Enraf Tanksystem HERMetic UTImeter Rtex Operation And Service Manual

50455/RTEX/0807 1 UTImeter Rtex

Operation and Service Manual

for HERMetic UTImeter Rtex

Connectors Q1 and Q2

Portable Electronic Restricted Gauging Device

Ullage - Temperature - Interface detector

Note : before using the

instrument please

read this book.

50455/RTEX/0807 2 UTImeter Rtex

1. Table of contents

1. TABLE OF CONTENTS .................................. 2

2. GENERAL INFORMATION ........................... 4

2.1 SHIPMENT NOTE............................................ 4

2.2 INITIAL INSPECTION....................................... 4

2.3 DOCUMENTATION DISCREPANCIES................ 4

2.4 WARRANTY .................................................. 4

2.5 CERTIFICATION............................................. 5

2.6 SPARE PARTS ................................................ 5

2.7 SERVICE AND REPAIR ................................... 5

3. WORLDWIDE SERVICE STATIONS

NETWORK ................................................................ 7

4. RECOMMENDATION FOR S AFE USE........ 9

5. FUNCTIONS - KEY FEATURES.................. 10

6. DESCRIPTION................................................ 11

6.1 GENERAL.................................................... 11

6.2 ULTRASENSINGPROBE ............................. 13

6.2.1 Introduction ....................................... 13

6.2.2 Ullage detection................................. 13

6.2.3 Interface detection ............................. 14

6.2.4 Temperature measurement................. 14

6.3 TAPE........................................................... 15

6.4 TAPE PROTECTION ...................................... 16

6.5 READING INDEX.......................................... 17

6.6 TAPE CLEANER ........................................... 18

6.7 ADDITIONALLOAD (OPTION)...................... 19

6.7.1 Viscous liquids (> 800 Cst)................ 19

6.7.2 Reference height and innage.............. 19

6.8 OTHERS ...................................................... 19

7. EXAMPLES OF INSTALLATION OF THE

GAUGING SYSTEM .............................................. 20

7.1 GENERAL.................................................... 20

7.2 EXAMPLE OFINSTALLATION ON APIPE,

CONNECTOR Q2...................................................... 21

7.3 EXAMPLE OF INSTALLATIONON THE DECK,

CONNECTOR Q2...................................................... 22

7.4 EXAMPLE OFINSTALLATION ON APIPE,

CONNECTOR Q1...................................................... 23

7.5 EXAMPLE OFINSTALLATION ON THEDECK,

CONNECTOR Q1...................................................... 24

8. OPERATION ................................ ................... 25

8.1 BASIC RULES CONCERNING THE5-KEY

CONTROL PAD......................................................... 25

8.2 SELECTING THE LANGUAGE......................... 26

8.3 SELECTING THE TEMPERATURE SCALE ........ 27

8.4 SELECTING THE TEMPERATURE RESOLUTION

28

8.5 ACTIVATINGTHE LED ................................ 29

8.5.1 Temporary setting of the LED ............ 29

8.5.2 Permanent setting of the LED ............ 29

8.6 MUTING THEBUZZER .................................. 30

8.7 BACKLIGHT................................................. 30

8.8 CHECKING THE FUNCTIONS BEFORE USING THE

INSTRUMENT........................................................... 31

8.8.1 Battery................................................ 31

8.8.2 Temperature ....................................... 31

8.8.3 Ullage................................................. 31

8.8.4 Interface ............................................. 31

8.9 INSTALLATION OF THE INSTRUMENT............32

8.10 ULLAGE / INTERFACE MEASUREMENT .........32

8.11 REFERENCE HEIGHT / INNAGE MEASUREMENT

33

8.12 TEMPERATURE MEASUREMENT................... 34

9. CARE AND MAINTENANCE ....................... 35

9.1 CARE ..........................................................35

9.2 CHECKING THE BATTERY ............................36

9.2.1 Before starting gauging ..................... 36

9.2.2 During gauging .................................. 37

9.3 BATTERY REPLACEMENT ............................38

9.4 TAPE REPLACEMENT................................... 39

9.4.1 Disconnecting the tape from the sensor

39

9.4.2 Disconnecting the tape from the

electronic box ..................................................... 39

9.4.3 Disconnecting the tape from the reel

axle 40

9.4.4 Removing the tape from the frame ..... 40

9.4.5 Mounting the new tape ....................... 40

9.5 SENSING PROBE REPLACEMENT................... 41

9.5.1 Disconnecting the old sensing probe . 41

9.5.2 Connecting the new sensing probe..... 41

9.6 TAPE WIPERS REPLACEMENT AND REMOVING

OF TAPE COVER....................................................... 42

9.7 DISPLAY UNITREPLACEMENT...................... 43

9.7.1 Disconnecting the old display unit ..... 43

9.7.2 Connecting the new display unit ........ 43

9.8 VERIFICATIONAND CERTIFICATION OF TAPES

43

9.9 VERIFICATIONAND ADJUSTMENT OF THE

READINGINDEX....................................................... 44

9.10 TEMPERATURE VERIFICATION..................... 45

9.10.1 Equipment required............................ 45

9.10.2 Preparing the Ice Point bath.............. 45

50455/RTEX/0807 3 UTImeter Rtex

9.10.3 Checking the UTImeter...................... 45

9.11 ULLAGE/INTERFACE VERIFICATION............. 46

9.12 ELECTRICALCHECKING OF THETAPE

ASSEMBLY.............................................................. 47

9.13 VISUALINSPECTION FOR DAMAGEDOR

MISSINGPARTS........................................................ 48

9.14 COATED ALUMINIUM PARTS........................ 48

9.15 WINDING ACTION BECOMING STIFF ............. 48

10. TROUBLE SHOOTING ............................. 49

10.1 SAFETY WARNING....................................... 49

10.2 POWER SUPPLY TROUBLES.......................... 49

10.3 TRANSMISSION TROUBLES .......................... 49

10.4 ULLAGE AND/OR INTERFACE TROUBLES..... 50

10.5 TEMPERATURE TROUBLES .......................... 50

11. SPECIFICATIONS................................ ...... 51

12. SPARE PARTS ............................................ 52

12.1 HOW TO PROCEED....................................... 52

12.2 LIST OFPARTS DESCRIPTIONS...................... 52

12.3 SPARE PARTS DRAWINGS............................. 54

13. VALVES DRAWINGS & DECLARATION

OF CONFORMITY ................................................ 63

13.1 VALVES ...................................................... 63

13.2 DECLARATION OF CONFORMITY.................. 63

50455/RTEX/0807 4 UTImeter Rtex

2. General information

2.1 Shipment note

The following parts should be included in the

shipment:

- 1 instrument fitted out with one battery in the

display;

- 1 set of 4 Allen keys: 1.5, 2, 2.5 and 3 mm;

- 1 Operation and Service Manual.

2.2 Initial inspection

Check the contents of the shipment for

completeness and note whether any damage has

occurred during transport. Carry out the “Initial test

before installing the instrument” to verify the good

functioning. If the contents are incomplete, or if

there is a damage, not use the device. A claim

should be filled with the carrier immediately, and

Enraf Tanksystem SA Sales or Service

organization should be notified in order to facilitate

the repair or replacement of the instrument.

2.3 Documentation discrepancies

The design of the instrument is subject to

continuous development and improvement.

Consequently, the instrument may incorporate

minor changes in detail from the information

contained in the manual.

2.4 Warranty

Two (2) years after installation but max. 30

months after delivery ex works except

batteries.

The Vendor undertakes to remedy any defect

resulting from faulty design materials or

workmanship. The Vendor's obligation is

limited to the repair or replacement of such

defective parts by his own plant or one of his

authorized service stations. The Purchaser

shall bear the cost and risk of transportation

of defective parts and repaired parts supplied

in replacement of such defective parts.

When returned to Enraf Tanksystem SA or any

of its agreed Service Stations equipment must

be contamination -free. If it is determined that

the Purchasers equipment is contaminated, it

will be returned to the Purchaser at the

Purchasers expense. Contaminated equipment

will not be repaired, replaced, or covered

under any warranty until such time that the

said equipment is decontaminated by the

Purchaser.

The Purchaser shall notify by fax, telex or in

writing of any defect immediately upon discovery,

specifying the nature of the defect and/or the

extend of the damage caused thereby.

Where no other conditions have been negotiated

between the Vendor and the Purchaser "General

Conditions 188" of United Nations shall apply.

This instrument has been certified as Intrinsically

Safe Instrumentation for only those classes or

categories of hazardous areas stated on the

instrument label, bearing the mark of the

applicable approval authority. No other usage is

authorized.

Unauthorized repair or component replacement by

the Purchaser will void this guarantee and may

impair the intrinsic safety of the instrument. In

particular it is not allowed to repair electronic

circuits.

