Page 1

MPR-1 SERIES NETWORK ANALYZER

OPERATING MANUAL

Index

SAFETY AND WARNING ................................................................................................................................ 2

Attention .................................................................................................................................................. 2

Safety ....................................................................................................................................................... 3

Guarantee ................................................................................................................................................ 3

OPERATING CONDITIONS ............................................................................................................................. 4

INTRODUCTION ............................................................................................................................................ 5

General Specifications ................................................................................................................................. 5

Applications.............................................................................................................................................. 6

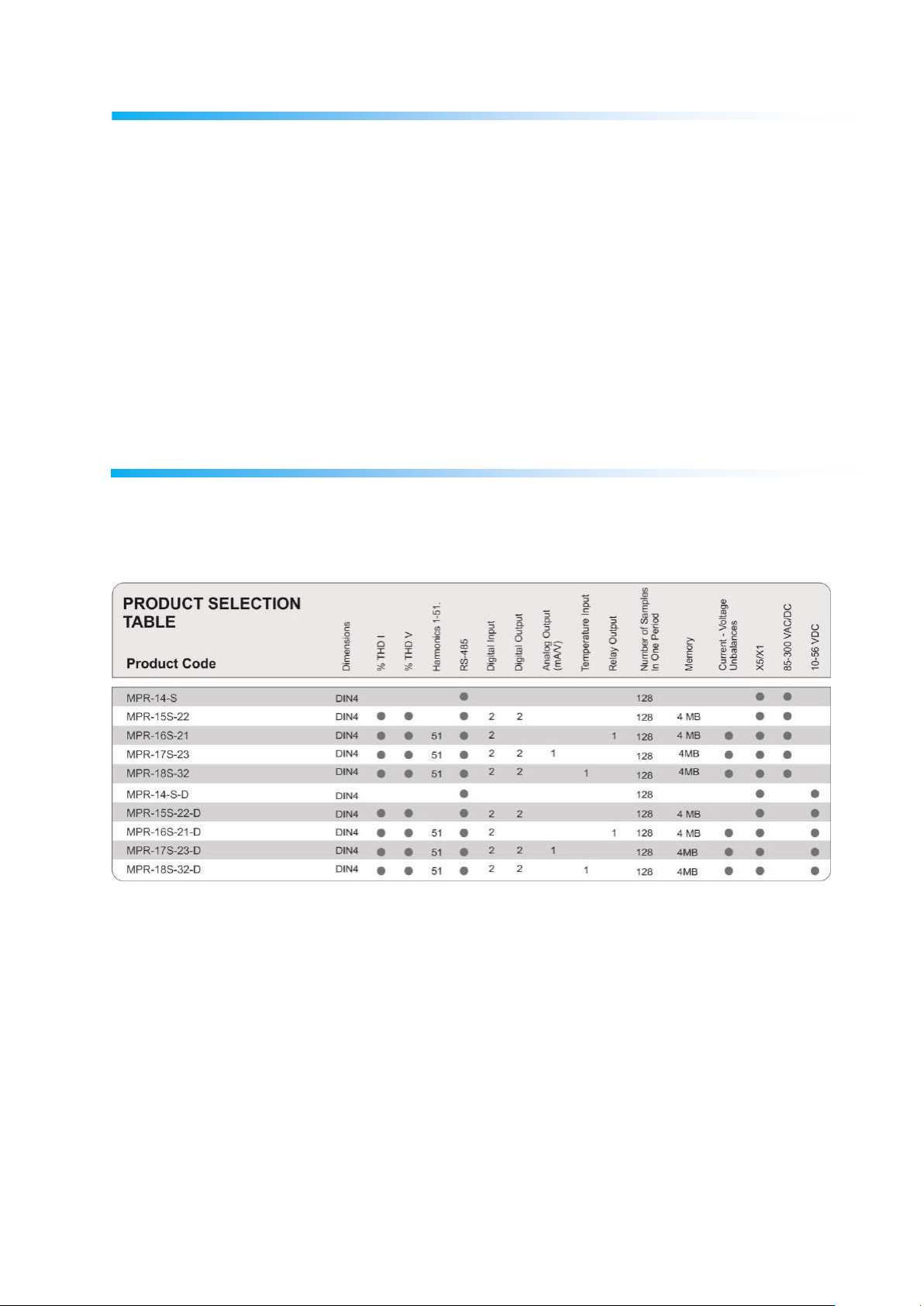

MPR-1 Product Family ............................................................................................................................. 6

