Page 1

ASR

Service Manual

I

EN50Ni’alm

P/N

9312001801 . B

November 1995

Page 2

Table

of

Contents

TABLE OF CONTENTS

IMPORTANT THINGS TO KNOW

Known Areas of Concern

Avoid Damage from ESD (Electrostatic Discharge)

SIMMS

What SIMMs to Use .............................................................................................................

What Changed?

How to Tell Which Rev Board You Have

THE DISK DRIVE

Transporting a unit

What disks

Testing the Disk Drive.. ........................................................................................................

UNIT SOUNDS DISTORTED..

FUSES ..................................................................................................................................

The 20-pin

Customer Thinks the Unit is Broken

MECHANICAL ISSUES.. ..................................................................................................

ASR

High - retention Force Connectors (Repair Technicians

OEX-6sr Connector on ASR Keyboard and ASR-88 Caution! Important!

HOW THE

Keyboard

Communications Path ...........................................................................................................

CHECKING THE POWER SUPPLY

Analog Board Regulator Voltages

POWER SUPPLY

Fuse Ratings

TESTING THE POWER SUPPLY UNLOADED

CHECKING THE DISPLAY

DISPLAY SELF-TEST

Using Self-Test Mode to Diagnose

Troubleshooting an ASR-10 With No LEDS Lit

Troubleshooting an ASR-10 With All LEDS Lit, No Display

KEYBOARD AND FOOTSWITCH INPUTS

The ASR-10 Keyboard and the

ASR-10 Footswitch and Patch Select Inputs

ASR-88 KEYBOARD

Key

Pressure Response

ERROR MESSAGES .........................................................................................................

ASR-10188

ASR TEST PROCEDURE..

1.

Power Up and Load in Sounds..

2.

..................................................................................................................................

.....................................................................................................................

.............................................................................................................

................................................................................................................

to use ..................................................................................................................

KeyboardIKPC Simulator Ribbon Cable

Case

(Avoid Stripping Screws).

ASR WORKS..

and Rack Similarites..

VOLTAGE CHECK POINTS

..........................................................................................................................

Response Problems.. ......................................................................................................

Problems..

SOFTWARE NOTES..

Test

Keyboard

(ASR-10188

...................................................................................................

............................................................

............................................................................

.........................................................................................

...........................................................

....................................................................................

...................................................................................

Label)

...................................................................................

...........................................................................................

TROUBLESHOOTING

..............................................................................

........................................................................................

..........................................................

...........................................................

............................................................................................

MODE

........................................................................................:................ 20

.........................................................................................

the Keypad/Display Board..

..................................................................

.................................................................

KPC

Simulator Board..

........................................................................

............................................................................................... 22

.................................................................................... 25

............................................................................................... 35

........................................................................................ 35

Keyboard Only)

................................................................... 35

.......................................................

...........................................

..........................

..........................................

.............................................

.

.............

1

1

1

1

3

-

3

-

3

3

3

3

4

5

5

5

6

6

6

7

7

9

9

12

12

13

13

14

16

16

16

17

18

19

19

19

20

23

c

i-

ASR Service Manual

Page 3

Table

of

Contents

3. Headphone Check

.............................................................................................................

35

4. MIDI

Test..

........................................................................................................................

35

5.

Anlog Page..

......................................................................................................................

36

6. Disk Check.. ......................................................................................................................

37

7.

Sampling Check..

.............................................................................................................. 37

8. OEX-6sr Check..

...............................................................................................................

38

REPLACING

ASR-lOh38

MODULES

..............................................................................

41

Section A - Replacing the Digital Board

.............................................................................. 41

Section B-Replacing the Analog Board..

............................................................................

42

Section

C -

Replacing the Power Supply

Board

................................................................... 43

Section D-Replacing the Keypad/Display Board..

.............................................................. 44

Section E-Replacing the Keyboard

(ASR-10) ....................................................................

45

Section E-Replacing the Keyboard

(ASR-88) .................................................................... 46

Section F-Replacing the Digital Jack Board..

.....................................................................

47

Section G -Replacing the Analog Jack Board..

.................................................................... 47

Section H-Replacing the Disk Drive..

................................................................................. 48

Section

I -

Replacing the Transformer..

................................................................................ 48

Section J-Replacing the Line Filter..

...................................................................................

49

SectionK -

Installing and Removing the SCSI Board..

........................................................ 50

Section L -Replacing the Digital I/O Option Board

............................................................

5 1

Section

M-Replacing the

O.S.

EPROMs..

.......................................................................... 53

Section N -Replacing the Wheel Assembly..

.......................................................................

54

REPLACING ASR RACK MODULES..

..........................................................................

56

Section A-Replacing the Rack Digital Board

..................................................................... 56

Section B - Replacing the Rack Analog Board

..................................................................... 57

Section

C -

Replacing the Rack Power Supply Board..

........................................................ 58

Section D-Replacing the Rack Keypad/Display Board

...................................................... 59

Section E-Replacing the Rack KPC

Simulator Board

........................................................ 60

Section F -Replacing the Rack Digital Jack Board..

............................................................ 60

Section G -Replacing the Rack Analog Jack Board

............................................................

60

Section H-Replacing the Rack

Disk Drive

......................................................................... 61

Section I-Replacing the Rack Transformer..

.......................................................................

62

Section J - Replacing the Rack Line Filter

........................................................................... 62

SectionK-

Replacing the Rack

SCSI

Board..

...................................................................... 63

Section L -Replacing the Rack Digital

I./O

Option Board

................................................... 63

Section M - Replacing the Rack O.S. EPROMs

................................................................... 65

SectionN-

Replacing the Rack OEX-6sr Board..

................................................................ 65

Section 0- Replacing the

PCB

Mounting Bracket

.............................................................. 66

IMPORTANT INFORMATION ABOUT

SJMMs.. ........................................................

67

SCSI INFORMATION..

..................................................................................................... 74

DIGITAL I/O INFORMATION..

......................................................................................

76

OEX-6sr INFORMATION

................................................................................................ 77

Glossary..

............................................................................................................ Inside back cover

Part Numbers for ASR Modules

........................................................................

Inside back cover

Contacting ENSONIQ..

......................................................................................

Outside

back cover

ASR Service Manual

Page 4

Table of Contents

LIST OF FIGURES

Figure 1 - Note the single jumper above the Simm slots

Figure 2 - Note the two different jumpers above

Figure

3 -

Rear view of Panasonic Disk Drive .....................................................................

Figure 4-Correct Sony 420-l jumper settings..

Figure

Figure6-

Figure7Figure

Figure9-

5 -

Correct tool for removing cables..........................................................................

ASR Block Diagram.. ...........................................................................................

Communications Path

8 -

AC Line Voltage Check Points ............................................................................

ASR-10 Power Supply

..........................................................................................

Board..

.............................................................................

theSEvIM

...................................................................

Figure 10 - Incorrect Analog Power Supply Voltages (flow chart)

Figure 11 - Incorrect Digital Power Supply Voltages (flow chart)

Figure

Figure

Figure

Figure

Figure

Figure

Figure 18 - ASR-10 Analog Board

Figure

Figure 20-ASR- 10

Figure

Figure 22 - SCSI Board Mounting

12 -

No

LEDs Lit (flow chart) ...................................................................................

13 -

All LEDs Lit,

14 -

ROM and disk Compatibility

15 -

ASR-10 Exploded View.. ...................................................................................

16 -

ASR-88 Exploded View.. ................................................................................... 40

17 -

ASR-10 Digital Board..

No

Display (flow chart).

.............................................................................

......................................................................................

.......................................................................................

19 -

ASR-10 Center Support Bracket Assembly.. .....................................................

Keyboard Mounting Bracket..

21-ASR-88 Bracket locations..

................................................................................

........................................................................................

Figure 23 - Installing a DI-10 Board into an ASR-10 Keyboard Unit

Figure

24-ASR-1OR

Exploded View.. ................................................................................

Figure 25 - Top Side of the ASR-10 Rack PCB Mounting Bracket

......................................................

slots .........................................

......................................

.......................................

..............................................................

..............................................................

..................................

.....................................

Figure 26 - Installing a DI-10 Board into an ASR-10 Rack Unit.. ........................................

Figure

Figure

Figure

Figure

Figure

Figure 32

Figure

Figure

Figure

Figure

27-SIMM Layout.. ...................................................................................................

28-Board differences ...............................................................................................

29-Simm Access on the new Rev Board .................................................................

30 -

THESE ARE THE ONLY CONFIGURATIONS THAT WILL WORK PROPERLY!.

3 1 -

SIMM Access on the Old Rev Board..

-

THESE ARE THE ONLY CONFIGURATIONS THAT WILL WORK PROPERLY!.

...............................................................

33-SIMM Socket Components ................................................................................

34-Removing SIMMs ..............................................................................................

34-Installing SIMMs.. ..............................................................................................

36-A properly Installed SIMM

................................................................................

.7 1

.

.72

.

2

2

3

4

6

7

10

12

13

14

15

17

18

25

39

42

42

44

46

46

50

52

55

64

64

67

68

70

71

72

73

73

73

ASR Service Manual

Page 5

Important

IMPORTANT THINGS TO KNOW ABOUT THE ASR-1

O/88

About this manual: The instructions in this manual are for both the

ASR-10/M?

Keyboard and Rack

unless otherwise noted. When you are troubleshooting an ASR Rack and the instructions say to check the

keyboard, substitute a check of the KPC simulator board. When you are troubleshooting an a ASR-88 and the

instructions say to check the keyboard, substitute a check of the keyboard adapter board.

As with every ENSONIQ product, all ASR service is handled through the ENSONIQ Module Exchange

Program. Rather than diagnose and exchange individual components, you will replace complete modules.

We feel that this is the most time and cost effective method of repair, both for you and your customers.

Known Areas of Concern

The four known problem areas of ASRs have been: 1) SIMMs; 2) the disk drive; 3) distorted sound; and 4)

fuses blowing. Those items marked with a

G+=

are known areas of concern, other items are important things to

know about the ASR.

*

Avoid Damage from ESD

(Electra

Static Discharge) !!!

How can we minimize the possibility of causing ESD dama,e

0 ?

Here are some procedures you can follow

when working on ENSONIQ products.

l

Before beginning any work you should be grounded. Discharge any static electric charge built up on the

body. This will be accomplished by using a ground strap that attaches to your wrist and ground leaving your

hands free to work.

l

Always look for ESD warnings before opening any packages from ENSONIQ.

l Always avoid unnecessary physical movement, such as scuffing the feet when handling ESD sensitive

devices. That kind of movement can generate additional charges of static electricity.

l Minimize handling of ESD sensitive devices. Keep ESD sensitive devices in their static free packages

until needed. Only transport or store ESD sensitive devices in their protective packages.

l When handling ESD sensitive devices, avoid touching any connector pins, leads, or any other electrical

connections on the board. Try to handle ESD sensitive devices by the edges only.

a=SIMMs

Often a customer may think that a unit is broken, when it simply does not have the correct SIMMs installed.

It is important to thoroughly qualify the SIMMs that are installed before troubleshooting further.

Read and

understand the following notes about SIMMs, and refer to the special SIMMs section at the rear of this

manual to be sure a customer is not experiencing problems due to incorrect SIMMs, or SIMMs that are not

installed properly.

What

SlMMs

to Use

The ASR-10 and ASR-88 mainboard has been redesigned. It changes the type of SlMMs that can be used, and

the way that you install the

SIMMs.

The new mainboard is used starting from the following serial numbers:

ASR-10

-

20677

ASR- 1 ORack

-

014567

ASR-10 w/SCSI

-

13126

ASR-88

-

all units

4SR Service Manual

1

Page 6

Important

Note: It is possible that your unit has a different rev board than these cutoffs suggest, due to a repair or other

circumstance. Be sure to check it against the diagrams here to confirm which rev board you have.

What Changed?

The newer board can accept 2 chip and 8 chip 4meg SIMMs. The older board can only use the 8 chip parts.

Since the 2 chip parts are becoming more common (and possibly less expensive) we redesigned the board to

allow you to use them.

