EnSmart 160-400kVA User Manual

SMART TP UPS

Models 160-400kVA

H Version For External Battery

Halk Ca d. No :8/ A3 , Ata seh ir

Ist an bul – Tur ke y 347 52

T: +9 0 21 6 225 8 4 66

E:s al es@ ens ma rtp owe r. com

User Manual

FOREWORD

Thank you for choosing this product of SMART-TP UPS 160kVA - 400kVA range.

EnSmart Power is highly specialised in the development and production of uninterruptible power

supplies (UPS). The UPS device described in this manual is designed and manufactured with care

to guarantee uninterrupted power for your equipments and give you the best performance. The

UPS are only designed for commercial/industrial purposes. It is not used to power life-support

equipment of any kind.

This manual contains detailed instructions for product use and installation/operation of the

stand-alone and parallel UPS systems. The SMART-TP UPS can be only used only by

authorized engineers appointed by manufacturer or its agents.For information on using and

getting the best performance from your UPS, this manual must be stored in a safe place

and CONSULTED BEFORE TAKING ANY ACTION ON THE UPS.

Due to the constant update and improvement of the product and the technology, contents in this

manual may not be consistent with the actual conditions of the product. We appreciate your

understanding for that. Please contact the manufacturer or the supplier for the latest

information if necessary.

Note: Because of the continuous improvements, our products may differ somewhat from the

contents included in this manual. You can contact local office to get the information when

necessary.

Contents

1 Introduction ............................................................................................................................................... 7

1.1 Features .............................................................................................................................................. 7

1.2 Design Concept .................................................................................................................................. 8

1.2.1 System Design .................................................................................................................................... 8

1.2.2 Bypass Circuit ..................................................................................................................................... 8

1.2.3 System Control Principle .................................................................................................................... 9

1.2.4 ECO Mode (only suitable for the UPS standalone machines) ......................................................... 11

1.2.5 UPS Power Switch Setting ............................................................................................................... 11

1.2.6 System Capacity Expansion ............................................................................................................. 11

1.3 Operation Mode ................................................................................................................................ 11

2. Mechanical Installation ......................................................................................................................................... 13

2.1 The Do’s and Don’ts ......................................................................................................................... 13

2.2 Environment Requirements .............................................................................................................. 13

2.2.1 Site Selection for the UPS ................................................................................................................ 13

2.2.2 Site Selection for the Battery ............................................................................................................ 14

2.3 Mechanical Requirements ................................................................................................................ 14

2.3.1 System Configuration ....................................................................................................................... 14

2.3.2 Moving the Cabinets ......................................................................................................................... 14

2.3.3 Operation Space ............................................................................................................................... 14

2.3.4 Wiring ................................................................................................................................................ 14

2.4 Initial Check ...................................................................................................................................... 14

2.5 Installation Diagram .......................................................................................................................... 15

3.Electrical Installation ........................................................................................................................................... 18

3.1 Wiring of Power Cables .................................................................................................................... 18

3.1.1 System Configuration ...................................................................................................................... 18

3.1.2 Cable Specification ......................................................................................................................... 18

3.1.3 The Do’s and Don’ts ....................................................................................................................... 19

3.1.4 Cable Connector ............................................................................................................................. 19

3.1.5 Protected Area ................................................................................................................................ 19

3.1.6 Protector .......................................................................................................................................... 19

3.1.7 Connection Procedure for the Power Line ...................................................................................... 20

3.2 Distance between the Connection Point and the Floor .................................................................. 24

3.3 W iring of Control Cables ................................................................................................................ 24

3.3.1 Monitor Board Port .......................................................................................................................... 24

4. Display Panel of Operation Control ................................................................................................................... 29

4.1 Introduction ....................................................................................................................................... 29

4.1.1 LED Indicator .................................................................................................................................... 29

4.1.2 Alarm Buzzer .................................................................................................................................... 30

4.1.3 Control Buttons ................................................................................................................................. 30

4.1.4 LCD and Menu Button ...................................................................................................................... 31

4.1.5 Detailed Menu ................................................................................................................................... 32

4.1.6 EPO Button ....................................................................................................................................... 36

4.2 Prompt Windows ............................................................................................................................... 36

4.3 UPS Alarm Message List .................................................................................................................. 37

5.UPS Operation Instruction ................................................................................................................................. 41

5.1 Introduction ....................................................................................................................................... 41

5.1.1 The Do’s and Don’ts ......................................................................................................................... 41

5.2 UPS Start-up Procedure (Entering the Inverter Power Supply Mode) ............................................. 41

5.3 UPS Start Procedure (Entering the Economic Mode) ...................................................................... 42

5.4 Battery Test Procedure ..................................................................................................................... 42

5.5 UPS Self-detection Procedure .......................................................................................................... 43

5.6 Maintenance Bypass Operation Procedure (UPS Shutdown Procedure) ........................................ 43

5.7 Shut-down Procedure (Complete Shut-down of the UPS and Loads) ............................................. 44

5.8 Emergency Shutdown (EPO) Procedure .......................................................................................... 45

5.9 UPS Reset Procedure ...................................................................................................................... 45

5.10 Automatic Start .................................................................................................................................. 45

5.11 Language Selection .......................................................................................................................... 45

5.12 Alteration of the Current Date and Time ........................................................................................... 46

6.Battery ..................................................................................................................................................................... 47

6.1 Introduction ....................................................................................................................................... 47

6.2 Safety ................................................................................................................................................ 47

6.3 UPS Battery ...................................................................................................................................... 48

6.4 Installation and Design Notice .......................................................................................................... 48

6.5 Installation Environment and Number of Batteries to be Installed ................................................... 49

6.5.1 Installation Environment ................................................................................................................... 49

6.5.2 Number of Batteries .......................................................................................................................... 49

6.6 Connecting the Battery ..................................................................................................................... 50

6.6.1 Battery Assembling ........................................................................................................................... 50

6.6.2 Battery Wiring ................................................................................................................................... 50

6.7 Battery Installation ............................................................................................................................ 50

6.8 Battery Maintenance ......................................................................................................................... 50

6.9 Battery Recycle ................................................................................................................................. 51

7.Parallel System ..................................................................................................................................................... 52

7.1 Introduction ....................................................................................................................................... 52

7.2 Installation of the ―1+N‖ Parallel System .......................................................................................... 52

7.2.1 Initial Check ...................................................................................................................................... 52

7.2.2 Cabinet Installation ........................................................................................................................... 52

7.2.3 Protector ........................................................................................................................................... 53

7.2.4 Power Cables .................................................................................................................................... 53

7.2.5 Control Cables .................................................................................................................................. 53

7.3 Operation Procedure for ―1+N‖ Parallel System ............................................................................... 54

7.3.1 Start-Up Procedure (Entering the Inverter Power Supply Mode) ..................................................... 54

7.3.2 Operation Procedure for the Maintenance Bypass (UPS shut down) .............................................. 55

7.3.3 Shut Down and Isolate One of the UPS Machines in the Parallel System ...................................... 55

7.3.4 Resume the Isolated Stand-alone Machine in the Parallel System ................................................. 55

7.3.5 Shut-down Procedure (Complete Shut-down of the UPS and Loads) ............................................. 56

7.4 Dual Bus System (Optional) ............................................................................................................. 56

7.4.1 Cabinet Installation ........................................................................................................................... 56

