Page 1

ENMETENMET Corporation

PO Box 979

Ann Arbor, MI 48106-0979

Spectrum RAL

Compressed Air Line

Carbon Monoxide Monitor

Instrument Manual

80002-033

07/10/96

MCN #189, 04/03/98

MCN #204, 10/20/98

MCN #218, 06/15/99

MCN #246, 12/28/00

MCN #258, 07/18/01

MCN #268, 11/05/01

Page 2

Table of Contents

1.0 INTRODUCTION................................................................................................................................1

1.1 Unpack ................................................................................................................................................................................1

1.2 Check Order.......................................................................................................................................................................1

1.3 Serial Numbers .................................................................................................................................................................. 1

1.4 Check Instrument..............................................................................................................................................................2

2.0 SPECTRUM-RAL FEATURES AND INSTALLATION...............................................................................2

2.1 Features...............................................................................................................................................................................2

2.2 SPECTRUM-RAL Installation.......................................................................................................................................4

2.2.1 Mount Enclosure....................................................................................................................................................4

2.2.2 Air Supply...............................................................................................................................................................4

2.2.3 Relay Contacts.......................................................................................................................................................4

3.0 SPECTRUM-RAL OPERATION.........................................................................................................5

3.1 Operational Menu..............................................................................................................................................................5

3.2 Gas Concentration Display and Alarms ........................................................................................................................6

3.3 Alarm Acknowledge.........................................................................................................................................................6

3.4 Data......................................................................................................................................................................................6

3.5 Interference Gases ............................................................................................................................................................. 7

4.0 MAINTENANCE................................................................................................................................8

4.1 Maintenance Menu...........................................................................................................................................................8

4.2 Key.......................................................................................................................................................................................9

4.3 Zero......................................................................................................................................................................................9

4.4 Calibration ..........................................................................................................................................................................9

4.5 Changing the Alarm Level.............................................................................................................................................10

4.6 Setting a New Key..........................................................................................................................................................10

4.7 Changing Components ................................................................................................................................................... 10

5.0 REPLACEMENT PART NUMBERS ...................................................................................................... 11

6.0 WARRANTY............................................................................................................................... 12

APPENDIX A....................................................................................................................................... 13

The Characteristics and Effects of Carbon Monoxide.....................................................................................................13

List of Illustrations

FIGURE 1: SPECTRUM-RAL F EATURES ................................................................................................3

FIGURE 2: SPECTRUM-RAL INTERIOR VIEW ..........................................................................................4

TABLE 1: RELAY CONNECTIONS TO TERMINAL STRIP..................................................................................4

FIGURE 3: OPERATION M ENU DIAGRAM ...................................................................................................5

TABLE 2: KNOWN INTERFERENCE GASES .................................................................................................7

TABLE 3: KNOWN GASES WITH NO RESPONSE...........................................................................................7

FIGURE 4: MAINTENANCE M ENU DIAGRAM ...............................................................................................8

FIGURE 5: REMOVE SHORTING CLIP......................................................................................................10

FIGURE 6: % COHB VS TIME................................................................................................................ 13

Page 3

SPECTRUM RAL ENMET Corporation

1.0 Introduction1.0 Introduction

The SPECTRUM-RAL carbon monoxide monitor is a small 110 VAC operated instrument for the detection of carbon

monoxide gas in compressed air lines. An electrochemical cell detects the gas, and the gas concentration is displayed

on an LCD. Audio and visual alarms occur when the gas concentration exceeds a preset alarm point. At relatively low

concentrations of CO, an alarm can be acknowledged, which results in the temporary cessation of the audio alarm.

Operation and maintenance procedures are managed with two pushbutton switches.

A description of the characteristics and toxic effects of carbon monoxide is given in Appendix A, and should be

reviewed by the user.

NOTE: All specifications stated in this manual may change without notice.

1.1 Unpack

Unpack the SPECTRUM-RAL and examine it for shipping damage. If such damage is observed, notify both

ENMET customer service personnel and the commercial carrier involved immediately.

