Ennera Windera S Installation & Maintenance Manual

Code: I.H4.V10.3003

Installation and Maintenance Manual Version: 07

Installation and Maintenance

Manual

Windera S wind turbine

Ennera Energy and Mobility S.L.

1 / 66

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

Ennera Energy and Mobility, S.L.

Code: I.H4.V10.3003

Installation and Maintenance Manual Version: 07

CONTENTS

1. INTRODUCTION ...................................................................................................................4

1.1. Aim ..............................................................................................................................4

2. PRIOR CONSIDERATIONS ....................................................................................................5

3. PACKING LIST ......................................................................................................................5

4. LIST OF ASSEMBLY TOOLINGS .............................................................................................6

4.1. Foundation ..................................................................................................................6

4.2. Elevation ......................................................................................................................6

4.3. Tower assembly ...........................................................................................................7

4.4. Wind turbine assembly ................................................................................................7

5. INSTALLATION .....................................................................................................................8

5.1. Foundation ..................................................................................................................8

5.2. Ennera design multi-section tower assembly ............................................................. 13

5.3. Ennera design 2-section tower assembly .................................................................... 17

5.4. Ambor design 3 section tower assembly .................................................................... 17

5.5. Lifting mechanism ...................................................................................................... 17

5.6. Anemometer installation ........................................................................................... 21

5.7. Small Wind Turbine assembly .................................................................................... 21

5.7.1. Windera S packaging ........................................................................................................................ 21

5.7.2. Yaw.................................................................................................................................................. 22

5.7.3. Generator ........................................................................................................................................ 23

5.7.4. Rotor................................................................................................................................................ 24

5.7.5. Tail .................................................................................................................................................. 26

5.8. Electrical connections ................................................................................................ 26

5.8.1. Converter set .................................................................................................................................... 26

5.8.2. Cable connections............................................................................................................................. 28

5.8.3. Electrical scheme .............................................................................................................................. 31

5.8.4. Anemometer .................................................................................................................................... 31

5.9. Wind turbine erection ................................................................................................ 32

6. SCREW KITS ....................................................................................................................... 35

6.1. Tower assembly kit .................................................................................................... 35

6.2. Wind turbine assembly kit ......................................................................................... 35

6.3. Anemometer assembly kit ......................................................................................... 36

6.4. Converter assembly kit............................................................................................... 36

7. COMMISSIONING .............................................................................................................. 36

7.1. Load new firmware .................................................................................................... 36

7.2. Change parameters .................................................................................................... 37

2 / 66

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

Ennera Energy and Mobility, S.L.

Code: I.H4.V10.3003

Installation and Maintenance Manual Version: 07

8. MAINTENANCE.................................................................................................................. 41

8.1. Safety procedures ...................................................................................................... 41

8.2. Routine inspections ................................................................................................... 41

8.3. Maintenance plan ...................................................................................................... 42

9. TROUBLESHOOTING .......................................................................................................... 43

10. FREQUENTLY ASKED QUESTIONS .................................................................................. 43

11. RECYCLING .................................................................................................................... 44

12. LOGBOOK ...................................................................................................................... 45

13. ANNEX 1: GENERAL DIMENSIONS DRAWING ................................................................ 46

14. ANNEX 2: SINGLE LINE DIAGRAM .................................................................................. 47

15. ANNEX 3: ELECTRICAL SCHEME ..................................................................................... 48

16. ANNEX 4: INSTALLATION CONTROL FORM .................................................................... 49

17. ANNEX 5: MAINTENANCE CONTROL FORM ................................................................... 52

18. ANNEX 6: INSTALLATION DRAWINGS ............................................................................ 54

19. ANNEX 7: LIST OF ALARMS ............................................................................................ 63

3 / 66

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

Ennera Energy and Mobility, S.L.

Code: I.H4.V10.3003

Installation and Maintenance Manual Version: 07

1. INTRODUCTION

1.1. Aim

This Installation and Maintenance Manual describes the procedures to be carried out in order to

satisfy the requirements of the installation and maintenance process of the Windera S small wind

turbine (SWT).

4 / 66

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

Ennera Energy and Mobility, S.L.

Code: I.H4.V10.3003

Installation and Maintenance Manual Version: 07

2. PRIOR CONSIDERATIONS

ONLY TRAINED PERSONNEL SHOULD INSTALL A WINDERA S WIND TURBINE.

A wrong installation of the turbine could lead to a serious damage.

Read this procedure carefully before starting any installation.

The Windera S wind turbine must not be installed with a wind speed average greater

than 10m/s. The loads at this wind speed could cause damage in the tower base and

pivoting point.

During wind turbine installation, the area surrounding the wind turbine should be free of people

not related with the installation.

FAILURE TO FOLLOW THE PROCEDURES DESCRIBED IN THIS MANUAL CAN CAUSE

SERIOUS INJURY.

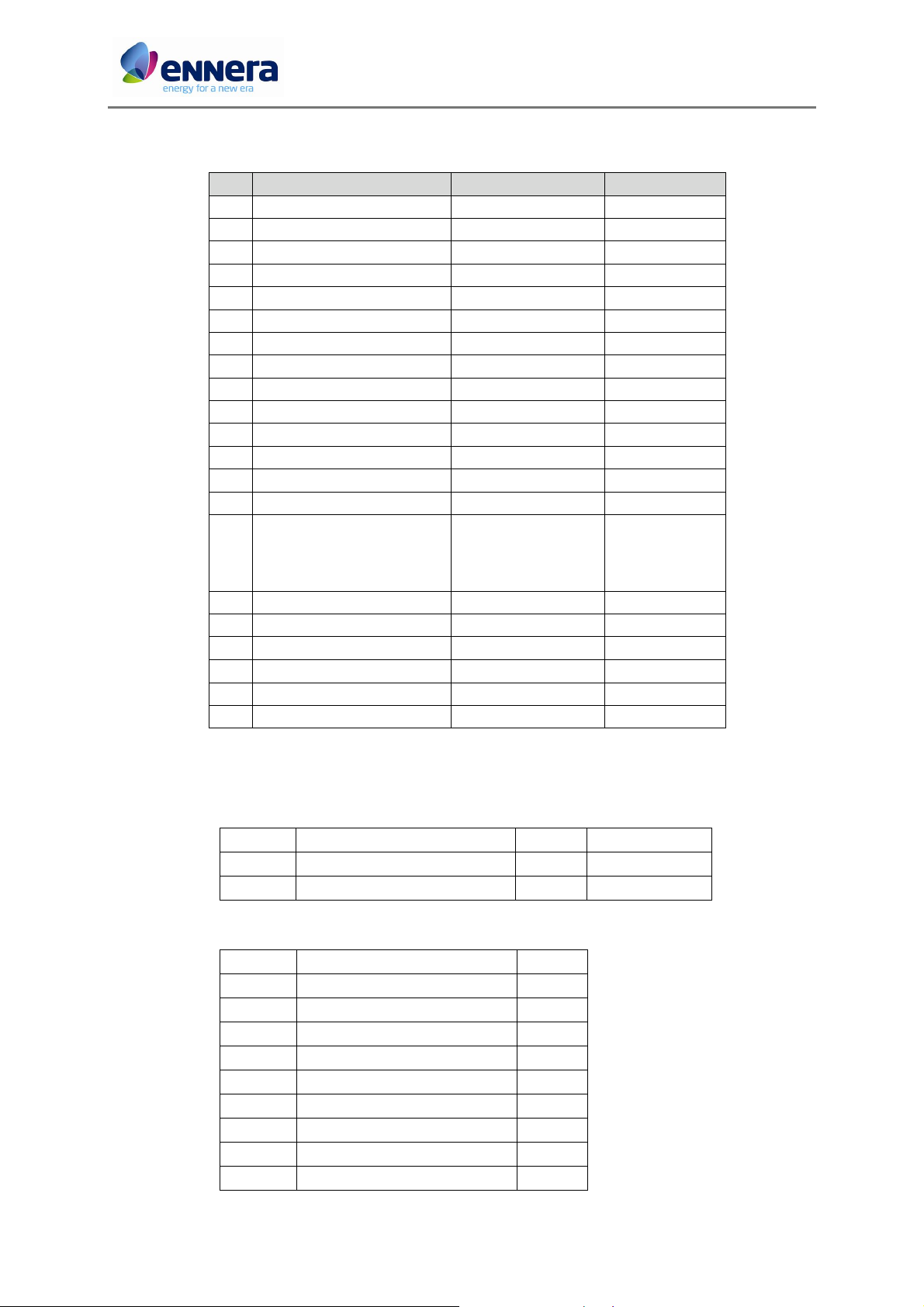

3. PACKING LIST

The Windera S small wind turbine is supplied in 2 packages: One with the tower and one with

the wind turbine.

