Entrematic Ditec EL34 Installation Manual

www.ditecentrematic.com

IP2152EN

Ditec EL34

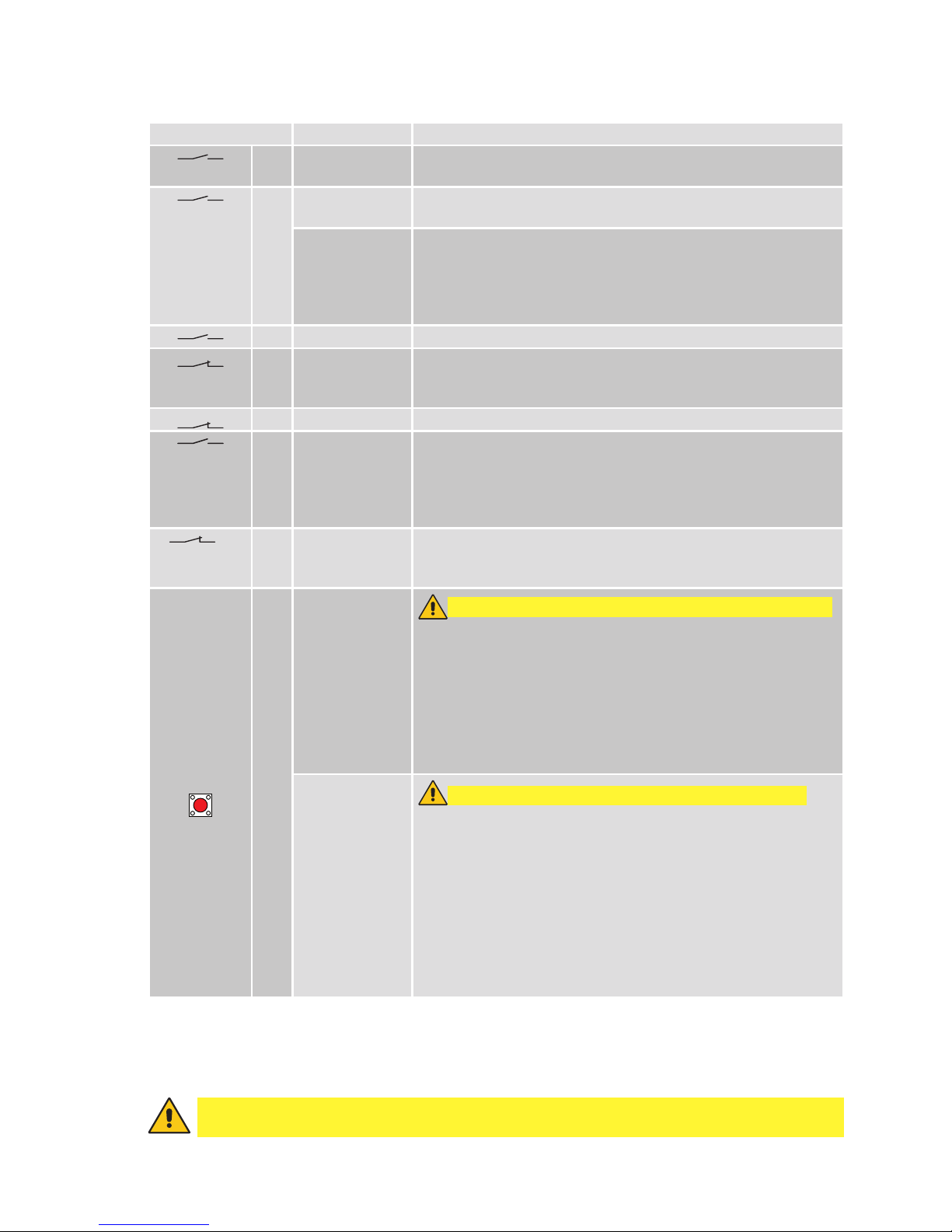

Control panel installation manual for QIK80EH barrier

(Original instructions)