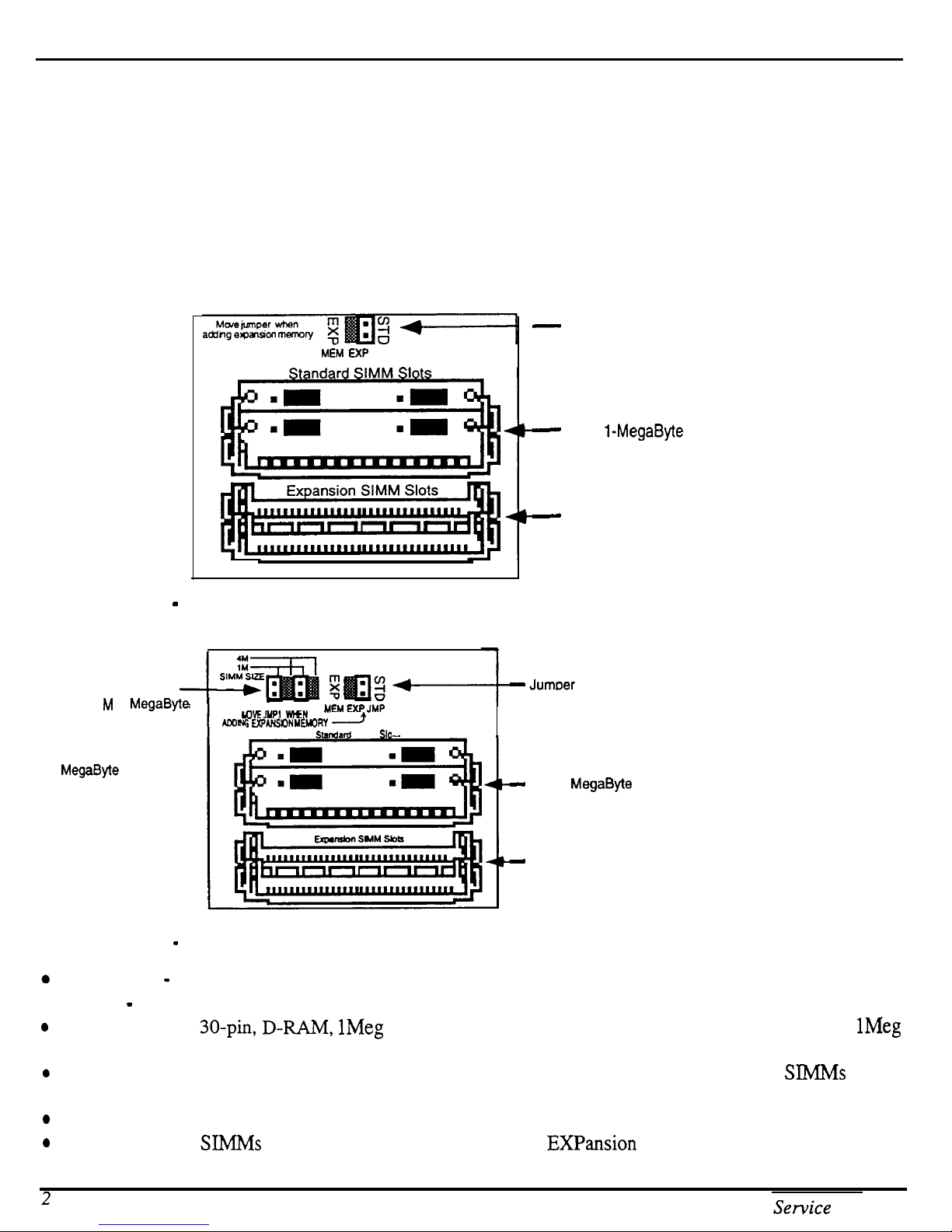

How to Tell Which Rev Board You Have

The old rev board looks like this:

-

Jumper is connected for

M6.4 EXP JMP

STANDARD SIMM Memory.

Move to the other pins when

using Expansion SIMM Slots.

-

Two 1-MegaByte SlMMs

Figure 1 - Note the single jumper above the SIMM slots.

The new rev board looks like this:

SIMM Size Jumpers (2)

are set to 1 M (1

SIMMS). Move the

jumpers to the 4M

positions when changing

to 4

MegaByte

MegaByte

SIMMS.

Figure 2 - Note the two different jumpers above the SIMM slots.

y- - -

DEJYPI

i EXPANSON

-.. M

WN

YMRY

Smndrfd

IEM EXF’JMP

)

SIMM Sk

-

Expansion slots are empty

-

Jumoer is connected for

STANDARD SIMM Memory.

Move to the other pins when

using expansion SIMM slots.

-

Two 1 MegaByte SlMMs

-

Expansion slots are empty

0

Keyboard - SIMMs may be installed by customer.

l

Rack - SlMMs must be installed by Repair Stations because the lid must be removed.

0

The ASR uses 30-pin, D-RAM,

9 or 4Meg x 9 parity SlMMs). The ASR will not accept static RAM or ROMs.

0

We do not recommend using parity SIMMs (designed for IBM PC compatibles). These SIMMs may not

operate properly, and may cause damage to the ASR.

0

We recommend using SIMMs with an access speed of 80 nanoseconds or faster.

0

When installing SIMhJs be sure to move the jumper to the Expansion position.

2

1Meg

x 8 or 4Meg x 8 (Macintosh-type) non-parity SIMMs (not

ASR Sewice Manual

1Meg

x

Page 7

Important

l

If SIMMs are installed in a less than optimal configuration (see pp.

71-72),

the display will read SIMMs

IN WRONG SOCKETS after booting. If this message is displayed, you should power off and check the

SIMMs configuration.

l

SIMMs that have GAL (gate array logic) or PAL (programmable array logic) chips on them may be too

thick to fit into the standard sockets that are used on the ASR. Even if the SIMMs with

GALS

or

PALS

fit, they will draw too much power and certain configurations (i.e. 2M x8 SIMMs) will not work

properly.

l

See Important Information About SIMMs, p. 67.

THE DISK DRIVE

Transporting a unit

We do not, under any circumstances, recommend the insertion of an actual disk during transport. Only

transport the unit with the drive empty. Please do not ship an ASR or a replacement disk drive in a box

packed with foam peanuts. If you must use foam peanuts, wrap the entire unit in plastic first. Foam peanuts

may cause severe damage to the disk drive or keyboard.

What disks to use

It is very important to use double-sided, double-density (DD) or high density (HD) 3.5” micro-floppy disks.

The ASR writes information to every track on a disk, so it is imperative that the disk be of superior quality.

Disks that have been pre-formatted for MS DOS are not always reliable and should not be used.

Testing the Disk Drive

The best way to test the disk drive is by formatting a disk. When a disk is formatted, the ASR reads and

writes every track on that disk. If the formatting fails, the disk itself may be faulty. Try formatting another

disk before determining that the disk drive is faulty. Unlike some computer systems, the ASR does not

automatically discard bad sectors when formatting. The entire disk must be good for successful formatting.

There is an exception, a disk that has been pre-formatted for MS DOS may be able to be formatted for use in

an ASR and still not work reliably in the ASR.

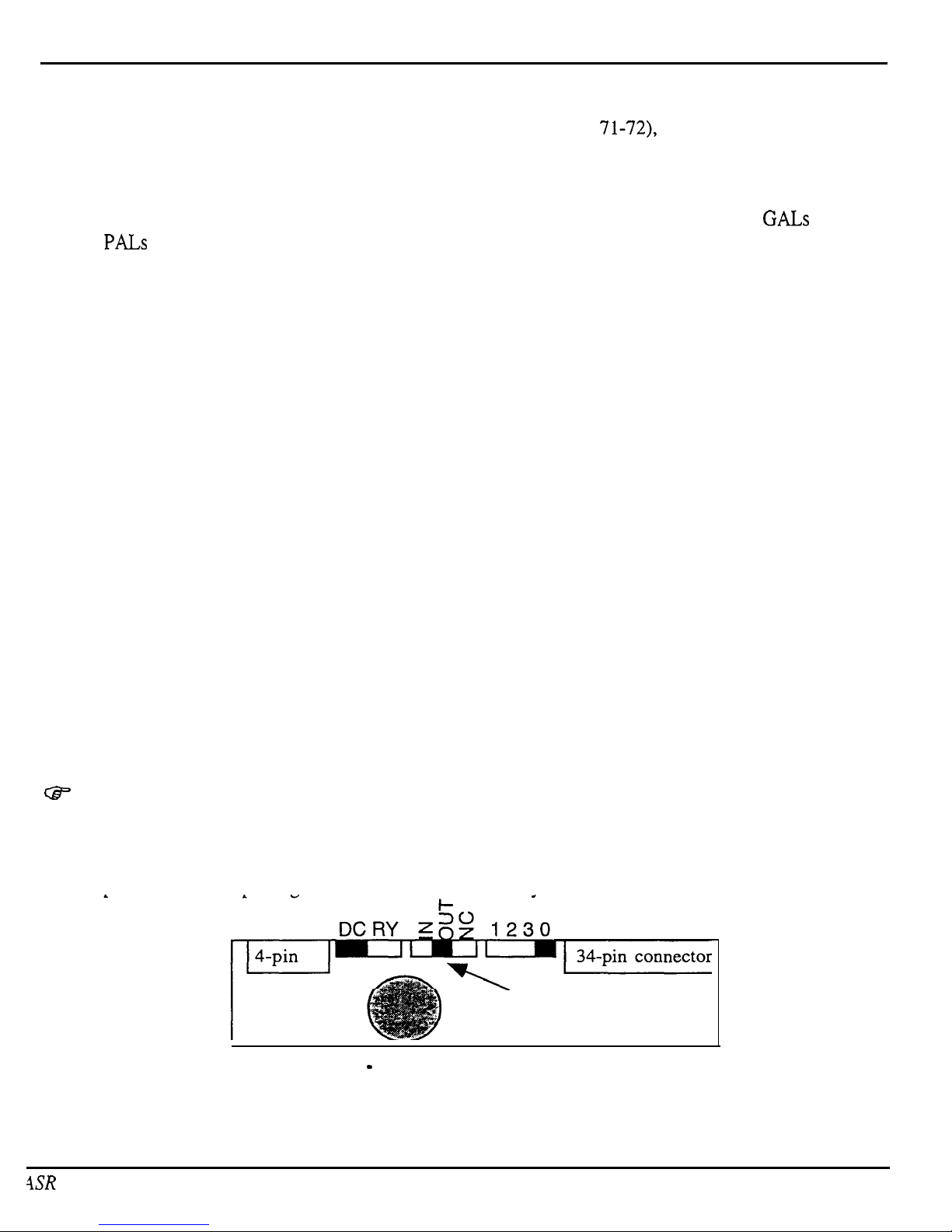

e

A few different disk drives were used in the ASR: two types of Panasonic drive and one Sony drive.

Make sure that when you install a new Panasonic disk drive that the switches on the rear of the drive are set as

shown in Figure 3. On some Panasonic disk drives, the Drive Select Switch has only two positions instead of

four. The drive select should always be set to zero (0). If the drive cable is too short, you may also need a

new 34 pin cable when replacing a Panasonic drive with a Sony drive.

-Make

sure that this

switch is in the middle!

Figure 3 - Rear view of Panasonic Disk Drive

4SR

Service Manual

3

Page 8

Imoortant

e

Customers may complain that their ASR will not read some of their disks.

Density

(I-ID)

disks that have been formatted as Double Density (DD) on a DD drive in a unit such as an EPS,

Please be aware that High

EPS-16 PLUS, or a Macintosh Plus will not be recognized in machines that have an HD drive. This would

include the ASR, as well as an IBM PC or clone. Disks that have been pre-formatted for MS DOS are not

always reliable and should not be used.

e

On early units, removing the disk drive causes the disk drive bezel to break.

