Page 1

RFID UHF Short Range Controller

RF2400

Product Specification

Revision 1.0

Prepared by: Synergy Technology, Inc. & Synaptec Enterprises, Inc.

Author: Richard L. Hicksted & Michael A. Spahr

________________________________________________________________________

- C

ONFIDENTIAL

3/30/2008

-

Page 2

L

EGAL NOTICES

Copyright © 2007 Ensyc Technologies. All rights reserved.

Ensyc Technologies maintains intellectual property rights pertaining to technology

incorporated in the product(s) described in this document; including without limitation

certain patent rights or patent pending applications in the U.S. and other countries

This document and related product(s) are distributed under licenses restricting use,

copying, distribution, and decompilation. No part of this documentation may be

reproduced without prior written consent of Ensyc Technologies

FCC C

OMPLIANCE

Every effort has been made to design and manufacture this product in accordance with

the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to limit interference when the equipment is used in a commercial

environment. The related equipment generates, uses, and radiates radio frequency energy

and if not installed and used in accordance with this specification may cause harmful

interference with radio communications. Operation in a residential area is likely to result

in interference in which case the user will be required to correct the interference at his

expense.

It is the responsibility on an OEM to obtain certification to operate per FCC Part 15

Subpart A Section 15.21 regulations for the entire system into which this product is

installed.

FCC RF R

ADIATION EXPOSURE STATEMENT

:

The antenna(s) used for this transmitter must be installed to provide a separation distance

of at least 20 cm from all persons and must not be co-located or operating in conjunction

with any other antenna or transmitter. End-users and installers must be provided with

antenna installation instructions and transmitter operating conditions for satisfying RF

exposure compliance.

________________________________________________________________________

- C

ONFIDENTIAL

3/30/2008

-

Page 3

NOTE

Part 15.21

Changes or modifications not expressly approved by the

party responsible for compliance could void the user’s

authority to operate the equipment.

NOTE: The manufacturer is not responsible for any radio

or TV interference caused by unauthorized modifications to

this equipment. Such modifications could void the user’s

authority to operate the equipment.

________________________________________________________________________

- C

ONFIDENTIAL

3/30/2008

-

Page 4

Table of Contents

1 Scope...................................................................................................................................................1

2 Revision History..................................................................................................................................3

3 Reference Documents .........................................................................................................................5

3.1 Specifications & Requirements.........................................................................................5

3.2 Reference Material ............................................................................................................5

4 Overview.............................................................................................................................................7

4.1 DSP Processor...................................................................................................................8

4.2 Transmitter Circuitry.........................................................................................................8

4.3 Receiver Circuitry .............................................................................................................9

4.4 User Interface....................................................................................................................9

4.5 Power Regulation ..............................................................................................................9

4.6 Battery Operation ..............................................................................................................9

5 Functional Description........................................................................................................................11

5.1 Host Protocol.....................................................................................................................11

5.1.1 Message Format...............................................................................................11

5.1.1.1 Message Packet Format.................................................................12

5.1.1.2 Host-to-Reader Payload.................................................................12

5.1.1.3 Reader-to-Host Payload.................................................................13

5.1.1.4 Response Data Formats .................................................................15

5.1.1.4.1 Simple Command Response ........................................15

5.1.1.4.2 Low-Level Command Response..................................15

5.1.1.4.3 Error Response.............................................................15

5.1.2 Reader Commands...........................................................................................16

5.1.2.1 Get Firmware Version (0x00)........................................................16

5.1.2.2 Set Baud Rate (0x03).....................................................................17

5.1.2.3 Set IO Port Value (0x05)...............................................................17

5.1.2.4 Get IO Port Value (0x06) ..............................................................18

5.1.2.5 Get Reader Status (0x0F) ..............................................................18

5.1.2.6 Get Reader Hardware Information (0x11).....................................19

5.1.2.7 Set Reader Hardware Information (0x13) .....................................20

5.1.2.7.1 Paper Sensor Triggered Read ......................................21

5.1.2.8 Set Bi-Directional I/O DDR (0x16)...............................................22

5.1.2.9 Get Bi-Directional I/O DDR (0x17)..............................................22

5.1.3 Tag Commands................................................................................................23

5.1.3.1 Sleep Tag (0x21) ...........................................................................23

5.1.3.2 Get Tag ID (0x24) .........................................................................23

5.1.3.3 Auto Get Tag ID (0x26) ................................................................24

5.1.3.4 Dump ID Data (0x28)....................................................................25

5.1.3.5 Get Raw Tag ID (0x3E).................................................................26

5.1.3.6 Program Tag (0x50).......................................................................27

5.1.3.7 Erase Tag (0x51) ...........................................................................28

5.1.3.8 Kill Tag (0x52)..............................................................................29

5.1.3.9 Lock Tag (0x53)............................................................................30

5.1.3.10 Program Tag Init (0x54)................................................................31

5.1.3.11 LockG2 (0x55) ..............................................................................32

5.1.3.12 Access G2 (0x56) ..........................................................................34

5.1.3.13 Read Tag Memory (0x57) .............................................................35

5.1.3.14 Write Tag Memory (0x58).............................................................36

5.2 Service Port Commands....................................................................................................37

5.2.1 Standard Commands........................................................................................37

5.2.1.1 Baud Rate (baud) command..........................................................37

________________________________________________________________________

P

i

RODUCT SPECIFICATION

Page 5

5.2.1.2 Transmit Power Step (Txp[0-3]) command...................................37

5.2.1.3 Receive Threshold (rxt) command ................................................38

5.2.1.4 Phase (phs) command....................................................................38

5.2.1.5 Tag Class (tc) command................................................................39

5.2.1.6 Read Retry (rrty) command...........................................................39

5.2.1.7 Read Tag (rt) command.................................................................39

5.2.1.8 Read Loop (rl) command...............................................................39

5.2.1.9 Sequential Loop (sl) command......................................................40

5.2.1.10 Write Tag (wt) command...............................................................40

5.2.1.11 Lock Tag (lt) command .................................................................40

5.2.1.12 Lock Tag G2 (l2) command...........................................................41

5.2.1.13 Access (apw)..................................................................................41

5.2.1.14 Kill Tag (kt) command...................................................................41

5.2.1.15 Quiet Tag (qt) command................................................................41

5.2.1.16 Erase Tag (et) command................................................................42

5.2.1.17 Paper Sensor Triggered Read (pstr) command..............................42

5.2.1.18 Paper Sensor (ps) command ..........................................................42

5.2.1.19 Paper Sensor Threshold (pst) command ........................................43

5.2.1.20 Auto Read Tag (art) command......................................................43

5.2.1.21 Dump ID Data (did) command......................................................44

5.2.1.22 Program Flash (pf) command ........................................................44

5.2.1.23 Speaker Test (st) command............................................................44

5.2.1.24 Beep (beep) command...................................................................45

5.2.1.25 Set EEPROM Defaults (eedef) command......................................45

5.2.1.26 Read EEPROM (ree) command.....................................................45

5.2.1.27 No initial message (noim) command .............................................45

5.2.1.28 Diagnostic (di) command ..............................................................46

5.2.1.29 Ignore CRC (icrc) command .........................................................48

5.2.1.30 Exit (exit) command.......................................................................48

5.2.1.31 Display menu (??) command.........................................................48

5.2.1.32 Standard command summary.........................................................49

5.2.2 Protected Commands.......................................................................................50

5.2.2.1 Password (pw) command...............................................................50

5.2.2.2 Transmit power (txp) command.....................................................50

5.2.2.3 Maximum transmit power (txpmax) command..............................50

5.2.2.4 Minimum transmit power (txpmin) command...............................50

5.2.2.5 Channel select (chan) command....................................................51

5.2.2.6 Hop (hop) command......................................................................52

5.2.2.7 Gen2 Read (g2r) command ...........................................................52

5.2.2.8 Gen2 Write (g2w) command .........................................................52

5.2.2.9 Transmit zeros (t0) command........................................................52

5.2.2.10 Transmit ones (t1) command.........................................................53

5.2.2.11 Transmit alternating (ta) command ...............................................53

5.2.2.12 Transmit random (tr) command.....................................................53

5.2.2.13 Transmit data (td) command..........................................................53

5.2.2.14 Carrier on (con) command.............................................................54

5.2.2.15 Carrier off (coff) command............................................................54

5.2.2.16 Localization (local) command.......................................................54

5.2.2.17 Chipcon register read (ccr) command............................................54

5.2.2.18 Chipcon register write (ccw) command.........................................54

5.2.2.19 Protected command summary........................................................55

5.2.3 Service port error codes...................................................................................56

5.3 Radio Frequency Interface ................................................................................................57

________________________________________________________________________

P

ii

RODUCT SPECIFICATION

Page 6

5.3.1 Auto-ID Class 1...............................................................................................57

5.3.1.1 Class 1 Reader-Tag RF communications.......................................57

5.3.1.2 Class 1 Tag-Reader RF communications.......................................58

5.3.2 Class 1 – Gen 2................................................................................................59

5.3.2.1 Gen 2 Reader-Tag RF communications.........................................59

5.3.2.2 Gen 2 Tag-Reader RF communications.........................................60

5.4 Logical Structures and Data content..................................................................................62

5.4.1 Gen 2 Tag Structures and Data content...........................................................62

5.5 Autonomous Operation .....................................................................................................63

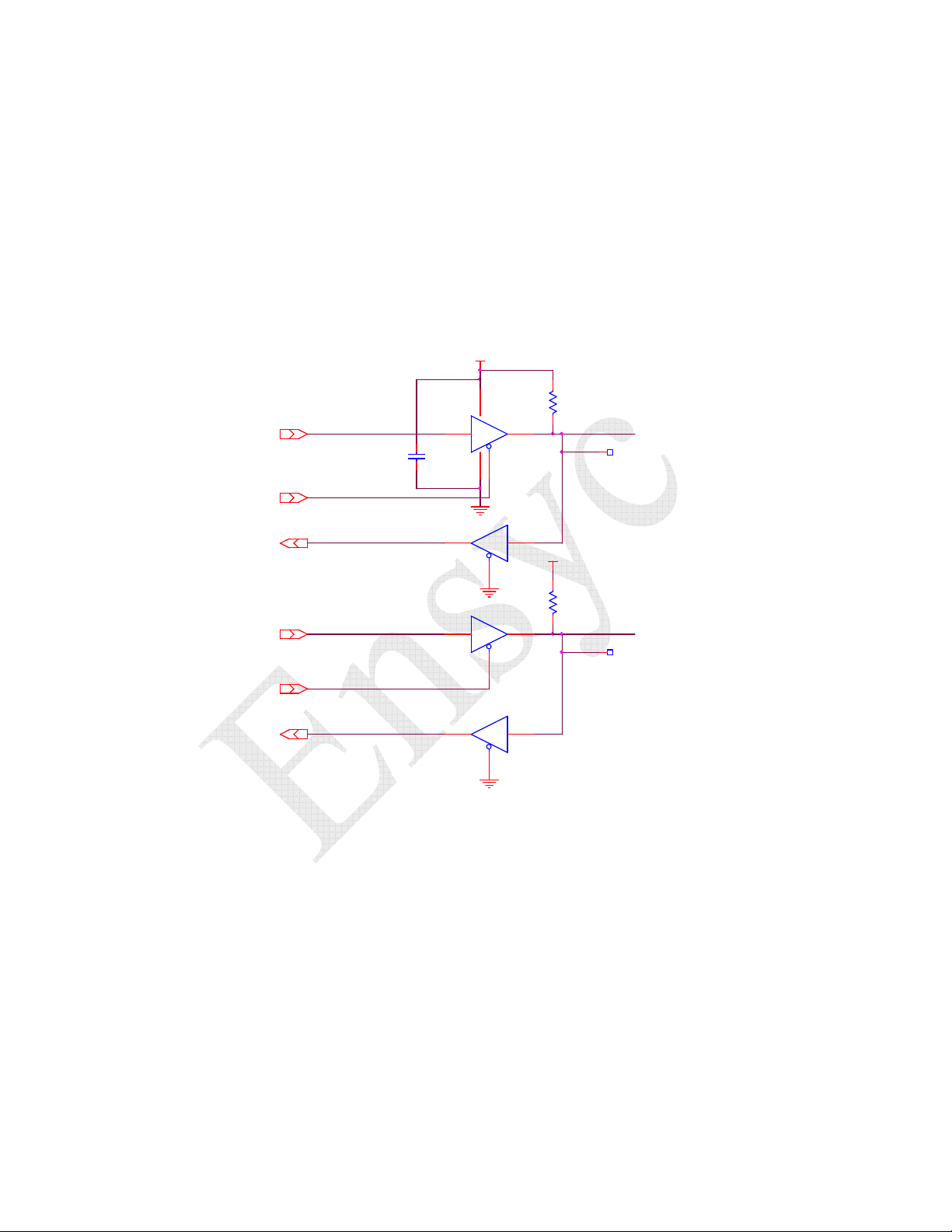

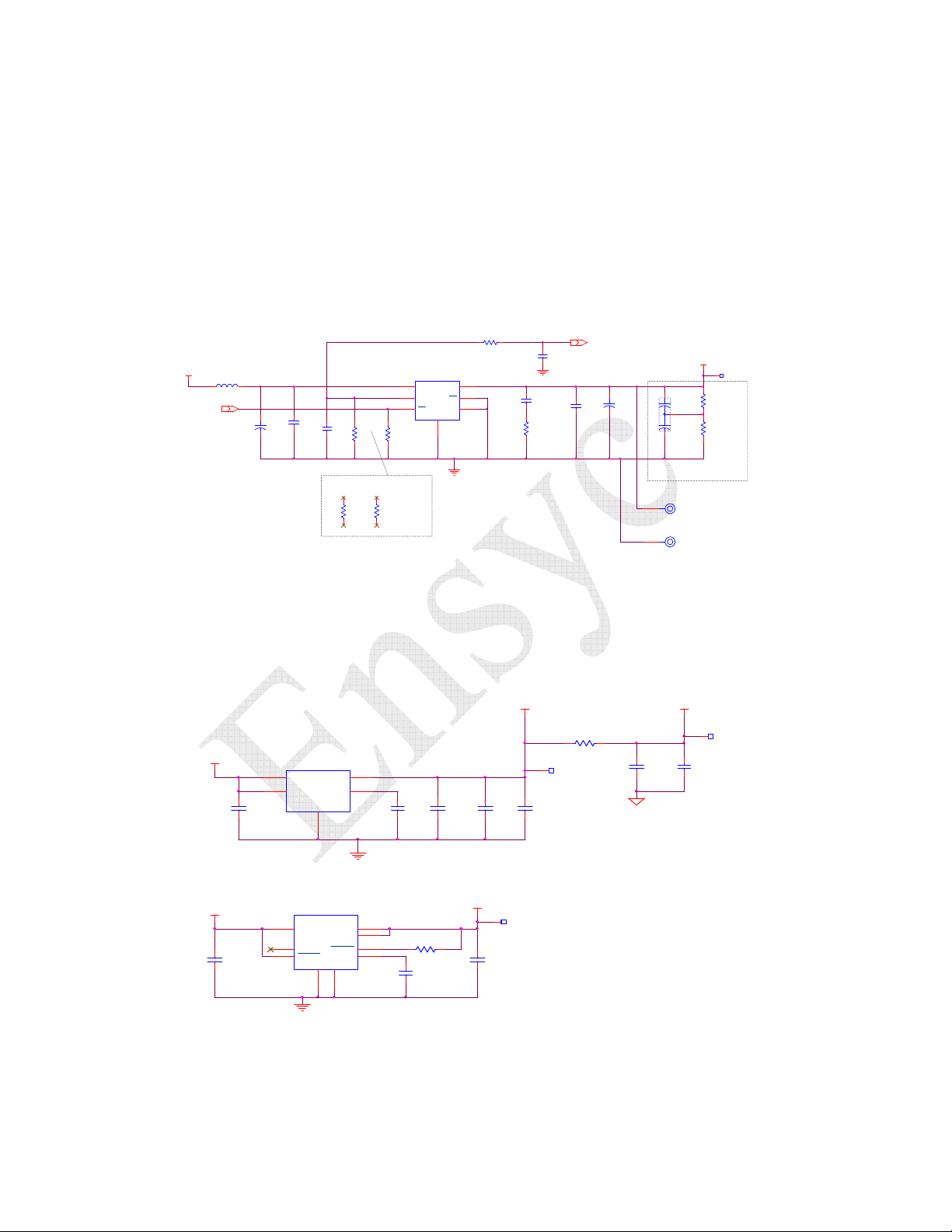

6 Hardware Description .........................................................................................................................65

