Enthermics EC230L, EC340L, EC390L, EC770L Operation And Care Manual

P H O N E :

U. S .A ./CA NA DA F A X :

U. S .A ./CA NA DA

EC230L

EC390L

Fluid

Warming

Cabinet

EC340L

EC230L

EC340L

EC390L

EC770L

230V

p ri nt e d in u . s. a.

EC770L

OPERATION AND CARE MANUAL

Corporate Headquarters:

W164 N9221 Water Street ● P.O. Box 443

Menomonee Falls, Wisconsin 53052-0443

262.251.8356 800.TO.B.WARM

www.enthermics.com 800.862.9276

AN ISO 13485:2003 CERTIFIED COMPANY

●

U.S.A.

262.251.7067

8 0 0 . 3 2 9 . 8 7 4 4

MN-28671 Rev 1 • 07/12

INDEX

Transport and Storage ..............................1

Delivery.........................................1

Unpacking.......................................1

Safety Procedures and Precautions ....................2

Installation

Preparation ...................................3

Electrical Information & Capacities .................3

General Information ............................4

Dimension Drawings ...........................5-6

Operating Instructions

Control Features ...............................7

Operational Procedures ..........................8

Care and Cleaning

Cleaning and Preventative Maintenance............9-10

Troubleshooting Guide ...........................11

Service Parts Lists and Drawings .................12-16

Wire Diagrams (Always refer to wire diagram under top

cover of unit for most current version)

Warranty

Transportation Damage and Claims ......... Back Cover

Limited Warranty ...................... Back Cover

TRANSPORT AND STORAGE

Transport and Storage Environmental Conditions (not to exceed 15 days)

• Ambient temperature range of -40° to +70°C (-40° to +159°F)

• Relative humidity range of 10% to 100%, including condensation

• Atmospheric pressure range of 50KPa to 106KPa

UNPACKING AND SET-UP

DELIVERY

This warming cabinet has been thoroughly

tested and inspected to insure only the highest

quality unit is provided. Upon receipt, check for

any possible shipping damage and report it at once

to the delivering carrier. See Transportation Damage

and Claims section located in this manual.

This appliance, complete with unattached items

and accessories, may have been delivered in one or

more packages. Check to ensure that all standard

items and options have been received with each

model as ordered.

Save all the information and instructions packed

with the appliance. Complete and return the warranty

card to the factory as soon as possible to assure

prompt service in the event of a warranty parts and

labor claim.

This manual must be read and understood by

all people using or installing the equipment model.

Contact the service department if you have any

questions concerning installation, operation,

or maintenance.

NOTE: All claims for warranty must include the

full model number and serial number of

the unit.

UNPACKING

1. Carefully remove the

appliance from the

carton or crate.

NOTE: Do not discard the

carton and other

packaging material

until you have

inspected the unit

for hidden damage

and tested it for

proper operation.

2. Read all instructions in this manual carefully before

initiating the installation of this appliance.

DO NOT DISCARD THIS MANUAL.

This manual is considered to be part of the

appliance and is to be provided to the owner

or manager of the business or to the person

responsible for training operators. Additional

manuals are available from the service department.

3. Remove all protective plastic film, packaging

materials, and accessories from the appliance

before connecting electrical power.

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 1

must remain with the device if the item is sold or moved

SAFETY PROCEDURES AND PRECAUTIONS

NOTE

Knowledge of proper procedures is essential to the safe

operation of electrically and/or gas energized equipment. In

accordance with generally accepted product safety labeling

guidelines for potential hazards, the following signal words

and symbols may be used throughout this manual.

Used to indicate the presence

of a hazard that will cause

severe personal injury, death,

or substantial property

damage if the warning

included with this symbol

is ignored.

Used to indicate the presence

of a hazard that can cause

personal injury, possible

death, or major property

damage if the warning

included with this symbol

is ignored.

1. This fluid warming cabinet is intended for warming

injection and/or irrigation fluids ONLY. No other use

for this device is authorized or recommended.

2. This device is intended for use in commercial

establishments where all operators are familiar with

the purpose, limitations, and associated hazards of this

device. Operating instructions and warnings must be

read and understood by all operators and users.

3. Any troubleshooting guides, component views, and

parts lists included in this manual are for general

reference only and are intended for use by qualified

technical personnel.