In no event shall Enraf Tanksystem SA be liable

for indirect, incidental or consequential loss or

damage or failure of any kind connected with the

use if its products or failure of its products to

function or operate properly.

Enraf Tanksystem SA do not assume the

indemnification for any accident or damage

caused by the operation of its product and the

warranty is limited to the replacement of parts or

complete goods.

50455/RTEX/0807 5 UTImeter Rtex

2.5 Certification

The equipment has been approved for the

electrical intrinsic safety by the following

authorities :

ATEX

II 1 G EEx ia IIB T4 / Tamb. 50 °C

Factory Mutual (FM Approvals)

CL I, DIV 1, GP C&D, T4 Tamb. 50 °C and

CL I, ZN 0, AEx ia IIB T4 Tamb. 50 °C

The equipment has been approved as oil/water

interface detector according to MARPOL

Resolution MEPC.5(XIII) of 13 June 1980 by

National Maritime Authorities and/or Classification

Societies.

If you need a copy of any of these certificates

please contact:

Enraf Tanksystem SA

Rue de l'industrie 2

1630 Bulle, SWITZERLAND

Telephone : +41-26-91 91 500

Telefax : +41-26-91 91 505

Web site : www.tanksystem.com

E-mail : info@tanksystem.com

2.6 Spare parts

When ordering spares identify the spare part by

TS number and description. Refer to section

“Drawings”.

Some spares might be repairable; in this case

send the part(s) to any authorised service center

or to the factory.

In case of urgency, complete replacement units

can be made available. Contact the factory or

nearest Service Station for details.

2.7 Service and Repair

The customer is responsible for any freight and

customs clearance charges. If units are sent on a

"freight collect" the charges will be invoiced to the

customer.

When returning units or parts for repair to the

factory please fill out a service request form (see

next page). The serial number (letter "R" followed

by 5 digits) is printed on the identification plate as

shown on the Figure 6-1.

When returned to Enraf Tanksystem SA

equipment must be contamination-free. If it is

determined that the customers equipment is

contaminated, it will be returned to the

customer at the customers expense.

Contaminated equipment will not be repaired

until such time that the customer

decontaminates the said equipment.

Enraf Tanksystem SA is an

ISO 9001 certified company

by Det Norske Veritas

Certification GmbH.

50455/RTEX/0807 UTImeter Rtex

6

Service Request

Customer's address: ..............................................................................

................................................................................................................

................................................................................................................

................................................................................................................

................................................................................................................

Telephone: ..............................................................................................

E-mail: .....................................................................................................

Fax: .........................................................................................................

Type of unit or part: .................................................................................

.................................................................................................................

Serial number: .........................................................................................

Short description of trouble: .....................................................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

Do you want a quotation before repair is started:..........yes / no.............

Repaired unit has to be returned to the following address:

..................................................................................................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

50455/RTEX/0807 UTImeter Rtex

7

3. Worldwide Service Stations network

The updated list can be found on our website www.enraftanksystem.com

COUNTRY ADDRESS TELEPHONE/FAX/E-MAIL

SWITZERLAND ENRAF TANKSYSTEM SA Tel : +41-26-91 91 500

2, rue de l'Industrie Fax : +41-26-91 91 505

CH-1630 BULLE info@tanksystem.com

CANADA PYLON ATLANTIC Tel : +1-902-4683344

A Div. Of Pylon Electronics Inc. Fax : +1-902-4681203

31 Trider Crescent., halifax_csr@pylonelectronics.com

DARTMOUTH, N.S. B3B 1V6

CHINA HUA HAI EQUIPMENT &

ENGINEERING CO LTD

Tel : +86-21-68183183

Factory 7, Lane 1365, East Kang Qiao

Road

Fax : +86-21-68183115

Kang Qiao Industrial Zone, Pu Dong huahaish@huahaiee.com

SHANGHAI, P.C. 201315

GREECE SPANMARIN Tel : +30-210-4294498

86, Filonos Street Fax : +30-210-4294495

GR-185 36 PIRAEUS spanmarin@ath.forthnet.gr

JAPAN DAIWA HANBAI CORPORATION LTD Tel : +81-6-64714701

10-31, Mitejima 2-Chome,

Nishiyodogawa-ku

Fax : +81-6-64729008

daiwa471@silver.ocn.ne.jp

OSAKA 555-0012

KOREA World Ocean CO., LTD

Hang-Woon Building

1168-11, Cho Ryang 3 Dong

Dong-Ku

PUSAN

Tel : +82-51-462-2554/5

Fax : +82-51-462-0468

marine@worldocean.co.kr

MEXICO URBAN S.A. DE C.V.

Ave. Ejército Mexicano 1902

Col. Loma del Gallo

89460 CD.MADERO, TAMPS. MEXICO

Tel : +52-833-2170190

Fax : +52-833-2170190

E-mail : urbansa@prodigy.net.mx

NETHERLANDS B.V. TECHNISCH BUREAU

UITTENBOGAART

Tel : +31-10-4114614

Fax : +31-10-4141004

Brugwachter 13 info@tbu.nl

NL-3034 KD ROTTERDAM

50455/RTEX/0807 UTImeter Rtex

8

The updated list can be found on our website www.enraftanksystem.com

COUNTRY ADDRESS TELEPHONE/FAX/E-MAIL

PORTUGAL CONTROLIS Tel : +351-21-2740606

Soc. Com. Equipamentos de Controlo,

Lda.

Fax : +351-21-2740897

controlis@netc.pt

Rua Conceiçao Sameiro Antunes, 26E

P-2800 COVA DA PIEDADE

RUSSIA NPP "GERDA" Tel : +7-495-7558845

Vilisa Latsisa str. 17

Building 1

Fax : +7-495-7558846

info@gerda.ru

125480 MOSCOW

SINGAPORE HUBBELL INT'L (1976) PTE LTD Tel : +65-6-2557281

322 Thomson Road Tel : +65-6-2550464

SINGAPORE 307665 Fax : +65-6-2532098

hubbell@mbox2.singnet.com.sg

SPAIN E.N.I. Tel : +34-94-4746263

Electronica y Neumatica Industrial, S.A. Fax : +34-94-4745868

C/Jon Arrospide, 20 (Int.) eni.tecnica@eni.es

48014 BILBAO

SWEDEN INSTRUMENTKONTROLL Tel : +46-31-240510

Lars Petersson AB Tel : +46-31-240525

Varholmsgatan 1 Fax : +46-31-243710

414 74 GÖTEBORG Info@instrumentkontroll.se

UNITED ARAB

EMIRATES

MARITRONICS TRADING L.L.C.

P.O. Box 6488

Shed # 72, Jadaf Ship Docking Yard

Tel : +971-4-3247500

Fax :+971-4-3242500

maritron@emirates.net.ae

DUBAI

UNITED

KINGDOM

ENERGY MARINE (INTERNATIONAL)

LTD.

12 Clipstone Brook Industrial Estate

Cherrycourt Way

LEIGHTON BUZZARD, BEDS LU7 8TX

Tel : +44-1525-851234

Fax :+44-1525-852345

info@engmar.com

U.S.A/ HERMETIC, INC. Tel: +1-281-930 1777

TEXAS 4522 Center Street Fax: +1-281-930 1222

DEER PARK, TX 77536 Toll free call in the USA:

1-800-900 1778

info@hermeticinc.com

50455/RTEX/0807 UTImeter Rtex

9

4. Recommendation for safe use

1. This Operation and Service Manual is a guide in order to help the user to operate the instrument to our

best knowledge.

2. Nevertheless the maker disclaims all responsibility and liability for damage resulting from the use of the

equipment regardless of the cause of the damage.

3. Attention is drawn to the possible hazard due to electrostatic charges which may be present in the

tank. This may happen in particular with static accumulator liquids, i.e. liquids which have low conductivity

of 50 picoSiemens/metre (pS/m) or less.

4. It is very important that the instrument is grounded to the tank before the probe is introduced into

the tank and remains grounded until after complete withdrawal from th e tank.

4.1. If the instrument is installed with the quick connect coupler, grounding is effected through the quick

connect coupler and the mating nipple of the valve provided that these parts are kept clean and free

from corrosion in order to guarantee electrical conductivity. If a grease is used for this purpose, it

must be one which contains graphite.

4.2. If the instrument is not connected to the mating deck valve, the instrument has to be also earthed by

means of the grounding cable and clamp.

5. It is anticipated that the user will have specific operating methods laid down to ensure safety

when using this type of apparatus. In this case the user's instructions shall be strictly observed.

6. In the absence of such instructions the following should be noted:

6.1. If a metal sounding pipe is fitted beneath the deck valve or tank is inerted, then ullaging, etc. is

permissible at any time with no restriction.