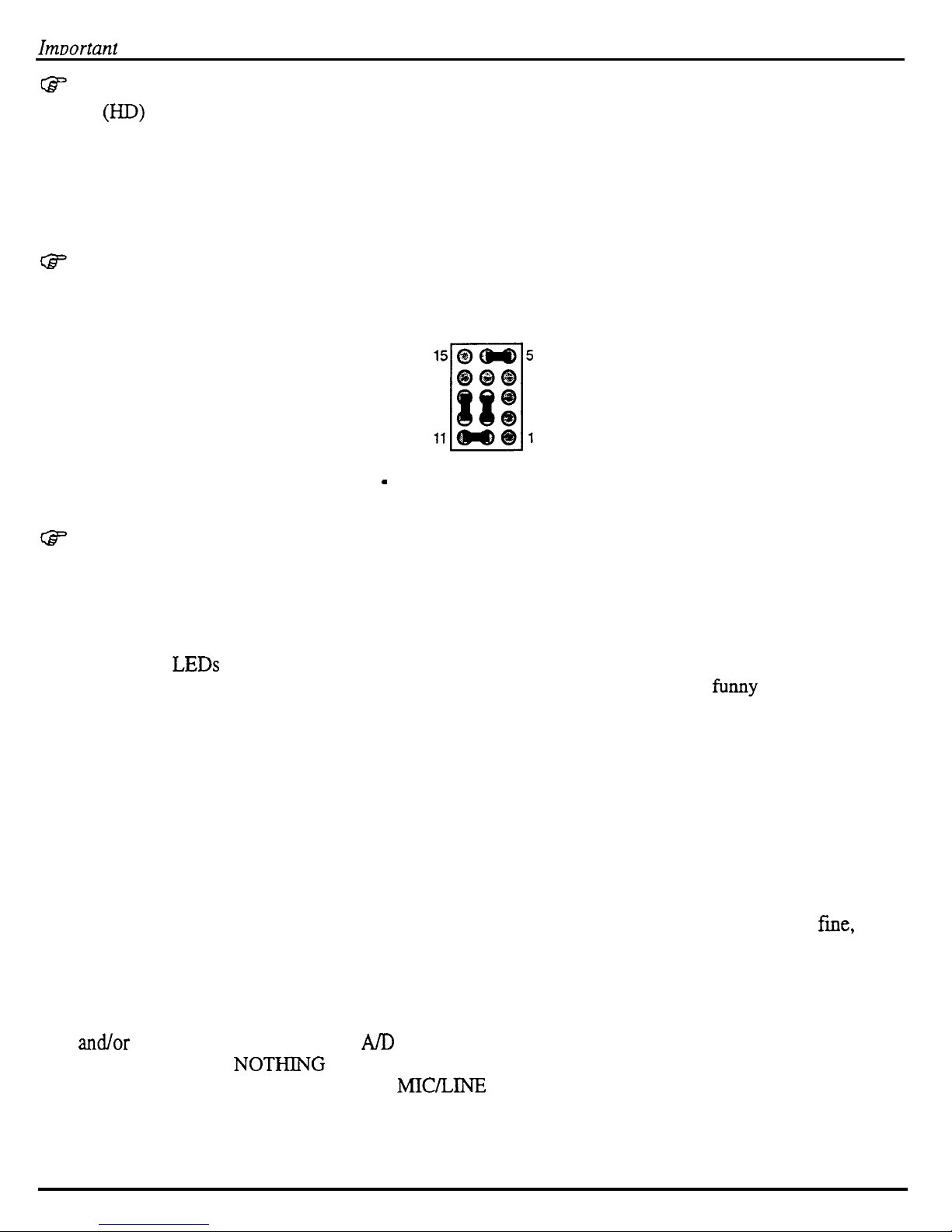

The Sony 420-l disk drive has a jumper block. The correct jumper settings are shown in figure 4.

Figure 4 - Correct Sony 420-l jumper settings

CF In keyboard units, some plastic on both the wheel cover and end cap has to be removed. Replacement

disk drives now come with a template and instructions for cutting the plastic on the wheel cover for older

units. See the information included with the new drive.

UNIT SOUNDS DISTORTED

l

If the Peak LEDs on the Input Level are always on, this usually indicates a blown fuse.

l

Setting the loop end point before the loop start point can cause the unit to make funny sounds. To check

this, select the sound that this is occurring on, then select the wavesample: press Edit, underline WS, and

play a key that plays the offending sound so that the display shows a number (rather than ALL). If no

number will show up, underline layer and choose a new layer, then try again. Press Wave, press right

arrow repeatedly until the display shows LOOP START. Note the percentage number in the parenthesis.

Press right arrow again until the display shows LOOP END and note the number in the parenthesis for

loop end. The loop end number must be larger than the loop start number. No factory sounds are shipped

this way, so this is most likely to occur on sounds that the customer has created or modified.

l

Make sure that the cable for each jack board is connected properly.

l

ESP download failures will show up as either a “SYSTEM ERROR xxx” or as the outputs playing “dry”

without any effects, with garbled effects, or with no sound at all. If sounds set to DRY sound fine, but

sounds with effects don’t, replace the digital board.

l KEYBOARD ONLY: If there is distortion on the tail of every sound, and the serial number of the unit is

between 10970 and 11700, replace the analog board.

l

If a sample that the customer recorded into the ASR sounds distorted or there is a click in the beginning

and/or end of the sound, check the A/D chip on the Analog board:

a)

Make sure that NOTHlNG is plugged into either of the ASR Audio Input jacks.

b)

Keyboard only: Make sure that the MIC/LINE switch is in the LINE (down) position.

C

)

Make sure that the Input Level pot is turned fully down (counterclockwise when facing the back of

the ASR).

d) Press Command, then Env 1.

4

ASR Service Manual

Page 9

Imnortant

e)

Press the right arrow button until the display shows DC OFFSET.

fj’

Press

Enter*Yes.

The display should show: LEFT=

+/-0000x

RIGHT=

+/-OOOOy

g)

If one or both of the values is 32,767 replace the analog board.

h)

In a properly functioning unit, the reading should not be greater than 20 counts from zero (+/-

00020). If the values exceed this: RACK: Replace the analog board.

KEYBOARD: You can adjust each pot on the analog board to be as close to zero as possible:

1)

You can adjust the pots (these are the only two pots on the analog board) with your fingers. You

must reach under the unit and locate the pot that needs to be adjusted. Locate this visually before

grabbing it. Slowly turn the pot clockwise (to the RIGHT) to increase the reading, or counter-

clockwise (to the LEFT) to decrease the reading.

2)

If they cannot be adjusted within the allowable range of +/-00020, replace the Analog Board.

i) Press

Cancel*No

to stop the test. The display shows: DC OFFSET

FUSES

l

A system error may be the result of blown fuses. Check the fuses first.

0

If the Peak LEDs are always on, fuses may be blown. When the sample peak LEDs are on, it is usually a

blown fuse.

.

Fuse Ratings (as of October, 1995)

UL rated fuses

IEC 127 rated fuses Where Used

(lOOV, 12OV,24OV)

(230V units only)

Fl and F2

1.6A

fast blow

Tl

.OA slow blow

Analog

F3 and F4 4.OA

fast blow

F4.OA

fast blow +VD Digital/Display/KbdSCSI/DI-10

F5 1.6A

fast blow

F1.6A

fast blow Display

F6 and F7

l.OA slow blow Tl.OA slow blow

AIldOg

F9 2.OA

fast blow

F2.OA

fast blow Line Fuse

The 20-pin

Keyboard/KPC

Simulator Ribbon Cable

When reconnecting this cable to the digital board, make sure that the striped side is aligned with pin 1 and that

the cable is not mis-pinned. If the cable & r&-pinned or installed backward, fuses F3 and F4 on the power

supply board will blow. NOTE: If one fuse blows, the other will blow also; you must replace both.

Customer Thinks the Unit is Broken

l

Version 240 KPC software, when you hold down up arrow and press down arrow, numbers would

scroll instead of going to the halfway point. A new keyboard with 2.41 fixes this problem. See Software

Notes.

0

The sampling “Level Detect” screen should be looked at as an averaging meter and not as an accurate or

realtime signal. Some customers were concerned that their units were broken because the level detect

indicator bounces all over the place or does not respond to peaks.

.

Customers may complain that their ASR will not read some of their disks. Please be aware that High

Density (I-ID) disks that have been formatted as Double Density (DD) on a DD drive in a unit such as an

EPS, EPS-16 PLUS, or a Macintosh Plus will not be recognized in machines that have an HD drive. This

would include the ASR, as well as an IBM PC or clone. Disks that have been pre-formatted for DOS

are not always reliable and should not be used.

ISR Service Manual

5

Page 10

Important

MECHANICAL ISSUES

Keyboard:

two 6-32s into main board heat sink, and self-tapping into the extrusion. The 6-32s were eventually

changed to

Keyboard:

unit. The wheel cover was modified on later units to prevent this.

Keyboard: If the mounting posts for the wheel brackets break, call ENSONIQ for a new wheel cover

that has the posts reinforced.

Keyboard: Early units may have buttons sticking or keys clacking. To make sure that buttons don’t

stick on later units, a M4xlOmm hex head set screw was added to the extrusion rail that the

keypad/display board mounts to locate the keypad/display board properly. Don’t remove this set screw.

Rack:

screws are not used. Nylock screws have a patch of nylon on the threads for greater holding power.

Rack: On ASR Racks with serial numbers between 10000 and 10500, the rack ear screw PEMs (screw

mounting standoffs) may fall inside the unit.

W

ASR Case (Avoid Stripping Screws)

Be careful when assembling or disassembling any part of the ASR. Avoid over-tightening screws when

repairing a unit! Use no more than 8

made of aluminum extrusions and steel. Some parts are held in place by screws that

tighten into aluminum mounting rails that are part of the case. When replacing any of these screws, it is

possible to over-tighten the screws and strip out a hole.

Originally, three different types of screws were used in the ASR keyboard base pan 832s,

8-32s,

so that there are now only two different types of screws.

On early units, you may break the disk drive bezel when removing the disk drive from the

On Rack units, use a drop of Loctite on screws that hold the circuit boards in place if nylock

incMbs

of torque when tightening any screw. The ASR case is

W

High-Retention Force Connectors (Repair Technicians Label)

Inside the ASR is warning/information label just for you. We wanted to let you know that we use high

retention force connectors in the ASR. This means it is very difficult to remove a connector by just pulling.

We recommend the use of a scribe, screwdriver or similar object when disconnecting cables. Watch out for

them, and please don’t pull on the wires!

We have found that some units develop further problems once a module has been changed. This

may be

a result of improper handling of cables. We suggest removing all cable connectors using the angled end of a

scribe (see Figure 5).

Figure 5 - Correct tool for removing cables

Scribes can be found in the following catalogs:

l Techni-Tool catalog part number 400PR144.

l Newark catalog part number

76-

15 10.

6

ASR Service Manual

Page 11

Important

GF OEX-6sr CONNECTOR ON ASR KEYBOARD AND ASR-88 CAUTION!!! IMPORTANT!!!

The OEX-6sr should never be plugged in or unplu,,

OOed

with the ASR power on, as this could damage the

ASR. The 8-pin mini-DIN connector on the rear panel of the ASR should only be used to connect the

OEX-6sr Output Expander to the unit. This connector does not simply supply audio outputs and signal

ground and, therefore, cannot be used to generate separate outputs without the OEX-6sr. The ASR

generates digital signals that must be converted externally. The signals present on this connector include

digital control signals and

+/- 15VDC.

Improper connections to these signals could easily damage the

ASR or any external device connected.

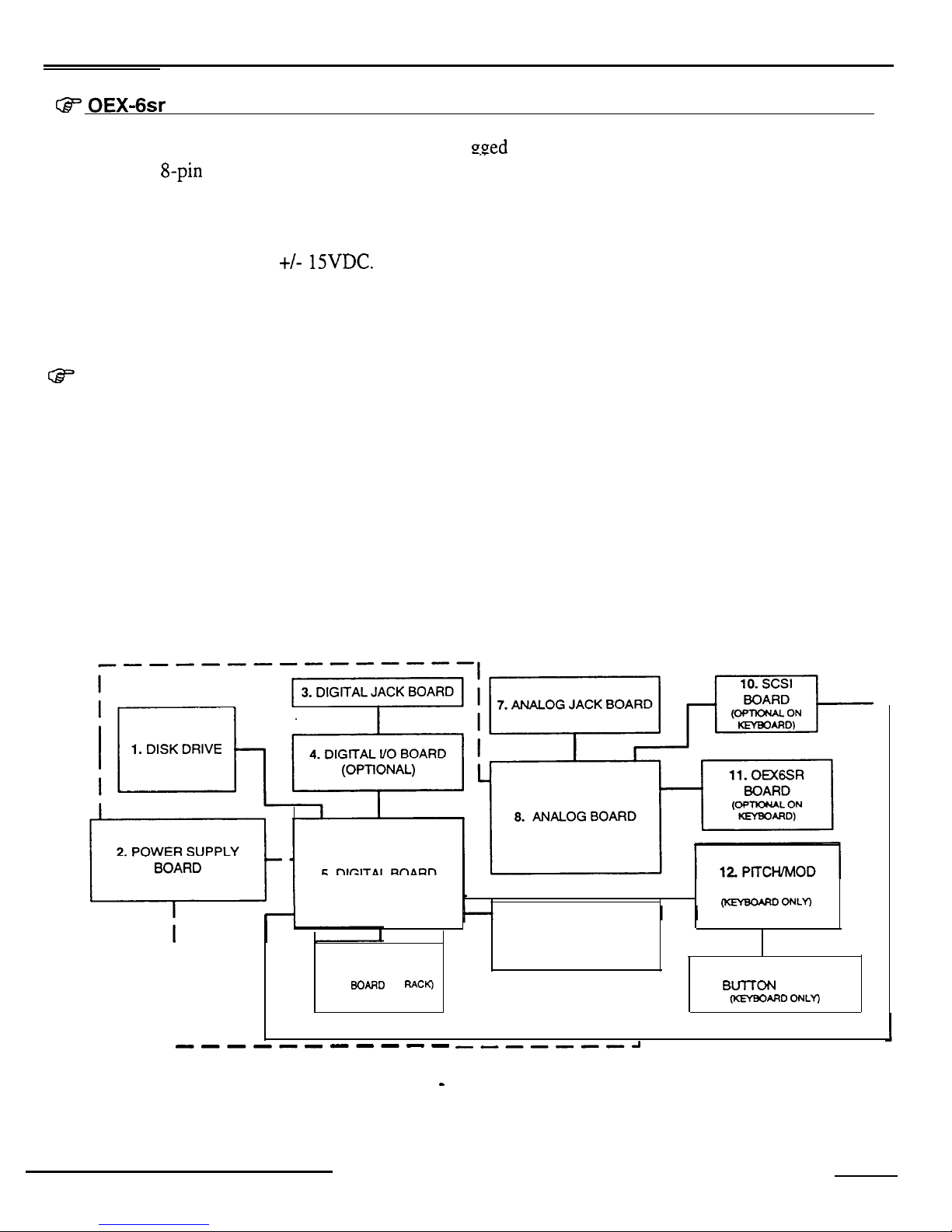

HOW THE ASR WORKS

W

This section should help you understand what each module in the ASR does. Reading this may help you

decide what module is faulty by just knowing the ASR system better.

