P/N 1030-104 | REV. C 03/19 | INSTRUCTION SHEET

*

P7 Diaphragm/retainer/

Integra® Manually Operated

Diaphragm Valves

1

⁄2" Orifice, 2-way, Multi-turn Designs

REPAIR INSTRUCTIONS

—

For models:

201-38, 201-39, 201-40, 201-41, 201-42, 201-41-SI,

201-41-SO, 201-42-SI, 201-42-SO, 201-38-01,

201-39-01, 201-40-01, 201-41-01, 201-42-01,

201-41-SI-01, 201-41-SO-01, 201-42-SI-01,

201-42-SO-01

REPAIR PROCEDURE – DISASSEMBLY

—

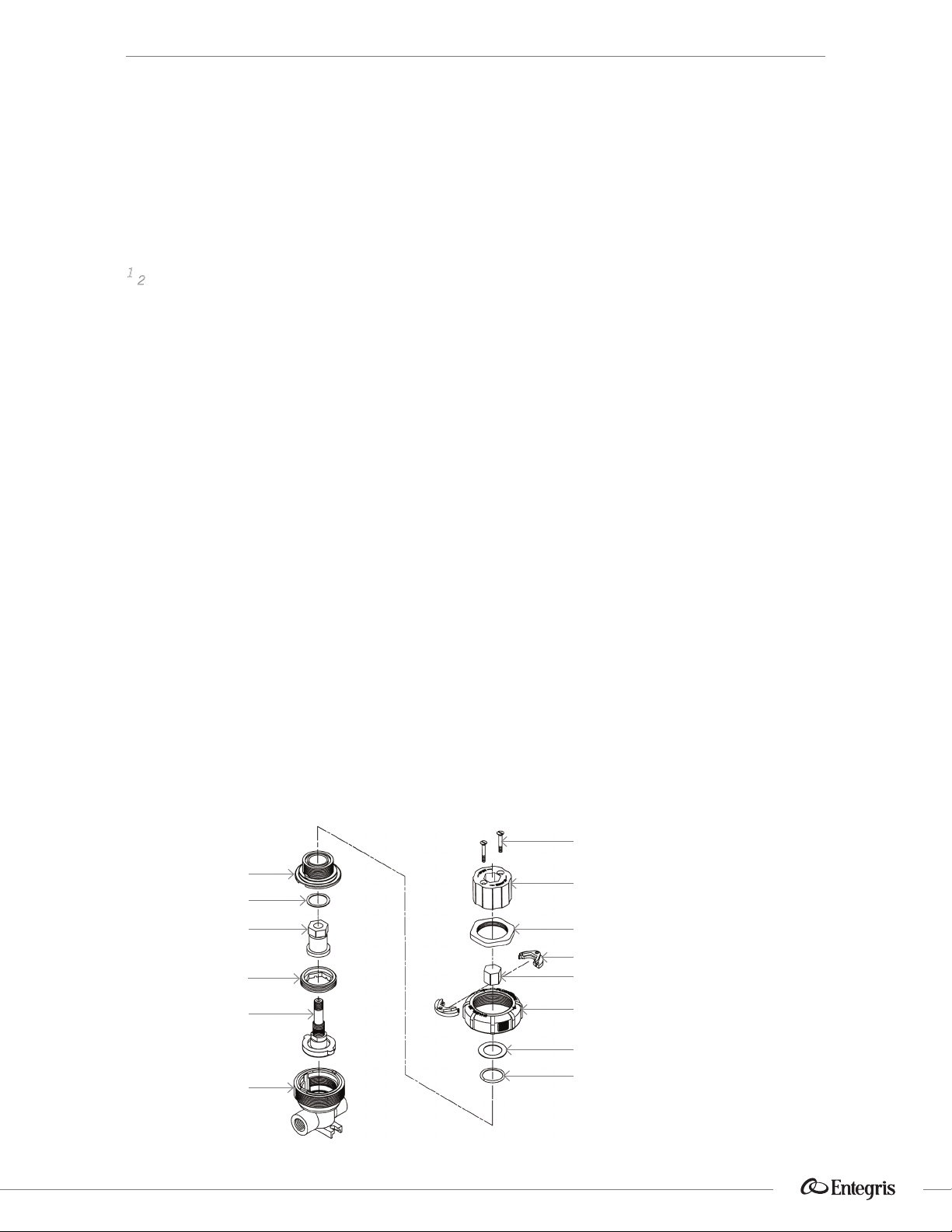

1. Begin disassembly by referring to Figure 1.

2. Remove the two screws (P1) on top of the handle

(P8) with a screwdriver (S1). Discard screws.

