Entre Matic Ditec TOP603H, Ditec TOP903H Technical Manual

Ditec TOP603H / TOP903H

Automation for sectional

doors (translation of the original instructions)

www.ditecentrematic.com

IP2179EN

Technical Manual

52

IP2179EN - 2015-11-24

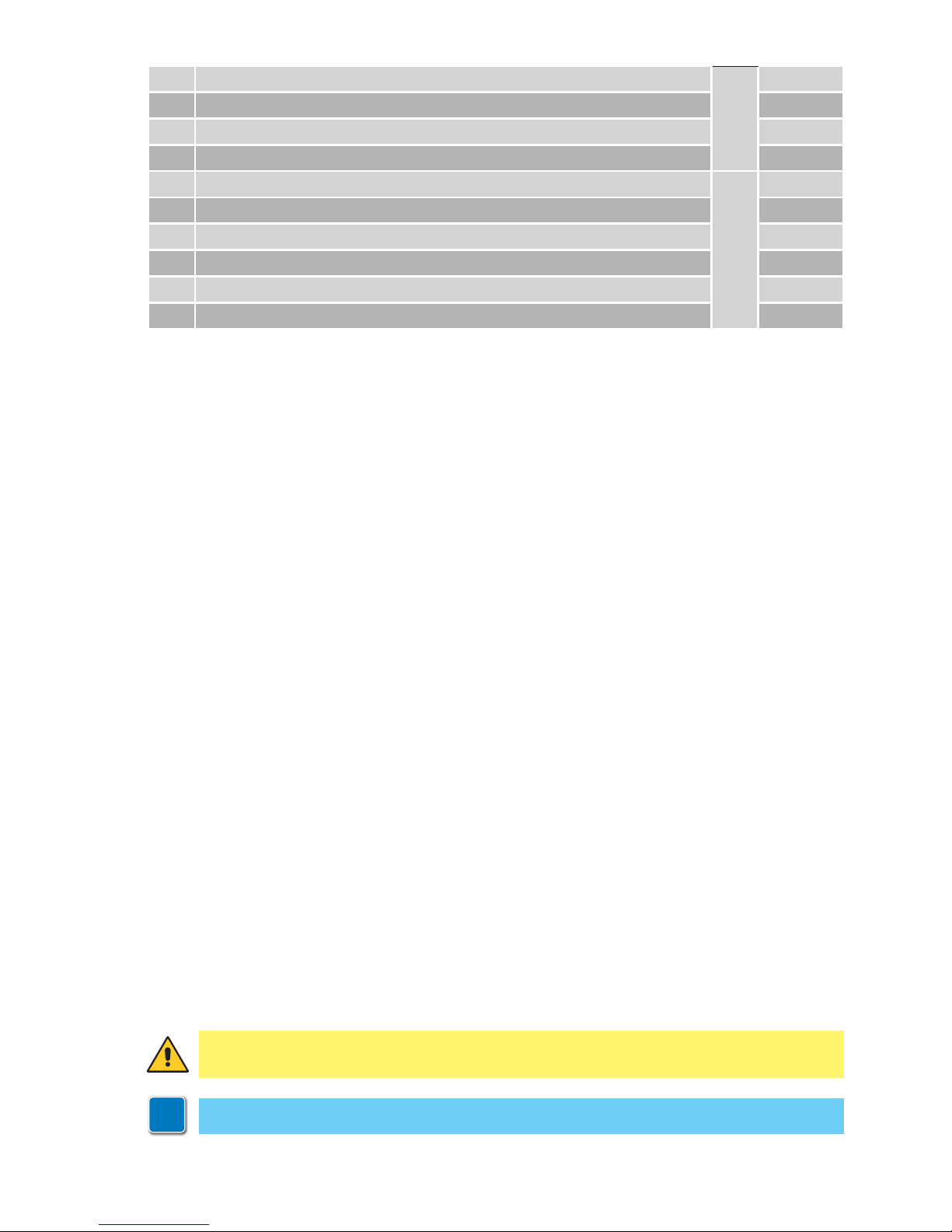

Contents

Subject Page

1. General safety precautions

TOP603H - TOP903H

54

General safety precautions for the user 55

Machinery Directive 56

2. Declaration of Incorporation 57

3. Technical specifications 58

3.1 Operating instructions 58

3.2 Possible applications with general sectional doors 59

3.3 Possible applications with ENTREMATIC sectional doors 60

4. Dimensions 61

5. Standard installation 62

6. Main components 63

7. Assembly guide 64

8. Tensioning the belt 65

9. Assembling the automation 66

10. Mechanical installation 67

11. Assembling and fastening the arm 68

12. Installing the adapter for TOPSB tilting doors 70

13. Electrical connections TOP603H

TOP603H

71

13.1 Wiring the accessories 72

13.2 Commands TOP603H 74

13.3 Outputs and accessories 74

14. Commands and indications 75

14.1 Deleting the memorised stroke values 75

14.2 Restoring the factory settings 75

15. Self-learning of the stroke TOP603H 76

16. Memorising / Deleting remote controls 77

17. Adjusting the parameters 77

18. Parameters 78

19. Electrical connections TOP903H

TOP903H

81

19.1 Wiring the accessories 82

19.2 Commands TOP903H 84

19.3 Outputs and accessories 84

20. Commands and indications 85

20.1 Deleting the memorised stroke values 85

20.2 Restoring the factory settings 85

53

IP2179EN - 2015-11-24

Key

i

This symbol indicates instructions or notes regarding safety, to which special attention must be paid.

