and illustration with arm.20

Updated Art. No. and deleted 600149.21

Updated texts.24

Updated illustration with arm.28

Updated illustration with arm.29

Changed "PUSH-325" to "PUSH-335" and updated illustration with arm.30

Updated dimension.32

Updated illustration with arm.34

Updated illustration with arm.35

Updated illustration with arm.36

Updated illustration with arm.38

Updated illustration with arm.39

Updated illustration with arm.40

Updated illustration with arm.41

Added "Note".38

Updated illustration.55

Updated illustration with arm.56

Updated illustration with arm.63

Updated illustration with arm.64

Updated illustration with arm.66

Added the fault for "1 flashing LED".67

Updated Art. No. for PUSH and PULL/PULL-220 service kit and added PUSH-335.68

5Issue 2016-01-271004291-EMEI-10.0

1 Revision

Page 6

2 Instructions for safe operation

• Failure to observe the information in this manual may result in

personal injury or damage to equipment.

• Toreduce the risk of injurytopersons - use this operatorwithsingle

or double pedestrian swinging or folding doors only.

• Do not use the equipment if repair or adjustment is necessary.

• Disconnect supply when cleaning or other maintenance is to be

carried out.

• The operator can be used by childrenage8andabove, and persons

with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, if they have been given supervision or instruction by a person responsible for their safety concerning safe

operator use and the possible hazards involved.

This doesnothowever prevent those persons touse the door where

the operator is installed.

• Cleaning and user maintenance shall not be made by children

without supervision.

• Do not let children climb on or play with the door or the fixed/remote controls.

• In all instances, where work is being done, the area is to be secured

from pedestrian traffic, and the power removed to prevent injury.

• The doorset can be operated automatically by sensors or manually

by activators. It can also be used manually as a door closer.

1004291-EMEI-10.0Issue 2016-01-276

2 Instructions for safe operation

Page 7

3 Important information

3.1 Intended use

The door is designed to offer continuous use, a high degree of safety and maximum lifetime. The

system is self-adjusting to the effects caused by normal variations in the weather conditions and

to minor friction changes caused by e.g. dust and dirt.

For escape in emergency situations the doorset is opened manually.

This manual contains the necessary details and instructions for the installation, maintenance and

service of the Swing Door Operator EM EMSW.

The EM EMSW is an automatic swing door operator developed to facilitate entrances to buildings

and within buildingsthrough swingdoors. The EMEMSW isan electrohydraulic operatorapproved

for fire door applications. It is to be installed indoors where it is suitable for almost all types of external and internal swing doors. This widely-used operator can be found on applications ranging

from handicapped-access in private homes to high-traffic retail operations.

Door operator usedin escape routesshall beinstalled so thatthe door opensin theescape direction

unless the system allows breakout in this direction.

These operators shall be connected to a fire alarm system, see section 11.1, 14.2 or 14.3.

The motor,oil pump and hydraulic unitare combined into a compact unit mounted alongside the

control unit within the cover. The operator is connected to the door leaf with a range of different

arm systems.

For use see User manual 1004131.

Save these instructions for future reference.

3.2 Safety precautions

Be sure tocomplete a riskassessment and siteacceptance test beforetaking thedoor into operation.

Toavoid bodily injury,material damage andmalfunction ofthe product, theinstructions contained

in this manual must be strictly observed during installation, adjustment, repairs and service etc.

Trainingis neededto carry outthese taskssafely. Only EntrematicGroup-trained techniciansshould

be allowed to carry out these operations.

7Issue 2016-01-271004291-EMEI-10.0

3 Important information

Page 8

3.3 Electronic equipment reception interference

The equipment complies with the European EMC directive (US market FCC Part 15), provided installed according to Installation and Service manual.

The equipment maygenerate and useradio frequencyenergy and ifnot installed and used properly,

it may cause interference to radio, television reception or other radio frequency type systems.

If other equipment does not fully comply with immunity requirements interference may occur.

There is no guarantee that interference will not occur in a particular installation. Ifthis equipment

does cause interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of

the following measures:

• Re-orient the receiving antenna.

• Relocate the receiver with respect to the equipment.

• Move the receiver away from the equipment.

• Plug the receiver into adifferent outlet sothat equipment and receiver are on different branch

circuits.

• Check that protective earth (PE) is connected.

If necessary, the user should consult the dealer or an experienced electronics technician for additional suggestions.

3.4 Environmental requirements

Entrematic Group productsare equipped withelectronics andmay also beequipped with batteries

containing materials whicharehazardous totheenvironment. Disconnect powerbefore removing

electronics and batteryand makesure it isdisposed ofproperly according tolocal regulations(how

and where) as was done with the packaging material.

1004291-EMEI-10.0Issue 2016-01-278

3 Important information

Page 9

4 Technical specification

Ensure that the door operator with technical specification below is suitable for the installation.

Entrematic Group ABManufacturer:

Lodjursgatan 10, SE-261 44 Landskrona, SwedenAddress:

EM EMSWType:

230 V AC ±10%, 50 Hz, mains fuse max 10AMains power supply:

Note! The mains power supply shall be installed with protection and an all-pole

mains switch with isolating capability of Category III, at least 3 mm between contacts, shall beinstalled according tolocal regulations. Thesearticles are notprovided

with the door.

Max. 230 W (Max 460 W Double door set)Power consumption:

24 V DC, 700 mA (stabilized)Auxiliary voltage:

6,3 ATMotor fuse F1:

250 mATControl fuse F2:

Max 250 kgDoor weight:

Max 1600 mmDoor width:

For PUSH = 80 kg m

2

Max. Inertia J:

For PULL = 28 kg m

2

Inertia = Door weight x (Door width)2/ 3

The EM EMSW complies with the door weights/widths stated in the:

Controlled door closing, EN 1154 Table I, size 3-6

Coordination unit for rebated doors, EN 1158

Türschliesser mit Öffnungsautomatik(Drechflügelantrieb), DIN 18263-4AU Grösse

3-6

In compliance with DIN 18650–1/2Safety requirements:

-15°C to +30°CAmbient temperature:

max. 85%Relative humidity:

Length: EM EMSW (standard cover) 716 mmDimensions:

EM EMSW-SPEC 750--1600 mm

EM EMSW-2 1435--3200 mm

Height: 110 mm

Depth: 110 mm

IP20Degree of protection:

IP54Degree of protection, con-

trol actuators:

Third party approvals from established certification organizations valid for safety

in use, see Declaration of Incorporation.

Approvals:

9Issue 2016-01-271004291-EMEI-10.0

4 Technical specification

Page 10

This product is to be installed internally.

38

298

110

110

8013

Classification to DIN 18650-1

Digit 8Digit 7Digit 6Digit 5Digit 4Digit 3Digit 2Digit 1

41,2,3,41,2,3,41,2,32131

swing door drive1Type of drive, digit 1.

1 000 000 test cycles, at 4 000 cycles/day3Drive durability, digit 2.

swing door1Type of door leaf, digit 3.

suitable for use as a fire door2Suitability for use as a fire

protection door, digit. 4

force limitation1Drive safety devices, digit

5.

connection for external safety systems2

low energy3

in escape routes with a break-out system1Special requirements for

drives/functions/fittings,

digit 6.

in escape routes without a break-out system2

for self-closing fire protection doors with a break-out system3

for self-closing fire protection doors without a break-out system.4

with sufficiently dimensioned safety distances1Safety at door leaf or

leaves, digit 7.

with protection to prevent fingers being crushed, shorn off or drawn in2

with integrated break-out unit3

with presence sensor4

temperature range as specified by the manufacturer4Ambienttemperature, digit

8.

