Page 1

ENMET Corporation

PO Box 979

Ann Arbor, MI 48106-0979

MED AIR 2000

Operation and Maintenance

Manual

80002-031

06/03/96

Revised 06/11/97

MCN-167, 09/20/00

MCN-176, 03/06/98

MCN-200, 09/04/98

MCN-204, 01/29/99

MCN-237, 09/21/00

MCN-274, 05/01/02

MCN-327, 02/03/05

MCN-332, 04/15/05

Page 2

Page 3

Table of Contents

1.0 INTRODUCTION ......................................................................................................................................... 1

1.1 Unpack .............................................................................................................................................................1

1.2 Check Order .....................................................................................................................................................1

1.3 Serial Numbers.................................................................................................................................................1

2.0 I

NSTRUMENT FEATURES ............................................................................................................................ 2

2.1 Exterior Features ..............................................................................................................................................2

2.2 Display Panel Features ..................................................................................................................................... 2

2.3 Circuit Board Features......................................................................................................................................4

2.4 Power Supply ...................................................................................................................................................4

2.5 Dew Point Sensor.............................................................................................................................................4

2.6 Dew Point Circuit.............................................................................................................................................4

3.0 I

NSTALLATION .......................................................................................................................................... 5

3.1 Mounting of Instrument....................................................................................................................................5

3.2 Sample Air Supply ...........................................................................................................................................6

3.3 Power Supply ...................................................................................................................................................6

3.4 Outputs .............................................................................................................................................................6

3.4.1 Relay Contacts .......................................................................................................................................6

3.4.2 Optional 4-20mA Outputs ......................................................................................................................7

3.5 Initial Calibration .............................................................................................................................................7

4.0 O

PERATION .............................................................................................................................................. 8

4.1 Normal Operation Condition............................................................................................................................ 8

4.2 Alarm Set Points...............................................................................................................................................8

4.3 Alarm Latching ................................................................................................................................................8

4.4 Audio Defeat ....................................................................................................................................................9

4.5 Display .............................................................................................................................................................9

4.6 Operational Menu.............................................................................................................................................9

4.7 Fault Indications.............................................................................................................................................10

4.7.1 Low Flow Indication ............................................................................................................................10

4.7.2 Other Fault Indications........................................................................................................................10

4.8 Dew Point Sensor Response...........................................................................................................................10

5.0 M

AINTENANCE........................................................................................................................................ 11

5.1 Maintenance Menu.........................................................................................................................................11

5.1.1 Key .......................................................................................................................................................12

5.1.2 Automatic Zeroing................................................................................................................................13

5.1.3 Calibration...........................................................................................................................................14

5.1.4 Select Alarm Set Points ........................................................................................................................15

5.1.5 Set Latches ...........................................................................................................................................16

5.1.6 Set the Key............................................................................................................................................16

5.1.7 Exit .......................................................................................................................................................16

5.2 Sensor Replacement .......................................................................................................................................17

5.2.1 CO Sensor ............................................................................................................................................17

5.2.2 Oxygen Sensor......................................................................................................................................17

5.3 Humidifier Tube.............................................................................................................................................17

5.4 Dew Point Sensor...........................................................................................................................................17

5.5 Flow Control Orifice ...................................................................................................................................... 17

5.6 Particulate Filter Replacement .......................................................................................................................17

6.0 R

EPLACEMENT PART NUMBERS .............................................................................................................. 19

7.0 WARRANTY......................................................................................................................................... 20

A

PPENDIX A ................................................................................................................................................. 21

Page 4

List of Figures and Tables

FIGURE 1: FEATURES OF MED AIR 2000 EXTERNAL................................................................................................ 3

F

IGURE 1A: REGULATOR ....................................................................................................................................... 3

FIGURE 2: MED AIR 2000 INTERIOR FEATURES....................................................................................................... 4

F

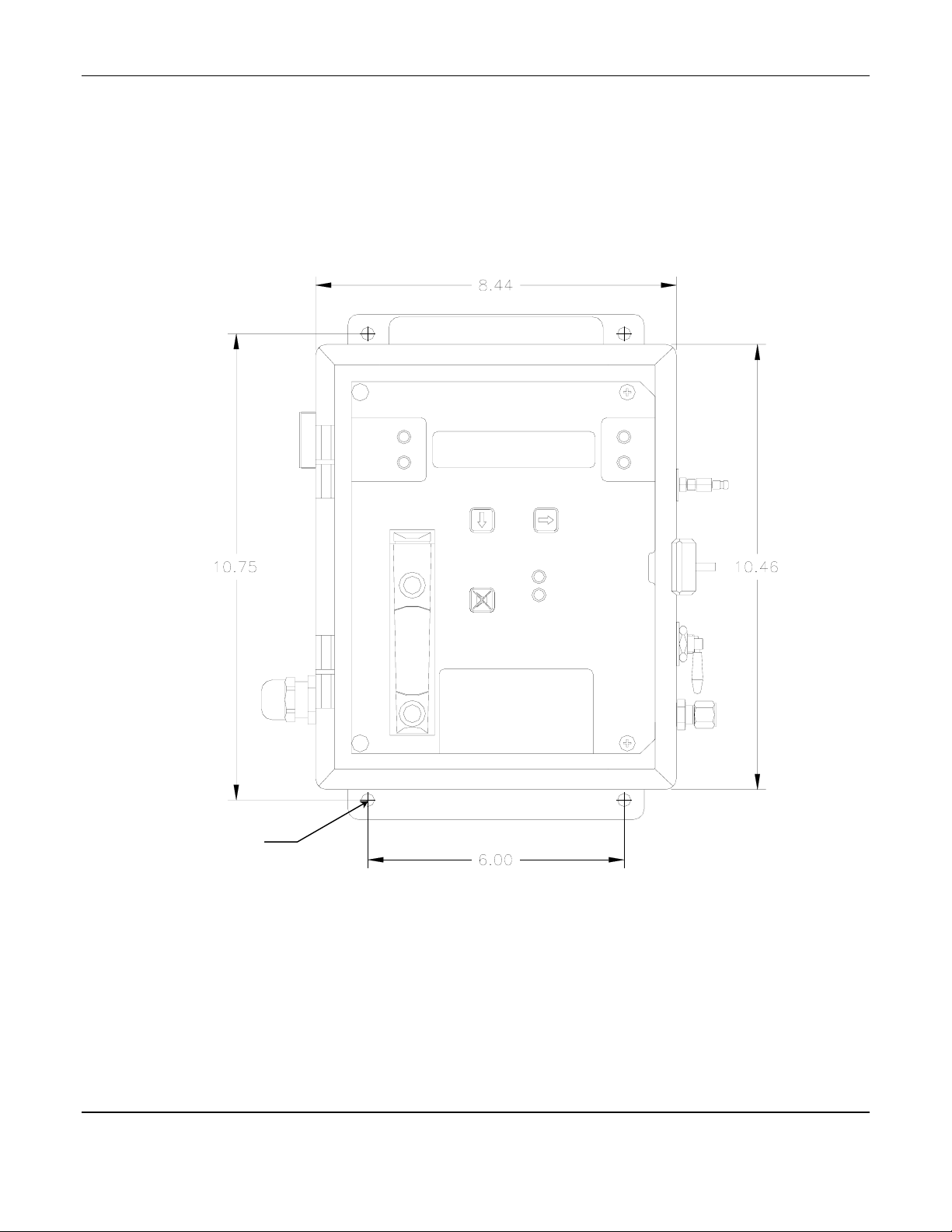

IGURE 3: MED AIR 2000 MOUNTING DIMENSIONS ................................................................................................. 5