6.1 Host Communication Interface..........................................................................................66

6.2 DSP Processor...................................................................................................................67

6.3 EEPROM...........................................................................................................................67

6.4 Transmitter/VCO...............................................................................................................68

6.5 Power Splitter....................................................................................................................68

6.6 Power Amplifier................................................................................................................68

6.7 PA Modulation..................................................................................................................68

6.8 Directional Coupler/RF FIlter ...........................................................................................69

6.9 Selectable LC Phase Delay/Mixer.....................................................................................69

6.10 Base-band Amplifier .........................................................................................................69

6.11 General Purpose Digital I/O Port ......................................................................................70

6.12 Digital I/O Interface ..........................................................................................................71

6.13 Buzzer Circuit....................................................................................................................72

6.14 Optical Sensor Interface....................................................................................................72

6.15 Power Regulators ..............................................................................................................73

7 Specifications......................................................................................................................................75

7.1 Electrical Specifications....................................................................................................75

7.1.1 RF Interface.....................................................................................................75

7.1.2 Communications Interface...............................................................................75

7.1.3 Power Supply ..................................................................................................75

7.1.4 Battery (optional).............................................................................................76

7.2 Environmental Specifications............................................................................................76

7.3 Mechanical Specifications.................................................................................................76

7.4 I/O Connectors ..................................................................................................................77

________________________________________________________________________

P

iii

RODUCT SPECIFICATION

Page 7

Figures

Figure 4-1

Figure 5-1

Figure 5-2

Figure 5-3

Figure 5-4

Figure 5-5

Figure 5-6

Figure 5-7

Figure 5-8

Figure 5-9

Figure 6-1

Figure 6-2

Figure 6-3

Figure 6-4

Figure 6-5

Figure 6-6

Figure 6-7

Figure 7-1

RF2400 Block Diagram __________________________________________________ 7

Message Packet Format _________________________________________________ 12

Host to Reader Payload Format___________________________________________ 12

Reader to Host Payload Format___________________________________________ 13

Low-Level Command Response ___________________________________________ 15

Class 1 Reader Modulation Timing for Binary 0______________________________ 58

Class 1 Reader Modulation Timing for Binary 1 ______________________________ 58

Class 1 Tag to Reader Encoding __________________________________________ 59

Gen 2 Reader to Tag PIE Encoding ________________________________________ 60

Gen2 Tag to Reader Encoding ____________________________________________ 61

Host Interface _________________________________________________________ 66

Digital I/O Port________________________________________________________ 70

Digital I/O Interface ____________________________________________________ 71

Buzzer Circuit_________________________________________________________ 72

Optical Sensor Interface_________________________________________________ 72

Main Power 4.2V Regulator ______________________________________________ 73

+3.3V and +1.8V Regulator ______________________________________________ 73

RF2400 Mechanical Assembly ____________________________________________ 78

________________________________________________________________________

P

iv

RODUCT SPECIFICATION

Page 8

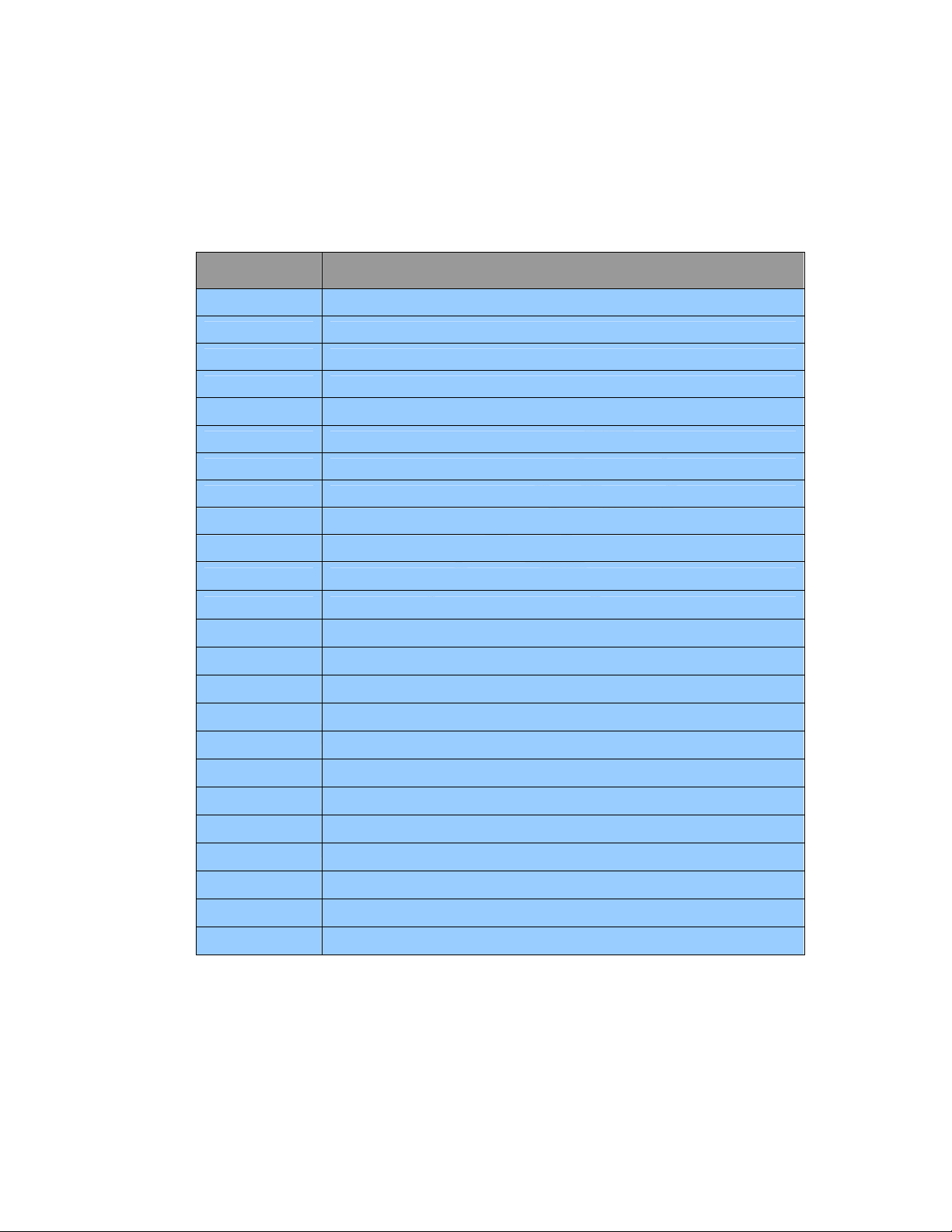

Tables

Table 5-1

Table 5-2

Table 5-3

Table 5-4

Table 5-5

Table 5-6

Table 5-7

Table 5-8

Table 5-9

Table 5-10

Table 5-11

Table 5-12

Table 5-13

Table 5-14

Table 5-15

Table 5-16

Table 5-17

Table 5-18

Table 5-19

Table 5-20

Table 5-21

Table 5-22

Table 5-23

Table 5-24

Table 5-25

Table 5-26

Table 5-27

Table 5-28

Table 5-29

Table 5-30

Table 5-31

Table 5-32

Table 5-33

Table 5-34

Table 5-35

Table 5-36

Table 5-37

Table 5-38

Table 5-39

Table 5-40

Table 5-41

Table 5-42

Message Encapsulation Characters ________________________________________ 12

Command/Response Payload Fields _______________________________________ 13

Communication Codes __________________________________________________ 14

Low-Level Response Fields ______________________________________________ 15

Get Firmware Version __________________________________________________ 16

Set Baud Rate _________________________________________________________ 17

Set IO Port Value ______________________________________________________ 17

Get IO Port Value______________________________________________________ 18

Get Reader Status ______________________________________________________ 18

Get Reader Hardware Information_________________________________________ 19

Set Reader Hardware Information _________________________________________ 20

Set Bi-Directional I/O DDR ______________________________________________ 22

Get Bi-Directional I/O DDR______________________________________________ 22

Sleep Tag ____________________________________________________________ 23

Get Tag ID ___________________________________________________________ 23

Auto Get Tag ID _______________________________________________________ 24

Dump ID Data Command________________________________________________ 25

Get Raw Tag ID _______________________________________________________ 26

Program Tag__________________________________________________________ 27

Erase Tag ____________________________________________________________ 28

Kill Tag______________________________________________________________ 29

Lock Tag _____________________________________________________________ 30

Program Tag Init ______________________________________________________ 31

LockG2 ______________________________________________________________ 32

Lock bit usage_________________________________________________________ 33

Lock action field functionality ____________________________________________ 33

AccessG2_____________________________________________________________ 34

Read Tag Memory______________________________________________________ 35

Write Tag Memory _____________________________________________________ 36

Service Port Lead-in sequence ____________________________________________ 37

Transmit Power Level___________________________________________________ 38

Service Port Commands - Standard ________________________________________ 49

RF2400 USA Hopping Table _____________________________________________ 51

RF2400 E.U. Hopping Table TBD _________________________________________ 51

RF2400 Japan Hopping Table TBD________________________________________ 51

Service Port Commands - Protected________________________________________ 55

Service Port Error Codes ________________________________________________ 56

Class 1 Reader-Tag Modulation Parameters_________________________________ 57

Class 1 Tag-Reader Communication Parameters _____________________________ 58

Gen 2 Reader-Tag Modulation Parameters __________________________________ 60

Gen 2Tag-Reader Communication Parameters _______________________________ 61

Class 1 Gen 2 Memory Map ______________________________________________ 62

________________________________________________________________________

P

v

RODUCT SPECIFICATION

Page 9

________________________________________________________________________

P

vi

RODUCT SPECIFICATION

Page 10

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

1 SCOPE

This document is a detailed technical specification for the RFID UHF Short Range

Controller (RF2400). It provides a comprehensive description of the hardware with

detailed design notes and a complete functional description of the product. This

document is contains proprietary and confidential information and is not intended to be

used as an end user’s manual.

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

1 11:56:13 AM

- M

ARCH

30, 2008

Page 11

Page 12

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

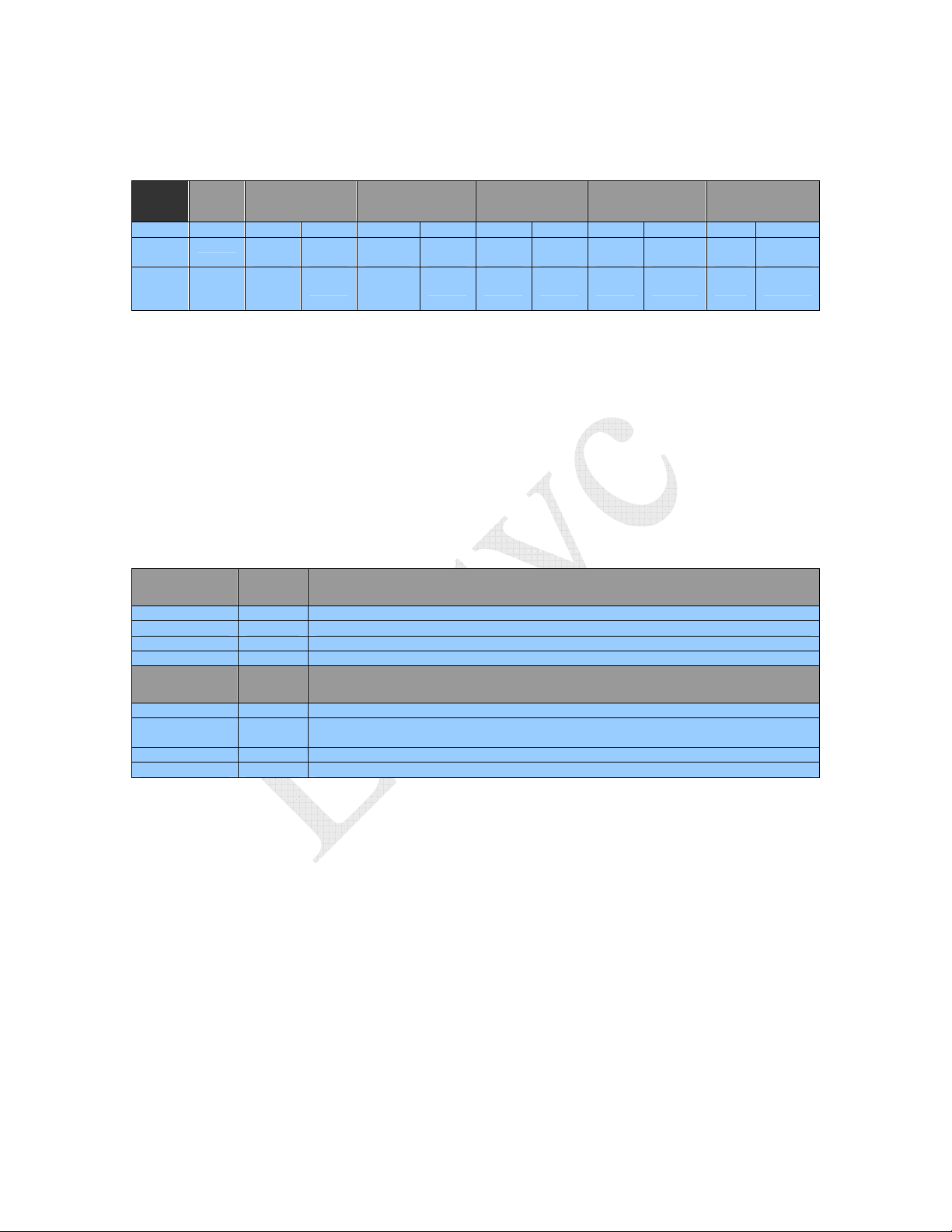

2 REVISION HISTORY

1.0 11/28/07 Initial Release

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

3 11:56:13 AM

- M

ARCH

30, 2008

Page 13

Page 14

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

3 REFERENCE DOCUMENTS

The following documents form part of this specification to the extent specified herein. In

the event of a conflict between the requirements of this specification and the associated

product drawings, referenced documents or firmware listings, the drawings, documents

and listings shall take precedence.

3.1 SPECIFICATIONS & REQUIREMENTS

MIT Auto-ID Center – Operational Specification for a UHF Radio Frequency Identification (RFID) System – Part I.

Class 1 UHF Devices - May 29, 2002

MIT Auto-ID Center – Technical Report - 860MHz–930MHz Class 1 Radio Frequency Identification Tag Radio

Frequency & Logical Communication Interface Specification Candidate Recommendation, Version 1.0.1 – November

14, 2002

EPC™ Radio-Frequency Identity Protocols Class-1 Generation-2 UHF RFID Protocol for Communications at 860

MHz – 960 MHz Version 1.0.9 – January 31, 2005

FCC - Title 47 Part 15.247 – Operation within the bands 902-928MHz, 2400-2483.5 MHz, and 5725-5850 MHz.

