Page 1

2H258-17R

SmartSwitch 2200

Installation User’s Guide

FAST ETHERNET WORKGROUP SWITCH

2H258-17R

9033068-01

RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX

123456 8910 151611 12 14137

PWR

RESET

CPU

COM

Page 2

Page 3

ELECTRICAL HAZARD: Only qualified personnel should perform installation

procedures.

NOTICE

Enterasys Networks reserves the right to make changes in specifications and other information contained in this

document and its web site without prior notice. The reader should in all cases consult Enterasys Networks to determine

whether any such changes have been made.

The hardware, firmware, or software described in this document is subject to change without notice.

IN NO EVENT SHALL ENTERASYS NETWORKS BE LIABLE FOR ANY INCIDENTAL, INDIRECT, SPECIAL,

OR CONSEQUENTIAL DAMAGES WHATSOEVER (INCLUDING BUT NOT LIMITED TO LOST PROFITS)

ARISING OUT OF OR RELATED TO THIS DOCUMENT, WEB SITE, OR THE INFORMATION CONTAINED IN

THEM, EVEN IF ENTERASYS NETWORKS HAS BEEN ADVISED OF, KNEW OF, OR SHOULD HAVE KNOWN

OF, THE POSSIBILITY OF SUCH DAMAGES.

Enterasys Networks, Inc.

35 Industrial Way

Rochester, NH 03867

2003 Enterasys Networks, Inc. All rights reserved.

Printed in the United States of America.

Part Number: 9033068-01 March 2003

ENTERASYS NETWORKS, ENTERASYS MATRIX, NETSIGHT, LANVIEW, MATRIX, WEBVIEW, and any logos

associated therewith, are trademarks or registered trademarks of Enterasys Networks, Inc. in the United States and other

countries.

All other product names mentioned in this manual may be trademarks or registered trademarks of their respective

companies.

FCC NOTICE

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions: (1) this device

may not cause harmful interference, and (2) this device must accept any interference received, including interference that

may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a class A digital device, pursuant to Part

15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment uses, generates, and can radiate radio frequency

energy and if not installed in accordance with the operator’s manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause interference in which case the user

will be required to correct the interference at his own expense.

WARNING: Changes or modifications made to this device which are not expressly approved by the party responsible

for compliance could void the user’s authority to operate the equipment.

Page 4

INDUSTRY CANADA NOTICE

This digital apparatus does not exceed the class A limits for radio noise emissions from digital apparatus set out in the

Radio Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils

numériques de la class A prescrites dans le Règlement sur le brouillage radioélectrique édicté par le ministère des

Communications du Canada.

VCCI NOTICE

This is a class A product based on the standard of the Voluntary Control Council for Interference by Information

Technology Equipment (VCCI). If this equipment is used in a domestic environment, radio disturbance may arise. When

such trouble occurs, the user may be required to take corrective actions.

CLASS A ITE NOTICE

WARNING: This is a class A product. In a domestic environment this product may cause radio interference in which

case the user may be required to take adequate measures.

BSMI EMC STATEMENT — TAIWAN

This is a class A product. In a domestic environment this product may cause radio interference in which case the user

may be required to take adequate measures.

Page 5

ENTERASYS NETWORKS, INC.

PROGRAM LICENSE AGREEMENT

BEFORE OPENING OR UTILIZING THE ENCLOSED PRODUCT,

CAREFULLY READ THIS LICENSE AGREEMENT.

This document is an agreement (“Agreement”) between the end user (“You”) and Enterasys Networks, Inc. on behalf of

itself and its Affiliates (as hereinafter defined) (“Enterasys”) that sets forth Your rights and obligations with respect to

the Enterasys software program (including any accompanying documentation, hardware or media) (“Program”) in the

package and prevails over any additional, conflicting or inconsistent terms and conditions appearing on any purchase

order or other document submitted by You. “Affiliate” means any person, partnership, corporation, limited liability

company, or other form of enterprise that directly or indirectly through one or more intermediaries, controls, or is

controlled by, or is under common control with the party specified. This Agreement constitutes the entire understanding

between the parties, and supersedes all prior discussions, representations, understandings or agreements, whether oral or

in writing, between the parties with respect to the subject matter of this Agreement. The Program may be contained in

firmware, chips or other media.

BY INSTALLING OR OTHERWISE USING THE PROGRAM, YOU REPRESENT THAT YOU ARE AUTHORIZED

TO ACCEPT THESE TERMS ON BEHALF OF THE END USER (IF THE END USER IS AN ENTITY ON WHOSE

BEHALF YOU ARE AUTHORIZED TO ACT, “YOU” AND “YOUR” SHALL BE DEEMED TO REFER TO SUCH

ENTITY) AND THAT YOU AGREE THAT YOU ARE BOUND BY THE TERMS OF THIS AGREEMENT, WHICH

INCLUDES, AMONG OTHER PROVISIONS, THE LICENSE, THE DISCLAIMER OF WARRANTY AND THE

LIMITATION OF LIABILITY. IF YOU DO NOT AGREE TO THE TERMS OF THIS AGREEMENT OR ARE NOT

AUTHORIZED TO ENTER INTO THIS AGREEMENT, ENTERASYS IS UNWILLING TO LICENSE THE

PROGRAM TO YOU AND YOU AGREE TO RETURN THE UNOPENED PRODUCT TO ENTERASYS OR YOUR

DEALER, IF ANY, WITHIN TEN (10) DAYS FOLLOWING THE DATE OF RECEIPT FOR A FULL REFUND.

IF YOU HAVE ANY QUESTIONS ABOUT THIS AGREEMENT, CONTACT ENTERASYS NETWORKS, LEGAL

DEPARTMENT AT (603) 332-9400.

You and Enterasys agree as follows:

1. LICENSE. You have the non-exclusive and non-transferable right to use only the one (1) copy of the Program

provided in this package subject to the terms and conditions of this Agreement.

2. RESTRICTIONS. Except as otherwise authorized in writing by Enterasys, You may not, nor may You permit any

third party to:

(i) Reverse engineer, decompile, disassemble or modify the Program, in whole or in part, including for reasons of

error correction or interoperability, except to the extent expressly permitted by applicable law and to the extent

the parties shall not be permitted by that applicable law, such rights are expressly excluded. Information

necessary to achieve interoperability or correct errors is available from Enterasys upon request and upon

payment of Enterasys’ applicable fee.

(ii) Incorporate the Program, in whole or in part, in any other product or create derivative works based on the

Program, in whole or in part.

(iii) Publish, disclose, copy, reproduce or transmit the Program, in whole or in part.

(iv) Assign, sell, license, sublicense, rent, lease, encumber by way of security interest, pledge or otherwise transfer

the Program, in whole or in part.

(v) Remove any copyright, trademark, proprietary rights, disclaimer or warning notice included on or embedded in

any part of the Program.

Page 6

3. APPLICABLE LAW. This Agreement shall be interpreted and governed under the laws and in the state and federal

courts of New Hampshire without regard to its conflicts of laws provisions. You accept the personal jurisdiction and venue

of the New Hampshire courts. None of the 1980 United Nations Convention on Contracts for the International Sale of

Goods, the United Nations Convention on the Limitation Period in the International Sale of Goods, and the Uniform

Computer Information Transactions Act shall apply to this Agreement.

4. EXPORT RESTRICTIONS. You understand that Enterasys and its Affiliates are subject to regulation by agencies

of the U.S. Government, including the U.S. Department of Commerce, which prohibit export or diversion of certain

technical products to certain countries, unless a license to export the Program is obtained from the U.S. Government or

an exception from obtaining such license may be relied upon by the exporting party.

If the Program is exported from the United States pursuant to the License Exception CIV under the U.S. Export

Administration Regulations, You agree that You are a civil end user of the Program and agree that You will use the

Program for civil end uses only and not for military purposes.

If the Program is exported from the United States pursuant to the License Exception TSR under the U.S. Export

Administration Regulations, in addition to the restriction on transfer set forth in Sections 1 or 2 of this Agreement, You

agree not to (i) reexport or release the Program, the source code for the Program or technology to a national of a country

in Country Groups D:1 or E:2 (Albania, Armenia, Azerbaijan, Belarus, Bulgaria, Cambodia, Cuba, Estonia, Georgia,

Iraq, Kazakhstan, Kyrgyzstan, Laos, Latvia, Libya, Lithuania, Moldova, North Korea, the People’s Republic of China,

Romania, Russia, Rwanda, Tajikistan, Turkmenistan, Ukraine, Uzbekistan, Vietnam, or such other countries as may be

designated by the United States Government), (ii) export to Country Groups D:1 or E:2 (as defined herein) the direct

product of the Program or the technology, if such foreign produced direct product is subject to national security controls

as identified on the U.S. Commerce Control List, or (iii) if the direct product of the technology is a complete plant or any

major component of a plant, export to Country Groups D:1 or E:2 the direct product of the plant or a major component

thereof, if such foreign produced direct product is subject to national security controls as identified on the U.S. Commerce

Control List or is subject to State Department controls under the U.S. Munitions List.

5. UNITED STATES GOVERNMENT RESTRICTED RIGHTS. The enclosed Program (i) was developed solely

at private expense; (ii) contains “restricted computer software” submitted with restricted rights in accordance with section

52.227-19 (a) through (d) of the Commercial Computer Software-Restricted Rights Clause and its successors, and (iii) in

all respects is proprietary data belonging to Enterasys and/or its suppliers. For Department of Defense units, the Program

is considered commercial computer software in accordance with DFARS section 227.7202-3 and its successors, and use,

duplication, or disclosure by the Government is subject to restrictions set forth herein.

6. DISCLAIMER OF WARRANTY. EXCEPT FOR THOSE WARRANTIES EXPRESSLY PROVIDED TO YOU

IN WRITING BY ENTERASYS, ENTERASYS DISCLAIMS ALL WARRANTIES, EITHER EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY,

SATISFACTORY QUALITY, FITNESS FOR A PARTICULAR PURPOSE, TITLE AND NON- INFRINGEMENT

WITH RESPECT TO THE PROGRAM. IF IMPLIED WARRANTIES MAY NOT BE DISCLAIMED BY

APPLICABLE LAW, THEN ANY IMPLIED WARRANTIES ARE LIMITED IN DURATION TO THIRTY (30)

DAYS AFTER DELIVERY OF THE PROGRAM TO YOU.

7. LIMITATION OF LIABILITY. IN NO EVENT SHALL ENTERASYS OR ITS SUPPLIERS BE LIABLE FOR

ANY DAMAGES WHATSOEVER (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF

BUSINESS, PROFITS, BUSINESS INTERRUPTION, LOSS OF BUSINESS INFORMATION, SPECIAL,

INCIDENTAL, CONSEQUENTIAL, OR RELIANCE DAMAGES, OR OTHER LOSS) ARISING OUT OF THE USE

OR INABILITY TO USE THE PROGRAM, EVEN IF ENTERASYS HAS BEEN ADVISED OF THE POSSIBILITY

OF SUCH DAMAGES. THIS FOREGOING LIMITATION SHALL APPLY REGARDLESS OF THE CAUSE OF

ACTION UNDER WHICH DAMAGES ARE SOUGHT.

