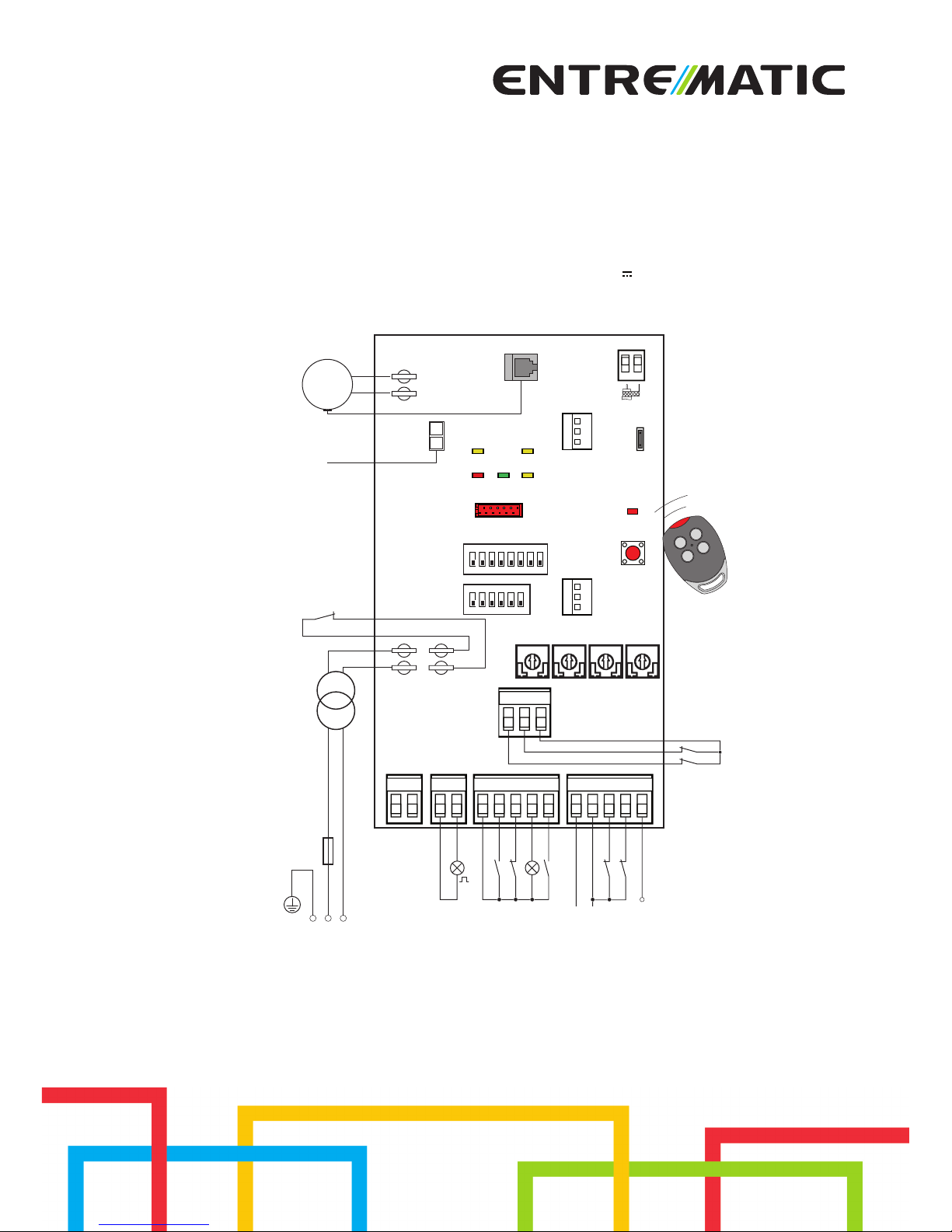

Entre Matic Ditec EL31R Installation Manual

Ditec EL31R

Installation Manual for control panel for 24V automations with

built-in radio.

