Page 1

Matrix V-Series

VSER-RPU-SYS

Redundant Power Supply

Hardware Installation Guide

P/N 9033948

Page 2

Page 3

ELECTRICAL HAZARD: Only qualified personnel should

perform installation procedures.

NOTICE

ENTERASYS NETWORKS reserves the right to make changes in specifications and other

information contained in this document and its web site withou t prior noti ce. The reader shou ld

in all cases consult EN TERASYS NETWORKS t o determine whether any such changes have

been made.

The hardware, firmware, or softwar e described in this document i s subject to change without

notice.

IN NO EVENT SHALL ENTERASYS NETWORKS BE LIABLE FOR ANY INCIDENTAL,

INDIRECT, SPECIAL, OR CONSEQUENTIAL DAMAGES WHATSOEVER (INCLUDING

BUT NOT LIMITED TO LOST PROFITS) ARISING OUT OF OR RELATED TO THIS

DOCUMENT, WEB SITE, OR THE INFORMATION CONTAINED IN THEM, EVEN IF

ENTERASYS NETWORKS HAS BEEN ADVISED OF, KNEW OF, OR SHOULD HAVE

KNOWN OF, THE POSSIBI LI TY O F SUCH DAMAGES.

Enterasys Networks, Inc.

50 Minuteman Road

Andover, MA 01810

2004 Enterasys Networks, Inc. All rights reserved.

Printed in Taiwan

Release Date: March 2004

ENTERASYS NETWORKS, ENTERASYS MATRIX, LANVIEW, MATRIX, NETSIGHT,

WEBVIEW, and any logos associated ther ewith , ar e t rademarks or registered trademarks of

Enterasys Networks, Inc. in the United States and other countries.

All other product names mentioned in this manual may be trademarks or registered trademarks

of their respective companies.

Matrix V-Series Documentation URL: http://www.enterasys.com/support/manuals

i

Page 4

Notice

Regulatory Compliance Information

Federal Communications Commission (FCC) Notice

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept

any interference re ceived, including interfer ence that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a class A

digital device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmf ul interference when the equipment is operated in a

commercial environment . This equipment uses, generates, and can radiate radio frequency

energy and if not installed in accordance with the operator’s manual, may cause harmful

interference to radio communi cation s. Operat ion of this equi pment in a re side ntial a rea is lik el y

to cause interfer ence in which case the user will be requi red to correct the int erference at his

own expense.

WARNING: Changes or modifications made to this device w hi ch are not expressly approved

by the party responsible for compliance could void the user’s authority to operate the

equipment.

Industry Canada Notice

This digital apparatus does not exceed the class A limits for radio noise emissions from digital

apparatus set out in the Radio Interference Regulations of the Canadian Department of

Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites

applicables aux a ppareils numériques de la class A prescrites dans le Règlement sur le

brouillage radioélectrique édicté par le ministère des Communications du Canada.

VCCI NOTICE

This is a class A product based on the standard of the Voluntary Control Council for Interference

by Information Technology Equipment (VCCI). If this equipm ent is used in a domest ic

environment, radio disturbance may arise. When such trouble occurs, the use r may be required

to take corrective actions.

Class A ITE Notice

WARNING: This is a class A product. In a domesti c environment this product ma y cause

radio interference in which case the user may be required to take adequate measures.

ii

Page 5

Notice

BSMI EMC Statement — Taiwan

This is a class A product. In a domestic environment this product may cause radio interference

in which case the user may be required to take adequate measures.

Safety Compliance

Please read the following safety information carefully before installing the

RPS:

WARNING: Installation a nd re moval of the unit m ust be ca rri ed out by qualified personnel only.

• The unit must be connected to an earthed (grounded) outlet to comply with international

safety standards.

• Do not connect the unit to an A.C. outlet (power supply) without an earth (ground)

connection.

• The appliance coupler (the connector to the unit and not the wall plug) must have a

configuration for m at in g w i th an EN 60320/IEC 320 appliance inlet.