Appearance and Interface ....................................................................................................................... 7

Terminals ...................................................................................................................................................... 7

Front Panel ................................................................................................................................................... 7

Terminal Structures.................................................................................................................................. 8

CONNECTION ............................................................................................................................................. 12

3P4W (Three-Phase Four-Wire) Connection ......................................................................................... 12

3P3W (Three-Phase Three-Wire) Connection ....................................................................................... 13

ARON Connection .................................................................................................................................. 13

3P4W BLN (Three-Phase Four-Wire Balanced) Connection .................................................................. 14

3P3W BLN (Three-Phase Three-Wire Balanced) Connection................................................................. 14

Communication Line Termination Resistance ....................................................................................... 15

OPERATING DEVICE .................................................................................................................................... 16

Device Communication Settings………………………………………………………………………………………………..…….…..16

TECHNICAL INFORMATION AND ATTACHMENTS………………………………………………………………………………….17

Technical Information…………………………………………………………………………………………………………………………..17

Standards………………………………………………………………………………………………………….………………………………….19

1

Page 2

SAFETY AND WARNING

Attention

If the following instructions are not carefully followed, the circumstances which can

cause death and serious injuries might happen.

The installation of the device must be performed by the qualified and trained

personnel.

Please, cut the whole power while installing the device. Please, use a suitable

circuit breaker on the installation terminal.

You must connect the power lead-ins of the device by using a current

transformer. Do not apply direct current connection.

Never, remove the front panel while the device is connected to the mains.

Never, clean the device by any solvent or similar material. Only use dry cloth for

cleaning it.

Before, turning on the device, make sure that the connections are correct.

Please, contact your authorized dealer in case of any problem with your device.

The device is only for interior electrical / fire enclosure panel type assembly.

Only the front panel of the device should be accessible from the switchboard.

The fuse to be used must be CATIII and F type and the current limit value

should be 1A.

Current measurement inputs must be connected with auxiliary current

transformers which have reinforced insulation.

The power meter shall not be used for primary protection or applications where

its failure can cause harm or death.

Please de-energize the device before replacing RTC backup battery. It must be

Li/MnO2 battery.

The manufacturer firm cannot be held responsible in any way for any circumstance

which might arise if the aforementioned precautions are not implemented

.

2

Page 3

Safety

Please, read the entire operating manual before using the device.

Connect a button or a circuit breaker between the mains and the supply inputs

of the device.

The button or circuit breaker to be connected should be close to the device.

It should be labeled that the button or circuit breaker to be connected will be

used for separating the device from the mains.

This device is used for analyzing the electricity mains and it must not be used for

main protection function.

Guarantee

The guarantee term of the device is 2 (two) years. In case of any problem, the repair of

the device must be done only by the manufacturer firm; otherwise, the guarantee of the

device becomes invalid.

Manufacturer Firm

ENTES Elektronik Cihazlar Imalat ve Ticaret A.S.

Address: Dudullu OSB, 1. cadde, No:23 34776 Umraniye, Istanbul / TR.

Telephone: +90 (216) 313 0110

Fax: +90 (216) 314 1615

3

Page 4

General Specifications

Operating Conditions

Value Range

Operating voltage

95 - 270 VAC/VDC ,12 – 50 VDC (for D series)

(Tolerances up to +/-10%)

Frequency Range

50 ~ 60 Hz.

