entegris InVue NT6520, InVue NT6510 User Manual

P/N 01-1032525 (Rev. A 09/15) CRITICAL MATERIALS HANDLING

INVUE™ INTEGRATED

FLOW CONTROLLERS,

MODELS NT6510, NT6520

User guide

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

Table of Contents

Introduction ....................... 2

Identifying Nonstandard

Product Configurations ...... 2

Principle of Operation ......... 2

Factory Configured ............. 3

Continuous versus

Batch Control ................. 3

Calibration Reference

Conditions ..................... 3

General Considerations ......... 4

Power Supply Requirements ... 4

Storage Temperature Range ... 4

Operating Ambient

Temperature Range .......... 4

Operating Process

Temperature Range .......... 4

Line Pressure .................... 4

Pressure Drop .................... 4

Dimensions ...................... 5

Installation ........................ 9

Provided Equipment ........... 9

Mounting Requirements ...... 10

Mechanical Installation ...... 11

Power Supply Requirements .. 12

Electrical Connections ....... 14

Wiring Diagram ................ 16

Optional Connections ......... 17

Setpoint Signal Setup ......... 18

Calibration Graphs ............ 19

Unit Operation .................. 20

Operating Environment ...... 20

Performance ................... 21

Operational Reliability ........ 22

Status and Alarming .......... 22

LED Status Codes ............. 23

Diagnostic Guide ................. 24

Maintenance .................... 27

Normal Operation ............. 27

Re-zero Function .............. 27

Reference ........................... 28

Physical Specifications ....... 28

Electrical Specifications ..... 28

Performance Specifications ... 28

Ordering Information .......... 29

Certifications ................... 32

CE Compliance ................ 32

Repair and Warranty Service ... 32

Technical Support .............. 32

For More Information ......... 32

Terms and Conditions ......... 32

Product Warranties ............ 32

ENTEGRIS, INC. USER GUIDE 1

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

Introduction

This manual is for use with a standard

InVue™ Integrated Flow Controller,

Models NT6510 and NT6520. These

instruments have been designed for

use in high-purity fluid applications

within industries that need tightly

controlled chemical processes such

as the semiconductor, biomedical

and solar cell industries. The wetted

parts are constructed with Modified

PTFE, PTFE, PFA or other similar

high-purity inert materials.

WARNING! Attempting to install or

!

operate standard InVue Integrated

Flow Controllers without reviewing

the instructions contained in this

manual could result in personal

injury or equipment damage.

Identifying Nonstandard

Product Configurations

This User Guide applies to product

manufactured as the standard

InVue Integrated Flow Controller.

Entegris also manufactures nonstandard product to meet the needs

of spe cific applications. Nonstandard

product may have different materials

of construction, accuracy specifications, performance and other

specifications that differentiate the

nonstandard product from the standard offering.

NOTE: Nonstandard InVue Integrated Flow Controllers may be

iden tified by the model number

found on the product label.

Specifications for nonstandard

InVue Integrated Flow Controllers

are available by contacting Entegris.

Nonstandard InVue Integrated Flow

Controllers, Model NT6510, are

identified with an “N” followed by

a number code.

For example, in part number

6510-T2-F03-B06-A-P7-U3-N02, the

“N02” designates the product as a

nonstandard product manu factured

to certain specifications designated

under the “N02” code.

Nonstandard InVue Integrated

Flow Controllers, Model NT6520,

are identified with an “R” followed

by a number code.

For example, in part number

6520-T6-F03-B06-A-P7-U3-R02, the

“R02” designates the product as a

nonstandard product manufactured

to certain specifications designated

under the “R02” code.

Contact Entegris for assistance with

nonstandard product applications.

