Page 1

ENMET Corporation

PO Box 979

Ann Arbor, MI 48106-0979

www.enmet.com

Operation and Maintenance

PGD2

Manual

Manual Part Number

80006-020

MCN-13-001, 04/04/13

Page 2

CONTENTS

1 WARNING NOTICES ..................................................................................................................................................................... 1

1.1 S

1.2 B

1.3 E

1.4 B

1.5 D

1.6 E

1.7 R

ENSOR “POISONING

ATTERY CHARGING, CALIBRATION & TESTING

LECTROSTATIC HAZARD

ATTERY DISPOSAL

ISPOSAL OF GAS SENSORS

LECTROMAGNETIC COMPATIBILITY

APID READING CHANGES

” ................................................................................................................................................................. 1

........................................................................................................................................................... 1

.................................................................................................................................................................... 1

........................................................................................................................................................ 1

........................................................................................................................................... 1

.......................................................................................................................................................... 1

......................................................................................................................... 1

2 CERTIFICATION DATA ............................................................................................................................................................... 1

2.1 S

PECIAL CONDITIONS FOR SAFE USE

........................................................................................................................................... 1

3 DEFINITIONS AND ABBREVIATIONS ..................................................................................................................................... 2

4 PGD2 FEATURES AT A GLANCE ............................................................................................................................................... 2

5 INTRODUCTION ............................................................................................................................................................................ 3

5.1 S

5.2 G

PECIFICATION

ENERAL DESCRIPTION

............................................................................................................................................................................ 3

.............................................................................................................................................................. 4

6 OPERATING INSTRUCTIONS .................................................................................................................................................... 6

6.1 S

6.2 S

6.3 P

6.4 S

6.5 M

6.6 D

6.7 A

6.8 C

6.9 STEL

6.10 A

6.11 F

6.12 S

6.13 PGD S

6.14 A

6.15 L

6.16 D

6.17 S

6.18 EXP / LEL / VOL

6.19 C

6.20 U

6.21 D

6.22 O

6.23 F

6.24 A

WITCHING ON

WITCHING OFF

EAK READINGS MODE

ENTINEL WORKING MODE

ENU FACILITIES

ATE / TIME

DJUST SOUNDER

ALIBRATION DUE DATE

AND

LARM LEVELS

LAMMABLE DISPLAY

ET

LCD C

ERIAL NO

LARM ACCEPT

OW BATTERY ALARM

ISPLAY BACKLIGHT

ENSOR ZERO

ONFIDENCE BLEEP

SER IDENTIFICATION

ATA LOGGING

VERRANGE INDICATION

AULT INDICATION

SPIRATION

............................................................................................................................................................................ 7

........................................................................................................................................................................... 7

............................................................................................................................................................... 7

........................................................................................................................................................................ 8

............................................................................................................................................................................... 8

....................................................................................................................................................................... 8

TWA V

ALUES

........................................................................................................................................................................ 10

............................................................................................................................................................... 11

ONTRAST

................................................................................................................................................................. 12

. ...................................................................................................................................................................... 12

........................................................................................................................................................................ 12

............................................................................................................................................................. 12

................................................................................................................................................................ 12

........................................................................................................................................................................... 13

DISPLAY OPTIONS

.................................................................................................................................................................. 13

............................................................................................................................................................... 13

......................................................................................................................................................................... 14

................................................................................................................................................................... 15

.............................................................................................................................................................................. 15

.......................................................................................................................................................... 7

............................................................................................................................................................ 8

........................................................................................................................................................... 9

....................................................................................................................................... 13

.......................................................................................................................................................... 15

7 PUMPED INSTRUMENTS .......................................................................................................................................................... 16

7.1 P

7.2 P

UMP OPERATION

UMP BLOCKAGE

..................................................................................................................................................................... 16

...................................................................................................................................................................... 16

8 CALIBRATION ............................................................................................................................................................................. 17

8.1 C

8.2 K

8.3 E

ALIBRATION

EYPAD CALIBRATION PROCEDURE

XAMPLES OF STANDARD

............................................................................................................................................................................ 17

ENMET C

......................................................................................................................................... 17

ALIBRATION GAS & ACCESSORIES

................................................................................... 19

9 BATTERY CHARGING EQUIPMENT ...................................................................................................................................... 19

Page 3

9.1 C

9.2 5-W

9.3 V

9.4 C

9.5 B

OMPACT CHARGER TYPE

AY CHARGER TYPE

EHICLE-MOUNTED CHARGER TYPE

HARGER TYPE

ATTERY MODULE CHARGING

PGDC2, PGDC2/I .......................................................................................................................................... 20

PGDC4 .......................................................................................................................................... 20

PGDC5 ............................................................................................................................................... 20

................................................................................................................................................. 20

PGDC3 .......................................................................................................................... 20

10 BATTERY REPLACEMENT .................................................................................................................................................. 20

11 HAZARDOUS AREA USE ....................................................................................................................................................... 21

11.1 A

11.2 M

11.3 B

11.4 C

12 SENSORS ................................................................................................................................................................................... 22

12.1 F

12.2 T

12.3 O

13 CALIBRATION, CONFIGURATION & PROGRAMMING ............................................................................................... 27

REAS OF USE

ETHODS OF USE

ASIC PRECAUTIONS

ONFINED SPACE PRE-ENTRY CHECKS

LAMMABLE SENSORS

12.1.1 LEL Flammable Sensors .................................................................................................................................................. 22

12.1.2 0 - 100% Volume Flammable Sensors ............................................................................................................................. 23

OXIC SENSORS

12.2.1 Cross Sensitivity ............................................................................................................................................................... 24

12.2.2 Temperature Dependence ................................................................................................................................................ 24

12.2.3 Stabilization ..................................................................................................................................................................... 24

12.2.4 Toxic Sensor Types and Characteristics .......................................................................................................................... 25

XYGEN SENSORS

12.3.1 Cross Sensitivity ............................................................................................................................................................... 26

12.3.2 Temperature ..................................................................................................................................................................... 26

12.3.3 Pressure Transients .......................................................................................................................................................... 26

12.3.4 Humidity ........................................................................................................................................................................... 26

12.3.5 Oxygen Sensor Types and Characteristics ....................................................................................................................... 26

........................................................................................................................................................................... 21

...................................................................................................................................................................... 21

................................................................................................................................................................. 21

..................................................................................................................................... 21

.............................................................................................................................................................. 22

........................................................................................................................................................................ 24

.................................................................................................................................................................... 26

13.1 PC I

13.2 C

13.3 C

13.4 P

14 TROUBLESHOOTING ............................................................................................................................................................ 28

15 WARRANTY .............................................................................................................................................................................. 29

NTERFACING (USING OPTIONAL ACCESSORIES

ALIBRATION

ONFIGURATION (USING OPTIONAL SOFTWARE & HARDWARE

ROGRAMMING (USING OPTIONAL SOFTWARE & HARDWARE

............................................................................................................................................................................ 27

).................................................................................................................. 27

) ............................................................................................... 27

) ................................................................................................. 27

Page 4

ENMET Corporation PGD2

1 W

ARNING NOTICES

1.1 Sensor “Poisoning”

Silicone based lubricants, corrosion inhibitors and water repellents must not be used in close proximity to the sensors. Such

compounds may poison the flammable sensors (pellistors) resulting in a loss of sensitivity.

This poisoning effect is common to all catalytic sensors.

1.2 Battery Charging, Calibration & Testing

Equipment used for charging, calibration and testing of the Portable Gas Detector must be located outside a hazardous area i.e. in an

atmosphere where it is known that there is no risk of the presence of combustible gas.

1.3 Electrostatic Hazard

The blue plastic instrument case and red lens must only be cleaned in a safe area.

1.4 Battery Disposal

Rechargeable battery packs or individual cells must be disposed of via an appropriate battery recycling scheme.

1.5 Disposal of Gas Sensors

The toxic and oxygen sensors used in the PGD2 contain toxic compounds. They should be disposed of according to local waste

management requirements and environmental legislation. They should not be burnt since they may emit toxic fumes.

Flammable sensors do not represent a hazard.

1.6 Electromagnetic Compatibility

The PGD2 Portable Gas Detector and associated equipment complies with the current European standards for both electromagnetic

emissions and immunity. However, this does not imply that the apparatus will be immune from interference under all operational

conditions and may exhibit temporary instability if exposed to high levels of interference for example, when in very close proximity to a

mobile phone transmission.