4. This manual should be considered a permanent part of

this device. This manual and all supplied instructions,

diagrams, schematics, parts lists, notices, and labels

to another location.

NOTE:

Used to indicate the presence

of a hazard that can or will

cause minor or moderate

personal injury or property

damage if the warning

included with this symbol

is ignored.

Used to indicate the presence

of a hazard that can or will

cause minor personal injury,

property damage, or a

potential unsafe practice if the

warning included with this

symbol is ignored.

Used to notify personnel of

installation, operation, or

maintenance information that is

important but not hazard related.

For equipment delivered for use

in any location regulated by the

following directive:

DO NOT DISPOSE OF ELECTRICAL

OR ELECTRONIC EQUIPMENT WITH

OTHER MUNICIPAL WASTE.

NOTE

This unit should not be left unattended for

periods of more than 24 hours. In case of

absences longer than 24 hours, disconnect

the warmer from its power source.

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 2

Safety Class I

Equipment

PREPARATION

DANGER

230 V.A.C. — 50 Hz, 1 ph

230 V.A.C. — 50 Hz, 1 ph

230 V.A.C. — 50 Hz, 1 ph

230 V.A.C. — 50 Hz, 1 ph

Before operating the cabinet, clean both the interior and exterior of the unit with a damp cloth and

mild soap solution. Wipe with an appropriate disinfectant.

Wipe dry with a clean cloth or air dry.