Regarding Damaged Shipments

NOTE: It is your responsibility to follow these instructions. If they are not followed, the carrier will

not honor any claims for damage.

q This shipment was carefully inspected, verified and properly packaged at our company and delivered to the

carrier in good condition.

q When it was picked up by the carrier at ENMET, it legally became your company’s property.

q If your shipment arrives damaged:

• Keep the items, packing material, and carton “As Is.” Within 5 days of receipt, notify the carrier’s local

office and request immediate inspection of the carton and the contents.

• After the inspection and after you have received written acknowledgment of the damage from the carrier,

contact ENMET Customer Service for return authorization and further instructions. Have your Purchase

Order and Sales Order numbers available.

q ENMET either repairs or replaces damaged equipment and invoices the carrier to the extent of the liability

coverage, usually $100.00. Repair or replacement charges above that value are your company’s responsibility.

q The shipping company may offer optional insurance coverage. ENMET only insures shipments with the

shipping company when asked to do so in writing by our customer. If you need your shipments insured, please

forward a written request to ENMET Customer Service.

Regarding Shortages

If there are any shortages or questions regarding this shipment, please notify ENMET Customer Service within 5 days

of receipt at the following address:

ENMET Corporation

680 Fairfield Court

Ann Arbor, MI 48108

734-761-1270 734-761-3220 Fax

1.2 Check Order

Check, the contents of the shipment against the purchase order. Verify that the SPECTRUM-RAL is received as

ordered. If there are accessories on the order, ascertain that they are present. Check the contents of calibration kits.

Notify ENMET customer service personnel of any discrepancy immediately.

1.3 Serial Numbers

Each SPECTRUM-RAL is serialized. These numbers are on tags on the equipment and are on record in an ENMET

database.

1

Page 4

ENMET Corporation SPECTRUM RAL

1.4 Check Instrument

Turn the instrument ON, by plugging into a standard 110 VAC wall outlet and attach to your compressed air line

system. In uncontaminated air, the display should read 0000 within ten seconds of turn-on.

Check display operations by pressing the OPTION and SELECT switches as described in Figure 1.

The SPECTRUM-RAL instrument is calibrated prior to shipment. However, it is advisable to apply a known source

of carbon monoxide to the instrument to verify the sensor has not been damaged during shipment.

If there is access to a source of CO in compressed air, such as in a calibration kit, expose the sensor to CO, and

observe that the instrument is responsive.

If the concentration of CO is greater than 10 ppm, the instrument indicates an alarm condition. Acknowledge the

alarm by pressing and releasing the right hand pushbutton, SELECT; this silences the audio alarm for four minutes

unless the concentration of CO is greater than 50 PPM.

Remove source of CO. After the display reads zero or close to it, turn the instrument off, by removing the power

adapter from the wall outlet.

If the instrument does not operate as described, contact ENMET customer service personnel immediately.