3. Remove the handle (P8) by pulling up on it.

4. Remove the stop nut (P2) by rotating it counterclockwise, then discard it.

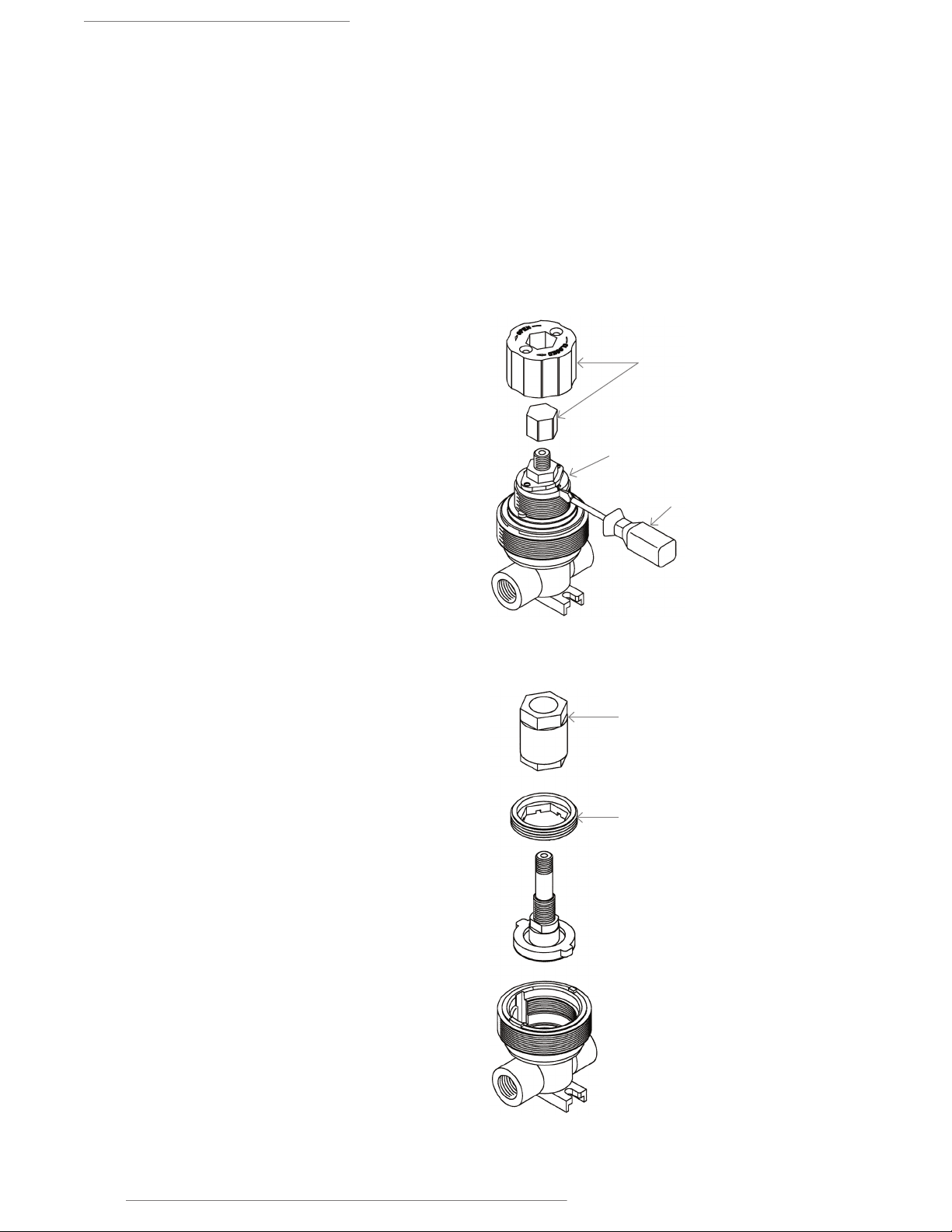

5. Remove the collar halves (P9) by inserting a

screwdriver (S1) into the slot and separating

them as shown in Figure 2.

6. Remove the panel mount nut (P10).

7. Remove the outer cap (P11) with the outer

cap wrench (T1) by turning it slowly counterclockwise.

8. Remove and discard the thrust washer (P3)

and O-ring (P4).

9. Remove the inner cap (P12).

10. Remove and discard the thrust washer (P5).

11. Remove the actuator nut (P6) by rotating it

clockwise. Discard this part.