• The socket outlet must be near to th e unit a nd easily accessib le. You ca n only r emove power

from the unit by di s c onnecting the power cord from the o ut le t.

• This unit operat es under SELV (Safety Ext r a Low Voltage) conditi ons according to

IEC 60950. The conditions are only maintained if the equipment to which it is connected also

operates un der SELV conditions.

France and Peru only

This unit cannot be powered from IT

powered by 230 V (2P+T) via an isolation transformer ratio 1:1, with the secondary connection point

labelled Neutral, connected directly to earth (groun d).

†

Impédance à la terre

†

supplies. If your supplies are of IT type, this unit mu st be

iii

Page 6

Notice

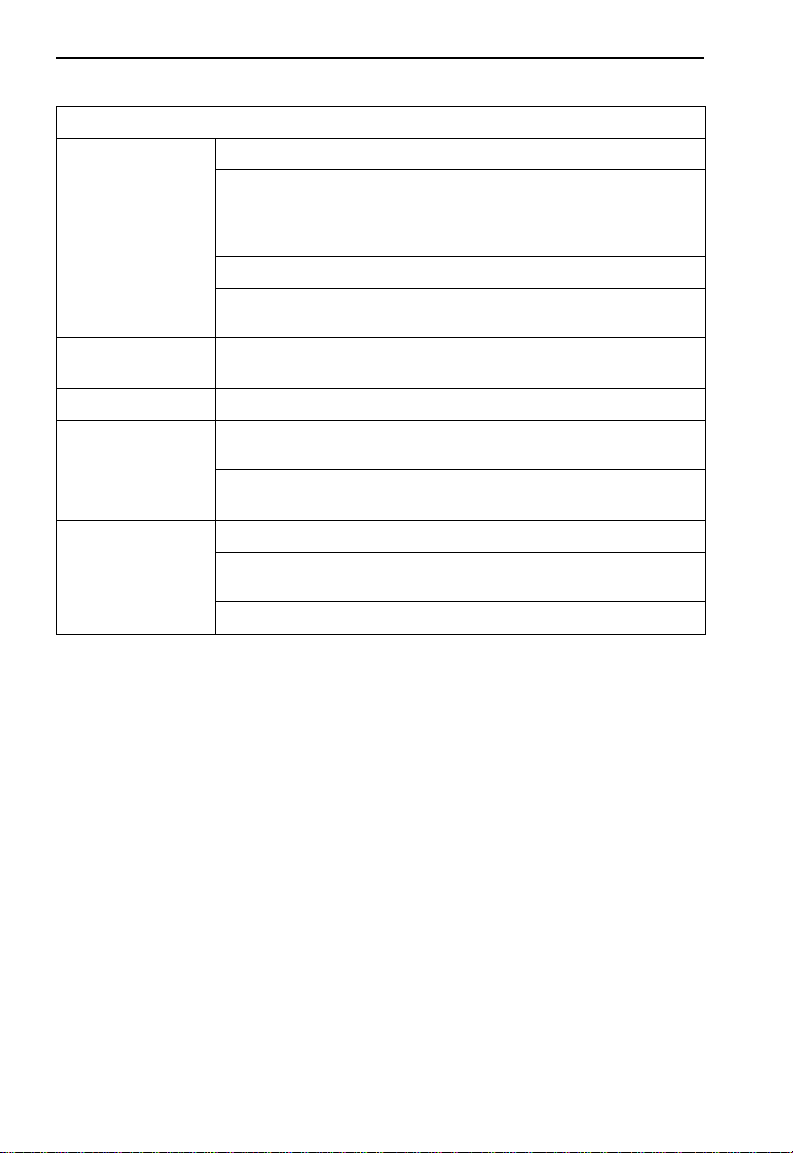

Power Cord Set

U.S.A. and Canada The cord set must be UL-approv ed and CSA certified.