www.ditecentrematic.com

IP1851EN

POWER

SA

11IN

Limit switch

Limit switch

Accessories output

12

VAAVC TC R1

AUX

A

N

T

B

A

T

SAFETY24V~

1591320 016841CNO

1112 0

14 0

PRG

COM

ENC

JR1

1ON23456

B

1ON23456 78

EL31R

SIG

-M

+M

Power supply

Step-by-step

Safety stop

Safety reopening

Stop

Safety test

Flashing light

Gate open indicator light

Partial opening

GOL4

F1

Transformer

Safety switch

24V=

Motor

BATK3

28

IP1851EN - 2014-09-30

29

IP1851EN - 2014-09-30

Index

Subject Page

1. General safety precautions 30

2. EC declaration of conformity 31

3. Technical specifications 31

3.1 Applications 31

4. Commands 32

4.1 Self-controlled safety edge 33

5. Sliding gates outputs and accessories 34

6. Barriers outputs and accessories 35

7. Settings 36

7.1 Trimmers 36

7.2 Sliding gates dip-switches 37

7.3 Barriers dip-switches 38

7.4 Jumper 39

7.5 Signals 39

8. Radio 40

9. Working modes for sliding gates 41

10. Start-up 42

10.1 Sliding gates start-up 42

10.2 Barriers start-up 43

11. Troubleshooting 44

12. Application example for sliding gates 46

13. Application example for barriers 47

14. Example of operator present function mode 47

15. Application example for parallel automations 48

Key

i

This symbol indicates useful information for the correct functioning of the product.

This symbol indicates instructions or notes regarding safety, to which special attention must be paid.

30

IP1851EN - 2014-09-30

1. General safety precautions

This installation manual is intended for qualified personnel only.

Installation, electrical connections and adjustments must be performed in accordance

with Good Working Methods and in compliance with the present standards.

Read the instructions carefully before installing the product.

Bad installation could be dangerous.

The packaging materials (plastic, polystyrene, etc.) should not be discarded in the environ-

ment or left within reach of children, as these are a potential source of danger.

Before installing the product, make sure it is in perfect condition.

Do not install the product in explosive areas and atmospheres: the presence of inflammable

gas or fumes represents a serious safety hazard.

The safety devices (photocells, safety edges, emergency stops, etc.) must be installed taking

into account: applicable laws and directives, Good Working Methods, installation premises,

system operating logic and the forces developed by the automation.

Before connecting the power supply, make sure the plate data correspond to that of the

mains power supply.

An omnipolar disconnection switch with minimum contact gaps of 3 mm must be included

in the mains supply.

Check that upstream of the electrical installation there is an adequate residual current circuit

breaker and a suitable overcurrent cutout.

When requested, connect the automation to an effective earthing system that complies with

current safety standards.

During installation, maintenance and repair operations, cut off the power supply before opening

the cover to access the electrical parts.

The electronic parts must be handled using earthed antistatic conductive arms.

The manufacturer of the motorisation declines all responsibility in the event of component

parts being fitted that are not compatible with the safe and correct operation.

Use original spare parts only for repairs or replacements of products.

1.1 Installation precautions

Fix the control panel permanently. Pass the cables along the lower side of the container.

If they are accessible, block the cables with cable glands (not supplied). Keep the line and motor

conductors separated from the command conductors by at least 8mm in the terminal boards

connection points (e.g. using straps).

Connect together the protection conductors (yellow/green) of the line and the motors, using the

clamp supplied.

At the end of the installation, close the container.

Failure to observe the information in this manual may result

in minor personal injury or damage to equipment.

Save these instructions for future reference.