Maximum Measured Current

Connected to current transformer

Maximum Measured Voltage

300 VAC (VLN) / 480 VAC (VLL)

Operating Temperature Range

-10 ~ +55 ºC

Storage Temperature Range

-20 ~ +70 ºC

Maximum Ambient Humidity

% 95

Communication Speed

2400 ~ 115200 bps

4

Page 5

INTRODUCTION

General Specifications

Wide supply voltage range (95 – 270 VAC-DC) (10-56 VDC for D series)

3 voltage measurement input

3 current measurement input

4 MB Internal Memory

Real time clock

Alarm

Time counters (Operating time and overall time)

Measured parameters via RS-485 (MODBUS):

o Current

o Neutral current

o Voltage (Phase to Phase, Phase neutral)

o Active, Reactive and Apparent power

o Frequency

o Active Power

o Reactive Power

o Apparent Power

o Cos φ

o Power Factor

o Total Active Power

o Total Reactive Power

o Total Apparent Power

o Total Cos φ

o Total Power Factor

o Total Harmonic Distortion of the Current

o Total harmonic distortion in current from phase to phase

o Total harmonic distortion in neutral current from phase to phase

Instant minimum and maximum measured parameters:

o Current

o Phase to Phase Voltage

o Phase Neutral Voltage

o Active Power

o Reactive Power

o Apparent Power

o Frequency

o Total Harmonic Distortion of the Current

o Total harmonic distortion in current from phase to phase

o Total harmonic distortion of phase-neutral current

Demand and Maximum Demand parameters measured by integration time:

o Current

o Active Power

o Apparent Power

Insulated Digital Input and Output, Relay and Analog Output

Saving 256 event logs

DIN4 type rack assembly

Measurement by 5 different connections: 3-phsae 4-wire, 3-phase 3-wire, 3-phase Aron, 3-

phase 4-wire balanced, 3-phase 3-wire balanced

Adjustable Demand and Integration time

Summer-Winter time application

5

Page 6

Applications

This is a MPR-2 series 3-phase mains analyzer. It is a microprocessor based device which is designed

for measuring all parameters of an electricity main; calculate consumptions and transferring desired

parameters with Modbus and I/O outputs.

Thanks to its clock chip and flash memory of the device, the blackout logs and the processes performed

by the operator such as the time and setting changes, resets and etc. are saved in real time. These logs

can be read and followed by the Modbus RTU protocol through the RS-485 communication port.

Current connection is done according to the selected model through 5A direct connection to the current

transformer with CT25 and RJ-45 connector and mV voltage output.

The connection control function which is described in detail in the 15th page should be used against

open live ends due to possible fractures at terminals.

MPR-1 Product Family

6

Page 7

Appearance and Interface

The appearance of the Device’s front is as below:

7

Page 8

Terminal Structures

The terminal structures according to the models are described in this section:

Structure of the MPR-14S Terminal:

Current Terminals: K1, L1, K2, L2, K3, L3

An external current transformer must be used for the 3-phase system connection to

these terminals where the current up to 5A can be input.

Supply Terminals: A1, A2

Please, apply 85-300 VAC/DC supply connection through these terminals.

Voltage Terminals: N, L1, L2, L3

Please, apply 3-phase voltage connection through these terminals

8

Page 9

Structure of the MPR-15S-22 Terminal:

DOC terminals is referred to digital output common, digital output reference connection

is done with this terminal.DO1 and DO2 is also referred to 1st and 2nd digital output

terminals.

INC terminal is referred to Input Common and it is the digital input reference. IN1 and

IN2 are also referred 1st and 2nd digital input terminals.

9

Page 10

Structure of the MPR-16S-21 Terminal:

Different from the MPR-16S-21’den these terminals which are used for relay output are

the terminals next to the voltage terminals. They are indicated with the key symbol on

the front view. The terminal structure of the MPR16S-21 model is as in the following:

Structure of the MPR-17S-23 Terminal:

As the AOC terminal will be the joint point (reference), the analogue current or voltage

output is ensured respectively through the AIO and AVO terminals. Only one of the

AVO and AIO terminals are used at the same time.