The ASR- 10 is a powerful self-contained computer system. It offers users the ability to accomplish many

tasks, some of these are:

l Sampling audio information from external sources

l Resampling its own audio output

l Adding digital effects to samples

l Sequencing

l Digital audio track recording

l Disk storage and retrieval

The ability to accomplish these tasks makes the ASR-10 a complex system.

Figure 6 shows the ASR-10’s main components as a complete system.

WHEEL ASSEMBLY

m

ONLY)

9. KEYPAD/DISPLAY

BOARD

I

6. KEYBOARD

13. PATCH SELECT

I

(KPC

BOARD

ON

RACK)

I

BmON

BOARD

I

I

(KFfBOARO ONLY)

I

--------s-s

,,-----a

Figure 6 - ASR Block Diagram

ASR Service Manual

7

Page 12

Important

The block diagram also represents the modular design of the ASR-10. Each one of the main components

represented in the diagram can be replaced, if necessary, without disturbing the other components in the

system. Looking at the diagram you see:

1. Disk Drive

2. Power Supply Board

3. Digital Jack Board

4. Digital I/O Board

5. Digital Board

6. Keyboard (KPC Board on Rack)

Data storage and retrieval device.

Converts AC voltages to regulated DC and unregulated AC and DC to

be distributed throughout the system.

Connections to facilitate the use of the optional digital I/O board. MIDI

jacks, CV pedal jack, and footswitch jacks

Optional board that enables the ASR-10 to use digital audio data directly

from a digital source, such as DAT. It also allows the ASR-10 to output

digital audio data directly to a digital recorder, such as DAT.

The engine of the ASR-10. It has the microprocessor, the sound

processor, operating system memory, sound memory, effects processor,

and floppy disk controller. It also has the circuitry to control all inputs

to and outputs from the system.

Sends performance information (note on, note off, pressure) to the ASR-

10 digital board. Also handles communications to and from the

keypad/display board.

7. Analog Jack Board

8. Analog Board

9. Keypad/Display Board

10. SCSI Board

ll.OEX6sr

.12.

Pitch and Mod. Wheel

Board

Assembly

Has the input pre-amp circuitry on it, all of the audio inputs and outputs

(except for OEX-6).

Converts analog audio signals into digital audio signals and passes them

to the digital board. Converts digital audio signals to analog audio

signals and supplies them to the audio outputs and headphone amplifier

Transmits button presses to the digital board through the keyboard, and

receives display data from the digital board through the keyboard. See

figure 7 for further details.

Allows access to SCSI devices for storage and retrieval of data, and disk

track digital recording. It is an optional board on the ASR- 10 keyboard.

Optional board on the ASR-10 keyboard. Adds three additional stereo D

to A converters for six additional analog outputs.

Transmits pitch and modulation wheel movements to the digital board. It

is not included on the ASR-10 rackmount.

8

ASR Service Manual

Page 13

ImDortant

13. Patch Select Button Board

Transmits patch select button presses to the digital board. It is not

included on the ASR-10 rackmount.

The ASR-10 was designed with the analog and digital sections on different boards, and the analog and digital

jack boards separate, for some specific reasons.

l

Only the digital board requires a four-layer circuit board so there is a cost savings using a two-layer board

for the analog section.

l

It is easier to break the connections between the analog board and the digital board to install the optional

optically isolated SCSI board. This ensures that no matter how much digital noise is induced on the digital

board due to SCSI, it won’t reach the analog section.

l

Having separate jack boards allows the interface points with the outside world to be placed away from

circuitry that can be damaged by Electra Static Discharge that can be introduced at these points. This

decreases the instruments susceptibility to damage from ESD.

Keyboard and Rack Similarities

The Keyboard and the Rack use the same operating system (OS.) disk. The ASR-88 uses different EPROMs.

All circuit boards except the keypad/display board are the same for both the keyboard and the rack. However,

there are physical differences that will require you to specify for which unit you are ordering parts.

Instead of a Poly-Key keyboard assembly, the Rack has a KPC simulator board. The KPC simulator board

passes information between the keypad/display board and the digital board (like the keyboard does for the

keyboard unit). In the rest of this manual, whenever you see “keyboard,” substitute KPC simulator for the

Rack and keyboard adapter board for the ASR-88 (except where otherwise noted). The ASR Rack has the

OEX-6sr Output Expander and SCSI Interface (SP-3) built-in. These two expanders are options for the

Keyboard unit. Digital I/O is an option for all ASR models. The ASR-88 has 16Meg of RAM standard, and

SCSI. The ASR-88 has a keyboard adapter board instead of a KPC board.

Communications Path

It is important that you completely understand the communications path

of

the ASR.

Please read this

carefully.

The ASR digital board, keypad/display board and keyboard are complete computer systems in themselves,

each with its own microprocessor and operating software. The modules communicate with each other using

serial communication ports. Whenever a key is played on the keyboard, for example, the keyboard assembly

microprocessor transmits this information to the microprocessor on the digital board.

The keypad/display board communicates with the digital board through the keyboard. Whenever the digital

board wants to put a message on the display, it sends the message to the keyboard which then passes it on to

the display. Whenever a button is pressed on the control panel, the keypad/display board’sends the message to

the keyboard which, in turn, passes it on to the digital board.

The communications path is shown in Figure 7. The digital board communicates with the keyboard over a

two-line asynchronous interface carried by the 20-pin keyboard ribbon cable. The keyboard communicates

with the keypad/display board over a three-line synchronous interface that is carried over to the digital board

via the 20-pin ribbon cable, then up to the keypad/display board via the 24-pin ribbon cable.

ASR Service Manual

9

Page 14

Imoortant

Due to the complexity of the modules involved, it is often difficult to determine which module is at fault when

a communications problem occurs.

KEYPAD/DISPLAY BOARD

1

DIGITAL BOARD

DATA DATA CLOCK

IN

/

I

OUT OUT

DATA DATA

IN

ASYNCHRONOUS

OUT

PORT

DATA

DATA CLOCK

I

Figure 7 - Communications Path

I

24 PIN DISPLAY

CABLE

If a communication problem occurs (i.e., no display or no response to button presses or keys), it could be

something as simple as a bad cable, or it could be a problem in one of the modules. To help you identify a

faulty module, a Communication Test Board is available from ENSONIQ Customer Service*. The

Communication Test Board simulates the operation of the keyboard and can be used as a “known good”

module in place of the keyboard for troubleshooting.

*This is the same communications test board that was sent out to service centers in 1990 to troubleshoot

polypressure keyboard problems.

IMPORTANT!

When using the Communication Test Board, keep in mind that it is sensitive to static discharge. Handle the

board by the edges and store it in the anti-static shipping bag when not in use. Do not let the board short out

when testing, place an insulator (cardboard, paper, etc.) underneath it,

Attaching the Communications Test Board

If an ASR has a communications problem, turn the unit off and unplug the 20-pin keyboard ribbon cable from

the digital board at connector J7. Plug the 20-pin ribbon cable from the Communication Test Board into

57.

This will eliminate the keyboard as a variable. Turn the system on. If the communications problem persists,

you know the keyboard is not at fault. If communication is restarted, however, the keyboard is at fault.

There is one further complication. Since the communications path between the keyboard and keypad/display

board is routed through the digital board, there is a remote possibility that the printed circuit connections

10

ASR Service Manual

Page 15

Important

between the two connectors are defective. If you have an ASR that has a problem communicating with its

keypad/display board, you may want to verify continuity between the connectors on the digital board.

Turn off the power and unplug the 20-pin ribbon cable from the ASR digital board at J7 and the ASR 24-pin

display cable from the digital board at Jl. Using an ohmmeter, verify continuity between the following points

on the digital board:

57 (20~Din

connector)

J 1

(24-Din

connector)

Pin 1

to

Pin 9

Pin3 to Pin 10

Pin 5

to

Pin 11

TROUBLESHOOTING

Often the faulty module in an ASR can be determined through normal use. Sometimes, it is difficult to

isolate the problem. The following flowcharts can help you diagnose units that appear dead (no display).

When troubleshooting an ASR, always disconnect any expansion devices that may be present (such as the

SCSI Interface or OEX-6sr Output Expander). This will prevent a faulty expander from complicating your

troubleshooting. Remember, when you take out the SCSI board, connect the analog board to the digital

board via a 34 pin ribbon cable to J6 on the digital board and Jl on the analog board.

The following pages include troubleshooting information:

Pao,e

Problem

12

AC Line Voltages

13

Power Supply Voltage Check Points

14

ASR with Incorrect Analog Power Supply Voltages (flow chart)

15

ASR with Incorrect Digital Power Supply Voltages (flow chart)

16

Display Self-test Chart

17

ASR with No LEDs Lit (flow chart)

18

ASR with All LEDs Lit, No Display (flow chart)