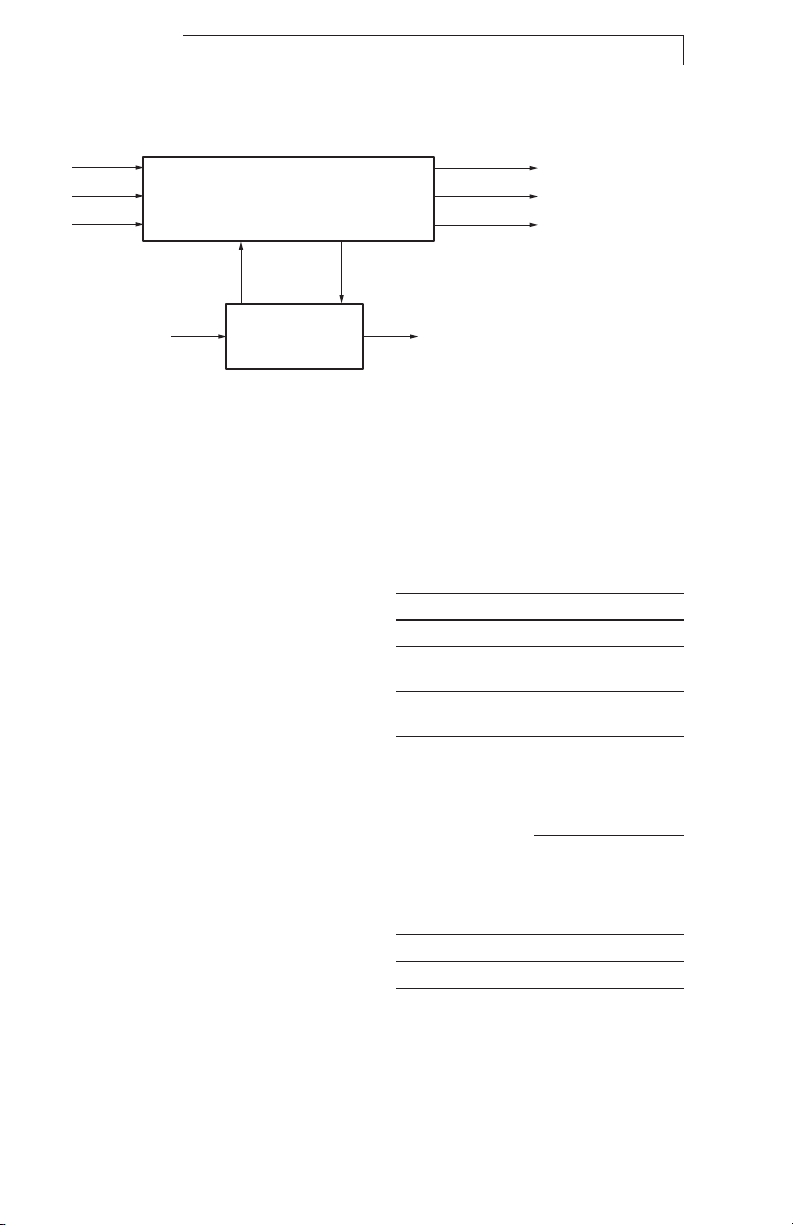

Principle of Operation

The user provides a setpoint signal

that corresponds to the desired

amount of flow. The standard InVue

Integrated Flow Controller compares

the setpoint to the actual flow signal

from the flow module. If the actual

flow is greater than the setpoint, the

unit closes the valve. If the actual

flow is less than the setpoint, the

unit opens the valve. The flow controller does this in a precise manner

until the actual flow signal is equal

to the setpoint.

2 USER GUIDE ENTEGRIS, INC.

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

NT Integrated Flow Controller System Diagram

Powe

S

Re

r

etpoint

-zero

NT Integrated Flow Controller

control interface

Sensor

measurement

Fluid

flow

Flow/valve module

Factory Configured

The standard InVue Integrated Flow

Controller is pre-configured from the

factory for the flow range specified

by the user. The specified flow range

is found on the label of the unit. The

unit control algorithm uses pressure

and flow measurements to ensure

proper operation within specification.

Continuous Versus

Batch Control

The standard InVue Integrated

Flow Controller may be ordered

as a continuous type controller or

a batch type controller.

The continuous controller type is

for applications requiring continuous

flow rate control, where the integral

valve module is never required to

fully close. Typically, another valve

is used in conjunction with the flow

controller to stop the liquid flow.

