Enomatic enoline 4, enoline 8 User Manual

UM.02

ENOLINE

WINE CARD

Page 1 of 46

Rev 09, May

2010

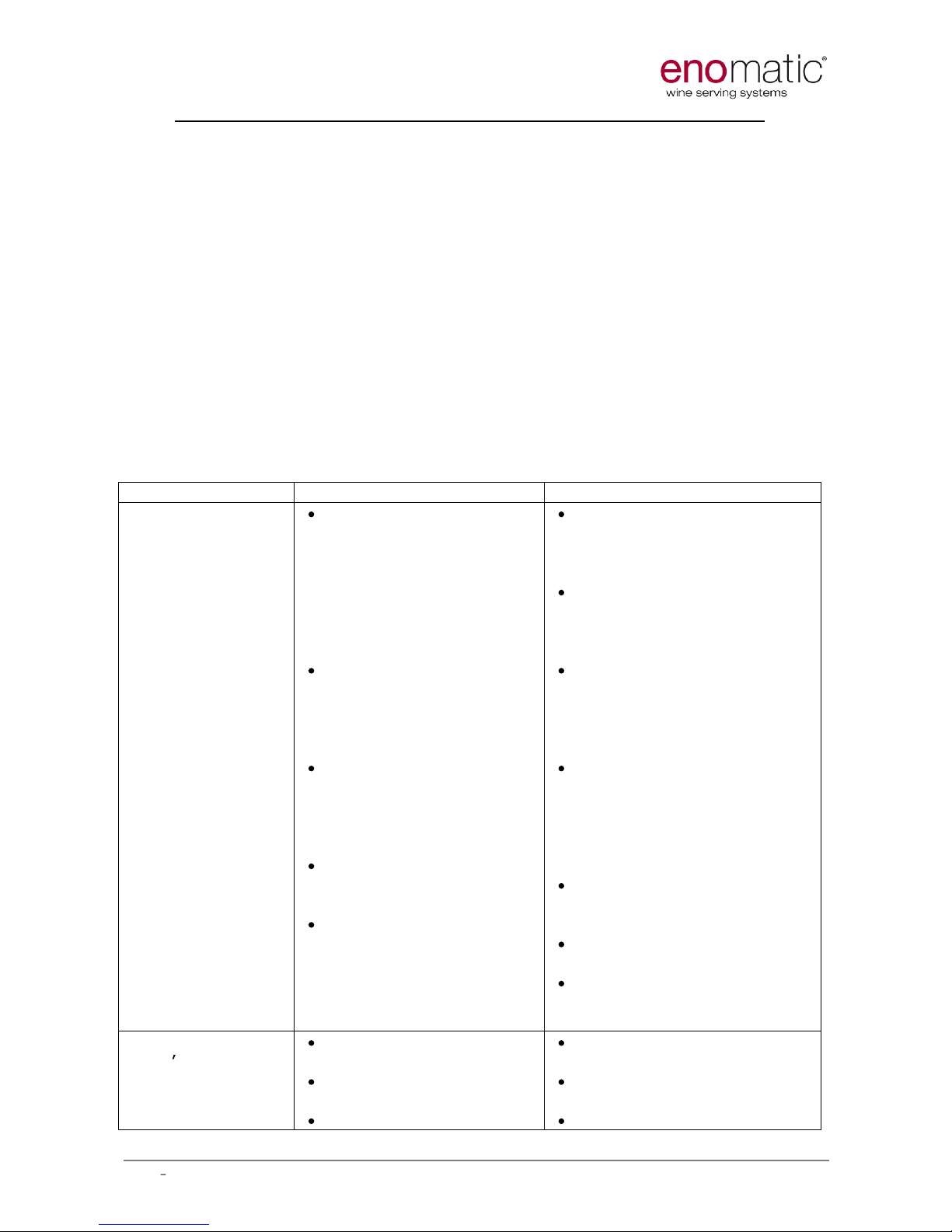

Enoline 8 Wine Card

Enoline 8 Wine Card (temperature control model)

eno

line 4 wine card

eno

line 4 wine card temperature control

eno

line

8 wine card

enoline

8 wine card temperature control

User s Manual

UM.02

Rev. 0

8

May 20

10

Enomatic srl

Via di Meleto,1/19

I-

50027 Greve in Chianti

Firenze - Italy

Tel. +39 055 8547272

Fax. +39 055 8547807

www.enomatic.it

UM.02

ENOLINE WINE CARD

Page 2 of 46

Rev 0

8, May 2010

WARNING

Should warranty terms be a

pplied, please return the

product, included original

packing, all

accessories and

docum entation ( i.e. user s manual and power supply cable).

ATTENZIONE

Nei casi in cui l'applicazione della garanzia pr

eveda la

restituzione del prodotto, il bene dovrà essere restituito dal

cliente nella confezione originale, completa di tutte le sue

parti (compresi imballo, eventuale documentazione ed

accessori: manuale di istruzioni e cavo alimentazione)

.

UM.02

ENOLINE WINE CARD

Page 3 of 46

Rev 0

8, May 2010

INDEX

1. Intro

duction

4

2.

Model identification

...

4

3.

Warning

..

.5

4.

Transportation and storage

...

...6

5.

Unpack ..6

6. In

stallation .6

7.

Operating I nstructions 11

8.

Troubleshooting .18

9. Mainte

na

nce and cleaning

20

10. Techni

cal characteristics .. 22

Decla

ration of Compliance

23

Important notice f

or the user .25

Statement of W arranty ..26

UM.02

ENOLINE WINE CARD

Page 4 of 46

Rev 0

8, May 2010

1.

Introduction

This

Operating Manual is an integral part of the

Enomatic Wine Serving System, therefore w e

recommend

you

to keep it available for future

reference

s.

Before proceeding to i

nstall

and operate your Enomatic Wine Serving System

,

please

read carefully the instructions contained in this Operating Manual. They

provide important information

on

safety during installation,

duty

and

maintenance.

The manufacturer will not be liable in any way for any damage that may be

caused by unsuitable or unreasonable use and incorrect interpretation of the

safety rules and installation

instructions.

2.