7.4.2 Protector ........................................................................................................................................... 56

7.4.3 Power Cable ..................................................................................................................................... 56

7.4.4 Control Wire ...................................................................................................................................... 56

8.Product Specification .......................................................................................................................................... 59

8.1 Compliance and Standards............................................................................................................... 59

8.2 Environment Condition ..................................................................................................................... 59

8.3 Mechanical Characteristics ............................................................................................................... 59

8.4 UPS Electrical Characteristics (Rectifier Input) ................................................................................ 60

8.5 UPS Electrical Characteristics (Intermidiate DC Circuit) .................................................................. 60

8.6 UPS Electrical Characteristics (Inverter Output) .............................................................................. 61

8.7 UPS Electrical Characteristics (Bypass Input) ................................................................................. 62

9.Maintenance and Repair ..................................................................................................................................... 63

9.1 Safety ................................................................................................................................................ 63

9.2 UPS Key Components and the Service Life ..................................................................................... 63

9.2.1 Magnetics: Transformer and Inductor .............................................................................................. 63

9.2.2 Power Semiconductor ....................................................................................................................... 63

9.2.3 Electrolytic Capacitor ........................................................................................................................ 63

9.2.4 AC Capacitor ..................................................................................................................................... 63

9.2.5 Service Life for the UPS Key Components ...................................................................................... 64

9.2.6 Change Fuse .................................................................................................................................... 64

警告

危险

Compliance and Standards

This equipment meets the following UPS reference standards:

IEC60950-1and IEC62040-1-1 safety requirements for operating area

IEC/EN62040-2 EMC requirements

IEC62040-3 performance requirements and test method

The installation must comply with the above requirements and use the required attachment by the

manufacturer.

警告

危险

WARNING

Earth leakage current: Before connecting with the input power, please ensure a safe and reliable

grounding.

The grounding must comply with the local electrical code.

The protection device for the power-connected end of the UPS system must comply with the local

electrical code.

In case the internal fuse of the UPS breaks down, it should be replaced with a fuse of the same

electrical specifications and the replacement should be done by professional staff.

警告

危险

Watch Out

This equipment contains a RFI(radio frequency interference) filter.

The earth leakage current ranges between 3.5mA and 1,000mA.

When selecting RCCBs(residual current circuit breaker) or other RCDs(Residual current Device),

you should take into account the transient state and steady state of the leakage current upon

starting the equipment.

The selected RCCB should not be sensitive to one-way DC pulse (A) and transient current pulse.

Attention: The earth leakage current of the loads will also flow through RCCB or RCD.

警告

危险

General Safety

Like other high-power equipment, UPS and its battery box have high voltage. Yet as the

high-voltage components will only be exposed to the outside when the front door (with a lock) is

opened, thus the possibility of exposure to high voltage is reduced to the minimum. In accordance

with the IP20 standards, the equipment includes other internal safety shields.

No danger will be involved if you follow the general standards and the procedure suggested in this

manual.

As all the maintenance and repair of the equipment involves the internal components, it should be

done by professional staff.

警告

危险

Battery

The battery manufacturer offers the do’s and don’ts for using large-scale battery and staying

around such place, which should be strictly followed at all times. Particular attention should be paid

Safety

to suggestions about local conditions and regulations on the protective work suits, first-aid

equipment and fire fighting apparatus.

警告

危险

Dangerous Voltage

When doing the maintenance, pay attention that the N wire has electricity.

警告

危险

Multiple Power Input

The UPS has multiple powers. All the AC powers and DC powers should be cut off before

maintenance and repair.

Attention

The output neutral line is connected to the input neutral line. It would cause danger if external

device disconnect the neutral line, which results in the miss of the output neutral line.

The standard UPS system can be connected to the three-phase four-wire (earth connected) TN

and TT AC power distribution system (IEC60364-3) . If used in IT AC power distribution system, the

input end requires a four-pole breaker, which may follow the related IT system standard.

Pay attention to electric shock. Even when the AC input power is cut off, there is still high voltage of

electric conduction components supplied by battery inside the equipment.

The UPS is equipped with large-volume capacitors. When the equipment is cut off from electric

supply and battery, the voltage at the terminal of the capacitors remain for some time. Before the

maintenance and repair of the equipment’s internal part, wait for at least 5 minutes after the UPS is

shut down, and measure the voltage between the bare metal parts to make sure that the voltage is

below the safety threshold. Failure to observe the instruction may lead to serious electric shock and

even death.

警告

危险

This warning sign stands for all kinds of safety warnings.

1. Introduction

This chapter briefly introduces the features, design concept and operation model of the UPS.

1.1. Features

The UPS is connected between the three-phase input power and important loads (like computer) and offers quality

three-phase power to the loads. It has the following features:

Full digitalized technology

Dual-DSP control chip, advanced control technology, enhanced logic management and eliminated zero drift with

analog control; convenient use of modern control technology; convenient debugging, system update and

maintenance; perfect logic functions; diverse interactive data for the customers; convenient communication and

network functions

Highly reliable topological structure

The rectifier adopts the most reliable thyristor phase-control technology; the inverter adopts IGBT module half-wave

structure and the inverter transformer helps isolate the input and output electricity, which increases safety and

shock resistance of the system; the battery is directly connected to the bus bar, and the transfer time from

AC-inverter Mode to Battery Mode and vice. Versa is zero. which increases the reliability of the system; the

switching between inversion and bypass is controlled by a static transfer switch, and the switching time is as short

as 0ms.

Outstanding input and output features

The POWER WALK IN helps achieve gradual connection to oil engine so as to prevent unreliable start of the

engine in the parallel operation system; applicable in several voltage systems, i.e. 380V/400V/415V; 50HZ, 60HZ;

meets most of the voltage systems in the world; high output power factor (0.9 lagging) which strengthens the

system’s load capacity and ensures sufficient overload capacity.

Generator mode:Set the maximum output power of the generator when a smaller one than needed is employed to

extend the battery duration time. In this case, the load is supplied by both the generator and battery.

Smart Battery Management

The automatic switch between equalizing charge and floating charge, prediction for the discharge time, and regular

self-examination increase the service life of the battery.

N+X parallel operation mode

It is convenient to achieve parallel operation. You only need to connect the parallel cables and set the UPS, and the

host is automatically produced. In case the host breaks down, the slave automatically becomes the host, which

increases the reliability of the system. The system can have at most 6 sets of UPS connected in parallel.

LBS synchronization

LBS synchronization allows the system synchronization of two sets of UPS. It is suitable for STS (Static Transfer

Switch) Dual Bus configuration, in which the STS input, connected to the output of the two independent UPS and

the output to the load.

Perfect protection

Over-voltage protection; over-frequency protection; over-current protection; over-voltage protection for bus bar;

over-temperature protection; fault protection for auxiliary power supply; output overload protection; output

short-circuit protection; emergency power-off.

Perfect monitoring

Support RS232 and RS485, large LCD screen display; monitoring parts help monitor the working condition of UPS,

give instructions, record fault time and other local monitoring functions, and also help achieve the communication

between UPS lower machine and monitoring upper computer, and control the auxiliary system.