5 / 66

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

Ennera Energy and Mobility, S.L.

Code: I.H4.V10.3003

Installation and Maintenance Manual Version: 07

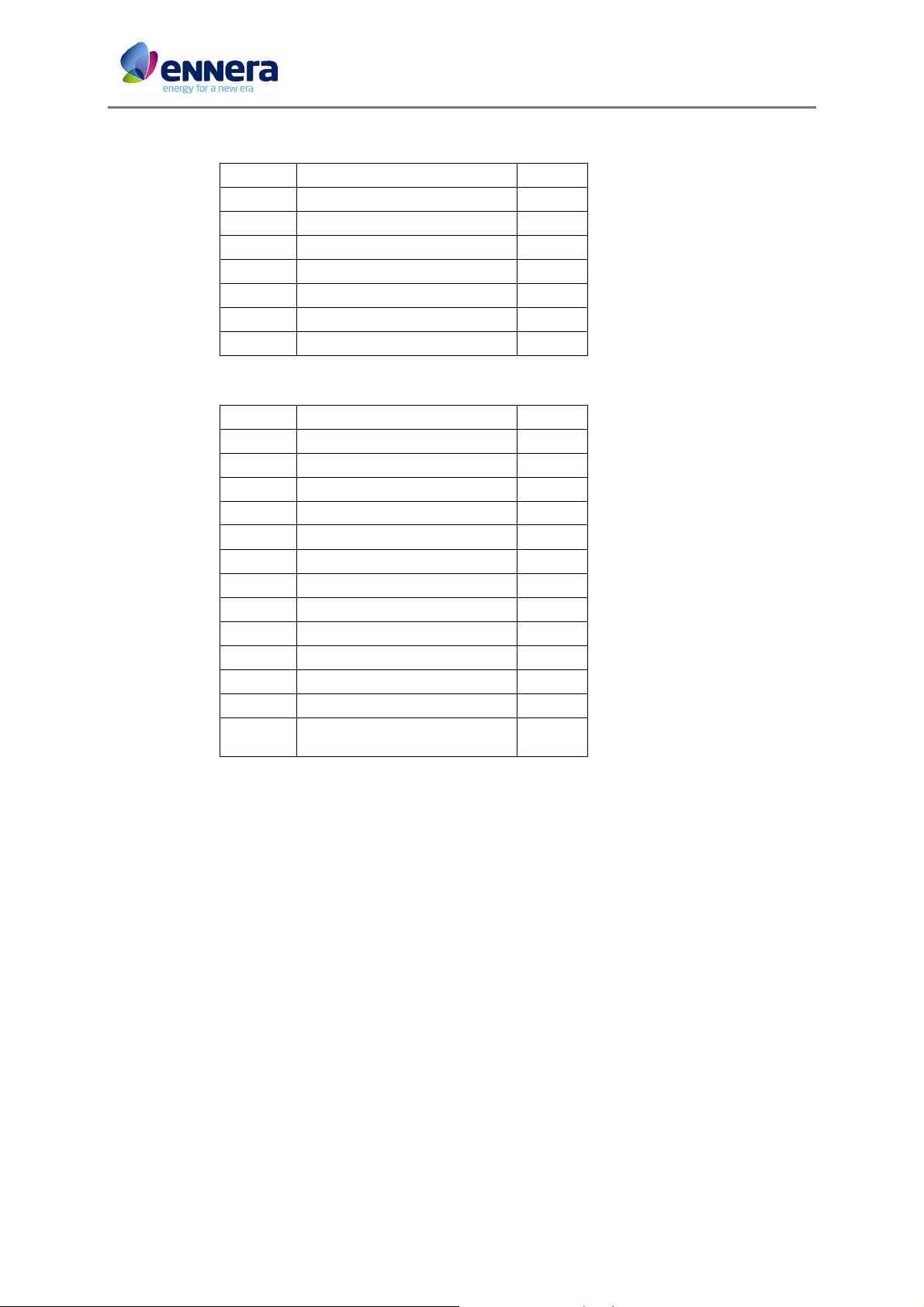

Inside the wind turbine package there are the following components:

COMPONENT CODE UNITS

W1 Generator JI.H4.G5.4000.00 1

W2 Brake JI.H4.K5.4000.00 1

W3 3 blade set JI.H4.B5.4000.01 1

W4 Converter JI.H4.P5.4000.01 1

W5 Tail JI.H4.N5.4000.01 1

W6 Yaw JI.H4.Y5.4000.00 1

W7 Tower cable (3x6mm2) JI.H4.P5.4000.05 1

W8 Cone JI.H4.B5.4000.05 1

W9 Hub JI.H4.B5.4000.04 1

W10 Hub bushing JI.H4.B5.4000.06 1

W11 Blade fixing plate JI.H4.B5.4000.07 3

W12 Yaw cover JI.H4.Y5.4000.50 1

W13 Converter housing JI.H4.P5.4000.04 1

W14 Converter structure JI.H4.P5.4000.02 1

JI.H4.V5.4000.03

W15 Screw kits (4 ref.)

JI.H4.P5.4000.07

JI.H4.T5.4000.05

JI.H4.T5.4000.13

W16 Earthing cable JI.H4.P5.4000.06 1

W17 Elevation cable 8.3m JI.H4.T5.4000.06 1

W18 Shackle 3.25Tn JI.H4.T5.4000.10 1

W19 Anemometer JI.H4.T5.4000.11 1

W20 Anemometer structure JI.H4.T5.4000.12 1

W21 Nameplate JI.H4.V5.4000.06 1

1

1

1

1

4. LIST OF ASSEMBLY TOOLINGS

4.1. Foundation

Reference Tooling Nº units Drawing

FD-1 Tower bolts 8 JI.H4.T5.4000.04

FD-2 Bolts position tooling 1 JI.H4.V10.4000.51

4.2. Elevation

Reference Tooling Nº units

EL-1 Tractel ground fixing point 1

EL-2 Fixing point tooling 1

EL-3 Tractel 1600 kg 1

EL-4 Shackle 3.25Tn 2

EL-5 Tractel cable 15m 1

EL-6 GinPole Ø114.3mm, L=4m 1

EL-7 Hydraulic jack 2

EL-8 Hexagon bolt M20x180 1

EL-9 Spanner 46 1

6 / 66

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

Ennera Energy and Mobility, S.L.

