entegris A192-81M-0215, A192-80M-0215, A192-82M-0215, A198-80M-47C02, A198-80MB-47C02 Installation And Use Manual

...

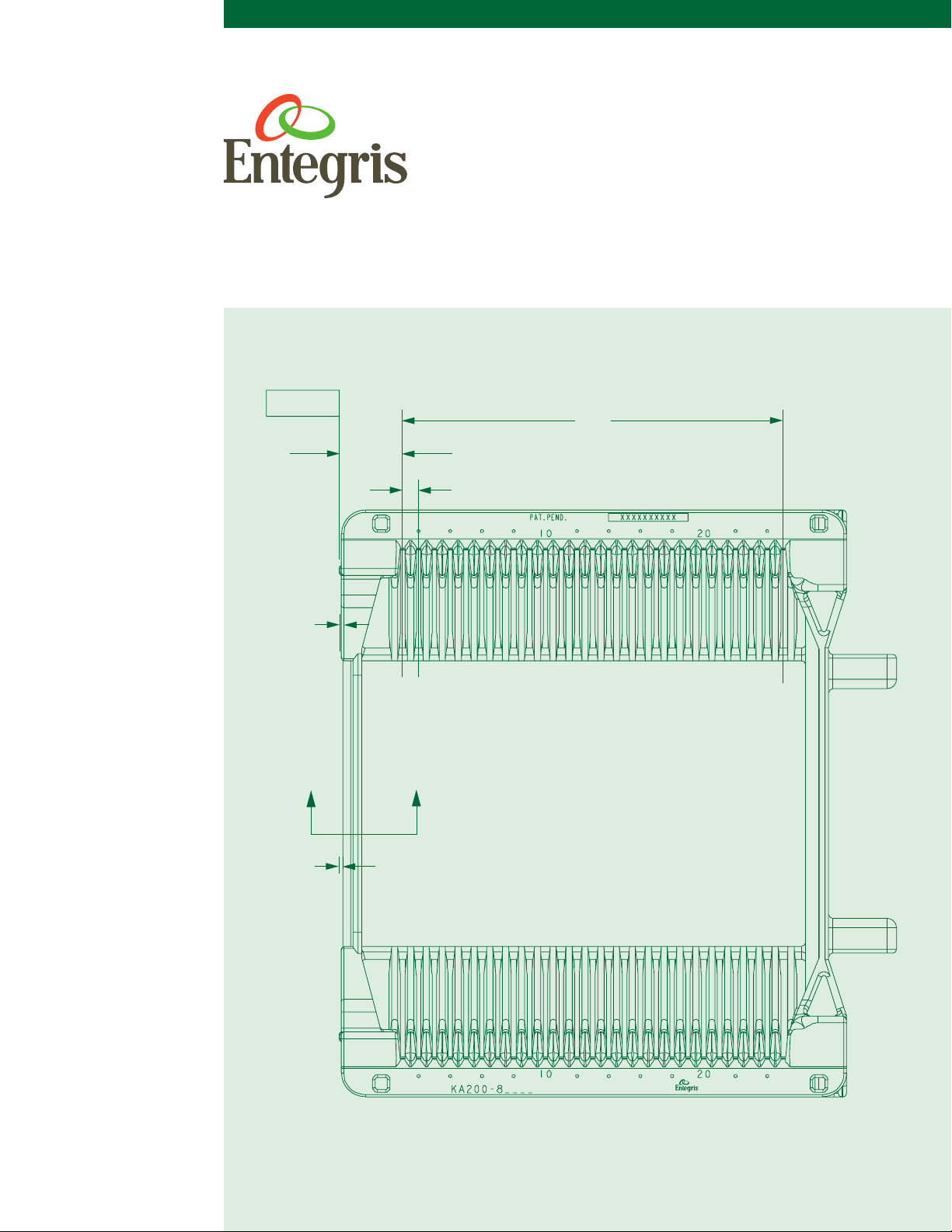

Datum A

CRITICAL MATERIALS HANDLING

200 MM WAFER CARRIER

INTERFACE MANUAL

Installation and use manual

B3

D1

B2

D3b

BB

D3a

Table of Contents

200 MM WAFER CARRIER INTERFACE

Overview ............................................ 1

General Terminology and Definitions ......... 2

Definitions .............................................3

Wafer Plane ........................................ 4

Specification Purpose ............................... 4

Benefits ................................................4

General Definitions .................................. 4

Specification Description ..........................5

Specification Values .................................5

Use with Automated Equipment ..................5

Four Point Contact ................................ 6

Contact Location ..................................... 6

Benefits of Four Point Contact .................... 6

Equipment Interface ................................6

Wafer Carriers Included and Exceptions ........6

General Interface Information .................. 7

Recommended Contact Points ....................6

Print Based Interface Design .....................6

Benefits of Four Point Contact .................... 6

Interface Points: Wafers Horizontal ........... 7

General Recommendations ........................7

Sample Interface Plate .............................7

Contact Area A ........................................ 8

Contact Area B ........................................8

Contact Area C ........................................8

Interface Points: Wafers Vertical .............. 9

General Recommendations ........................9

Sample Interface Plate .............................9

Contact Area A ........................................ 9