2.0 2.0 SPECTRUM-RAL Features and Installation Features and Installation

2.1 Features

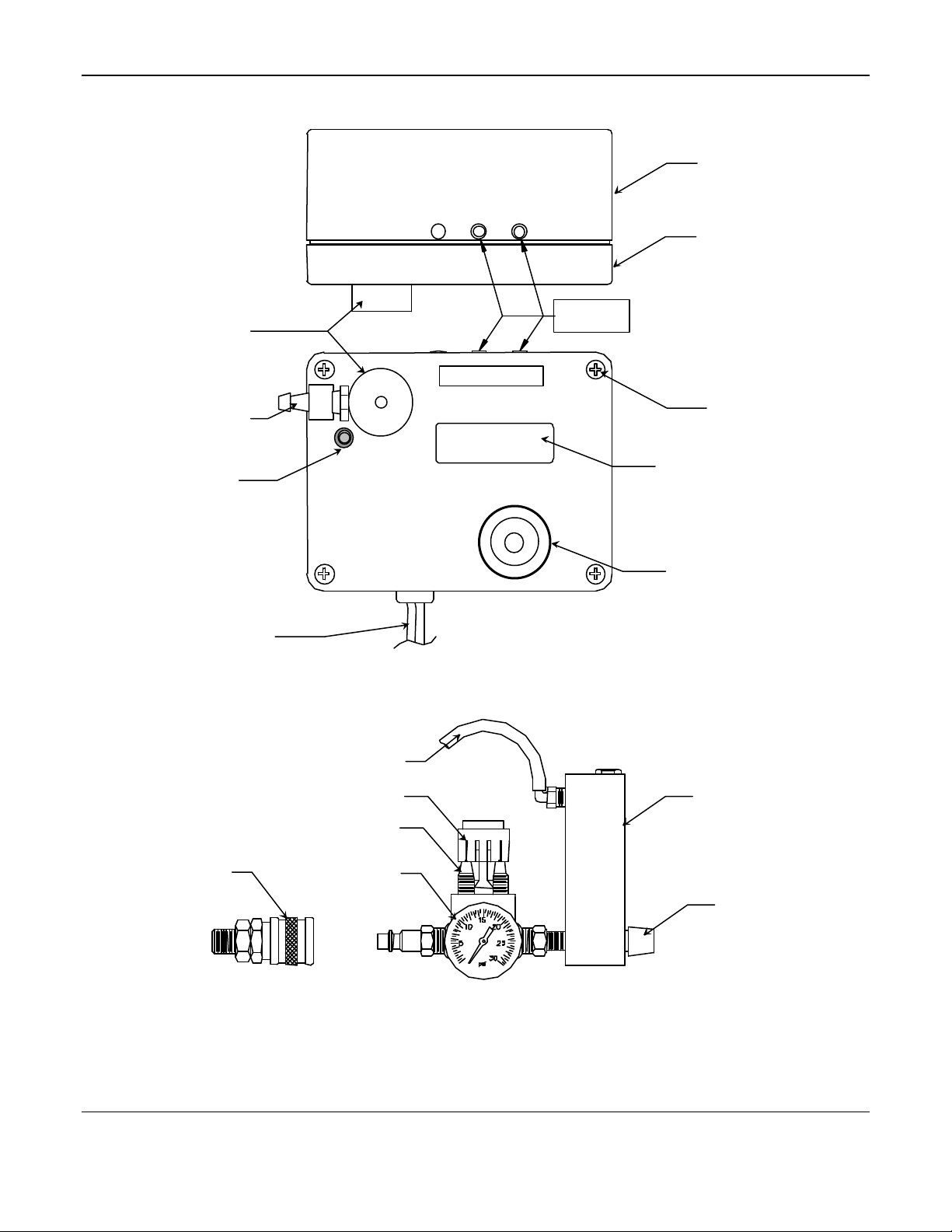

The features of the SPECTRUM-RAL Carbon Monoxide monitor are shown in Figure 1. These are:

DISPLAY LCD indicates the gas concentration, or prompts for the operational and

maintenance menus

PUSHBUTTON

SWITCHES

These switches are used to access and utilize the operational and maintenance menus.

There are two of these, as follows:

OPTION, the left hand switch.

SELECT, the right hand switch.

SENSOR HOUSING A small cylindrical turret on the display surface; the membrane of the

electrochemical sensor is exposed to the compressed air through the air supply line.

REGULATOR A pressure regulator with a gauge.

FLOWMETER Flowmeter with an adjustable valve, connected by tubing to the sensor housing.

VISUAL ALARM A red LED, which is ON whenever, the CO concentration is above the alarm point.

AUDIO ALARM A small horn, which is ON whenever, the gas concentration is above the alarm

point, until the alarm is acknowledged.

COVER Retained with four screws and removed to change the sensor and access the

terminal strip.

RELAY CONTACT

TERMINAL STRIP

A terminal strip inside the enclosure that enables access to the alarm relay contacts.

See Figure 2.

