Page 1

Rhein Tech Laboratories, Inc. Client: EnOcean GmbH

360 Herndon Parkway Model: STM110C

Suite 1400 Standards: FCC 15.231/IC RSS-210

http://www.rheintech.com

Report #: 2007284

ID’s: SZV-STM110C/5713A-STM110C Herndon, VA 20170

Appendix K: Manual

Please see the following pages.

Page 22 of 26

Page 2

USER MANUAL V0.904

RF Sensor Transmitter Module

STM110C

February 18, 2008

Patent protected:

WO98/36395

DE 100 25 561

DE 101 50 128

WO 2004/051591

DE 103 01 678 A1

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 1/40

Page 3

USER MANUAL V0.904

STM110C

REVISION HISTORY

The following major modifications and improvements have been made to the first version of

this document:

No Major Changes

Published by EnOcean GmbH, Kolpingring 18a, 82041 Oberhaching, Germany

www.enocean.com, info@enocean.com, phone ++49 (89) 6734 6890

© EnOcean GmbH

All Rights Reserved

Important!

This information describes the type of component and shall not be considered as assured

characteristics. No responsibility is assumed for possible omissions or inaccuracies. Circuitry

and specifications are subject to change without notice. For the latest product specifications, refer to the EnOcean website: http://www.enocean.com.

As far as patents or other rights of third parties are concerned, liability is only assumed for

modules, not for the described applications, processes and circuits.

EnOcean does not assume responsibility for use of modules described and limits its liability

to the replacement of modules determined to be defective due to workmanship. Devices or

systems containing RF components must meet the essential requirement s of the local le gal

authorities.

The modules must not be used in any relation with equipment that supports, directly or

indirectly, human health or life or with applications that can result in danger for people,

animals or real value.

Components of the modules are considered and should be disposed of as hazardous waste.

Local government regulations are to be observed.

Packing: Please use the recycling operators known to you. By agreement we will take packing material back if it is sorted. You m ust bear the costs of transport. For packing material

that is returned to us unsorted or that we are not obliged to accept, we shall have to invoice you for any costs incurred.

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 2/40

Page 4

USER MANUAL V0.904

STM110C

TABLE OF CONTENT

1

GENERAL DESCRIPTION ...................................................................................... 5

1.1 Basic Functionality ......................................................................................... 5

1.2 Typical Applications ....................................................................................... 5

1.3 Technical Data .............................................................................................. 6

1.4 Physical Dimensions ...................................................................................... 7

1.5 Environmental Conditions ............................................................................... 7

1.6 Ordering Information ..................................................................................... 7

2 FUNCTIONAL DESCRIPTION ................................................................................. 8

2.1 Block Diagram .............................................................................................. 8

Module power supply ........................................................................................... 8

Power control ..................................................................................................... 9

Power supply outputs .......................................................................................... 9

Wake-up timer .................................................................................................... 9

Processor .......................................................................................................... 10

RF transmitter ................................................................................................... 10

2.2 Pin Description and operational characteristics .................................................. 11

2.3 Absolute maximum ratings ............................................................................ 13

2.4 Equivalent schematics of Inputs and Outputs ................................................... 14

Equivalent schematic of WAKE and /WAKE inputs ................................................... 14

Equivalent schematic of wake-up cycle time inputs CW_0 to CW_1 ............................ 14

Equivalent schematic of LED output ...................................................................... 15

Equivalent schematic of V_SC1 input .................................................................... 15

Equivalent schematic of V_SC2 input .................................................................... 16

Equivalent schematic of analog inputs AD_0 to AD_2 .............................................. 16

Equivalent schematic of voltage outputs V_0UT and V_REF ...................................... 16

2.5 Encoding Scheme of CW and CP Input Pins ...................................................... 17

Wake-up cycle time ............................................................................................ 17

Redundant retransmission ........................... ... .. .................................... ... ............ 17

2.6 Solar Energy Balance Calculation .................................................................... 18

2.7 Radio Telegram of STM110C .......................................................................... 20

Frequency range and modulation scheme .............................................................. 20

Transmission timing ........................................................................................... 20

2.7 Serial Interface for module configuration ......................................................... 21

Serial protocol ................................................................................................... 22

Command list .................................................................................................... 23

2.8 Serial Data Reception via Transceiver Modules TCM 200C / TCM 210C .................. 27

3 APPLICATIONS INFORMATION ............................................................................ 28

3.1 Module Mounting .......................................................................................... 28

3.2 Antenna Mounting ........................................................................................ 29

3.3 Transmission Range ...................................................................................... 30

3.4 Connecting the solar cell ............................................................................... 31

3.5 Solar Cell Handling, Soldering & Mounting ........................................................ 32

Handling ........................................................................................................... 32

Soldering .......................................................................................................... 32

Gluing .............................................................................................................. 34

Corrosion protection ........................................................................................... 35

Shade .............................................................................................................. 35

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 3/40

Page 5

USER MANUAL V0.904

STM110C

3.6

Using an Alternative Power Supply, e.g. Battery ............................................... 36

3.7 Learn Push Button ........................................................................................ 36

4 AGENCY CERTIFICATIONS .................................................................................. 37

4.1 FCC (United States) Certification .................................................................... 37

4.2 IC (Industry Canada) Certification .................................................................. 38

5 SPECIFICATION OF SS3513 SOLAR CELL .............................................................. 39

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 4/40

Page 6

USER MANUAL V0.904

STM110C

1 GENERAL DESCRIPTION

The extremely power-saving RF transmitter module STM110C from EnOcean enables the

implementation of wireless and maintenance-free sensors. Power supply is provided by a

solar cell. An integrated energy storage allows operation for several days in total darkness.

1.1 Basic Functionality

Three 8-bit A/D converter inputs and 4 digital inputs facilitate multif unctional detector systems, based on passive sensing components. This allows easy and convenient monitoring of

temperature, illumination, etc. – or controlling window and door states – or supervising

input voltages or input currents respectively.

Figure 1: STM110C sensor transmitter module

1.2 Typical Applications

• Building installation

• Industrial automation

• Consumer electronics

The STM110C module serves the 315 MHz air interface protocol of EnOcean. Together with

the transceiver modules TCM200 / TCM210C, this module can be easily integrated into operation and control units for the realization of various application-specific system solutions.

The module is part of a powerful RF system solution from EnOcean for operation and control applications. Because the RF transmitters are self-powered, maintenance-free RF systems can be implemented.

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 5/40

Page 7

USER MANUAL V0.904

STM110C

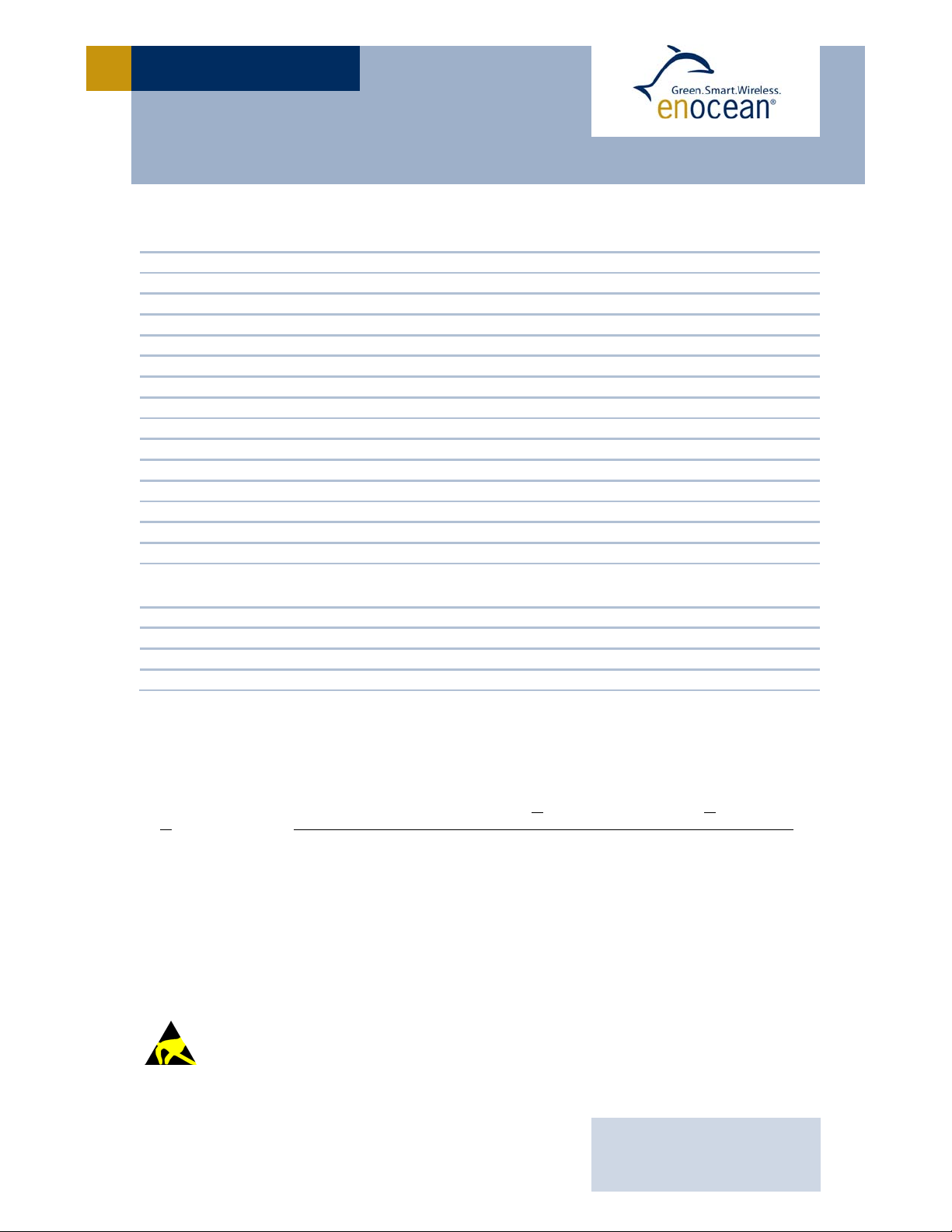

1.3 Technical Data

Power supply Solar Power Generator (discrete optical cell), or 2.2 - 5.0V external

