Enthermics DC250, Designer Series, DC150, DC350, DC750 Operation And Care Manual

...

Enthermics Medical Systems

Operation and Care Manual

Designer Series Blanket Warmer

DC150

DC350

DC250

DC150

(shown with optional timer)

DC750

(shown with optional timer)

DC400

(shown with optional timer)

W164 N9221 Water St, Menomonee Falls WI 53051

Printed in the U.S.A. Specifications are Subject to Change Without Notice

DC250

DC350

DC400

DC750

An ISO 13485:2003 certified company

PO Box 443, Menomonee Falls WI 53052-0443

Tel 262-251-8356 | 800-TO-B-WARM

generalinfo@enthermics.com

www.enthermics.com

Made in the U.S.A.

MN-37072 • Rev 2 • 05/16

Table of Contents

Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Transportation Damage and Claims . . . . . . . . . . . . . . . . 1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electrical Information . . . . . . . . . . . . . . . . . . . . . . . . 6

Operation Instructions . . . . . . . . . . . . . . . . . . . . . . . 9

Cleaning and Preventative Maintenance . . . . . . . . . . . . 14

Dimension Drawings . . . . . . . . . . . . . . . . . . . . . . . 16

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Wiring Diagrams Refer to the wire diagram located under the lid of the appliance.

REPEC

MN-37072 • Rev 2 • 05/16 • Designer Series Blanket Warmer

Authorized Representative:

MDSS GmbH

Schi graben 41

30175 Hannover

Germany

Delivery

Environmental Conditions

Transport and storage environmental conditions (not to exceed 15 days)

• Ambient temperature range of -40°C to +70°C (-40°F to +159°F)

• Relative humidity range of 10% to 95%, non-condensing

• Atmospheric pressure range of 50KPa to 106KPa

Operational environmental conditions

• Appliance must acclimate to room temperature in the environment it will be placed. 24 hours is recommended.

• Recommended environmental temperature range is 15°C to 32°C (60°F to 90°F).

• Recommended relative humidity is above 20%, non-condensing.

Receipt of Appliance

The appliance has been thoroughly tested and

inspected to ensure only the highest quality appliance

is provided. Upon receipt, check for any possible

shipping damage and report it at once to the delivering

carrier. See Transportation Damage and Claims section

locatedbelow.

This appliance, complete with unattached items and

accessories, may be delivered in one or more packages.

Confi rm that all standard items and options have been

received with each appliance as ordered. Save all the

information packed with the appliance.

This manual must be read and understood by all

people using or installing the appliance. Contact the

Enthermics service department if there are any questions

concerning installation, operation, or maintenance.

Transportation Damage and Claims

All Enthermics Medical Systems appliances

are sold F.O.B. shipping point, and when

accepted by the carrier, such shipments

become the property of the consignee.

Should damage occur in shipment, do not put the

appliance into service until the damage has been

inspected by an authorized service provider.

Should damage occur in shipment, it is a matter between

the carrier and the consignee. In such cases, the carrier

is assumed to be responsible for the safe delivery of the

merchandise, unless negligence can be established on the

part of the shipper.

1. Conduct an immediate inspection while the appliance

is still in the truck or immediately a er it is moved

to the receiving area. Do not wait until a er the

appliance is moved to a storage area.

2. Do not sign a delivery receipt or a freight bill until

a proper count has been made and inspection of all

appliances are received.

3. Note all damage to packages directly on the carrier’s

delivery receipt.

Register the unit online to assure prompt service in the

event of a warranty parts and labor claim.

http://www.enthermics.com/warranty-registration

Serial number is required for all inquiries.

Always include both model and serial number(s) in any

correspondence regarding the appliance.

Model: ______________________________________________

Serial Number: ______________________________________________

Purchased From: ______________________________________________

Date Installed: ____________________ Voltage: _____________

4. Have the driver sign the delivery receipt. If he refuses

to sign, make a notation of this refusal on the receipt.

5. If the driver refuses to allow inspection, write the

following on the delivery receipt: Driver refuses to

allow inspection of containers for visible damage.

6. Contact the carrier’s offi ce immediately upon fi nding

damage, and request an inspection. Mail

a written confi rmation of the time, date, and the

person called.

7. Save any packages and packing material for further

inspection by the carrier.

8. Promptly fi le a written claim with the carrier and

attach copies of all supporting paperwork.

Enthermics will continue our policy of assisting our

customers in collecting claims which have been properly

fi led and actively pursued. Enthermics cannot, however,

fi le any damage claims, assume the responsibility of any

claims, or accept deductions in payment for such claims.

MN-37072 • Rev 2 • 05/16 • Designer Series Blanket Warmer

1

Unpacking

1. Carefully remove the appliance from the carton or crate.

NOTE: Do not discard the carton and other packaging material

until the appliance has been inspected for hidden

damage and tested for proper operation.

2. Read all instructions in this manual carefully before initiating

the installation of this appliance, using the appliance or

performing routine maintenance. Following procedures

other than those indicated in this guide to use and clean

the appliance is considered inappropriate and may cause

damage, injury or fatal accidents, in addition to invalidating

the guarantee and relieving the manufacturer of all liability.

3. Do not discard this manual. This manual is considered to

be part of the appliance and is to be provided to the owner

or manager of the business or to the person responsible for

training operators. Additional manuals are available from

the service department.

4. Remove all protective plastic fi lm, packaging materials,

and accessories from the appliance before connecting

electrical power. Store any accessories in a convenient

place for future use.

