Page 1

ENMET

ENMET Corporation

ENMETENMET

PO Box 979

Ann Arbor, MI 48106-0979

MX32 E

NGUARD

Operation and Maintenance

Manual

Manual Part Number

80003-040

MCN-370, 05/30/07

Page 2

Page 3

Table of Contents

1.0 INTRODUCTION........................................................................................................................................................1

1.1 U

NPACK

......................................................................................................................................................................1

1.2 C

HECK ORDER

1.3 S

ERIAL NUMBERS

2.0 FEATURES..................................................................................................................................................................2

.............................................................................................................................................................1

........................................................................................................................................................1

2.1 MX32 C

2.2 F

ONTROL ELEMENTS

RONT PANEL FEATURES

.........................................................................................................................................2

..............................................................................................................................................3

3.0 INSTALLATION .........................................................................................................................................................5

3.1 M

3.2 W

OUNTING

IRING THE

MX32 C

MX32 C

ONTROL

ONTROL

.......................................................................................................................................5

......................................................................................................................................6

3.2.1 Relay Contacts.....................................................................................................................................................6

3.2.2 Wiring Requirements............................................................................................................................................6

4-20 Sensor/Transmitter................................................................................................................................................8

4.0 OPERATION................................................................................................................................................................9

4.1 F

RONT PANEL PUSHBUTTON SWITCHES

4.2 D

ISPLAY AT START-UP

4.3 D

ISPLAY CYCLE OF CHANNEL MEASUREMENTS

...............................................................................................................................................10

........................................................................................................................9

..........................................................................................................11

4.3.1 Display of No Measurements Mode ....................................................................................................................11

4.3.2 Display of a Single Channel Mode......................................................................................................................11

5.0 MAINTENANCE .......................................................................................................................................................12

5.1 E

NTER THE MAINTENANCE MENUS

..............................................................................................................................12

5.1.1 Entering the Maintenance Menus........................................................................................................................12

5.1.2 Exit the Maintenance Menus...............................................................................................................................12

5.1.3 MX32 C

5.2 P

ROGRAMMING MENU

5.3 I

NITIALIZATION

5.4 C

ALIBRATION MENU

ONTROL

(INI)

Sequence of Maintenance Menus.............................................................................................13

................................................................................................................................................14

MENU

.......................................................................................................................................17

MX32 C

ONTROL

.......................................................................................................................18

5.4.1 Calibration Following an Initialization Non Oxygen Transmitter........................................................................18

5.4.2 Calibration For regular preventive maintenance ................................................................................................19

5.5 C

HANGING ACCESS CODE

5.6 B

UZZER MENU

...........................................................................................................................................................20

..........................................................................................................................................20

6.0 WARRANTY..............................................................................................................................................................21

List of Illustrations

F

IGURE

F

IGURE

F

IGURE

F

IGURE

T

ABLE 1A

F

IGURE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

1: MX32 F

2: MX32 F

3: MX32 D

4: M

: F

5: MX32 C

1:

WIRING TERMINAL

2: W

3: W

4: MX32 C

EATURES

RONT PANEL

ISPLAY

OUNTING

AULT AND ALARM RELAY SETTING

ONTROL MAIN POWER AND CHANNEL BOARD

.................................................................................................................................. 2

............................................................................................................................. 3

..................................................................................................................................... 4

MX32 .................................................................................................................................. 5

........................................................................................................ 6

.................................................................................................................................... 8

IRING FOR A TWO WIRE

IRING FOR A THREE WIRE

ONTROL SEQUENCE OF MAINTENANCE MENUS

S/T.................................................................................................................. 8

S/T............................................................................................................... 8

.............................................................................. 7

.............................................................................13

Page 4

Page 5

MX32 E

1.0 Introduction

1.0 Introduction

1.0 Introduction1.0 Introduction

N

NGUARD

The MX32 C

sensor/transmitter.

The measurement output form the sensor is displayed on the MX32 C

thresholds. If the thresholds are exceeded, the control unit activates audio alarms, visual alarms and relays that may be

used to control external devices.

OTE

: All specifications stated in this manual may change without notice.

ONTROL

unit can monitor one or two independent channels. Each channel is connected to one

ONTROL

unit and compared with preset alarm

ENMET Corporation

1.1 Unpack

Unpack the MX32 C

customer service personnel and the commercial carrier involved immediately.

ONTROL

and examine it for shipping damage. If such damage is observed, notify both ENMET

Regarding Damaged Shipments

N

OTE

: It is your responsibility to follow these instructions. If they are not followed, the carrier will

not honor any claims for damage.

This shipment was carefully inspected, verified and properly packaged at our company and delivered to the

carrier in good condition.

When it was picked up by the carrier at ENMET, it legally became your company’s property.

If your shipment arrives damaged:

• Keep the items, packing material, and carton “As Is.” Within 5 days of receipt, notify the carrier’s local

office and request immediate inspection of the carton and the contents.

• After the inspection and after you have received written acknowledgment of the damage from the carrier,

contact ENMET Customer Service for return authorization and further instructions. Have your Purchase

Order and Sales Order numbers available.

ENMET either repairs or replaces damaged equipment and invoices the carrier to the extent of the liability

coverage, usually $100.00. Repair or replacement charges above that value are your company’s responsibility.

The shipping company may offer optional insurance coverage. ENMET only insures shipments with the

shipping company when asked to do so in writing by our customer. If you need your shipments insured, please

forward a written request to ENMET Customer Service.

Regarding Shortages

If there are any shortages or questions regarding this shipment, please notify ENMET Customer Service within 5 days

of receipt at the following address:

ENMET Corporation

680 Fairfield Court

Ann Arbor, MI 48108

734-761-1270 734-761-3220 Fax

1.2 Check Order

Check, the contents of the shipment against the purchase order. Verify that the MX32

ordered. If there are accessories on the order, ascertain that they are present. Check the contents of calibration kits.

Notify ENMET customer service personnel of any discrepancy immediately.

CONTROL

is received as

1.3 Serial Numbers

Each MX32 C

database.

ONTROL

is serialized. These numbers are on tags on the equipment and are on record in an ENMET

