Page 1

www.entrematic.com

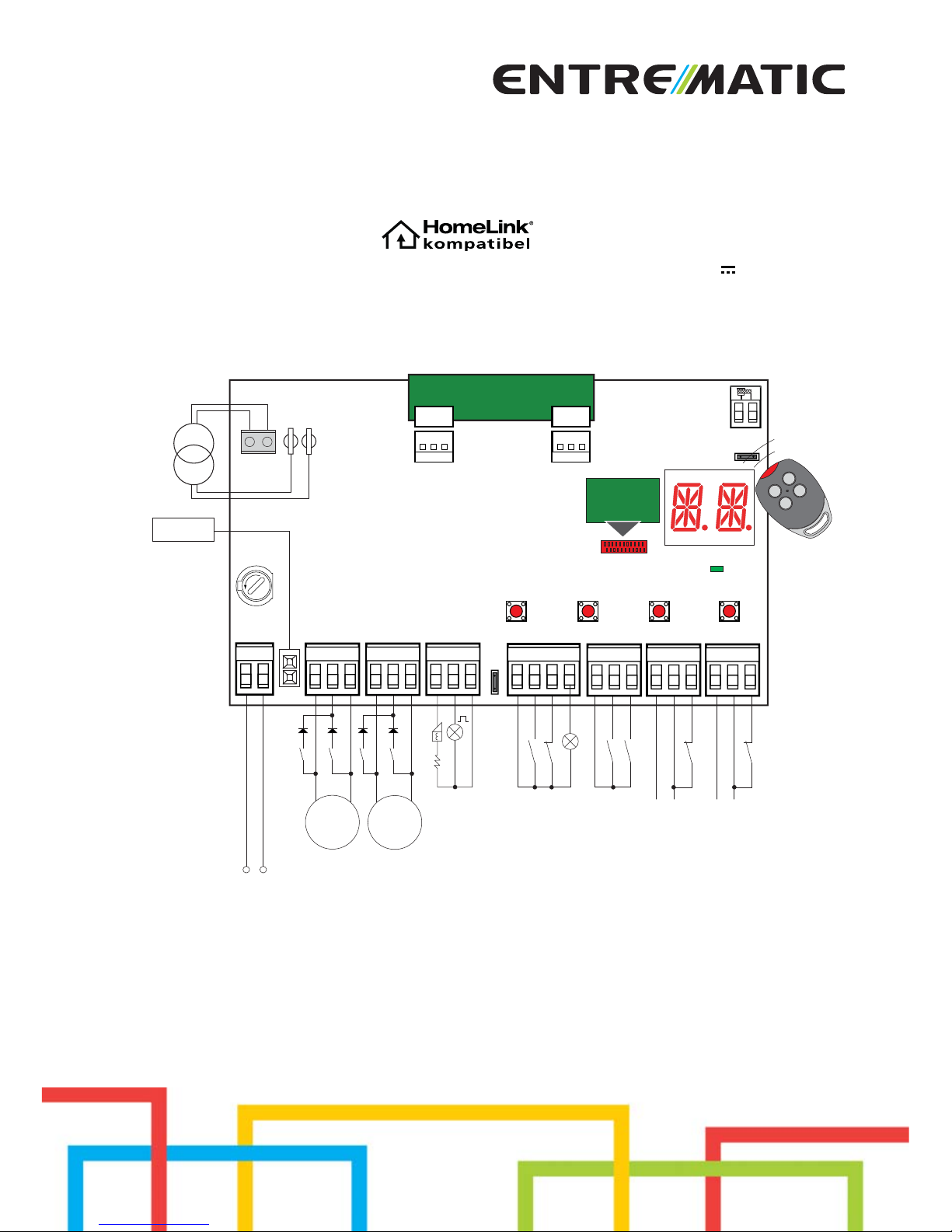

Ditec E2H

Installation manual for control panel for 2-motor 24V

automations with built-in radio

IP1967EN

F1

BATK1

UP

JR5

COM

DOWN

ENTERESC

24V

LN

POWER

TRF

-

+

-

+

AUX

JR1

BAT

ANT

GOL

4

24V= 24V=

F

U

S

E

LN

36 35 34 33 32 31

15 139

15 14 0

1520 016 018

Power supply

Motor 1Motor 2

Power unit

Memory

card

Flashing light

Electric lock

Stop safety contact

Lamp

Step by step

Step by step

Partial opening

Stop

Output 24 V=

Output 24 V=

eversal saf

ety contact

Page 2

40

IP1967EN - 2016-08-01

Subject Page

1. General safety precautions 41

2. EC declaration of conformity 42

3. Technical data 42

3.1 Applications 42

4. Connection of power supply 43

5. Commands 44

5.1 SOFA1-SOFA2 or GOPAVRS self-controlled safety edge 45

6. Outputs and accessories 46

7. Selection 47

8. Signals 47

9. Adjustments 48

9.1 Switching on and off 48

9.2 Key combination 48

9.3 Main menù 49

9.4 Second level menù - AT (Automatic Configurations) 50

9.5 Second level menù - BC (Basic Configurations) 51

9.6 Second level menù - BA (Basic Adjustment) 53

9.7 Second level menù - RO (Radio Operations) 57

9.8 Second level menù - SF (Special Functions) 59

9.9 Second level menù - CC (Cycles Counter) 61

9.10 Second level menù - AP (Advanced Parameters) 62

10. Display viewing mode 65

10.1 Automation status display 65

10.2 Commands and safety devices display 65

10.3 Alarms and anomalies display 67

11. Start-up 69

12. Troubleshooting 70

13. Example application of automation with two swinging door wings 72

14. Example application of automation with one swinging door wings 73

This symbol indicates instructions or notes regarding safety issues which require particular attention.

This symbol indicates instructions or notes intended for technical and expert personnel.

This symbol indicates options and parameters which are only available with the indicated

item.

This symbol indicates options and parameters which are not available with the indicated

item.

This symbol indicates operations not to be effected for not compromise the correct operation of the automation.

This symbol indicates informations which are useful for correct product function.

i

STOP

Caption

Index

All the rights concerning this material are the exclusive property of Entrematic Group AB. Although the contents of this publication have been drawn up with the greatest care, Entrematic Group AB cannot be held

responsible in any way for any damage caused by mistakes or omissions in this publication.

We reserve the right to make changes without prior notice. Copying, scanning and changing in any way are

expressly forbidden unless authorised in writing by Entrematic Group AB.

Page 3

41

IP1967EN - 2016-08-01

This installation manual is intended for qualified personnel only.

Installation, electrical connections and adjustments must be performed in accordance

with Good Working Methods and in compliance with the present standards.

Read the instructions carefully before installing the product. Bad installation could

be dangerous.

The packaging materials (plastic, polystyrene, etc.) should not be discarded in

the environment or left within reach of children, as these are a potential source

of danger.

Before installing the product, make sure it is in perfect condition.

Do not install the product in explosive areas and atmospheres: the presence of inflammable gas or fumes represents a serious safety hazard.

The safety devices (photocells, safety edges, emergency stops, etc.) must be installed

taking into account: applicable laws and directives, Good Working Methods, installation premises, system operating logic and the forces developed by the automation.

Before connecting the power supply, make sure the plate data correspond to that

of the mains power supply. An omnipolar disconnection switch with minimum

contact gaps of 3 mm must be included in the mains supply.

Check that there is an adequate residual current circuit breaker and a suitable overcurrent cut-out upstream of the electrical installation in accordance with Good Working

Methods and with the laws in force.

When requested, connect the automation to an effective earthing system that complies

with current safety standards.

During installation, maintenance and repair operations, cut off the power supply before

opening the cover to access the electrical parts.

The electronic parts must be handled using earthed antistatic conductive arms.

The manufacturer of the motorisation declines all responsibility in the event

of component parts being fitted that are not compatible with the safe and correct

operation.

Use original spare parts only for repairing or replacing products.

1. General safety precautions

“Important instructions for installation safety.

Incorrect installation can cause serious injury”

1.1 Safety functions

The E2H control panel has the following safety functions:

- obstacle recognition with force limiting;

The maximum response time of the safety functions is 0.5 s. The reaction time to a faulty safety

function is 0.5 s.

The safety functions comply with the standards and performance level indicated below:

EN ISO 13849-1:2008 Category 2 PL=c

EN ISO 13849-2:2012

The safety function cannot be bypassed either temporarily or automatically. Fault exclusion

has not been applied.