10

Page 11

Current Terminals: K1, L1, K2, L2, K3, L3

5-30 VDC

Relay Coil

MPR 1X terminal

OC

O1

O2

An external current transformer must be used for the 3-phase system connection to

these terminals where the current up to 5A can be input.

Supply Terminals: A1, A2

Please, apply 85-300 VAC/DC supply connection through these terminals.

Voltage Terminals: N, L1, L2, L3

Please, apply 3-phase voltage connection through these terminals.

Digital Input Terminals: INC, IN1, IN2

As the INC terminal will be the joint point (reference), the IN1 and IN2 inputs are used

as digital inputs between 5-30V. Inputs have 1kV insulation level.

Digital Output Terminals: OC, O1, O2

As the OC terminal will be the joint point (reference), the O1 and O2 terminals are used

as insulated outputs. As it can be seen from the following figure, these Open Collector

outputs should be fed by an external supply for operation.

11

Page 12

Analogue Output Terminals: AOC, AVO, AIO

As the AOC terminal will be the joint point (reference), the analogue current or voltage

output is ensured respectively through the AIO and AVO terminals. Only one of the

AVO and AIO terminals are used at the same time.

Communication Terminals: A(+), B(-), GND, TR

RS-485 communication terminals are used for A(+) and B(-) communication

connection. As the communication distance becomes longer, the TR terminal and GND

terminal are short-circuited and 120 ohm line termination resistance is activated and

line stabilization is completed.

CONNECTION TYPES

As there are shunts at the current measurement inputs of the device, it is mandatory to use a current

transformer except for the connections of current inputs. If, the device will be used on the same current

line by means of analyzers with other shunts, it is recommended that the device is located at the extreme

point.

The device has 5 different connection types. These connection types are described in the following

schemes:

3P4W (Three-Phase Four-Wire) Connection

As it is seen below, four voltage and three current connections including the neutral line are established

in this connection type. Voltage inputs should be connected with 100 mA fuses as shown below.

12

Page 13

3P3W (Three-Phase Three-Wire) Connection

As it is seen below, three voltage and three current connections are established in this connection type.

ARON Connection

Three voltage and two current connections are established in this connection type. As it is seen in the

following figure, the current connections are established with the 1st and 3rd phases.

13

Page 14

3P4W BLN (Three-Phase Four-Wire Balanced)

Connection

Four voltages and one current connection are established in this connection type. The device displays

the value measured at the current input connected to the first phase on its screen for other phases in the

same value.

3P3W BLN (Three-Phase Three-Wire Balanced)

Connection

Three voltage and one current connection are established in this connection type. As it is seen below,

the device displays the value measured at the current input connected to the first phase on its screen for

other phases in the same value.

14

Page 15

Communication Line Termination Resistance

If, the communication distance of RS485 lines is longer than 10 meters and there are more than one

device on the line, a 120 Ω line termination resistance should be installed between the A and B ends of

the farthest device of the communication terminal.

For this process, as it is seen from the following figure, it is enough to short-circuit the GND and TR

terminals of the device.

