ENSTROM 280FX Series, F28-F Series Pilot's Manual

Piill

P

ott

o

G

G

Trr

T

uii

u

aii

a

d

e

d

e

nii

n

n

n

g

g

MMaarrcchh 1100,, 22000088

Enstrom Helicopter Corporation 1

Menominee, Michigan 49858-0490 U.S.A.

FFoorr ttrraaiinniinngg ppuurrppoosseess oonnlly

Phone (906) 863-1200

22000088 EEddiittiioonn 22

Post Office Box 490

y

Table of Contents

Introduction 3

Aircraft Description & Construction Details 4

Aircraft servicing 18

Aircraft Systems 20

Electrical 20

Caution and Warning 24

Instruments 29

Fuel System 32

Power Train 34

Flight Controls 39

Power Plant 42

Operation Procedures 48

Airframe 48

Powerplant 55

Weight & Balance 61

Performance 63

Emergency 69

Prefight 78

Pilot Notes 84

Enstrom Helicopter Corporation 2

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

INTRODUCTION

Enstrom 280FX and F28-F series Helicopter Pilot Training

Course Objectives

The purpose of this course is to prepare an experienced helicopter pilot for a

smooth transition into the Enstrom Piston powered helicopters.

This course includes descriptions and theory of operation for the systems, and

the location of the system components.

The course also includes the description of the pilot pre-flight procedures and the

pilots are expected to perform these pre-flight Inspections.

Enstrom Helicopter Corporation 3

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

AIRCRAFT DESCRIPTON & CONSTRUCTION DETAILS

GENERAL DESCRIPTION

The Enstrom 280FX and F28-F helicopters are 3 bladed, single engine

helicopters manufactured by the Enstrom Helicopter Corporation and certified by

the FAA under part 6 of the Civil Air Regulations.

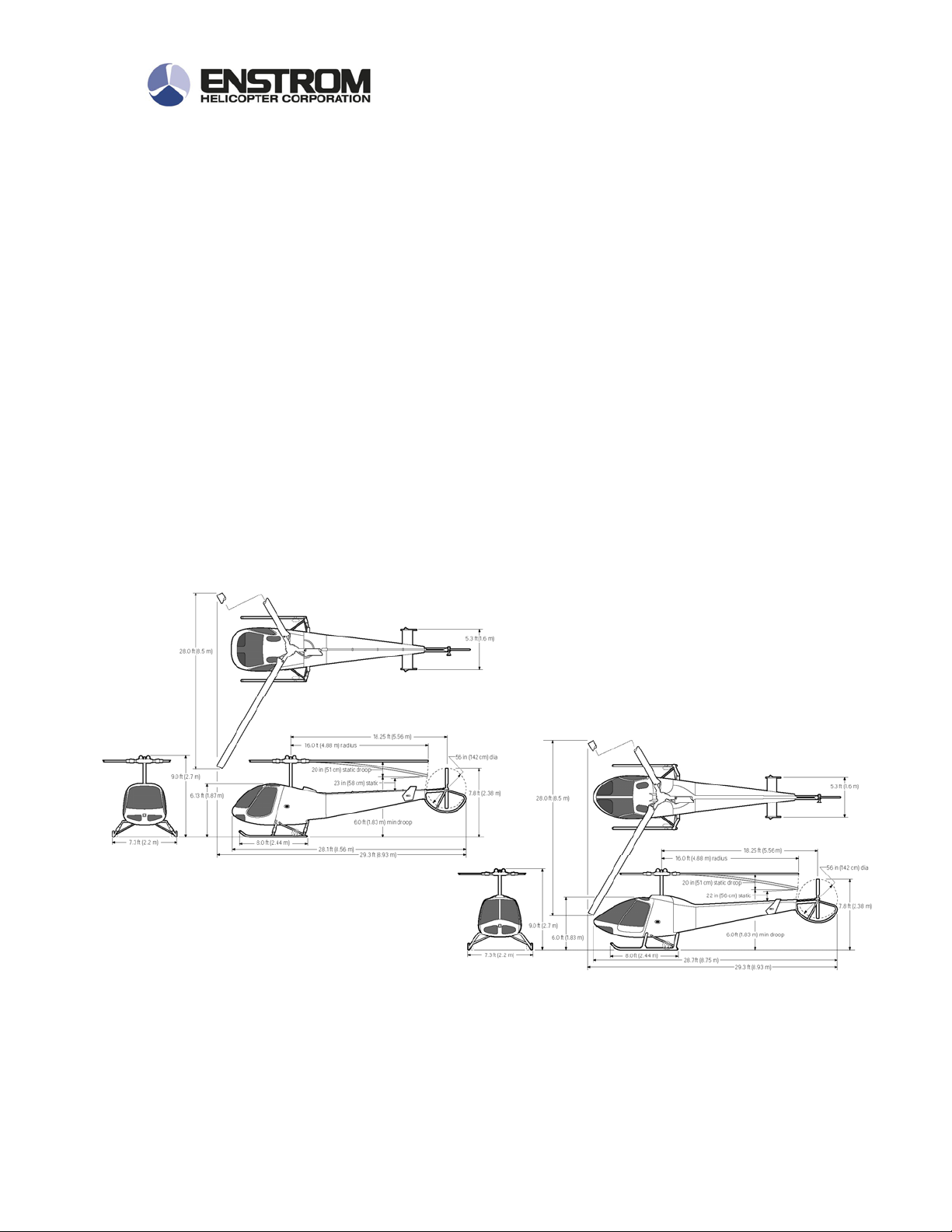

Turning Radius

The turning radius is about 23 feet when pivoted on the wheels about the mast.

Principal Dimensions

Enstrom Helicopter Corporation 4

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

CHARACTERISTICS

Helicopter description

The Enstrom 280FX and F28 F helicopters are a single engine, piston powered

helicopter certified for day and night VFR flight and that can be equipped for IFR

flight training. The F28 F helicopter was originally certified in 1980 and the 280

FX in 1985 to the CAR 6 regulations.

Early F28 F and 280F helicopters were certified to 2350 lb maximum gross

weight and can be changed to 2600 lb gross weight by incorporating the

appropriate modifications.

Enstrom Helicopter Corporation 5

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

Beginning in 1984, F28 F and 280FX helicopters were produced with the gross

weight limitation of 2600 pounds.

Enstroms are relatively quiet helicopters due to the installation of the turbocharger, and the slow turning main and tail rotors. They can be equipped with an

optional secondary muffler that lowers the noise signature significantly.

All Enstrom helicopters feature a three bladed, fully articulated main rotor system

which has over 4,000,000 flight hours and which has never had a catastrophic

failure or thrown a blade. The tail rotor is two bladed and completely unblocked

for exceptional effectiveness. Due to the high inertia rotor design, the helicopter

possesses out-standing auto-rotational capabilities.

In addition to being a versatile and crashworthy helicopter, the 280FX and F28 F

helicopters were designed to be procured and operated for minimum costs. The

helicopter does not require hydraulic boost or stability augmentation systems.

The limited number of fatigue critical parts, the long overhaul intervals, and the

low hour/flight ratio resulting from high reliability and easy maintenance combine

to yield low operation and support costs.

