Page 1

IP2266EN • 2019-06-14

Technical manual

Ditec DAS200

DAS200HD-DAS200RF-DAS200RG

Sliding doors automation

(Original instructions)

www.entrematic.com

Page 2

Contents

Subject Page

1. General safety precautions 3

Declaration of incorporation of partly completed machinery 4

2. Technical data 5

2.1 Operating instructions 5

3. Standard installation 6

4. Main components 7

5. Installing the automation 8

5.1 Installing / Removing the cover 8

5.2 Installation/removal of the cover if installed side presence sensor 9

6. Fastening of box using supplied wing anchoring brackets 10

6.1 Examples with DAS11M8 11

6.2 Examples with DAS18M8 12

6.3 Example with DAS35M8 13

6.4 Example with DAS40M8 14

6.5 Example with ACV 14

7. Preparation of the glass door wing 15

7.1 Installing and adjusting the door wings 16

7.2 Installing the floor guides 18

7.3 Checking and adjusting the belt tension 19

7.4 Sensor positioning on the cover 19

7.5 External sensor cable fixing 19

8. Electrical connections 20

8.1 Electrical connections 21

8.2 Control panel commands 23

8.2.1 Commands 23

8.3 DAS902MP plus module (optional) 25

8.4 DAS902MP commands 26

9. Adjustment and selection of control functions 28

9.1 Display test 29

9.2 Status indication on the display 29

10. Start up 30

11. Parameters 32

11.1 Configuration parameters according to function 32

11.2 Main control board parameters 36

12. Example of connection 46

13. Troubleshooting 48

13.1 Active error indication 49

14. Routine maintenance plan 53

EN

Key

This symbol indicates instructions or notes regarding safety, to which special attention must be paid.

This symbol indicates useful information for the correct functioning of the product.

i

2

IP2266EN

Page 3

1. General safety precautions

Failure to respect the information given in this manual

may cause personal injury or damage to the device.

Keep these instructions for future reference

This assembly and installation manual is intended exclusively for the use of qualified personnel.

Installation, electrical connections and adjustments must be performed by qualified personnel, in

accordance with Good Working Methods and in compliance with the current regulations.

Read the instructions carefully before installing the product.

Incorrect installation could be dangerous.

The packaging materials (plastic, polystyrene, etc.) should not be discarded in the environment

or left within reach of children, as they are a potential source of danger.

Before installing the product, make sure it is in perfect condition.

Do not install the product in explosive areas and atmospheres: the presence of inflammable gas

or fumes represents a serious safety hazard.

Before installing the motorisation device, make all the necessary structural modifications to

create safety clearance and to guard or isolate all the crushing, shearing, trapping and general

hazardous areas.

Make sure the existing structure is up to standard in terms of strength and stability. The motorisation device manufacturer is not responsible for failure to observe Good Working Methods when

building the frames to be motorised, or for any deformations during use.

The safety devices (photocells, safety edges, emergency stops, etc.) must be installed taking into

account the applicable laws and directives, Good Working Methods, installation premises, system

operating logic and the forces developed by the motorised door or gate.

The safety devices must protect against crushing, cutting, trapping and general danger areas of

the motorised door or gate.

Display the signs required by law to identify hazardous areas.

Each installation must bear a visible indication of the data identifying the motorised door or gate.

When necessary, connect the motorised door or gate to an effective earthing system that complies

with the current safety standards.

During installation, maintenance and repair operations, cut off the power supply before

opening the cover to access the electrical parts.

The automation protection casing must be removed by qualified personnel only.

The electronic parts must be handled using earthed antistatic conductive arms. The manufac-

turer of the motorisation device declines all responsibility if component parts not compatible

with safe and correct operation are fitted.

Only use original spare parts when repairing or replacing products.

The installer must supply all information concerning the automatic, manual and emergency operation of the motorised door or gate, and must provide the user with the operating instructions.

IP2266EN

3

EN

Page 4

Declaration of incorporation of partly completed

g

Mat

Mat

teo

t

machinery

We:

Entrematic Group AB

Lodjursgatan 10

SE-261 44 Landskrona

Sweden

declare under our responsibility that the following types of equipment:

Ditec DAS200, Ditec DAS200HD, Ditec DAS200RF, Ditec DAS200RG

comply with the following directives:

2014/30/EU Electromagnetic Compatibility Directive (EMCD)

2006/42/EC Machinery Directive (MD) for the following essential health and safety requirements: 1.1.2, 1.2.1, 1.2.2, 1.2.3, 1.2.4.2, 1.2.6, 1.3.9, 1.4.3, 1.7.2, 1.7.4, 1.7.4.1, 1.7.4.2

Technical documentation for safe integration supplied.

Harmonised European standards which have been applied:

EN 60335 -1:2012+A13:2017 EN ISO 13849 -1:2015 EN 61000 -6-2:2005

EN 60335-2-103:2015 EN 16005:2012/AC:2015 EN 61000 -6-3:2007+A1:2011

Other standards or technical specifications, which have been applied:

IEC 60335-1: 2010 ed.5 IEC 60335-2-103:2006+A1:2010 AutSchR: 1999

DIN 18650-1:2010 DIN 18650-2:2010

The production process aims to guarantee that the equipment complies with the technical

documentation.

The production process is regularly assessed by an independent body.

The equipment must not be put into service until the final door system installed has been

declared compliant with the Machinery Directive 2006/42/EC by the installer.

Person in charge of technical data sheet:

Matteo Fino E-mail: matteo.fino@entrematic.com

Entrematic Group AB

Lodjursgatan 10

SE-261 44 Landskrona

Sweden

Place Date Signature Position

Landskrona 2018-06-14 Matteo Fino Entrance Automation President

Fi

4

EN

IP2266EN

Page 5

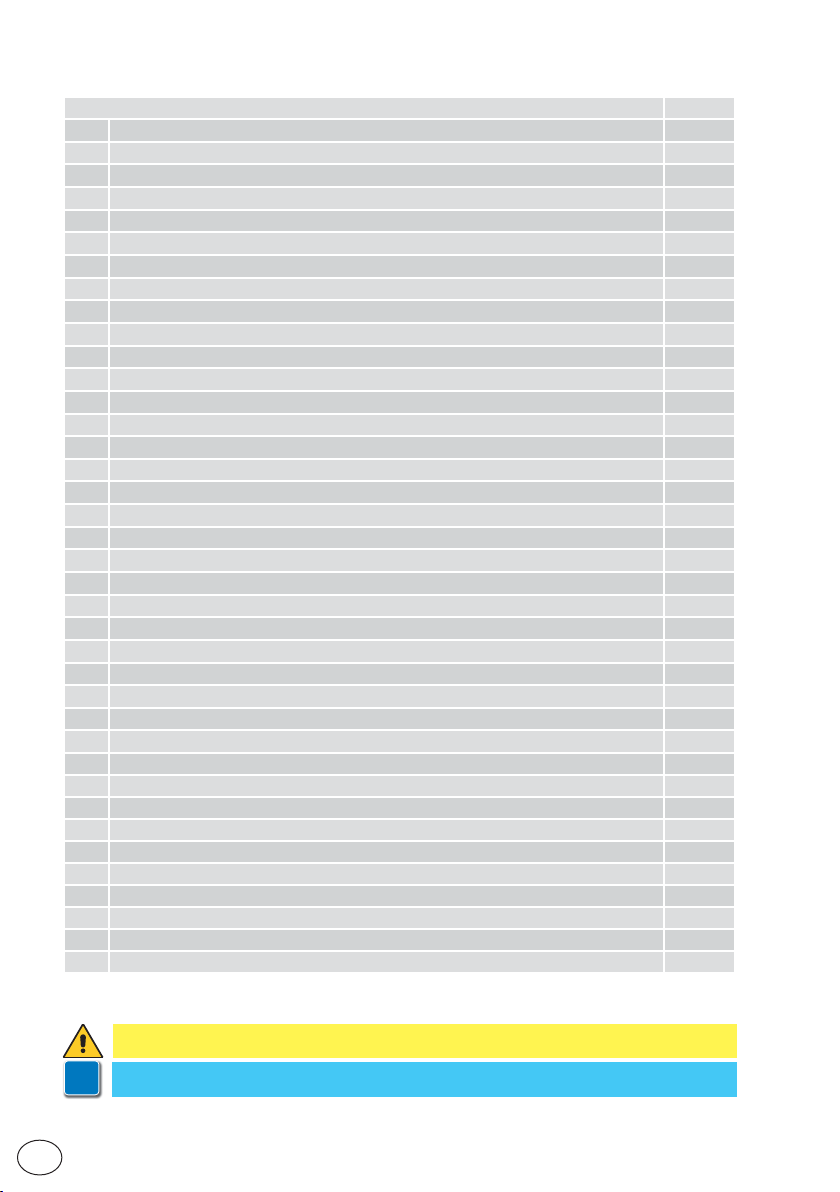

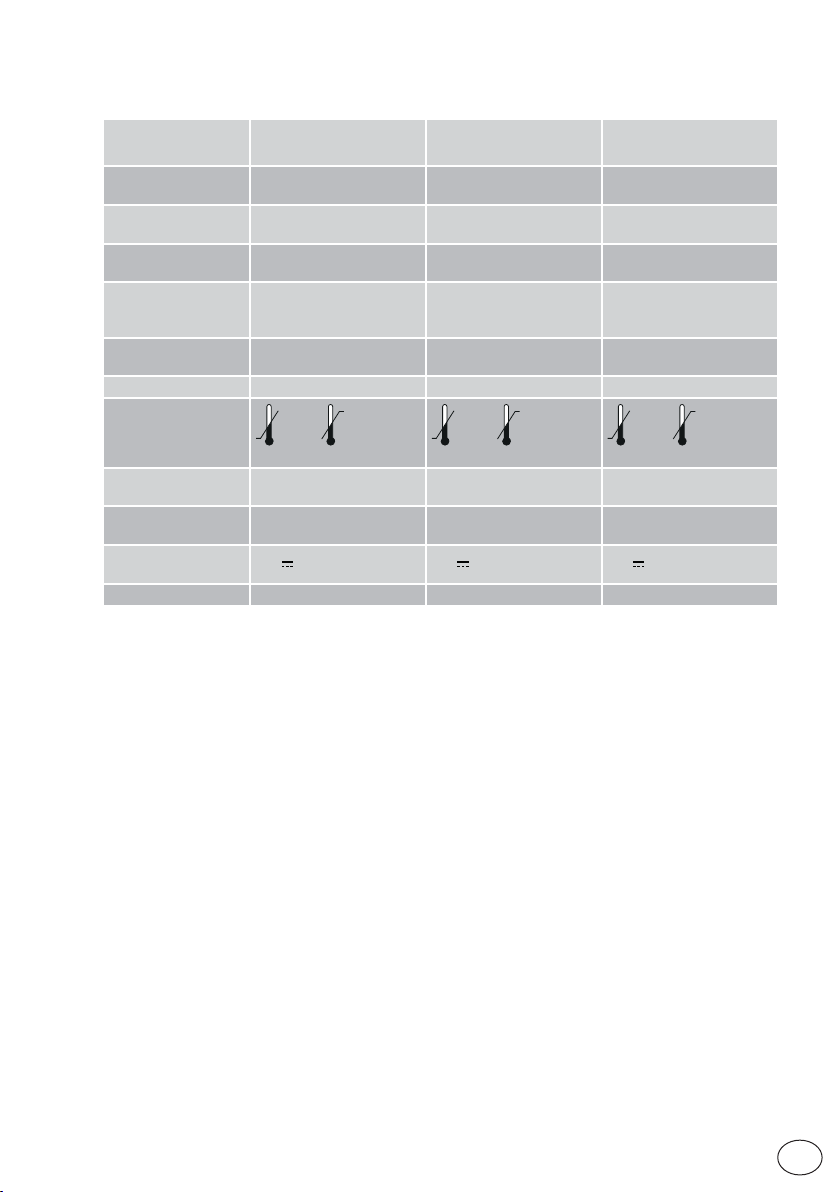

2. Technical data

Ditec DAS200

Power supply

Power supply rated

power (PS)

Max Opening speed

(2 door wings)

Maximum load

Service class

Intermittence S3=100% S3=100% S3=100%

Temperature

Degree of protection

Control panel

(MCU/MCU-ER)

Accessories power

supply

Durability test 1.000.000 cycles 1.000.000 cycles 1.000.000 cycles

110V~ / 240V~

50/60Hz

75W 150W 150W

1,3m/s 1,4m/s 1,4m/s

120kg (1 wing)

200kg (2 wings)

5

(HEAVY DUTY)

-20°C +50°C

(FOR INTERNAL USE ONLY)

1DAS20QE 1DAS20HDQE 1DAS20RGQE

24V

IP20

0,64A 24V 1A 24V 1A

Ditec DAS200HD

Ditec DAS200RF

110V~ / 240V~

50/60Hz

150kg (1 wing)

DAS200HD 280kg (2 wings)

DAS200RF 240kg (1 wing)

5

(HEAVY DUTY)

-20°C +50°C

IP20

(FOR INTERNAL USE ONLY)

Ditec DAS200RG

110V~ / 240V~

50/60Hz

150kg (1 wing)

280kg (2 wings)

5

(HEAVY DUTY)

-20°C +50°C

IP20

(FOR INTERNAL USE ONLY)

2.1 Operating instructions

Service class: 5 (minimum 5 years of working life with 600 cycles per day).

Applications: HEAVY DUTY (for entrances with very intense pedestrian use).

• The performance characteristics refer to the recommended weight (approx. 2/3 of the maximum weight allowed). When used with the maximum permissible weight a reduction in

the above mentioned per formance can be expected.

• The service class and number of consecutive cycles should be taken merely as a rough

indication. having been statistically determined under average operating conditions, and

are therefore not necessarily applicable to specific conditions of use.