Page 4

42

IP1967EN - 2016-08-01

ARCBH

OBBI3BH

LUXO3BH

LUXO4BH

FACIL3H

FACIL3EH

Memory module

3M1OB

3M1AR

3M1LX

3M1FC

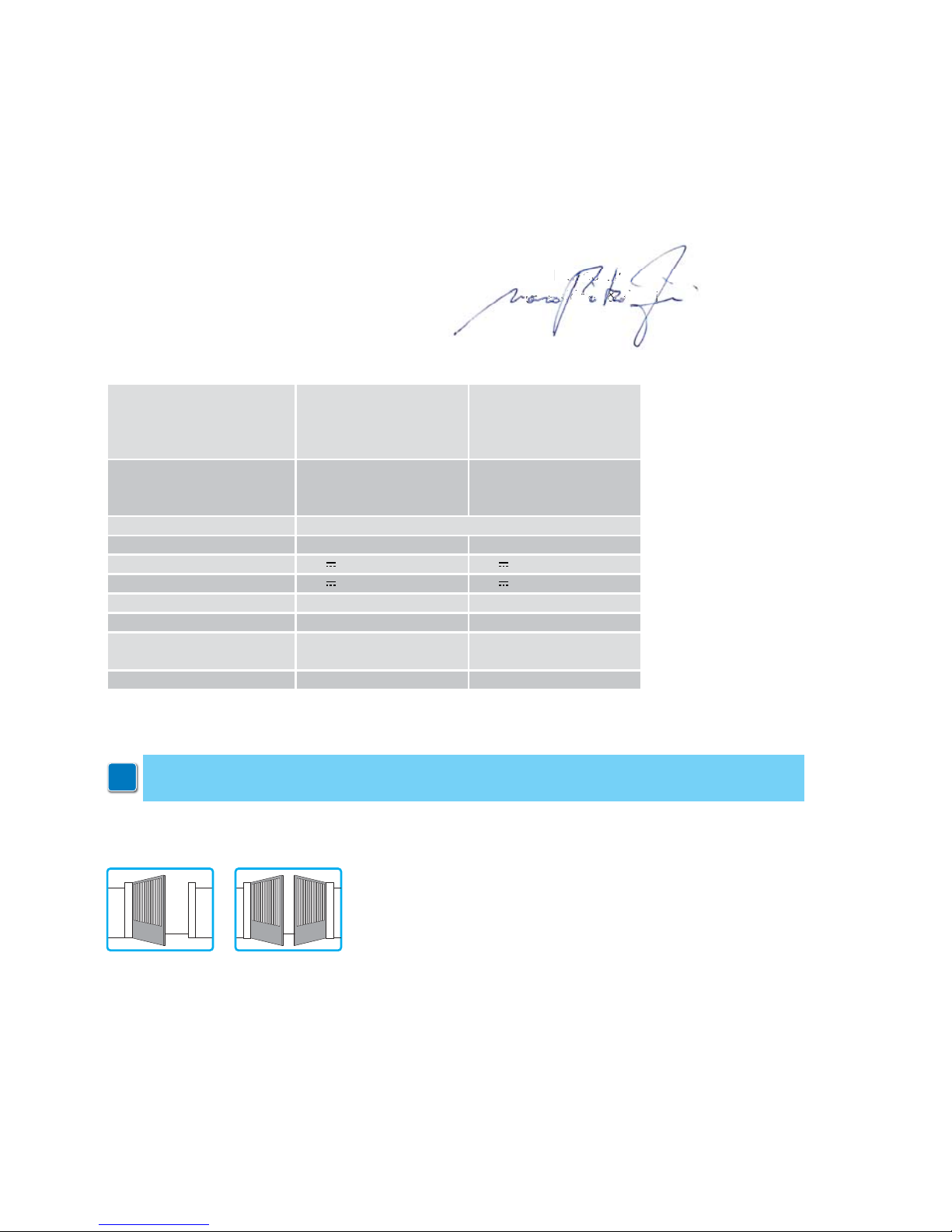

Power supply 230 V~ 50/60 Hz

F1 fuse F1,6A F1,6A

Motor output 24 V

2x4,5 A max 24 V 2x6 A max

Accessories power supply 24 V 0,5 A 24 V 0,5 A

Temperature min -20 °C max 55 °C min -20 °C max 55 °C

Degree of protection IP55 IP54

Memorizable

radio codes

100

200 [BIXMR2]

100

200 [BIXMR2]

Radio frequency 433,92 MHz 433,92 MHz

i

3. Technical data

2. EC declaration of conformity

3.1 Applications

NOTE: the given operating and performance features can only be guaranteed with the use

of DITEC accessories and safety devices.

The manufacturer Entrematic Group AB, with headquarters in Lodjursgatan 10, SE-261 44 Landskrona, Sweden, declares that the Ditec E2H type control panel complies with the conditions

of the following EC directives:

EMC Directive 2004/108/EC

Low Voltage Directive 2006/95/EC

R&TTE Directive 1999/5/EC.

L a n d s k r o n a , 0 8 - 0 9 - 2 0 1 4 M a r c o Z i n i

(President & CEO)

arrooZiniii

Pre

Pre

Pre

Pre

Pre

Pre

sid

sid

sidsss&&CEO

CEO

CEO

)))

)

)

)

)

Page 5

43

IP1967EN - 2016-08-01

4. Connection of power supply

Before connecting the power supply, make sure the plate data correspond to that of the mains

power supply.

An omnipolar disconnection switch with minimum contact gaps of 3 mm must be included in

the mains supply.

Check that upstream of the electrical installation there is an adequate residual current circuit

breaker and a suitable overcurrent cutout.

Use a H05RN-F 3G1,5 or H05RR-F 3G1,5 type electric cable and connect to the terminals L

(brown), N (blue),

(yellow/green) in the automation.

Secure the cable using the special cable clamp and remove the outer sheath near the terminal

only.

Connection to the mains power supply, in the section outside the automation, is made with

independent channels and separated from the connections to the control and safety devices.

The channels must penetrate a few centimetres inside the automation thorough a hole maximum Ø16 mm.

Make sure there are no sharp edges that may damage the power supply cable.

Make sure that the mains power supply (230 V) conductors and the accessory power supply

(24 V) conductors are separate.