2

MN-37072 • Rev 2 • 05/16 • Designer Series Blanket Warmer

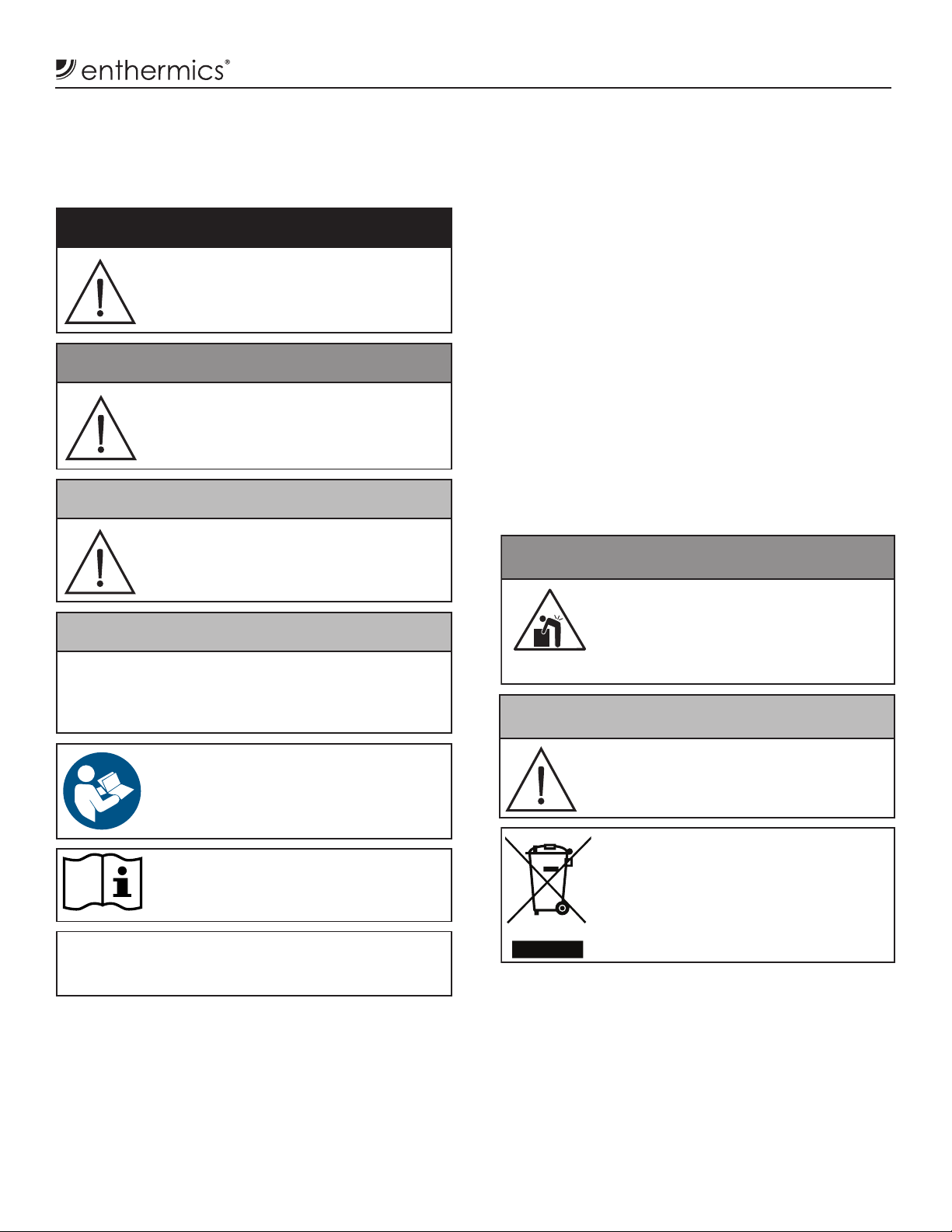

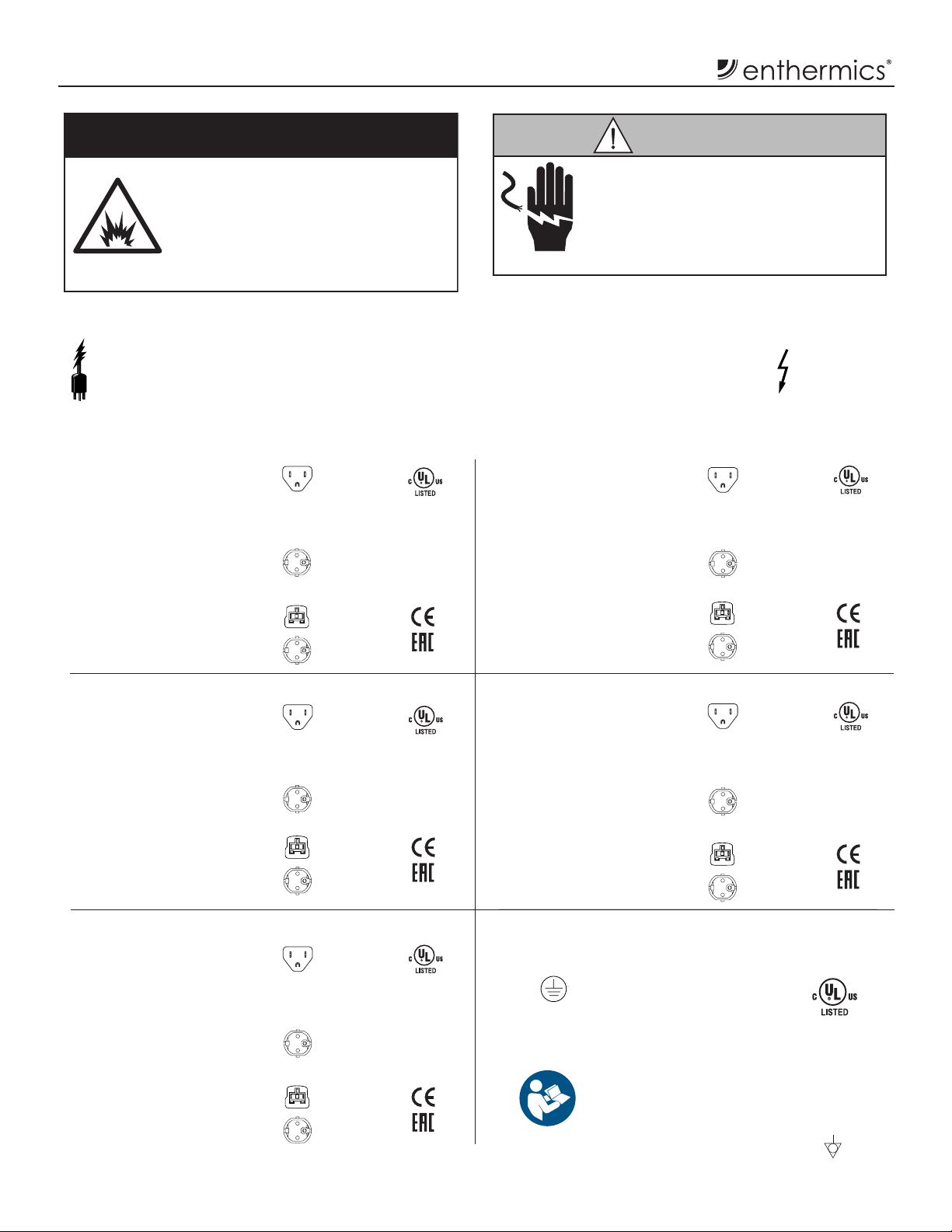

Safety Procedures

Knowledge of proper procedures is essential to the

• This blanket warmer is intended for warming dry,

CAUTION

WARNING

NOTICE: A temporary odor may be noticeable upon initial

continuous use.

safe operation of electrically energized appliances. The

following hazard signal words and symbols may be used

throughout this manual.

DANGER

Used to indicate the presence of a hazard

that will cause severe personal injury, death,

or substantial property damage if the warning

included with this symbol is ignored.

WARNING

Used to indicate the presence of a hazard

that CAN cause personal injury, possible

death, or major property damage if the

warning included with this symbol is ignored.

CAUTION

Used to indicate the presence of a hazard

that can or will cause minor or moderate

personal injury or property damage if the

warning included with this symbol is ignored.

CAUTION

Used to indicate the presence of a hazard that can or

will cause minor personal injury, property damage, or a

potential unsafe practice if the warning included with this

symbol is ignored.

cotton blankets only. No other use for this appliance is

authorized or recommended.

• This warmer is intended for use in commercial

establishments where all operators are familiar with

the purpose, limitations, and associated hazards of

this device. The warmer can be used wherever there

is appropriate space and electrical source including

patient support areas, ER, ICU, PACU, surgical suites,

patient rooms, and nursing stations.

• Operating instructions and warnings must be read and

understood by all operators and users.

• Any troubleshooting guides, component views, and

parts lists included in this manual are for general

reference only and are intended for use by qualifi ed

technical personnel.

• This manual should be considered a permanent

part of the appliance. This manual and all supplied

instructions, diagrams, schematics, parts lists, notices,

and labels must remain with the appliance if the item is

sold or moved to another location.

Appliance and accessories may be

heavy. To prevent serious injury, always

use a su icient number of trained and

experienced workers when moving or

leveling appliance and handling accessories.

Used to indicate that referral to operating

instructions is a mandatory action. If not

followed, the operator or patient could su er

personal injury.

Used to indicate that referral to operating

instructions is recommended to understand

operation of the appliance.

NOTICE: Used to notify personnel of installation,

operation, or maintenance information that is

important but not hazard related.

start-up of the appliance. Contact manufacturer

if the odor persists a er a day or more of

MN-37072 • Rev 2 • 05/16 • Designer Series Blanket Warmer

The door may swing during transport. Only

transport the appliance when the door is

closed and secure.

NOTICE: For appliances delivered for use

in any location regulated by the

following directive (

Do not dispose of electrical or

electronic appliances with other

municipal waste.

NOTICE: Due to the energy e icient design of the

appliance and tight seal around the door, water

vapor from moist or damp blankets placed in the

appliance may cause condensation to collect on

interior surfaces. To avoid this accumulation, use

dry blankets or towels.

2012/19/EU -WEEE):

3

Installation

DANGER

use water jet toclean. Failure

DANGER

Not category AP or APG equipment

Speci cations:

Electronic Control:

Additional features:

Clearance requirements:

Preparation

General Information

• Single-chamber warming appliance

• White epoxy-coated steel exterior

casing and interior insert

• Single pane, energy-effi cient,

e-coated glass window in door

allows for inventory observation

• Easy push-button door for handsfree operation

• Door is fully gasketed and hinged on

the right side of the unit

• WarmSafe™ incorporates a multiple

zone warming technology (Patent

No: US 8,217,316; US 8,581,152) that

heats where and when it is needed.

