1

MPR-3 SERIES NETWORK ANALYSER USER

MANUAL

INDEX

SAFETY AND WARNINGS ........................................................................................................ 3

Warning .................................................................................................................................. 3

Safety ..................................................................................................................................... 3

Warranty................................................................................................................................. 3

OPERATING CONDITIONS....................................................................................................... 4

INTRODUCTION ....................................................................................................................... 5

General Features ................................................................................................................... 5

Applications ........................................................................................................................... 6

MPR-3 Series Products .......................................................................................................... 6

Overview ................................................................................................................................ 7

Terminals ............................................................................................................................... 7

Front Panel ......................................................................................................................... 8

Button Functions ................................................................................................................. 9

Terminal Structure ............................................................................................................ 10

INSTALLATION ....................................................................................................................... 10

3P4W (3 Phase with Neutral) Connection............................................................................. 10

3P3W (3 Phase without Neutral) Connection........................................................................ 11

Aron without Neutral Connection .......................................................................................... 11

3P4W BLN (3 Phase Balanced with Neutral) Connection ..................................................... 12

3P3W BLN (3 Phase Balanced without Neutral) Connection ................................................ 12

Connection Test ................................................................................................................... 13

Line Termination Resistor..................................................................................................... 13

OPERATING INSTRUCTIONS ................................................................................................ 14

Measurement Screens ......................................................................................................... 14

Current, Voltage and Frequency Screens ......................................................................... 14

Power and Power Factor Screens..................................................................................... 15

Energy and Harmonics Screens........................................................................................ 17

Minimum, Maximum and Demand Screens ....................................................................... 19

2

Setup Screen........................................................................................................................ 25

Device Installation Settings .............................................................................................. 25

Display Settings ............................................................................................................... 30

Time Settings ................................................................................................................... 31

RS-485 Communication Settings ..................................................................................... 33

Input Parameter Settings .................................................................................................. 34

Output Parameter Settings................................................................................................ 35

Pulse Output Settings ....................................................................................................... 36

Operating Hours Settings .................................................................................................. 38

Alarm Settings ............................................................................................... .................. 39

Reset Settings .................................................................................................................. 42

System Settings ................................................................................................................ 44

Reporting Screen .............................................................................................................. 47

Reading the Records via Modbus ..................................................................................... 48

TECHNICAL FEATURES AND APPENDIX ............................................................................. 49

Technical Features ............................................................................................................... 49

Applicable Standards ........................................................................................................ 50

IEC 61557-12.................................................................................................................... 50

3

SAFETY AND WARNINGS

Warning

Failure to follow the instructions below may result in serious injury or death.

Cut all power before connecting the device.

Do not connect the current measurement inputs directly to the current source. Always connect

the current source using a current transformer.

Once the device is energized, do not remove the front panel.

Do not attempt to clean the device with a solvent or another similar agent. Use only a dry piece of

cloth.

Check the correct connections before energizing the device.

Contact your authorized seller in case of any problems with your device.

Device is only for panel mounting.

F Type fuse must be used and its current limit must be 1 A.

The manufacturing company is not responsible for the consequences resulting from failure to comply with

these precautions.

Safety

Read the entire user manual before using the device.

A switch or circuit breaker must be connected between the network and the auxiliary supply of

the device.

Connected switch or circuit breaker must be in close proximity to the device.

Connected switch or circuit breaker must be marked as the disconnecting device for the

equipment.

Warranty

Device has a 2 (two) year warranty. Any repairs on the device must be done only by the manufacturer.

Otherwise, the device warranty will be void.

OPERATING CONDITIONS

Operating Conditions

Range

Supply Voltage

95 - 270 VAC/VDC(Tolerance up to ±10%)

Supply Frequency

50 ~ 60 Hz.

Maximum Measuring Current

5,5 A

Maximum Measuring Voltage

480 VAC (VLL)

Operating Temperature

-10 ~ +55 ºC

Storing Temperature

-20 ~ +70 ºC

Maximum Ambient Humidity

95%

Communication Speed

2400 ~ 115200 bps

4

5

INTRODUCTION

General Features

o Wide supply range (95 – 270 Vrms)

o Custom FSTN display with backlight

o 3 voltage measuring inputs

o 3 current measuring inputs

o 4 language options

o 1MB internal memory

o Real time clock

o Alarm

o Hour counters (Operating hour and total hour)

o Communication via RS-485

o Measured parameters:

Current

Neutral Current

Voltage (Phase-Phase, Phase-Neutral)

Active, Reactive and Apparent Power

Frequency

Active Energy

Reactive Energy

Apparent Energy

Cos φ

Power Factor

Total Active Power

Total Reactive Power

Total Apparent Power

Total Cos φ

Total Power Factor

Total Harmonic Distortion for Current

Total Harmonic Distortion for Phase-Phase Voltages

Total Harmonic Distortion for Phase-Neutral Voltages

o Minimum and Maximum values are available for following parameters:

Current

Phase-Phase Voltage

Phase-Neutral Voltage

Active Power

Reactive Power

Apparent Power

Frequency

Total Harmonic Distortion for Current

Total Harmonic Distortion for Phase-Phase Voltages

Total Harmonic Distortion for Phase-Neutral Voltages

o Demand and Maximum Demand values are available for following parameters measured

with integration time:

Current

Active Power

Apparent Power

o Isolated digital input and output

6

o Capable of recording 256 events

o User password

o Changing primary and secondary values of current and voltage transformers

o Making measurements on 5 different connection type systems: 3 Phase 4 Wires, 3

Phase 3 Wires, 3 Phase Aron, 3 Phase 4 Wires Balanced, 3 Phase 3 Wires Balanced

o Contrast setting

o Backlight setting

o Demand and integration time setting

o Daylight savings time switching

Applications

MPR-3 Series devices are microprocessor-based devices which are designed to measure all parameters

of an electrical network, calculate the consumption values and display these on its LCD screen. Events

like interruptions, time and settings changes, reset operations will be recorded in real-time thanks to its

internal flash memory and Real Time Clock chip. These events then can be accessed and monitored

remotely via RS-485 line with Modbus RTU protocol.

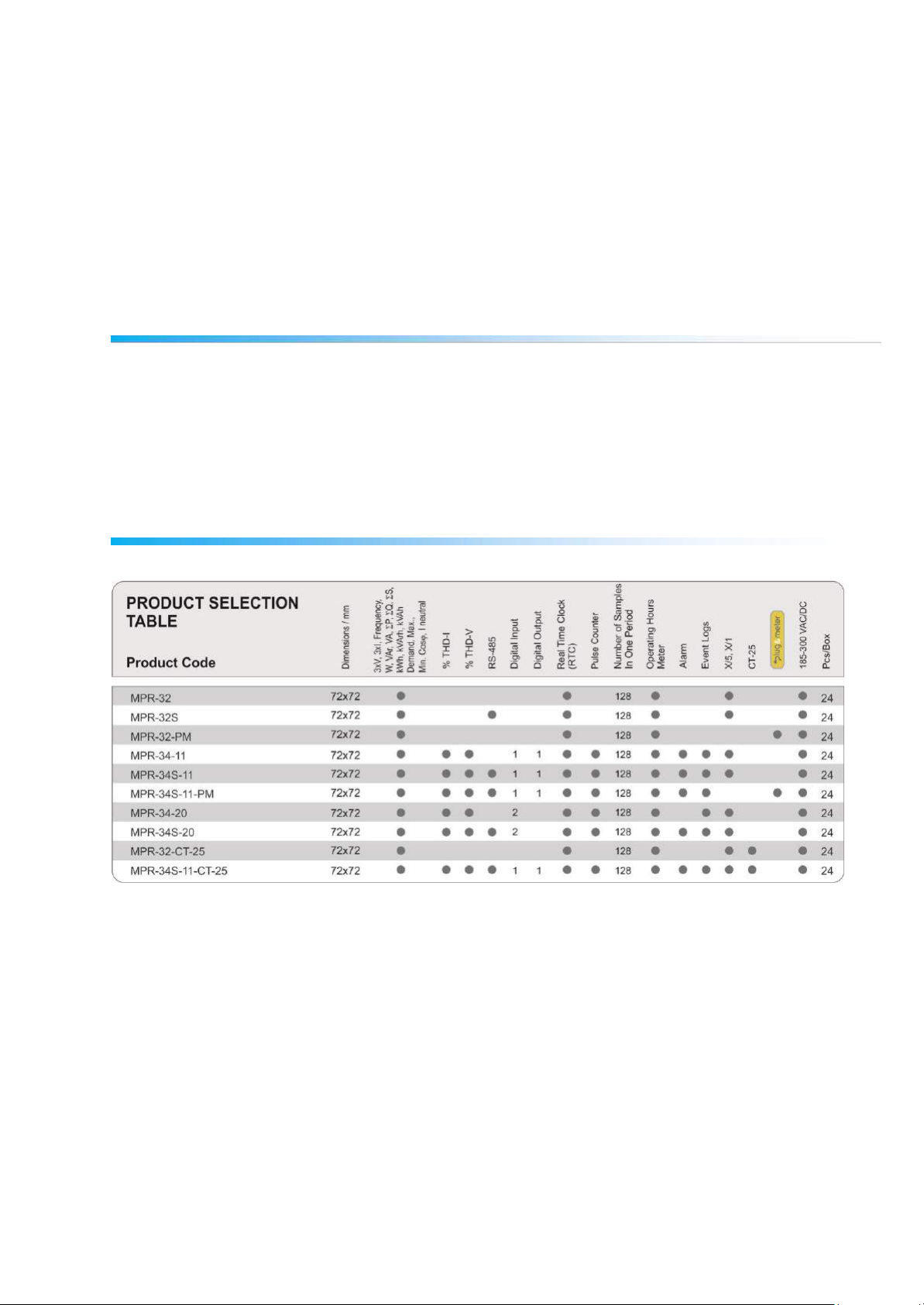

MPR-3 Series Products

7

Overview

1

2

3

4

5

1

2

3

4

5

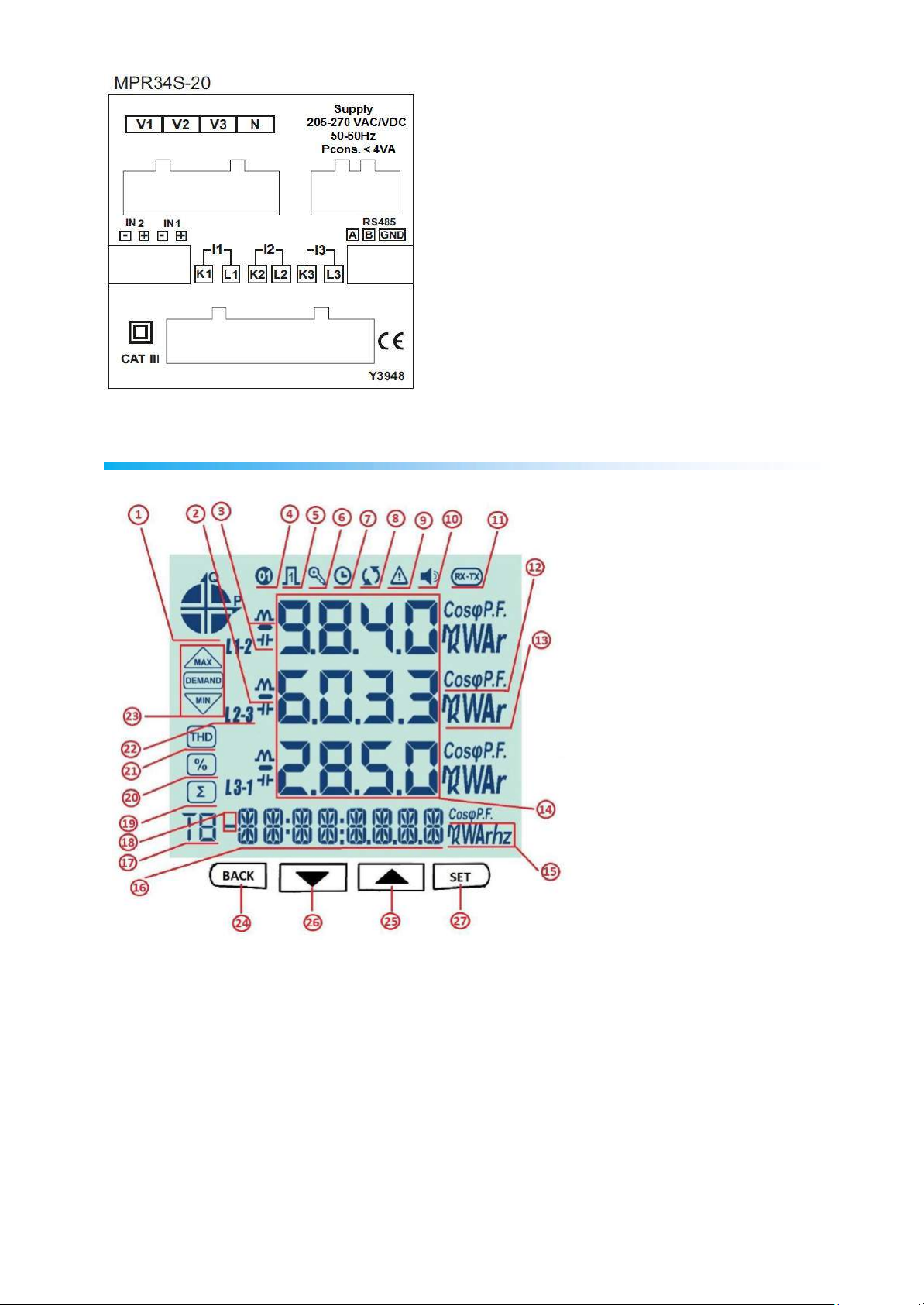

Terminals

Back Panel of the model with one input one output

1. Voltage Inputs

V1 -> 1st Phase Voltage Input

V2 -> 2nd Phase Voltage Input

V3 -> 3rd Phase Voltage Input

N -> Neutral Input

2. Supply Input

3. Digital Input / Output (On models with

two inputs, they are used as IN1 and

IN2 inputs)