The minimum specifications for the flexible cord are:

- No. 18 AWG - not longer than 2 meters, or 16 AWG.

- Type SV or SJ

- 3-conductor

The cord set must ha ve a rated current capacity of at least 10 A

The attachment plug must be an earth-grounding type with NEMA 5-15P

(15 A, 125 V) or NEMA 6-15P (15 A, 250 V) configuration.

Denmark The supply plug must comply with Section 107-2-D1, Standard DK2-1a

Switzerland The supply plug must comply with SEV/ASE 1011.

U.K. The supply plug must comply with BS1363 (3-pin 13-amp) and be fitted

Europe The supply plug must comply with CEE7/7 (“SCHUKO”).

or DK2-5a.

with a 5 A fuse which complies with BS 1362.

The mains cord must be <HAR> or <BASEC> marked and be of type

HO3VVF3GO.75 (minimum).

The mains cord must be <HAR> or <BASEC> marked and be of type

HO3VVF3GO.75 (minimum).

IEC-320 receptacle.

Veuillez lire à fond l'information de la sécurité suivante avant d'installer le

RPS:

AVERTISSEMENT: L’installation et la dépose de ce groupe doivent être confiés à un personnel

qualifié.

• Ne branchez pas votre appareil sur une prise secteur (alimentation électrique) lorsqu'il n'y a pas de

connexion de mise à la terre (mise à la masse).

• Vous devez raccorder ce groupe à une sortie mise à la terre (mise à la masse) afin de respecter les

normes internationales de sécurité.

• Le coupleur d’appareil (le connecteur du groupe et non pas la prise murale) doi t re spe ct er une

configuration qui perm et un branchement sur un e e n tr ée d’appareil EN 60320/IE C 320.

• La prise secteur doit se trouver à proximité de l’ap pa reil et son accès doit être facile. Vous ne

pouvez mettre l’app are il hors circuit qu’en débranchant son cordon élec trique au niveau de cette

prise.

• L’appareil foncti onne à une tension ex trêmement basse d e sécurité qui est co nforme à la norme IEC

60950. Ces conditions ne sont mai nt enues que si l’équipement auq uel il est ra cc ordé fonctionne

dans les mêmes conditions.

iv

Page 7

Notice

France et Pérou uniquement:

Ce groupe ne peut pas être alimenté par un dispositif à impédance à la terre. Si vos alimentations sont

du type impédance à la terre, ce gro upe doit être alimenté par une tensio n de 230 V (2 P+T) par le

biais d’un transformateur d’isolement à rapport 1:1, avec un point sec ondaire de connexion portant

l’appellation Neutre et avec raccordement direct à la terre (masse).

Cordon électrique - Il doit être agréé da ns le pay s d’ uti l isa tion

Etats-Unis et Canada:

Danemark: La prise mâle d’alime nta tion doit respecter la section 107-2 D1 de la

Suisse: La prise mâle d’alim e nta tion doit respecter la norme SEV / A S E 1011.

Europe La prise secteur doit être conforme aux normes CEE 7/7 (“ SCHUKO”)

Le cordon doit avoir reç u l’h omologation des UL et un certific at de la

CSA.

Les spe'cification s minimales pou r la corde flexible so nt AWG No. 18, ou

A WG No. 16 pour une longueur infe'rieure a` 2 me'tres:

- type SV ou SJ

- 3 conducteurs

Le cordon doit être en mesure d’acheminer un courant nominal d’au

moins 10 A.

La prise femelle de branchement doit être du type à mise à la terre (mise

à la masse) et respecter la configuration N E MA 5-15P (15 A, 125 V) ou

NEMA 6-15P (15 A, 250 V).

norme DK2 1a ou DK2 5a.

LE cordon secteur doit porter la mention <HAR> ou <BASEC> et doit

être de type HO3VVF3GO.75 (minimum).

Bitte unbedingt vor dem Einbauen des Switches die folgenden Sicherheitsanweisungen durchlesen:

WARNUNG: Die Installation und der Ausbau des Geräts darf nur durch Fachperson al erfo lg en.