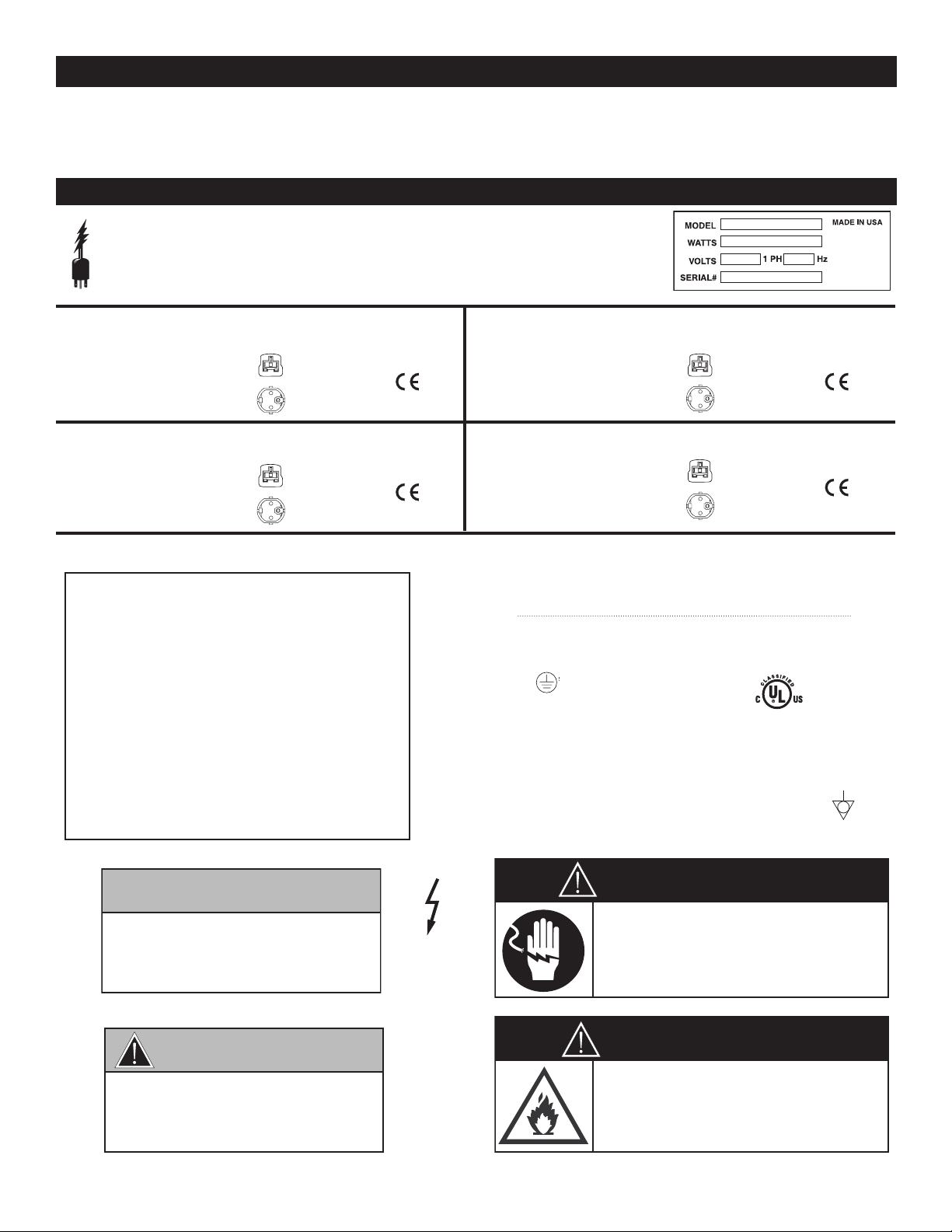

ELECTRICAL INFORMATION

The power specifications are located on the unit identification rating tag. This tag is

permanently attached to the unit and must be located to verify power requirements.

EC390L POWER REQUIREMENTSEC230L POWER REQUIREMENTS

BS 1363 Plug

0.8 kW, 3.5 Amps

Type B Equipment

(UK only)

CEE 7/7

220-230V Plug

EC340L POWER REQUIREMENTS

BS 1363 Plug

0.7 kW, 3.0 Amps

Type B Equipment

(UK only)

CEE 7/7

220-230V Plug

Other international plugs are available, contact factory for more information.

IMPORTANT

Do not load each basket beyond the recommended

maximum capacity:

EC230L = 16 liters/basket

EC340L = 14 liters/basket (28 total liters/unit)

EC390L = 18 1-liter bottles or 29 1-liter bags

EC770L = 24 liters/basket (72 total liters/unit)

Overloading may cause lower or uneven

temperatures of product and damage to basket

and basket rail supports. Baskets that are

overloaded may slip off rail supports, resulting

in possible damage to product and equipment, as

well as causing possible injury.

BS 1363 Plug

0.82 kW, 3.6 Amps

Type B Equipment

(UK only)

CEE 7/7

220-230V Plug

EC770L POWER REQUIREMENTS

BS 1363 Plug

0.9 kW, 3.9 Amps

Type B Equipment

(UK only)

CEE 7/7

220-230V Plug

Wire diagram located under top cover of unit

Grounding reliability can only be achieved when equipment is

connected to an equivalent receptacle marked “Hospital Grade.”

Medical Equipment classified by Underwriters

Laboratories with Respect to Electrical

Protective Earth

Ground Symbol

To prevent an electrical shock hazard between the appliance and

other appliances or metal parts in close vicinity, an equalizationbonding stud is provided. An equalization bonding lead must be

connected to this stud and the other appliances / metal parts

to provide sufcient protection against potential difference.

The terminal is marked with the following symbol.

Shock, Fire and Mechanical Hazards only, in

Accordance with UL 2601-1 and CAN/CSA

C22.2 No. 601.1.

UL File No.

E201645

CAUTION

THIS UNIT HAS NOT BEEN

APPROVED FOR WARMING OF

BLOOD OR BLOOD PRODUCTS.

CAUTION

INJECTION FLUID MANUFACTURER

SUGGESTS NOT TO WARM INJECTION

ENSURE POWER SOURCE

Hazardous

Voltage Present

MATCHES VOLTAGE IDENTIFIED

ON APPLIANCE RATING TAG.

DANGER

DO NOT use this warming appliance

in the presence of flammable

anesthetic mixture (with air or

FLUIDS OVER 40°C (104°F).

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 3

with oxygen or nitrous oxide).

THIS COULD RISK AN EXPLOSION!

GENERAL INFORMATION

This warming cabinet is designed to safely warm and store either

electrothermal cable is positioned in the oor and two sides of the

Fluid warming chamber

The warming cabinet can be programmed to warm either irrigation

The warming cabinet is equipped with one (1) white, epoxy-

The warming cabinet is equipped with two (2) white, epoxyThe warming cabinet is equipped with one (1) stationary

The warming cabinet is equipped with three (3) white, epoxy-

irrigation uids or injection uids.