1.7 Rapid Reading Changes

FLAMMABLE INSTRUMENTS ONLY

CAUTION: ANY RAPID UP-SCALE READING FOLLOWED

BY A DECLINING OR ERRATIC READING MAY INDICATE

A GAS CONCENTRATION BEYOND UPPER SCALE LIMIT

WHICH MAY BE HAZARDOUS.

2 C

The Portable Gas Detector Model PGD2 is Baseefa ATEX certified for use in Group IIC potentially explosive atmospheres under the

following certificate number: Certificate No. Baseefa 03ATEX0235X

ERTIFICATION DATA

2.1 Special Conditions for Safe Use

The above certificate specifies the following conditions for safe use:-

1. The rechargeable battery pack Type PGD/BATT may only be recharged in the safe area.

2. The enclosure is manufactured from plastic and has a surface resistivity of greater that 1 Gohm and therefore poses a risk

from electrostatic ignition. The rubber boot is to be fitted to the apparatus. By virtue of its shape and design, the apparatus is

not considered to be an electrostatic risk; however, the apparatus must not be installed in a position where it may be

subjected to an excessive air/fluid flow or be subjected to rubbing that may cause an electrostatic build-up.

3. The apparatus is not designed for use in oxygen enriched atmospheres i.e. greater than 21% oxygen.

1

Page 5

ENMET Corporation PGD2

3 D

Aspirator

Data Logging

EXP

LEL

%LEL

TWA

PC

Pellistors

PGD2

PPM

STEL

T90 Response Time

EFINITIONS AND ABBREVIATIONS

A hand operated pump attachment which enables gas to be drawn into the instrument.

The automatic recording of readings stored in the solid state memory of the instrument

for later retrieval.

Explosive Gas.

Lower Explosive Limit, the volume ratio of flammable gas or vapor in air below which an

explosive gas atmosphere will not be formed.

The percentage of the Lower Explosive Limit

e.g. the LEL for methane is 5% volume in air, therefore 20% LEL is equivalent to 1%

volume in air (i.e. 20% of 5% volume)

Time-Weighted-Average, taken over an 8 hour reference period.

Also referred to as LTEL, Long Term Exposure Limit

A ‘personal computer’ based on the original IBM standard.

Devices used for the detection of a wide range of flammable gases normally comprising

of individual detector and compensator ‘bead’ elements operating on the principle of

catalytic oxidation.

Portable Gas Detector - 2nd generation, monitoring up to 4 gases.

Parts per Million.

Short Term Exposure Limit, the average exposure over a 15 minute sampling period.

The time taken to reach 90% of the true value

4 PGD2 F

♦ Monitoring of up to 4 gases

♦ Pumped versions available

♦ Sensors can be added or removed after purchase

♦ Robust construction - high impact resistance

♦ Data Logging in 3 modes

♦ STEL and TWA monitoring

♦ Flammable gas selection from built -in menu

♦ Peak readings facility for pre - entry testing

♦ Sentinel working mode

♦ Displays in scientific units

♦ Programmable alarm levels for each sensor

♦ Audible and visual alarms

♦ Sensor zero function

♦ Fully reprogrammable without removal from protective case

♦ Serial number and calibration due dates stored within instrument

♦ Display contrast adjustable via instrument menu

♦ Audible alarm level adjustable via instrument menu

♦ Display backlighting

♦ Power and Fault indicators

♦ Low battery alarm

♦ Choice of mains powered or vehicle powered chargers

♦ Calibration via a PC using specially designed Windows software

♦ Extensive software support

♦ Accessories to provide aspiration

♦ Protective rubber case and body harness

EATURES AT A GLANCE

2

Page 6

ENMET Corporation PGD2

5 I

NTRODUCTION

This Instruction Manual No.1 provides information on the General Operation of the PGD2 instrument.

Instruction Manual No.2 The Data Processing-Calibration-Configuration & Programming of the PGD2 provides information on the use

of the specially designed Windows based software package available for use with the instrument.

5.1 Specification

Size

Weight

No. of Gases

Gas Types

Internal Pump

Power Sources

Minimum operating times

Visual indications

Audible indication

Alarm levels

Data Logging Modes

Display formats

Controls

Temperature range

Environmental Rating

Humidity range

Electromagnetic compatibility

Air Pressure Operating Range

185mm high x 108mm wide x 50mm deep.(excluding boot)

1Kg.

Up to four.

Flammable, Toxic, Oxygen (See section 12 for sensor specifications).

Available to order (suffix P).

3.5 Volts dc.

i). rechargeable battery pack Model PGD/BATT.

12 hours.

i). 2 x 16 character LCD display with backlight.

ii). large flashing red lens section used to indicate alarm conditions.

iii). Green ‘Power’ and amber ‘Fault’ indicators in lens.

Electromagnetic alarm in red lens section.

Flammable : single level instant alarm.

Toxic (each sensor) : 3 levels - instant, STEL, TWA.

Oxygen : 2 levels - instant low, instant high.

Automatic calculation of STEL and TWA readings.

i). Automatic variable rate according to gas levels.

ii). Fixed rate.

iii). Fixed fast rate.

iv). Off.

ppm, %, LEL.

i). Front panel - on/off, right arrow, left arrow, on/off/menu.

ii). Top panel - display backlight, alarm mute.

i). operating -5 to + 40

ii). storage -20 to + 50

IP66.

15% to 95% relative humidity, non-condensing. Operation is possible in

the range 0-100% R.H. however, sensor life will be reduced by

continuous operation at extremes of humidity and temperature.

CE Marked, Tested to EN50081-2, EN50082-1, EN55022 (Limit B).

920 mbar to 1150 mbar.

O

O

C.

C.

3

Page 7

ENMET Corporation PGD2

5.2 General Description

The PGD2 is an intrinsically safe portable multi-gas instrument for use in Group IIC potentially explosive atmospheres. The instrument

is intended to be used for the protection of personnel entering or working in an environment where a gas hazard may, or is known to

exist.

The instrument produces both an audible and visual alarms if any of the monitored gas levels fall outside pre-set limits.

It can be fitted with up to 4 gas sensors in various combinations of flammable, toxic and oxygen to provide simultaneous monitoring of

each gas. The data logging facilities available within the instrument allow the exposure levels for each gas to be stored for

downloading to a personal computer at the end of the work period. The instrument also automatically calculates the STEL and TWA

values.

Pumped versions are available at additional cost.

Note: The Model PGD3-IR Portable Gas Detector is also available. This instrument uses the latest technology miniature

infrared gas sensors for the detection of a wide range of hydrocarbon gases and carbon dioxide. Infrared gas sensors offer

several advantages including immunity to ‘poisoning’, fail-safe operation and a longer operating life.