Model

Identification

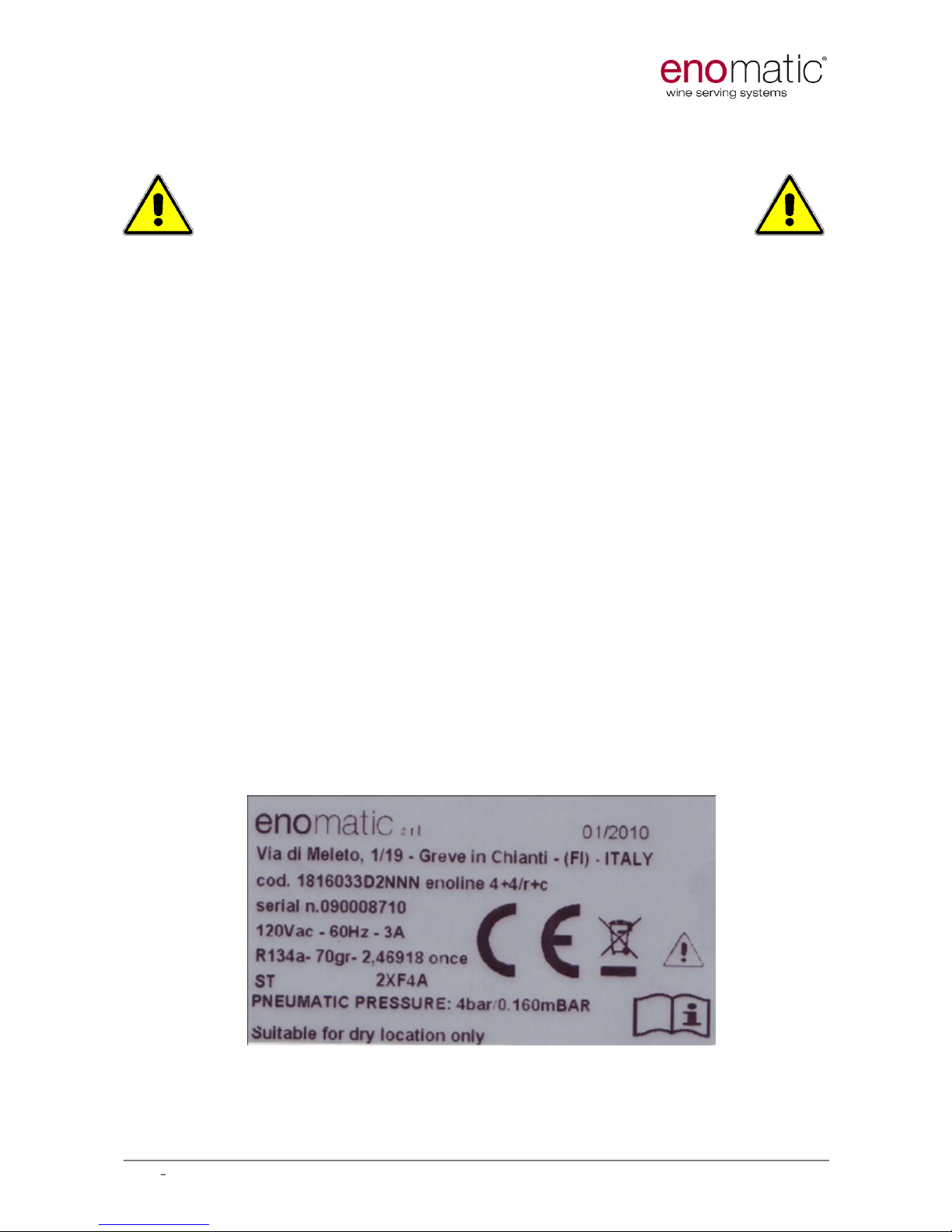

Every Enomatic

model

is identified with a unique serial number printed on a

D

ata Label

.

There are two Data Labels on the machine: one is on the rear panel, close to

electric socket, the other one is on the fro

ntal side and lays beneath the drop

tray.

The D

ata Label

is the only means of identification authorised by the

manufacturer and it contains all the data needed by the manufacturer to

provide prompt and clear information concerning any technical aspects and to

facilitate the replacement of parts.

AVOID DAMAGE OR REMOVAL OF THE DATA

LABEL

.

Example:

UM.02

ENOLINE WINE CARD

Page 5 of 46

Rev 0

8, May 2010

3.

Warnings

During operation it is essential to pay attention to these safety requirements to avoid

the risk of fire, electric shocks or other

incidents.

1. Before operating the Enomatic Wine Serving System, carefully read the

instructions contained in this Operating Manual and all other documentation you

received.

2. Do not immerse the electrical cord, plugs or the Enomatic model in water or any

ot

her liquid.

3. Be extra careful when operating the Enomatic Wine Serving System in the

presence of children.

4. Always unplug the Enomatic model from the electrical socket and let it cool down

before carrying out extraordinary maintenance operations.

5. Do not operate the Enomatic model if the electrical cord, plug or any other parts

are damaged or broken, but rather remove it immediately pulling it out of plug

and contact your local distributor.

6. Do not use electrical appliances inside the food storage compartments of the

appliance, unless they are of the type recommended by the manufacturer.

7. For any repairs contact only Service Centres authorised by the manufacturer or

supplier and insist to get only original spare parts. Failure to comply with the

above may harm

persons, damage property and will invalidate the Warranty.

8. This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction concerning use of the

appliance by a person responsible for their safety. Children should be supervised

to ensure that they do not play with the appliance

.

9.

Do not operate the Enomatic Wine Serving System outdoors.

10.

Avoid the electrical cord hanging down the supporting surface (table, counter,

etc.) and from coming into contact with hot surfaces. Do not place the Enomatic

model on top of its electrical cord. Never connect a damaged cord, but ask your

local distributor for a spare part. Us

e original spare parts only.

11.

Keep the Enomatic Wine Serving System far away from heat sources.

Keep

ventilation openings, in the appliance enclosure or in the built-in structure, clear of

obstruction

.

12. Before plugging the Enomatic model into the electrical

socket, check that the main

switch General is set to 0 (off) mode.

13.

Before supplying the Enomatic model, check the voltage indicated on the Data

Label, it has to correspond to your country s standard voltage supply value. You

may require an adapter to

plug the cable into your electrical socket.

14.

Do not clean with corrosive detergents or scraping tools. Use only a soft damp

cloth.

4.

Transportation and Storage

Because of the weight and size of the

Enomatic

models

, two people are needed for transportation

.