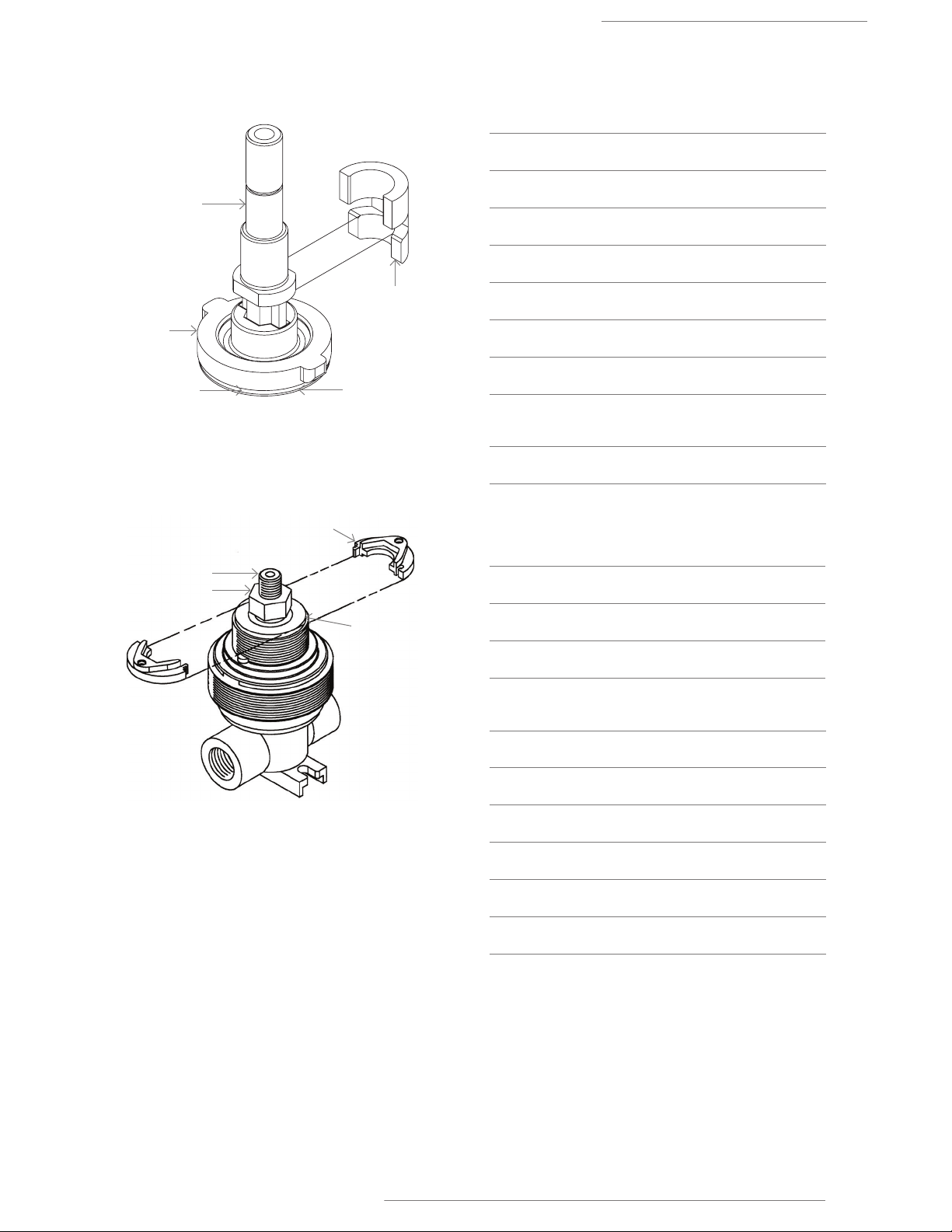

12. Use the retainer nut adaptor (T2) and an adjustable wrench (S2) to remove the retainer nut (P13).

See Figure 3.

13. Remove the diaphragm/retainer/stem assembly

(P7) by pulling up on it. Discard this assembly.

P12 Inner cap

P5 Thrust washer*

P6 Actuator nut*

P13 Retainer nut

stem assembly*

Figure 1.

P14 Body

P1 Screws (2)*

P8 Handle

P10 Panel mount nut

P9 Collar halves (2)

P2 Stop nut*

P11 Outer cap

P3 Thrust washer*

P4 O-ring*

*Repair parts kit

INTEGRA MANUALLY OPERATED DIAPHRAGM VALVES

REPAIR PROCEDURE – ASSEMBLY

—

1. Before beginning assembly, clean the internal

body surfaces (P14) and the parts not supplied

in the kit with isopropyl alcohol (S3).