The batch controller type is for applications requiring flow rate control

where the integral valve module will

fully close between batch dispense

cycles. If total volume needs to be

controlled, an additional separate

totalizer device must be employed.

Pressure signal

Flow signal

Alarm

Valve

control

Fluid

flow

Calibration Reference

Conditions

Unless otherwise noted, the specifications listed for the InVue Integrated Flow Controller are referenced

under the following operating

conditions:

Parameter Reference Condition

Process fluid Deionized water

Process

temperature

Ambient

temperature

Process pressure 207 kPa (30 psig)

Supply voltage 24 VDC ±10%

Operation Re-zeroed

23°C ±3°C (73°F ±5°F)

23°C ±3°C (73°F ±5°F)

for operating range

option 10 –100 % of

full scale flow

("T" code flow range)

276 kPa (40 psig)

for operating range

option 5–100% of

full scale flow

("Y" code flow range)

ENTEGRIS, INC. USER GUIDE 3

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

General Considerations

The following requirements and

specifications are briefly provided

here. Before installing and operating

the InVue Integrated Flow Controller,

see the Installation and Unit Opera-

tion sections of this user guide for

more detailed information.

NOTE: The flow controller has been

factory sealed. Do not attempt to

remove the cover of the unit. Any

attempt at removal of the unit

cover will void the warranty.

Power Supply Requirements

The power supply range for the

flow controller is 24 VDC ±10%.

The power supply to the unit must

provide clean power and must

be used only to power similar

measurement-type devices.

Storage Temperature Range

The flow controller can withstand

storage temperatures between

-15°C – 40°C (5°F –104°F) with

no permanent effect on the

performance of the device.

Operating Ambient

Temperature Range

The flow controller is designed to

operate in ambient temperature,

cleanroom environments. It is specified to operate at temperatures of

10°C –65°C (50 °F –149°F).

Operating Process

Temperature Range

The flow controller is designed to

operate in process temperatures of

10°C –65°C (50 °F –149°F).

Line Pressure

Depending on the operating range

of the flow controller being used,

the system line pressure (measured

at the inlet of the unit) must be

69 kPa – 414 kPa (10 psig – 60 psig)

for operati ng range option 10 – 100 %

of full scale flow (“T” code flow

range) or 172 kPa – 414 kPa

(25 psi g – 60 psig) for operating

range option 5 – 100% of fu ll

scale flow (“Y” code flow range).

Pressure Drop

The flow rate is calculated using

Entegris’ differential pressure flow

technology. Depending on the flow

range of the flow controller being

used, the minimum pressure drop

(inlet to outlet port differential

pressure) required for the unit

is 69 kPa (10 psig) for operating

range option 10 – 100% of fu ll scale

flow (“T” code flow range) or

172 kPa (25 psig) for operating

range option 5 – 100% of fu ll scale

flow (“Y” code flow range).