Code: I.H4.V10.3003

Installation and Maintenance Manual Version: 07

4.3. Tower assembly

Reference Tooling Nº units

TW-1 Ratchet tensioner 15m 2

TW-2 Metallic mallet 1

TW-3 Molykote spray (grease) 1

TW-4 Cable guide 1

TW-5 Galvanizing spray 1

TW-6 Level 2

TW-7 Trestle 1

4.4. Wind turbine assembly

Reference Tooling Nº units

WT-1 Allen keys 1

WT-2 Torque wrench 30-200Nm 1

WT-3 Spanner nº 17 1

WT-4 Spanner nº 19 1

WT-5 Spanner nº 50 1

WT-6 Loctite 243 Threadlocker 1

WT-7 Rotor extraction M20 screw 1

WT-8 Ratchet set with sockets 1

WT-9 Round file Ø10mm 1

WT-10 Screwdriver set 1

WT-11 RAL 9003 matt colouring spray 1

WT-12 Galvanizing spray 1

Set of steel inserts for aluminium

WT-13

(Helicoil type-M5, M6, M8, M10)

1

7 / 66

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

Ennera Energy and Mobility, S.L.

Code: I.H4.V10.3003

Installation and Maintenance Manual Version: 07

5. INSTALLATION

5.1. Foundation

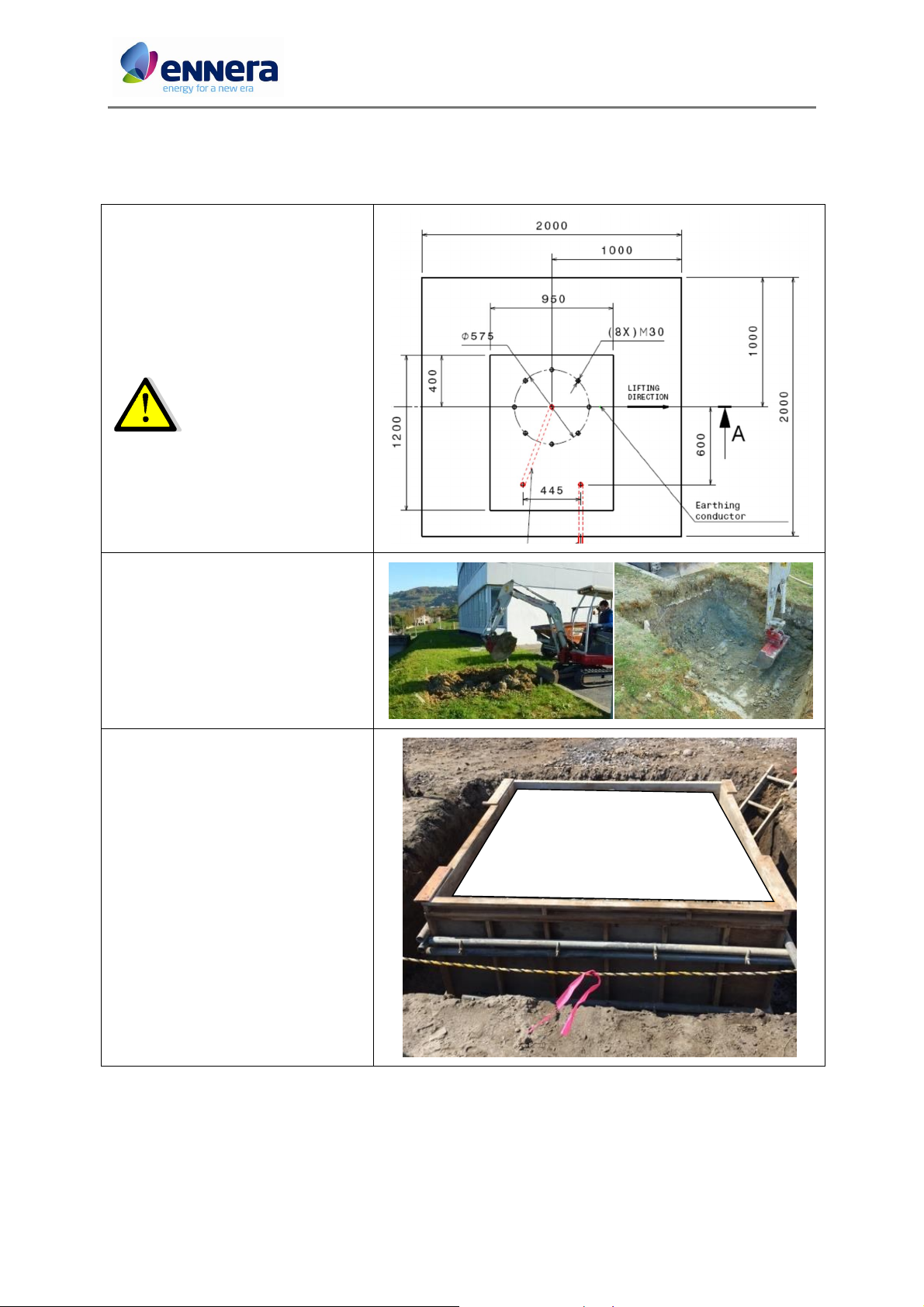

See drawing JI.H4.V10.4000 (Annex 4)

for foundation construction details.

The foundation must be

done at least 3 weeks

before wind turbine

installation.

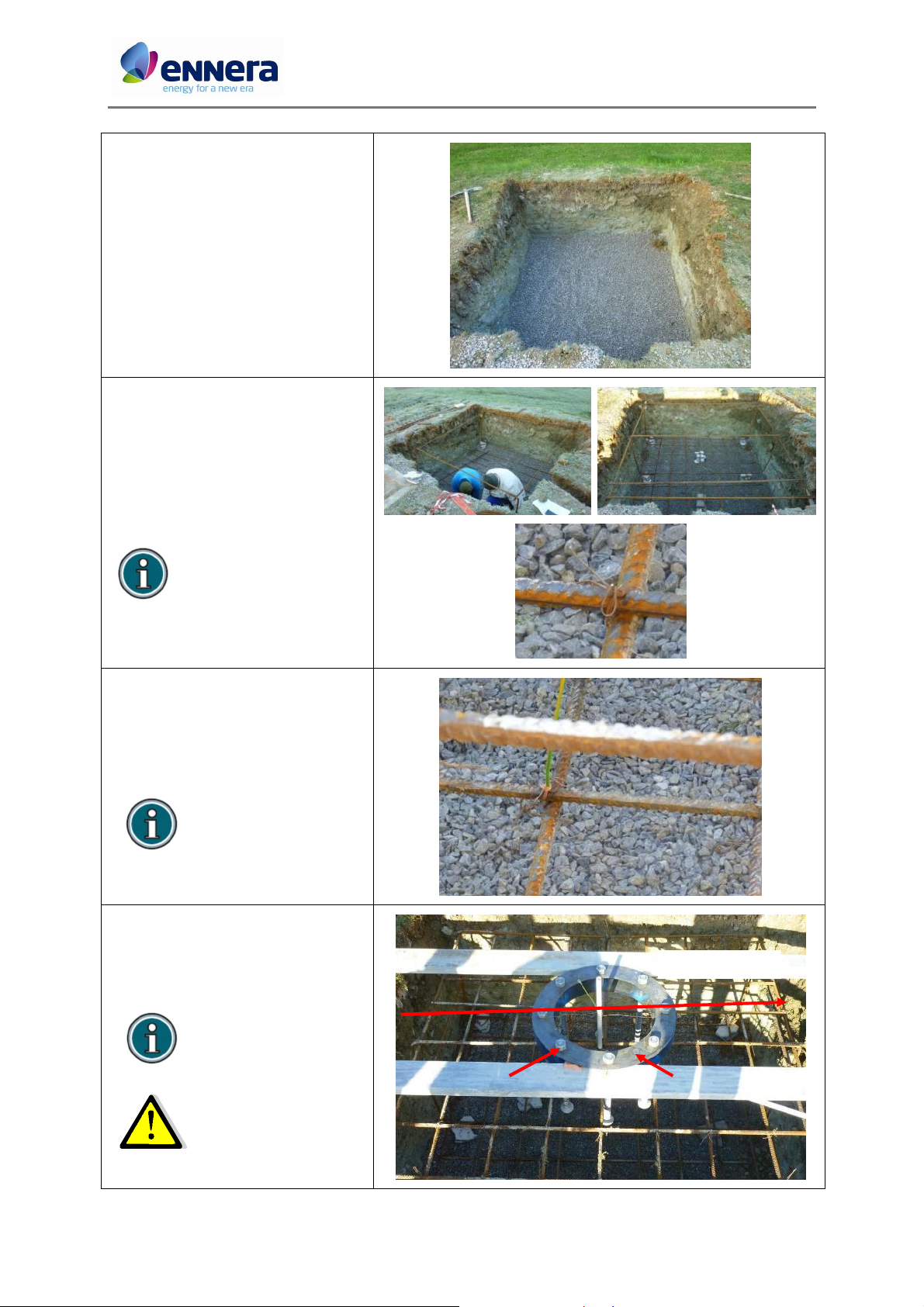

1. Make a hole of 2x2m and 1m depth.

2. If the soil is not consistent, make a

box of wood to sustain the walls of the

hole.