Page 6

44

IP1967EN - 2016-08-01

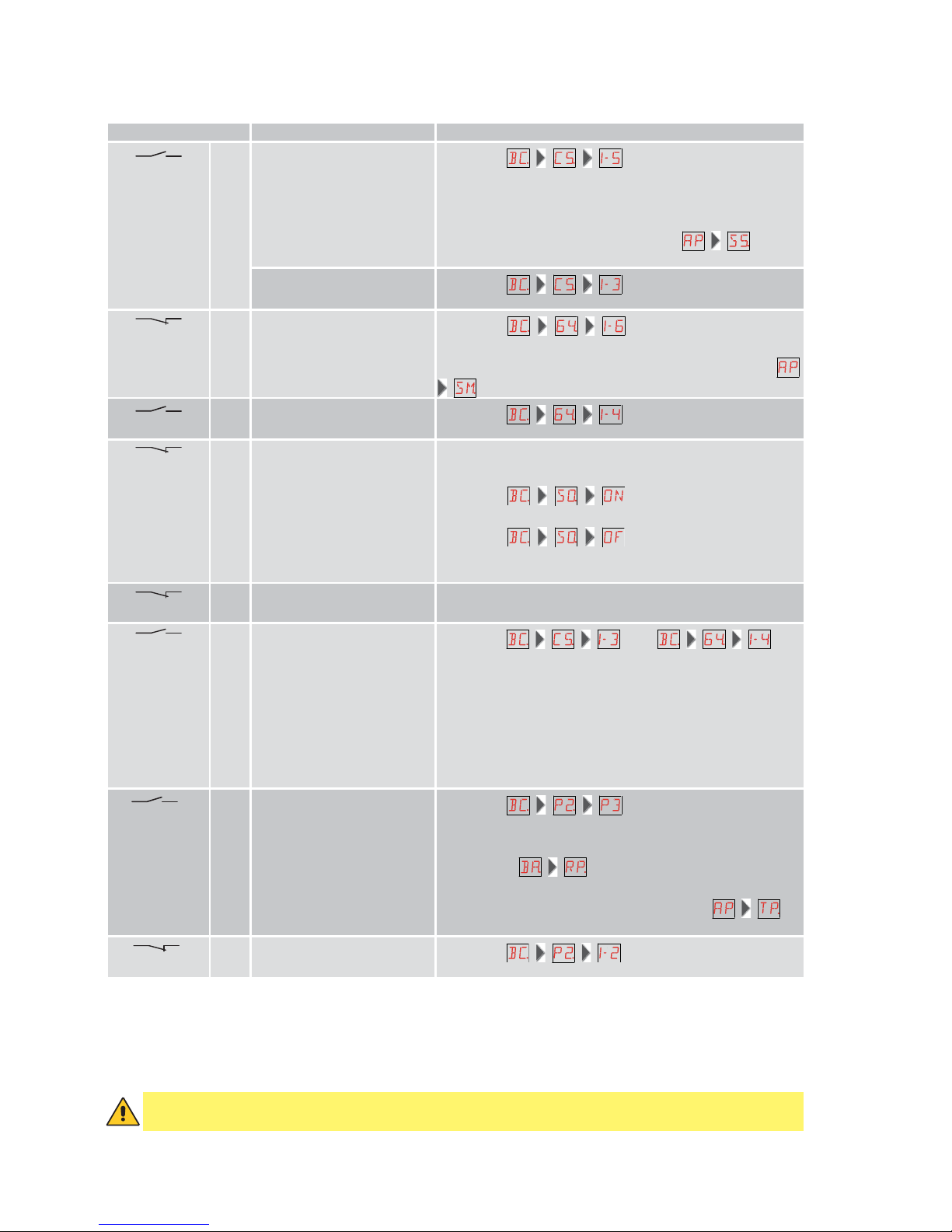

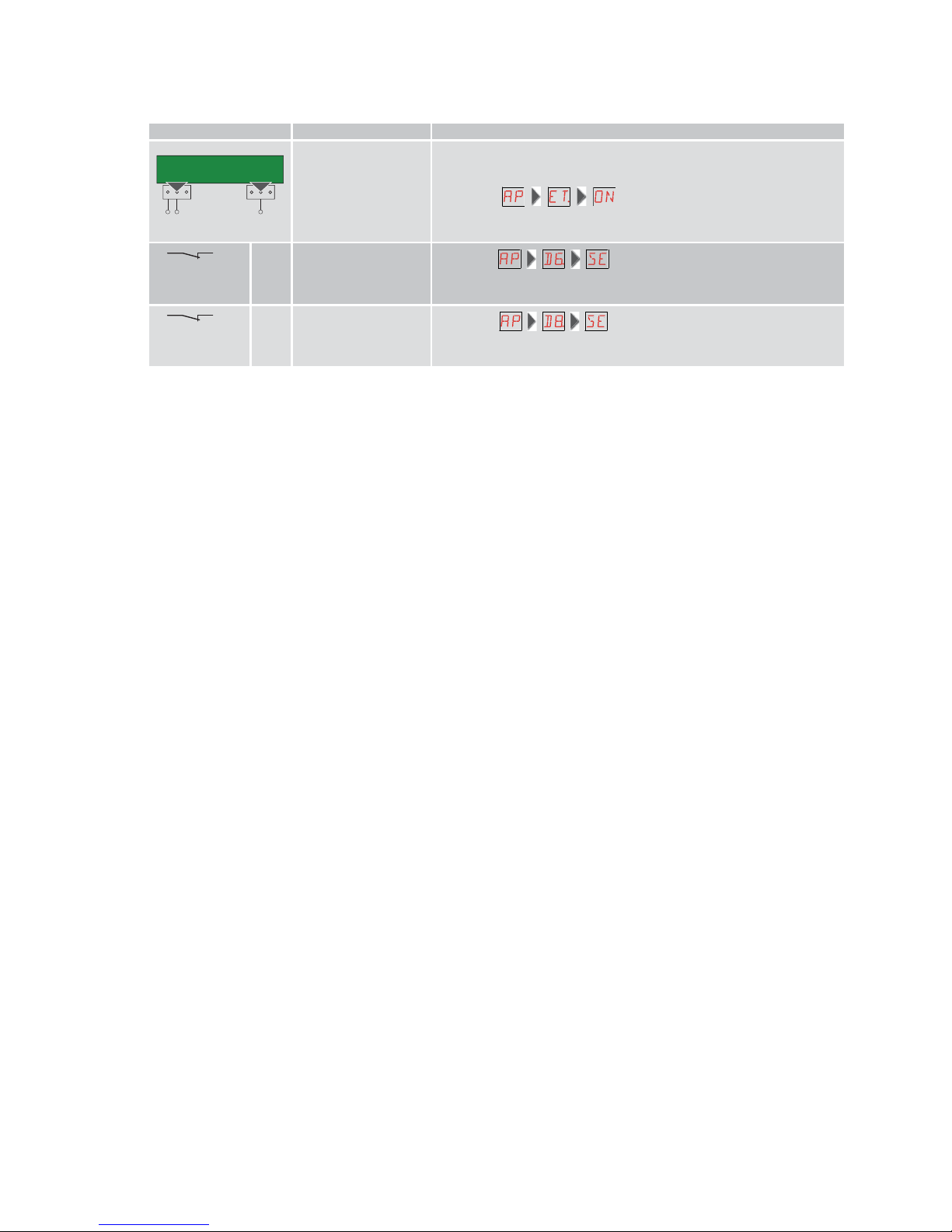

Command Function Description

1

5 N.O. STEP BY STEP

Selecting , the closure of the contact

activates a closing or opening operation in the sequence: open-stop-close-open.

Warning: if automatic closing is enabled, the duration of

the stop is selected via the selection

.

OPENING

Selecting

, the closure of the contact

activates an opening operation.

1

6 N.C. SAFETY STOP

Selecting

, the opening of the safety

contact stops and prevents any movement.

Note: to set the different contact safety functions, see the

parameter settings.

1 6 N.O. CLOSING

Selecting

, the closure of the contact

activates a closing operation.

1

8 N.C. REVERSAL SAFETY

CONTACT

The opening of the safety contact triggers a reversal of

motion (re-opening) during a closing operation.

Selecting

, with the automation idle,

the opening of the contact prevents any operation.

Selecting , with the automation idle,

the opening of the contact prevents the closing operation only.

1

9 N.C. STOP Opening the safety contact stops the current operation.

Note: the flashing light flashes.

1

9 N.O. HOLD TO RUN FUNCTION

Selecting

and , the

permanent opening of the safety contact enables the

hold to run function.

In this state, the opening (1-5) and closing (1-6) controls

function only if held in the pressed position, and the automation stops when the controls are released.

Any safety devices, plus the automatic closing, are disabled.

1

20 N.O. PARTIAL OPENING

Selecting

, the closure of the contact

activates a partial opening operation of the door wing

commanded by motor 1, and the duration is fixed by

adjustment

.

Warning: if automatic closing is enabled, the duration

of the stop is selected via the adjustment

.

1

20 N.C. AUTOMATIC CLOSING

Selecting

, the permanent closure of

the contact enables automatic closing.

5. Commands

WARNING: Make a jumper on all NC contacts if not in use. The terminals with the same

number are equal

Page 7

45

IP1967EN - 2016-08-01

Command Function Description

SOFA1-SOFA2

GOPAVRS

0411

SAFETY TEST Insert the electronic card SOFA1-SOFA2 or GOPAVRS in the

housing AUX on the control panel.

Selecting

, the terminal 41 activates a safety

ed ge te s t bef ore each ope r ation. I f the test fails, an alar m message is visualised on the display.

1

6 N.C. OPENING SAFETY

DEVICE

Selecting

, connect the output contact of device

SOFA1-SOFA2 to terminals 1-6 on the control panel (in series with

the photocell output contact, if installed).

1 8 N.C. REVERSAL

SAFETY

CONTACT

Selecting

, connect the output contact of device

SOFA1-SOFA2 to terminals 1-8 on the control panel (in series

with the photocell output contact, if installed).