To avoid damages, it is necessary to take big care during loading and unloading

operations. It is necessary to lift according to the symbol found on the

cardboard package. It is important that

the

Enomatic

models are not placed on

top of each other and

that the right vertical position (indicated by arrows on the

package) is maintained at all times. Avoid shaking or turning the

Enomatic

models

upside down.

UM.02

ENOLINE WINE CARD

Page 6 of 46

Rev 0

8, May 2010

5. Unpack

When you

removed the packaging, check that the Enomatic model has not been

damaged during transport. If you have any doubts, do not operate the

Enomatic model

and quickly contact your Enomatic distributor in order to define

a supervising visit. Please make sure that following items are included in the

delivery:

- 1x -

Enoline, 4 bottles capaci

ty or 1x

Enoline, 8 bottles capacity;

-

1x - Enoline Wine Card

Series

1 - User and Maintenance Manual;

-

5x - plastic straws

or 10x

plastic straws

;

-

2x - steel holders to secure Enoline to the wall;

-

1x - Ø 10mm pipe for water drainage;

-

1x

electrical cord;

-

1x

spirit level;

-

1x - tap seals kit;

-

2x - fuses;

Never leave the packaging contents (plastic

bags, foamed polystyrene, nails, etc.) within

the reach of children, since they are a source

of potential danger. Please be eco

-

friendly and

recycle

the packaging components.

Above-mentioned operations

must be run by skilled personnel only and authorized by the

Manufacturer.

6.

Installation

For an optimum installation, a technical inspection is needed where the

installation will be performed, in order to establish the correct positioning,

ensure

there is a suitable space for the location of the inert gas cylinder

(

nitrogen

or argon) and air compressor (if required)

and

an earthed

electrical

socket which complies with the regulations.

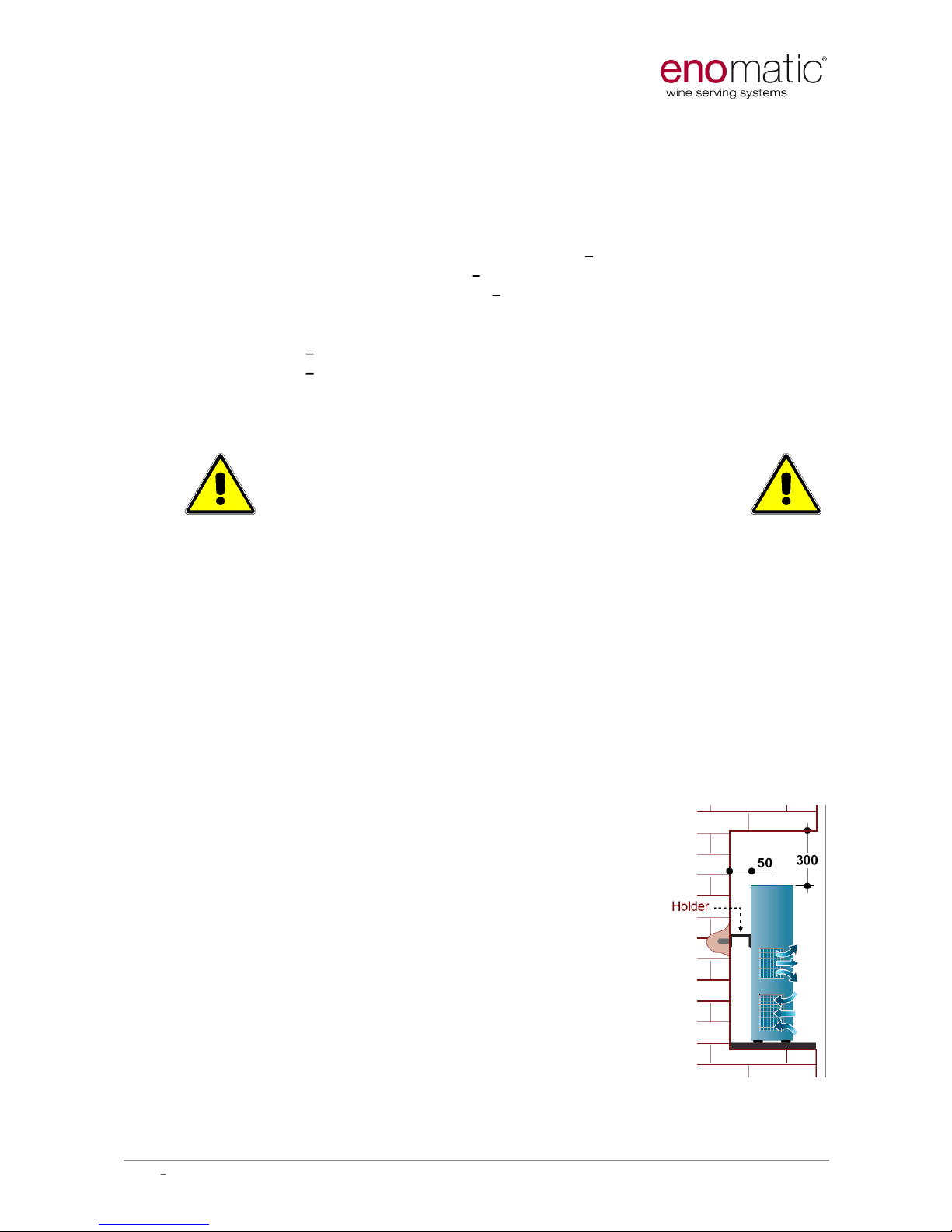

1.

After unpacking

your Enomatic Wine Serving System, place it on a solid

desk

or holder, between 800 and 1300mm from floor. The surface where the

dispenser will be placed must be made by fire-extinguisher materials.

2. Please consider a 300mm clereance on fridge

compressor

side and 50mm aback in order to ensure

proper exhaust

air

exchange.

3. Check the stance and correct it if necessary actin

g

on proper adjusting foot/feet. Refer to delivered

spirit level for accurate placement.

4. Secure the machine through supplied holders to th

e

wall if needed.

5. Tight pressure regulator (6434) to nitrogen or argon

tank, using supplied seal (if previewed).

6. Connect FOODGRADE LLDPE 4mm pipes in order to

bond machine and nitrogen source.

7.

Connect the electrical cord

and turn the machine on.

8. Open the nitrogen or argon tank and turn the outlets

levers on vertical position; the gas will then reach

the machine.

9. From now on Your Enomatic wine Serving System is ready for bottles

engagements. Enjoy your wines!!!!