Frequency / Conducted transmission power 315.0 MHz / 12dBm

Data rate / Modulation type 125 kbps / ASK

Transmission range 300m free field, typ. 30m indoor

Module identifier individual 32-bit ID factory-programmed

EnOcean telegram type 4BS (“Four Byte Sensor”)

Telegram packet length (sub-telegram) 1.2 ms ±5%

No. of (redundant) packets 3 packets within about 40ms, delay effected at random

Input channels 3 x analog inputs (8-bit resolution), 4 x digital inputs

Spontaneous wake-up differential external trigger signal, minimum wake interval 7ms

Cyclic wake-up user-configurable (every 1, 10, 100, or 110 s, tolerance ± 20%)

Redundant retransmission user-configurable, affected at random

Illumination 100 lx up to 100. 00 0 lx

Operation startup time with empty energy store < 10 min @ 400 lx

Operation time during total darkness > 60 h 1)

1)

RF transmission statistically every 17 min, 100s wake-up, temperature 25°C, Goldcap formatted

Ext. power supply output 3.0 V ±3%, 1mA max., ~2.6ms (during wake-up time)

Ext. voltage reference output 2.05V ±3%, 1mA max., ~2.6ms (during wake-up time)

Input sample time after wake-up >1.7 ms

Transmitting indication output (LED) 3.0V ±3%, 2mA max., 3 x 1.2 ms within 40ms

A change of WAKE pin status forces the onboard controller instantly to check all current

analog and digital input values. In addition, a user-programmable cyclic wake-up is provided.

After wake-up, a radio telegram (input data, unique 32-bit sensor ID, checksum) is transmitted in case of a change of any digital input value compared to the last sendin g or in case

of a significant change of measured analog values: >

or >

14LSB of AD_2. In case of a triggered wake-up a radio telegr am is sent in any case.

In case of no relevant input change, a redundant retransmission is sent after a while to

announce all current input values. Between the wake-up phases, the module is in sleep

mode for minimum power consumption.

There is a serial interface which allows to configure several parameters of the module:

- Threshold values of the AD inputs which lead to immediate radio transmission

- Manufacturer code (information about manufacturer and type of device)

In case a manufacturer code is programmed into the module and DI3=0 at wake-up the

module will transmit a dedicated teach-in telegram containing the manufacturer code.

Observe Precautions, electrostatic sensitive devices!

storage is filled @ 1000 lx (4.2V in Goldcap)

5LSB of AD_1 input, >6LSB of AD_0

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 6/40

Page 8

USER MANUAL V0.904

STM110C

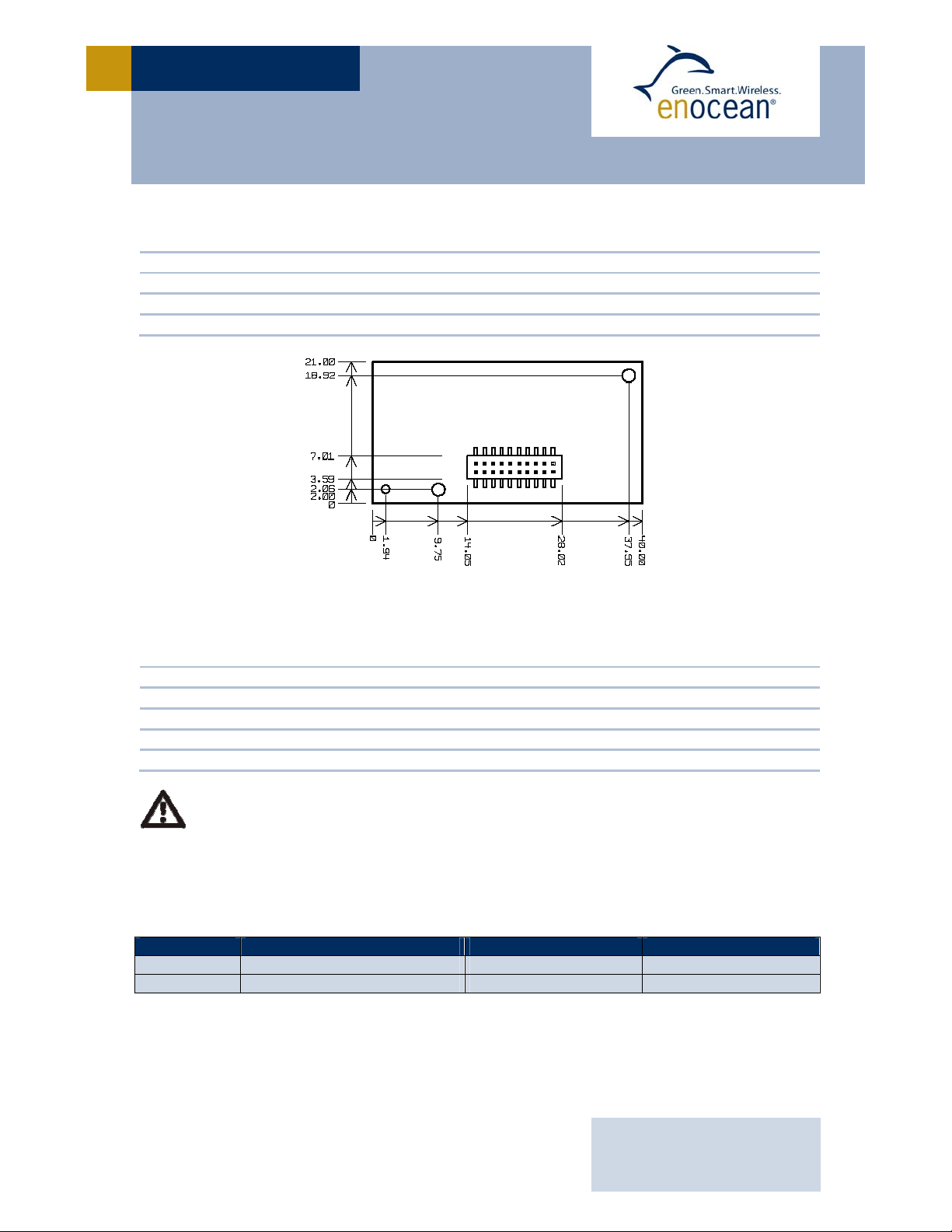

1.4 Physical Dimensions

Dimensions of PCB 21.0 x 40.0 x 9.0 mm (incl. energy store and wiring pins)

Dimensions of solar cell 35.0 x 13.0 x 1.1 mm (for details see chapter 5)

Antenna pre-installed 15 cm whip antenna

Connector: 20 pins, dual row male, grid 1.27 mm

20

19

2

1

Figure 2

: STM110C package outlines

1.5 Environmental Conditions

Operating temperature -25°C up to + 65 °C

Storage temperature -25°C up to +65 °C

Humidity (PCB) 0% to 95% r.h.

Humidity (Solar cell, rear side) 0% to 60% r.h., no condensate 1)

1)

For corrosion protection, see chapter 3.5

The product life strongly depends on the temperature as the Goldcap used for

energy storage degrades with higher temperature. As a reference the lifetime (capacitance reduced to 70% of nominal value) of the Goldcap is reduced from

100.000 h to 5.000 h when the temperature is raised from 25°C to 65°C.

1.6 Ordering Information

Type EnOcean Ordering Code Radio Frequency Solar Cell

STM110C S3031-D110 315.0 MHz Included

STM111C S3031-D111 315.0 MHz Not included

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 7/40

Page 9

USER MANUAL V0.904

STM110C

2 FUNCTIONAL DESCRIPTION

2.1 Block Diagram

V_SC1

V_SC1

Goldcap

Goldcap

V_SC2

V_SC2

*) DI_x and AD_x input values are transmitted ...

*) DI_x and AD_x input values are transmitted ...

- If wake-up and an input value has changed

- If wake-up and an input value has changed

- At wake-up and presence signal time

- At wake-up and presence signal time

RF Transmitter

RF Transmitter

Power , Da ta*)

Power , Da ta*)

ANT

ANT

(whip)

(whip)

LED

LED

Processor

Processor

Redundant

Redundant

retransmission

retransmission

(every 70th - 140th,

(every 70th - 140th,

every 7t h - 14t h,

every 7t h - 14t h,

every cycl ic wake-u p)

every cycl ic wake-u p)

CP_1CP_0

CP_1CP_0

Digital

Digital

Inputs

Inputs

A/D

A/D

8-bit

8-bit

DI_0

DI_0

DI_1

DI_1

DI_2

DI_2

DI_3

DI_3

AD_0

AD_0

AD_1

AD_1

AD_2

AD_2

WAKE

WAKE

WAKE

WAKE

CW_1

CW_1

CW_0

CW_0

Powe r c on t ro l &

Powe r c on t ro l &

wake -u p timer

wake -u p timer

Spontaneous

Spontaneous

wake-up

wake-up

Cyclic wake-up

Cyclic wake-up

(every 1,10, 100,

(every 1,10, 100,

or 110 s)

or 110 s)

Active during

Active during

wake-up only

wake-up only

V_REFV_OUT

V_REFV_OUT

Wake-up

Wake-up

(pow er on)

(pow er on)

Ready

Ready

(power off)

(power off)

GND

GNDGND

Figure 3: STM110C block diagram

Module power supply

The supplied solar cell has been designed especially for the STM110C for maximum module

performance at smallest dimensions. The active solar area is divided into two to provide

independent module power supplies:

V_SC1: Main power supply input. Must be connected to the STM110C solar cell

(small active area) or by another external energy source respectively

V_SC2: Goldcap charging input by connecting to the STM110C solar cell (big active

area)

The capacitance of the Goldcap may be reduced after long term storage of modules without energy supply. It may take up to one day of charging until the full

capacitance is recovered.