Out -> Digital Output

In -> Digital Input

4. RS-485 Input

5. Current Terminals

K1 -> 1st Phase Current

L1

-> 1st Phase Current Output

K2 -> 2nd Phase Current Input,

L2 -> 2nd Phase Current Output

K3 -> 3rd Phase Current Input,

L3 -> 3rd Phase Current Outpu

Input,

8

Back Panel of the model with two inputs

Front Panel

1 – Indicates on which quadrant the network is operating.

2 – Indicates that the displayed value is negative.

3 – Indicates that the measurement is inductive or capacitive

4 – Indicates that the digital output is active.

5 – Indicates that the pulse input is active.

6 – Indicates that password is needed to enter the programming menu.

9

7 – Indicates that the RTC is reset and stays on until RTC is adjusted.

8 – Indicates that there is a phase sequence error.

9 – Indicates that there is a warning

10 – Indicates that the alarm output is active.

11 – Indicates that the communication is active.

12 – Indicates whether the value is CosØ or Power Factor.

13 – Indicates the unit of the value (W, kVAr, MVA, etc.).

14 – Indicates the measured values of the corresponding screen.

15 – Indicates the unit of the energy or the corresponding setting.

16 – Indicates energy value or time.

17 – Indicates for which tariff the energy measurement is.

18 – Indicates that the energy value is negative.

19 – Indicates the total screen. (I.e. Total powers).

20 – Indicates the percent values. (I.e. Harmonics)

21 – Indicates that the displayed values are for Total Harmonic Distortion.

22 – Indicates L1, L2, L3 and L1-2, L2-3 and L3-1 measurements.

23 – Indicates that the corresponding screen is one of Minimum, Maximum, Demand or Maximum

Demand screens.

Button Functions

In addition to their main functions, the 4 buttons on the front panel can be used as shortcut buttons for

easily reaching screens.

BACK button (24): It has 3 main functions:

Exiting from any menu is done by pressing BACK

While on measuring screen: As seen on the symbols (V I F) above the button, it is used to

browse between voltage, current and frequency measurement screens.

While on measuring screen: As seen on the symbols (Event) below the button, event screen is

reached when pressed for 3 seconds.

DOWN Button (26) : It has 3 main functions:

button.

While on measuring screen: As seen on the symbols (P PF) above the button, it is used to

browse between active power, reactive power, apparent power, power factor and Cos φ

measurement screens.

It is used to select the previous digit while entering a numerical value in the menu or to browse

back to a previous menu level.

While on measuring screen: As seen on the symbols (Test) below the button, connection control

is reached when pressed for 3 seconds.

UP Button (25) : It has 2 main functions:

While on measuring screen: As seen on the symbols (E H) above the button, it is used to browse

between energy and harmonics screens.

While on menu screens: It is used to browse between menu options and to decrease a value

during adjustment.

SET Button (27) : It has 3 main functions:

It provides access to menu screens when pressed for 3 seconds. When the PIN is active, a

password is asked before entering the menu. After the correct password is entered, access to

menu is allowed.

It is used to reach the desired adjustment screen and to save the changed settings. Pressing the

button is enough for this operation.

While on measuring screen: It is used to browse between Min, Max, Demand and Max Demand

screens.

10

Terminal Structure

1) 185 - 300 VAC/VDC Supply Input 3 terminal connections (2 pins)

2) Current measuring input terminal block (6 pins): L1 L2 L3 ve N

3) Voltage measuring input terminal block (4 pins): L1 L2 L3 and N

4) RS-485 terminal block (2 pins)

5) Digital Input/Output terminal (4 pins)

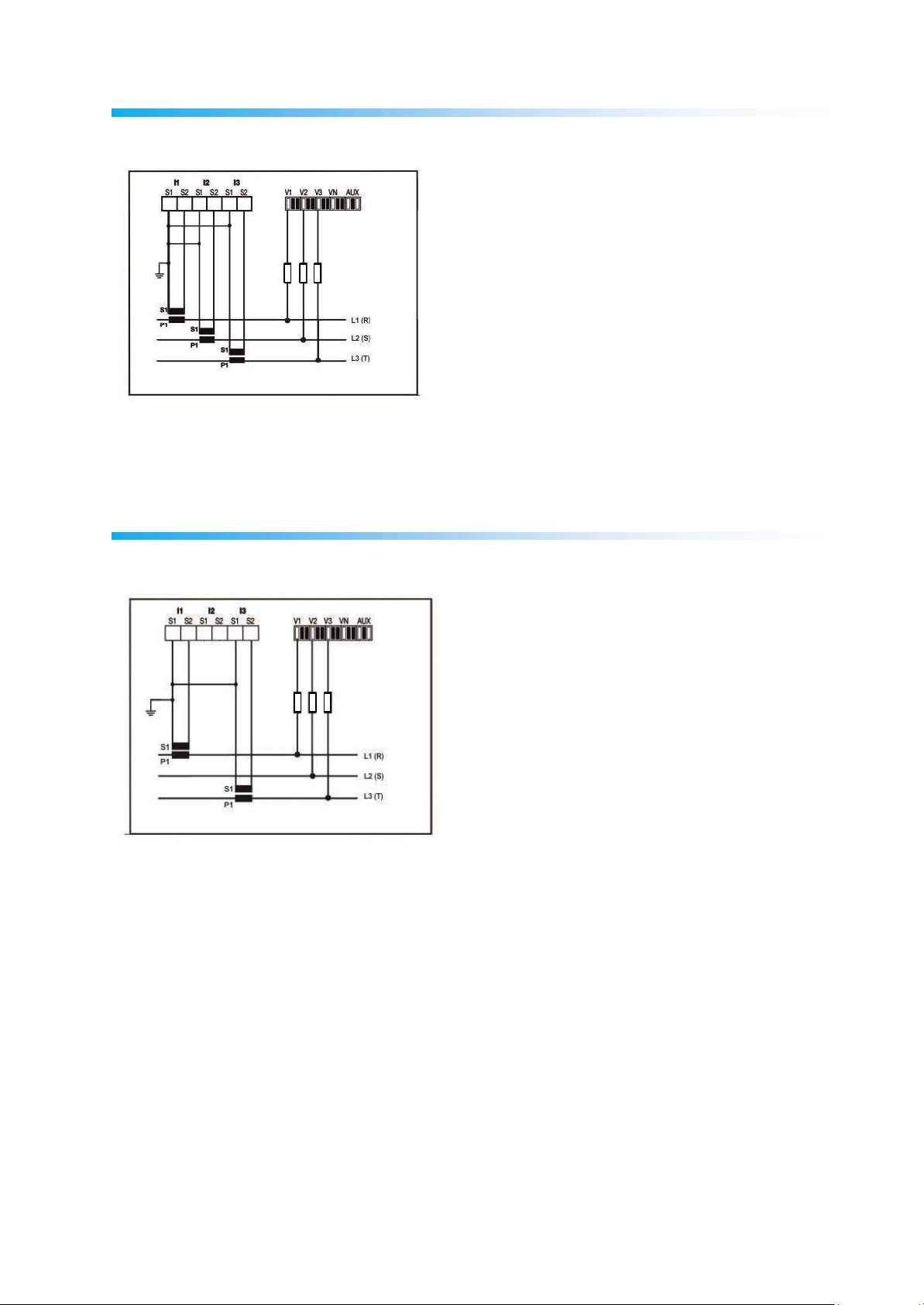

INSTALLATION

The device has shunts for current measurement element there for it must be used with external current

transformers.If the device will be use with other analysers on the same panel ,it is recommented that the

device will be the last point on the current measurement line.

Device has 5 different connection configurations. These configurations are explained with diagrams

below:

3P4W (3 Phase with Neutral) Connection

For this configuration, four voltage connections (including neutral line) and three current connections are

used. Voltage inputs should be connected with 100 mA fuses as shown below.

11

3P3W (3 Phase without Neutral) Connection

For this configuration, three voltage connections and three current connections are used.

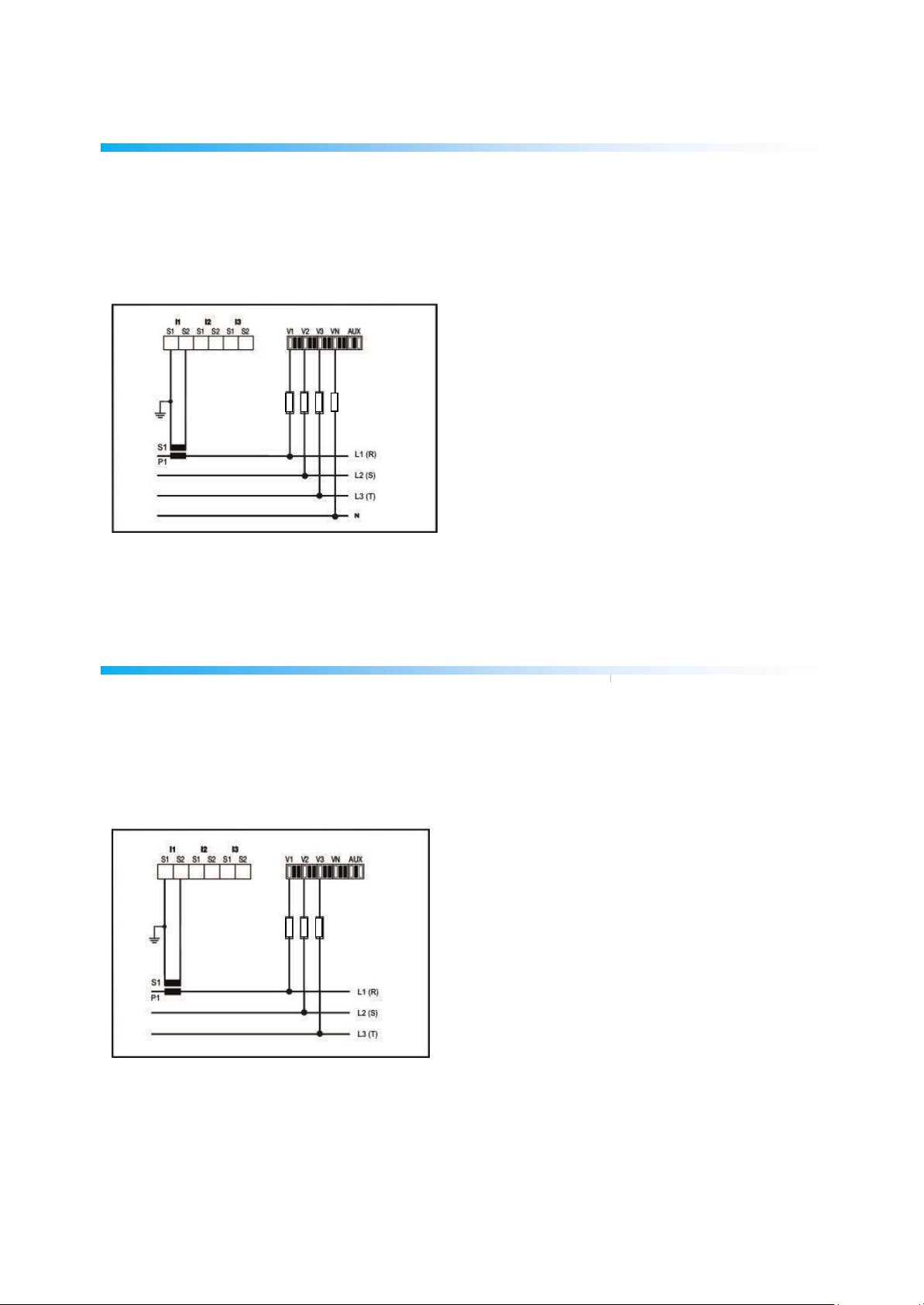

Aron without Neutral Connection

For this configuration, three voltage connections and two current connections are used.