6.2. If there is no sounding tube or tank is not inerted, the following precautions shall be taken:

6.2.1. If the cargo is not a static accumulator liquid, i.e. its conductivity is more than 50 pS/m, then

ullaging is permitted provided that the instrument is properly grounded and earthed before

the probe is inserted into the tank and remains earthed until the probe has been removed

from the tank.

6.2.2. If the cargo is a static accumulator liquid, i.e. its conductivity is less than 50 pS/m, then

ullaging is permitted provided that:

6.2.2.1. The instrument is properly grounded and earthed before the probe is inserted into

the tank and remains earthed until the probe has been removed from the tank.

6.2.2.2. The apparatus is not introduced into a tank until at least 30 minutes have elapsed

after completion of any loading operation or stopping the injection of inert gas.

6.3. For further guidance refer to International Safety Guide for Oil Tankers and Terminals (ISGOTT),

ISBN 1 85609 081 7, Fith Edition 2006, or consult the appropriate Legislative Authority for the

installation.

7. Warning: change of battery must be carried out in safe area only (non flammable atmosphere).

50455/RTEX/0807 UTImeter Rtex

10

5. Functions - Key Features

This HERMetic instrument is a portable multiple

functions gauging system that is designed to

perform under restricted conditions in a single

operation 3 measurements:

a) Ullage (outage). Optionally innage is available¹.

b) Oil/water Interface level.

Tape resolution: 1 mm (1/16 ")

Tape accuracy: ±3.2 mm for 30 m

(±1/8 " approx. for 100 feet)

Ullage/interface detection accuracy:

±2 mm (±0.08 " approx.)

Minimum detectable tank bottom interface or liquid

level: 4 mm (0.16" approx.).

c) Temperature by continuous reading at any

level.

Ambient temperature range: -20°C to 50°C

( -4°F to 122°F)

Sensor measurement range:-40°C to 90°C

( -40°F to 194°F)

Resolution: 0.01° or 0.1°, selectable

Accuracy over calibration range: ±0.1°C (0°C to

70°C); ±0.2°F (32°F to 158 °F)

Temperature reading: °C or °F, selectable.

This HERMetic device meets the requirements of

API MPMS Chapter 7 2001, table 3, ISO 4268 and

IP PMM Part IV.

Thanks to the small diameter of the sensing probe

this instrument can be used with valves of

diameters down to 25 mm (1”) only.

A tape protection tube prevents closing the valve

on the tape through inadvertence.

¹ An additional device, usable with 2” valves only,

can be provided that allows Reference Height

and Innage measurement. Available on “Visc”

models.

Tank top

Ullage level

Interface level

Water

Product

Vapour

Tape protection

Zero reference level

50455/RTEX/0807 UTImeter Rtex

11

6. Description

6.1 General

Each HERMetic instrument is individually

identified with a 6 digits serial number starting

with the letter R, example R10058. This serial

number is printed on the identification plate as

shown on Figure 6-1.

The HERMetic instrument is fitted with an ULTRA

sensing probe.

The unit emits control beep, continuous beep and

intermittent beep.

When the sensing probe is surrounded by air, a

control beep occurs every 2 sec.

When the sensing probe is in contact with any

petroleum product, the beep is continuous.

When the sensing probe is in contact with water

the beep is intermittent.

Control beep

• •

Continuous beep • • • • • • • • • •

Intermittent beep • • • • • •

A light signal (LED) can also be activated that

blinks at the same frequency as the buzzer tones.

This can be useful in noisy environments or at

night.

A backlight can be used at night to light up the

display.

The HERMetic instrument is powered by a 9 Volt

battery stored in the electronic terminal named

instrument unit. Current consumption is very low,

ensuring long operation without battery

replacement. A continuous tone means that the

battery needs replacement. If the battery power

is too low, it is no more possible to read the

temperature.

Maintenance is easy because design is modular

and allows quick exchange of parts.

See also Figure 6-2 to get to know the equipment.

identification plate

serial number

Figure 6-1

50455/RTEX/0807 UTImeter Rtex

12

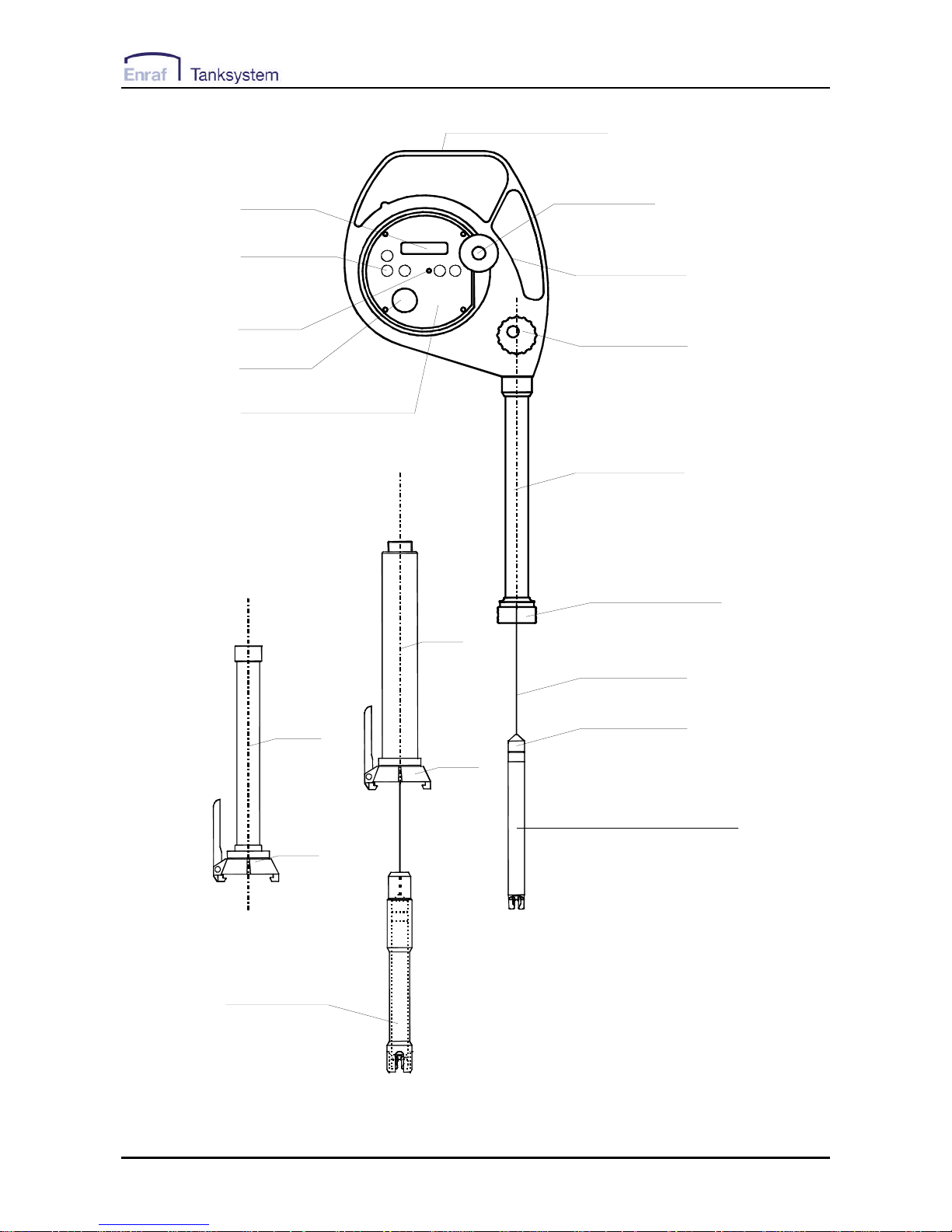

Storage tube SS1

Quick connector Q1

Tape cleaner

Reading index

Buzzer

Tape

Sensing probe ULTRA

Tape adaptor

Display

SS1

SS2

Q2

Q2

Visc

device for

innage measurement

Display unit

LED

Identification plate

Crank

5 keys pad

Figure 6-2

50455/RTEX/0807 UTImeter Rtex

13

6.2 ULTRA sensing probe

6.2.1 Introduction

The ULTRA sensing probe consists of a

stainless steel tube terminated by a hightech plastic head which cannot be

removed from the tube. The sensing

probe includes an ultrasonic liquid level

sensor, a temperature sensor and a

conductivity electrode. The sensitivity for

ullage and interface measurement is not

adjustable. The temperature

measurement is calibrated at the factory

and does not require subsequent

adjustment.

6.2.2 Ullage detection

The ullage detector consists of two

piezoceramic plates and electronic

circuits. When the sensor head is

immersed in a non-conductive liquid (oil or

petroleum), the emitted ultrasonic signal is

detected by the receiver, coded and sent

to the instrument unit which activates the

buzzer with the continuous beep.