1.2. Design Concept

1.2.1 System Design

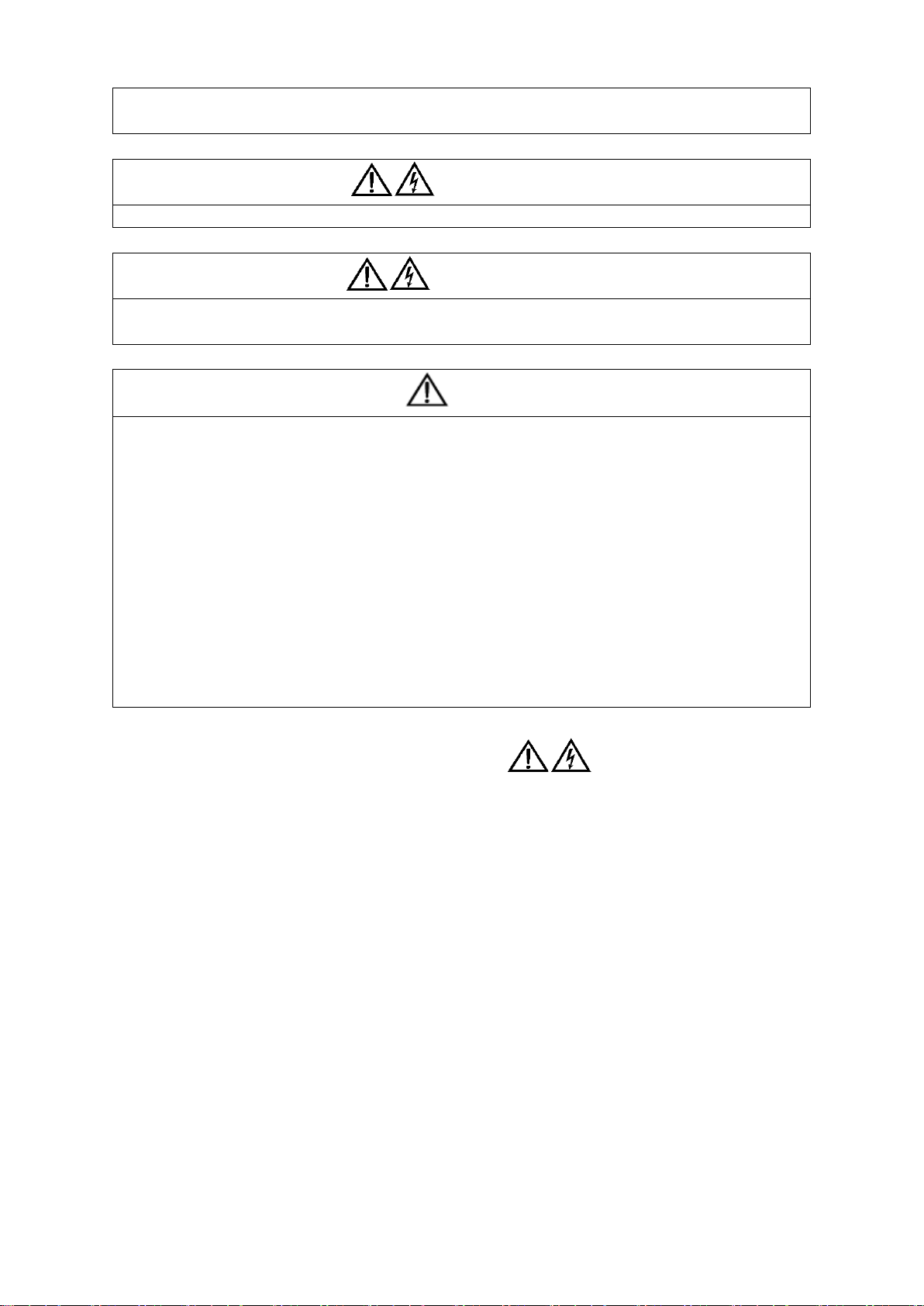

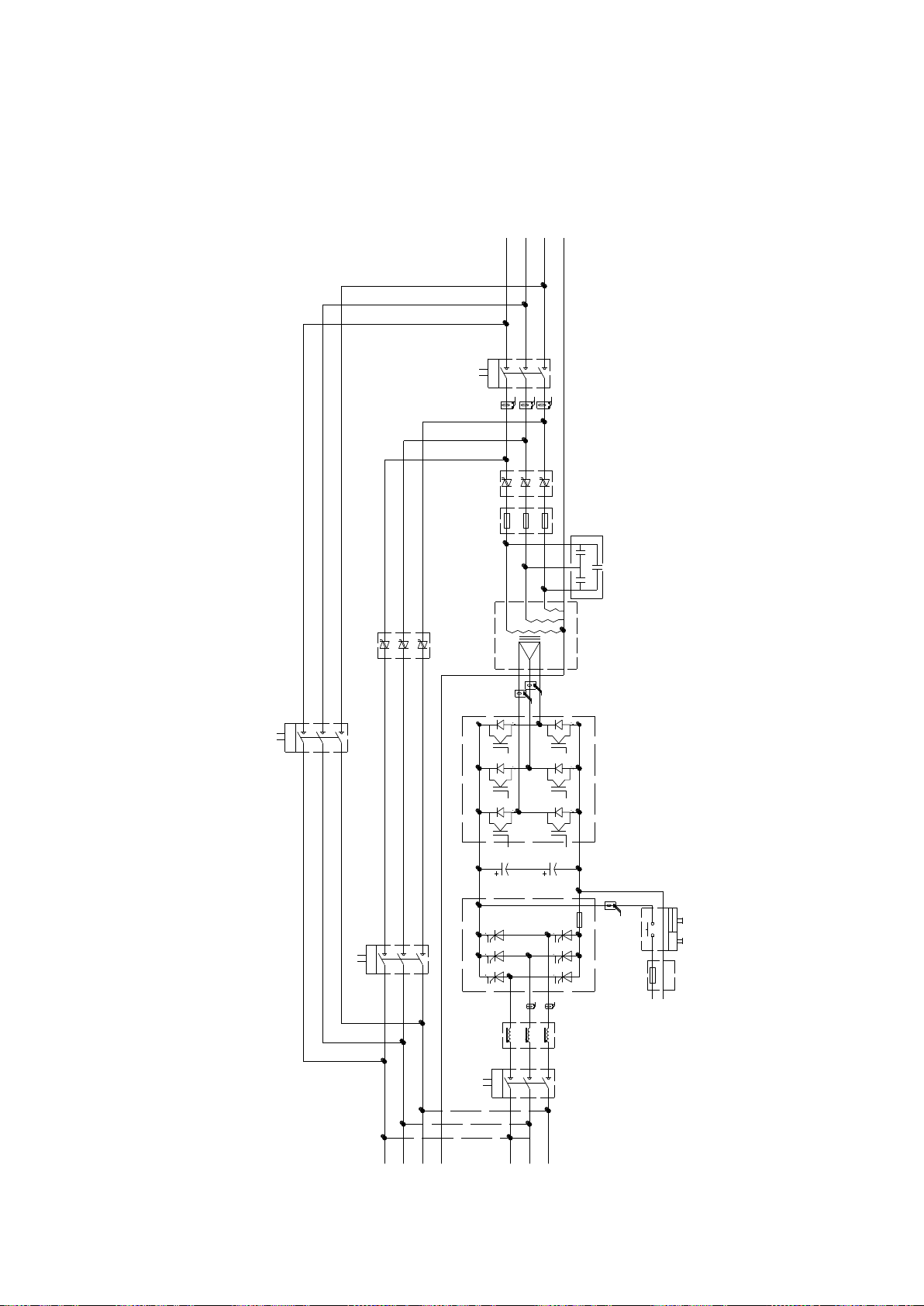

This section introduces the operating principle of the stand-alone UPS. The UPS adopts AC-DC-AC converter (see

Figure 1-1). The first AC-DC conversion adopts three-phase full bridge controlled rectifier to convert the

three-phase AC input power into the steady DC bus voltage.