Enstrom Helicopter Corporation 6

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

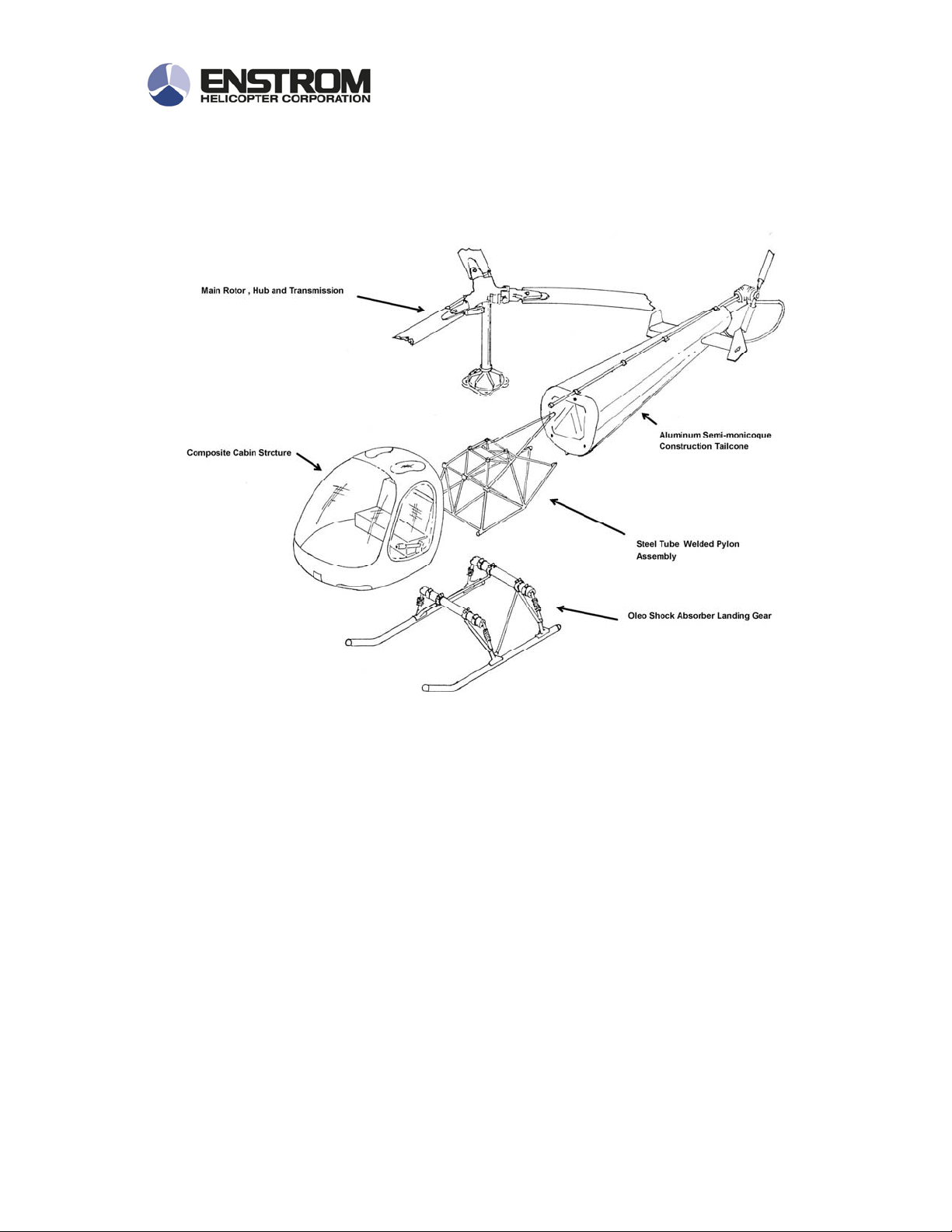

CONSTRUTION DETAILS

Fuselage

The fuselage is the forward section of the airframe extending from the nose to

the forward end of the tailcone. The cabin shell is molded out of fiberglass and

the aluminum seat and floor structure is fabricated and then bonded into the

fiberglass shell.

The pylon structure is welded up out of high carbon molybdenum steel. The

landing gear, cabin and tail cone are bolted on to the pylon structure. The engine

and main rotor transmission are also attached to the pylon.

Enstrom Helicopter Corporation 7

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

Tailcone

The tail cone is bolted to the aft end of the pylon. It is a tapered semimonocoque structure comprised of skins, bulkheads, longerons and stringers.

The tailcone supports the tail rotor, tail-rotor transmission, horizontal and vertical

stabilizers, and the tail-rotor guard. It houses the tail rotor drive shaft and can be

used to mount some of the helicopter electrical equipment.

Enstrom Helicopter Corporation 8

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

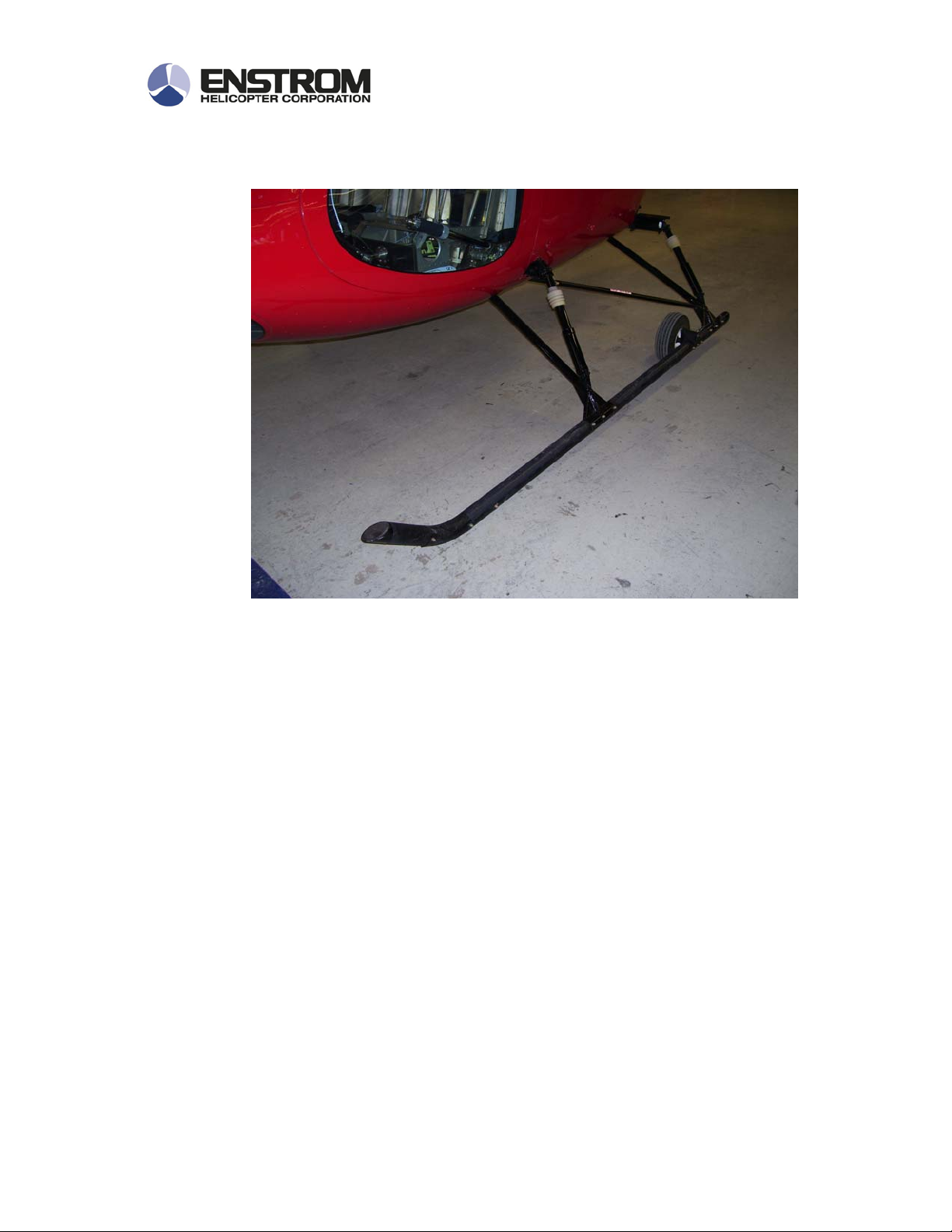

Landing Gear

Main Landing Gear: The main landing gear consists of two tubular

aluminum skids attached to the airframe by means of the forward and aft cross

tubes through four air-oil oleo struts. The struts cushion ground contact during

landing.