This symbol indicates useful information for the correct functioning of the product.

21. Self-learning of the stroke TOP903H

TOP903H

86

22. Memorising / Deleting remote controls 87

23. Adjusting the parameters 88

24. Parameters 89

25. Troubleshooting

TOP603H

TOP903H

93

25.1 Alarms 94

26. Maintenance 95

Replacing the fuse 95

Replacing the courtesy light 95

Replacing the remote control battery 96

54

IP2179EN - 2015-11-24

1. General safety precautions

This installation manual is intended for qualified personnel only.

Installation, electrical connections and adjustments must be performed by qualified personnel, in accordance with Good Working Methods and in compliance with the current regulations.

Read the instructions carefully before installing the product.

Incorrect installation could be dangerous.

The packaging materials (plastic, polystyrene, etc.) should not be discarded in the environ-

ment or left within reach of children, as they are a potential source of danger.

Before installing the product, make sure it is in perfect condition.

Do not install the product in explosive areas and atmospheres: the presence of inflammable

gas or fumes represents a serious safety hazard.

Before installing the motorisation device, make all the necessary structural modifications to

create safety clearance and to guard or isolate all the crushing, shearing, trapping and general

hazardous areas.

Make sure the existing structure is up to standard in terms of strength and stability. The motorisation device manufacturer is not responsible for failure to observe Good Working Methods

when building the frames to be motorised, or for any deformations during use.

The safety devices (photocells, safety edges, emergency stops, etc.) must be installed taking

into account the applicable laws and directives, Good Working Methods, installation premises,

system operating logic and the forces developed by the motorised door or gate.

The safety devices must protect against crushing, cutting, trapping and general danger areas

of the motorised door or gate.

Display the signs required by law to identify hazardous areas.

Each installation must bear a visible indication of the data identifying the motorised door

or gate.

When necessar y, connect the motorised door or gate to an effective ear thing system that complies with the current safety standards.

During installation, maintenance and repair operations, cut off the power supply before opening

the cover to access the electrical parts.

The automation protection casing must be removed by qualified personnel only.

The electronic parts must be handled using earthed antistatic conductive arms. The

manufacturer of the motorisation declines all responsibility if component parts not compatible with safe and correct operation are fitted.

Only use original spare parts when repairing or replacing products.

The installer must supply all information concerning the automatic, manual and emergency operation of the motorised door or gate, and must provide the user with the operating instructions.

Failure to respect the information given in this manual

may cause personal injury or damage to the device.

Keep these instructions for future reference

55

IP2179EN - 2015-11-24

These precautions are an integral and essential part of the product

and must be supplied to the user.

Read them carefully since they contain important information on safe

installation, use and maintenance.

These instructions must be kept and forwarded to all possible future

users of the system.

This product must only be used for the specific purpose for which it

was designed.

Any other use is to be considered improper and therefore dangerous.

The manufacturer cannot be held responsible for any damage caused

by improper, incorrect or unreasonable use.

Avoid operating in the proximity of the hinges or moving mechanical

parts. Do not enter within the operating range of the motorised door

or gate while it is moving.

Do not obstruct the motion of the motorised door or gate, as this may

cause a dangerous situation.

The motorised door or gate may be used by children over the age of 8

and by people with reduced physical, sensorial or mental abilities, or

lack of experience or knowledge, as long as they are properly supervised

or have been instructed in the safe use of the device and the relative

hazards.

Children must be supervised to make sure they do not play with the

device, nor play/remain in the sphere of action of the motorised door

or gate.

Keep remote controls and/or any other command devices out of the

reach of children, to avoid any accidental activation of the motorised

door or gate.

The self-adhesive label (supplied) highlighting the risk of children getting trapped must be attached in a clearly visible place.

In the event of a product fault or malfunction, turn off the power supply

switch. Do not attempt to repair or intervene directly, and contact only

qualified personnel.

Failure to comply with the above may cause a dangerous situation.

Any repairs or technical interventions must be carried out by qualified

personnel.

Cleaning and maintenance work must not be carried out by children

unless they are supervised.

General safety precautions for the user

56

IP2179EN - 2015-11-24

To ensure that the system works efficiently and correctly, the manufacturer’s indications must be complied with and only qualified personnel

must perform routine maintenance on the motorised door or gate. In

particular, regular checks are recommended in order to verify that the

safety devices are operating correctly.