Continuous operation at temperatures higher than 50°C may decrease th e capacitance of the Goldcap. This will result in shorter charging times and shorter operating times in total darkness!

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 8/40

Page 10

g

USER MANUAL V0.904

STM110C

Power control

The power control supervises V_SC1 supply and charging status of the energy store. It controls the power supply for wake-up timer, microprocessor, HF transmitter and the supply

outputs.

Power supply outputs

Two power supply outputs are available:

a) V_OUT

b) V_REF (stabilized reference voltage)

The outputs are active after wake-up during the active state of the module to drive an external sensor user circuitry.

Wake-up timer

The wake-up timer provides user-programmable wake-up time intervals for activating the

processor and an external wake-up opportunity (WAKE pins).

Features:

Extremely low power consumption during sleeping time period

Cyclic processor wake-up configurable by user through external pin configuration

(CW_0, CW_1)

The sleep mode can be terminated immediately by changing the pin status of the

differential WAKE inputs. Note that the WAKE inputs are part of a special capacitor

circuitry that offers lowest operating power consumption (current flow at switching

over time only).

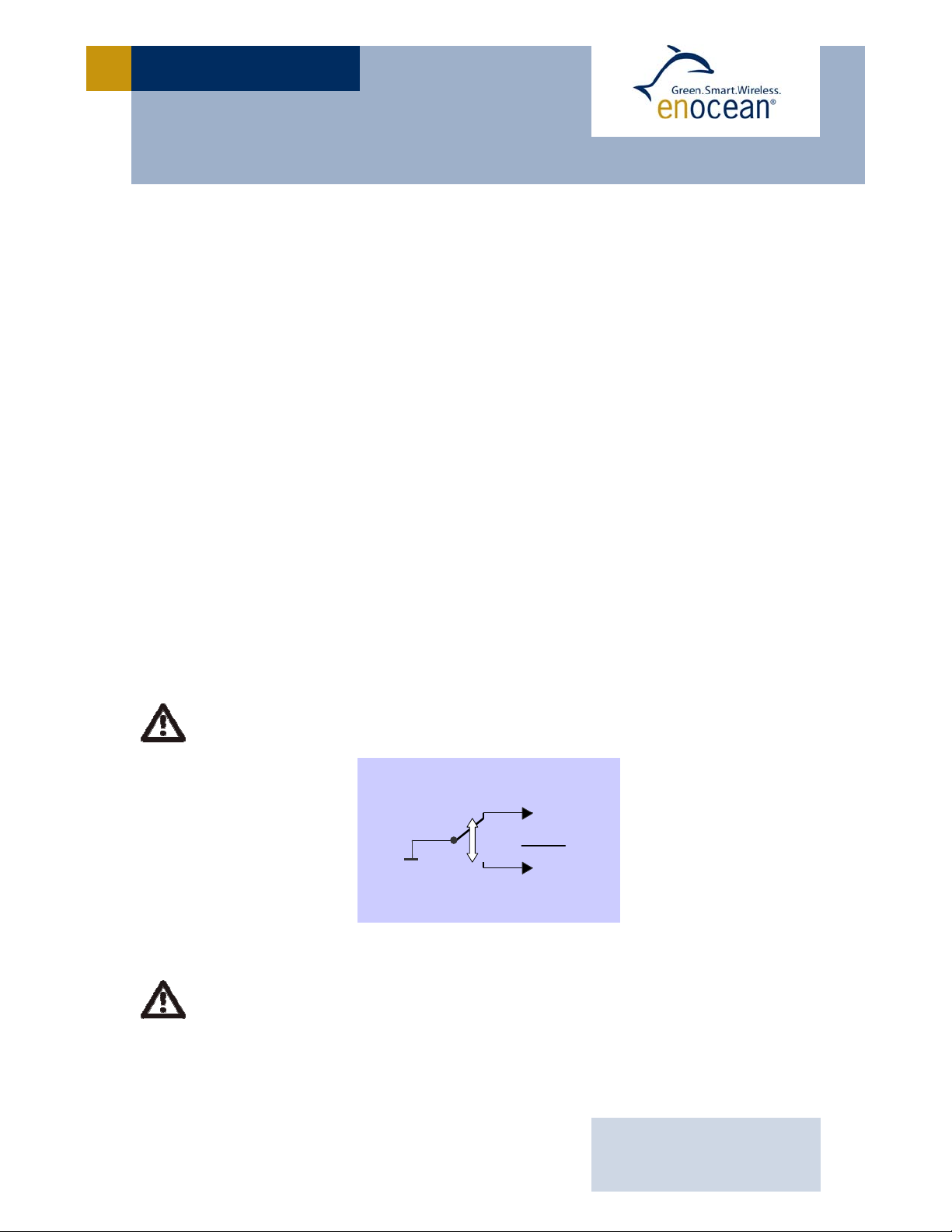

WAKE and /WAKE always have to be operated via switch-over as shown in the

following:

WAKE

WAKE

WAKE

WAKE

GND

GND

Figure 4: External WAKE pin circuit

A radio telegram is always transmitted after wake-up via WAKE pins!

After transmission the counter for redundant retransmission is reset to a random

number in the confi

ured range.

See chapter 2.5 for configuration of wake-up cycle times.

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 9/40

Page 11

USER MANUAL V0.904

STM110C

Processor

Controls all functionalities after wake-up: First, the values of all measurement inputs are

sampled. After that, RF signal transmission is triggered if one or more of the following conditions are met:

a) One of the input values has changed since the last radio transmission (one of the 4

digital inputs has changed or one of the 3 analog inputs has changed equal to or

more than a defined value of the total measurement range), or

b) Counter for redundant retransmission is elapsed

c) The wake-up has been triggered via the WAKE pins

After every RF transmission, all measurement values are stored for data comparison at

next wake-up time.

See chapter 2.5 for configuration of timing of redundant retransmission.

RF transmitter

The radio transmitter is powered up by the processor when the sending condition is positive. The output LED is activated temporarily during telegram transmission.