12

3P4W BLN (3 Phase Balanced with

Neutral) Connection

For this configuration, four voltage connections and one current connection is used.

The device shows the same current value, which is measured from the first phase, for the unconnected

phases.

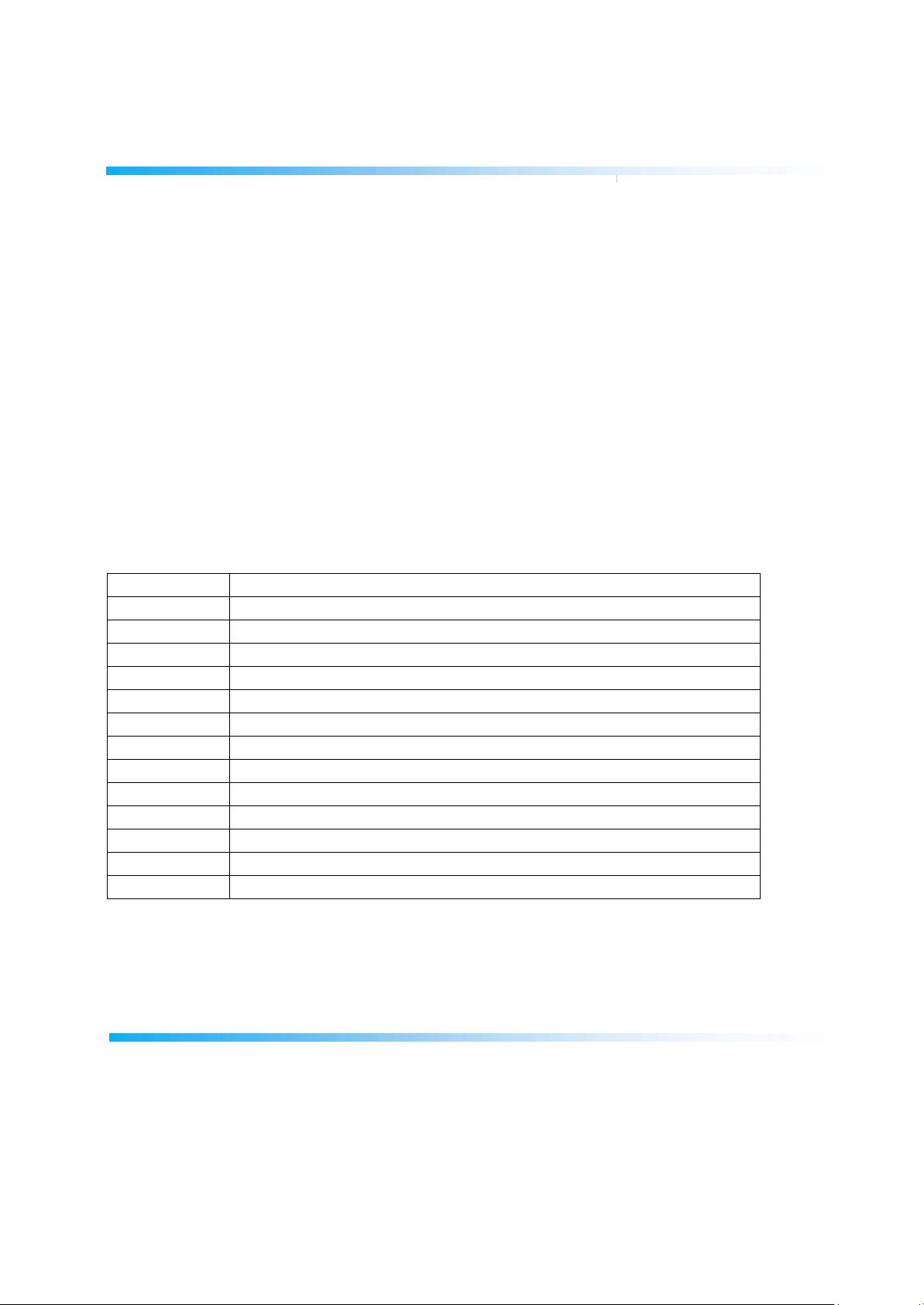

3P3W BLN (3 Phase Balanced without

Neutral) Connection

For this configuration, three voltage connections and one current connection is used.

The device shows the same current value, which is measured from the first phase, for the unconnected

phases.

13

Test Error Code

Test Code

Description

0

All connections are correct

1

Phase-1 current direction is reversed

2

Phase-2 current direction is reversed

3

Phase-3 current direction is reversed

4 Phase-1 and Phase-2 voltage connections are reversed

5 Phase-1 and Phase-3 voltage connections are reversed

6 Phase-2 and Phase-3 voltage connections are reversed

7

Voltage connection phase sequence will be changed as L1,L2,L3 - L3,L1,L2.

8

Voltage connection phase sequence will be changed as L3,L2,L1 - L3,L1,L2.

9

CT-1, CT-2 will be swapped.

10

CT-1, CT-3 will be swapped.

11

CT-2, CT-3 will be swapped.

12

Test conditions are not met.

Connection Test

After finishing device connections, you can check the connection that you’ve done by using the

automatic test function.

When you press the BACK button for 3 seconds, it switches to test mode. During this mode, at least 20%

of the nominal voltage must be applied to the voltage measuring inputs, at least 10% of the nominal

current must be applied to the current measuring inputs and the angle difference between current and

voltage inputs must be less than 30 degrees. These test conditions must be met.

During connection test, the device controls the connections and it can correct them internally or it can

leave the physical correction to the user.

If there’s an error between voltage inputs, it can only be corrected by changing physical connections.

If you encounter Error 12, make sure that all connections are done and minimum current/voltage values

are applied to the device.

On the following table, possible connection errors that may be encountered during connection test and

their corresponding error codes that are displayed on the device screen.

Line Termination Resistor

Line termination resistors are used when communication line length is longer than 10 metres. Usage of

accompanying line termination resistor between A and B terminals can enhance communication

performance in case of multiple devices on the same network.

14

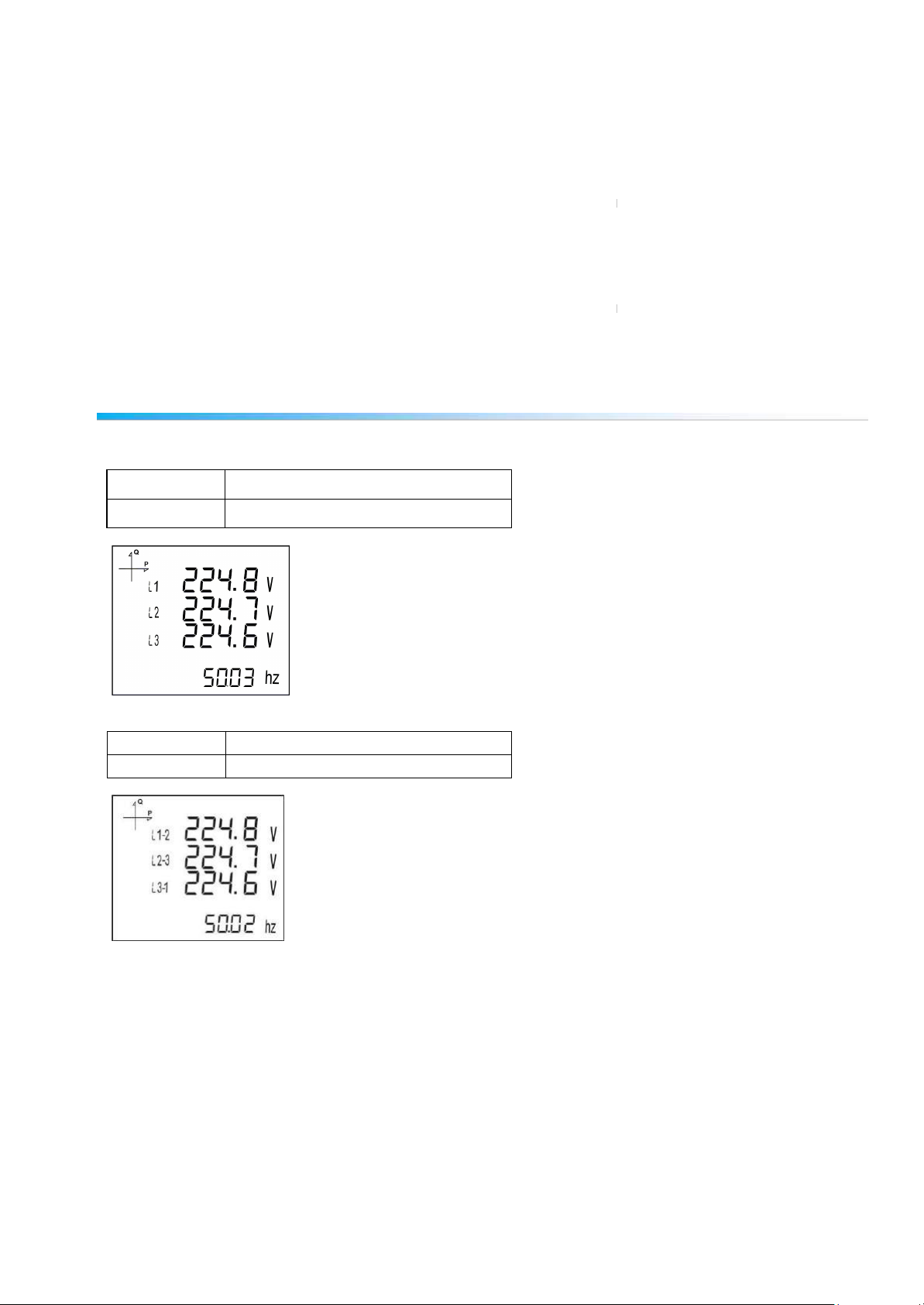

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

BACK (VIF)

VOLTAGE (L-N)

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

BACK (VIF)

VOLTAGE (L-L)

OPERATING INSTRUCTIONS

Measurement Screens

Measurement screens, which can be accessed by pressing the related buttons, are explained in this

section.