THE CUMULATIVE LIABILITY OF ENTERASYS TO YOU FOR ALL CLAIMS RELATING TO THE PROGRAM,

IN CONTRACT, TORT OR OTHERWISE, SHALL NOT EXCEED THE TOTAL AMOUNT OF FEES PAID TO

ENTERASYS BY YOU FOR THE RIGHTS GRANTED HEREIN.

Page 7

8. AUDIT RIGHTS. You hereby acknowledge that the intellectual property rights associated with the Program are of

critical value to Enterasys and, accordingly, You hereby agree to maintain complete books, records and accounts showing

(i) license fees due and paid, and (ii) the use, copying and deployment of the Program. You also grant to Enterasys and

its authorized representatives, upon reasonable notice, the right to audit and examine during Your normal business

hours, Your books, records, accounts and hardware devices upon which the Program may be deployed to verify

compliance with this Agreement, including the verification of the license fees due and paid Enterasys and the use, copying

and deployment of the Program. Enterasys' right of examination shall be exercised reasonably, in good faith and in a

manner calculated to not unreasonably interfere with Your business. In the event such audit discovers non-compliance

with this Agreement, including copies of the Program made, used or deployed in breach of this Agreement, You shall

promptly pay to Enterasys the appropriate license fees. Enterasys reserves the right, to be exercised in its sole discretion

and without prior notice, to terminate this license, effective immediately, for failure to comply with this Agreement. Upon

any such termination, You shall immediately cease all use of the Program and shall return to Enterasys the Program and

all copies of the Program.

9. OWNERSHIP. This is a license agreement and not an agreement for sale. You acknowledge and agree that the

Program constitutes trade secrets and/or copyrighted material of Enterasys and/or its suppliers. You agree to implement

reasonable security measures to protect such trade secrets and copyrighted material. All right, title and interest in and to

the Program shall remain with Enterasys and/or its suppliers. All rights not specifically granted to You shall be reserved

to Enterasys.

10. ENFORCEMENT. You acknowledge and agree that any breach of Sections 2, 4, or 9 of this Agreement by You

may cause Enterasys irreparable damage for which recovery of money damages would be inadequate, and that Enterasys

may be entitled to seek timely injunctive relief to protect Enterasys’ rights under this Agreement in addition to any and

all remedies available at law.

11. ASSIGNMENT. You may not assign, transfer or sublicense this Agreement or any of Your rights or obligations

under this Agreement, except that You may assign this Agreement to any person or entity which acquires substantially all

of Your stock or assets. Enterasys may assign this Agreement in its sole discretion. This Agreement shall be binding upon

and inure to the benefit of the parties, their legal representatives, permitted transferees, successors and assigns as

permitted by this Agreement. Any attempted assignment, transfer or sublicense in violation of the terms of this Agreement

shall be void and a breach of this Agreement.

12. WAIVER. A waiver by Enterasys of a breach of any of the terms and conditions of this Agreement must be in

writing and will not be construed as a waiver of any subsequent breach of such term or condition. Enterasys’ failure to

enforce a term upon Your breach of such term shall not be construed as a waiver of Your breach or prevent enforcement

on any other occasion.

13. SEVERABILITY. In the event any provision of this Agreement is found to be invalid, illegal or unenforceable, the

validity, legality and enforceability of any of the remaining provisions shall not in any way be affected or impaired

thereby, and that provision shall be reformed, construed and enforced to the maximum extent permissible. Any such

invalidity, illegality or unenforceability in any jurisdiction shall not invalidate or render illegal or unenforceable such

provision in any other jurisdiction.

14. TERMINATION. Enterasys may terminate this Agreement immediately upon Your breach of any of the terms and

conditions of this Agreement. Upon any such termination, You shall immediately cease all use of the Program and shall

return to Enterasys the Program and all copies of the Program.

Page 8

DECLARATION OF CONFORMITY

Application of Council Directive(s): 89/336/EEC

73/23/EEC

Manufacturer’s Name: Enterasys Networks, Inc.

Manufacturer’s Address: 35 Industrial Way

PO Box 5005

Rochester, NH 03866-5005

European Representative Address: Enterasys Networks Ltd.

Nexus House, Newbury Business Park

London Road, Newbury

Berkshire RG14 2PZ, England

Conformance to Directive(s)/Product Standards: EC Directive 89/336/EEC

EC Directive 73/23/EEC

EN 55022

EN 55024

EN 60950

EN 60825

Equipment Type/Environment: Networking Equipment, for use in a Commercial

or Light Industrial Environment.

Enterasys Networks, Inc. declares that the equipment packaged with this notice conforms to the above directives.

Page 9

Contents

Figures ............................................................................................................................................ix

Tables.............................................................................................................................................. x

ABOUT THIS GUIDE

Using This Guide.............................................................................................................xi

Structure of This Guide ...................................................................................................xi

Related Documents........................................................................................................xii

Document Conventions................................................................................................. xiii

1

2

INTRODUCTION

1.1 Overview ......................................................................................................... 1-1

1.1.1 Connectivity .................................................................................... 1-2

1.1.2 Runtime IP Address Discovery ....................................................... 1-2

1.1.3 Full Duplex Switched Ethernet........................................................ 1-3

1.1.4 SmartTrunk ..................................................................................... 1-3

1.1.5 Remote Monitoring (RMON) ........................................................... 1-3

1.1.6 Broadcast Suppression................................................................... 1-4

1.1.7 Port/VLAN Redirect Functions ........................................................ 1-4

1.1.8 Traffic Rate Limiting........................................................................ 1-4

1.1.9 Flow Control.................................................................................... 1-5

1.1.10 GARP Switch Operation ................................................................. 1-5

1.1.11 802.1 Port Priority ........................................................................... 1-5

1.1.12 Management ................................................................................... 1-6

1.1.13 Switching Options ........................................................................... 1-6

1.1.14 Optional HSIMs and VHSIMs.......................................................... 1-6

1.1.15 Standards Compatibility .................................................................. 1-6

1.1.16 Year 2000 Compliant ...................................................................... 1-6

1.1.17 LANVIEW Diagnostic LEDs ............................................................1-7

1.2 Getting Help .................................................................................................... 1-7

NETWORK REQUIREMENTS

2.1 SmartTrunk...................................................................................................... 2-1

2.2 100BASE-FX Network..................................................................................... 2-1

Contents vii

Page 10

3

INSTALLATION

3.1 Unpacking the Device ..................................................................................... 3-2

3.2 Installing Options.............................................................................................3-2

3.3 Installing the Device ........................................................................................ 3-3

3.3.1 Tabletop or Shelf Installation .......................................................... 3-3

3.3.2 Rackmount Installation.................................................................... 3-4

3.3.3 Connecting Power........................................................................... 3-7

3.4 Connecting to the Network.............................................................................. 3-8

3.5 Completing the Installation............................................................................3-11

4

A

B

TROUBLESHOOTING

4.1 Using LANVIEW.............................................................................................. 4-1

4.2 Troubleshooting Checklist...............................................................................4-4

4.3 Using the RESET Button................................................................................. 4-8

SPECIFICATIONS

A.1 Device Specifications ......................................................................................A-1

A.2 Physical Properties .........................................................................................A-1

A.3 Electrical Specifications ..................................................................................A-2

A.4 Environmental Requirements ..........................................................................A-2

A.5 Input/Output Ports ...........................................................................................A-2

A.6 COM Port Pinout Assignments .......................................................................A-3

A.7 Regulatory Compliance...................................................................................A-3

OPTIONAL INSTALLATIONS AND

MODE SWITCH BANK SETTINGS

B.1 Required Tools................................................................................................B-1

B.2 Removing the Chassis Cover..........................................................................B-2

B.3 Setting the Mode Switches..............................................................................B-5

B.4 SIMM Upgrade ................................................................................................B-7

B.4.1 Locating SIMMs ..............................................................................B-7

B.4.2 Installing the DRAM SIMM..............................................................B-8

B.5 Installing Optional HSIM or VHSIM Interface Modules ...................................B-9

INDEX

viii Contents

Page 11

Figures

Figure Page

1-1 The 2H258-17R SmartSwitch 2200................................................................................. 1-1

3-1 Tabletop or Shelf Installation ........................................................................................... 3-4

3-2 Attaching the Strain-Relief Bracket ................................................................................. 3-5

3-3 Attaching the Rackmount Brackets .................................................................................3-6

3-4 Installing the Device in a Rack ........................................................................................3-7

3-5 2H258-17R Rear View .................................................................................................... 3-8

3-6 Fiber Optic Connection.................................................................................................. 3-10

4-1 LANVIEW LEDs .............................................................................................................. 4-1

4-2 RESET Button .................................................................................................................4-8

B-1 Removing the Chassis Cover......................................................................................... B-4

B-2 Mode Switch Location .................................................................................................... B-5

B-3 SIMM Slot Locations ...................................................................................................... B-7

B-4 Installing the DRAM........................................................................................................ B-8

B-5 HSIM and VHSIM Connector Locations ......................................................................... B-9

Figures ix

Page 12

Tables

Ta bl e Page

3-1 Contents of 2H258-17R Carton ....................................................................................3-2

4-1 LANVIEW LEDs ............................................................................................................4-2

4-2 Troubleshooting Checklist.............................................................................................4-4

A-1 COM Port Pin Assignment ........................................................................................... A-3

x Ta bl e s

Page 13

About This Guide

Welcome to the 2H258-17R SmartSwitch 2200 Installation User’s Guide. This guide describes

the 2H258-17R SmartSwitch 2200 device and provides information concerning network

requirements, installation, and troubleshooting. For information about how to use Local

Management to configure and manage the 2H258-17R, refer to the SmartSwitch Series 2E253,

2H252, 2H253, and 2H258 Local Management User’s Guide.

Important Notice

Depending on the firmware version used in the 2H258-17R, some features described in

this document may not be supported. Refer to the Release Notes shipped with the

2H258-17R to determine which features are supported.

USING THIS GUIDE

Read through this guide to completely understand the 2H258-17R capabilities and how to install it.

A general working knowledge of Ethernet and IEEE 802.3 type data communications networks

and their physical layer components is helpful when using this device.

NOTE: In this document, the device is referred to as either the “2H258-17R” or the

“device”.

STRUCTURE OF THIS GUIDE

This guide is organized as follows:

Chapter 1, Introduction, provides an overview of the 2H258-17R and its features. Directions for

obtaining additional information or help from Enterasys Networks are also included in this

chapter.

Chapter 2, Network Requirements, explains the network requirements to consider before

installing the 2H258-17R.

Chapter 3, Installation, provides instructions on how to install the 2H258-17R and connect

segments to the device.

About This Guide xi

Page 14

Related Documents

Chapter 4, Troubleshooting, describes the function of the LANVIEW LEDs, which can help to

quickly diagnose network/operational problems.

Appendix A, Specifications, contains information on functionality and operating specifications,

connector pinouts, environmental requirements, and physical properties.

Appendix B, Optional Installations and Mode Switch Bank Settings, describes how to remove

the cover from the device, set the Mode Switch, and shows the location of an optional High Speed

Interface Module (HSIM) or Very High Speed Interface Module (VHSIM) when one is installed.