1

Page 6

ENMET Corporation MX32 E

Access Cover

Smoke Grey

2.0 Features

2.0 Features

2.0 Features2.0 Features

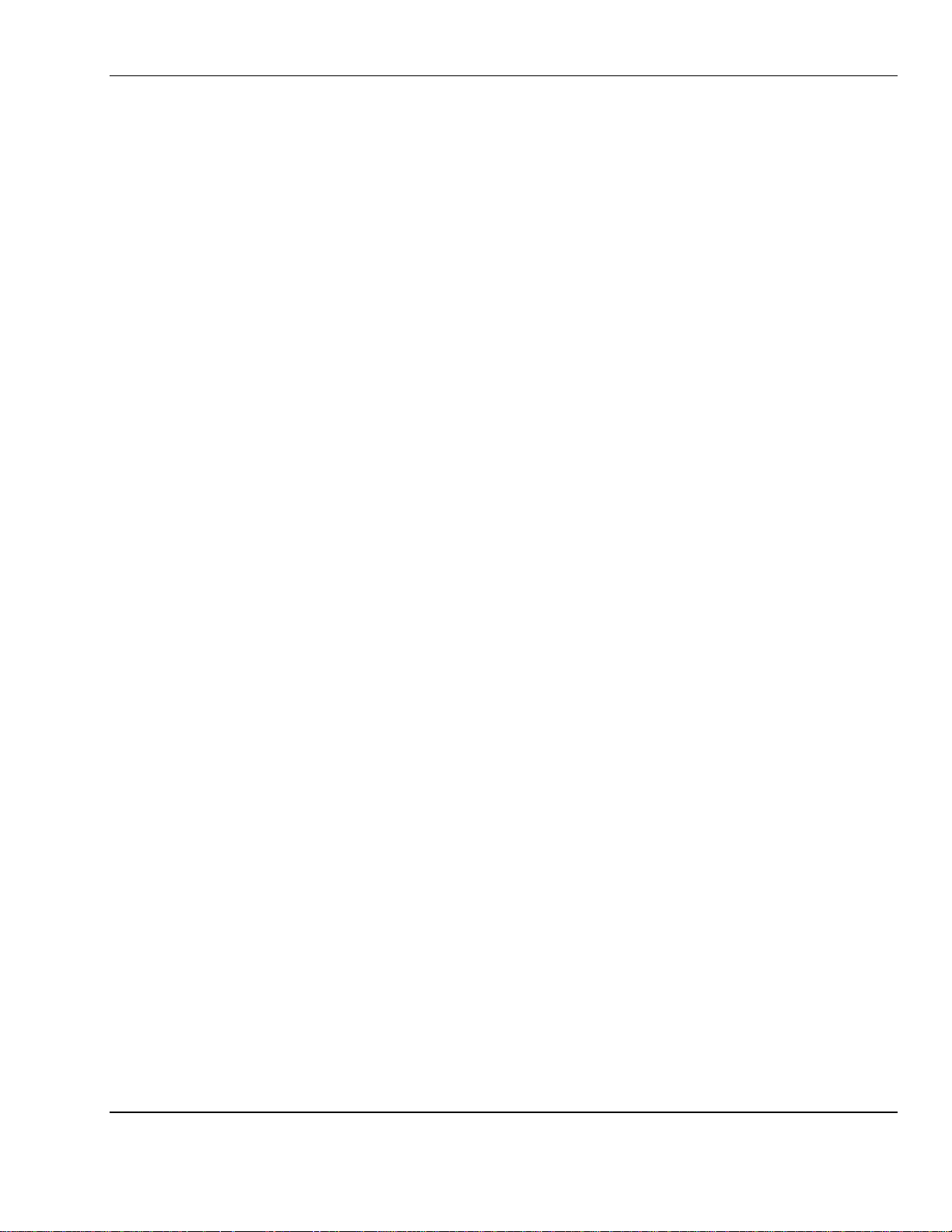

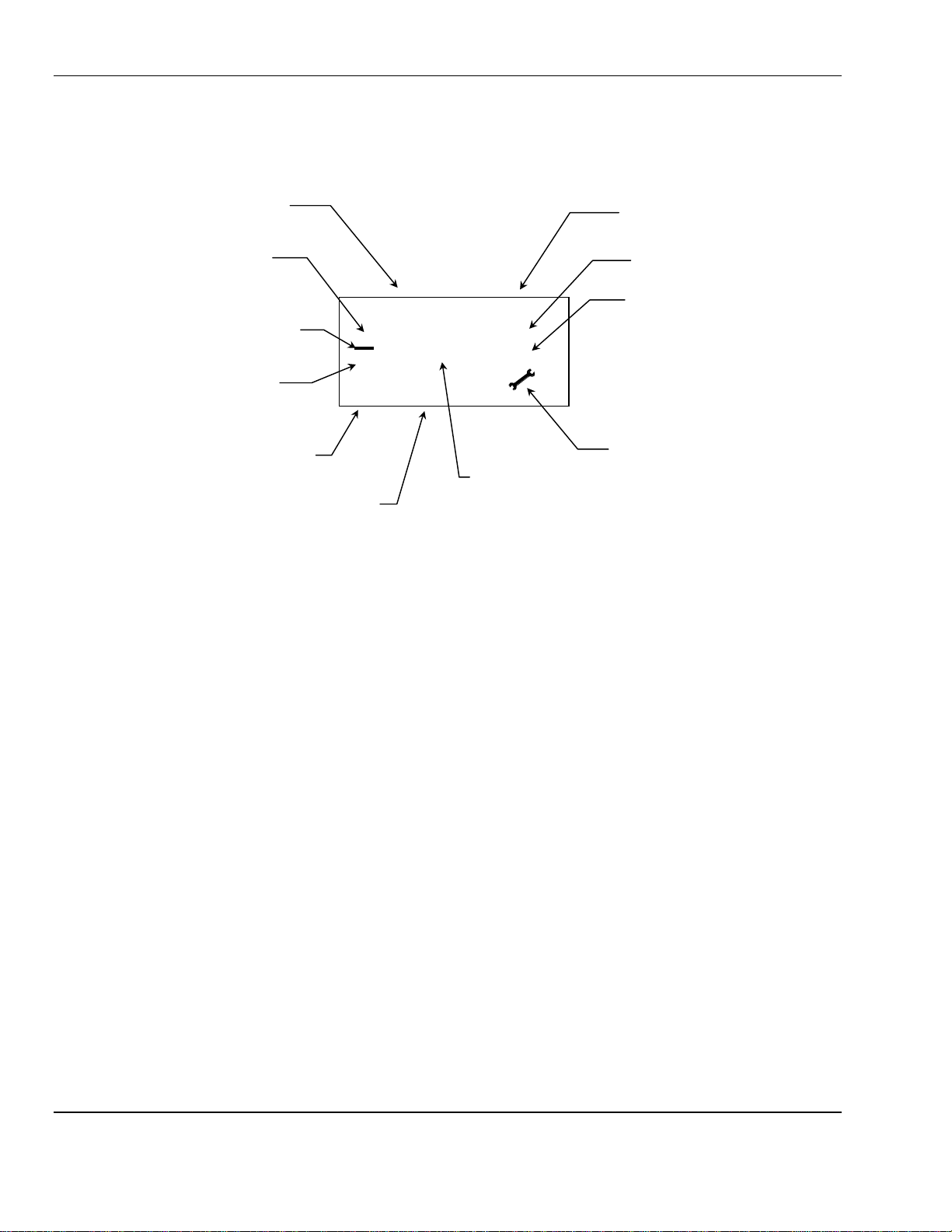

2.1 MX32 Control elements

The MX32 C

Enclosure rated IP 65, NEMA-12, 12K.

Hinged smoke gray viewing cover.

Main power and channel board, that has terminals for power, sensors and relays. Located under access cover.

Display board, attached to front panel.

Front panel with display, alarm LEDs, buzzer (horn) and pushbutton switches.

Enclosure

ONTROL

unit is made up of the following elements:

Display Board

Front Panel

NGUARD

Power, Sensor

and Relay

Terminal

Viewing Cover

Hinged on the

left side

Figure 1: MX32 Features

2

Page 7

MX32 E

Display LCD

Strain Relief

Fault / Calibration /

Channel 2

Alarm 2 LED for

Alarm 1 LED for

each channel

Display / Operation

Front Panel

NGUARD

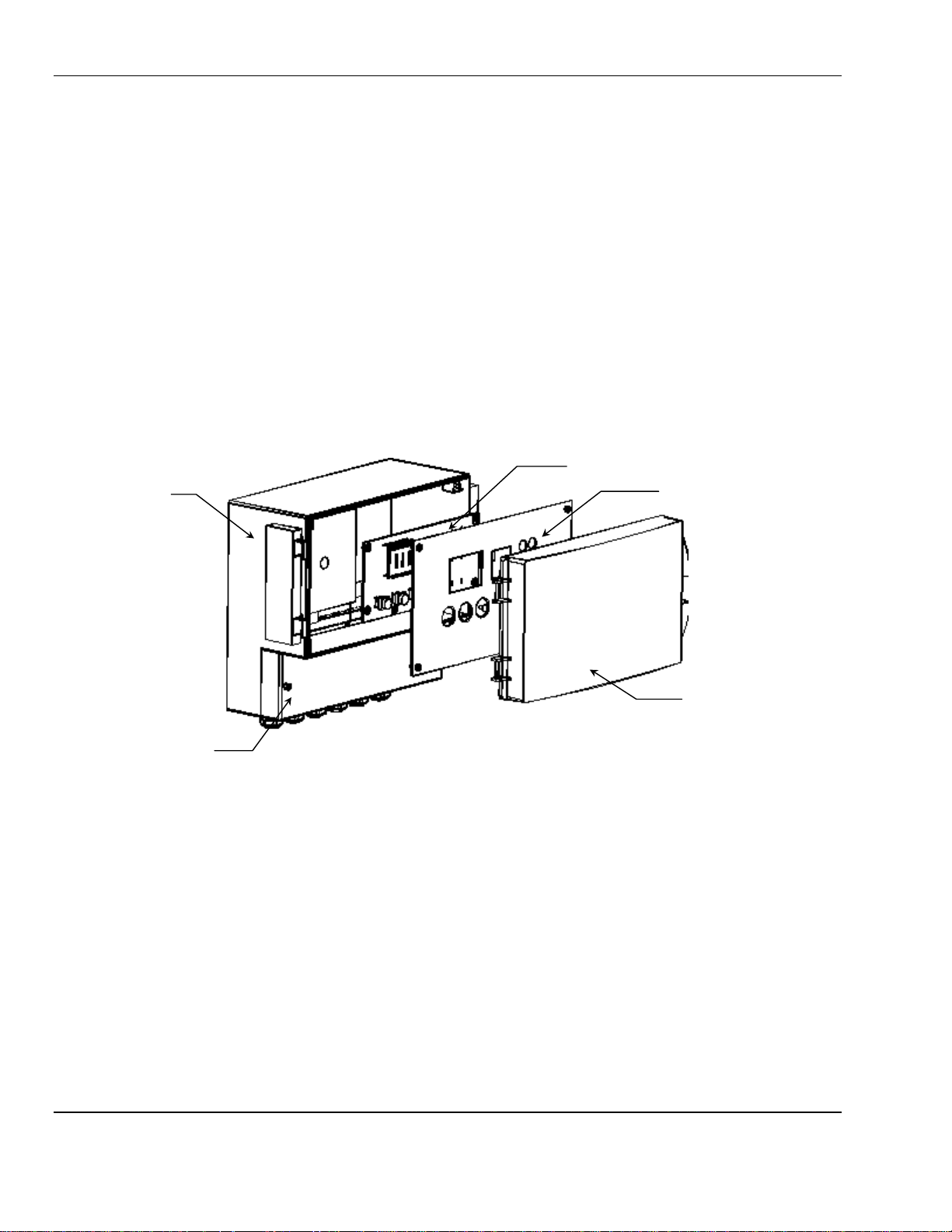

2.2 Front panel features

See Figure 2 for location of features.

LED Description

ENMET Corporation

Display/Operation

[ Lighting bolt on front panel ]

Green LED

When the green LED is blinking the channel is in program mode.

When the green LED is on steady the channel is in operation.

AL1 [ Bell on front panel ] Alarm 1 red LED when in alarm

AL2 [ Bell on front panel ] Alarm 2 red LED when in alarm

Fault / Calibration / Program

[ Wrench on front panel]

Lower most yellow LED

When the yellow LED is on steady, it indicates a malfunction on the line.

When the yellow LED is blinking the channel is in calibration or program mode.

Channel 1 LEDs

See figure 3 for details

Buzzer

LEDs

LED for each channel

Switches

For input cables

each channel

Program LED for

each channel

Figure 2: MX32 Front Panel

3

Page 8

ENMET Corporation MX32 E

%

Increasing

Indicator

Descending

Indicator

AL1 Alarm

AL 2 Alarm

Smaller Characters for:

Larger Characters for:

NGUARD

Channel 1 Indicator

Value

Negative Sign

Value

indicator

1 2

indicator

8888

HHH

Gas Measurement

Access Code

Maintenance Menus

May display SAVE or ENRG

Channel 2 Indicator

Percent Sign

Gas type

Unit of Measure

Maintenance Menus

May display

YES or OUI

NO or NON

Maintenance Menu Indicator

Figure 3: MX32 Display

N

OTE

: In some applications, slight electronic noise between the Sensor/Transmitter and the Control can cause

fluctuations in the display reading. These minor fluctuations are considered to be insignificant in terms of the

range, detection limit and alarm values of the gas being monitored.

4

Page 9

MX32 E

3.0 Installation

3.0 Installation

3.0 Installation3.0 Installation

NGUARD

The MX32 C

preferably be placed in a ventilated and monitored location, such as guardhouse, control room, instrumentation room,

etc.

N

OTE

: To be able to fully open the hinged front cover of the MX32 C

cover.

ONTROL

can be installed in any indoor area that is not classified a hazardous atmosphere. It should