FIGURE 2A: TERMINAL STRIP................................................................................................................................. 6

ABLE 1: RELAY CONTACTS .................................................................................................................................. 6

T

T

ABLE 2: FAULT RELAY CONTACTS ....................................................................................................................... 7

TABLE 3: OUTPUTS FOR 4-20MA FOR S/N 599 AND BELOW.................................................................................... 7

TABLE 3A: OUTPUTS FOR 4-20MA FOR S/N 600 AND ABOVE.................................................................................. 7

F

IGURE 4: MED AIR 2000 OPERATIONAL DISPLAY.................................................................................................. 8

TABLE 4: FACTORY ALARM SET POINTS................................................................................................................. 8

FIGURE 5: MED AIR 2000 OPERATION MENU FLOW CHART..................................................................................... 9

F

IGURE 6: MED AIR 2000 MAINTENANCE MENU FLOW CHART. ............................................................................. 11

FIGURE 7: CONNECTION OF CALIBRATION GAS CYLINDER..................................................................................... 13

TABLE 5: FAULT ALARM ...................................................................................................................................... 15

F

IGURE 8: REMOVE SHORTING CLIP..................................................................................................................... 18

FIGURE 9: MANIFOLD ........................................................................................................................................... 18

FIGURE 10: LOCATION OF PARTS FO R REPLACEMENT........................................................................................... 18

F

IGURE 11: CARBON MONOXIDE CONCENTRATION ............................................................................................... 21

Reference Information:

N

OTE: [important information about use of instrument]

C

AUTION: [affects equipment – if not followed may cause damage to instrument, sensor etc…]

WARNING: [affects personnel safety – if not followed may cause bodily injury or death.]

Page 5

MED AIR 2000 ENMET Corporation

1.0 Introduction

The MED AIR 2000is a gas and dew point detection instrument that monitors compressed air from medical air supply

systems for certain hazards to the user. The instrument is available with sensors that monitor air for carbon monoxide

(CO), for variations in the oxygen (O

can be used together. In the instrument, a sample of the compressed air is passed over electrochemical CO and O

sensors, a solid state dew point sensor and the resultant electrical outputs are used to evaluate the air for the target

gases. Some features of the instruments are as follows:

continuous monitoring of the sample air

continuous LCD display of gas and vapor concentrations

menu driven operational and maintenance controls

menu driven calibration procedure

audio and visual alarms indicate unsafe conditions

alarm relay contacts available on terminals

a fault relay and visual fault alarm

flowmeter plus low flow fault indication and display

alarm acknowledgement capability including audio defeat

mA outputs for each target gas

NEMA-12 packaging

NOTE: All specifications stated in this manual may change without notice.

1.1 Unpack

Unpack the MED AIR 2000and examine it for shipping damage. If such damage is observed, notify both ENMET customer

service personnel and the commercial carrier involved immediately.

) content and for dew point. The sensors can be used alone or up to three sensors

2

2

Regarding Damaged Shipments

NOTE: It is your responsibility to follow these instructions. If they are not followed, the carrier will

not honor any claims for damage.

This shipment was carefully inspected, verified and properly packaged at our company and delivered to the carrier in good

condition.

When it was picked up by the carrier at ENMET, it legally became your company’s property.

If your shipment arrives damaged:

• Keep the items, packing material, and carton “As Is.” Within 5 days of receipt, notify the carrier’s local office and request

immediate inspection of the carton and the contents.

• After the inspection and after you have received written acknowledgment of the damage from the carrier, contact ENMET

Customer Service for return authorization and further instructions. Have your Purchase Order and Sales Order numbers

available.

ENMET either repairs or replaces damaged equipment and invoices the carrier to the extent of the liability coverage, usually

$100.00. Repair or replacement charges above that value are your company’s responsibility.

The shipping company may offer optional insurance coverage. ENMET only insures shipments with the shipping company

when asked to do so in writing by our customer. If you need your shipments insured, please

ENMET Customer Service.

forward a written request to

Regarding Shortages

If there are any shortages or questions regarding this shipment, please notify ENMET Customer Service within 5 days of receipt at

the following address:

ENMET Corporation

680 Fairfield Court

Ann Arbor, MI 48108

734-761-1270 734-761-3220 Fax

1.2 Check Order

Check, the contents of the shipment against the purchase order. Verify that the MED AIR 2000 is received as ordered. If there are

accessories on the order, ascertain that they are present. Check the contents of calibration kits. Notify ENMET customer service

personnel of any discrepancy immediately.

1.3 Serial Numbers

Each MED AIR 2000 is serialized. These numbers are on tags on the equipment and are on record in an ENMET database.