31

IP1851EN - 2014-09-30

The manufacturer Entrematic Group AB, with headquarters in Lodjursgatan 10, SE-261 44 Land-Lodjursgatan 10, SE-261 44 Landskrona, Sweden,

declares that the EL31R type control panel complies with the conditions of the following EC

directives:

EMC Directive 2004/108/EC

Low Voltage Directive 2006/95/EC

R&TTE Directive 1999/5/EC

Landskrona, 29-01-2013 Marco Pietro Zini

(President & CEO)

2. EC Declaration of Conformity

3. Technical specifications

CROSS3E

ALTA5EH

CROSS5EH

CROSS5EH1

ALTA7EH

CROSS7EH

CROSS7EH1

QIK7EH

QIK7YEH

Storage module 3M1CR3

3M1CR5

3M1CR5C5

3M1CR7

3M1CR7C5

3M1QK

3M1QKC7

Power supply 230 V~ 50/60 Hz 230 V~ 50/60 Hz 230 V~ 50/60 Hz 230 V~ 50/60 Hz

F1 fuse

F1,6A F1,6A F2A F1,6A

Motor output

24 V 8 A 24 V 9,5 A 24 V 14 A 24 V 7 A

Accessories

power supply

24 V 0,3 A 24 V 0,3 A 24 V 0,3 A 24 V 0,3 A

Temperature

min -20° C

max +55° C

min -20° C

max +55° C

min -20° C

max +55° C

min -20° C

max +55° C

Degree of

protection

IP24D IP24D IP24D IP24D

Radio frequency

433,92 MHz 433,92 MHz 433,92 MHz 433,92 MHz

Storable transmitters

100

(200-BIXMR2)

100

(200-BIXMR2)

100

(200-BIXMR2)

100 (200-BIXMR2)