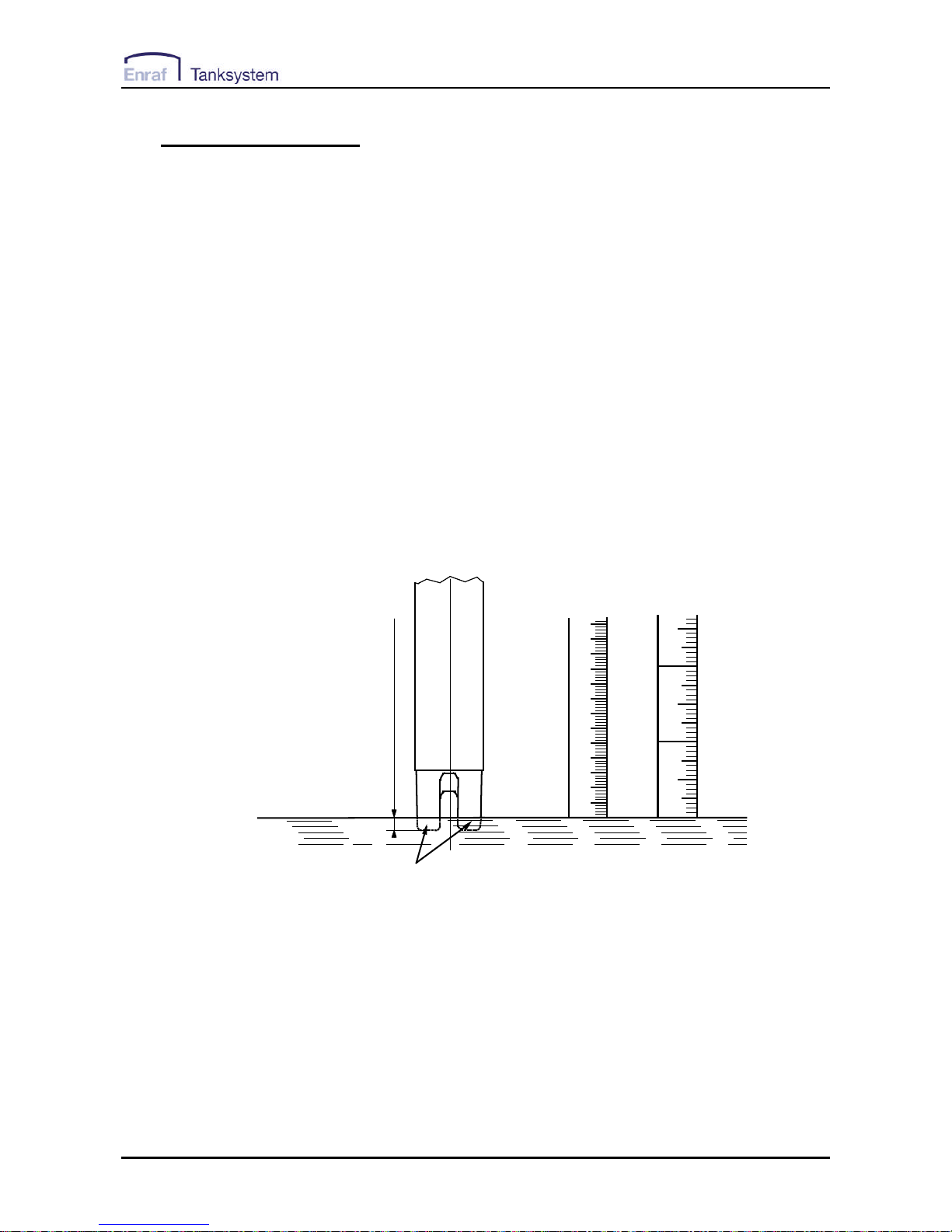

1

60 1 2 3 4 5

0

1

1 2

1

Reaction point

Ultrasonic level sensor

4 mm

Air

Liquid

Figure 6-3

The reaction point is located 4 mm (5/32") from the sensor bottom and identical with the zero-point of the tape graduation.

50455/RTEX/0807 UTImeter Rtex

14

6.2.3 Interface detection

The principle consists of a conductivity

measurement between an active

electrode and a grounded electrode.

When the liquid is conductive (as water),

the ullage sensor detects the presence of

the liquid as well and the conductivity

electrodes and associated electronic

circuits modulate the coded signal to

generate the intermittent beep.

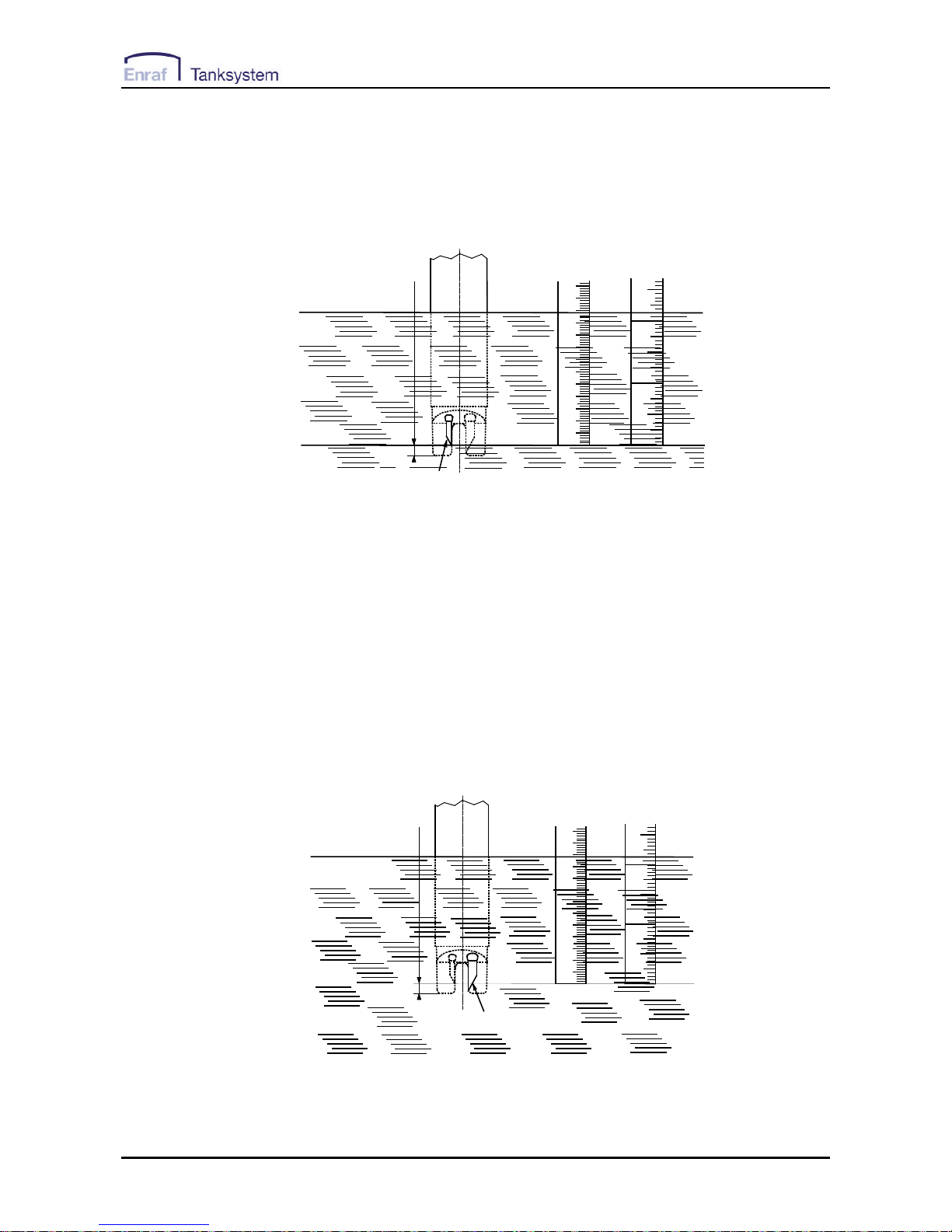

1

60 1 2 3 4 5

0

1

1 2

1

Interface level

Interface sensor

4 mm

Water

Oil

Air

Oil

Figure 6-4

The reaction point is located 4 mm (5/32") from the sensor bottom and identical with the zero-point of the tape graduation.

6.2.4 Temperature measurement

The sensing element is a Platinum Resistance

Temperature Detector (RTD) element. The

element is located in the temperature electrode,

which is filled in with a heat transfer compound

paste to reduce the response time.

The RTD element signal is digitized, and then all

errors (offset, non-linearity and drift) are corrected

and compensated by the micro-controller located

in the sensor probe. The RTD element

characteristics are stored in the sensor memory

and are dedicated to one sensor. For this reason,

changing a sensor does not require a new

calibration.