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 10/40

Page 12

USER MANUAL V0.904

STM110C

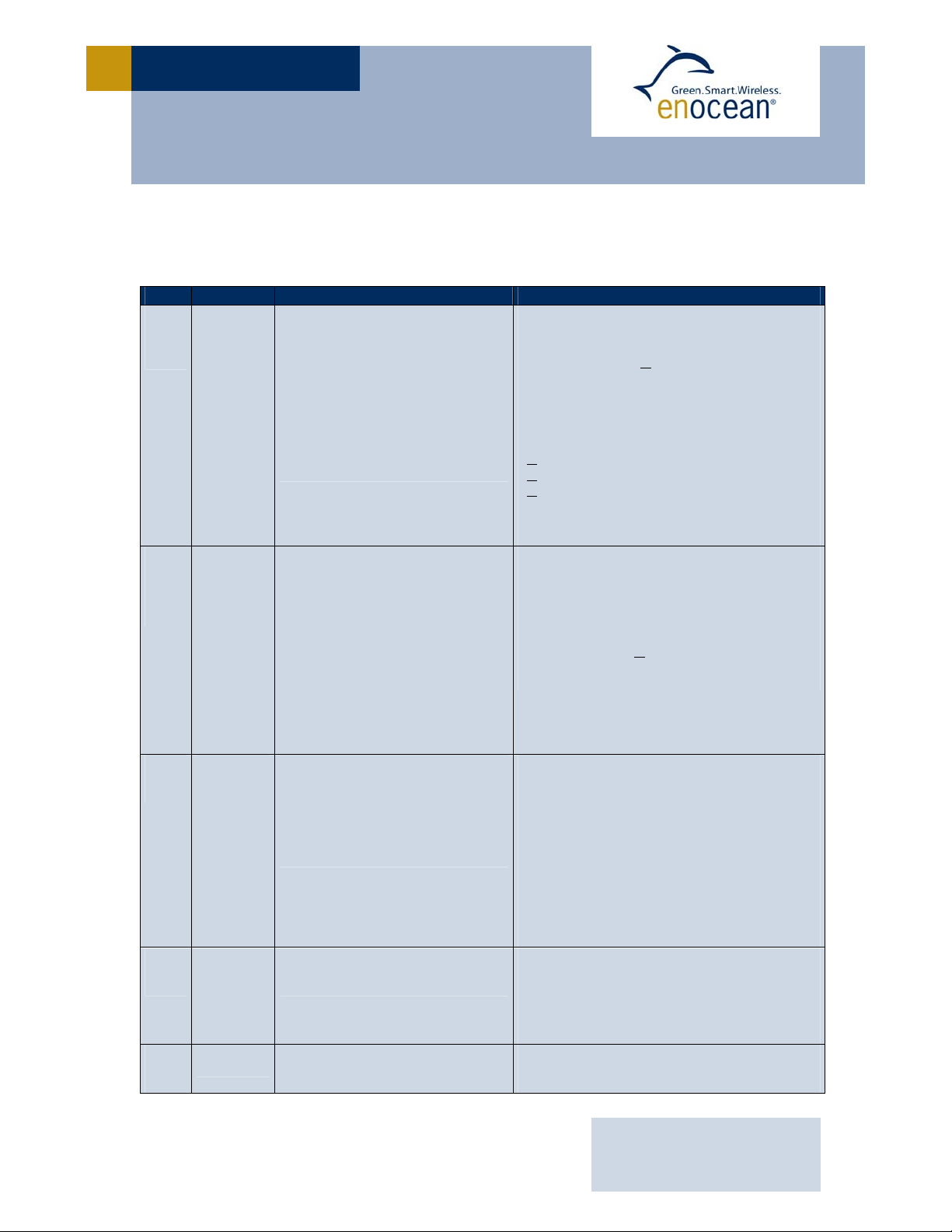

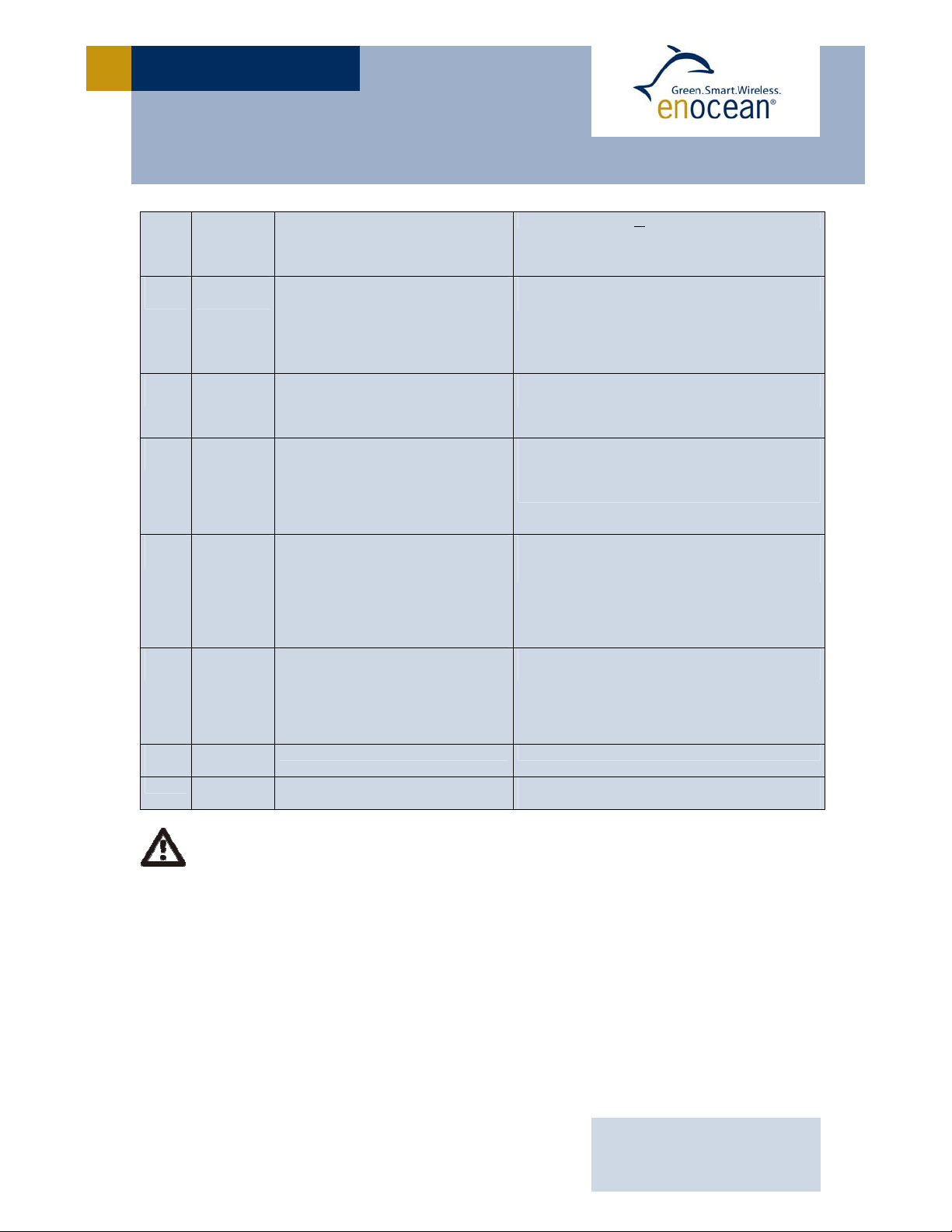

2.2 Pin Description and operational characteristics

Pin Symbol Function Operational Characteristics

5

6

7

2

1

4

3

18

20

12

14

13

15

AD_0

AD_1

AD_2

DI_0

DI_1

DI_2

DI_3

WAKE

/WAKE

CW_0

CW_1

CP_0

CP_1

Analog inputs sampled at every

wake-up.

The analog input values are

transmitted as sensor data

bytes:

AD_0 = DATA_BYTE1

AD_1 = DATA_BYTE2

AD_2 = DATA_BYTE3

Digital inputs sampled at every

wake-up.

Digital inputs are transmitted

within sensor DATA_BYTE0

(least significant 4 bits): DI_0 =

Bit 0, DI_1 = Bit 1, DI_2 = Bit

2, DI_3 = Bit3).

DI_2 and DI_3 are also us ed as

serial interface pins for the configuration of the module. See

page 21.

A signal change of WAKE inputs

stops sleep mode immediately.

A radio telegram is always

transmitted after wake-up via

WAKE pins! (change compared

to STM100!)

Encoding input for processor

wake-up cycle time: 1, 10, 100,

or 110 seconds approximately.

Encoding input for determining

the number of cyclic wake-up

signals that trigger the redun-

Sample moment after wake-up: 1.7 ms …

2.6 ms

Resolution: 8-bit

Input impedance: >100kΩ

(1 bit = V_REF/256 = 8mV

Accuracy vs. V_REF @25°C typ. ±2LSB,

max ±4LSB).

Relevant input change:

> 5 LSB of AD_1

> 6 LSB of AD_0

> 14 LSB of AD_2

These default values may be changed. See

page 23

Sample moment after wake-up: 1.7 ms …

2.6 ms

Real digital TTL input with internal pull-up

(change compared to STM100!)

LOW voltage: <0.45 V

HIGH voltage: > 2.45V

Input impedance >100kΩ

Differential input (capacitive):

- connect to GND via switch

over only

- Resistance to GND < 100 Ω

- Switch over time < 1ms

- Minimum time between wake

signals > 7ms

- Pins should be connected to

V_SC1 if not needed in

application

- max. external allowed leakage

current 100pA

Pins should be left open or connected to

GND

Resistance to GND < 10 Ω

Cyclic wake-up time value strongly depends

on actual power supply voltage and temperature (up to ±20%)

Pins should be left open or connected to

GND

Resistance to GND < 100 Ω

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 11/40

Page 13

USER MANUAL V0.904

STM110C

9

10

11

19

17

8

16

ANT

dant retransmission: Every

Input impedance >100kΩ

wake-up signal, or every 7th 14th, or every 70th - 140th or no

redundant retransmission.

V_OUT Module power supply output

available during wake-up phase

to drive an external sensor cir-

3.0V ±3%, ~2.6ms,

I

= 1 mA max.

Vout

cuitry by the user.

Also used for starting serial

mode.

V_REF Reference voltage output availa-

ble during wake-up phase to

drive an external sensor circuit

2.05 V ±3%, ~2.6ms,

I

= 1 mA max.

Vref

by the user.

LED Output for optional external LED

to indicate every telegram

transmission (short flashing)

3.0 V ±3%, 2 mA max.,

source impedance 470 Ω ±1%,

~3 x 1.2 ms within 40 ms

Also used for starting serial

mode.

V_SC1 Main power supply input. Con-

nect V_SC1 in series with a

Schottky diode of Type BAS 125

When using other energy source than the

supplied solar panel (see chapter 3.6):

2.2 – 5.0 V

to SOL1 of the STM110C solar

cell (smaller area, see Figure 9).

Or connect to another external

energy source respectively.

V_SC2 Goldcap charging input. Connect

V_SC2 in series with a Schottky

For use with the solar cell only (Vo < 5.0 V)!

diode of Type BAS 125 to SOL2

of the STM110C solar cell (bigger area, see Figure 9).

GND

Ground connections

Whip antenna λ/4

Please find recommendations on antenna

mounting in chapter 3.2

Never connect an input (like CP_0..1, AD_0..2, DI_0..3) to a permanent supply

voltage! These inputs should be always left open, connected to GND or connected

to the own V_OUT and / or V_REF (active only during measurement time!). Otherwise they would permanently draw current from the permanent power supply

and could also damage the device (see absolute maximum ratings 2.3 below)

If such a function is absolutely needed, please insert a diode to avoid the problem.

For socket positions, see Figure 2.