1004291-EMEI-10.0Issue 2016-01-2710

4 Technical specification

Page 11

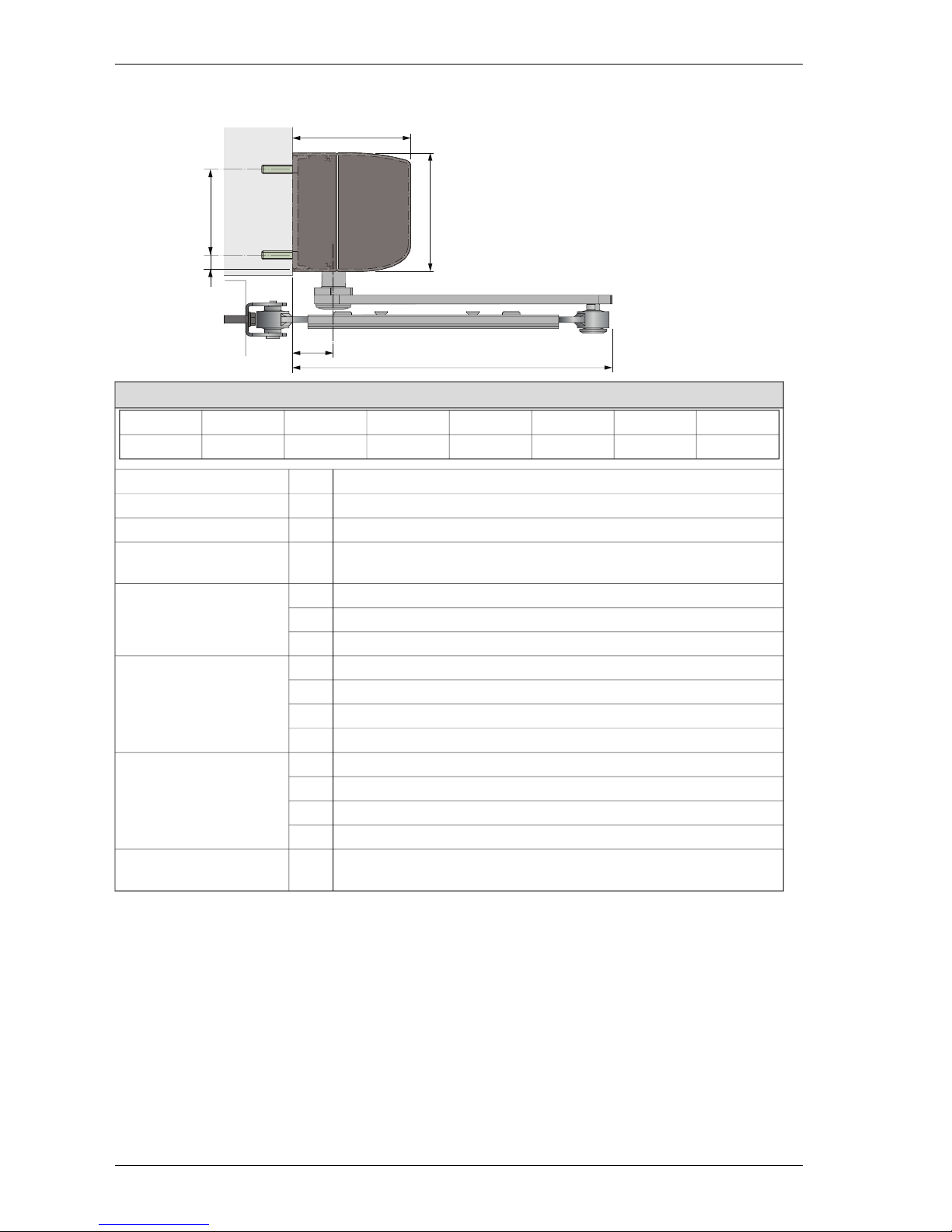

4.1 Permitted door weight and door width

0

50

100

150

200

250

300

350

400

450

0.8 0.9 1 1.1 1.2 1.3 1.4

PUSH arm

PULL arm

J=80 kgm²

J=28 kgm²

PUSH arm

PULL arm

Door weight (kg)

Door width (m)

11Issue 2016-01-271004291-EMEI-10.0

4 Technical specification

Page 12

5 How the EM EMSW works

The EM EMSW works electro-hydraulically. It opens with an AC-motor that via a hydraulicunit and

an arm system transmits the power to the door leaf. The closing power is from a coil spring. The

movement of the door is controlled by limit switches and valve screws.

5.1 Opening

When an opening impulse is received by the control unit, the motor starts and the hydraulic unit

rotates the drive shaft and arm system (door) with high speed towards open position. Before fully

open position, the speed is reduced to low speed. The door stops and the motor rotation ceases

when the selected door opening angle is reached. This open position is kept by a hydraulic valve.

5.2 Closing

The spring closing starts when the hold open time has run out. Before fully closed position the

speed is reduced to low speed, which will be kept until the door is completely closed. The door is

kept closed by spring power. To overcome the resistance of a striking plate a “lock kick” can be

adjusted to required level.

5.3 Functions on the Control Unit CSDB

5.3.1 Key Impulse

Key impulse will open the door in programme selection OFF, EXIT and AUTO and keep the door

open during key hold open time.

Key hold open time can be adjusted between 0-30 sec.

5.3.2 Outer Impulse

Outer impulse will open the doorif programme selection is AUTO and keep the door open during

the outer hold open time, which can be adjusted between 0-30 s.

1004291-EMEI-10.0Issue 2016-01-2712

5 How the EM EMSW works

Page 13

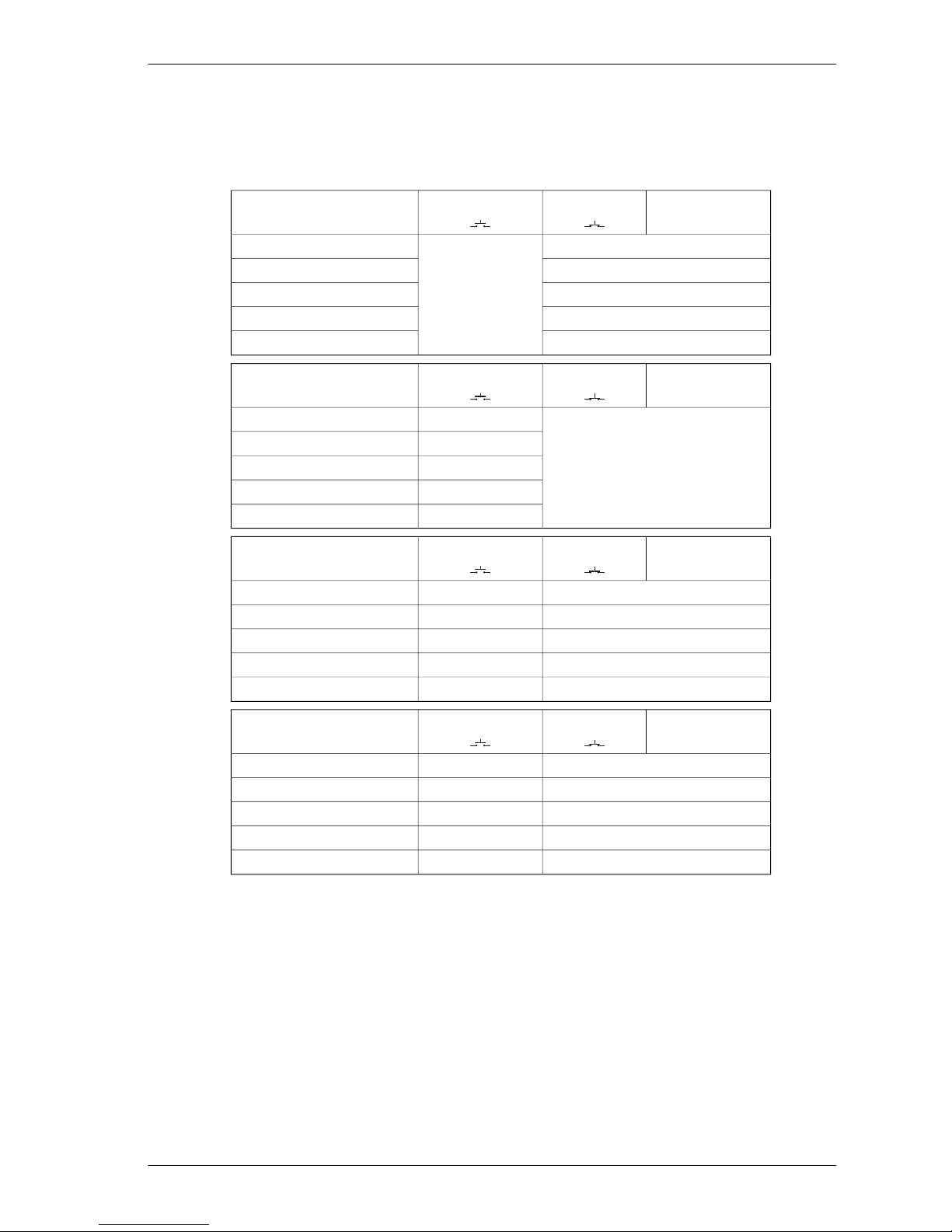

5.3.3 Multi Voltage Input (MVI)

MVI impulse accepts a potential-free contact or 6-24 V AC/DC.