Drag struts give the gear stability and strength and prevent fore and aft

movement during ground contact maneuvers. Due to their design, the drag struts

will sustain landings with significant forward movement of the helicopter;

however, landing with rearward movement may overload the structure and cause

its collapse.

Replaceable hardened steel skid shoes are installed on each skid to resist

skid wear on hard surfaces.

Enstrom Helicopter Corporation 9

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

Crew Compartment

The crew compartment consists of pilot and

passenger/co-pilot seating, Instrument

panel, radio console and pilot and co-pilot

flight controls mounted to the aluminum floor

structure and enclosed in the fiberglass

cabin shell.

The co-pilot controls are removable and a

seat cushion for the third passenger is

inserted into the space vacated when the

co-pilot collective is removed.

Enstrom Helicopter Corporation 10

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

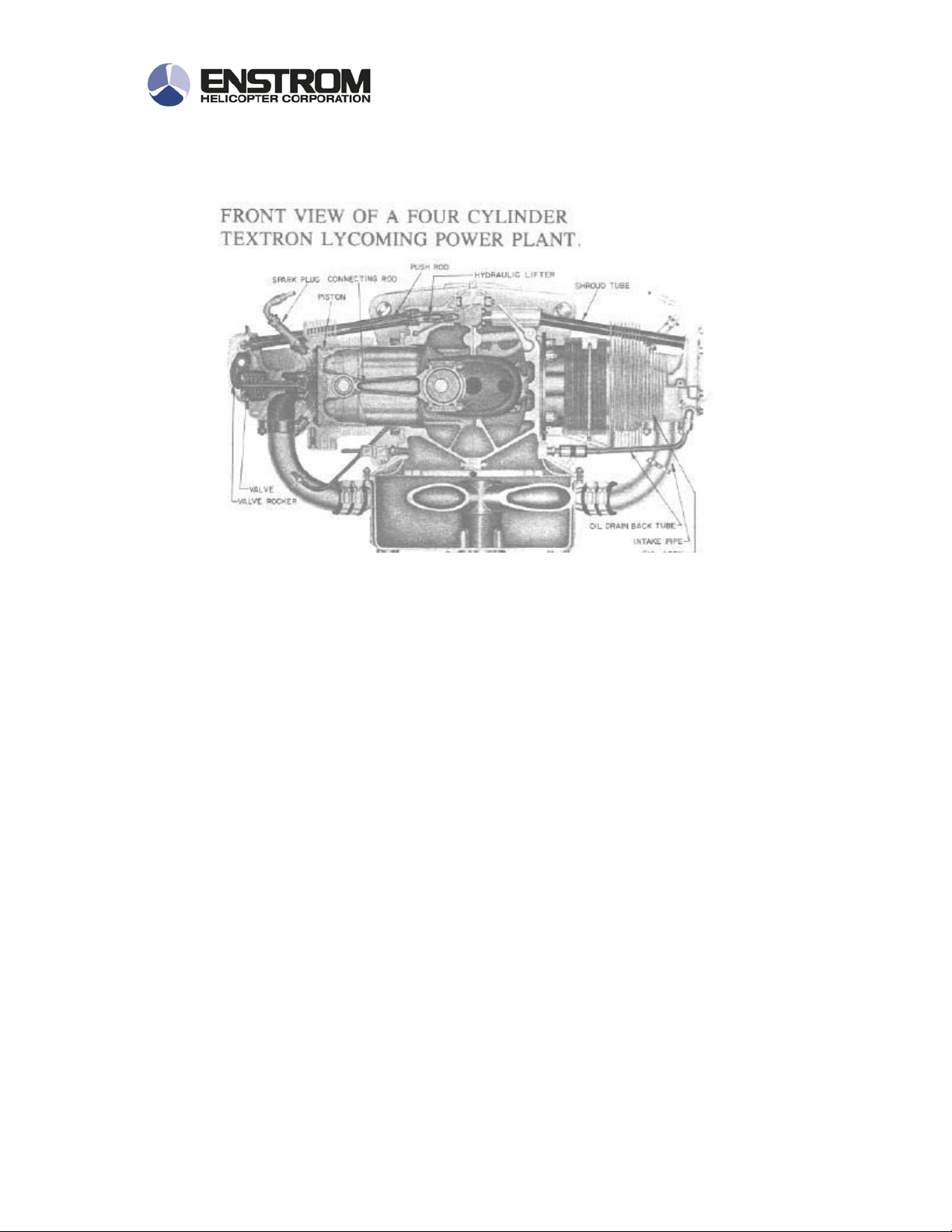

Engine

The piston powered Enstrom helicopters are powered by a Lycoming built HIO360-FIAD four cylinder, air cooled engine that produces 225 Shaft Horse Power.

The maximum horsepower is achieved with the aid of a Kelley Aerospace

turbocharger that incorporates an adjustable waste gate that is controlled by a

breakaway control rod.

The engine is cooled by a large fan that is installed between the crankshaft and

the lower belt pulley. Cooling air for the engine is drawn in from the overhead

scoop mounted behind the main rotor mast, through the fan and then around the

cylinders and through the oil coolers.

There are clean out traps mounted adjacent to the two oil coolers to facilitate

cleaning out debris.

Enstrom Helicopter Corporation 11

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

Power Train

The power train includes the main rotor transmission, an upper pulley assembly

incorporating the overrunning clutch, jack strut, drive belt, lower pulley, drive

shaft and tail rotor gearbox.