15

Page 16

OPERATING DEVICE

Number written

to Modbus

17124 address

DIP switch

setting

Address

1

10000 1 1

01000 2 …

… … 1

11111

31

32

00000

32

32

10000

33 … … … 32

11111

63 … … … 64

00000

64

64

10000

65

64

01000

66 … … … 200

00000

192

200

10000

193

232

00000

224 … … … 232

11101

247

Baud rate

0 0 0 : 2400

1 0 0 : 4800

0 1 0 : 9600

1 1 0 :19200

0 0 1 :38400

1 0 1 :57600

0 1 1 :115200

1 1 1 :115200

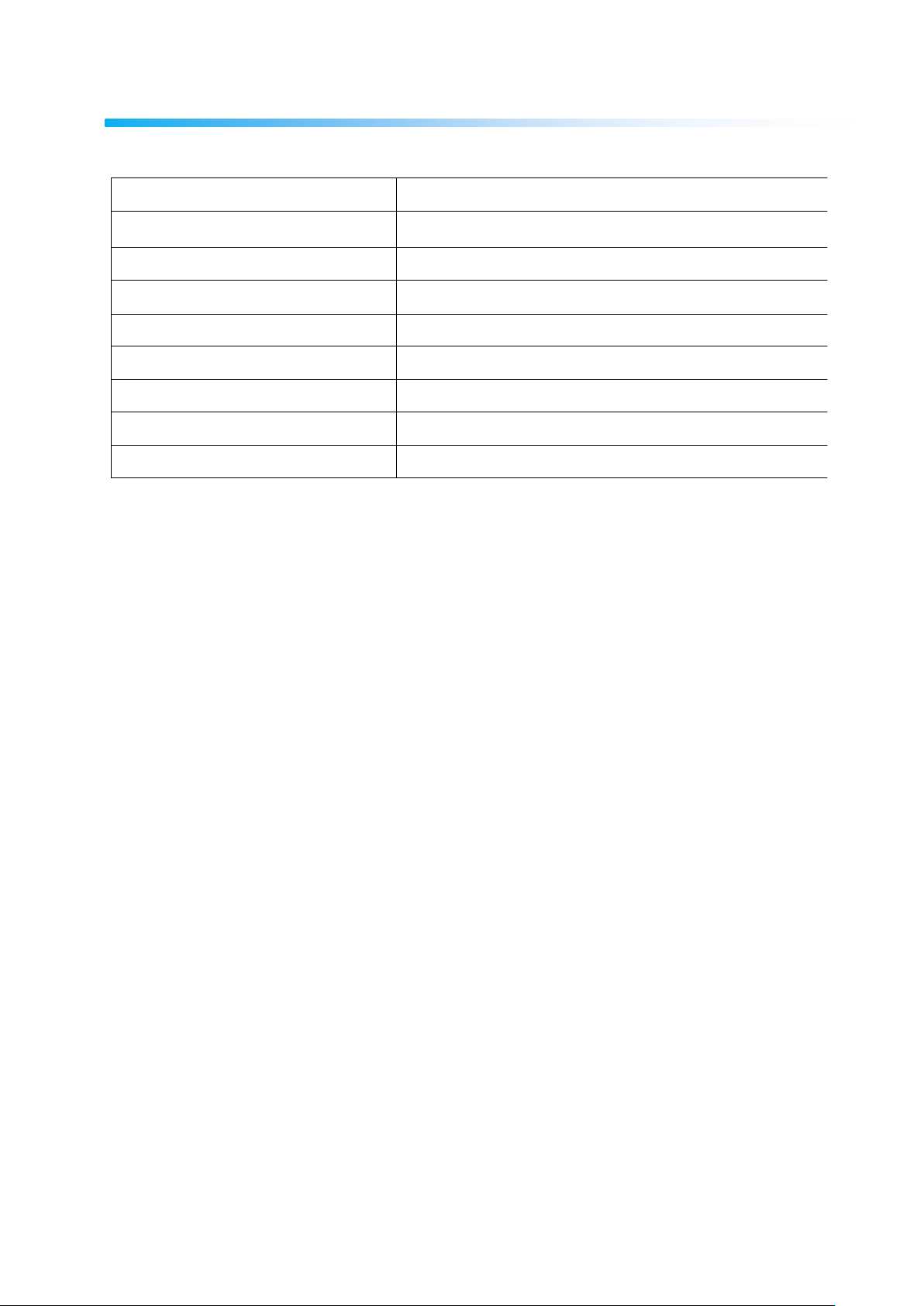

Device Communication Settings

Device communication address and baud rate settings are adjustable from the DIP switches located at

the device’s front panel. Devices communication address settings can be done, as shown at the

below table.

Number written to the Modbus 17124 address and the DIP switch’s 1st and 5th positions determines the

devices communication address. Factory settings for Modbus address is 1.