All chamber surface temperatures

are monitored, providing an

effi cient balance of heat, low-energy

consumption and minimal heat loss.

• DC350 & DC750 include a heated

center shelf to further optimize heat

distribution throughout the cavity

• Four (4) non-skid rubber feet

are standard

To prevent serious personal injury, death, or

property damage:

Do not steam clean, hose down or flood the

interior or exterior with water or liquid solution

of any kind. Do not

to observe this precaution will void the warranty.

Before operating the appliance, clean both the interior and exterior with a damp cloth and mild soap

solution. Wipe with an appropriate disinfectant. Wipe dry with a clean cloth or air dry.

• Adjustable temperature range of

32°C - 71°C (90°F - 160°F)

• Operates in celsius or fahrenheit

• Four digit LED display

• On/Off button

• Up and down adjustment buttons

• Actual temperature button

• Interior light button

• Built-in speaker for audible feedback

• Integrated control lockout feature

1" (25mm) from top and sides

3/4" (19mm) from bottom

3" (76mm) from rear

To prevent serious injury, death, or

property damage:

Do not use this warming appliance in

the presence of flammable anesthetic

mixtures (with air or with oxygen or

nitrous oxide).

• LED interior lighting casts a

comforting blue glow with two (2)

different intensity settings and

off mode.

• Safety: In the event of a power

failure the appliance will retain

its programming and operates as

previously set when power

is restored.

• Safety: A warming shut-off system,

separate from the electronic

control, prevents overheating.

• Convenience: Access point

and removable cover on the

back panel allows the addition

of data logging or temperature

management hardware.

• Convenience: Stackable

confi gurations are available

for additional capacity or to

pair with fl uid warmers.

4

MN-37072 • Rev 2 • 05/16 • Designer Series Blanket Warmer

Dimensions (H x W x D)

Capacity

Weight**

Dimensions (H x W x D)

Capacity

Weight**

Dimensions (H x W x D)

Capacity

Weight**

DC150

**Domestic ground shipping information. Contact factory for export weight and dimensions.

Dimensions (H x W x D)

Capacity

Weight**

Dimensions (H x W x D)

Capacity

Weight**

With feet (standard): 17.0" x 18.5" x 22.7" (431mm x 470mm x 577mm)

With casters

(optional): 20.5" x 18.5" x 22.7" (520mm x 470mm x 577mm)

1.5 3

(est.)

Net: 56 lbs (25 kg) Ship: 98 lbs (44 kg)

DC250

With feet (standard): 21.9" x 18.5" x 25.7" (557mm x 470mm x 653mm)

With plate and

(optional):

casters

With bumper and

casters

(optional):

(est.)

26.3" x 18.5" x 25.7" (667mm x 470mm x 653mm)

26.3" x 21.3" x 25.9" (667mm x 540mm x 657mm)

3

2.5

Net: 67 lbs (30 kg) Ship: 118 lbs (54 kg)

DC350

Dimensions

With feet (standard): 27.9" x 18.5" x 25.7" (709mm x 470mm x 653mm)

With plate and

(optional):

casters

With bumper and

casters

(optional):

DC400

With feet (standard): 21.9" x 24.0" x 28.0" (557mm x 610mm x 712mm)

With plate and

(optional):

casters

With bumper and

casters

(optional):

DC750

With feet (standard): 35.4" x 24.0" x 28.0" (900mm x 610mm x 712mm)

With bumper and

(optional):

casters

With casters

32.2" x 18.5" x 25.7" (819mm x 470mm x 653mm)

32.2" x 21.3" x 25.9" (819mm x 540mm x 657mm)

3.5 3

(est.)

(est.)

(optional): 40.7" x 24.0" x 28.0" (1033mm x 610mm x 712mm)

(est.)

Net: 91 lbs (41 kg) Ship: 146 lbs (66 kg)

26.1" x 24.0" x 28.0" (664mm x 610mm x 712mm)

26.2" x 26.8" x 28.9" (665mm x 679mm x 734mm)

4.0 3

Net: 85-1/2 lbs (439 kg) Ship: 160 lbs (73 kg)

39.3" x 26.8" x 28.0" (997mm x 679mm x 712mm)

7.5 3

Net: 134 lbs (61 kg) Ship: 196 lbs (89 kg)

MN-37072 • Rev 2 • 05/16 • Designer Series Blanket Warmer

5

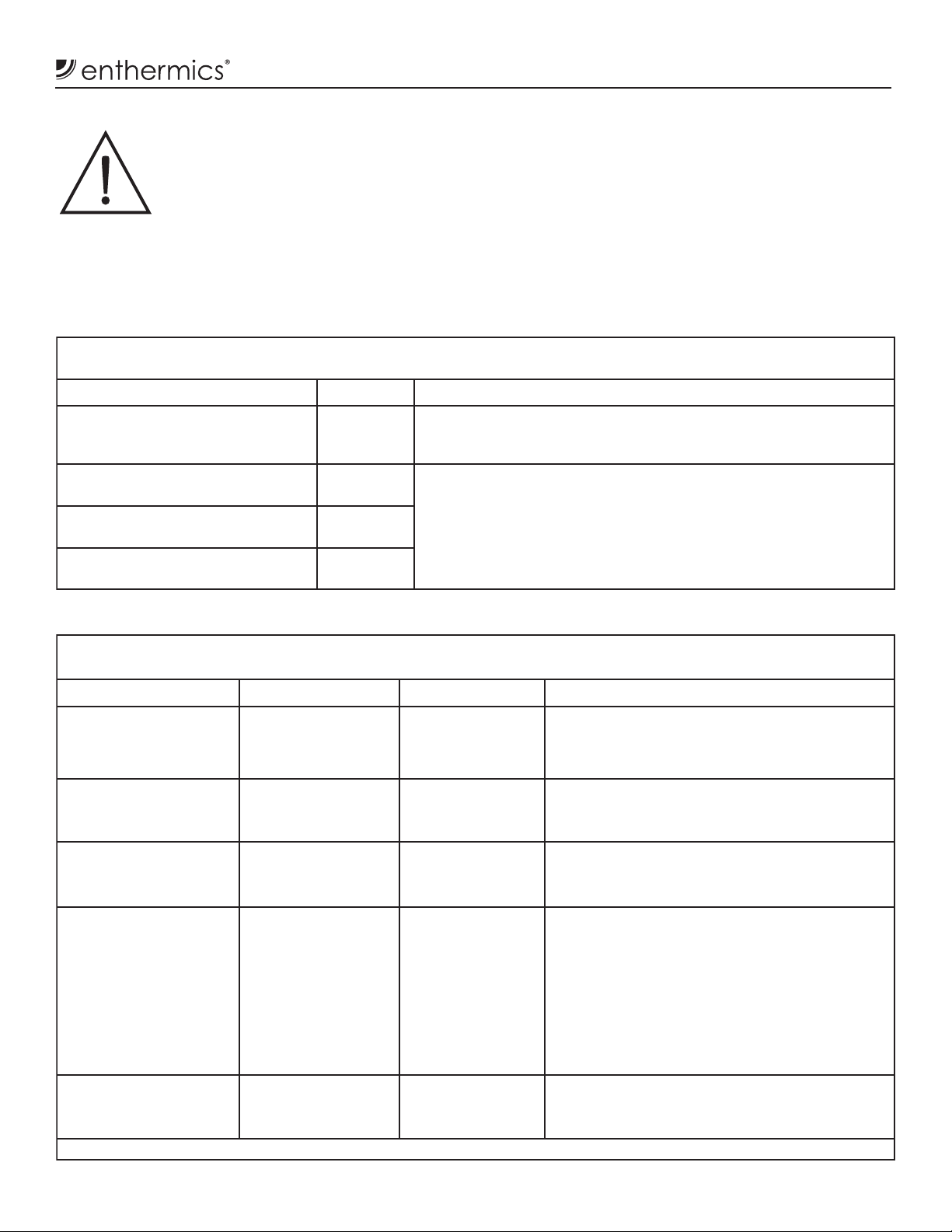

Electrical Information

CAUTION

DANGER

Not category AP or APG equipment

For CE approved appliances: To prevent an

following symbol.