Enstrom Helicopter Corporation 12

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

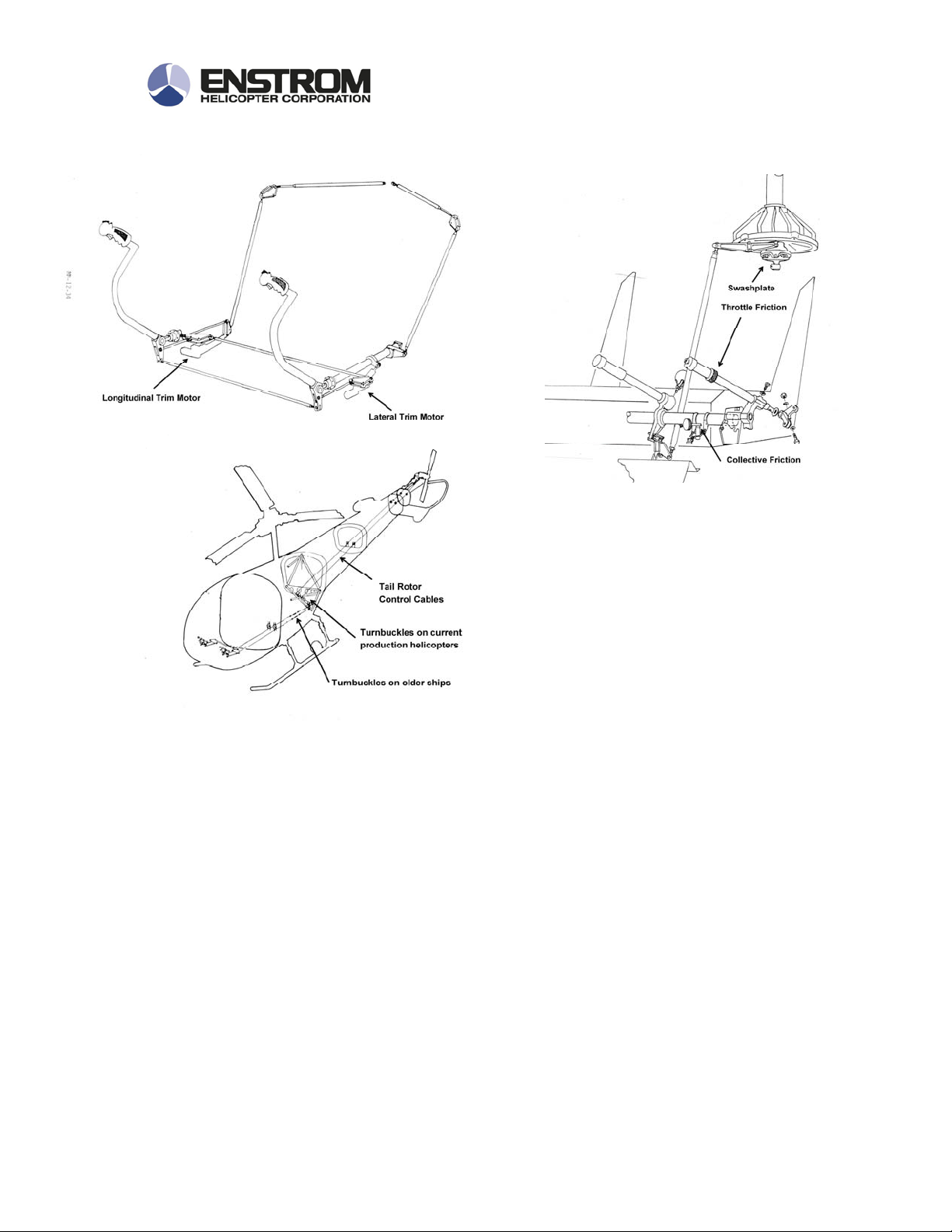

Flight Controls

The flight controls include three primary systems: the collective, cyclic, and antitorque or directional controls. There is no hydraulic system installed on Enstrom

Helicopters, cyclic forces are relieved using electric mechanical trim motor

operated spring capsules. Collective forces are managed using a spring capsule

assembly.

The helicopters also have fixed horizontal and vertical stabilizers that are

mounted on the tail cone to help provide stability and attitude control during

forward flight.

Enstrom Helicopter Corporation 13

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

Main Rotor System

The main rotor system is a three bladed, high inertia, fully articulated rotor

system. The main rotor hub assembly is composed of two opposing forged

aluminum hub plates separated by an aluminum cylindrical spacer. Through

bolts hold these items together along with steel spline adapters.

Three steel universal blocks are mounted on roller bearing units that permit

flapping and lead-lag motions. Laminated phenolic pads are used to limit blade

travel in both the lead-lag and flapping axes. A thrust nut on the bottom of each

universal block transfers vertical blade forces to both hub plates through the

universal block.

Enstrom Helicopter Corporation 14

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

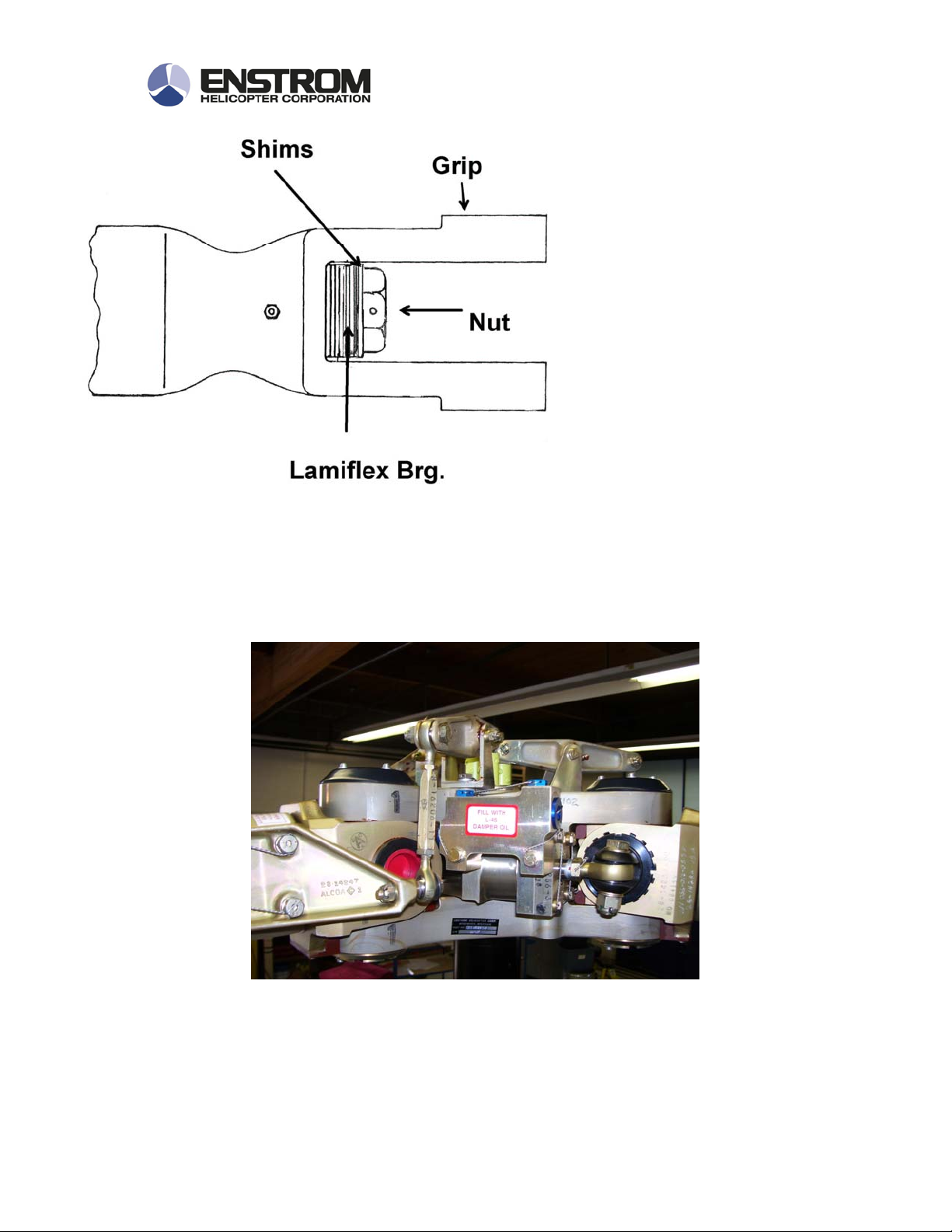

The rotor blades are

secured to each universal

block on the hub through a

forged aluminum grip which

is in turn secured to a steel

spindle assembly through an

elastomeric feather bearing

(Lamiflex Bearing) and a

retention nut.

Closed circuit hydraulic dampers are incorporated between each flapping pin and

the rotor hub to limit the lead-lag velocity of the blades. Because the hydraulic

dampers have no centering spring, they are quite limber; this, coupled with the

large heavy blades causes the ground rock that is often experienced while the

helicopter rotor system is spooling up.