RELATED DOCUMENTS

The following Enterasys Networks documents may help to set up, control, and manage the

2H258-17R:

• SmartSwitch Series 2E253, 2H252, 2H253, and 2H258 Local Management User’s Guide

• Ethernet Technology Guide

• Cabling Guide

• SmartTrunk User’s Guide

• WAN Series Local Management User’s Guide

The following are Enterasys Networks documents associated with the optional interface modules:

• HSIM-A6DP User’s Guide

• HSIM-F6 User’s Guide

• HSIM-FE6 User’s Guide

• HSIM-W6 Installation Guide

• HSIM-W84 Installation Guide

• HSIM-W87 User’s Guide

• HSIM-G01/G09 User’s Guide

• VHSIM-G6 User’s Guide

• VHSIM-A6DP User’s Guide

xii About This Guide

Page 15

Document Conventions

The HSIM-W6 Installation Guide, the HSIM-W84 Installation Guide, and the WAN Series Local

Management User’s Guide are included on the QuickSET CD-ROM and, along with the other

manuals listed above, can be obtained from the World Wide Web in Adobe Acrobat Portable

Document Format (PDF) at the following site:

http://www.enterasys.com/

NOTE: All documentation for the Enterasys Networks SecureFast VLAN Manager

software is contained on the VLAN Manager CD-ROM.

DOCUMENT CONVENTIONS

This guide uses the following conventions:

NOTE: Calls the reader’s attention to any item of information that may be of special

importance.

TIP: Conveys helpful hints concerning procedures or actions.

CAUTION: Contains information essential to avoid damage to the equipment.

ELECTRICAL HAZARD: Warns against an action that could result in personal injury or

death due to an electrical hazard.

WARNING: Warns against an action that could result in personal injury or death.

About This Guide xiii

Page 16

Page 17

1

Introduction

This chapter introduces the 2H258-17R SmartSwitch 2200 device and provides information about

how to obtain additional support from Enterasys Networks.

Important Notice

Depending on the firmware version used in the 2H258-17R, some features described in this

document may not be supported. Refer to the Release Notes shipped with the 2H258-17R to

determine which features are supported.

1.1 OVERVIEW

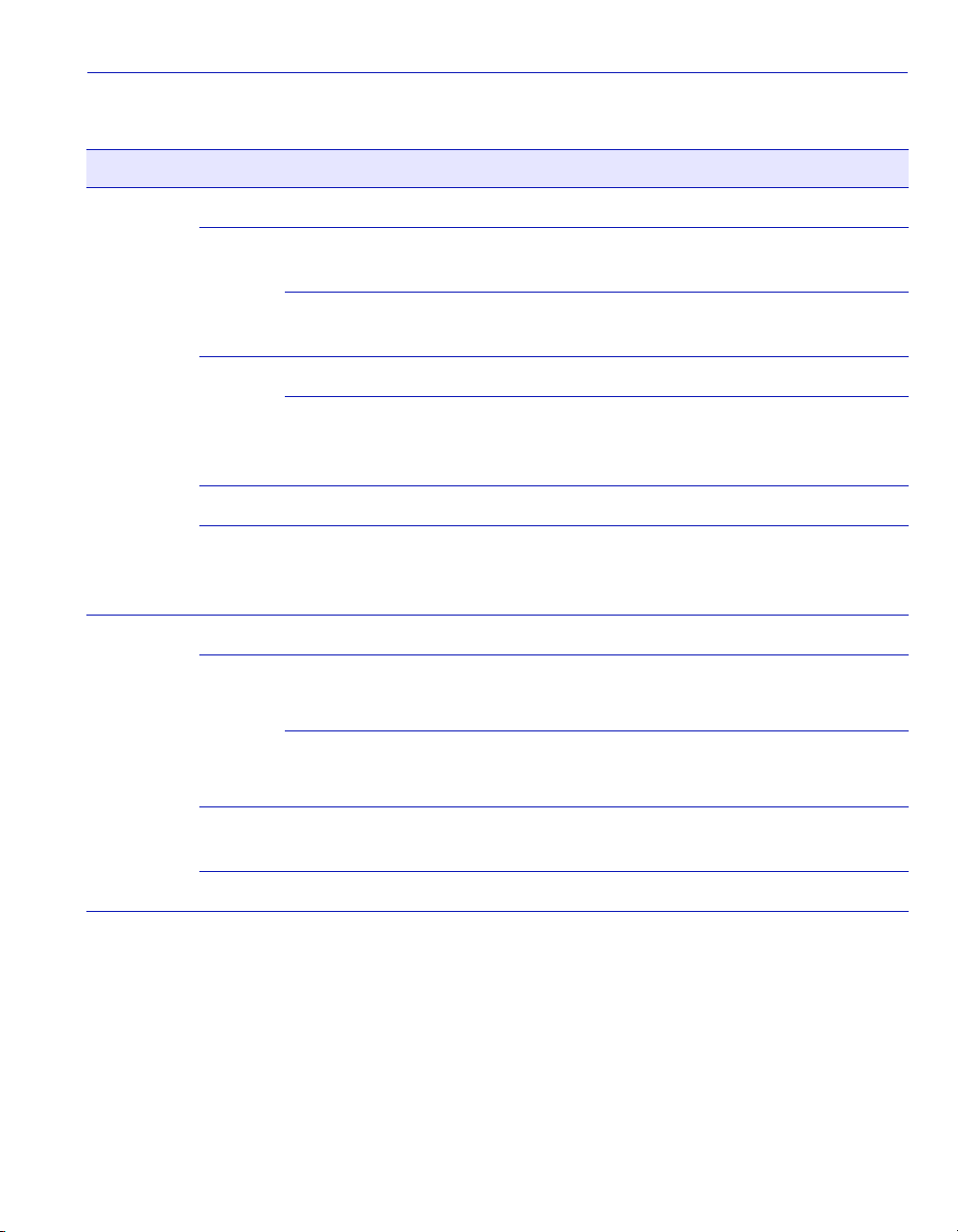

The 2H258-17R (Figure 1-1) is a standalone device with 16 100BASE-FX fiber optic MT-RJ

switched ports and 1 slot for an optional High Speed Interface Module (HSIM) or Very High

Speed Interface Module (VHSIM).

Figure 1-1 The 2H258-17R SmartSwitch 2200

FAST ETHERNET WORKGROUP SWITCH

2H258-17R

Reset

Button

RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX

123456 8910 151611 12 14137

RESET

COM

Port

COM

PWR

CPU

System

LEDs

RX and TX

Port Status

HSIM/VHSIM Slot

LEDs

100 Mbps Fiber Optic Ports (1-16)

3068-01

Introduction 1-1

Page 18

Overview

The 2H258-17R is used to connect individual high-bandwidth user devices, such as workstations,

or to provide a central switching point for multiple 100-Mbps Fast Ethernet segments. The

optional HSIMs provide high speed uplinks to networking technologies such as Fast Ethernet,

Gigabit Ethernet, Fiber Distributed Data Interface (FDDI), Wide Area Network (WAN), and

Asynchronous Transfer Mode (ATM). Some HSIMs can provide additional Fast Ethernet ports in

varying media types. The optional VHSIMs provide very high speed uplinks to networking

technologies such as Gigabit Ethernet and ATM.

The 2H258-17R ports can be configured to control frame traffic in several ways, including

prioritizing traffic flow according to protocol type. The 2H258-17R can also be configured to

establish Virtual Local Area Networks (VLANs) and control the flow of frames associated with

each VLAN according to priority and Ether type. Detailed information about VLANs is provided

in the SmartSwitch Series 2E253, 2H252, 2H253, and 2H258 Local Management User’s Guide.

The 2H258-17R may be used as a tabletop unit or can be installed in a standard 19-inch rack using

the supplied rack mounting hardware.

The 2H258-17R has two power supplies. The power supplies load share 50% (+/-5%) of the power

required by the device. If one power supply fails, the remaining power supply assumes the entire

load of the device without interruption to network traffic. Each power supply module supports its

own ac input connection, which enables each power supply to be connected to a different ac power

circuit.

1.1.1 Connectivity

The 2H258-17R connects to Ethernet networks or workstations through the 16 fiber-optic

multimode MT-RJ ports on the front panel. These ports are in full compliance with the optical

performance requirements of 100BASE-FX version of IEEE 802.3u.The ports support multimode

fiber optic cables with 1300-nm surface emitting InGaAsP LEDs at lengths up to 2 kilometers for

100 Mbps.

The device also has a slot for an optional HSIM or VHSIM to provide additional connectivity to

various networking technologies.

1.1.2 Runtime IP Address Discovery

This feature enables the 2H258-17R device to automatically accept an IP address from a Boot

Strap Protocol (BootP) server on the network without requiring a user to enter an IP address

through Local Management.

When the device is connected to the network and powered up, Runtime IP Address Discovery

(RAD) checks the device for an IP address. If one has not yet been assigned (device IP address set

to 0.0.0.0), RAD checks to see if any of the device interfaces have a link. If so, RAD sends out

Reverse Address Resolution Protocol (RARP) and BootP requests to obtain an IP address from a

BootP server on the network.

1-2 Introduction

Page 19

Overview

The RAD requests start at an interval of 1 per second. The interval then doubles after every

transmission until an interval of 300 seconds is reached. At this point, the interval remains at 300

seconds. The RAD requests continue until an IP address is received from a RARP or BootP server,

or an IP address is entered using Local Management.

NOTE: The 2H258-17R will reboot after RAD is successful.

1.1.3 Full Duplex Switched Ethernet

Each switched Fast Ethernet port on the 2H258-17R supports 100 Mbps operation, and can operate

in Full Duplex Switched Ethernet (FDSE) mode. FDSE enables each port to provide up to

200 Mbps of bandwidth to connected devices that support FDSE.

1.1.4 SmartTrunk

Traditional 802.1D Spanning Tree Bridges only allow one active data path between any two

switches; all other parallel data paths are in Standby or Blocking mode. If one interface or path

should fail, then the other interface automatically comes out of Blocking mode and forwards all of

the traffic. This is fine for redundancy purposes. However, it is not the most efficient use of

resources.

SmartTrunk, also referred to as SmartTrunking, is Enterasys Networks’ terminology for load

balancing or load sharing. SmartTrunk provides the ability to take full advantage of the network’s

redundant bandwidth. SmartTrunk divides network traffic across multiple ports in parallel to

provide additional throughput. The SmartTrunk application can be used with any of Enterasys

Networks’ switch modules (except ATM modules).

For more information about SmartTrunk and how to configure it the SmartSwitch device, refer to

the Enterasys Networks SmartTrunk User’s Guide.

1.1.5 Remote Monitoring (RMON)

The 2H258-17R supports all nine Ethernet RMON groups. The Statistics, Alarms, Events and

History groups are enabled on all ports by default.

Enterasys Networks RMON Actions is a vendor-specific extension of RMON and provides the

ability to set an “Action” on any SNMP MIB variable. The Action can be triggered by any RMON

Event and/or Alarm. An example of an Action would be to turn off a MIB-2 interface if a

broadcast threshold is crossed.

Introduction 1-3

Page 20

Overview

1.1.6 Broadcast Suppression

Broadcast Suppression enables a user to set a desired limit of receive broadcast frames per port/per

second to be forwarded out the other ports on the device. Any broadcast frames above this

specified limit are dropped. In the event that broadcast frames are being suppressed, multicast and

unicast frames continue to be switched.