• Each automatic entrance has variable elements such as: friction, balancing and environmental factors, all of which may substantially alter the performance characteristics of

the automatic entrance or curtail its working life or parts thereof (including the automatic

devices themselves). The installer should adopt suitable safety conditions for each particular installation.

IP2266EN

5

EN

Page 6

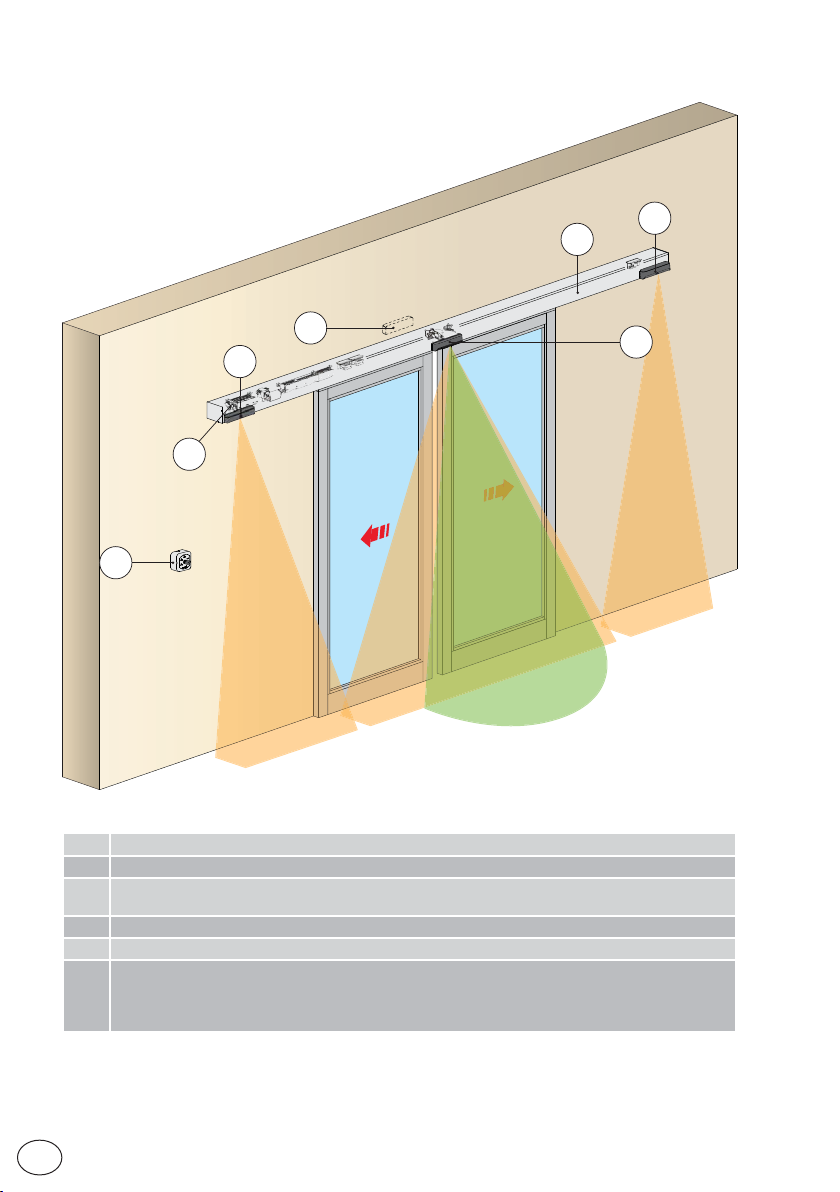

3. Standard installation

4

1

3

2

4

A

5

Ref. Description

1 Automation for sliding doors

2

Combined opening and safe closing sensor

3

4 Safe opening sensor

5 Safety photocell

A Connect the power supply cable to a type-approved omnipolar switch with category III insulation and

a contact opening distance of at least 3 mm.

The connections to the mains and low voltage wires must be made on an independent channel separated from the connections to the command and safety devices (SELV = Safety Extra Low Voltage).

EN

IP2266EN

6

Page 7

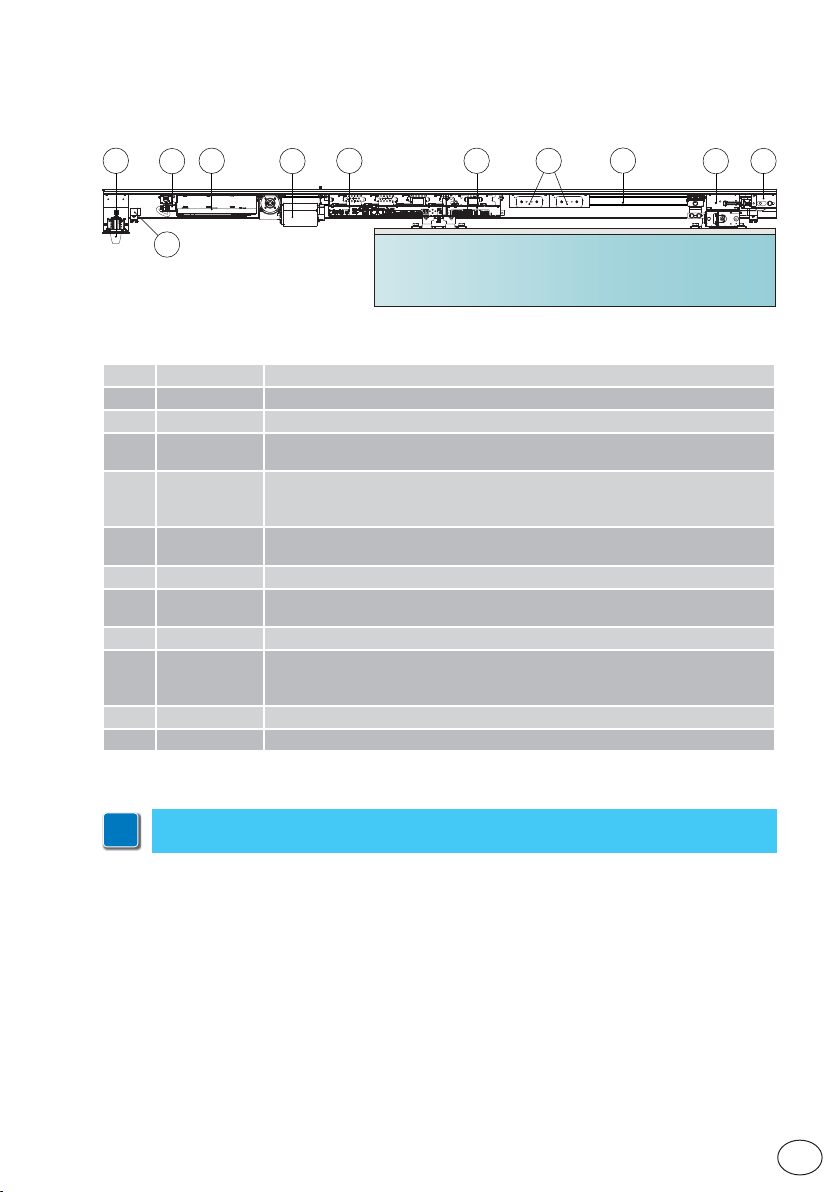

4. Main components

6

8

7

10 11

9

16

Ref. Code Description

6 DASLOKSB Built-in manual release device (optional)

7- Mains power supply

1DAS20AL

8

1DAS20HAL

1DAS20MR

9

1DAS20HMR

1DAS20RGMR

1DAS20QE

10

1DAS20RGQE

11 DAS902MP DAS902MP plus module

DAS901BAT1

12

DAS902BAT2

13 DAS802B50 Drive belt

DAS802LOK

14

DAS802LOKA

DAS802LOKB

15 - Belt transmission

16 - Mechanical stops

75W power supply unit (PS)

150W power supply unit (PS)

DAS200 gearmotor

DAS200HD gearmotor

DAS200RG gearmotor

DAS200-DAS200HD-DAS200RF (MCU) control panel

DAS200RG control panel (MCU-ER)

12V batteries

24V batteries

Standard lock. Locked with power - LD

Anti-panic lock. Locked without power - LDP

Bi-stable lock-LDB

12

13

14

15

IP2266EN

NB: the given operating and performance features can only be guaranteed with the

i

use of DITEC Entrematic accessories and safety devices.

7

EN

Page 8

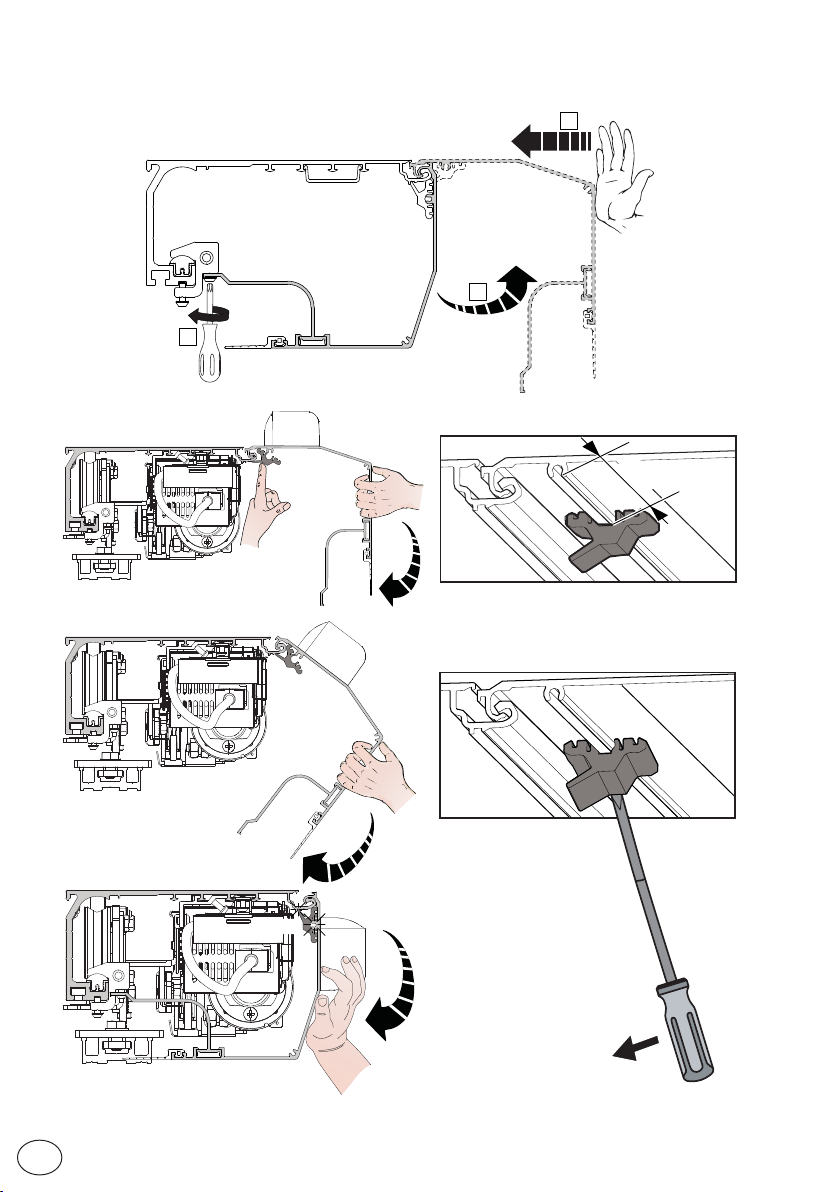

5. Installing the automation

5.1 Installing / Removing the cover

1

• Secure and unsecure the open cover as shown below.