1

Page 6

ENMET Corporation MED AIR 2000

2.0 Instrument Features

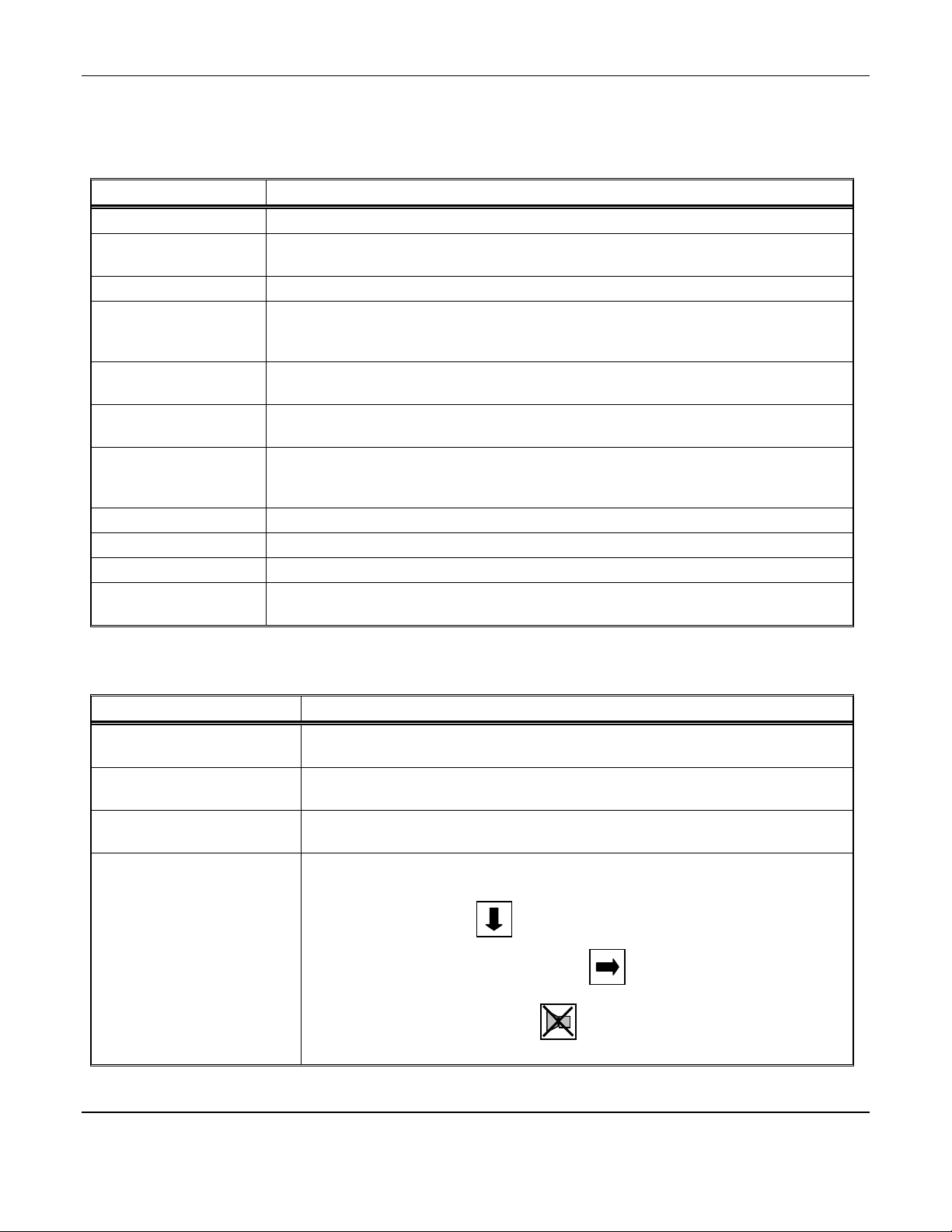

2.1 Exterior Features

The exterior of the instrument is shown in Figure 1. The exterior features are as follows:

Feature Description

Enclosure

Sample Air Hose

Sample Port

Sample/Calibration

Valve

Calibration Port

Front Cover Latch

Humidifier Tube

Line Cord

Audio Alarm

Mounting Flanges

Regulator

(Not supplied)

A NEMA-12 plastic box, approximately 10x8x6, with a clear hinged front cover.

A five foot long hose to conduct a sample of the air from the source to the instrument.

See Figure 1A.

The fitting for the sample air hose.

A red handled ball valve which directs the air from either the sample or the calibrate port.

The handle points at the port, sample or calibrate, which is providing the air to the

instrument

The entrance for the calibration gas. The quick release fitting mates with one on the

calibration adapter.

A quick-release latch that holds the clear front cover in place, and is capable of being

padlocked if desired.

Located under a black sheet metal cover. Is a tube that extracts moisture from the

atmosphere and adds it to dry sample air, before it is presented to the carbon monoxide and

oxygen sensors.

A cord to supply 110 V

A loud horn activated by certain alarm conditions.

Flanges with holes for mounting the enclosure to a vertical surface.

To connect to the compressed air line. Line pressure to the M

55 PSI. See note Figure 1A

AC to the equipment. Not illustrated.

ED AIR 2000 should be set to

2.2 Display Panel Features

The display panel, shown in Figure 1, is viewed through the clear front cover of the enclosure, and is accessed by

opening the cover. Features are as follows:

Feature Description

Display

Flowmeter

Visual Alarms

Pushbutton Switches

•Option Switch

•Select Switch

•Alarm Acknowledge/

Audio Defeat Switch

A 2 line, 16 character per line, LCD with backlight. The numerical values of gas

concentrations, and other information are displayed.

A flow indicator located at the output of the sample flow stream, which indicates

quantitatively the flow of sample air or calibration gas through the instrument.

On both sides of the display, a red LED for each sensor on the instrument.

Near the center of the panel,. a green power LED and a red fault LED,

There are three of these, located near the center of the panel; they are yellow

rectangular membrane switches. They are:

The top left switch.

Directly to the right of the option switch.

Directly under the option switch.

2

Page 7

MED AIR 2000 ENMET Corporation

r

f

p

Visual Alarm

Dew Point

If Dew Point option is installed)

(

Audio Alarm

OPTION

Switch

ALARM ACKNOWLEDGE/

LARM DEFEAT

A

Switch

Flow Mete

Strain Relie

for Line Cord

CO

ppm

Dew

Point

ALARM

ACKNOWLEDGE

Visual Alarm

CO

AUDIO

DEFEAT

SELECTOPTION

POWER

FAULT

Cover, Humidifier Tube

Display

Visual Alarm O2

(If Oxygen option is installed)

O

2

%

Power LED

Calibration

Port

SELECT

Switch

Front Cover Latch

Fault LED

Sample/Calibration

Valve

Mounting Flanges

2 places

Figure 1A: Regulator

Figure 1: Features of MED AIR 2000 External

NOTE: When connecting to a standard 55 PSI USA Medical

air systems, Regulator is Not required.