Figure 1-1 Working Principle of the Stand-alone UPS

The rectifier can also be used as a charger. The inverter takes IGBT half-wave circuit as its inversion topology. The

advanced Space Vector Pulse Width Modulation (SVPWM) is used to control the system, which inverts the DC bus

voltage into AC voltage output.

When the AC is normal, the rectifier and the inverter work at the same time and simultaneously charge the battery.

In case of abnormal AC, the rectifier stops working and the battery supplies power via the inverter. If the battery

voltage drops below the cutoff voltage and the AC is not yet back to normal, the UPS shuts down (If the major

circuit and the bypass circuit are not of the same source and the bypass circuit is normal, the system is powered by

the bypass circuit). The cutoff voltage is preset (eg. the factory setting is 1.67V and the battery cutoff voltage is

320Vdc).

In case of abnormal AC, the battery powers the UPS until its voltage drops to the cutoff voltage. This period of time

is called the ―backup time‖, the length of which depends on the battery’s capacity and the loads.

1.2.2 Bypass Circuit

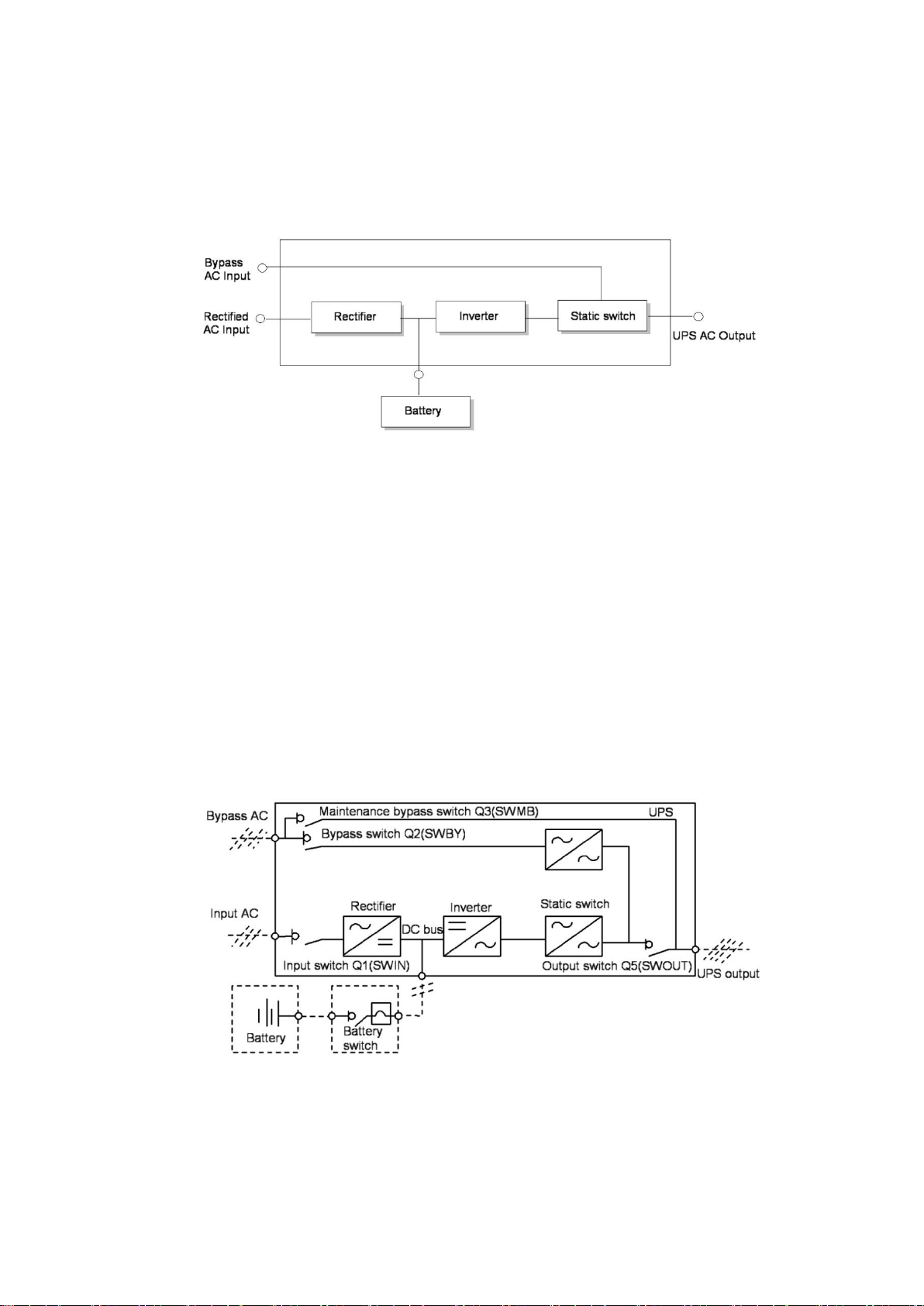

1. With the intelligent control for the ―static switch‖ which consist of the controlled electronic switching circuit(see

Figure 1-2). The loads can be powered by both the inverter output and the bypass input. Under normal

conditions, the loads are powered by the inverter whose static switch is closed. In case of overload (beyond

the overload time limit) or fault with the inverter, the static switch will automatically switch to the bypass circuit.

Figure 1-2 UPS switch

In normal conditions, complete synchronization of the inverter output and bypass power is a must for achieving

uninterrupted switch between inverter output and bypass power.

Given such requirement, when the bypass power frequency is within the locking range, the inverter output

frequency in the inverter-controlled circuit is tracking the bypass power frequency.

What’s more, there is also a manual maintenance bypass switch in the UPS system. When the UPS needs to be

shut down for maintenance, the bypass power will directly supply power the important loads via the manual

maintenance switch.

Note: When the loads are powered by bypass or maintenance bypass circuit, the power supply is not guaranteed.

U

V

W

N

Inductor

Inverter

fuse

(normal open)

(normal open)

(normal open)

(normal open)

Bat.-

1 4

Bat.+

STS-INV

STS-BY

1

24

1

Aux.switch

control

DC24V

Bat. external

Bat.fuse

Bat.

contactor

21

21

2

1

Output

SWOUT

SWMB

1

2

Aux.switch

1

2

Aux.switch

1

2

Aux.switch

1

2

Aux.switch

R

S

T

N

T

S

R

21

2

1

Mains

input

Rectifier

Inverter

Transformer

SWIN

Output

cap.

R S T

R

S

T

G2R

K2R

1

BUS+

G1R

K1R

G2S

K2S

G1S

K1S

G2T

K2T

G1T

K1T

bus.fuse

Bypass

input

BUS-

4

41

SWBY

(normal open)

1.2.3 System Control Principle

The system control chart is as Figure1-3:

Figure 1-3 UPS system control chart

Normal operation

警告

危险

WARNING

If the UPS system consists more than two UPS standalone machines connected in parallel, do not use the internal

maintenance bypass switch.