ONTROL

, allow space for opening the viewing

ENMET Corporation

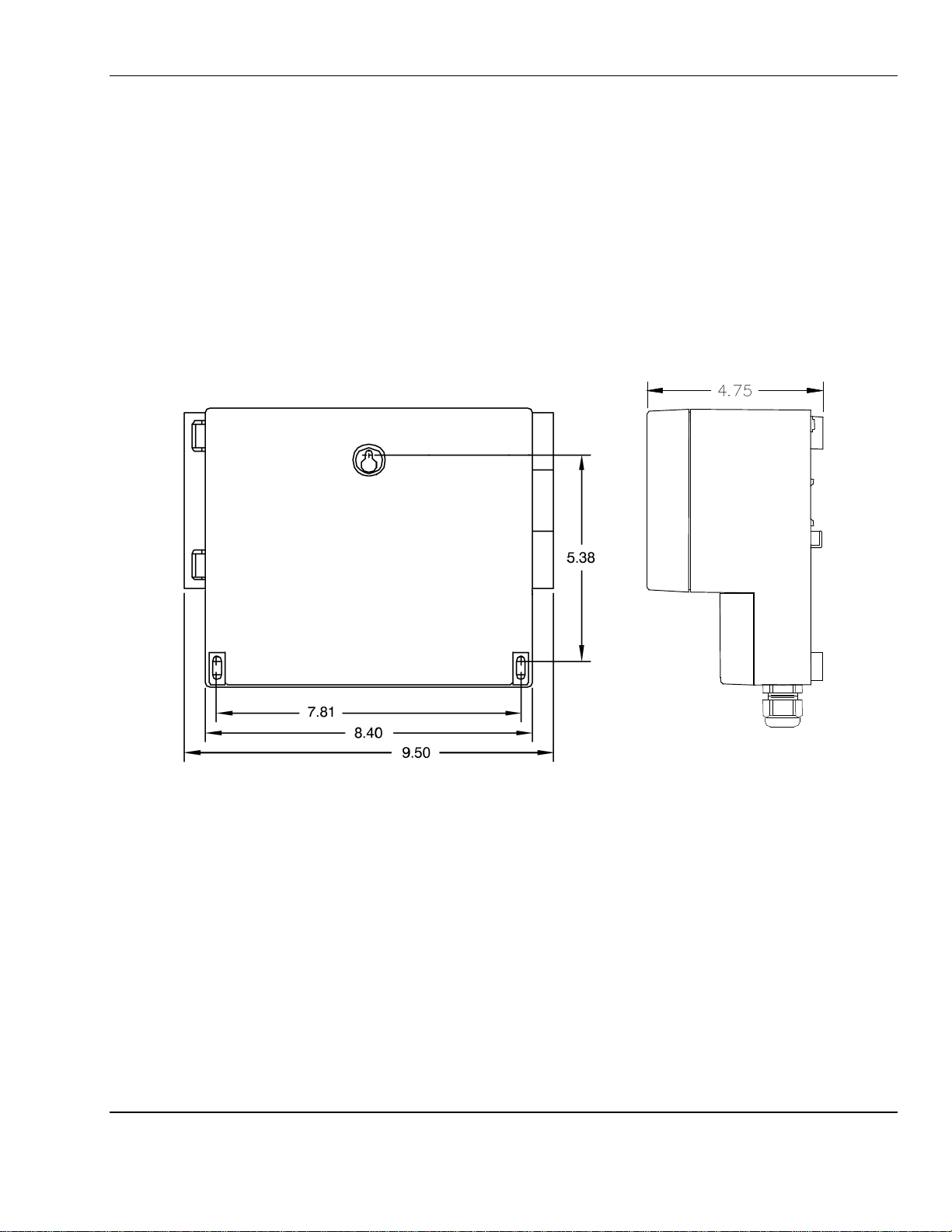

3.1 Mounting MX32 Control

The MX32 C

are also marked on the rear of the enclosure in mm.

ONTROL

is mounted to the wall with 3 screws. Demotions are given in inches in Figure 4. Demotions

Rear View Side View

Figure 4: Mounting MX32

5

Page 10

ENMET Corporation MX32 E

3.2 Wiring the MX32 Control

The electrical installation should conform to appropriate electrical codes, such as the National Electrical Code in the

United States.

W

ARNING

:

The compliance of the installation to appropriate codes is not ENMET’s responsibility.

NGUARD

The MX32 C

W

ARNING

:

Each channel of the MX32 C

two-channel circuit board is shown in Figure 5 and wiring for this terminal is shown in Table 1.

ONTROL

Continuous gas detection and alarm systems (110VAC/220VAC / 24VDC/12VDC powered) become

inoperative upon loss of primary power. Contact factory for specifications and pricing of backup

battery systems.

should be powered through circuit breakers provided for this purpose.

ONTROL

has a terminal strip to which all wiring for that channel is connected. A typical

3.2.1 Relay Contacts

MX32

CONTROL

terminal strip, as indicated in Figure 5 and Table 1. There are 3-pin headers for setting relays to normally open or

normally closed operation. The location of these headers is indicated in Figure 5. To set the relays, place the jumpers

on the position 2 & 3 pins for NO operation or positions 1 & 2 for NC operation. These jumpers are placed in the NC

operation positions at the factory. See Table 1a. These relays have a maximum capacity of 2 Amp at 230 Volts.

The Fault Relay (DEF), system alarm relay contacts are on the main board, as shown in Figure 5.

Auxiliary alarms should be powered from an independent power source separate form the instrument power to avoid

alarm failure due to controller malfunction.

relay contacts for the first two alarm levels are on the RL, 1, RL and 2 positions of each channel

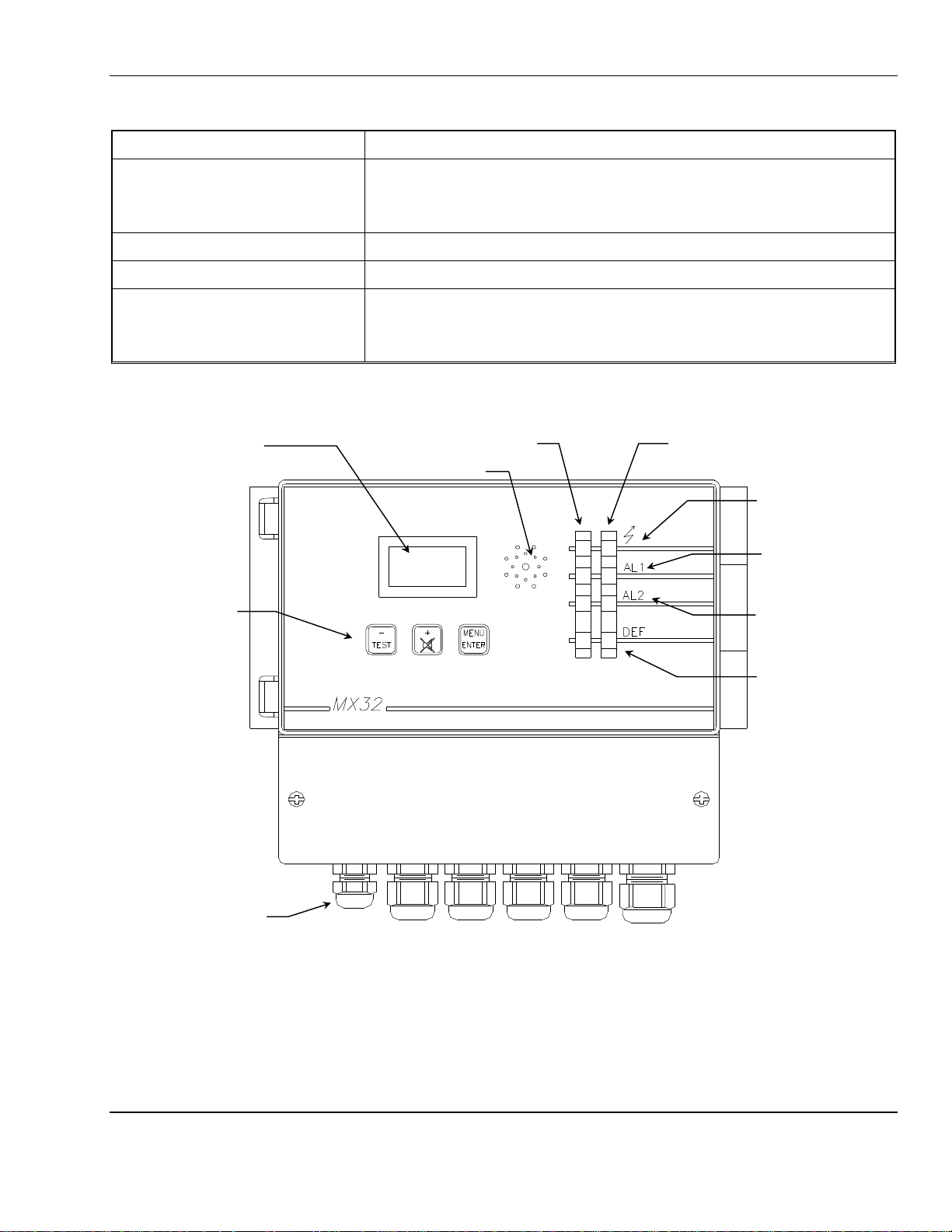

Table 1a: Fault and Alarm Relay Setting

Jumper Position Relay setting

3-pin header

Pin # 1 2 3

2-pin jumper

3-pin header located near associated relay:

Fault relay (DEF) = J103

Channel 1 – AL1 relay = J105, AL2 relay = J101

Channel 2 – AL1 relay = J108, AL2 relay = J107

See Figure 5 for location of each 3-pin header.

Jumper on pins 1 & 2 Jumper on pins 1 and 2 relay NC operation (no power and alarm condition)

(Factory Setting)

Jumper on pins 2 & 3 Jumper on pins 2 and 3 relay NO operation

3.2.2 Wiring Requirements

Sensor/Transmitters:Wiring to the Sensor/Transmitters should be by two or three wire shielded cable. The

recommended cable is 18 gauge three wire, ENMET part number 66017-006, Alpha-1747C or

equivalent.