• Das Gerät sollte nicht an eine ungeerdete Wechselstromsteckdose angeschlossen werden.

• Das Gerät muß an eine geerdete Steckdose angesch losse n w er de n, welc he die internationalen

Sicherheitsnormen erfüllt.

• Der Geräteste cker (der Anschluß an das Gerät, nicht der Wandsteckdosenstecker) muß einen

gemäß EN 60320/IEC 320 konfi gurierten Geräteeingang haben.

• Die Netzsteckdose muß in der Nähe des Geräts und leich t zu gänglich sein. Die Stromversorgun g

des Geräts kann nur durch Herausziehen des Gerätenetzkabels aus der Netzsteckdose unterbrochen

werden.

• Der Betrieb dieses Geräts erfol gt unte r de n SELV-Bedingungen (S icherheitskleinstspannun g)

gemäß IEC 60950. Diese Bed in gungen sind nur gegeben, wenn auch die an das Gerät

angeschlossenen Geräte unter SELV-Bedingungen bet rieben werden.

v

Page 8

Notice

•

Stromkabel. Dies muss von dem Land, in dem es be nutzt wird geprüft werden:

Schweiz Dieser Stromstecker muß die SEV/ASE 1011Bestimm ungen einhalten.

Europe Das Netzkabel muß vom Typ HO3 V V F3G O .75 (Mindestanforderung )

sein und die Aufschrift <HAR> oder <BASEC> tragen.

Der Netzstecker muß die Norm CEE 7/7 erfüllen (”SCHUKO”).

Declaration of Conformity

Application of Co uncil Directive(s): 89/336/EEC

73/23/EEC

Manufacturer’s Name: Enterasys Networks, Inc.

Manufacturer’s Address: 50 Minuteman Road

Andover, MA 018 10

USA

European Representative Address: Enterasys Networks, Ltd.

Nexus House, New bury Business Park

London Road, Newbury

Berkshire RG14 2PZ, England

Conformance to D ir ective(s)/Product Standards: EC Directive 89/336/E E C

EC Directive 73/2 3/EEC

EN 55022

EN 55024

EN 60950

Equipment Type /E nvi ronment: Networking Equipment, for use in

a Commercial or Li ght Industrial

Environment.

Enterasys Netw orks, Inc. declares that the equipment packaged

with this n o tice conforms to th e a bove directives.

vi

Page 9

Contents

Chapter 1: About the Redundant Power Supply 1-1

Overview 1-1

Features and Benefits 1-1

Front and Rear Panels 1-1

LEDs 1-2

Chapter 2: Installing the Redundant Power Supply 2-1

Installation 2-1

Selecting a Site 2-1

Equipment Checklist 2-1

Package Contents 2-2

GettingHelp 2-2

Optional Rack-Mounting Equipment 2-3

Mounting 2-3

Rack Mounting 2-3

Desktop or Shelf Mounting 2-5

Connecting Switches to the RPS 2-5

Appendix A: Troubleshooting A-1

Diagnosing RPS Indicators A-1

Power and Cooling Problems A-1

Installation A-1

Appendix B: Specifications B-1

Physical Characteristics B-1

Compliances B-2

Index

vii

Page 10

Tables

Table 1-1. Port Status LEDs 1-2

Table A-1. Troubleshooting Chart A-1

viii

Page 11

Figures

Figure 1-1. Front and Rear Panels 1-1

Figure 1-2. LEDs 1-2

Figure 2-1. Attaching the Brackets 2-4

Figure 2-2. Installing the RPS in a Rack 2-4

Figure 2-3. Attaching the Adhesive Feet 2-5

Figure 2-4. Power Receptacle 2-5

Figure 2-5. Connecting Several Switches to an RPS 2-6

ix

Page 12

Figures

x

Page 13

Chapter 1:

About the Redundant Power Supply

Overview

Note: The VSER-RPU-SYS is compatible with V2H124-24 and V2H124-24T only.