8 / 66

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

Ennera Energy and Mobility, S.L.

Code: I.H4.V10.3003

lifting direction

Installation and Maintenance Manual Version: 07

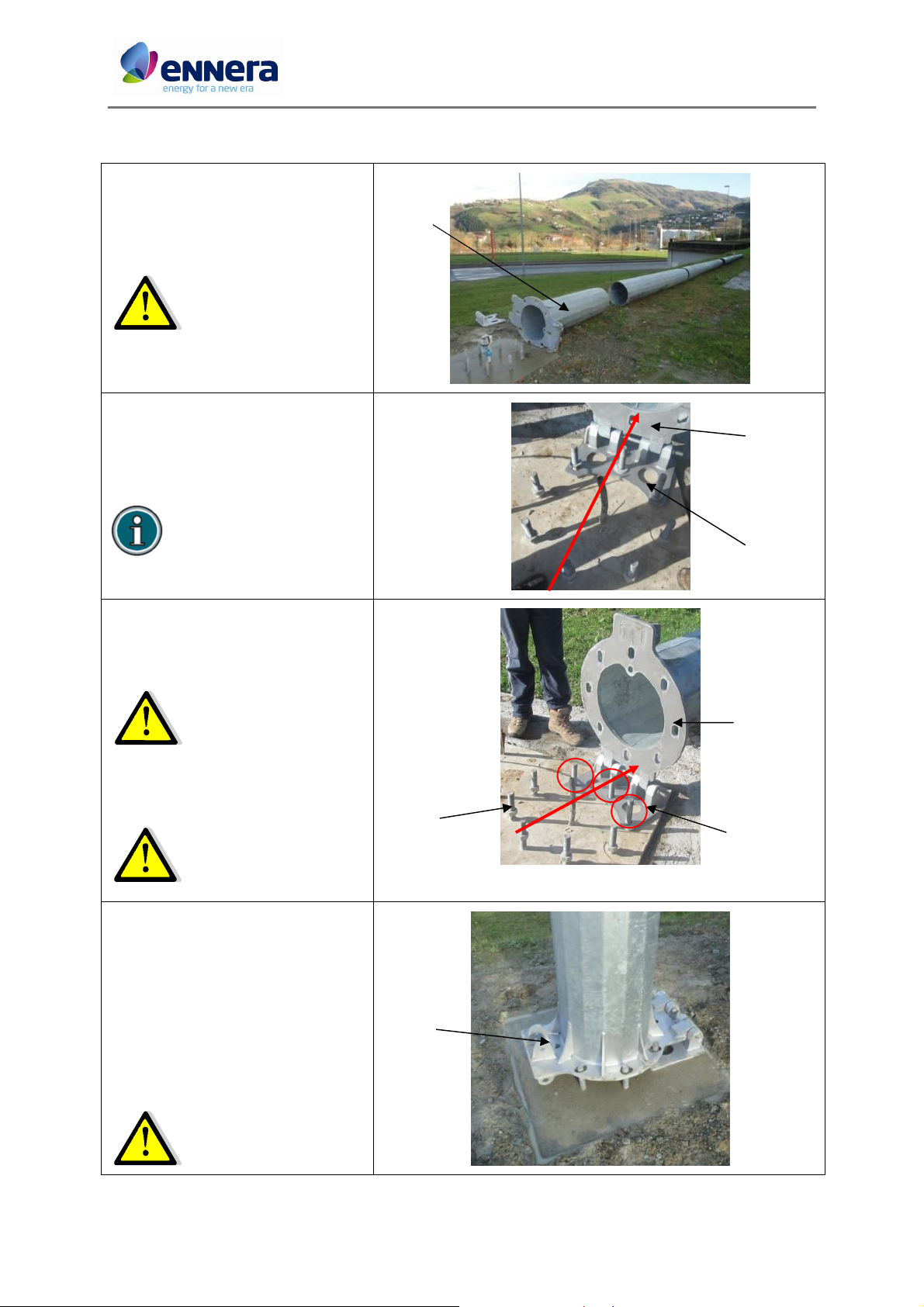

3. Add a 75mm of thick plain cement

concrete layer.

4. Place the foundation reinforcement

steel bars inside the hole, fixing the bars

between them with metallic wire (up

and bottom).

Lower reinforcement at a

distance of 100mm from

plain cement concrete.

5. Attach an earthing cable of 6mm2 to

the bottom part of the reinforcement

bars.

(Foundation earthing

cable not supplied.

Length = 2m)