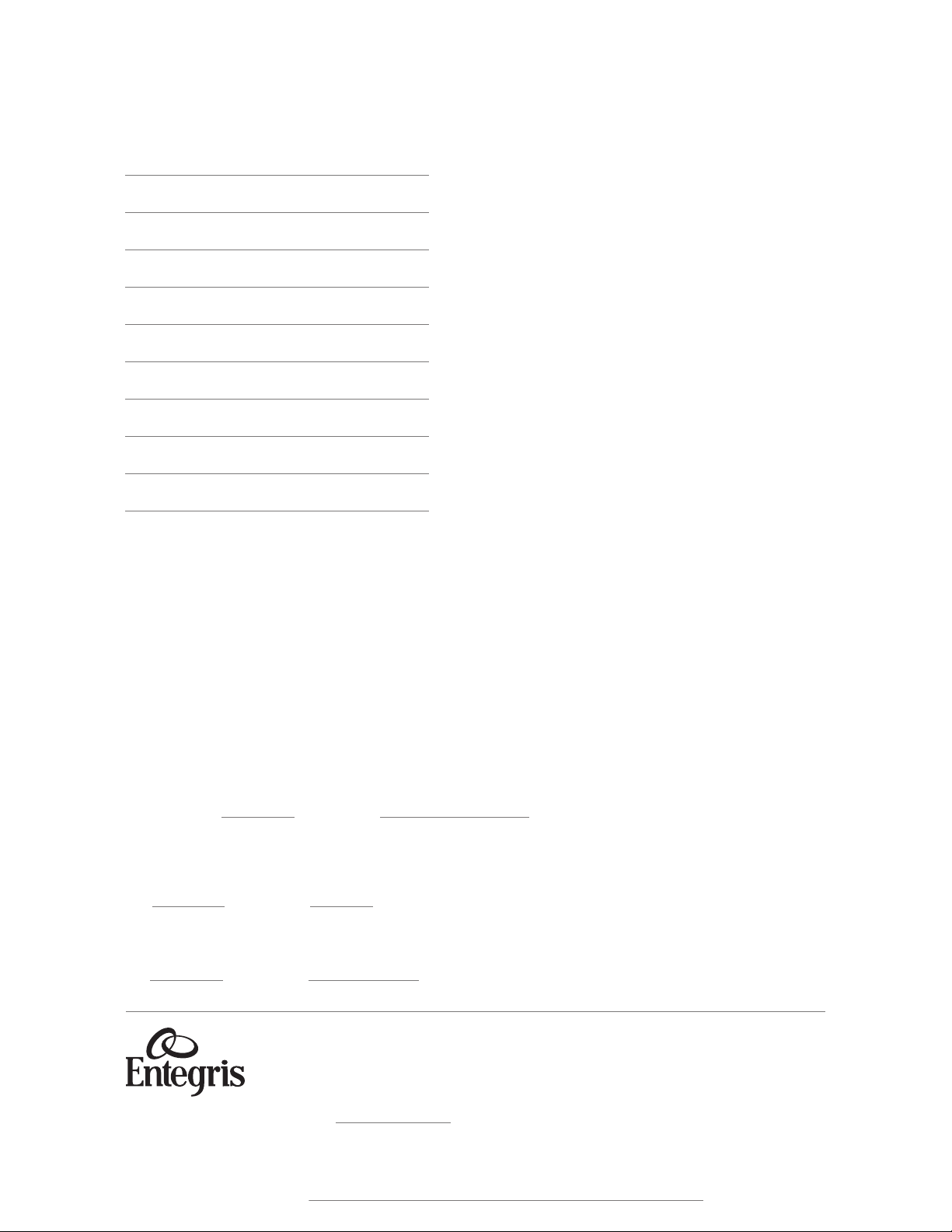

2. Begin assembly by making sure the O-ring

between the diaphragm and retainer is evenly

in place. Snap O-ring pre-set tool (P15) on stem

(see Figure 4). Then position the diaphragm/

retainer/stem assembly (P7) into the body (P14),

lining up the tabs on the retainer with the slots

on the body (P14).

3. Thread the retainer nut (P13) into the body (P14)

until the retainer nut (P13) just contacts the

retainer. See Figure 3.

4. With the retainer nut adaptor (T2) tighten the hex

portion of the adaptor to 5.65 N•m (50 in•lbs)

using the torque wrench (S4) and 1⁄" crow’s foot

(S5). Discard O-ring pre-set tool (P15).

5. Thread the actuator nut (P6) onto the stem until

it bottoms out.

6. Place the thrust washer (P5) onto the actuator

nut.

actuator nut (P6) first lines up with the hex on

the stop nut (P2).

15. Install the handle (P8) so that the holes in the

handle line up with the holes in the collar halves

(P9).

16. Insert two screws (P1).

17. Proceed to test the valve.

P8 Handle and

P2 Stop nut removed

P9 Collar half

S1 Screwdriver

7. Place the inner cap (P12) onto the valve body,

aligning the bosses on the body with the slots in

the cap.

8. Install the outer cap (P11) and slowly torque to

13.5 N•m (120 in•lbs) using the torque wrench

(S4), 1⁄" crow’s foot (S5) and outer cap wrench

(T1).

9. Turn actuator nut (P6) clockwise until it contacts

the inner cap (P12).

10. Place O-ring (P4) and thrust washer (P3) into the

groove on the inner cap (P12).

11. Install collar halves (P9) onto the stem as shown

in Figure 5.

12. Thread on the panel mount nut (P10).

13. Set up valve so that 552 kPa (80 psi) can be

applied to the outlet port.

14. Place the handle (P8) onto the actuator nut (P6)

and slowly close the valve until a seal is just

made. Remove the valve handle without disturbing the stem position, and turn the stop nut (P2)

clockwise until it first contacts the actuator nut

(P6). Then turn the stop nut (P2) counterclockwise less than ⁄ of a turn so the hex on the

Figure 2.