1.1.7 Port/VLAN Redirect Functions

The port redirect function, also referred to as “Port Mirroring,” is a troubleshooting tool used to

map traffic from a single source port to a single destination port within the device. This feature

allows frames, including those with errors, to be copied and sent to an analyzer or RMON probe.

The analyzer or RMON probe will see the data as if it were directly connected to the LAN segment

of the source port.

The VLAN redirect function is similar to the port redirect function except that the frames received

by the device are redirected to a designated destination port according to the VLAN classification

of the frames received. Multiple VLANs can be directed to the same destination port. The VLAN

redirect function is only supported when the device is operating as an 802.1Q switch.

1.1.8 Traffic Rate Limiting

The Rate Limiting feature enables the SmartSwitch device to have control over traffic rates on a

per-port, per-priority basis. The network administrator can configure a rate limit (from 100 kbps to

1 Gbps) for a given port with an associated list of IEEE 802.1p priorities (which can include one,

some, or all of the eight priority levels defined in 802.1p). Each rate limit is specified as an

inbound or an outbound limit. The combined rate of all traffic on the port that matches the listed

priorities cannot exceed the programmed limit. If the rate exceeds the defined limit, frames are

dropped until the rate falls below the limit.

Administrators can configure up to four rate limit rules per port; however, each rule must not

include conflicting 802.1p priority values. In order to control traffic inbound and outbound on the

same port, two rate limit rules must be configured (one inbound and one outbound). Since the rate

limiting operation occurs after the processing of the multi-layer classification rules, the two

features can be combined to provide application-aware rate limiting.

NOTE: This rate limiting function is not supported on ports connected to SmartTrunk

ports.

For more information about the application of

2H252, 2H253 and 2H258 Local Management User’s Guide.

1-4 Introduction

rate limiting, refer to the SmartSwitch Series 2H253,

Page 21

Overview

1.1.9 Flow Control

Flow control is a method of managing the flow of frames between two devices. It ensures that a

transmitting device does not overwhelm a receiving device with data. This is accomplished by the

transmitting device pausing its transmission while the receiving device processes the frames

already received.

The 2H258-17R supports the following two types of flow control:

• Frame based 802.3x

• Back pressure

Frame based 802.3x flow control is supported on all Ethernet ports operating in the full duplex

mode. Flow control can be enabled or disabled on a port-by-port basis.

Back pressure flow control is supported on all Ethernet ports operating in the standard mode of

operation. Flow control can be enabled or disabled on a port-by-port basis.

1.1.10 GARP Switch Operation

Some or all ports on the switch may be activated to operate under the Generic Attribute

Registration Protocol (GARP) applications, GARP VLAN Registration Protocol (GVRP) and/or

GARP Multicast Registration Protocol (GMRP).

GARP is a protocol, or set of rules, that outlines a mechanism for propagating the port state and/or

user information throughout a bridged LAN to keep track of users and VLANs on the network

fabric. MAC bridges and end users alike can take part in the registration and de-registration of

GARP attributes such as VLAN and multicast group membership. For more details on how GVRP

and GMRP handle frames under GARP, and how to configure the switch ports to take advantage of

this operation, refer to the SmartSwitch Series 2E253, 2H252, 2H253, and 2H258 Local

Management User’s Guide.

1.1.11 802.1 Port Priority

The 802.1 port priority is used to assign a default priority to the frames received without priority

information in their tag header, map prioritized frames to the appropriate transmit queues, and

prioritize frames according to protocol type. The 802.1 port priority is part of the IEEE 802.1D

standard.

Introduction 1-5

Page 22

Overview

1.1.12 Management

Management of the 2H258-17R is accomplished using SNMP compliant management tools for

in-band Local Management. Out-of-band Local Management is provided through the RJ45 COM

port on the front panel using a VT100 terminal or a VT100 terminal emulator. In-band remote

management is possible through any SNMP compliant Network Management Software.

Local Management described in the SmartSwitch Series 2H253, 2H252, 2H253 and 2H258 Local

Management User’s Guide provides the ability to manage the 2H258-17R, and optional HSIMs

and VHSIMs that support Ethernet. For information about Local Management for optional

non-Ethernet HSIMs or VHSIMs, refer to their respective user’s guide.

1.1.13 Switching Options

The 2H258-17R provides 802.1Q switching or SecureFast Switching Virtual Network Services

between all of the front panel interfaces including the optional HSIM or VHSIM interface. In the

802.1Q mode (the default mode of operation), the 2H258-17R functions as an 802.1D switch until

VLANs are configured.

IEEE 802.1Q switching and SecureFast switching allow migration to Virtual Network

technologies without requiring the replacement of existing equipment.

1.1.14 Optional HSIMs and VHSIMs

Optional HSIMs and VHSIMs are available from Enterasys Networks for additional connectivity

to various networking technologies. The HSIMs and VHSIMs available for the 2H258-17R are

listed in the Release Notes shipped with the device.

1.1.15 Standards Compatibility

The 2H258-17R is fully compliant with the IEEE 802.3, 802.3u, 802.3x, 802.1D, and 802.1Q

standards. The 2H258-17R provides IEEE 802.1D Spanning Tree Algorithm (STA) support to

enhance the overall reliability of the network and protect against “loop” conditions. The

2H258-17R supports a wide variety of industry standard MIBs including RFC 1213 (MIB II),

RFC 1757 (RMON), RFC 1493 (Bridge MIB), RFC 1354 (FIB MIB), and RFC 1190 (Path MTU

Discovery). A full suite of Enterasys Networks Enterprise MIBs provide a wide array of statistical

information to enhance troubleshooting. For information on how to extract and compile individual

MIBs, contact Enterasys Networks.

1.1.16 Year 2000 Compliant

The 2H258-17R has an internal clock that can maintain the current time and date beyond the year

1999.

1-6 Introduction

Page 23

Getting Help

1.1.17 LANVIEW Diagnostic LEDs

LANVIEW diagnostic LEDs serve as an important troubleshooting aid by providing an easy way

to observe the status of individual ports and overall network operations.

1.2 GETTING HELP

For additional support related to the module or this document, contact Enterasys Networks using

one of the following methods:

/

World Wide Web http://www.enterasys.com

Phone 603-332-9400

1-800-872-8440 (toll-free in U.S. and Canada)

For the Enterasys Networks Support toll-free number in your country:

http://www.enterasys.com/support/gtac-all.html

Internet mail support@enterasys.com

To send comments or suggestions concerning this document to the Technical Writing

Department: TechWriting@enterasys.com

Make sure to include the document Part Number in the email message.

Before contacting Enterasys Networks for technical support, have the following information

ready:

• Your Enterasys Networks service contract number

• A description of the failure

• A description of any action(s) already taken to resolve the problem (e.g., changing mode

switches, rebooting the unit, etc.)

• The serial and revision numbers of all involved Enterasys Networks products in the network

• A description of your network environment (layout, cable type, etc.)

• Network load and frame size at the time of trouble (if known)

• The device history (i.e., have you returned the device before, is this a recurring problem, etc.)

• Any previous Return Material Authorization (RMA) numbers

Introduction 1-7

Page 24

Page 25

2

Network Requirements

Before installing the 2H258-17R, review the requirements and specifications referred to in this

chapter concerning the following:

• SmartTrunk (Section 2.1)

• 100BASE-FX Twisted Pair Network (Section 2.2)

The network installation must meet the requirements to ensure satisfactory performance of this

equipment. Failure to do so will produce poor network performance.

NOTE: The SmartTrunk User’s Guide and Cabling Guide referred to in the following

sections can be found on the Enterasys Networks World Wide Web site:

http://www.enterasys.com/

2.1 SmartTrunk

To connect the 2H258-17R to a network so it can take advantage of the SmartTrunk feature, there

are certain rules concerning port connections and configurations that must be followed for proper

operation. Refer to the SmartTrunk User’s Guide for additional information.

2.2 100BASE-FX NETWORK

The fixed ports (1 through 16) of the 2H258-17R provide fiber optic multimode connections via

MT-RJ connectors. Segments connected to these ports must meet the optical performance

requirements for 100BASE-FX IEEE 802.3u. The front panel slot for optional modules can also

support Enterasys Networks fiber optic interface modules. The device at the other end of the

segment must meet the 100BASE-FX Fast Ethernet network requirements to operate at 100 Mbps.

Refer to the Enterasys Networks Cabling Guide for details.

Network Requirements 2-1

Page 26

Page 27

3

Installation

ELECTRICAL HAZARD: Only qualified personnel should install the 2H258-17R.

NOTE: Read the Release Notes shipped with the device to check for any exceptions to

the supported features and operation documented in this guide.

This chapter provides the instructions required to install the 2H258-17R. A Phillips screwdriver is

required to install options into the device or install the device into a rack. Follow the order of the

sections listed below to correctly install the device.

• Unpacking the Device (Section 3.1)

• Installing Options (Section 3.2)

• Installing the Device (on a shelf or tabletop, or into a standard rack) (Section 3.3)

• Connecting to the Network (Section 3.4)

• Completing the Installation (Section 3.5)

Installation 3-1

Page 28

Unpacking the Device

3.1 UNPACKING THE DEVICE

Unpack the device as follows:

1. Open the box and remove the packing material protecting the 2H258-17R.

2. Verify the contents of the carton as listed in Table 3-1.

Table 3-1 Contents of 2H258-17R Carton

Item Quantity

2H258-17R 1

Antistatic Wrist Strap 1

Console Cable Kit 1

Rackmount Kit 1

Strain-Relief Bracket 1

Manual Accessory Kit 1

Power Cord 2

3. Remove the tape seal on the non-conductive bag to remove the 2H258-17R.

4. Perform a visual inspection of the device for any signs of physical damage. Contact Enterasys

Networks if there are any signs of damage. Refer to Section 1.2 for details.

3.2 INSTALLING OPTIONS

NOTE: Install any optional equipment before proceeding to Section 3.3.

If the 2H258-17R is to be installed with an optional HSIM or VHSIM, refer to the user’s guide of

that device for the installation instructions.

3-2 Installation

Page 29

Installing the Device

3.3 INSTALLING THE DEVICE

The 2H258-17R may be installed on a tabletop, shelf, or in a 19-inch rack. Section 3.3.1 describes

a tabletop or shelf installation and Section 3.3.2 describes the rackmount installation.

ELECTRICAL HAZARD: To prevent possible personal injury and/or damage to the unit,

do NOT connect power to the 2H258-17R until instructed to do so.

3.3.1 Tabletop or Shelf Installation

The following two subsections provide guidelines for installation on a tabletop or shelf.

Guidelines for Tabletop and Shelf Installations

Tabletop and shelf installations must be within reach of the network cabling and meet the

requirements listed below:

• Locate the 2H258-17R within seven feet of an appropriately grounded power receptacle that

meets the power supply requirements listed in Appendix A.

• In a shelf installation, the shelf must support 13.5 kg (30 lb) of static weight for each

2H258-17R.

• Maintain a temperature of between 5°C (41°F) and 40°C (104°F) at the installation site with

fluctuations of less than 10°C (18°F) per hour.