Contact Areas B and C ............................. 10

Interface Points: Robotic Handling ........... 10

General Recommendations ...................... 10

Robotic Handling Features ...................... 10

Endwall Flanges .................................... 10

“H” Bar End Flanges ............................... 11

Endwall Handle ..................................... 11

Top Flanges ......................................... 11

Material Information ............................ 12

Material Properties and

Equipment Interface ........................... 12

Static Protection ................................... 12

Moisture Absorption ............................... 12

Applications ......................................... 12

Wafer Transport Carriers ........................ 12

Process Wafer Carriers ........................... 13

Detailed Material Properties ..................13

For More Information ...........................14

Terms and Conditions ...........................14

Product Warranties .............................. 14

Overview

At Entegris, we are committed to working with you, the equipment

supplier, to provide simple solutions for our joint customers in the

semiconductor industry. Our experience has shown that semiconductor manufacturers want to order their equipment and their wafer carriers without worrying about wafer carrier/equipment interface

issues. By sharing information with you we can provide our joint

customers a compatible equipment and wafer

carrier combination.

ENTEGRIS, INC. INSTALLATION AND USE MANUAL 1

200 MM WAFER CARRIER INTERFACE

D6b

General Terminology and Definitions

This section contains dimensions called out on standard

carrier drawings. These dimensions, as well as general wafer

carrier terms, are defined below.

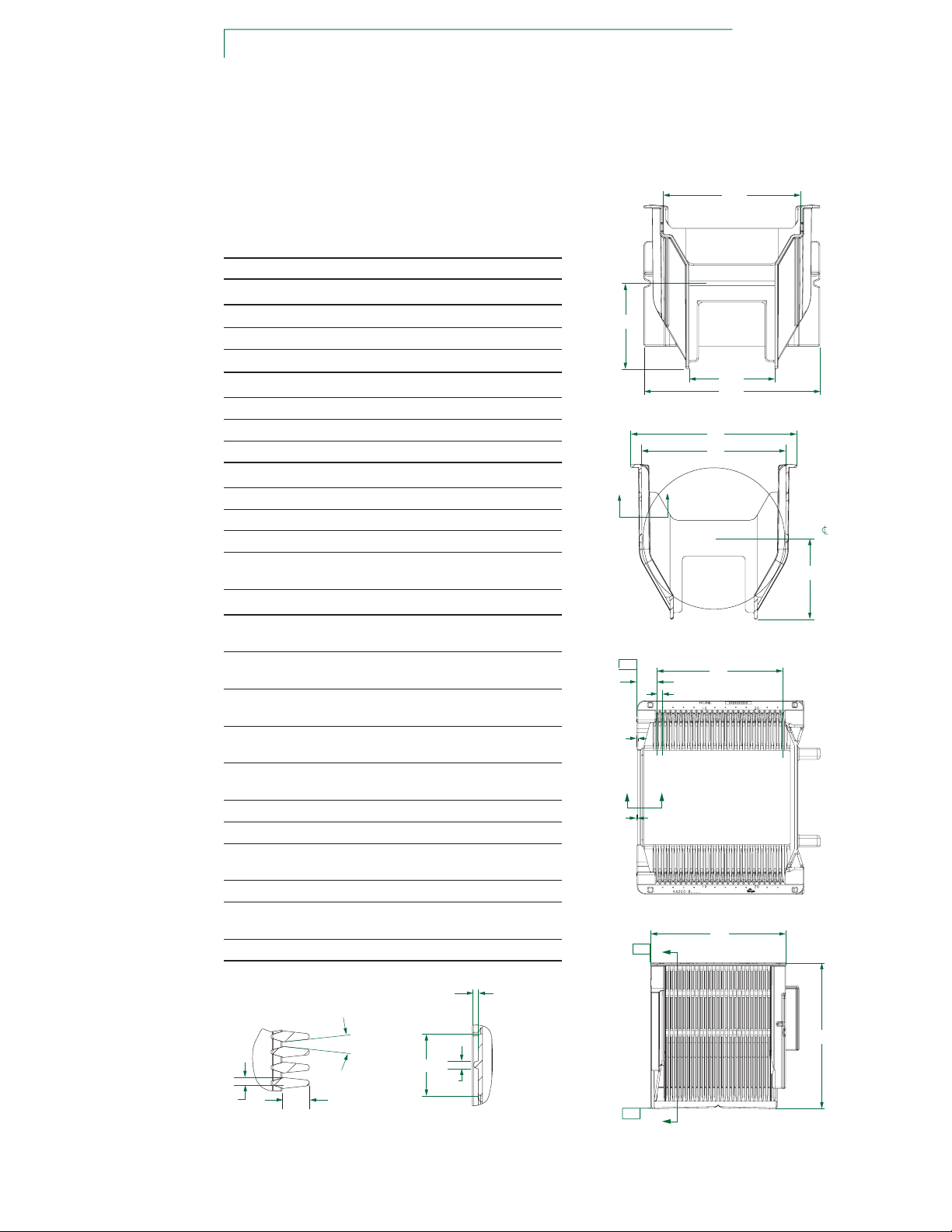

Number Description

OVERALL DIMENSIONS

A1 Length

A2 Width (with/without flanges) includes stripper rails

A3 Height (excluding pin)