2

Page 5

SPECTRUM RAL ENMET Corporation

Valve

O

Enclosure Cover

Sensor Housing

Pushbutton

Switches

Fitting

Enclosure Body

(Sensor)

PTIONSELECT

Cover Screws

(Tubing from Flowmeter)

4 places

Visual Alarm

Power Cord

Ref: Fitting to Air line

Tubing to Monitor

Pressure Control Knob

Regulator

Gauge

Display

Audio Alarm

Exterior View

Flowmeter

Flowmeter

Regulator with Flow meter

Figure 1: SPECTRUM-RAL Features

3

Page 6

ENMET Corporation SPECTRUM RAL

Relay Contact

Mounting Holes

2.2 SPECTRUM-RAL Installation

2.2.1 Mount Enclosure

Mount the enclosure at an appropriate location using the two mounting holes accessible inside the enclosure. See

Figure 2. The location should be far enough upstream from the user that the sample air reaches the monitor before the

air reaches the user.

2 places

Terminal Strip

Figure 2: SPECTRUM-RAL Interior View

2.2.2 Air Supply

The male quick disconnect pneumatic connector on the regulator-flowmeter assembly is a Foster 3003 series. Plumb

the associated female connector into the airline. See Figure 1.

Connect the regulator-flowmeter and set the pressure at approximately:

20 PSIG and the flow at 1.0 SCFH or 0.5 l min.

2.2.3 Relay Contacts

Relay contacts are accessible on a spring-clamp terminal strip inside the enclosure after removing the cover. Terminal

strip locations are listed in Table 1.

Table 1: Relay connections to terminal strip

Relay contact Terminal position

C 10

NC 11

NO 12

NOTE: Some versions of the SPECTRUM-RAL have two sets of relay contacts. If there is a second set of relay

contacts there will be 13 – 15 positions on the terminal strip. If present position 13=C, 14=NC and 15=NO.

Contact position refers to the unpowered condition that is also the alarm condition. Relay contacts are rated at 2 amps

@ 110 V. Instrument ground is accessible at terminal strip locations 1, 2, and 3, and +12 VDC is available at locations

4, 5, and 6. When powering an auxiliary device with +12 V DC, do not overload the power supply (exceed 200 mA).

To exit relay wires, drill a hole in the lower right surface of the enclosure, and use a strain relief.

4

Page 7

SPECTRUM RAL ENMET Corporation

3.0 3.0 SPECTRUM-RAL Operation

Plug the power supply into an 110 VAC outlet. The display should read "0000" within ten seconds when the monitor is

supplied with uncontaminated air.

3.1 Operational Menu

The operational menu flow diagram is shown in Figure 3. This menu is accessed with the OPTION pushbutton

switch, the left hand switch as viewed from the front of the instrument. Successive displays are achieved by

repeatedly pushing the OPTION switch, as indicated by "O" in the menu flow diagram. The alarm acknowledgement

function, and displays and function in the "see DATA" area, are accessed with SELECT pushbutton, indicated by "S"

in the menu flow diagram.

Operational

Display

XXXX

O

Batt=OK*

O

Alm=XXXX

O

O

go Setup

O

*may also be

“low” or “LOW”

S

O = OPTION Switch

S = SELECT Switch

S

S

S

S

Acknowledge

Alarm

No

Function

No

Function

Max=XXXXSee DATA

Min=XXXX

S

O

S

O

No

Function

No

Function

Maintenance

Menu Key

See Figure 4

Maintenance Section 4.0

Figure 3: Operation Menu Diagram

5

Clr DATA

O

XX YY °C

O

S

S

Reset

Data

No

Function

Page 8

ENMET Corporation SPECTRUM RAL

3.2 Gas Concentration Display and Alarms

The LCD furnishes a numerical display of CO concentration from 0000 to 100 PPM. If the CO concentration exceeds

100 ppm, the display reads "100+." When the concentration of CO exceeds the preset alarm point, the audio and

visual alarms are activated. The gas concentration continues to be displayed during alarm. The alarm point is

adjustable between 5 and 100 ppm CO by accessing the maintenance menu; the factory setting of the alarm point is 10

ppm CO, the value recognized by OSHA as the acceptable exposure limit for compressed air lines. A user should have

a justifiable application-based reason for setting the alarm point higher than 10 PPM. When the CO concentration

drops below the alarm point, the audio and visual alarms cease operation. The alarm point setting can be observed on

the display by pushing the OPTION switch twice.