3

2

500

EN

CLICK

IP2266EN

8

Page 9

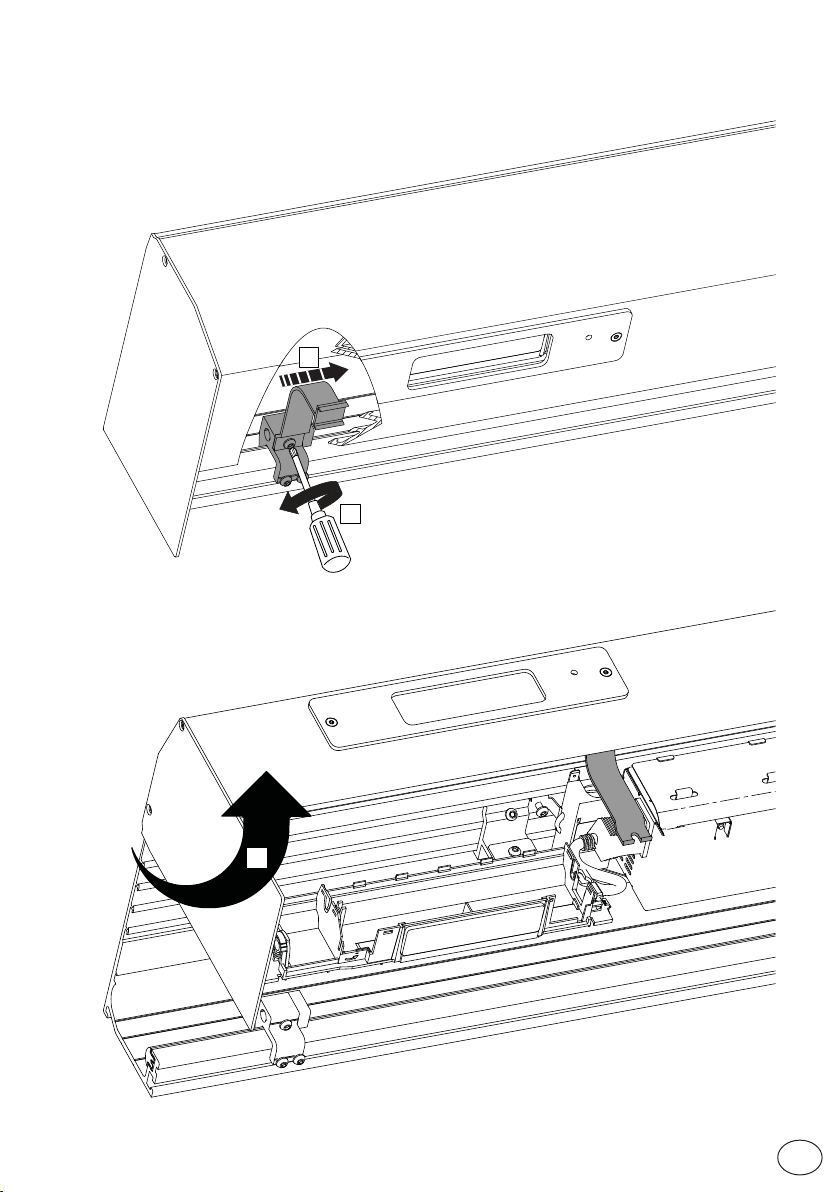

5.2 Installation/removal of the cover if installed side presence

sensor

2

1

IP2266EN

3

9

EN

Page 10

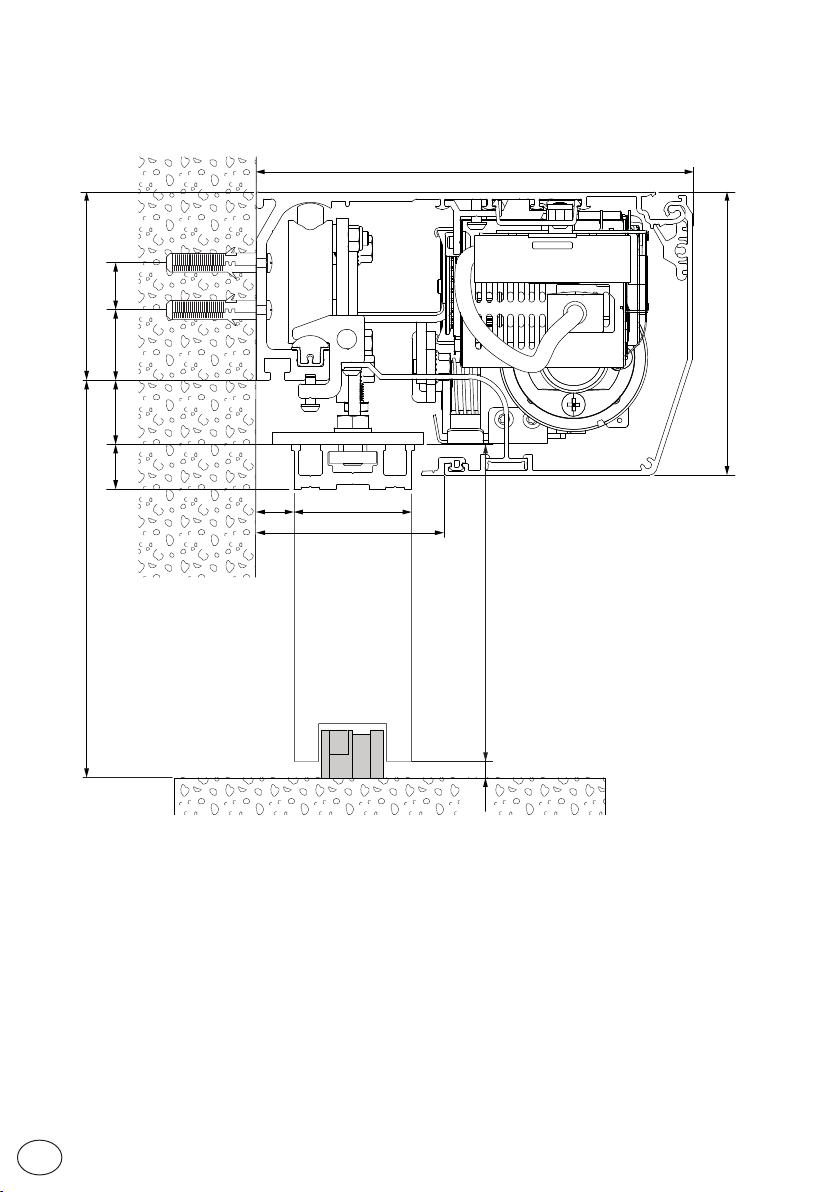

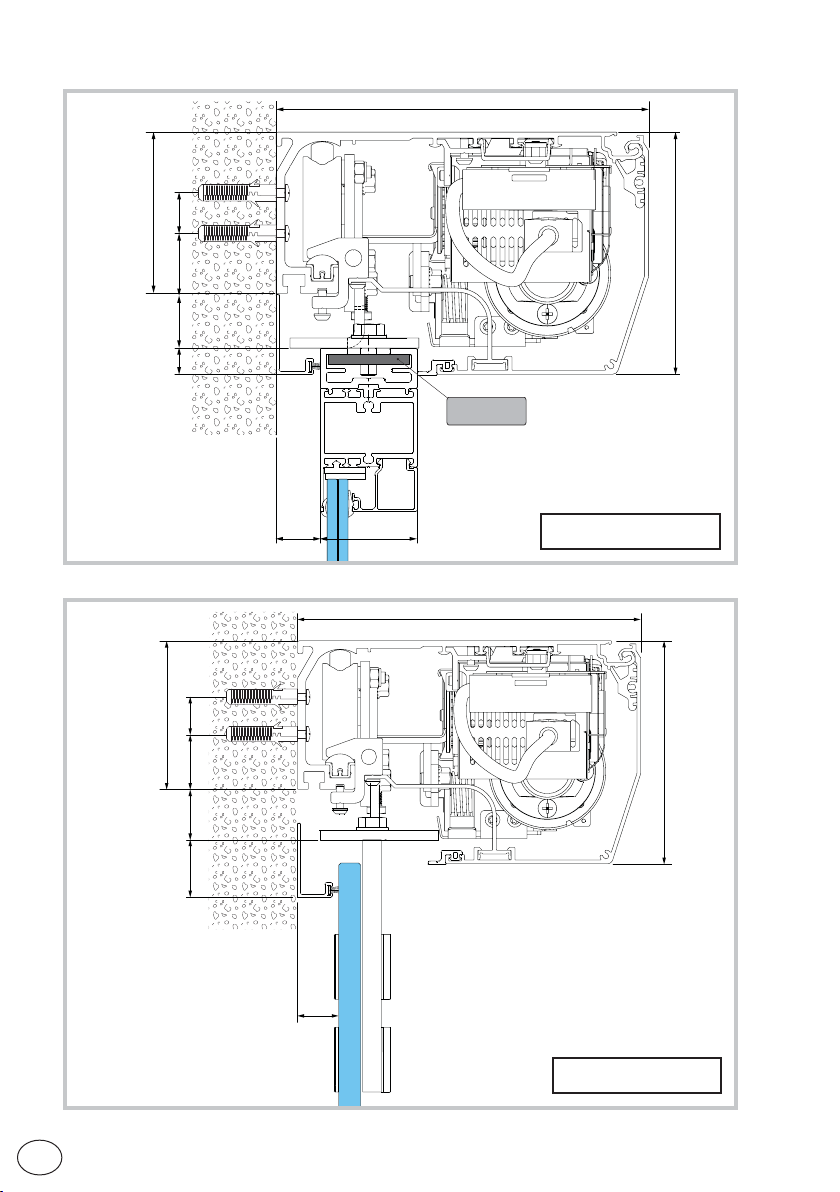

6. Fastening of box using supplied wing anchoring brackets

185

80H

2030

19 27

16

50

80

HM= H-37

120

10

Unless otherwise specified, all measurements are expressed in millimetres (mm).

The figure shows the measurements for fastening the automation to the wall, considering that the

automation door wings are made using profiles not manufactured by us.

If the door wings are made with DITEC profiles in the ALU/PAM series: refer to the measurements

given in the relative manuals.

Drill a hole in the box using the reference line on the back and fasten it with M6 Ø12 steel plugs

or 6MA screws (not supplied).

Distribute the fixing points approx. every 400 mm.

Make sure the box is positioned evenly, with its back surface perpendicular to the floor and not

deformed lengthwise by the shape of the wall. If the wall is not straight and smooth, iron plates

must be fixed to it and then the box in turn fixed to the plates.

WARNING: the fastening of the box to the wall must be sufficient to sustain the door wing weight.

WARNING: do not damage the wheel guide during assembly. Clean the guide thoroughly before

installing the wings.