Current, Voltage and Frequency Screens

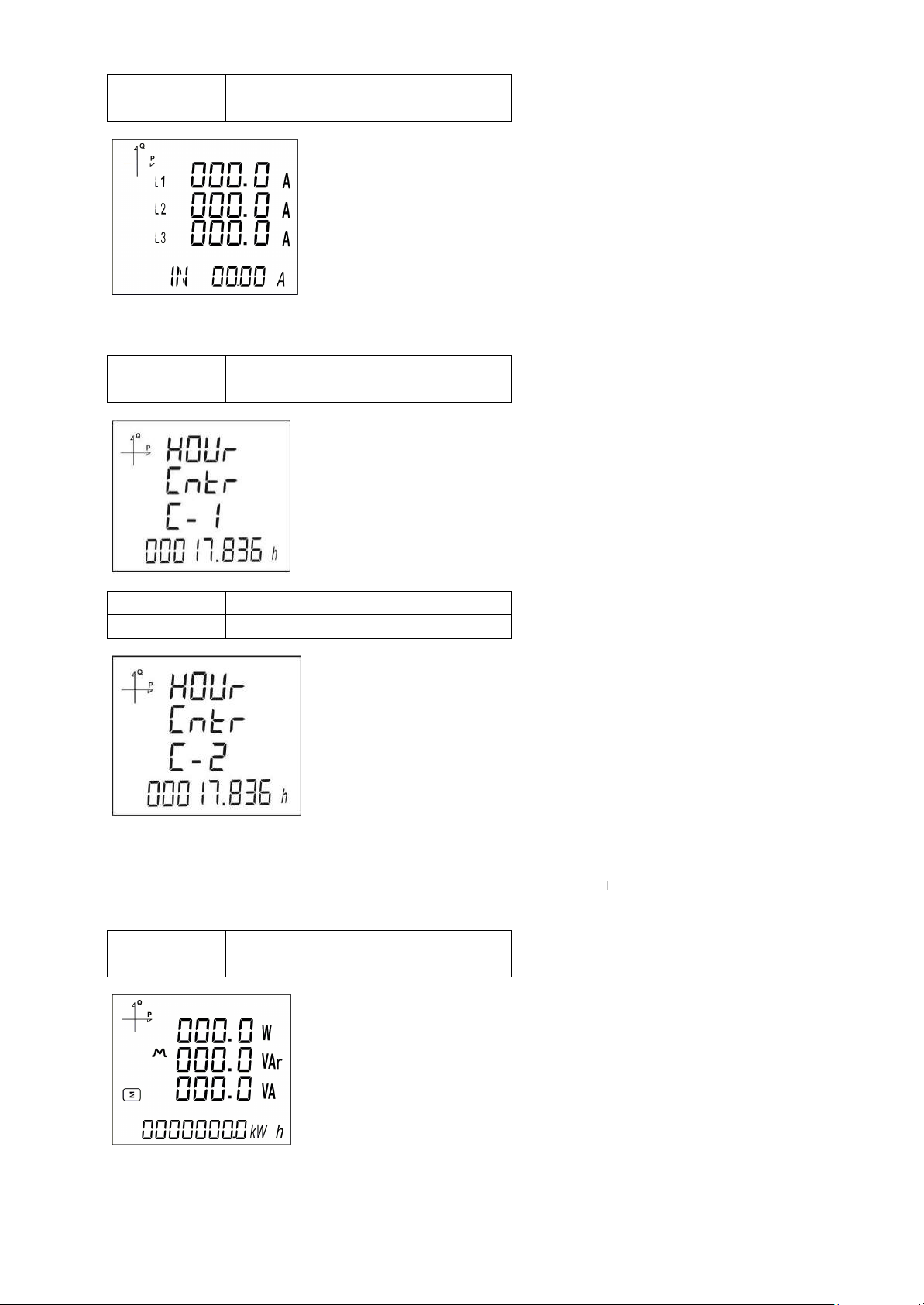

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

BACK (VIF)

CURRENT

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

BACK (VIF)

FIRST HOUR COUNTER

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

BACK (VIF)

SECOND HOUR COUNTER

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

DOWN (P PF)

TOTAL POWER

Power and Power Factor Screens

15

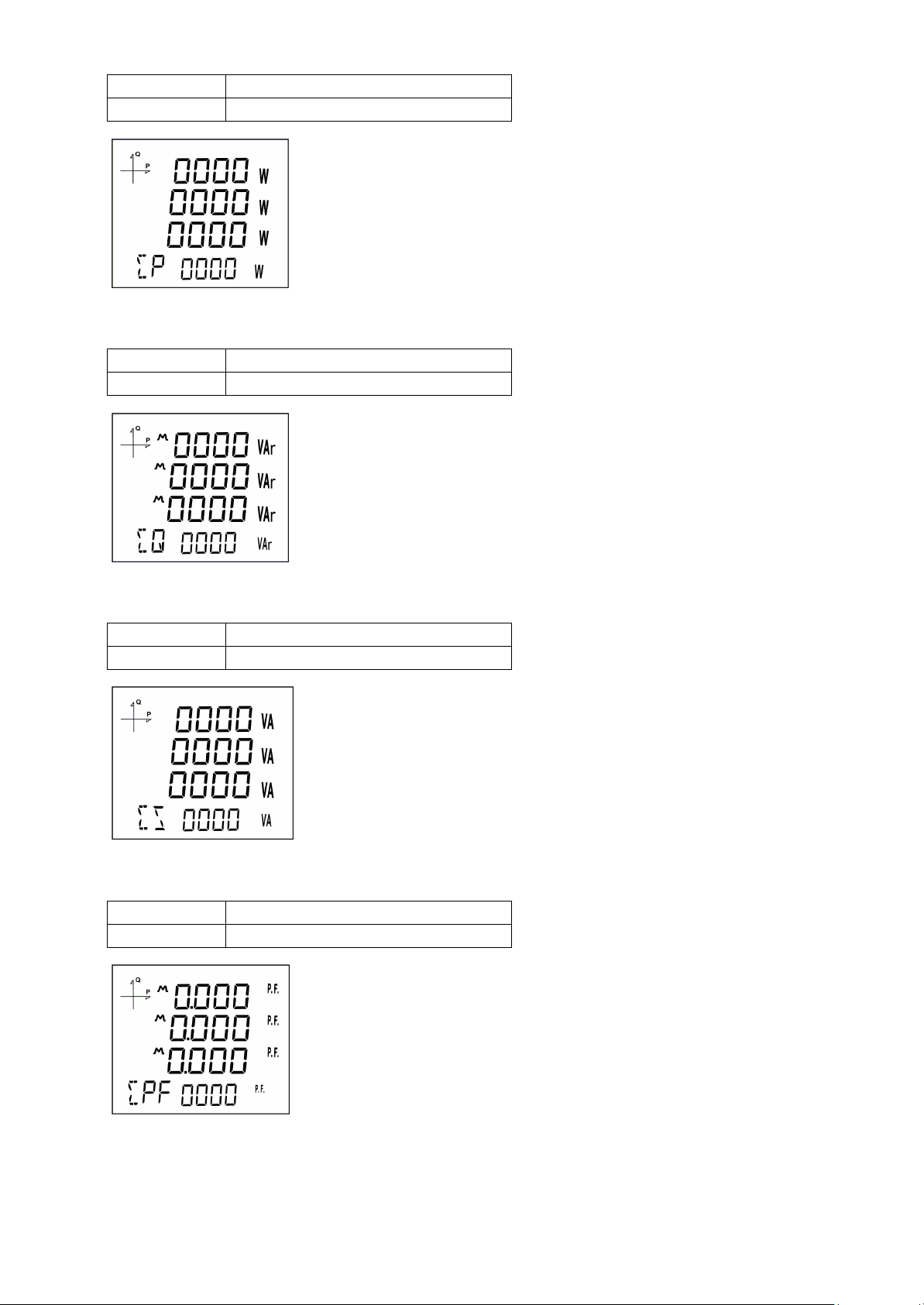

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

DOWN (P PF)

ACTIVE POWER

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

DOWN (P PF)

REACTIVE POWER

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

DOWN (P PF)

APPARENT POWER

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

DOWN (P PF)

POWER FACTOR

16

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

DOWN (P PF)

COS φ

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

UP

THD L-N

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

UP

THD L-L

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

UP

THD IN

Energy and Harmonics Screens

17

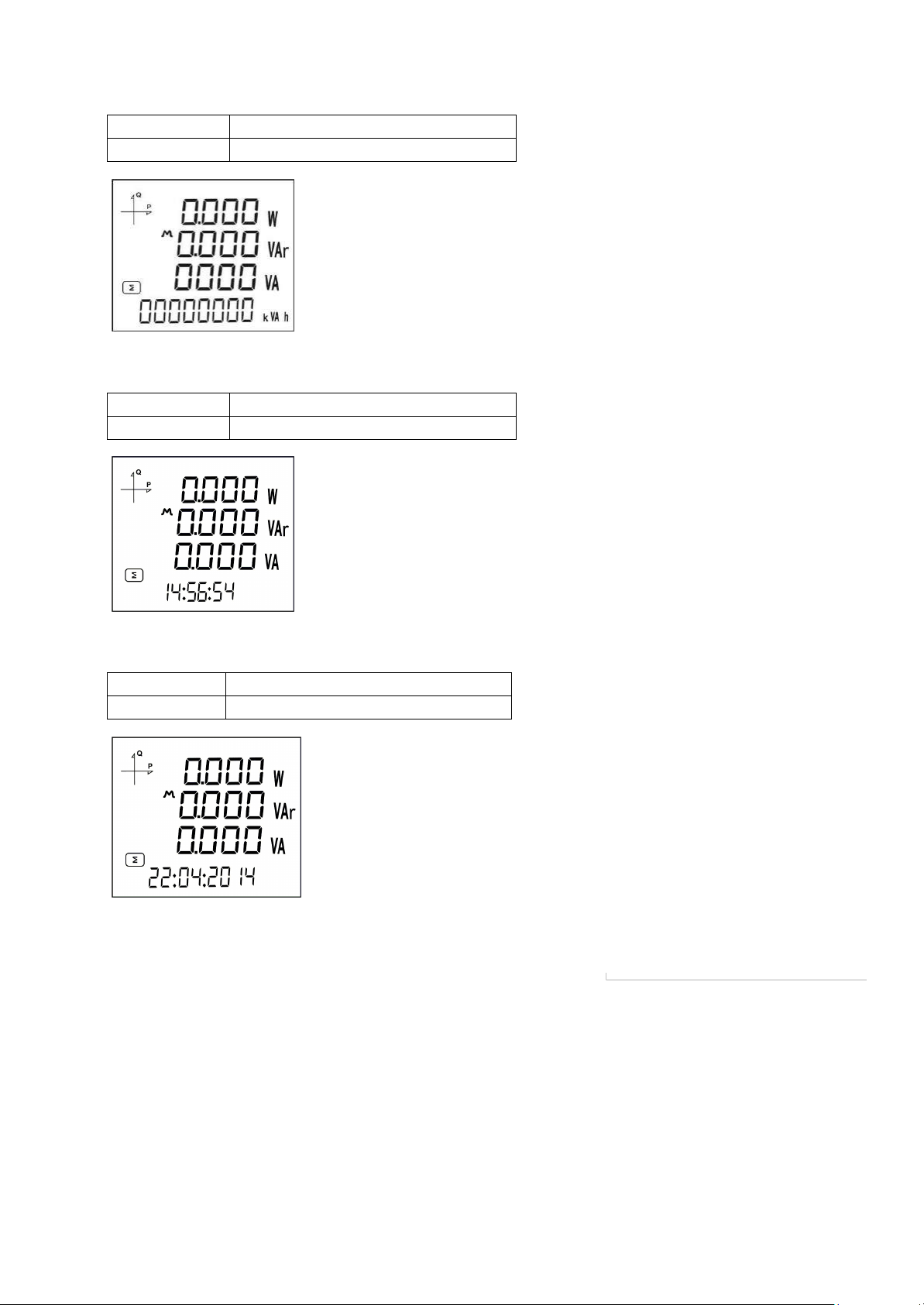

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

UP

Import Active Energy

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

UP

Export Active Energy

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

UP

Import Reactive Energy

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

UP

Export Reactive Energy

18

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

UP

Apparent Energy

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

UP

Time

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

UP

Date

Minimum, Maximum and Demand Screens

To see the minimum and maximum values of current and voltage, first select the relevant screen with “V I

F” button.

Afterwards, you can display the following screens with MAX/MIN DEMAND button.