26.3" x 18.5" x 25.7" (667mm x 470mm x 653mm)

26.3" x 21.3" x 25.9" (667mm x 540mm x 657mm)

2.5 3

Net: 67 lbs (30 kg) Ship: 118 lbs (54 kg)

120 V.A.C. — 60 Hz, 1 ph

0.6 kW, 5.0 Amps

NEMA 5-15P

220 V.A.C. — 50Hz, 1 ph

0.6 kW, 2.7 Amps

Type B Equipment

CEE 7/7*

IPX-0

230 V.A.C. — 50 Hz, 1 ph

0.6 kW, 2.6 Amps

IPX-0

39.3" x 26.8" x 28.0" (997mm x 679mm x 712mm)

7.5 3

Net: 134 lbs (61 kg) Ship: 196 lbs (89 kg)

120 V.A.C. — 60 Hz, 1 ph

0.8 kW, 6.7 Amps

NEMA 5-15P

220 V.A.C. — 50Hz, 1 ph

0.8 kW, 3.6 Amps

Type B Equipment

CEE 7/7*

IPX-0

230 V.A.C. — 50 Hz, 1 ph

0.8 kW, 3.5 Amps

IPX-0

1.5 3

Net: 56 lbs (25 kg) Ship: 98 lbs (44 kg)

120 V.A.C. — 60 Hz, 1 ph

0.6 kW, 5.0 Amps

NEMA 5-15P

220 V.A.C. — 50Hz, 1 ph

0.6 kW, 2.7 Amps

Type B Equipment

CEE 7/7*

IPX-0

230 V.A.C. — 50 Hz, 1 ph

0.6 kW, 2.6 Amps

IPX-0

26.1" x 24.0" x 28.0" (664mm x 610mm x 712mm)

26.2" x 26.8" x 28.9" (665mm x 679mm x 734mm)

4.0 3

Net: 85-1/2 lbs (439 kg) Ship: 160 lbs (73 kg)

120 V.A.C. — 60 Hz, 1 ph

0.8 kW, 6.7 Amps

NEMA 5-15P

220 V.A.C. — 50Hz, 1 ph

0.8 kW, 3.6 Amps

Type B Equipment

CEE 7/7*

IPX-0

230 V.A.C. — 50 Hz, 1 ph

0.8 kW, 3.5 Amps

IPX-0

32.2" x 18.5" x 25.7" (819mm x 470mm x 653mm)

32.2" x 21.3" x 25.9" (819mm x 540mm x 657mm)

3.5 3

Net: 91 lbs (41 kg) Ship: 146 lbs (66 kg)

120 V.A.C. — 60 Hz, 1 ph

0.8 kW, 6.7 Amps

NEMA 5-15P

220 V.A.C. — 50Hz, 1 ph

0.8 kW, 3.6 Amps

CEE 7/7*

IPX-0

230 V.A.C. — 50 Hz, 1 ph

0.8 kW, 3.5 Amps

Safety Class I

Equipment

Wire diagram is located under top lid of appliance.

*Other international plugs are available, contact factory for more information.

To prevent serious injury, death, or

property damage:

Do not use this warming appliance in

the presence of flammable anesthetic

mixtures (with air or with oxygen or

nitrous oxide).

Locate Rating Tag

Verify power requirements. The power speci cation is located on the appliance identi cation

rating tag. This tag is permanently attached to the appliance.

Power Requirements

DC150 DC400

15A - 125V Plug

Safety Class I Equipment

No Applied Parts

Mode of Operation: Continuous

Type B Equipment

Hospital Grade

220-230V Plug

BS 1363 Plug*

(UK only)

CEE 7/7*

220-230V Plug

E471516

IPX-0

Power source must match voltage identified

on appliance rating tag. The rating tag

provides essential technical information

required for any appliance installation,

maintenance or repairs. Do not remove,

damage or modify the rating tag.

Safety Class I Equipment

No Applied Parts

Mode of Operation: Continuous

Type B Equipment

Voltage Present

15A - 125V Plug

Hospital Grade

220-230V Plug

BS 1363 Plug*

(UK only)

CEE 7/7*

220-230V Plug

Hazardous

E471516

IPX-0

DC250 DC750

15A - 125V Plug

Safety Class I Equipment

No Applied Parts

Mode of Operation: Continuous

Type B Equipment

DC350

Safety Class I Equipment

No Applied Parts

Mode of Operation: Continuous

Type B Equipment

Type B Equipment

6

MN-37072 • Rev 2 • 05/16 • Designer Series Blanket Warmer

Hospital Grade

220-230V Plug

BS 1363 Plug*

(UK only)

CEE 7/7*

220-230V Plug

15A - 125V Plug

Hospital Grade

220-230V Plug

BS 1363 Plug*

(UK only)

CEE 7/7*

220-230V Plug

E471516

IPX-0

E471516

IPX-0

15A - 125V Plug

Safety Class I Equipment

No Applied Parts

Mode of Operation: Continuous

Type B Equipment

Grounding reliability can only be achieved when appliance is

connected to an equivalent receptacle marked “Hospital Grade.”

Medical Equipment classi ed by Underwriters

Protective Earth

Ground Symbol

Laboratories with Respect to Electrical Shock,

Fire and Mechanical Hazards only, in Accordance

with UL 61010–1 and CAN/CSA C22.2 No. 61010–1.

electrical shock hazard between the appliance and

other appliances or metal parts in close vicinity,

an equalization-bonding stud is provided. An

equalization bonding lead must be connected to

this stud and the other appliances/metal parts

to provide sufficient protection against potential

difference. The terminal is marked with the

Hospital Grade

220-230V Plug

BS 1363 Plug*

(UK only)

CEE 7/7*

220-230V Plug

E471516

E471516

IPX-0

Electrical Information

Guidance and Manufacturer’s Declaration

The appliance requires special precautions

regarding EMC (Electromagnetic

Compatibility) and needs to be installed

and put into service according to the

EMC information provided in the

accompanying documents.

Portable and mobile RF communications equipment can

affect medical electrical equipment.

A risk of increased emissions or decreased immunity

Electromagnetic Emissions

The appliances are intended for use in the electromagnetic environment speci ed below. The customer or the end

user of this appliance should assure that it is used in such an environment.

Emissions test Compliance Electromagnetic environment - guidance

RF emissions; CISPR 11 Group 1 The appliance uses RF energy only for internal function.

Therefore, its RF emissions are very low and are not likely to cause

any interference in nearby electronic equipment.

RF emissions; CISPR 11 Class B The appliance is suitable for use in all establishments, including

domestic establishments and those directly connected to the public

Harmonic emissions; IEC 61000-3-2 Class A

low-voltage power supply network that supplies buildings used for

domestic purposes.

may result if the power cord attached is altered or a

manufacturer supplied power cable is not used.

The appliance should not be used adjacent to or stacked

with other equipment.

Observe to verify normal operation if it is necessary to use

adjacent to or stacked with other equipment.

The essential performance of the appliance is to not

exceed an internal temperature of 180°F / 82°C (+10%) for

blanket warmers or 150°F / 66°C (+10%) for uid warmers.

Voltage uctuations/Flicker

emissions; IEC 61000-3-3

Complies

Electromagnetic Immunity

The appliance is intended for use in the electromagnetic environment speci ed below. The customer or the end user

of this appliance should assure that it is used in such an environment.

Immunity test IEC 60601 test level Compliance level Electromagnetic environment - guidance

Electromagnetic

discharge (ESD)

IEC 61000-4-2

Electrical fast

transient/burst

IEC 61000-4-4

Surge

IEC 61000-4-5

Voltage dips, short

interruptions and

voltage variations on

power supply input lines

IEC 61000-4-11

Power frequency (50/60

Hz) magnetic eld

IEC 61000-4-8

NOTE: UT is the a.c. mains voltage prior to application of the test level.