i

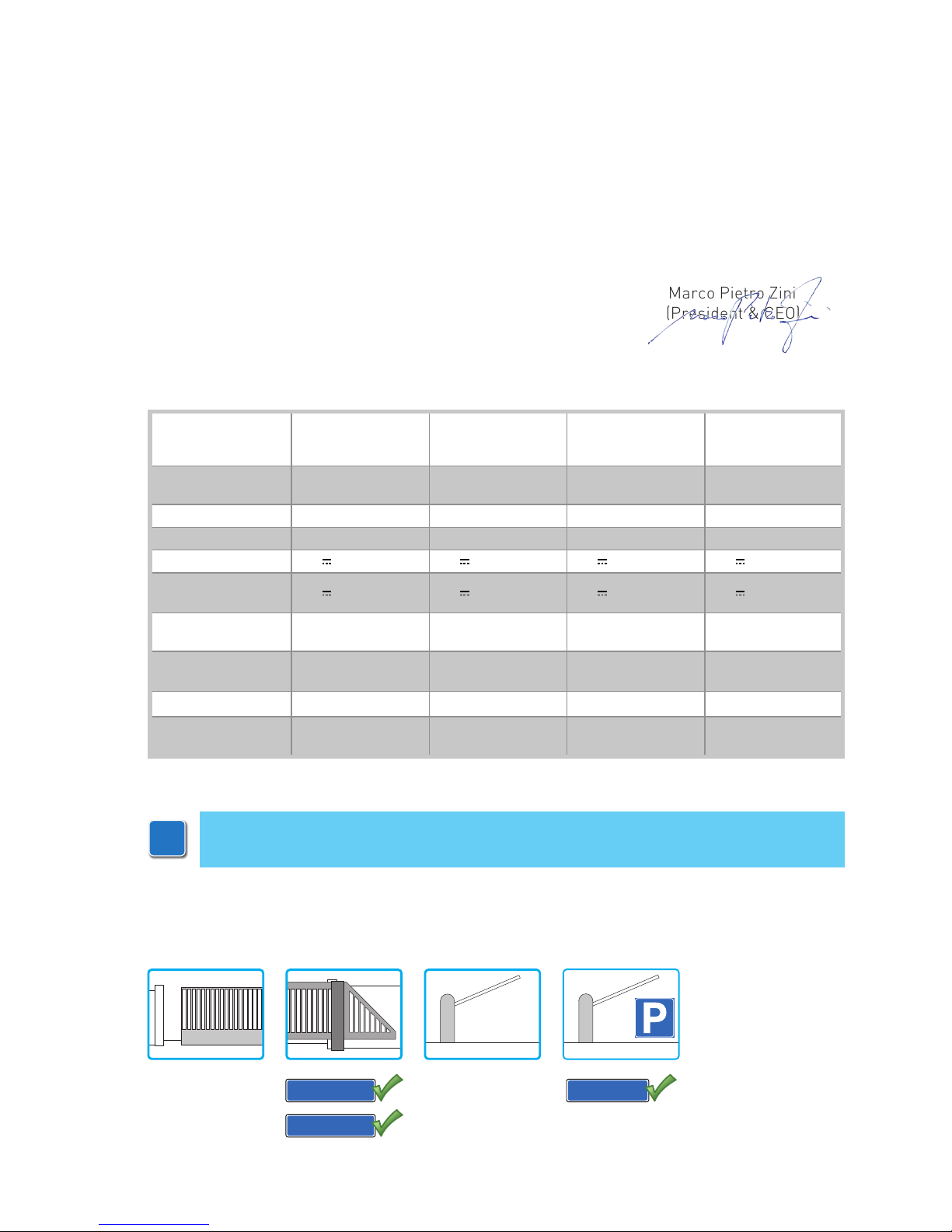

3.1 Applications

N.B.: The given operating and performance features can only be guaranteed with the

use of DITEC Entrematic accessories and safety devices.