The single-chambered warming cabinet is constructed with 20

gauge stainless steel exterior casing and door with handle and

hinges designed to withstand heavy usage. A door with window

allows observation of inventory with the door closed. The cabinet

is warmed using low-heat-density electrothermal cable array. The

warming cabinet, providing even heating of the interior chamber.

The interior chamber temperature is regulated by an electronic

control consisting of a 4 digit L.E.D. display, ON/OFF key,

INCREASE and DECREASE keys, integrated LOCK feature and a

series of prompt sequence indicators.

The electronic control can easily be set to operate in Fahrenheit

or Celsius. After a power failure, the cabinet will remember its

programming and begin to operate as before. The ON/OFF

indicator will blink to indicate a failure occurred; pressing the

ON/OFF key once will eliminate this blinking. A thermal shutoff system, separate from the electronic control, is included as an

additional safety feature.

The control will display temperature in whole degrees.

uids (IRR) or injection uids (INJ), with separate temperature

ranges provided depending on the choice selected.

• IRR temperature range: 37° to 66°C (98° to 150°F),

• INJ temperature range: 37° to 40°C (98° to 104°F).

A fan located inside the chamber mixes the air to prevent

temperature strati cation and to ensure an accurate chamber

temperature for each mode.

• Within +0/-1.67°C (+0/-3ºF) for set points of

43° to 66°C (110° to 150°F)

• Within +0/-1.12°C (+0/-2ºF) for set points of

37° to 43°C (98° to 109°F).

If selected, an alarm will sound if temperatures exceed 6°C (10°F)

over the set-point temperature, and an OVERTEMP indicator will

blink indicating an over-temperature condition.

EC230L INFORMATION:

coated wire basket to accommodate uids packaged in bags

or bottles, mounted on basket rail supports. The basket

has a 16 liter maximum capacity. The cabinet is furnished

with four (4) 1-1/4" (31mm) non-skid rubber feet.

EC340L INFORMATION:

coated wire baskets to accommodate uids packaged in bags

or bottles, mounted on basket rail supports. Each basket

has a 14 liter maximum capacity. The cabinet is furnished

with a full perimeter rubber bumper assembly and one set of

5" (127mm) heavy duty casters, two with locking brakes.

EC390L INFORMATION:

white, epoxy-coated shelf to accommodate uids packaged in

bags or bottles. The basket has a capacity of 18 1-liter bottles

or 29 1-liter bags. The cabinet is furnished with one set of

0.5" (13mm) levelling feet.

EC770L INFORMATION:

coated wire baskets to accommodate uids packaged in bags

or bottles, mounted on basket rail supports. Each basket has

a 24 liter maximum capacity. The cabinet is furnished with

a full perimeter rubber bumper assembly and one set of

5" (127mm) heavy duty casters, two with locking brakes.

CAUTION

THIS UNIT HAS NOT BEEN

APPROVED FOR WARMING OF

BLOOD OR BLOOD PRODUCTS.

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 4

DANGER

AT NO TIME SHOULD THE INTERIOR

OR EXTERIOR BE STEAM CLEANED,

HOSED DOWN, OR FLOODED WITH

WATER OR LIQUID SOLUTION OF

ANY KIND. DO NOT USE WATER JET

TO CLEAN.

(IPX-0 - Listed as Ordinary)

SEVERE DAMAGE OR

ELECTRICAL HAZARD

COULD RESULT.