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 12/40

Page 14

USER MANUAL V0.904

STM110C

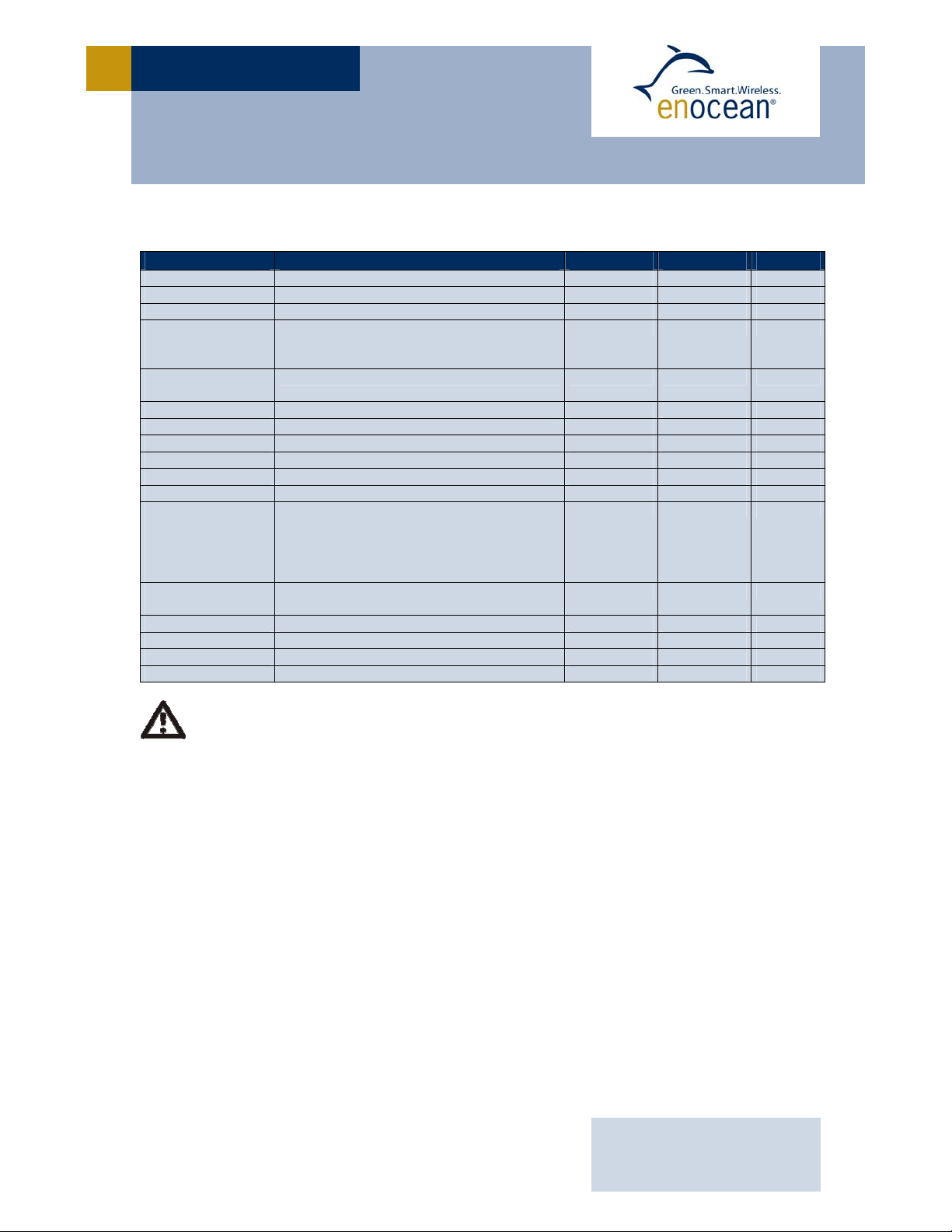

2.3 Absolute maximum ratings

Symbol Parameter Min Max Units

V_SC1, V_SC2 Input voltage 0 5.5 V

V_SC1 Input current ripple 95 mA

V_SC2 Input current ripple 0.2 A

LED, V_REF,

V_OUT, DI0..3,

AD0..2, CP_0..1

LED, DI0..3,

AD0..2

V_OUT Input voltage while serial mode is active 0 3.09 V

CW_0, CW_1 Input voltage 0 V

WAKE, /WAKE Input voltage 0 V_SC1 V

ANT Input voltage 5 V

V_REF, V_OUT Output current 1 mA

LED Output current 2 mA

V_SC1, V_SC2,

CW_0, CW1,

WAKE, /WAKE,

V_OUT, V_REF,

ANT, GND

CP_0, CP_1, LED,

DI_0..3, AD_0..2

Module Temperature -25 65 °C

Module Humidity 95 % r.h.

Solar cell Illumination 100.000 lx

Solar cell Humidity 60 % r.h.

Exceeding these values may destroy the module!

Input voltage while µC not active (=

0 0.7 V

module completely switched off or sleep

timer running)

Input voltage while µC active 0 V_OUT V

Electrostatic discharge 1 kV

Electrostatic discharge 2 kV

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 13/40

Page 15

USER MANUAL V0.904

STM110C

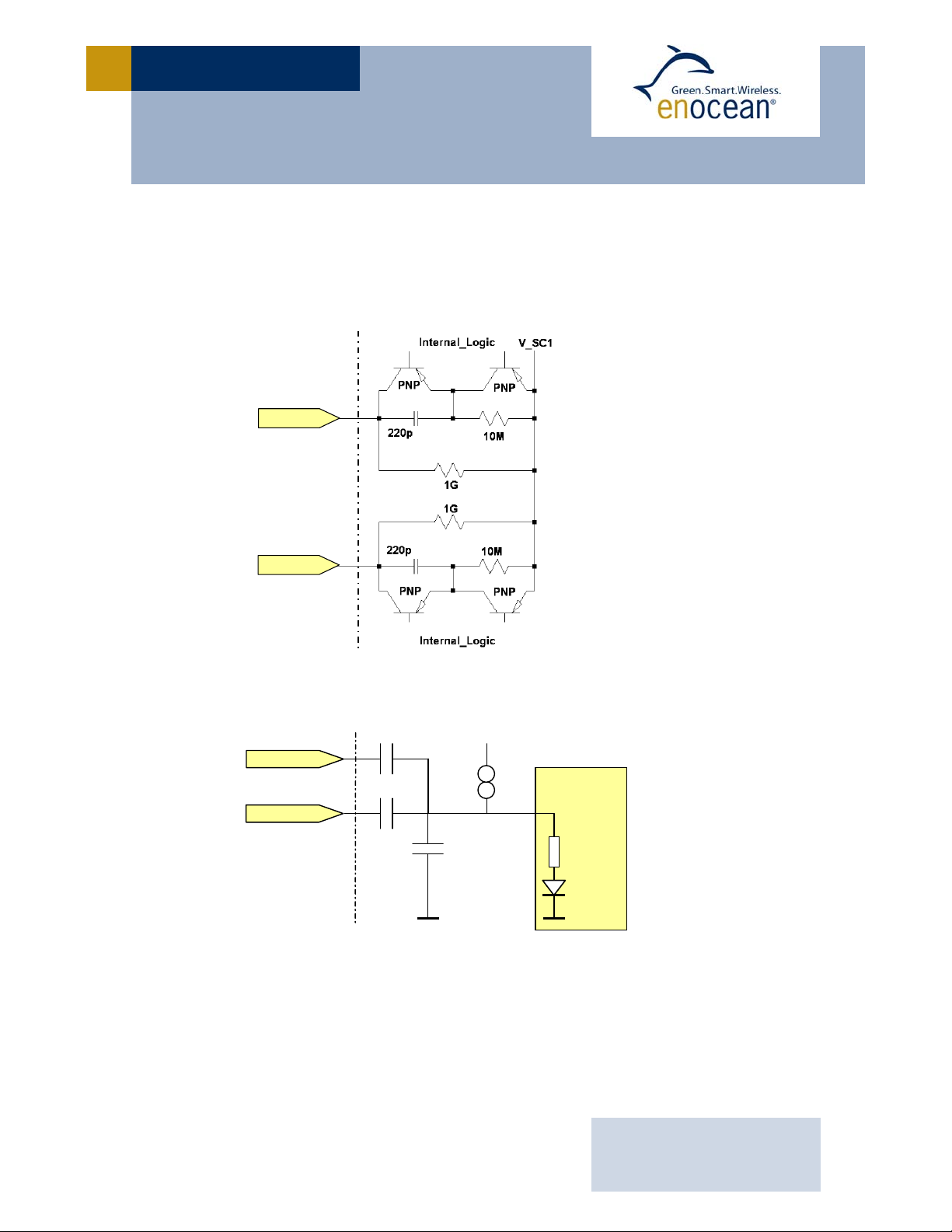

2.4 Equivalent schematics of Inputs and Outputs

Equivalent schematic of WAKE and /WAKE inputs

WAKE

______

WAKE

Equivalent schematic of wake-up cycle time inputs CW_0 to CW_1

CW_0

CW_1

83n

1µ

6.8n

5nA

Threshold

detector

1M

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 14/40

Page 16

USER MANUAL V0.904

STM110C

Equivalent schematic of LED output

Equivalent schematic of V_SC1 input

V_SC1

C1

470µF

R_C1

R_STM

R_C1: ~6 MΩ after 3 V applied for 10 min, >>10MΩ after 24h.

R_STM: depends on wake-up cycle time, transmit intervals and supply voltage.

In the following table R_STM is given at a supply voltage of 3V (typical values):

R_STM [kΩ]

Every wake-up 24 240 2400 2600

Every 10th wake-up (average) 63 630 6300 6900

Every 100th wake-up (average) 75 750 7500 8300

1s 10s 100s 110s

The current consumption is almost independent from the supply voltage

(typical values):

I_STM [µA] 1s 10s 100s 110s

Every wake-up 130 13 1.3 1.1

Every 10th wake-up (average) 50 5.0 0.50 0.45

Every 100th wake-up (average) 40 4.0 0.40 0.35

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 15/40

Page 17

USER MANUAL V0.904

STM110C

Equivalent schematic of V_SC2 input

V_SC2

C2

0.1F

R_C2

R_C2: ~375 kΩ after 3 V applied for 10 min., ~5MΩ after 24h

Equivalent schematic of analog inputs AD_0 to AD_2

Sample Switch

AD_x

Rs =

10k max

1M

V_SC1

120p

Equivalent schematic of voltage outputs V_0UT and V_REF

470

470

Vpulse

Vpulse

1 mA

1 mA

<

<

LMV 358

LMV 358

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 16/40

V_OUT

V_OUT

V_REF

V_REF

Page 18

USER MANUAL V0.904

STM110C

2.5 Encoding Scheme of CW and CP Input Pins

The encoding input pins have to be left open or connected to GND in correspondence with

the following connection schemes:

Wake-up cycle time

CW_0 CW_1 Wake-up cycle time

NC NC 1 sec. ±20%

GND NC 10 sec. ±20%

NC GND 100 sec. ±20%

GND GND 110 sec. ±20%

Redundant retransmission

Via CP_0 and CP_1 an internal counter is set which is decreased at every wake-up signal.