All installation, maintenance and repair work must be documented and

made available to the user.

Only lock and release the door wings when the motor is switched off.

Do not enter within the operating range of the wing.

To dispose of electrical and electronic equipment correctly, users

must take the product to special "recycling centres" provided by

the municipal authorities.

Machinery Directive

Pursuant to the Machinery Directive (2006/42/EC), the installer who motorises a door or gate has

the same obligations as the manufacturer of machinery and as such must:

- prepare the technical data sheet which must contain the documents indicated in Annex V of the

Machinery Directive;

(The technical data sheet must be kept and placed at the disposal of competent national authori-

ties for at least ten years from the date of manufacture of the motorised door);

- draw up the EC Declaration of Conformity in accordance with Annex II-A of the Machinery Directive and deliver it to the customer;

- affix the EC marking on the motorised door or gate, in accordance with point 1.7.3 of Annex I of

the Machinery Directive;

- ensure compliance of the motorised door or gate with safety regulations, by installing the necessary safety devices.

57

IP2179EN - 2015-11-24

We:

Entrematic Group AB

Lodjursgatan 10

SE-261 44 Landskrona

Sweden

declare under our sole responsibility that the type of equipment :

The TOP603H and TOP903H automation with remote control for residential garages complies

with the following directives:

2004/108/EC Electro Magnetic Compatibility Directive (EMCD)

2002/95/EC Restriction of the use of Hazardous Substances in electrical and electronic

equipment (RoHS)

1999/5/EC Radio and Telecommunications Terminal Equipment Directive (R&TTE)

2006/42/EC Machinery Directive (MD), in particular the following essential health and safety

requisites:

1.1.2,1.1.3,1.2.1,1.2.3,1.2.4,1.2.6,1.3.2,1.3.4,1.5.1,1.5.2,1.5.3,1.5.8,1.5.9,1.5.10,1.5.11,1.6.3,1.7.3,1.7.4

Technical documentation for safe integration is provided

Harmonised European standards which have been applied:

EN 13849-1 EN 61000-6-2 EN 61000-6-4 EN 60204-1 EN 60335-1

Other standards or technical specifications, which have been applied:

EN 60335-2-95 EN 60335-2-103 EN 55014

EC type examination or certificate issued by a notified or competent body (for full address, please

contact Entrematic Group AB) concerning the equipment:

The manufacturing process ensures the compliance of the equipment with the technical file.

The manufacturing process is regularly checked by third parties.

The equipment must not be used until the installation company has declared that the final installed door system complies with Machinery Directive 2006/42/EC.

Compilation of technical file:

Marco Pietro Zini E-mail: marco.zini@entrematic.com

Entrematic Group AB

Lodjursgatan 10

SE-261 44 Landskrona

Sweden

Place Date Signature Position

Landskrona 2014-07-31 Marco Pietro Zini President Entrance Automation

Declaration of Incorporation

58

IP2179EN - 2015-11-24

3. Technical specifications

3.1 Operating instructions

Service class: 3 (minimum 10-5 years of working life with 30-60 cycles per day).

Applications: FREQUENT (for multi-family type entrances or small apartment blocks with frequent

vehicle access).

- The performance characteristics refer to the recommended weight (approx. 2/3 of the maximum

permitted weight). When used with the maximum permitted weight, a reduction in the above

mentioned performance levels can be expected.

- The service class, running times and number of consecutive cycles are merely indicative, having

been statistically determined under average operating conditions and therefore not necessarily

applicable to specific conditions of use.

- Each automatic entrance has variable elements such as friction, balancing and environmental

factors, all of which may substantially alter the performance characteristics or working life of

the entrance itself or its components (including the automatic devices). The installer should

apply suitable safety conditions for each particular installation.