19

ASR Foot Switch and Patch Select Inputs

20

ASR-88 Keyboard

ASR Service Manual

Page 16

Checking the Power Supply

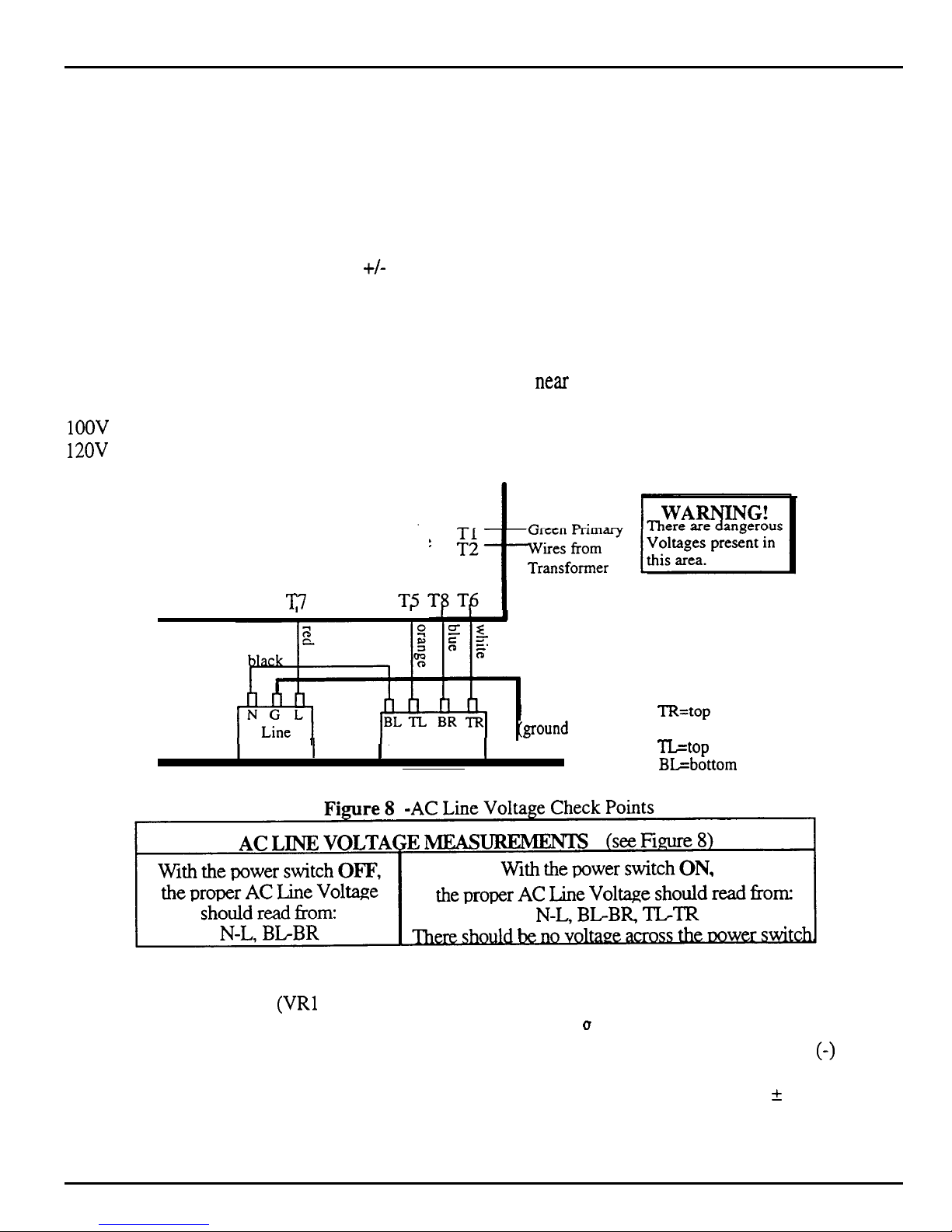

CHECKING THE POWER SUPPLY

Some ASR-10 problems may be related to a faulty power supply, transformer or line filter. You should

check these before troubleshooting the rest of the unit. Measure continuity across all the fuses to

make sure they are not blown.

Make sure that all the cable connections are secure and correct. Plug the ASR-10 in and turn it on.

After it has warmed up for five minutes, begin to test the voltages at the points shown in Figures 8 and 9.

It is normal for Line Voltage to vary

+/-

10%. If the voltages vary outside the allowable limits, follow

the procedure described under TESTING THE POWER SUPPLY UNLOADED (pp. 14-15) before

replacing it.

The voltage and part number of the chassis mount transformer are on the label on the top of the

transformer. The power supply part number is silk-screened near the center of the power supply PC

board. The chassis mount transformer part numbers for the ASR-10 are:

1OOV

1450000722 230V

12OV

1450000342 240V

1450000352

1450000932

These lugs are on the

power supply board.

v

NOTE: Wiring

is the same for

the ASR-10 Rack

Filter 1

Power Switch

green wire

Tground

I

to

case)

TR=top

BR=bottom right lug

TL=top left lug

BL=bottom left lug

right lug

Rear of ASR-10 Keyboard Unit

Analog Board Regulator Voltages

There are seven regulators (VRl through VR7) attached to the analog board heat sink. On the keyboard

(J

version, you can easily check to make sure that they are generatin,

voltages are silkscreened onto the analog board next to the regulator name. Place your ground

the correct voltages. The correct

(-)

probe

on the tab of VR5. To measure the output, place the other probe on pin 3 of the regulator (when the

regulator legs are closest to you, pin 3 is the right leg). It is normal for the voltage to vary f 5%.

12

ASR Service Manual

Page 17

Checking The Power Supply

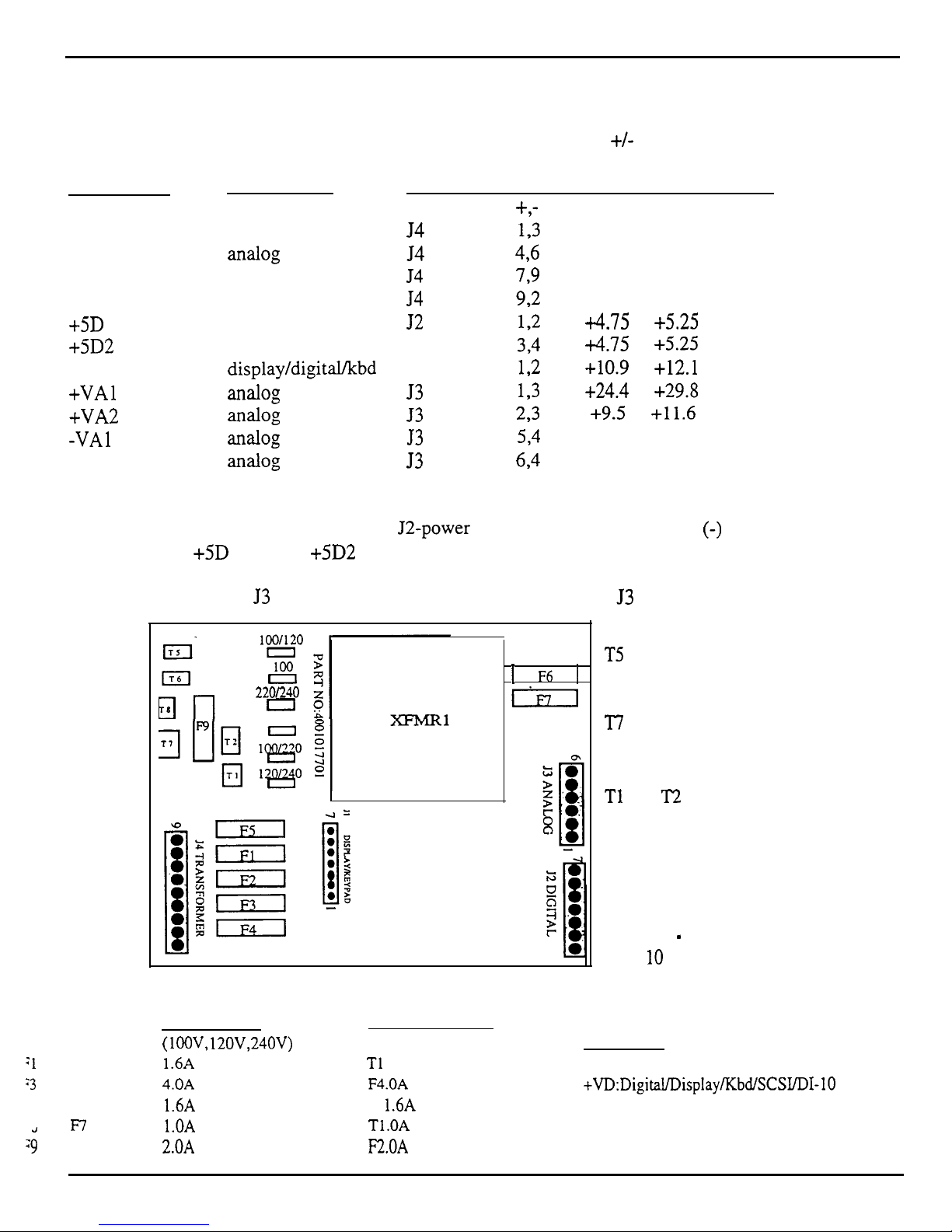

POWER SUPPLY VOLTAGE CHECK POINTS

Below are the voltage ranges for proper operation of each fully loaded supply and the pins to read across

with the voltmeter (see Figure 9). It is normal for line voltage to vary +/- 10%.

Designation

Where Used

Connector Pins Allowable range Units

+,-

Digital Supply

digital

54

193

18.7 to 22.8

VACrms

Analog Supply

XXil0g

54

496

17.1 to 20.9

VACrms

Display Filament display

54

799

5.1 to 6.2

VACrms

Display Offset

display

54

92

-25.0 to -30.6

VDC

+5D 1

digital

52

172

i4.75 to

+5.25 VDC

+5D2

digital J2

3-4

+4.75

to

+5.25 VDC

+VD

display/digital/kbd J 1

12

+10.9

to

+12.1 VDC

+VAl LUlal0g

53

193

+24.4

to

+29.8 VDC

+VA2

aIMlog

53

2,3

+9.5

to

+11.6 VDC

-VA1

Wtl0g

53

534

-27.6 to -33.8 VDC

-VA2

TilldOg

53

694

-10.9 to -12.1 VDC

J2 was marked Xl on some early versions of the power supply board. These voltages can also be

measured on the digital board (near the J2-power connector) with the ground

(-)

probe on the digital

board heat sink:

+5D

1 at FB3; +5D2 at FB2; and +VD at FB 1.

On keyboard units, the 53 power supply voltages may be measured at 53 of the analog board.

:l

and F2

:3

and F4

.,

and

F7

29

li%”

El

22OL240

0

120

t F6

1

Gil

T5 orange

T6 white

T8 blue

‘I7 red

Tl

and T2 are green

transformer wires

Figure 9

-

ASR- 10 Power Supply Board

UL rated fuses

(lOOV, 12OV,24OV)

1.6A fast blow

4.OA

fast blow

1.6A fast blow

l.OA slow blow

2.OA

fast blow

Fuse Ratings (as of October 1995)

IEC 127 rated fuses

(230V units only)

Where Used

Tl

.OA slow blow Analog

F4.OA

fast blow

+VD:DigitaL/Display/bdfSCWDI-10

F

1.6A

fast blow Display

Tl.OA slow blow

Analog

F2.OA

fast blow

Line Fuse

ASR Service Manual

13

Page 18

Checking the Power Supply

TESTING THE POWER SUPPLY UNLOADED

If the power supply readings exceed the indicated tolerance it is possible that a defective component one

of the other boards is drawing the power supply down. In this case, you should test the power supply

unloaded before proceeding. This involves unplugging circuit boards from the power supply one at a

time to see what board might be causing the incorrect readings. The procedure for doing this is shown in

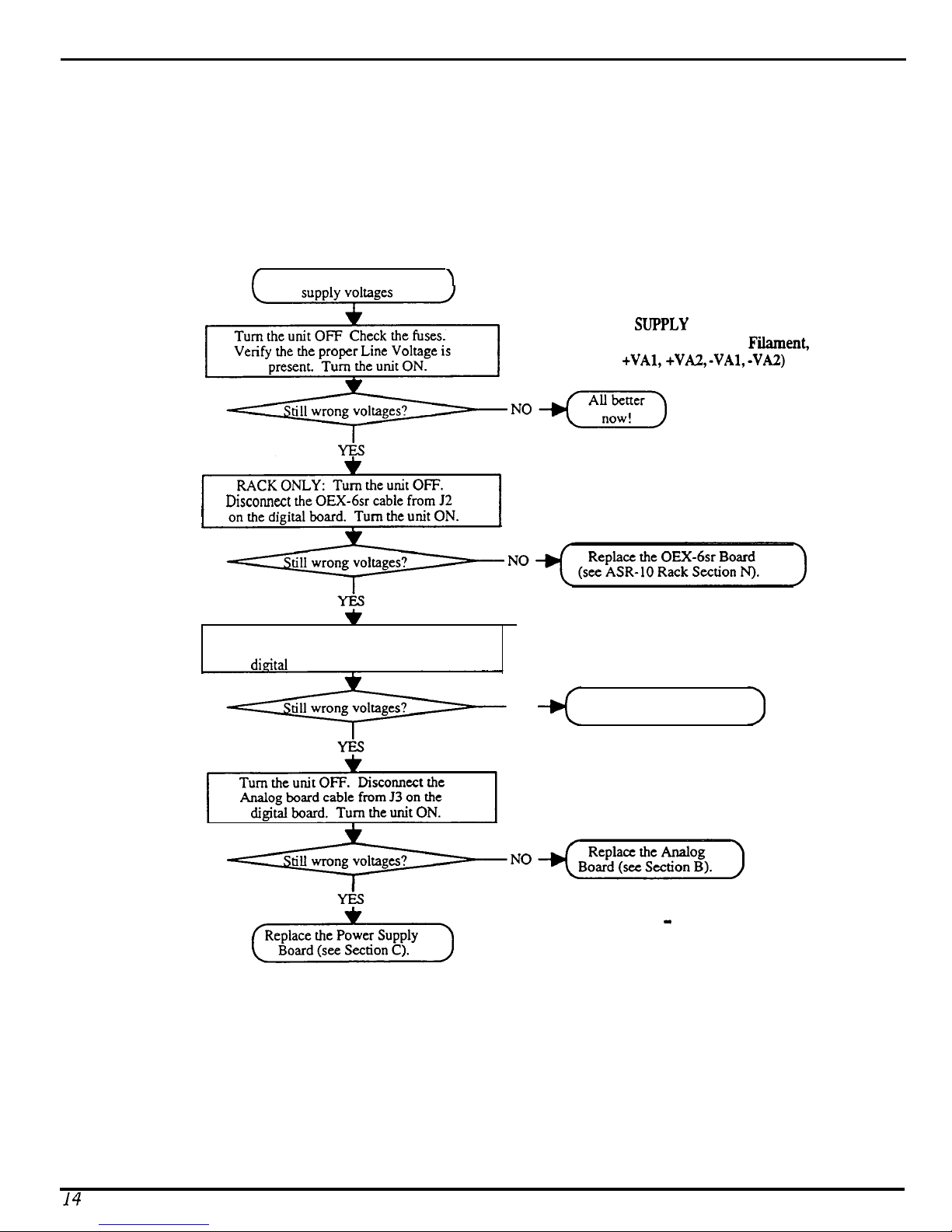

the flow charts, figures 8 and 9.