Lens

Gas Inlet

Front Panel

Keypad

Gas Inlet

LCD Display

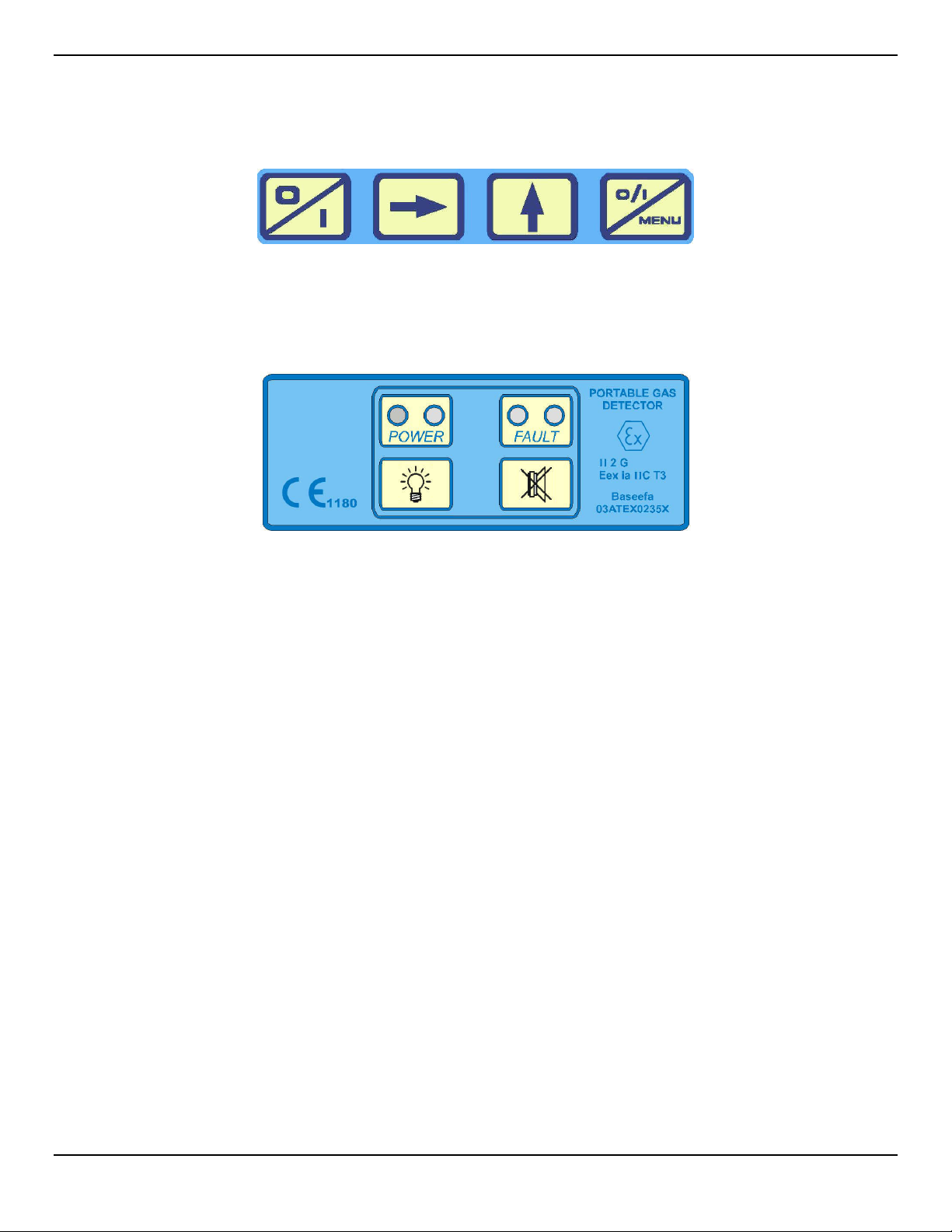

Figure 1 - Front View of Portable Gas Detector with Case Removed

Figure 2 - Top View Showing Lens Keypad and Certification Data

4

Page 8

ENMET Corporation PGD2

Battery Pack

Rear Cover Retaining

Screws –

3 Positions

Battery Retaining

Screws –

3 Positions

Nameplate with

Serial Number

Charging Pins

Rechargeable

Figure 3 - Rear View of Rechargeable

Portable Gas Detector with Case Removed

Reference to Figures 1 to 3 shows that the instrument comprises the following main parts: -

• The main instrument case moulded in high impact resistance “Bayblend” internally coated to provide electromagnetic shielding. A

belt clip and suspension hook may be optionally fitted during manufacture.

• A removable battery pack.

• A large red lens section containing flashing led indications, audible alarm and infra-red communications link.

• Gas sensors and control electronics (contained in anti-impact mountings) housed within the main instrument case section.

• A two line by 16-character liquid crystal display with backlight.

• A four-key membrane type front panel control switch, large enough to be operated by a gloved hand.

• A two-key membrane type top panel control switch. This membrane also carries the power and fault indicators and certification

data.

• Gas sensor inlets which are separately sealed to help prevent water ingress to the instrument electronics.

• A nameplate carrying the serial number of the instrument

The instrument is supplied fitted with a moulded rubber boot which provides good protection in hostile environments. The instrument

can be both charged and calibrated without removal from the boot. It is a condition for safe use that the boot is always fitted when

used in a potentially explosive atmosphere – see section 2.1.

A body harness is also supplied as standard and comprises shoulder and waist straps which attach to the moulded rubber boot. These

straps can also be utilised to lower the instrument during pre-entry checks.

The instrument is powered from a rechargeable battery pack. It is a condition for safe use that the battery pack may only be

recharged in a safe area – see section 2.1.

5

Page 9

ENMET Corporation PGD2

6 O

PERATING INSTRUCTIONS

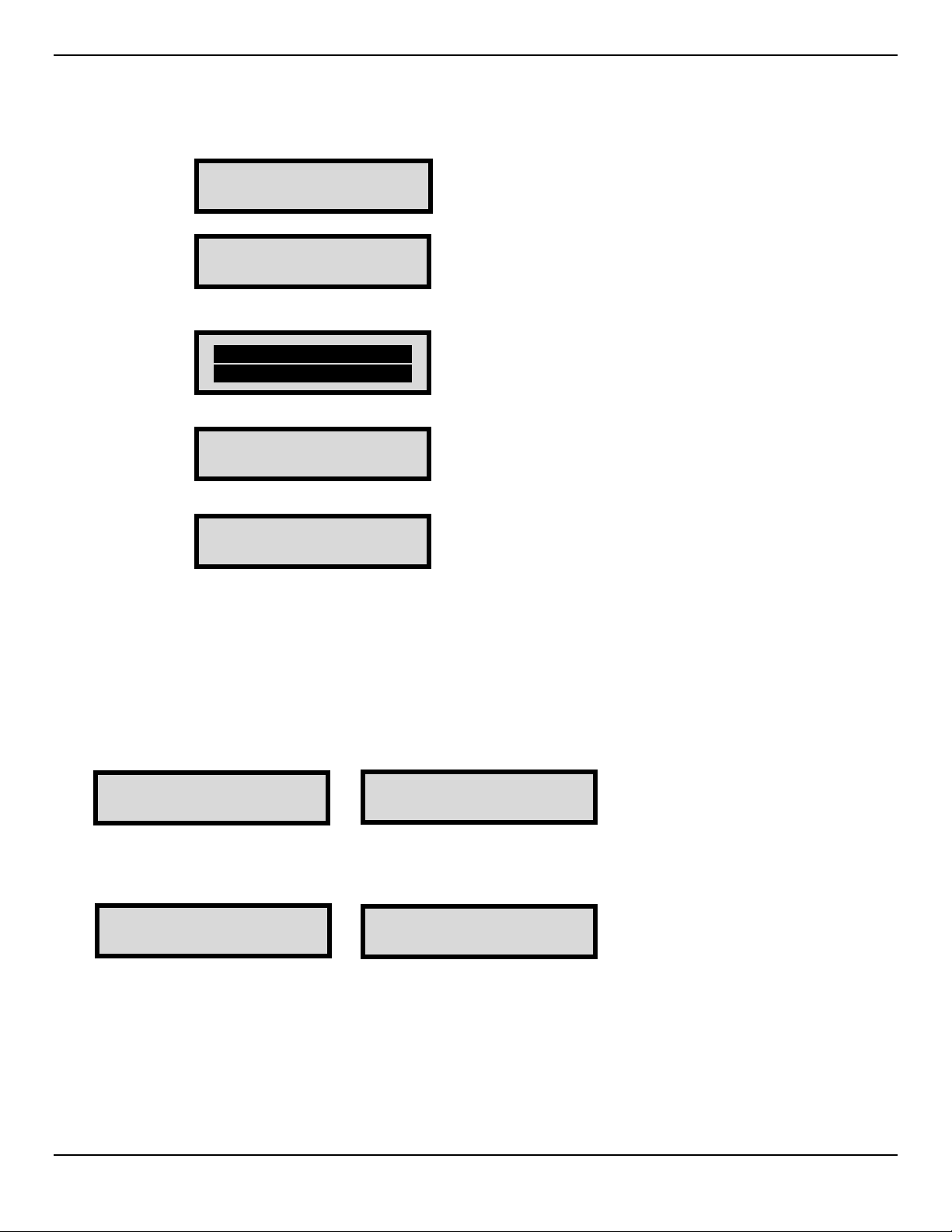

A B C D

FRONT PANEL SWITCHES

TOP PANEL SWITCHES

E F

6

Page 10

ENMET Corporation PGD2

6.1 Switching on

To switch the instrument on, press buttons A and D together.

The instrument goes through a self-check cycle, check that the audible and visual alarms are operating and that the display shows the

following sequence: -

Note : Instruments fitted with PGD1 emulation code do not show PGD2

Note - The top line of this display will vary according to the software and instrument configuration.

*V=1.13 is the software version which may vary

After 2 seconds the display shows the date and time followed by the gas levels.

The gas level display shown depends upon the gas sensors fitted. A typical display for a 4-gas instrument is shown below: -

CHECKING PROGRAM

PGD2 V4.4.2PAp Da

FLAM = METHANE

DATE 10 / 04 / 07

TIME 14 : 12 : 34

H2S 0.0 ▐ LEL 0

CO 0 ▐ O2 20.9

6.2 Switching off

To switch the instrument off, press and hold buttons A and D together until the display goes off.