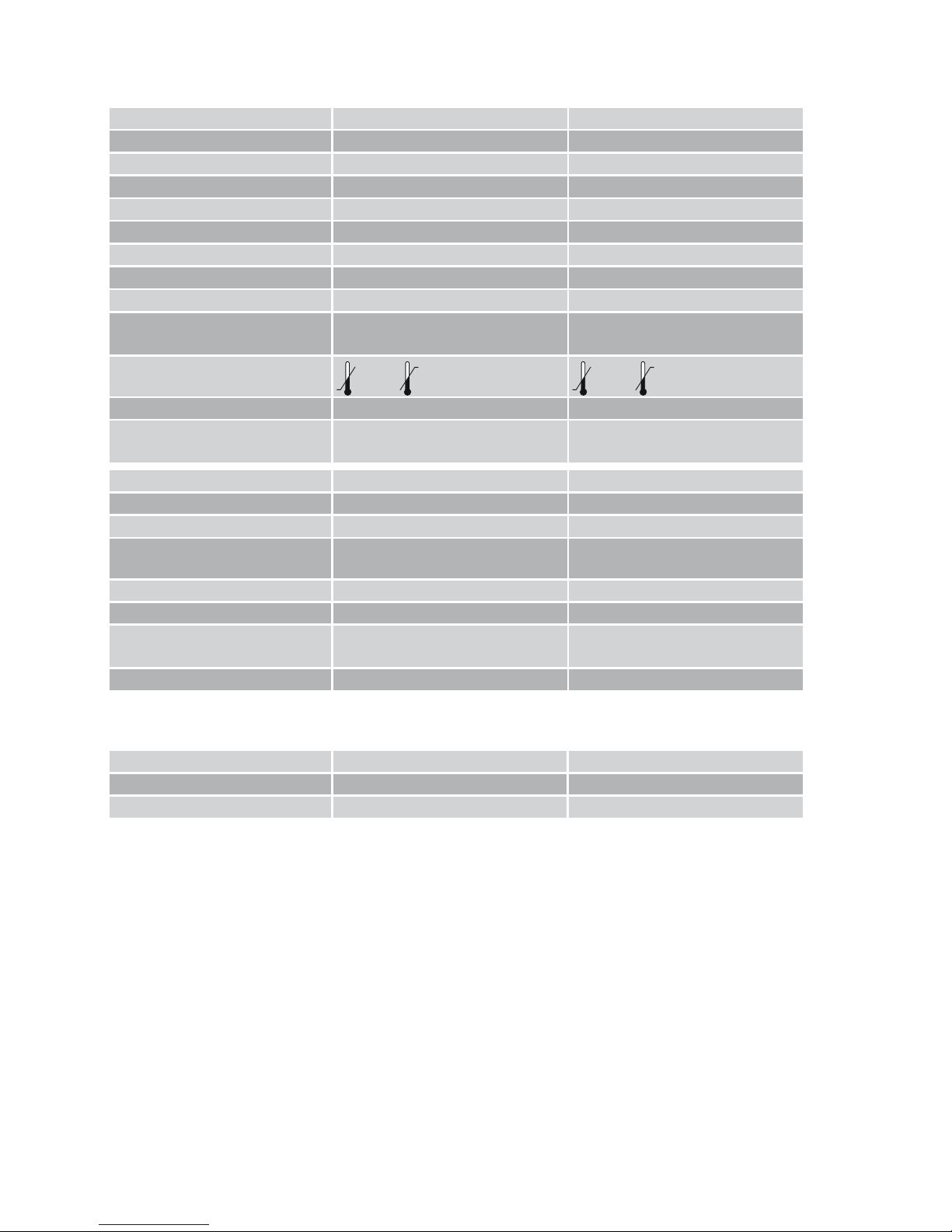

Ditec TOP603H Ditec TOP903H

Power 230V~, 50/60 Hz 230V~, 50/60 Hz

Power 140W 170W

Thrust 600 N 1000 N

Opening speed 210mm/s 210mm/s

Closing speed 140mm/s 140mm/s

Maximum door area (*) 9.5 m² 17.3 m²

Maximum door weight 116kg 210kg

Service class 3 - FREQUENT 3 - FREQUENT

Intermittence

S2 = 5 min

S3 = 25%

S2 = 5 min

S3 = 25%

Ambient temperature

-20°C +50°C -20°C +50°C

Degree of protection IP20 IP20

Acoustic pressure emitted at a

distance of 2m

≤69 dB (A) ≤69 dB (A)

Control panel TP603EL TP903EL

Control panel fuse 1.6A T (delayed) 2x1.6A T (delayed)

Motor power supply 24V= / 9.5A 24V= / 10.5A

Power supply for accessories

24V= / 0.3A max 2 s

24V= / 0.08A continuous

24V= / 0.3A max 2 s

24V= / 0.08A continuous

Radio frequency 433.92 MHz 433.92 MHz

Maximum remote control range 15-50m 15-50m

Remote control functions /

programmable keys

50 50

Courtesy light E14 max 60W E14 max 60W

TOP803T3 guide TOP803T4 guide

Max. carriage stroke 2890 +/- 25mm 3978 +/-25mm

Maximum height of door 2450mm 3500mm

(*) N.B.: the maximum door area has been calculated using a specific door weight of 12 kg/ m² (most common).