Once the counter reaches zero the redundant retransmission signal is sent.

CP_0 CP_1 Number of wake-ups that

trigger a redundant retransmission

NC NC Every timer wake-up signal

GND NC Every 7th - 14th timer wake-up signal, affected

at random

NC GND Every 70th - 140th timer wake-up signal, affected

at random

GND GND No redundant retransmission

A radio telegram is always transmitted after wake-up via WAKE pins!

After transmission the counter is reset to a random value within the specified interval.

According to FCC 15.231a) a redundant retransmi ssion at every timer wake-up to

determine the system integrity is only allowed in safety and security appli cations!

In this case the total transmission time must not exceed two seconds per hour,

which means that a combination with a 1s wake-up cycle time is not allowed!

If applied in other (non-safety, non-security) applications a minimum of 10s between periodic transmissions is required. In addition the device has to comply with

the lower field strength limits of 15.231e). The limited modular approval of

STM110C is not valid in this case.

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 17/40

Page 19

USER MANUAL V0.904

STM110C

2.6 Solar Energy Balance Calculation

The following diagrams are showing operational performance data of STM110C.

6

5

4

3

Voltage V_SC2[V]

2

1

0

0 5 10 15 20 25

charging time [h]

Charging time [h]

Charging at 1000 lx

Charging at 1000 lxCharging at 1000 lx

Charging at 200 lx

Charging at 200 lx

Charging at 50 lx

Charging at 50 lx

Figure 5: Graphs of the goldcap charging process (typ. @25°C). Measured with

white light LEDs, illustration of the illumination level as fluorescent lamp equivalent (EL). Measured with 100s wake up timer.

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 18/40

Page 20

USER MANUAL V0.904

STM110C

1 sec timer

Operating time in darkness [h]

Operating time in darkness [h]

6

5

4

Figure 6: STM110C operation time

in darkness (typ. @25°C)

3

2

1

0

0123

6

Voltage V_SC1 [V]

10 sec timer

100 sec timer

Operating time in darkness [h]

Operating time in darkness [h]

5

4

3

Voltage V_SC1 [V]

Voltage V_SC2[V] Voltage V_SC2[V]Voltage V_SC2[V] Voltage V_SC2[V]

2

1

0

051015202530

6

5

4

3

Voltage V_SC1 [V]

2

1

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Operati ng ti me in darkn ess [ h]

Operating time in darkness [h]

Telegram transmission at every wake up

Telegram transmission at every wake up

Telegram transmission every 10th wake up

Telegram transmission every 10th wake up

Telegram transmission every 100th wake up

Telegram transmission every 100th wake up

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

(average)

(average)

0

0306090120150

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 19/40

Page 21

USER MANUAL V0.904

STM110C

In the figure left typical values are shown. In worst case the operating time in

darkness may be 20% less!

2.7 Radio Telegram of STM110C

Frequency range and modu lation scheme

Because of the very low radiated field strength on average, products based on STM110C

(315.0 MHz) can be approved in the USA and in Canada. The approval requirements can be

found in chapter 4 of this paper.

STM110C is based on ASK (amplitude shift keying) modulation with a bit rate of 125 kbit/s.

Telegram content

The payload of the telegram consists of:

8 bit 8 bit 8 bit 4 bit 32 bit

AD_2 AD_1 AD_0 DI_3..0 ID

Transmission timing

The transmission timing of the radio module STM110C has been developed to avoid possible collisions with data packages of other EnOcean transmitters as well as disturbances

from the environment.

With each transmission cycle, 3 identical subtelegrams are transmitted. The transmission of

a subtelegram lasts approximately 1.2 ms. To optimize data security, each telegram is repeated twice within about 40 ms, whereas the delay between the three transmission bursts

is effected at random.

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 20/40

Page 22

USER MANUAL V0.904

STM110C

2.7 Serial Interface for module configuration

It is possible to change some parameters of the module via a serial interface:

- Read / write threshold values of AD_0 to AD_2 which lead to a transmission

of a radio protocol

- Read the firmware version of the module

- Read / write manufacturer ID, device profile and type

The following pins are needed:

- LED

- V_OUT

- DI_3 as USR_RX

- DI_2 as USR_TX

In order to activate the serial mode please take the following steps:

1. Connect LED pin to V_OUT pin

2. Activate STM110C using the timer or the WAKE inputs.

The module will then enter the serial mode. It will receive information via the USR_RX

(DI_3) pin and transmit information via the USR_TX (DI_2) pin. It will not react on WAKE

signals or timer interrupts while in serial mode.

In order to terminate the serial mode the LED pin has to be connected to GND.

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 21/40

Page 23

USER MANUAL V0.904

STM110C

Serial protocol

The data rate is 9600 baud, 1 start bit ,1 stop bit, LSb first. The inter byte time out is

50ms.

The default logic value is 1(3V).

A serial command consists of 14 bytes as shown in the following.

SYNC_BYTE1 (A5 Hex)

SYNC_BYTE0 (5A Hex)

HEADER

ORG

DATA_BYTE0

DATA_BYTE1

DATA_BYTE2

DATA_BYTE3

DATA_BYTE4

DATA_BYTE5

DATA_BYTE6

DATA_BYTE7

DATA_BYTE8

CHECKSUM

SYNC_BYTE1 (8 bit) = 0xA5 (fixed)

SYNC_BYTE0 (8 bit) = 0x5A (fixed)

HEADER (8 bit) = 0x8B telegram sent from STM

0xAB telegram sent to STM

ORG (8 bit) = 0 .. 255 telegram type (see description of commands)

DATA_BYTE0..8 (8 bit) = 0 .. 255 information

CHECKSUM (8 bit) = 0 .. 255 checksum (Last 8LSB from addition of all octets

except sync bytes and checksum)

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 22/40

Page 24

USER MANUAL V0.904

STM110C

Command list

WR_SYS_AD_THRES

Description:

With this command the user can modify the threshold values at the analog inputs which

lead to a radio transmission. The default values are 6LSB on AD_0, 5LSB on AD_1 and 14

LSB on AD_2.

The module will answer with OK_SYS_WR or ERR_SYS_WR.

Command encoding

Bit 7 Bit 0

0xA5

0x5A

0xAB

0x02

AD_2_MIN_VARIATION

AD_1_MIN_VARIATION

AD_0_MIN_VARIATION

0xXX

0xXX

0xXX

0xXX

0xXX

0xXX

ChkSum

AD_2_MIN_VARIATION: Treshold at AD_2: 0..0xFF LSB

AD_1_MIN_VARIATION: Treshold at AD_1: 0..0xFF LSB

AD_0_MIN_VARIATION: Treshold at AD_0: 0..0xFF LSB

0xXX Ignored field

A reduction of the thres hold values m ay lead to a higher number of transmissions

and therefore increased energy consumption! The measurement accuracy versus

V_REF is typ. ±2LSB, max ±4LSB!

RD_SYS_MEM

Description:

With this command the user can retrieve all the configuration data from the module.

The module answers with 3 telegrams:

• INF_SYS_SW_VERSION

• INF_SYS_ID_DEV_MAN

• INF_SYS_AD_THRES

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 23/40

Page 25

g

USER MANUAL V0.904

STM110C

Command encoding

Bit 7 Bit 0

0xA5

0x5A

0xAB

0x40

0xXX

0xXX

0xXX

0xXX

0xXX

0xXX

0xXX

0xXX

0xXX

ChkSum

0xXX ingored field

INF_SYS_ID_DEV_MAN

Description:

This message contains the manufacturer ID, and the device profile and type.

Command encoding

Bit 7 Bit 0

0xA5

0x5A

0x8B

0x00

DATA_BYTE3

DATA_BYTE2

DATA_BYTE1

0x00

ID_Byte3

ID_Byte2

ID_Byte1

ID_Byte0

0x00

ChkSum

Data_Byte3..0:

Data_Byte3 Data_Byte2 Data_Byte1

7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0

Profile Type Manufacturer ID

ID_Byte3..0:

as follows:

STM110 ID bytes.

In order to prevent fraudulent use, the commands for writing manufacturer ID,

device profile and type to the module are only available to customers signing an

reement with EnOcean!

a

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 24/40

Page 26

USER MANUAL V0.904

STM110C

INF_SYS_SW_VERSION

Description:

This telegram contains the SW version of the module.

Command encoding

Bit 7 Bit 0

0xA5

0x5A

0x8B

0x8C

SW Version Byte3

SW Version Byte2

SW Version Byte1

SW Version Byte0

0x00

0x00

0x00

0x00

0x00

ChkSum

SW Version Byte3..0: Software version, MSB first

INF_SYS_AD_THRES

Description:

This telegram contains the current threshold values at the analog inputs which lead to a

radio transmission.

Command encoding

Bit 7 Bit 0

0xA5

0x5A

0x8B

0x01

AD_2_MIN_VARIATION

AD_1_MIN_VARIATION

AD_0_MIN_VARIATION

0x00

0x00

0x00

0x00

0x00

0x00

ChkSum

AD_2_MIN_VARIATION: Treshold at AD_2: 0..0xFF LSB

AD_1_MIN_VARIATION: Treshold at AD_1: 0..0xFF LSB

AD_0_MIN_VARIATION: Treshold at AD_0: 0..0xFF LSB

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 25/40

Page 27

USER MANUAL V0.904

STM110C

OK_SYS_WR

Description:

This message is sent after successful execution of a user request.