Enstrom Helicopter Corporation 15

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

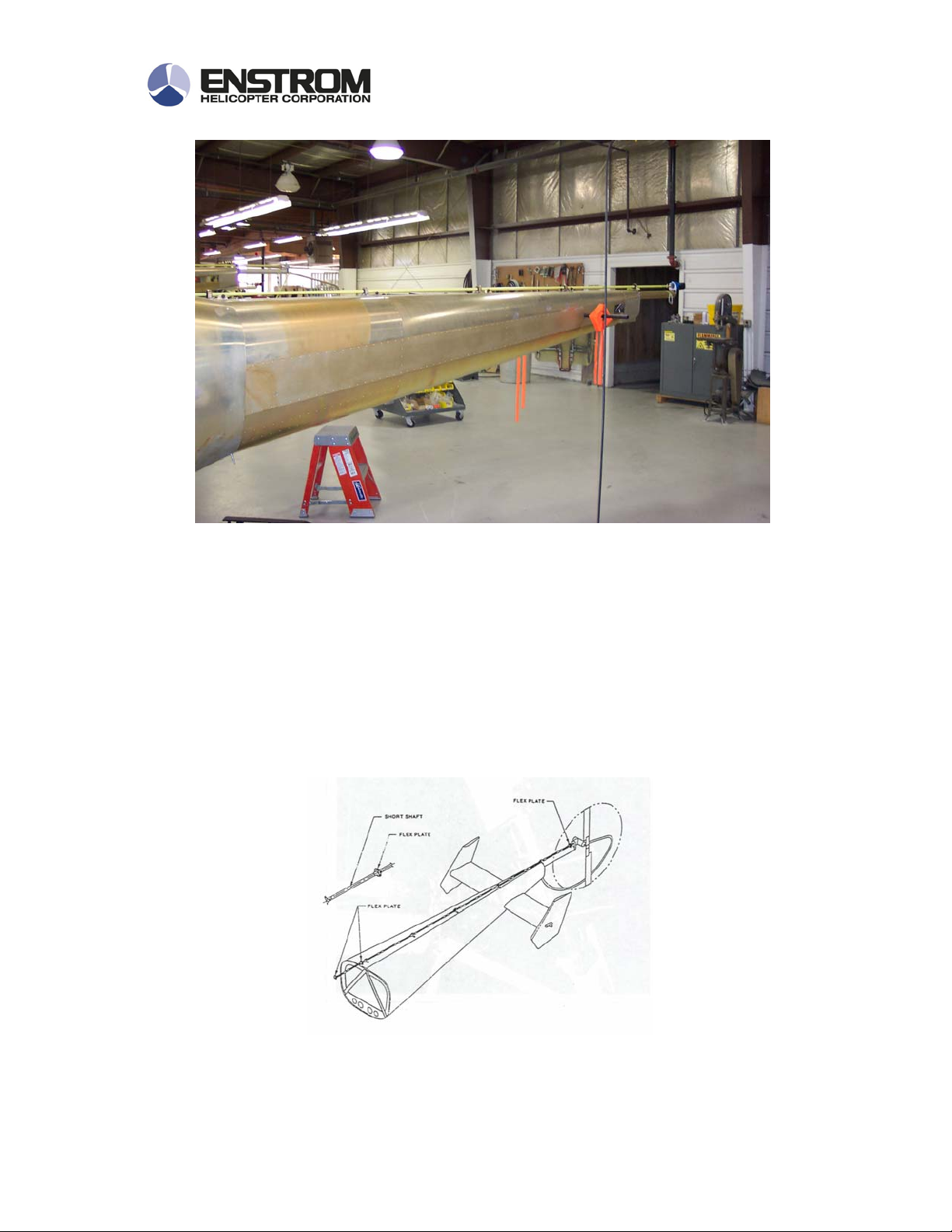

The main rotor blades are of hollow construction consisting of an extruded

leading edge spar, with a 7 degree twist, to which is bonded upper and lower

aluminum skins. The blade root is composed of a bonded doubler assembly.

A single retention pin connects the blade root to the grip and a non-adjustable

drag brace connects the trailing edge of the blade to the grip.

A cap is bonded to the tip of each blade in which there are provisions for

spanwise and cordwise balance weights. Two tracking tabs are riveted to the

trailing edge of each blade.

Enstrom Helicopter Corporation 16

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

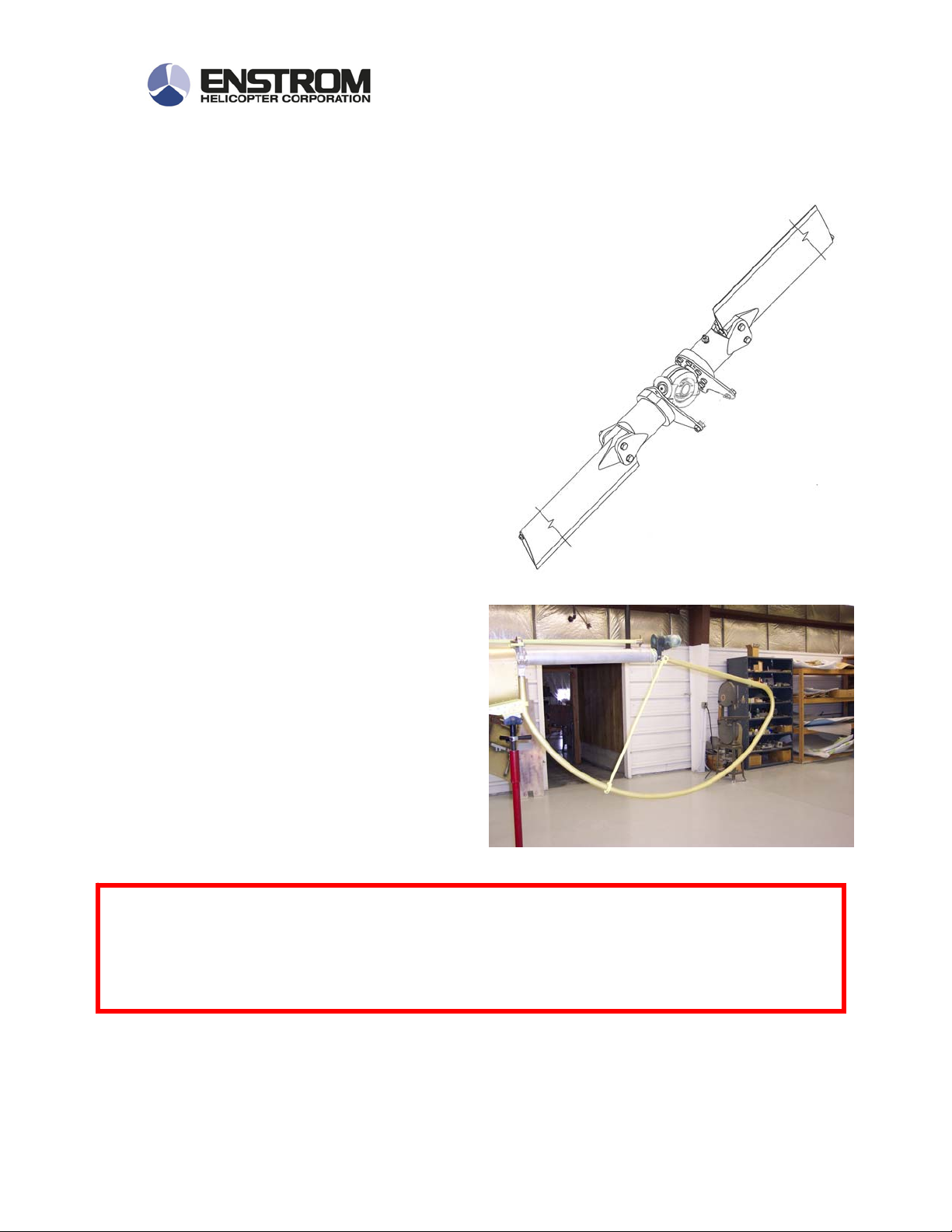

Tail Rotor Assembly

The tail rotor assembly is a two

bladed, wide cord, teetering, delta hinged

rotor assembly.

The fly-weights on the blade

retention plates unload the tail rotor

twisting forces in flight so that the pilot

does not need to carry left pedal at cruse

power settings. They are weighted so

that when the aircraft is being flown at

approximately 29 in mp, the pedals are

neutralized and the slip ball centered.

For this reason, the aircraft requires very

little left pedal in hover and in climb, and

significant right pedal in low power

situations.

Tail Rotor Guard: A tubular

aluminum tail rotor guard is installed on

the aft end of the tailcone. It aids in

ground handling and protecting the tail

rotor from damage while the helicopter

is on the ground.

The tail rotor guard will not prevent damage to the tail rotor in the event

IMPORTANT!

of a hard landing.

Enstrom Helicopter Corporation 17

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

SERVICING

Fuel

100/130 Aviation Grade Mil-G-5572

100LL Aviation Grade

Engine Lubrication Oils

Oil, Ashless Dispersant MIL-L-22851

Flight Control Lubricants

Grease, MIL-G-81322 (Mobil 28, Shell 22)

Landing Gear Oleos

Oil, MIL-H-5606

Nitrogen

Main Rotor Dampers

Oil, L-45 Silicone Oil (GE Silicone L-45-20)

Main and Tail Transmissions

Oil, MIL-PRF-2105 (Mobil 1 Gear Oil (Mobil 1 Synthetic Gear

Lubricant (75W-90)

Enstrom Helicopter Corporation 18

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

Overrunning Clutch

Oil, MIL-L-23699 (Mobil Jet II, Shell Turbine Oil 500 or equivalent)

Tach

Drive Cables

Grease, 2701-109 (S.S. White CO, LPS 2)

Notes:

Landing gear oleos should be serviced with the weight of the helicopter off of the

landing gear, and should be all serviced at the same time or at the very least, in

pairs, front and back.