19

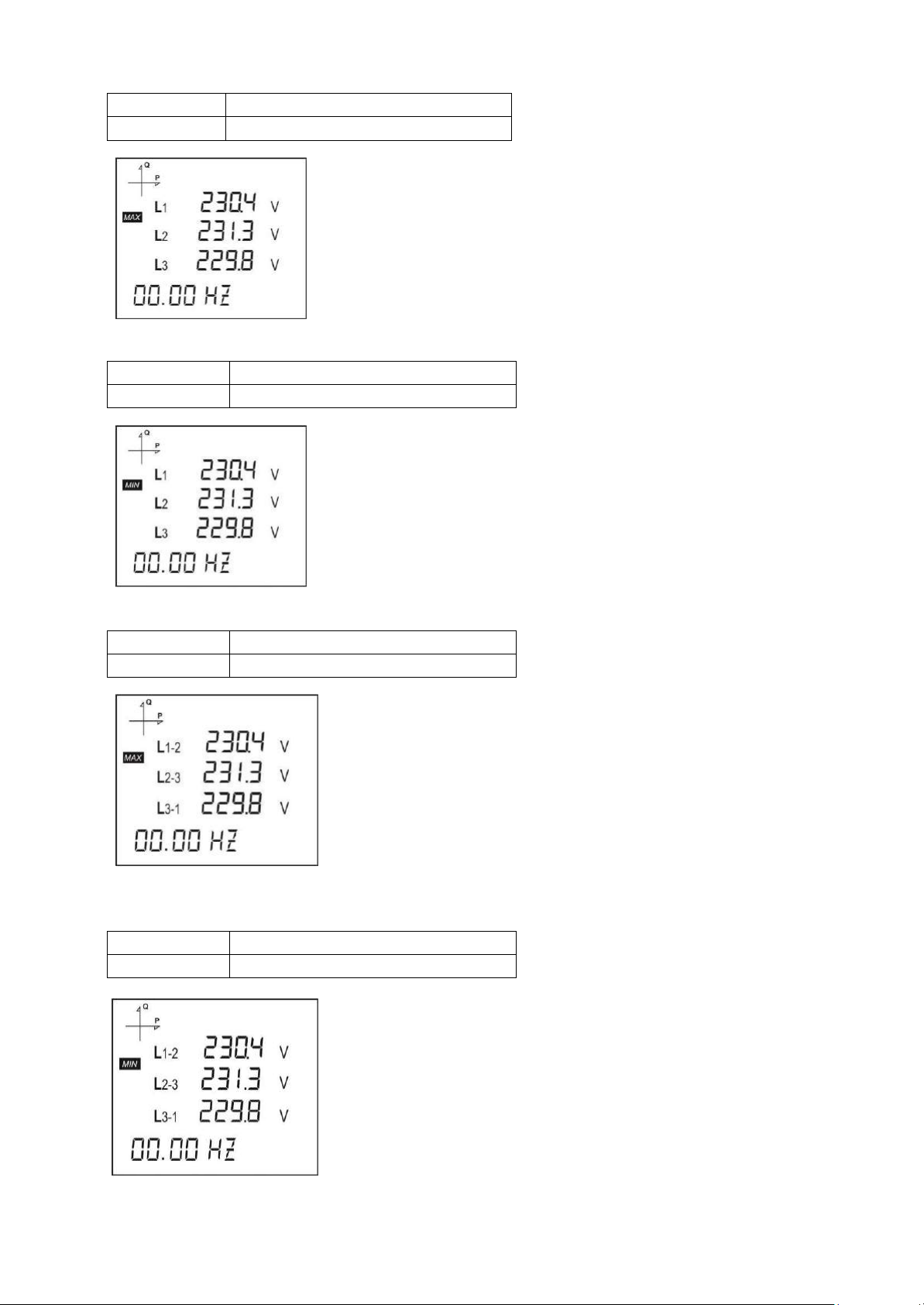

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

SET (MAX/MIN)

MAX(Phase-Neutral Voltage)

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

SET (MAX/MIN)

MIN(Phase-Neutral Voltage)

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

SET (MAX/MIN)

MAX (Phase-Phase Voltage)

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

SET (MAX/MIN)

MIN (Phase-Phase Voltage)

20

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

SET (MAX/MIN)

DEMAND I

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

SET (MAX/MIN)

MAX DEMAND I

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

SET (MAX/MIN)

MAX I

21

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

SET (MAX/MIN)

MIN I

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

SET (MAX/MIN)

DEMAND P

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

SET (MAX/MIN)

MAX DEMAND P

To see the minimum, maximum and demand values of power parameters, first select the relevant screen

with “P PF” button.

Afterwards, you can display the following screens with MAX/MIN DEMAND.

22

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

SET (MAX/MIN)

MAX P

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

SET (MAX/MIN)

MIN P

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

SET (MAX/MIN)

MAX Q

23

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

SET (MAX/MIN)

MIN Q

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

SET (MAX/MIN)

DEMAND S

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

SET (MAX/MIN)

MAX DEMAND S

24

25

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

SET (MAX/MIN)

MAX S

BUTTON NAME

DISPLAYED MEASUREMENT SCREEN

SET (MAX/MIN)

MIN S

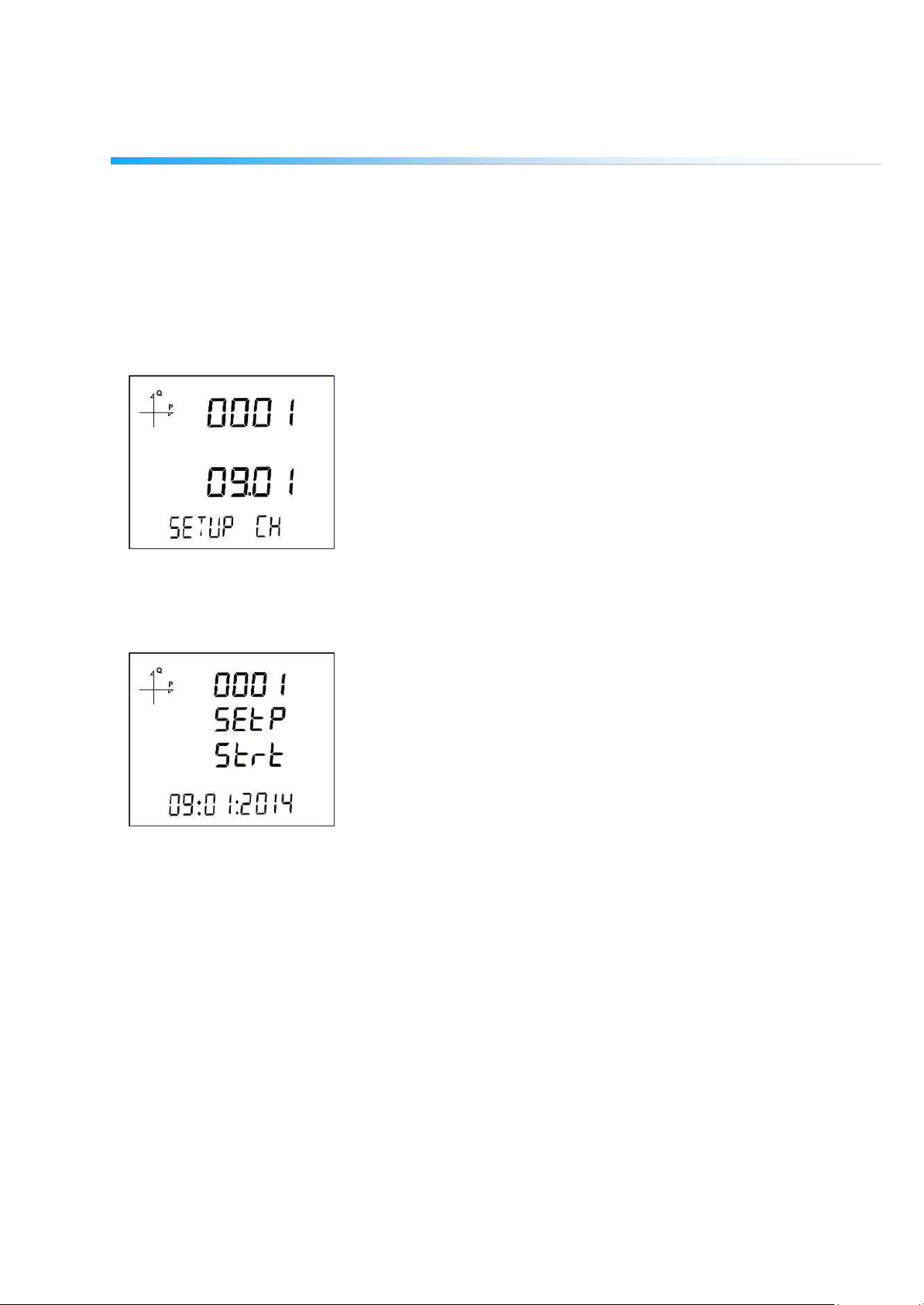

Setup Screen

Accessing the Programming Menu

When the SET button of the device is pressed for 3 seconds with PIN feature activated, entry screen is

displayed. When the password is entered correctly, programming menu is reached.

If PIN feature is not activated, programming menu is reached directly. Password for the device is 1234

as factory default.

Device Installation Settings

In order for the device to become operational, information of current and voltage transformers on the

system and the connection type must be entered to the device.

When the device is energized for the first time, it will require the user to enter this information.

Adjust the following settings accordingly by using SET and UP/DOWN buttons.

26

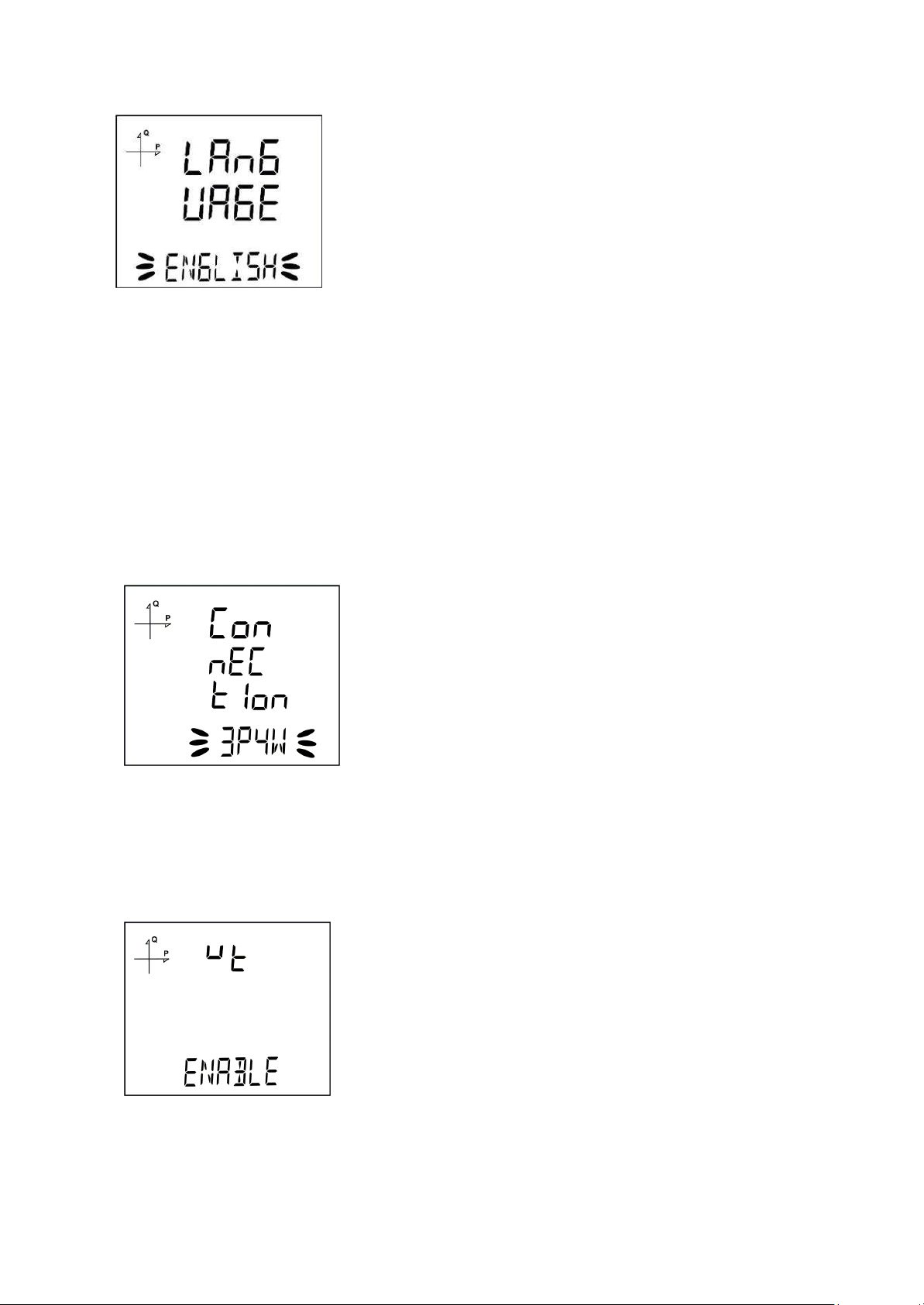

Language

Setting

Messages on the device screen can be viewed in four languages:

1.

Turkish

2.

English

3.

German

4.

French

After selecting your language with UP/DOWN buttons, Press the SET button and go to the next step.

Connection Type Setting

1. By using UP/DOWN buttons, select your network connection type as 3P4W, 3P3W, ARON,

3P4W Balanced or 3P3W Balanced.

2. For unbalanced systems, 3P4W or 3P3W should be selected.

3. Press the SET button and go to the next step.

Voltage Transformer Usage

1. By using UP/DOWN buttons, select Enable or Disable indicating whether you use a voltage

transformer on your system.

2. Press the SET button and go to the next step.

27

VT Secondary Value

1. Enter the secondary value of your VT by using SET and UP/DOWN buttons.

2. You can approve a digit value by pressing the SET button.

3. After entering the necessary value, Press the SET button and go to the next step.

VT Primary Value

1. Enter the primary value of your VT by using SET and UP/DOWN buttons.

2. You can approve a digit value by pressing the SET button.

3. After entering the necessary value, Press the SET button and go to the next step.

CT Secondary Value Selection

1. By using UP/DOWN buttons, select your CT secondary value type as 1A or 5A.

2. After selecting the necessary value, Press the SET button and go to the next step.

28

CT Primary Value

1. Enter the primary value of your CT between 1 and 9999 A by using SET and UP/DOWN

buttons.

