Entre Matic Ditec PWR50H, Ditec PWR50HV, Ditec PWR50HR Technical Manual

Ditec PWR50H/HV/HR

Automation for swing

gates

(translation of the original instructions)

www.entrematic.com

IP2253EN

Technical Manual

22

IP2253EN - 2017-08-21

Contents

Key

Subject Page

1. General safety precautions 23

2. Declaration of incorporation of partly completed machinery 24

2.1 Machinery Directive 24

3. Technical specifications 25

4. Standard installation 27

5. Dimensions and gearmotor references 28

6. Installation 29

6.1 Preliminary checks 29

6.2 Fastening the brackets 30

6.3 Using the positioning template 31

6.4 Installing the gearmotor 32

6.5 Adjusting the mechanical end stops 33

6.6 Adjusting the lever limit switch 33

6.7 Electrical connections 34

7. Routine maintenance plan 35

8. Troubleshooting 35

9. Disposal 35

Operating instructions 36

General safety precautions for the user 36

Manual release instructions 37

i

This symbol indicates instructions or notes regarding safety, to which special attention must be paid.

This symbol indicates useful information for the correct operation of the product.

23

IP2253EN - 2017-08-21

1. General safety precautions

Failure to respect the information given in this manual

may cause personal injury or damage to the device.

Keep these instructions for future reference

This installation manual is intended for qualified personnel only.

Installation, electrical connections and adjustments must be performed in accordance

with Good Working Methods and in compliance with the present standards.

Read the instructions carefully before installing the product.

Incorrect installation could be dangerous.

Before installing the product, make sure it is in perfect condition.

Before installing the motorisation device, make all the necessary structural modifications to create safety clearance and to guard or isolate all the crushing, shearing,

trapping and general hazardous areas.

Make sure the existing structure is up to standard in terms of strength and stability.

The motorisation device manufacturer is not responsible for failure to observe Good

Working Methods when building the frames to be motorised, or for any deformations

during use.

The safety devices (photocells, safety edges, emergency stops, etc.) must be installed

taking into account the applicable laws and directives, Good Working Methods, installation premises, system operating logic and the forces developed by the motorized gate.

The safety devices must protect the crushing, shearing, trapping and general hazardous

areas of the motorised door.

Display the signs required by law to identify hazardous areas.

Each installation must bear a visible indication of the data identifying the motor-

ized gate.

When requested, connect the motorized gate to an effective earthing system that

complies with current safety standards.

During installation, maintenance and repair operations, cut off the power supply before

opening the cover to access the electrical parts.

The automation protection casing must be removed by qualified personnel only.

The manufacturer of the motorisation device declines all responsibility if compo-

nent parts not compatible with safe and correct operation are fitted.

Only use original spare parts when repairing or replacing products.

The installer must supply all information on the automatic, manual and emergency operation of the motorised gate, and must provide the user with the operating instructions

.

24

IP2253EN - 2017-08-21

2. Declaration of incorporation of partly completed machinery

(Directive 2006/42/EC, Annex II-B)

The manufacturer Entrematic Group AB, with headquarters in Lodjursgatan 10, SE-261 44

Landskrona, Sweden, declares that the Ditec PWR50 automation for swing gates:

- is designed to be installed on a manual gate to form a machine pursuant to Directive 2006/42/

EC. The manufacturer of the motorised gate must declare conformity with Directive 2006/42/

EC (annex II-A) prior to initial machine start-up;

- complies with the applicable essential safety requirements indicated in Annex I, Chapter 1 of

the Directive 2006/42/EC;

- complies with the Electromagnetic Compatibility Directive 2014/30/EU;

- complies with the RED Directive 2014/53/EU;

- the technical documentation complies with Annex VII-B of the Directive 2006/42/EC;

- the technical documentation is managed by the Technical Office of Entrematic Italy (with

headquarters in Largo U. Boccioni 1 – 21040 Origgio (VA) – ITALY) and is available upon request,

sending an e-mail to ditec@entrematic.com ;

- a copy of the technical documentation will be given to competent national authorities, following

a suitably justified request.