5.1 SOFA1-SOFA2 or GOPAVRS self-controlled safety edge

Page 8

46

IP1967EN - 2016-08-01

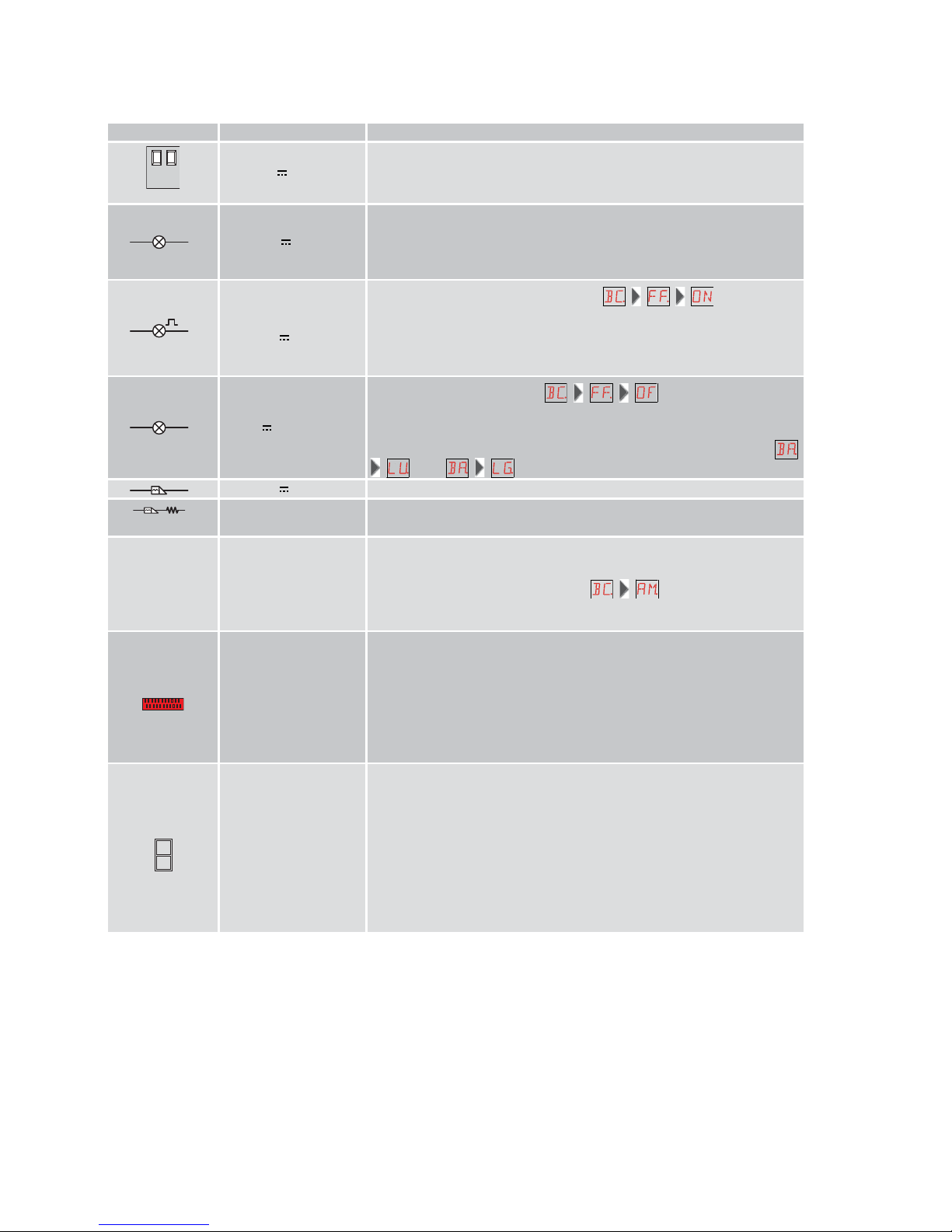

6. Output and accessories

Output Value - Accessories

Description

01

+-

24 V / 0,5 A

Power supply output for external accessories, including automation status lamp. Electronically protected output.

1

13

24 V

/ 3 W

Automation status lamp (proportional).

The light switches off when the automation is closed; the light switches

on when the automation is open; the light flashes with a variable

frequency while the automation is operating.

0

14

LAMPH

24 V / 25 W

Flashing light (LAMPH). Selecting

, the flashing

light activates simultaneously with the opening and closing operation.

NOTE: with automatic closing enabled, there is a pre-flashing of 3

s that cannot be regulated.

0

14

24 V

/ 25 W max.

Courtesy light. Selecting

, it is possible to connect a cour tesy light that activates each time a total or partial

opening command or closing command is received.

The duration of the light can be regulated via the adjustment

and .

0

15 24 V / 1,2 A Electric block 24V.

0

15

12V~ / 15 W

Electric lock 12 V. Connect the supplied 8.2 Ω / 5W resistance in

series.

AUX

The control panel is fitted with a housing for a plug-in card, such

as radio receivers, magnetic spirals, etc. The action of the card

can be selected via the selection .

WARNING: the plug-in cards must be inserted and removed with the

power supply disconnected.

COM

Storage

module

The storage module allows remote controls to be stored and the type

of control panel application to be defined (see TECHNICAL DETAILS

on page 4).

If the control panel is replaced, the storage module being used can

be inserted in the new control panel.

WARNING: the storage module must be inserted and removed with

the power supply disconnected.

BAT

BATK1

2 x 12 V / 2 Ah

Battery operating. The batteries are kept charged when the power

supply is on. If the power supply is off, the control panel is powered

by the batteries until power is re-established or until the battery

voltage drops below the safety threshold. If this occurs, the control

panel turns off.

WARNING: the batteries must always be connected to the control

panel for charging. Periodically check the efficiency of the batteries.

NOTE: the operating temperature of the rechargeable batteries is

approximately +5°C/+40°C.

Page 9

47

IP1967EN - 2016-08-01

7. Selection

8. Signals

Description OFF ON

JR1 Display mode setting. Visualization mode. It is

only possible to visualize

the values and parameters

present.

Maintenance mode. It is

possible to visualize and

modify the values and parameters present. The entry in maintenance mode is

indicated by the permanent

switching on of the righthand point.

JR5 Built-in radio receiver. Disabled Enabled

LED ON Flashing

POWER

24 V= power supply. Indicates the transfer of data during

DMCS programming.

Page 10

48

IP1967EN - 2016-08-01

The procedure to switch on the display is as follows:

- press the ENTER key

- start of display functioning check

- visualisation of first level menu

The procedure to switch off the display is as follows:

- press the ESC key and keep it pressed

NOTE: the display switches off automatically after 60 s of inactivity.

The simultaneous pressing of the keys S and ENTER performs an opening command.

+ =

The simultaneous pressing of the keys T and ENTER performs a closing command.

+ =

The simultaneous pressing of the keys S and T performs a POWER RESET command.

(Interruption of the power supply and restart of the automation).

+ =

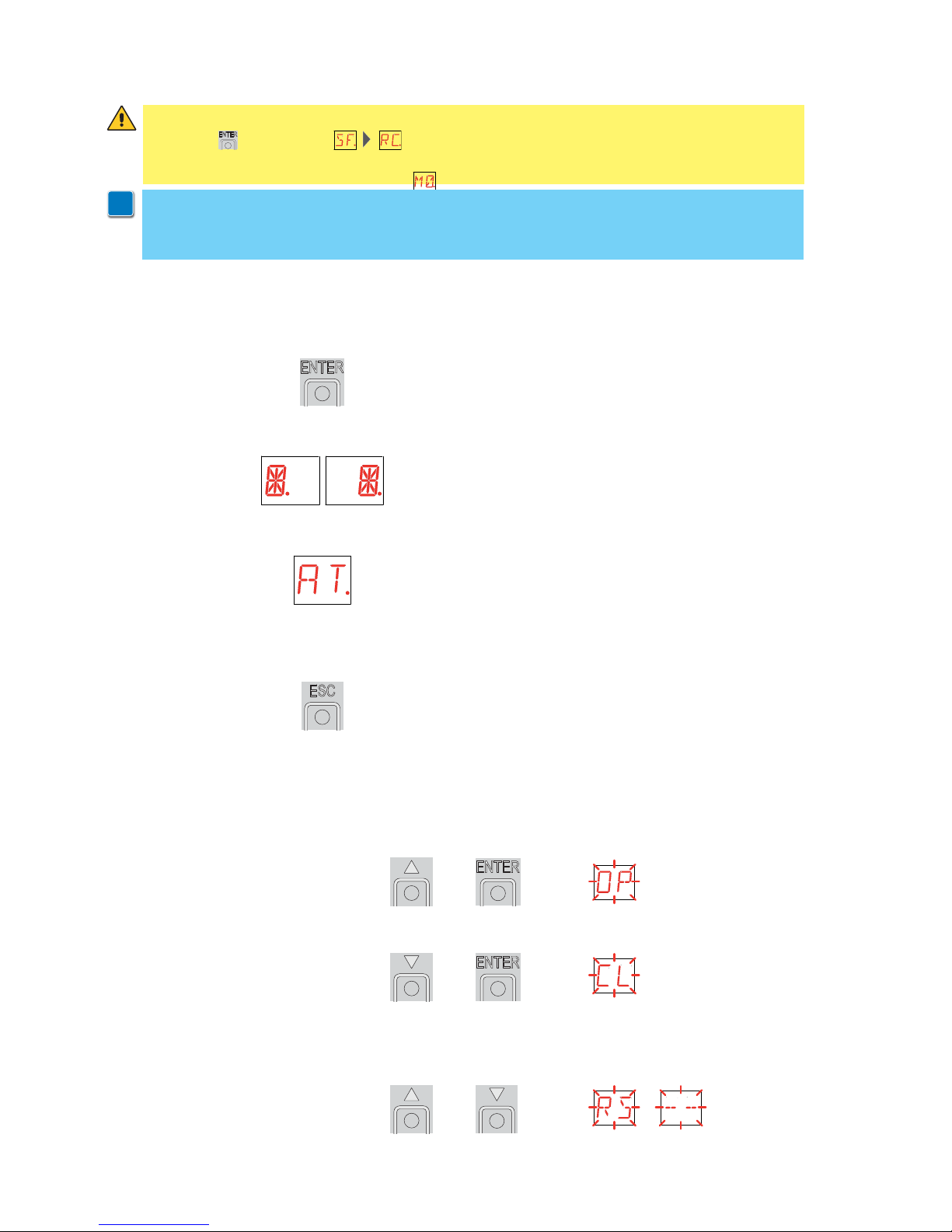

9. Adjustment

9.1 Switching on and off

9.2 Key combinations

NOTE: before making all the automation adjustments, insert the dedicated memory module

and press , or load the configuration applying to the automation installed (see

options). When the power is connected or in the case of motor non-selection, the display

will block all operations and give an error message.