2. You can approve a digit value by pressing the SET button.

3. After entering the necessary value, Press the SET button and go to the next step.

Nominal Frequency Value

Selection

1. By using UP/DOWN buttons, select your nominal network frequency as 50 Hz or 60 Hz.

2. After selecting the necessary value, Press the SET button and go to the next step.

Nominal Operating Voltage

Value

1. Enter the nominal operating voltage value between 25 and 300 V by using SET and

UP/DOWN

buttons.

2. You can approve a digit value by pressing the SET button.

3. After entering the necessary value, Press the SET button and go to the next step.

29

Time Zone Setting

Date Setting

Hour Setting

1. By using UP/DOWN buttons, you can select the time zone information about the device

location between -12:00 and +12:00 in 30 minute intervals.

2. After selecting the necessary value, Press the SET button and go to the next step.

1. Enter the date by using SET and UP/DOWN buttons.

2. You can approve a digit value by pressing the SET button.

3. After entering the correct date, Press the SET button and go to the next step.

1. Enter the time by using SET and UP/DOWN buttons.

2. You can approve a digit value by pressing the SET button.

3. After entering the correct date, Press the SET button and go to the next step.

After initial setup measurement screen appears.These parameters may later be changed by accessing

setup menu.

30

Display Settings

Language settings, display contrast and backlight settings are located under Display Settings section.

Language Setting

Messages on the device screen can be viewed in four languages:

1. Turkish

2. English

3. German

4. French

1. Select Language option under Settings/Display and press SET button.

2. Current language option will start blinking. Select one of the options above and press SET button.

3. When exiting from the menu with the BACK button, don’t forget to save the changes.

Backlight Setting

There are three settings for the backlight of the device:

1. Always ON,

2. Always OFF,

3. Automatic.

When “Automatic” option is selected, the backlight turns on after a button is pressed and turns off after

no button is pressed for 3 minutes.

1. Select Backlight option under Settings/Display and press SET button.

2. Current backlight option will start blinking. Select one of the options above and press SET button.

3. When exiting from the menu with the BACK button, don’t forget to save the changes.

31

Display Contrast Setting

Display contrast of the device can be selected between 0 and 15.

The factory default value is 3.

1. Select Contrast option under Settings/Display and press SET button.

2. Current contrast option will start blinking. Select one of the options and press SET button.

3. When exiting from the menu with the BACK button, don’t forget to save the changes

Time Settings

Hour Setting

The time of the device’s RTC(Real Time Clock) module can be set in hours, minutes and seconds.

To set the time, follow these steps:

1. Press the SET button while on Setup Clock screen.

2. Press the SET button on the Hour Set screen, which is the first option.

3. Hour value will start to blink.

4. Adjust the hour by using UP/DOWN buttons.

5. Press the SET button to switch to the minute value. Repeat these steps for minutes and seconds

parts.

6. When exiting from the menu with the BACK button, don’t forget to save the changes.

Date Setting

32

The date of the device’s RTC module can be set in hours, minutes and seconds.

To set the date, follow these steps:

1. Press the SET button on the Date Set screen.

2. Press the SET button. Adjust the day with UP/DOWN buttons.

3. Press the SET button. Adjust the month with UP/DOWN buttons.

4. Press the SET button. Adjust the year with UP/DOWN buttons.

5. When exiting from the menu with the BACK button, don’t forget to save the changes.

Time Zone Setting

1. Press the SET button while “Clock Time Zone” is displayed.

2. Selected Time Zone screen is displayed.

3. Enter the menu by pressing the SET button.

4. Select your time zone in 30 minutes increments by using UP/DOWN buttons.

5. Press the SET button after you’re finished with selection.

6. When exiting from the menu with the BACK button, don’t forget to save the changes.

DST Mode Setting

1. Press the SET button while Clock DST Mode screen is displayed.

2. Daylight Save screen is displayed.

3. Press the SET button and select one of EUROPE, USA, MANUEL and DISABLE options.

4. If you select MANUEL option; you will have to enter month, week, day and hour for the start of

DST in that order.

5. After finishing the DST Start settings; you will have to enter month, week, day and hour for the

end of DST in that order.

6. After selecting your DST setting, press the SET menu and exit from this menu.

7. When exiting from the menu with the BACK button, don’t forget to save the changes.

33

RS-485 Communication Settings

RS-485 Address Setting

1. Select Address option under Settings/RS-485 and press SET button.

2. Current address option will start blinking. You can browse between digits with SET and BACK

buttons. Select an address between 1 and 247 and press SET button.

3. When exiting from the menu with the BACK button, don’t forget to save the changes.

RS-485 Baudrate Setting

RS-485 communication speed of the device can be set to one of the following options:

1. 2400 baud

2. 4800 baud

3. 9600 baud

4. 19200 baud

5. 38400 baud

6. 57600 baud

7. 115200 baud

1. Press the SET button while on RS-485 baud rate screen.

2. Press the SET button to start selecting the baudrate value.

3. Select your communication speed by using UP/DOWN buttons.

4. When exiting from the menu with the BACK button, don’t forget to save the changes.

34

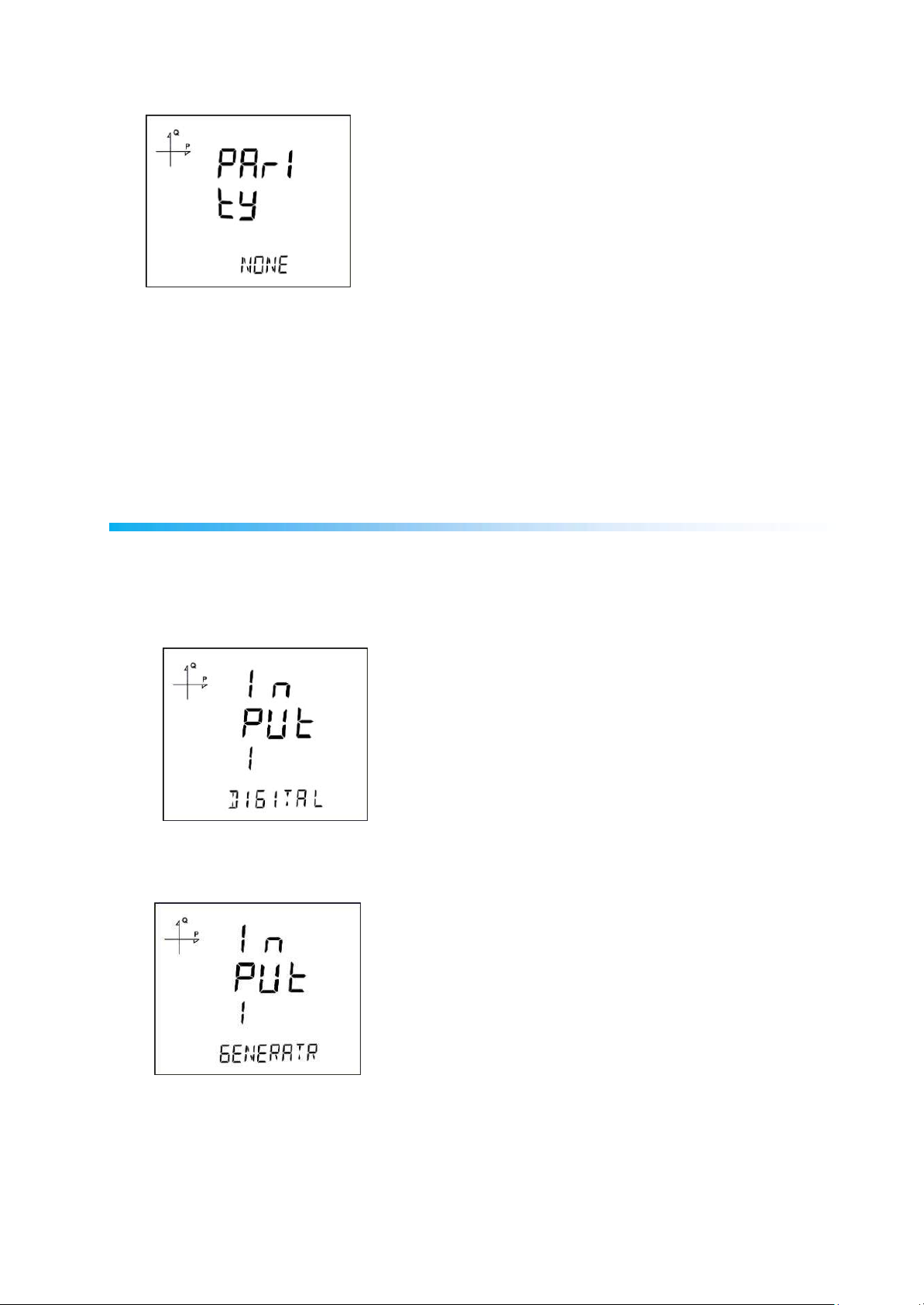

RS-485 Parity Setting

Communication parity of the device can be set as Odd, Even or None.

Factory default setting for parity is NONE.

1. Press the SET button while on RS-485 parity screen.

2. Press the SET button to start selecting the parity option.

3. Select your parity by using UP/DOWN buttons.

4. When exiting from the menu with the BACK button, don’t forget to save the changes.

Input Parameter Settings

One of the operating types is selected for the input of the device.

1. Digital Input: When this option is selected, the device detects the logic level on the input.

2. Generator Input: When this option is selected, the device records the energy to the generator

register depending on the ınput state.

1. Press the SET button while on Inputs menu.

2. Select the relevant output number and press the SET button to start the selection.

3. Select an output operation type mentioned above by using UP/DOWN buttons.

4. When exiting from the menu with the BACK or ESC button, don’t forget to save the changes.

35

Output Parameter Settings

Digital output of the device can be used for one of the following applications:

1. Output as Pulse: When this option is selected, the device creates output pulses depending on

selected value of active or reactive energy consumption.

2. Output as Alarm: When this option is selected, the output changes from logic-1 to logic-0 if the

selected parameter exceeds or is below the limit value.

When the alarm condition is resolved, output returns to logic-1.

3. Output as Remote Control: When this option is selected, the user can change the output of the

device from logic-1 to logic-0 remotely via RS-485 communication.

This option can be used to control a circuit remotely.

1. Press the SET button while on Outputs menu.

2. Select the relevant output number and press the SET button to start the selection.

3. Select an output operation type mentioned above by using UP/DOWN buttons.

4. When exiting from the menu with the BACK or ESC button, don’t forget to save the changes.

36

Pulse Output Settings

Pulse Output According to Active Energy

1. Press UP button while OUTPUT 1 PULSE is displayed.

2. Select the energy value for which the device will create pulse signals.

3. Exit from the menu when selection is complete.

4. When exiting from the menu with the BACK button, don’t forget to save the changes.

When Pulse Output is selected, the device can create pulses for import or export active energy according

to the increments listed below.

Import or export energy can be selected as the source.

1 Wh

10 Wh

100 Wh

1 kWh

10 kWh

100 kWh

1 MWh.

Pulse Output According to Reactive Energy

1. Press SET button while OUTPUT 1 PULSE is displayed.

2. Select the energy value for which the device will create pulse signals.

3. Exit from the menu when selection is complete.

4. When exiting from the menu with the BACK button, don’t forget to save the changes. When Pulse

37

Output is selected, the device can create pulses for import or export reactive energy according to the

increments listed below.

Reactive energy values from Q1, Q2, Q3 and Q4 quadrants can be used as source.

1 VArh

10 VArh

100 VArh

1 kVArh

10 kVArh

100 kVArh.

1 MVArh

Pulse Output Duration Setting

The duration during the pulse stays at logic-1 level is entered here.

1. Press SET button while PULS DURATION is displayed.

2. Enter the duration in seconds with 0.01 second increments with UP/DOWN buttons.

3. Exit from the menu when selection is complete.

4. When exiting from the menu with the BACK button, don’t forget to save the changes.

Pulse Output Inactive Time Setting

The duration during the pulse stays at logic-0 level is entered here.

1. Press SET button while PULSE DUTY is displayed.

2. Enter the inactive time in seconds with 0.01 second increments with UP/DOWN buttons.

3. Exit from the menu when selection is complete.

4. When exiting from the menu with the BACK button, don’t forget to save the changes.

38

Operating Hours Settings

The device can count the time when a selected parameter exceeds or falls below an adjusted limit

value. This feature is explained in this section.