For values <12 kg/m² the maximum area in m² is larger. For values >12 kg/m² the maximum area in m² is

smaller (see graphs in par. 3.2 and 3.3)

59

IP2179EN - 2015-11-24

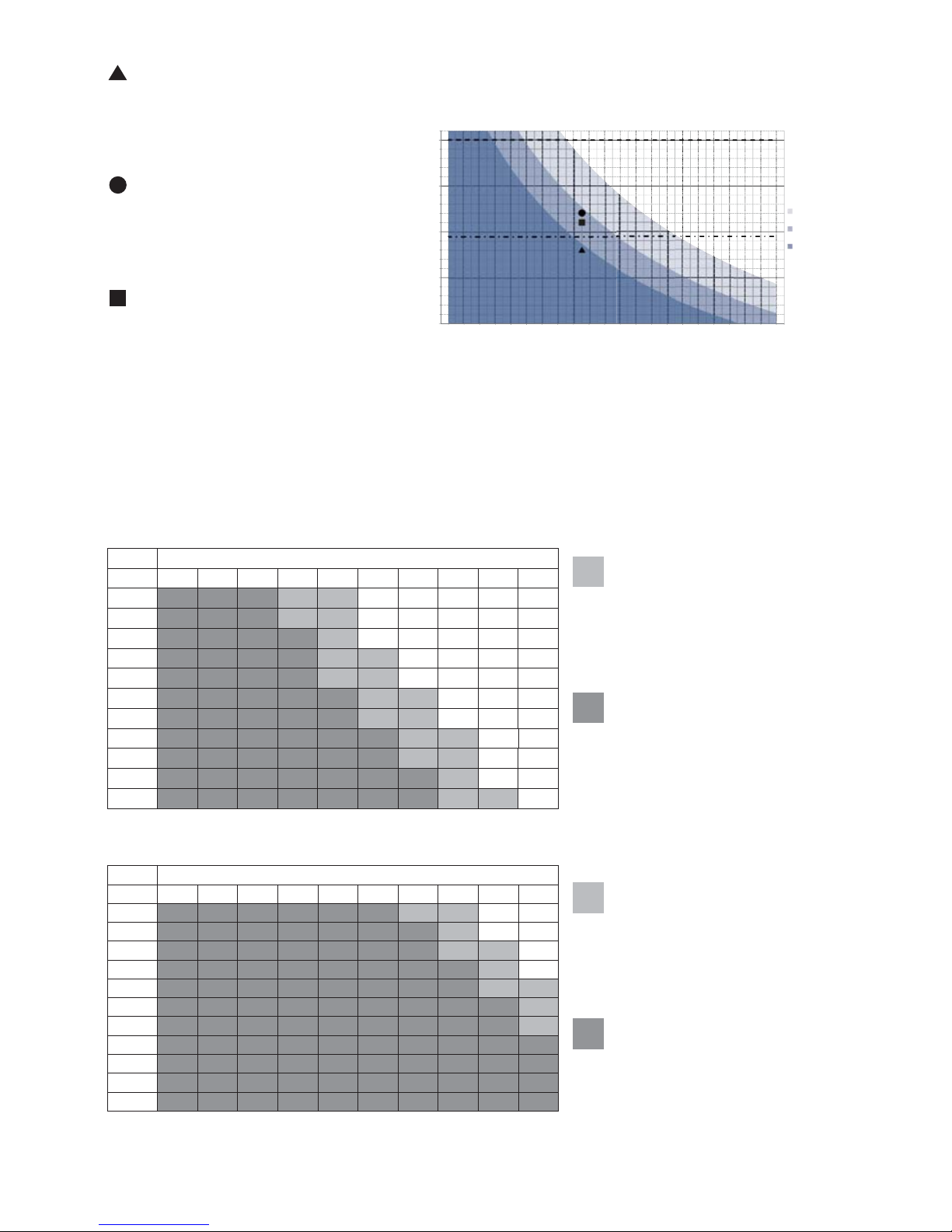

3.2 Possible applications with general sectional doors

1500

2000

2500

3000

3500

1800 2000 2200 2400 2600 2800 3000 3200 3400 3600 3800 4000 4200 4400 4600 4800 5000 5200 5400 5600 5800 6000

Door height H (mm)

Door width W (mm)

Maximum dimensions of door - TOP603H (Max. door weight = 116 kg)

10

12

14

Weight of door

per square

metre

(kg/m

2

)

H

Max

TOP803T3 = 2450 mm

H

Max

TOP803T4 = 3500 mm

1500

2000

2500

3000

3500

1800 2000 2200 2400 2600 2800 3000 3200 3400 3600 3800 4000 4200 4400 4600 4800 5000 5200 5400 5600 5800 6000

Door height H (mm)

Door width W (mm)

Maximum dimensions of door - TOP903H (Max. door weight = 210 kg)

10

12

14

Weight of door

per square

metre

(kg/m

2

)

H

Max

TOP803T3 = 2450 mm

H

Max

TOP803T4 = 3500 mm

60

IP2179EN - 2015-11-24

3.3 Possible applications with ENTREMATIC sectional doors

Width

Height 1800 2000 2500 3000 3500 4000 4500 5000 5500 6000

3150

2965

2815

2795

2639

2483

2538

2250

2125

2000

1900

Width

Height 1800 2000 2500 3000 3500 4000 4500 5000 5500 6000

3150

2965

2815

2795

2639

2483

2538

2250

2125

2000

1900

TOP603H

TOP903H

Dimensions allowed for Style

Comfort series doors with

Plain design (0.6 mm sheet

and above)

Dimensions allowed for Style

Comfort series doors with

Plain design (0.6 mm sheet

and above)

Dimensions allowed for

Style Basic and Style Comfort series doors with Cortex

and Tekno design (0.33 mm

sheet)

Dimensions allowed for Style

Comfort series doors with

Cortex and Tekno design

(0.33 mm sheet)

Example 1: sectional door 3.5 metres wide

and 2.3 m high, weight 12 kg/m

2

TOP603H can be used with the 3 m TOP803T3

guide because it falls within the area enclosed by the 12 kg/m

2

curve.