WARNING: the pressure on the keys can be quick (less than 2 s) or prolonged (longer than 2

s). Unless specified otherwise, quick pressure is intended.

To confirm the setting of a parameter, prolonged pressure is necessary.

i

Page 11

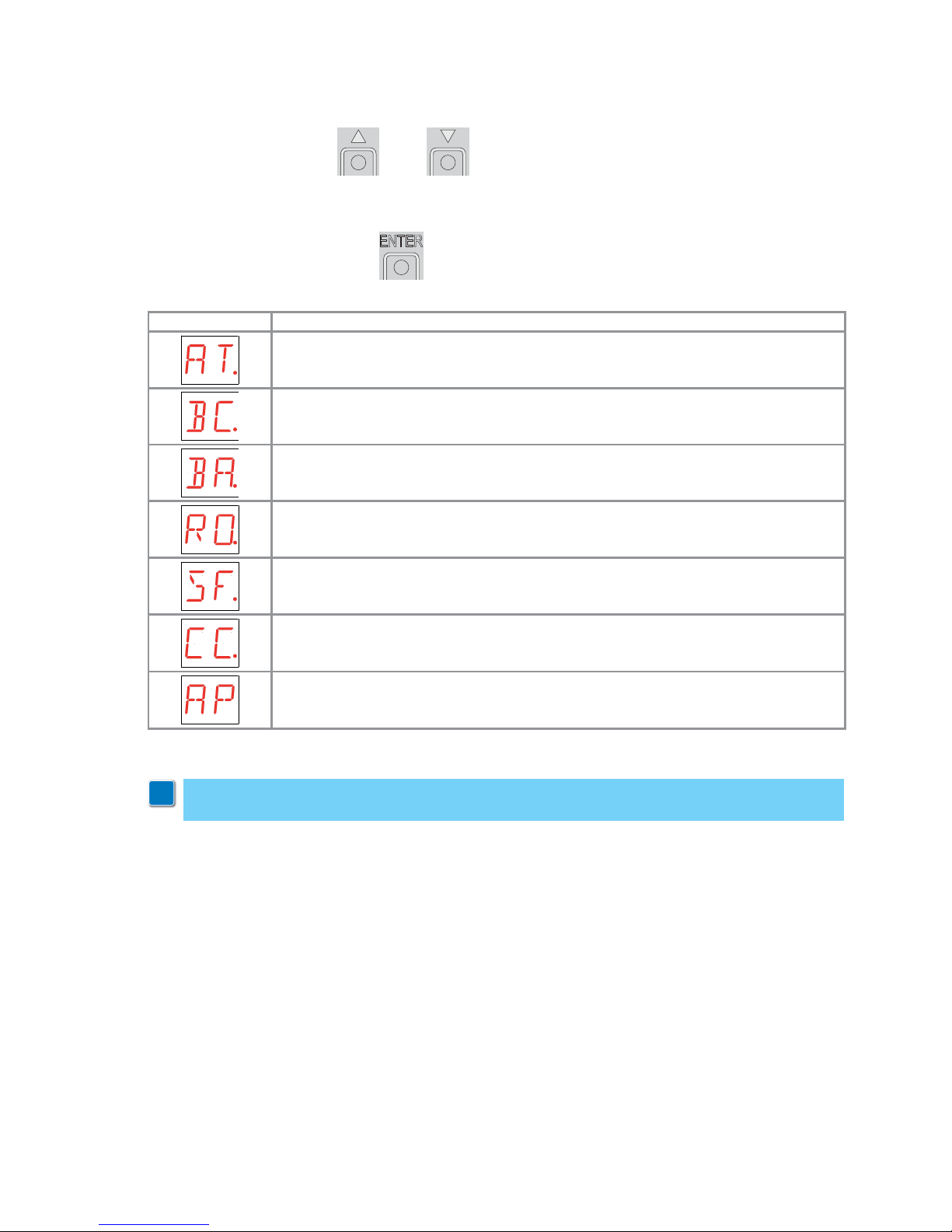

49

IP1967EN - 2016-08-01

- use the keys S and T to select the required function

- press the ENTER key to confirm

Display Description

AT - Automatic Configurations.

The menu allows you to manage the automatic configurations of the control panel.

BC - Basic Configurations.

The menu allows to visualise and modify the main settings of the control panel.

BA - Basic Adjustments.

The menu allows to visualise and modify the main adjustments of the control panel.

RO - Radio Operations.

The menu allows you to manage the radio operations of the control panel.

SF - Special Functions.

The menu allows to set the password and manage the special functions in the control

panel.

CC - Cycles Counter.

The menu allows to visualise the number of operations carried out by the automation, and

manage the maintenance interventions.

AP - Advanced Parameters.

The menu allows to visualise and modify the advanced settings and adjustments of the

control panel.

After confirming the selection, you access the second level menu.

9.3 Main menu

WARNING: it is possible that, owing to the type of automation and control panel, certain

menus are not available.

i

Page 12

50

IP1967EN - 2016-08-01

Display Description

H0 - Predefined setting for residential use 0.

2 s

H1 - Predefined setting for residential use 1.

2 s

C0 - Predefined setting for condominial use 0.

2 s

RD - Resetting the basic settings (SETTINGS RESET).

2 s

- use the keys S and T to select the required function

- press the ENTER key to confirm

9.4 Second level menu - AT (Automatic Configurations)

This selection loads predefined values for cer tain standard parameters:

AC - enabling of automatic closing : disabled

C5 - step-by-step/opening command operation : step-by-step

RM - remote control operation : step-by-step

AM - AUX coupling board operation : step-by-step

SS - selection automation status at start up : open

This selection loads predefined values for cer tain standard parameters:

AC - enabling of automatic closing : enabled

TC - setting of automatic closing time : 1 minute

C5 - step-by-step/opening command operation : step-by-step

RM - remote control operation : step-by-step

AM - AUX coupling board operation : step-by-step

SS - selection automation status at start up : closed

This selection loads predefined values for cer tain standard parameters:

AC - enabling of automatic closing : enabled

TC - setting of automatic closing time : 1 minute

C5 - step-by-step/opening command operation : opening

RM - remote control operation : opening

AM - AUX coupling board operation : opening

SS - selection automation status at start up : open

WARNING: it is possible that, owing to the type of automation and control panel, certain

menus are not available.

i

The procedures to activate the functions are described in the table.

Page 13

51

IP1967EN - 2016-08-01

- use the keys S and T to select the required function

- press the ENTER key to confirm

Display Description

VS - Selecting mechanical stops verification.

When enabled (ON), with every power supply connection

the automation automatically checks the mechanical

opening and closing end stops and/or the stop limit

switches during opening and closing operation at the

speed set with the adjustment .

During the learning operation, the display visualizes the

message .

OFF ON

NW - Selecting number of door wings.

1 2

AC - Enabling of automatic closing.

OFF ON

C5 - Step-by-step/opening command operation.

STEP-BY-STEP OPENING

RM - Radio receiver functionality.

STEP-BY-STEP OPENING

AM - AUX coupling board operation.

STEP-BY-STEP OPENING

SS - Selection of automation status at activation.

Indicates how the control panel considers the automation

at the time of switch-on, or after a POWER RESET command.

OPEN CLOSED

EL - Enablement of electric lock release stroke.

When an electric lock is present, the enablement of the

release stroke is recommended.