4 USER GUIDE ENTEGRIS, INC.

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

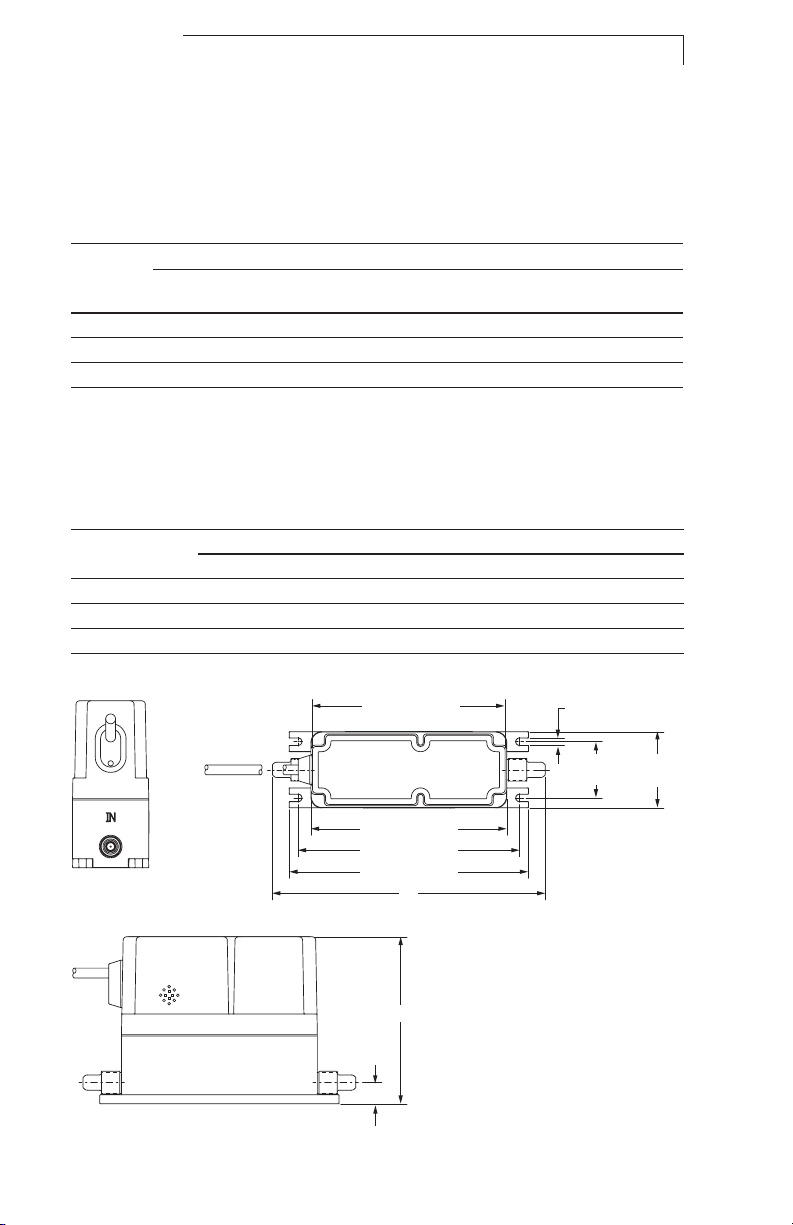

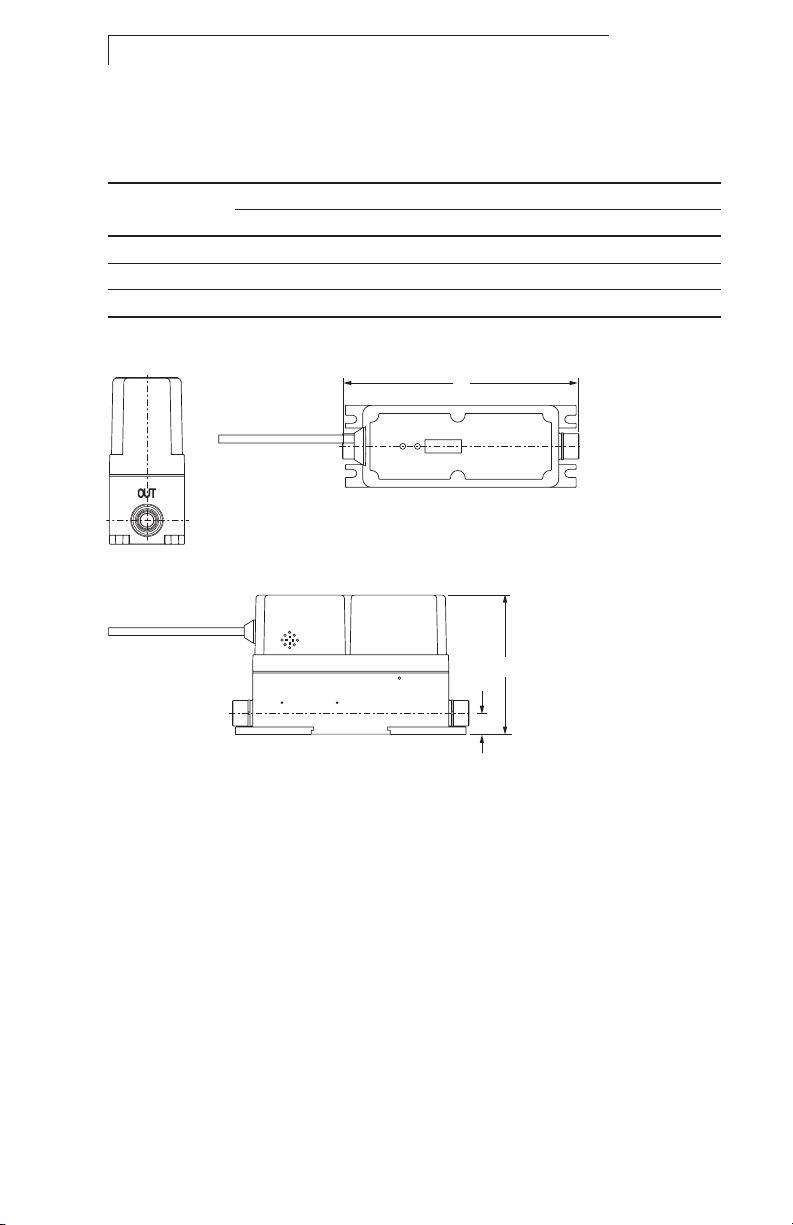

Dimensions

NT6510

The following fitting size and flow range combinations

are available (Flaretek® and Pillar® unless otherwise noted):

Flow Range (mL/min)

TL

Fitting Size

1

⁄4” Yes Yes Yes Yes Yes Yes Yes

3

⁄8” Yes Yes Yes Yes Yes Yes Yes

1

⁄2” — — — — — Yes* Yes*

0–15

* Flaretek® only.

Note: The operating range for "T" code flow ranges (default) is 10 –100% of full scale flow.

The operating range for "Y" code flow ranges is 5 –100% of full scale flow.

Please consult Entegris for PrimeLock® tube fitting options and custom flow range.

Flaretek Tube Fittings

Inlet/Outlet

Port Connection

1

⁄4” 117.9 mm (4.64") 17.0 mm (0.67") 187.5 mm (7.38”)

3

⁄8” 117.9 mm (4.64") 17.0 mm (0.67") 191.0 mm (7.52”)

1

⁄2” 120.8 mm (4.76”) 17.0 mm (0.67") 195.1 mm (7.68”)

TT

0–25

T0/Y0

0–50

T1/Y1

0–125

T2/Y2

0–250

Dimensions

A B C

T3/Y3

0–500

T4/Y4

0–125 0

End View Top View

134.9 mm (5.31”)

137.2 mm (5.40”)

154.9 mm (6.10” )

167.6 mm (6.60”)

C

5.1 mm

(0.20”)

39.4 mm

(1.55”)

53.2 mm

(2.10”)

Side View

A

B

ENTEGRIS, INC. USER GUIDE 5

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

End View Top View

Super 300 Type Pillar Tube Fittings

Inlet/Outlet

Port Connection

1

⁄4” 117.9 mm (4.64”) 17.0 mm (0.67”) 159.3 mm (6.27")

3

⁄8” 117.9 mm (4.64”) 17.0 mm (0.67”) 167.1 mm (6.58")