Enstrom Helicopter Corporation 19

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

AIRCRAFT SYSTEMS

ELECTRICAL SYSTEMS

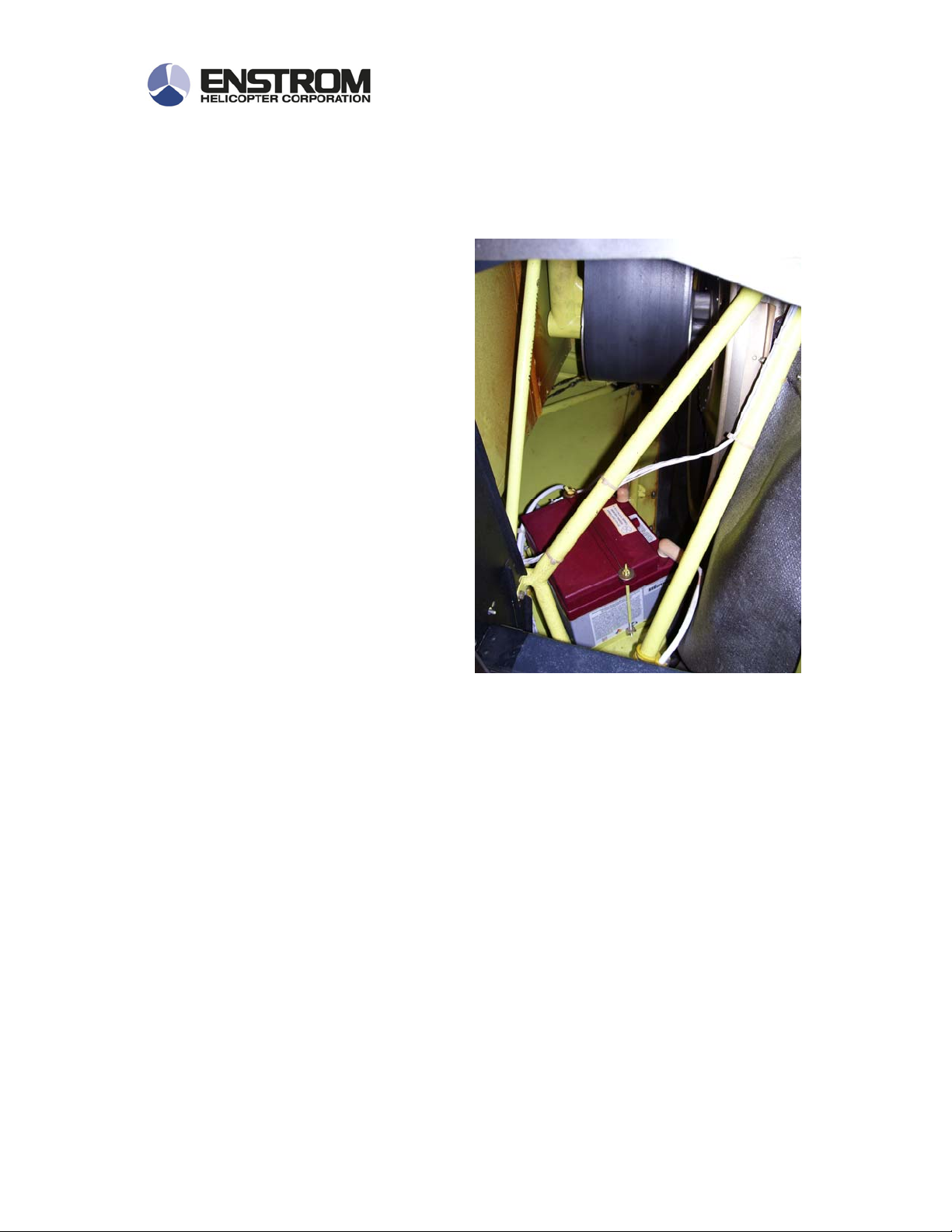

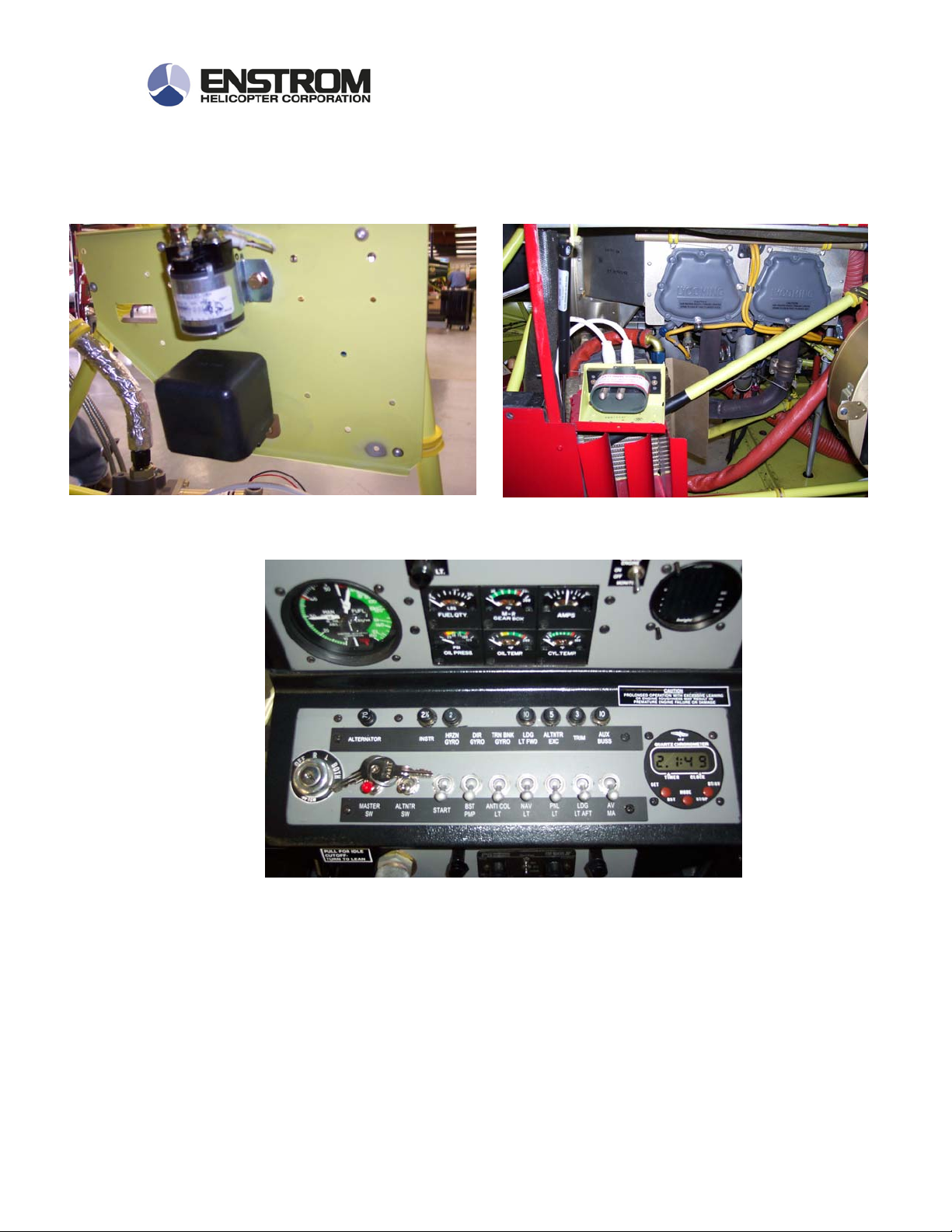

Most helicopters manufactured after

the mid 1990’s have 24 volt electrical

systems with the battery mounted

under the baggage compartment. On

earlier 12 volt helicopters, the battery

is installed under the co-pilot seat.