3M1CR5C5

3M1QKC7

3M1CR7C5

32

IP1851EN - 2014-09-30

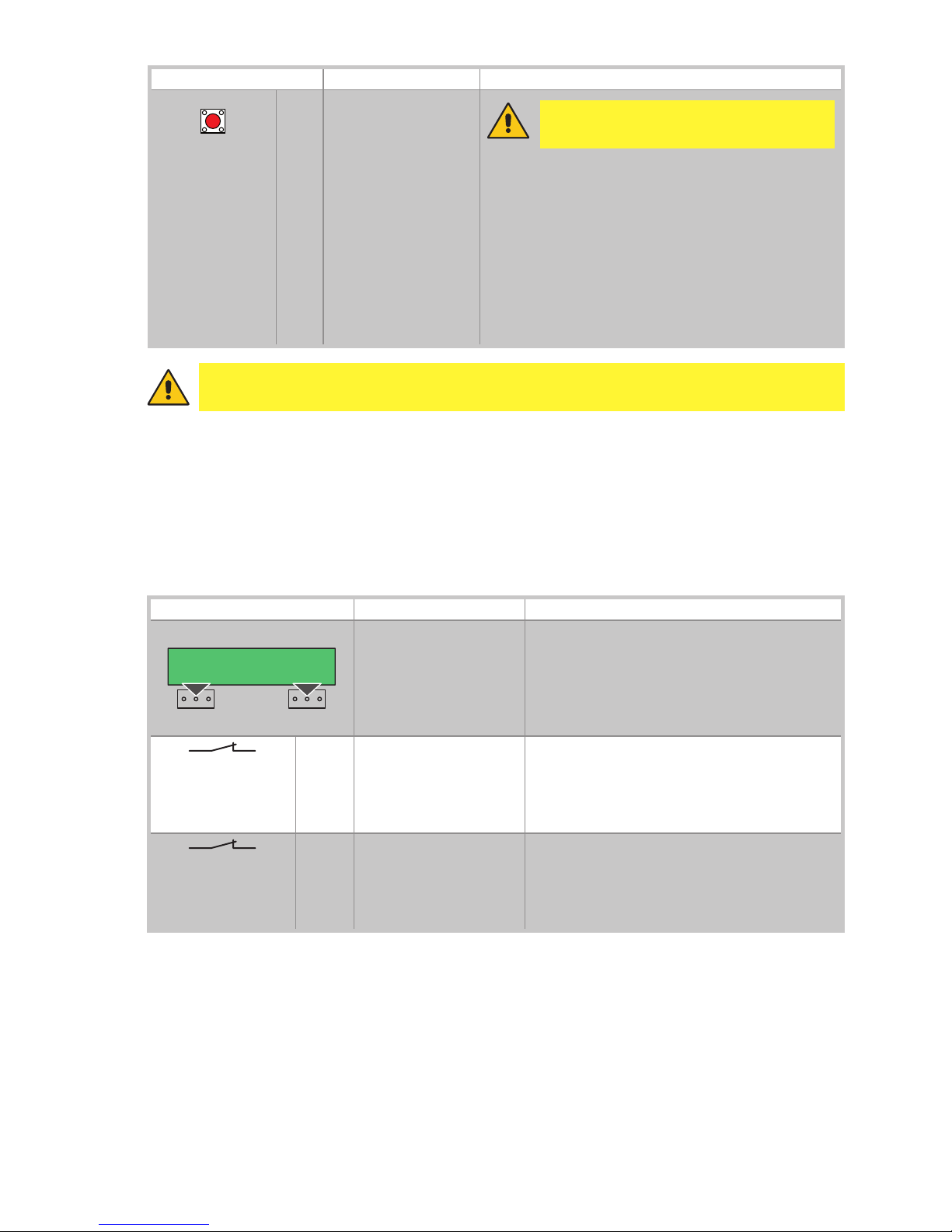

4. Commands

Command Function Description

1 5 N.O. STEP-BY-STEP

WITH AUTOMATIC

CLOSING

With DIP1A=OFF and TC<MAX, closing of the contact

activates an opening or closing operation in the following

sequence: opening-stop-closing-opening.

N.B.: the stop is not permanent, but has the duration set

with the TC trimmer.

STEP-BY-STEP

WITHOUT AUTOMATIC

CLOSING

With DIP1A=OFF and TC=MAX, closing of the contact

activates an opening or closing operation in the following

sequence: opening-stop-closing-opening.

OPENING

WITH AUTOMATIC

CLOSING

With DIP1A=ON and TC<MAX, closing of the contact

activates an opening operation.

OPENING WITHOUT

AUTOMATIC

CLOSING

With DIP1A=ON and TC=MAX, closing of the contact

activates an opening operation.

N.B.: Once the automation stops, command 1-5 performs

the opposite operation to the one performed before the

stop.

1 6

N.O. CLOSING With DIP2B=OFF, closing of the contact activates a clos-

ing operation.

1 6 N.C. OPENING

SAFETY CONTACT

With DIP2B=ON, opening of the safety contact stops and

prevents any movement.

1 8 N.C. REVERSAL

SAFETY CONTACT

Opening the safety contact triggers a reversal of the

movement (reopening) during the closing operation.

1 9 N.C. STOP Opening the safety contact stops the current operation.

1 9

N.O. OPERATOR PRESENT

CONTROL

Opening of contact 1-9 enables the operator present

function.

- opening with operator present 1-5 [with DIP1A=ON

and TC=MAX];

- closing with operator present 1-6 [with DIP2B=OFF].

N.B.: any safety devices, automatic closing and plug-in

cards in the AUX housing are disabled.

1 20

N.O. PARTIAL

OPENING

With DIP3B=ON, closing of the contact activates a partial opening operation.

Once the automation stops, the partial opening control

performs the opposite operation to the one performed

before the stop.

1 20

N.O. AUTOMATIC

CLOSING

With DIP3B=OFF, permanent closing of the contact enables automatic closing.

0 11 N.C. CLOSING LIMIT

SWITCH

Opening of the contact stops the closing operation.

0 12

N.C. OPENING LIMIT

SWITCH

Opening of the contact stops the opening operation.