Landskrona, 01-07-2016 Matteo Fino

(Chairman)

2.1 Machinery Directive

Pursuant to the Machinery Directive (2006/42/EC), the installer who motorises a door or gate has

the same obligations as the manufacturer of machinery and as such must:

- prepare the technical data sheet which must contain the documents indicated in Annex V of the

Machinery Directive;

(the technical data sheet must be kept and placed at the disposal of competent national author-

ities for at least ten years from the date of manufacture of the motorised door or gate);

- draw up the EC Declaration of Conformity in accordance with Annex II-A of the Machinery

Directive and deliver it to the customer;

- affix the EC marking on the motorised door or gate, in accordance with point 1.7.3 of Annex I of

the Machinery Directive.

25

IP2253EN - 2017-08-21

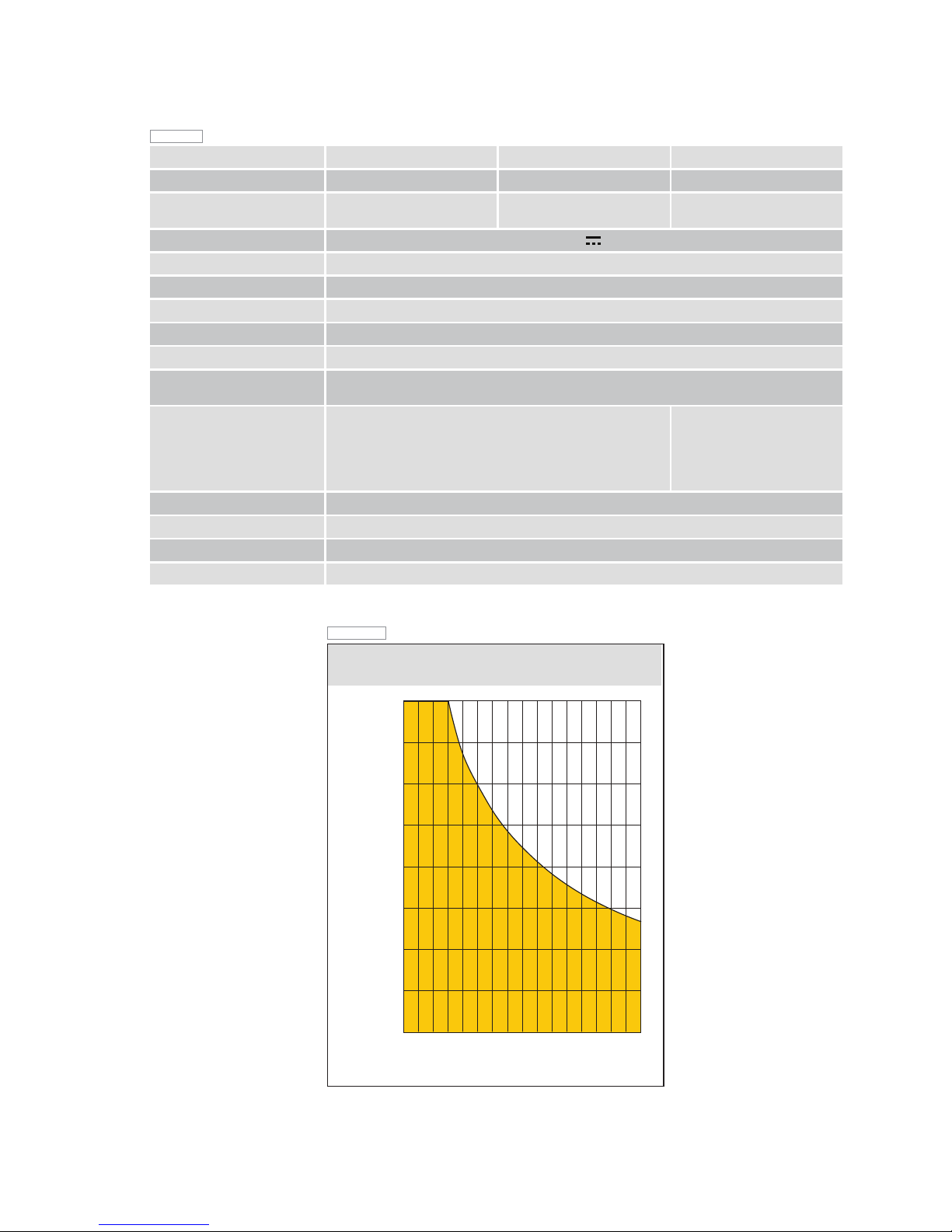

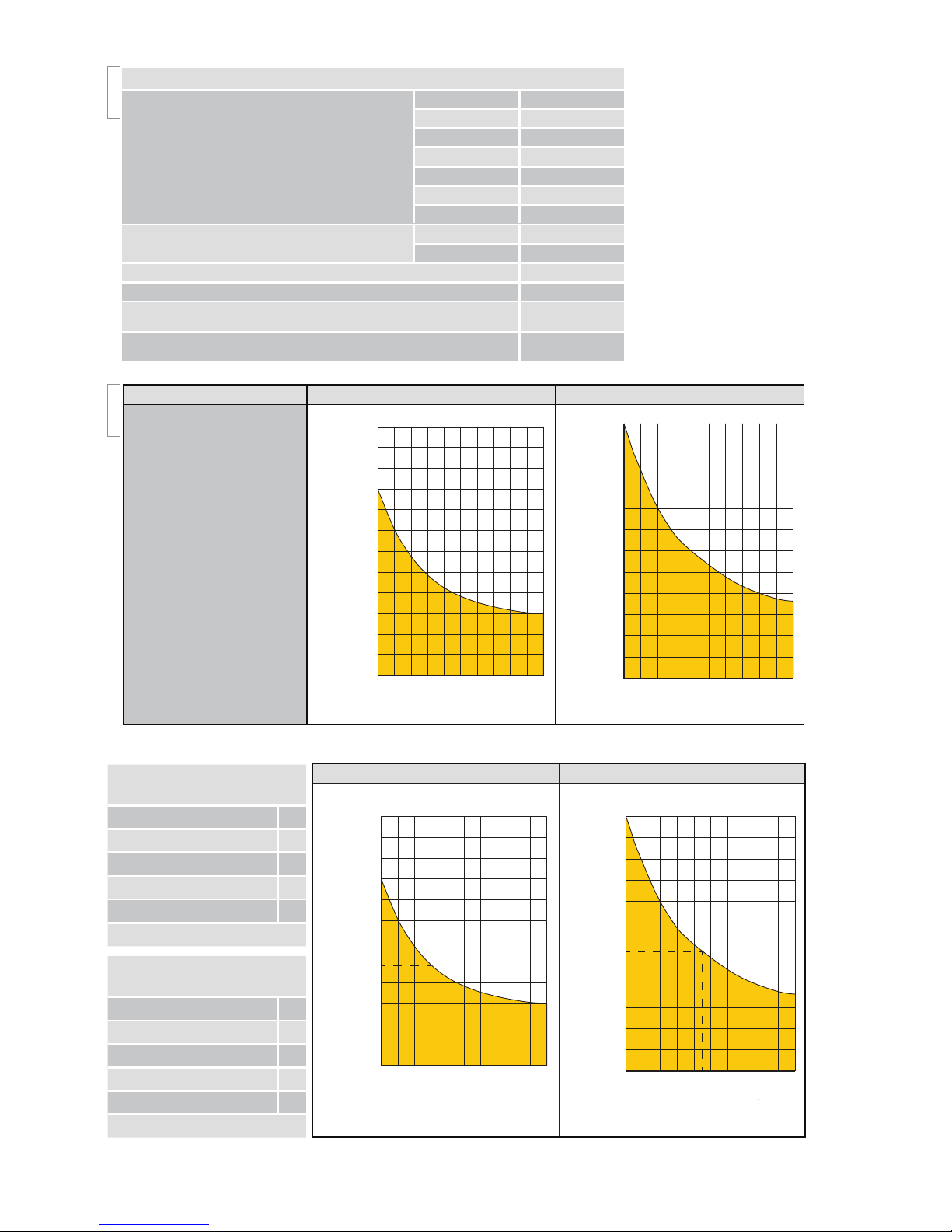

3. Technical specifications

PWR50H PWR50HV PWR50HR

Type Non-reversible Non-reversible Reversible

Stroke management (limit

switch)

Mechanical close stops Magnetic limit switches Mechanical close stops

Power supply 24V

Max absorption 12A

Power absorbed 65W nom / 288W max

Max thrust 6000 N

Maximum stroke 500mm

Opening time 14÷80 s / 90°

Intermittence

200 cycles/day [max]

60 consecutive cycles at 20°C