3.2 REFERENCE MATERIAL

Texas Instrument – TMS320F2808 Data Manual – SPRS230H – October 2003-Revised June 2006

Chipcon AS / Texas Instrument – CC1070 Single Chip Low Power RF Transmitter for Narrowband Systems –

SWRS043 - Rev 1.3

Chipcon AS – AN014 Frequency Hopping Systems (Rev 1.0) – 2002-03-20

Hittite Microwave Corporation – HMC545 GaAs MMIC SPDT Switch, DC-3 GHz – V00.0905

Triquint Semiconductor – TQM7M4006 - 3V Quad-Band GSM850/GSM900/DCS/PCS Power Amplifier Module Data

Sheet-Revision E – February 22, 2006

Mini-Circuits – ADE-2 – Surface Mount Frequency Mixer Level 7 (LO Power +7dBm) 5 to 1000MHz REV. D. –

M102713, RVN/TD/CP/AM 070412

Linear Technology – LT6231 – 215MHz, Rail-to-Rail Output, 1.1nV/Hz

623012fs

Analog Devices – ADG723 – CMOS, Low Voltage, 4Ω Dual SPST Switch – Rev B - C00045-0-2/07(B)

Analog Devices – ADG823 - <1 Ω 1.8V to 5.5V, Dual SPST Switch – REV.0 – C02851-0-8/02(0)

1/2

, 3.5mA Op Amp Family – sn623012

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

5 11:56:13 AM

- M

ARCH

30, 2008

Page 15

Page 16

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

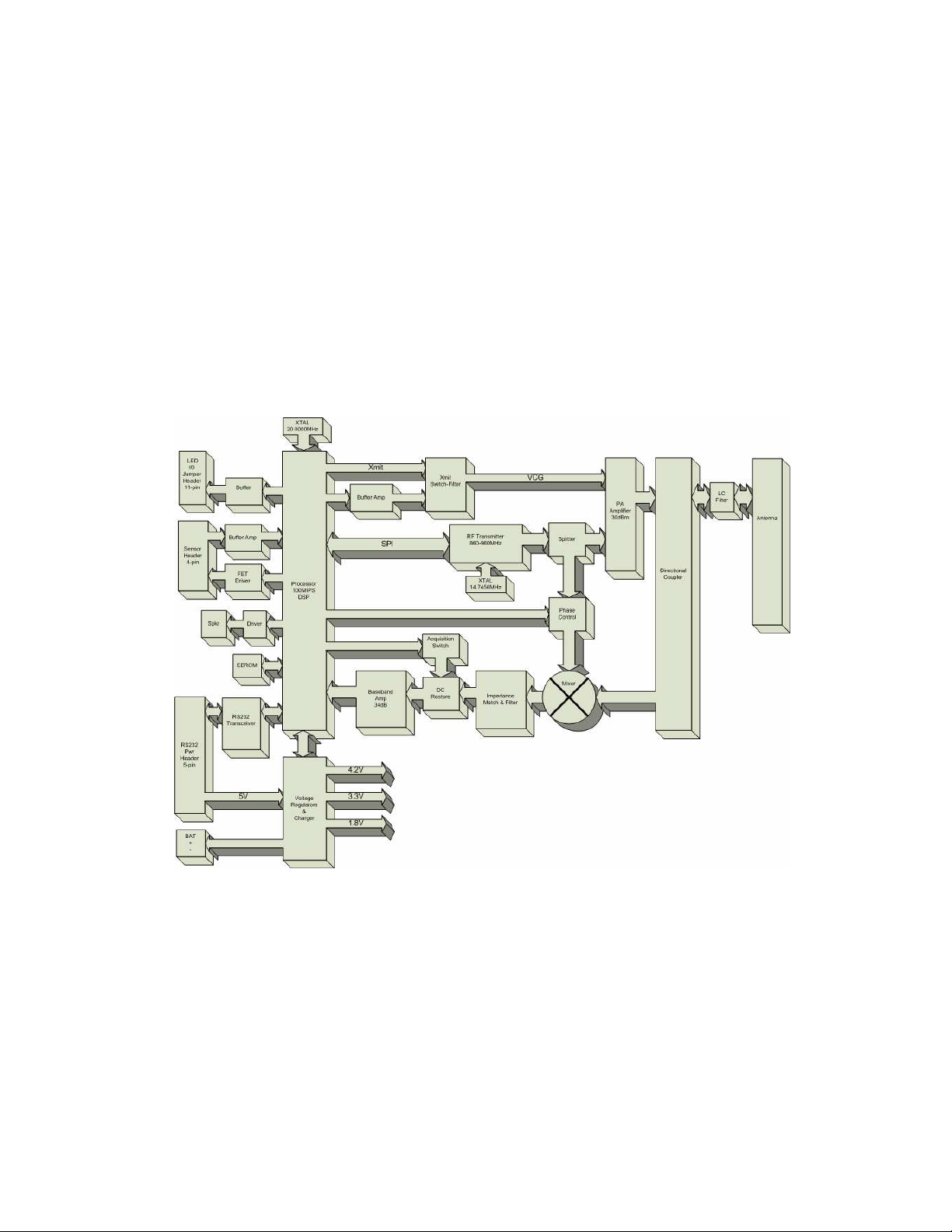

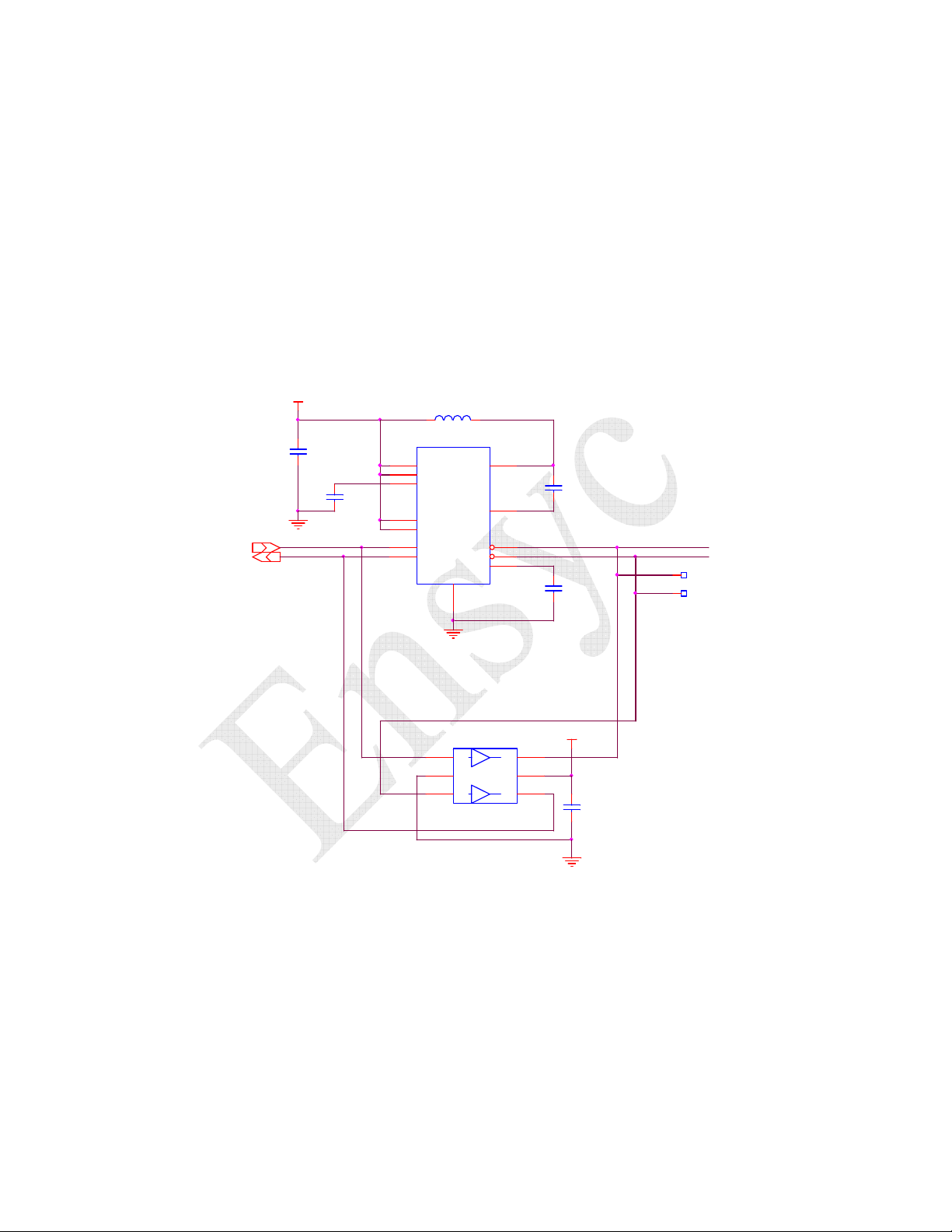

4 OVERVIEW

The RF2400 RFID Controller is a low cost implementation of a UHF RFID reader

designed specifically for short range applications. The Controller has been designed to

read, write, and verify EPC Class 1 and Generation 2 tags, is implemented as a single

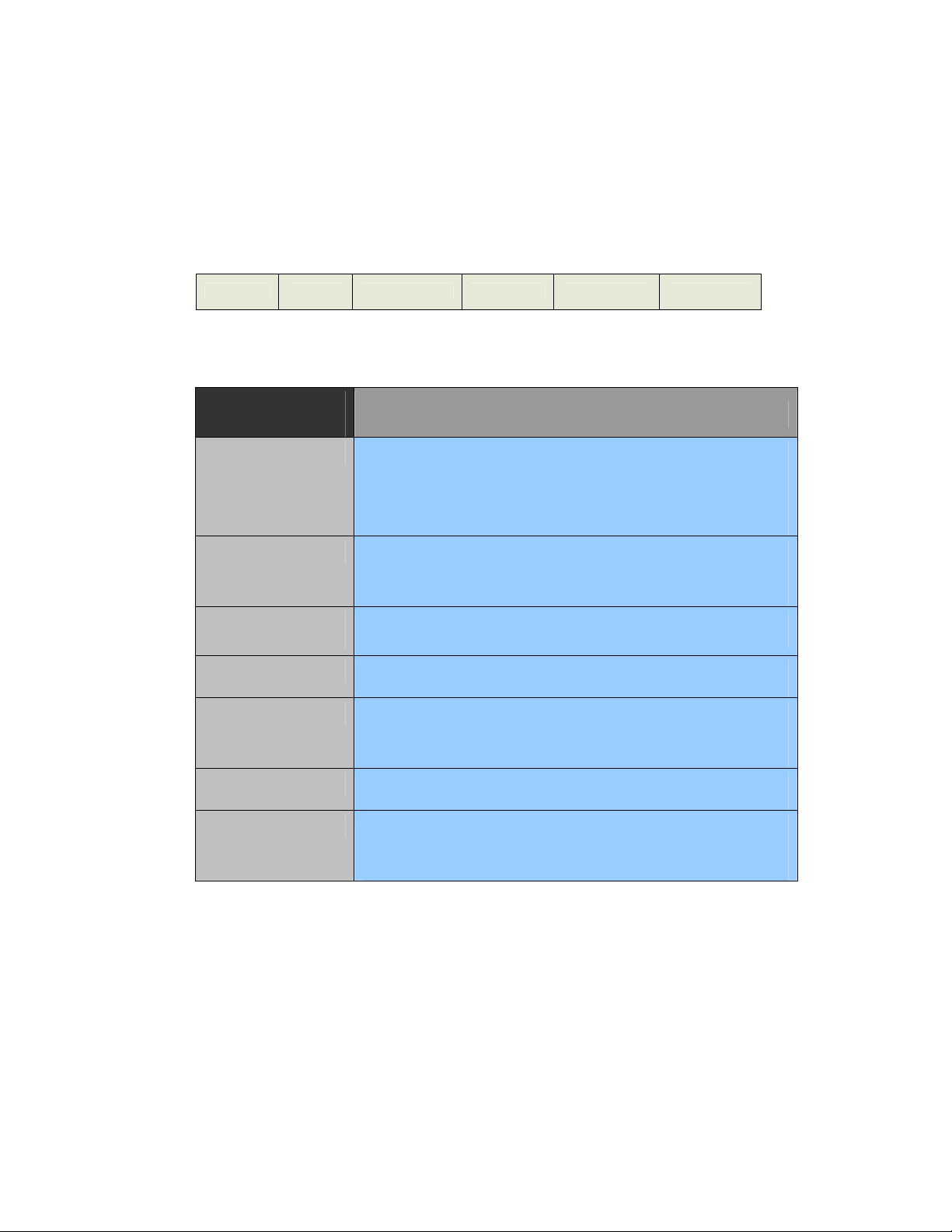

electronics module and requires a separate antenna. (Refer to Figure 4-1)

Figure 4-1 RF2400 Block Diagram

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

7 11:56:13 AM

- M

ARCH

30, 2008

Page 17

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

4.1 DSP PROCESSOR

The heart of the RF controller is a 100 MIPS DSP processor. The processor

communicates with the host over an RS232 interface using a media independent protocol.

Message packets from the host direct all RF2400 reader operations and upon completion

the processor sends a response packet.

The processor is interfaced to a highly integrated single chip UHF transmitter/VCO over

an SPI bus which provides the RF carrier and Frequency Hopping Spread Spectrum

(FHSS) signaling. Using a PWM the processor establishes the gain of a RF amplifier and

amplitude shift keys (ASK) modulates the carrier by switching this signal on/off.

The processor demodulates the backscatter signal from a tag using a high-pass filter and a

FET switch to remove the DC component from the signal and samples the output of the

base-band amplifier using a 12-bit A/D input. The processor phase locks to the signal,

synchronizes to clock edges, and follows the average signal level/gain to properly decode

the data.

Additionally, the processor controls an optical sensor to identify the presence of a tag to

implement auto interrogation. A scheme involving modulation of the sensor emitter and

demodulation of the reflected signal is used as a means to suppress ambient light and

improve the reliability of the sensor. The sensor input can be configured as a switch

input and used to manually trigger reads.

Finally, the processor drives several LEDs to indicate power, activity and error

conditions as well as a speaker to attract user attention.

4.2 TRANSMITTER CIRCUITRY

An integrated single chip transmitter is used and controlled by the DSP processor to

produce the RF carrier required to communicate with a UHF RFID tag. Additionally,

this component incorporates the necessary circuitry to implement Frequency Hopping

Spread Spectrum (FHSS) signaling for noisy environments and to meet agency spectral

requirements. To enhance speed of operation, the Transmitter/VCO includes dual sets of

frequency control registers to allow overlapped frequency configuration during operation.

UHF frequency is synthesized from an inexpensive crystal using a programmable

fractional divider to achieve high resolution and is ideal for narrow band applications. An

external loop filter is provided to meet the stabilization requirements imposed by FHSS.

A power splitter is used to divide the VCO output for use as both a local oscillator and

RF carrier. An LC phase shifter between the splitter and mixer is used to select the inphase and 90 degree phase components providing a mechanism to compensate for the

phase of the received signal

A 2-watt GSM Power Amplifier is used to boost the RF carrier and is adjustable from

0dBm (1mW) to 24dBm (250mW). The amplifier is designed for low cost cellular phone

applications and requires only a few external power filtering components. Output power

is adjusted using a voltage control input from the DSP processor. A PWM output sets the

voltage which is filtered by a 2-pole Sallen-Key low-pass filter. The filtered voltage is

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

8 11:56:13 AM

- M

ARCH

30, 2008

Page 18

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

switched to the power amplifier through two independent time constants. This shaping

meets EPCTM and FCC requirements reducing transmit spurs by controlling the on and

off rate of the power amplifier. The output of the amplifier is connected to the antenna

using a PCB implemented directional coupler with 8dB coupling loss and directivity

between 25dB and 30dB. A LC PI filter couples the output of the filter to the antenna

filtering any harmonic components.