Description – Starter / Generator Systems

The starter on current production Enstrom 280FX and F28-F helicopters consists

of a Skytech manufactured high-speed starter mounted on the engine, behind the

main oil cooler driving on a ring gear that is mounted on the outside of the

engine flywheel.

A 24 volt battery is mounted just aft of the engine and below the baggage

compartment on the right side of the aircraft. The starter solenoid is mounted on

the battery tray, and the master switch solenoid is mounted on the firewall just

inboard of the engine air cleaner. The aux power plug is mounted above the oil

cooler, inside the right engine cowl door.

Master Solenoid

Enstrom Helicopter Corporation 20

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

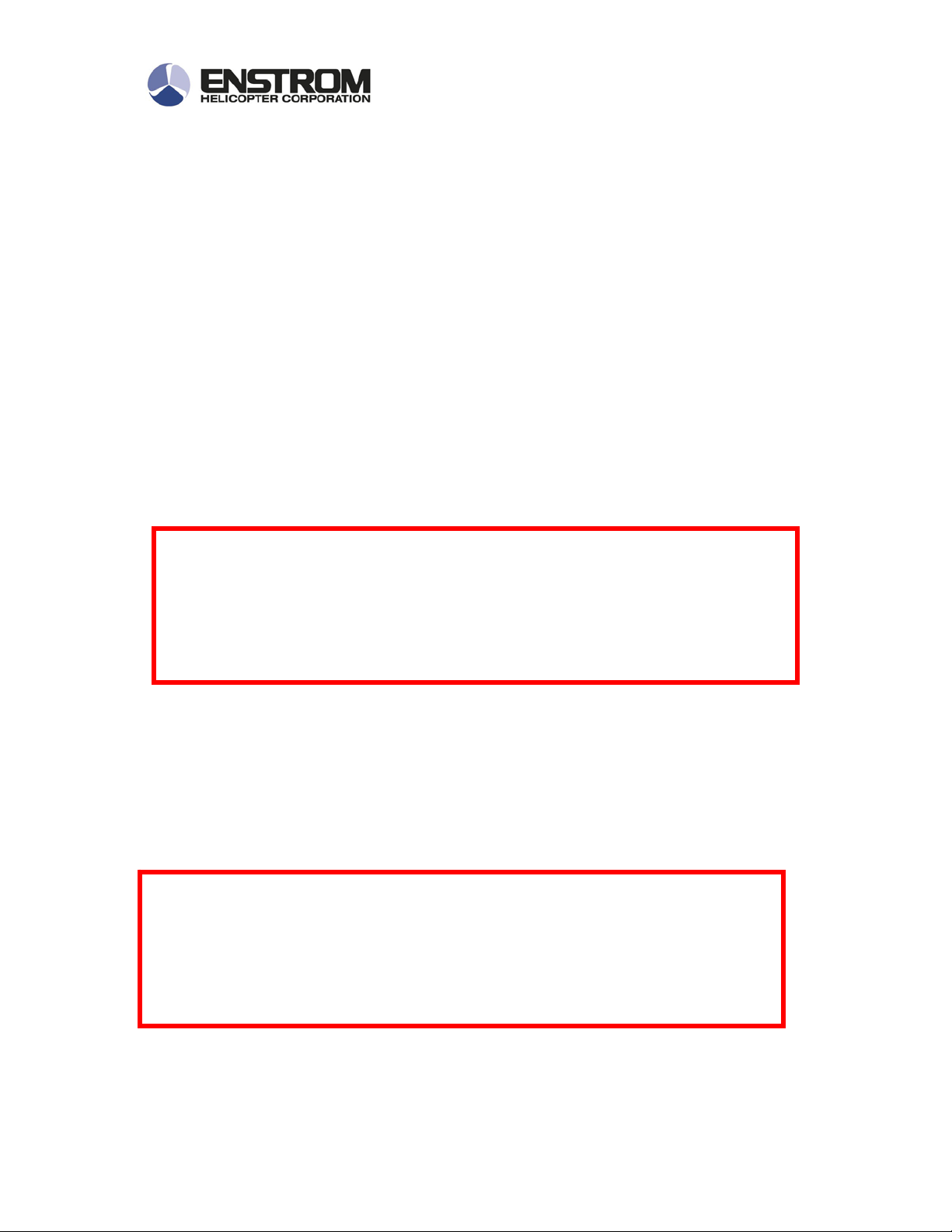

The master switch on the instrument panel energizes the master switch relay

which powers up the helicopter systems. The alternator switch powers the

voltage regulator which controls the alternator output. The start switch energizes

the starter button on the pilot collective.

Enstrom Helicopter Corporation 21

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

Starting systems

For aircraft starting the master switch, alternator switch, and the start switch are

placed in the on position, and the magneto switch is placed in the both position..

If an APU unit is used, the alternator switch is left in the off position. When the

starter switch on the collective is pressed, the starter solenoid energizes the

starter and the starting vibrator.

The starting vibrator has an internal relay that switches off the right magneto for

starting and that directs a hot steady spark through the left magneto and the

retard points to the spark plugs. This is to facilitate the start and prevent the

engine from kicking back. It’s important to note that the starting vibrator requires

over 13 volts to operate (24 volt systems) so the engine generally will not start if

it is cranked with a low battery. (9 volts is required to start 12 volt systems)

NOTE

The engine magneto develops electrical power to fire the sparkplugs

internally and there is no connection between the magneto and the

Because the magneto is not connected to the helicopter electrical system, turning

off the battery switch while flying will not affect the operation of the engine,

except that the electric boost pump will not operate.

NEVER PERFORM A MAGNETO CHECK IN A HELICOPTER WHILE

FLYING. IF THE ENGINE IS SWITCHED TO AN INPERATIVE

MAGNETO THE ENGINE WILL STOP RUNNING.

helicopter electrical system.

IMPORTANT

Enstrom Helicopter Corporation 22

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

Alternator Systems

The electrical generating system in the 280 FX and the F28-F consists of the 24

volt battery, 60 amp alternator and a solid state voltage regulator. Power to the

voltage regulator is controlled by the switch marked Alternator on the instrument

consol switch panel. When the switch is turned on, the voltage regulator is

energized which then controls the voltage produced by the alternator by varying

the field voltage.

The battery is located behind the engine, just under the forward side of the

baggage compartment, and the voltage regulator is located under the right side

of the co-pilot seat. The alternator is located on the aft left side of the engine

compartment and the alternator belt can be inspected through a removable panel

just above the auxiliary oil cooler.

On the Enstrom helicopters, the ammeter measures the

voltage that is going in and out of the battery; it is not a

load meter. After the engine is first started, the ammeter

will indicate a high rate-of-charge until the battery charge is

replenished. As the battery becomes charged, the rate-ofcharge indicated by the ammeter will drop off slowly until it

reads only slightly above zero. If the alternator stops

charging, the Alternator segment on the annunciator

panel will light, and the ammeter will indicate negative

amperage equal to the electrical load being used by the

helicopter.

The voltage regulator is sensitive to both over-voltage and

momentary charging interruptions. If the operator notices

the alternator caution light is illuminated, the voltage

regulator may be reset by turning off the alternator switch

for a few seconds and then turning it back on.