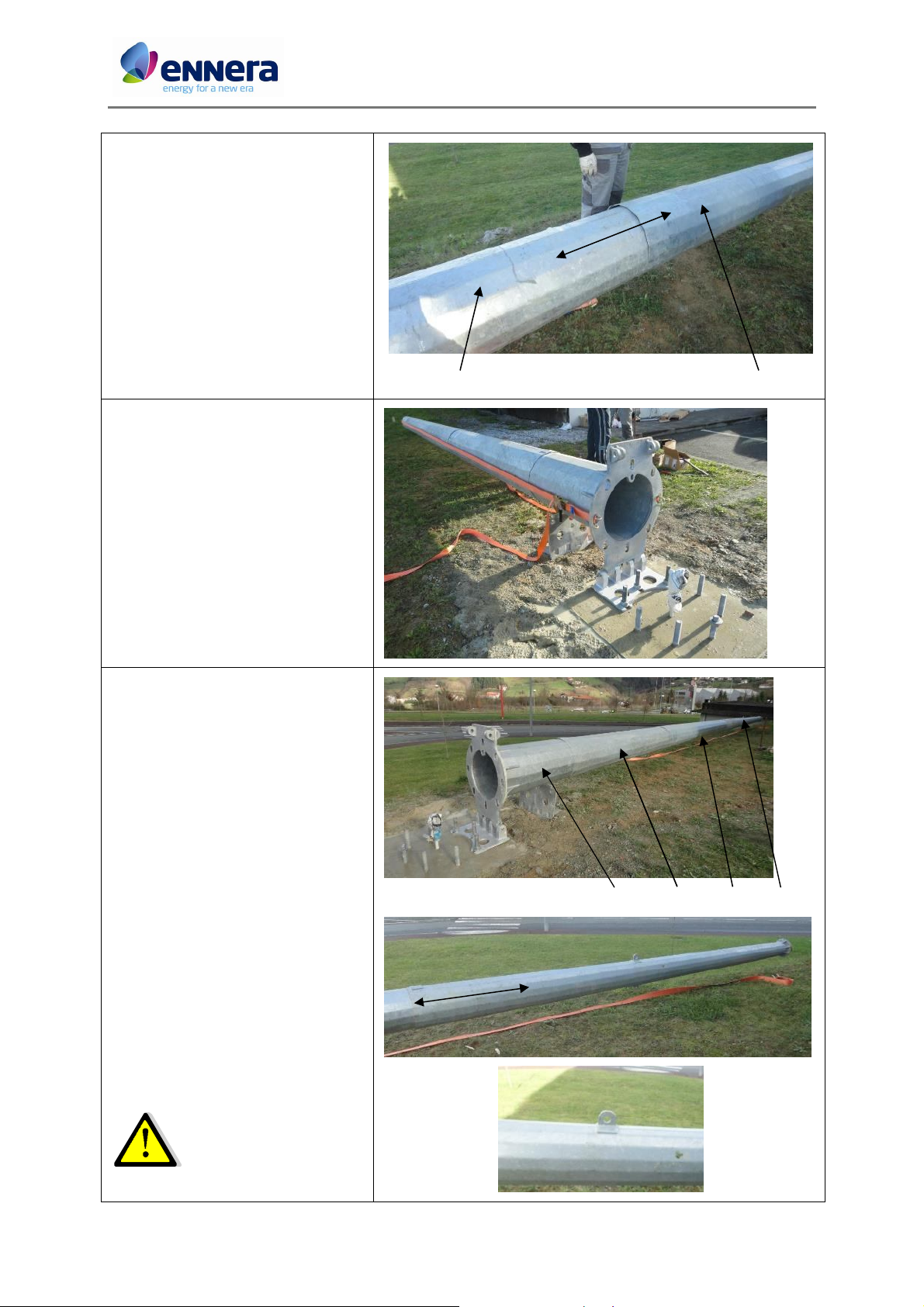

6. Place the 8xM30 fixing steel bolts

(FD-1) with the template (FD-2), so that

the 8 bars are perfectly vertical and

concentrically to tower axis.

Follow dimension of the

drawing “Bolts position

tooling” in Annex 4.

FD-1 FD-2

2 bolts must be aligned

with the lifting direction.

After placing the template, level it.

9 / 66

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

Ennera Energy and Mobility, S.L.

Code: I.H4.V10.3003

Installation and Maintenance Manual Version: 07

7. Place the Ø32mm corrugated tube.

One from the tower axis to the

converter and the other from the

converter to the grid connection point.

Avoid sharp corners in the

corrugated tube.

8. The other part of the earthing

conductor must be out of the

foundation at least 1m, from the middle

point of the fixing bolts.

9. Review the levelling of the template

with the bolts and the lifting direction.

10 / 66

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

Ennera Energy and Mobility, S.L.

Code: I.H4.V10.3003

Installation and Maintenance Manual Version: 07

10. Pour the concrete inside the hole.

Reinforced Cement Concrete (minimum

30N/mm2 at 28 days).

11. During the concrete pouring, review

the levelling of the template with the

bolts and the lifting direction.

12. Finish pouring the concrete until it

has reached the mark in the bolts

(185mm of the bolt out of the concrete)

and vibrate the concrete.

13. Review the levelling and the

alineation of the bolts.

In case the top surface

finishing is good, 160mm of

the bolt out of the

concrete.

11 / 66

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

Ennera Energy and Mobility, S.L.

Code: I.H4.V10.3003

160mm

Installation and Maintenance Manual Version: 07

14. In case the top surface finishing of

the foundation is good (flat and

smooth), the foundation is finished.

15. In case the finishing of the top

surface is not good, a final layer must be

added.

16. When the concrete is cured, remove

the fixing bolts template. Make a

rectangle of wood and pour a 25mm

layer with non shrink grout according to

the drawing.

The bolt must have 160mm

out of the non shrink grout.

17. Take away, with the help of a

hammer, the 4 pieces of wood located

around the foundation and cover the

concrete area with the soil removed

from the hole.

12 / 66

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

Ennera Energy and Mobility, S.L.

Code: I.H4.V10.3003

T0T1

Lifting

direction

T0 T1 FD-1

Installation and Maintenance Manual Version: 07

5.2. Ennera design multi-section tower assembly

First

section

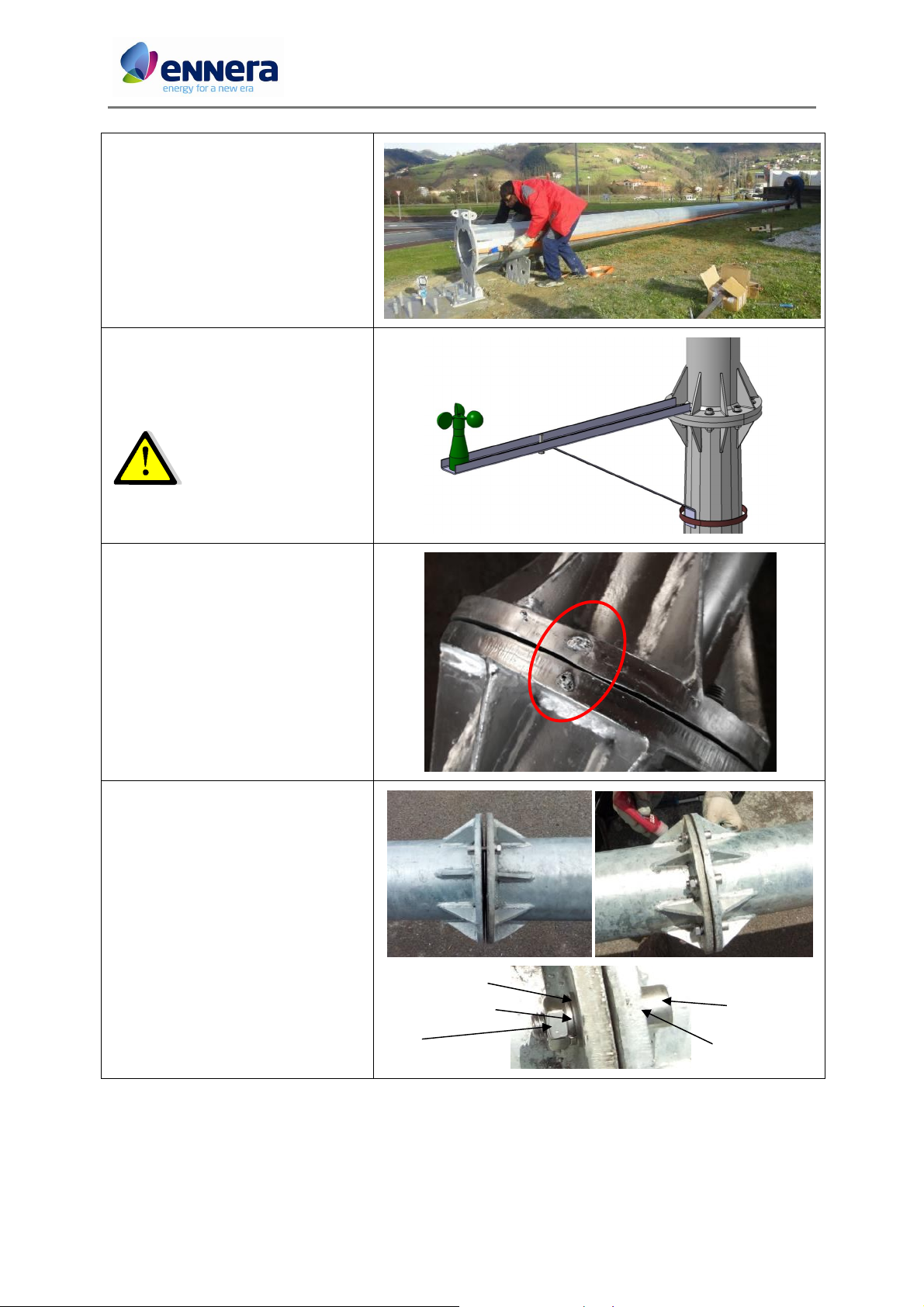

1. Put the tower sections in a

sequential way close to the foundation.