±6 kV contact

±8 kV air

±2 kV for power

supply lines; ±1 kV

for input/output lines

±1 kV differential

mode; ±2 kV

common mode

<5 % UT (>95 % dip in

UT) for 0.5 cycle

40 % UT (60 % dip in

UT) for 5 cycles

70 % UT (30 % dip in

UT) for 25 cycles

<5 % UT (>95 % dip in

UT) for 5 sec

3 A/m 3 A/m Power frequency magnetic elds should be at

±6 kV contact

±8 kV air

+2 kV for power

supply lines

±1 kV differential

mode; ±2 kV

common mode

<5 % UT (>95 % dip

in UT) for 0.5 cycle

40 % UT (60 % dip

in UT) for 5 cycles

70 % UT (30 % dip

in UT) for 25 cycles

<5 % UT (>95 % dip

in UT) for 5 sec

Floors should be wood, concrete or ceramic tile.

If oors are covered with synthetic material, the

relative humidity should be at least 30%.

Main power quality should be that of a typical

commercial or hospital environment. The

appliance does not have any input/output lines.

Mains power quality should be that of a typical

commercial or hospital environment.

Mains power quality should be that of a typical

commercial or hospital environment. If the

user of the appliance requires continued

operation during power mains interruptions, it

is recommended that the appliance be powered

from an uninterrupted power supply or a

battery.

levels characteristic of a typical location in a

typical commercial or hospital environment.

MN-37072 • Rev 2 • 05/16 • Designer Series Blanket Warmer

7

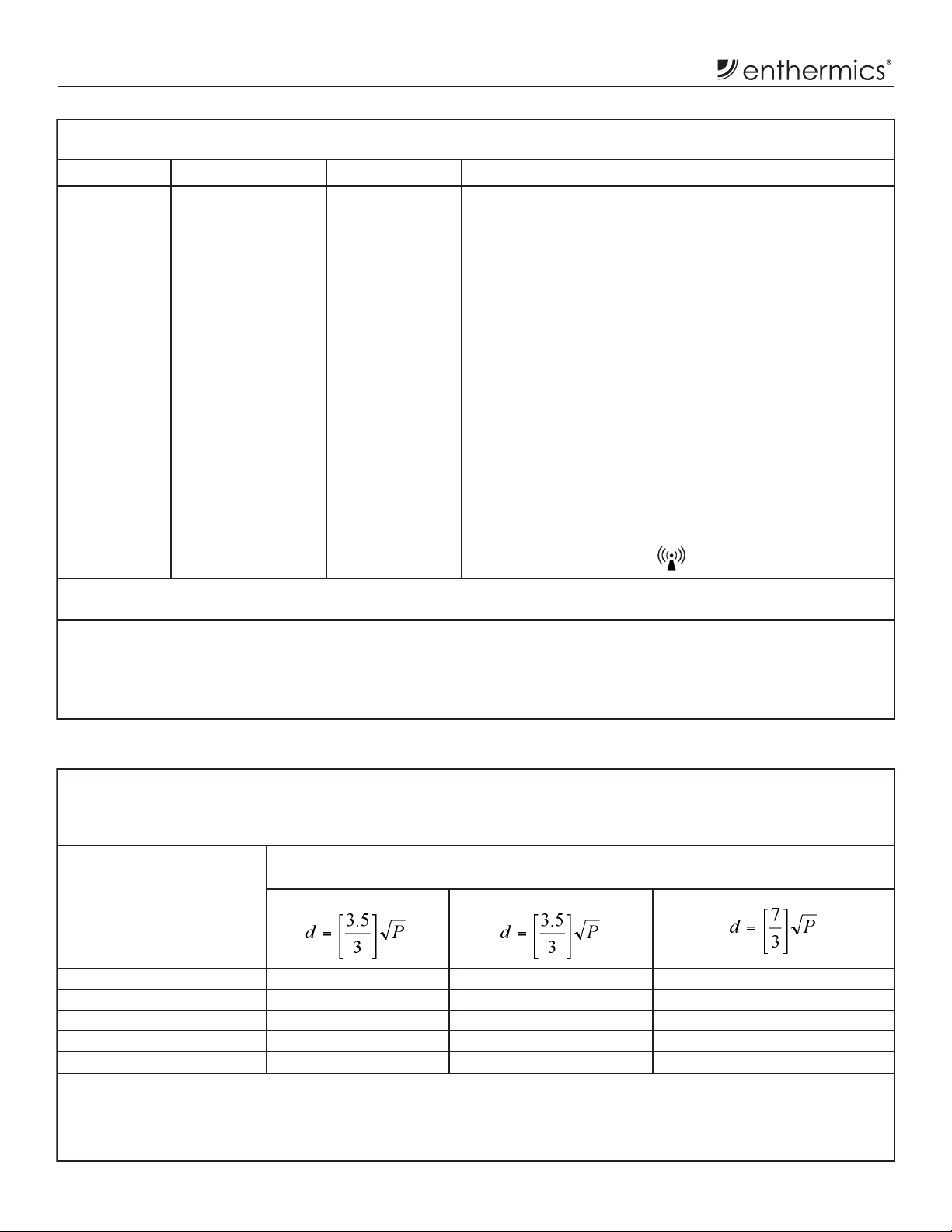

Electrical Information

fi xed RF transmitters, an electromagnetic site survey should be considered. If the measured fi eld strength in the location in which the appliance is

Electromagnetic Emissions

The appliance is intended for use in the electromagnetic environment speci ed below. The customer or the end user

of this appliance should assure that it is used in such an environment.

Immunity test IEC 60601 test level Compliance level Electromagnetic environment - guidance

Portable and mobile RF communications equipment should

be used no closer to any part of the appliance, including

cables, than the recommended separation distance

calculated from the equation applicable to the frequency of

the transmitter.

Recommended separation distance

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

3 V/m

150 kHz to 80 MHz

3 V/m

80 MHz to 2.5 GHz

3 V/m

3 V/m

d = [3.5/3] √P

d = [3.5/3] √P 80 MHz to 800 MHz

d = [7/3] √P 800 MHz to 2.5 GHz

where P is the maximum output power rating of the

transmitter in watts (W) according to the transmitter

manufacturer and d is the recommended separation distance

in meters (m).

Field strengths from xed RF transmitters, as determined

a

by an electromagnetic site survey,

compliance level in each frequency range.

should be less than the

b

Interference may occur in the vicinity of equipment marked

with the following symbol:

NOTE: 1. At 80 MHz and 800 MHz, the higher frequency range applies. 2. These guidelines may not apply in all situations.

Electromagnetic propagation is a ected by absorption and reflection from structures, objects and people.

a. Field strengths from fi xed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile radios, amateur radio, AM

and FM radio broadcast and TV broadcast cannot be predicted theoretically with accuracy. To assess the electromagnetic environment due to

used exceeds the applicable RF compliance level above, the appliance should be observed to verify normal operation. If abnormal performance is

observed, additional measures may be necessary, such as reorienting or relocating the appliance.

b. Over the frequency range 150 kHz to 80 MHz, fi eld strengths should be less than [VI] V/m.

Electromagnetic Immunity Recommended Separation Distance Between Portable And Mobile

RF Communications Equipment And This Unit.

The appliance is intended for use in an electromagnetic environment in which radiated RF disturbances are

controlled. The customer or the user of the appliance can help prevent electromagnetic interference by maintaining a

minimum distance between portable and mobile RF communications equipment (transmitters) and the appliance as

recommended below, according to the maximum output power of the communications equipment.

Separation distance according to frequency of transmitter

Rated maximum output

power of transmitter

150 kHz to 80 MHz 80 MHz to 800 MHz 800 MHz to 2.5 GHz

W

0.01 0.117 0.117 0.233

0.1 0.369 0.369 0.738

1 1.167 1.167 2.333

10 3.689 3.689 7.379

100 11.667 11.667 23.333

For transmitters rated at a maximum output power not listed above, the recommended separation distance d in meters (m) can be estimated using

the equation applicable to the frequency of the transmitter, where P is the maximum output rating of the transmitter in watts (W) according to the

transmitter manufacturer.