T2 Retainer nut adaptor

P13 Retainer nut

Figure 3.

P/N 1030-104 | Rev. C 03/19 | Entegris, Inc.2

INTEGRA MANUALLY OPERATED DIAPHRAGM VALVES

*Repair parts ki

P7 Stem assembl

P7 Diaphragm/Retainer/Stem Assembly

Stem

P15 O-ring

pre-set tool*

Retainer

O-ring

t

Figure 4.

P9 Collar half

Diaphragm

Repair Parts Kit

(See part numbers listed below)

ITEM DESCRIPTION QUANTITY

P1 Screw 2

P2 Stop nut 1

P3 Thrust washer 1

P4 O-ring 1

P5 Thrust washer 1

P6 Actuator nut 1

P7 Diaphragm/retainer/

1

stem assembly

P15 O-ring pre-set tool 1

Repair Tool Kit

(Part number 213-103)

P6 Actuator nut

Figure 5.

y

ITEM DESCRIPTION

P4 O-ring

with P3

Thrust washer

on top

T1 Outer cap wrench

T2 Retainer nut adaptor

Customer Supplied Items

ITEM DESCRIPTION

S1 Screwdriver

S2 Adjustable wrench

S3 Isopropyl alcohol

S4 Torque wrench 22 N•m (200 in•lbs) scale

S5 1⁄" Crow’s foot

Entegris, Inc. | P/N 1030-104 | Rev. C 03/19 3

ORDERING INFORMATION

—

All of the following valves use repair parts kit part number 201-74.

Valve part number

201-38 201-42-01

201-39 201-41-SI

201-40 201-41-SO

201-41 201-42-SI

TESTING

—

The valve must be tested in the following ways:

Outlet to Inlet Leakage

With 552 kPa (80 psi) air pressure applied to the outlet

and the valve fully closed, no leakage at the inlet

should be seen when the inlet port is submerged in

water. If leakage occurs, back o the stop an additional ⁄ turn. If this does not correct the leakage,

disassemble and inspect the valve seat for a defect.

201-42 201-42-SO

201-38-01 201-41-SI-01

External Media Leakage

With the inlet plugged with a taped plug or Flaretek®

fitting cap, apply 552 kPa (80 psi) air pressure to the

201-39-01 201-41-SO-01

outlet. No leakage should be observed from around

the outer cap.

201-40-01 201-42-SI-01

201-41-01 201-42-SO-01

LIMITED WARRANTY

Entegris’ products are subject to the Entegris, Inc. General Limited Warranty. To view and print this

information, visit entegris.com and select the Legal & Trademark Notices link in the footer. Entegris

does not warranty any failure in the case of customers using unapproved foreign components.

FOR MORE INFORMATION

Please call your Regional Customer Service Center today to learn what Entegris can do for you.

Visit entegris.com and select the Contact Us link to find the customer service center nearest you.

TERMS AND CONDITIONS OF SALE

All purchases are subject to Entegris’ Terms and Conditions of Sale. To view and print this information,

visit entegris.com and select the Terms & Conditions link in the footer.

Corporate Headquarters Customer Service

129 Concord Road

Billerica, MA 01821

USA

Entegris®, the Entegris Rings Design®, and other product names are trademarks of Entegris, Inc. as listed

on entegris.com/trademarks. All third-party product names, logos, and company names are trademarks or

registered trademarks of their respective owners. Use of them does not imply any aliation, sponsorship,

or endorsement by the trademark owner.

©1996-2019 Entegris, Inc. | All rights reserved. | Printed in the USA | 3220-10453ENT-0319

P/N 1030-104 | Rev. C 03/19

Tel +1 952 556 4181

Fax +1 952 556 8022

Toll Free 800 394 4083

www.entegris.com

Loading...

Loading...