The tower first section

should be located next to

the foundation.

2. Join the first section and the tower

base plate with the J bolt M20x500 as

shown in the figure.

Place the base plate in the

middle of the lifting

direction as shown in the

figure.

3. Place the first section and the tower

base plate over the foundation bolts

(FD-1) as shown in the figure.

Make sure that the base

plate is aligned with the

lifting direction.

4. Fix the tower base plate to the

foundation bolts with M30 nuts.

Do not tight them fully.

Before that, alignment of

foundation bolts and base

holes should be verified.

5. Manually check the clearance of first

section holes and tower bolts:

• Put one M30 nut on the guide bolt in

order to hold the tower base section

during the checking process.

• Hold the tower base section from

top of it and pull it up.

• Ensure that the foundation bolts

pass freely through the base holes.

Guide

bolt

If there is a misalignment,

correct the position of the

base plate with a hammer.

13 / 66

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

Ennera Energy and Mobility, S.L.

Code: I.H4.V10.3003

Installation and Maintenance Manual Version: 07

6. Put the tower first section back to

previous position and tight fully the 3

M30 nuts of the tower base.

Once tightened, ensure

again that the tower fixing

bolts pass freely through

the first section holes as

shown on step 5.

7. With the tower first section in

parallel to the ground, pass the cable

guide (TW-4) through it.

The cable guide helps to

pass the tower cable

through the whole tower.

8. Insert the tower second section over

the first section. To do this:

• Ensure that the weld seam of the

new section is aligned with the

previous section.

• Pass the guide through the new

section.

• With tape, mark the interference

distance. In this case, at 520mm

from the edge.

• Apply some grease or oil over the

lower up section (interference area).

• Fit manually first and second tower

sections.

TW-4

Weld seam indicator

520 mm

The interference distance is the distance that one

section should be introduced in the previous one.

9. Adjust both sections until

interference distance mark is reached:

• Put both tractels hooks on the new

section edges.

• Secure both hooks of the other side

to the base section.

• Using the tractels adjust joined

sections until the interference

distance mark is reached.

In case that the mark

cannot be reached, put a

wooden block across the

upper section and hit it

with a mallet.

14 / 66

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

Ennera Energy and Mobility, S.L.

Code: I.H4.V10.3003

Installation and Maintenance Manual Version: 07

10. Insert the third tower section over

the second section:

• Ensure that the weld seam of the

new section is aligned with the

previous section.

• Pass the guide through the third

section.

• With tape, mark the interference

distance. In this case, at 470mm

from the edge.

• Apply some grease or oil over the

lower up section (interference area).

• Fit manually 2nd and 3rd sections.

11. Adjust both sections until in-

terference distance mark is reached by

the third section (follow step 9).

Second section Third section

470mm

12. Insert the fourth section over the

third section. To do this:

• Ensure that the weld seam of the

new section is aligned with the

previous section.

• Pass the cable guide through the

fourth section.

• With tape, mark the interference

distance. In this case, at 400mm

from the edge.

• Apply some grease or oil over the

lower up section (interference area).

• Fit manually third and fourth

sections.

T1

T2

T3 T4

400mm

The eyebolt of the fourth

section should be pointing

up as shown in the picture.

15 / 66

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

Ennera Energy and Mobility, S.L.

Code: I.H4.V10.3003

Allen screw

Plain washer

Plain washer

Grower washer

Nut

Installation and Maintenance Manual Version: 07

13. Adjust both sections until inter-

ference distance mark is reached by the

fourth section (follow step 9).

14. Before connecting the fifth section,

make the anemometer assembly.

See section 5.5.

15. To connect the fourth and fifth

sections, align the welding spot in both

sides of the flange.

16. Fix the fourth and fifth sections by

means of a flange:

• Pass the cable guide through the

fifth section.

• Using a screw as a guide, fit

manually the fourth and fifth

sections.

• Fix them with allen M12x50 screws,

washers and nuts.

• Apply Loctite 243 adhesive and tight

them with a torque of 90 Nm.

16 / 66

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

Ennera Energy and Mobility, S.L.

Code: I.H4.V10.3003

705mm

Installation and Maintenance Manual Version: 07

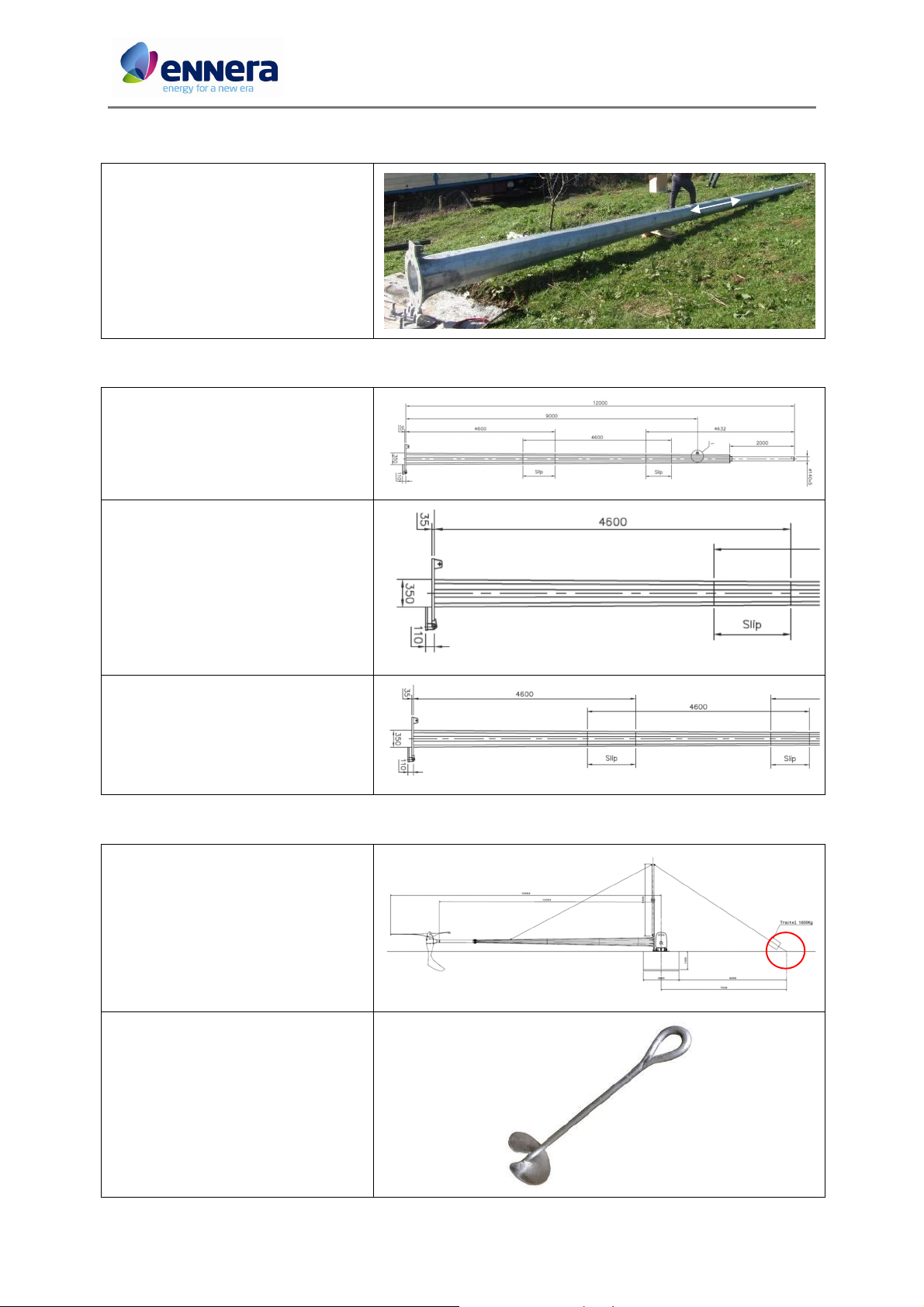

5.3. Ennera design 2-section tower assembly

1. In case the tower is a 2 section

tower (plus the cylindrical pipe), the

interference distance is 705mm.