Regulator is Not supplied by ENMET

Sample Air Hose

to Sam

le Port

3

Sample Port

Input

See note below

Page 8

ENMET Corporation MED AIR 2000

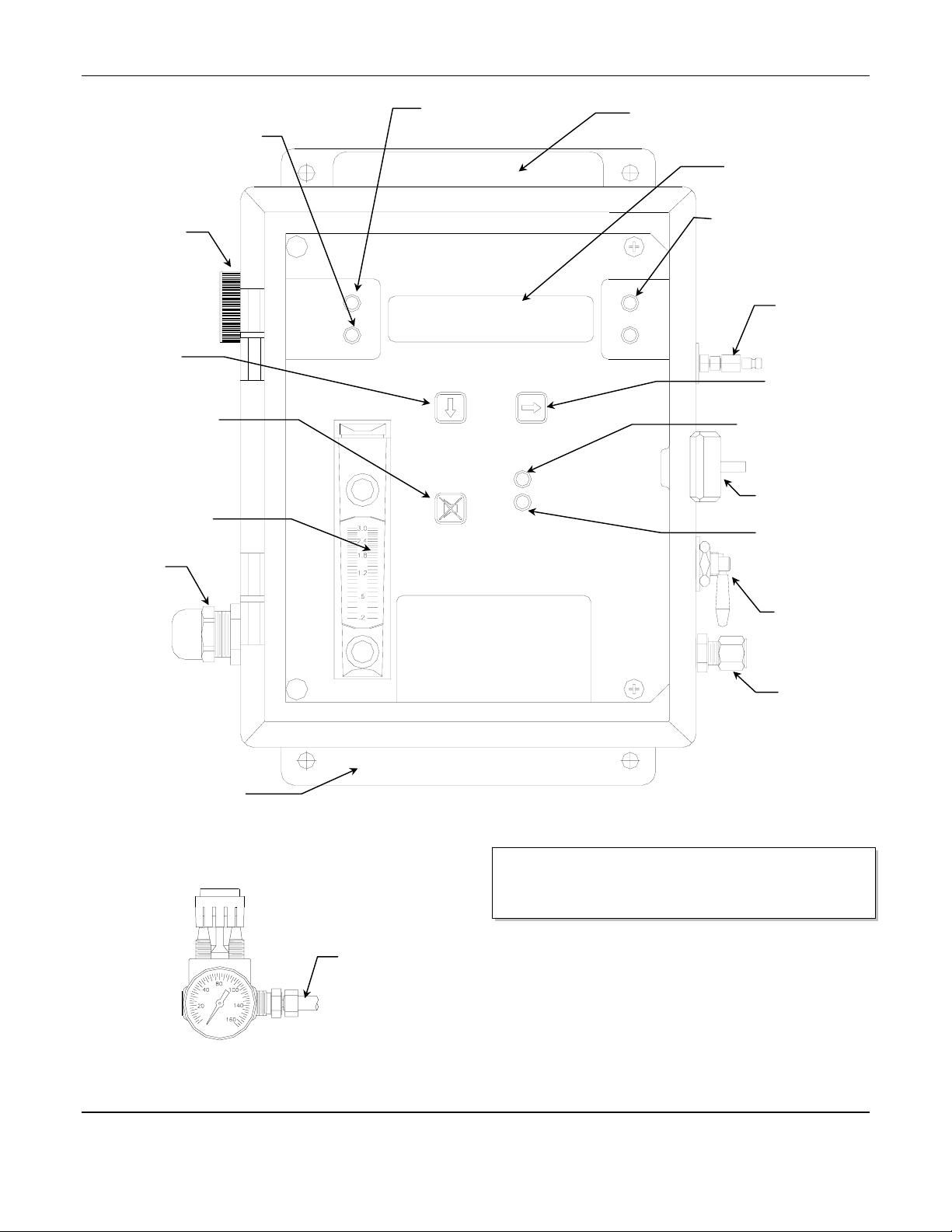

2.3 Circuit Board Features

The Display Panel is hinged on the right and is released by unscrewing the 2 thumb screws located in the left corners.

After releasing the panel, it is swung to the right, exposing the interior of the enclosure. The Circuit Board is mounted

on a plate at the back surface of the enclosure interior. Features are shown in Figure 2.

Feature Description

Terminal Strip

Manifold Housing

This twenty-three position terminal is located at the bottom of the Circuit Board. On

it are twelve positions for three contacts for each of four alarm relays, and three

positions for the contacts of a fault relay.

There are also two positions for each of the 4-20 mA outputs. (optional)

The sample manifold, the carbon monoxide and oxygen sensors are located under

this small aluminum housing. Not illustrated in figure 2, see Figure 8.

2.4 Power Supply

The power supply circuit is located on the bottom surface of the inside of the enclosure. The circuit is protected by

two 1.0 Amp fuses mounted in fuse holders on the power supply board.

2.5 Dew Point Sensor

If present in the instrument, the solid state dew point sensor is located on the plate to the right of the main circuit board.

2.6 Dew Point Circuit

If present in the instrument, the dew point circuit is located on the top surface of the inside of the enclosure.

Cover, Humidifier Tube

Humidifier

Tube

Audio Alarm

Sensor Dew Point

If Dew Point option

is installed

Particulate

Filter

Fuse Holder

Power Supply

PCB

Sensor O2

If Oxygen option is

installed

Sensor CO

Terminal Strip

Power Supply

PCB

Figure 2: MED AIR 2000 Interior Features

4

Page 9

MED AIR 2000 ENMET Corporation

3.0 Installation

3.1 Mounting of Instrument

The MED AIR 2000 should be located near the pipe or tank containing the air to be monitored, and upstream from

where the air is being used. So that, the air sample enters the instrument before it reaches the users.

Upright (plumb and level) vertical orientation of the instrument is necessary for proper operation. Mount the

instrument on an appropriate vertical surface using the mounting flanges provided. Avoid areas with excessive

vibration. The holes in the flanges are 0.31 inch in diameter and form a 6 x 10.75 inch rectangle. See Figure 3.

Mounting Holes

0.31” dia. 4 places

Dimensions are in inches.

SELECTOPTION

AUDIO

DEFEAT

ALARM

ACKNOWLEDGE

POWER

FAULT

Figure 3: MED AIR 2000 Mounting Dimensions

5

Page 10

ENMET Corporation MED AIR 2000

3.2 Sample Air Supply

Tap the pipe or tank containing the breathing air and use appropriate fittings to connect the sample input hose. The

instrument is designed to operate from an air supply pressure of 50-55 PSIG; adjust the regulator and set the pressure at

55

PSIG. The flowmeter on the display panel indicates approximately 2 SCFH when the input pressure is 55 PSIG.

The sample air exits the instrument from two separated ports on the back surface of the enclosure. Take care not to

obstruct these exit ports. After mounting the enclosure, they are not accessible.

Be sure that the red sample-calibrate valve handle on the right side of the enclosure is pointed down toward the sample

input port.

3.3 Power Supply

Plug the line cord in a source of 110VAC power. The input power can vary from 100 to 240VAC, 50/60 Hz; if other

than 110 V

Upon supplying air and power to the instrument:

The green power on LED is lit.

The display backlight is lit, and numbers are given on the display.

The instrument may go into alarm briefly, but the sensors stabilize quickly. If the instrument persists in alarm,

acknowledge the alarm by pressing the ALARM ACKN/AUDIO DEFEAT switch. If alarm persists longer than 30

minutes, call ENMET customer service personnel.

AC power is desired, the plug on the line cord must be changed.

3.4 Outputs

Two types of alarm outputs are available, relay contacts and optional 4-20mA outputs.