Lifespan

From 150,000 to 450,000 cycles based on the condi-

tions indicated in table 3.1 (see the durability graphs

of the product)

From 180,000 to 600,000

cycles based on the conditions indicated in table

3.1 (see the durability

graphs of the product)

Operating temperature -20°C / +55°C

(-35°C + 55°C with NIO active)

Degree of protection IP44

Dimensions (mm) 1044 x 100 x 120h

Weight (kg) 10.5

Tab. 3.0

Chart 3.0

Usage limits

(gate wing weight and width)

1

0

100

200

300

400

500

600

700

800

2 3

(m)

(Kg)

4 5

(m)

(kg)

26

IP2253EN - 2017-08-21

Index of conditioning factors

Gate wing weight

>150kg >200kg >300kg >400kg >500kg 10

>600kg 20

>700kg 30

Gate wing width

>3m 10

>4m 20

Solid gate wing 15

Windy area 15

VA/VC/PO/PC speed setting higher than the default values 10

Force R1/R2 setting higher than the default values 10

PWR50H-HV PWR50HR

Durability of the product

0

102030

405060

70

80

90

100

0

50.000

indice di gravosità

250.000

300.000

350.000

100.000

150.000

200.000

400.000

450.000

500.000

550.000

600.000

n° massimo di cicli

0

102030

405060

70

80

90

100

0

50.000

indice di

g

ravosità

250.000

300.000

350.000

100.000

150.000

200.000

400.000

450.000

500.000

550.000

600.000

n° massimo di cicli

PWR50H-HV PWR50HR

0