Status of lock (operation mode) can be selected via a function selector FS2 and depends on input

TB2:11 and 13.

TB2:11 and 13

6-24 V AC/DC*

TB2:11 and 13TB2:11 and 13FS-2 = OFF /factory setting)

FS-3 = OFF (factory setting)

AUTO

OFF

CSDB (No PS)

OFFEXB OFF

EXITEXB EXIT

AUTOEXB AUTO

OPENEXB OPEN

TB2:11 and 13

6-24 V AC/DC*

TB2:11 and 13TB2:11 and 13sFS-2 = ON

FS-3 = OFF (factory setting)

OFF

AUTOCSDB (No PS)

OFFEXB OFF

EXITEXB EXIT

AUTOEXB AUTO

OPENEXB OPEN

TB2:11 and 13

6-24 V AC/DC*

TB2:11 and 13TB2:11 and 13FS-2 = OFF (factory setting)

FS-3 = ON

Open doorOFFCSDB (No PS)

Open doorOFFEXB OFF

Open doorEXITEXB EXIT

Open doorAUTOEXB AUTO

Open doorOPENEXB OPEN

TB2:11 and 13

6-24 V AC/DC*

TB2:11 and 13TB2:11 and 13FS-2 = ON

FS-3 = ON

OFFOpen doorCSDB (No PS)

OFFOpen doorEXB OFF

EXITOpen doorEXB EXIT

AUTOOpen doorEXB AUTO

OPENOpen doorEXB OPEN

* +6-24 V DC must be connected to TB2:13 and MVI jumper must be removed.

Programme selector mustnot beconnectedto TB2:13 ifinput is 6-24V.Connectinstead programme

selector to EXB.

MVI impulse willunlock thelock and open the dooror onlyunlock thelock (changes the operation

mode of the operator). Can be selected via the function selector FS3.

MVI hold open time can be adjusted between 0-30 sec.

13Issue 2016-01-271004291-EMEI-10.0

5 How the EM EMSW works

Page 14

5.3.4 Kill Input

When kill is activated, the door will close immediately if not already closed. Hold open and low

pass filter timers are reset.

Key impulse will open lock during activated kill if not connected to TB2:5 for 0 V DC.

When kill is deactivated, the door will act according to current input status.

Several kill inputs are possible to connect in parallel with other CSDB control units. Connect kill

on the first operator according to the connection diagram. The second, third etc. operator is only

to be connected in parallel, from terminal 5 to 5 and 6 to 6.

Kill function is selected via a function selector (Kill jumper).

As an alternative to the shown connection under Connection of activation units and accessories

on page 50, an alarm loop 24 VDC can be connected to the CSDB connect +24 VDC to terminal 6

and 0 VDC to terminal 5.

5.3.5 Limit Switch Open

The limit switch indicates a fully open door and can be adjusted for opening angles up to 120º.

When the limitswitch isactivated the motor will stop.If thelimit switch isnot activated,the motor

will stop after 14 sec.

If the limit switch is deactivated when the door is open, the motor will restart to reposition the

door.

The LED indicates an activated limit switch.

Contact rating: 1A, 48 V DC, normally open.

5.3.6 Home Switch (optional)

When no home switch is mounted and the limit switch is deactivated in open position, a timer

starts and after 6 sec the status will change from closing to closed door.

If the optional home switch is mounted, this will indicate closed door instead of the timer.

“Opening delay” for lock (0-3s) is ignored as soon as home switch is not activated.

“Slave delay” (0,5s) is ignored as soon as home switch for the master is not activated.

Presence impulse is ignored when home switch indicates a closed door within 6 seconds.

The LED indicates an activated home switch.

5.3.7 Lock output

The lock output is short circuit proof and can source a lock with 24V, 375 mA.

The output can be locked with power or locked without power. It can be selected via a function

selector (Locked w. / w.o. power).

The lock activation time can be either 1,5 s + (opening delay) or until closing. It can be selected

via a function selector (Lock time 1,5 s/until closing).

“Opening delay” for lock, the time that will pass before the motor starts, can be adjusted from 0-3

s.

If ahome switch is installed, the lock opening time will first start when thehome switch is deactivated. This to prevent door to jam in the lock, if presence detection is activated.

1004291-EMEI-10.0Issue 2016-01-2714

5 How the EM EMSW works

Page 15

5.3.8 Double Door

The CSDB works as the master in a double door application and is connected to the slave unit

CSDA-S.

The slave unit has a standard opening delay of 0,2 sec. The delay can be increased to 0,5 sec. to

prevent jamming of thicker door leaves. This can be selected via a function selector (Slave Delay).

Home switch is recommended to prevent delay during closing.

When there is a need for more power supply than a single CSDB can deliver, a second CSDB can

be connected as a slave. The CSDB on the slave unit must then be configured as a slave. This can

be selected via a function selector (Master / Slave).

To enable only one door to open, connect impulse parallel on both units. Slave door must have

CSDB+EXB and the low pass filter potentiometer adjusted.

5.3.9 Push to Go

A push on the door will, from closed position, start an automatic opening cycle if the programme

selection is AUTO or EXIT and remain open during the hold open time “Outer HOT” (0-30 s).

A home switch on the operator is needed to achieve Push to Go. Can be selected via a function

selector (Push to Go).

The LED indicates when the home switch is active.

5.3.10 Error Messages

The LED indicates:

• Sensor error; 1 flash of 0,2 sec and then 1 sec pause etc.

• Lock error(too high current draw or short circuit); 1 flash of 0,2sec and then 0,2 sec pause etc.

• CSDB defect; 3 or 4 flashes of 0,2 sec and 0,2 pause

• No slave connected and Slave monitoring jumper is missing; 7 flashes of 0,2 sec and 0,2 pause

• Slave connected but Slave monitoringjumper isnot removed;7 flashes of 0,2 secand 0,2pause

• Defect slave CSDA-S; 7 flashes of 0,2 sec and 0,2 pause

• Old slave connected and Slave monitoring jumper removed; 7 flashes of 0,2 sec and 0,2 pause

5.3.11 Programme Selector

Aprogramme selector PS-3B,with three positionsOFF-AUTO-OPEN,can be connectedto the CSDB.

Note! If the MVI-input is used for 6-24 V, the PS-3B can not be used.

The key impulse is still valid in programme selection OFF.

Presence sensors are enabled in all programme selector settings but not when kill is active.

5.4 Functions on the Extension Unit EXB

5.4.1 Inner impulse

Inner impulse will open the door if programme selection is AUTO or EXIT and keep the door open

during the hold open time.

The hold open time is adjustable from 0-30 sec.

5.4.2 Low Pass Filter (automatic cycle delay)

This function demands a constant inner impulse fora certain timeto start an automatic cycle. The

time can be adjusted from 0-5 sec.

During closing the door will reopen immediately if impulsed.

15Issue 2016-01-271004291-EMEI-10.0

5 How the EM EMSW works

Page 16

5.4.3 Presence Impulse

Presence impulse will prevent an open door from closing and will re-open a closing door and the

control will make sure that the hold open time is not shorter than 1,5 s.

Presence impulse is ignored when home impulse is active.

Presence impulse is not a valid impulse if the door is manually opened.

Presence impulse is a valid impulse if the door is opened with Push to Go.

The inputcan beeither “normally open” or “normally closed”, which can beselected viaa function

selector (Presence Impulse NO/NC).

5.4.4 Presence Detection

Presence Detection will prevent a closed door from opening and stop an opening door.

A blankout switch is used toblank out the sensor fromseeing for instance a wall close to the open

door. There can be two switches overlapping each other for the master door and two for the slave

door.

Two LED’s indicate the blank out switch status. One LED for the master door and one for the slave

door. The LED will light up if either of the two blanking switches is activated.

Presence detection can be selected via two function selectors, “Presence Detect Master” and

“Presence Detect Slave”.

5.4.5 Sensor Monitoring

Test of Presence detection is performed before opening. Test of Presence impulse is performed

before closing. Themaster sensors aretested first andthe slavesensors are testedwhen the answer

is received from master sensors.

If sensor test is not performed successfully the door will enter manual mode and report sensor

error. The sensor test will continue during manual mode.

If no slave operator is present, when sensor monitoring is enabled, the “presence impulse slave”

should be connected to “sensor test slave”.