12 3 4567891011121314151617181920 21 22 23

NC C NO NC C NO NC CNO NC C NO NC CNO G + G + G + G

CO O2 DP N/A Fault LOOP

Figure 2A: Terminal Strip

3.4.1 Relay Contacts

Relay contacts are available for each alarm; these are SPDT, rated at 2.0Amp at 110VAC, and may be latching or nonlatching as required by the application. They are accessed on the terminal strip at the bottom of the circuit board see

Figure 2 & 2A. The positions given in Table 1:

Table 1: Relay Contacts

Position Function Contact

1 CO Alarm NC

2 CO Alarm C

3 CO Alarm NO

4 O2 Alarm* NC

5 O2 Alarm* C

6 O2 Alarm* NO

7 DP Alarm NC

8 DP Alarm C

9 DP Alarm NO

10 Not Used

11 Not Used

12 Not Used

* This relay is activated by both the deficiency and abundance alarms.

These relay coils are energized when they are in the non-alarm state; the contact conditions given above are for the

non-energized state, which is identical to the alarm state.

6

Page 11

MED AIR 2000 ENMET Corporation

In addition, there is a fault relay, which changes state whenever the instrument is in a fault condition.

The contact positions are given in Table 2:

Table 2: Fault Relay Contacts

Position Function Contact

13 Fault NC

14 Fault C

15 Fault NO

The coil of this relay is energized when the instrument is in the non-fault state; the contact conditions given above are

for the non-energized state, which is identical to the fault state.

These relay contacts can be used to operate auxiliary alarms or other functions. Punch a hole at the bottom of the left

side of the enclosure for a wire exit, and use appropriate cable and fittings to preserve the NEMA-12 rating of the

enclosure.

3.4.2 Optional 4-20mA Outputs

Isolated 4-20 mA outputs are available for data logging or other purposes. An output is supplied for each sensor

supplied in a particular instrument, and can be added when a sensor is added in the field. When all three sensors are

supplied, these outputs are available on the terminal strip in the positions given in Table 3:

Table 3: Outputs for 4-20mA for S/N 599 and below

Position Channel Function Range

16 CO Ground 4 mA = 0 ppm

17 CO + 4 to 20 mA 20 mA = 100 ppm

18* DP Ground 4 mA = –100°F

19* DP + 4 to 20 mA 20 mA = +50°F

20* O

21* O

2

2

*When two of the three sensors are supplied, one sensor is for CO, and the output for this sensor is on positions 16

& 17 as shown in Table 3 above. The second output is on positions 20 & 21. Positions 18 & 19 are not used.

Ground 4 mA = 0%

+ 4 to 20 mA 20 mA = 25.5%

Table 3A: Outputs for 4-20mA for S/N 600 and above

Position Channel Function Range

16 CO Ground 4 mA = 0 ppm

17 CO + 4 to 20 mA 20 mA = 100 ppm

18 DP Ground 4 mA = –100°F

19 DP + 4 to 20 mA 20 mA = +50°F

20 O

21 O

2

2

Ground 4 mA = 0%

+ 4 to 20 mA 20 mA = 25.5%

Wiring requirements are the same as for the relays.

3.5 Initial Calibration

All instruments are calibrated at the factory. You may, if a calibration kit is available, calibrate the CO and O

channels of the instrument 24 hours after installation. The dew point sensor can not be calibrated in the field. See

Section 5.0, Maintenance, for calibration instructions. After calibration, be sure to return the red sample-calibrate

valve handle to the down position, pointing toward the sample input port.

7

2

Page 12

ENMET Corporation MED AIR 2000

4.0 Operation

4.1 Normal Operation Condition

With the MED AIR 2000 installed as described in section 3, and in clean air, the POWER green LED is on, the display

is lit, the flowmeter reads approximately 2

for the sensor(s) installed in the M

ED AIR 2000. The red alarm and fault LEDs are not lit.

SCFH, and the information on the display is as shown in Figure 4 Display,

CO

PPM

DEW

POINT

Example of display with Dew Point and Oxygen option installed

000 PPM 20.9%

o

037

F FLOW:y

O

2

%

Figure 4: MED AIR 2000 Operational Display

4.2 Alarm Set Points

There is one alarm set point for CO and dew point, and two for oxygen. The factory settings of these alarm set points

are shown in Table 4.

Table 4: Factory Alarm Set Points

Gas Set Point

Carbon Monoxide 10 ppm

Dew point 39°Fahrenheit at 55PSIG

Oxygen Deficiency 19.5 % by volume

Oxygen Abundance 23.5 % by volume

These alarm set points can be changed within limits; see the maintenance section of this manual for the procedure.

If the CO concentration increases above that of the alarm set point, the associated red LED is lit, the associated

relay changes state, and the audio alarm is activated.

If the dew point increases above that of the alarm set point, the associated red LED is lit, the associated relay

chances state, and the audio alarm is activated.

If the oxygen content of the sample air decreases below the deficiency alarm set point, the associated red LED is

lit, the associated relay chances state, and the audio alarm is activated.

If the oxygen content of the sample air exceeds that of the abundance alarm set point, the associated red LED is lit,

the audio alarm is activated, and both the oxygen alarm relay and the oxygen high alarm relay change state.

There is one alarm LED for both the deficiency and abundance alarms.

4.3 Alarm Latching

An instrument is shipped with the alarms in the non-latching mode. The alarms may be independently configured in

the non-latching mode by use of the maintenance menu.

N THE LATCHING MODE: at the cessation of the condition which causes an alarm, the alarm indications do not

I

cease, and the alarm relay contacts do not revert to the non-alarm state, until the ALARM ACKN/AUDIO

DEFEAT switch is pressed. An alarm can also be acknowledged by pressing the switch during the alarm

condition; then at the cessation of the alarm condition, alarm indications cease and alarm relays revert to the nonalarm state. After an alarm is acknowledged, alarms in the latching configuration are re-armed to latch at the next

alarm condition.

I

N THE NON-LATCHING MODE: at the cessation of the condition which causes an alarm, the alarm indications

automatically cease, and the alarm relay contacts revert to the non-alarm state.

8

Page 13

MED AIR 2000 ENMET Corporation

N

N

N

4.4 Audio Defeat

With the alarms in the non-latching configuration, pressing the ALARM ACKN/AUDIO DEFEAT switch during an

alarm silences the audio alarm.

With an alarm in the latching configuration, pressing the ALARM ACKN/AUDIO DEFEAT switch during an alarm

silences the audio alarm and unlatches the associated relay(s).

4.5 Display

In clean air with the correct dew point, the display is as shown in Figure 4, for the sensor(s) installed in the MED AIR

2000. This position of the display is termed the "operational display". As explained below, the display can be

changed to furnish other information by using the OPTION and SELECT switches.

Concentrations of CO are given in PPM (parts per million parts of air). Dew point is given in degrees Fahrenheit at 55

PSIG; this can be changed to degrees Centigrade by pressing the SELECT switch. Oxygen concentration is given in

per cent by volume. When sample flow is reduced below a limit, the display switches from "Flow: yes" to" Flow: no",

or from "Flow: y" to "Flow: n".

