Enovation Controls Murphy DF Series, Murphy DF755, Murphy DF757 Installation And Operation Manual

Page 1

DF Series Hydrostatic Head Level

Switches

Installation and Operations Manual

00-02-0831

2013-03-21

Section 15

1-800-548-1191 - http://www.partdeal.com - info@partdeal.com

Page 2

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our

specifications and designs at any time. The latest version of this manual can be found at www.fwmurphy.com.

Please read the following information before installing.

BEFORE BEGINNING INSTALLATION OF THIS MURPHY

PRODUCT:

Read and follow all installation instructions.

Please contact Enovation Controls immediately if you have any

questions.

1-800-548-1191 - http://www.partdeal.com - info@partdeal.com

Page 3

Table of Contents

Table of Contents ...................................................................................................................... iii

Introduction ................................................................................................................................. 1

Basic Operation ............................................................................................................1

Typical Applications .................................................................................................................. 3

Water Flood Control Systems ......................................................................................3

Low Pressure Gas Blanket on Tank .............................................................................3

Typical Wiring Diagrams ..............................................................................................4

Installation of a Volume Air Cell ............................................................................................... 6

Overview ......................................................................................................................6

Specifications ............................................................................................................................. 8

Service Parts ................................................................................................................9

1-800-548-1191 - http://www.partdeal.com - info@partdeal.com

Page 4

(THIS PAGE INTENTIONALLY LEFT BLANK)

1-800-548-1191 - http://www.partdeal.com - info@partdeal.com

Page 5

Introduction

The DF series are diaphragm-operated ‘hydrostatic head pressure’ level switches. A pressure

sensitive diaphragm operates a snap-switch that can be wired directly to electric pilot circuits to

control pumps at pre-determined levels. A typical application is starting and stopping electric

driven pump(s) to maintain tank levels. This series of level switches can also be used with

engine driven pumps.

The nitrile sensing-diaphragm is impervious to most liquids and is sensitive enough to control

levels with ¼ in. (6 mm) repeatability. See the next section, Basic Operation, for limits of

switch trip-point adjustability. The case is aluminum with a glass-filled nylon bottom plate.

This is a highly reliable level switch and can be worked into almost any new or existing system

without major modification or special tools.

The DF755 and DF757 are suitable for atmospheric tanks in non-hazardous areas. The SPDT

snap-switch for the DF755 is preset for a 4 in. (102 mm) differential in liquid level. The DF757

trip point is adjustable over a 108 in. (2743 mm) range.