WARRANTY BECOMES VOID IF

APPLIANCE IS FLOODED

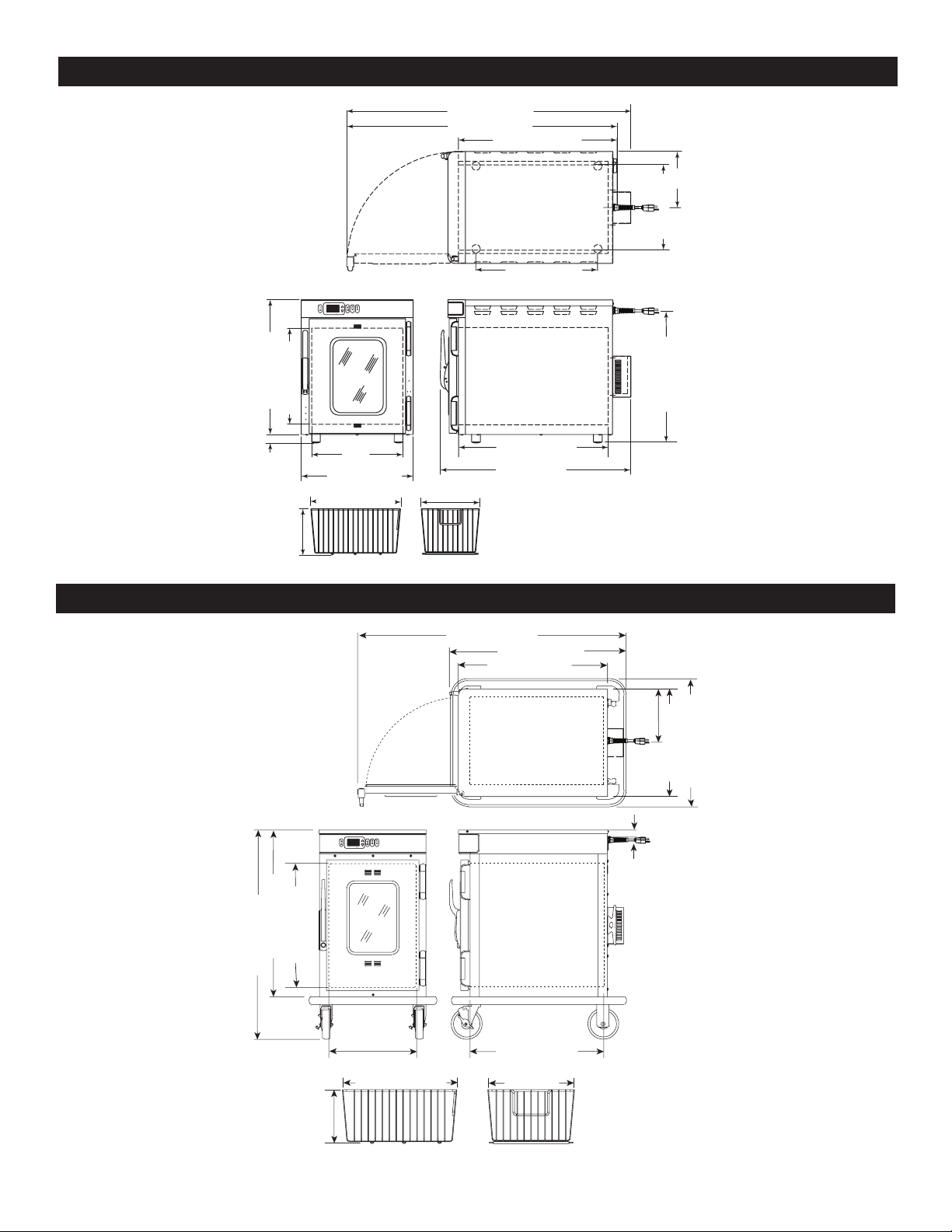

EC230L DIMENSIONS

40.91" (1039.0mm)

38.88" (986.8mm)

22.813" (580.2mm)

C

L

8.07"

ELECTRICAL

(204.5mm)

11.89" (301.9mm)

19.41" (492.8mm)

1.24"

(31.4mm)

17.50" (445.3mm)

CAVITY

13.84" (351.4mm)

13.12" (333.2mm)

CAVITY

16.2" (410.4mm)

17.85" (453.4mm)

9.189" 233.4mm)

11.50" (292.1mm)

21.50" (546.7mm)

CAVITY

28.0" (710.7mm)

EC340L DIMENSIONS

43.38" (1101.8mm)

28.53" (724.5mm)

24.13" (612.7mm)

CORD LENGTH (est.)

8' (2,438mm)

18.96" (475.1mm)

ELECTRICAL CONNECTION

OVERALL

HANDLE TIP

CAVITY HEIGHT

26.96" (684.6mm)

20.0" (508.0mm)

33.4" (849.2mm)

"

7.69

14.13" (358.7mm)

CAVITY WIDTH

16.27

(195.28mm)

" (413.05mm)

CORD LENGTH (est.)

8' (2,438mm)

21.63" (549.3mm)

CAVITY DEPTH

12.27

"

(311.56mm)

8.70"

CORD POS.

(220.8mm)

17.37" (441.1mm)

20.67" (525.0mm)

CORD

1.462" (36.9mm)

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 5

Loading...

Loading...