/

Incorrect analog power

\

INCORRECT ANALOG POWER

SUPPLY VOLTAGES

(Analog Supply, Display

+VAl, +VAZ, -VA& -VA2)

Fiient,

Disconycf

the OEX-6sr cable from J2

$1

Turn the unit OFF. Disconnect the

Analog Jack board cable from J4 on the

dieital

board. Turn the unit ON.

NO

Replace the Analog Jack

Board (see Section G).

Figure 10

Incorrect Analog Power

Supply Voltages

-

14

ASR Service Manual

Page 19

Checking The Power Supply

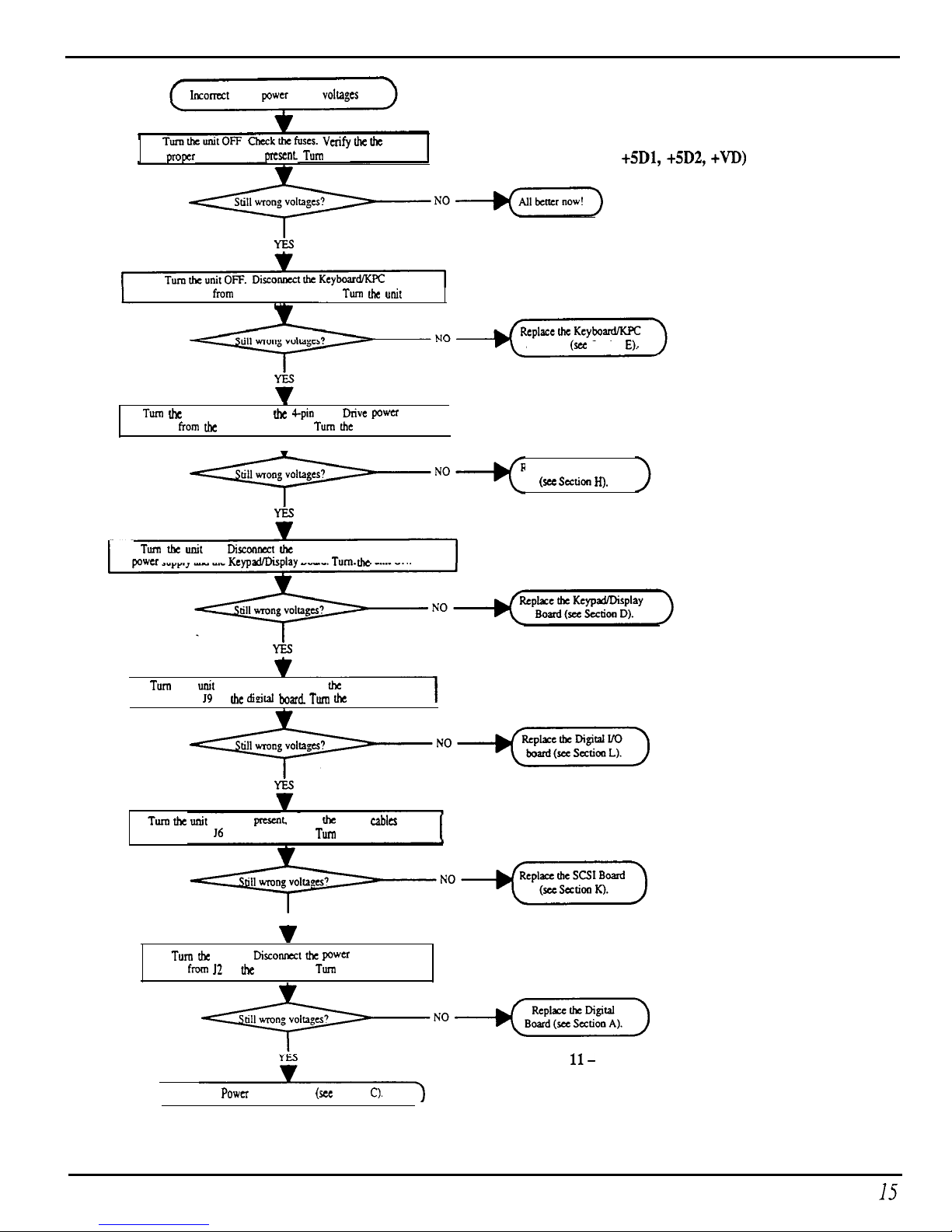

Incomct

digital power supply voltags

INCORRECT DIGITAL

TumtheunitOFF Checkthefuscs.

Vetifythetbe

pmpcr Line Voltage is present Turn the unit ON.

POWER SUPPLY VOLTAGES

(Digital Supply +5Dl, +5D2, +VD)

NO+=)

Simulator cable from J7 of tbe digital board. Turn the unit

Simulator (see Section E).

Turn tbc unit Off. Disconnect tbc Cpin Disk Drive power

cable

From

tbc keypad/display board. Turn dx unit ON.

I

l

Replace the Disk Drive

T-0+(

(see section IQ.

Turn tbz unit Off. Disconnect the ‘I-pin cable between the

power supply and the KcypxVDisplay Board. Turn the unit ON.

Turn the unit OFF. If present. disc-t tbc Digital I/O

cable fmm 19 on he didtal board. Turn the unit ON.

I

Turn the unit

OFF. If

prescn~

disc-t

tbc

SCSI

cables

fmm J4 and 16 on the digital board.

TUTI

the unit ON.

YES

v

Turn bc unit Off. Disconnect the

pwa

supply

cable fmm I2 on the digital board. Turn the unit ON.

Replace tbe Power Supply Board

(WC

Section C).

Figure

ll-

Incorrect Digital Power

Supply Voltages

ASR Service Manual

I.5

Page 20

Checking the Display

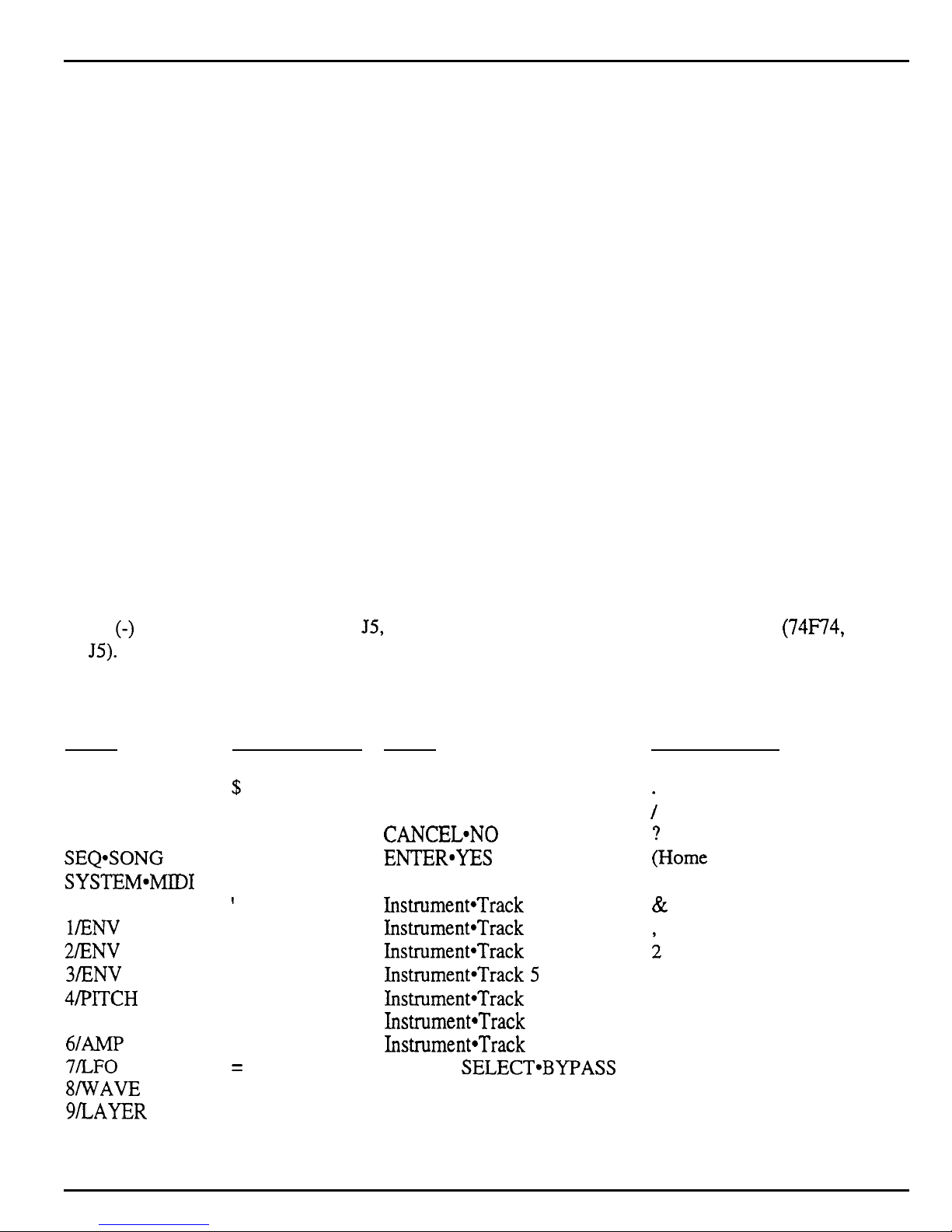

DISPLAY SELF-TEST MODE

When the keypad/display is receiving power from the power supply but is not in proper communication

with the digital board, the keypad/display board enters self-test mode. In self-test mode, the display

remains blank until you press the buttons on the control panel. Pressing various control panel buttons

will cause the display to print characters, home the cursor, etc.*

Using Self-test Mode to Diagnose the Keypad/Display Board

1.

If the unit comes in with a blank display, but is in self-test mode (i.e., the display prints

characters when buttons are pressed according to the chart below) this indicates the problem is either

the digital board or the communication link between the digital board, keyboard and the

keypad/display board. Before replacing anything, check all connections, particularly the 20-pin cable

to the keyboard.

If pressing buttons causes only the leftmost character of the display to change, this usually indicates a

defective cable connection (20-pin ribbon cable) between the digital board and keyboard or possibly

a bad keyboard.

2.

If the unit is in self-test mode but the display does not respond according to the chart below,

the problem is most likely in the keypad/display board. If certain buttons do not function properly

during normal ASR-10 operation, test them while the display is in self-test mode.

If you can’t isolate a problem that seems related to the display, the display can be forced into Self-test

mode using the following procedure. With the power off, face the front of the unit, then jumper the

minus

to

(-)

side of C83 (located below

JS).

On power up, the display will stay in self-test as long as the jumper is connected, allowing you to

J5,

the digital jack board connector) to pin 1 of U64

(74F74,

next

check the keypad/display board independently. The chart below details how the control panel buttons

are mapped in self-test mode:

Press:

LOAD

COMMAND

EDIT

INSTRUMENT

SEQ*SONG

SYSTEM~MIDI

EFFECTS

l/ENV

1

2lENV 2

3fENV 3

4/PlTCH

S/FILTER

6lAMP

7fLFO

8fWAVE

g/LAYER

O/TRACK

up Arrow

Displav Reads:

8

$

1.

3

9

I

+

0

1

6

7

<

=

(Home Cursor)

(Home Cursor)

*

3.