2. The assembly process is the same

than multi-section tower.

5.4. Ambor design 3 section tower assembly

1. In case the tower is an Ambor design

3 section tower, the assembly process is

the same.

2. The interference (slip) between the

first and second tower sections is 700 ±

240mm.

3. The interference (slip) between the

first and second tower sections is 650 ±

240mm.

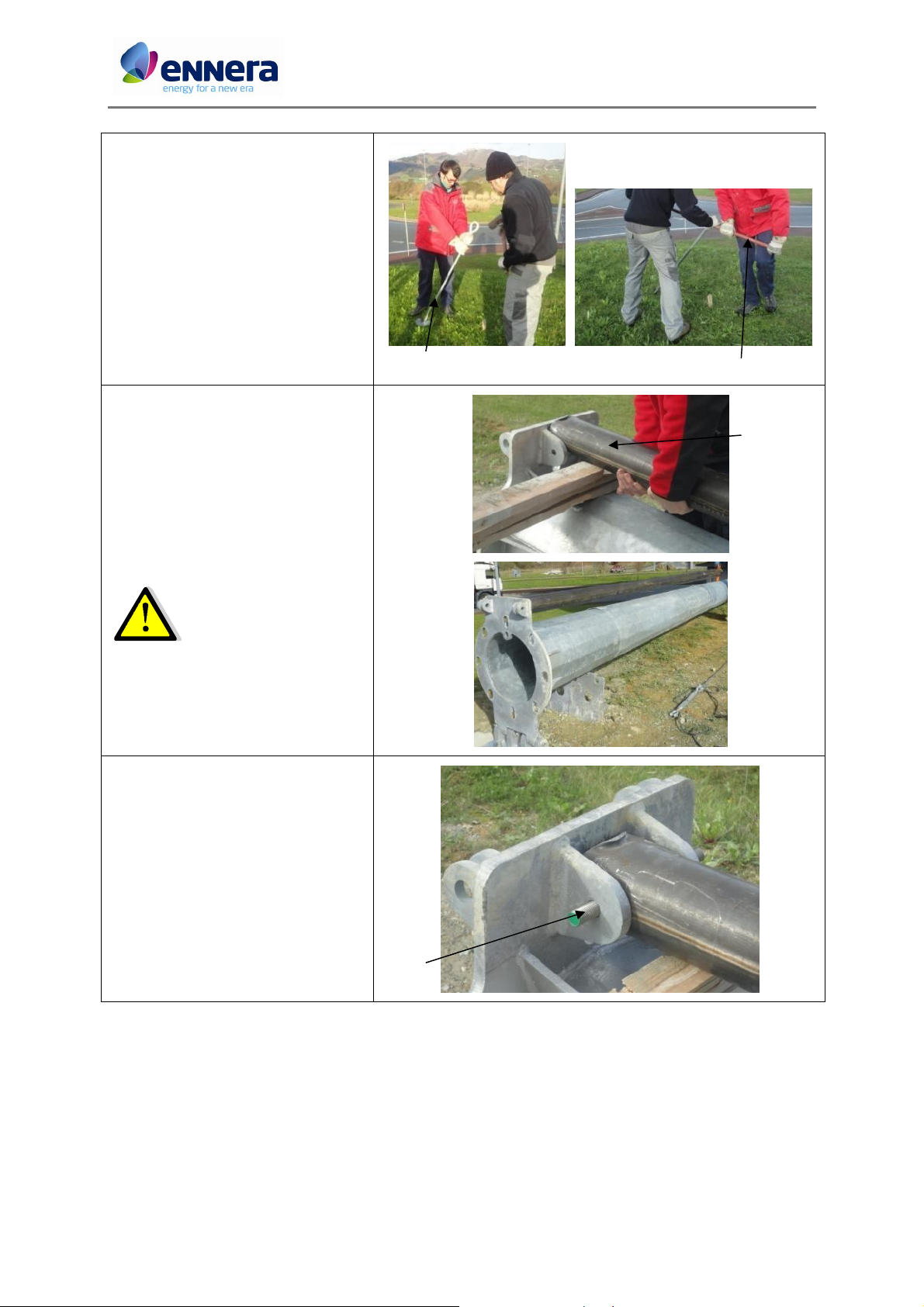

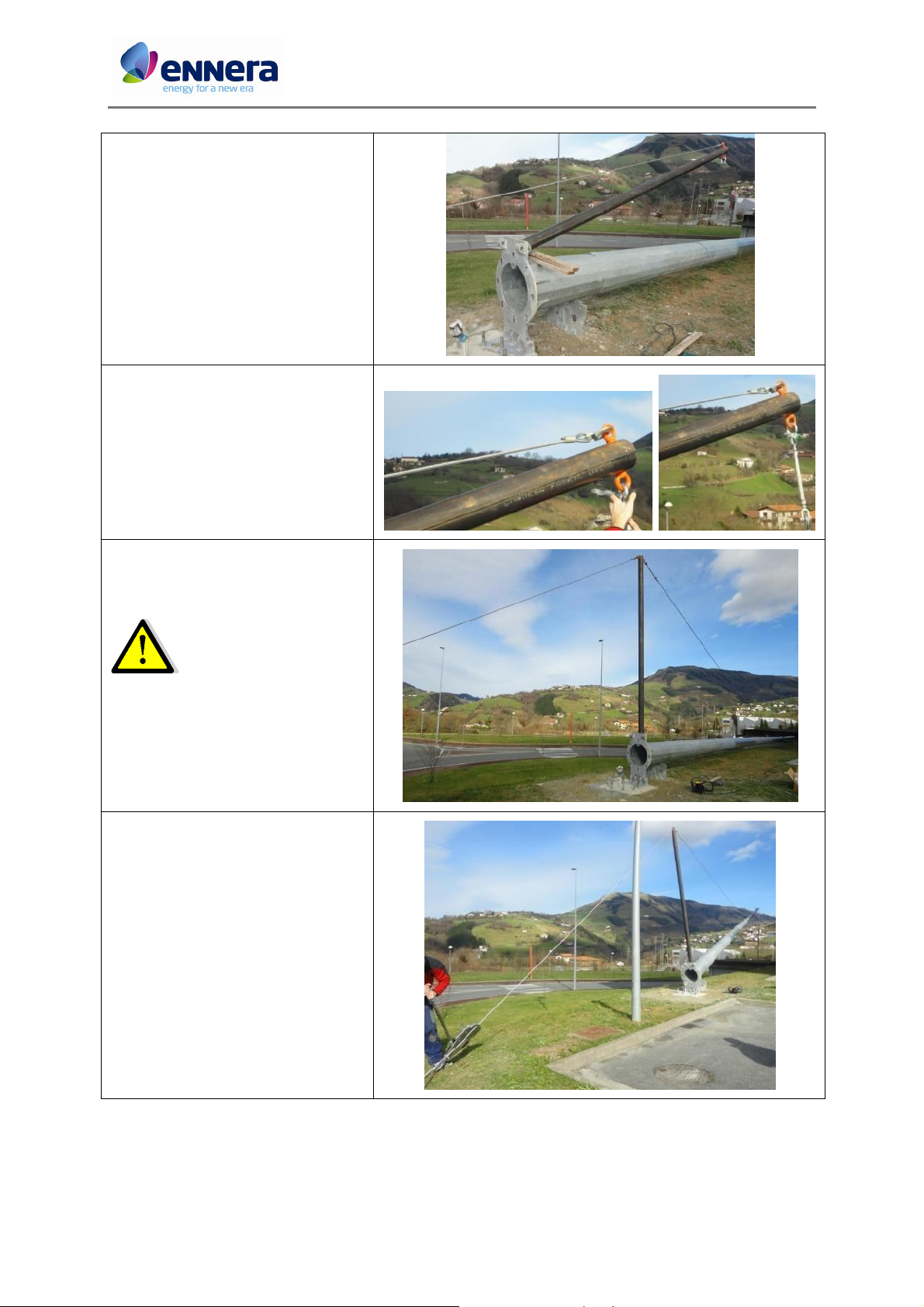

5.5. Lifting mechanism

1. The tractel fixing point should be

located 7m away from the foundation

area, aligned with the tower. See Annex

6.