Command encoding

Bit 7 Bit 0

0xA5

0x5A

0x8B

0x58

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

ChkSum

ERR_SYS_WR

Description:

This message is sent if the execution of a user request has failed.

Command encoding

Bit 7 Bit 0

ChkSum

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

0xA5

0x5A

0x8B

0x19

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 26/40

Page 28

USER MANUAL V0.904

STM110C

2.8 Serial Data Reception via Transceiver Modules TCM 200C / TCM 210C

For a detailed description please refer to the User Manual of TCM200C/TCM210C.

Type of STM110C protocol which is seen at the serial outputs of the receiver modules

is “4BS” (4 Byte Sensor):

Description of STM110C radio data content:

ORG = 7 dec. always (EnOcean module type “4BS”)

DATA_BYTE3 = Value of AD_2 analog input

DATA_BYTE2 = Value of AD_1 analog input

DATA_BYTE1 = Value of AD_0 analog input

DATA_BYTE0 = Digital sensor inputs as follows:

Bit 7 Bit 0

Reserved DI_3 DI_2 DI_1 DI_0

ID_BYTE3 = module identifier (Byte3)

ID_BYTE2 = module identifier (Byte2)

ID_BYTE1 = module identifier (Byte1)

ID_BYTE0 = module identifier (Byte0)

In case manufacturer ID, device profile and type have been stored in the module the following telegram will be seen on the TCM200C/TCM210C serial interface if DI_3=0:

Description of STM110C learn telegram:

ORG = 7 dec. always (EnOcean module type “4BS”)

DATA_BYTE0..3 see below

LRN Type = 1

LRN = 0

DI0..DI2: current status of digital inputs

Profile, Type, Manufacturer-ID defined by manufacturer

ID_BYTE3 = module identifier (Byte3)

ID_BYTE2 = module identifier (Byte2)

ID_BYTE1 = module identifier (Byte1)

ID_BYTE0 = module identifier (Byte0)

ORG Data_Byte3 Data_Byte2 Data_Byte1 Data_Byte0 ID

Profile

6 Bit

Type

7 Bit

Manufacturer-ID

11 Bit

LRN Type

1Bit

RE2

1Bit

RE1

1Bit

RE0

1Bit

LRN

1Bit

DI2

1Bit

DI1

1Bit

DI0

1Bit

With this special learn telegram it is possible to identify the manufacturer of a device and

the profile and type of a device. There is a list available describing the function alities of the

respective products. Please contact EnOcean to receive this list.

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 27/40

Page 29

USER MANUAL V0.904

STM110C

3 APPLICATIONS INFORMATION

3.1 Module Mounting

The STM110C module requires some external circuitry configuration and connecting to the

application-specific sensorics circuit. This external circuitry should easily find place on a

small PCB that can be connected upside down to the EnOcean module via the STM dual row

header. This allows the realization of very compact sensor units.

User PCB

User PCB

User PCB

d

d

e

e

r

r

i

i

u

u

q

q

STM

STM

e

e

r

r

110

110

e

e

c

c

Module

Module

a

a

p

p

S

S

User PCB

y

y

s

s

g

g

e

e

r

r

r

r

e

e

o

o

t

t

n

n

s

s

E

E

STM

STM

110

110

Module

Module

9 mm

9 mm

9 mm

9 mm

Figure 7: Examples of compact sensor unit

The following features have to be available on the user PCB:

Power supply by connecting V_SC1 and V_SC2 to the supplied solar cell or by con-

necting V_SC1 to another suitable external energy source

Configuration of the STM firmware by connecting the input pins CW_0..1 and

CP_0..1

If needed, an application-specific sensor circuitry connected to an alog input pin s

(AD_0, AD_1, and/or AD_2) and powered by V_OUT, V_REF and GND

If needed, connections to digital signal inputs DI_0..3. The digital inputs can also

be used for an individual sensor type identification defined by the user.

If needed, a changeover switch connected to the differential WAKE pins for provid-

ing spontaneous wake-up

If needed, a light emitting diode connected between the LED and GND pins for pro-

viding optical feedback of sending

To avoid radio frequency pickup from the environment, st rip lines of the user circuit should be designed as short as possible, and the use of a PCB ground plane

layer is recommended.

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 28/40

Page 30

USER MANUAL V0.904

STM110C

3.2 Antenna Mounting

Positioning and choice of receiver and transmitter antennas are the most important factor

in determining system transmission range. The STM110C transmitter module is supplied

with a soldered whip antenna as standard. By using that antenna, very compact sensor

equipment can be implemented with good radio transmission characteristics. For mounting

the antenna, some notes should be considered to optimize syste m performance:

For best transmitter performance, the space immediately around the antenna has to be

strictly considered, since this has a strong influence on screening and detuning the antenna. The antenna should be drawn out as far as possible and must be never cut off. Mainly

the far end of the wire should be mounted as far as possible away from all metal parts, PCB

strip lines and fast logic components (e.g. the STM microprocessor). Don’t short the whip

λ/4).

(

For a good antenna performance don’t roll up or twist the whip and please draw

attention to an overall whip distance of at least 10 mm (20 mm is better) from

any PCB strip, ground plane and conductive part or electric part.

Note that whip antennas do not show any directional effects under free-field radio-wave

propagation conditions (spot-wise radiator). The RSSI voltage output of the receiver module can be used for evaluating the influence of intuitive RF optimizations.

STM110C: L=150 ± 2 mm, color orange

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Figure 8: Specification of the whip antenna

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 29/40

Page 31

USER MANUAL V0.904

STM110C

3.3 Transmission Range

The main factors that influence the system transmission range are type and location of the

antennas of the receiver and the transmitter, type of terrain and degree of obstruction of

the link path, sources of interference affecting the receiver, and “dead” spots caused by

signal reflections from nearby conductive objects. Since the expected transmission range

strongly depends on this system conditions, range tests should categorically be performed

before notification of a particular range that will be attainable by a particular application.

The following figures for expected transmission range are considered by using a PTM, a

STM or a TCM radio transmitter device and the TCM radio receiver device with preinstalled

whip antenna and may be used as a rough guide only:

Line-of-sight connections: Typically 30m range in corridors, up to 100m in halls

Plasterboard walls / dry wood: Typically 30m range, through max. 5 walls

Brick walls / aerated concrete: Typically 20m range, through max. 3 walls

Ferroconcrete walls / ceilings: Typically 10m range, through max. 1 ceiling

Fire-safety walls, elevator shafts, staircases and supply areas should be

considered as screening.

The angle at which the transmitted signal hits the wall is very important. The effecti v e wall

thickness – and with it the signal attenuation – varies according to this angle. Signals

should be transmitted as directly as possible through the wall. Wall niches should be

avoided. Other factors restricting transmission range:

Switch mounted on metal surfaces (up to 30% loss of transmission range)

Hollow lightweight walls filled with insulating wool on metal foil

False ceilings with panels of metal or carbon fiber

Lead glass or glass with metal coating, steel furniture

The distance between EnOcean receivers and other transmitting devices such as computers, audio and video equipment that also emit high-frequency signals should be at least

0.5m.

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 30/40

Page 32

USER MANUAL V0.904

STM110C

3.4 Connecting the solar cell

The supplied solar cell has been designed especially for maximum module performance at

smallest dimensions. The active solar area is divided into two to provide independent module power supplies:

V_SC1: Main power supply input. Must be connected to the small active area of the

solar cell or to another external energy source respectively

V_SC2: Goldcap charging input. Must be connected to big active area of solar cell

The solar cell must be connected to the module in series with Schottky Diodes of type

BAS 125. In Figure 9 the dual diode BAS 125-07 (SMD, parallel pair) is used.

For outdoor use in addition the BZX84-B5V1 diodes (leakage current at 2V must

be below 2µA) are needed to avoid damage of the module by over voltage.

SOLAR CELL

30% 70%

SOL1

2x BZX84-B5V1

for outdoor applications

GND

SOL2

BAS 125-07W

V_SC1

V_SC2

Figure 9: Connecting the solar cell

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 31/40

Page 33

USER MANUAL V0.904

STM110C

3.5 Solar Cell Handling, Soldering & Mounting

The EnOcean solar cell technology guarantees the highest stabilized efficiency values. At

the front, the solar modules have a glass covering that protects the photovoltaic layer from

the effects of the environment and weather. The rear features contacts for the electrical

connection.

Handling

Prevent injuries due to the sharp glass edges.

Always handle the modules carefully, avoid damage of the glass edges that leads to

glass breakage or glass chips. The layers are sensitive to punctual pressure, scratching or grinding. During handling and processing, always make sure that no particles are pushed into the coating. Scratches, i mprints or particles pushed into the

layer can lead to short-circuiting of the module, thus deterioration.

The processing of the modules with lacquer spray process es or edge grinding could

lead to an impairment of the electrical function of the module (electrostatic influences).

In case of necessary module cleaning, the following cleaning agents are suggested:

Kleenex (200 tissues, Code 7107, D 0261 8930, Kimberly-Clark) / highpure DI- water / Ethanol (min. 99,8 Vol.%).

Soldering

The solar panel has 3 connection pads on the rear side. On one side you will see the minus

sign. This is the GND connection.

Apparatus

Soldering iron: Temperature-controlled type with 60W heater at least and +/- 5°C

control range is recommended.

Soldering iron tip: Slant type or point type.

Temperature Measuring Device: A calibrated contact-type temperature meter (e.g.

Anritsu Model No. HL-100).

Materials

Pb-free solder wire: Sn96.5/Ag3.0/Cu0.5, ∅ 0.8 mm, (e.g. Kester 245)

Lead wire: Dependent on the type of solar cell, use 20 - 30 AWG multi-threads

stranded type. For Pb-free soldering, the lead wire component shall be compli ed

with RoHS requirement.