• Maintain a 2-inch clearance from the left, right, and rear sides of the device to provide adequate

ventilation.

Installation

For a tabletop or shelf installation, locate the 2H258-17R within seven feet of its power source and

on an unrestricted free surface area as shown in Figure 3-1. Proceed to Section 3.3.3 for power

connection instructions.

CAUTION: To ensure proper ventilation and prevent overheating, leave a minimum

clearance space of 5.1 cm (2.0 in) at the left, right, and rear of the 2H258-17R.

Installation 3-3

Page 30

Installing the Device

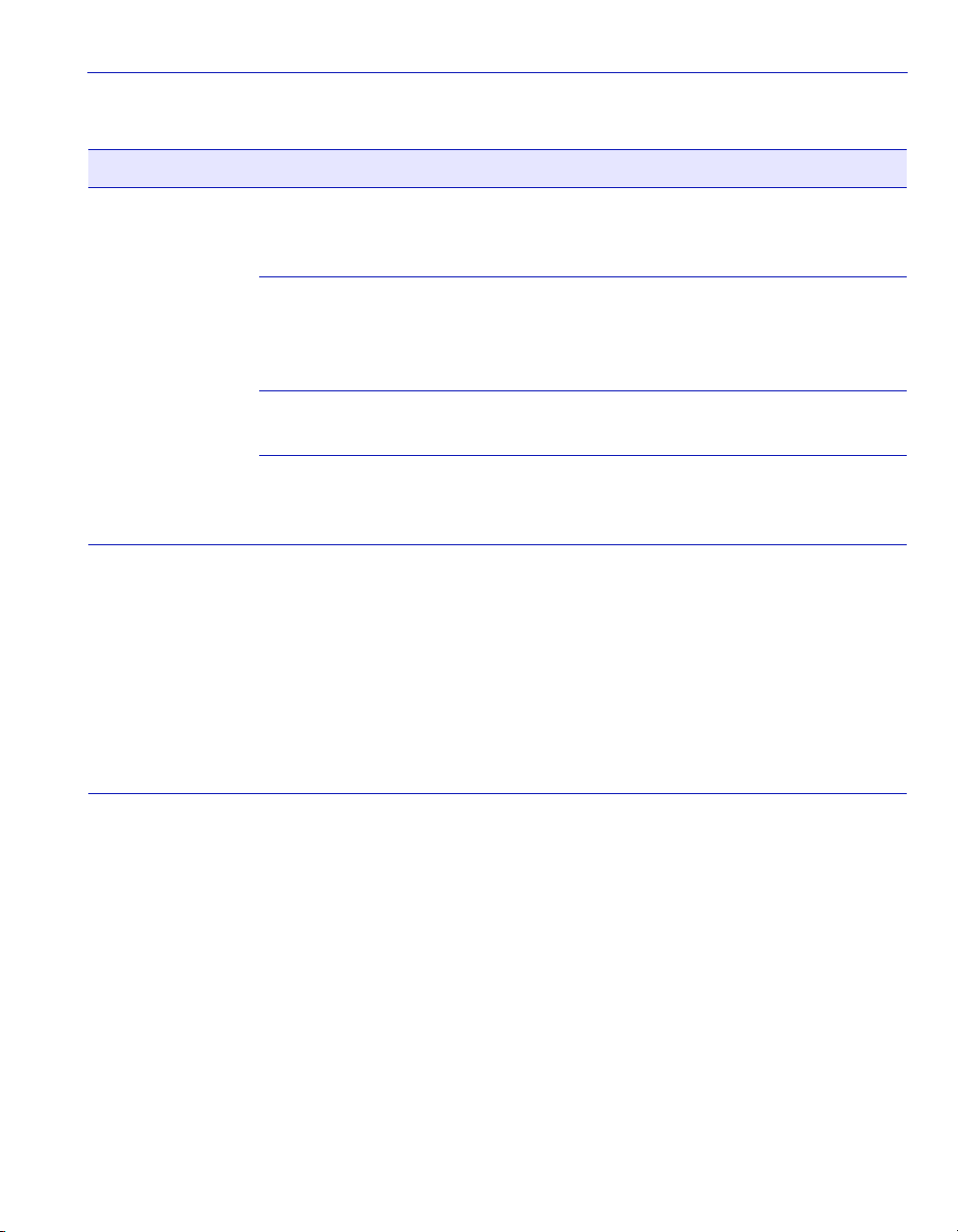

Figure 3-1 Tabletop or Shelf Installation

B

C

FAST ETHERNET WORKGROUP SWITCH

RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX

A

A = 15 cm (6 in)

2H258-17R

123456 8910 151611 12 14137

PWR

CPU

RESET

COM

D

B = 57 cm (22.5 in)

C = 53 cm (21 in)

D = 213 cm (7 ft)

3068-02

3.3.2 Rackmount Installation

To install the 2H258-17R in a 19-inch rack, Enterasys Networks includes a strain-relief bracket for

cable management and an accessory kit containing the rackmount brackets, and mounting screws

to attach the rackmount brackets and strain-relief bracket.

Guidelines for the Rackmount Installation

The installation site must be within reach of the network cabling and meet the requirements listed

below:

• An appropriate grounded power receptacle must be located within seven feet of the location.

• Maintain a temperature of between 5°C (41°F) and 40°C (104°F) at the installation site with

fluctuations of less than 10°C (18°F) per hour.

CAUTION: To ensure proper ventilation and prevent overheating, leave a minimum

clearance space of 5.1 cm (2.0 in) at the left, right, and rear of the 2H258-17R.

WARNING: Before installing the 2H258-17R into a rack, ensure that the rack supports

the device(s) without compromising the stability of the rack. Otherwise, personal injury

and/or equipment damage may result.

3-4 Installation

Page 31

Installing the Device

Installation

Rack mounting the 2H258-17R involves the following:

• Attaching the strain-relief bracket

• Rack mounting the 2H258-17R (attaching the mounting brackets and fastening the device to the

rack)

Attaching the Strain-Relief Bracket

Attach the strain-relief bracket to the 2H258-17R as follows:

1. Locate the strain-relief bracket and four 8-32 x 5/16-inch pan-head screws in the rackmount kit.

CAUTION: Do not attempt to attach the strain-relief bracket with screws other than the

8-32 x 5/16-inch screws included with the 2H258-17R. Use of longer screws may

damage the unit.

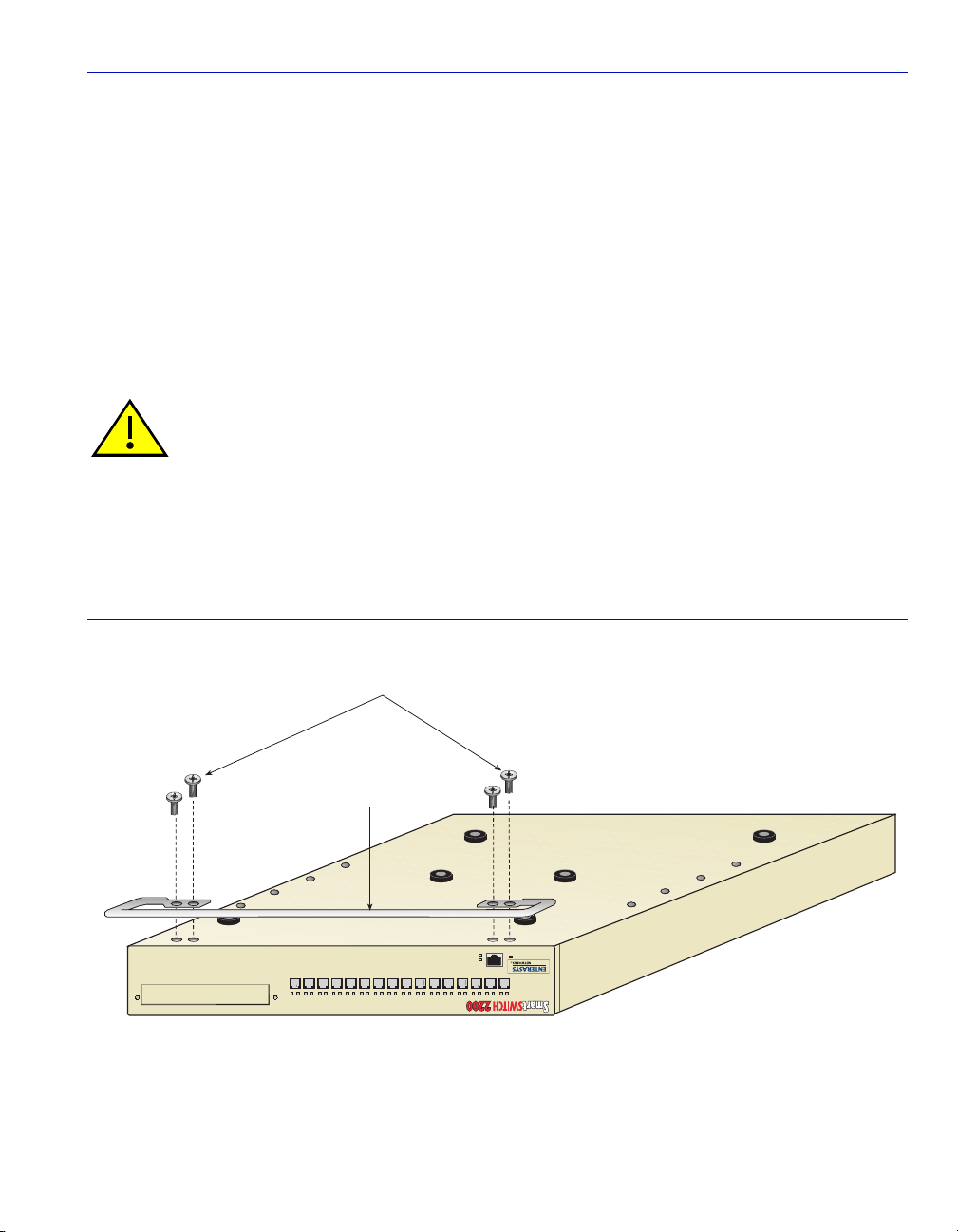

2. Place the 2H258-17R upside down (as shown in Figure 3-2) on a clean flat surface. Then attach

the strain-relief bracket to the bottom of the 2H258-17R using the four 8-32 x 5/16-inch

pan-head screws.