It is only possible to monitor sensors with output of type normally closed (NC).

If the sensor error disappears during manual mode the door will re-enter automatic mode again.

Monitoring can be selected via a function selector (Presence Sensor Monitoring).

5.4.6 Overhead Presence Detection (OPD)

OPD impulse will prevent a closed door from opening and an open door from closing.

A moving door will ignore the OPD input. The OPD will be active 6 sec. after the door has started

to close. If a home switch is mounted, the OPD will be active as soon as the door is closed.

OPD can be selected via a function selector (Sensor type OPD/Mat).

5.4.7 Mat Safety

Mat safety impulse will prevent a closed door from opening and an open door from closing.

No impulses are accepted during closing if mat is activated.

Mat safety can be selected via a function selector (Sensor type OPD/Mat).

5.4.8 LockOut

LockOut is used to ignore the OPD sensor during opening and closing. Output will be low when

the door isconsidered closed,high during openingand open andtoggling whenthe dooris closing.

LockOut output will be low when the door is manually opened.

1004291-EMEI-10.0Issue 2016-01-2716

5 How the EM EMSW works

Page 17

5.4.9 Programme selector

Programme selector PS-4C can be connected to the EXB.

The PS-4C, compared toPS-3B, hasa fourth position EXIT that will make the CSDB ignore theouter

impulse device.

Presence sensors are enabled in all programme selector settings but not when kill is active.

17Issue 2016-01-271004291-EMEI-10.0

5 How the EM EMSW works

Page 18

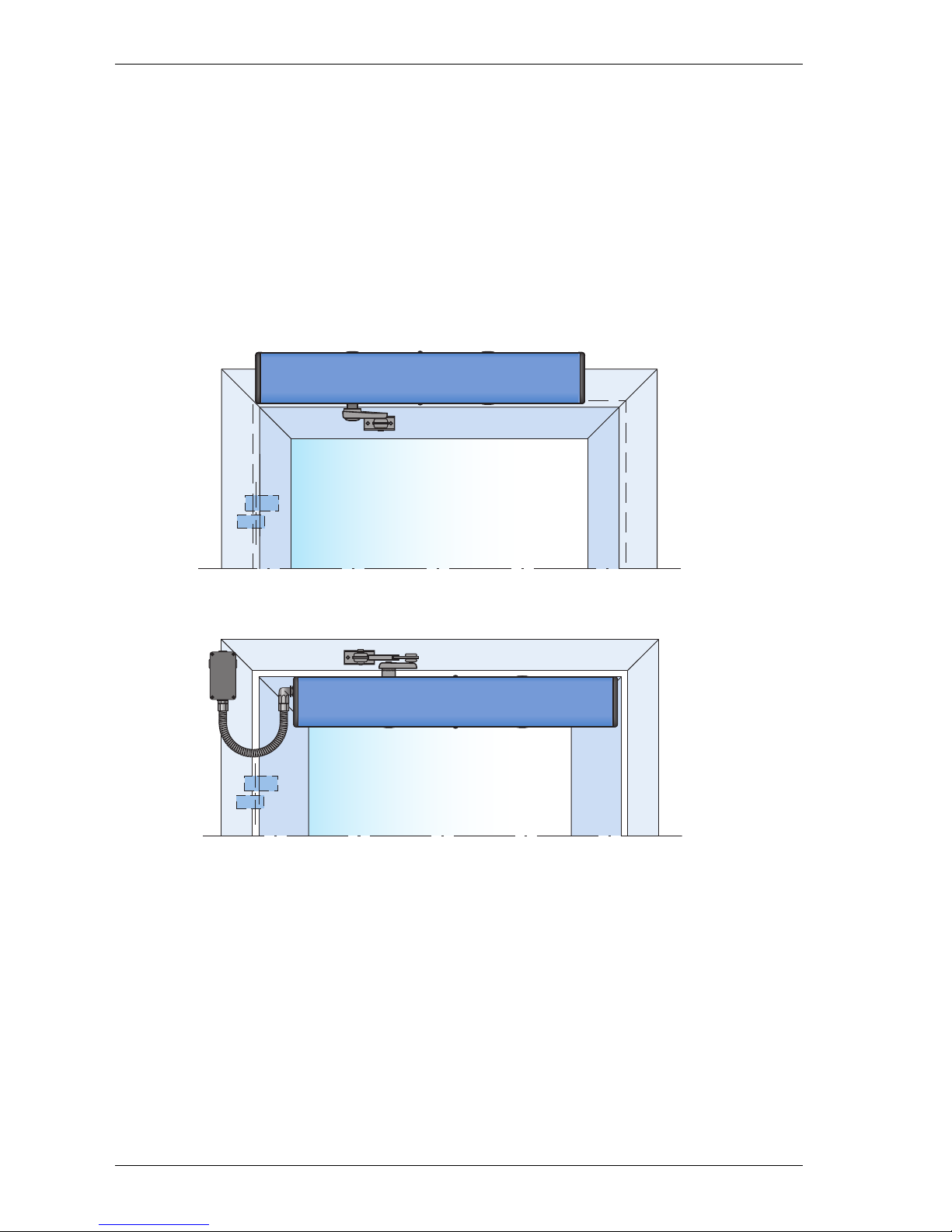

6 Models

One main model with standard cover is available of the EM EMSW.

The operator are non-handed and not dependent on the hinges. The operator suits both pushing

and pulling arm systems.

6.1 EM EMSW, standard cover (wall or door leaf mounted)

EM EMSW is the standard operator. Pushing arm system on a wall-mounted and on a door leafmounted operator shown.

Wall mounted

AAD174

Door leaf mounted

ILL-01652

1004291-EMEI-10.0Issue 2016-01-2718

6 Models

Page 19

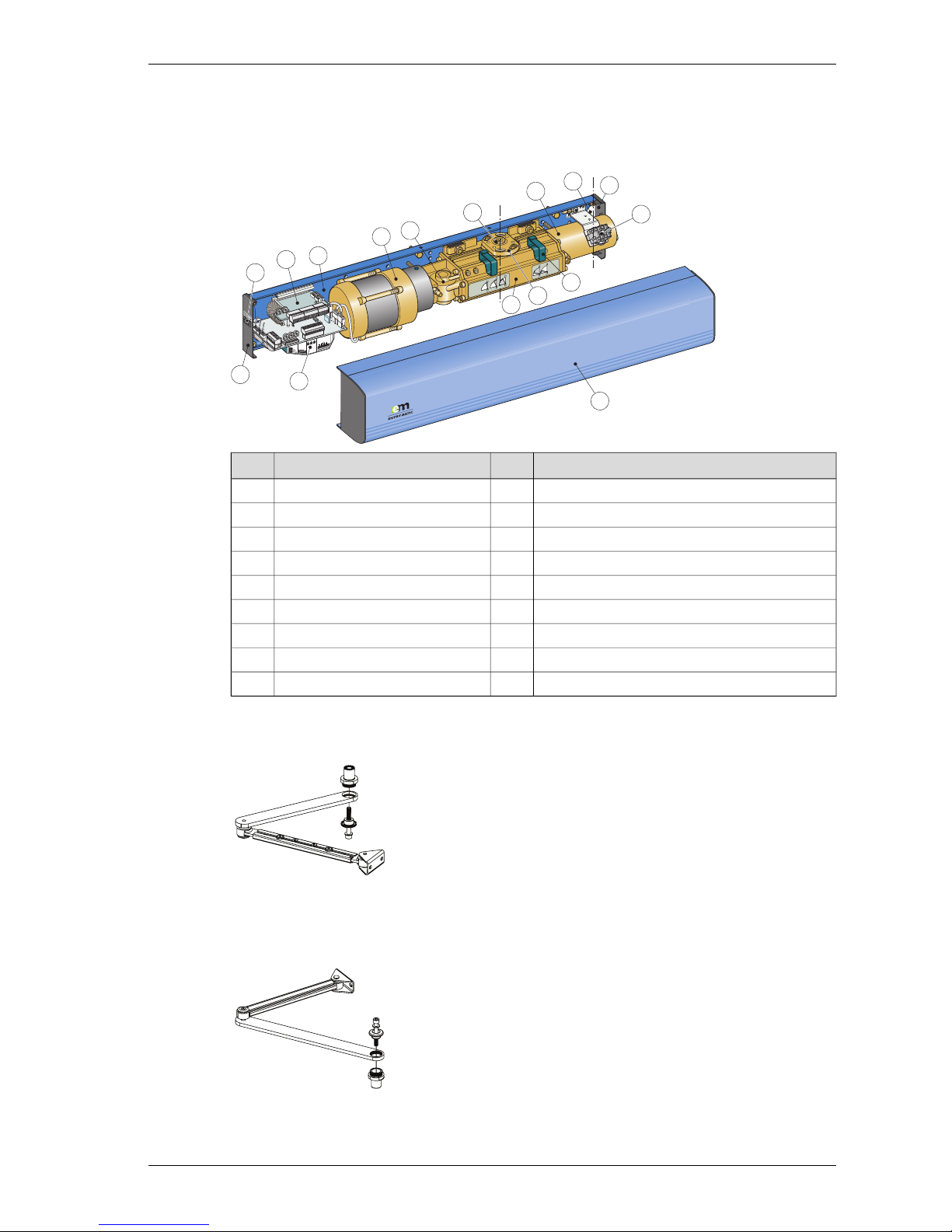

7 Part identification & Accessories

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

12 3 4

TB2

TB2

0 V DC

24 V DC

0 V DC

Kill

Key Impulse

Lock 24 V DC

Kill jumper

MVI N.O. / N.C.