Parameter is selected under Hour Counter menu. If you select VLN for example, display changes as

following.

1. Press SET button while HOUR COUN PARA is displayed.

2. Select the parameter with UP/DOWN buttons.

3. Press the SET button.

Afterwards, the limit value is selected. When the parameter exceeds this limit value, hour counter will

start.

1. Press SET button while HOUR COUN LEVL is displayed.

2. Enter a limit value by using UP/DOWN buttons. You can select different digits with SET or BACK

buttons.

3. Exit from the menu when selection is complete.

4. When exiting from the menu with the BACK button, don’t forget to save the changes.

39

Alarm Settings

Different parameters can be assigned to the 4 alarms that the device has.

Following operations are described for a single alarm but they are the same for the other 3 alarms.

Activating Alarm

Alarm is activated by following these steps:

1. Press the SET button while Setup Alarm is displayed.

2. While Alarm Enable is displayed, Press the SET button and select ENABLE or DISABLE with

UP/DOWN

3. Press the SET button after completing your selection.

4. When exiting from the menu with the BACK button, don’t forget to save the changes.

buttons.

Alarm Parameter Selection

Alarm parameter is selected by following these steps:

1. Press the SET button while Alarm Setup is displayed.

2. Find Alarm Parameter by pressing UP/DOWN buttons.

3. Enter Alarm Parameter menu by pressing the SET button.

4. Select one of the following parameters with UP/DOWN buttons:

a. Phase currents

b. Total Current

c. Current Demand

d. Total Current Demand

e. Active Power

f. Reactive Power

g. Apparent Power

h. Total Active Power

i. Total Reactive

j.

Total Apparent Power

k. Active Power Demand

l. Apparent Power Demand

m. Total Active Power Demand

n. Total Apparent Power Demand

Power

40

o. Cos phi

p. Total Cos phi

q. Frequency

r. THDV

s. THDU

t. THDI

u. Hour Counter

v. Digital Input

w. Tariffs

x. Phase-Neutral Voltage

y. Phase-Phase Voltage

5. Press the SET button after completing your selection. You can start selecting the Alarm

Operation Type by pressing the UP button.

Alarm Operation Type Selection

1. While AL-1 OPE RAND is displayed, press the SET button to select the alarm operation type.

2. Select one of the following options by using UP/DOWN buttons:

a. In window

b. Out window

c. Lower than

d. Higher than

3. When “In window” or “Out window” options are selected, high and low limit values are entered.

4. When “Higher than” option is selected, a high limit value is entered. When “Lower than” option is

selected, a low limit value is entered.

5. Press SET button to approve your selection.

6. When exiting from the menu with the BACK button, don’t forget to save the changes.

High Alarm Limit Setting

A high limit for the alarm is entered in this menu.

1. While Alarm Enable is selected, find Alarm High menu with UP/DOWN buttons.

2. Press the SET button. Enter the high alarm limit with UP/DOWN buttons.

3. Press the SET button after completing your selection.

4. Alarm parameters can be saved for 4 different alarms separately.

41

5. When exiting from the menu with the BACK button, don’t forget to save the changes.

Low Alarm Limit Setting

A low limit for the alarm is entered in this menu.

1. While Alarm Enable is selected, find Alarm Low menu with UP/DOWN buttons.

2. Press the SET button. Enter the low alarm limit with UP/DOWN buttons.

3. Press the SET button after completing your selection.

4. Alarm parameters can be saved for 4 different alarms separately.

5. When exiting from the menu with the BACK button, don’t forget to save the changes.

Alarm Hysteresis Setting

A hysteresis value for the alarm is entered in this menu.

1. While Alarm Enable is selected, find Alarm Hyst menu with UP/DOWN buttons.

2. Press the SET button. Enter the hysteresis value for the alarm as % with UP/DOWN buttons.

3. Press the SET button after completing your selection.

4. Alarm parameters can be saved for 4 different alarms separately.

5. When exiting from the menu with the BACK button, don’t forget to save the changes.

Alarm Delay Times Setting

1. After entering a hysteresis value, press the UP button to find the Alarm On Delay menu.

2. Press the SET button. Enter the alarm ON delay value in seconds for the alarm UP/DOWN

buttons. Go to the next digit with SET button. When the alarm conditions occur on the system,

the alarm will be activated after the entered time passes.

42

3. Press the SET button after completing your entering.

4. Find oFF dELY menu with UP/DOWN buttons to enter an Alarm Off Delay value.

5. Press the SET button. Enter the alarm OFF delay value in seconds for the alarm UP/DOWN

buttons. Go to the next digit with SET button. When the alarm conditions are cleared on the

system, the alarm will be deactivated after the entered time passes

6. When exiting from the menu with the BACK button, don’t forget to save the changes.

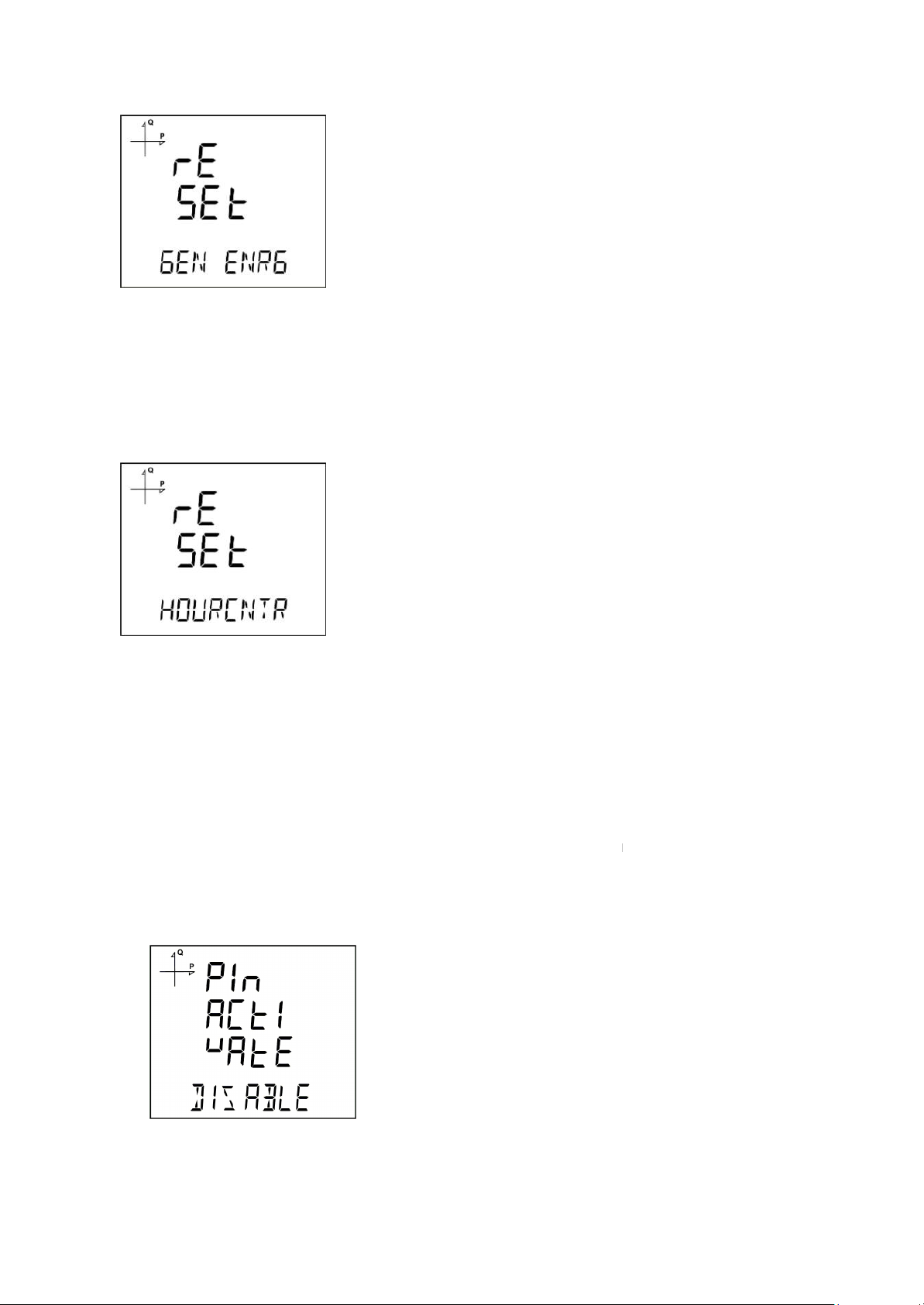

Reset Settings

Users can reset the minimum, maximum, demand values that the device has stored.

Resetting Maximum Values

1. Select Maximum under Reset menu and press the SET button.

2. Press the SET button while "Reset High" is displayed and select YES option with UP/DOWN

buttons.

3. Press the SET button.

4. When exiting from the menu with the BACK button, don’t forget to save the changes.

Resetting Minimum Values

1. Select Minimum under Reset menu and press the SET button.

2. Press the SET button while "Reset Low" is displayed and select YES option with UP/DOWN

buttons.

3. Press the SET button.

4. When exiting from the menu with the BACK button, don’t forget to save the changes.

43

Resetting Demand Values

1. Select Demand under Reset menu and press the SET button.

2. Press the SET button while "Reset High d" is displayed and select YES option with UP/DOWN

buttons.

3. Press the SET button.

4. When exiting from the menu with the BACK button, don’t forget to save the changes.

Resetting Maximum Demand Values

1. Select Max Demand under Reset menu and press the SET button.

2. Press the SET button while "Reset de" is displayed and select YES option with UP/DOWN

buttons.

3. Press the SET button.

4. When exiting from the menu with the BACK button, don’t forget to save the changes.

Resetting Energy Values

1. Select Energy under Reset menu and press the SET button.

2. Press the SET button while "Reset Energ" is displayed and select YES option with UP/DOWN

buttons.

3. Press the SET button.

4. When exiting from the menu with the BACK button, don’t forget to save the changes.

44

Resetting Generator Energy Values

1. Select Gen Energy under Reset menu and press the SET button.

2. Press the SET button while "Reset GenE" is displayed and select YES option with UP/DOWN

buttons.

3. Press the SET button.

4. When exiting from the menu with the BACK button, don’t forget to save the changes.

Resetting Hour Counter Value

1. Select Hourcntr under Reset menu and press the SET button.

2. Press the SET button while "Reset Hour" is displayed and select YES option with UP/DOWN

buttons.

3. Press the SET button.

4. When exiting from the menu with the BACK or ESC button, don’t forget to save the changes.

System Settings

Pin Code Activation

Preventing access to settings menu with a password can be accomplished from this menu.

1. Find "Pin Act" option under System Menu. Press the SET button.

45

2. When you press the SET button while "Pin Acivate" is displayed, you will have to enter the 4 digit

factory default pin (mentioned below).

3. Select the default pin digits with UP/DOWN buttons and confirm the digit with SET button.

4. After entering the correct default pin, you can change Disable option to Enable. Press the SET

button after selecting Enable.

5. When exiting from the menu with the BACK button, don’t forget to save the changes.

Factory default pin is 1234.

Changing the Pin Code

1. Find "Pin Chng" option under System Menu. Press the SET button.

2. While "Pin CHAnGE" is displayed, press the SET button.

3. Enter the old pin digit by digit with UP/DOWN buttons.

4. If you enter the old pin incorrectly, "ERROR" will be displayed.

5. If “ERROR” is displayed, press the SET button and enter the pin again correctly.

6. If you enter the old pin correctly, "Pin CHnGnE" will be displayed.

7. Enter your new 4 digit pin and press the SET button.

8. Enter your new 4 digit pin again and press the SET button.

9. After entering the new pin correctly twice, "Pin CHAnGE CHANGED" will be displayed.

10. When exiting from the menu with the BACK don’t forget to save the changes. You can use your

new pin next time you enter the Setup Menu.