This VSER-RPU-SYS External Redundant Power Supply (RPS) can supply 600

Watts of backup power to four switching devices in the event of an AC loss or failure

of an internal power supply.

The system operates in a parallel capacity with a switch’s internal power supply. If a

switch's internal power supply fails, the RPS will support the full load of the switch

without affecting network operation.

Features and Benefits

• Supports four switching devices with 12V DC output

• Easy management LEDs located on the front panel

• AC line cord can draw power from a different supply circuit

• DC line cord provides backup power to the attached device

• The power supply will operate under a no-load condition.

Front and Rear Panels

Four power indicators (LEDs) and one fan indicator are located on the RPS’s front

panel. The AC supply and DC backup receptacles are located on the RPS’s rear

panel.

Figure 1-1. Front and Rear Panels

VSER-RPU-SYS

2

1

3

4

Fan

Rear Panel

1-1

Page 14

About the Redundant Power Supply

1

LEDs

The following diagram and table describe the functions of the LEDs on the Front

Panel.

Figure 1-2. LEDs

VSER-RPU-SYS

2

1

3

4

Fan

Table 1-1. Port Status LEDs

LED Condition Status

RPS 1, 2, 3, 4 On Green Power is being supplied to the RPS, the unit is functioning

Flashing Green Power is being supplied to the RPS, the unit is functioning

Off Power is off, or a failure has occurred.

Fan On Green The fans are functioning normally.

Flashing Red One or more fans have failed.

Off The unit is not connected to an AC power source.

normally, and the RPS port is connected to a switch.

normally, but no switch is connected to the RPS port.

1-2

Page 15

Chapter 2:

Installing the Redundant Power Supply

Installation

Note: The VSER-RPU-SYS is compatible with V2H124-24 and V2H124-24T only.

The RPS may be placed on a desktop or mounted in a rack.

Caution: DO NOT place the RPS on the floor as the case is not waterproof. It is

recommended that this RPS be installed in a network equipment rack.

Selecting a Site

RPS units can be mounted in a standard 19-inch equipment rack or on a flat surface.

Be sure to follow the guidelines below when choosing a location.

• The site should:

• be at the center of all the devices you want to link and near a power outlet.

• be able to maintain its temperature within 0 to 40 °C (32 to 104 °F) and its

humidity within 5% to 95%, non-condensing

• provide adequate space (approximately two inches) on all sides for proper air

flow

• be accessible for installing, cabling and maintaining the devices

• allow the status LEDs to be clearly visible

• Make sure that a separate grounded power outlet that provides 100 to 240

VAC, 50-60 Hz, is within 2.44 m (8 feet) of each device and is powered from an

independent circuit breaker. As with any equipment, using a filter or surge

suppressor is recommended.

Equipment Checklist

After unpacking the RPS, check the contents to be sure you have received all the

components. Then, before beginning the installation, be sure you have all other

necessary installation equipment.

2-1

Page 16

Installing the Redundant Power Supply

2

Package Contents

• Redundant Power Supply Unit

• One AC Supply Power Cord — US, Continental Europe or UK

• Four DC Backup Power Cords with IEC connectors on both ends (length 152 cm

[60 in.] each)

• Rack Mounting Kit containing brackets and screws

• Adhesive feet

• This Manual

• User Agreement Envelope

• Registration Card

GettingHelp

For additional support related to the RPS or this document, contact

Enterasys Networks using one of the following methods:

/

Web http://www.enterasys.com/support

Phone 603-332-9400

1-800-872-8440 (toll-free in U.S. and Canada)

For the Enterasys Networks Support toll-free number in your country:

http://www.enterasys.com/support/gtac-all.html

Internet mail support@enterasys.com

To expedite your message, please type [eth] in the subject line.