6.3 Peak Readings mode

The instrument can be set to measure and hold the highest flammable and toxic gas readings and the lowest oxygen reading, this

feature is particularly useful for carrying out pre-entry testing for gas. For example, by lowering the instrument into a manhole and then

withdrawing it to observe the peak readings to ensure that it is safe to enter.

To turn Peak Readings on / off, press buttons B and C together until the display reads: -

either or

PEAK READINGS ON

PEAK READINGS OFF

When Peak Readings is on, the display alternates between :typically and

H2S 0.0 ▐ LEL 0

CO 0 ▐ O2 20.9

PEAK READINGS

6.4 Sentinel working mode

Because of it’s large, 360 degree visible, red alarm top, the instrument can be suspended in a hazardous area to provide protection to

more than one person. Used in this way, all personnel in the vicinity will be able to observe the change in visual flash rate should an

alarm occur.

This method eliminates both the requirement for multi-headed devices traditionally used in the past, or for additional units in order to

achieve sentinel working.

7

Page 11

ENMET Corporation PGD2

6.5 Menu facilities

The Menu button allows the instrument to be interrogated to obtain information on any of the items listed below. These are sequentially

selected by successive operation of button D: -

DATE / TIME

ADJUST SOUNDER

CALIBRATION DUE DATE

STEL & TWA VALUES

ALARM LEVELS

FLAMMABLE DISPLAY

SET LCD CONTRAST

PGD SERIAL No.

If more details are available on a particular item then the user is prompted to press one of the arrow keys as described in the following

sections.

Note that the instrument automatically returns to the gas level display after approximately 4 seconds if the menu button or arrow button

is not operated again.

6.6 Date / Time

The current date and time are momentarily displayed when the instrument is first switched on (Section 6.1) and may also be accessed

via the menu button (Section 6.5).

Changing the date and time can only be carried out via a PGD2 Interface Unit, Interface/Charger Unit or Autocalibration Unit. Refer to

the instruction manuals for the individual items for further details.

6.7 Adjust Sounder

The frequency and hence the volume of the sounder can be adjusted via the menu button. From the menu, the user is prompted to

press the up arrow key:-

Sequential operation of the up arrow key varies the frequency/volume. Pressing the right arrow key sequentially steps the

frequency/volume in the opposite direction.

ADJUST SOUNDER

PRESS [] KEY

6.8 Calibration Due Date

The date when the instrument is due for its next calibration can be viewed via the menu button (Section 6.5).

The PGD2 can be configured via the PC configuration software(optional accessory) to either allow an instrument to be used beyond it’s

calibration due date or to prohibit further use until calibration has been carried out. Where the instrument is set to permit further use, a

warning is given each time the instrument is switched on to alert the user that calibration is required. Where it is set to prohibit further

use, then when the instrument is switched on the alarm continually sounds with the message: -

The calibration due date is updated each time an instrument is calibrated.

CALIBRATION DUE

8

Page 12

ENMET Corporation PGD2

6.9 STEL and TWA Values

The current STEL and TWA values may be viewed via the menu button (Section 6.5). These values represent the calculated Short

Term Exposure Levels (STEL) and Time Weighted Average Long (TWA)/ Term Exposure Levels (LTEL) for the toxic gases to which

the user has been most recently subjected.

From the menu, the user is prompted to press the up arrow key to view the readings: -

Sequential operation of the up arrow key shows in turn the STEL and TWA readings for toxic sensor 1 followed by those for toxic

sensor 2, for example:-

STEL

H2S 1 ppm

Readings for toxic sensor 1 – Hydrogen Sulphide

STEL

CO 23 ppm

Readings for toxic sensor 2 - Carbon Monoxide

Pressing the menu button after viewing the above displays returns the instrument to the next menu item.

COSHH VALUES

PRESS [] KEY

TWA

H2S 2 ppm

TWA

CO 34 ppm

9

Page 13

ENMET Corporation PGD2

6.10 Alarm Levels

The alarm level settings for the instrument may be viewed via the menu button (Section 6.5). These values represent the alarm setpoints which have been programmed into the instrument during calibration.

From the menu, the user is prompted to press the up arrow key to view the readings: -

Sequential operation of the up arrow key shows in turn the alarm set points for each sensor. A typical display sequence for a 4-gas

instrument would be:-

ALARM LEVELS

PRESS [ ] KEY

INSTANT ALARM

O2 LOW 19%

Alarm settings for the Oxygen sensor - two settings

INSTANT ALARM

FLAM 20 % LEL

Alarm setting for the Flammable sensor - one setting

INSTANT ALARM

H2S 15 ppm

STEL ALARM

H2S 10 ppm

Alarm settings for toxic sensor 1, Hydrogen Sulphide - three settings

INSTANT ALARM

CO 400 ppm

INSTANT ALARM

O2 HIGH 23%

or FLAM 1.00 %VOL if in the volume mode

TWA ALARM

H2S 5 ppm

STEL ALARM

CO 200 ppm

Alarm settings for toxic sensor 2, Carbon Monoxide - three settings

Important: - The Instantaneous Alarm settings must be greater than both the Short Term and Time-Weighted-Average/Long

Term exposure alarm settings. The Flammable sensor alarm setting cannot be set above 60% LEL.

TWA ALARM

CO 50 ppm

10

Page 14

ENMET Corporation PGD2

6.11 Flammable Display

Note : From software version 1.20 this facility can be disabled via the PC configuration program and may therefore be unavailable on

certain instruments.

The flammable sensor display can be programmed to show the readings for a variety of different flammable gas types, these are

selected via the menu button (Section 6.5). Selection of the appropriate gas to be monitored also automatically adjusts the calibration

factor within the instrument.

From the menu, the user is prompted to press the up arrow key to view the readings: -

Sequential operation of the up arrow key shows in turn the flammable display options e.g.: -

To select, press the right arrow key when the required gas is being displayed.

Confirmation of the selection can be made by switching the instrument off and then on and observing the display as illustrated in

Section 6.1.

A typical list of flammable gas and vapors types available through the menu is given in the table below. Additional gases may be

added using optional software upgrades. For reference, the lower explosive limit (LEL) in % by volume for each gas is listed. In some

cases there are slight differences between the accepted values of the % by volume concentrations which equal the 100% LEL of some

gases and vapors depending upon the international source of such technical data.

* The “user” option allows gases not on the above list to be configured into the instrument. This is achieved by use of the PGD2

Interface Unit option in conjunction with a PC. A calibration factor for the gas is required, contact ENMET for further information.

FLAM DISPLAY

PRESS [ ] KEY

METHANE

PRESS [ ] KEY

Gas Range in % Vol

Methane 5.0 to 4.4

Ethane 3.0 to 2.5

Propane 2.1 to 1.7

Butane 1.6 to 1.4

Pentane 1.5 to 1.4

Hexane 1.2 to 1.1

Heptane 1.1 to 1.1

Nonane 0.8 to 0.7

Methanol 6.0 to 5.5

MEK (Butanone) 1.8 to 1.7

Ketone

Ethylene 2.7 to 2.3

Iso Propyl Alcohol 2.0 to 2.0

Propylene (Propene) 2.0 to 2.0

Triethylamine 1.2 to 1.2

User*

11

Page 15

ENMET Corporation PGD2

6.12 Set LCD Contrast

The visual contrast of the 2 line by 16-character liquid crystal display can be adjusted via the menu button (Section 6.5).

From the menu the user is prompted to press the up arrow key: -

Sequential operation of the up arrow key, or holding it down, varies the contrast. The right arrow key varies the contrast in the opposite

direction. This function is cyclic.

SET LCD CONTRAST

PRESS [ ] KEY

6.13 PGD Serial No.

The serial number of the instrument may be viewed via the menu button (Section 6.5).

The serial number given should correspond with that shown on the rear cover nameplate.

Display format :-

Also see section 6.20 for details of the user identification facility available for use with the Serial No.

PGD SERIAL No.

SSC 16105

6.14 Alarm Accept

The instruments’ alarm condition is indicated by the red lens section flashing once per second together with a continual audible sound.

For the gas causing the alarm, the display alternates between the measured level and a blank reading.

For example, for an LEL alarm: -

H2S 0.0 ▐ LEL 23

CO 0 ▐ O2 20.9

An alarm condition can be accepted by pressing the accept button on the top panel of the instrument:-

Note: An alarm condition can only be muted when the sensor readings have returned to within the non-alarm level/s.