46

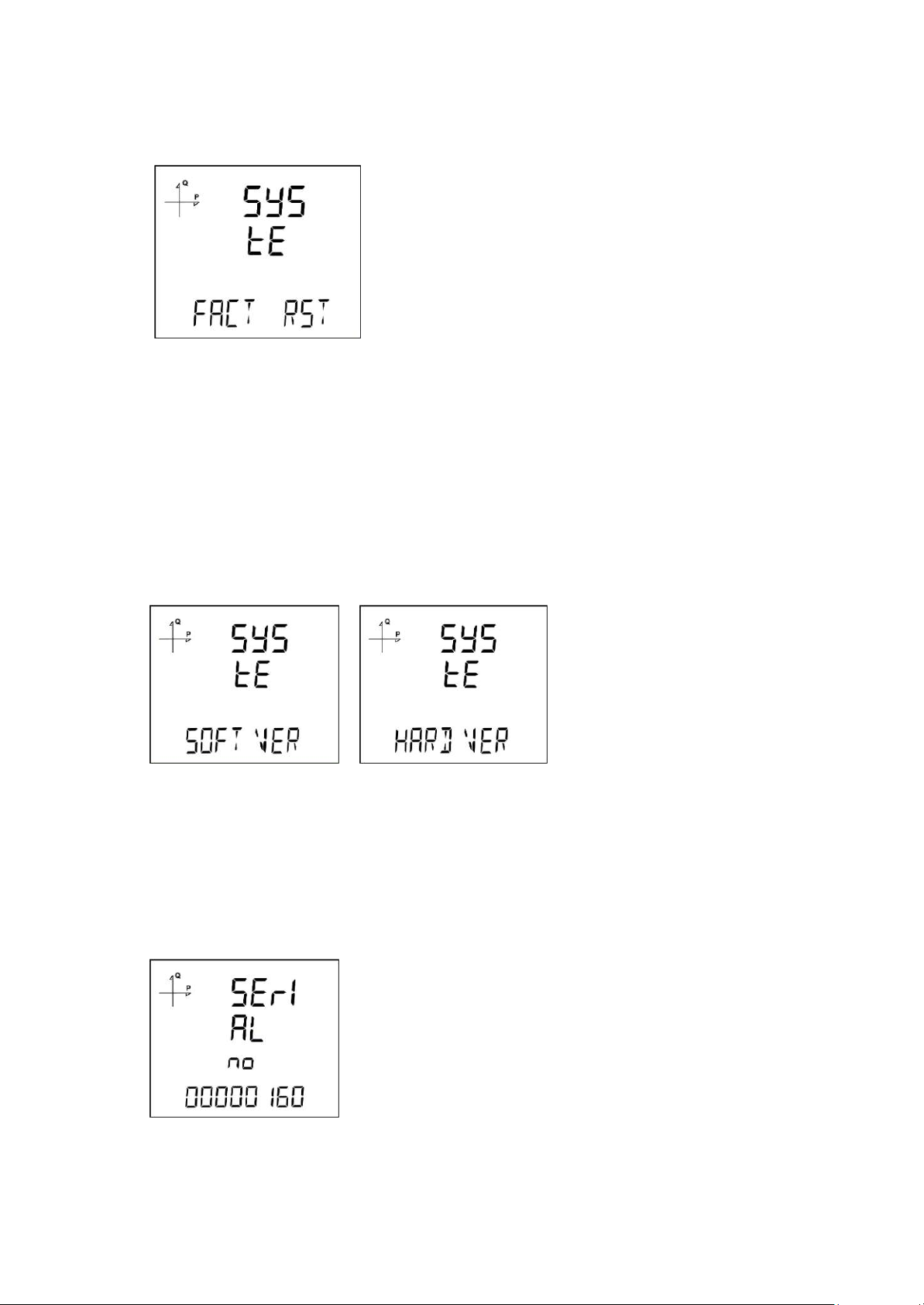

Resetting to Factory

Settings

1. To reset the device to factory settings, press the SET button while "FACT RST" is displayed.

2. While "FACtorY rSET" is displayed, pin code must be entered when the SET button is pressed.

3. Enter your pin code with UP/DOWN buttons. Press the SET button.

4. If the pin is entered correctly, “No” will be displayed at the bottom of the screen.

5. Press the SET button and change the “No” option to “Yes” with UP/DOWN buttons.

6. When exiting from the menu with the BACK button, don’t forget to save the changes.

7. 3 seconds after you exit from the menu, device version will be displayed and device installation

process will start.

After completing the settings, voltage measurement screen will be

displayed.

Displaying Software and Hardware Version

The device’s hardware and software version can be displayed under this

menu:

1. Press the SET button while "Soft VER" is displayed under System menu.

2. Software version of the device will be displayed on the bottom of the screen.

3. When you press the UP button here, hardware version of the device will be displayed under

"HArd

VerSIon".

Displaying Serial Number of the Device

1. Press the SET button while "Serial N" is displayed under System menu.

2. 8 digit serial number of the device will be displayed under "SErIAL no".

47

Reporting Screen

When the BACK button of the device is pressed for 3 seconds, recorded event details can be browsed.

The device can record 255 events.

Recorded event types: First commission, short interruption (<3 s), long interruption, alarm, settings

change, time change and value reset.

Different records can be viewed with UP/DOWN buttons.

Events are listed according to their occurrence times.

First event is the newest that has occurred, last event is the oldest one that has occurred.

After pressing the SET button, details of the event can be displayed in the following order;

1. Start date,

2. Start time,

3. End date,

4. End time,

5. Duration,

6. Parameter,

7. Source of the event (if the event type is alarm),

8. Value that caused the event (if the event type is alarm).

If no button is pressed for 60 seconds, the device returns to measuring screen.

48

Reading the Records via Modbus

There are two options for accessing the records via Modbus:

Accessing the records according to time

For this method, the date of the record to be accessed is entered in UNIX time format to the Modbus

addresses starting from 21000. There are 5 address fields. These addresses are for Load Profile,

Voltage, Current, Power and THD in that order. The device finds the record closest to the entered date

and writes the index belonging to this record to the related index registers.

When the user writes this index to the index register at the bottom of the tables at register addresses

23000, 24000, 25000 etc., the details of the entered register will be accessible on the same tables.

A free software is available to read the log values that are stored on the device. It can be downloaded

from the following link:

http://www.entes.com.tr/dosyalar/Applications/Mpr3x4xLogReader/publish.htm

Accessing the records according to index

For this method, the user writes the record index number to the index register at the bottom of the

tables at register addresses 23000, 24000, 25000 etc., the details of the entered register will be

accessible on the same tables.

49

TECHNICAL FEATURES AND APPENDIX

Operating Voltage (Un)

95 - 270 VAC/VDC (Tolerance up to ±10%)

Operating Frequency (f)

50-60 Hz

Supply Input Burden

<4 VA

Voltage Measuring Input Burden

<0.5 VA

Current Measuring Input Burden

<1 VA

Measuring Voltage Input (Vin)

10 – 300 VAC (L-N)

10 – 480 VAC (L-L)

Voltage Measuring Range with Transformer

10 – 999 kV

Measuring Current Input (Iin)

0.05 – 5.5A ~

Current Measuring Range with Transformer

0.05 – 10 kA

Power Measuring Range

0 – 1 G (W, VAr, VA)

Energy Measuring Range

9999999.9 k (Wh, VArh)

Class

Voltage

0.5%

Current

0.5%

Frequency

0.1%

cosφ

±0.2%

Active Power

1%, Class 1

Reactive Power

1%, Class 2

Demand Time

Adjustable between 1-60 minutes

Communication (Isolated)

MODBUS RTU (RS-485)

Baud Rate

2400 – 115200 bps

Address

1 – 247

Parity

None, Even, Odd

Stop Bit

1

Max Communication Distance

1200 m (MODBUS/RS-485 side, with signal

amplifier)

Internal Memory

1MB

Digital Input Operating Voltage

5...48 VDC

Digital Input Switching Current

Max. 50 mA

Minimum Pulse Period

100 ms pulse period, 80 ms pulse width

Connection Type

3P4W, 3P3W, ARON, 3P4W balanced, 3P3W

balanced

Operating Temperature

-10...+55ºC

Storage Temperature

-20…+70ºC

Humidity

Maximum 90%

Display

Backlit FSTN Custom LCD

Real Time Clock

Available

Tariffs

8+1 (Generator)

Dimensions

72x72x70 mm

Device Protection Class

Double Insulation

Front Panel Protection Class

IP51

Terminals Protection Class

IP20

Enclosure Material

Nonflammable

Installation

Front Panel Mounting

Cable Thickness For Voltage Connection

Max. 2.5 mm

2

Cable Thickness For Current Connection

Max. 2.5 mm

2

Cable Thickness For RS-485 Connection

CAT 5 Cable

Weight

230 gr

Technical Features

50

Applicable Standards

CONFORMITY IEC 61557-12 Edition 2

PMD SPECIFICATIONS

Type of Specification

Examples of possible

specification values

Other additional

specifications

Supply quality evaluation function (option)

/ /

PMD Classification SD

/

Setpoint

K55

/

Humidity + Altitude

/ /

Operationg performance class for active power or

active energy (if function availible)

0,5

/

Symbol for

functions

Measurement

range

Operating performance

class,

according to CEU

61557-12

according to KI

Other additional

specifications

P

10% to 120% In

0,5

Qa, Qv

10% to 120% In 1

Sa, Sv

10% to 120% In 1

Ea

0 to 99999999 kW/h

0,5

Era, Erv

0 to 99999999 kVar/h

1

Eapa

0 to 99999999 kVA/h

0,5

f

50 - 60 Hz

0,02

I

10% to 120% In

0,2

In,

Inc

10% to 120% In

0,2

U

10 to 480Vac ph/ph

0,2

Pfa, Pfv

0,5 ind to 0,8 cap

0,5

Udip, Uswl

Unavailable

function

Utr

Unavailable

function

Uint

Unavailable

function

Unba, Unb

Unavailable

function

Uh

Unavailable

function

THDu

Fn=50Hz - range 1 to 50

Fn=60Hz - range 1 to 50

1

THD-Ru

Unavailable

function

Ih

Unavailable

function

THDi

Fn=50Hz - range 1 to 50

Fn=60Hz - range 1 to 50

1

THD-Ri

Unavailable

function

Msv

Unavailable

function

IEC 61557-12

Standard

Year

Title

IEC 61557-12

2008

Electrical safety in low voltage distribution systems up to 1000 V a.c. and 1500 V d.c.

- Equipment for testing, measuring or monitoring of protective measures - Part 12:

Performance measuring and monitoring devices

IEC 61326-1

2005

Electrical equipment for measurement, control and laboratory use - EMC

requirements - Part 1: General requirements

EN 61000-6-2

2005

Generic immunity standard: Industrial environment

IEC 60050(161)

2011

International Electrotechnical Vocabulary Chapter 161- Electromagnetic Compatibility

EN 62053-21

2003

Electricity metering equipment (a.c) – Particular requirements - Part 21: Static meters

for active energy (Classes 1 and 2)

EN 62053-23

2003

Electricity metering equipment (a.c) – Particular requirements Part 23: Static meters

for reactive energy (classes 2 and 3)

EN 61000-4-2

1995

Electrostatic discharge immunity test.

EN 61000-4-3

2006

2008

Radiated RF electromagnetic field immunity test.

EN 61000-4-4

2004

Electrical fast transient/burst immunity test.

EN 61000-4-5

2006

Surge immunity test.

EN 61000-4-6

2007

Immunity to RF conducted disturbances.

EN 61000-4-8

2010

Power frequency magnetic field immunity test.

EN 61000-4-11

2004

Voltage dips, short interruptions and voltage variations immunity tests.

EN 61000-6-3

2007

Electromagnetic compatibility (EMC) - Part 6-3: Generic standards; Emission

standard for residential, commercial and light-industrial environments

EN 61000-3-2

2010

2011

2011

Limits for harmonic current emissions (equipment input current ≤ 16 A per phase)

EN 61000-3-3

2011

Limitation of voltage changes, voltage fluctuations and flicker in public low-voltage

supply systems, for equipment with rated current ≤ 16 A per phase and not subject to

conditional connection

EN 55016-2-1

2009

Specification for radio disturbance and immunity measuring apparatus and methods Part 2-1: Methods of measurement of disturbances and immunity - Conducted

disturbance measurements

EN 60068-2-2

2008

Environmental testing, Dry Heat

EN 60068-2-6

2007

Environmental testing, Vibration (sinusoidal)

EN 60068-2-30

2008

Environmental testing, Damp heat, cyclic (12 h + 12 h cycle)

EN 60068-2-31

2010

Environmental testing, Rough handling shocks, primarily for equipment-type

specimens

EN 60068-2-75

1997

Environmental testing, Hammer tests

BS EN 61010-1

2010

Safety requirements for electrical equipment for measurement, control and laboratory

use - Part 1: General requirements

EN 61010-2-030

2010

Safety requirements for electrical equipment for measurement, control, and laboratory

use - Part 2-030: Particular requirements for testing and measuring circuits

EN 62262

2010

Degrees of protection provided by enclosures for electrical equipment against

external mechanical impacts (IK code)

51

Loading...

Loading...