Press:

Down Arrow

Left Arrow

Right Arrow

CANCEL*NO

ENTER*YES

Instrument-Track 1

Instrument*Track

Instrument*Track

2

3

Instrument*Track 4

Instrument*Track

5

Instrument*Track 6

Instrument*Track

Instrument*Track

7

8

EFFECT SELECT*BYPASS

SAMPLE

RECORD

STOP/CONTINUE

PLAY

Displav Reads:

4.

;

;Home Cursor)

Space

&

;

(Home Cursor)

5.

4

2.

>

0.

5

6.

16

ASR Service Manual

Page 21

Checking the Display

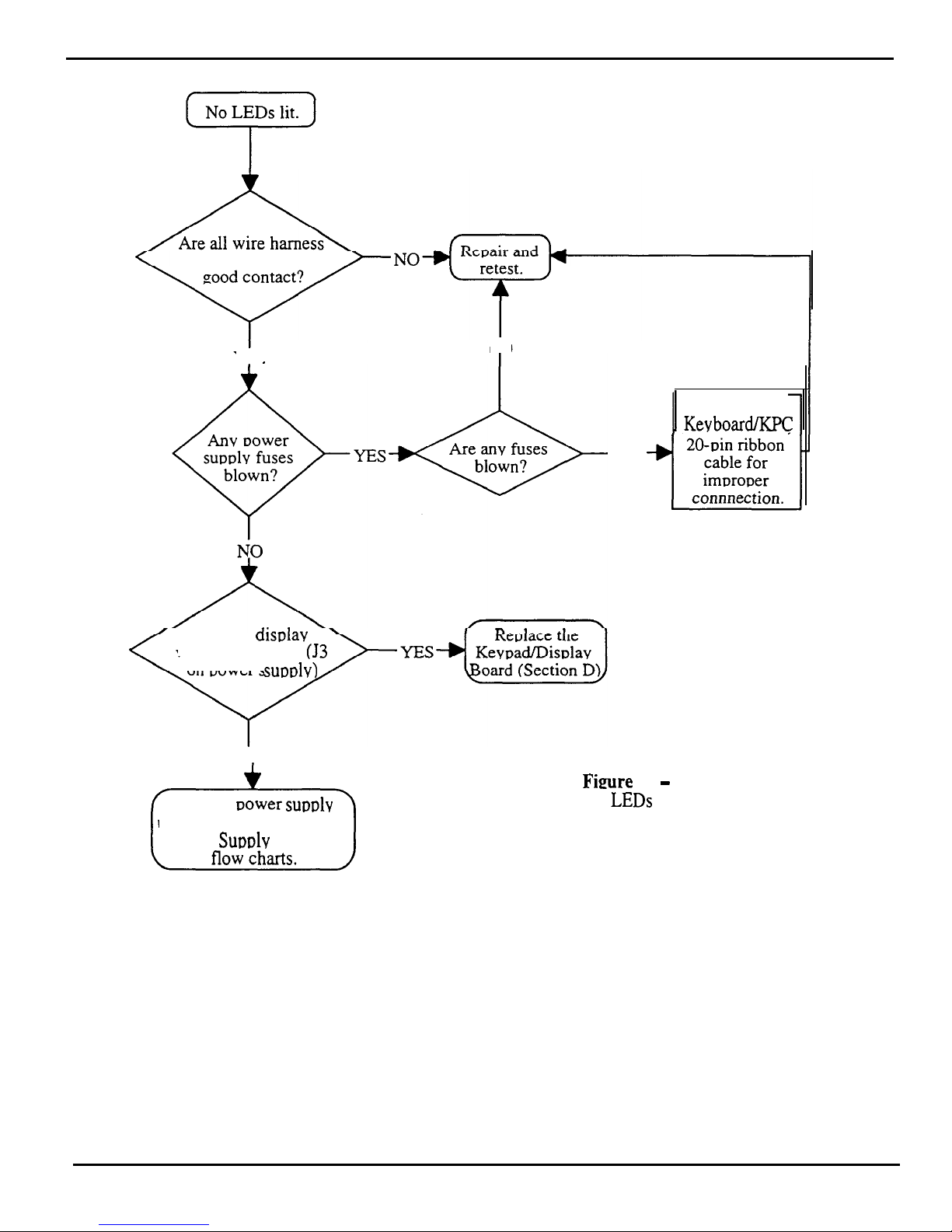

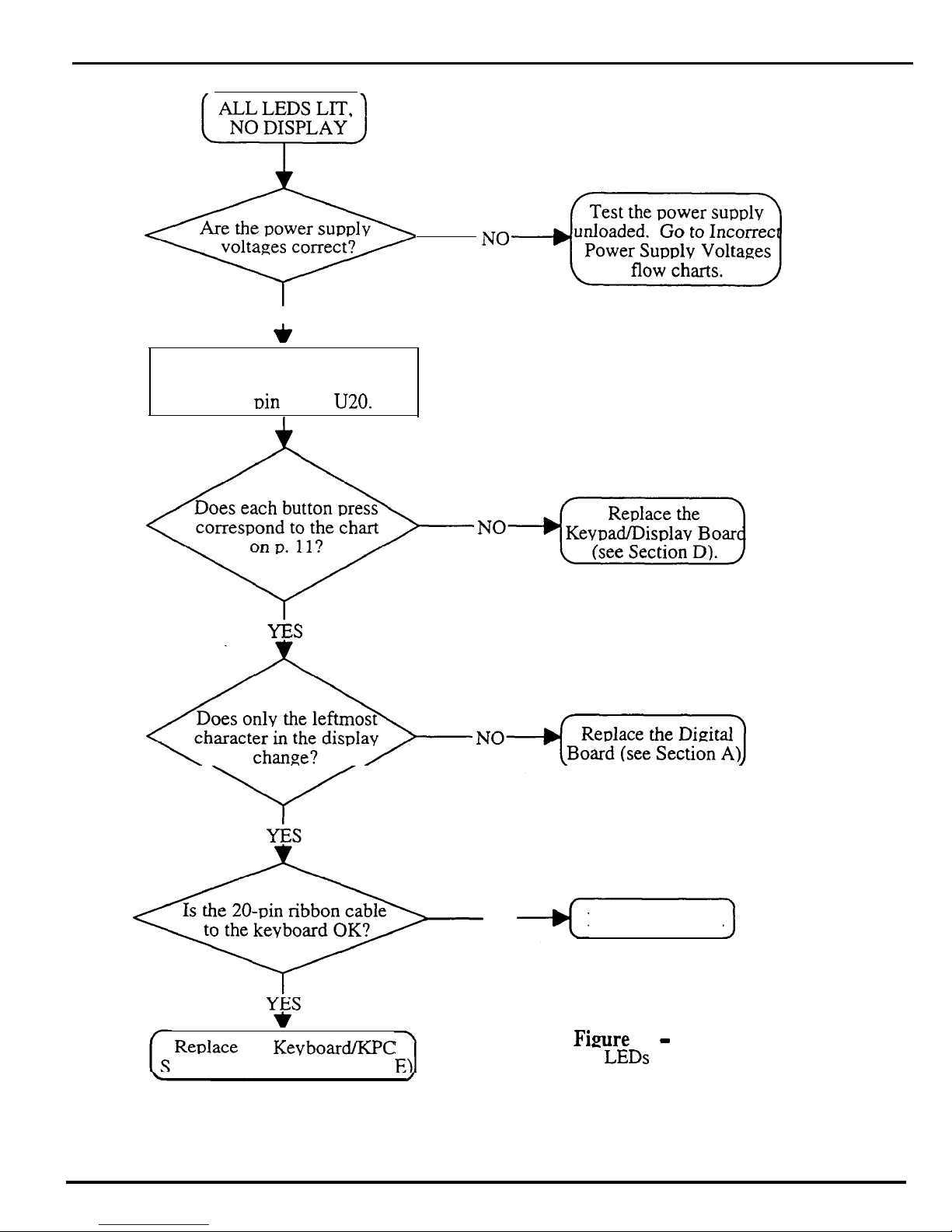

TROUBLESHOOTING AN

ASR-10 WITH NO LEDS LIT

connections making

YES

NO

I

Check

Kevboard/KPC

YES

Are the disulav

voltages correct?

(53

on Dower

suoolv)

NO

Test the

Dower

su~ulv

unloaded. Go to Incorrect

Power Supolv Voltages

Fimre 12

-

No LEDs Lit

ASR Service Manual

17

Page 22

Checking the Display

ALL LEDS LIT,

NO DISPLAY

z

Are the power supply

voltages correct?

YES

*

Force the unit into self-test mode

Jumper the negative (left) side

Cl9 to

Din

13 of

U20.

TROUBLESHOOTING AN ASR-10

WITH ALL LEDS LIT, NO DISPLAY

Reulace the KevboardXPC

imulator board (see Section

18

NO

Repair and retest.

Figure

13

-

All LEDs Lit, No Displav

ASR Service Manual

Page 23

Kevboard and Footswitch

Inuuts

The ASR-10 Keyboard and the KPC Simulator Board

The Poly-Key

-r~

Pressure Keyboard on the ASR-10 (and the KPC simulator board on the Rack) is a

complex module that contains its own computer and software. So, when necessary, you will be

swapping it out as a whole unit. Display information sent to and from the digital board is processed

through the keyboard/KPC simulator. What might appear to be a frozen display, therefore, could be a

bad keyboard/KPC simulator. For more troubleshooting hints, see Communications Path p. 10.

The 20-pin Ribbon Cable

(Kevboard/K.PC

Simulator)

When reconnecting this cable to the digital board, make sure that the striped side is aligned with pin 1

and that the cable is not r&-pinned. If the cable & mis-pinned or installed backward, fuses F3 and F4

on the power supply board will blow. NOTE: If one fuse blows, the other will blow also; you must

replace both.

ASR-10 Foot Switch and Patch Select Inputs

Foot Switch Jack

A single pedal foot switch (like the SW-5) plugged into the Ft. SW. jack is always a Sustain pedal.

When a dual foot switch (piano-type, like the SW-lo) is plugged into the Ft. SW. jack, the right pedal is

always a Sustain pedal and the left pedal is programmable (OFF, FX MODSRC, SAMPL YES, or

STOP/CONT).

To check to see what the left foot switch is set to, press Edit, then press

System*MIDI

repeatedly until the display shows LEFT Ff SWITCH=OFF (default).

Although the foot switch jack is mounted on the digital jack board, the foot switch signals go to the

keyboard, where they are sensed by the keyboard microprocessor.

Patch Select Jack

A single pedal foot switch (like the SW-5) plugged into the Patch Select jack causes the ASR-10 to think

that the left patch select button is always down

(X0).

The single pedal acts as the right patch select

button (XX).

When a dual foot switch (piano-type, like the SW-lo) is plugged into the patch select jack, the right acts

as the right patch select button and the left pedal acts as the left patch select button.

ASR Service Manual

19

Page 24

ASR-88 Kevboard

ASR-88 KEYBOARD

The ASR-88 uses the same keyboard as the KT-88 that has “bubble” switches, the ASR-88 keyboard is

only different in the adapter board. Instead of mechanical switches, this keyboard has a molded rubber

bubble under each key. The keyboard circuit board has conductive carbon contacts printed on it (which

appear as small black strips under each key). Each rubber bubble also has small conductive carbon dots

printed on the inside. The bubbles are made in strips which attach to the circuit board using small nubs.

The nubs on a strip are pushed through holes in the circuit board, in order to hold the strip in place.

As a key is pressed, it forces the bubble down until the carbon dots on the bubble hit the carbon contacts

on the circuit board. This completes the circuit. The circuit has two contacts per key, a back contact and

a front contact. The back contact closes first when a key is pressed, then the front contact closes. We

measure the amount of time between when the back contact closes and when the front contact closes.

This tells us how fast the key was hit, making the keyboard “velocity-sensitive”. In other words, we can

tell how hard the musician is playing and can adjust the volume and brightness of the sound in response

to the playing style. Each bubble switch also has a diode in series with it for proper circuit operation.

Key Response Problems

Although bubble switches are more reliable than mechanical switches, there are still many things that

can go wrong with this keyboard. If the bubble switches don’t switch in the proper order (first the back

contact, then the front contact) or if the switches don’t make clean contact, several problems can occur.