4.6 Operational Menu

The operational menu allows the user to:

View alarm set point concentration values

View alarm latching configurations

Enter the maintenance menu with the proper key.

The operational menu is accessed with the OPTION and SELECT switches. The operational menu flow chart is

shown in Figure 5,

The OPTION switch is indicated with a "O"

The select switch is indicated with a "S".

If the instrument is left at any location in the operational or maintenance menus, other than the operational display,

with no action taken for a period of 45 seconds, it returns to the operational display.

Operational Display

000 PPM 20.9%

037 °FFLOW:y

S

DEW POINT

°C ↔ °F

O

View

Alarms & Latches

O

S

ppm CO: 10

Latch: Yes

O

°F DP: 39.0

Latch: Yes

S

S

o Function

o Function

O

%O2: 19.5 23.5

Latch: Yes Yes

S

o Function

O

run Maintenance

Menu

O

S

To Key

O = Option Switch

S = Select Switch

Figure 5: MED AIR 2000 Operation Menu Flow Chart

9

Page 14

ENMET Corporation MED AIR 2000

4.7 Fault Indications

4.7.1 Low Flow Indication

A sensitive pressure switch is used to furnish a low flow indication. When the sample air pressure drops below

approximately 30

n", depending upon the number of sensors installed in the instrument.

PSIG, the fault light and audio alarm are activated, and the display reads either "Flow: no" or "Flow:

4.7.2 Other Fault Indications

Other fault indications are associated with sensor zero and calibration activities, and are described in the maintenance

section 5.0 of this manual.

4.8 Dew Point Sensor Response

It is a characteristic of this solid state sensor that it takes more time to extract moisture from it by passing dry air over

it, than it does to add moisture to it by passing moist air over it. Therefore, the time response of the sensor to a step

change from moist to dry air is relatively slow, while the response to a step change from dry to moist air is rapid.

10

Page 15

MED AIR 2000 ENMET Corporation

5.0 Maintenance

5.1 Maintenance Menu

The MED AIR 2000 maintenance menu is accessed with the OPTION and SELECT switches. The maintenance menu

diagram is shown in Figure 6 Maintenance Menu Flow Chart. From the operational display, press the OPTION

switch twice; "run MAINTENANCE MODE" is displayed.

Figure 6: MED AIR 2000 Maintenance Menu Flow Chart.

11

O = Option Switch

S = Select Switch

Page 16

ENMET Corporation MED AIR 2000

5.1.1 Key

Entrance to the maintenance menu is guarded with a four-digit key. The factory default setting of the key is 1270.

When a valid numerical key is inserted, the user is allowed to enter the maintenance menu.

In the "run MAINTENANCE MODE" position

Press the SELECT switch; "KEY = 0000" is displayed.

In the "KEY = 0000" position, the underline cursor is under the left digit.

Press the OPTION switch to change the left digit; select the correct digit.

Press the SELECT switch, which locks the correct digit in place and moves the cursor one digit to the right.

Continue this process until the four-digit key is complete. When a valid key is inserted in this manner, the display is

transferred to the "run AUTOMATIC ZEROING" portion of the menu. If an invalid key is inserted, "INVALID" is

displayed briefly; then the M

ED AIR 2000 returns to the operational display.

CO

PPM

DEW

POINT

KEY = 1270

From Operational Menu

To Operational

Display

run MAINTENANCE

O

MODE

Example: Key Display and Flow Chart

S

KEY=0000

Invalid

O

Changes digit indicated by underscore cursor

S

Locks underscore digit and moves cursor to next digit

Valid entry

To Automatic Zeroing

O

2

%

O = Option Switch

S = Select Switch

12

Page 17

MED AIR 2000 ENMET Corporation

E

5.1.2 Automatic Zeroing

A valid key entry sets the instrument in the "run AUTOMATIC ZEROING" position, which enables the setting of the

zero gas concentration point. This is desirable if the zero reference of one of the sensors has drifted over time. For

CO, the zero reference point is 0000 ppm CO; the zero reference point for oxygen is 20.9% oxygen by volume. Note

that the calibration procedure described in section 5.1.3 also includes setting the zero point. If a full calibration is

required, instead of setting just the zero point, press the OPTION switch once; "run FULL CALIBRATION" is

displayed. See section 5.1.3.

T

O SET THE ZERO POINT WITHOUT PERFORMING FULL CALIBRATION:

From the "run AUTOMATIC ZEROING" position, see flow chart.

Press the SELECT button; "ATTACH ZERO GAS" is displayed.

OTE: While it is possible to zero the sensor(s) using a sample from a "clean" air line, this entails using the sample as

N

a standard, and is best avoided. The best zero gas is a cylinder of 20.9% oxygen in nitrogen with no CO

present. This is available in the calibration kit listed in section 6.0

Pressing the OPTION switch at this point aborts the procedure and transfers the display to the "exit MAINTENANCE

MODE" position.

From Valid Key Entry

run AUTOMATIC

ZEROING

S

O

To Full Calibration

Example: Automatic Zeroing Flow Chart

ATTACH

ZERO GAS

S

ZERO=30 .00V

20.9 130 00.0

O

Exit Maintenance Mode

Valid

Invalid

Return to Operational Display

Return to Operational Display with

“Fault 01” in place of the PPM reading

O = Option Switch

S = Select Switch

O CONTINUE THE PROCEDURE: attach a cylinder of zero gas to the Calibration Port using the calibration adapter, as

T

shown in Figure 7. Open the cylinder valve, set the regulator at 55

PSIG, and turn the red handle of the sample-

calibrate valve up toward the calibration port. Let the gas flow for about a minute

Calibration Port

Cylinder Valve

and Regulator

SELECTOPTION

AUDIO

POWER

DEFEAT

ALARM

ACKNOWLEDG

FAULT

Cylinder of Gas

Sample/Calibration

Valve – Up to Calibrate

Figure 7: Connection of Calibration Gas Cylinder

13

Page 18

ENMET Corporation MED AIR 2000

press the SELECT switch.

"ZERO = 30 .00V" is displayed. This is a timer that counts down from 30 seconds, at the end of that time the

procedure is finished. The instrument sets the clean air voltage point for the CO sensor and the 20.9% O

point for

2

the oxygen sensor if it is present. It then examines the validity of these values; if they are valid, it goes back to the

operational display. If a failure occurs, "Fault-01" is displayed in place of PPM reading in the operational display.

FAULT 01 indicates a clean air fault. Verify the proper zero gas is attached to the calibration Port and the samplecalibrate valve is up toward the calibration port. Repeat automatic zeroing procedure. If fault 01 still occurs, replace

sensor in accordance with section 5.2.

After this procedure is complete, be sure to return the red handle of the Sample-Calibrate valve to the down position,

pointing toward the Sample Port. If the Sample-Calibrate valve is not switched back to the sample port, the low flow

fault indication is activated when the zero gas is removed.