Attention: If the input power supply does not have an automatic circuit breaker, the output bus bar and the input

bus bar of the closed UPS standalone machine are dangerous for high voltage.

UPS input AC is normal, the rectifier and the inverter are functioning properly, the loads are powered by the inverter.

And battery switch closed, the battery is under the steady floating charge by the DC bus bar voltage.

(“1+N” parallel UPS system) Note: As the output of all the UPS stand-alone machines are connected in parallel,

the system will check whether all the inverter-controlled circuits are operating synchronously, and whether the

frequency and phase are in consistence with those of the bypass circuit. The output of each circuit should stay the

same. The current for the loads is evenly supplied by each UPS stand-alone machine. In the course of

synchronization, the UPS system will display corresponding warning message.

Only when the above requirements are met will the static switch of the stand-alone machine is closed.

Abnormal AC

In case of AC power failure or abnormality, the rectifier will automatically stop working, and the system will switch to

battery inverter output, the backup time depends on the loads and the battery capacity. If the AC is still not back to

normal during this period of time, the inverter will automatically stop working, and the UPS operating control panel

will display corresponding warning message.

The interruption and recovery of the AC do not disrupt power supply to the loads.

AC Recovery

If the AC recovers within certain time, the rectifier will automatically start (and its output power gradually increases),

supply power to the loads and charge the battery, hence no interruption in the power supply.

Disconnecting Battery

In case of a need to detach the battery from the UPS system for maintenance, the external disconnector can be

used. At this moment, except the battery backup function during AC power failure, all the other functions of the UPS

and the required steady-state performance indexes are not affected.

Failure with UPS Stand-alone Machine

In case of failure with the inverter, the loads will be automatically powered by the bypass circuit, hence no

interruption in output power. Under such condition, please contact the customer service center for technical support.

(“1+N” UPS parallel system) In case of failure with certain standalone machine in the parallel system, this

machine will quit the parallel system. If the machines left can provide sufficient power to the loads, the system will

continue with the power supply, hence no interruption. If the machines left cannot provide sufficient power, the

system will switch to the bypass AC for power supply.

Overload

In case of overload with the inverter which goes beyond the required time limit or current range (see table 8-6), the

inverter will shut down and the system will automatically switch to the bypass circuit for power supply without

interruption. In case the overload falls within the time limit and current range, and when the parallel system can

provide sufficient power supply, the system will switch to the inverter for power supply. In case of short circuit, the

loads switch to the bypass and the inverter will shut down. The switch is first of all decided by the characters of the

protective device used in the system.

For the above two circumstances, the UPS operating control panel displays warning messages.

(“1+N” UPS parallel system) The control logic system continuously monitors the power requirement of the loads

and controls each UPS standalone machine. If the overload time exceeds the set value and the system cannot

provide the loads with sufficient power, the loads will switch to the bypass power. When the load value drops to the

point where the system can provide sufficient power, the system will switch to the inverter for power supply.

Maintenance Bypass Circuit

There is another bypass circuit for the UPS system, i.e. the maintenance bypass circuit, which is used to provide a

safe working environment for the technical staff when they are carrying out regular maintenance or repair for the

UPS system, and also to provide AC power for untreated loads. The maintenance bypass circuit can be manually

selected via the bypass circuit switch, and cut off when switched to ―OFF‖.

1.2.4 ECO Mode (only suitable for the UPS standalone machines)

警告

危险

WARNING

Under the ECO mode, there is no AC voltage distortion protection for the loads.

Under the ECO mode, the loads are primarily powered by the AC bypass circuit while the inverter is in the bypass

state. When the AC exceeds the standard frequency and voltage range (which can be set), the system will switch to

the inverter for power supply.

The ECO mode can be set in the operating control panel.

The operating method of the ECO mode is the same as the description in Chapter 5 UPS Operation Instruction.

Under normal conditions, the loads are powered by the bypass AC. At this time, the inverter power supply indicator

is off and the warning shows ―bypass power supply‖.

1.2.5 UPS Power Switch Setting

Figure 1-2 is a block chart of the UPS standalone machine with ―separated bypass power‖. In the separated bypass,

the static bypass circuit and the maintenance bypass circuit both have an independent bypass power. Without a

separated bypass power, make a short circuit between the input of the bypass switch Q2 and the input of the

bypass switch Q1 (for standard machines, there is expected to be a short circuit here) so that the bypass input and

the rectifier input use the same AC.

When the UPS is operating properly, all the switches should be closed except the maintenance bypass switch Q3.

1.2.6 System Capacity Expansion

The UPS system can have at most 6 UPS standalone machines connected in parallel. By expanding the capacity, it

is able to supply more power to the loads. Capacity expansion should be set or adjusted on the operating control

panel of each standalone machines.

Attention: Capacity Expansion should only be carried out by professional staff. The capacity of all the standalone

machines should be the same, i.e. the system does not support parallel-connected machines with different

capacities.

1.3. Operation Mode

The UPS systems works in one of the following modes:

AC-inverter Power Supply

Mains being converted to DC by the rectifier and inverted to AC by the inverter, the UPS can provide continuous AC

power to the loads. Meanwhile, the charger (the rectifier) charges the battery via floating charge or equalizing

charge.

Battery

Under the battery mode, the battery, after being inverted by the inverter, provides the loads with backup power. In

case of AC failure, the system will automatically switch to the battery mode, hence no interruption in power supply.

When AC power recovers, the system will switch back to the AC-inverter mode automatically, and power supply to

the loads will not stop.

Automatic Power On

The UPS system offers automatic power on. Specifically, if the AC failure extends too long, the battery discharges

till the cut-off voltage and the inverter shuts down. After the AC recovers, after the preset delay time, the UPS will

automatically start up. This function and the delay time are set by the commissioning engineer.

Bypass

Under this mode, the loads are powered by the static bypass AC, which can be seen as an intermediate power

supply mode when the loads are switching between the inverter power supply and the maintenance bypass power

supply. It is also the working mode under abnormal conditions.

Maintenance Bypass

When the UPS is off, the loads are connected to the bypass power via the maintenance bypass switch.

Joint Power Supply

The UPS system offers joint power supply. AC input power together with battery backup power to meet the demand

of the loads. It is useful in the occasions which high electricity charge during peak hours or in the occasions where

the oil engine cannot meet the power demand of the loads during the AC failure. Joint power supply can be set by

the users, and the share of AC input can be set from 20% to 100%.

ECO Mode (only applicable in the stand-alone system)

All the power switches and battery switches are closed, and the loads are primarily powered by the bypass circuit.

When the bypass power is within the normal frequency and voltage ranges, the loads are powered by the bypass

circuit and the inverter serves as a backup. When beyond the ranges, the system will switch to the inverter output.

Parallel Redundancy (system capacity expansion)

In order to increase system capacity or reliability, or both, you may set the UPS stand-alone machines to be directly

connected in parallel, which ensures even load sharing among all the stand-alone machines through their internal

control logic. The parallel system can have at most 6 stand-alone machines connected together.

Frequency Converter

The UPS has a frequency converter mode which offers 50Hz and 60 Hz firm outputs. The input frequency ranges

between 45Hz and 65Hz. Under this mode, the bypass switch should be cut off, the static bypass circuit is invalid,

and the battery is optional in light of whether there is a need to operate in the battery mode.