If an alarm concentration is encountered when the display is at a location in the operational menu other than the

concentration numerical display, the audio and visual alarms are activated and the alarm cannot be acknowledged.

If the display is left idle at a location other than the concentration numerical display for 45 seconds it automatically

transfers to the concentration numerical display.

3.3 Alarm Acknowledge

When the instrument is in alarm, and the CO concentration is below 50 PPM, the alarm can be acknowledged by

pressing and releasing the SELECT pushbutton, but only when the instrument is in the numerical concentration

location of the operational menu. The acknowledgement causes the temporary cessation of the audio alarm; the red

LED continues to be ON. The audio alarm is OFF for a period of four minutes, after which it is reactivated, if the gas

concentration is still above the alarm point. The alarm can again be acknowledged. However, acknowledgement of

the alarm at gas concentrations above 50 PPM, does not result in audio alarm cessation, and if the gas concentration

rises above 50 PPM during an alarm condition which has been acknowledged, the audio alarm resumes operation.

3.4 Data

The SPECTRUM-RAL monitor retains the maximum and minimum gas concentration values encountered since turnon, or since the data was cleared and reset. There is a one minute delay from the time the instrument is turned on until

when it starts storing the information. To access this press the OPTION switch three times; "see DATA" is displayed.

Press the SELECT switch; the maximum concentration since turn-on or last reset is displayed. Press the OPTION

switch again; the minimum concentration since turn-on or last reset is displayed. Press the OPTION switch again;

"clr DATA" is displayed. Pushing the SELECT switch clears the data and resets it to the current concentration.

Pushing the OPTION switch once more results in a display of both the countdown to the confidence beep and the

internal temperature of the instrument in degrees centigrade. Push the OPTION switch three more times to return to

the gas concentration numerical display.

6

Page 9

SPECTRUM RAL ENMET Corporation

3.5 Interference Gases

Some gases other than CO cause a sensor response, and thus are termed "interference gases".

Known interference gases are shown in Table 2.

Table 2: Known Interference Gases

Gas Concentration in PPM Reading in ppm

Hydrogen 1,000 100+

Nitric oxide 100 25

Table 3 shows levels of gases that are known to cause no sensor response.

Table 3: Known gases with no response

Gas Concentration

Ammonia 100 ppm

Carbon dioxide 5,000 ppm

Chlorine 5 ppm

Ethylene

Gasoline vapor

Hydrogen cyanide 10 ppm

Hydrogen sulfide

Isopropanol

Methane 10,000 ppm

Nitrogen dioxide

Sulfur dioxide

*

For indicated gases or vapors, prolonged exposure may reduce the efficiency of the sensor filter.

*

*

*

*

*

*

2 %

saturated

10 ppm

1,025 ppm

10 ppm

10 ppm

7

Page 10

ENMET Corporation SPECTRUM RAL

INVALID

z30:0.0v

run CAL

To Exit

new=XXXX

To Exit

To Exit

4.0 Maintenance4.0 Maintenance

4.1 Maintenance Menu

From the gas concentration numerical display, push the OPTION button four times; "go SETUP" is displayed. This is

the entrance to the maintenance menu. The maintenance menu flow diagram is shown in Figure 4.

To Operational

Display

go SETUP

S

Key=0000

VALID

run ZERO

From Operational Display

O

S

S

O

S

O

Changes digit indicated by underscore cursor

Locks underscored digit and moves cursor

AIR SET ?

S

AIR SET ?

S

z30:0.0v No Function

GAS=XXXX

S

GAS SET?