4.3 RECEIVER CIRCUITRY

Tag backscatter is coupled to a precision mixer from the directional coupler. The output

of the mixer is coupled to the receiver circuitry using an impedance matching amplifier.

An acquisition switched high-pass filter removes the DC component before applying the

signal to the 34dB base-band amplifier/800KHz filter. The amplified signal is sampled

by the DSP using a 12-bit A/D input. The DSP processor tracks the average value of the

signal; phase locks to the signal, and synchronizes to the clock edges in order to decode

the data.

4.4 USER INTERFACE

The RF2400 reader is interfaced to the host using an RS232 serial connection.

Commands and responses are communicated using packets. The protocol includes

commands to configure and status the reader as well as commands to program and read

tags. Several LED outputs and an integrated speaker provide user feedback of power,

activity and error conditions. A separate optical sensor interface allows to processor to

sense presence of a tag providing a means to auto interrogate the tag

4.5 POWER REGULATION

The RF2400 reader is powered from a single 5volt power source and requires only 900

mA to provide 24dBm(250mW) of RF power. Main 5 volt power is converted to 4.2

volts by a Li-Ion battery charger. This can charge an optional battery for portable

operations. The 4.2V power is used directly by the RF power amplifier but also feeds the

3.3volt low noise RF power and 1.8 volt processor core voltage LDO regulators.

4.6 BATTERY OPERATION

An optional 3.7V 3200mA/hr Li-Ion battery can be used for remote operation. A battery

charging circuit maintains the battery voltage between 4.0 and 4.1V. In order to extend

battery life and prevent overheating and the possibility of explosion, both the battery and

charging circuit include protection circuitry. Additionally, firmware monitors the charge

state and shuts down the charger when the battery is fully charged.

While operating on battery, steps have been taken to reduce the operating current in order

to extend the operational time between charges. Normally the processor runs at

100MHz, which is required while accessing tags. When idle, the processor clock is

decreased to 20 MHz, greatly reducing the required current.

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

9 11:56:13 AM

- M

ARCH

30, 2008

Page 19

Page 20

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

5 FUNCTIONAL DESCRIPTION

The RF2400 reader is a radio frequency identification (RFID) communication interface

designed specifically for short range applications. The reader interfaces to a host

processor with an industry standard RS232 or optional USB interface adapter using a

media independent protocol. The RF2400 reader supports the reader commanded

functionality required for both the Auto-ID Center Class1 and Gen 2 Tags operating in

the frequency range of 860MHz-960MHz.

5.1 HOST PROTOCOL

This section describes the format and commands for the bi-directional communication

between the RF2400 reader and the host including command codes, parameters, and

response data.

Commands are divided into several code groups:

00 – 1F setting and retrieving RF2400 reader parameters

20 – 3F reader-to-tag modulation commands that return a single response message

40 – 4F reader-to-tag modulation commands that result in a tag-list response

50 – 5F tag programming commands

60…6F setting and retrieving RF2400 reader configuration data

D0 – DF loading RF2400 firmware code

F0 – FF reserved for managing a tag list

The following section describes the binary protocol for serial communication between

the host and the RF2400 Module. This protocol is media independent and can be

implemented using RS232, USB, or other serial interfaces

5.1.1 Message Format

Messages encapsulate commands from the host and responses from the RF2400 reader

that are sent as packets over the serial interface between the host and the RF2400 reader.

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

11 11:56:13 AM

- M

ARCH

30, 2008

Page 21

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

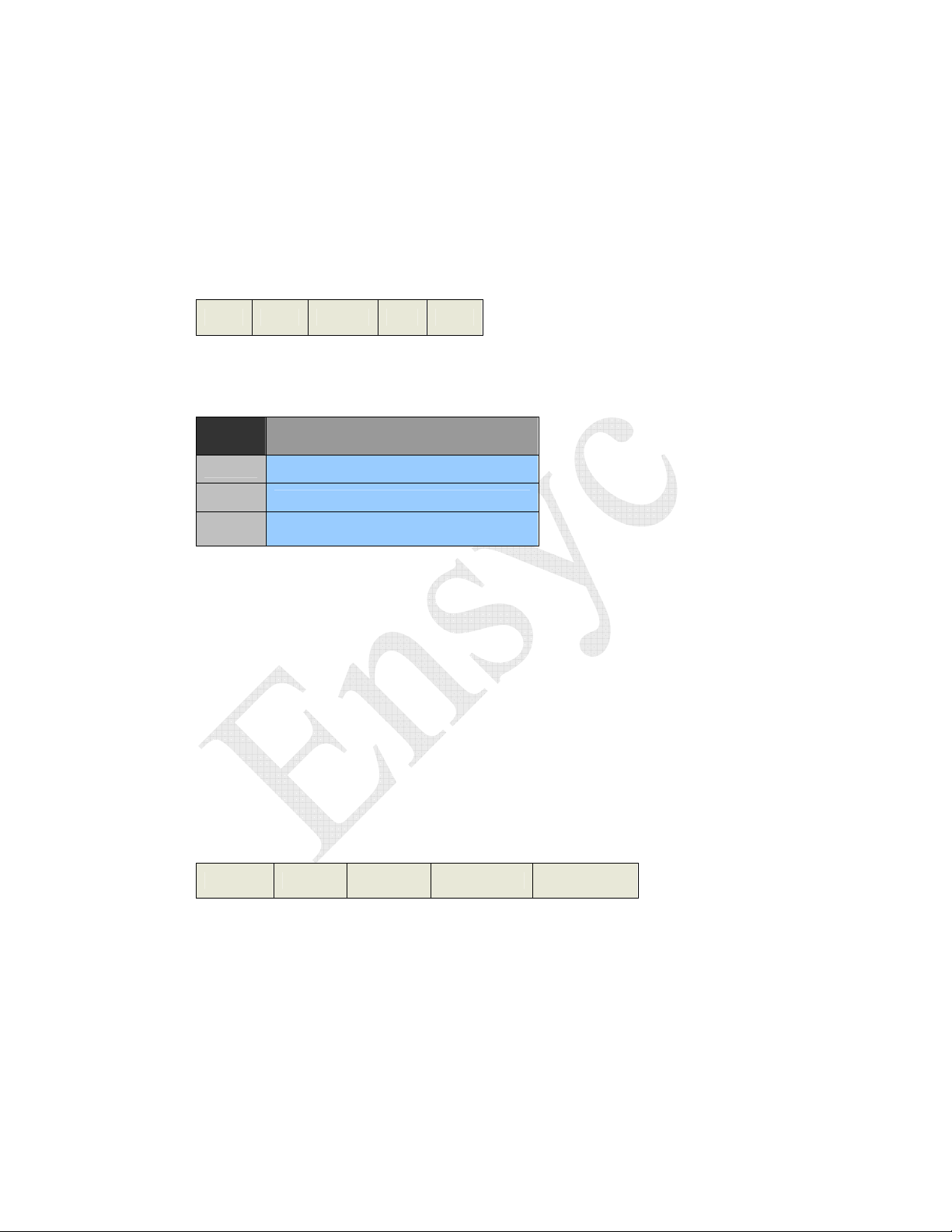

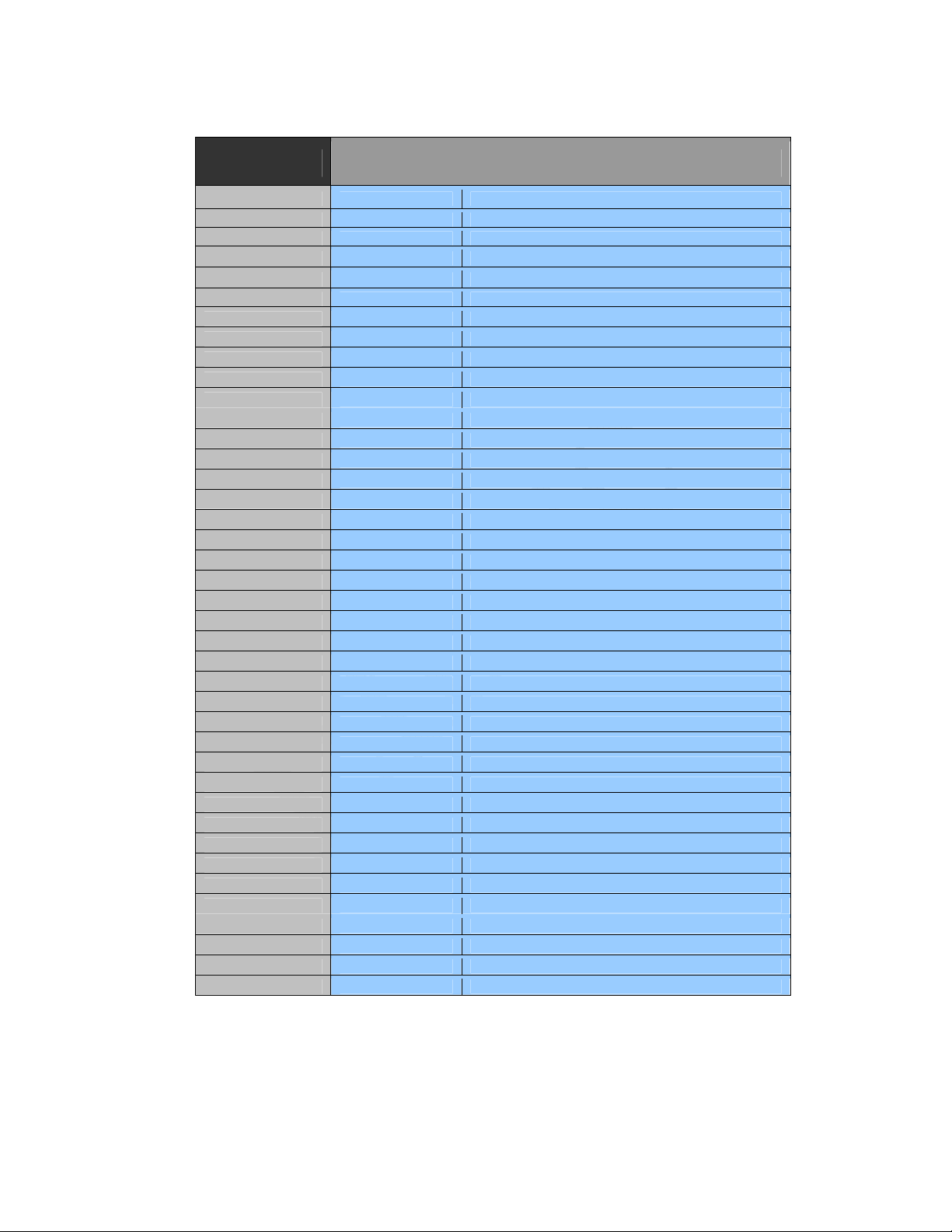

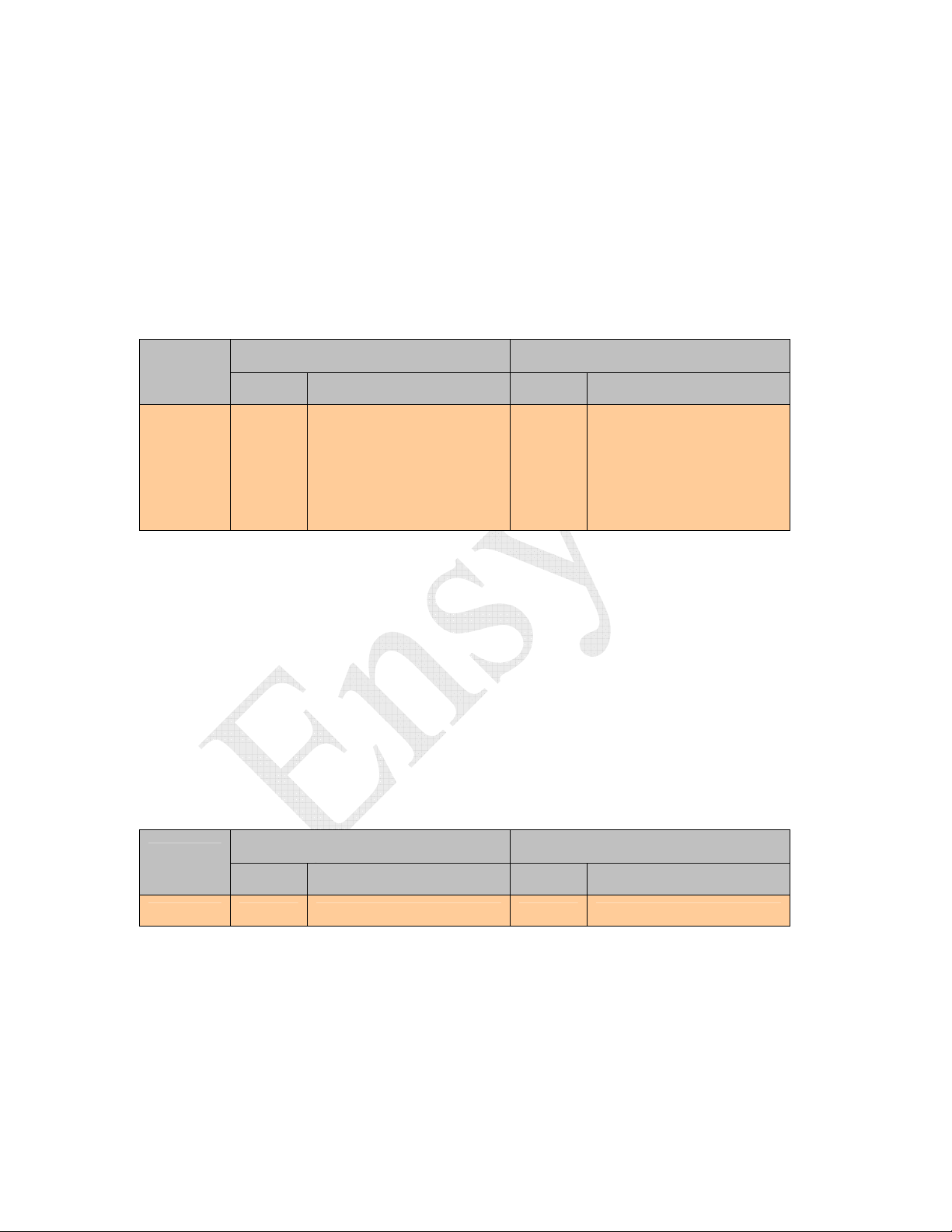

5.1.1.1 Message Packet Format

Messages between the host and reader are binary data packets, consisting of a message

payload encapsulated with two bytes preceding any message (

completing any message (

[DLE][EOM]

). All communications are initiated by the host.

[DLE][SOM]

) and two bytes

(Refer to Figure 5-1 and Table 5-1)

Note: ITEMS IN PARENTHESIS (…) ARE NOT REQUIRED FOR ALL MESSAGES.

[DLE] [SOM] [Payload] [DLE] [EOM]

Figure 5-1 Message Packet Format

Token Description

[DLE]

[SOM]

[EOM]

Data Link Escape token; 0x10

Start of Message token; 0x01

End of Message token; 0x02

Table 5-1 Message Encapsulation Characters

In order to avoid ambiguities, if a data value in the payload is a DLE (0x10) character, the DLE (0x10) is

repeated as the message packet is formed.