警告

危险

WARNING

Before the commissioning engineer powers on the UPS for debugging, make sure to keep the dust cover on top of

the UPS to prevent accumulation of dust in the machine which may result in system failure and safety hazards.

警告

危险

WARNING

Do not power on the UPS before the commissioning engineer comes.

警告

危险

WARNING

The installation of the UPS should be carried out according to instructions in the manual by professional engineers.

For issues that are not mentioned in the manual. Please refer to the detailed mechanical and electrical installation

materials as supplement enclosed in the products.

警告

危险

WARNING: Battery is Dangerous

Installing the battery requires enormous carefulness. When the battery is connected, its terminal voltage exceedes

400Vdc, which may lead to electric shock.

1. Please wear eye shield to prevent harm from electric arcs.

2. Please take off your metal accessories like ring, watch and things alike.

3. Use tools with insulated handles.

4. Wear rubber gloves.

5. In case of leakage of the battery electrolyte or damage, the battery must be replaced. Put the discarded battery

in an anti-acid container and scrap it according to relevant requirements.

6. If the electrolyte drops on the skin, wash it immediately.

警告

危险

WARNING

The UPS system can be connected to the neutral and ungrounded power system (i.e. IT system).

2. Mechanical Installation

This chapter briefly introduces the mechanical installation of the UPS, including the do’s and don’ts, environment

requirements, mechanical requirements, initial check before installation and installation diagram.

2.1 The Do’s and Don’ts

This chapter introduces the environment and mechanical requirements for the siting and wiring of the UPS system.

Due to the distinctive characteristics of each locale, this chapter does not introduce the detailed installation

procedure, but rather offers a general installation procedure and method to the installation staff who may make

specific treatments according to the conditions of the locale.

2.2 Environment Requirements

2.2.1 Site Selection for the UPS

The UPS should be installed in a cool, dry, clean and well-ventilated environment. The dust should not have

conductive powder (like metal powder, sulfide, sulfur dioxide, graphite, carbon fiber, conductive fiber etc.), acid mist

or other conducting medium (dense ionized materials). Specific environment indicators should meet national

standards and regulations, as well as the requirements of this manual. (See table 8-2)

警告

危险

WARNING

The hoisting equipment must have sufficient ability to lift the UPS cabinets.

Forced air cooling is provided by the internal fan. The cool air enters the UPS via the air grids of the UPS machine

and exhaust through the top of the UPS. If the UPS is installed on the raised floor, with wires connected at the

bottom, the cool air may also enter the UPS via the gaps of the floor. Exhaust fan recommended to be installed if

necessary to accelerate ventilation in the environment. In an environment where there is much dust, an air filter is

needed.

Note1: When the battery is installed near the UPS, the upper limit of room temperature is decided by the battery,

not the UPS.

Note2: Under the ECO mode, the power consumption is relatively small. Under the mode of inverter power supply,

the power consumption is quite big, which requires appropriate air conditioning.

2.2.2 Site Selection for the Battery

Temperature is a major factor for the battery capacity and service life. The standard room temperature for the

battery is 20℃, above which the service life might be undermined and below which the battery capacity is reduced.

Under normal conditions, acceptable room temperature is between 15℃ and 25℃. The room temperature should

remain constant and the battery should be kept away from heat or major vents.

The battery recommended to be installed in the battery cupboard close to the UPS. If the battery is placed on the

raised floor, just like the UPS, a holder is required to be put below the floor. If the battery is placed in the battery

shelf or other places away from the UPS, the battery switch should be installed as close to the battery as possible

to ensure the shortest wiring.

2.3 Mechanical Requirements

2.31 System Configuration

According to the different design requirements, a UPS system may consist of several equipment cabinets, for

example UPS cabinet and battery cabinet. In normal circumstances, all the cabinets are installed abreast of the

same height to make them neat.

2.32 Moving the Cabinets

Make sure the weight of the UPS is within the loading capacity of the hoisting equipment. See Table 8-3 for the

weight of UPS.

The UPS cabinets can be carried by the forklift. Before loaded onto the forklift, remove the grid plates at the bottom,

front (or side) of cabinets.

If the forklift is not available, use the rollers.

2.33 Operation Space

There is no fan at both sides of the UPS, hence no special requirement for the space. Please leave a space of

1,000mm for the sake of maintenance operation over the magnetic components at the back. Sufficient room should

be left in front of the UPS so that people may freely walk past the UPS with front door open vertically.

2.34 Wiring

The UPS adopts bottom wiring. It is suggested to choose appropriate cable route and proper wiring to ensure that

the cables can be smoothly connected to the UPS line bank.

2.4 Initial Check

Before installing the UPS, check the following items:

1. Make sure that the room environment meets the requirements of the product technical specifications,

particularly the temperature, ventilation and dust.

2. Unpack the UPS and the battery and have a visual inspection over whether there is any damage within and

outside the UPS and the battery. If so, contact the common carrier.