CAPACITY

B1 Pockets per carrier

B2 Pocket spacing

B3 Center distance from the first to last pocket

DETAIL DIMENSIONS

C1 Pocket width

C2 Pocket depth

C3 Pocket flat

C4 Pocket size (inside pocket across to

MACHINE FIT SPECIFICATIONS

D1 Distance from Datum A to the center line of the

D3a Distance from Datum A to the front of the

D3b Distance from Datum A to the front of the “H”

D4a Distance from Datum B to the center line of the

D4b Distance from Datum B to the center line of the

D5a Bar web width

D5b Bar width

D5c Distance from Datum A to the front of the

D6a Inside width of the bottom track

D6b Overall width of the “H” bar at the top of the

D8a Overall width of the robotic pick-up flanges

inside pocket)

first pocket

“H” bar at the center of the carrier

bar 13 mm (0.5”) from the side of the carrier

D3b

“H” bar

wafer

D3a

“H” bar web

wafer carrier

D4a

EE

Section A-A

-A-

D1

B2

BB

-A-

A

D6a

D8a

A2

C4

Wafer

D4b

B3

A1

D5c

C11

D5a

D5b

C3

C2

Section E-E

Section B-B

-B-

A

A3

2 INSTALLATION AND USE MANUAL ENTEGRIS, INC.

Definitions

200 MM WAFER CARRIER INTERFACE

Bar end

Crossbar

End wall

Flange

”H“ bar

Hole

Left side

Overall size

Pin

Pocket

Pocket flat

Pocket spacing

Pocket width

Right side

Track clearance

Wafer transfer

See “H” bar.

The mass of material connecting the two sides of the carrier at the bar end

of the carrier.

The wall of the carrier opposite the “H” bar end of the carrier.

Mass of material on the exterior of a carrier, perpendicular to the side walls.

The end of the wafer carrier that has only one crossbar and is capable of

elevator equipment interface.

The area for the pin of another carrier to enter for transferring wafers.

The left side of the carrier when viewed from the “H” bar end while

positioned on its track.

Overall size is measured by length by width by height as shown in the diagram.

Pin height is not included in the height measurement for wafer carriers.

The mass of material which enters the hole or slot of another carrier for

transferring wafers.

The area in which the wafer is located in the carrier.

The width of the pocket along the vertical walls at its most narrow distance.

The distance between pocket centerlines.

The width of the pocket at its widest distance.

The right side of the carrier when viewed from the “H” bar end while

positioned on its track.

The unobstructed area between the two carrier sides on the bar end.

The act of relocating wafers from one carrier into another.

ENTEGRIS, INC. INSTALLATION AND USE MANUAL 3

200 MM WAFER CARRIER INTERFACE

Wafer Plane

This section provides an explanation of the

wafer plane concept and discusses the benefits

of an improved wafer plane. Carriers that hold

each wafer in a predictable location perform

better on automated wafer transfer equipment.

A carrier that does not hold wafers in a predictable

location can cause numerous robotics and wafer

transfer problems. To reduce these problems,

Entegris continually strives to improve wafer

plane dimensions.

Specification Purpose

The wafer plane specification provides the specific,

predictable location of each wafer in a carrier.

Benefits

The benefits of an improved wafer plane include:

• Reduced equipment adjustments

• Improved accuracy in wafer transfers

• Minimized missed wafer transfers

• Reduced equipment shut downs

• Minimized damage or breakage of wafers

• Reduced particle generation caused by wafers

rubbing on carriers

General Definitions

The following definitions define and clarify the

wafer plane concept:

Wafer plane

Wafer plane

zone

Pocket center

plane

Wafer seated

surface

Offset

dimension

Datum A

Datum B

The position of the wafer in a carrier.

The acceptable position for a wafer,

defined by the offset dimension and

tolerance.

The imaginary plane that exactly

bisects each pocket.

The bottom of the wafer, typically the

unfinished side of a wafer in process.

All dimensional data is derived from

this surface.

The distance from the pocket center

plane to the bottom, or seated surface

of the wafer.

The flat surface defined by the “H” bar

end of a wafer carrier. Datum A can be

established by placing the carrier “H”

bar end down on a flat surface.

The flat surface defined by the bottom,

or track of the carrier. Datum B can be

established by placing the carrier track

end down on a flat surface.

4 INSTALLATION AND USE MANUAL ENTEGRIS, INC.

Loading...

Loading...