H2S 0.0 ▐ LEL

CO 0 ▐ O2 20.9

6.15 Low Battery Alarm

A low battery condition is indicated as below and is accompanied by an audible and visual alarm:-

When a low battery condition arises the instrument can no longer be used and must be re-charged. See section 0 for further details.

It is important to ensure that before the instrument is used that there will be adequate battery life to cover the period for which the

instrument is required.

LOW BATTERY

6.16 Display Backlight

Pressing the backlight button on the top panel of the instrument illuminates the display: -

The backlight will remain illuminated for 10 seconds or until the button is released. This time can be increased up to a maximum of 60

seconds using the PGD2 Interface Unit in conjunction with a PC running the configuration software supplied by Status Scientific

Controls.

Note that continued use of the backlight facility will reduce the instrument operating time.

12

Page 16

ENMET Corporation PGD2

6.17 Sensor Zero

Note: From software version 1.20 this facility can be disabled via the PC configuration program and may therefore be unavailable on

certain instruments.

The sensors can be automatically zeroed without the need for a complete re-calibration of the instrument. This is performed using the

sensor zero function. This function can only be accessed during the first minute of the instrument being switched on.

WARNING: This must only be carried out by authorized personnel in a fresh air environment, i.e. where it is known that there

are no toxic (e.g. fumes from vehicles) or flammable gases present.

Slight variations in the zero readings may occur if the instrument is moved between environments of significantly different

temperature. (Also refer to Section 12.3.4. for instruments containing Oxygen Sensors).

To carry out the zeroing function (during the first minute of the instrument being switched on) select the PGD Serial No. via the menu

button (Section 6.5) and press the right arrow key.

The instrument will show: -

This process takes approximately 30 seconds to complete. The instrument then returns to the normal display with the toxic and

flammable sensor readings set at zero and the oxygen reading set at

ZEROING SENSORS

PLEASE WAIT

20.9%.

6.18 EXP / LEL / VOL Display options

The display format for the flammable sensor can be configured to read in either of the following modes:-

EXP or LEL

VOL

For example, Methane gas is explosive with air in concentrations between approximately 5% and 15%. The Lower Explosive Limit

(LEL) is therefore 5% by volume.

The following table gives examples of how various Methane gas concentrations would be displayed: -

Gas concentration

(% Volume)

0.5%

1.25%

2%

2.75%

Configuration is carried out using the PGD2 Interface Unit in conjunction with a PC running the configuration software available as an

optional accessory.

both of these modes display the flammable sensor

reading as a % of the Lower Explosive Limit (LEL) for

the gas being measured.

this mode displays the flammable sensor reading as a

concentration of the gas being measured in % volume.

Reading shown in

‘VOL’ mode

0.5% 10

1.25% 25

2% 40

2.75% 55

Reading shown

in ‘EXP’ & ‘LEL’ modes

6.19 Confidence Bleep

The instrument can be configured to operate with or without a “confidence bleep” which is a visual and audible indication to the user

that the instrument is operational. Configuration is carried out using the PGD2 Interface Unit in conjunction with a PC running the

optional configuration software.

Where the “confidence bleep” is selected to be on, the time interval between bleeps is normally set at 10 seconds but can be set to an

alternative interval if required using the configuration software.

The red lens and the green power indicators flash in conjunction with the confidence beep.

6.20 User Identification

Instruments can be given unique user identification codes in addition to the serial number allocated during manufacture. This provides

a means to instantly identify instruments for example by user, site, company, hirer etc.

The user identification is programmed into the instrument using the PGD2 Interface Unit in conjunction with a PC running the optional

configuration software.

The identification can consist of up to 8 alphanumeric or other standard keyboard characters and is shown on the instrument display

preceding the serial number. for example :-

PGD SERIAL No.

A. SMITH 16105

13

Page 17

ENMET Corporation PGD2

6.21 Data Logging

All PGD2 instruments are fitted with data logging facilities which allow readings to be automatically recorded inside the solid state

memory of the instrument while in use. These readings can then be downloaded via a PGD2 Interface Unit to a PC containing the data

logging software available from Status Scientific Controls. This enables the gas levels to which personnel have been exposed, to be

examined and where necessary archived in accordance with the COSHH Regulations.

Data logging is configured using a PGD2 Interface Unit in conjunction with a PC running the configuration software supplied by Status

Scientific Controls. The data logging options are: i). Automatic

In automatic mode, the data logging rate (i.e. the interval between storing the readings) is varied according to the prevailing gas levels

present thereby optimizing the use of the data logging capacity available within the instrument. With no significant gases present the

instrument logs readings at the background rate (e.g. 5 min intervals). If any of the gas levels being monitored begin to rise then, at a

pre-determined level based upon the alarm set-points for each individual gas, the time interval between readings taken for all the

gases is reduced to the moderate rate of 30 seconds. Should any of the gas levels increase to the alarm level then the instrument

reduces the time between readings further to the fast rate (e.g. 10 seconds).

When the gas levels begin to fall the instrument reverses the above procedure.

The time intervals are configurable via the PGD2 Interface and PC to suit individual requirements.

The results stored in the automatic data logging mode vary according to whether the instrument is logging at the background,

moderate or fast rate:-

Background and moderate rates

Results stored are: -

a) An average reading for each gas during each sampling period. For example, if the logging rate is set at 5 minutes, then

the instrument will take 300 readings (1 per second) and calculate the averages which are then stored.

b) The minimum and maximum oxygen levels and the maximum flammable and toxic gas levels during the sampling period.

Fast rate

Results stored are: - as in a). above.

Note that the min / max levels are not stored in this mode.

Instruments configured in automatic data logging mode have the letters ‘Da’ after the software version which is displayed when the

instrument is switched on: -

ii). Fixed

In fixed mode, the data-logging rate (i.e. the interval between storing the readings) does not vary and the results are stored at the

intervals set during the configuration (e.g. 5 minutes).

Results stored are: -

a) An average reading for each gas during each sampling period. For example, if the fixed logging rate is set at 1 min then

the instrument will take 60 readings (1 per second) and calculate the averages which are then stored.

b) The minimum and maximum oxygen levels and the maximum flammable and toxic gas levels during the sampling period.

Instruments configured in fixed data logging mode have the letters ‘Df’ after the software version which is displayed when the

instrument is switched on:-

iii). Fixed Fast

This mode operates in the same way as the Fixed rate but date is stored at 10 second intervals.

iv). None

The configuration software also allows the data logging to be inoperative. In this case no data logging symbols appear after the

software version.

Normally the data logging will operate in a continuous loop ‘overwrite’ mode whereby old data is overwritten by new data once the end

of the data log memory is reached.

However, if the data logging memory becomes full when the instrument is in use, a warning message is given on the instrument

display which alternates with the normal readings: -

The instrument continues to operate normally but the data logging ceases.

If the data log is full when the instrument is switched on the display alternates between the following messages: -

PGD2 V4.4.2PAp Da

FLAM = METHANE

PGD2 V4.4.2PAp Df

FLAM = METHANE

CO 0 ▐ O2 20.9

DATA LOG FULL

DOWNLOAD IF REQ.

DATA LOG FULL H2S 0.0 ▐ LEL 0

PRESS [ ] KEY TO

CLEAR OLD DATA

14

Page 18

ENMET Corporation PGD2

6.22 Overrange Indication

If the concentration of the sampled gas exceeds the range of the sensors, the reading on the display changes to “HIGH” and the fault

indicators in the red lens section flash.

Readings are restored once the concentration falls back within the range of the sensor.

Note, however, that the flammable gas readings will permanently show “HIGH” until the instrument is switched off and then on again in

a fresh air base.

6.23 Fault Indication

The instrument is designed to continuously self-check itself for errors, either in the software or the hardware. Various fault messages

are displayed dependent on the program version and are accompanied by flashing fault indicators in the red lens section.

For example the following message is displayed if the PGD requires configuring:

Failure of a flammable gas sensor would lead to the following display:-

PGD NOT

CONFIGURED

H2S 0.0 ▐ LEL FAIL

CO 0 ▐ O2 20.9

6.24 Aspiration

The PGD2 instrument normally relies upon the gases present in the atmosphere naturally diffusing into the instrument sensors through

the gas inlets either side of the instrument. However, for certain gases, and in some situations it is necessary to take in gas samples

from an atmosphere away from the location of the instrument, for example, from down inside a manhole or from up in the roof of an

underground tunnel.