Output Loop: Wiring to output loop should be similar two wire shielded cable.

Relay: Relay wiring can be suitable insulated wire.

6

Page 11

MX32 E

See Fuse Table

See Fuse Table

J8 J9 J10

POT

channel 1

channel 2

Fault Relay

J110

J105

J11 J12

J13 J14

J15 J16 J17

J18 J19

J20 J21

115 / 220

F7

F9

F11

F13

NGUARD

ENMET Corporation

3-pin header

J103

Fuse 24v

See Fuse Table

Fuse AC

Fuse AC

Input

Input

Input

F8

Figure 5: MX32 C

Fault Relay

DEF

J103

J1 J2 J3 J4 J5

V

AC

J6 J7

ONTROL

Fuse 24v

Output Channel 1

Relay RL2

AL2 Channel 1

Relay RL1

AL1 Channel 1

Sensitivity POT

Sensitivity

Fuse 24v

Output Channel 2

Relay RL2

AL2 Channel 2

Relay RL1

AL1 Channel 2

channel 2

Zero POT

Zero POT

channel 1

Main Power and Channel Board

J107

Ch2, AL2 relay

3-pin header

J108

Ch2, AL1 relay

3-pin header

MX32 C

F7 24v Input

ONTROL

Fuse Table

1.25A Time delay

F9,F8 for 115VAC Input 315mA Time delay

F9,F8 for 230VAC Input 160mA Time delay

F11,F13 24v Output

400mA Time delay

7

Page 12

ENMET Corporation MX32 E

Table 1: wiring terminal

NGUARD

Ref

Label

P J1 Input, AC high

N J2 Input, AC neutral

0 J4 Input, DC minus

+24V J5 Input, DC positive

DEF J6 Fault relay*

C1 J8 Channel 1, Sensor signal – (See Table 2, 3 for 2 or 3 wire S/T)

C2 J9 Channel 1, Sensor ground if used (See Table 2, 3 for 2 or 3 wire S/T)

C3 J10 Channel 1, Sensor + (See Table 2, 3 for 2 or 3 wire S/T)

RL1 J11 Channel 1, Alarm 1 relay*

RL2 J13 Channel 1, Alarm 2 relay*

C1 J15 Channel 2, Sensor signal – (See Table 2, 3 for 2 or 3 wire S/T)

C2 J16 Channel 2, Sensor ground if used (See Table 2, 3 for 2 or 3 wire S/T)

C3 J17 Channel 2, Sensor + (See Table 2, 3 for 2 or 3 wire S/T)

RL1 J18 Channel 2, Alarm 1 relay*

RL2 J20 Channel 2, Alarm 2 relay*

* See Table 1a for setting relays to NO or NC operation.

Terminal

Label

J3 Ground

J7 Fault relay*

J12 Channel 1, Alarm 1 relay*

J14 Channel 1, Alarm 2 relay*

J19 Channel 2, Alarm 1 relay*

J21 Channel 2, Alarm 2 relay*

Wiring

4-20 Sensor/Transmitter

Sensor/Transmitters are connected to positions C1, C2 and C3 on each channel terminal strip. Connections are shown

in Table 2 for two wire S/T and Table 3 for three wire S/T. See Figure 5 for location of channel terminal strips.

Table 2: Wiring for a Two Wire S/T Table 3: Wiring for a Three Wire S/T

Two Wire Sensor/Transmitter Three wire Sensor/Transmitter

C1

C2 Not used C2 Ground

C3 Signal plus, +24VDC power C3 +24VDC power

Signal minus (––––)

8

C1 Signal

Page 13

MX32 E

––––

––––

++++

++++

4.0 Operation

4.0 Operation

4.0 Operation4.0 Operation

NGUARD

The MX32 C

When a visual or audio alarm is activated,

ONTROL

display is independent of the LEDs and relays for each channel.

4.1 Front Panel Pushbutton Switches

Three pressure switches (buttons) on the MX32 C

ENMET Corporation

the display does not automatically display the channel in alarm

ONTROL

FRONT panel.

.

––––

T

TTEESST

++++

MMEENNU

EENNTTEER

––––

T

TTEESST

Manual display of other channel (if 2 channels)

Manual display of previous menu

Decrease value of a digit while setting a value

Combined with “+” switch to step through normal display cycle

Manual display of other channel (if 2 channels)

Manual display of next menu

Increase value of a digit while setting a value

Combined with “–” switch to step through normal display cycle

U

R

To enter maintenance menus

ENTER

++++

MENU

ENTER

9

Page 14

ENMET Corporation MX32 E

4.2 Display at start-up

When power is supplied to the MX32 C

1. Current software version and buzzer test.

Examples of Display:

2. Current menu access code.

Example of Display:

3. Current AL1 threshold displayed for channel 1, while the AL1 and fault light for channel 1 light up.

Example of Display:

ONTROL

120

1270

20

, the unit goes through a self-test sequence as follows:

ver

co

See section 5.0 for Maintenance Menus

Section 5.5 for Access Code

1 0

m32

1

4. Current AL2 threshold displayed for channel 1, while the AL2 and fault light for channel 1 light up.

40

co

Example of Display:

2

5. Current AL1 threshold displayed for channel 2, while the AL1 and fault light for channel 2 light up.

19.5

o2

Example of Display:

1

6. Current AL2 threshold displayed for channel 2, while the AL2 and fault light for channel 2 light up.

23.5

o2

Example of Display:

2

7. Count down (in seconds), time for the sensor(s) to stabilize, and both fault LED are lit.

Example of Display:

0.40

min

This time is programmed at the factory

for best results. See section 5.2 to change

programmed setting.

NGUARD

8. Then the MX32 C

Examples of Display:

ONTROL

will begin the normal display cycle

0

co

10

20.9

o2

See section 4.4 for

Normal Display Cycle

Page 15

MX32 E

NGUARD

ENMET Corporation

4.3 Display Cycle of Channel measurements

C

AUTION

: The display and audio alarms operate independently.

display does not automatically switch to the channel in alarm.

4.3.1 Display of No Measurements Mode

No measurements displayed.

By pressing both the – & + switches at the same time the display changes to no measurement display mode.

Example of the no

measurement Display:

- - - - -

ok

In the no measurement mode to display a channel manually press the + or – switch.

Examples of typical Display:

Press – to display

channel 1 for 1 minute

After about 1 minute, the display returns to the no measurement display mode.

0

co

The display will remain in the no measurement mode

until the + & – switches are pressed at the same time to

change to the single channel display mode.

Examples of typical Display:

Press + to display

channel 2 for 1 minute

4.3.2 Display of a Single Channel Mode

The display will remain in the channel selected by pressing the + or – switch.

By pressing both the – & + switches at the same time a second time, the display changes to a single channel display mode.

By pressing the – switch, the display is manually changed to channel 1 and will continue to display channel 1 until the +

switch is pressed. By pressing the + switch, the display is manually changed to channel 2 and will continue to display

channel 2 until the – switch is pressed.

Examples of typical Display:

Press – to display

channel 1

0

co

Press + to display

channel 2

When an audio and visual alarm are active the

20.9

20.9

o2

o2

To return to the normal display mode press the – and + switches at the same time once more.

11

Page 16

ENMET Corporation MX32 E

5.0 Maintenance

5.0 Maintenance

5.0 Maintenance5.0 Maintenance

The MX32 C

valid access code. The access code is set at the factory and may be changed by following the access code menu

explained in section 5.5.

C

AUTION

See section 4.1 for a description of the pushbutton switches

NOTE: There may be differences in the display for request to save what has been entered in the maintenance menus.