41 SAFETY TEST With DIP6A=ON, connecting terminal 41 enables a safety

edge test cycle before every operation. If the test fails the

SA LED flashes and the test is repeated.

N.C. SAFETY SWITCH The SAFETY SWITCH contact is connected to the release

system of the automation. Opening the release contact

stops the operation.

CROSSQIK

33

IP1851EN - 2014-09-30

WARNING: make a jumper for all N.C. contacts if not in use. The terminals with the

same number are equal.

4.1 SOFA1-SOFA2 or GOPAVRS self-controlled safety edge

Command Function Description

GOPAV

SOFA1-SOFA2

SAFETY TEST Place the SOFA1-SOFA2 or GOPAVRS device into

the special housing for AUX plug-in cards.

With DIP6A=ON, connecting terminal 41 enables

a safety edge test cycle before every operation.

If the test fails the SA LED flashes and the test

is repeated.

1 6

N.C. SAFETY

STOP

Connect the output contact of the device to terminals 1-6 on the control panel (in series with the

photocell output contact, if installed).

WARNING: if not used, make a jumper for terminals 41-6.

1 8

N.C. REVERSE

SAFETY CONTACT

Connect the output contact of the device to terminals 1-8 on the control panel (in series with the

photocell output contact, if installed).

WARNING: if not used, make a jumper for terminals 41-8.

Command Function Description

PRG

N.O. TRANSMITTER

STORAGE AND

CANCELLATION

Transmitter storage:

- press the PRG key (the SIG LED turns on),

- proceed with transmission from the transmitter to be

stored (the SIG LED flashes),

- wait 10 s for storage to be completed (the SIG LED

turns off).

Transmitter cancellation:

- press the PRG key for 3 s (the SIG LED flashes),

- press the PRG key again for 3 s (the SIG LED flashes

faster).

WARNING: the storage module must

be inserted.