This can be accomplished by use of the optionally available internal pump in conjunction with the specially designed sampling kits –

see Section 7.

Required Accessories:

Description

Sampling Adaptor, Stainless Steel 03700-048

Sampling Adapter PTFE 03700-050

Sampling Hose 03700-031

Sampling Probe 03700-018

Filter Assembly Hydrophobic 02612-011

ENMET Part Number

15

Page 19

ENMET Corporation PGD2

7 P

Instruments having the pump option are fitted with an integral pump.

When the pump is switched on the gas sample is drawn through one sensor inlet and exhausted through the opposite sensor inlet

such that all of the sensors are exposed to the gas sample.

UMPED INSTRUMENTS

7.1 Pump Operation

Turn the instrument on. When the normal gas display appears, press the menu key:

until the following display appears:

Press the up arrow key. The pump will start and the following display appears:

At this stage, connect the adaptors of the sampling kit into the gas inlets of the instruments. Note that the inlets are different sizes and

will only fit the appropriate gas inlet. This prevents the sampling kit being fitted incorrectly.

After the sampling kit has been tightly fitted, press the up arrow key and the following display appears:

The gas readings are masked for 10 seconds. This is because the oxygen sensor is pressure sensitive and would otherwise create a

false oxygen alarm when the pump is turned on due to the temporary pressure transient that is created.

To turn the pump off, press the menu key:

until the following display appears:-

PUMP ON

PRESS [ ] KEY

CONNECT TUBING

PRESS [ ] KEY

PLEASE WAIT

█ █ █

Press the up arrow key and the following display appears:-

Remove the sampling kit and then press the up arrow key.

The pump switches off and the readings are masked for 10 seconds before the display returns to normal operation.

PUMP OFF

PRESS [ ] KEY

DISCONNECT TUBING

PRESS [ ] KEY

7.2 Pump Blockage

If a blockage occurs in the sampling kit during pump operation, the instrument will display:-

This is accompanied by an alarm and fault indication. The pump will automatically switch off.

The blockage must be located and removed before attempting further use.

If the blockage is within the instrument it must be returned to an approved workshop for dismantling and repair.

SAMPLING FAIL

DISCONNECT TUBE

16

Page 20

ENMET Corporation PGD2

8

C

AUTION

CALIBRATION

: PGD2 Instruments require that all active channels be calibrated after entering the calibration program. Do Not

enter the calibration program unless all calibration materials are available. Failure to calibrate an active channel will cause

a fault condition. See section 8.3 for examples of standard ENMET calibration gases.

8.1 Calibration

In order to ensure that the PGD2 instrument continues to provide accurate measurement of the intended gas levels it is vitally

important that the instrument receives regular calibration using precise reference gases traceable to National Standards. This is

necessary to correct for drift and ageing of the individual gas sensors and enables any sensors that require replacement to be

identified.

In general it is recommended that the period between calibrations should not exceed six months - unless otherwise requested, this is

the “calibration due” period programmed into the instrument during manufacture.

Calibration can either be carried out:

a). by returning the instrument to ENMET or authorized ENMET service center.

b). by the customer using the appropriate calibration equipment.

8.2 Keypad Calibration Procedure

Press the key until the display shows:

Press the up arrow key to begin calibration. The display will show:

CALIBRATE

PRESS [] KEY

ZERO CALIBRATE

[ ] OK [] EXIT

Press the right arrow key to zero the PGD’s sensors, or the up arrow key to exit.

WARNING

carried out in a fresh air environment, i.e. where it is known that there are no toxic (e.g. fumes from vehicles) or flammable

gases present.

C

AUTION: CO2 sensors require the sensor zero function be performed with bottled 20.9% oxygen that does not contain trace

amounts of CO2 and a calibration adapter. See Section 8.3 for gas and accessory list.

Slight variations in the zero readings may occur if the instrument is moved between environments of significantly different

temperature. (Also refer to Section 12.3.4. for instruments containing Oxygen Sensors).

To carry out the zeroing function press the menu button until zero sensors appears then press the right arrow key.

The instrument will show:

If your PGD2 has a CO2 sensor, connect the calibration adapter to the appropriate port and flow 20.9 air.

This process takes approximately 60 seconds to complete. The instrument then goes to calibrate. Press the up arrow key to exit.

If you choose to go on to zero calibration, the display will show:

Press the menu button. The display will show:

: Sensor zero is performed on all active sensors when the zero function program is entered. This must only be

ZEROING SENSORS

PLEASE WAIT

ZEROING O2 LEVEL

APPLY ZERO GAS

[ ] OK

20.9

N

OTE

: If the instrument has a CO2 sensor installed connect a calibration plug to the correct port and connect the zero gas to the plug.

Press the [ ] button and start the flow of the zero gas (20.9 Air). The display will show:

ZEROING SENSORS

PLEASE WAIT

17

Page 21

ENMET Corporation PGD2

In approximately 60 seconds the display will change to:

Then progress through all active channels.

C

AUTION: If you choose [ ] OK you must calibrate all active channels. Make sure all required materials are available.

The PGD2 instrument enters the Span/Calibrate gas selection. The display will show the last concentration of gas used for calibration.

You may change the Span/Calibration by pressing the [ ] button to decrease the value and the [ ] button to increase the value.

Press the menu button to accept the value

Then progress to the next active channel.

Example: Then Then

SET SPAN GAS SET GAS LEVEL

After all active channels Span/Calibration gas level sets the PGD2 enters Span/Calibration gas application.

Connect the calibration adapter to the appropriate ports.

The display will show:

ZEROING SENSORS

PLEASE WAIT

CH4 LEVEL (R1)

2.5

(2.5 = 50% LEL)

N

OTE

: Some sensors for example, Chlorine, Ozone, Hydrogen chloride require longer periods of span/calibration gas application. For

this type of sensor it is recommended that you apply the span/calibration gas for 3 to 5 minutes prior to pressing the OK button.

Press the [ ] OK button, the display will show:

Example:

Apply the Span/Calibration gas. Example, 2.5%Ch4 (50% LEL). The display will show:

The PGD2 will auto calibrate, calibration time is approximately 3 minutes. At the end of the calibration the display will show:

And the will move on to the next channel to be calibrated.

N

OTE

: Some sensors for example, Chlorine, Ozone, Hydrogen chloride have cross sensitivity to other types of gasses and therefore

require the application of clean/zero air before they can be calibrated properly.

The Display will show:

APPLY 2.5 CH4

[ ] OK

READING CH4

WAITING FOR GAS

CH4 Ready

XXX LEVEL

ADJUST TO

XXX ADJUSTED VALUE

APPLY XXX (NEXT GAS)

[ ] OK

Remove the Span/Calibration gas for the completed calibrated channel

Repeat the calibration steps for all active channels.

When the last active channel is calibrated the

PGD2

instrument returns to operation mode.

18

Page 22

ENMET Corporation PGD2

8.3 Examples of standard ENMET Calibration Gas & Accessories

Part number Description

03296-209 Gas Cylinder, Clean Air/Zero Gas, 20.9% oxygen in nitrogen

03220-050 Gas Cylinder, 25% by vol/50%LEL methane/CH4 in nitrogen

03220-199 Gas Cylinder, 100% by vol methane/CH4

03314-020 Gas Cylinder, 20ppm H2S in air

03223-2000 Gas Cylinder, 2000 ppm CO2 in air

03302-010 Gas Cylinder, 10 ppm HCL in air

03331-010 Gas Cylinder, 10 ppm CL2 in air

02506-002 Cylinder Regulator

02506-004 Cylinder Regulator

03700-041 Calibration Adapter, Stainless Steel

03700-046 Calibration Adapter, PTFE

03700-048 Sampling Adapter, Stainless Steel

03700-050 Sampling Adapter, PTFE

9 B

ATTERY CHARGING EQUIPMENT

Warning: Equipment used for charging of the Portable Gas Detector battery must be located in a safe area i.e. in an

atmosphere where it is known that there is no risk of the presence of combustible gas.

The PGD2 instrument is fitted with a rechargeable battery pack. There are a number of different purpose designed chargers which can

be used and these are detailed later in this section. Improvements to the battery charging equipment have been made over the lifetime

of the product and so earlier equipment which is no longer manufactured is not listed below.

The battery module can either be charged: -

a) within the instrument without removal from it’s protective boot using the equipment detailed in the following sections.

or,

b) separately when removed from the instrument using the equipment detailed in Section 9.5.