Example:

May display

ENRG or SAVE

ONTROL

: The procedures and adjustments described in the following sections must be performed by authorized

personal. Failure to follow instructions may jeopardize accurate measurements.

unit has 5 maintenance menus that are accessed by pressing the MENU switch and entering a

enrg

oui

Example: May display:

OUI or YES

NON or NO

sa e

yes

5.1 Enter the maintenance menus

When the MENU/ENTER switch is pressed the MX32 C

maintenance portion for programming, initialization, calibration, changing access code and buzzer setting.

If no switch is pressed for one minute, the MX32 C

5.1.1 Entering the Maintenance Menus

To enter the maintenance menus press the MENU/ENTER switch.

If no switch is pressed for one minute, the MX32 C

The request for Access Code display appears. The Access Code set at the factory is 1270.

Example of Displays

The first digit will

be flashing.

0000

cod

To enter the access

code. Press + or – to

select value of digit

ONTROL

ONTROL

ONTROL

unit will request an access code to enter the

will return to normal display mode.

will return to normal display mode.

Press ENTER to move

1000

cod

to next digit.

NGUARD

Press + or – to select

value of digit

Press ENTER to

move to next digit

If the access code is invalid, the display will return to the normal mode.

If the access code is valid, the display will enter the maintenance menus

See Table 4 for the sequence of maintenance menus and a description of their uses. Press the + switch to move to the

next menu or the – switch to move back to the previous menu.

1200

cod

Press + or – to select

value of digit

Press ENTER to move to

next digit

1270

cod

When access code is

complete,

press ENTER.

5.1.2 Exit the Maintenance Menus

To exit the maintenance menus at any point:

Press + & – switches at the same time. The EnrG display will appear.

Press + & – to go

to the save (exit)

display

Press + or – to select OUI (yes) or NON (no). Press ENTER

Press + or – to

select yes or no

The MX32 C

ONTROL

enrg

enrg

will return to the normal display mode.

0

oui

oui

co

12

Page 17

MX32 E

NGUARD

ENMET Corporation

5.1.3 MX32 C

See Table 4 for the sequence of maintenance menus and a description of their uses.

Press the + switch to move to the next menu (↓) or the – switch to move back to the previous menu (↑).

ONTROL

Sequence of Maintenance Menus

Table 4: MX32 Control Sequence of Maintenance Menus

Menu Description Display (flashing)

Access Code

Enter Valid Code ↓

Programming

Press + ↓ or – ↑

Calibration

*

Factory set

Do Not use without

consulting ENMET Corp

Press + ↓ or – ↑

Initialization

*

Factory set

Do Not use without

consulting ENMET Corp

Press + ↓ or – ↑

Access Code Change

Press – ↑

Buzzer

The key used to enter the maintenance

menus.

See section 5.1.1

Used to program the parameters of a

measurement channel. See section 5.2

Used to check and make adjustments to

zero (clean air) and calibration gas.

See section 5.4

Used to initialize the measurement curve

managed by the microprocessor with a

sensor. See section 5.3

Used to change the access code for

entering the maintenance menus.

See section 5.5

Used to set the buzzer active or inactive.

See section 5.6

0000

cod

prg

CAL

ini

%

cod

buz

* C

AUTION

: Do Not enter without first consulting ENMET Corporation.

Improper use will cause the MX32 to be Non-Functional

Use + to by pass this function.

13

Page 18

ENMET Corporation MX32 E

5.2 Programming menu

To set a channel active or inactive, gas to be measured, alarm thresholds, relay timing and sensor type.

See section 5.1.1 to enter a valid access code to enter the maintenance menus. Press the + switch to move through the

maintenance menus until the PRG is flashing.

1. Press ENTER switch while PRG is flashing to enter programming menu

Press ENTER

PRG

The wrench symbol will appear in the lower right corner of the display and the yellow LED of the corresponding

channel is flashing, indicating the MX32 C

2. Select ON or OFF, if the channel is to be active or inactive. The on or off will be flashing.

Press + or – to

select ON or OFF

3. Select the gas to be measured by scrolling through the symbols until the proper symbol appears on the display.

Press + or – to

move through the

symbols

on

Press + or –

to select channel to be

programmed.

ONTROL

CO

is in maintenance mode and the relays are inhibited.

Press ENTER when

correct state is selected

Press ENTER when

correct symbol is

selected

prg

co

ppm

When the channel

indicator is correct,

Press ENTER

Next the symbol for

the gas to be measured

will be flashing

Next the symbol for

the unit of measure

will be flashing

NGUARD

4. Select the symbol for unit of measure by scrolling through the symbols until the proper symbol appears on the display.

1

1

500

35

35

35

Ppm

Ppm

Ppm

Ppm

man

Press ENTER when

correct symbol is

selected

Press ENTER when

correct scale is selected

Press ENTER when

correct decimal place is

selected

Press ENTER when

correct threshold is

selected

Press ENTER when

correct alarm type is

selected

Press + or – to

move through the

symbols

5. For measurement scale Press + to change digit value and ENTER to move to next digit.

Press + or – to

modify the scale

digit by digit

5a. For measurement scale decimal point Press + to change position and ENTER to move to next digit.

Press + or – to

modify the

decimal place

6. This display indicates the Alarm threshold 1 and manual clearance. The red LED for the corresponding alarm is lit.

To modify the alarm threshold AL1 if necessary, Press + to change digit value and ENTER to move to next digit.

Press + or – to

modify the alarm

digit by digit

7. Press + or – to select increasing or decreasing alarm type. Press ENTER

Press + for increasing

Press – for decreasing

N

OTE

: The change may or may not be indicated on the display.

500

1

1

1

35

35

35

man

ppm

man

35

man

man

Next the measurement

scale will be flashing

Next the decimal

placement

Next the AL1

threshold will be

flashing

Next the increasing

decreasing indicator is

flashing

Next the MAN or

AUT is flashing

14

Page 19

MX32 E

NGUARD

Manual alarm clearing: If the gas content drops below the preset alarm threshold again this alarm must be cleared

manually by pressing the + (clear alarm) switch.

Automatic alarm clearing: If the gas content drops below the pre-set alarm threshold again the relay will be

automatically cleared.

8. Press + or – to select manual (MAN) or automatic (AUT) mode for alarm clearing. Press ENTER

Press + or – to

select alarm clear

mode

When the alarm threshold is exceeded the time delay is counted down then the alarms (buzzer and LED) are activated

the relay is activated. Use a 0 min setting for an instantaneous relay activation, this may cause nuisance alarms.

9. Press + or – to select time delay (in minutes) for alarm 1 relay. Press ENTER

Press + or – to

modify the time

digit by digit

10. This display indicates the Alarm threshold 2 and manual clearance. The red LED for the corresponding alarm is lit.

To modify the alarm threshold AL2 if necessary, Press + to change digit value and ENTER to move to next digit.

Press + or – to

modify the alarm

digit by digit

1

00.05

1

35

100

2

MAN

min

Ppm

Press ENTER when

correct alarm clear mode

is selected

Press ENTER when

correct time is selected

Press ENTER when

correct threshold is

selected

00.05

1

100

100

2

2

man

man

man

ENMET Corporation

Next the relay delay

time (in minutes) is

flashing

Next alarm AL2

threshold will be

flashing

Next the increasing

decreasing indicator is

flashing

11. Press + or – to select increasing or decreasing alarm type. Press ENTER

Press + for increasing

Press – for decreasing

N

OTE

: The change may or may not be indicated on the display.