NOTE: 1. At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies. 2. These guidelines may not apply

in all situations. Electromagnetic propagation is a ected by absorption and reflection from structures, objects and people.

m

8

MN-37072 • Rev 2 • 05/16 • Designer Series Blanket Warmer

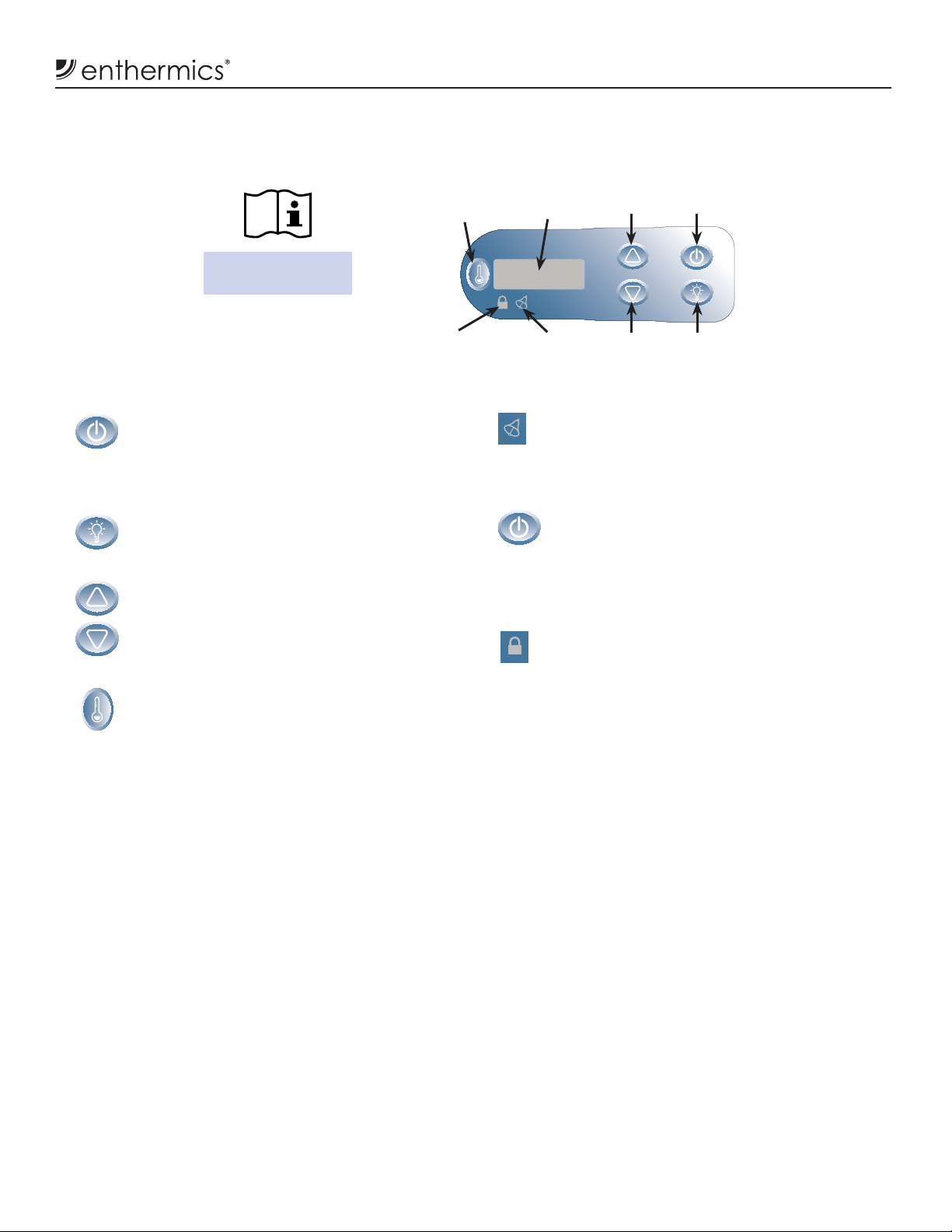

Operation Instructions

Blanket Electronic Control Features

The following refers to features that are available when the electronic control is powered on.

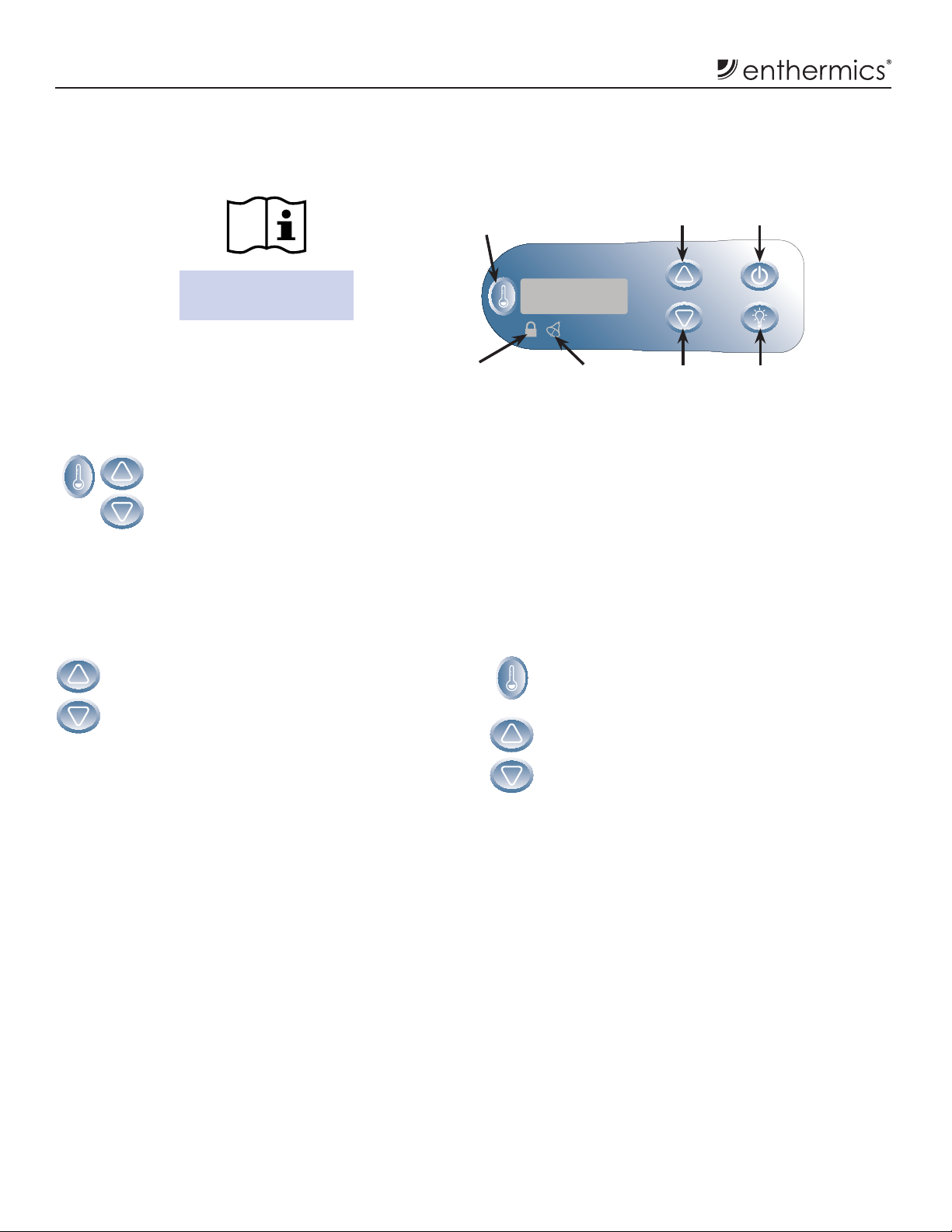

Electronic Control Panel

changes can be made to the temperature set-point

Electronic Control and LED Display

Temperature

Recall Button

LED Digital

Display

Temperature Range:

32°C-71°C (90°F-160°F)

Up Arrow

Button

On/Off

Button

On/Off Button

Press the On/Off button to power on the

electronic control. Press and hold the

On/Off button for three (3) seconds to power

the electronic control off.