List of recommended chargers.

Description Type

‘Smart’ Charger PGDC2

Charger Interface Unit PGDC2/I

Vehicle Mounted ‘Smart’ Charger PGDC3

Compact Charger PGDC4

5-Way Charger PGDC5

Multi-volt Charger PGDC6

Note – The Compact Charger is the standard charger that is supplied with each new instrument unless otherwise requested.

19

Page 23

ENMET Corporation PGD2

9.1 Compact Charger Type PGDC4

Compact Charger & Transformer

This is the standard charger that is supplied with each new instrument unless otherwise requested.

The Compact Charger is designed to optimize the charging of the battery and minimise the charge time by continuously electronically

monitoring the state of charge. When used with these chargers the instrument must be switched off during the charge period.

Note that these chargers only make use of two of the three charging pins on the rear of the instrument.

9.2 5-Way Charger Type PGDC5

This charger operates in the same manner as the compact charger but is directly powered from the mains supply via an IEC mains

connector.

9.3 Vehicle-Mounted Charger Type PGDC3

The PGDC3 charger is specially designed for use in vehicles where the charging power is derived from the vehicle battery. The

charger is designed to optimize the charging of the battery and minimize the charge time by continuously electronically monitoring the

state of charge.

9.4 Charger Type PGDC2, PGDC2/I

The PGDC2 single instrument ‘Smart’ charger and PGDC2/I single instrument ‘Smart’ charger/interface unit are designed to optimize

the charging of the battery and minimize the charge time by continuously electronically monitoring the state of charge. When used with

these chargers the instrument must be switched off during the charge period.

Note that these chargers only make use of two of the three charging pins on the rear of the instrument.

9.5 Battery Module Charging

Rechargeable battery modules may be charged separately from the PGD2 instrument using a Battery Module Charger Adaptor Plate

Type PGD/ADT.

This provides a flexible and economical method of separately charging the PGD2 battery module.

The plate can only be used with the single instrument mains powered ‘Smart’ charger Model PGDC2.

The plate locates into the lower section of the charger with the charger pins passing through the cut-out of the adaptor plate. The

battery module is first removed from the instrument as shown in Section 10 and then placed into the adaptor and is charged in the

same manner as for a complete instrument as described in Section 9.4.

10 B

To replace the rechargeable battery module, remove the instrument from its protective rubber boot. In order to remove the rubber

boot, first remove the straps (if fitted). This is performed by depressing the clips on both sides of the instrument. With the straps

removed, ensure that the rubber boot is not snagged on the three charging pins at the rear of the instrument. Hold the instrument in

the palms of the hand with your thumbs on the vacant strap clips. Place the base of the instrument across the edge of a firm surface

e.g., a table or workbench. Push down on the vacant strap clips firmly and the PGD2 will release from the tapered rubber boot. The

boot can then be pulled off the instrument thus avoiding the need to ‘peel’ back the boot and potentially damage it. Undo the lower

three ‘Allen’ screws using the tool supplied (2mm A/F) – see Figure 3 in section 5. It is then possible to pull out the complete battery

module.

Note that the screws are retained in the cover by small ‘O’ rings over the screw threads.

ATTERY REPLACEMENT

Figure 4 - Rubber Boot Removal

20

Page 24

ENMET Corporation PGD2

11 H

AZARDOUS AREA USE

11.1 Areas of use

The PGD2 Portable Gas Detector is intended to be used for personnel protection and is specifically designed and certified to be safe

in the following areas: -

i) Confined spaces

that is, areas where normal atmospheric ventilation is not available,

e.g. sewers, tunnels, ducts, storage vessels etc.

ii) Hazardous areas

classified as follows: -

Zone 0 - Explosive gas/air mixture continuously present, or present for long periods.

Zone 1 - Explosive gas/air mixture is likely to occur in normal operation.

Zone 2 - Explosive gas/air mixture not likely to occur and, if it occurs, it will exist only for a short time.

11.2 Methods of use

The PGD2 can be utilized for: -

i) Personal protection

where the instrument is worn on the person as close to the breathing area as possible and switched on at all times.

ii) Group protection

used in a ‘Sentinel’ mode where the instrument is switched on and suspended at a suitable point in the working area, and the

360 degree visual and audible alarms are utilised.

11.3 Basic Precautions

The following basic precautions should be observed in order to ensure that the instrument provides the protection for which it is

intended: a) Ensure that the instrument is of the correct Model for the gases to be detected.

b) Before use, check that the instrument is within its calibration period - see Section 6.8.

c) Before use, check that the instrument is not physically damaged and that all covers are intact.

d) Before use, establish that the instrument has been charged sufficiently.

e) When in use, ensure that the gas sensor inlets are not obstructed - the instrument must not be used whist in a pocket, bag or

other confined container.

f) When lowering the instrument into for example, a manhole, ensure that it is not lowered into water.

g) Use the instrument in its rubber boot at all times.

h) If an instrument fitted with dry cells is out of use for more than a week, or if the cells are exhausted, they should be removed to

prevent corrosion of the instrument due to leakage of the cell electrolyte.

11.4 Confined Space Pre-entry Checks

The area to be investigated prior to entry can be checked in two ways: -

i). Peak Reading Mode

With the instrument selected for this mode as described in Section 6.3, it can be lowered into the confined space. It should be

left there for a minimum period of 1 minute; upon withdrawal the display will show the maximum readings obtained for the

flammable and toxic sensors and the minimum reading for the oxygen sensor. If any of the sensors detect gas above or below

(in the case of oxygen) the pre-set alarm levels then the visual and audible alarm will be operating and reference should be

made to supervisory personnel.

ii). Aspiration

Having selected and fitted an aspirator appropriate to the duty (refer to Section 6.24), a sample can be drawn, either manually

or by use of the internal pump if fitted, from the confined space. Care should be taken to ensure that a representative sample

has been obtained from the area under investigation using the guidelines given in Section 6.24. If any of the sensors detect

gas above or below (in the case of oxygen) the pre-set alarm levels then the visual and audible alarm will be operating and

reference should be made to supervisory personnel.

21

Page 25

ENMET Corporation PGD2

12 S

ENSORS

12.1 Flammable Sensors

The PGD2 instrument can be fitted with sensors for the detection of various types of flammable gases. The sensors used are of the

catalytic oxidation type generally referred to as “pellistors”. Sensors of this type consist of a matched pair of elements known as the

detector and compensator.

Either one or two pairs of pellistors may be fitted within the instrument depending upon whether it is required to measure only up to the

Lower Explosive Limit of the gas (one pair fitted) or up to 100% volume of the gas (two pairs fitted). The warm up time for either type is

less than 15 seconds, this takes place when the instrument is switched on. No readings are displayed during this period.

The flammable sensors are non-selective that is, they will detect a range of hydrocarbon gases. However, during manufacture of the

PGD2 instrument the sensors are calibrated to methane gas and the user may then select other gases from the menu selection as

described in Section 6.11. The instrument automatically applies the appropriate calibration factor according to the gas selected so that

the correct reading is given on the display.

12.1.1 LEL Flammable Sensors

Where only one set of pellistors is fitted, to enable measurement up to the Lower Explosive Limit of the flammable gases

(approximately 5% volume), the pellistor detector and compensator are encapsulated into individual stainless steel housings behind

individual stainless steel sintered flame arrestors. The stainless steel housings are contained within in a blue coloured plastic

moulding which also houses the oxygen sensor (if fitted).

Where fitted, the flammable sensor and oxygen sensors are located behind the instruments’ right hand side gas inlet as viewed from

the front.

There are two types of LEL sensors available:-

i). Type SS10 – for general hydrocarbons e.g. Methane, Propane etc. and Hydrogen.

ii). Type VQ41 – for detection of fuels e.g. diesel, aviation fuels etc.

LEL Flammable Sensor Specification

Gases detected - Various combustible gases and vapors

Range - 0 - 100% LEL

Resolution - 1% LEL

Operating Voltage - 2 ± 0.1 Volts dc

Operating Current - 180 mA

T

Response Time - < 10 Seconds

90

Linearity - Linear 0-100% LEL Methane

Long Term Sensitivity

Drift - < 5% signal / month

Long Term Zero Drift - < 2% LEL methane / month

22

Page 26

ENMET Corporation PGD2

12.1.2 0 - 100% Volume Flammable Sensors

For measurement of flammable gas concentrations up to 100% volume two pairs of pellistors are fitted one pair covering

measurements up to approximately the Lower Explosive Limit as specified in the previous section 12.1.1 and a second pair covering

measurements from the Lower Explosive Limit up to 100% volume.