Manual alarm clearing: If the gas content drops below the preset alarm threshold again this alarm must be cleared

Automatic alarm clearing: If the gas content drops below the pre-set alarm threshold again the relay will be

12. Press + or – to select manual (MAN) or automatic (AUT) mode for alarm clearing. Press ENTER

Press + or – to

select alarm clear

mode

When the alarm threshold is exceeded the time delay is counted down then the alarms (buzzer and LED) are activated

the relay is activated. Use a 0 min setting for an instantaneous relay activation, this may cause nuisance alarms.

13. Press + or – to select time delay (in minutes) for alarm 2 relay. Press ENTER

Press + or – to

modify the time

digit by digit

14. Press + or – to select time delay (in minutes) for alarm Fault relay. Press ENTER

Press + or – to

modify the time

digit by digit

100

man

2

manually by pressing the + (clear alarm) switch.

automatically cleared.

100

MAN

2

00.05

00.05

min

2

min

Press ENTER when

correct alarm type is

selected

Press ENTER when

correct alarm clear mode

is selected

Press ENTER when

correct time is selected

Press ENTER when

correct time is selected

00.05

00.05

1.00

100

2

2

man

man

min

min

Next the MAN or

AUT is flashing

Next the relay delay

time (in minutes) is

flashing

Next the fault relay

time delay will be

flashing

Next the stabilization

time count down at start

up will be flashing

15

Page 20

ENMET Corporation MX32 E

15. Press + or – to select the stabilization time at start up. Press ENTER

Press + or – to

modify the time

digit by digit

16. Press + or – to scroll through the different types of sensor if necessary. Press ENTER

Press + or – to

modify the type

See choices below

or AUT = Other, for toxic or Oxygen (for 4-20mA Sensor/Transmitter)

or InC = ionic, optical etc… (not used)

EHP or EHP = Combustible (not used)

or POnt = Bridge (not used)

17. Press + or – to select MAN or AUT. Press ENTER

MAN: no visual alarm, yellow LED flashing, when s/t is in calibration mode

AUT: visual alarm, yellow LED flashing, when s/t is in calibration mode

Press + or – to

select MAN or

AUT

1.00

AUT

AUT

min

man

man

Press ENTER when

correct time is selected

Press ENTER when

correct sensor type is

selected

Press ENTER when

correct choice is selected

auT

auT

0.120

man

man

min

Next the sensor type

will be flashing

May display: OtH

Next the MAN or

AUT will be flashing

Will be displayed

Press ENTER 4 times

NGUARD

enrg

18. Press + or – to select OUI (yes) or NON (no). To update the programming for the channel, Press ENTER

If you select NON and press ENTER the programming will not be updated.

If you select OUI and press ENTER the programming will be updated.

Press + or – to

select yes or no

19. Programming is complete the MX32

enrg

non

oui

Next the save (update)

programming will be

flashing

Press ENTER when

correct choice is selected

CONTROL

display returns to normal display mode.

0

co

Next the MX32

Control returns to the

normal display mode.

16

Page 21

MX32 E

NGUARD

5.3 Initialization (INI) menu

C

AUTION

: This procedure is not used with 4 – 20mA Sensor/Transmitters. Continue to the next

menu.

ENMET Corporation

This menu is used to automatically I

connected to the channel.

Initialization should be done when the unit is first installed and when a cell or sensor is replaced.

See section 5.1.1 to enter a valid access code to enter the maintenance menus. Press the + switch to move through the

maintenance menus until the INI is flashing.

1. Press ENTER switch while INI is flashing to enter initialization menu

Press ENTER

Next the channel indicator is flashing.

2. Press + or – to Select channel to be initialized.

When the channel indicator is correct. Press ENTER

Next the save initialization display is flashing

3. Press + or – to select OUI (yes) or NON (no) for channel initialization to be updated. Press ENTER

Press ENTER

enrg

NITIALIZE

ini

ini

oui

the measurement curve managed by the microprocessor of sensor

4. Initialization is complete the MX32 Control display returns to normal display mode.

0

co

17

Page 22

ENMET Corporation MX32 E

5.4 Calibration Menu MX32 C

C

AUTION

: This procedure is to align the MX32 C

without first consulting ENMET Corporation. Calibration of sensors M

ONTROL

ONTROL

and S/T displays only. Do Not enter

UST

be done at

the sensor/transmitter, in accordance with the S/T manual.

The S/T for Oxygen does not have a zero point. Therefore, a calibration of the S/T in accordance with the S/T manual

should be adequate for alignment.

The MX32 C

of the display compared to the sensor signal.

There are two ways to calibrate the MX32 C

Following an Initialization. See section 5.4.1.

For regular preventive maintenance of unit. See section 5.4.2.

5.4.1 Calibration Following an Initialization Non Oxygen Transmitter

See section 5.1.1 to enter a valid access code to enter the maintenance menus. Press the + switch to move through the

maintenance menus until the CAL is flashing.

1. Press ENTER switch while CAL is flashing to enter the calibration menu.

Press ENTER

2. Apply clean 20.9 oxygen (clean air) to the sensor. Display will show the current zero value, the XO over the

wrench indicates zero adjustment.

3. If necessary (display does not equal Zero) adjust the measurement to Zero by adjusting the Zero Potentiometer

corresponding to the channel concerned. See Figure 5 for location of Zero POT. O = 4mA.

Press ENTER

ONTROL

calibration menu can be used to check and make minor adjustments to the zero and sensitivity

0

ONTROL

cal

Xo

:

Press + or –

to select channel to be

programmed.

CAL

When the channel

indicator is correct,

Press ENTER

NGUARD

4. Apply calibration gas to the sensor and wait until the signal stabilizes. Display will show the current gas

measurement, the XF over the wrench indicates sensitivity adjustment.

W

ARNING

:

Do not make adjustment or press ENTER without applying calibration gas, a fault condition will be triggered.

5. Press ENTER, to indicate

sensitivity adjustment

6. If necessary (display does not equal calibration gas) adjust the measurement to the calibration gas by adjusting the

Sensitivity Potentiometer corresponding to the channel concerned. See Figure 5 for location of Sensitivity POT.

Press ENTER to update

adjustment

Then the request to save calibration is displayed

7. Press + or – to select OUI (yes) or NON (no) for channel calibration to be updated. Press ENTER.

If you select NON and press ENTER the calibration will not be updated.

If you select OUI and press ENTER the calibration will be updated.

Press ENTER

8. Calibration is complete MX32 C

enrg

ONTROL

30

Xf

30

Xf

oui

display returns to normal display mode.

0

co

18

Page 23

MX32 E

NGUARD

ENMET Corporation

5.4.2 Calibration For regular preventive maintenance

C

AUTION

The S/T for Oxygen does not have a zero point. Therefore, a calibration of the S/T in accordance with the S/T manual

should be adequate for alignment.

See section 5.1.1 to enter a valid access code to enter the maintenance menus. Press the + switch to move through the

maintenance menus until the CAL is flashing.

1. Press ENTER switch while CAL is flashing to enter the calibration menu.

2. Apply clean 20.9 oxygen (clean air) to the sensor.

Display will show the current zero value, the XO over the wrench indicates zero adjustment.

3. If necessary (display does not equal Zero) adjust the measurement to Zero by pressing + or – switches until display

shows Zero. Press ENTER.

4. Apply Calibration gas to the sensor and wait until the signal stabilizes

Display will show the current gas measurement, the XF over the wrench indicates sensitivity adjustment.

5. Press ENTER, to indicate sensitivity adjustment

: This procedure is to align the MX32 C

sensors M

Press ENTER

Press ENTER

UST

be done at the sensor/transmitter, in accordance with the S/T manual.

cal

0

Xo

30

Xf

ONTROL

Press + or –

to select channel to be

programmed.

and S/T displays only. Calibration of

CAL

When the channel

indicator is correct,

Press ENTER

6. If necessary (display does not equal Span) adjust the measurement to the Span by pressing + or – switches until

display shows the correct measurement. Press ENTER.