Interior Light Button

Press the Interior Light button to toggle blue

interior LED light intensity to high, low, or off.

Up Arrow/Down Arrow Buttons

Used to increase or decrease the temperature

set-point. Additionally used to set the current to

increase or decrease time, date, auto-start, and

auto-stop times.

Temperature Recall Button

Press the Temperature Recall button to view

the actual temperature captured with the

cavity sensor. The display will show the actual

cavity temperature for fi ve (5) seconds before

reverting back to displaying the current

temperature set-point.

LED Digital Display

The control has a four-digit LED display.

Button Lockout

Indicator Light

Error

Indicator Light

Down Arrow

Button

LED Display Status Indicators

Error Indicator Light

This indicator will illuminate and an alarm will

sound if the electronic control senses an error has

occurred (see troubleshooting guide). The alarm

can be muted by pressing the on button.

Error Acknowledgement

To clear or acknowledge an error, press the

On/Off button. Press the On/Off button to

acknowledge the periodic alarm. If the alarm

continues or returns, the appliance is still

experiencing an error and may need service.

Button Lockout Indicator Light

The electronic control can be locked so that no

or the mode selection. Press and hold the

On/Off button and the Up Arrow button at the

same time. The lock indicator will illuminate.

Attempts to operate the on/off button, or

to change the temperature set-point will be

unsuccessful. To unlock the electronic control,

press and hold the On/Off button and the Down

Arrow button at the same time. The electronic

control will unlock, and the lock indicator will

go out.

Power Fail Detection

If the power were to fail for any reason while electronic

control is powered on, the electronic control will retain

in memory its current operating state. When the power

is restored, the electronic control alarms once and

resumes operating in its previously set mode. The on/

off status indicator will blink, alerting the operator that

such an event has occurred. Press the On/Off button

once to acknowledge that the power has been restored.

Interior

Light Button

NOTE: If the timer option is installed, the appliance must

be off for more than 60 seconds to signal a power

failure alarm. When acknowledging a power

interruption, the display will show the length of

time in hours and minutes that the control has

been off due to the power outage.

MN-37072 • Rev 2 • 05/16 • Designer Series Blanket Warmer

9

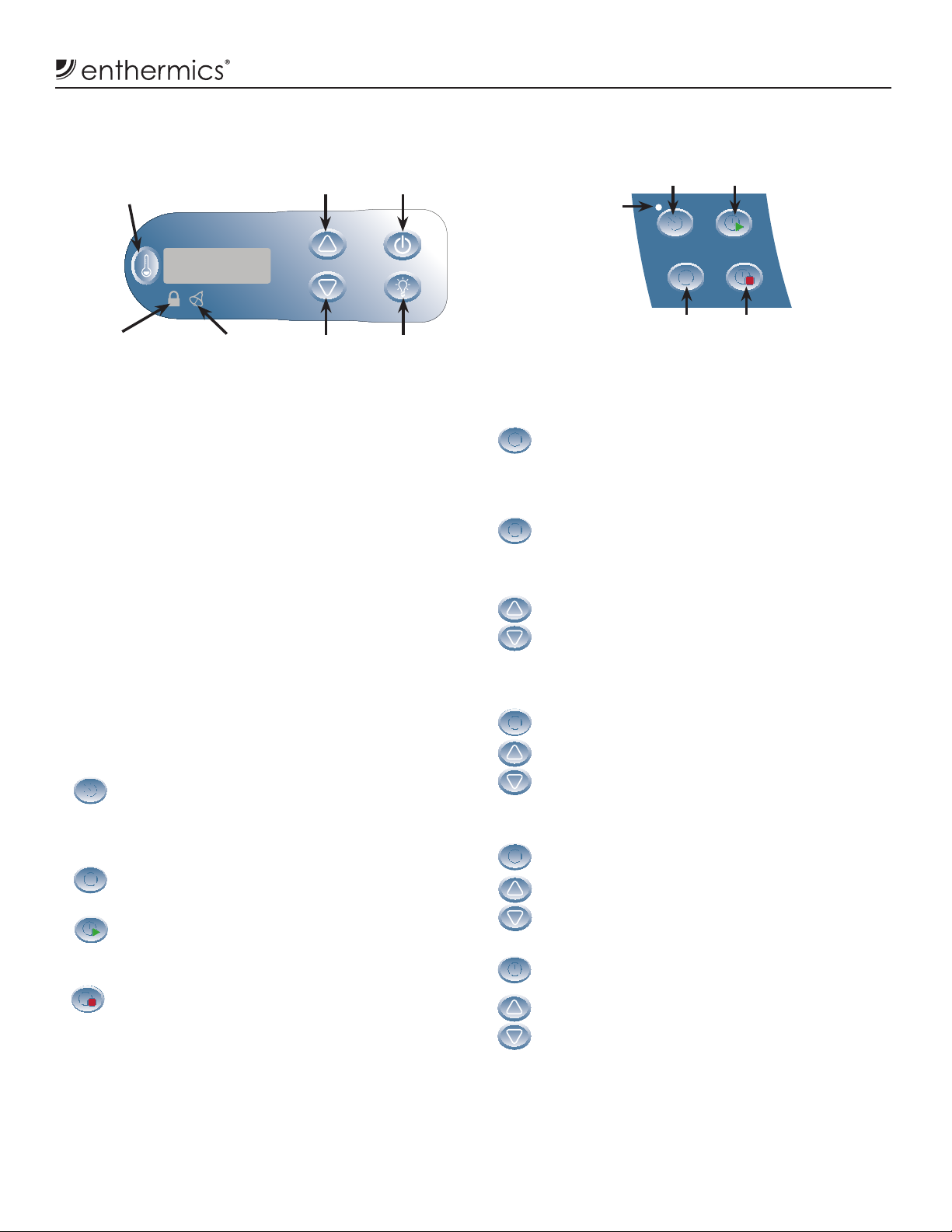

Operation Instructions

Blanket Electronic Control Features (continued)

Temperature Range:

32°C-71°C (90°F-160°F)

Temperature Format Selection

While the electronic control is in off

state, press and hold the Temperature

Recall button for four (4) seconds to

display the current temperature scale.

Press the Up Arrow or Down Arrow

buttons to switch between °F (fahrenheit)

or °C (celsius).

Sound Function

(Prior to September 2015)

The sound function can be turned on or off.

1. While the appliance is off, press and hold the

Down Arrow button for four (4) seconds.

2. The display will indicate the current sound

status, 0 (off) or 1 (on). Press the Up Arrow

or Down Arrow button to toggle between the

two choices.

Electronic Control and LED Display

Temperature

Recall Button

Button Lockout

Indicator Light

(A er September 2015)

Error

Indicator Light

The sound volume can be changed:

1. While the appliance is on, press the

Temperature Recall button and the Down

Arrow button to display the current volume

setting. Release.

2. Press the Up Arrow or Down Arrow button to

adjust the volume. Volume settings range from

0 (mute)to 12 (loud).

NOTE: The alarm volume is set at the maximum

Up Arrow

Button

Down Arrow

Button

Light Button

(12) and can not be disabled.

On/Off

Button

Interior

10

MN-37072 • Rev 2 • 05/16 • Designer Series Blanket Warmer

Operation Instructions

Optional Timer Control Feature

NOTE:

The appliance time must be manually reset for daylight

The times are displayed in 24-hour format (hh:mm).

If the display has changed due to user interaction, the

If the start and stop times are the same, the appliance

The timer option must be off to reset the appliance time.

An E-60 error is displayed if the clock is not set or

Timer Control Panel

Electronic Control and LED Display

Temperature

Recall Button

Button Lockout

Indicator Light

Error

Indicator Light

Up Arrow

Button

Down Arrow

Button

If the appliance is not equipped with this optional

automated timer feature or it is not in use this section

can be skipped.

saving time.