To send comments or suggestions concerning this document to the Technical Writing

Department: techwriting@enterasys.com

To expedite your message, please type [techwriting] in the subject line, and include

the document Part Number in the email message.

Before contacting Enterasys Networks for technical support, have the

following information ready:

• Your Enterasys Networks service contract number

• A description of the failure

• A description of any action(s) already taken to resolve the problem (e.g.,

changing mode switches, rebooting the unit, etc.)

• The serial and revision numbers of all involved Enterasys Networks products in

the network

• A description of your network environment (layout, cable type, etc.)

• Network load and frame size at the time of trouble (if known)

2-2

Page 17

Mounting

• The device history (i.e., have you returned the device before, is this a recurring

problem, etc.)

• Any previous Return Material Authorization (RMA) numbers

Optional Rack-Mounting Equipment

If you plan to rack-mount the RPS, be sure to have the following equipment

available:

• Four mounting screws for each device you plan to install in a rack—these are not

included

• A screwdriver (Phillips or flathead, depending on the type of screws used)

Mounting

RPS units can be mounted in a standard 19-inch equipment rack or on a desktop or

shelf. Mounting instructions for each type of site follow.

Rack Mounting

Before rack mounting the unit, pay particular attention to the following factors:

• Temperature: Since the temperature within a rack assembly may be higher than

the ambient room temperature, check that the rack-environment temperature is

within the specified operating temperature range.

• Mechanical Loading: Do not place any equipment on top of a rack-mounted unit.

• Circuit Overloading: Be sure that the supply circuit to the rack assembly is not

overloaded.

• Grounding: Rack-mounted equipment should be properly grounded. Particular

attention should be given to supply connections other than direct connections to

the mains.

2

2-3

Page 18

Installing the Redundant Power Supply

2

To rack-mount devices:

1. Attach the brackets to the device using the screws provided in the Rack

Mounting Kit.

Figure 2-1. Attaching the Brackets

1

VSER-RPU-SYS

2

3

4

Fan

2. Mount the device in the rack, using four rack-mounting screws (not provided).

Figure 2-2. Installing the RPS in a Rack

2-4

1

VSER-RPU-SYS

2

3

4

Fan

Page 19

Connecting Switches to the RPS

Desktop or Shelf Mounting

1. Attach the four adhesive feet to the bottom of the first RPS unit.

Figure 2-3. Attaching the Adhesive Feet

anel

P

Rear

2. Set the device on a flat surface near an AC power source, making sure there

are at least two inches of space on all sides for proper air flow.

Connecting Switches to the RPS

Caution: DO NOT connect the RPS to an AC power source until DC power cords have

been connected to the supported switches.

To connect switches to the RPS, refer to Figure 2-4 and Figure 2-5 and proceed as

follows:

1. Power up the switch by connecting one end of the AC cord to the AC receptacle

on the supported switch, and the other end to a grounded power outlet.

2

Figure 2-4. Power Receptacle

2. Connect one end of a DC cord to the redundant power receptacle on the

supported switch and the other end to an available receptacle on the RPS.

3. Repeat steps 1 and 2 for connecting up to four supported switches to the RPS.

2-5

Page 20

Installing the Redundant Power Supply

2

4. Power up the RPS by connecting one end of the AC cord to the AC receptacle

on the RPS, and the other end to a grounded power outlet.

5. Check the LEDs on the RPS to ensure proper operation. The Fan LED and the

RPS LED for connected switches should light up. If the LEDs indicate

otherwise, see "Troubleshooting" on page A-1 for more information.

Figure 2-5. Connecting Several Switches to an RPS

Stac k

RPS input port

100-240V,50/60Hz12.5A

RPS Unit

RPS output port

AC Power

Supply No.1

AC Power

Supply No.2

Note: For International use, you may need to change the AC line cord. You must use a

line cord set that has been approved for the receptacle type in your country.

2-6

Page 21

Appendix A: Troubleshooting

Diagnosing RPS Indicators

Table A-1. Troubleshooting Chart

Symptom Action

LEDs are Off • Internal power supply is disconnected.