Press ENTER to update adjustment

30

Xf

Then the request to save calibration is displayed

7. Press + or – to select OUI (yes) or NON (no) for channel calibration to be updated. Press ENTER.

If you select NON and press ENTER the calibration will not be updated.

If you select OUI and press ENTER the calibration will be updated.

Press ENTER

8. Calibration is complete MX32 C

enrg

ONTROL

0

oui

display returns to normal display mode.

co

19

Page 24

ENMET Corporation MX32 E

5.5 Changing Access Code

This menu allows MX32 C

See section 5.1.1 to enter a valid access code to enter the maintenance menus. Press the + switch to move through the

maintenance menus until the % COD is flashing.

Press ENTER switch while the % COD is flashing to enter the access code menu.

The current access code is displayed.

1. Press + or – select value of digit, press ENTER to move to next digit. When access code is complete, press ENTER.

Press + or – to select

value of digit

Press ENTER to

move to next digit

Then the request to save new access code is displayed.

2. Press + or – to select OUI (yes) or NON (no). To update the access code, Press ENTER

If you select NON and press ENTER the new access code will not be updated.

If you select OUI and press ENTER the new access code be updated.

Press + or – to

select yes or no

If the access code is invalid, the display will return to the normal mode.

If the access code is valid, the display will enter the maintenance menus

ONTROL

1270

enrg

unit access code to be changed.

Press + or – to select

%

cod

oui

value of digit

Press ENTER to move to

next digit

Press ENTER when

correct choice is selected

8888

0

%

cod

co

When access code is

complete,

press ENTER.

Next the MX32

Control returns to the

normal display mode.

NGUARD

5.6 Buzzer menu

This menu allows MX32 C

See section 5.1.1 to enter a valid access code to enter the maintenance menus. Press the + switch to move through the

maintenance menus until the BUZ is flashing.

1. Press ENTER switch to enter the Buzzer menu.

Press ENTER

2. Press + or – to select ON (buzzer active) or OFF (buzzer is non-active). Press ENTER

Press + or –

to select buzzer

setting

3. Press + or – to select OUI (yes) or NON (no) for buzzer setting to be updated. Press ENTER

If you select NON and press ENTER the buzzer setting will not be updated.

If you select OUI and press ENTER the buzzer setting will be updated.

Press + or – to

select yes or no

4. Buzzer setting is complete, the MX32 C

ONTROL

Yes BUZ

enrg

unit to set the buzzer (horn) active or inactive.

buz

oui

0

co

When the buzzer

setting is correct,

Press ENTER

Press ENTER when

correct choice is selected

ONTROL

display returns to normal display mode.

20

Page 25

MX32 E

6.0 WARRANTY

6.0 WARRANTY

6.0 WARRANTY6.0 WARRANTY

NGUARD

ENMET warrants new instruments to be free from defects in workmanship and material under normal use for a period

of one year from date of shipment from ENMET. The warranty covers both parts and labor excluding instrument

calibration and expendable parts such as calibration gas, filters, batteries, etc... Equipment believed to be defective

should be returned to ENMET within the warranty period (transportation prepaid) for inspection. If the evaluation by

ENMET confirms that the product is defective, it will be repaired or replaced at no charge, within the stated

limitations, and returned prepaid to any location in the United States by the most economical means, e.g. Surface

UPS/FedEx Ground. If an expedient means of transportation is requested during the warranty period, the customer is

responsible for the difference between the most economical means and the expedient mode. ENMET shall not be

liable for any loss or damage caused by the improper use of the product. The purchaser indemnifies and saves

harmless the company with respect to any loss or damages that may arise through the use by the purchaser or others of

this equipment.

This warranty is expressly given in lieu of all other warranties, either expressed or implied, including that of

merchantability, and all other obligations or liabilities of ENMET which may arise in connection with this equipment.

ENMET neither assumes nor authorizes any representative or other person to assume for it any obligation or liability

other than that which is set forth herein.

NOTE: When returning an instrument to the factory for service:

Be sure to include paperwork.

A purchase order, return address and telephone number will assist in the expedient repair and return of your unit.

Include any specific instructions.

For warranty service, include date of purchase

If you require an estimate, please contact ENMET Corporation.

ENMET Corporation

There are Return for Repair Instructions and Form on the last pages of this manual. This Form can be copied or used

as needed.

Manual Part Number

80003-040

February 2001

MCN-271, 01/14/02

MCN-278, 06/07/02

MCN-286, 10/02/02

MCN-328, 03/24/05

MCN-330, 04/01/05

MCN-357, 11/13/06

MCN-370, 05/30/07

21

Page 26

ENMET Corporation MX32 E

Notes:

NGUARD

22

Page 27

PO Box 979

680 Fairfield Court

Ann Arbor, Michigan 48106-0979

734.761.1270 Fax 734.761.3220

Returning an Instrument for Repair

ENMET instruments may be returned to the factory or any one of our Field Service Centers for regular

repair service or calibration. The ENMET Repair Department and Field Service Centers also perform

warranty service work.

When returning an instrument to the factory or service center for service, paperwork must be included

which contains the following information:

A purchase order number or reference number.

A contact name with return address, telephone and fax numbers

Specific instructions regarding desired service or description

of the problems being encountered.

Date of original purchase and copy of packing slip or invoice

for warranty consideration.

If a price estimate is required, please note it accordingly and be

sure to include a fax number.

Providing the above information assists in the expedient repair and return of your unit.

Failure to provide this information can result in processing delays.

ENMET charges a one hour minimum billing for all approved repairs with additional time billed to the

closest tenth of an hour. All instruments sent to ENMET are subject to a minimum $30 evaluation fee,

even if returned unrepaired. Unclaimed instruments that ENMET has received without appropriate

paperwork or attempts to advise repair costs that have been unanswered, after a period of 60 days,

may be disposed of or returned unrepaired COD with the evaluation fee.

Service centers may have different rates or terms. Be sure to contact them for this information.

Repaired instruments are returned by UPS/FedEx Ground and are not insured unless otherwise

specified. If expedited shipping methods or insurance is required, it must be stated in your

paperwork.

Note: Warranty of customer installed components.

If a component is purchased and installed in the field, and fails within the warranty term, it can

be returned to ENMET and will be replaced, free of charge, per ENMET’s returned goods

procedure.

If the entire instrument is returned to ENMET Corporation with the defective item installed, the

item will be replaced at no cost, but the instrument will be subject to labor charges at half of the

standard rate.

Page 28

Page 29

Repair Return Form

Mailing Address:

ENMET Corporation

PO Box 979

Ann Arbor, Michigan 48106

Phone Number: 734.761.1270

FAX Number: 734.761.3220

Your Mailing Address: Your Shipping Address:

Contact Name: __________________________ Your Phone: _______________________

Your PO/Reference Number: _______________ Your FAX: _______________________

Shipping Address:

ENMET Corporation

Attn: Repair Department

680 Fairfield Court

Ann Arbor, Michigan 48108

Payment Terms: COD

(Check one) VISA / MasterCard______________________ ________

Card number Expiration

Return Shipping Method:

UPS: Ground 3 Day Select Next Day Air ND Air Saver 2-Day Air

Federal Express: Ground Express Saver P-1 Standard 2-Day Air

FedEx Account number: ________________________

Would you like ENMET to insure the return shipment?

No Yes Insurance Amount: $_________________

Page 30

Loading...

Loading...