5.1.3 Calibration

Insertion of a valid key results in the display: "run AUTOMATIC ZEROING". Press the OPTION switch once; "run

FULL CALIBRATION" is displayed. Press the SELECT switch; "ATTACH ZERO GAS" is displayed; this is the

start of the automatic zeroing procedure as described in paragraph 5.1.2, above. When this procedure is complete,

"ATTACH SPAN GAS - SPAN = 20" is displayed to indicate that the correct span gas for this procedure is 20 ppm

CO in a mixture of 20.9% oxygen in nitrogen. Do Not Use Any Other Than The Correct Span Gas For This

Procedure.

Pressing the OPTION switch at this point aborts the procedure and sets the display at the "exit MAINTENANCE

MODE" position.

From Automatic Zeroing

run FULL

CALIBRATION

O

To Selectable Alarms

S

ATTACH

ZERO GAS

S

ZERO=30 .00V

20.9 130 00.0

S

ATTACH SPAN

GAS PPM CO

S

SPAN=120 .65V

20.9 130 00.0

O

Exit Maintenance Mode

O

Exit Maintenance Mode

Valid

Return to Operational Display

Invalid

Return to Operational Display with

“Fault 01, Fault 02 or Fault 03”

O = Option Switch

S = Select Switch

Example: Full Calibration Flow Chart

T

O CONTINUE THE PROCEDURE:

Attach the correct span gas to the Calibration Port with the calibration adapter turn the red handle of the Sample-

Calibrate valve up toward the Calibration Port. See Figure 7.

Open the cylinder valve, set the regulator at 55

Allow the calibration gas to flow for

AUTION: Pressure fluctuations may lead to aberrant oxygen readings if the SELECT switch is activated in less than

C

at least one minute, then press the SELECT switch.

PSIG.

one minute.

"SPAN = 120 .00V" is displayed. This is a timer that counts down 120 seconds, at that point the procedure is

complete. The “.00V”portion of the display reflects the sensor signal, as it responds to the CO gas. This value

should increase.

After a valid zero and calibration, the instrument reverts to the operational display.

14

Page 19

MED AIR 2000 ENMET Corporation

A

r

y

After an invalid zero or calibration one of the following will be displayed in place of the PPM reading in the

operational display:

Table 5: Fault Alarm

Displayed Cause Possible remedy

• Fault 01

An invalid zero

·verify proper zero gas is attached to calibration port and

sample-calibration valve handle is up

·perform automatic zero

·change sensor in accordance with section 5.2

• Fault 02

An invalid calibration

·verify proper calibration gas is attached to calibration port and

sample-calibration valve handle is up

·perform calibration

·change sensor in accordance with section 5.2

• Fault 03

An invalid zero and

calibration

·verify proper calibration gas is attached to calibration port and

sample-calibration valve handle is up

·perform calibration

·change sensor in accordance with section 5.2

After this procedure is complete, return the red handle of the Sample-Calibrate valve to the down position, pointing

toward the Sample Port. If the Sample-Calibrate valve is not returned to the sample port, the low flow alarm is

activated when the calibration gas is removed.

OTE: During the zero and span process, the sensor singles must fall within a preset limit. If they do not, the fault

N

codes above are generated. If a fault code 02 is generated with calibrating the CO sensor, and the span voltage

is close to, but not greater then 0.38V, an adjustment may be capable of being made, to extend the life of the

sensor. Follow the procedure foe calibrating a sensor as outlined in section 5.2.

5.1.4 Select Alarm Set Points

Factory alarm set points are discussed in paragraph 4.2. To change the alarm set points, after inserting a valid key,

Press the OPTION switch twice; "set SELECTABLE ALARMS" is displayed.

Press the SELECT switch; "ALARM = 0000" is displayed, with the underscore cursor under the left digit.

Press the OPTION switch to change the left digit; select the correct digit.

Press the SELECT switch to lock in the correct digit and move the cursor one digit to the right. When a valid new

alarm is selected, the "NEW = XXXX" is displayed.

Press the OPTION or the SELECT switch, and the display changes to the next sensor. After all sensors have been

displayed, the display returns to the "set SELECTABLE ALARMS" position.

Valid alarm ranges are as follows:

• CO: 5 to 99 ppm

• Dew Point: 0° to 37°C (30° to 98.6°F)

• The Oxygen alarm set points are 19.5% for deficiency and 23.5% for abundance, and are not adjustable.

From Full Calibration

set SELECTABLE

ALARMS

S

set CO Alarm

O

O

To Set Latches

Example: Selectable Alarms Flow Chart

Invalid entr

S

LARM=0000

NEW=0000

Changes digit indicated by

O

underscore curso

S

Locks underscore digit and

moves cursor to next digit

S or O

Exit Maintenance Mode

O = Option Switch

S = Select Switch

15

Page 20

ENMET Corporation MED AIR 2000

5.1.5 Set Latches

To latch and unlatch the alarm relays, after inserting a valid key, press the OPTION switch three times; "set

LATCHES" is displayed.

Press the Select switch; the particular alarm relay and its latch mode is displayed, for example, "RELAY: 10ppm

CO, LATCH: no".

Use the OPTION switch to toggle the latch mode between "yes" and "no". Select the desired mode. See section 4.3.

Press the SELECT switch to step to the next relay. The procedure steps sequentially to all alarm relays in this

manner; when complete, it returns to the "set LATCHES" position.

From Selectable Alarms

set LATCHES

O

S

RELAY 10 PPM CO

LATCH: no

O

Toggles “Yes” and “No”

S

RELAY O2

LATCH: no

O

Toggles “Yes” and “No”

O = Option Switch

S = Select Switch

S

To Set Key

RELAY FAULT

S

LATCH: no

O

Toggles “Yes” and “No”

Example: Set Latches Flow Chart

5.1.6 Set the Key

To set a new key, after inserting a valid key, press the OPTION switch four times; "set KEY” is displayed. Press the

SELECT switch; "KEY = 0000" is displayed, with the underscore cursor under the left digit. Use the OPTION switch

to change the left digit, select the desired digit, and use the SELECT switch to lock the digit in place and move the

cursor one digit to the right. When all four digits of the new key have been selected, "NEW = XXXX" is displayed.

Record the new key; without it, the maintenance menu cannot be reentered once it is left. If the key is lost, call

ENMET customer service personnel.

From the "NEW = XXXX" position, press either the OPTION or the SELECT switch; "exit MAINTENANCE

MODE" is displayed.

From Set Latches

set KEY

S

O

To exit Maintenance Mode

Example: Set Key Flow Chart

KEY=0000

NEW = XXXX

S or O

O

Changes digit indicated by underscore cursor

S

Locks underscore digit and moves cursor to next digit

O = Option Switch

S = Select Switch

5.1.7 Exit

From the "exit MAINTENANCE MODE" position

Press the SELECT switch to resume the operational display.