These include:

l Keys that don’t sound at all

l Erratic keys that “chatter” as they are played, held or released

l Keys that sound much louder than other keys

l Keys that sound much quieter that other keys

These problems can be caused by several things, including:

l Open or shorted traces on the circuit boards

l Bad or dirty carbon contacts on the circuit boards

l Bad or dirty carbon contacts on the bubbles

l Tom or otherwise damaged bubbles

l Bubble strips that are installed backward

l Interference between the key and the bubble (such as foreign material trapped between the key and

the bubble)

l Improper alignment between the key and the bubble

l Bad diodes

Usually failures will fall into two categories; either one key is bad, or a group of keys is bad. If a group

of keys is bad, all the keys may be grouped together (usually a group of eight) or they may be spread

across the keyboard (usually every eighth key).

If keys fail in a group of eight or every eighth key fails, the problem is most likely an open or shorted

trace on the circuit board or a problem with the keyboard processor board (that is mounted to the bottom

of the keyboard).

20

ASR Service Manual

Page 25

ASR-88 Keyboard

If only one key is bad (or if groups of keys are bad but not in groups of eight or every eighth key), the

problem could be any of the above. The first thing to do is remove the key and see if there is anything

obviously wrong with the bubble:

Look for damage to the bubble itself.

If the bubble is damaged, the circuit board must be removed so the strip can be replaced.

Check that the bubble strip is seated flat against the circuit board.

If the strip is improperly seated, use an appropriate tool (a straightened paper clip works well; don’t

use a sharp tool as it can puncture the rubber strip) to force the nubs on the strip into the holes on the

circuit board. The strip should lay flat against the circuit board.

Check that the bubble isn’t backward. If installed correctly, the deeper of the two bubble

contacts should be at the rear of the keyboard.

If the strip is in backward, remove the circuit board, pull the strip off the circuit board, turn it around

and reinstall it.

Remove any foreign material caught between the bubble and the key.

See if the plunger on the key makes proper contact with the top of the bubble.

If the piunger on the key forces the bubble down unevenly (with one side of the bubble being much

higher than the other side), loosen the screws that hold the circuit board in place and slide the circuit

board over slightly to better align the key and the bubble, then re-tighten the screws,

Check that both diodes for that key are inserted properly (the banded end of all diodes should

face the same way).

If a diode is in backward, the circuit board must be removed and the diode must be unsoldered,

reversed and re-soldered.

Check that both diodes for that key are working properly.

Select the “diode check” setting on an ohmmeter and test the diodes. The diode should conduct

when the negative (black) lead of the ohmrneter is on the cathode (banded) end of the diode and the

positive (red) lead of the ohmmeter is on the anode (unbanded) end of the diode. The diode should

not conduct when the negative (black) lead of the ohmmeter is on the anode (unbanded) end of the

diode and the positive (red) lead of the ohmmeter is on the cathode (banded) end of the diode. If a

diode is bad, replace it with a lN914B diode.

If there is no obvious problem, remove the circuit board:

l Examine the circuit board for short circuits.

These are usually caused by solder bridging. Touch up any shorts with a soldering iron and/or razor

knife.

l Look for open traces.

These usually occur at the break-away points along the edge of the board and near the connectors.

Solder a wire jumper in place to fix any broken connections.

l Remove the bubble strip and clean both the circuit board contacts and the bubble contacts

with alcohol and a cotton swab.

Allow them to air dry before putting the bubbles back on the circuit board.

If after all this the keyboard still doesn’t work properly, replace the entire keyboard assembly.

ASR Service Manual

21

Page 26

ASR-88 Keyboard

Pressure Response Problems

The ASR-88 keyboard, like the KT-88 and TS-12, has mono pressure response. This allows a

modulation effect to increase as you press harder on a key. Pressing harder on any key will affect all

other keys. To produce mono pressure, two pressure sensitive strips are inside the keyboard assembly.

Pressing on a key exerts a downward pressure on the strips. Two strips are used because of the large

88-

note span. The signals from the two strips are combined by the mono pressure circuit that resides on the

keyboard processor board that is mounted to the bottom of the 88-note keyboard near the wheel

assembly. Note that it is normal for pressure response to vary depending on the number of keys being

pressed.

If pressure response is not working properly, check the alignment of the pressure strips, and make sure

they are securely connected to the keyboard adapter board. Replacement of the pressure strips is not

practical on this keyboard assembly, if there is damage to the pressure strips, replace the entire keyboard

assembly.

22

ASR Service Manual

Page 27

Error Messages

ERROR MESSAGES

Occasional error messages are not unusual, and unless they become chronic, they are not a cause for

concern. It is important to realize that these messages are diagnostics and do not necessarily indicate a

problem. These messages were designed to help our software engineers in the development of the

software, not as hardware diagnostics.

Software Messages

The following error messages could be caused by software:

IDnU

Descrintion

ID#

Desctiution

013

software error in voice assignments

132

chk instruction register out of bounds

016

poly or mono pressure events sent to VC

133

trapv instruction ovefflow error

020 unknown button event

134 privilege violation

048 parameter error

135 trace

049 layer error

137 line 1111 emulator

080

bad buffer to MIDI

138 spurious interrupt

128 bus error

139 unused vector

129 odd address error

192

load all data error (from MIDI or card)

130 divide by zero

193

keyup

playback error

13 1llegal instruction

194

out of SDBs error

Digital Board Problems

The following error messages could be caused by a problem on the digital board:

005

could not synchronize audio input

033 bad ESP chip

006

could not synchronize audio input

034 bad

ESPFWM

019 Bad

OTTO

interrupt

040* bad ESP error

032 bad download

145

unknown DUART interrupt error

Analog or Digital Board Problem (clock comes from analog board, make sure there are no analog

fuses blown and that the analog power supplies are O.K.)

009

No

LRCLK

input to 68302

MIDI or Main Board Problems

The following error is usually caused by too much incoming MIDI data. It also could be caused by a

problem with the keyboard.

144

out of buffers

Disk File Operation Errors

The following error messages could be caused by software:

ID# DescriDtion

ID# Descrintion

00 illegal block # during read/write

07

current DIR & FAT info in buffer is not valid

01 Missing End of File marker

08 not enough space to save file

02 Premature End of File marker

10

file size > free blocks on device

03 file linked list points to unused block

15

no free blocks found on

the

diskette

04 file linked list points to bad block

16

illegal fat block # load was attempted

ASR Service Manual

23

Page 28

Error

05

06 current info in FAT buffer is not valid data 32-35 and 40*-44 NEC PD 72069 errors

*Please note that error 40 error 040 are separate errors. Error 40 is always a disk controller or disk drive related

problem. Error 040 is always an ESP problem. In the case of error 040 the problem will always be an ESP

problem, in the case of error 40 the problem can be the disk drive controller (located on the digital board) or a

disk drive problem. Replace the disk drive with a known good drive first. If the error still persists, than replace

the digital board.

The following errors could be caused by a bad disk or disk drive:

09 block write attempt failed

11

12

The following errors could be caused a bad external SCSI cable or a SCSI termination problem:

18

20 scsi last command ignored

2 1

MessaPes

current info in DIR buffer is not valid data 17 file size greater than limit = 33 Mbytes

13

directory save verify error

14

device id pcb load/save error

operating system pcb load/save error

scsi command not complete/no disconnect ret

scsi check condition error

fat save verify error

22 possible disk drive index pulse problem

The following special message is not an error message:

for further explaination.

Not an EPS device. See the SCSI section of this manual

24

ASR Service Manual

Page 29

Sofhyare Notes

ASR-1 O/88

SOFIWARE

NOTES

The O.S. version on the disk can be easily updated (call ENSONIQ Customer Service for the latest O.S.

version). You cannot copy the O.S. to a disk onto which you have already saved instruments or

sequences, but not the O.S. Attempts to do so will result in an error message.

To Check the ASR-10 Software Version:

l Press Command, then Env 1. The display shows NO COMMANDS ON PAGE.

l Repeatedly press the left or right arrow button until the display shows SOFIWARE

INFORMATION.

l Press Enter-Yes. The display shows RAM VERSION = X.Xx.

l Press

EntereYes.

The display shows ROM VERSION = Y.YY.

l Press Enter-Yes. The display shows KEYBOARD VERSION ZZZ. For the Rack, this will

always show 1.

Keyboard Software

In keyboard version 2.40 software, when you hold down up arrow button and press down arrow

button, numbers would scroll instead of going to the halfway point. A new keyboard with keyboard

software version 2.41 fixes this problem (released 16 March 93).

On March 16, 1993, Keyboard Software Version 2.41 went into production. Version 2.41 addresses

problems that were inherent in version 2.40. The problems that were addressed are:

l Rapid button presses (e.g. direct dialing or holding inc/dec to center a parameter value) could cause

any of the following symptoms:

1)

Garbled display. For example: message not centered properly in the display, characters

missing or repeating in a message. Subsequent messages are displayed properly.

2)

Missed buttons. For example: holding down the up arrow button and pressing the down

arrow button to center a parameter could cause unit to miss a button-up, which would make

the parameter value scroll to the extreme high or low end of its range. Subsequent button

presses are handled properly.

3) Display/Button lock-up in extreme cases. Power off/on corrects problem.

ASR-10 ROM/DISK Compatibility Issues

The following chart summarizes the Operating System compatibility of the ASR-10 Keyboard and

Rack. The Rack was released with

1SOB

EPROMs and must have at least version 1.50 disk.

* From version 2.00 on,

the OS uses more space in RAM

than previous versions.This is

due to the Disk Tracks feature.

Version 3.50 ROMS are for

the ASR-88 only.

Figure 14 - ROM and disk Compatibility

ASR Service Manual

25

Page 30

So&are Notes

Special note on making copies of the Operating System (O.S.) disk:

The code that loads the O.S. from disk at bootup is stored in the ROMs.

1 .OO ROMs made some

assumptions about the location and format of the O.S. on the disk. For that reason, there are some

limitations that we must impose when using the COPY OS TO DISK command to copy an O.S.

from one disk to another. Generally, if the O.S. that you are copying is the same version that you are

running with, you will have no problems. Where things get tricky is when you are copying an O.S.

that is different from what you are running with. Here are the rules:

O.S. That’s running:

1.00 thru 1.25

1.00 thru 1.25

1.50

1.50

1.60 and higher

1.60 and higher

O.S.

to c0I.w:

1.00 thru 1.25

Results/Rules:

OK

1.50 or higher DESTINATION DISK MUST BE EMPTY. Use a

freshly formatted disk as the destination, otherwise

system will report not enough space on disk.

1 .OO thru 1.25

DESTINATION DISK MUST BE EMPTY

AND

DESTINATION DISK MUST BE SAME DENSITY

AS SOURCE DISK. Use a freshly formatted disk as

the destination with same density as the source disk,

otherwise command appears to work but the system

was not copied correctly.

1.50 or higher

OK

1.00 thru 1.25 DESTINATION DISK MUST BE SAME DENSITY

AS SOURCE DISK. Otherwise the system is not

copied correctly. May get the message DISK

WRONG SIZE.

1.50 or higher

OK

Note: Version compatibility is not an issue if using the COPY DISK command.

To update O.S. Version on a floppy disk:

l Insert the disk containing the O.S. you want to copy (the source disk) into the floppy drive.

l Press Command, then SystemWIDI.

l Press the right arrow button until the display shows COPY OS TO DISK.

The OS. version on the disk can be easily updated (call ENSONIQ Customer Service for the latest O.S.

version). You cannot copy the O.S. to a disk onto which you have already saved instruments or

sequences, but not the O.S. Attempts to do so will result in an error message.

To Check the ASR-10 Software Version:

l Press Command, then Env 1. The display shows NO COMMANDS ON PAGE.

l Repeatedly press the left or right arrow button until the display shows SOFTWARE

INFORMATION.

l Press

l Press

EnteraYes.

EntereYes.

The display shows RAM VERSION = XXX.

The display shows ROM VERSION = Y.YY.

26

ASR Service Manual

Page 31

So&are Notes

l Press

EnteraYes.

The display shows KEYBOARD VERSION ZZZ. For the Rack, this will

always show 1.

Version 1.25 disk (released 8 FEB 93)

For ASR-10 Keyboards ONLY.

This disk is only compatible with 1.00 ROMS. This is not u typical O.S. Release?

This

OS.

update is intended for customers who have a keyboard with 1.00 ROMs but do not need or want the SCSI kit. (When they buy

SCSI, they automatically get 1.50 ROMs if they don’t have them.) This release provides them with a method of upgrading their operating

system without the expense of a ROM change. Because this was a patch to the existing 1.20 O.S. disk, there are some known problems

that still exist in this release. The purpose of this release is to address the serious problems that can cause a crash or corrupt data. No new

features are added.

SEQUENCER