Baud rate is determined from DIP switch’s 6th, 7th and 8th pins as shown at the below:

16

Page 17

TECHNICAL INFORMATION AND ATTACHMENTS

Technical properties

Value

Dimensions

DIN 4

Voltage measurement range

10~300 VAC(VLN) 10~480 VAC(VLL)

Measurement range with transformer

10~999 kV

Accuracy

%0.5 +/- 1 digit

Input Impedance

1.8 MΩ

Burden (Input Load)

< 0.5 VA

Current measurement accuracy

%0.5 +/- 1 digit

Nominal Current

1A, 5A

Lowest current

5 mA

Current measurement range

50 mA ~ 5,5A

Measurement range with transformer

50 mA ~ 10 kA

Burden (Input Load)

< 1 VA

Active power accuracy

%1 +/- 1 digit

Reactive power accuracy

%1 +/- 1 digit

Active energy measurement accuracy

Class 1

Reactive energy measurement accuracy

Class 2

Active power measurement range

0 ~ 1 GW

Reactive power measurement range

0 ~ 1 GVar

Apparent power measurement range

0 ~ 1 GVA

Power consumption

< 5 VA

Active energy measurement ceiling

9 999 999.9 kWh

Reactive energy measurement ceiling

9 999 999.9 kVarh

Operating voltage

95 - 270 VAC/VDC ,12 – 50 VDC (for D series)

(Tolerances up to +/- 10%)

Operating frequency

50 ~ 60 Hz.

Digital input processing voltage

5 ~ 30 VDC

Digital input switching current

Max 50 mA

Minimum pulse time

100 ms pulse period, 80 ms pulse width

Operating Temperature Range

-10 ~ +55 ºC

Storage Temperature Range

-20 ~ +70 ºC

Maximum operating humidity

% 95

Assembly

Assembled to the wall box from the front.

Connection terminals

Screw terminal

Connection types

3 phase + neutral, 3 phase balanced, 3 phase imbalanced,

Aron.

Communication Protocol

RS-485 / MODBUS RTU

Communication Speed

2400 ~ 115200

Max. Voltage / Max. Current (For Relay)

250 VAC / 5A

Technical Information

17

Page 18

CONFORMITY IEC 61557-12 Edition 2

PMD SPECIFICATIONS

Type of Specification

Examples of possible

specification values

Other additional

specifications

Supply quality evaluation function (option)

/

/

PMD Classification

SD

/

Set point

K55

/

Humidity + Altitude

/

/

Operating performance class for active power or

active energy (if function available)

0,5

/

Symbol for

functions

Measurement

range

Operating performance class,

according to CEU 61557-12

according to KI

Other additional

specifications

P

10% to 120% In

0,5

Qa, Qv

10% to 120% In

1

Sa, Sv

10% to 120% In

1

Ea

0 to 99999999 kW/h

0,5

Era, Erv

0 to 99999999 kVar/h

1

Eapa

0 to 99999999 kVA/h

0,5

f

50 ~ 60 Hz.

0,02

I 10% to 120% In

0,2

In, Inc

10% to 120% In

0,2

U 10 to 480Vac ph/ph

0,2

Pfa, Pfv

0,5 ind to 0,8 cap

0,5

Udip, Uswl

Unavailable function

Utr

Unavailable function

Uint

Unavailable function

Unba, Unb

Unavailable function

Uh

Unavailable function

THDu

Fn=50Hz - range 1 to 50

Fn=60Hz - range 1 to 50

1

THD-Ru

Unavailable function

Ih

Unavailable function

THDi

Fn=50Hz - range 1 to 50

Fn=60Hz - range 1 to 50

1

THD-Ri

Unavailable function

Msv

Unavailable function

IEC 61557-12 Properties

18

Page 19

Standard

Year

Title

IEC 61557-

12

2008

Electrical safety in low voltage distribution systems up to 1kV (a.a.) and

1,5kV DC(d.a.) – Equipment for testing, measuring or monitoring of

protective measures - Part 10: Performance measuring and monitoring

arrangements

IEC 61326-

1

2005

Electrical equipment for measurement, control and laboratory use - EMC

requirements - Part 1: General conditions

EN 61000-

6-2

2005

Electromagnetic compatibility (emc) - Part 6-2: General standards -

Immunity for industrial environments

IEC

60050(161)