5.1.1.2 Host-to-Reader Payload

The host to reader payload includes a session identification

number

(CommandData)

[Reader#]

,

a command to execute

, followed by a two byte CRC

[Command]

[CRC-CCITT16]

[SessionID]

,

optional command data

,

a target reader

. (Refer to Figure 5-2 and

Table 5-2)

[SessionID] [Reader#] [Command] (CommandData) [CRC-CCITT-16]

Figure 5-2 Host to Reader Payload Format

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

12 11:56:13 AM

- M

ARCH

30, 2008

Page 22

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

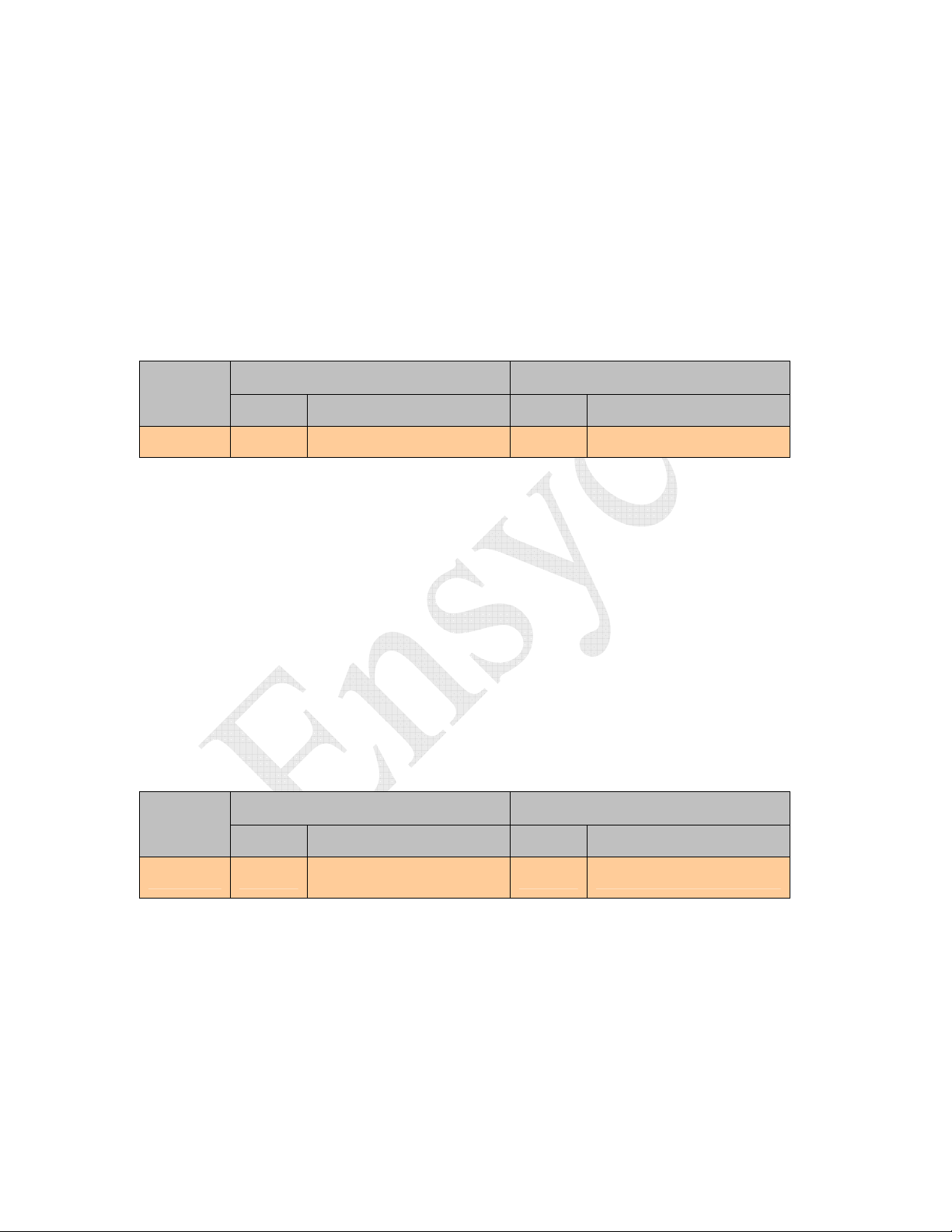

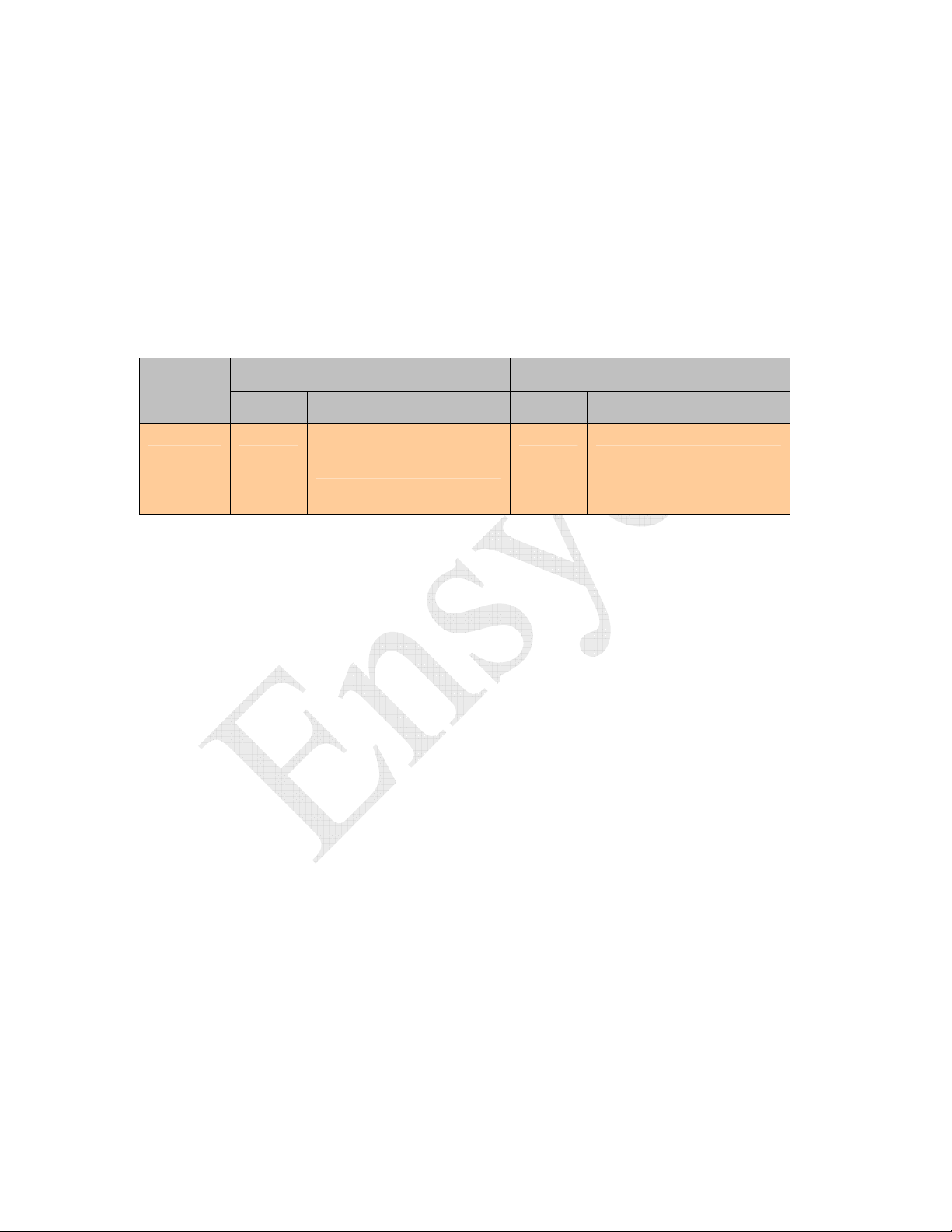

5.1.1.3 Reader-to-Host Payload

The reader to host payload includes a session identification

number

[CommCode],

CCITT16]

[Reader#]

,

the command executed

optional response data

[CommandEcho],

(ResponseData)

, followed by a two byte CRC

. (Refer to Figure 5-3, Table 5-2 and Table 5-3)

[SessionID]

,

a target reader

type of communication

[SessionID] [Reader#] [CommandEcho] [CommCode] (ResponseData) [CRC-CCITT16]

Figure 5-3 Reader to Host Payload Format

Payload

Field

Description

[CRC-

[SessionID]

[Reader # ]

[Command]

[CommandEcho]

(CommandData)

[CommCode]

(ResponseData)

[CRC-CCITT16]

Single-byte value. Every command gets a new number defined by the host.

Every response matches the session ID of the initiating command. Normal

session IDs can range from 0x01 to 0xFF. A SessionID of 0x00 in a

command message forces the reader to repeat the previous response. This

feature allows the Host to request the previous response in case of a

communication error.

Single-byte value. In a Host command, a Reader # of 0x00 indicates that the

command is addressed to all readers. A Reader will reply to commands only

if its internal RDRNUM matches or if a command is addressed to all readers

The factory default reader number is 0xFF.

Single-byte value. Defines the command to be executed or has been

executed (refer to section 5.1.2 for details).

Variable length value specifying command parameters (refer to the section

5.1.2 for details)

Single-byte value. Indicates the type of message or error. CommType < 0x80

indicates that a valid command was received. CommType >= 0x80 indicates

that an error occurred, either in the command format, parameters, or in the

execution of the command. (refer to Table 5-3 for details)

Contains a variable number of bytes (including none) (refer to section 5.1.1.4

for details).

Two bytes of CRC-CCITT16 polynomial (X^16+X^12+X^5+1) seed 0xFFFF.

The CRC is calculated over all data from Session ID to Response Data

inclusive. DLE packetization is not included into the CRC. The CRC is sent

MSB first, LSB last.