10

EN

IP2266EN

Page 11

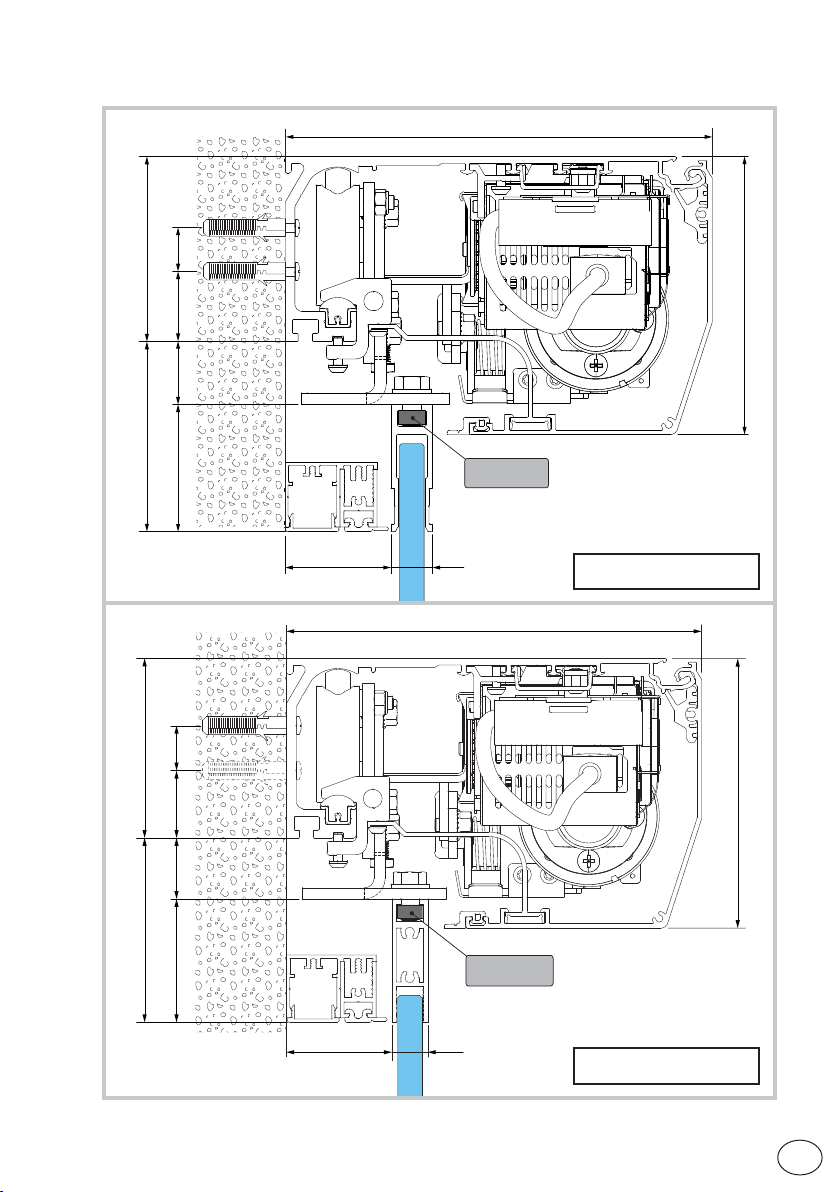

6.1 Examples with DAS11M8

2030

8082

2755

185

120

DAS11M8

IP2266EN

46 18

185

20302755

8082

DAS200-AC1356

185

DAS11M8

47 16

DAS200-PAM16

11

EN

Page 12

80

2030

9

15 27

55

6.2 Examples with DAS18M8

185

120

DAS11M8

DAS200-PAM30

185

EN

80

2030

120

31 27

DAS18M8

44 25

DAS200-AC4255

IP2266EN

12

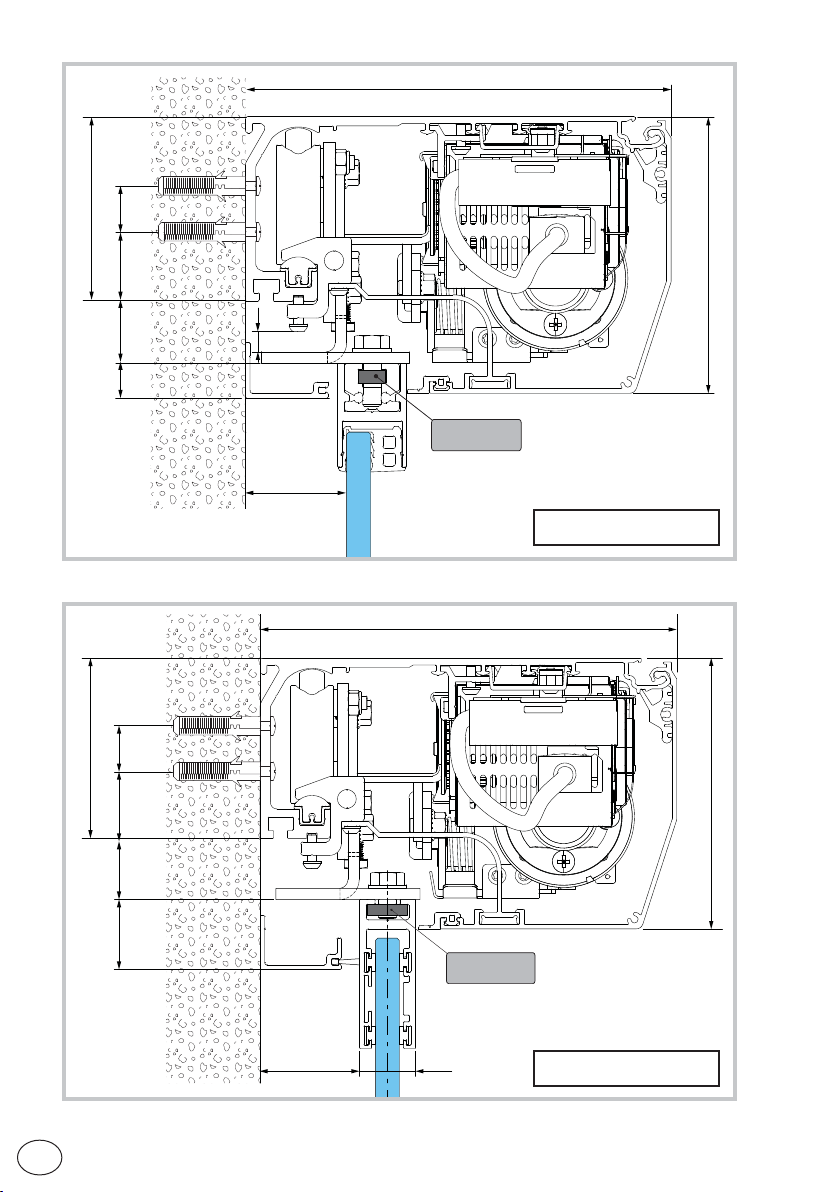

Page 13

185

80

2030

120

31 27

DAS18M8

6.3 Example with DAS35M8

80

2030

14 27

IP2266EN

44 25

185

DAS35M8

16 60

DAS200-PAMH60

DAS200-AC4870

120

13

EN

Page 14

6.4 Example with DAS40M8

80

2030

13 27

185

120

DAS40M8

6.5 Example with ACV

80

2030

31 27

22

22

48

185

DAS200-ALU48

120

DAS200-ACV

IP2266EN

EN

14

Page 15

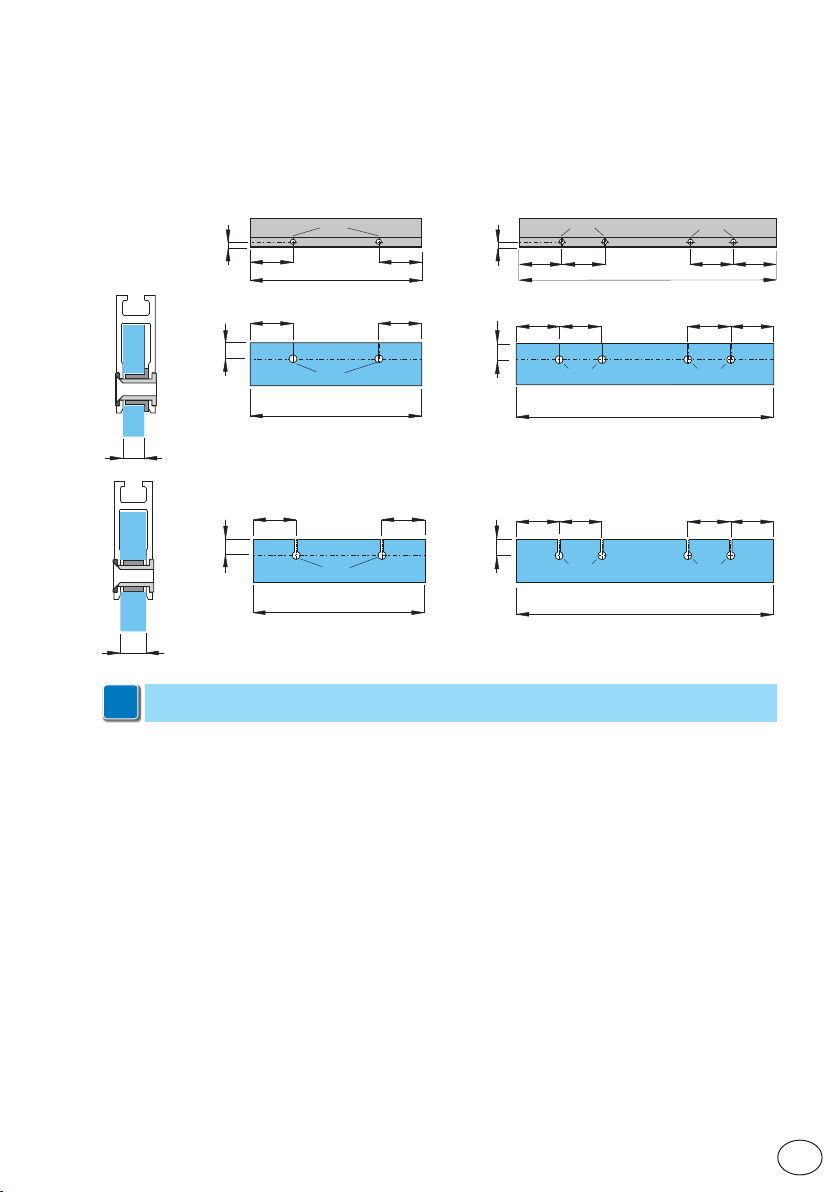

7 Preparation of the glass door wing

The diagram indicates the process measurements of the aluminium profile AC1356 and glass.

Ø10 through holes are required on the aluminium profile and Ø15 on the glass for fastening. The

number of holes and related distance between centres are based on the door wing width. Silicon

should ideally be used between the edge of the glass and the internal base of the profile.

Ø10

11

100

L≤1000

30

Ø15

L≤1000

10

30

12

With AC4255 or AC4870 glass wing attachment applications, see the respective ma-

i

nual.

Ø15

L≤1000

100

100100

100100

11

3030

Ø10

100 100 100 100

L>1000

100 100 100 100

Ø15 Ø15

L>1000

100 100 100 100

Ø15

L>1000

Ø10

Ø15

IP2266EN

15

EN

Page 16

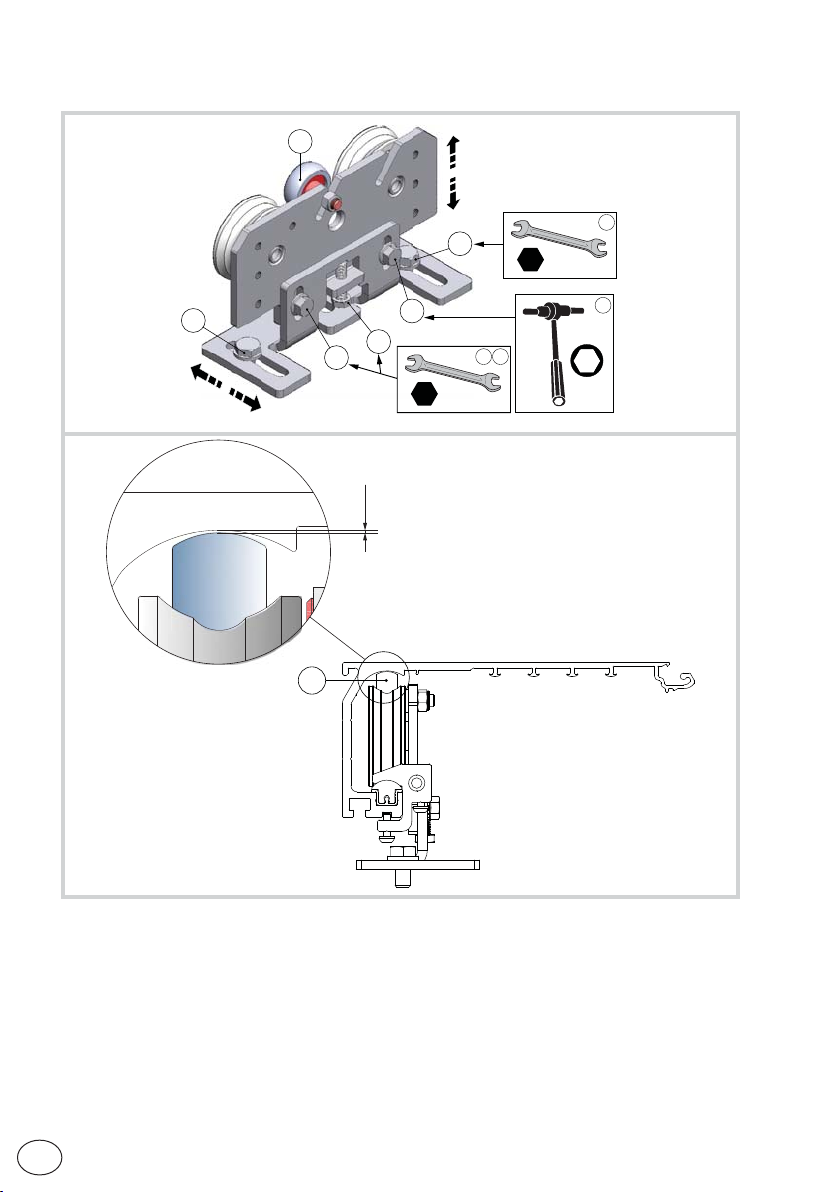

7.1 Installing and adjusting the door wings

D

+/- 8

A

A

13

A

+/- 19

B

C

B

10

CB

B

10

0,5

D

Make sure that the central wheel [D] is adjusted as illustrated in the picture.

Fix the door wing to the carriage with screws (A).

The door wing can be adjusted as shown in the figure.

• Loosen the screws [B] and adjust the height by turning the screws [C];

• Adjust the side position of the door wing by turning the screws [A];

• Move the door wings manually and make sure they move smoothly and freely and that all

the wheels rest on the guide.

WARNING: for all-glass door wings without seals, leave a gap of at least 10 mm in the closed position

to avoid contact between the glass sheets.