Midnight is 00:00. Noon is 12:00. 1:00 P.M. is 13:00.

display will reset a er five (5) seconds of inactivity.

will recognize the off time only and will not turn on

without user intervention. This is the best way to set the

warmer for the days when it is not needed.

On/Off

Button

Interior

Light Button

Optional Timer Control

Timer On/Off

Button

On/Off

Indicator

Light

Time Button

Resetting the Time

1. Acknowledge E-60 error

a. Press the Time button to acknowledge the

E-60 error displayed when the control has

been inactive.

2. View and adjust time

a. Press and hold the Time button for four (4)

seconds until the auto-timer on/off indicator

light blinks slowly and the display shows the

current set time.

b. Press the Up Arrow or Down Arrow button to

adjust the time in increments of one (1) minute

or press and hold the Up Arrow or Down Arrow

button to adjust the minutes more quickly.

Set or View

Start Time Button

Set or View

Stop Time Button

the control has been off too long and the memory

has become corrupted.

Press the Timer On/Off button to initiate the

automatic start/stop timer operation. The on/off

indicator light next to this button will illuminate

when the timer is turned on.

Press the Time button to view the current time,

date, and day and initiate changes to the settings.

Press the Start Time button to view the current

automatic start time and initiate changes to

the set time.

Press the Stop Time button to view the current

automatic stop time and initiate changes to

the set time.

3. View and adjust year

a. Press the Time button again to view or set

the year.

b. Press the Up Arrow or Down Arrow button to

adjust the year. The year will always adjust by

one (1).

4. View and adjust date

a. Press the Time button again to view or set

the date.

b. Press the Up Arrow or Down Arrow button to

adjust the date.

5. View and adjust day code (optional)

a. Press the Time button again to set the day

code (d1-d7).

b. Press the Up Arrow or Down Arrow button to

adjust the day code.

NOTE: Setting the day code is optional unless the user

configures the auto-timer to start or stop at a

diff erent time for each day of the week. Typically

Monday=d1, Tuesday=d2, etc.

MN-37072 • Rev 2 • 05/16 • Designer Series Blanket Warmer

11

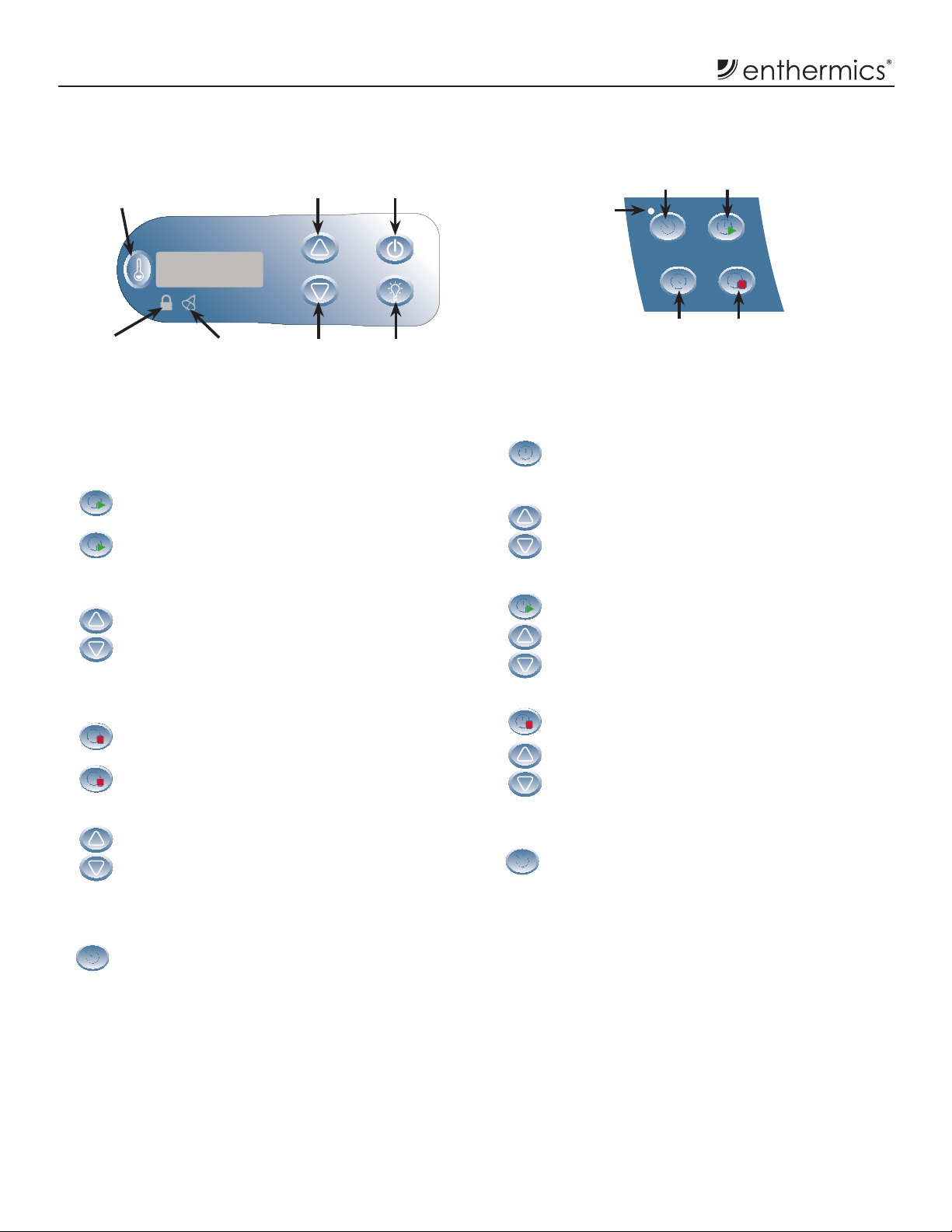

Operation Instructions

Optional Timer Control Feature (continued)

Same Start and Stop Times for the Week

Note:

Activating this mode overrides all individual

Electronic Control and LED Display

Temperature

Recall Button

Button Lockout

Indicator Light

Error

Indicator Light

The timer option must be off to set the start time.

day programming.

1. View and adjust start time

a. Press the Start Time button to view the start

time for that day.

b. Press and hold the Start Time button for four

(4) seconds to set the current day’s start time

as the same time for every day of the week.

The on/off indicator light will blink slowly.

c. Press the Up Arrow or Down Arrow button

to change the default start time minutes.

Press and hold the Up Arrow or Down Arrow

button to adjust the hour.

2. View and adjust stop time

a. Press the Stop Time button to view the stop

time for that day.

b. Press and hold the Stop Time button for four

(4) seconds to set the current day’s stop time

as the same time for every day of the week.

The on/off indicator light will blink slowly.

c. Press the Up Arrow or Down Arrow

button to change stop time. Press and

hold the Up Arrow or Down Arrow button

to adjust the hour.

3. When both times are set, allow the on/off indicator

light to extinguish and then press and hold the

Timer On/Off button until the on/off indicator

light stays on steadily.

Up Arrow

Button

Down Arrow

Button

On/Off

Button

Interior

Light Button

Optional Timer Control

Set or View

Start Time Button

Set or View

Stop Time Button

On/Off

Indicator

Light

Timer On/Off

Button

Time Button

Different Start and Stop Times for Each Day of

the Week

1. View and adjust specifi c day

a. Press and hold the Time button for eight (8)

seconds. The on/off indicator light will

blink rapidly. The display will show the

current day.

b. Adjust the day by pressing the Up Arrow or

Down Arrow button.

2. View and adjust start time for that day

a. Press the Stop Time button to display the

start time for that day.

b. Press the Up Arrow or Down Arrow button

to adjust the automatic start time.

3. View and adjust stop time for that day

a. Press the Stop Time button to display the

start time for that day.

b. Press the Up Arrow or Down Arrow button

to adjust the automatic stop time.

4. Repeat steps 1-3 for each day of the week

5. When all days and times are set, allow the on/off

indicator light to extinguish and then press and

hold the Timer On/Off button until the on/off

indicator light stays on steadily.

12

MN-37072 • Rev 2 • 05/16 • Designer Series Blanket Warmer

Loading...

Loading...