MVI Open Lock / Door

Lock w. / w.o. power

Lock time 1.5 s / until closing

Slave delay off / on

Master / Slave

Push & Go

Outer Impulse

MVI Impulse

1003870

ALL TB1 AND TB2,

CLASS 2 SUPPLY

MAX. 24 V

0 V DC

24 V DC

Motor control

"Slave"

ON

1234 56

78

H.O.T

Opening Delay

MVI H.O.T

1

2

3

4

S

W

5

6

7

8

9

10

11

13

12

14

8

9

7

6

2

3

1

10

11

11

5

L2

C

L1

C

4

15

14

12

13

DescriptionNo.DescriptionNo.

Extension unit, EXB (option)10Mounting plate1

End plate11Motor/pump2

Programme selector, PS-3B (option)12Magnetic valve3

Cover13Hydraulic unit4

Bearing sleeve14Drive shaft5

Cable holder15Spring tube6

Centre line, drive shaftCL1=Cable inlet7

Centre line, hingeCL2=Mains connection8

Control unit, CSDB9

7.1 Arm systems, PUSH

Art. No. 1014113BK/SI

PUSH

It is used if the operator is installed on the wall on the opposite side of

the door swing and approved for fire applications.

7.2 Arm systems, PUSH-335

Art. No. 1011706BK/SI

PUSH-335

It is used if the operator is installed on the door leaf hinge side.

19Issue 2016-01-271004291-EMEI-10.0

7 Part identification & Accessories

Page 20

7.3 Arm system, PULL

Art. No. 1011707BK/SI

PULL

It is used if the operator is installed on the wall on the same side as the

door swing.

7.4 Arm system, PULL-220

Art. No. 1014114BK/SI

PULL-220

It is used if the operator is installed on the wall on the same side as the

door swing and when the door is 450-700 mm wide.

7.5 Arm system, ST-V / ST-H

ST-V, Art. No. 172312SI, 172313BK

ST-H, Art. No. 172314SI, 172315BK

Note! Door fitting not included.

It is used if the operator is installed on the wall on the same side as the

door swing and break-out unit is required.

7.5.1 Options for ST-V / ST-H

Door fitting standard

Art. No.: 172071

Door fitting Break-out

Art. No. 172325 for pivot (break-out) door, right when the reveal A = 0-60 mm (0-2 3/8”) or left

when A > 60-100 mm (>2 3/8”-3 15/16”) for ST-H/ST-V

Art. No. 172327 for pivot (break-out) door, right when A > 60-100 mm (>2 3/8”-3 15/16”) or left

when A = 0-60 mm (0-2 3/8”)

Arm extension

Art. No. 172320 required when the reveal A >60-100 mm (>2 3/8”-3 15/16”)

1004291-EMEI-10.0Issue 2016-01-2720

7 Part identification & Accessories

Page 21

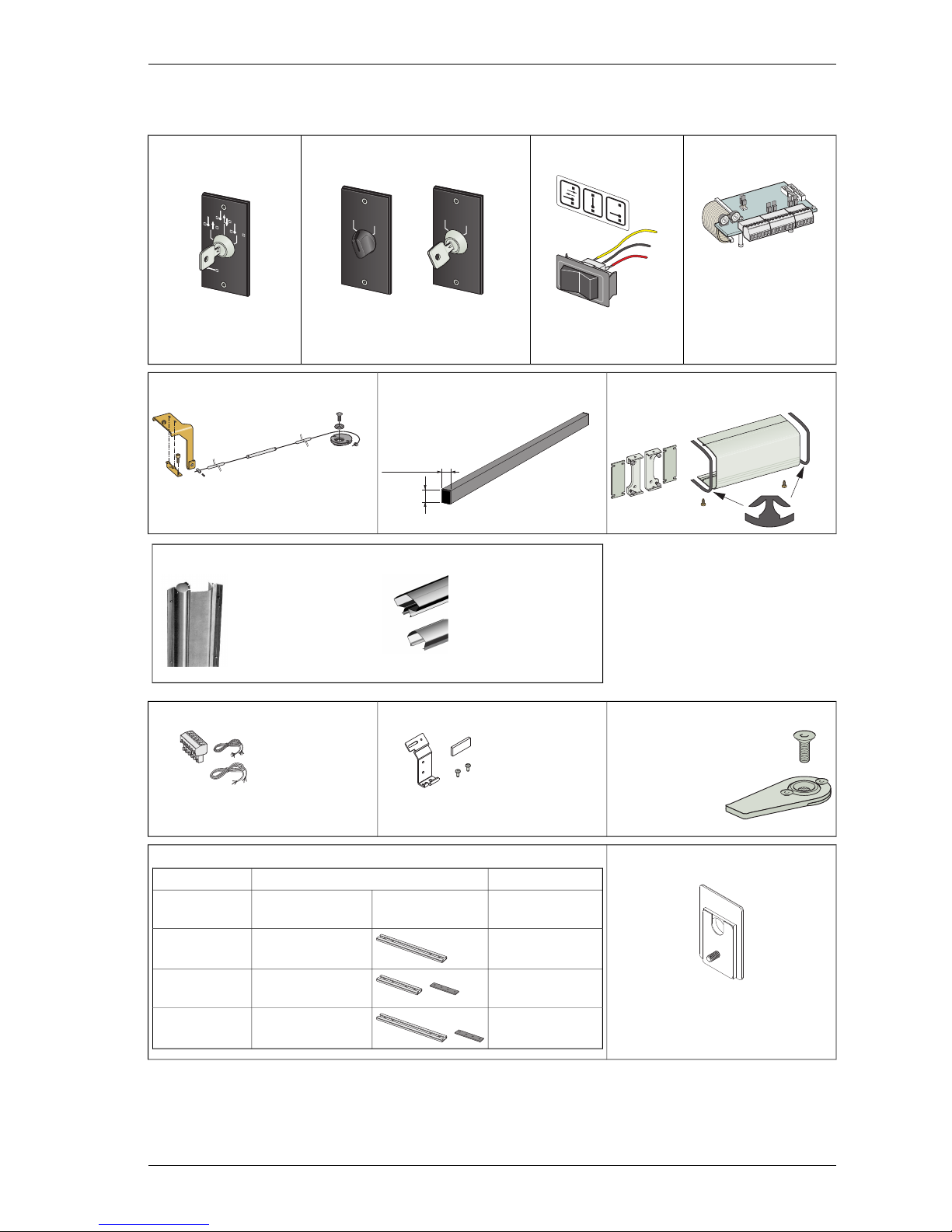

7.6 Further accessories

Extension unit3-Position2-Position Switch4-Position Switch

EXBSwitch PS-3B

PSK-2PSW-2

0

1

0

1

ILL-01578

Art. No.

655844

Art. No.

655843

(with EXB)

PS-4C

Art. No.