16

EN

IP2266EN

Page 17

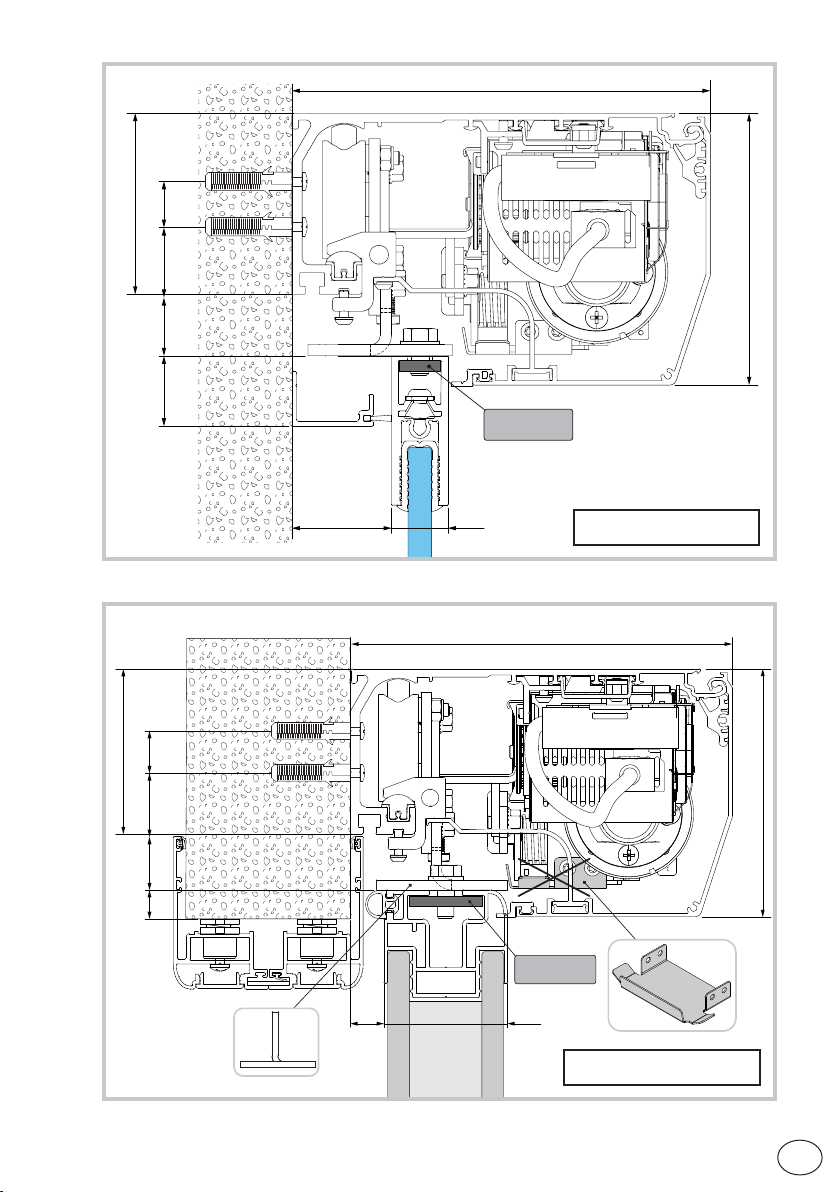

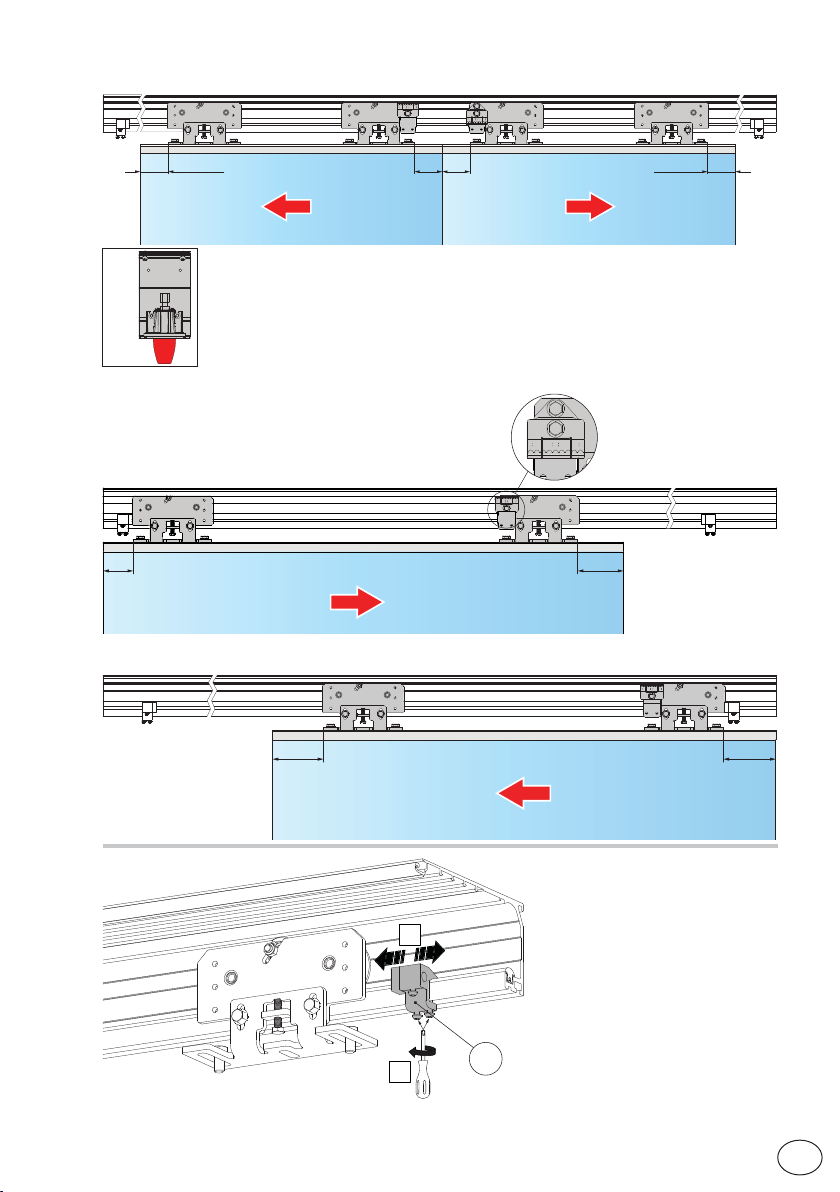

Automation with two door wings

60 (100*)

60 60

*se

*if

*si

*ob

*si

*se

Automation with one door wing with right-hand

opening

60

Automation with one door wing with left-hand opening

100

se

if

si

ob

si

se

60 (100*)

DAS200RG

IP2266EN

100100

Place the end stops (16) on the

opening and closing positions.

2

For the 2 wing automations, a

third end stop is provided which

must be placed near the end of

the box which is used as a stop for

the cover support.

1

16

17

EN

Page 18

7.2 Installing the floor guides

The floor guides must be made of an anti-friction material such as PVC, NYLON or TEFLON.

The length of the floor guide should be no greater than the overlap between the fixed and mobile

door wings, and should not enter the passage opening.

Examples of floor guides

KP515AB

KP48

10

22

50

46

min 21

max 40

HM

10

EN

K4345

18

KAMC16KP369

IP2266EN

Page 19

7.3 Checking and adjusting the belt tension

LT ≤ 3000 = 2 mm

5

LT > 3000 = 3 mm

1

6

10

3

T20

2

4

5

10

2

5

7.4 Sensor positioning on the cover

7.5 External sensor cable fixing

4

cable fixingexternal sensor cable tie

2

1

≥18

4

6

IP2266EN

19

EN

Page 20

8. Electrical connections

Connect the automation to an efficient earthing system that complies with current safety

standards.

During installation, maintenance and repair operations, cut off the power supply before opening

the cover to access the electrical parts.

The automation protection casing must be removed by qualified personnel only.

An omnipolar disconnection switch with a contact opening distance of at least 3 mm must be fitted

on the mains supply.

Check there is an adequate residual current circuit breaker and overcurrent cutout upstream of

the electrical system.

Install an electric switch next to the automatic system.

Make sure there are no sharp edges that may damage the power supply cable.

If the power cable is damaged, have it replaced by the manufacturer or qualified personnel.

• Use a H05RN-F 3G1,5 or H05RR-F 3G1,5 type electric cable.

• Remove the protective cover [1].

• Connect the power cable [2] to the terminal board [4], locking it in place with the cable fastener [3].

• Replace the protective cover [1].

• Connect the connection cable [5] to the power supply unit [6].

LN

4

2

3

5

1

6

IP2266EN

EN

20

Page 21

8.1 Standard electrical connections

PS

A

MCU

C

program selector (0MS)

D

C

B

A

B

F

B

C

A

MCU-ER

D

C

B

E

DAS902BAT2 (24 V)

DAS901BAT1 (12 V)

DAS902MP

F

E

DAS902MP

IP2266EN

Left side presence

sensor

FUTURE USE

Inner combination

sensor

LEARN/EXIT

MMI

Right side presence

UP

DOWN

21

E

E

sensor

Outer combination

sensor

SELECT

EN

Page 22

Output Description

A

Power supply unit connection

green LED

D

jumper

E

B

F

Motor connection

Encoder connection

C

Connection for:

- Program selector;

- Network connection of interconnected operators;

- Connector for Bluetooth interface;

Green LED: If this LED is switched off or flashing, it means the control

panel is malfunctioning.

JUMPER: For interconnecting more than two units (control unit and/or

operation mode selectors).

DAS901BAT1 - DAS902BAT2 battery kit connection (optional)

In the event of a power failure the operator will carry out an opening

operation (factory setting).

See parameters 10, 38 , 40 and 41 for selection of continuous operation

and monitoring with DAS902BAT2.

NOTE: Monitoring will be made if parameter 10 is set to Convenience

Monitoring (01).

To charge the batteries, connect the mains power and the battery kit at

least 30 minutes before starting the system.

WARNING: for charging purposes, the battery kit must be connected to

the control panel at all times. Periodically check the efficiency of the

battery kit. When there is no voltage, the door can only be opened with

a KEY com-mand connected between 8-12.

NOTE: use battery type 12V, 1,2mAh NiMH.If a different type of battery is

used it can damage!

DAS200RG motor connection

EN

IP2266EN

22

Page 23

8.2 Control panel commands

Jumper the unused N.C. contacts

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

8.2.1 Commands

1

(ref. parameter 27)

1

(ref. parameter 46)

1

(ref. parameter 28)

1

6

(ref. parameter 29)

1

7

IP2266EN

DO NOT USE

Blocking device

Blocking device

(+) 24V

Inner side opening

(-) 0V

(+) 24V

Central presence sensor test

Key opening

blocking device connection

}

(main coil)

NOTE: Power supply output for external

accessories 24V .

0,64 A: DAS200;

1 A: DAS200HD-DAS200RF-DAS200RG.

The maximum absorption of corresponds

to the sum of all terminals power supply

output (1-7; 8-14; 15-17)

Central presence sensor 2

Inner impulse (motion) monitoring

Central presence sensor 1

(use this contact if used only one sensor)

(-) 0V

(+) 24V

Side presence sensor test

Outer side opening

Side presence sensor 2

Stop

Side presence sensor 1

(use this contact if used only one sensor)

(-) 0V

Contact Description

2

N.C.

3

N.C. STOP

4

N.C.

5 N.O.

-

+

SIDE

PRESENCE

SENSOR 1

SIDE

PRESENCE

SENSOR 2

OUTER SIDE

OPENING

SIDE

PRESENCE

SENSOR TEST

POWER SUPPLY

TO

ACCESSORIES

Connect side presence sensor 1 as shown in the example in

paragraph 12.

The opening of the safety contact causes the current operation

to stop.

WARNING: when the contact closes again, the door closes.

WARNING: The emergency opening (battery 12V), is priority

(=door opens in case of mains power failure even if STOP

contact is open).

Connect side presence sensor 2 as shown in the example in

paragraph 12.

Connect the external sensor as shown in the example in paragraph 12.

The closure of the contact activates the door opening operation.

Connect the test clamp of the side sensors.

Clamp 6 activates a test on the side safety sensors before every

operation.

If the test fails, an alarm message appears on the display.

accessories power supply.

24 V

23

EN

Page 24

Contact Description

8

(ref. parameter 07)

10

(ref. parameter 16)

8

(ref. parameter 08)

8

(ref. parameter 04)

13

(ref. parameter 09)

8

14

15 16 N.O.

15

17 +

18

(ref. parameter 05)

9

11

12

+

-

19

CENTRAL

N.C.

PRESENCE

SENSOR 1

INNER IMPULSE

(MOTION)

MONITORING

CENTRAL

N.C.

PRESENCE

SENSOR 2

N.O. KEY OPENING

CENTRAL PRESENCE SENSOR

TEST

POWER SUPPLY

TO

ACCESSORIES

INNER SIDE

OPENING

POWER SUPPLY

TO

ACCESSORIES

BLOCKING

DEVICE

CONNECTION

(main coil)

Connect central presence sensor 1 as shown in the example

in paragraphs 12.

Connect the test clamp of the escape route. If the test fails, an

alarm message appears on the display.

Connect central presence sensor 2 as shown in the example

in paragraph 12.

Closing the contact via a key command activates an opening

operation and a closing operation after the time selected by

parameter 04.

If used for opening in DOOR CLOSED mode:

•In the presence of a mains power supply or continuity batteries,

a 8-12 command partially opens the door and closes it after

the time selected by parameter 04.

•If there is no mains power supply, a 8-12 command reactivates

the batteries, if present, for the time required to perform a complete opening operation and then the batteries are disconnected

from the control panel.

Connect the test clamp of the presence sensors.

Command 13 activates a test on the central safety sensors

before every operation. If the test fails, an alarm message

appears on the display.

accessories power supply.

24V

Connect the internal sensor as shown in the example in paragraph 12.

The closure of the contact activates the door opening operation.

accessories power supply.

24V

Output for connecting an electro-mechanical block (optional).

The blocking device is automatically selected during the learning

phase (except bistabel lock).

EN

IP2266EN

24

Page 25

8.3 DAS902MP plus module (optional)

For extra functionality like:

• close impulse;

• nurse impulse;

• open/closeimpulse;

• emergency open impulse (fireman’s opening);

• bi-stable lock;

• connection of optional operation mode selector;

• fire impulse;

• sustainable function off;

• relay out put for external erroror status indication, maximum 15W, 42VAC/ 30VDC (SELV),

resistive load only;

• interlock off (interconnected operators);

• second monitored inner impulse;

• mode selector COM500ER enable impulse.

IP2266EN

25

EN

Page 26

8.4 DAS902MP commands

22

21

20

NC

COM

NO

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Contact Description

1

(ref. parameter 93)

1 3

(ref. parameter 90)

1

(ref. parameter 91-92)

1

(ref. parameter 96)

1

(ref. parameter 99)

2

N.O.

N.O.

4

N.O.

5

N.C.

6

max 15

error / status

42V~ / 30V (SELV)

}

RESISTIVE LOAD ONLY

Fire

External alarm loop

12-24V

Fire

}

Bistable lock

(auxiliary coil)

}

(+) 24V

Open

Auto partial

Exit

Off

Reset

(-) 0V

(+) 24V

Battery wake up

Sustainable drive mode OFF /mode selector enable

Emergency open

Open /Close / Inner impulse 2 monitoring / Interlock OFF

"Nurse" function / Interlock out

Close/ Inner impulse 2

(-) 0V

a) CLOSE

b) INNER IMPUL-

SE 2

a)“NURSE”

FUNCTION

b) INTERLOCK

OUT

a) OPEN/CLOSE

b) INNER

IMPULSE 2

MONITORING

c) INTERLOCK

OFF

EMERGENCY

OPEN

a)

SUSTAINABLE

DRIVE MODE OFF

b) MODE SELEC-

TOR ENABLE

USE ONLY to have

priority on the function

selector or in the absence

of function selectors

}

a) Close impulse.

b) When two inner impulses are to be used. Sets input to inner

impulse 2.

a)The door will open to partial opening in operation mode se-

lections EXIT, AUTO and PARTIAL.

b) When configuring for interlock also set parameter 6A = 01.

a) One impulse opens the door the next impulse closes the door.

Available in mode EXIT, AUTO, PARTIAL.

b) Inner impulse 2 monitoring for the second inner impulse. Set

also parameter 93=03.

c) Disables interlock, both doors can be open at the same time.

d) When configuring for interlock also set parameter 6A = 01.

Used to give opening (fireman’s opening) impulse to the door in

any operation mode selector setting. With electrical emergency

unit also during power failure.

a) Disables Sustainable drive mode.

b) Enable the Mode Selector with a key (only COM500ER).

Interlock in

/

IP2266EN

EN

26

Page 27

1 7 N.O.

1

8 +

-

BATTERY WAKEUP IF NO MAIN

POWER

POWER SUPPLY

TO ACCESSORIES

The impulse opens the door fully and stop there.

24V accessories power supply.

Connection of additional functions (ref. parameter 97)

Contact Description

9 10 N.O. RESET It deletes all the data learned by the control panel.

9

9

9

9

9

15 +

16

(ref. parameter 98)

18

19

(ref. parameter 36)

11 N.O. OFF The door closes and remains closed and locked (if lock is present).

12 N.O. EXIT For one-way operation from the inside of the door.

13 N.O. AUTOPARTIAL For two-way partial opening.

14 N.O. OPEN The door opens and remains open.

-

Contact Description

POWER SUPPLY

TO ACCESSORIES

17

BISTABLE LOCK

(AUXILIARY COIL)

FIRE ALARM

CIRCUIT

CONNECTION

24V accessories power supply.

Power supply for bistable lock (auxiliary coil)

Fire closing or Emergency opening.

Example of connection:

18

19

or

9

15

18

19

12-24V external alarm loop

N.C.

N.O.