A B C

C

Dimensions

Side View

A

B

6 USER GUIDE ENTEGRIS, INC.

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

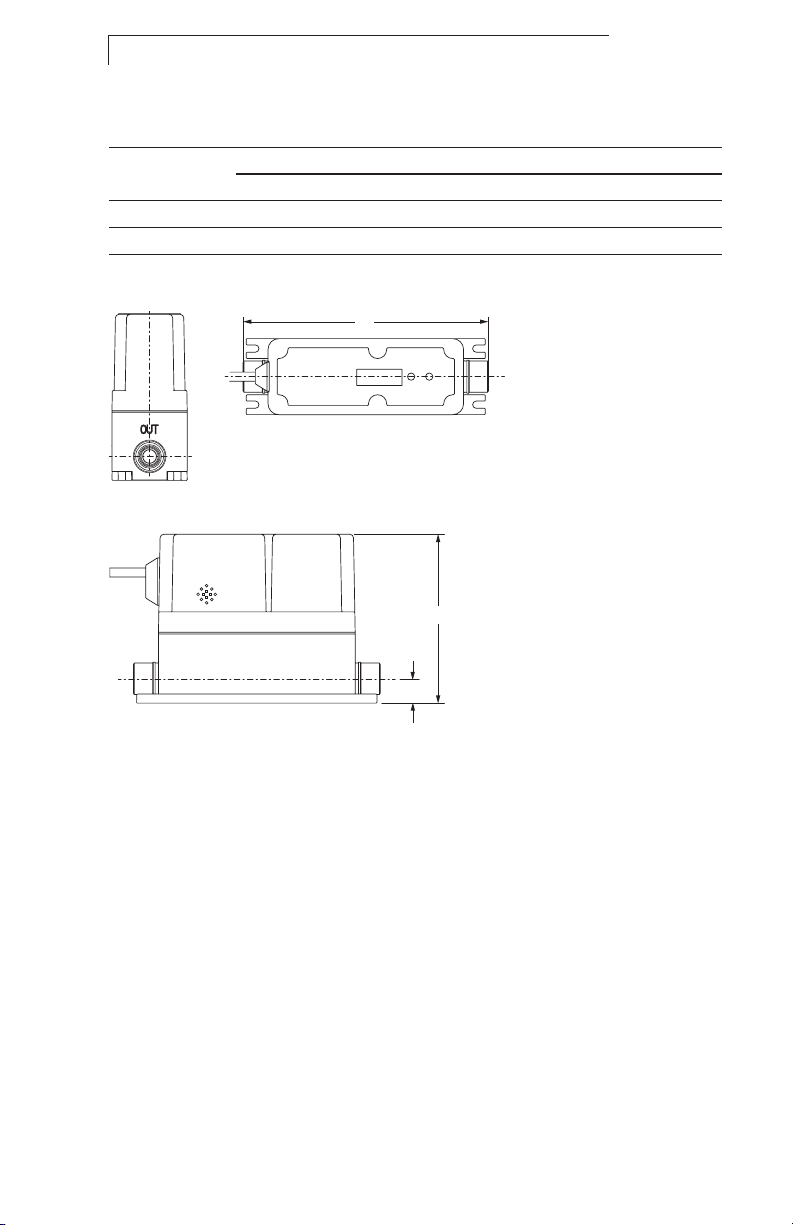

NT6520

The following fitting size and flow range combinations

are available (Flaretek and Pillar unless otherwise noted):

Flow Range (mL/min)

T5/Y5

Fitting Size

3

⁄8”

1

⁄2”

3

⁄4”

0–2.5

Yes Yes — — —

Yes Yes Yes — —

— — — Yes Yes

Note: The operating range for "T" code flow ranges (default) is 10 –100% of full scale flow.

The operating range for "Y" code flow ranges is 5 –100% of full scale flow.

Please consult Entegris for PrimeLock tube fitting options and custom flow range.

T6/Y6

0–5

T7/Y7

0–10

T8/Y8

0–20

Flaretek Tube Fittings

T9/Y9

0–40

Inlet/Outlet

Port Connection

3

⁄8” 117.3 mm (4.62”) 15.7 mm (0.62” ) 224.0 mm (8.82”)

1

⁄2” 120.9 mm (4.76”) 18.3 mm (0.72”) 228.0 mm (8.98”)

3

⁄4” 129.0 mm (5.08”) 23.6 mm (0.93”) 234.2 mm (9.22”)

A B C

End View

7.1 mm

(0.28”)

7.1 mm

(0.28”)

Dimensions

Top View

170.2 mm (6.70”)

187.5 mm (7.38”)

200.2 mm (7.88”)

Side View

A

B

C

47 mm

(1.85”)

71.1 mm

(2.80”)

ENTEGRIS, INC. USER GUIDE 7

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

NT6520

Super 300 Type Pillar Tube Fittings

Inlet/Outlet

Port Connection

3

⁄8” 117.3 mm (4.62”) 15.7 mm (0.62” ) 200.2 mm (7.88”)