All data are serialised and sent by the microcontroller to the Display Unit.

Temperature settings (resolution, scale) are easy

to select by pressing the 5-key control panel.

1

60 1 2 3 4 5

0

11 21

Temperature level

Temperature sensor

4 mm

Liquid

Air

Figure 6-5

The reaction point is located 4 mm (5/32") from the sensor bottom and identical with the zero-point of the tape graduation.

50455/RTEX/0807 UTImeter Rtex

15

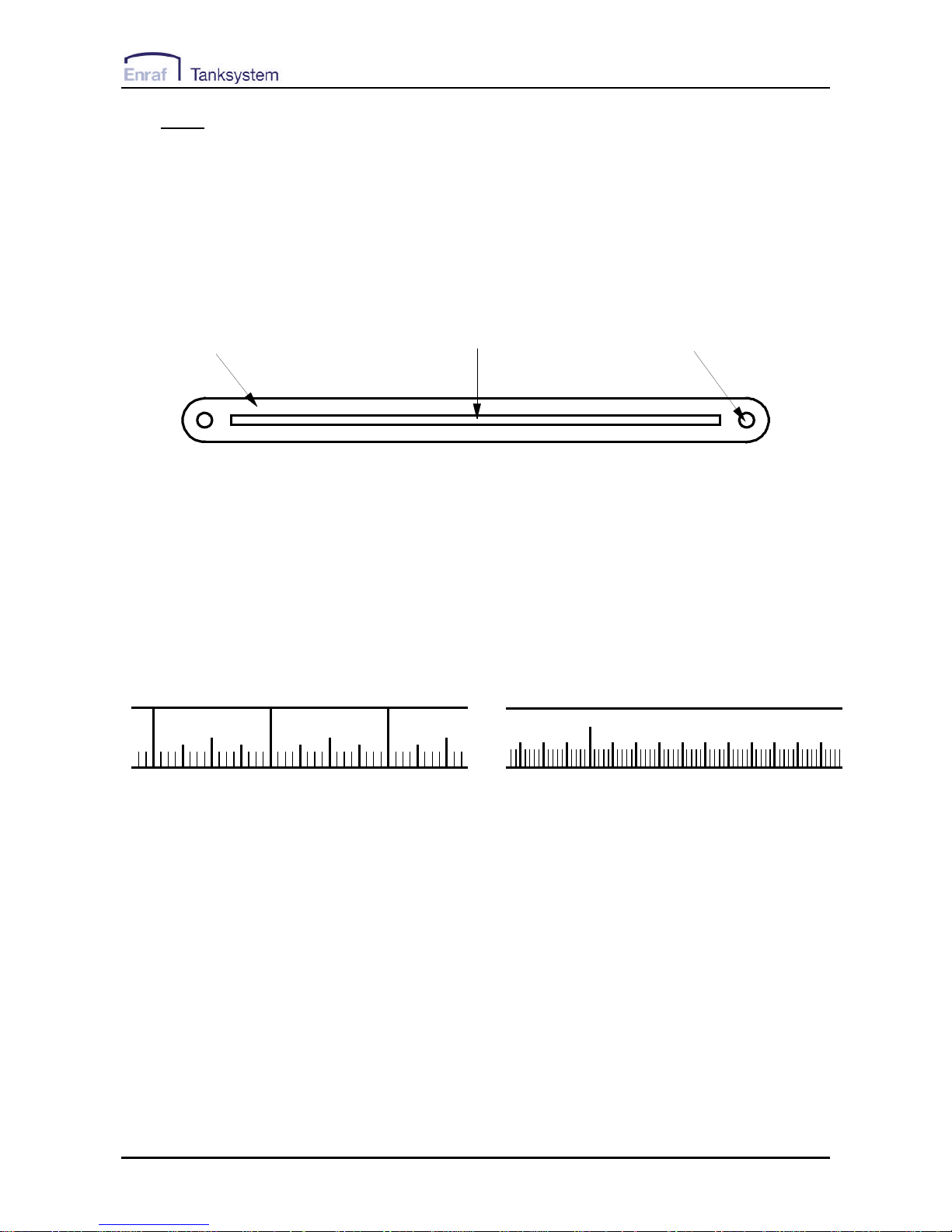

6.3 Tape

The ETFE (TEFZEL) coated tape provides 3 main

functions :

It holds the sensing probe.

It is graduated and therefore makes it possible

to determine the distance between the reaction

point and the reading index. If the reading

index is set up at the zero ullage level, the

reading of the tape is identical to the ullage.

It contains 2 wires for transmitting the signal

and the power between the display unit and the

probe. The steel tape itself is used as a

grounding wire between the sensing probe

tube and the display unit.

TEFZEL

STEEL TAPE

WIRE

Figure 6-6

The standard graduation is a double side type that shows the metric graduation on one side and the inch one

on the other side. The tape is mounted on the equipment according to the need.

3 4

23

10 11 12 13 14 15

7

7

5

23

9

23

metric sideinch side

Figure 6-7

50455/RTEX/0807 UTImeter Rtex

16

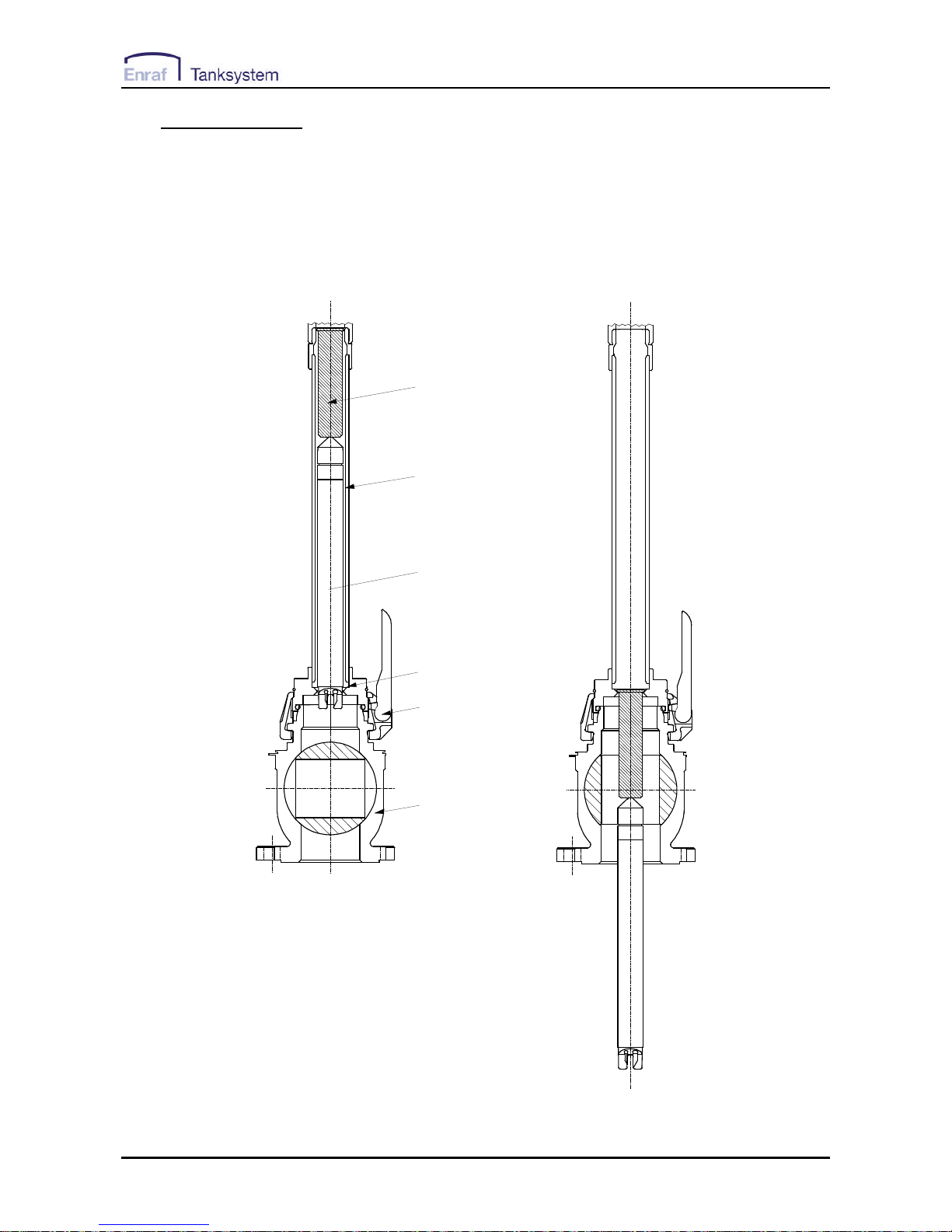

6.4 Tape protection

The tape protection tube is a mechanical safety

device which prevents the valve from being closed

as long as the sensing probe is inside the tank.