Procedure for hand soldering

Environment: Soldering operation shall be performe d in a clean environment with

ventilation to remove soldering fume during the operation.

Soldering temperature calibration

o Temperature measuring device: The device (e.g. Anritsu Model No. HL-100)

shall be stabilized at room temperature prior to and during calibration.

o Timing: Calibrate the soldering iron tip before the operation or every 30

minutes after the soldering.

o Procedure

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 32/40

Page 34

USER MANUAL V0.904

STM110C

(a) In Pb alloy soldering, the soldering iron shall be set up and stabilized

at 240°C before and in the calibration. For Pb-free solder wire, the soldering iron shall be set up and stabilized at 255°C before and in the

calibration.

(b) Take little solder wire on the solderin g iron tip and put the tip in con-

tact with the contact-pad of the temperature meter for 1 minute.

(c) Temperature shown on the temperature meter shall be 255°C (Pb-

free) at least for one minute otherwise re-adjust the temperature setting of the soldering iron.

Soldering operation

Step 1: Make soldering iron tip and solder wire contact with the copper paste

of solar cell together. At this moment, tin pot formed in a shape of

half ball type or makes a plane type on the copper paste. All the

processes shall be well done less than 2 seconds.

Step 2: Melt solder wire on the top of solder lead wire. Weld the tin pot

again and put the lead wire into the inside of tin pot. Take off the

solder iron tip. Finish this step within 2 second also.

Soldering operation on the solar cell shall be non-destructive. At any time, only

make the soldering iron tip contact the copper paste of the solar cell less than

2 seconds.

Attention

o Hold the soldering iron at an angle of 30° to 45° with the solar cell in the

welding process

o Lead wire is in the contact with the copper paste at an angle of 15°

o Make sure the welding process not more than the time limit and th e l ead

wire in good contact with copper paste through the solder. Please watch

out the loose contact between the lead wire and the copper paste if any

o Do not move the lead wires and solar cell before cooling the tin pots

o Weld soldering is always with smooth surface and with shine.

Test criteria

o Pull strength in vertical direction: more than 500 gram

o Pull strength in horizontal direction: more than 200 gram

Note 1: For pull strength test, the lead wire used should be 28-30 AWG multi-

threads stranded type

Note 2: Lead wire breakage is excluded

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 33/40

Page 35

USER MANUAL V0.904

STM110C

Operation illustration

Step 1 Step 2 Step 3 Step 4

Some solder

Soldering iron

Temperature meter

The function of the solar module may be impaired by exceeding the recommended

soldering temperature and the specified soldering ti me!

SOLAR CELL

Less than 2 sec

Solder

Solder

Lead

wire

Some solder

30°-45°

SOLAR

Less than 2 sec

CELL

Lead

15°

Gluing

Loctite 403 XE16-508

Figure 10: Gluing the solar cell

Instead of soldering it is also possible to glue the solar cell onto a PCB.

It is proposed to use the following adhesives:

a) GE Bayer Silicones XE16-508 (electroconductive adhesive)

b) Loctite 403 (to increase mechanical stability)

First the XE16-508 is put onto the contact pads of the solar cell. Then a drop of Loctite 403

is put in the middle of the solar cell.

After that the solar cell is put onto the PCB. Then the solar cell is pressed onto the PCB accompanied by small rotary movements (<<1mm).

Wear gloves to avoid finger prints on solar cell!

The curing time of Loctite 403 is only 5 seconds once the solar cell is pressed onto the PCB.

Positioning must be finished by then!

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 34/40

Page 36

USER MANUAL V0.904

STM110C

Corrosion protection

Corrosion protection is essential to the lifetime of the solar module. The solar module is

extremely resistant to temperature effects. But mounting must particularly provide protection against humidity. The proper choice of suitable sealing material is important.

The best method is protection by a transparent cover, mainly important for outdoor applications. Also well-suited is a casing by silicone (not acrylic!). With every kind of protection

solution, it is very important that the cell edges and the metallic contact areas are covered.

Figure 11: Examples of solar cell mounting

Shade

During installation, care should be taken to ensure that the active photovoltaic area is not

shaded. The cells (strips), which produce the least current due to shade, determine the

total module current.

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 35/40

Page 37

USER MANUAL V0.904

STM110C

3.6 Using an Alternative Power Supply, e.g. Battery

Alternatively to the use of the supplied solar cell, the module power supply input V_SC1 can

be driven by another suitable external energy source.

The external energy source must fulfill the following requirements:

Parameter Min Typ Max Unit

Open circuit voltage 2.2 5.0 V

Ampacity (Peak) 10 mA

Ampacity (continuous) 1 µA

When using a battery please take care that the transistion resistance between battery and battery holder is << 10Ω to avoid voltage drop!

Wrong polarity will damage the module!

3.7 Learn Push Button

There are two fundamental methods for transmitter assignments to a receiver:

1.) Manual input of the transmitter ID into the receiver system

2.) The receiver systems automatically learns the ID of a received radio telegram by a

special teach-in routine

In the second case please note that cyclic sending sensors can be unintentionally learned,

mainly if there are some sensors in operation at the same time. Because of that it is recommended to implement a learn procedure that is reacting to a dedicated “Learn Telegram”

only. This special learn procedure has to be realized by the system intelligence after

TCM200C/TCM210C serial interface. For example this can be realized as follows.

Recommendation for the realization of a learn push button:

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 36/40

Page 38

USER MANUAL V0.904

STM110C

4 AGENCY CERTIFICATIONS

4.1 FCC (United States) Certification

STM110C LIMITED MODULAR APPROVAL

This is an RF module approved for Limited Modular use operating as an intentional transmitting device with respect to 47 CFR 15.231(a-c) and is limited to OEM installation. The

module is optimized to oper ate using small amounts of harvested energy, such as can be

collected by a small solar cell exposed to ambient light. The module transmits short radio

packets comprised of control signals, (in some cases the control signal may be accompanied with data) such as those used with alarm systems, door openers, remote switches,

and the like. The module does not support continuous streaming of voice, video, or any

other forms of streaming data; it sends only short packets containing control signals and

possibly data and is typically powered by a solar cell in ambient li ght. The module is designed to comply with, has been tested according to 15.231(a-c), and has been found to

comply with each requirement. Thus, a finished device containing the STM110C radio module can be operated in the United States without additional Part 15 FCC approval (approval(s) for unintentional radiators may be required for the OEM’s finished product), under

EnOcean’s FC C ID num be r. Thi s gr ea tly sim pli fies and shortens the design cycle and development costs for OEM integrators.

The module can be triggered manually or automatically, which cases are described below.

Manual Activation

The radio module can be configured to transmit a short packetized control signal if

triggered manually. The module can be triggered, by pre ssing a switch, for example. The packet contains one (or more) control signals that is(are) intended to control something at the receiving end. The packet may also contain data. Depending

on how much energy is available from the energy source, subsequent manual triggers can initiate the transmission of additional control signals. This may be necessary if prior packet(s) was(were) lost to fading or interference. Subsequent triggers

can also be initiated as a precaution if any doubt exists that the first packet didn’t

arrive at the receiver. Each packet that is transmitted, regardless of whether it was

the first one or a subsequent one, will only be transmitted if enough energy is available from the energy source.

Automatic Activation

The radio module also can be configured to transmit a short packetized control signal if triggered automatically, by a relevant change of its inputs, for example.

Again, the packet contains a control signal that is intended to control something at

the receiving end and may also contain data. As above, it is possible for the packet

to get lost and never reach the receiver. However, if enough energy is available

from the energy source, and the module has been configured to do so, then another

packet or packets containing the control signal may be transmitted at a later, unpredictable time.

OEM Requirements

In order to use EnOcean’s FCC ID number, the OEM must ensure that the following conditions are met.

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 37/40

Page 39

USER MANUAL V0.904

STM110C

End users of products, which contain the module must not have the ability to alter the

firmware that governs the operation of the module. The agency grant is valid only when

the module is incorporated into a final product by OEM integrators.

The end-user must not be provided with instructions to remove, adjust or install the

module.

The Original Equipment Manufacturer (OEM) must ensure that FCC labeling requirements

are met. This includes a clearly visible label on the outside of the final product. Attaching a label to a removable portion of the final product, such as a ba ttery cover, is not

permitted. The label must include the following text:

Contains FCC ID: SZV-STM110C

The enclosed device complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions: (i.) this device may not cause

harmful interference and (ii.) this devi ce must accept any interference received, including interference that may cause undesired operation.

The user manual for the end product must also contain the text given above.

Changes or modifications not expressly approved by EnOcean could void the user's au-

thority to operate the equipment.

The module must be used wit h o nl y the f ollowing approved antenna(s).

Part Number Type Gain

N.A. Integrated Wire/Monopole 1.0 dBi

4.2 IC (Industry Canada) Certification

Labeling requirements for Industry Canada are similar to those required by the FCC. The

Original Equipment Manufacturer (OEM) must ensure that IC labeling requirements are

met. A clearly visible label on the outside of a non-removable part of the final product must

include the following text:

Contains IC: 5731A-STM110C

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 38/40

Page 40

USER MANUAL V0.904

STM110C

5 SPECIFICATION OF SS3513 SOLAR CELL

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 39/40

Page 41

USER MANUAL V0.904

STM110C

EnOcean GmbH

Kolpingring 18a

82041 Oberhaching

Germany

Phone +49.89.67 34 689-0

Fax +49.89.67 34 689-50

info@enocean.com

www.enocean.com

Subject to modifications

STM110C User Manual V0.904

February 18, 2008 2:00 PM

Page 40/40

Loading...

Loading...