UM.02

ENOLINE WINE CARD

Page 7 of 46

Rev 0

8, May 2010

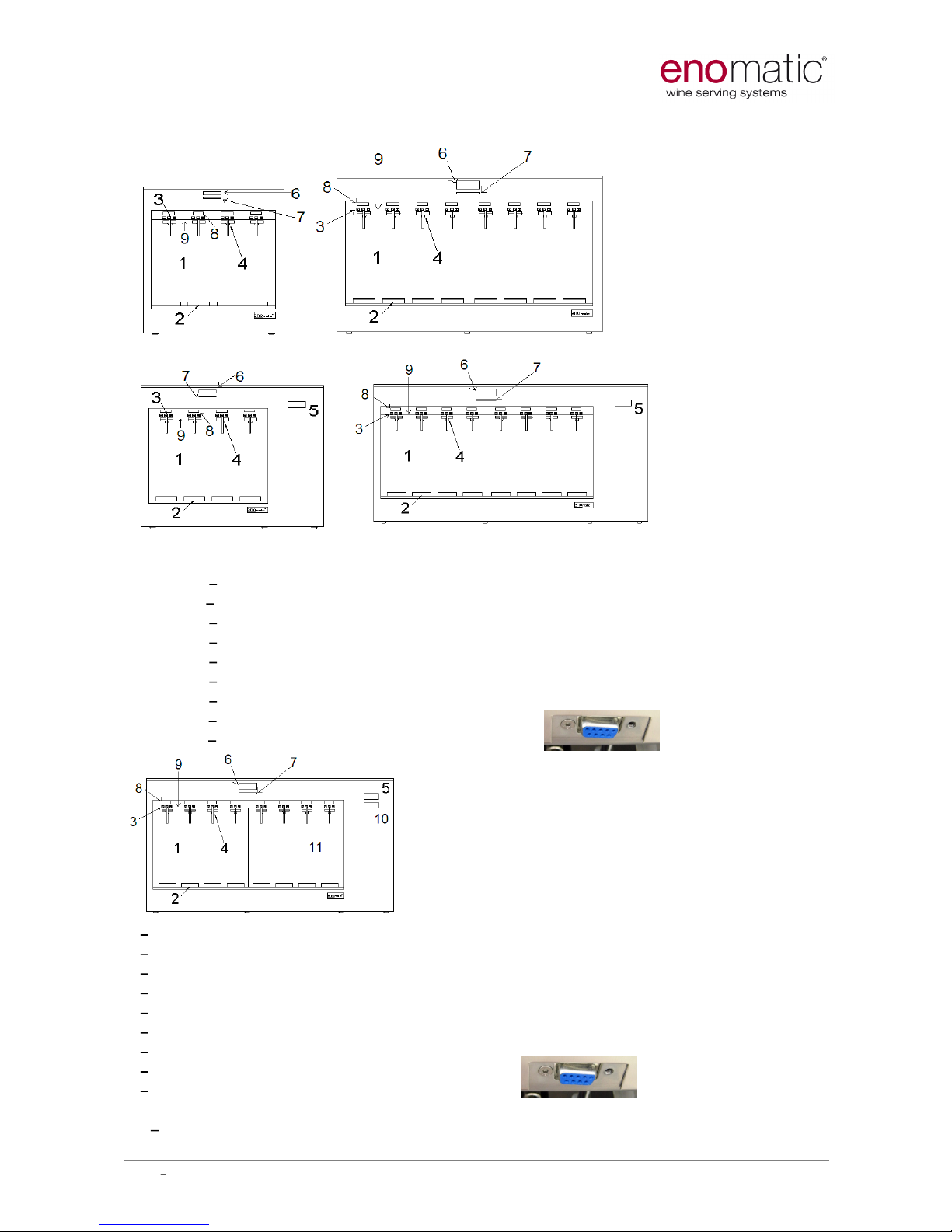

6.1

Parts of the Enomatic Wine Serving Syste

m

1

Bottle space

2

Bottle Piston with cover

3

Serving Buttons

4

Serving Spouts

5

Thermostat (available on temperature models only)

6

Wine card Display

7

Wine Card Reader slot

8 Price displays

9 Enoprog socket (see picture aside

)

Enoline 4+4 Wine Card

1

Red Wines b

ottle space

2

Bottle Piston with cover

3

Serving Buttons

4

Serving Spouts

5

Thermostat for red wines bottle space

6

W

ine card Display

7

Wine Card Reader slot

8

Price displays

9

Enoprog socket (see picture aside

)

10 - Thermostat for white wines bottle space

11

White wines bottle space

UM.02

ENOLINE WINE CARD

Page 8 of 46

Rev 0

8, May 2010

6.2 Electrical supply

The

eno

line models operate at either 110 or 220V

de

pending upon the country. Before connecting

these models to the electrical sockets, check the

voltage detailed on the Data Label on the back

panel. The room temperature

eno

line models have

one main switch on the power panel (photo on

right) which also cont

ains the fuses

(left side)

.

Ensure enough access to switch

es, fuses

and cable plug.

The temperature controlled

eno

line models have three (3) switches located on

the back

refer to the photo below. The enoline models feature also external

RJ45 connecti

ons to enable them to be connected to a data network.

For all switches O is OFF and

or | is ON.

The Enomatic models must be connected to a supply system equipped with an

effective earth connection in accordance with the rules and provisions

prescribed by law.

Switch all switches to O mode. Connect the electrical supply cord. With a

ll

models black main switch turns power onto the model.

For temperature controlled enoline (right

side reference)

models secondary switches are:

Right side - turns on and off the compressor for

the temperature control.

Left side - turns on and off the electronics inside

the enoline model.

6.3 Gas Line Connections

Two different pressure lines are typically required to operate your Enomati

c

Wine Serving System

, and those are:

Bottle Piston Supply - 4.0 Bar pressure

Nitrogen or air compressor

Nitroge

n (or Argon) Gas Supply - 0.16 Bar pressure

4mm pipe connection outlets are located at the back of enoline models, on the

bottom (photo below); 4 bar line (bottle pistons movements) can be supplied

by compressed air coming from an external source (not p

rovided), as well as by

nitrogen.