2011

International Electro-technical Vocabulary Chapter 161- Electromagnetic

Compatibility

EN 62053-

21

2003

Electricity measurement equipment (a.a.) - Special rules - Chapter 21:

Static meters for active energy (class 1 and class 2)

EN 62053-

23

2003

Electricity measurement equipment (a.a.) - Special rules - Chapter 23:

Static meters - Reactive energy (class 2 and class 3)

EN 61000-

4-2

1995

Electromagnetic compatibility (EMC) - Part 4-2: Test and measurement

techniques - Electrostatic discharge immunity test

EN 61000-

4-3

2006

Electromagnetic compatibility (emc) - Part 4-3: Test and measurement

techniques-Radiated, radio- frequency, electromagnetic field immunity

test

EN 61000-

4-4

2004

Electromagnetic compatibility (EMC) - Part 4-4: Test and measurement

techniques - Electrical fast transient/burst immunity test

EN 61000-

4-5

2006

Electromagnetic compatibility (emc) - Part 4-5: Test and measurement

techniques - Surge immunity test

EN 61000-

4-6

2007

Electromagnetic compatibility (EMC) - Part 4-6: Test and measurement

techniques - Immunity to conducted disturbances, induced by radio-

frequency fields

EN 61000-

4-8

2010

Electromagnetic compatibility (EMC) - Part 4-8: Test and measurement

techniques-Power Frequency Magnetic Field Immunity Test

EN 61000-

4-11

2004

Electromagnetic compatibility (EMC) - Part 4-11: Test and measurement

techniques - Voltage dips, short interruptions and voltage variations

immunity tests

EN 61000-

6-3

2007

Electromagnetic compatibility (EMC) - Chapter 6-3: General standards -

Emission Standard for residential, Commercial and light-industrial

environments

EN 61000-

3-2

2010

Electromagnetic compatibility (emc) - Part 3-2: Limit values - limits for

harmonic current emissions (equipment input current ≤ 16 A per phase)

Compliance with the Standards

19

Page 20

EN 61000-

3-3

2011

Electromagnetic compatibility (EMC) - Part 3-3: Limits - Limitation of

voltage fluctuations and flicker in low- voltage supply systems for

equipment with rated current kleiner 16 A

EN 55016-

2-1

2009

Specification for radio disturbance and immunity measuring apparatus

and methods - Chapter 2-1: Methods of measurement of disturbances

and immunity - Conducted disturbance measurements

EN 60068-

2-2

2008

Basic environmental testing procedures Part 2:tests-Test B: Dry heat

EN 60068-

2-6

2007

Environment test - Chapter 2-6: Tests - Fc tests: Vibration (sinus

formed)

EN 60068-

2-30

2008

Environmental testing -- Part 2-30: Tests - test db: Damp heat, cyclic (12

h + 12 h cycle)

EN 60068-

2-31

2010

Environmental testing -- Part 2-31: Tests - test ec: Rough handling

shocks, primarily for equipment-type specimens

EN 60068-

2-75

1997

Basic Environmental Testing Procedures Part 2: Tests - test eh:

Hammer tests

BS EN

61010-1

2010

Safety requirements for electrical equipment for measurement, control

and laboratory use-Part 1:General requirements

EN 61010-

2-030

2010

Safety requirements for electrical equipment for measurement, control

and laboratory use-Part 2-030: Specific rules for test and measurement

of circuits

EN 62262

2010

Degrees of protection provided by enclosures for electrical equipment

against external mechanical impacts (IK code) / Note: Includes

Corrigendum of July 2002 (EN 50120 + A1 are renumbered as EN

62262:2002)

20

Loading...

Loading...