IP2266EN

Contact Description

20 21 22

ERROR / STATUS

A door / alarm status signaling device can be connected.

max 15W

42V ~ / 30V

only resistive loads

(SELV)

27

EN

Page 28

9. Adjustment and selection of control functions

The control panel has a two-figure display that displays text and/or numbers.

It has four buttons. (MMI)

UP

1

UP

LEARN / EXIT

LEARN / EXIT SELECT

The procedure to switch on the display is as follows:

press the 2-SELECT key to launch the display test

NB: make sure all seven segments of the two displays light up correctly to avoid incorrect reading.

- 1 UP: to increase the parameter number or value in it;

- 2 SELECT: to enter a parameter or value to be programmed in the memory;

- 3 DOWN: to decrease the parameter number or value in it;

- 4 LEAR/EXIT:

• LEARN has 3 functions: 1, 2, 3.

1. Quick learning. If pressed for longer than 1 second but less than 2, the electronic

accessories connected to the control board are recognised.

2. Normal learning. If pressed for longer than 2 seconds, the display flashes . Two

seconds after releasing the button, a complete learning cycle begins which performs an

opening and closing operation to carry out the operations described in chapter 8.

3. Restore factory settings. If pressed for longer than 10 seconds, the control panel

restores the factory settings.

• EXIT quits the parameter menu or value without saving the changes. If EXIT is not

pressed, the control panel returns to the default display after 3 minutes of inactivity.

4

3

DOWN

DOWN

SELECT

2

N.B.: the set value is stored by the control panel by pressing SELECT irrespective of whether the

value has been modified or not. Press EXIT if you do not want to store the value.

When a value is programmed, that parameter is excluded from the learning cycle. Even if a new

learning cycle is executed, that value will not be modified.

To include the parameters in the learning cycle again, the factory settings must be set.

28

EN

IP2266EN

Page 29

9.1 Display test

a. When the display shows " ", push the SELECT button and each of the two display win-

dows make a rotating test pattern.

b. Verify that all seven segments of the two display windows are lit during the test. If not there is

a risk of misjudgment of the digits shown in a defective display.

c. When the display test is finalized the display shows two steady digits indicating the first parameter.

Display

Char

act er

Display

Char

act er

Display

Char

act er

Display

Char

act er

Display

Char

act er

9.2 Status indication on the display

The display shows the different impulses that are active. The status viewing starts with showing

“ ” as for Status, then one or many numbers representing the different active impulses in to

the operator.

The different impulses are:

00= Key Impulse

01= Inner impulse

02= Outer impulse

03= Synchronisation

05= Presence impulse 1

06=Presence impulse 2

07= Side Presence impulse 1

08= Side Presence impulse 2

09= Stop impulse

10= Emergency open impulse

13= Close command

14= Nurse impulse

24= Push and Go impulse

25= Open-Close impulse

28= Fire impulse

47= Interlock Disable

IP2266EN

29

EN

Page 30

10. Start up

NOTE: for DAS200RF follow the start up procedure indicated in the DA S200RFKA kit

i

manual.

Before per forming any type of oper ation, make sure that the automation is turned off

and the batteries are disconnected.

Start-up and adjustment must be performed in the following order when the automation is installed:

1. Connect the accessories, opening and safety sensors, blocking device, batteries and selector.

2. Jumper the safety contacts 1-2, 1-3, 1-4, 8-9, 8-11 on the control panel and 1-5 on plus

module DAS902MP, if not used.

3. Connect the mains power supply to the automation.

4. Set the following parameters:

Parameter Description Settings

Lock configuration (main control)

05

Central presence sensor test

09

Selection of opening direction

12

Inner Impulse (motion) Monitoring

16

Side presence sensor test

29

Selection of the type of automation

67

Lock Configuration, terminal 16-17

98

DAS902MP

Set ONLY if installed bistable lock DAS802LOKB. 12= bistable

lock.

10= No lock.

11= Antipanic lock (locked with power – LDP).

12= Standard lock (locked without power – LD) and bi-

stable lock (LDB).

00= None (factory setting).

01= Presence sensor 1 (set if a presence sensor with

monitoring is installed).

02= Presence sensor 1 and 2 (set if two presence sensors

with monitoring are installed).

00= right hand opening for single door wing automation.

01= left hand opening for single door wing automation and

for double door automation (factory setting).

According to EN16005 or DIN18650 it is a demand to have

Inner impulse monitoring= On in escape routes.

00= Disables monitoring.

01= Enables monitoring.

NOTE: on DAS200RF set to 01.

NOTE: on DAS200RG this parameter is set to 01.

00= None ( factory setting)

01= Presence sensor 1 (set if a presence sensor with

monitoring is installed).

02= Presence sensor 1 and 2 (set if two presence sensors

with monitoring are installed).

00= Automation with one door wing.

01= Automation with two door wings.

NOTE: Set ONLY if installed bistable lock DAS802LOKB.

11= bistable lock

EN

NOTE: Parameter 10 ( Emergency Unit Monitoring ) on DAS00RG is not visible and it is

i

set up on 02= redundant monitoring

30

IP2266EN

Page 31

5. *Leave ajar the casing and, if there are safety sensors, check that they are in standby mode

and that there are no people or objects moving in the sensors detection area.

*

6. Press the LEARN button for 2 seconds, the display flashes .

To enable the stroke and weight of the door wings to be acquired correctly, the acquisition phase must be per formed with the door wings installed.

7. Free the area of action of the sensors so that they are detected and monitored during the

learning cycle.

8. The automation performs opening and closing operations.

During this cycle, the following accessories connected to the control panel are recognised and

some parameters detected:

Accessory / Parameter Parameter number

High Speed Closing 02

Presence of block and type, except bistable lock 05, 06, 98

Whether the sensors are monitored or not 9, 16, 29, 31, 91

Presence of battery and type 41

Power supply type 64

Door type 67

Measurement of width of passage opening -

Calculation of weight of door wing(s) 68

Calculation of friction in the system 69

At the end of the learning cycle, the door remains closed and the display indicates .

If some parameters have not been automatically configured during the learning cycle, the door

opens. The display first indicates , and then the parameter that has not been acquired automatically, for example, if the door is a 2-wing or 1-wing door (parameter 67).

These parameters must be configured by the installer and/or check that there are no obstacles

and friction which prevents correct learning.

IP2266EN

31

EN

Page 32

1. Press the SELECT button to start to modify the parameters.

2. Press SELECT again to display the parameter value in flashing mode.

3. Select the correct value using the UP and DOWN buttons.

4. Press SELECT to confirm and program the selected value.

5. Continue to configure the other parameters that have not been acquired

6. Press LEARN/EXIT for more than 2 seconds and the display will indicate , after 2 seconds,

the door closes and is ready for operating.

If necessary, you can adjust the following main parameters:ain parameters:

Parameter Description Settings

High Speed Opening (cm/s) 10÷70cm/s

00

High Speed Closing (cm/s) 10÷70cm/s

02

Hold Open Time (00÷60s)

03

Partial opening (00-99%)

11

Performance adjustment. Sets how fast or slow the

Run Program (01÷05)

15

Convenience battery 24V,

38

DAS902BAT2 (00÷01)

Opening Max Force (02÷23N x10)

49

door shall accelerate or break.

01= Smooth, for light doors.

05= Max Performance. For heavy doors.

00= Off

01= On

NOTE: on DAS200RG this display is not visible and is

set to 00.

If the reopening maneuver occurs too abruptly, set

parameter 49 with a value lower than the factory value

(10), example 04 - 05.

• For other parameter variations, see the “Parameters” chapter.

• Make sure the installation complies with the current regulations and the essential requisites laid down by the relevant authorities.

• At the end of the start-up close the cover and fix it with the appropriate screws, see chapter 5.1.

EN

IP2266EN

32

Page 33

11. Par ameters

11.1 Configuration parameters according to function

For more information on the parameters, see paragraph 9.2

SPEED parameters

Parameter Description Range

High speed opening

00

Low speed

01

High speed closing

02

TIME parameters

Parameter Description Range

03 Hold open time 00÷60s

04 Key hold open time 00÷60s

20 Partial hold open time 00÷60s

21 Push & Go hold open time 00÷60s

22 Auto width activation time 00÷60s

23 Auto width resume time 00÷60s

24 Jam hold time 00÷10s

25 Interlock disable time 00÷60s

26 Presence hold open time 00÷60s

92

(DAS902MP)

Parameter Description Range

IP2266EN

Open/Close timeout ref. terminal 4 00÷03

FUNCTION parameters

5E Status indication. Off (00) / On (01) 00÷01

5F Default programming. Off (00) / On (01) 00÷01

Opening direction. 1 wing Right (00) / 1 wing Left or 2 wings (01).

12

On DAS200RG not selectable

13 Hold force 00÷60N

2A Side presence function. Safe speed (00) / Stop door (01) 00÷01

32 Active brake on stop. Off (00) / On (01) 00÷01

33 Push & Go in EXIT mode selection. Off (00) / On (01) 00÷01

34 Hold force in EXIT and OFF mode selection. Off (00) / On (01) 00÷01

35 Toggle operation mode selector after stop. Off (00) / On (01) 00÷01

53 Operator type. Slider (00) / mechanical emergency unit DAS200RF (04) 00÷04

54 Service Needed Operating Hours 00÷60h x 1000

55 Service needed opening cycles

60 Learn. Off (00) / On (01) 00÷01

61 Auto width. Off (00) / On (01) 00÷01

65 Sustainable Drive Mode. Off(00) / On(01) 00÷01

6A Interlock function. Off (00) / On (01) 00÷01

6B Synchronizing Function. Off(00) / On(01) 00÷01

6C External bus device ID 00÷99

10÷70cm/s

05÷70cm/s

10÷70 cm/s

00÷01

00÷50 x

100.000

33

EN

Page 34

FUNCTION parameters

Parameter Description Range

6D Extended hold open time function. Off (00) / On (01) 00÷01

67 Door type. Single sliding (00) / Biparting (01) 00÷01

90

(DAS902MP)

91

(DAS902MP)

93

(DAS902MP)

99

(DAS902MP)

Function select terminal 3. No function (00) / Nurse function (01) / Interlock

out (03)

Function select terminal 4. No function (00) / Open/Close function (01) / Interlock

disable (02) / inner impulse 2 monitoring (03) / Interlock in (04)

Function select terminal 2. No function (00) / Close function (01) / Inner impulse

2 (03)

Function select terminal 6. No function(00) / Sustainable Disable (01)/

Selector Disable (02).

00÷03

00÷04

00÷03

00÷02

POSITION parameters

Parameter Description Range

11

57

58

Partial open position

Low speed distance, opening

Low speed distance, closing

00-99%

00-99cm

00-99cm

DRIVE parameters

Parameter Description Range

15 Run program. Smooth (01) to max performance (05) 01÷05

49 Opening max force 02÷23N x10

4A End checking closing thrust 00÷23N x10

50 Closing max force 02÷23N x10

64 Power supply type.150W (01) / 75W (02) 00÷02

68 Door weight 00÷40kg x10

69 Friction 00÷99N

70 Motor type. DAS200 (15) / DAS200HD-RF (16) / DAS200RG (17) 15÷17

71 Max motor power 03÷15W x10

EMERGENCY parameters

Parameter Description Range

10

36 Emergency action. Closing (00) / opening (01) 00÷01

37 Emergency Action in OFF Mode. Off (00) / On (01) 00÷01

38 Convenience battery. Off (00) / On (01) 00÷01

40 Emergency unit test interval 04÷23hours

41 Battery type. No battery (00) / 12V (01) / 24V (02) 00÷02

94

(DAS902MP)

95

(DAS902MP)

96

(DAS902MP)

Emergency unit monitoring. Off (00) / Convenience monitoring (01) / Redundant

monitoring (02)

Fire impulse function terminal 18/19. Off (00) / On (01) 00÷01

Emergency open impulse function 5. Off (00) / On (01) 00÷01

Emergency button configuration 5. N.O. (00) / N.C. (01) 00÷01

34

EN

00÷02

IP2266EN

Page 35

LOCK parameters

Parameter Description Range

(DAS902MP)

Lock configuration (main control). No lock (10) / antipanic (11) / standard and

05

bistable (12)

06 Lock release. Off (00) / On (01) 00÷01

43 Opening delay for lock 00÷99s x0,1

44 EXIT lock. Off (00) / On (01) 00÷01

51 Push & Close. Off(00) / On (01) 00÷01

52 Push & Close Timeout 00÷99s x10

98

Lock configuration terminal 16/17. No lock (10) / bistable (11) 10÷11

10÷12

SENSOR parameters

Parameter Description Range

07 Presence impulse 1 configuration. N.O. (00) / N.C. (01) 00÷01

08 Presence impulse 2 configuration. N.O. (00) / N.C. (01) 00÷01

09 Presence impulse monitoring. None(00)/sensor 1(01)/sensor 1 and 2(02) 00÷02 units

16 Inner impulse (motion) monitoring. Off (00) / On (01) 00÷01

27 Side presence input 1 configuration. N.O. (00) / N.C. (01) 00÷01

28 Side presence input 2 configuration. N.O. (00) / N.C. (01) 00÷01

29 Side presence impulse monitoring. None (00) / sensor 1 (01) / sensor 1 and 2 (02) 00÷02 units

30 Side presence activation distance 00÷99dm

31 Sensor type.1-wire (00) / 2-wire (01) monitoring 00÷01

45 STOP function. Off (00) / On (01) 00÷01

46 STOP configuration. N.O. (00) / N.C. (01) 00÷01

91

(DAS902MP)

93

(DAS902MP)

Function select terminal 4. No function (00) / Open / Close function (01) / Interlock

disable (02) / inner impulse 2 monitoring (03)

Function select terminal 2. No function (00) / Close function (01) / inner impulse

2 (03)

00÷04

00÷03

OPERATION MODE SELECTOR parameters

Parameter Description Range

B0 Operation mode selector variant. Electronic program selector (04) 00÷04

B1 Operation mode selector key lock. Off (00) / Hold for 2 s.(01) /Passcode (02) / key (03) 00÷03

B2 Operator mode selector service indication. Off (00) / On (01) 00÷01

Choose priority of the operation mode selector. The lower the number the higher

B3

the priority.