Table 5-2 Command/Response Payload Fields

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

13 11:56:13 AM

- M

ARCH

30, 2008

Page 23

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

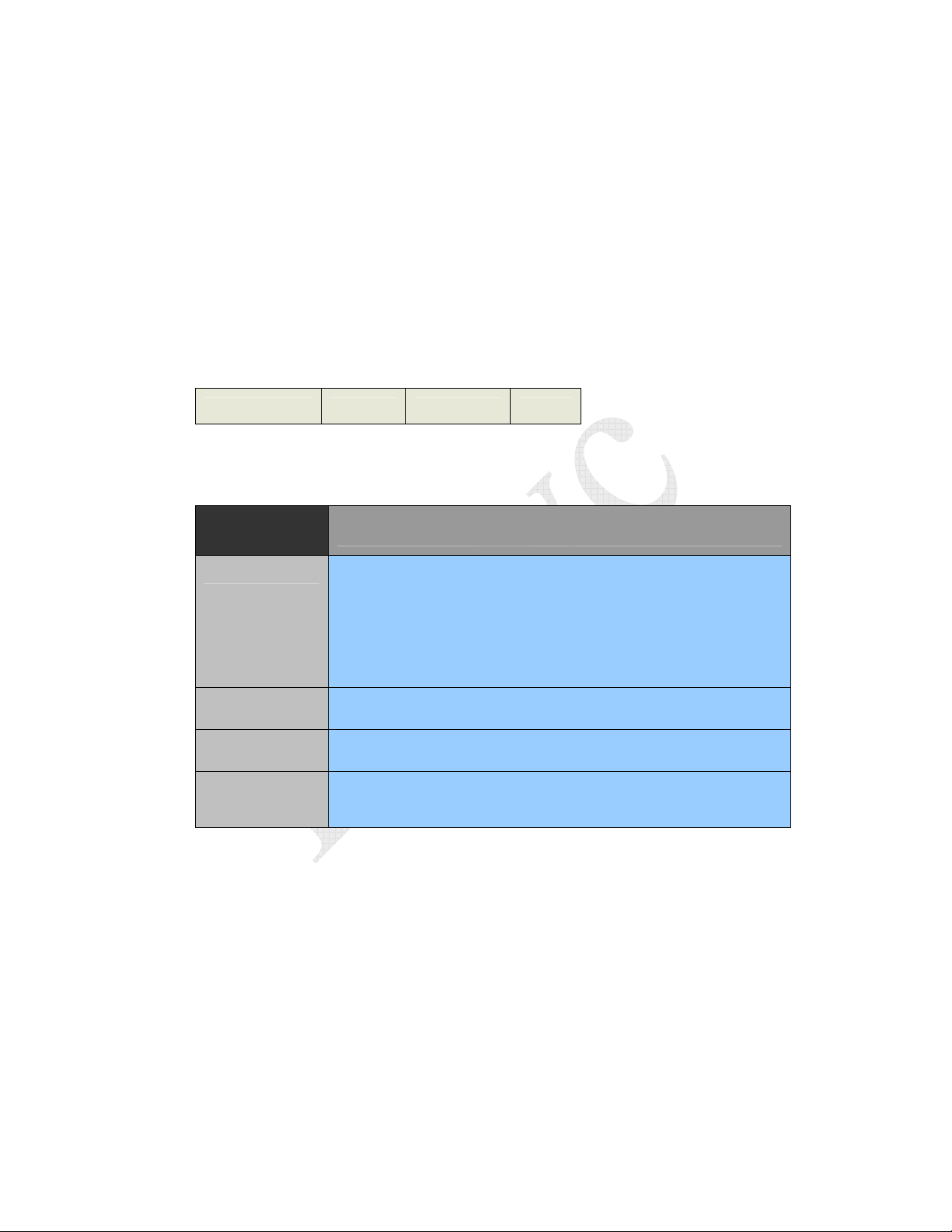

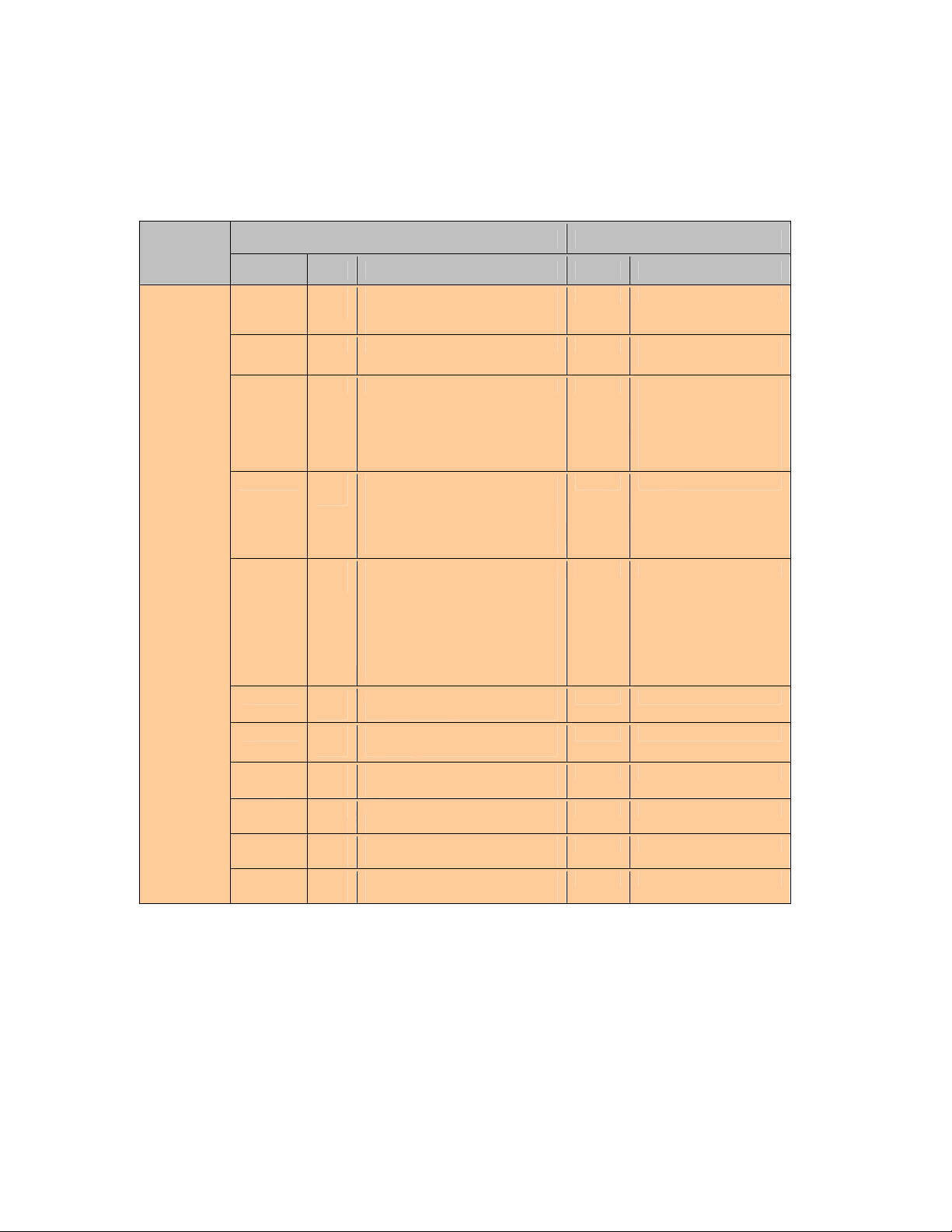

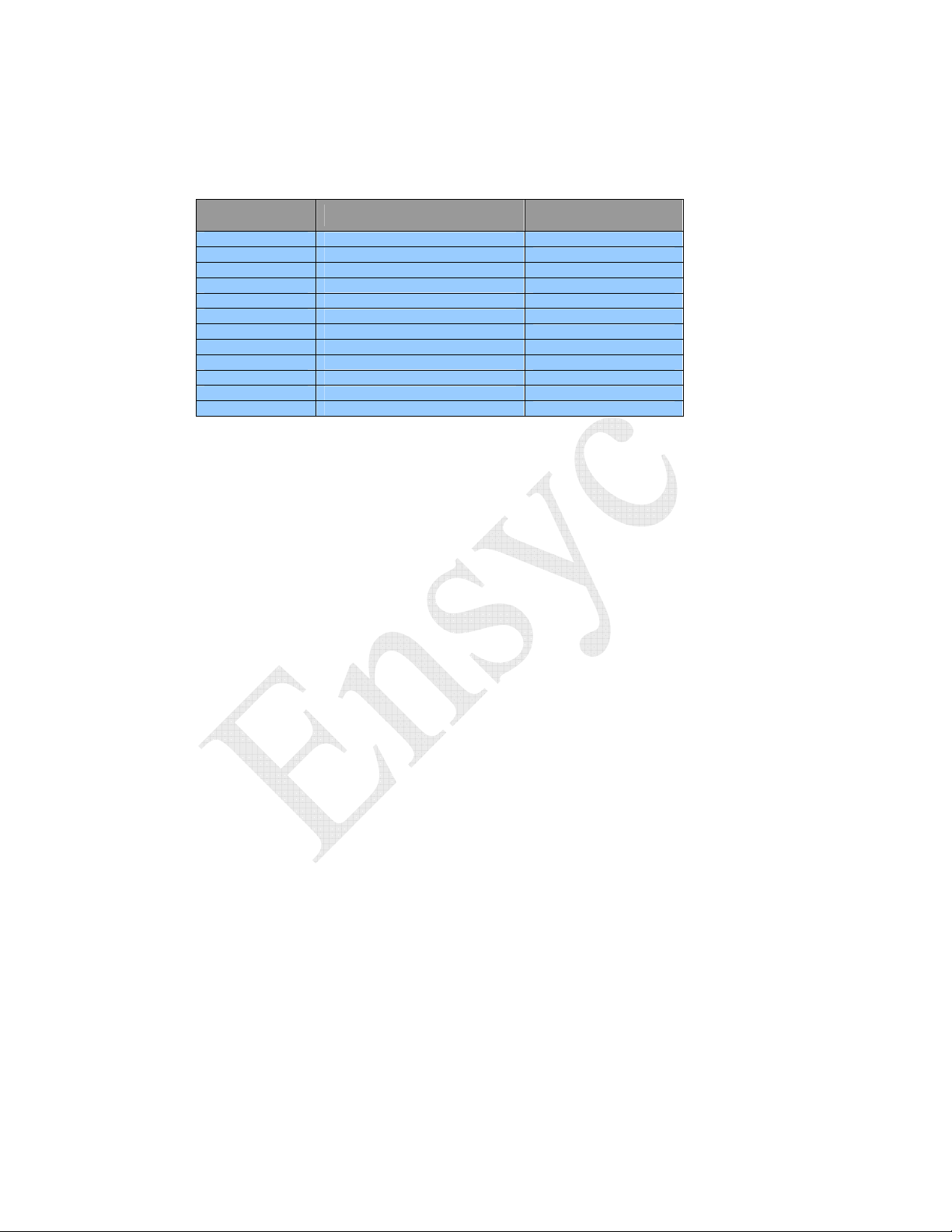

CommCode Description

0x00

0x01

0x02

0x03

0x04

0x05

0x06

0x07

0x08

0x09

0x0A

0x0B

0x0C

0x0D

0x40

0x41

0x81

0x82

0x83

0x84

0x85

0x86

0x87

0x88

0x89

0x8A

0x8B

0x8C

0x8D

0x8E

0x8F

0x90

0x91

0x92

0x93

0x94

0x95

0x96

0x97

0x98

MSGOK Success

STARTINV Starting inventory message

TAGINV Tag Data inventory message

ENDINV Ending inventory message

STARTLIST Starting list dump

RECLIST List dump data record

ENDLIST End of list dump

STARTDIAG Starting diagnostic message

DIAGDATA Diagnostic data message

ENDDIAG End of diagnostic message

UPLOADOK Upload line success

UPLOADEND Upload complete

SUSPEND Reader entering suspend state

RESUME Reader resuming from suspend state

NO PASSW Kill password is locked, can’t be read

LOCKNPW EPC locked but Kill password not set because locked

UNKLEN Unknown message length

UNKVAL Unknown value

UNKCMD Unknown command

UNKTAGCMD Unknown or disabled tag command

OVRERR Overflow error on directed list entry

NOTAG No tag to read or program

ERASEFAIL Erase failure

PROGFAIL Program data verification error

TAGLOCK Tag is locked, cannot program error

KILLFAIL Kill failure

LOCKFAIL Lock attempt failure

DATASIZE Tag data memory size mismatch

HWERR Hardware error

LISTFULL List for directed inventory is full

UPLOADERR Upload line contained an error

UPLOADINV Command invalid for bootloader

UPLOADCRC Upload Program Memory CRC Error

NVFAIL EEPROM error

RESV Reserved

RESV Reserved

UNKIDLEN Unknown ID Length

TAGLOST Tag lost after earlier communication

TAGNXM Addressed word doesn’t exist

LOGFULL EEPROM ID storage is full

Table 5-3 Communication Codes

CommCode < 0x80 indicates a successful operation, CommCode >= 0x80 indicates an error condition of

some kind.

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

14 11:56:13 AM

- M

ARCH

30, 2008

Page 24

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

5.1.1.4 Response Data Formats

The following sub-sections detail specific response data formats

5.1.1.4.1 Simple Command Response

The RF2400 reader responds to a simple command (for example getting a reader

parameter) with the specified number of bytes.

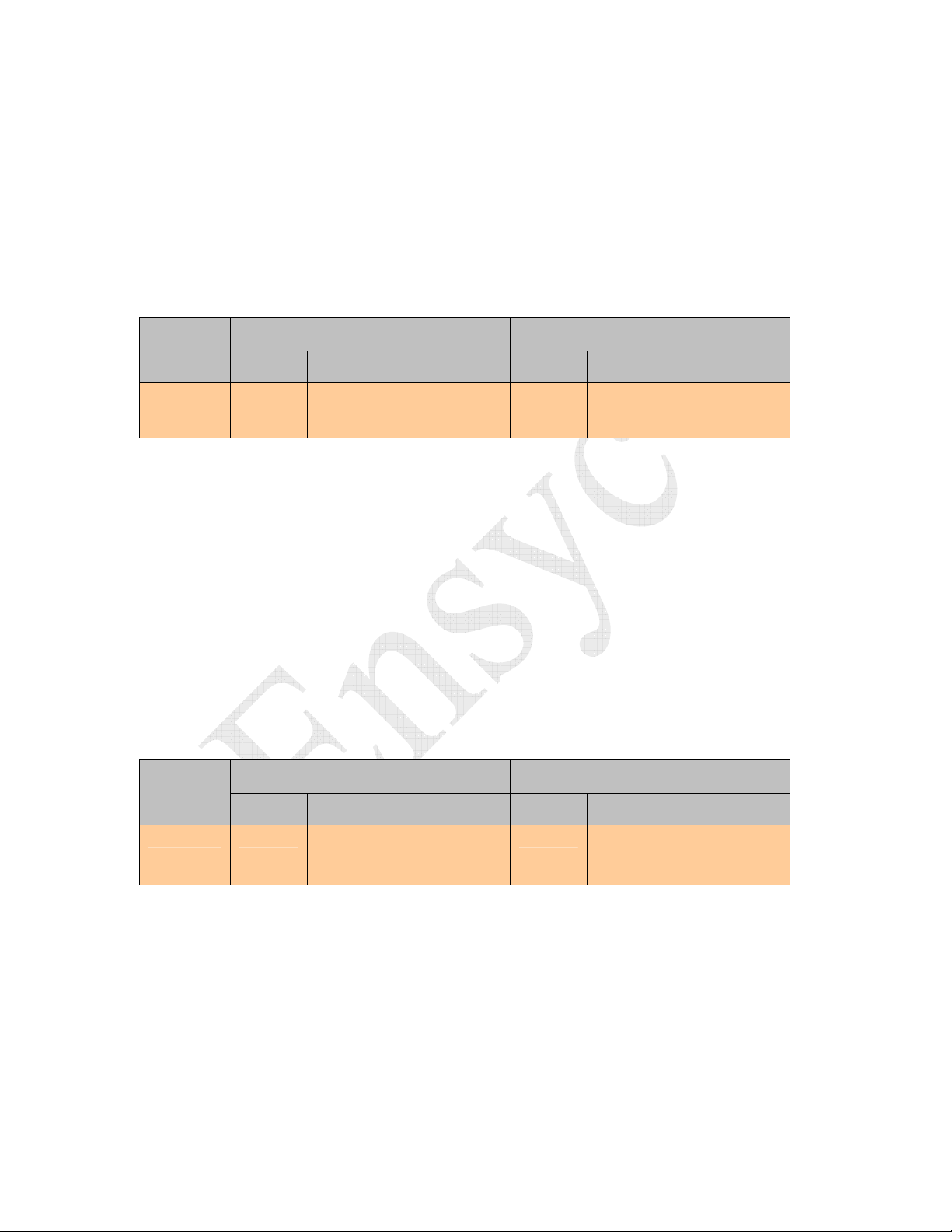

5.1.1.4.2 Low-Level Command Response

In response to a tag-related low-level command such as Get Tag ID. The Response Data

is sent to the Host in the following format (Refer to Figure 5-4 and Table 5-4)

[TagDecodeStatus] [Antenna#] (TagDataLength) (TagData)

Figure 5-4 Low-Level Command Response

Low-Level

Field

[TagDecodeStatus]

[Antenna # ]

(TagDataLength)

(TagData)

Description

Single-byte value indicating status of data acquisition by a low-level command

0x00 – Good ID

0x01 – No tag

0x02 – Collision

0x03 – CRC Error (returned for Get Tag ID only)

Bit4 – Kill password is locked

Bit5 – Access password is locked

Single-byte value indicating the Antenna number used for the current air

interface transaction. The only valid value for the RF2400 is 0x00

Length of Tag Data in bytes

Included for TagDecodeStatus of 0x00 "GoodID and 0x03 "CRC Error" only

Variable length defined by TagDataLength. Data is sent MSB first ending with

the LSB of the last byte.

Included for TagDecodeStatus of 0x00 "GoodID and 0x03 "CRC Error" only

Table 5-4 Low-Level Response Fields

5.1.1.4.3 Error Response

The RF2400 reader responds to every host command except when a communication error

is detected. If a reader detects a CRC Error in a host payload, the message will be

ignored. However, if the host detects a CRC Error, it may request the previous response

by sending a packet with a

[SessionID]

of zero.

If the host payload is less than four bytes long including the two bytes of CRC (no

Reader# or Command) the reader will ignore the message. If the payload is four bytes

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

15 11:56:13 AM

- M

ARCH

30, 2008

Page 25

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

long including the two bytes of CRC (no Command), the reader will respond with a 0x81

UNKLEN “unknown message length”

[CommCode]

.

5.1.2 Reader Commands

The RF2400 controller responds to numerous commands using the media independent

format described in paragraph 5.1. These commands provide a mechanism to configure

(Set) the reader as well as retrieve (Get) reader status. The reader will respond to all Set

commands with an echo of

followed by a two byte CRC

will respond to all Get commands with an echo of

[CommCode]

CCITT16]

and a variable length

as described in paragraphs 5.1.1.3 and 5.1.1.4.

[SessionID], [Reader#], [CommandEcho]

[CRC-CCITT16]

(ResponseData)

as described in paragraph 5.1.1.3. The reader

[SessionID], [Reader#], [CommandEcho],

field followed by a two byte CRC

, and

[CommCode]

[CRC-

Any command may result in a

[CommCode]

of one of the following: MSGOK, UNKLEN,

UNKVAL, and UNKCMD as defined in Table 5-1. Other possible codes are identified in

the description of the specific command. If the RF2400 has been initialized into its

integral bootloader firmware, there will be no response to host reader commands

5.1.2.1 Get Firmware Version (0x00)

The Reader will reply with five (5) bytes specifying Localization Code, Reader Type,

and Firmware Version Number. Response data is in binary hex format.

The localization code and the reader type are stored in non-volatile memory and

automatically configured for USA (0x01) operation on the initial firmware upload.

Subsequent firmware updates preserve the existing configuration in non-volatile memory.

Command

Code

0x00 0 Bytes

Size Valid Values Size Valid Values

Command Data Response Date

--

5 Byte

1st Byte -- Localization Code

0x01 -- USA

0x02 -- Japan

0x03 -- E.U.

2nd Byte -- Reader Type

0x09 – RF1200 Reader

0x0A – RF2400 Reader

3rd Byte -- 0x00

4th Byte -- Major Revision #

5th Byte -- Minor Revision #

Table 5-5 Get Firmware Version

COMMAND DLE SOM SesID Rdr# Cmd CRCH CRCL DLE EOM

10 01 01 FF 00 54 0C 10 02

RESPONSE DLE SOM SesID Rdr# Echo Mtype Local Rtype Nused FverH FverL CRCH CRCL DLE EOM

10 01 01 FF 00 00 01 09 00 00 0A 75 A8 10 02

Get Firmware Version Example

Note: this example reflects firmware version V0.10

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

16 11:56:13 AM

- M

ARCH

30, 2008

Page 26

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

5.1.2.2 Set Baud Rate (0x03)

This command will only accept 0 thru 5 as valid data fields. The reader will respond to

the command at the old baud rate before changing to the new rate. The updated baud rate

will be stored in non-volatile memory replacing the previous value. The factory default

setting is 19,200 baud using 8 data bits, no parity, and one stop bit.

If the user inadvertently sets the baud rate to one not supported by the host, a hardware

reset is provided. Disconnect power from the board, connect pins 1 to 2 of the 11 pin

connector, re-connect power. The EEPROM will be reset to defaults (19,200 baud).