Use certified FOODGRADE materials and

LLDPE pipes for nitrogen (argon)

connections

UM.02

ENOLINE WINE CARD

Page 9 of 46

Rev 0

8, May 2010

6.3.1

Bottle Piston Supply

The 4 bar line supplies the Bottle Pistons to raise and hold the bottles upwards,

in order to ensure an air tight seal on the Tap. It is recommended to use a

compressed air supply in case of more than 12 bottles installations

.

4.0 Bar pressure must be provided from either:

an air compressor

the Nitrogen (or Argon) Gas supply cylinder

a Nitrogen Generator (recom

mended for very large installations)

If an air compressor is used, the air source must be equipped with a sluice

gate, a pressure regulator

(4

Bar

outlet required

) and a filter to avoid impurities

blocking the pneumatic circuits. A moisture trap is also required in humid

environments.

Connect the Bottle Piston Supply to the Enomatic model by firmly pushing the

4mm FOODGRADE LLDPE pipe

into the friction fitting.

6.3.2

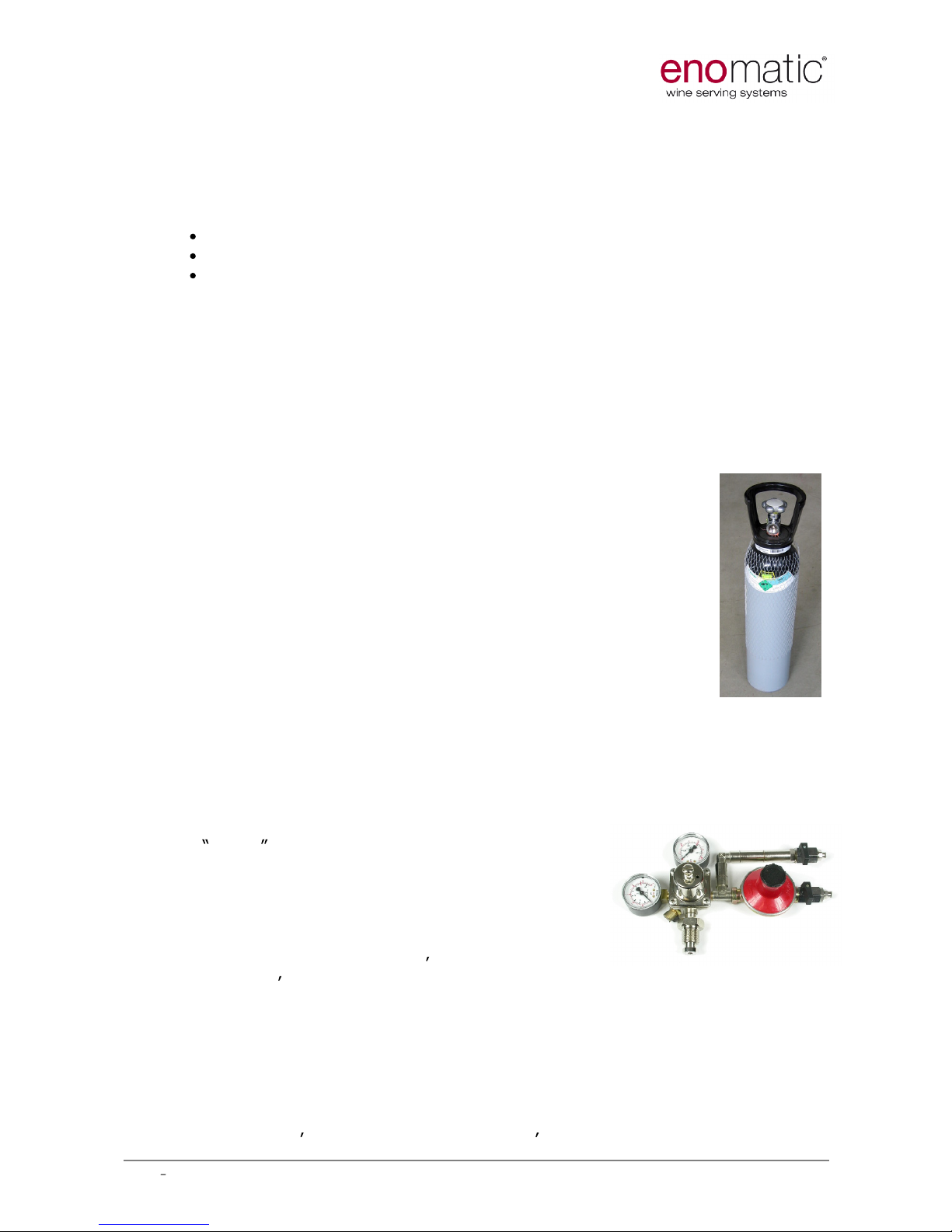

Nitrogen (Argon) Gas Supply

Main purpose for the use of Nitrogen or Argon is to preser

ve

wines from oxidation processes. As soon as a bottle is engaged

into the machine, Nitrogen is inflated into it and the preservation

starts. Second main purpose for Nitrogen is to dispense wines

from the bottle to the Serving Spout. It is also used to clean the

Serving Spout after each serve.

Foodgrade Nitrogen (or Argon) Gas of greater than 99.5% purity

must be used. This is typically supplied as a compressed gas

stored in cylinders, at high pressure. The pressure varies

between countries but it is typically between 150 or 200 Bar.

Alternatively a

certified n

itrogen generator can be used.

The Nitrogen (or Argon) Gas cylinder must be secured in a

vertical position and stored in a ventilated space. It must be connected to a

regulator to reduce the pressure to 0.16 Bar (that value may vary depending

installation features)

.

The following procedure must be carried out when connecting the Nitrogen (or

Argon) Gas cylinder:

1. Ensure the regulator outlet valves are in the

closed position (as shown in the p

hoto).

2. Insert the seal (if previewed) and tight

the

regulator system to the cylinder and ensure an

air-tight connection.

3. Open the cylinder valve, note down the

indicated max pressure value, and close the

cylinder; the value doesn t have to decrease

withi

n 15 in order to avoid risk of leak.

4. Connect the Nitrogen (or Argon) Gas Supply

from the regulator to the outlets on the Enomatic model by firmly pushing

the 4mm FOODGRADE LLDPE pipe into the friction fitting, on the Enomatic

model and

on

the regulator

as

well

.

5.

Completely open the valve of the cylinder.

6.

Open the regulator levers

.

7. Note down the indicated max pressure value, and close the cylinder; the

value doesn t have to decrease within 15 in order to avoid risk of leak.