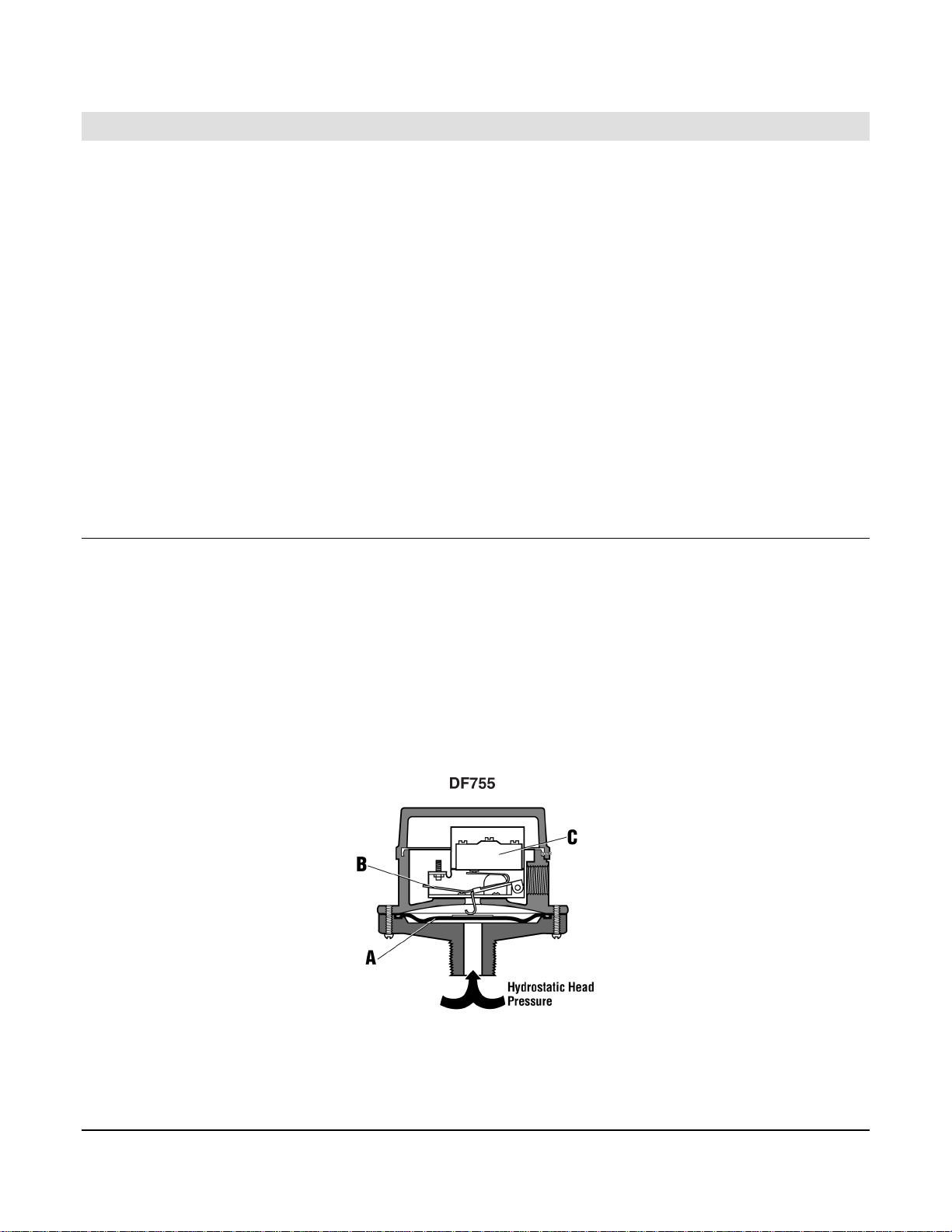

Basic Operation

As the liquid level rises, hydrostatic head pressure is applied to the diaphragm (A) as shown

below. The diaphragm moves upward pressing the actuator arm (B) to activate the snapswitch (C).

Model DF755 is factory set and operates at approximately 2 in. (51 mm) and 6 in. (152 mm)

above the level at which the diaphragm is mounted. The trip point(s) for Model DF757 are

adjustable between 2 in. (51 mm) and 110 in. (2794 mm) for high and low (make/break)

operation by knobs (D).

Section 15 00-02-0831

2013-03-21 - 1 -

1-800-548-1191 - http://www.partdeal.com - info@partdeal.com

Page 6

Set Point Adjustment for the DF757

Locate the threaded adjustment shaft and adjustment knobs (see the

1.

following drawings).

To increase the low-level set point, rotate the lower knob

2.

counterclockwise.

NOTE: If the adjustment shaft turns when rotating the adjustment knobs,

firmly grasp the adjustment shaft with a pair of needle nose pliers, and

then rotate the knob.

Section 15 00-02-0831

2013-03-21 - 2 -

1-800-548-1191 - http://www.partdeal.com - info@partdeal.com

Page 7

Typical Applications

This section covers some general situations where the rugged DF Series switches provide a

simple-to-install solution. Applications include:

Water Flood Systems Diesel Day Tanks

Crude Oil Tanks Sumps

Salt Water Disposal Systems Cooling Towers

Water Flood Control Systems

The diagram below displays eight DF Series switches installed on Raw Water and Clear Water

tanks. When raw water rises to a predetermined level, DF#1 stops the supply pump. As tank

level falls below the set level, DF#2 starts the supply pump. If the tank level continues to fall,

DF#3 initiates a shutdown of the supply pump. DF#4 stops the transfer pump before the raw

water tank is completely pumped out.

When clear water reaches the predetermined level, DF#5 stops the transfer pump. As tank

level falls to the set low level, DF#6 starts the transfer pump. If the tank level continues to fall

due to the failure of the filters section, DF#7 initiates shutdown of the transfer pump. (A DF755

located at this level will also operate backwash equipment). DF#8 stops the injection pump

before tank pumps completely out. An OPL Series Pressure SWICHGAGE® stops the injection

pump when pressure reaches an established high or low pressure.

Low Pressure Gas Blanket on Tank

The level switches shown at right are installed

on a crude oil tank where a low-pressure gas

blanket is used to prevent evaporation loss.

The switches are mounted directly to the side

of the tank (or can be mounted on a riser pipe

4 to 7” [102 to 178 mm] below the level to be

controlled). The pump automatically stops or

starts when the gas liquid reaches

predetermined high or low level.

Section 15 00-02-0831

2013-03-21 - 3 -

1-800-548-1191 - http://www.partdeal.com - info@partdeal.com

Page 8

Typical Tank Mounting

The following graphics show different methods of mounting DF755 switches in tank

applications.

Typical Wiring Diagrams

Presented as an assist to wiring typical DF Series level switches.

Starts at Low Level, Stops at

High – Start motor when pre-

determined low level is reached

and stop when high level is

reached. Keeps tank level within

selected limits. Motor starter is

equipped with Hands Off Auto

(HOA).

Starts at High Level, Stops at

Low – Start motor when pre-

determined high level is

reached, and stop when low

level is reached. Motor starter

equipped with HOA.

Section 15 00-02-0831

2013-03-21 - 4 -

1-800-548-1191 - http://www.partdeal.com - info@partdeal.com

Page 9

Single Magneto Shutdown –

Wiring of magneto to Normally

Open (NO) switch terminal shuts

engine down at a pre-determined

high level (Shown at right). Wire

to Normally Closed (NC) terminal

to shutdown on low level.