Command

Code

0x03 1 Bytes Baud Rate

Size Valid Values Size Valid Values

Command Data Response Date

0 Byte - 0x00 9,600

0x01 19,200 (default)

0x02 38,400

0x03 57,600

0x04 115,200

Table 5-6 Set Baud Rate

5.1.2.3 Set IO Port Value (0x05)

Sets or clears specified output port pins. Ports start at LSB corresponding to physical port

0 and are bitmapped toward the MSB. The RF 2400 has two bi- directional IO ports. Bits

in the send data with no corresponding physical port will be ignored. Additionally, since

the RF2400 IO ports are bi-directional, the value will be ignored in the case of the

corresponding port pin defined as input. A bit value of 1 in the send data will cause the

corresponding port to be driven high. A bit value of 0 will cause the corresponding port

pin to be pulled low. A Get Reader Hardware Information command can be issued to

determine the number and type of output ports available. The Set Bi-Directional I/O

DDR and Get Bi-Directional I/O DDR commands may be used to setup and determine

the I/O port configuration.

Command

Code

0x05 1 Bytes 0x00 -- 0xFF 0 Byte --

Size Valid Values Size Valid Values

Command Data Response Date

Table 5-7 Set IO Port Value

COMMAND DLE SOM SesID Rdr# Cmd Data CRCH CRCL DLE EOM

10 01 01 FF 05 01 F8 26 10 02

RESPONSE DLE SOM SesID Rdr# Echo Mtype CRCH CRCL DLE EOM

10 01 01 FF 05 00 E8 07 10 02

Set IO Port Value Example

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

17 11:56:13 AM

- M

ARCH

30, 2008

Page 27

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

5.1.2.4 Get IO Port Value (0x06)

This command returns the current state of the input port pins. Response data is a bitmap

with the LSB corresponding to physical port 0. The RF2400 reader has two bidirectional ports and will return a 0 bit value for all remaining bit positions.

Additionally, since the RF2400 IO ports are bi-directional, any port defined as an output

will return the current level of the IO port. A Get Reader Hardware Information

command can be issued to request the hardware configuration. The Set Bi-Directional

I/O DDR and Get Bi-Directional I/O DDR commands may be used to setup and

determine the I/O port configuration.

Command

Code

0x06 0 Bytes -- 1 Byte 0x00 -- 0xFF

Size Valid Values Size Valid Values

Command Data Response Date

Table 5-8 Get IO Port Value

COMMAND DLE SOM SesID Rdr# Cmd CRCH CRCL DLE EOM

10 01 01 FF 06 34 CA 10 02

RESPONSE DLE SOM SesID Rdr# Echo Mtype Data CRCH CRCL DLE EOM

10 01 01 FF 06 00 01 17 0F 10 02

Get IO Port Value Example

Note: this example assumes that the SET IO Port and Set Bi-Directional I/O DDR examples have been executed first

5.1.2.5 Get Reader Status (0x0F)

This command returns operating status information from the reader. The sensor status

returns the state of the optical sensor indicating the presence of a tag for subsequent

RFID interrogation.

Command

Code

Size Valid Values Size Valid Values

Command Data Response Date

0x0F 1 Bytes

0x00 General Status

0x10 Get Sensor Status

1 Byte 0x01 Tag Present (Reflection)

Table 5-9 Get Reader Status

Note: When getting general status, if the EEPROM log is full, the Mtype returned will be

0x98 (LOGFULL).

COMMAND DLE SOM SesID Rdr# Cmd Sub Rpt CRCH CRCL DLE EOM

10 01 01 FF 0F 10 10 3D F7 10 02

RESPONSE DLE SOM SesID Rdr# Echo Mtype Data CRCH CRCL DLE EOM

10 01 01 FF 0F 00 01 BF 73 10 02

Get Sensor Status Example (with reflection)

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

18 11:56:13 AM

- M

ARCH

30, 2008

Page 28

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

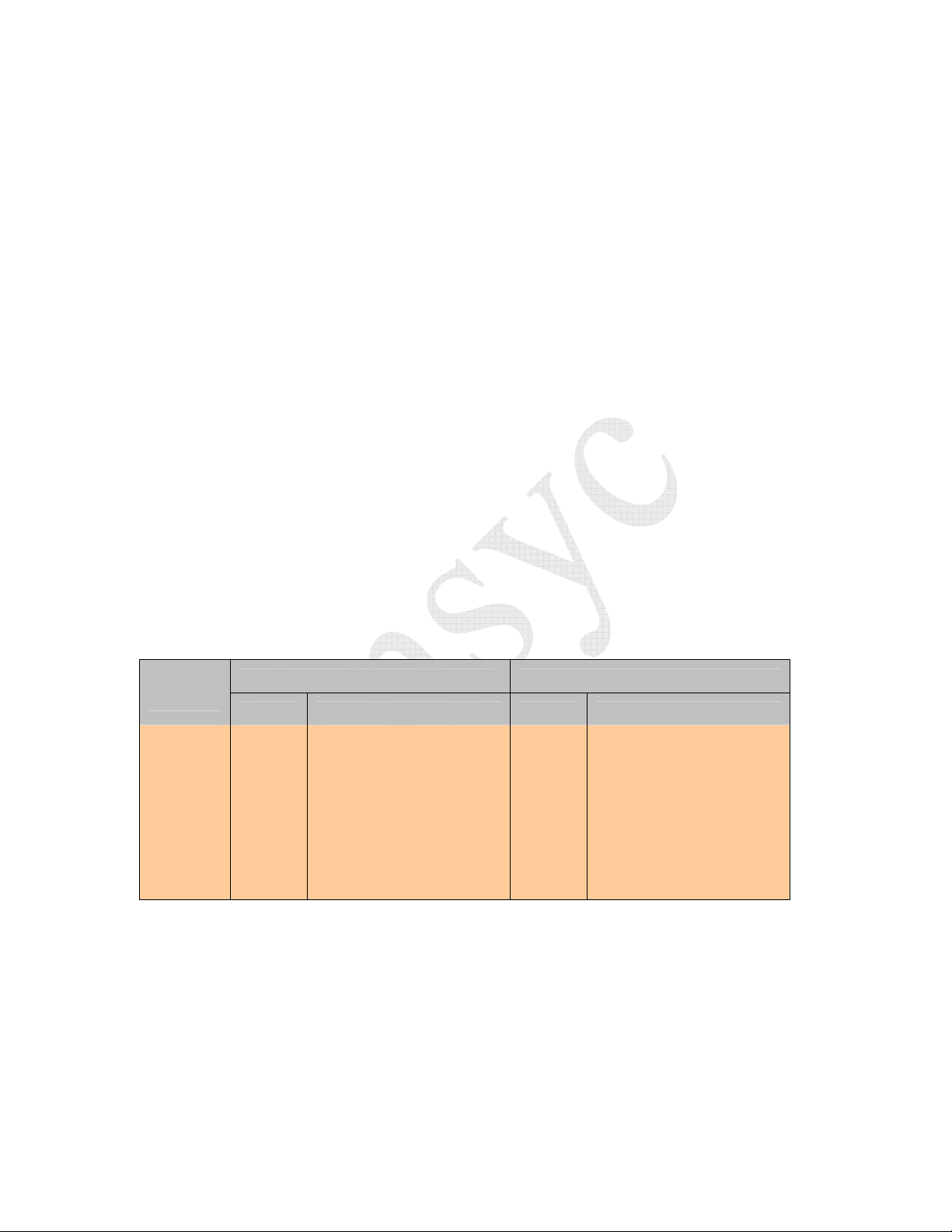

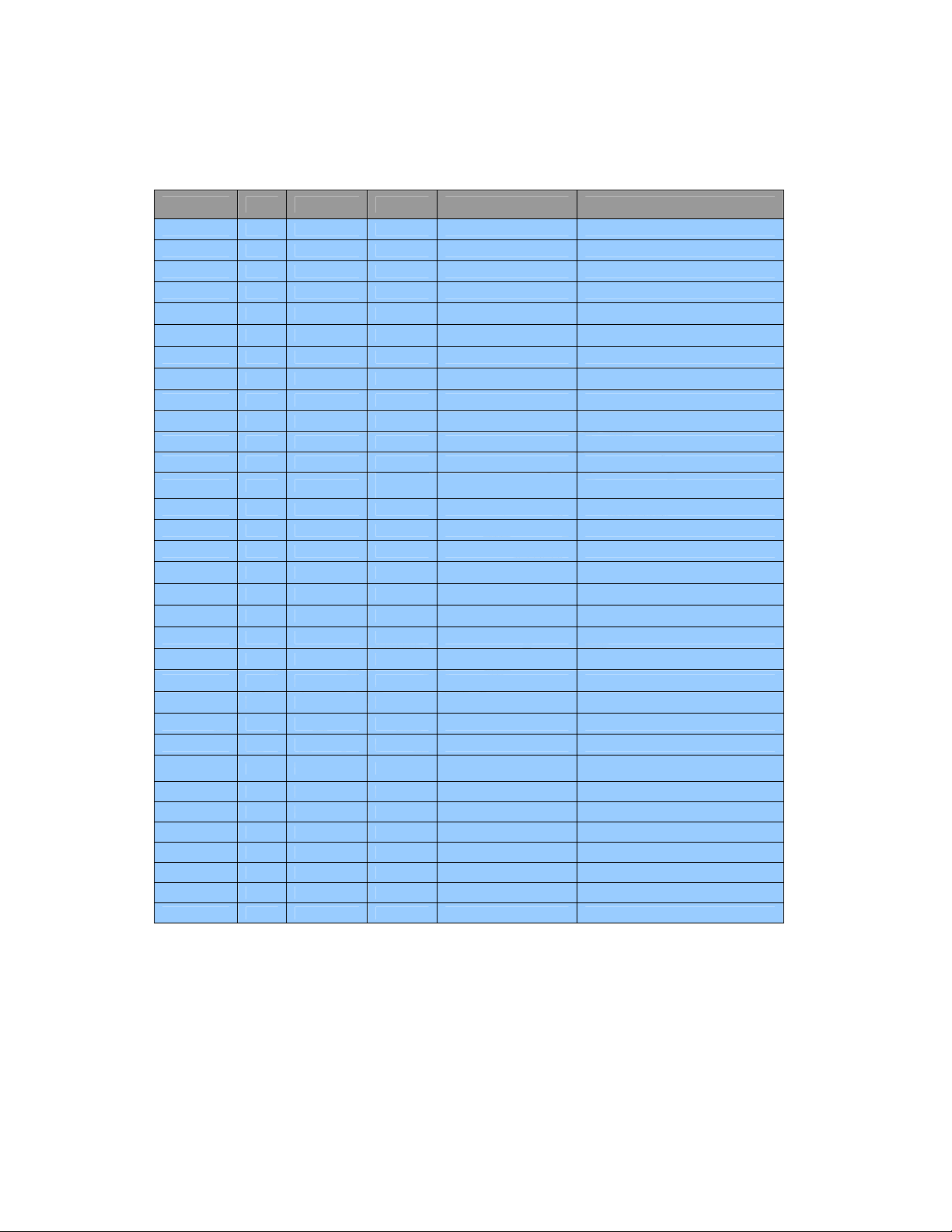

5.1.2.6 Get Reader Hardware Information (0x11)

The Get Reader Hardware Information command provides a mechanism for the host to

identify various aspects of the hardware. Command Data values are used to select

specific parameters.

Command

Code

0x11

Command Data Response Date

Size Valid Values Size Valid Values

1 Byte 0x01 – Get Bidirectional ports (1) 1 Byte

1 Byte 0x02 – Get Flags

1 Byte 0x05 – Get Reader Type (1) 1 Byte

1 Byte 0x06 – Localization Code (1) 1 Byte

1 Byte 0x07 – Radio Type (1) 1 Byte

1 Byte 0x11 -- Tag Class 1 Byte

1 Byte 0x17 – Paper Sensor Trigger 1 Byte

1 Byte 0x18 – Get TagID & Raw ID Retries 1 Byte TagID & Raw ID -- # of Retries

1 Byte 0x20 – Get Tx power step 0

1 Byte 0x21 – Get Tx power step 1 2 Bytes

1 Byte 0x22 – Get Tx power step 2 2 Bytes

1 Byte 0x23 – Get Tx power step 3 2 Bytes

1 Byte 0x24 – Get Receive threshold 1 Byte

1 Byte

2 Bytes

Bitmap:

bit 0 -- port 0

bit 1 -- port 1

bit N – port N

0= not-existent -- 1= exists

Bitmap

Bit 0 = ignore host command CRC

Reader Type

0x09 -- Single RFID Reader

Localization Code

0x01 -- USA

0x02 -- Japan

0x03 -- E.U.

Upper Nibble -- # of Antennas

0x0X -- One Antenna

Lower Nibble – Frequency Band

0xX1 -- 868MHz

0xX2 -- 915MHz

0xX3 -- 950MHz

Bitmap:

bit 0 – Class1

bit 1 – Gen2

Bitmap:

bit 0 – enabled

bit 1 – 0=reflection, 1=no reflection

bit 3 – persistent

Bit 4 – use switch instead of sensor

Bit 5 – store ID in EEPROM

0x00 – 0xFF

Tx power

Tx power

Tx power

Tx power

Receive threshold

Table 5-10 Get Reader Hardware Information

(1) These commands are not currently implemented (unknown value Message Type returned)

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

19 11:56:13 AM

- M

ARCH

30, 2008

Page 29

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

5.1.2.7 Set Reader Hardware Information (0x13)

The Set Reader Hardware Information command provides a mechanism for the host to

establish various aspects of the hardware. Command Data values are used to select

specific parameters.

Command

Code

0x13

Command Data Response Date

Size Byte Valid Values Size Valid Values

2 Byte 1st

1 Byte 1st 0x06 – Localization Code (2) 1 Byte Reader Type

1 Byte 1st 0x07 – Radio Type (2) 1 Byte Upper Nibble -- # of Antennas

2 Bytes 1st

2 Bytes 1st

2 Bytes 1st

3 Bytes 1st

3 Bytes 1st

3 Bytes 1st

3 Bytes 1st

2 Bytes 1st

0x02 – Set Flags

2nd

Bitmap

Bit 0 – set to ignore host cmd CRC

0x11 – Tag Class

2nd

Bitmap:

bit 0 – Class1

bit 1 – Gen2

Both set = auto detect

0x17 – Paper Sensor Trigger

2nd

Pstrs Bitmap:

bit 0 – enable

bit 1 – 0= reflection, 1= no reflection

bit 2 – is ignored

bit 3 – persistent

bit 4 – use switch instead of sensor

bit 5 – Store ID in EEPROM

0x18 – Set TagID & Raw ID Retries

2nd

# Retries

0x20 – Set Tx power step 0

2,3

Tx power

0x21 – Set Tx power step 1

2,3

Tx power

0x22 – Set Tx power step 2

2,3

Tx power

0x23 – Set Tx power step 3

2,3

Tx power

0x24 – Set Receive Threshold

2nd

Threshold [102 (0x66) = 75mV]

0 Bytes

0x09 -- Single RFID Reader

0x0X -- One Antenna

Lower Nibble – Frequency Band

0xX1 -- 868MHz

0xX2 -- 915MHz

0xX3 -- 950MHz

0 Bytes --

0 Bytes --

0 Bytes Def = 7--

0 Bytes

0 Bytes

0 Bytes

0 Bytes

0 Bytes

Table 5-11 Set Reader Hardware Information

(2) These commands are not yet implemented (unknown value Message Type returned)

COMMAND DLE SOM SesID Rdr# Cmd Sub Data CRCH CRCL DLE EOM

10 01 01 FF 13 02 01 5E 62 10 02

RESPONSE DLE SOM SesID Rdr# Echo Mtype CRCH CRCL DLE EOM

10 01 01 FF 13 00 xx xx 10 02

Set Reader Hardware Example (Ignore CRC)

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

20 11:56:13 AM

- M

ARCH

30, 2008

Page 30

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

5.1.2.7.1 Paper Sensor Triggered Read

The paper sensor triggered read (PSTR) mode can be set-up and enabled using the “Set

Hardware Information” command, sub-command 0x17. This mode is used to enable

automatic tag reading based on the state of the optical reflection sensor. Using this

command, triggered reading can be enabled or disabled, set to operate in host or service

port mode, based on reflection or no reflection and set to persist over power cycling. The

triggered read state (pstrs) is set using the data byte following the sub-command. The bit

definitions for pstrs follow:

Bit 0 enables or disables triggered reads where a one (1) indicates triggered read is

enabled and a zero (0) indicates disabled.