UM.02

ENOLINE WINE CARD

Page 10 of 46

Rev 0

8, May 2010

8. Check that the pressure on the low pressure gauge is correct= 4 bar.

Also

check every 6-7 days the pressure of the cylinder.

9. When the tank is almost empty and change is required, close all inlets and

outlets and pull the safety valve ring to discharge residual pressure; loose

mano

meter bolt and replace the tank.

6.4

Water

Drain

age

E

noline Temperature Controlled

models only

A condensate drain tube (10mm O/D) must be

connected into the back of the temperature

controlled enoline models and discharged to a

permanent drain or into a bottle that is emptied

regularly.

7

Operating Instructions

Turn on the power.

Switch on main black switch and two secondary switches (for temperature

controlled enoline only).

7.1 Inserting the Bottle Tube

Insert the Bottle Tube into the centre of each Tap by pushing it firmly to create

a secure fit (pic A).

PIC A

PIC B

The Bottle Tube has a filter (pic B) to prevent sediment from red wines entering

the Tap valve. The Bottle Tube should extend to the bottom of the bottle.

However, for heavy

sediment red wines, it is recommended to cut

the

tube shorter, in order not to reach the bottom of the bottle; this is to

avoid the

sediment entering the tap.

7.2 Loading the Bottle

Open the bottle, remove any eventual foreign object from bottle neck u

pper

part and slide the Bottle Tube inside the bottle while lifting the bottle towards

the tap. Place the bottle on the piston (pic C). Insert a Technical Card (*) into

the slot and firmly press the central button above the bottle you desire to

engage. Th

e maximum bottle size is 360mm high. The Enomatic model is

supplied with plastic packers below the bottle piston covers. These packers can

be removed to fit the tallest bottles

, or added to fit shortest ones.

PIC C

UM.02

ENOLINE WINE CARD

Page 11 of 46

Rev 0

8, May 2010

Ensure that the neck of the bottle

lines u

p to

the conical neck of the Tap (

pic D

)

in order to enter it. Some

bottles

may feature

particular cork-necks

dimensions

;

should they be too large, please use the apposite large-

corks

-adapter (6510

item

code

).

PIC D

Once the bottle has been engaged, turn it lightly on its axis in order to increase

and improve air-tight on the neck seal. The lights above the bottle will flash.

Select a wine from Enosoft database to match to it

(*)

, and insert a User Card

with sufficient money on (*). Hold a glass be

neath

the Serving Spout, push the

Serving Button and verify the supply of the wine. Repeat the instructions above

for all bottles, the same actions to lift down engaged ones. To calibrate

the

serve, insert the Technical Card and keep buttons #1 and #3 pressed (about

4sec); the display will show

Cali

and then 100. Hit central button to pour and

measure the serve, adjusting 100ml value on display by tapping buttons #1 (to

decrease) and #3 (to increase); repeat till 100ml are poured, then remove the

Technical

Card to store the value; repeat same procedure for all taps.

Please remember to remove the frontal Plexiglas panel only when

loading/replacing the bottle, and in any case no longer than strictly required

time. Please remember also to load in your Enomatic Wine Serving System

already cold white wines.

(*

): to get information about Technical C

ard, User Card and Enosoft in general

,

pleas

e refer to

manual

UM.13

enosoft 2.0

.

7.3 Use of the Enomatic Wine Serving System

When no card is inside the card slot, the name of the

installation and insert card are shown; that is the re

st

condition.

In order to activate a dispensing, it s necessary

to insert a card with a sufficient amount of money and hit

the desired volume/price button. The name of the selected

wine will be shown on main display.

The

system will

decrease relative price from your card balance and will pour

the wine. Remaining credit on the card is shown on main

display.

7.4 Replacing Bottles

In order to lower the Bottle Piston, insert a T

echnical Card (*) and press firmly

central button related to the bottle you want to remove

.

Remove the empty bottle and the straw inside. Clean thoroughly the straw

under a flush of water.

Repeat procedure from 7.2 to engage another bottle. Press the central bu

tton

to confirm same wine indication when the display above the bottle will display

SAME , or remove the Technical Card to assign a new wine.

(*):

to get information about Technical Card and User Card, please refer to

manual

UM.13

enosoft 2.0

.