OFF ON

9.5 Second level menu - BC (Basic Configurations)

Page 14

52

IP1967EN - 2016-08-01

Display Description

SO - Enabling reversal safety contact functionality.

When enabled (ON) with the automation idle, if the contact

1-8 is open, all operations are prevented.

When disabled (OFF) with the automation idle, if the contact 1-8 is open, it is possible to activate the opening operation.

OFF ON

NI - Activation of NIO electronic anti-freeze system.

When enabled (ON), it maintains the efficiency of the motors even in low temperatures.

Note: for correct operation, the control panel must be exposed to the same ambient temperature as the motors.

OFF ON

64 - Functioning of safety stop/closing command.

STOP CLOSING

P2 - Functioning of partial opening command contact 1-20.

P3 - Partial opening command.

1-2 - Enablement of automatic closing

PARTIAL

OPENING

AUTOMATIC

CLOSING

EO - Functioning of electric lock/electric brake.

SC - Functioning of electric lock (functioning time set

via adjustment )

SF - Functioning of electric magnet powered with automation closed

ELECTRIC

LOCK

ELECTRIC

MAGNET

FF - Setting function of 0-14 exit.

OF - Courtesy light

ON - Flashing light

COURTESY

LIGHT

FLASHING

LIGHT

WARNING: it is possible that, owing to the type of automation and control panel, certain

menus are not available.

i

Page 15

53

IP1967EN - 2016-08-01

Display Description

MT - Selection of automation type.

NO - None

O3 - OBBI-ARC

F3 - FACIL

L3 - LUXO

NONE

FACIL

OBBI-ARC

LUXO

R1 - Adjustment of motor 1 thrust on obstacles. [%]

The control panel is fitted with a safety device which, when

it detects an obstacle:

- in opening, stops the movement with a disengagement

operation;

- in closing, before the deceleration, inverts the move-

ment;

- in closing, during the deceleration, stops or inver ts the

movement according to the type of limit switch installed.

0% 99%

R2 - Adjustment of motor 2 thrust on obstacles. [%]

The control panel is fitted with a safety device which, when

it detects an obstacle:

- in opening, stops the movement with a disengagement

operation;

- in closing, before the deceleration, inverts the move-

ment;

- in closing, during the deceleration, stops or inver ts the

movement according to the type of limit switch installed.

0% 99%

RP - Adjustment of the partial opening measurement. [%]

Adjusts the percentage of operation in relation to the total

opening of the automation.

10% 99%

9.6 Second level menu - BA (Basic Adjustments)

- use the keys S and T to select the required function

- press the ENTER key to confirm

i

WARNING: the gap between the adjustment values of the parameters may vary according

to the type of automation.

WARNING: it is essential to set the type of automation

before making the adjustments.

Page 16

54

IP1967EN - 2016-08-01

Display Description

FA - Selection of opening limit switch mode.

NO - None

RA - Deceleration limit switch

(after the activation, the door wing slows down its

movement)

SX - Stop limit switch

(after the activation, the door wing stops its movement)

PX - Proximity limit switch

(after the activation, the door wing continues as far as

the end stop)

NONE

STOP

DECELERATION

PROXIMITY

FC - Selection of closing limit switch mode.

NO - None

RA - Deceleration limit switch

(after the activation, the door wing slows down its

movement)

SX - Stop limit switch

(after the activation, the door wing stops its movement)

PX - Proximity limit switc

(after the activation, the door wing continues as far as

the end stop)

NONE

STOP

DECELERATION

PROXIMITY

VA - Setting opening speed. [V]

MIN MAX

VC - Setting closing speed. [V]

MIN MAX

VR - Setting acquisition manoeuvre speed. [V]

MIN MAX

TC - Setting automatic closing time. [s]

Adjustment occurs with intervals of varying sensitivity.

- from 0 to 59 sec with 1 sec intervals;

- from 1 to 2 min with 10 sec intervals.

0 SECONDS

1 MINUTE

59 SECONDS

2 MINUTE

M1 - Setting motor 1 manoeuvre time. [s]

Adjustment, in seconds, of the total manoeuvre time for

motor 1.

Example: = 7 seconds

= 7,5 seconds

MIN MAX

i

WARNING: adjustment occurs with a sensitivity interval of 0.5 sec, indicated by the switching on of the

right-hand point.

i

WARNING: the acquisition manoeuvre speed can

only be adjusted with the setting .

Page 17

55

IP1967EN - 2016-08-01

Display Description

M2 - Setting motor 2 manoeuvre time. [s]

Adjustment, in seconds, of the total manoeuvre time for

motor 2.

Example:

= 7 seconds

= 7,5 seconds

MIN MAX

TR - Setting motor 1 closing delay time. [s]

Adjustment, in seconds, of the delay time for starting the

manoeuvre of motor 1, in relation to motor 2.

MIN MAX

TO - Impostazione tempo di ritardo motore 2 in apertura. [s]

Regolazione in secondi del tempo di ritardo della partenza

di manovra del motore 2 rispetto al motore 1.

MIN MAX

LU - Setting switch-on time for courtesy light. [s]

Adjustment occurs with intervals of varying sensitivity.

- from 0 to 59 sec with 1 sec intervals;

- from 1 to 2 min with 10 sec intervals;

- from 2 to 3 min with 1 min intervals;

NO - Disabled

ON - Permanent switch-on, switch-off using radio

command

i

WARNING: the courtesy light switches on at the start

of each operation.

DISABLED

1 SECOND

1 MINUTE

3 MINUTES

59 SECONDS

2 MINUTES

ON

LG - Setting switch-on time for independent light. [s]

Adjustment occurs with intervals of varying sensitivity.

- from 0 to 59 sec with 1 sec intervals;

- from 1 to 2 min with 10 sec intervals;

- from 2 to 3 min with 1 min intervals;

NO - Disabled

ON - Switch-on and switch-off using radio command

i

WARNING: the switching on of the light does not depend on the start of an operation, but it is possible to

control it separately using the relevant transmitter

key.

DISABLED

1 SECOND

1 MINUTE

3 MINUTES

59 SECONDS

2 MINUTES

ON

i

WARNING: adjustment occurs with a sensitivity interval of 0.5 sec, indicated by the switching on of the

right-hand point.

Page 18

56

IP1967EN - 2016-08-01

Display Description

LR - Setting electric lock release time. [s]

ON - Active throughout the entire operation

MIN

ON

MAX

TS - Setting renewal of automatic closing time after safety

release. [%]

MIN MAX

WO - Setting opening pre-flashing time. [s]

Adjustment, in seconds, of the lead time for the switch-on

of the flashing light, in relation to the start of the manoeuvre from a voluntary command.

MIN MAX

WC - Setting closing pre-flashing time. [s]

Adjustment, in seconds, of the lead time for the switch-on

of the flashing light, in relation to the start of the manoeuvre from a voluntary command.

MIN MAX

WARNING: it is possible that, owing to the type of automation and control panel, certain

menus are not available.

i

Page 19

57

IP1967EN - 2016-08-01

Display Description

SR - Transmitter memory storage.

...x2, x3...

ER - Deleting a single transmitter.

2 s

EA - Total memory deleting.

2 s 2 s

EC - Deleting a single code. (FUTURE USE)

RE - Setting memory opening from remote control.

When enabled (ON) remote programming is activated. To

memorise new transmitters without using the control panel,

press and hold down the PRG key of an already-memorised

GOL4 transmitter for 5 seconds until the LED switches on

(within the capacity of the receiver) and press any CH key of

the new transmitter.

NOTE: make sure that undesired transmitters are not accidently memorized.

OFF ON

MU - Setting the maximum number of transmitters that

can be memorized on a memor y module.

It is possible to memorise up to 100 or 200 rolling code

transmitters.

200 100

- use the keys S and T to select the required function

- press the ENTER key to confirm

9.7 Second level menu - RO (Radio Operations)

It is possible to directly access the Transmitter memory storage menu with the display switched off, but only with Display visualization mode set at 00 or 03:

- by transmitting a remote control not present in the memory,

- by transmitting an unstored channel of a remote control already present in the memory.

The procedures to activate the functions are described in the table.

NOTE: it is necessary to set to allow the

system configuration to be saved on the memory module

Page 20

58

IP1967EN - 2016-08-01

Display Description

C1 - Setting key 1 function of memorized transmitter.

C2 - Setting key 2 function of memorized transmitter.

C3 - Setting key 3 function of memorized transmitter.

C4 - Setting key 4 function of memorized transmitter.