655845

Art. No. 1004116

Art. No. 1004117

Middle piece kitPULL-Arm Reveal SpacerCoordination unit, COOA

Art. No. 1008385Art. No. 1014667BK/SI

40 mm (1-37/64")

60 mm

(2-23/64")

Art. No. 100091

Finger protection strips

Art. No. 833334Art. No. 833333

Door stopPCB Attachment plateCable kit slave

Art. No. 100147

Art. No. 1003884

Art. No. 656064

1

2

3

4

S

W

Cable inletPUSH, Arm Extensions

Art. No. 1007567

Art. No.ExtensionReveal

--None (Standard arm)0-110 mm

Up to 4-3/8”

173005BK/SI345 mm110-235 mm

4-3/8” to 9-1/4”

173004BK/SI +

173191

+

230 mm + Joint part235-360 mm

9-1/4” to 14-1/8”

173005BK/SI +

173191

+

345 mm + Joint part360-485 mm

14-1/8” to 19”

21Issue 2016-01-271004291-EMEI-10.0

7 Part identification & Accessories

Page 22

Control unit, CSDA-F

Art. No. 600081

Drive Shaft Extension Kits

20 mm

(3/4")

50 mm

(2")

70 mm

(2-3/4")

Art. No.

173109/173109SI

Art. No.

173108/173108SI

Art. No.

173107/173107SI

Drilling template

Art. No. 1000219

Limit SwitchRestore after alarm buttonTool kit to change rotation direction

Art. No. 655614 (L = 500 mm)Art. No. 600090Art. No. 173719

Art. No. 1004205 (L = 2000 mm)

Smoke Detector ORS 142

Art. No. 738794

Ceiling socket 143W

for smoke detector

Art. No. 738795

Ceiling socket 143A

for smoke detector

Art. No. 738795

Shaft extension, SEKDoor mounting kitMounting plate

(including bearing for extension 70-420

mm)

Art. No. 173039

8x

2x

(for door leaf mounted operators)

Art. No. 100132

Art. No.T

(mm)

H

(mm)

L

(mm)

1736806125

State

1736618160

1004291-EMEI-10.0Issue 2016-01-2722

7 Part identification & Accessories

Page 23

7.7 Labels

Label kit - including all below

Art. No. 1005227

Emergency break-out, DIN right door

Art. No. 1001785

Emergency break-out, DIN left door

Art. No. 1001786

Activation by disabled people

Art. No. 1003963

Click!

Operator designed for disabled people

Art. No. 1003964

Supervision of child

Art. No. 1001695

23Issue 2016-01-271004291-EMEI-10.0

7 Part identification & Accessories

Page 24

8 Pre-Installation

8.1 General tips/Safety concerns

In all instances, where work is being done, the area is to be secured from pedestrian traffic, and the power removed to prevent injury.

• If there are sharp edges after drilling the cable outlets, chamfer the edges to avoid damage to

the cables.

• For enhanced security and vandalism protection, always mount the operator access in the interior of a building whenever possible.

• Make sure the ambient temperatureis in the range specified in section Technical specification.

• Make sure that the power is off before installing.

• Make sure that the door leaf and the wall are properly reinforced at the installation points.

• Unpack the operator and makesure that all parts are delivered in accordance with the packing

note and that the operator is in good mechanical condition.

• Ensure proper material is being used for the door leaves and that there are no sharp edges.

Projecting partsshall not create any potential hazards. If glassis used bare glass edges shall not

come in contact with other glass. Toughened or laminated glass are suitable glasses.

• Ensure that entrapment between the driven part and the surrounding fixed parts due to the

opening movement ofthe driven partisavoided. Thefollowingdistances areconsideredsufficient

to avoid entrapments for the parts of the body identified;

- for fingers, a distance greater than 25 mm or less than 8 mm

- for heads, a distance greater than 200 mm

- for feet, a distance greater than 50 mm

- and for the whole body, a distance greater than 500 mm

• Danger points shall be safe guarded up to a height of 2.5 m from the floor level.

• The operator shall not be used with a doorset incorporating a wicket door.

It is not possible to replace a EM operator component with a component from

a different brand.

8.2 Fastening requirements

Minimum requirements of wall profile*Base material

5 mm **Steel

6 mm **Aluminium

min. 50 mm from the undersideReinforced concrete

50 mmWood

Expansion shell bolt, min. M6x85, UPAT PSEA B10/25, min. 50

mm from the underside

Brick wall

* Entrematic Group minimum recommended requirements. Building Codes may give different

specifications. Refer to AHJ (Authority Having Jurisdiction).

** Thinner wall profiles must be reinforced with rivnuts.

1004291-EMEI-10.0Issue 2016-01-2724

8 Pre-Installation

Page 25

8.3 Tools required

• Torx T8, T10, T20 and T25

• Metric hexagonal key 3, 4 and 6 mm

• Flatblade screwdriver, small

• Torque wrench with metric Allen socket 6 mm

8.4 Installation on double doors

If the operators are to be mounted at the same height with pushing and pulling arm systems, the

height is determinedby the pullingarm system, PULL/ST. Thepushing arm systemPUSH mustalways

have a shaft extension, minimum 50 mm.

Example: If PULL has a 20 mm extension, the PUSH must have a 70 mm extension.

For installation follow the instructions for the applicable arm system.

25Issue 2016-01-271004291-EMEI-10.0

8 Pre-Installation

Page 26

8.5 Installation examples for fire approved doors

Illustrations below show examples of approved reinforcements when mounting a fireproof swing

door operator.

Note! The type approval for fireproof swing doors is valid only with the arm system PUSH. Reveal

max 480 mm and shaft extension max 70 mm.

Min.

45

Min.

45

2

1

2

7

8

4

2

6

8

3

5

9

DescriptionNo.DescriptionNo.

Wood screw M6, KST, L=45 (2x)6Steel min. 50x5, L=min.100, centered for mountingholes

(4x)

This is a requirement with aluminium profiles.

Screw M6, FS-TT FZB, Taptite, L=40 (4x)

1

Rivnut M6, FTT/ST, L=15,9 (4x)

Screw M6, FS-TT FZB Tabtite, L=40 (4x).

Rivnuts are only allowedtobe used with steelprofileswith

thickness of min 1,5 mm.

7Steel min. 50x5, L=min. 150, centered at the arms length

on the door.

This is a requirement with aluminium profiles.

Screw M6, FS-TT FZB, Tabtite, L=40 (2x).

2

Rivnut M6, FTT/ST, L=15,9 (2x)

Screw M6, FS-TT FZB, Tabtite, L=40 (2x).

Rivnuts are only allowed to be used with steel profiles

8Steel min. 50x5,L=min.100, centered for mountingholes

(4x)

This is a requirement with aluminium profiles.

Screw M6, FS-TT FZB, Tabtite, L=50 (4x) Distance piece

ø10/13

3

Rivnut M6, FTT/ST, L=15,9 (4x)

Screw M6, FS-TT FZB, Tabtite, L=50 (4x)

Distance piece ø10/13.

Rivnuts are only allowed to be used together with a plas-

terboard beam made of steel with a material thickness of

min 1,5 mm.

9Expansion-shell bolt (4x)

(for brickwall min. M6x85, UPAT PSEA B 10/25)

4

Wood screw M6, KST, L=min. 70 (4x)

Distance piece ø10/13

5

1004291-EMEI-10.0Issue 2016-01-2726

8 Pre-Installation

Page 27

9 Mechanical installation

This instruction comprises the installation of the EM EMSW with arm systems PUSH, which push

the door openand PULL / ST-V/H, which pullthe door open.See also“QuickStart” which isenclosed

with each operator.

9.1 Wall mounted operator with arm system PUSH

1

80

13

X

Y

0-110 (485)

C

L

1

Y

45

248

X

2

X

ø 5,1 mm, 8x

102

217

364

13

2 – 17 48

2 – 37 68

2 – 67 98

2 – 87

X Y

20

50

70 118

C

L

2

Drilling template

Art. No. 1000219

27Issue 2016-01-271004291-EMEI-10.0

9 Mechanical installation

Page 28

Cont. “Wall mounted operator with arm system PUSH”

6

5

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

C

L

1

C

L

2

4

C

L

1

210

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

C

L

2

2x

C

L

1

3

25

ø 16 mm

15

(Cable inlet hole)

1004291-EMEI-10.0Issue 2016-01-2728

9 Mechanical installation

Page 29

Cont. “Wall mounted operator with arm system PUSH”

7b

7

9

90°

60

90°

Adjust +/– 1 tooth = ±5°

7a

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

25 Nm

8

29Issue 2016-01-271004291-EMEI-10.0

9 Mechanical installation

Page 30

9.2 Door leaf mounted operator with arm system PUSH-335

716

0

0

1

max. 135

min. 45

min. 120

C

L

1

C

L

2

245 45

210

180

108,5

108,5

2

110

110

3

3

80 4813

min. 5017

min. 45

min. 120

min. 50

max. 135

Pivot or butt hinges

CL1

Operator drive shaftCL2

Cable inlet at end plate1

Door mounting kit,Art. No. 100132,

optional

2

Reinforcements required indoorleaf

and at the fixing holes

3

1004291-EMEI-10.0Issue 2016-01-2730

9 Mechanical installation

Page 31

9.3 Wall mounted operator with arm system PULL, PULL-220 and ST

Note! If the operator is not ordered for pulling arm system, the direction of rotation must be reversed.