UM.02

ENOLINE WINE CARD

Page 12 of 46

Rev 0

8, May 2010

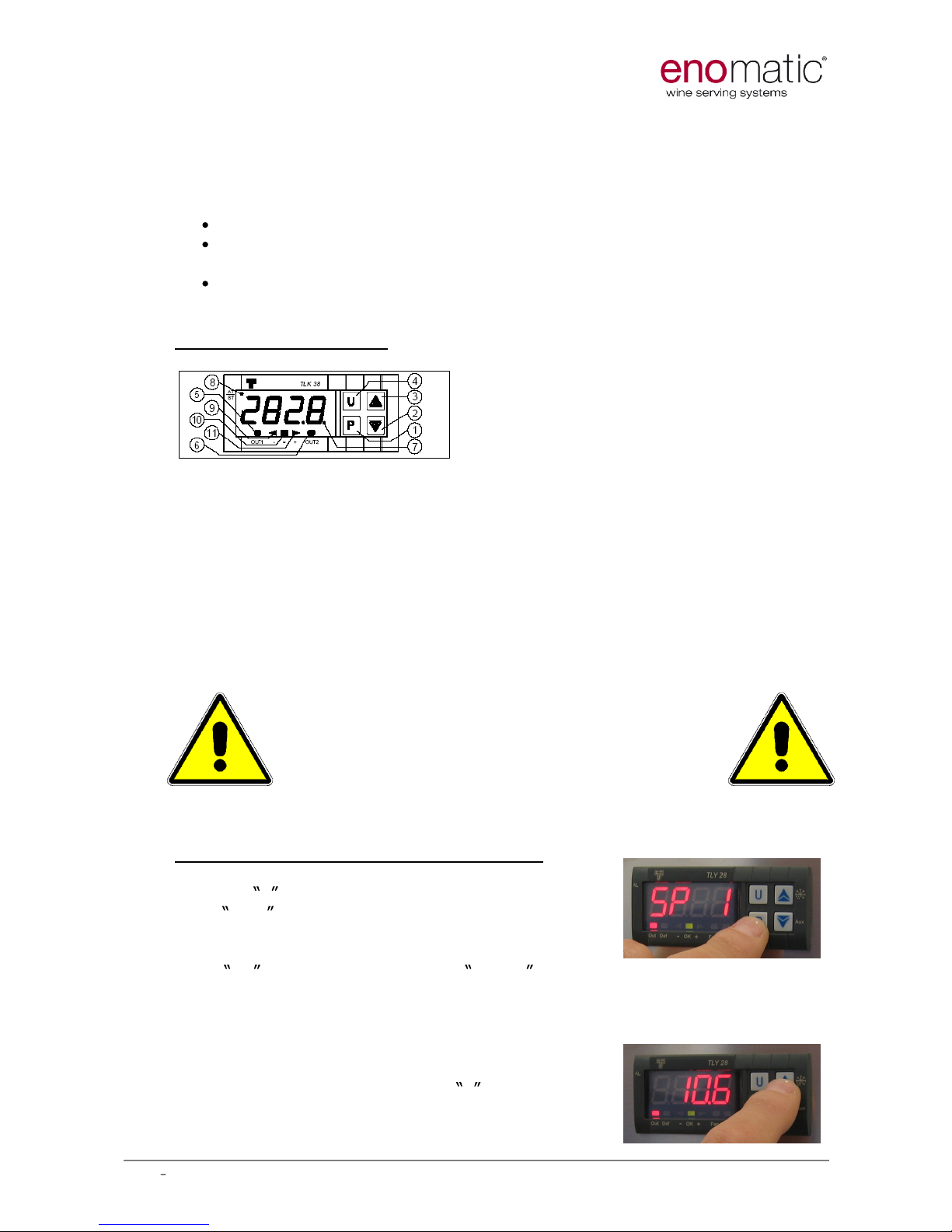

7.5 Change

the

Temperature

Set Point

(enoline temperature controlled models only)

If your enoline is a temperature controlled model it will typically be supplied

pre-programmed to:

8°C for refrigerated models (down to 7°C is possible), or

18°C for climate controlled models (between 7°C to 20°C range is

possible)

, or

8°C and 18°C for dual climate models.

If you wish to change these temperatures, please refer to the following

instructions.

Front Panel Description

1

- Key P : This is used to access the programming parameters and to confirm

selection.

2 - Key DOWN

: This is used to decrease the values to be set and to select the

parameters. If the key is held down, the controls return to the previous

programming level until it exits the programming mode.

3

- Key UP : This is used to increase the values to be set and to select the

parameters. If the key is held down, the controls return to the previous

programming level until it exits the programming mode.

The other buttons and functions are not required to change the

temperature set

point.

Please settle the Enomatic Wine

Serving System in environments

with temperature range between

10°C and 30°C, and relative humidity

lower than 60%.

Programming

the Temperature Set Point

Push key P , then release it and the disp

lay will

show SP 1 . (If you

press the button

too

long it will

enter another menu;

to return to the SP mode, wait

for

10 seconds).To modify t

he temperature value,

press

UP

key to increase it or the DOWN key to decrease it. These keys

change the valu

e one-by-one digit but if they are pressed longer than three

seconds, the value increases or decreases rapidly; after two seconds in the

same condition, the changing speed increases in order to allow the desired

value to be reached rapidly.

Adjust until the desired temperature value has been

reached.

Exit by pushing key P and after 15

seconds the set temperature will be displayed.

UM.02

ENOLINE WINE CARD

Page 13 of 46

Rev 0

8, May 2010

Programming the Temperature set points on dual climate models

Dual climate models involve two separated rooms where two diff

erent

temperatures can be set, in order to typically engage 4 red wine bottles and 4

white wine bottles. Red wine bottle space thermostat allows to modify the

temperature between 16°C and 20°C, whilst white wine bottle space thermostat

permits a settable range between 7°C and 20°C. Upper thermostat (TLK38)

refers to red zone bottle space, while lower one (TLY28) is about white wine

bottle space. White wine bottle space is the one closer to thermostat (right side

if your model is right hand compressor as in picture at page 7). White wines

must be already cold before being engaged into the dispenser, and the frontal

Plexiglas panel must be removed just for strictly necessary replacement bottle

time.