When the sensing probe is lowered the protection

tube will follow the sensing probe by gravity until

the tube is retained by a ring located inside the

coupler. In that position the protection tube

prevents closing the valve. When the tape is

wound up the protection tube will stay in position

until it is pushed up by the sensing probe. Before

instrument is used check that the protection tube

is moving freely. For cleaning purposes the

protection tube is slotted.

VALVE CLOSED

VALVE OPEN

TAPE PROTECTION TUBE

STORAGE TUBE

SENSOR

RETAINER

QUICK CONNECT

COUPLER

BALL VALVE

Figure 6-8

50455/RTEX/0807 UTImeter Rtex

17

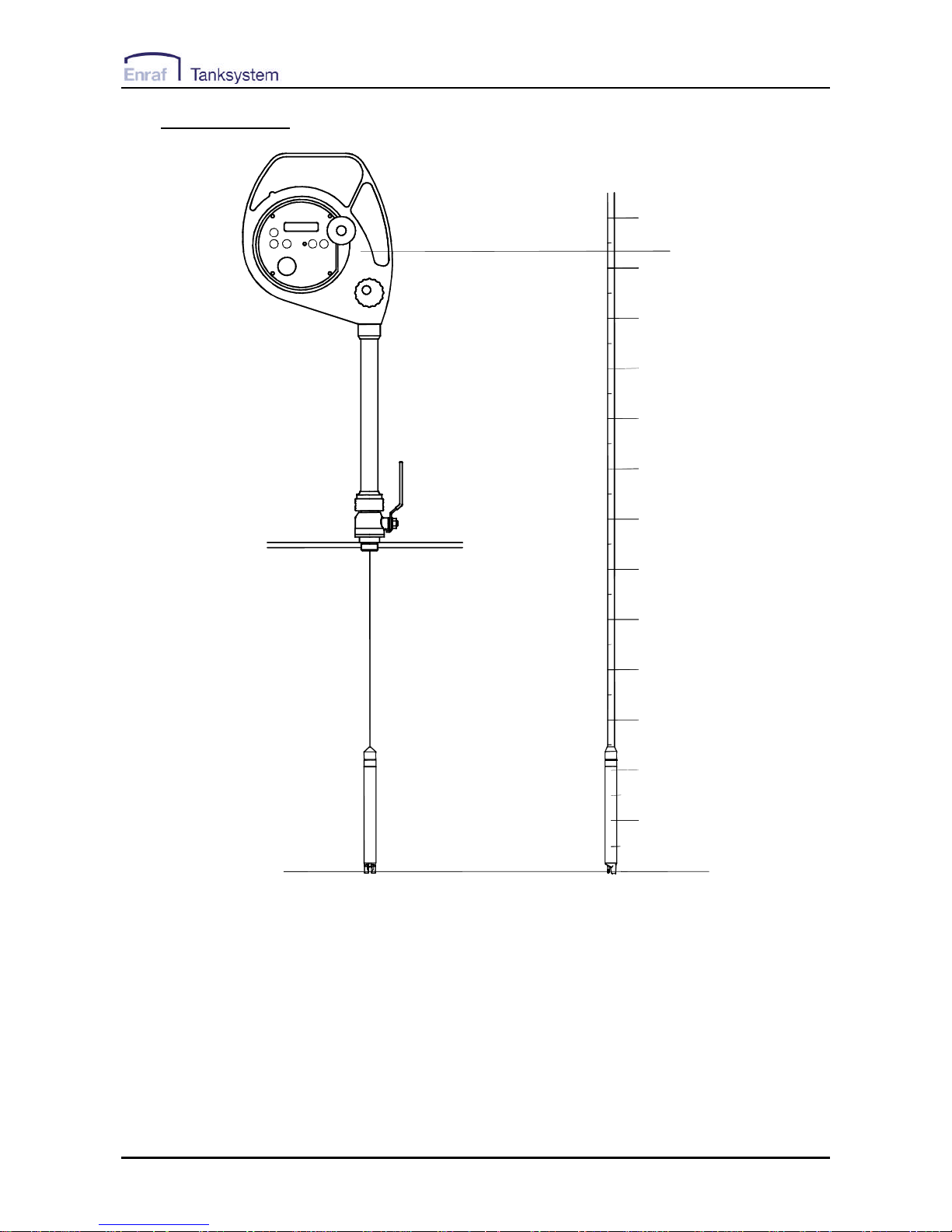

6.5 Reading index

Zero ullage

Reference level of tank

Liquid level

Reaction point

100

200

300

400

500

600

700

800

900

1000

1100

1200

0

1300

Figure 6-9

The tape reading at the height of the reading index

of the instrument is indicating the distance

between the reaction point and the reading index.

If the instrument is installed in such a way that the

reading index is at the same level as the zeroullage reference level the reading of the tape

corresponds to the ullage providing the reaction

point of the sensing probe is positioned at the

liquid level.

If the reading index is positioned below or above

the reference level a positive or negative

correction of the tape reading is necessary.

See also chapter 7 “Examples of installation of the

gauging system”.

50455/RTEX/0807 UTImeter Rtex

18

6.6 Tape cleaner

This HERMetic equipment is fitted with a tape

cleaner that helps draining the liquid back to the

tank when rewinding the tape. It is very easy to

operate:

- position "DOWN": the wipers are not working,

the tape is free;

- position "UP": the wipers are cleaning the

tape.

Refer to Figure6-10.

Tape cleaner DOWN = wipers not engaged

Tape cleaner UP = wipers engaged

Figure 6-10

50455/RTEX/0807 UTImeter Rtex

19

6.7 Additional Load (option)

An additional load (see Figure 6-2) on the sensing

probe can be provided for one of the following

reasons. This option is available on UTImeter

Rtex Visc equipped with the storage tube Q2 (2”)

and needs valves of at least 2” size.

6.7.1 Viscous liquids (> 800 Cst)

For gauging viscous liquids the load can

help the sensing probe in penetrating the

liquid and in keeping the tape straight.

6.7.2 Reference height and innage

For measuring the reference height of a

tank and innages the load allows the

sensing probe to touch the dip/datum

plate.

6.8 Others

The tape is coiled on a reel which holds also the

electronic box and the display unit.

The reel is assembled to the electronic box and

can be locked at discrete positions by means of a

stopping mechanism in the crank. Pull the crank to

free the stopping mechanism.

The external reel flange and the frame are made

in aluminium coated with polyamid PA 11

(RILSAN).

The storage tube is threaded to the frame.

The storage tube is equipped with a quickconnector which fits on the HERMetic valves.

50455/RTEX/0807 UTImeter Rtex

20

7. Examples of installation of the gauging system

7.1 General

The gauging system consists of the HERMetic

instrument and the associated HERMetic valve.

Two types of connector can be provided as shown

on Figure 7-1.

Figure 7-1

The following sections, respectively 7.2, 7.3 for

connector Q2 and 7.4, 7.5 for connector Q1,

describe 2 examples for installing the valves and

adjusting the height of the gauging system.

The valves should be installed in such a way that

the zero-ullage level coincides with the reading

index level, so that no correction would be

necessary. For achieving this it may be necessary

to install an adjusting pipe between the deck and

the valve.

If the valves are installed directly on deck or if for

any reason the level of the reading index is below

or above the zero-ullage level, then a correction

table should be used.

There should be no internal tank structure

between the valve outlet and the tank bottom such

that will impede the path of the equipment into the

tank.

All valves shall be installed at the same level.

Small systematic level error can be corrected by

adjusting the reading index accordingly.

When designing the gauging port and to avoid

damaging the tape during rewinding it is advised

to chamfer or to grind all sharp edges (on pipes,

flanges, etc.) that could damage the tape when

operating the gauge.