B4 Choose group of the operation mode selector. 00÷10

Choose display mode of the operation mode selector. Show system mode (00) /

B5

Show local mode (01)

Choose terminal mode of the operation mode selector. The buttons are disabled

B6

(00) / adapts to system mode (01) / it si setting the operation mode (02)

B7 Mode selector, self service indication. Off (00) / On (01) 00÷01

B8 Mode selector, key impulse. Disabled (00) / Login required (01) / Enabled (02) 00÷02

Bluetooth Power Mode. Always disabled(00), Disabled in OFF mode(01), Always

B9

enabled (02).

Default(02)

25÷29

00÷01

00÷02

00÷02

IP2266EN

35

EN

Page 36

11.2 Main control board parameters

In the “INSTALL ATION SETTINGS” column you can note the modified setting values.

i

Parameter Description

High Speed Opening (cm/s)

Sets the maximum opening speed.

DAS200 (10÷70, 10= 10cm/s; 70= 65cm/s).

DAS200HD/RF/RG (10÷70cm/s).

Low speed

(05÷70, 05= 5cm/s; 69= 69cm/s; 70= automatic)

The low speed is self adjusting to optimal operation if this

parameter is set to max. Depending on authority or installation requirements the low speed, distance opening and/

or closing can be further reduced.

High Speed Closing (cm/s)

Sets the maximum closing speed.

DAS200 (10÷70, 10= 10cm/s; 70= 65cm/s).

DAS200HD/RF/RG (10÷70cm/s).

Hold Open Time (00÷60s)

The general hold open time for inner and outer impulses.

Key Hold Open Time (00÷60s)

Hold open time for key impulse.

Lock Configuration (main control) (10÷12)

10= No lock.

11= Antipanic lock (locked with power – LDP).

12= Standard lock (locked without power – LD) and bi-stable

lock (LDB).

*NOTE: the bistable block is not automatically learned and

must be selected 12.

Lock release (00÷01)

00= Off

01= On

If“LockRelease”is On the door will apply force in the closing

direction when the lock is un locking.This is made to prevent

a lock from being stuck in locked position when opening.

*NOTE: set 01 if using bistable lock.

*NOTE: on DAS200RG this parameter is set to 01.

Presence Impulse 1 Configuration (00÷01)

00 = N.O.

01= N.C.

Presence Impulse 2 Configuration (00÷01)

00= N.O.

01= N.C.

Presence Impulse Monitoring (00÷02)

00= No monitoring of precense impulse.

01= Set to “01” if one Presence impulse sensor shall be

monitored (if only one sensor is used this sensor has

to be connected to terminal 9, Presence impulse 1).

02= Set to“02” if two Presence impulse sensors shall be

monitored.

Factory

setting

AUTOMATIC

AUTOMATIC*

AUTOMATIC*

TO BE SET

Installation

setting

IP2266EN

EN

36

Page 37

Parameter Description

Emergency Unit Monitoring (00÷02)

The emergency unit will be tested by shutting of the power

to the control panel and open the door with the emergency

unit. The test is never done in operation mode selection

OPEN and normally not in OFF, unless parameter 37

“Emergency Action In OFF Mode” is set to On, see below.

Authorities can demand that the emergency unit is monitored on a regular

basis, see parameter 40 “Emergency Unit Test Interval” below. Half an hour before this time has elapsed the following

outer impulse generates an emergency opening test . If there

is no outer impulse within the next half hour, the operator

control unit generates the opening impulse by it self (ghost

impulse). The test is also always performed after a Reset

and after changing operation mode selection from a position

where a test is not done to a position where the test is made.

00= Off.

01= Convenience monitoring. Is a simpler one-channel

monitoring. Convenience monitoring can be used for

monitoring battery.

02= Redundant monitoring. Is a redundant two-channel

monitoring that is a demand for escape route according

to: EN16005 or DIN18650.

*NOTE: on DAS200RF set to 02.

*NOTE: on DAS00RG is not visible and it is set up on 02.

Partial Open Position (00-99%)

Sets the “winter opening” size.

NOTE: A building is certified for a certain COW. Depending

on how many people that is allowed to be in the specific

area there also has to be a certain opening width. Partial

open position must be set to 80% of the certified distance

in escape routes.

Factory

setting

(DAS200)

(DAS200HD/RF)

Installation

setting

IP2266EN

Opening direction (00÷01)

00= 1 wing Right.

01= 1 wing Left or 2 wings.

NOTE: On DAS200RG this parameter cannot be selected,

the opening direction is defined with the position of the

belt attachment bracket.

Hold force (00÷60 N)

Adjustment of the force used to keep the door in closed position.

Run Program (01÷05)

Performance adjustment. Sets how fast or slow the door

shall accelerate or break.

01= Smooth, for light doors.

05= Max Performance. For heavy doors.

Inner Impulse (motion) Monitoring (00÷01)

According to EN 16005 or DIN18650 it is a demand to have

Inner impulse monitoring = On in escape routes.

00= Disables monitoring.

01= Enables monitoring.

*NOTE: on DAS200RF set to 01.

*NOTE: on DAS200RG this parameter is set to 01.

37

(DAS200RG)

AUTOMATIC*

EN

Page 38

Partial Hold Open Time (00÷60s)

Hold open time for Inner & Outer impulses with operation

mode selection PARTIAL and for the Nurse impulse.

Push & Go Hold Open Time (00÷60s)

Hold open time after a Push&Go.

Auto Width Activation Time (00÷60s)

Auto width activation time is available if parameter 61=01

"Auto Width" is selected. If the door has not closed during the

auto width activation time and the door is open or opening

the door will open to full open door.

Auto Width Resume Time (00÷60s)

When the door have been closed during the auto width

resume time, the next opening impulse will open the

door to partial open position. Only available if parameter

"AutoWidth" 61=01

Jam Hold Time (00÷10s)

Sets how long time the door shall be stopped when a jam

is detected during opening and also the time until the door

can restart after a Stop impulse.

Interlock Disable Time (00÷60s)

FUTURE USE

Presence Hold Open Time (00÷60s)

Hold open time for Presence impulses 1&2.

Side Presence Input 1 Configuration (00÷01)

00= N.O.

01= N.C.

Side Presence Input 2 Configuration (00÷01)

00= N.O.

01= N.C.

EN

Side Presence Impulse monitoring (00÷02)

Side presence impulse monitoring is a demand to be activated according to EN16005 or DIN18650

00= No monitoring of Side Precense impulse. Set to “00” if no

monitoring of Side Presence impulse sensors is required

or if no Side Presence impulse sensors are installed.

01= Side Presence impulse 1. Set to “01” if one Side

Presence impulse sensor shall be monitored (if only

one sensor, it has to be connected to terminal 2, Side

Presence impulse 1).

02= Side Presence impulse 1 and 2. Set to “02” if two Side

Presence impulse sensors shall be monitored.

Side Presence Function (00÷01)

00= Safe Speed. If a Side Presence Impulse is activated

during opening, the door shall continue to open with a

safe speed (0,1 m/s).

01= Stop Door. If a Side Presence Impulse is activated during

opening, the door shall stop and be stopped during the

set Presence Hold Open Time (see parameter 26).

38

TO BE SET

IP2266EN

Page 39

Side Presence Activation Distance (00÷99dm)

This is an inhibit signal for side presence.

The door will act according to the value entered in parameter 2A.

The value has to be according to local legislation. In an escape route the door has to open to 80% of the certified distance

(see parameter 11) within 3 sec. after an inner impulse.

00= If value 00 is selected side presence impulse is valid

from fully closed to fully open position.

01-99= The distance is counted from open position.

During opening, the side presence impulse is inhibited

until the door reaches the entered value in the parameter.

Sensor Type (00÷01)

Select type of monitoring for the combined sensors. Choose

between 1-wire (00) or 2-wire (01) monitoring.

00= 1-wire monitoring. 1-wire monitoring is used when

combined sensors have only one monitoring input for

both presence and impulse field.

01= 2-wire monitoring. 2-wire monitoring is used when a

sensor has separate monitoring inputs for both presence

and impulse field.

Active Brake on Stop (00÷01)

00= Off. The door will freewheel until it stops.

01= On. The operator will brake the doors actively during

1s on a Stop impulse.

Push & Go in EXIT and OFF Mode Selection (00÷01)

00= Off.

01= On.

Hold Force in EXIT and OFF Mode Selection (00÷01)

00= Off.

01= On.

With an electromechanical lock this hold force can be

unnecessary.

Toggle Operation Mode Seector after Stop (00÷01)

In operation mode selection OFF the mode must be changed

before normal operation after a Stop impulse.

00= Off.

01= On.

Emergency Action (00÷01)

Fire closing or Emergency opening.

00= Closing (The door will close on fire impulse or power failure).

01= Opening (The door will open on fire impulse or power failure).

NOTE: on this DAS200RG this display is not visible and is set to 01.

Emergency Action in OFF Mode (00÷01)

Decides if “Emergency Action” shall be performed also in

modes election OFF (= opens also in the middle of the night).

00= Off.

01= On.

NOTE: on this DAS200RG this display is not visible and is

set to 00.

IP2266EN

39

EN

Page 40

Convenience battery 24V, DAS902BAT2 (00÷01)

When this parameter is set to On (01), with a 24V (UPS)

battery the operator will continue its normal operation in

case of mains power failure (flat batteries: last operation=

opening). Monitoring will be made if parameter 10 is set to

Convenience Monitoring (01).

Not approved in escape routes!

00 = Off.

01= On.

on DAS200RG this display is not visible and is set to 00.

*NOTE:

*NOTE: on DAS200RF set to 00.

Emergency Unit Test Interval (04÷23hours)

The time set in this parameter controls the maximum

time until the next automatic test of the emergency unit

is performed.

Battery Type (00÷02)

What type of battery that is mounted in the operator is

identified during the Learn.

00= No battery.

01= 12V.

02= 24V.

Opening Delay For Lock (00÷99s x0,1)

The time the opening is delayed (0.0-9.9 sec) after an

opening impulse is given in operation mode selections

OFF and EXIT.

Exit Lock (00÷01)

This parameter controls the electromechanical lock in the

operation mode selector setting EXIT.

00= Off. The electromechanical lock is not locked in EXIT.

01= On. The electromechanical lock is locked in EXIT.

NOTE: on DAS200RG this display is not visible and is set to 00.

NOTE: on DAS200RF set to 00.

Stop Function (00÷01)

When this parameter is set to On (01) the Stop impulse is

enabled, otherwise it is disabled.

00= Off.

01= On.

Stop Configuration (00÷01)

00 = N.O.

01 = N.C.

Opening Max Force (02÷23N x10)

The force applied from the operator to the door leaf during

opening.

If the reopening maneuver occurs too abruptly, set parameter 49 with a value lower than the factory value (10),

example 04 - 05.

Close Kick Force (00÷23N x10)

The force applied from the operator to the door leaf during

the close kick.

Closing Max Force (02÷23N x10)

The force applied from the operator to the door leaf during

closing.

AUTOMATIC

IP2266EN

EN

40

Page 41

Push&Close (00÷01)

When this parameter is set to On (01) the motor will in

operation mode selections OFF or EXIT try to close the door

with the force selected by parameter 50 “Closing Max Force”,

if someone tries to open it manually.

Push & Close is also known as “poor man’s lock”.

00= Off.

01= On.

Push & Close Timeout(00÷99s x0,1)

Adjustable time for how long time the door will continue to

“fight back” when someone is trying to force it open.

00 = infinite time.

Operator Type (00÷04)

00= Slider.

01= DO NOT USE.

02= DO NOT USE

03= DO NOT USE

04= Mechanical Emergency Unit Slider (Sets for DAS200RF).

NOTE: on DAS00/DAS200RG this display is not visible and

is set to 00.

Service needed Operating Hours (00÷60hours x 1.000)

Set time before yellow LED in operation mode selector will

start flashing.

To clear the service needed indication you have to push

both UP and DOWN arrow on the MMI at the same time for

5 seconds when the display shows on. After 5 s the display

will show “SE” during another 5s., release the UP and DOWN

buttons. While the display shows “SE” pres SELECT button

and the Counters Operating hours will be set to zero.

Service Needed Opening Cycles (00÷50 x 100.000)

Set number of openings before yellow LED in operation

mode selector will start flashing.

To clear the service needed indication you have to push both

UP and DOWN arrow on the MMI at the same time for 5

seconds when the display shows on. After 5 s the display will

show “SE” during another 5s., release the UP and DOWN

buttons. While the display shows “SE”CO pres SELECT

button and the Counters Operating cycles will be set to zero.

Low Speed Distance, Opening (00÷99cm)

“Creep speed” distance during opening.

IP2266EN

Low Speed Distance, Closing (00÷99cm)

“Creep speed” distance during closing.

Status indication (00÷01)

The operator shows the status indication on the LED

display of the control panel. See paragraph 9.2 for more

information.

00= Off.

01= On.

41

EN

Page 42

Default programming (00÷01)

Default programming sets the parameters to the factory

default values.

00= Off (It is not possible to perform a default programming

from the MMI).

01= On (It is possible to perform a default programming

from the MMI).

Learn (00÷01)

Sets the possibility to performa learn cycle..

00= Off (It is not possible to perform a learn cycle from MMI).

01= On (It is possible to perform a learn cycle from MMI).

AutoWidth (00÷01)

If this function is selected (01) and the operation mode

selection is AUTO PARTIAL. The door will open from partial

open width to full open width, if an opening impulse is given

and the door has not closed during the time selected in

parameter 22 “Auto Width Activation Time”.

00= Off.

01= On.