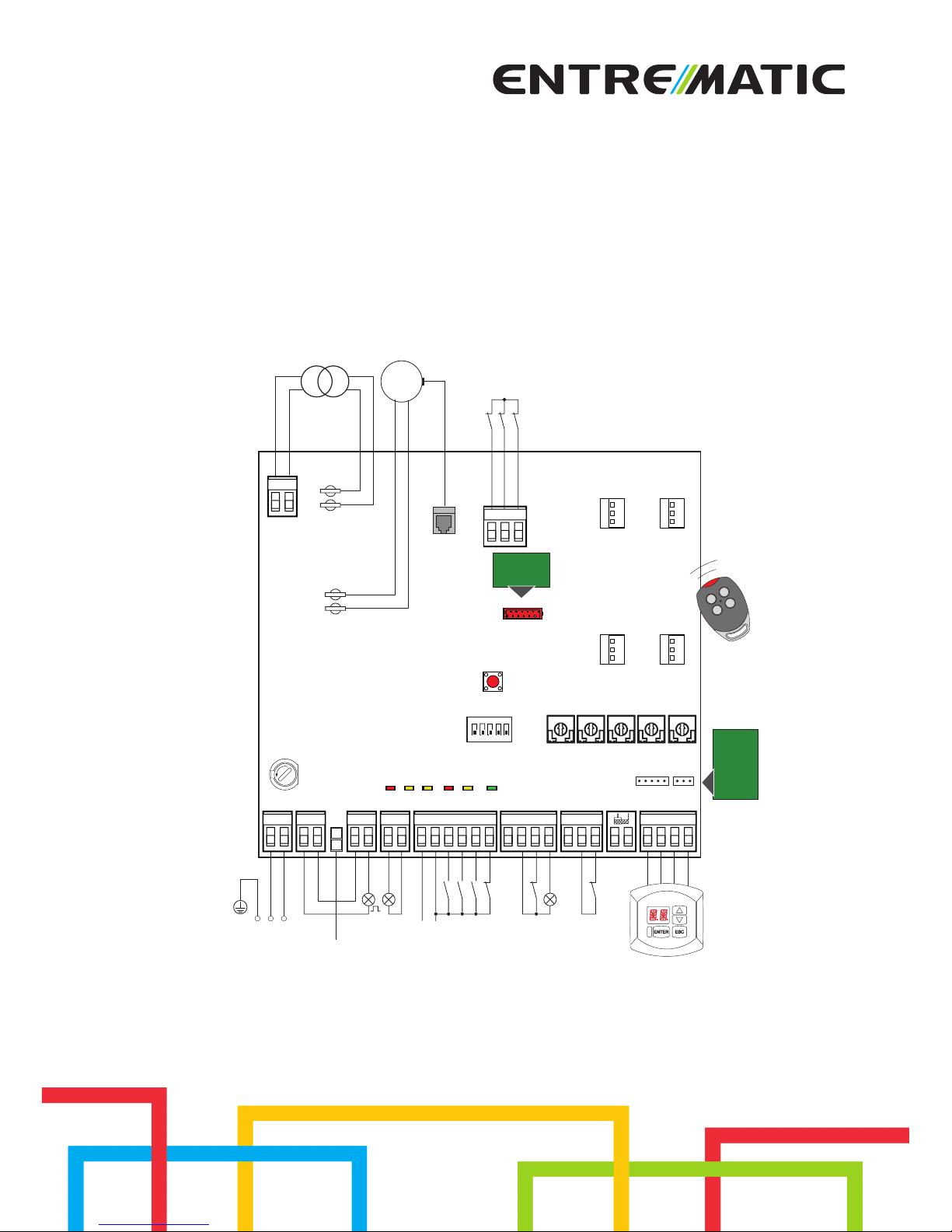

Safety reopening

Safety reopening

Automation status lamp

-

+

Output 24 V= / max 0,5 A

Power supply

BATKH

Flashing light

Lighting kit

Automatic closing

Opening

Closing

Stop

RDX

MD2

GOLR

POWER

ALARMSA11 IN12

VA VC TC R1 CB

AUX

24V~

012349 01G1 G3 0121 22018CNO

TRF

LN 14 0

PRG

COM

ENC

AUX

1ON2345

EL34

SIG

Transformer

24V=

Motor

BAT +G2-

1112 0

F1

F

U

S

E

BIXMR2

Limit switch

Limit switch

Safety switch

GOL4

+

M

-

20

IP2152EN - 2015-03-16

Index

Subject Page

1. General safety precautions 21

2.

EC declaration of conformity 22

3. Technical specifications 22

3.1

Applications 22

4. Commands 23

5. Outputs and accessories 24

6. Settings 25

6.1 Trimmers 25

6.2 Dip-switches

26

6.3 Jumper 26

6.4 Signals 26

7. Radio 27

8. Start-up 28

9. Troubleshooting 29

10. Example of application for parallel automations 30

11. Example of application for automations with two-way interlocking device without presence detection

31

12. Example of application for automations with two-way interlocking device with presence

detection

32

13. Example of application for automations with two-way operating mode 33

Key

All the rights concerning this material are the exclusive property of Entrematic Group AB. Although the contents of this publication have been drawn up with the greatest care, Entrematic Group AB cannot be held

responsible in any way for any damage caused by mistakes or omissions in this publication.

We reserve the right to make changes without prior notice. Copying, scanning and changing in any way are

expressly forbidden unless authorised in writing by Entrematic Group AB.

i

This symbol indicates useful information for the correct functioning of the product.

This symbol indicates instructions or notes regarding safety, to which special attention must be paid.

21

IP2152EN - 2015-03-16

This installation manual is intended for qualified personnel only.