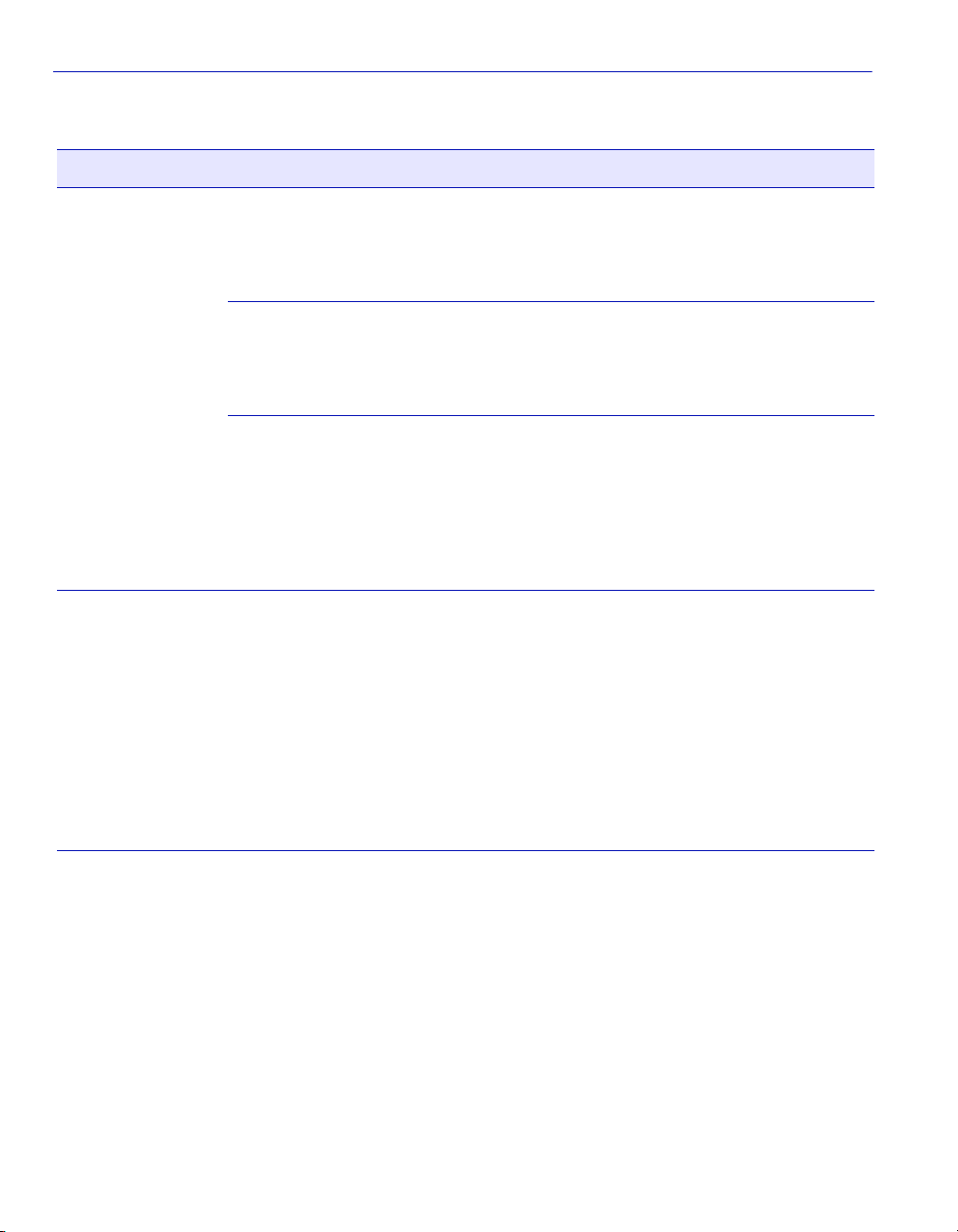

Figure 3-2 Attaching the Strain-Relief Bracket

Strain-Relief

Bracket Screws

Strain-Relief

Bracket

COM

2H258-17R

RESET

CPU

PWR

123456 8910 151611 12 14137

RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX

FAST ETHERNET WORKGROUP SWITCH

3068-03

Installation 3-5

Page 32

Installing the Device

Rack Mounting the 2H258-17R

Proceed as follows to install the 2H258-17R into a 19-inch rack:

1. There are several mounting holes in the rackmount brackets and the bottom of the chassis so that

each mounting bracket may be adjusted forward or backward to mount the device further into,

or out of the rack, depending on the installation requirements. Position the rackmount brackets

over the appropriate holes.

2. Locate the four 6-32 x 1/4-inch flathead screws in the rackmount kit. Use these screws to attach

the rackmount brackets to the bottom of the 2H258-17R as shown in Figure 3-3.

Figure 3-3 Attaching the Rackmount Brackets

Rackmount Bracket Screws

Rackmount Bracket

COM

CONSOLE

TELCO

CPU

PWR

2H258-17R

RESET

123456 8910 151611 12 14137

RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX

FAST ETHERNET WORKGROUP SWITCH

3. With the mounting brackets attached, position the 2H258-17R between the vertical frame

members of the 19-inch rack and fasten it securely with mounting screws as shown in

Figure 3-4.

3-6 Installation

3068-04

Page 33

Figure 3-4 Installing the Device in a Rack

FAST ETHERNET WORKGROUP SWITCH

RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX RX TX

123456 8910 151611 12 14137

PWR

CPU

RESET

2H258-17R

COM

Installing the Device

Screws

19-Inch Rack

3068-05

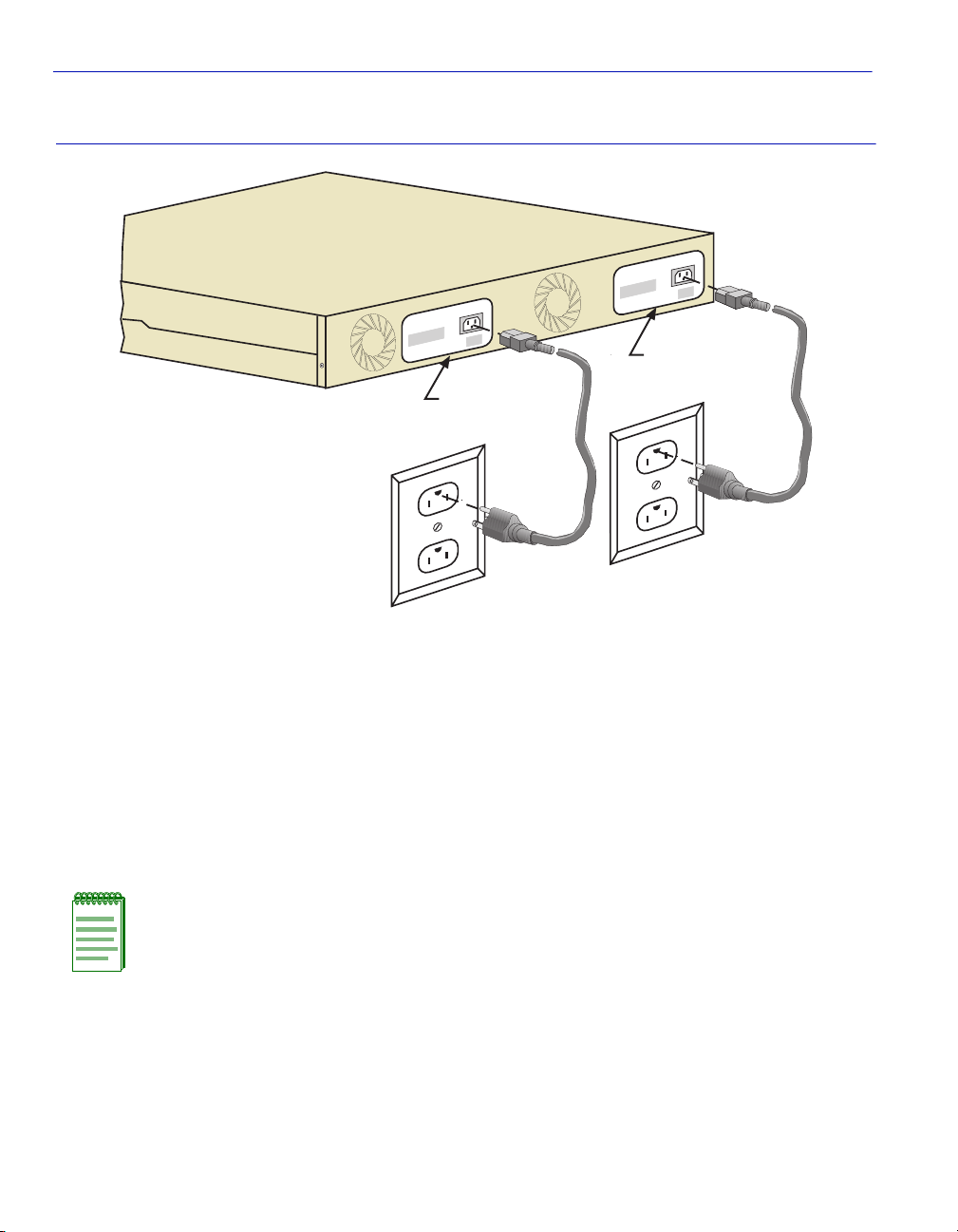

3.3.3 Connecting Power

NOTE: The two power supplies in the 2H258-17R have automatic voltage sensing that

allows connection to power sources ranging from 100–125 Vac, 2.5 A or 200–240 Vac,

1.25 A, 50/60 Hz.

To connect the 2H258-17R to the power sources, proceed as follows:

1. Plug each power cord into a grounded wall outlet, see Figure 3-5. To take advantage of the load

sharing and redundancy capabilities, each power cord must be plugged into a separate dedicated

ac outlet. The POWER (PWR) LED turns ON (green) and the CPU LED alternates between

green and amber during boot up. It takes approximately one minute for the 2H258-17R to boot

up.

NOTE: If the power-up sequence is interrupted on this device, or if optional hardware

has been installed or removed, this device may run an extended diagnostics sequence

that may take up to five minutes to complete.

Installation 3-7

Page 34

Connecting to the Network

Figure 3-5 2H258-17R Rear View

Redundant

AC outlets are

on separate circuits

Primary

26001-06

2. Observe the LANVIEW LEDs. After a successful boot, the PWR LED turns ON (green). If the

PWR LED is amber, there is no power redundancy. Check the power cord connections and the

power source. If there are no problems with the power cord connections or power source and the

PWR LED is still amber, contact Enterasys Networks. Refer to Section 1.2 for details.

3.4 CONNECTING TO THE NETWORK

This section provides the procedures for connecting fiber optic segments from the network or other

devices to the 2H258-17R.

NOTE: If the 2H258-17R is being installed in a network using SmartTrunking, there are

rules concerning the network cable and port configurations that must be followed for

SmartTrunking to operate properly. Before connecting the cables, refer to the

SmartTrunk User’s Guide for the configuration information.

Ports 1 through 16 on the 2H258-17R have MT-RJ connectors for multimode fiber optic cable

connections.

3-8 Installation

Page 35

Connecting to the Network

Each fiber optic link consists of two fiber optic strands within the cable: the transmit (TX) and the

receive (RX). The transmit strand from a 2H258-17R port connects to the receive port of a fiber

optic Fast Ethernet device at the other end of the segment. The receive strand of the applicable port

on the 2H258-17R connects to the transmit port of the fiber optic Fast Ethernet device.

Enterasys Networks recommends labeling fiber optic cables to indicate receive and transmit ends.

Many cables are prelabeled, providing matching labels or tapes at both ends of each strand of

cable.

The following instructions detail the process used to connect a MT-RJ connector to a 2H258-17R

port.

1. Remove the protective covers from the fiber optic ports on the applicable port on the device, and

from the connectors on each end of the cable.

NOTE: Leave the protective covers in place when the connectors are not in use to

prevent contamination.