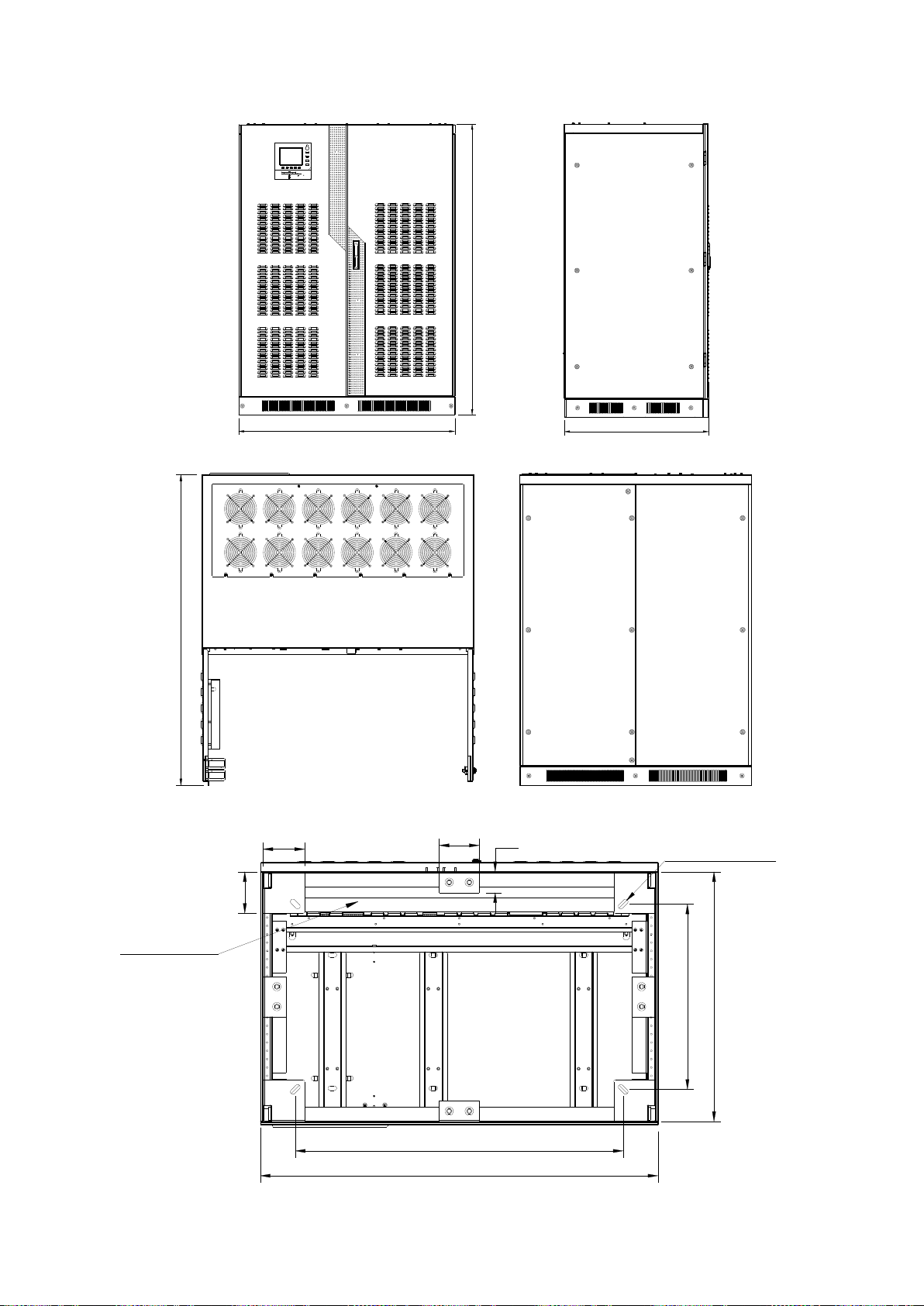

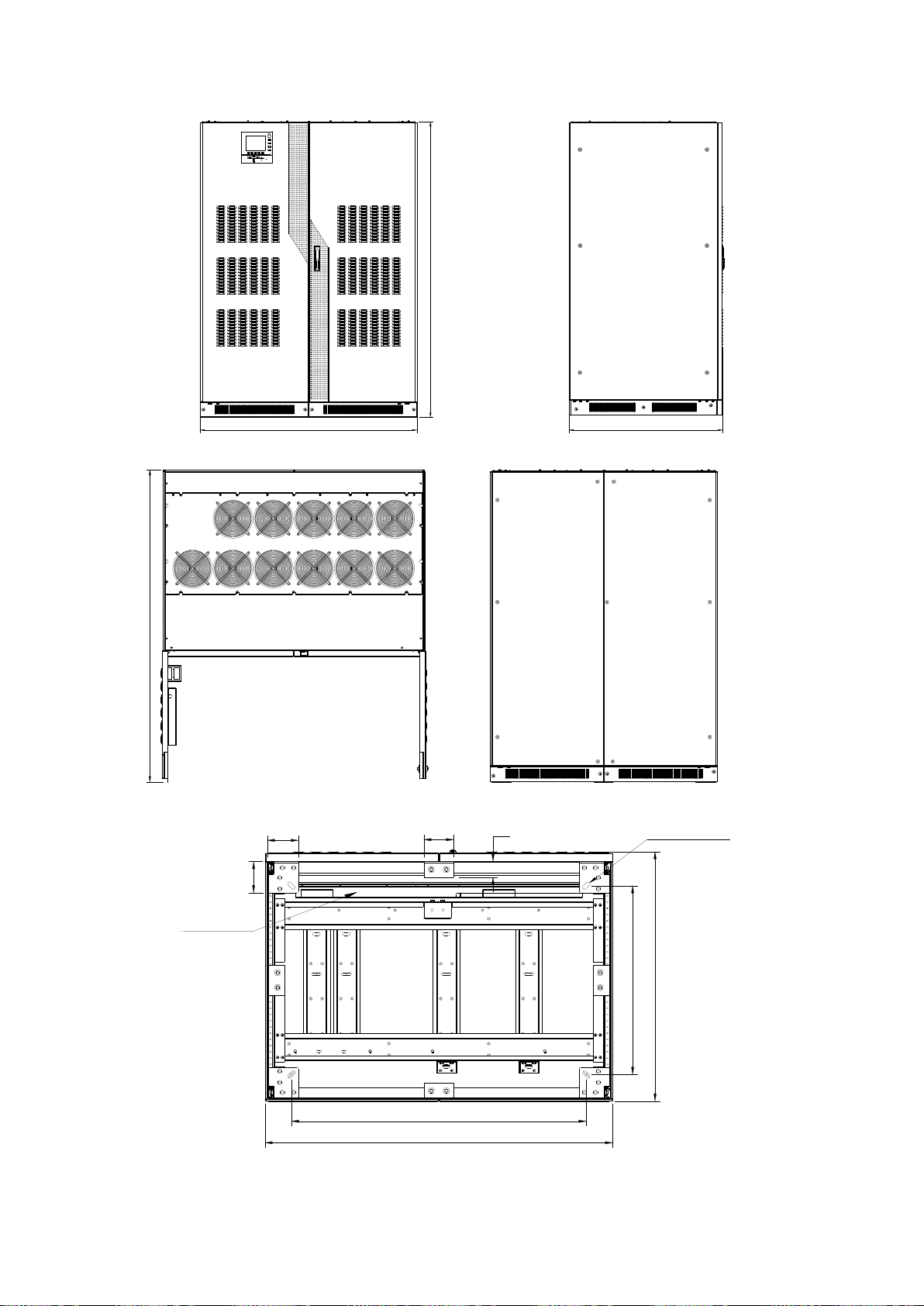

2.5 Installation Diagram

This section introduces the key mechanical characteristics of the UPS cabinets.

STATUS

OUTPUTINVERTER

BAT.

BYPASS

RECTIFIER

EPO

INVERTER ON

INVERTER OFF

FAULT CLEAR

F1 F2 F3 F4 HELP

SILENCE

ON/OFF

1190

1602

789

1363

557

750

982

1191

125

125

4-? 15×35

120

63

Entrance

Front View Side View

Top View Rear View

Figure 2-7 160kVA/200kVA UPS (6 pulse rectifier) front/side/top/rear view (mm)

Figure 2-8 160kVA/200kVA UPS (6 pulse rectifier) bottom view (mm)

1393

1906

STATUS

OUTPUTINVERTER

BAT.

BYPASS

RECTIFIER

EPO

INVERTER ON

INVERTER OFF

FAULT CLEAR

F1 F2 F3 F4 HELP

SILENCE

ON/OFF

1000

1663

757

4-? 15×35

1393

1182

125

125

120

63

1000

Entrance

Front View Side View

Top View Rear View

Figure 2-9

250kVA/300kVA/400kVA UPS (6 pulse rectifier) front/side/top/rear view (mm)

Figure 2-10 250kVA/300kVA/400kVA UPS (6 pulse rectifier) bottom view (mm)

警告

危险

Warning

Before wiring, please double check the switch on the upstream panel connected to the mains input /bypass input

/battery input of UPS. Make sure that the switch is off and attach a warning signal to prevent others from turning on

the switch.

3.Electrical Installation

This chapter mainly introduces the electrical installation of the UPS, including the procedure and method for

connecting the power cable and the control cable, as well as the distance between the equipment connection joint

and the floor.

After the mechanical installation of the UPS, it is time to connect the power cables and the control cables. All the

control cables, shielded or not, should have separate routing different from the power cables in the metal tubes

which are joined with the metal parts of the cabinets.

3.1 Wiring of Power Cables

Please refer to 2.3.4 Wring Method for cable wiring.

3.11 System Configuration

The wire diameter for the system’s power cables should meet the following requirements:

UPS Input Cable

The wire diameter for the UPS input cables varies in light of the UPS power and input AC voltage and should meet

the maximum input current requirement, including the maximum battery charging current. See Table 3-1.