Bit 1 indicates which optical state is used to trigger a read where one (1) triggers the

read on a no reflection and a zero (0) triggers the read on reflection. This bit is

ignored when a switch is used in place of the optical sensor(bit 4 is set to a 1)

Bit 2 is reserved and is ignored. (used internally to indicate host vs SP mode)

Bit 3 establishes if the state persists over power cycles where a one (1) indicates the

state persists over a power cycle and a zero (0) indicates that the state does not

persist.

Bit 4 set to one (1) indicates a switch is used instead of the sensor for triggering. When

Bit 5 determines whether the ID data are returned or stored. A zero (0) indicates to

the switch contacts are closed the state is triggered.

return the ID data immediately, while a one (1) causes the data to be stored in

EEPROM for future retrieval. Refer to the “Dump ID Data” command. Bad

reads are not stored in EEPROM.

When the PSTR mode is enabled using this host command, the triggered read tag data are

sent as a Binary packet in host mode or saved in EEPROM.

When storing to EEPROM, only good reads are stored. When the EEPROM log is full

(496 records), the PSTR function is terminated. An error message is sent to the host with

the Mtype set to 0x98 (LOGFULL).

Note: To use a switch in place of the paper sensor, wire between J3 pins 1 and 2.

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

21 11:56:13 AM

- M

ARCH

30, 2008

Page 31

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

5.1.2.8 Set Bi-Directional I/O DDR (0x16)

The data byte of this command defines the two bi-directional ports on the RF2400 as

either inputs or outputs. The command data is saved in non-volatile memory and

preserves the port definition through power interruptions. The LSB of the data byte

controls port 0 and bit 1 controls port 1. A logic one defines a port as an input while a

logic zero defines a port as an output. The factory default for the control byte is 0xFF

setting both IO pins as inputs

Command

Code

0x16 1 Byte

Size Valid Values Size Valid Values

Command Data Response Date

Bitmap:

0 = output

1 = input

0 Bytes --

Table 5-12 Set Bi-Directional I/O DDR

COMMAND DLE SOM SesID Rdr# Cmd Data CRCH CRCL DLE EOM

10 01 01 FF 16 02 D2 76 10 02

RESPONSE DLE SOM SesID Rdr# Echo Mtype CRCH CRCL DLE EOM

10 01 01 FF 16 00 F2 34 10 02

Set Bi-Directional I/O DDR Example

Note: Set Bi-Directional I/O DDR must be executed for the IO pin to be valid. This example Sets port 0 as an input and port

1 as an output

5.1.2.9 Get Bi-Directional I/O DDR (0x17)

This command returns the data byte defining the bi-directional IO ports

Command

Code

0x17 0 Bytes

Size Valid Values Size Valid Values

Command Data Response Date

--

1 Byte Bitmap:

0 = output

1 = input

Table 5-13 Get Bi-Directional I/O DDR

COMMAND DLE SOM SesID Rdr# Cmd CRCH CRCL DLE EOM

10 01 01 FF 17 36 DA 10 02

RESPONSE DLE SOM SesID Rdr# Echo Mtype Data CRCH CRCL DLE EOM

10 01 01 FF 17 00 02 89 67 10 02

Get Bi-Directional I/O DDR Example

Note: this example assumes that the Set Bi-Directional I/O DDR has been executed.

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

22 11:56:13 AM

- M

ARCH

30, 2008

Page 32

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

5.1.3 Tag Commands

Tag type commands result in the RF2400 reader sending commands to a tag by

modulating the RF carrier. Tags may respond by modulating the RF backscatter.

5.1.3.1 Sleep Tag (0x21)

This command issues an air interface SLEEP command…..(3)

Command

Code

0x21 0 Bytes

Size Valid Values Size Valid Values

Command Data Response Date

--

0 Bytes --

Table 5-14 Sleep Tag

(3) This command is not yet implemented (unknown value Message Type returned)

5.1.3.2 Get Tag ID (0x24)

This low-level command issues the required air interface commands to acquire one tag

ID. CRC checking is enforced and a Good ID Tag Decode Status is only available if the

CRC is validated. An ID response is only returned for a Good ID Decode status and

begins with two bytes of CRC followed by either eight or twelve bytes of ID data. The

LOCK and KILL fields are not included in the tag response data.

Class 1 tags are interrogated for both 64-bit and 96-bit standards. The CRC is initially

calculated over the first eight bytes and over twelve bytes if the eight byte calculation

fails. The Tag Data Length indicator identifies which CRC evaluated correctly

Command

Code

Size Valid Values Size Valid Values

Command Data Response Date

0x24 0 Bytes

--

N Bytes Tag Type Specific

Table 5-15 Get Tag ID

COMMAND DLE SOM SesID Rdr# Cmd CRCH CRCL DLE EOM

10 01 01 FF 24 30 EA 10 02

RESPONSE DLE SOM SesID Rdr# Echo Mtype Tsts Ant# Len tCRCH tCRCL

10 01 01 FF 24 00 00 00 0E 89 7C

TAG ID CRCH CRCL DLE EOM

01 02 03 04 05 06 07 08 09 0A 0B 0C E6 16 10 02

Get Tag ID Example

Note: this example assumes that the Program Tag example has been executed and both commands execute with success.

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

23 11:56:13 AM

- M

ARCH

30, 2008

Page 33

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

5.1.3.3 Auto Get Tag ID (0x26)

This low-level command issues the required air interface commands to repeatedly acquire

tag IDs. A response message is sent for each read, the format of which is identical to the

Get Tag ID command. A delay may be introduced between reads in 10ms increments.

The Dly byte follows the Cmd byte. Each read with the delay of 0 consumes

approximately 43mS. The operation repeats indefinitely until any other command is

executed.

A flag byte (Flg) allows setting options as follows:

Bit 0 = 1 Enables retries.

Bit 1 = 1 Store ID in EEPROM vs. send to host.

The retry count is set with the “Set Reader Hardware Information” command, Set Tag ID

& Raw ID retries with a default value of 7. With retries enabled and a count of 7 and no

tag present, a total of 16 reads are done which includes 8 for each of the two RF phases.

This consumes 688 mS plus any delay count. If auto class detect is enabled, this time is

doubled. Auto Class Detect should be disabled, set TC=2 for Gen2.

When storing to EEPROM, only good reads are stored. When the EEPROM log is full

(496 records), the Auto Get Tag ID function is terminated. A message is sent to the host

with the Mtype set to 0x98 (LOGFULL).

CRC checking is enforced and a Good ID Tag Decode Status is only available if the CRC

is validated. An ID response is only returned for a Good ID Decode status and begins

with two bytes of CRC followed by either eight or twelve bytes of ID data. The LOCK

and KILL fields are not included in the tag response data.

Class 1 tags are interrogated for both 64-bit and 96-bit standards. The CRC is initially

calculated over the first eight bytes and over twelve bytes if the eight byte calculation

fails. The Tag Data Length indicator identifies which CRC evaluated correctly

Command

Code

0x26 2 Bytes

Size Valid Values Size Valid Values

Command Data Response Date

1st Byte--Delay in 10mS 0x00 to 0xFF2nd Byte—Flags

.....Bit 0 = 1 enable retries

…..Bit 1 = 1 store IDs in EEPROM

N Bytes Tag Type Specific

Table 5-16 Auto Get Tag ID

COMMAND DLE SOM SesID Rdr# Cmd Dly Flg CRCH CRCL DLE EOM

10 01 01 FF 26 25 01 72 8D 10 02

RESPONSE DLE SOM SesID Rdr# Echo Mtype Tsts Ant# Len tCRCH tCRCL

10 01 01 FF 26 00 00 00 0E 89 7C

TAG ID CRCH CRCL DLE EOM

01 02 03 04 05 06 07 08 09 0A 0B 0C 1E A1 10 02

Auto Get Tag ID Example

Note: this example assumes that the Program Tag example has been executed and both commands execute with success.

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

24 11:56:13 AM

- M

ARCH

30, 2008

Page 34

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

5.1.3.4 Dump ID Data (0x28)

This command returns ID data that has been stored in EEPROM.

The Length byte indicates the number of records to return (max 16). An internal pointer

tracks records sent so that a repeat of this command can fetch the next group of records.

The data dump will stop when a zeroed record is encountered (end of stored data). A

response is sent with the length indicating the number of records that were returned.

The imbedded EEPROM (8Kx8) can store 496 entries.

Command

Code

0x28 2 Bytes

Size Valid Values Size Valid Values

Command Data Response Date

1st Byte—Subcmd

0x01 Dump after reset pointer

0x02 Dump using current pointer

0x03 Get number of records

stored

0x04 Clear all records

2nd Byte— Length in records 0x00 to

0x10

2 Bytes Number of records H/L byte

Table 5-17 Dump ID Data Command

COMMAND DLE SOM SesID Rdr# Cmd Sub Len CRCH CRCL DLE EOM

10 01 01 FF 28 01 01 E7 23 10 02

RESPONSE DLE SOM SesID Rdr# Echo Mtype SeqH SeqL# Len tCRCH tCRCL

10 01 01 FF 02 00 00 00 0E 89 7C

TAG ID CRCH CRCL DLE EOM

01 02 03 04 05 06 07 08 09 0A 0B 0C 85 71 10 02

RESPONSE DLE SOM SesID Rdr# Echo Mtype LenH LenL CRCH RPT CRCL DLE EOM

10 01 01 FF 28 00 00 01 10 10 64 10 02

Dump ID Data Example (Single Record)

Note: at least one record must have been previously stored in memory using SP mode

Paper Sensor Triggered Read

The Dump Record indicates the stored record number in SeqH/SeqL. The Echo byte

indicates which command stored this record as follows:

0x01 SP_ART SP mode Auto Read Tag

0x02 SP_PSTR SP mode Paper Sensor Triggered Read

0x11 H_PSTR Host mode Paper Sensor Triggered Read

0x26 H_AUTO Host mode Auto Get Tag ID

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

25 11:56:13 AM

- M

ARCH

30, 2008

Page 35

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

5.1.3.5 Get Raw Tag ID (0x3E)

This low-level command issues the required air interface commands to acquire one tag

ID without CRC checking. Response data varies in length and is specific to tag class.

Class 1 tags return a tag data length of 12 or 16. The response begins with two bytes of

CRC followed by either eight or twelve bytes of ID, a one byte kill code and ends with a

one byte lock code.

Gen 2 returns a tag ID length of 22. The response begins with two bytes of CRC

followed by twelve bytes of ID, a four byte kill password, and a four byte access

password. Although the Gen2 specification defines long EPC codes the RF2400 only

supports a 96-bit EPC. IF the kill password is read/write locked the password will be

returned as zeros (note: an all zero kill password is illegal).

The Tag Decode Status provides success or failure status for the command in addition to

other status indicators. If the command was successful bits 0-3 will all be zero. A binary

code of three in these bits indicates a CRC error. For a Class 1 tag, if Bits 4 & 5 are both

set, the tag is locked. For a Gen 2 tag, if Bit 4 in the Tag Decode status is set, the Kill

Password is locked and if Bit 5 in the Tag Decode status is set, the Access Password is

locked.

Command

Code

0x3E 0 Bytes

Size Valid Values Size Valid Values

Command Data Response Date

12/16 Bytes

-22 Bytes

Class 1 Tag

CRC (2-bytes)

….ID (8 or 12 bytes)

Kill Code (1-byte)

Lock Code (1-byte)

Class 2 Tag

CRC (2-bytes)

ID (12-bytes)

Kill Password (4-bytes)

Access Password (4-bytes)

Table 5-18 Get Raw Tag ID

COMMAND DLE SOM SesID Rdr# Cmd CRCH CRCL DLE EOM

10 01 01 FF 3E 83 91 10 02

RESPONSE DLE SOM SesID Rdr# Echo Mtype Tsts Ant# Len tCRCH tCRCL

10 01 01 FF 3E 00 00 00 16 89 7C

TAG ID

01 02 03 04 05 06 07 08 09 0A 0B 0C

Kill Password Access Password CRCH CRCL DLE EOM

00 00 00 00 00 00 00 00 86 21 10 02

Get Raw Tag ID (Gen2) Example

Note: this example assumes that the Program Tag example has been executed and both commands execute with success.

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

26 11:56:13 AM

- M

ARCH

30, 2008

Page 36

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

5.1.3.6 Program Tag (0x50)

The Program Tag command writes data to the tag ID. The command includes: four

control parameters and the ID data. The first three parameters (find tag retries, erase

retries, and program retries) establish retry counters for detecting the presence of a tag,

erasing the tag and finally programming the tag. The RF2400 only supports tags written

in 96 bit format. Correspondingly, the only valid ID length is twelve (0x0C) and must

match the number of ID data bytes in the command. If the Tag is Class 1, A CRC (

CCITT-16

) is generated for the 96-bits of ID data and programmed into the first two bytes

CRC-

in tag memory followed by the ID data. This command does not write the LOCK or

KILL bytes.

If successful, a MSGOK will be returned otherwise an error code indicating the failure

will be returned. Error codes (

CommCode

) include HWERR, UNKTAGCMD,

UNKIDLEN NOTAG, ERASEFAIL, PROGFAIL, TAGLOST, and TAGLOCK. If the

Mtype field in the response is non-zero, an error has occurred, and the tag must be

considered invalid.

Command

Code

0x50 16 Bytes

Size Valid Values Size Valid Values

Command Data Response Date

1st Byte—Find Tag retries 0x00-0xFF

2nd Byte--Erase retries 0x00-0xFF

3rd Byte--Program retries 0x00-0xFF

4th Byte—ID Length 0x0C

5th -16th Bytes—ID Data (12 Bytes)

0 Bytes --

Table 5-19 Program Tag

COMMAND DLE SOM SesID Rdr# Cmd Xrty Erty Wrty Len

10 01 01 FF 50 7 7 7 0C

Tag ID CRCH CRCL DLE EOM

01 02 03 04 05 06 07 08 09 0A 0B 0C 84 33 10 02

RESPONSE DLE SOM SesID Rdr# Echo Mtype CRCH CRCL DLE EOM

10 01 01 FF 50 00 5D 39 10 02

Program Tag Example

Note: this example assumes that the command executes successfully.

________________________________________________________________________

Ensyc

- C

Technologies P

ONFIDENTIAL

AGE

27 11:56:13 AM

- M

ARCH

30, 2008

Page 37

RFID UHF Short Range Controller (RF2400)

__________________________________________________________________________

5.1.3.7 Erase Tag (0x51)

The Erase Tag command erases and verifies the tag was properly erased. The command

begins with a tag search which repeats up to the given number of find tag retries or until

a valid tag is found. Subsequently, the Erase command is iterated up to the number of

times defined by erase retries or until the erase is verified. A Class 1 tag is written with

both the CRC and ID data set to zero. A Gen2 tag is written with only the ID data set to

zero since the CRC is calculated by the tag. A successful operation is determined if the

tag ID is erased to all zeros for both Class 1 and Gen2 tags and in addition the CRC is set

to zero for a Class 1 tag.

If successful a MSGOK will be returned otherwise an error code indicating the failure

will be returned. Error codes (

CommCode

) include HWERR, UNKTAGCMD, NOTAG,

ERASEFAIL, TAGLOST, and TAGLOCK.

Command

Code

0x51 2 Bytes

Size Valid Values Size Valid Values