NO - None

1-3 - Opening command

1-4 - Closing command

1-5 - Step-by-step command

P3 - Partial opening command

LG - Courtesy light status change command

1-9 - STOP command

i

WARNING: 1-3 (opening) and 1-5 (step-by-step) are

binary options and are dependent by the

selection.

NONE

CLOSING

PARTIAL

STOP

OPENING

STEP-BY-STEP

COURTESY

LIGHT

RK - Navigation via transmitter keyboard.

With the display switched off, quickly type the sequence of

keys 3 3 2 4 1 using the desired memorized transmitter.

Note: it is recommended to use a dedicated transmitter.

To test the new configuration, switch off the display and give

an open command using key 3.

12

34

Navigation via transmitter keyboard is automatically disabled after 4 minutes of inactivity or by setting .

OFF ON

WARNING: during navigation via transmitter keyboard, NONE of the memorized transmitters are active.

i

Warning: it is possible that, owing to the type of automation and control panel, certain menus

are not available.

Page 21

59

IP1967EN - 2016-08-01

Display Description

SP - Setting the password

IP - Inserting the password.

RD - Resetting the basic settings (SETTINGS RESET).

EU - Deleting of the user configurations and the last configuration set present in the

memory module.

SV - Saving user configuration.

Selecting it is possible to save up to 2 personalised configurations

in the memory positions and only with the storage module present on the

control panel.

(

EXAMPLE

)

2 s

2 s

(

EXAMPLE

)

2 s

2 s

2 s

(

EXAMPLE

)

9.8 Second level menu - SF (Special Functions)

- use the keys S and T to select the required function

- press the ENTER key to confirm

The procedures to activate the functions are described in the table.

It is possible to annul the set password by selecting the sequence JR1=ON,

JR1=OFF, JR1=ON.

i

i

Note: this is only possible when the password is not set.

The setting of the password prevents unauthorised personnel from accessing

selections and adjustments.

Note: this is only possible when the password is set.

When the password is not inserted, it is possible to access the visualisation

mode regardless of the selection made with JR1.

When the password is inserted, it is possible to access the maintenance mode.

Page 22

60

IP1967EN - 2016-08-01

Display Description

RC - Loading configuration.

It is possible to load the configurations previously saved, or load the predefined settings available in the memory positions , , and . The predefined settings are as follows:

: OBBI

: FACIL

: LUXO

: ARC

Loading a predefined setting, standard average values are automatically set for certain

parameters (type of automation, operation speed, operation times and deceleration

times).

RL - Loading the last configuration set

CU - Viewing the electronic panel’s firmware version.

= Release 0.3.4 (example)

2 s

2 s

NOTE: the control panel automatically saves the last configuration set, and

keeps it memorised in the storage module. In the event of a fault or the replacement of the control panel, it is possible to restore the last configuration of

the automation by inserting the storage module and loading the last configura-

tion set.

i

i

Note: view only.

WARNING: it is possible that, owing to the type of automation and control panel, certain

menus are not available.

Page 23

61

IP1967EN - 2016-08-01

Display Description

CV - View total manoeuvres counter.

= 241.625 manoeuvres (example)

CA - Setting the maintenance alarm interval. (max 500.000 partial manoeuvres)

= 08 08 50 00 = 85.000 manoeuvres (ex)

= 50

= 00

It is possible to set the required number of operations for the signalling of the maintenance alarm.

OA - Selecting maintenance alarm viewing mode.

00 - Display

(display alarm message )

01 - Flashing light

(when automation is closed it flashes 4 times every 60

minutes)

02 - Open gate indicator light

(when automation is closed it flashes 4 times every 60

minutes)

DISPLAY

INDICATOR

FLASHING

CP - View partial manoeuvres counter.

= 71.625manoeuvres (example)

ZP - Resetting partial manoeuvres counter.

To ensure correct operation, it is recommended to reset the partial manoeuvres counter:

- after each maintenance intervention,

- after each setting of the maintenance alarm interval.

2 s

(

EXAMPLE

)

(

EXAMPLE

)

2 s

9.9 Second level menu - CC (Cycles Counter)

- use the keys S and T to select the required function

- press the ENTER key to confirm

The procedures to activate the functions are described in the table.

i

Note: view only.

i

i

Note: view only.

Warning: it is possible that, owing to the type of automation and control panel, certain

menus are not available.

Page 24

62

IP1967EN - 2016-08-01

- use the keys S and T to select the required function

- press the ENTER key to confirm

Display Description

AA - Activating advanced parameters menu.

OFF ON

ET - Enabling of safety test (SOFA1-A2 card).

OFF ON

DO - Setting of disengagement on obstacle during opening. [s]

MIN MAX

DC - Setting of disengagement on obstacle during closing. [s]

MIN MAX

PP - Step-by-step sequence with commands 1-5.

OFF - Opening-Stop-Closing-Opening

ON - Opening-Stop-Closing-Stop-Opening

OFF ON

S5 - Duration of STOP in step-by-step sequence with commands 1-5.

TEMPORARY PERMANENT

R9 - Enablement of automatic closing after command 1-9

(STOP).

When enabled (ON), after a command 1-9 the automation

carries out the automatic closing (if enabled), after the set

time.

OFF ON

TA - Adjustment acceleration phase. [%]

FAST SLOW

9.10 Second level menu - AP (Advanced Parameters)

i

WARNING: the gap between the adjustment values of the parameters may vary according

to the type of automation.

Given the complexity of the parameters, use of the Advanced Parameters menu is recommended only for qualified technical personnel.

i

NOTE: activation necessary before being able to scroll

through the AP menu.

Page 25

63

IP1967EN - 2016-08-01

Display Description

TP - Setting of automatic closing time after partial opening. [s]

Adjustment occurs with intervals of varying sensitivity.

- from 0 to 59 sec with 1 sec intervals;

- from 1 to 2 min with 10 sec intervals.

0 SECONDS

1 MINUTE

59 SECONDS

2 MINUTES

PO - Approaching/deceleration speed during opening. [V]

MIN MAX

PC - Approaching/deceleration speed during closing. [V]

MIN MAX

OB - Deceleration/braking time during opening. [s]

MIN MAX

CB - Deceleration/braking time during closing. [s]

MIN MAX

DS - Setting of display viewing mode.

00 - No display

01 - Commands and safety devices with radio test (see

paragraph 10.2)

02 - Automation status (see paragraph 10.1)

03 - Commands and safety devices (see paragraph 10.2)

NONE

STATUS

RADIO TEST

COMMANDS

D6 - Selecting device connected to terminals 1-6.

NO - None

SE - Safety edge

PH - Photocells

NONE

PHOTOCELLS

EDGE

D8 - Selecting device connected to terminals 1-8.

NO - None

SE - Safety edge

PH - Photocells

NONE

PHOTOCELLS

EDGE

NOTE: setting 01 allows to view the reception of a radio

transmission for checking its range.

Page 26

64

IP1967EN - 2016-08-01

Display Description

SM - Selection of the operating mode of photocell terminals

1-6. (only with ).

00 - During manoeuvre, the opening of the safety contact

stops movement with disengagement.

01 - During manoeuvre, the opening of the safety contact

stops movement with disengagement. When the contact

is reclosed the interrupted manoeuvre resumes.

02 - During manoeuvre, the opening of the safety contact

stops movement with disengagement. When the contact

is reclosed an opening manoeuvre starts.

03 - During a closing manoeuvre, the opening of the safety

contact reverses the movement.

STOP +

DISENGAGE

STOP +

OPENING

STOP +

RESUME

REVERSE

CLOSING

TN - Setting intervention temperature for NIO anti-freeze

system. [°C]

Adjustment of the working temperature of the control

panel.

DOES NOT refer to outside temperature.

-6 ºC +6 ºC

TB - View control panel temperature.

DO NOT USE

OFF ON

OL - Selecting open gate indicator light mode.

When set ON, the light is switched off when automation is

closed; it is switched on when automation is open and during

the opening and closing phases.

When set OFF the light is switched off when automation is

closed; it is switched on when automation is open , it flashes

during the opening and closing phases.

FLASHING ON

i

WARNING: it is possible that, owing to the type of automation and control panel, certain

menus are not available.

Page 27

65

IP1967EN - 2016-08-01

Display Description

Automation closed.

Automation open.

Automation stopped in intermediate position.

Automation closing.

Automation opening.

Automation closing from partial opening.

Automation in partial opening.

Automation partially open.

10. Display viewing mode

10.1 Automation status display

10.2 Commands and safety devices display

i

i

i

WARNING: it is possible that, owing to the type of automation and control panel, certain

menus are not available.

WARNING: the automation status display mode is visible only with the Display viewing mode

set on 02.