CAUTION: Do not touch the ends of the fiber optic strands, and do not let the ends

come in contact with dust, dirt, or other contaminants. Contamination of cable ends

causes problems in data transmissions. If the ends of the fiber optic strands become

contaminated, use a canned duster to blow the surfaces clean. A fiber port cleaning

swab saturated with optical-grade isopropyl alcohol may also be used to clean the ends.

2. Insert the MT-RJ fiber optic cable connector on the cable into the MT-RJ connector on the

device until it clicks into place. See Figure 3-6.

.

CAUTION: To remove the cable connector, press on its release tab and then pull the

connector out of the MT-RJ connector on the device.

Installation 3-9

Page 36

Connecting to the Network

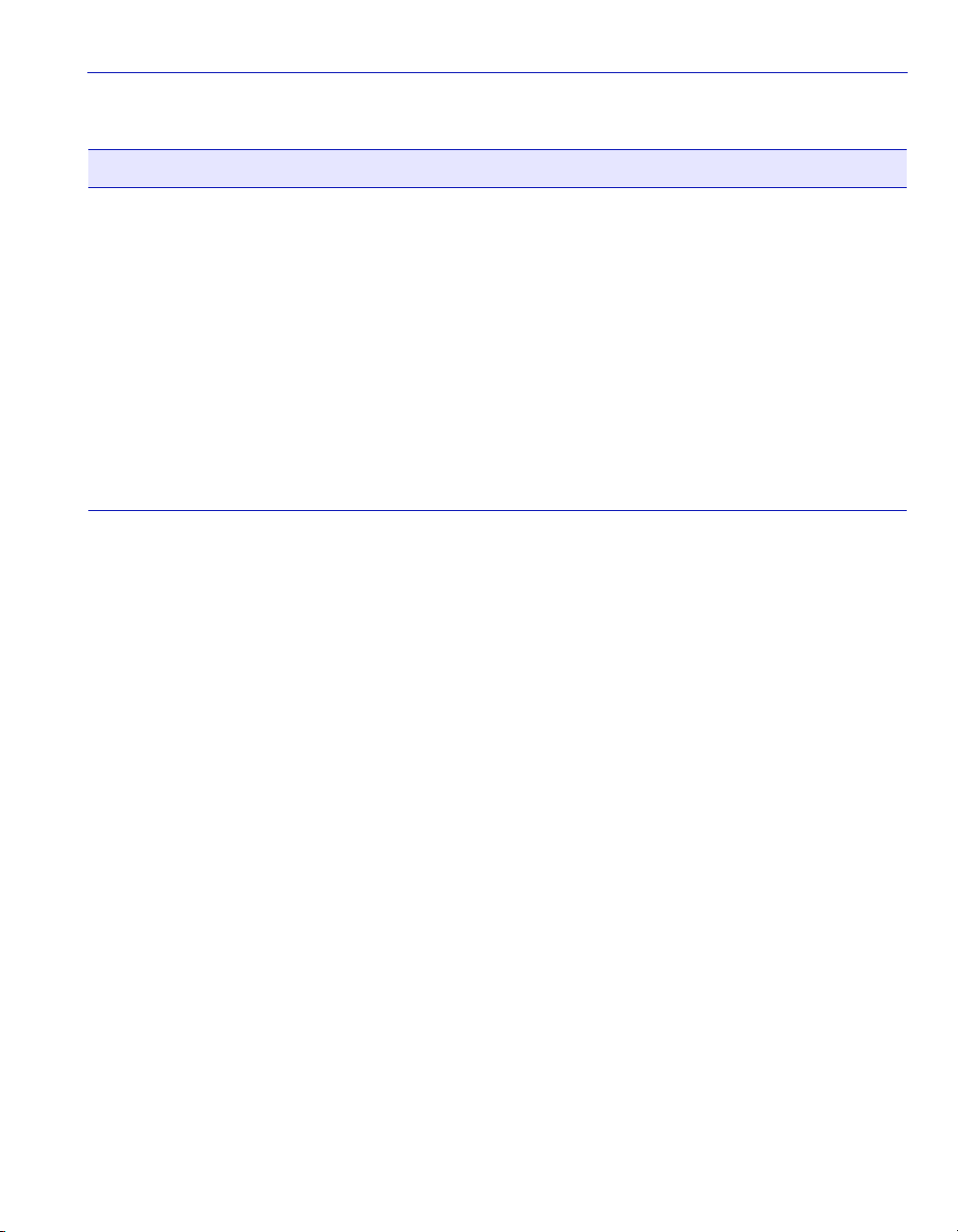

Figure 3-6 Fiber Optic Connection

Receive (RX)

FAST ETHERNET WORKGROUP SWITCH

E

2H258-17R

R

RX TX

RX TX

RX TX

123456 8910 1516

PWR

T

E

S

CPU

COM

MT-RJ Port

RX TX

RX TX

Transmit (TX)

RX TX

RX TX

RX TX

RX TX

RX TX

RX TX

RX TX

11 12 14137

Release Tab

RX TX

RX TX

RX TX

RX TX

Fiber Optic Cable

3068-07

3. Plug the other end of the cable into the appropriate port on the other device. Some cables may

be terminated at the other end with two separate connectors, one for each fiber optic strand. In

this case, ensure that the transmit fiber optic strand is connected to the receive port and the

receive fiber optic strand to the transmit port.

4. Verify that a link exists by checking that the port RX LED is on (flashing amber, blinking green,

or solid green). If the RX LED is off, perform the following steps until it is on:

a. Verify that the device at the other end of the segment is ON and connected to the segment.

b. If there are separate fiber optic connections on the other device, check the crossover of the

cables. Swap the cable connections if necessary.

c. Check that the fiber optic connection meets the dB loss and cable specifications outlined in

Enterasys Networks Cabling Guide for multimode mode cabling.

If a link is not established, contact Enterasys Networks. Refer to Section 1.2 for details.

5. Repeat steps 1 through 3, above, until all connections have been made.

3-10 Installation

Page 37

Completing the Installation

3.5 COMPLETING THE INSTALLATION

After installing the 2H258-17R and any optional HSIM or VHSIM, and making the connections to

the network, proceed as follows:

1. Secure the cables by running the cables along the strain-relief bracket and tying them to the

strain-relief bracket using cable ties.

2. The 2H258-17R is now ready to be configured through Local Management. Refer to the

SmartSwitch Series 2E253, 2H252, 2H253, and 2H258 Local Management User’s Guide for

information on how to access and use Local Management.

Installation 3-11

Page 38

Page 39

4

Troubleshooting

This chapter provides information concerning the following:

• Using LANVIEW (Section 4.1)

• Troubleshooting Checklist (Section 4.2)

• Using the RESET Button (Section 4.3)

4.1 USING LANVIEW

The 2H258-17R uses Enterasys Networks’ built-in visual diagnostic and status monitoring system

called LANVIEW. The LANVIEW LEDs (Figure 4-1) allow quick observation of the network

status to aid in diagnosing network problems.

Figure 4-1 LANVIEW LEDs

Receive (RX)

FAST ETHERNET WORKGROUP SWITCH

2H258-17R

RX TX RX TX

RX TX

123456 8910

T

E

S

E

R

COM

PWR

PWR

CPU

RX TX

CPU

RX TX

Transmit (TX)

RX TX

RX TX

RX TX

RX TX

RX TX

RX TX

RX TX

RX TX RX TX

RX TX

15 1611 12 14137

Troubleshooting 4-1

RX TX

3068-09

Page 40

Using LANVIEW

Table 4- 1 describes the LED indications and provides recommended actions as appropriate.

Refer to the HSIM or VHSIM user’s guide for a description of the HSIM or VHSIM LED

indications.

NOTE: The terms flashing, blinking, and solid used in Ta bl e 4 -1 indicate the following:

Flashing indicates an LED is flashing randomly.

Blinking indicates an LED is flashing at a steady rate (approximately 50% on, 50% off).

Solid indicates a steady LED light. No pulsing.

Table 4-1 LANVIEW LEDs

LED Color State Recommended Action

PWR Off Device electronics not

receiving power from

power supply(ies).

Green Functional. Power

supply(ies) operating

normally.

Amber Indicates loss of power

supply redundancy.

1. Ensure that the power cords are plugged

in correctly and that there is power at the

power source.

2. Contact Enterasys Networks for

assistance.

None.

1. Ensure that the power cords are plugged

in correctly and that there is power at the

power source.

2. Contact Enterasys Networks for

assistance.

4-2 Troubleshooting

Page 41

Table 4-1 LANVIEW LEDs (Continued)

LED Color State Recommended Action

CPU Off Power off. Power up device.

Using LANVIEW

RX

(Receive)

Red Blinking. Hardware

Contact Enterasys Networks for assistance.

failure has occurred.

Solid. Resetting, normal

power up reset.

If the LED remains red for several minutes,

contact Enterasys Networks for assistance.

Amber Blinking. Crippled. Contact Enterasys Networks for assistance.

Solid. Testing. If the LED remains amber for several

minutes, contact Enterasys Networks for

assistance.

Green Solid. Functional. None.

Amber

and

Booting. Blinks amber

and green while booting.

None.

Green

Off No link. None.

Green Solid. Port enabled, link,

None.

no activity.

Blinking. Port disabled,

None.

link.

Amber Flashing. Port enabled,

None.

link, activity.

Red Diagnostic failure. Contact Enterasys Networks for assistance.

Troubleshooting 4-3

Page 42

Troubleshooting Checklist

Table 4-1 LANVIEW LEDs (Continued)

LED Color State Recommended Action

TX

(Transmit)

Off Port enabled, and no

activity.

Should flash green every

two seconds indicating

BPDUs being sent if STA

is enabled and there is a

valid link.

Green Flashing. Indicates

activity. Rate indicates

data rate.

Amber Blinking. Port in

standby.

Port may be disabled due

to Spanning Tree.

Red Flashing. Indicates

collision rate.

Solid. Diagnostic failure. Contact Enterasys Networks for assistance.

1. Ensure that the STA is enabled and that

there is a valid link.

2. Contact Enterasys Networks for

assistance.

None.

1. Ensure that the port is not disabled.

2. Contact Enterasys Networks for

assistance.

None, unless there is a high amount of

activity. In this case, check for network

configuration problems or a defective

device.

4.2 TROUBLESHOOTING CHECKLIST

If the 2H258-17R is not working properly, refer to Tab le 4 -2 for a checklist of possible problems,

causes, and recommended actions to resolve the problem.

Table 4-2 Troubleshooting Checklist

Problem Possible Cause Recommended Action

All LEDs are

OFF.

4-4 Troubleshooting

Loss of power. Check for proper connection of the power

cable and its access to a live outlet.

Installed improperly. Ensure that the 2H258-17R was installed

properly according to the installation

instructions in Chapter 3.

Page 43

Table 4-2 Troubleshooting Checklist (Continued)

Problem Possible Cause Recommended Action

Troubleshooting Checklist

No Local

Management

Password screen.

Cannot navigate

beyond Password

screen.

Autobaud is enabled, but

the baud rate has not yet

been detected.

Terminal setup is not

correct.

Improper console cable

pinouts.

Corrupt firmware image,

or hardware fault.

Improper Community

Names Table.

Press ENTER (RETURN) (may take up to

four times).