Example 2: sectional door 3.5 metres wide

and 2.7 m high, weight 12 kg/m

2

TOP603H can be used with the 4 m TOP803T4

guide because it falls within the area enclosed by the 12 kg/m

2

curve.

Example 3: sectional door 3.5 metres wide

and 2.6 m high, weight 14 kg/m

2

TOP603H CANNOT be used with the 4 m

TOP803T4 guide because it does NOT fall within

the area enclosed by the 14 kg/m

2

curve.

We recommend using TOP903H.

1500

2000

2500

3000

3500

H

1800 2000 2200 2400 2600 28 00 3000 3200 3400 3600 3800 4000 4200 4400 4600 4800 5000 5200 5400 5600 5800 60 00

Maximum dimensions of door -

TOP603H (Max. door weight

= 116 kg)

10

12

14

H

Max

TOP803T3 = 2450 mm

H

Max

TOP803T4 = 3500 mm

61

IP2179EN - 2015-11-24

4. Dimensions

208

364 131

40

3505 (TOP603H/903H+TOP803T3)

4593 (TOP603H/903H+TOP803T4)

3375 (TOP603H/903H+TOP803T3)

4463 (TOP603H/903H+TOP803T4)

62

IP2179EN - 2015-11-24

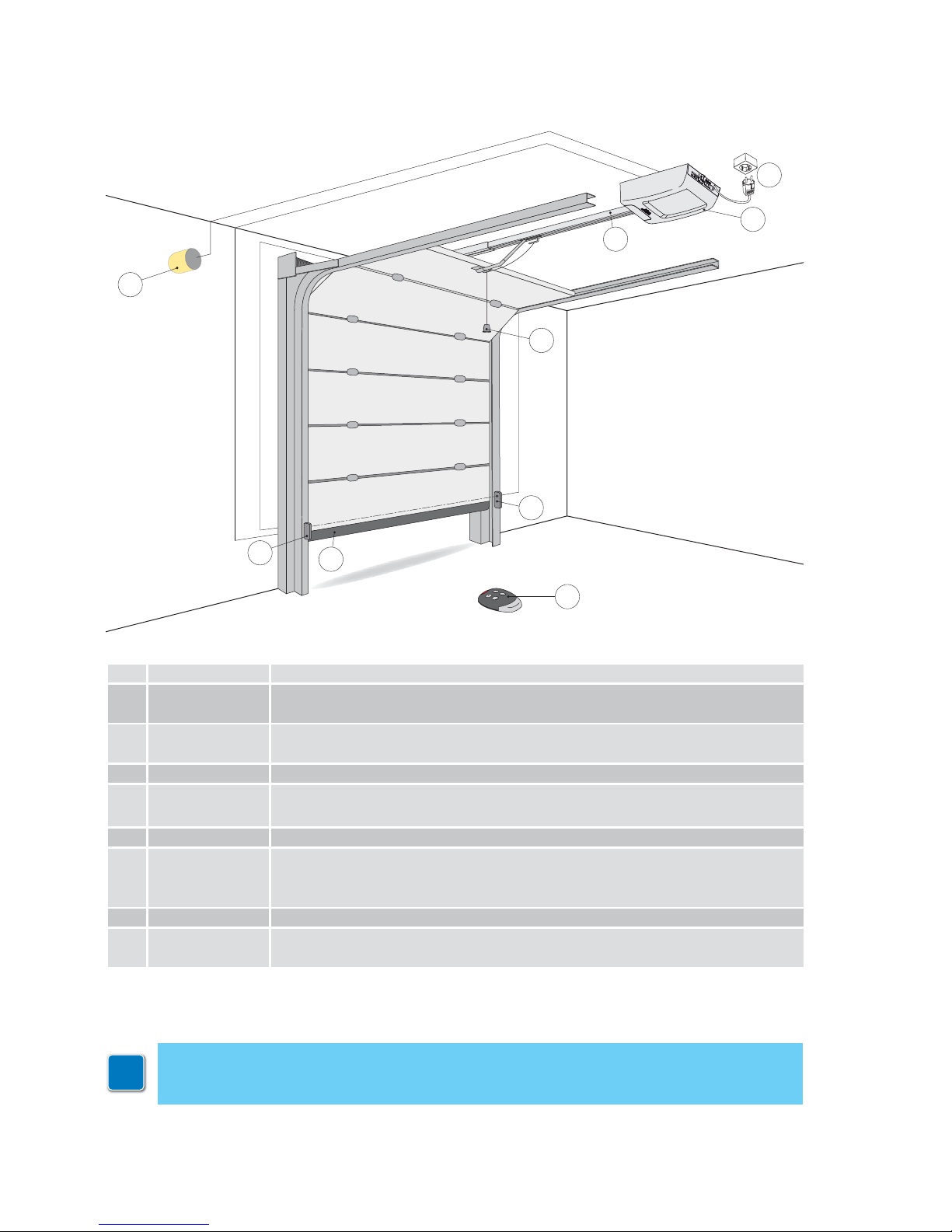

5. Standard installation

Ref. Code Description

1

TOP603H

TOP903H

Motor + control panel

2

TOP803T3

TOP803T4

Belt drive system with 3m steel guide

Belt drive system with 4m steel guide

3 LAMP Flashing light 230 V~ (requires the TOP905AC auxiliary card)

4

ASB1

ASB2

Kit for external release with cord and lock

Blocking device with cord (2000mm)

5 GOL4 Remote control

6

XEL2

LAB4

LAB4S

Photocells

7 Safety edge

A

Connect the power supply to a suitable earthed socket, about 10-50cm from the

pulling unit fixing position.

A

7

RG58 + 2x1.5 mm²

6

2

4

3

6

1

5

TOP905CAB2

TOP905CAB3

i

The declared operating and performance features can only be guaranteed with the use

of ENTREMATIC accessories and safety devices.

Unless otherwise specified, all measurements are expressed in mm.