WARNING: the commands and safety device display mode is only visible with the Display

viewing mode set on 01 or 03.

Display Description

1-2 - Automatic closing activation command.

1-3 - Opening command.

1-4 - Closing command.

Page 28

66

IP1967EN - 2016-08-01

1-5 - Step-by-step command.

1-6 - Safety with opening and closing stop.

1-8 - Safety with closing reversal.

1-9 - STOP command.

P3 - Partial opening command.

3P - Hold-to-run opening command.

4P - Hold-to-run closing command.

RX - Radio reception (of any memorised transmitter key present in the memory module).

NX - Radio reception (of any key not memorised).

CX - AUX coupling board command reception.

F1 - Generic limit switch relating to motor 1.

F2 - Generic limit switch relating to motor 2.

O1 - Detection of an obstacle by motor 1 or arrival of motor 1 at mechanical stop.

O2 - Detection of an obstacle by motor 2 or arrival of motor 2 at mechanical stop.

RV - Enablement/disablement of built-in radio receiver via JR5.

MQ - Acquisition of mechanical stops in progress.

HT - Heating of the motors (NIO function) in progress.

J1 - Variation of the JR1 jumper status.

1C - Closing manoeuvre 1 wing at a time.

Page 29

67

IP1967EN - 2016-08-01

Type of

alarm

Display Description Remedy

Mechanical alarm

M0 - Automation type not selected. If the dedicated memory module is present

press

.

Select a type of automation.

MB - Absence of motor 1 during an operation.

Check the connection of motor 1.

MC - Absence of motor 2 during an operation (if 2-motor functioning has been set).

Check the connection of motor 2.

MD - Irregular functioning of motor 1

opening limit switch.

Check the connection of the motor 1 opening limit switch.

ME - Irregular functioning of motor 1 closing limit switch.

Check the connection of the motor 1 closing limit switch.

MF - Irregular functioning of motor 2

opening limit switch.

Check the connection of the motor 2 opening limit switch.

MG - Irregular functioning of motor 2 closing limit switch.

Check the connection of the motor 2 closing limit switch.

MH - Incorrect wings overlap. Verify that the motor which opens first (M1)

is connected as shown in fig. 1.

MI - Detection of third consecutive obstacle.

Check for the presence of permanent obstacles along the automation path.

Radio operations

alarm

R0 - Insertion of a memory module containing more than 100 memorized transmitters.

Warning: the setting is

automatic.

To save the set configurations in the memory module, cancel a few memorized

transmitters to bring the total lower than

100.

Set .

R3 - Memory module not detected. Insert a memory module.

R4 - Memory module not compatible with

control panel.

Insert a compatible memory module.

10.3 Alarms and anomalies display

i

WARNING: alarms and anomalies are displayed when any display selection is made. The

signaling of alarm messages takes priority over all other displays.

Page 30

68

IP1967EN - 2016-08-01

Type of

alarm

Display Description Remedy

Accessories alarm

A0 - Failure of test of safety sensor on

contact 6.

Check the device SOFA1-A2 is working

correctly.

If the supplementar y SOF card is not in-

serted, check the safety test is disabled.

A3 - Failure of test of safety sensor on

contact 8.

Check the device SOFA1-A2 is working

correctly.

If the supplementar y SOF card is not in-

serted, check the safety test is disabled.

A7 - Incorrect connection of contact 9 to

terminal 41.

Connect the 1-9 contact

Service

V0 - Request for maintenance intervention.

Proceed with the scheduled maintenance

intervention.

Page 31

69

IP1967EN - 2016-08-01

11.1 Make a jumper for safety contacts 1-6, 1-8, 1-9. Set JR1=ON, JR5=ON.

11.2 If limit switches are used, adjust them by manually moving the wings as described here:

- deceleration limit switch: activation of the limit switch must occur before the mechanical

doorstop,

- stop limit switch: activation of the stop limit switch must occur in the open/close position of

the wings,

- proximity limit switch: activation of the proximity limit switch must occur near the mechanical

doorstop.

11.3 Switch on power.

Warning: the following operations are performed with no safety devices.

11.4 If the dedicated memory module is present, press , if it is not present, load the

configuration related to the type of automation installed.

11.5 If the automation has 1 door wing, set .

11.6 Verify the setting.

11.7 With the automation idle in the intermediate position, give a closing command + , and

check the door wings move in the correct direction. In the event of an incorrect connection,

invert the polarity of the motor.

Note: the first closing operation after a power supply interruption is carried out with one

door wing at a time, at reduced speed.

11.8 Give an opening command + and verify that the automation carries out the operation

at reduced speed stopping at the mechanical doorstops during the opening phase.

11.9 Load the predefined setting most suitable for system available in the menu.

11.10 If limit switches are used, define their use by means of settings and .

11.11 In order to save the configurations in the memory module it is necessary to set

.

11.12 To modify the operation and deceleration speed settings, the automatic closing times, and

the thrust on obstacles, consult the menus.

11.13 Connect the safety devices (removing all relevant jumpers) and verify their correct operation.

Note: ensure that the forces exerted by the door wings are compliant with EN12453-EN12445

regulations.

11.14 If desired, memorize the radio commands with command (refer to chapter 12).

11.15 Connect any other accessories and check operation.

11.16 Once the start up and check procedures are completed, close the container.

11. Starting

WARNING: the system must have mechanical doorstops of appropriate strength or limit

switches must be installed.

WARNING: if this control panel is being used to replace a faulty one, it is possible to reset the

last automation configuration by inserting the storage module of the old control panel in the

housing on the new one, then loading the last configuration set with the

command.

Page 32

70

IP1967EN - 2016-08-01

12. Troubleshooting

Problem Possible cause Alarm

signalling

Operation

The automation does not

open or close.

No power. Check power supply cable.

Short circuited accessories. Disconnect all accessories

from terminals 0-1 (a voltage

of 24V= must be present) and

reconnect them one at a time.

Contact Technical Service

Blown line fuse. Replace fuse.

Safety contacts are open.

Check that the safety contacts

are closed correctly (NC).

Safety contacts not correctly

connected or self-controlled

safety edge not functioning

correctly.

Check connections to terminals

6-8 on control panel and connections to the self-controlled

safety edge.

Photocells activated.

Check that the photocells are

clean and operating correctly.

The automatic closing does

not work.

Issue any command. If the

problem persists, contact

Technical Service

Faulty motor

Check motor connection, if

the problem persists, contact

Technical Service.

The external safety devices

are not activated.

Incorrect connections between the photocells and the

control panel.

Check that

/ is displayed

Connect NC safety contacts

together in series and remove

any jumpers on the control

panel terminal board.

Check the

→ and

→ setting

The automation opens/closes briefly and then stops.

There is a presence of friction.

Manually check that the automation moves freely and check

the

/ adjustment

Contact Technical Service

The remote control has limited range and does not work

with the automation moving.

The radio transmission is impeded by metal structures and

reinforced concrete walls.

Install the antenna outside.

Replace the transmitter batteries.

Page 33

71

IP1967EN - 2016-08-01

The remote control does not

work

No storage module or incorrect storage module.

Switch the automation off and

plug in the correct storage

module.

Check the correct memorisation of the transmitters on the

built-in radio. If there is a fault

with the radio receiver that is

built into the control panel, the

remote control codes can be

read by removing the storage

module.

Page 34

72

IP1967EN - 2016-08-01

When the E2H control panel is

used in applications for double

wings automations with overlapping it is possible to make

the following connections.

(Fig. 13.1) Installation with mechanical doorstops in opening and closing phases, without

the use of electric limit switches.

(Fig. 13.2) Installation with mechanical doorstop in closing phases, with the use of electric

limit switches.

36 35 34 33 32 31

24V=24V=

Motor 1Motor 2

12

36 35 34 33 32 31

24V=24V=

Motor 1Motor 2

12

Fig. 13.1

Fig.13.2

13. Example application of automation with two

swinging door wings

Page 35

73

IP1967EN - 2016-08-01

When the E2H control panel is

used in applications for single

wing automations it is possible

to make the following connections.

(Fig. 14.1) Installation with mechanical doorstops in opening and closing phases, without

the use of electric limit switches.

(Fig. 14.2) Installation with mechanical doorstop in closing phases, with the use of electric

limit switches.

33 32 31

24V=

1

Motor 1

33 32 31

1

24V=

Motor 1

Fig. 14.1

Fig. 14.2

14. Example applications for automation with

one swinging door wing

Page 36

IP1967EN - 2016-08-01

Entrematic Group AB

Lodjursgatan 10

SE-261 44, Landskrona

Sweden

www.entrematic.com

Loading...

Loading...