34

IP1851EN - 2014-09-30

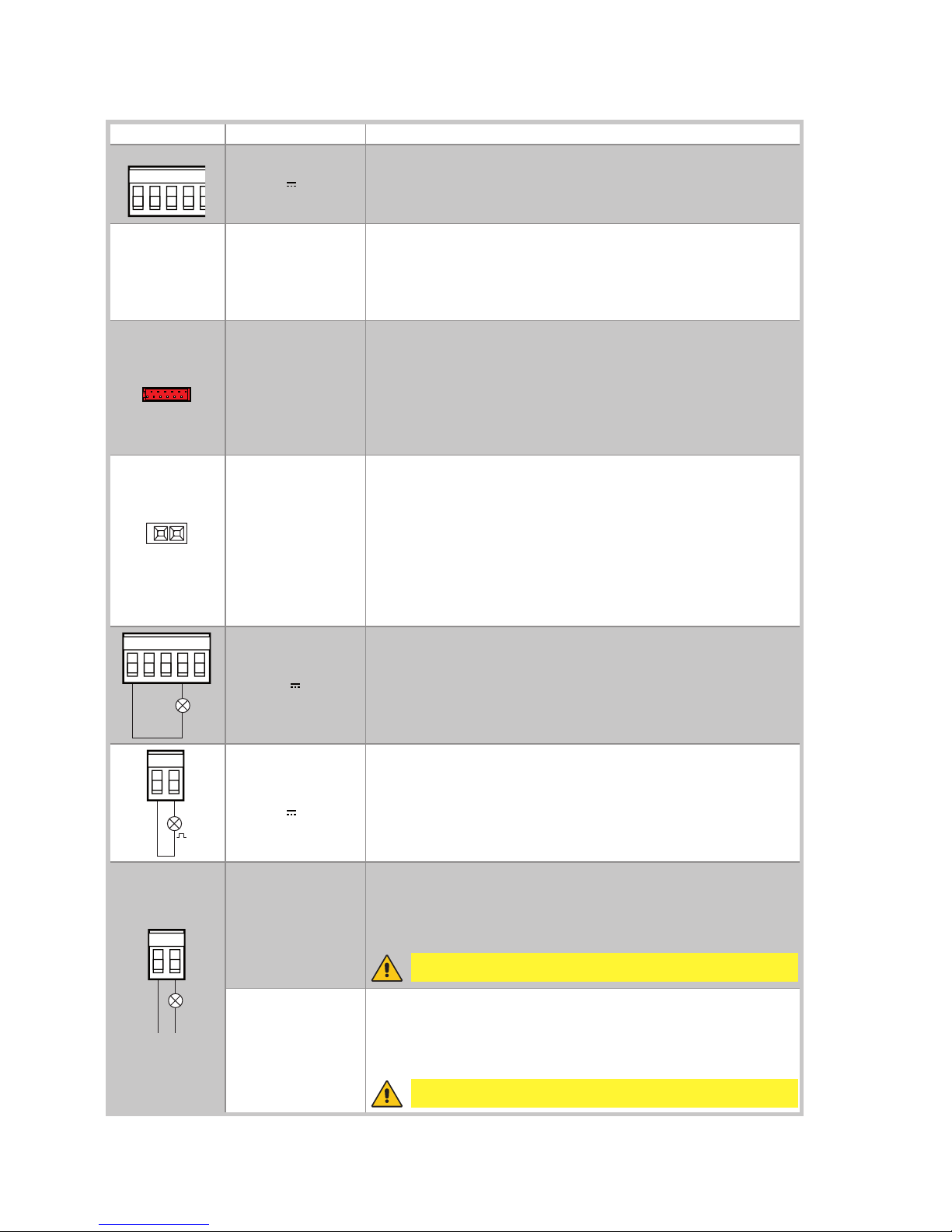

Output Value - Accessories Description

0-1

+

24 V 0.3 A

Accessories power supply.

Power supply output for external accessories, including automation status lamps.

AUX

SOFA1-SOFA2

GOPAV

The control panel is fitted with a housing for a plug-in card, such as

radio receivers, magnetic loops, etc.

Operating of the plug-in card is selected by DIP1A.

WARNING: the plug-in cards must be inserted and removed with

the power supply disconnected.

COM

STORAGE

MODULE

The storage module allows remote controls to be stored and the

type of control panel application to be defined (see TECHNICAL

SPECIFICATIONS on page 4).

If the control panel is replaced, the storage module being used can

be inserted in the new control panel.

WARNING: the storage module must be inserted and removed with

the power supply disconnected.

BAT

BATK3

2x12 V 2Ah

Barrier operation.

The batteries are kept charged when the power supply is on. If the

power supply is off, the panel is powered by the batteries until the

power is re-establish or until the battery voltage drops below the

safety threshold. The panel turns off in the last case.

WARNING: the batteries must always be connected to the control

panel for charging. Periodically check the efficiency of the batteries.

N.B.: the operating temperature of the rechargeable batteries is

approximately +5°C/+40°C.

15913 20

24 V 3 W

Automation status light (proportional)

The light goes off when the automation is closed.

The light comes on when the automation is open.

The light flashes with a variable frequency while the automation is

operating.

14 0

LAMPH

24 V 25 W

Flashing light.

The flashing light activates simultaneously with the opening and

closing operation.

CNO

LN

LUXK3E

LUXK7

230 V~ 60 W

Internal courtesy light.

A courtesy light that turns on for 180 seconds with every opening (total

or partial), step-by-step and closing command can be connected in

series to the NO contact.

230 V~ 400 W

External courtesy light.

An external courtesy light that turns on for 180 seconds with every

opening (total or partial), step-by-step and closing command can

be connected.

WARNING: use a double insulated cable

WARNING: use a double insulated cable

5. Sliding gates outputs and accessories

Loading...

Loading...