S

XXX:Y.Yv

O

VALID

INVALID

O

O or S

O

O

VALID

INVALID

To Exit

To Operational Display

C-FAULT

No Function

To Exit

To Operational Display

O = OPTION Switch

S = SELECT Switch

C-FAULT

INVALID

set ALM

O

set KEY

O

O

Exit

S

S

S

ALM=0000

KEY=0000

new=XXXX

To Operational Display

O

Changes digit indicated by underscore cursor

Locks underscored digit and moves cursor

S

O or S

O

Changes digit indicated by underscore cursor

Locks underscored digit and moves cursor

S

O or S

To Exit

Figure 4: Maintenance Menu Diagram

8

Page 11

SPECTRUM RAL ENMET Corporation

4.2 Key

Entrance to the maintenance menu is guarded with a four digit numerical key. The factory default setting of the key is

1270. When the valid numerical key is inserted, the user is allowed to enter the maintenance menu.

When in the "go SETUP" location, press the SELECT pushbutton; "Key=0000" is displayed. The underscore cursor

is under the left hand digit. To insert the key, press the OPTION pushbutton to index the left hand digit, and choose

the correct digit; then press the SELECT pushbutton, which locks in the chosen left hand digit and moves the

underscore cursor one space to the right. Continue this process until the four digit key is complete. When the valid

key is inserted in this manner, the display is transferred to the "run ZERO" portion of the maintenance menu. When an

invalid key is inserted, "INVALID" is briefly displayed, and the instrument returns to the operations menu.

The process that a different key is set is given in section 4.6.

4.3 Zero

A valid key entry sets the instrument at the "run ZERO" location, of the maintenance menu, which enables the setting

of the zero gas concentration point. This is desirable if the zero reference of the gas sensor has drifted over a period of

time, indicated by a persistent gas concentration reading in a clean environment. Note that the calibration sequence

given below also includes setting the zero point. If a full calibration is required, instead of setting just the zero point,

push the OPTION button once; "run CAL" is displayed. See section 4.4.

To set the zero point without performing full calibration, from the "run ZERO" location press the SELECT button;

"AIR SET?" is displayed. Be certain that the instrument is supplied with clean air, uncontaminated by carbon

monoxide. If uncertain of the environment, use pure compressed air from a pressurized cylinder, and flow it over the

sensor at a flow rate of 1 SCFH.

With the instrument in zero air, press the SELECT button again. "ZERO=30" is displayed; this is a counter that

counts down in seconds from 30 to 0. The validity of the new zero setting is then examined; if it is reasonable, the

display is transferred to the concentration numerical display in the operations menu.

If the new zero setting is not between reasonable parameters, "C-FAULT" is displayed. Turn the instrument OFF, the

ON again. This re-boots the system with the most recent valid zero setting.

4.4 Calibration

NOTE: Calibration should be performed at normal room temperature (20-25°C) for optimal performance. If the

instrument is exposed to temperature extremes just prior to calibration, it should be allowed to stabilize to

room temperature. The internal temperature of the instrument can be verified by cycling through the "see

DATA" menu.

In order to calibrate the instrument, it is first zeroed as described above. Then the sensor is exposed to a known

concentration of the target gas, in air or an inert gas such as nitrogen, called the "span gas". After an appropriate

interval, which is timed, the new span setting is examined for validity.

A valid key entry sets the instrument at the "run ZERO" location of the maintenance menu. Press the OPTION

pushbutton once to access the "run CAL" display, then press the SELECT pushbutton; "AIR SET" is displayed. Zero

the instrument as described in section 4.3. When the zero timer is complete, the display indicates "SPAN=XXX",

where the numbers indicate the correct span gas concentration for the instrument. The span gas value for this

instrument is 20 PPM CO.

Assure that the correct span gas is available, connect the calibration adapter to the cylinder, then press the SELECT

button; "GAS SET" is displayed. Unplug the regulator-flowmeter assembly from the airline, connect it to the

calibration adapter and set the flow at 1.0 SCFH . Then press the SELECT button; "XXX:0.Yv" is displayed. The

XXX is a counter which counts down in seconds to zero from 120 to provide the proper time interval for calibration.