Power Supply Type (00÷02)

00= DO NOT USE.

01= 150W.

02= 75W.

Sustainable Drive Mode (00÷01)

The electromechanical lock will never lock in Exit mode

selection even if parameter 44 is set to On (01). The (+) 24 V

DC to accessories like sensors is turned off when the mode

selector is in Off and the door is closed. Motor power is

limited to 75Weven if parameter 71 is set to a higher value.

00= Off.

01= On.

Door Type (00÷01)

00= single sliding.

01= biparting.

Door weight (00÷40kg x10)

Will be estimated during the Learn but can also be altered

manually.

NOTE: The weight of the door is not automatically learned

on the DAS200RF, it must be set manually.

Friction (00÷99N)

The friction when moving the door is automatically measured during a Learn.

NOTE: DAS200 not more than di 50N.

NOTE: DAS200HD/RF/RG not more than 70N.

Interlock Function (00÷01)

FUTURE USE

Synchronizing Function (00÷01)

FUTURE USE

External Bus Device ID (00÷99)

FUTURE USE

AUTOMATIC

TO BE SET

AUTOMATIC

(not on

DAS200RF)

AUTOMATIC

IP2266EN

EN

42

Page 43

Extended Hold Open Time Function (00÷01)

+ 5s hold open time on doors often reopening during closing.

00= Off.

01= On.

Control unit electronic mode selector group (01÷10)

FUTURE USE

MOTOR CONTROL PARAMETERS

Parameter Description

Motor Type (15÷17)

15= DA S2 00

16= DAS200HD / DAS200RF

17= DAS200RG

Max Motor Power (03÷15)

The max amount of power the motor can be supplied with.

DAS902MP PLUS MODULE PARAMETERS

Parameter Description

Function Select terminal 3 - DAS902MP (00÷03)

00= NO FUNCTION.

Nurse function. The door will open to partial opening in

01=

operation mode selections EXIT, AUTO and AUTO PARTIAL.

02= DO NOT USE.

03= Interlock out. When configuring for interlock also set

parameter 6A = 01.

Function Select terminal 4 - DAS902MP (00÷04)

00= NO FUNCTION.

01= Open/Close Function . One impulse opens the door the

next impulse closes the door. Available in operation

mode selections EXIT, AUTO, PARTIAL.

02= Interlock disable function. Disables interlock, both doors

can be open at the same time.

03= Inner impulse 2 monitoring. Sets inner impulse 2 mo-

nitoring for the second inner impulse on the DAS902MP

unit. Set also parameter 93 = 03.

04= Interlock in. When configuring for interlock also set

parameter 6A = 01.

Open/Close Timeout, terminal 4 - DAS902MP (00÷60

minutes)

The time set in this parameter controls when a door shall

start closing automatically if left open by an Open/Close

impulse.

00 min= no automatic closing.

Factory

setting

FACTORY SET

Factory

setting

Installation

setting

Installation

setting

IP2266EN

43

EN

Page 44

Function Select terminal 2 - DAS902MP (00÷03)

00= No function.

01= Close function. This impulse will immediately close the

door, even during opening, and remain closed as long

as the Close impulse is active. The electro-mechanical

lock will lock the closed door.

May not be used on an escape route door.

02= DO NOT USE.

03= Inner impulse 2. When two inner impulses are to be

used. Sets input to inner impulse 2.

Fire Impulse Function, terminal 18-19 - DAS902MP (00÷01)

Depending on configuration in Emergency Action (36),

the door will open or close on fire impulse. Fire impulse

override presence impulse. At closing, the door will not

reopen on jam.

00= Off.

01= On.

Emergency Open Impulse Function, terminal 5 - DAS902MP

(00÷01)

Fireman’s opening.

00= Off.

01= On.

Emergency Open Impulse Configuration, terminal 5 - DAS902MP (00÷01)

Configures the button used for Fireman’s opening.

00= N.O.

01= N.C.

Operation Mode Selector Functio, terminal 9÷14 - DAS902MP (00÷01)

Switch / timer / relay

00= Off.

01= On (Not allowed in escape route, according to EN16005

and DIN18650).

Lock Configuration, terminal 16-17 - DAS902MP (10÷11)

Bi-stable lock used as night lock of escape routes.

10= No Lock.

11= Bi-stable lock.

Function Select, terminal 6 - DAS902MP (00÷02)

00= No function.

01= Sustainable Disable Disables Sustainable drive mode.

It is possible to disable sustainable drive mode. As long

as contact is active the operator will run with full power .

02= Enable the Mode Selector with a key (only COM500ER)

DAS909MP mode selector and all other Mode Selectors

are not affected by this parameter.

When parameter is set to value 02 the OMS is locked.

If an impulse is given on IOU TB:6 the indication LED on

OMS will be steady red during 15 seconds and it is possible to change mode selection (set parameter B1= 00).

Priority of the operation mode selector DAS902MP, teminals 9÷14 (25÷99)

FUTURE USE

EN

IP2266EN

44

Page 45

Choose group of the DAS902MP operation Mode selector,

terminals 9÷14 (00÷10)

FUTURE USE

ELECTRONIC OPERATION MODE SELECTOR PARAMETERS

Parameter Description

Operation mode selector variant (01÷04)

01= DO NOT USE.

02= DO NOT USE.

03= DO NOT USE.

04= ELECTRONIC SELECTOR.

Operation mode selector key lock (00÷03)

COM501ES/ER

There are four different levels of access code choices for

the operation mode selector.

COM500ES/ER

There are three different levels of access code choices for

the operation mode selector.

00= No access code.

01= Hold for two sec.

COM500ES/ER, access is obtained by holding

for 2 seconds.

COM501ES/ER, access is obtained by holding any mode

selection button for 2 seconds.

02= Passcode.

COM500ES/ER, passcode can be selected where the access

is obtained by briefly pushing in turn

The entire passcode must be entered within 3 seconds.

COM501ES/ER, passcode can be selected where the access

is obtained by briefly pushing the buttons in correct order.

The entire passcode must be entered within 10 seconds.

The passcode can be changed through the DAS900CT.

Default passcode is

03= Key

COM501ER

To enable the use of the selector, rotate the key clockwise

towards the symbol

.

or

.

Factory

setting

AUTOMATIC

Installation

setting

IP2266EN

COM500ER

mode selector is not affected by this parameter.

See parameter 99.

45

EN

Page 46

Operator mode selector service indication (00÷01)

Yellow flashing service LED.

Service indication on operation mode selector.

No service indication (00).

Indicate service (01).

00= Off

01= On

Choose priority of the operation mode selector (25÷99)

FUTURE USE

Choose group of the operation mode selector (00÷10)

FUTURE USE

Choose display mode of the operation mode selector (00÷01)

In Show local mode the OMS shows the last setting made

on the OMS.

In Show system mode the OMS shows the setting that the

operator is put to. It is shown with one flach every 5s.

When the OMS is flashing every 5s it is not possible to change

the mode on the OMS.

00= Show system mode.

01= Show local mode.

Choose terminal mode of the operation mode selector (00÷02)

00=The buttons on OMS are disabled.

01= The OMS adapts to system mode.

02= The OMS keeps its selected mode.

Mode selector, self service indication 00÷01)

COM500ES/ER. Orange flashing service LED.

COM501ES/ER. Magenta flashing service LED.

Self service indication on operation mode selector.

00= Off. No self service indication.

01= On. Indicate self service. Indicating a status or condition

that can be cleared by the owner e.g. a break-out door

is standing open.

Mode selector, key impulse (00÷02)

Key impulse to the operator can be made in the following

ways by pushing the symbol below.

COM500ES/ER,

AUTOMATIC

AUTOMATIC

EN

COM501ES/ER,

00= Disabled. Disables the possibility to give key impulse.

01= Login Required. Login required on the OMS to enable

the possibility to give key impulse.

The login is configured through parameter 99 and b1.

02= Enabled. Enables the possibility to always give key

impulse.

Bluetooth Power Mode (00÷02)

00= Always disabled. The Bluetooth Power Mode is fully

disabled until other mode is set.

01= Disabled in OFF mode. The Bluetooth Power Mode is

disabled in OFF mode.

02= Always enabled. The Bluetooth Power Mode is fully

enabled until other mode is set.

Parameters from C0 to C9= FUTURE USE.

i

IP2266EN

46

Page 47

12. Example of connection

Combined opening and safety sensor + safety sensor on opening

The electrical connections must be made when the mains power supply is switched

off.

PAS024ADT (1)

PAS024AMR (1)

PAS024AS(W) (1)

PAS005AP(1)

PASAA2 (1)

PAS024AS(W) (2)

PASAA2 (2)

With these connections, the automation opens and makes a reversal safety contact on the passage

opening with a command from the internal and/or external sensor.

Opening safety is guaranteed by the auto-control side sensors.

NB: If only one sensor is connected, refer to the sensor connections (1).

INNER SENSOR

PASAA2 (1)

White

Brown

Green

Yellow

Pink

Blue

Red

Black

17

15

16

15

9

15

17

13

OUTER SENSOR

PASAA2

White

Brown

Green

Yellow

Pink

Blue

Red

Black

Set the selection DIP switches on sensor PASAA2 as shown below:

ON

1034 11 12 14

INNER SENSOR OUTER SENSOR

PAS024AS(W)

Green

Brown

Yellow

White

Pink

Grey

Red

Blue

IP2266EN

PAS024AS(W) (1)

Green

Brown

Yellow

White

Pink

Grey

Red

Blue

17

15

16

15

9

15

17

13

(2)

(2)

PAS005AP(2)

14

8

5

8

11

8

14

13

14

8

5

8

11

8

14

13

47

EN

Page 48

Green

Brown

Yellow

White

Pink

Grey

Red

Blue

(2)

7

1

1

4

7

6

PAS005AP (1)

Green

Brown

Yellow

White

Pink

Grey

Red

Blue

PAS005AP

7

1

1

2

7

6

INNER SENSOR

PAS024ADT (1)

White

Brown

Green

Yellow

Pink

Blue 15

Red

Black

Grey/Pink

Red/Blue

17

15

15

16

9

17

13

17

10

Set the selection DIP switches on sensor PAS024ADT as shown below:

ON

7 8

14

INNER SENSOR

PAS024AMR (1)

Green

Brown

Yellow

White

Pink

Grey 15

Red

Blue

Yellow/Black

Red/Blue

17

15

10

16

9

17

13

EN

For more information on sensors, refer to the relevant installation manuals.

i

48

IP2266EN

Page 49

13. Troubleshooting

Problem Solution

The automation doesn't open and the

motor doesn't start up

The motor starts up but the automation doesn't open

The automation doesn't close

The automation opens and closes

by itself.

The reopening maneuver occurs

too abruptly

Before starting the troubleshooting, check that the operation mode is correctly selected. Start

the troubleshooting by checking the mechanical and electrical parts of the operator in the order

listed below.

The electromechanical parts are fixed in the support beam. To replace these components, the

complete unit has to be loosened and replaced.

a. The main control unit is equipped with a two digit display for error indication.

• During normal operation the display shows '

• If all segments are off in the display check the mains power, power supply cable or perform a RESET. If the problem remains replace the main control unit or the power supply.

• When an error is active the display is alternating between an error type e.g. E4 (Motor /

En-coder Error) and a second two digit number specifying the error more in detail e.g.

03 (en-coder error). If several errors are active they will be displayed in sequence. On

each electronic unit there is also a green light emitting diode (LED). If the LED is off or

flashing it is indicating that this unit is failing.

Check and change the functions selector switch settings.

Make sure there are no objects on the sensor's detection path.

Check the power supply switch inside the building.

Check any locks, releasing them if necessary.

Make sure there are no objects hindering the opening of the automation.

Check and change the functions selector switch settings.

Make sure there are no objects on the sensor's detection path.

Make sure there are no moving elements on the sensor's detection area.

Set parameter 49 with a lower value , example 04-05

'.

1. (UP): to step up in parameter or

value menu.

2. (SELECT): enters into parameter

or value menu and program a value into memory.

3. (DOWN): to step down in parameter or value menu.

4. (LEARN/EXIT) (LEARN) has 3

functions:

- 1 quick learn,

- 2 Normal learn,

- 3 default setting; EXIT jumps out

from value menu without saving

or parameter menu.

b. Disconnect the mains power and batteries, if fitted. Unlock all mechani-

cal locks. Pull the door leaf manually and check that the door can be easily moved over the complete sliding track/floor guide. If the door leaf stops or is

IP2266EN

hard to move, the reason may be sand, stones, rubbish etc. in the floor guide.

49

EN

Page 50

The door leaf may also be jamming on the floor or on the weather proofing brush strips.

Clean the floor guide, adjust the door leaf height/depth or take other necessary measures

e.g. replacement of worn parts until the door leaf is running smoothly when manually

operated.

c. Check that there is the right belt tension (ref. paragraph 7.3).

13.1 Activ error indication

E1= flashing letter E followed by a digit displays an active error (1-9). The digit shows the main type of

error. The display switches between this main error and a two digit number to specify the error.

If several errors are active they are displayed in a sequence. Errors are cleared by a RESET from

the operation mode elector (OMS) or by turning off and on the mains power.

DEFINITIONS:

OMS= operation mode selector.

I/O= plus module DAS902MP.

MCU= control panel.

PSU= power supply unit.

Detailed error Reason Remedy

- -

Not enough power

There is not enough power to the MCU. Check that the power does not drop from

Main error: Power Supply

the PSU, check cables.

Replace the PSU.

Detailed error Reason Remedy

19

Inner Impulse Error

20

Fire Impulse Error

28

IOU Inner impulse 2

er- ror

29

Outer Impulse Error

30

Stop Impulse Error

31

Side Presence Impulse

Error

32

Presence Impulse Error

The control unit does not get a test

answer from the activation unit.

The control unit does not get a test

answer from the fire alarm.

The control unit does not get a test

answer from the activation unit.