Installation, electrical connections and adjustments must be performed in accordance

with Good Working Methods and in compliance with the present standards.

Read the instructions carefully before installing the product. Bad installation could

be dangerous.

The packaging materials (plastic, polystyrene, etc.) should not be discarded in

the environment or left within reach of children, as these are a potential source

of danger.

Before installing the product, make sure it is in perfect condition.

Do not install the product in explosive areas and atmospheres: the presence of inflammable gas or fumes represents a serious safety hazard.

The safety devices (photocells, safety edges, emergency stops, etc.) must be installed

taking into account: applicable laws and directives, Good Working Methods, installation premises, system operating logic and the forces developed by the automation.

Before connecting the power supply, make sure the plate data correspond to that

of the mains power supply. An omnipolar disconnection switch with minimum

contact gaps of 3 mm must be included in the mains supply.

Check that there is an adequate residual current circuit breaker and a suitable overcurrent cut-out upstream of the electrical installation in accordance with Good Working

Methods and with the laws in force.

When requested, connect the automation to an effective earthing system that complies

with current safety standards.

During installation, maintenance and repair operations, cut off the power supply before

opening the cover to access the electrical parts.

The electronic parts must be handled using earthed antistatic conductive arms.

The manufacturer of the motorisation declines all responsibility in the event

of component parts being fitted that are not compatible with the safe and correct

operation.

Use original spare parts only for repairing or replacing products.

1. General safety precautions

“Important instructions for installation safety.

Incorrect installation can cause serious injury”

22

IP2152EN - 2015-03-16

The manufacturer Entrematic Group AB, with headquarters in Lodjursgatan 10, SE-261 44 Landskrona, Sweden,

declares that the Ditec EL34 type control panel complies with the conditions of the following

EC directives:

EMC Directive 2004/108/EC

Low Voltage Directive 2006/95/EC

R&TTE Directive 1999/5/EC

Landskrona, 14-02-2013 Marco Pietro Zini

(President EA)

2. EC Declaration of Conformity

3. Technical specifications

QIK80EH

Power supply 230 V~ 50/60 Hz

F1 fuse F2A

Motor output 24 V 16 A

Accessories power supply 24 V 0.5 A

Temperature

min -20° C max +55° C

min -35° C max +55° C with NIO activated

min -10° C max +50° C with batteries

Degree of protection IP55

Radio frequency 433.92 MHz

Storable transmitters 200

3.1 Applications

i

NOTE: The given operating and performance features can only be guaranteed with the

use of DITEC accessories and safety devices.

23

IP2152EN - 2015-03-16

4. Commands

Command Function Description

1 2 N.O. AUTOMATIC

CLOSING

Permanently closing the contact enables automatic closing.

1 3

N.O. OPENING

With DIP1=ON, closing the contact activates an opening operation.

STEP-BY-STEP With DIP1=OFF, closing the contact activates an opening or clos-

ing operation in the following sequence: opening-stop-closingopening.

N.B.: if automatic closing is enabled, the stop is not permanent

but has a duration set with the TC trimmer.

1 4 N.O. CLOSING The closing operation starts when the contact is closed.

1 8 N.C. REVERSAL

SAFETY

CONTACT

Opening the safety contact triggers a reversal of the movement

(reopening) during the closing operation.

1 9 N.C. STOP Opening the safety contact stops the current operation.

1 9 N.O. OPERATOR

PRESENT

CONTROL

Opening of contact 1-9 enables the operator present function.

- opening with operator present 1-3 [with DIP1=ON];

- closing with operator present 1-4.

N.B.: any safety devices, automatic closing and plug-in cards in

the AUX1, AUX2 and RDX housings are disabled.

1 G1 N.C. REVERSAL

SAFETY

CONTACT

Opening the safety contact triggers a reversal of the movement

(reopening) during the closing operation.

PRG

N.O. TRANSMITTER

STORAGE AND

CANCELLATION

WARNING: the storage module MUST BE inser ted.

Transmitter storage:

- press the PRG key (the SIG LED turns on),

- proceed with transmission from the transmitter to be stored

(the SIG LED flashes),

- wait 10 s for storage to be completed (the SIG LED turns off).

Transmitter cancellation:

- press the PRG key for 3 s (the SIG LED flashes),

- press the PRG key again for 3 s (the SIG LED flashes faster).

SETTINGS

RESET

WARNING: the storage module must NOT be inserted.

- press the PRG key for 4 s (the IN LED flashes),

- press the PRG key within 4 sec for another 2 sec (the IN LED

comes on).

The SETTINGS RESE T deletes all the remote software settings

made using the MD2 display module. After SETTINGS RESET it

is possible to adjust the control panel directly.

WARNING: if the MD2 display module is disconnected from the

control panel, a SETTINGS RESET must be performed.

Warning: make a jumper for all NC contacts if not in use. The terminals with the same

number are equal.

Loading...

Loading...