The 0.Yv indicates a sensor signal which is used during the sensor replacement procedure. When the timer reaches

zero, the new calibration and zero gas settings are examined for validity. If the values are reasonable, the display is

transferred to the gas concentration numerical display in the operations menu. Return the regulator-flowmeter

assembly to the airline.

If the new zero and calibration settings are not reasonable, "C-FAULT" is displayed. Turn the instrument OFF, then

ON again. This re-boots the system with the most recent valid zero and calibration settings.

9

Page 12

ENMET Corporation SPECTRUM RAL

Sensor

4.5 Changing the Alarm Level

A valid key entry sets the instrument at the "run ZERO" location of the maintenance menu. Press the OPTION push

button twice to access the "set ALM" display, then press the SELECT button; ALM=0000" is displayed. This is

called the alarm update window, and the value displayed is the present alarm setpoint. The underscore cursor is under

the far left digit. Press the OPTION button to index the underscored digit; press the SELECT button to index the

underscore cursor one position to the right. When the desired new alarm point is set, press either the OPTION or

SELECT button to return to the alarm update window. If the new alarm setting is valid, "set ALM" is again

displayed. Press the OPTION button four times to return to the operations menu.

For the safety of the user, there is an upper limit past which the alarm setting is invalid, and the instrument does not

accept it. If an invalid alarm setting is attempted, after the numerical value is inserted in the "ALM=0000" window,

pressing the OPTION or SELECT button results in a momentary display of "INVALID" after which the display

returns to the alarm update window. Exiting the alarm update window at this point results in an alarm point setting

unchanged from the value present when the procedure was begun.

For the SPECTRUM-RAL , the factory default alarm setpoint is 10 PPM, and the upper alarm limit is 50 PPM.

4.6 Setting a New Key

A valid key entry sets the instrument at the "run ZERO" location of the maintenance menu. Press the OPTION button

four times to access the "set KEY" display. Press the SELECT pushbutton once; "KEY=0000 is displayed. A new

key can be set by indexing the underscored number with the OPTION button and indexing the underscore cursor with

the SELECT button. Four digit key numbers should be selected carefully and recorded. Without the correct key, the

maintenance menu cannot be accessed. If a four digit key number is lost, call ENMET customer service personnel.

4.7 Changing Components

Changing the sensor requires that the front of the instrument be removed; remove the four phillips head cover retaining

screws, and then the cover.

A sensor must be replaced when it no longer responds adequately to the target gas. This is indicated by a low gas

concentration reading when exposed to a known concentration of the target gas, and the inability to calibrate the

instrument, with a "C-FAULT" display after calibration. The expected sensor lifetime in normal environments is one

to two years.

CAUTION: New sensors come with a shorting clip that must be removed

for proper operation.

Remove the front cover of the instrument enclosure. Unplug the sensor

from the circuit board. Remove the shorting clip from the new sensor

and plug it in place. Allow the sensor to stabilize in the instrument with

the power on for one hour before recalibrating.

Bottom View

Figure 5: Remove Shorting Clip

The initial calibration of a new sensor must be performed with the front cover of the enclosure removed. A calibration

cup is provided with the calibration kit. Follow the procedure for calibrating the instrument as outlined in Section 4.4

of this manual with the following modification.

NOTE: During this procedure make sure the RED calibration cup, 02552-008, stays centered over the sensor.

During the application of the span gas, the counter counts down from 120. When the counter gets down to 30,

adjust the potentiometer next to the display module on the instrument PC board, so that the display to the right

of the counter reads 0.65v. This is a one-time adjustment to align the sensor output with the instrument

electronics. It should only be performed upon sensor replacement. All future calibrations should follow the

procedure in Section 4.4.

Replace the front cover on the instrument enclosure. Calibrate the instrument according to the procedure in section 4.4.