9.3.1 Changing the direction of rotation

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

1 2

3 4

5 6

165˚

30

(1 3/16")

34

(1 11/32")

30 34

(1 11/32")(1 3/16")

ILL-01556

31Issue 2016-01-271004291-EMEI-10.0

9 Mechanical installation

Page 32

9.3.2 Installation of operator with arm system PULL

80

13

46

66

96

116

Z

20

50

70

_

40 x 60

10

Z

≤ 60

1

C

L

1

652

74

Z10

2

Z

ø 5,1 mm, 8x

102

217

364

13

Top of door

Drilling template

Art. No. 1000219

(turnable)

1004291-EMEI-10.0Issue 2016-01-2732

9 Mechanical installation

Page 33

Cont. “Installation of operator with arm system PULL”

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

C

L

1

C

L

2

4

3

C

L

1

210

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

C

L

2

6x

5

0 V DC

24 V DC

TB

1 AN

D TB

2,

CLA

SS 2 S

UPPL

Y

MAX

. 24

V

5

6

7

8

9

10

11

13

12

14

TB2

C

L

1

25

ø 16 mm

15

(Cable inlet hole)

Connect mains power

33Issue 2016-01-271004291-EMEI-10.0

9 Mechanical installation

Page 34

Cont. “Installation of operator with arm system PULL”

7

8

9

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

25 Nm

C

L

1

C

L

2

C

L

2

2x

6

701500

HSO

HSO

LSO

LSO

HSC

701448

C

L

2

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

1004291-EMEI-10.0Issue 2016-01-2734

9 Mechanical installation

Page 35

Cont. “Installation of operator with arm system PULL”

0 V DC

24 V DC

CLASS 2 SUPPLY

MAX. 24 V

5

6

7

8

9

10

11

13

12

14

TB2

11

10

Click

Click

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

35Issue 2016-01-271004291-EMEI-10.0

9 Mechanical installation

Page 36

9.3.3 Installation of operator with arm system ST

80

13

40

61

A

1

C

L

1

6140

2

61

ø 5,1 mm, 6x

2x

102

81

217

364

A > 60 - 100

A = 0 - 60

C

L

2

Top of door

Drilling template

Art. No. 1000219

(Optional)

Outside open door

1004291-EMEI-10.0Issue 2016-01-2736

9 Mechanical installation

Page 37

Cont. “Installation of operator with arm system ST”

3

25

96

4

291

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

C

L

2

6x

ø 16 mm

Outside open door

(Cable inlet hole)

Outside open door

37Issue 2016-01-271004291-EMEI-10.0

9 Mechanical installation

Page 38

Cont. “Installation of operator with arm system ST”

7

6

C

L

2

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

5

C

L

2

0 V DC

24 V DC

CLASS 2 SUPPLY

MAX. 24 V

5

6

7

8

9

10

11

13

12

14

TB2

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

701500

LSO

143

Connect mains power

Note, the way of mounting the arm!

1004291-EMEI-10.0Issue 2016-01-2738

9 Mechanical installation

Page 39

Cont. “Installation of operator with arm system ST”

9

10

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

0 V DC

24 V DC

CLASS 2 SUPPLY

MAX. 24 V

5

6

7

8

9

10

11

13

12

14

TB2

0º

10a

10b

10c

≈ 45º

≈ 90º

8

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

25 Nm

C

L

2

39Issue 2016-01-271004291-EMEI-10.0

9 Mechanical installation

Page 40

Cont. “Installation of operator with arm system ST”

11

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

12

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

310

210

=

=

Break-out

1004291-EMEI-10.0Issue 2016-01-2740

9 Mechanical installation

Page 41

Cont. “Installation of operator with arm system ST”

ø 5,1 mm, 2x

13

14

2x

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

2x

701500

HSO

HSO

LSO

LSO

LSCLK

HSC

HSC

LSC

701448

LK

41Issue 2016-01-271004291-EMEI-10.0

9 Mechanical installation

Page 42

10 Electrical connection

Note! During any work with the electrical connections the mains power must be disconnected.

• Place the electric switch easily accessible from the operator. If a plug contact is used in the installation the wall socket shall be placed easily accessible from the operator.

• If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualified persons in order to avoid a hazard.

10.1 Control units

The operator can be equipped with different control units adapted to the functions required.

10.1.1 CSDB

This basiccontrol unit is equipped with inputs for connectionof automatic and manual activation

units such as radars, photocells, normal push buttons, emergency push buttons etc. Electromechanical striking-plate and slave control unit CSDA-S for double doors can be connected.

10.1.2 CSDA-S

This slave control unit is used together with CSDB for double doors as explained above.

10.1.3 EXB

This extension unit is mounted on top of the CSDB to extend the CSDB functions with inputs for

presence impulse, presence detection, inner impulse, off and exit.

10.1.4 CSDA-F

This unit is, together with CSDB, mainly used for fire doors. Electro-mechanical striking-plate 24 V

AC can be connected.

1004291-EMEI-10.0Issue 2016-01-2742

10 Electrical connection

Page 43

10.2 Connection of control unit CSDB – single doors

Connect the mains power to the mains terminal block.

Note! Accessories and activation units must not be connected until the adjustment of speeds etc.

has been carried out.

Note! It is important that the high and low voltage cables are well separated and fixed. The high

voltage cables must be routed and fixed on one side of the drive unit by using the enclosed cable

holders and the low voltage cables must be

routed on the opposite side using the same type of cable holders.

1 2 3 4

TB2

TB2

Kill jumper

MVI N.O. / N.C.

MVI Open Lock / Door

Lock w. / w.o. power

Lock time 1.5 s / until closing

Slave delay off / on

Master / Slave

Push & Go

1003870

0 V DC

24 V DC

Motor control

"Slave"

ON

H.O.T

Opening Delay

MVI H.O.T

LSCLK

HSC

LSC

LK

5

6

7

8

9

10

11

12

13

14

1

2

3

4

S

W

TB1

TB2

FS

ON

1

2

3

4

5

6

7

8

(–)

(–)

(+)

(+)

max. 700 mA

N L

F2 = 250 mAT

F1 = 6,3 ATH

TB2

TB1

FS

LED

12 34

TB2

TB2

0 V DC

24 V DC

0 V DC

Kill

Key Impulse

Lock 24 V DC

Kill jumper

MVI N.O. / N.C.

MVI Open Lock / Door

Lock w. / w.o. power

Lock time 1.5 s / until closing

Slave delay off / on

Master / Slave

Push & Go

Outer Impulse

MVI Impulse

1003870

ALL TB1 AND TB2,

CLASS 2 SUPPLY

MAX. 24 V

0 V DC

24 V DC

Motor control

"Slave"

ON

1

234 567 8

H.O.T

Opening Delay

MVI H.O.T

1

2

3

4

S

W

5

6

7

8

9

10

11

13

12

14

Limit switch open

Home switch

Opening valve

Mains power

230 V AC - 50 Hz,10A

F2= 250 mAT

F1= 6,3ATH

MVI / Key HOT

Opening delay

Outer HOT

Sensor Monitoring

OFF / ON

Kill jumper

MVI NO / NC

MVI Open Lock / Door

Locked w. / wo. power

Locked tome 1.5 s until closing

Slave delay off / on

Master / Slave

Push to Gp

Kill -

Kill +

1)

0 V DC

Key Impulse

Lock

24 V DC, 375 mA

0 V DC

24 V DC

MVI Impulse

Outer Impulse

Motor control

0 V DC

Slave control

24 V DC

MVI Jumper 2)

1) See page 48 when connecting "Kill"

2) If 6-24 VDC on TB2: 11-13, remove jumper

3) Remove jumper when connecting ta slave CSDA-S (but

not when connecting to slave CSDB).