Enstrom Helicopter Corporation 23

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

CAUTION AND WARNING SYSTEMS

Description- Caution and warning systems

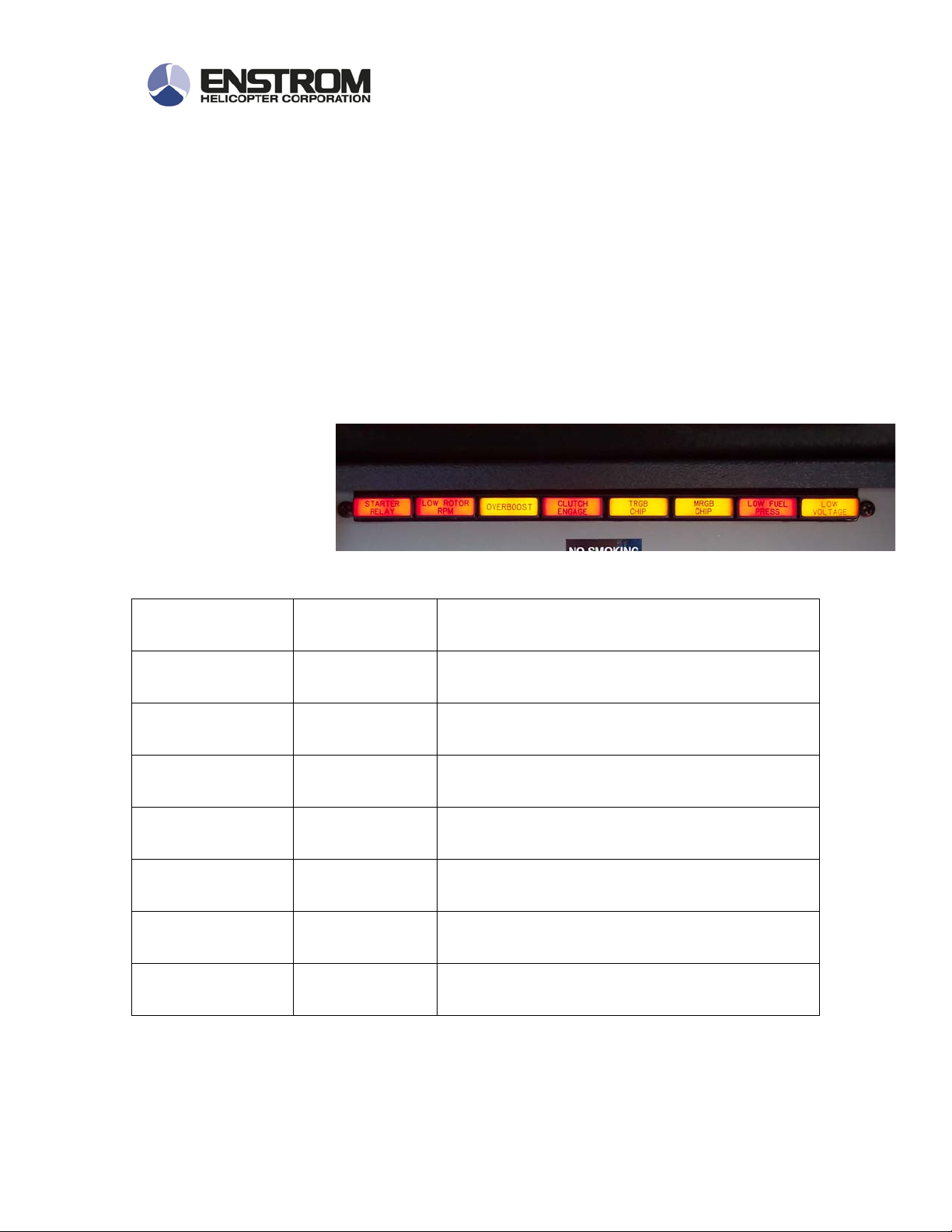

The annunciator panel is located at the top of the instrument console and

consists of 8 indicator lights with a press-to-test switch at the extreme left.

Pressing this switch will illuminate all of the indicator lights.

The following warning

and precautionary

information is

displayed on the

annunciator panel.

SEGMENT COLOR DESCRIPTION

STARTER

RELAY

RED

Starter is operating

LOW ROTOR

RPM

OVERBOOST AMBER

CLUTCH

ENGAGE

TRGB CHIP AMBER

MRGB CHIP AMBER

LOW FUEL

PRESSURE

LOW VOLTAGE AMBER

Enstrom Helicopter Corporation 24

RED

RED

RED

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

Main rotor RPM is below 334

Manifold pressure is approaching Red Line

Belt Clutch is disengaged

Tail rotor gearbox chip detector has

detected ferrous metal fragments

Main rotor gearbox chip detector has

detected ferrous metal fragments

Electric Boost pump is producing less than

15 PSI

Alternator is off-line

Warning Systems Descriptions

Starter Relay

The starter relay warning light is operated by a circuit connected to the starter

relay. Its purpose is to alert the pilot that the starter is operating or is engaged.

There is a slight possibility that the starter might not disengage after the starter

button is released. Continued operation of the helicopter with the starter

engaged, will cause damage to the starter and the starter ring gear, and result in

the helicopter not starting.

It is also possible that in the event of a starter solenoid failure, the starter might

remain engaged and also the magneto might remain in the retard mode which

would result in a sever reduction of power and rough running engine.

Low Rotor RPM

The Low Rotor RPM circuit consists of a magnetic sensor in the main rotor

gearbox, a signal generator located behind the passenger’s seat back, a light

located in the annunciator panel, and an audio warning horn.

The RPM sensor in the main rotor gearbox is a magnetic pick-up unit that is

installed in the forward section of the gearbox and that senses the ring gear

teeth passing and sends a signal to a relay and control box that are located on a

bulkhead just behind the right passenger seat back.

The sensor reads the signal that comes from the gearbox magnetic pickup and

routes it to the annunciator panel and the audio warning horn. The audio

warning system consists of a horn located in the head liner and a connection with

the helicopter intercom system that broadcasts the horn into the pilots head sets.

Because the low rotor warning system is armed by the clutch-engage switch, the

Low Rotor RPM warning light will only illuminate if the clutch is engaged. There

is also a switch on the collective system that disengages the Low Rotor RPM

warning system when the collective is in the full down position.

After the engine is started, the following sequences will occur in the Low Rotor

RPM warning system. The red Clutch Engage light will be on until the clutch is

engaged. When the clutch handle snaps into position, the red Clutch Engage

light will go out, and the red Low Rotor light will illuminate.

Enstrom Helicopter Corporation 25

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

The Low Rotor RPM warning light will remain on until the Rotor RPM exceeds

334, but the horn will not sound unless the collective is raised off the bottom stop

and the RPM is less than 334 RPM.

The Low Rotor RPM warning light and horn will activate anytime the clutch is

engaged, the rotor RPM is less than 334, and the collective is raised off of the

down stop.

The RPM that the low rotor RPM system operates at can be adjusted by turning

a potentiometer that is located on the sensor relay that is behind the passenger

seat.

Overboost

The overboost circuit consists of a pressure switch that is installed in the

manifold pressure gauge line and an amber light in the annunciator panel. The

switch is designed to illuminate the light at between 36 and 40 inches of manifold

pressure. The switch and light may be activated by short pressure pulses that

might not register on the manifold pressure gauge. The light is a warning to the

pilot that maximum manifold pressure limits may be exceeded and that the

manifold pressure gauge should be monitored.

The overboost light is intended to be a warning; the manifold pressure gauge

should be used to determine actual manifold pressure.

Clutch Engage

The clutch engage light is activated by a switch that is located on the belt clutch

capsule. It is a normally closed switch that is opened when the clutch overcenter mechanism snaps into place as the belt clutch is engaged. A second

circuit in the same switch is used for the low rotor warning system.

If the Clutch Engage light does not go out when the handle is stowed, or comes

on in flight, a problem with the clutch over-center locking mechanism is indicated.

DO NOT FLY THE AIRCRAFT UNTILL THE FAULT HAS BEEN REPAIRED.

Enstrom Helicopter Corporation 26

Post Office Box 490

Menominee, Michigan 49858-0490 U.S.A.

Phone (906) 863-1200

Loading...

Loading...