10

Page 13

SPECTRUM RAL ENMET Corporation

5.0 Replacement Part Numbers5.0 Replacement Part Numbers

ENMET replacement part numbers:

Description Part Number

Calibration Kit 03412-001

Calibration Cup 02552-008

Calibration Gas, 20 ppm CO 03219-020

Zero Gas, 20.9 % Oxygen 03296-209

Replacement CO Sensor

for instrument S/N 43-8099 and below

Replacement CO Sensor

for instrument S/N 43-8100 and above

Display Assembly 62022-001

PC Board Assembly 05215-002

Relay 60004-000

Power Supply 67052-004

67020-1200

67016-1204

11

Page 14

ENMET Corporation SPECTRUM RAL

6.0 WARRANTY6.0 WARRANTY

ENMET warrants new instruments to be free from defects in workmanship and material under normal use for a period

of one year from date of shipment from ENMET. The warranty covers both parts and labor excluding instrument

calibration and expendable parts such as calibration gas, filters, batteries, etc... Equipment believed to be defective

should be returned to ENMET within the warranty period (transportation prepaid) for inspection. If the evaluation by

ENMET confirms that the product is defective, it will be repaired or replaced at no charge, within the stated

limitations, and returned prepaid to any location in the United States by the most economical means, e.g. Surface

UPS/RPS. If an expedient means of transportation is requested during the warranty period, the customer is responsible

for the difference between the most economical means and the expedient mode. ENMET shall not be liable for any

loss or damage caused by the improper use of the product. The purchaser indemnifies and saves harmless the

company with respect to any loss or damages that may arise through the use by the purchaser or others of this

equipment.

This warranty is expressly given in lieu of all other warranties, either expressed or implied, including that of

merchantability, and all other obligations or liabilities of ENMET which may arise in connection with this equipment.

ENMET neither assumes nor authorizes any representative or other person to assume for it any obligation or liability

other than that which is set forth herein.

NOTE: When returning an instrument to the factory for service:

• Be sure to include paperwork.

• A purchase order, return address and telephone number will assist in the expedient repair and return of your unit.

• Include any specific instructions.

• For warranty service, include date of purchase

• If you require an estimate, please contact ENMET Corporation.

12

Page 15

SPECTRUM RAL ENMET Corporation

Appendix AAppendix A

The Characteristics and Effects of Carbon Monoxide

Carbon monoxide is a colorless odorless toxic gas generated by incomplete combustion of a hydrocarbon fuel in air. It

may be present where internal combustion engines, furnaces, boilers, and other combustion devices are present. It is

toxic when inhaled because of its great affinity to hemoglobin, the oxygen carriers in the red cells of the blood. CO

replaces the oxygen normally carried by the hemoglobin, and thus inhibits the delivery of oxygen throughout the body;

the victim suffers from oxygen deficiency, and may die from asphyxiation. The symptoms and degree of danger

resulting from exposure to CO depend upon the concentration of the gas and the length of exposure; this is shown in

Figure 6. The ENMET SPECTRUM-RAL carbon monoxide monitor is employed to warn the user of the presence of

CO, and to facilitate the assessment of the degree of danger that he or she is exposed to.

Based upon knowledge of the effects of CO, the Occupational Safety and Health Authority (OSHA) has set limits on

exposure to CO in the workplace. For ambient air conditions, these are 35 PPM (parts CO per million parts air) as an

time weighted average for an eight hour day, and a maximum exposure of 200 PPM. For compressed air line

applications, 10 PPM is the maximum acceptable limit. The SPECTRUM-RAL monitor is shipped with the adjustable

alarm set at 10 PPM; this alarm cannot be adjusted above 50 PPM.

The curves below are for percent carboxalhemoglobin with 50% being the top curve, 5% the bottom. %COHb is a

measure of the amount of hemoglobin occupied by CO rather than oxygen. CO effects upon children, adults engaging

in physical activity, and smokers, are more pronounced.

Figure 6: % COHb vs Time

13

Loading...

Loading...