1

⁄2” 120.9 mm (4.76”) 18.3 mm (0.72”) 205.2 mm (8.08”)

3

⁄4” 129.0 mm (5.08”) 23.6 mm (0.93”) 214.1 mm (8.43”)

A B C

End View

Dimensions

Top View

C

Side View

A

B

8 USER GUIDE ENTEGRIS, INC.

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

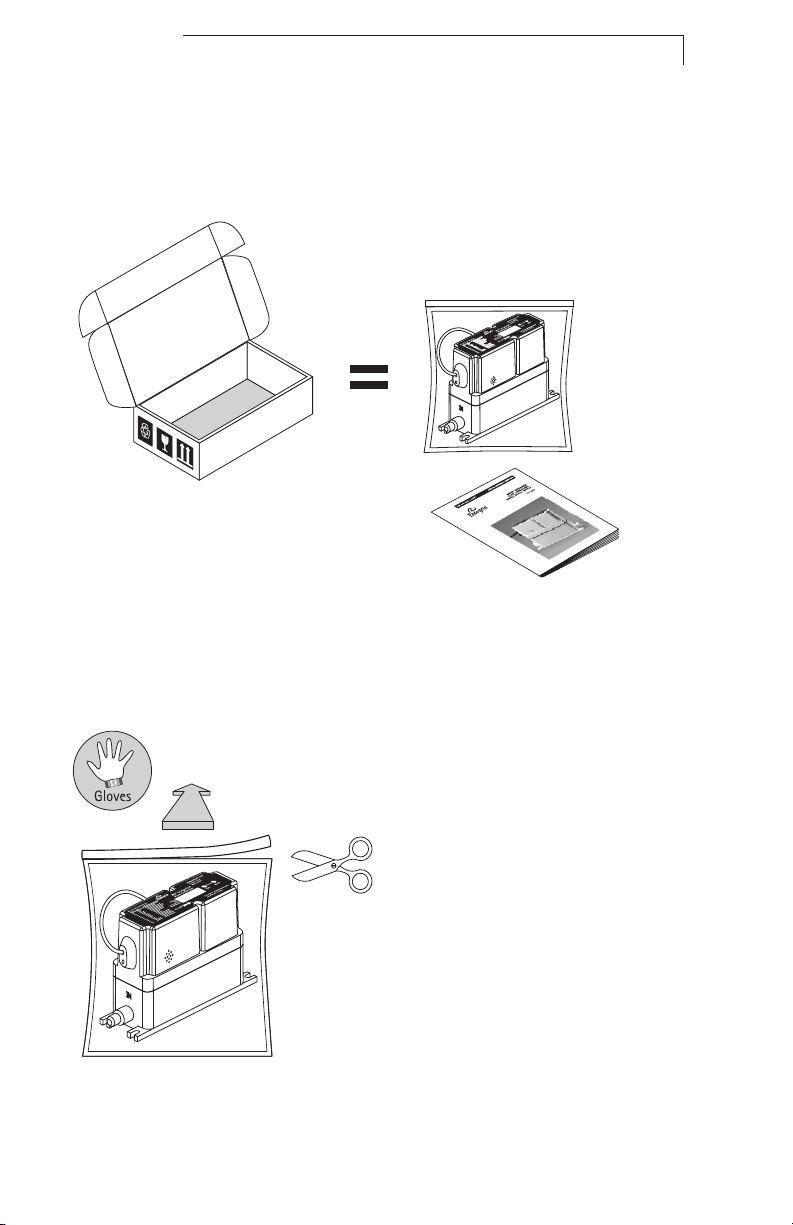

Installation

Provided Equipment

Verify:

CAUTION: Do not tighten the

!

nuts that protect the tube

connections during shipment.

(See the Prepare Fluid Lines

Section on page 9). Tightening

these nuts without the proper

tubing installed may damage

the unit’s tube connections.

NOTE: This unit has been assembled

and double-bagged under cleanroom

conditions. To maintain purity, only

open under cleanroom conditions.

Remove Unit from the Bag

ENTEGRIS, INC. USER GUIDE 9

Loading...

Loading...