Slave monitoring jumper 3)

Slave feed back

Watchdog

max. 700 mA

43Issue 2016-01-271004291-EMEI-10.0

10 Electrical connection

Page 44

10.3 Connection of control units CSDB and CSDA-S – double doors

For double door operators, both operators have to be connected to the mains. A six-pole cable

(enclosed) has to be connected between TB1 on the CSDB and TB6 on the CSDA-S.

Note! It is important that the high and low voltage cables are well separated and fixed. The high

voltage cables must be routed and fixed on one side of the drive unit by using the enclosed cable

holders and the low voltage cables must be routed on the opposite side using the same type of

cable holders.

12 34

TB2

TB2

0 V DC

24 V DC

0 V DC

Kill

Key Impulse

Lock 24 V DC

Kill jumper

MVI N.O. / N.C.

MVI Open Lock / Door

Lock w. / w.o. power

Lock time 1.5 s / until closing

Slave delay off / on

Master / Slave

Push & Go

Outer Impulse

MVI Impulse

1003870

ALL TB1 AND TB2,

CLASS 2 SUPPLY

MAX. 24 V

0 V DC

24 V DC

Motor control

"Slave"

ON

1

234 567 8

H.O.T

Opening Delay

MVI H.O.T

5

6

7

8

9

10

11

13

12

14

W

S

4

3

2

1

F1

TB1

TB1

CSDB

N L

F2

LSCLK

HSC

HSC

LSC

701448

LK

NL

TB6

TB6

CSDA-S

F2 = 250 mAT

F1 = 6,3 ATH

1

2

3

4

S

W

1

2

3

4

S

W

1

2

3

4

S

W

1 2 3 4

TB2

Kill jumper

MVI N.O. / N.C.

MVI Open Lock / Door

Lock w. / w.o. power

Lock time 1.5 s / until closing

Slave delay off / on

1003870

0 V DC

24 V DC

Motor control

"Slave"

ON

1

2

3

4

S

W

ON

1

2

3

4

5

6

7

8

Motor control

0 V DC

Slave control

24 V DC

Motor control

0 V DC

Slave control

24 V DC

Limit switch open

Mains power

230 V AC - 50 Hz,10A

Mains power

230 V AC - 50 Hz,10A

Opening valve

F2= 250 mAT

F1= 6,3 AT

Slave feed back

Watchdog

Watchdog

Slave monitoring Jumper.

Remove when connecting to slave

CSDA-S.

Slave feed back

1004291-EMEI-10.0Issue 2016-01-2744

10 Electrical connection

Page 45

10.4 Connection of control units CSDB/CSDB – double doors

For double door operators both operators have to be connected to the mains. A three-pole cable

(not enclosed) has to be connected between TB1 on the CSDB (master) and TB2 on the CSDB

(slave).

Note! It is important that the high and low voltage cables are well separated and fixed. The high

voltage cables must be routed and fixed on one side of the drive unit by using the enclosed cable

holders and the low voltage cables must be routed on the opposite side using the same type of

cable holders.

Door mounted sensors must be connected to it's own master and slave CSDB/EXB.

1 2 3 4

TB2

Kill jumper

MVI N.O. / N.C.

MVI Open Lock / Door

Lock w. / w.o. power

Lock time 1.5 s / until closing

Slave delay off / on

Master / Slave

Push & Go

1003870

0 V DC

24 V DC

Motor control

"Slave"

ON

H.O.T

1

2

3

4

S

W

5

6

7

12 34

TB2

TB2

0 V DC

24 V DC

0 V DC

Kill

Key Impulse

Lock 24 V DC

Kill jumper

MVI N.O. / N.C.

MVI Open Lock / Door

Lock w. / w.o. power

Lock time 1.5 s / until closing

Slave delay off / on

Master / Slave

Push & Go

Outer Impulse

MVI Impulse

1003870

ALL TB1 AND TB2,

CLASS 2 SUPPLY

MAX. 24 V

0 V DC

24 V DC

Motor control

"Slave"

ON

123

4

567 8

H.O.T

Opening Delay

MVI H.O.T

5

6

7

8

9

10

11

13

12

14

F1

CSDB

N L

F2

1

2

3

4

S

W

TB1

CSDB

CSDB

8

7

6

5

4

3

2

1

9

10

NL

TB2

LSCLK

HSC

HSC

LSC

701448

LK

Slave

Master

FS

FS-7 = ON

1

ON

2

3

4

5

6

7

8

5 6 7 8

TB2

9 10 11121314

(–)

(+)

(+)

F2 = 250 mAT

F1 = 6,3 ATH

max. 700 mA

TB1

1

2

3

4

S

W

Mains power

230 V AC - 50 Hz,10A

F2= 250 mAT

F1= 6,3 AT

Motor control

0 V DC

Slave control

24 V DC

Kill -

Kill +

0 V DC

Key Impulse

Lock

24 V DC, 375 mA

0 V DC

24 V DC

MVI Impulse

Outer Impulse

Mains power

230 V AC - 50 Hz,10A

Adjust opening

delay to "0"

Adjust MVI / Key

Hot to "0"

Slave feed back

Watchdog

45Issue 2016-01-271004291-EMEI-10.0

10 Electrical connection

Page 46

10.5 Connection of extension unit EXB – option

The extension unit EXB is to be installed on top of the CSDB.

a Connect the flat cable on the EXB to the CSDB.

b Snap on the EXB to the CSDB.

HSO

LSCLK

HSC

HSC

LSC

701448

LK

12 34

TB2

TB2

0 V DC

24 V DC

0 V DC

Kill

Key Impulse

Lock 24 V DC

Kill jumper

MVI N.O. / N.C.

MVI Open Lock / Door

Lock w. / w.o. power

Lock time 1.5 s / until closing

Slave delay off / on

Master / Slave

Push & Go

Outer Impulse

MVI Impulse

1003870

ALL TB1 AND TB2,

CLASS 2 SUPPLY

MAX. 24 V

0 V DC

24 V DC

Motor control

"Slave" control

ON

H.O.T

Opening Delay

MVI H.O.T

5

6

7

8

9

10

11

13

12

14

5

6

7

8

9

10

11

13

12

14

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

20 2122 23

TB3

24 25

26 27 28 29

TB4

30 3132

33 34 35 36

TB5

37

Blanking switch

Presence detect Slave

Blanking LED

Blanking switch

Presence detect Master

OPD / MAT

Sensor type

Presence impulse configuration

NC / NO*

Presence detect Slave

Presence impulse Slave

Presence impulse Master

Presence detect Master

Low pass filter

Inner HOT

0 V DC

24 V DC

Presence detect slave

Sensor test slave

0 V DC

24 V DC

Presence detect master

Sensor test master

Lock out

OPD / MAT

24 V DC

EXIT

OFF

0 V DC

Inner impulse

0 V DC

Presence impulse master

Presence impulse slave

* When selecting NO, remove both jumpers

for presence impulse Master and Slave.

Note! It is important that the high and low voltage cables are well separated and fixed. The high

voltage cables must be routed and fixed on one side of the drive unit by using the enclosed cable

holders and the low voltage cables must be routed on the opposite side using the same type of

cable holders.

1004291-EMEI-10.0Issue 2016-01-2746

10 Electrical connection

Page 47

10.6 Sensor cable inlet

15

,

5

12

2

9

ø 3,7

1 2

8

4 5

6 7

3

Alt. 1

8

Alt. 2

Alt. 1

Alt. 2

Alt. 1

Alt. 2

47Issue 2016-01-271004291-EMEI-10.0

10 Electrical connection

Page 48

11 Start-Up

Adjust the operator to have maximum 25% duty cycle, which means motor run time.

Give a short opening impulse bystrapping theimpulse inputand adjustif necessaryas follows.See

also illustration under Closing torque.

See the “Guide for installers of Powered Pedestrian Swing Doors”, document PRA-0006, for calculation of speed.

a Set the hold open time with the potentiometer on the control unit.

b Adjustment of the opening speed.

• Adapt the high speed opening HSO, to the existing traffic situation. Turning clockwise decreases the speed.

• The low speedopeningLSO, needs tobe adjusted onlyif the doorisextremely heavy.Turning

clockwise decreases the speed.

Note! If it is hard to obtain an even and smooth braking, the opening torque (pump pressure)

must be reduced.

c Adjustment of the closing speed.

• Adjust the low speed closing LSC as low as the traffic situation allows. Turning clockwise

decreases the speed.

• If a higher closing speed is required, open the high speed closing valve HSC (closed from

factory).

Note! If the installation requires adjustment of the closing torque follow the instructions on

page 48.