9

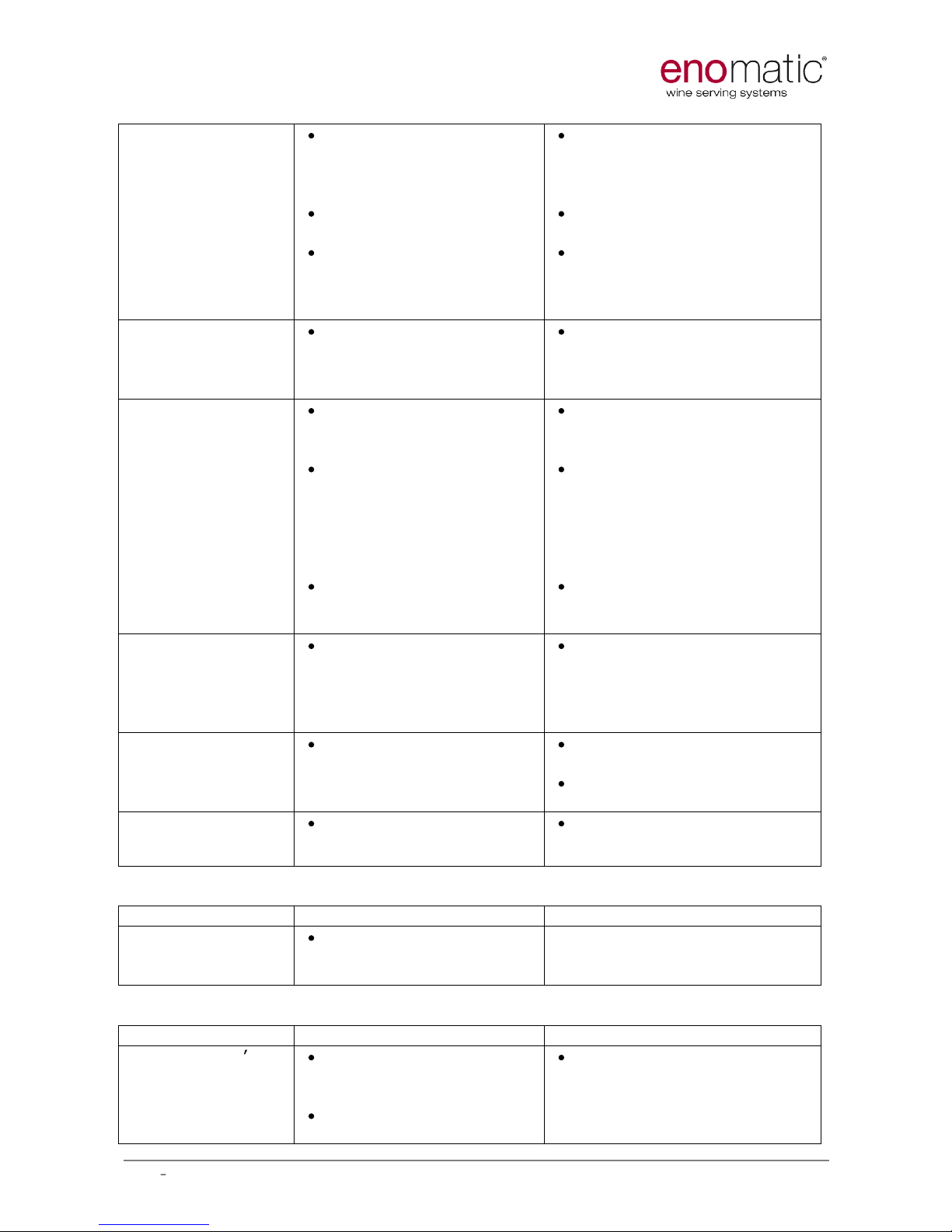

. Troubleshooting

This guide is to provide a quick support in case of faulty behaviours. I n case

the problems remain, please contact your local eno

matic

dealer.

Full list is available on www.enomatic.it

Trouble

Origin

Solution

There is a leak of

nitrogen

(or argon)

The bottle is not properly

engaged.

One

or more too short

bottle was engaged and

the sealing on the tap is

not correct.

If no bottle is engaged a

valve inside the tap

might be stucked.

Tank seal is missing (if

previewed).

Tank or pipes joints are

loose.

Check all the bottles triyng

to he

ar a whistle coming

from the necks or wet your

finger and surround them.

Check all the bottles are

pushed upwards and tight

against the seals.

Install cylindric adapter

(code 6012) between bottle

and piston.

Manually move the tap seal

downwards in order

to

release the valve anch for

leaks.

Puor cleaning

solutions.

Remove the manometer, fix

the seal and tight the bolt.

Check correct pipe fixing

and jointing.

Check manometer

tightening.

The machine

doesn t switch on.

Power failure.

Switch(es) is (are

) off.

Fuses are burned.

Plug the machine to a

power supply.

Switch on.

Change the fuses.

UM.02

ENOLINE WINE CARD

Page 14 of 46

Rev 0

8, May 2010

Bottle engagement

indicator led(s) is

(are) off.

Only some bottle

engagement

indicator leds are

on.

Bottle was engaged

while the machine was

off.

Bottle is m

issing.

Tap sealing is not

pushing the microswitch

behind the tap. (for off

ones)

Remove the bottle and

insert it while the machine

is on.

Engage the bottle.

Push manually upwards the

tap sealing checking the

click of the switch.

Bottle engagement

ind

icator led

switches off when

bottle is not empty.

Wrong operative

parameters.

Check parameter # 5 (full

bottle capacity) in

programmino mode.

Pouring is not

fluent.

Internal straw is not

properly inserted.

The filter at the bottom

of the internal straw i

s

stucked (especially with

sediment or aged

wines).

Tank is almost empty or

pressure is not enough.

Remove the bottle and fix it

properly.

Remove the bottle and

clean the filter.

Change the tank.

Wine drops falling

from the spouts.

Some wine sediments or

cork pieces are blocking

the dispensing valve.

Pour citric acid solution to

remove all the sediments

and foreign objects from the

valve.

Pistons fall down.

Loss or leak of pressure

on compressed

air/nitrogen supply pipe.

Check correct duty press

ure

(4 Bar).

Check the pipe not to be

pressed or pricked.

Wine bubbles in the

glass while pouring.

Wine is falling on the

bottom of the glass.

Lean the glass towards the

spout.

T

EMPERATURE CONTROLLED MODELS

Trouble

Origin

Solution

Set temperature is

n

ot reached.

Not enough air

circulation.

Check the free space aside the

compressor engine (300mm)

and provide it if missing.

WINE CARD MODELS

Trouble

Origin

Solution

Machine doesn t

react when a

winecard is

inserted.

The winecard is not

properly inserted.

The winecard reader is

not activated.

Insert the winecard with the

chip facing downwards.

Activate the card reader

through Module Card.

UM.02

ENOLINE WINE CARD

Page 15 of 46

Rev 0

8, May 2010

10.

Maintenance and Cleaning

A frequent and

severe

dispensing taps cleaning is

necessary to maintain you

r En

omatic Wine

Serving System in full performances

and

to grant wine flavours preservation. If

you respect the maintenance

programme your Enomatic Wine Serving

System will be efficient fo

r

long time. For repairs and

maintenance, in case of faults or faulty o

perations, call

only an authorised after

-

sales service centre, or contact

your local Distributor.

10 .1

Daily Maintenance

On a daily basis:

-

clean the drip tray with a damp sponge.

-

clean the Serving Spout by immersing it in water and then rinse thoro

ughly.

-

clean the

bodywork with a non-abrasive cloth.

10.2

Bottle Tube and Tap Cleaning

Dispensing taps and internal straws must be cleaned EVERY 10 POURED

BOTTLES PER DISPENSING POSITION (please note the chart available at the

end of this manual to

be ticked at any bottle engagement for tracking)

. A

n ideal

time to clean the entire Bottle Tube and Tap is when a bottle is being changed

this is because a partly used bottle can not be reinstalled into the system (it will

contain air

, and preservation

won t be effective); act as follow:

replacing the wine with a bottle containing diluted citric acid (3-4

teaspoons each 750 ml of water

, ca. 15-20 grams of product);

run some citric acid cleaning solution pours , wait 10 minutes and repeat

the

supply (serve approximately 300

mls

each time). Wait a few more

minutes and remove the bottle containing the cleaning solution;

insert

a bottle of clean water and flush the Bottle Tube and Tap with

the water (serve approximately 200mls);

replace the water with a new

bottle of the wine to be served and supply a

serve in order to fill the empty Bottle Tube.

Loading...

Loading...