Refer to the SmartSwitch Series 2E253,

2H252, 2H253, and 2H258 Local

Management User’s Guide for proper setup

procedures.

Refer to Appendix A for proper console port

pinouts.

If possible, attempt to download the image to

the 2H258-17R again. Refer to Section B for

instructions to clear NVRAM.

1. Refer to the SmartSwitch Series 2E253,

2H252, 2H253, and 2H258 Local

Management User’s Guide for Community

Names Table setup.

2. If you have forgotten the Community

Names, refer to Appendix B for

instructions on how to set the mode switch

to reset the Community Names to their

default values.

Troubleshooting 4-5

Page 44

Troubleshooting Checklist

Table 4-2 Troubleshooting Checklist (Continued)

Problem Possible Cause Recommended Action

Cannot contact

the 2H258-17R

through in-band

management.

Port(s) goes into

standby for no

apparent reason.

IP address not assigned. Refer to the SmartSwitch Series 2E253,

2H252, 2H253, and 2H258 Local

Management User’s Guide for IP address

assignment procedure.

Port is disabled. Enable port. Refer to the SmartSwitch Series

2E253, 2H252, 2H253, and 2H258 Local

Management User’s Guide for instructions

to enable/disable ports.

No link to device. 1. Verify that all network connections

between the network management station

and the 2H258-17R are valid and

operating.

2. The problem continues, contact Enterasys

Networks for assistance.

Loop condition detected. 1.Verify that Spanning Tree is enabled.

Refer to SmartSwitch Series 2E253,

2H252, 2H253, and 2H258 Local

Management User’s Guide for the

instructions to set the type of STA.

2. Review network design and delete

unnecessary loops.

4-6 Troubleshooting

3. If the problem continues, contact Enterasys

Networks for assistance.

Page 45

Table 4-2 Troubleshooting Checklist (Continued)

Problem Possible Cause Recommended Action

Troubleshooting Checklist

User parameters

(IP address,

Device and

Module name,

etc.) were lost

when the

2H258-17R

power was cycled

or the front panel

RESET button

was pressed.

1. Position of Mode switch

(7), NVRAM Reset, was

changed sometime before

either cycling power or

pressing the RESET

button, causing the

user-entered parameters to

reset to factory default

settings.

2. Clear NVRAM was set

through Local

Management.

1. Reenter the lost parameters as necessary.

Refer to SmartSwitch Series 2E253,

2H252, 2H253, and 2H258 Local

Management User’s Guide for the

instructions to configure the device

through Local Management.

2. If the problem continues, contact Enterasys

Networks for assistance.

Troubleshooting 4-7

Page 46

Using the RESET Button

4.3 USING THE RESET BUTTON

The RESET button shown in Figure 4-2 resets and re-initializes the 2H258-17R.

CAUTION: Pressing the RESET button resets the device, and all current switching

being performed by the device is halted. A network downtime of up to two minutes will

result from this action.

Figure 4-2 RESET Button

RX TX

RX TX

RX TX

RX TX

RX TX

RX TX

RX TX

RX TX

FAST ETHERNET WORKGROUP SWITCH

2H258-17R

RX TX

RX TX

123456 8910 1516

T

SE

E

R

COM

RESET Button

RX TX

PWR

CPU

RX TX

RX TX

RX TX

11 12 14137

RX TX

RX TX

3068-10

To reset the 2H258-17R processor, press and release the RESET button. The 2H258-17R goes

through a reset process for approximately 60 seconds. Additional downtime may result as the

device reenters the network.

NOTE: It is not recommended to press the RESET button while the device is already in

reset mode. If so, the device will enter an extended diagnostic procedure, which is

unnecessary for normal operation. This extended diagnostic procedure takes much

longer than a minute.

4-8 Troubleshooting

Page 47

A

Specifications

This appendix provides operating specifications for the Enterasys Networks 2H258-17R.

Enterasys Networks reserves the right to change these specifications at any time without notice.

A.1 DEVICE SPECIFICATIONS

Processors: Intel i960 RISC processor

Power PC

Dynamic Random Access

Memory (DRAM): 20 MB expandable to 32 MB

FLASH Memory: 8 MB

Shared Memory: 4 MB

A.2 PHYSICAL PROPERTIES

Dimensions: 7.11H x 43.18W x 46.99D (cm)

2.8H x 17W x 18.5D (in.)

Approximate Weight (Unit): 8.18 kg (18 lb)

MTBF (Predicted): 200,000 hours

Specifications A-1

Page 48

Electrical Specifications

A.3 ELECTRICAL SPECIFICATIONS

Line Input Range, Volts (Vac): 100–125 Vac 200–240 Vac

Input Current, Amperes (A): 2.3 A 1.2 A

Frequency, Hertz (Hz): 50/60 Hz 50/60 Hz

Input Power, Volt Amperes (VA): 250 VA 250 VA

A.4 ENVIRONMENTAL REQUIREMENTS

Operating Temperature: 5°C to 40°C (41°F to 104°F)

Storage Temperature: -30°C to 73°C (-22°F to 164°F)

Operating Relative Humidity: 5% to 90% (non-condensing)

A.5 INPUT/OUTPUT PORTS

Ports 1 through 16: Fast Ethernet 100 Mbps (100BASE-FX compliant)

with multimode optic fiber MT-RJ type connectors.

Interface Slot: Slot accepts optional High Speed Interface Module

(HSIM) or Very High Speed Interface Module

(VHSIM) to provide a variety of cabling

connections.

A-2 Specifications

Page 49

COM Port Pinout Assignments

A.6 COM PORT PINOUT ASSIGNMENTS

The COM port is a serial communications port that supports Local Management or connection to a

UPS.

Tabl e A- 1 shows the COM port pin assignments.

Table A-1 COM Port Pin Assignment

Pin Signal Name Input/Output

1 Transmit Data (XMT) Output

2 Data Carrier Detect (DCD) Output

3 Data Set Ready (DSR) Input

4 Receive Data (RCV) Input

5 Signal Ground (GND) NA

6 Data Terminal Ready (DTR) Output

7 Request to Send (RTS) Input

8 Clear to Send (CTS) NA

A.7 REGULATORY COMPLIANCE

This equipment meets the following safety and electromagnetic compatibility (EMC)

requirements:

Safety: UL 1950, CSA C22.2 No 950, 73/23/EEC, EN 60950,

IEC 950

Electromagnetic

Compatibility (EMC):

FCC Part 15, CSA C108.8, 89/336/EEC, EN 55022,

EN 61000-3-2, EN 61000-3-3, EN 50082-1, AS/NZS 3548,

VCCI V-3

Specifications A-3

Page 50

Page 51

B

Optional Installations and

Mode Switch Bank Settings

ELECTRICAL HAZARD: ONLY QUALIFIED SERVICE PERSONNEL SHOULD

ATTEMPT THE FOLLOWING PROCEDURES.

NUR QUALIFIEZIERTE SERVICE PERSONNAL DIE FOLGENDE PROCEDURE

FOLGEN SOLLTEN.

SOLAMENTE PERSONAL CALIFICADO DEBE INTENTAR ESTE PROCEDIMIENTO.

The top cover must be removed to gain access to the mode bank switches, to install optional

FLASH or DRAM Single In-line Memory Modules (SIMMs), or to install an optional High Speed

Interface Module (HSIM) or Very High Speed Interface Module (VHSIM).

This appendix covers the following items:

• Required tools (Section B.1)

• Removing the chassis cover (Section B.2)

• Locations, functions, and settings for the mode switches (Section B.3)

• Installing optional SIMM upgrades (Section B.4)

• Location of Optional HSIMs (Section B.5)

B.1 REQUIRED TOOLS

Use the following tools to perform the procedures provided in this appendix:

• Antistatic wrist strap

• Phillips screwdriver

Optional Installations and Mode Switch Bank Settings B-1

Page 52

Removing the Chassis Cover

B.2 REMOVING THE CHASSIS COVER

This section describes how to remove the 2H258-17R chassis cover.

ELECTRICAL HAZARD: DO NOT REMOVE THE COVER FROM THE 2H258-17R

WHILE POWER IS APPLIED TO THE UNIT. HAZARDOUS VOLTAGES ARE PRESENT

AND COULD CAUSE PERSONAL INJURY AND/OR DAMAGE THE UNIT.

DO NOT POWER UP THE 2H258-17R AGAIN UNTIL THE COVER AND SCREWS

ARE IN PLACE.

DECKEL VON DAS 2H258-17R NICHT ABZIEHEN UNTER SPANNUNG. GEFAHR

FÜR DAS PERSONNAL UND/ODER DAS GERÄT WEGEN GEFÄHRLICHE

SPANNUNGEN ENSTEHT.

2H258-17R NICHEINSCHALTEN SO LANG DER DECKEL UND SCHRAUBEN NICHT

EINGEBAUT SIND.

NO DEBE DE REMOVER LA TAPA DURENTE QUE ESTE CONELTADO A LA

CORRIENTE, UNA DESCARGA ELECTRICA LE PUEDE CAUSAR Y PROBOCARLE

DA

ÑOS, AL IGUAL QUE AL APARATO.

NO ENCHUFE A LA CORRIENTE HASTA QUE LA TAPA Y LOS TORNILLOS ESTEN

EN SU LUGAR.

CAUTION: THIS UNIT MAY HAVE MORE THAN ONE POWER SUPPLY CORD.

DISCONNECT TWO POWER SUPPLY CORDS BEFORE SERVICING TO AVOID

ELECTRIC SHOCK.

VORSICHT: DIESES GERÄT HAT MEHR ALS EINEN NETZANSCHLUß. TRENNEN

SIE VOR WARTUNGSARBEITEN DIE 2 NET ZANSCHLÜSSE VOM NETZ, UM

ELEKTRISCHE SCHLÄGE ZU VERMEIDEN.

ATTENTION: CET APPAREIL COMPORTE PLUS D’UN CORDON D’ALIMENTATION.

RAFIN DE PREVENIR LES CHOCS ELECTRIQUES, DEGRANCHER LES DEUX

CORDONS D’ALIMENTATION AVANT DE FAIRE LE DEPANNAGE.

B-2 Optional Installations and Mode Switch Bank Settings

Page 53

Removing the Chassis Cover

To remove the chassis cover, proceed as follows:

1. Disconnect the 2H258-17R from the network as follows:

a. Unplug both power cords from the rear of the chassis.

ELECTRICAL HAZARD: TURN OFF THE 2H258-17R BY UNPLUGGING THE

POWER CORD FROM THE REAR OF THE CHASSIS.

AM HINTEN DES 2H258-17R STECHEI ABZIEHEN UM AUS ZU SCHALTEN.

APAGUE EL 2H258-17R DESENCHUFE EL CABLE DE LA UNIDAD.

TIP: Before performing step b, mark the cables connected to the 2H258-17R according

to their associated port numbers. This is recommended for ease of reinstallation.

b. Disconnect all network cables attached to the 2H258-17R.

2. If the 2H258-17R is rack mounted, remove it from the rack and remove the rackmount brackets

(refer to Chapter 3).

3. Use a Phillips screwdriver to remove the four screws attaching the cover to the chassis. (See

Figure B-1.)

4. Remove the cover by sliding it back until it clears the front of the chassis and then lifting it