102030

405060

70

80

90

100

0

50.000

indice di gravosità

250.000

300.000

350.000

100.000

150.000

200.000

400.000

450.000

500.000

550.000

600.000

n° massimo di cicli

0

102030

405060

70

80

90

100

0

50.000

indice di gravosità

250.000

300.000

350.000

100.000

150.000

200.000

400.000

450.000

500.000

550.000

600.000

n° massimo di cicli

Tab. 3.1Tab. 3.2

Two examples of the operator durability calculation are shown below:

The product lifespan is

conditioned by the extent of other onerous

conditions:

with reference to Tab. 3.1,

various corrective factors

have been assessed in

relation to the weight and

width of the gate wing

and the usage conditions;

when taken as a whole,

they affect the lifespan of

the object (see Tab. 3.2).

Esempio di calcolo durata

per PWR50HR

Wing weight > 400 Kg 0

Wing width > 4,5m 20

R1/R2 = 80 (default 50) 10

Windy area 15

Total severity index 45

Estimated duration 280.000 cycles

Example of the duration

calculation for PWR50H-HV

Wing weight > 400 Kg 0

Wing width > 4,5m 20

R1/R2 = 80 (default 50) 10

Solid wing 0

Total severity index 30

Estimated duration 240.000 cycles

Severity index

Severity index

max no. of cycles

max no. of cycles

max no. of cycles

max no. of cycles

Severity index

Severity index

Loading...

Loading...