• Check connections between the RPS, the power cord, and the wall

outlet.

• Contact Technical Support.

Fan LED is Flashing Red • One or more fans are malfunctioning. Have the unit replaced as soon

as possible.

Power and Cooling Problems

If the fan LED does not turn on when the power cord is plugged in, you may have a

problem with the power outlet, power cord, or internal power supply. However, if the

unit powers off after running for a while, check for loose power connections, power

losses or surges at the power outlet, and verify that the fans on the unit are

unobstructed and running prior to shutdown. If you still cannot isolate the problem,

then the internal power supply may be defective. In this case, contact your

distributor for assistance.

Installation

Verify that all system components have been properly installed. If one or more

components appear to be malfunctioning (such as the power cord or RPS cable),

test them in an alternate environment where you are sure that all the other

components are functioning properly.

A-1

Page 22

A

Troubleshooting

A-2

Page 23

Appendix B: Specifications

Physical Characteristics

Ports

4 RPS DC power outlets

LEDs

Ports 1 to 4, and fan status LEDs.

Weight

5 kg (27.6 lbs)

Size

44.0 x 28.4 x 4.3 cm (17.34 x 11.19 x 1.69 in.)

Temperature

Operating: 0 to 40 °C (32 to 104°F)

Storage: -40 to 70 °C (-40 to 158 °F)

Humidity

Operating: 5% to 95%

AC Input

100 to 240 V, 50 to 60 Hz

EIA Ratings

115V/10A

230V/10A

Power Consumption

264 Watts maximum

900.5 BTU

DC Power Cable Connector

14-pin plastic cable

B-1

Page 24

B

Specifications

Power Supply

Internal, auto-ranging: 100 to 240 VAC, 50 to 60 Hz

Output 12 VDC

Current: 0 A (minimum), 13 A (maximum)

Line regulation: +/- 1%

Load regulation: +/- 10%

Overshoot and undershoot: 5%

Maximum Current

10 A @ 110 VAC

5 A @ 230 VAC

Fan

Voltage +12 VDC

Operating voltage range: 7 V to 13.8 V

Speed: 8200 RPM

Air delivery: 9.43 CFM

Noise: 30.5 dB

Compliances

Product Safety

UL 60950

CSA C22.2 No. 60950

73/23/EEC

EN 60950

IEC 60950

Electromagnetic Compatibility (EMC)

47 CFR Parts 2 and 15

CSA C108.8

89/336/EEC

EN 55022

EN 61000-3-2

EN 61000-3-3

EN 55024

AS/NZS CISPR 22

VCCI V-3

B-2

Page 25

Index

A

adhesive feet, attaching 2-5

air flow requirements 2-1

B

brackets, attaching 2-4

C

contents of package 2-2

cooling problems A-1

cord sets, international 2-6

D

desktop mounting 2-5

E

equipment checklist 2-2

F

front panel of RPS 1-1

G

grounding for racks 2-3

I

installation

desktop or shelf mounting 2-5

power requirements 2-1

problems A-1

rack mounting 2-3

site requirements 2-1

L

LED indicators

problems A-1

location requirements 2-1

M

mounting the RPS

in a rack 2-3

on a desktop or shelf 2-5

P

package contents 2-2

power, connecting to 2-5

problems, troubleshooting A-1

R

rack mounting 2-3

rear panel of RPS 1-1

rubber foot pads, attaching 2-5

S

screws for rack mounting 2-3

site selelction 2-1

specifications

compliances B-2

environmental B-1

physical B-1

power B-2

standards

compliance B-2

IEEE B-2

surge suppressor, using 2-1

T

temperature within a rack 2-3

troubleshooting

in-band access A-1

power and cooling problems A-1

RPS indicators A-1

Index-1

Page 26

Index

Index-2

Page 27

Page 28

E032004-R01

150200042500A

Loading...

Loading...