50455/RTEX/0807 UTImeter Rtex

21

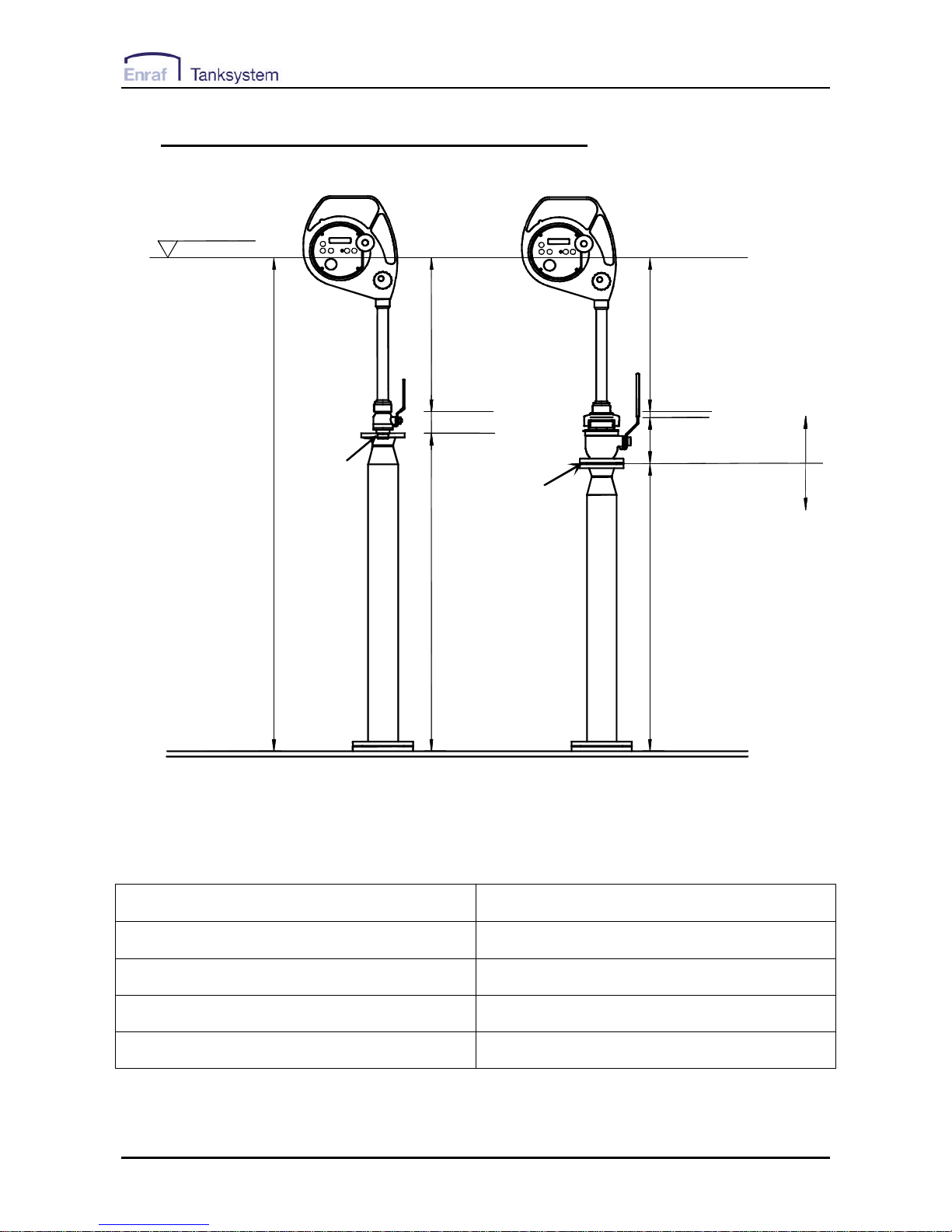

7.2 Example of installation on a pipe, connector Q2

Reading

index

Reading

index

H

460mm 460mm

HV

HV

HC

HT

HT

Tank Zero Ullage level

Thread

Flange

TS supply

Customer supply

SS1 Q1

SS1 Q1

Tank Deck

Figure 7-2

Valve designation C.2-SS; C.2-SS-W; C.2-SS-BL; C.2-SS-SEC

Bottom connection thread or flange

Boring 2”

*) HV (mm) 141

*) HT (mm) H-615

*) Dimension HV is without gasket. If gaskets are used dimension HT is reduced by thickness of gasket.

50455/RTEX/0807 UTImeter Rtex

22

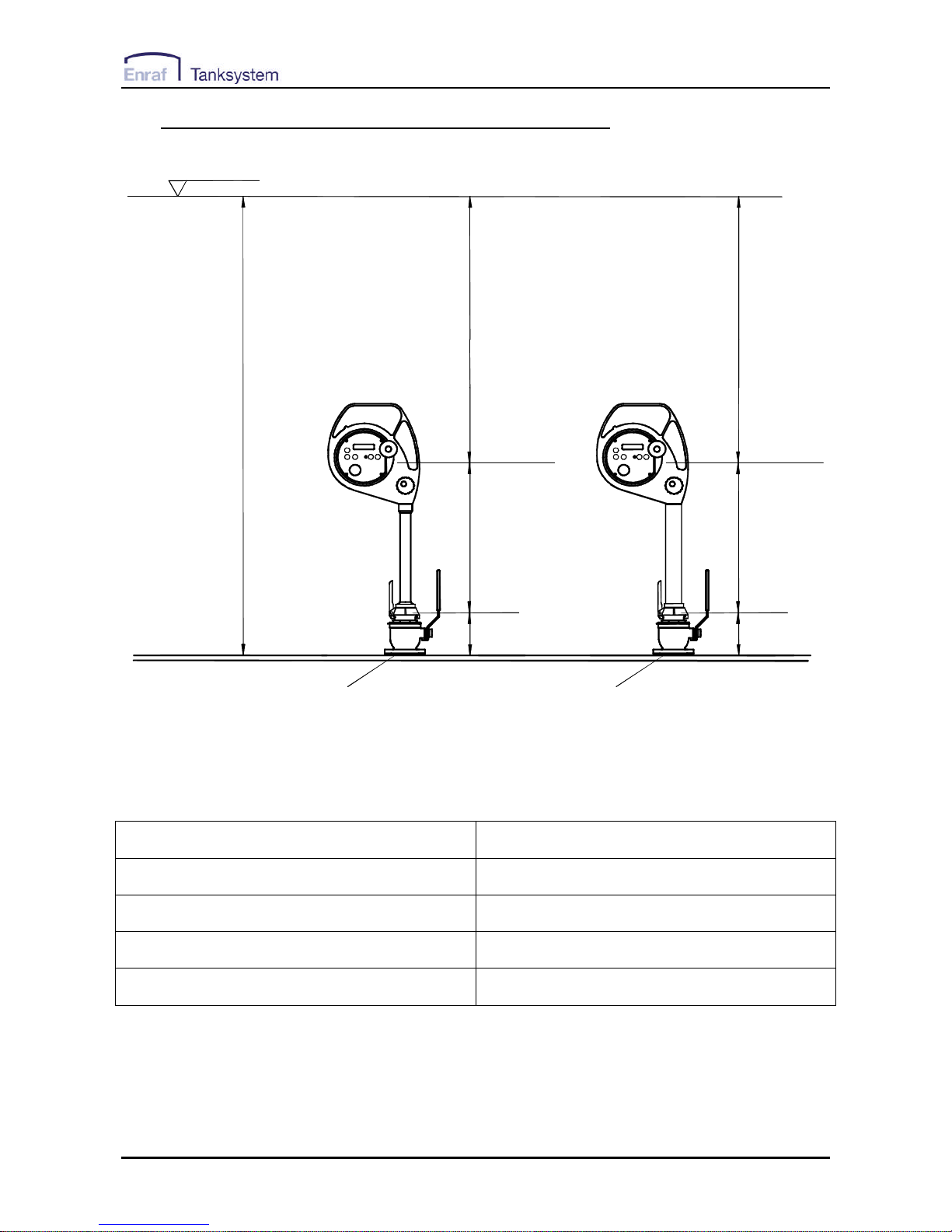

7.3 Example of installation on the deck, connector Q2

Tank Zero Ullage level

Flange

H

Reading

index

474mm

HV

HX

Tank Deck

SS1 Q2

Flange

Reading

index

474mm

HV

HX

SS2 Q2

Figure 7-3

Valve designation C.2-SS; C.2-SS-W; C.2-SS-BL; C.2-SS-SEC

Bottom connection thread or flange

Boring 2”

*) HV (mm) 141

*) HX (mm) H-615

*) Dimension HV is without gasket. If gaskets are used dimension HX is reduced by thickness of gasket.