The PGD2 instrument automatically switches between the pairs of pellistors according to the gas concentration present in order to

provide the most accurate reading.

The two pairs of pellistors are encapsulated into individual stainless steel housings. The LEL pellistors (both detector and

compensator) and the 100% volume detector pellistor are each behind individual stainless steel sintered flame arrestors while the

100% volume compensator housing is sealed.

The four individual stainless steel housings are contained within a black coloured plastic moulding which is normally mounted behind

the instruments’ right hand side gas inlet as viewed from the front.

Note that this arrangement represents the equivalent of two gas sensors such that instruments fitted with 0-100% flammable

sensors can only be fitted with an oxygen sensor plus one toxic sensor as a maximum.

Where an oxygen sensor is also fitted then this is mounted (via an oxygen sensor seal) behind the black coloured flammable sensor

housing.

Where a toxic sensor is also fitted then this must be of the ‘3 - series’ type e.g. 3CO, 3H, 3Cl etc.

0-100% Volume Flammable Sensor Specification

Gases detected - Various combustible gases and vapors

Range - 0 - 100% Volume

Resolution - 0.05% Volume

Operating Voltage - 2 ± 0.1 Volts dc

Operating Current - 180 mA

T90 Response Time - < 10 Seconds

Linearity - Linear 0-5% Methane

Linearised over the range 5% to 100% via the instrument software

Long Term Sensitivity

Drift (0-5%) - < 5% signal / month

Long Term Zero

Drift (0-5%) - < 2% LEL methane / month

Range Changing - Automatically carried out by the instrument

23

Page 27

ENMET Corporation PGD2

12.2 Toxic Sensors

The PGD2 instrument can be fitted with either one or two toxic gas sensors as detailed in the following sections. However, it should be

noted that where an instrument is fitted with two sets of pellistors to provide monitoring of flammable gases up to 100% volume then

only one toxic sensor (3-series type) can be accommodated.

The toxic gas sensors are of the three-electrode electrochemical type and are designated as either the ‘3-series’ or ‘4-series’

(miniature) toxic sensors. The type/s fitted within a particular instrument will depend upon the gas sensing application and also the

physical arrangement of the instrument internally in order to achieve the requirements of the particular intended application.

12.2.1 Cross Sensitivity

The user should be aware that although the toxic sensors are designed to respond to the presence of specific gases they may also

exhibit response to other gases. This is known as their cross-sensitivity.

Some toxic sensors can be supplied fitted with chemical inboard filters to reduce the cross-sensitivities to other gases.

It is not within the scope of this instruction manual to detail the cross-sensitivity of each toxic sensor to each interfering gas. For further

information on this subject contact ENMET customer service.

12.2.2 Temperature Dependence

Toxic sensors exhibit changes in output signal with changes in temperature.

When exposed to sharp changes in temperature the toxic sensor/s will exhibit a transient response which should die away within

approximately 20 seconds.

12.2.3 Stabilization

New toxic sensors when supplied as spares are fitted with a shorting link across the Sensing and Reference terminals which maintain

the sensor in a ‘ready to work’ condition. This shorting link must be removed before the sensor is fitted into the PGD2.

Once a sensor is fitted into the instrument it relies upon the main battery power to maintain its ‘ready to work’ status. If the battery pack

is removed or the battery life is exhausted, the instrument may alarm or display erroneous readings following battery pack

replacement. This is normal when the sensors have not been powered for a prolonged period. Normal readings will continue when the

sensors have been allowed to stabilise (within 2-3 hours following battery pack replacement dependant upon sensor type). This

condition only occurs after a prolonged period without batteries fitted and should not occur during normal battery changing when the

sensors should stabilise within 5 minutes.

Common characteristics

The following characteristics are common to all of the toxic sensor types:-

Common Characteristics of the Toxic Gas Sensors

Expected operating life - 2 years

Storage life - 6 months in container provided

Recommended storage temp. - 0 - 20 degrees C

Operational temp. range - -20 to +50 degrees C

Relative humidity - 15 to 90% non-condensing

Pressure range - Atmospheric ± 10%

Poison sensitivity - None

24

Page 28

ENMET Corporation PGD2

90

90

90

90

90

90

90

90

90

12.2.4 Toxic Sensor Types and Characteristics

Carbon Monoxide (CO)

Type No’s 4CF 3E Surecell CO 3E 300

Nominal Range

Resolution

T

Response Time

Inboard Filter (Y/N)

0-500ppm 0-1000ppm 0-500ppm 0-500ppm

1ppm 0.5ppm 1ppm < 3 ppm

<20 secs <25 secs <20 secs <30 secs

Yes No Yes Yes

Type No’s 3E/F 3F/F

Nominal Range

Resolution

T

Response Time

Inboard Filter (Y/N)

0-1000ppm 0-4000ppm

0.5ppm 1 ppm

<30 secs <30 secs

Yes Yes

Hydrogen Sulphide (H2S)

Type No’s 4HS 3H Surecell

Nominal Range

Resolution

T

Response Time

Inboard Filter (Y/N)

0-100ppm 0-200ppm 0-200ppm

0.1ppm 0.25ppm 0.1ppm

<30 secs <35 secs <10 secs

No No Yes

Sulphur Dioxide (SO2)

Type No’s 4S 3SH 3ST/F

Nominal Range

Resolution

T

Response Time

Inboard Filter (Y/N)

0-20ppm 0-20ppm 0-100ppm

0.1ppm 0.1ppm 0.5ppm

<15 secs <15 secs <20 secs

No No Yes

Nitric Oxide (NO)

Type No’s 4NT 3NT

Nominal Range

Resolution

T

Response Time

Inboard Filter (Y/N)

0-250ppm 0-100ppm

0.5ppm 0.5ppm

<20 secs <10 secs

No No

Nitrogen Dioxide (NO2)

Type No’s 4ND 3NDH

Nominal Range

Resolution

T

Response Time

Inboard Filter (Y/N)

0-30ppm 0-20ppm

0.1ppm 0.1ppm

<25 secs <35 secs

No No

Chlorine (Cl2)

Type No’s Surecell 3CLH

Nominal Range

Resolution

T

Response Time

Inboard Filter (Y/N)

0-20ppm 0-20ppm

0.1ppm 0.1ppm

<60 secs <60 secs

Yes No

Hydrogen (H2)

Type No’s 3HYT H2 3E 4%

Nominal Range

Resolution

T

Response Time

Inboard Filter (Y/N)

0-1000ppm 0-4%

2ppm 100ppm

<30 secs <60 secs

No Yes

Hydrogen Chloride (HCl)

Type No’s 3HL

Nominal Range

Resolution

T

Response Time

Inboard Filter (Y/N)

0-100ppm

0.5ppm

<120 secs

No

25

Page 29

ENMET Corporation PGD2

12.3 Oxygen Sensors

WARNING: The instrument is not designed for use in oxygen enriched atmospheres i.e. greater than 21% oxygen.

The PGD2 instrument can be fitted with either of the oxygen sensors detailed in the following section 12.3.5 to allow measurement of

oxygen deficiency.

With the exception of instruments fitted with 0-100% volume flammable sensors, the oxygen sensor is contained within a blue colored

plastic molding normally located behind the instruments’ right hand side gas inlet as viewed from the front. On instruments fitted with

0-100% volume flammable sensors, the oxygen sensor (type C/2 only) is mounted behind the black colored flammable sensor

housing.

12.3.1 Cross Sensitivity

In general, toxic gases at the levels of concentration experienced in normal use have no cross sensitivity effect on the oxygen sensor.

However, acid gases such as CO2 and SO2 give a small enhancement (e.g. about 0.3% of signal per 1% CO2) to the oxygen reading.

12.3.2 Temperature

The oxygen sensors themselves have a characteristic that varies with temperature. However, this is compensated in the PGD2

instrument software and is therefore insignificant to the user.

12.3.3 Pressure Transients

Oxygen sensors are sensitive to sudden changes in pressure as may be experienced when travelling in a lift shaft or through doors

underground where there is a significant ventilation pressure differential between the two sides of the door(s). Under such

circumstances the instrument may react to the pressure transient, possibly resulting in a temporary alarm condition being given. This

transient will normally fade away after approximately 10 seconds, whereupon the alarm can be reset.

12.3.4 Humidity