63

IP2179EN - 2015-11-24

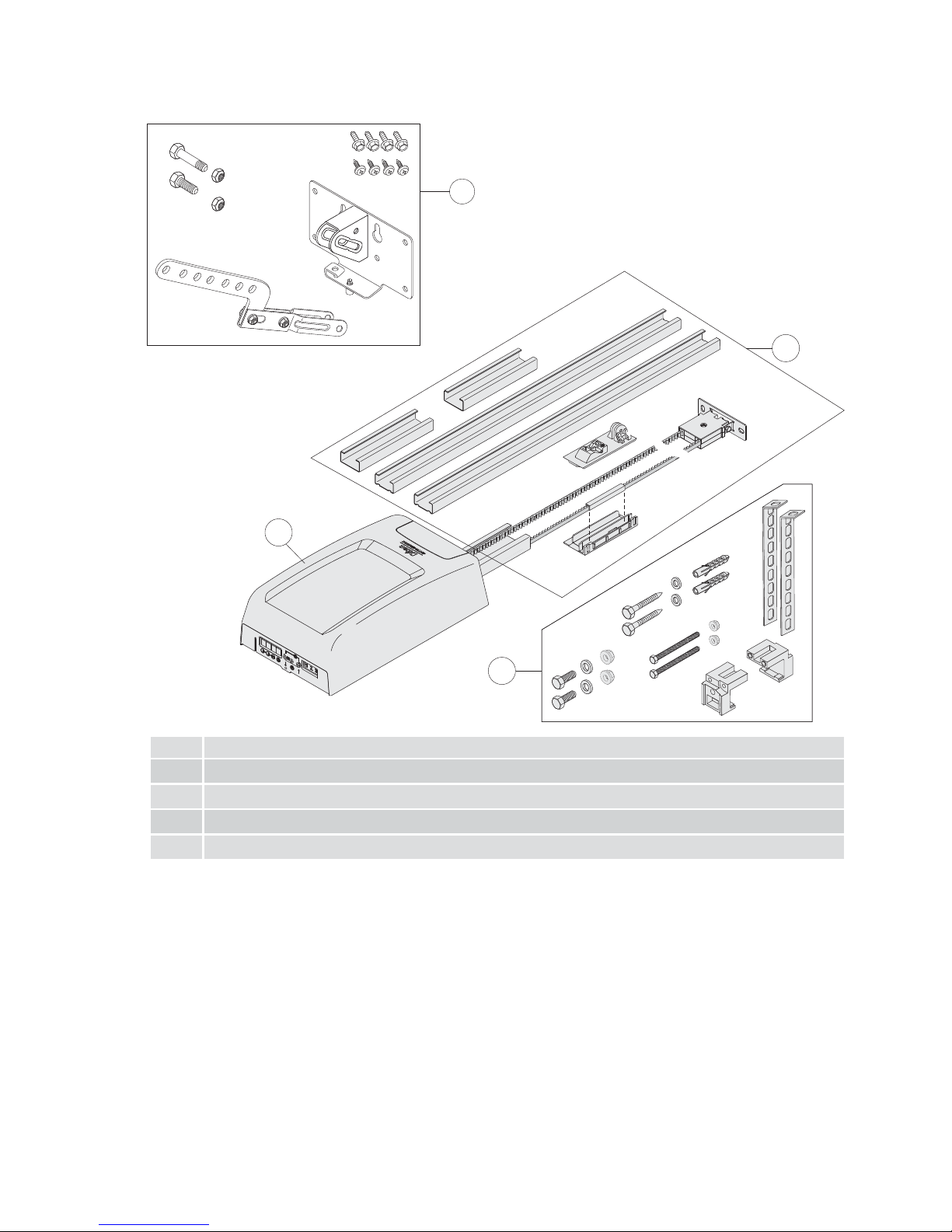

6. Main components

Ref. Description

1 Pulling unit

2 Drive system

3 Ceiling fixing system

4 Traction arm with retention bracket

4

3

2

1

64

IP2179EN - 2015-11-24

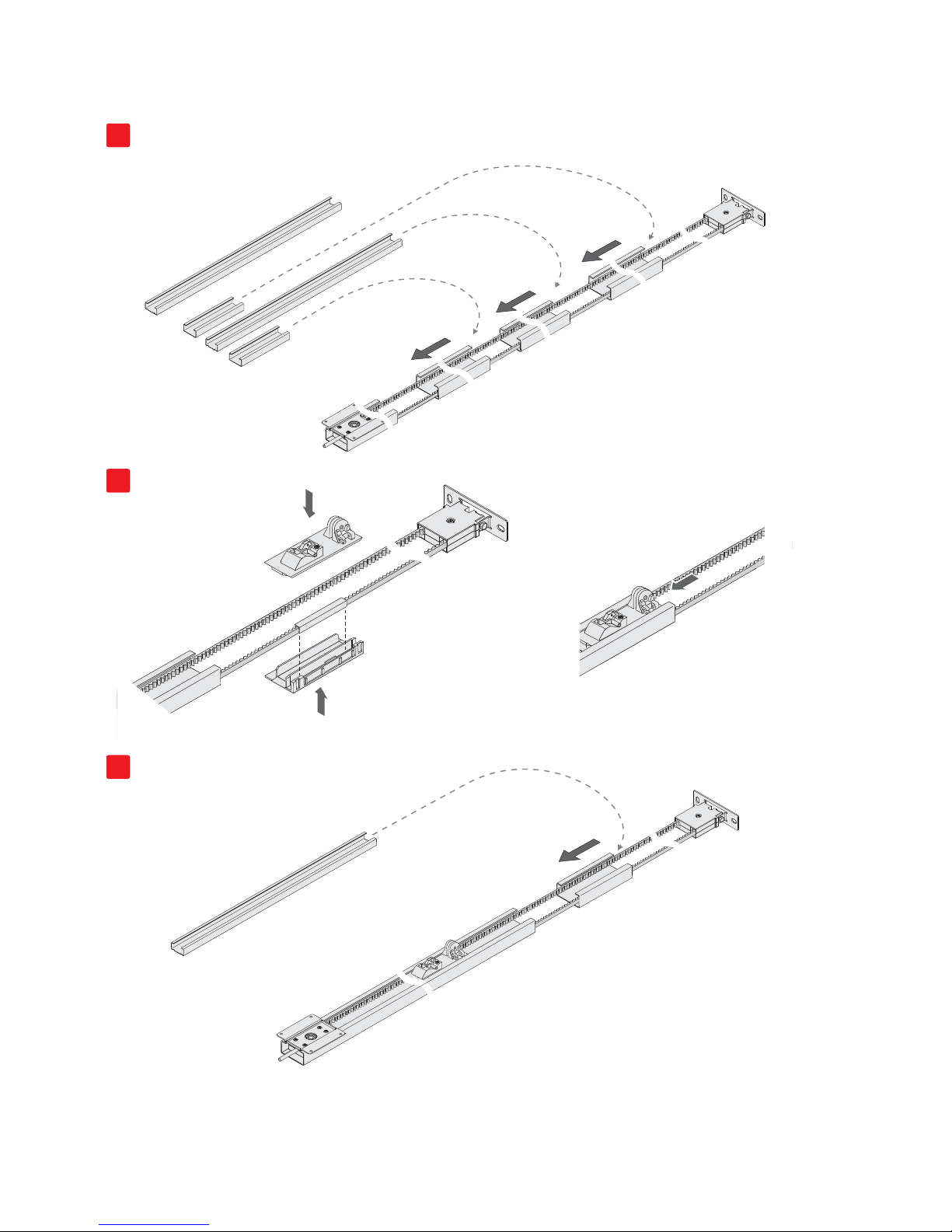

7. Assembly guide

1

2

3

Assemble the drive unit as shown in the figures.

65

IP2179EN - 2015-11-24

8. Tensioning the belt

AB

TOP803T3 4-6mm

TOP803T4 6-9mm

BX

X

1.

M8

A

NO

YES

Tighten the locking nut until the belt is correctly tensioned [X] within the guide.

Adjust the dimension [B] according to the type of guide used.

Loading...

Loading...