50455/RTEX/0807 UTImeter Rtex

23

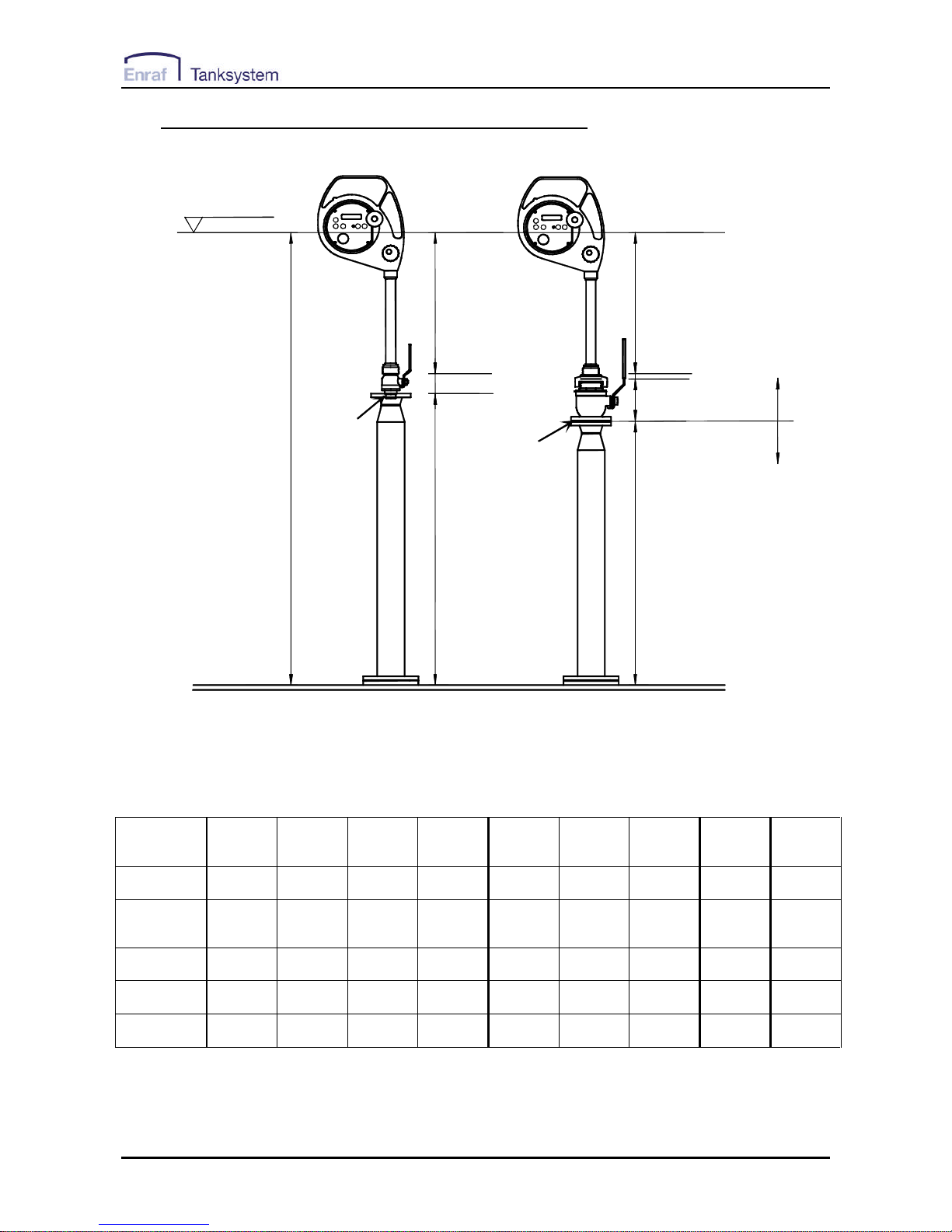

7.4 Example of installation on a pipe, connector Q1

Reading

index

Reading

index

H

460mm 460mm

HV

HV

HC

HT

HT

Tank Zero Ullage level

Thread

Flange

TS supply

Customer supply

SS1 Q1

SS1 Q1

Tank Deck

Figure 7-4

Valve

designation

A.1-SS C.1 -SS C.1-SS C.1-SS C.2-SS

C.2-SS-W

C.2-SS

C.2-SS-W

A.2-SS A.2,5-SS A.4-SS

Boring 1" 1" 1" 1" 2" 2" 2" 2,5” 4”

Bottom

connection

thread thread flange

JIS 5K25

flange

JIS 5K50

thread flange flange flange flange

*) HV (mm) 120 65 79 79 141 141 172 99 140

HC (mm) na na na na 14 14 41 53 58

*) HT (mm) H-580 H-525 H-539 H-539 H-615 H-615 H-673 H-612 H-658

*) Dimension HV is without gasket. If gaskets are used dimension HT is reduced by thickness of gasket.

50455/RTEX/0807 UTImeter Rtex

24

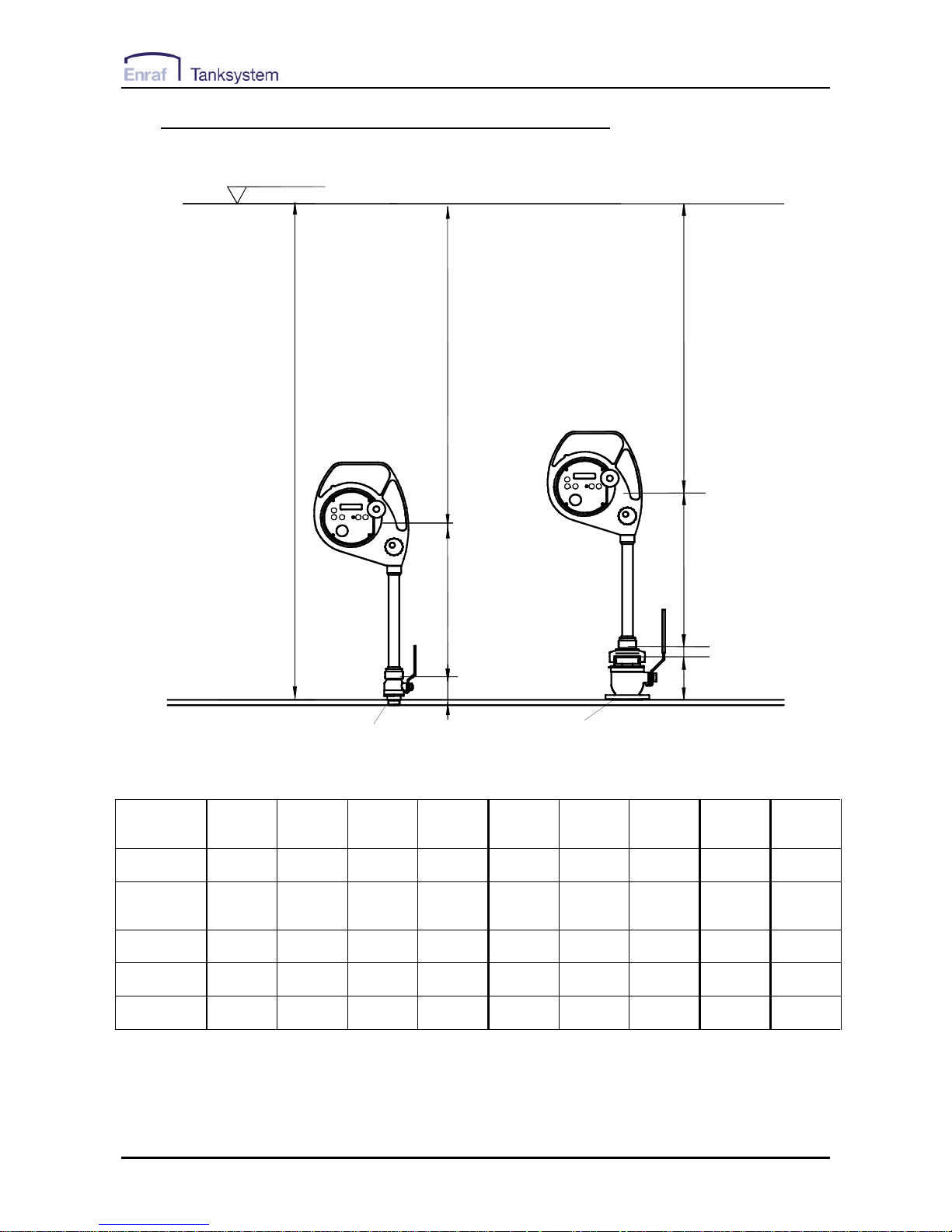

7.5 Example of installation on the deck, connector Q1

Tank Zero Ullage level

Thread Flange

Reading

index

Reading

index

H

HX

HV

HX

HV

460 mm

460 mm

HC

Tank Deck

SS1 Q1

SS1 Q1

Figure 7-5

Valve

designation

A.1-SS C.1 -SS C.1-SS C.1-SS C.2-SS

C.2-SS-W

C.2-SS

C.2-SS-W

A.2-SS A.2,5-SS A.4-SS

Boring 1" 1" 1" 1" 2" 2" 2" 2,5” 4”

Bottom

connection

thread thread flange

JIS 5K25

flange

JIS 5K50

thread flange flange flange flange

*) HV (mm) 120 65 79 79 141 141 172 99 140

HC (mm) na na na na 14 14 41 53 58

*) HX (mm) H-580 H-525 H-539 H-539 H-615 H-615 H-673 H-612 H-658

*) Dimension HV is without gasket. If gaskets are used dimension HX is reduced by thickness of gasket.

Loading...

Loading...