2. The tractel fixing point (EL-1) should

have a disk of 150mm diameter and a

length of 1.5m.

17 / 66

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

Ennera Energy and Mobility, S.L.

Code: I.H4.V10.3003

EL-1 EL-2

EL-6

Installation and Maintenance Manual Version: 07

3. Put the ground anchor (EL-1) on the

fixing point with an angle of around 45º

(pointing to the tower) and hit it on the

top with a hammer before start

screwing.

4. With a metal rod (EL-2) inserted in

the ground anchor (EL-1) eye, start

screwing as shown in the figure.

5. After screwing the only visible part

of the ground anchor should be the eye.

6. Connect the sections of the ginpole

(EL-6) with 4 M10x40 screws.

7. Place the ginpole on the tower as

shown in the figure.

The ginpole is heavy, be

careful transporting it.

8. Fix the ginpole (EL-6) to the tower

base (T1) with a M20x180 screw (EL-8).

EL-8

18 / 66

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

Ennera Energy and Mobility, S.L.

Code: I.H4.V10.3003

Installation and Maintenance Manual Version: 07

W17

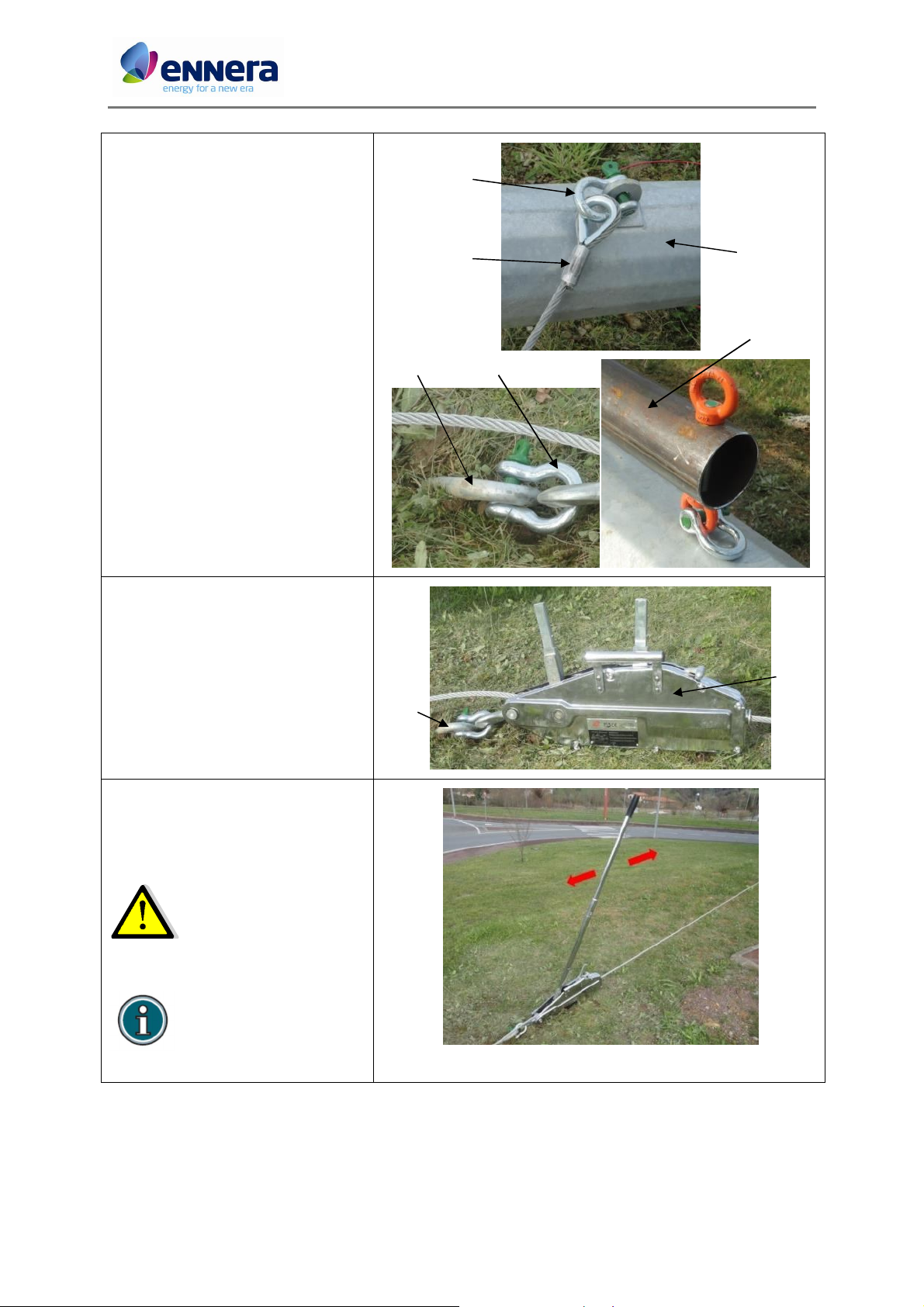

9. Connect the tower shackle (W18) to

the tower’s fourth section (T4) eyebolt.

Connect also the elevation cable (W17).

10. Connect the other shackles (EL-4) to

the ground anchor (EL-1) eye and the

ginpole (EL-6) end.

11. Connect the tractel (EL-3) to the

ground anchor (EL-1) eyebolt.

12. Insert the tractel cable trough it and

connect the other side to the top

eyebolt of the ginpole.

EL-1

EL-1

W16

T4

EL-6

EL-4

EL-3

13. Use the tractel (EL-3) in lift up mode

as shown in the figure to lift the ginpole

(EL-6) up around 1 m from the tower.

Be careful during the lifting

up process. No operators

around the ginpole and

tower while this is lifting.

If anytime the tower needs

to be lifted down during

the process, change the

helping rod of the tractel

and work in the same way

as lifting up.

19 / 66

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

Ennera Energy and Mobility, S.L.

Code: I.H4.V10.3003

Installation and Maintenance Manual Version: 07

14. Take the other tip of the elevation

cable (W17) (previously fixed to the

fourth section) and attach it to the

eyebolt of the ginpole with a shackle.

Check alignment of the

ginpole and the tower in

the lifting direction.

15. Once everything is connected,

continue lifting up the ginpole with the

tractel.

16. After the ginpole (EL-6) is in vertical

position, keep working with the tractel

(EL-3) until the tower is in vertical

position.

17. Level the nuts and washers to the

position where the tower is vertical.

18. Once the lift-up test is performed,

lift the tower down to its resting

position.

20 / 66

This document contains confidential information which is property of Ennera Energy and Mobility, S.L. The copy, transmission or use by other people, of the whole document or

part of its contents, is not allowed without written permission from Ennera Energy and Mobility S.L.

Ennera Energy and Mobility, S.L.

Loading...

Loading...