Dual Magneto Shutdown –

Shutdown dual magneto engines

using a Murphy MS2120

Magnetic Switch. Diagram at

right shows hookup for low-level

shutdown. Wiring changes and

mounting locations are

necessary for high-level

shutdowns.

Section 15 00-02-0831

2013-03-21 - 5 -

1-800-548-1191 - http://www.partdeal.com - info@partdeal.com

Page 10

Installation of a Volume Air Cell

This section provides installation and

operation information for using a DF755 level

switch with a Murphy MAC1 Volume Air

Cell.

Overview

When attached to the DF755 level switch, the MAC1 Volume Air Cell can monitor water levels

on a sump, activate alarms, or start a pump directly. The MAC1 Volume Air Cell is noncorrosive. Stainless steel ¼-20 mounting studs are provided with the unit.

The MACT1 Tubing Kit provides 4 ft (1.2 m) of flexible, non-corrosive ¼ in (6 mm) tubing (cut

to fit). The kit also includes fittings necessary to attach tubing

Volume Cell Operation

As liquid rises around the volume cell, it compresses the air inside the cell and forces it up in

the sensor line. As the water level continues to rise, the air pressure increases. In time

sufficient pressure is applied to activate the internal snap-switch, this starts the pump. As the

liquid level is pumped down, pressure decreases, the snap-switch reverses and the pump

stops. The pump is held in a standby condition. An air purge may be required in the sensor

line. For additional information, consult Enovation Controls.

Choosing a Volume Cell

The volume cell should be constructed of material which will be unaffected by the liquid being

measured. For proper pressure to level ratio, the minimum dimensions of the volume cell

should be 6 inches (152 mm) inside diameter and 3 inches (76 mm) inside depth. The sensor

line can be of any diameter or material either flexible or solid, as long as it is of sufficient length

to reach from the volume cell to the desired location for the DF755. All fittings and connections

should be airtight to avoid loss of charge. Tube lengths longer than 4 ft (1.2m) should have a

provision for intermittent air purging.

Section 15 00-02-0831

2013-03-21 - 6 -

1-800-548-1191 - http://www.partdeal.com - info@partdeal.com

Page 11

Installation of the Volume Cell

Install the volume cell with reference to the level at which you wish the pump to start and stop.

Secure the volume cell with a substantial bracket that will not allow the cell to float or tilt when

the water level rises. Install the DF755 well above the highest water level and in a position that

allows access for adjustment or repairs.

NOTE: Periodically operate the pump manually until the water level

reaches a point approximately ½ in (13mm) below the bottom of the

Volume Cell. This automatically recharges the unit, and compensates for

normal absorption of air into water. Small electric air pumps are available

to automatically charge the system continuously.

Section 15 00-02-0831

2013-03-21 - 7 -

1-800-548-1191 - http://www.partdeal.com - info@partdeal.com

Page 12

Specifications

Snap-switch Ratings

SPDT (standard–all models)

5 A @ 125, 250, or 480 VAC

•

•

1/2 A @ 125 VDC, 1/4 A @ 250 VDC

DPDT (optional)

10 A @ 28 VDC

•

•

10 A @ 120, 230 VAC

•

Case/Lid: Aluminum (standard).

Bottom Plate: Glass-filled Nylon.

Process Connection: 1 NPT (standard).

Maximum Pressure Rating: 25 psi (172 kPa [1.72 Bar]).

Conduit Connection (electrical): 1/2 NPT.

Section 15 00-02-0831

2013-03-21 - 8 -

1-800-548-1191 - http://www.partdeal.com - info@partdeal.com

Page 13

Service Parts

DF755

Description Part Number

Cover (aluminum) 15050081

Case (aluminum) 15050082

Cover Screws (3), #6–32 x 5/16 round head 80040607

SPDT snap-switch and movement assembly/repair kit (5 amp) 15000122

Screws (3) for switch assembly to case, #6–32 x 1/4 round head 80040605

Diaphragm repair kit 15000123

Bottom Plate (1 NPT connection) 15050083

Bracket and movement repair kit 15000313

SPDT snap-switch and insulator repair kit (5 amp) 15000121

DF757

Description Part Number

Cover (aluminum) 15050081

Case (aluminum) 15050594

Cover Screw (3), #6–32 x 5/16 round head 80040607

SPDT snap-switch and bracket assembly/repair kit (5 amp) 15000174

Screws (2) for switch bracket and assembly to case (#6–32 x 1/4 round head) 80040605

Spring and piston assembly/repair kit 15000190

Diaphragm repair kit 15000123

Bottom Plate (1 NPT connection) 15050083

Section 15 00-02-0831

2013-03-21 - 9 -

1-800-548-1191 - http://www.partdeal.com - info@partdeal.com

Page 14

(THIS PAGE INTENTIONALLY LEFT BLANK)

1-800-548-1191 - http://www.partdeal.com - info@partdeal.com

Page 15

(THIS PAGE INTENTIONALLY LEFT BLANK)

1-800-548-1191 - http://www.partdeal.com - info@partdeal.com

Page 16

1-800-548-1191 - http://www.partdeal.com - info@partdeal.com

Loading...

Loading...