UPS Bypass and Output Cable

The wire diameter for the UPS varies in light of the UPS capacity and input voltage level and should meet the

maximum input current requirement (max. charging current). See Table 3-1.

Battery Cable

Each UPS is connected with the battery via the positive and negative poles. The wire size for the battery cables

depends on the UPS capacity and should meet the max. battery discharge current requirements when the battery

voltage is close to the cut-off one. See Table 3-1.

3.12 Cable Specification

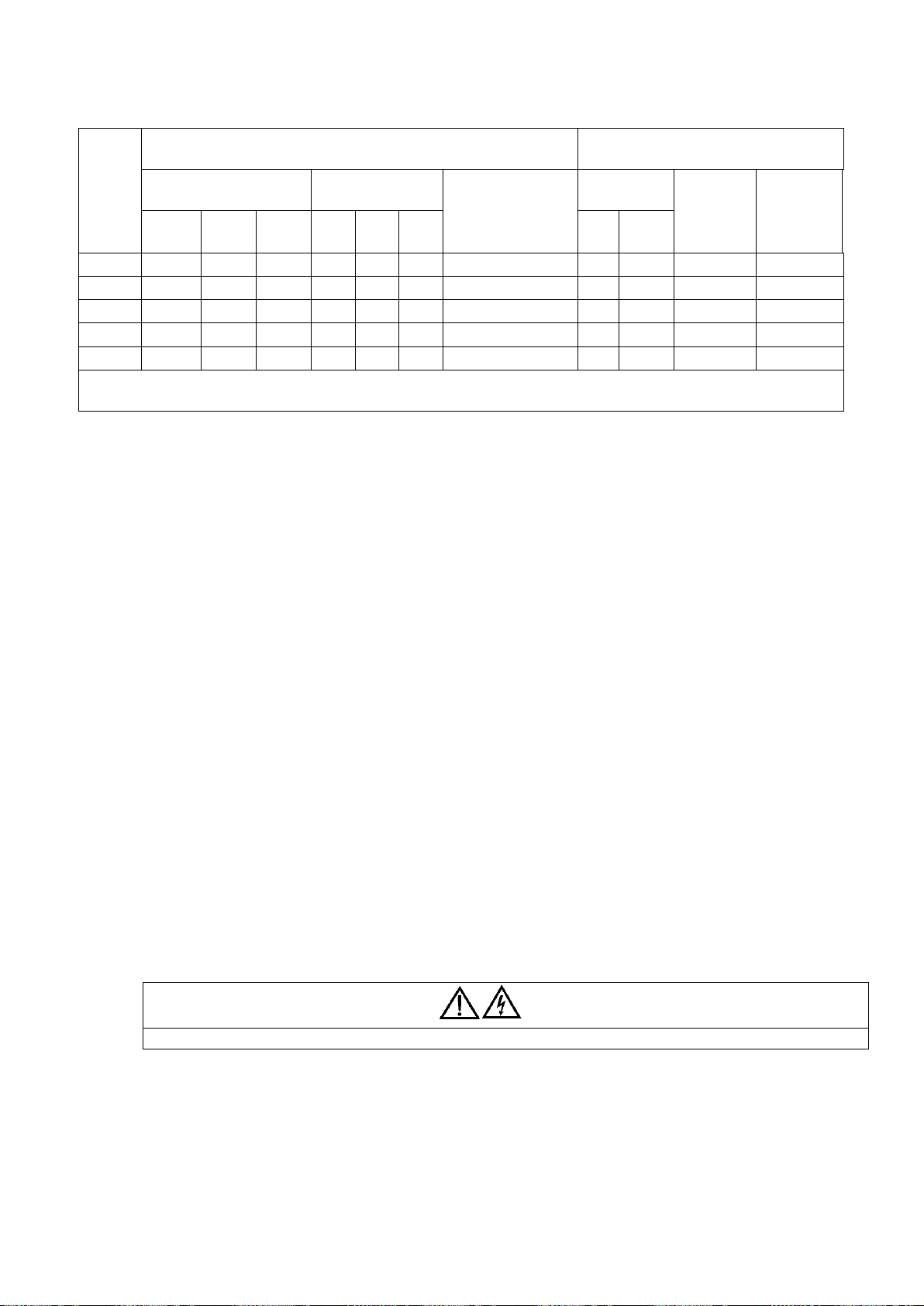

The specification for UPS with different powers is listed in Table 3-1.

UPS

power

(kVA)

Rated Current: Amps

Specifications for the stud bolt of the

busbar

Input AC when the battery

is full loaded

Full loaded output

Battery discharging

current at the lowest

battery voltage

(400Vac)*

Input/output

cable

Battery

cable

Moment of

force(Nm)

380V

400V

415V

380V

400V

415V

bolt

Copper

bar

160

341

324

312

243

231

222

464

M8

Ф9

M8 bolt

12~15

200

426

405

390

304

289

278

580

M8

Ф9

M8 bolt

12~15

250

533

506

488

380

361

348

725

M10

Ф11

M10 bolt

25~30

300

639

608

585

456

434

417

870

M10

Ф11

M10 bolt

25~30

400

852

810

780

608

578

556

1160

M10

Ф11

M10 bolt

25~30

Note*: For the 380Vac power input, the maximum battery discharging current increases by 3%;for the 415Vac input, the

maximum battery discharging current decreases by 3%.

警告

危险

Warning

If ground connection is not done as required, it may lead to electric shock and fire risk.

Table 3-1 UPS Power Cable Specifications

3.13 The Do’s and Don’ts

The following points only offer general guidance. If there are local standards, follow the local standards.

1. The wire diameter for neutral line should be chosen based on 1.5 times of the output/bypass phase current.

2. The wire diameter for the protective ground wire should be chosen based on 2 times of the output/bypass

conductor (which depends on the fault level, cable length and protection type etc.).

3. For cables with big current, thinner cables connected in parallel can be used, which may facilitate installation.

4. When choosing the wire diameter for the battery cables, refer to the current value in Table 3-1 and a voltage

drop of 3Vdc is allowed.

5. For most installation, particularly the installation of a system with multiple stand-alone machines connected in

parallel, the loading equipment is connected with the bus bar power distribution network powered by the UPS,

instead of directly connected with the UPS. Under such circumstances, the wire diameter for the UPS output

cables should meet the requirements of the output power distribution network, rather than depending on the full

load conditions of the stand-alone machines.

3.14 Cable Connector

The rectifier input, bypass, output and battery power cables are connected with the bus bar under the power switch.

See Figure 3-2~Figure 3-6.

3.15 Protected Area

There is ground connection near the input and output copper bar, as is shown in Figure 3-2~Figure 3-6. The

protective ground wire should be plugged into the ground connection and connected with each cabinet in the

system.

All the cabinets and cable troughs should have ground connection according to local requirements. The ground wire

should have wire turn secured over a metal bridge to prevent the fastening bolt from loosening when being pulled.

3.16 Protector

Out of concern for safety, it is necessary to install a breaker outside the UPS for the input power and battery. As the

specific installation conditions vary, the section only offers general information for the installers, including basic

knowledge about the operation practice, rules and regulations, equipment installation etc.

Rectifier and Bypass Input Power

1. Input current and short circuit protection

Loading...

Loading...