Press the OPTION switch to reenter the maintenance menu at the "run AUTOMATIC ZEROING" position.

Return to Run Automatic Zeroing

exit MAINTENANCE

MODE

16

SO

Return to Operational Display

Page 21

MED AIR 2000 ENMET Corporation

5.2 Sensor Replacement

5.2.1 CO Sensor

A CO sensor must be replaced when it can no longer be calibrated. To replace a sensor, perform the following steps.

Turn off the electrical power. The sample air can continue to flow.

Open the display panel and remove the two manifold retention screws and remove the manifold. See Figure 9.

Remove the old CO sensor, which is the bottom most sensor, and replace it with a new sensor.

AUTION: New sensors come with a shorting clip that must be removed for proper operation. See Figure 8.

C

Replace the manifold. Observe that the flowmeter reading is correct.

Turn on the electrical power.

Wait 30 minutes, then recalibrate the sensor per the instructions in Section 5.1.3. As the timer is counting down

during calibration, a voltage is displayed on the screen beside the timing count. This voltage must be between:

For Serial No. Range Adjust to

133 and above .38V - .68V .65V

132 and below .59V - .68V .64V

Adjust to: .65V if it is not between .38 – .68V. Adjust this voltage during the last 30 seconds of the calibration

interval, using the bottom most potentiometer on the sensor circuit board. See Figure 10.

Replace the manifold housing, and secure the display panel. An instrument without the manifold housing in place

is susceptible to RFI.

5.2.2 Oxygen Sensor

An oxygen sensor must be replaced when it can no longer be calibrated in clean air. To replace the sensor, follow the

general steps given for the replacement of the CO sensor, but effect a replacement of the oxygen sensor, which is the

large sensor in the center position of the manifold. After sensor installation, wait four hours before recalibrating.

When recalibrating, it is not necessary to make a voltage adjustment.

5.3 Humidifier Tube

The humidifier tube is used to assure that the CO and oxygen sensors are not subjected to extremely dry air for a long

period of time, which would decrease their useful life. Change the humidifier tube when changing a CO sensor at the

completion of its useful life.

To change the humidifier tube:

Remove the sheet metal cover from the top of the enclosure, exposing the humidifier tube. See Figure 10.

Note the coiled arrangement of the tube. Remove the old tube and replace it with the new one.

Replace the sheet metal cover.

5.4 Dew Point Sensor

Unlike the CO and O2 sensors, the dew point sensor cannot be field calibrated. To assure correct performance, the dew

point sensor should be calibrated biyearly. To minimize instrument downtime, take advantage of the dew point sensor

exchange program available through ENMET, in which a year old dew point sensor can be exchanged for a newly

calibrated sensor. Call ENMET customer service personnel for details.

5.5 Flow Control Orifice

A 0.006-inch diameter orifice is used to set the flow rate and to drop the air pressure. It is located where the air enters

the humidifier tube, see Figure 10. In well-maintained medical air systems, this orifice should not clog. However, if

difficulty is experienced in maintaining flow rate with assured inlet pressure, remove air pressure from the equipment

and examine this orifice; replace it if necessary.

5.6 Particulate Filter Replacement

On instruments with serial numbers S/N 332 and above, a filter is installed inside the enclosure, as shown in Figure 10.

To replace this filter:

Obtain a new filter

Note the correct direction of flow, as denoted by the arrow on the filter body

Remove the old filter

Replace with the new filter

17

Page 22

ENMET Corporation MED AIR 2000

Manifold

Sensor

Bottom View

Figure 8: Remove Shorting Clip

Figure 9: Manifold

Cover, Humidifier Tube

Humidifier Tube

Particulate Filter

Flow Control Orifice

Oxygen Sensor

CO Voltage adjustment

Potentiometer

CO Sensor

Figure 10: Location of Parts for Replacement

18

Page 23

MED AIR 2000 ENMET Corporation

6.0 Replacement Part Numbers

ENMET part numbers for replacement parts:

Part number Description

03009-001 Dew Point sensor

05221-001 Power Supply Circuit

64002-1000 Fuse, 1.0 Amp 5x20mm

67016-1106 Sensor, Oxygen

67020-1200 Sensor, CO (for units S/N 299 and below)

67016-1204 Sensor, CO (for units S/N 300 and above)

73070-009 Orifice

73108-002 Humidifier Tube

03401-000 Calibration Kit

03219-020 Gas Cylinder, 20 ppm CO in air

03296-209 Gas Cylinder, 20.9% oxygen in nitrogen

03700-022 Calibration Adapter

73089-002 Filter, particulate (for units S/N 332 and above)

19

Page 24

ENMET Corporation MED AIR 2000

7.0 WARRANTY

ENMET warrants new instruments to be free from defects in workmanship and material under normal use for a period

of one year from date of shipment from ENMET. The warranty covers both parts and labor excluding instrument

calibration and expendable parts such as calibration gas, filters, batteries, etc... Equipment believed to be defective

should be returned to ENMET within the warranty period (transportation prepaid) for inspection. If the evaluation by

ENMET confirms that the product is defective, it will be repaired or replaced at no charge, within the stated

limitations, and returned prepaid to any location in the United States by the most economical means, e.g. Surface

UPS/RPS. If an expedient means of transportation is requested during the warranty period, the customer is responsible

for the difference between the most economical means and the expedient mode. ENMET shall not be liable for any

loss or damage caused by the improper use of the product. The purchaser indemnifies and saves harmless the

company with respect to any loss or damages that may arise through the use by the purchaser or others of this

equipment.

This warranty is expressly given in lieu of all other warranties, either expressed or implied, including that of

merchantability, and all other obligations or liabilities of ENMET which may arise in connection with this equipment.

ENMET neither assumes nor authorizes any representative or other person to assume for it any obligation or liability

other than that which is set forth herein.

NOTE: When returning an instrument to the factory for service:

Be sure to include paperwork.

A purchase order, return address and telephone number will assist in the expedient repair and return of your unit.

Include any specific instructions.

For warranty service, include date of purchase

If you require an estimate, please contact ENMET Corporation.

There is Return for Repair Instructions and Form on the last pages of this manual. This form can be copied or used as

needed.

20

Page 25

MED AIR 2000 ENMET Corporation

Appendix A

The Characteristics and Effects of Carbon Monoxide

Carbon monoxide is a colorless odorless toxic gas generated by incomplete combustion of a hydrocarbon fuel in air. It

may be present where internal combustion engines, furnaces, boilers, and other combustion devices are present. It is

toxic when inhaled because of its great affinity to hemoglobin, the oxygen carriers in the red cells of the blood. CO

replaces the oxygen normally carried by the hemoglobin, and thus inhibits the delivery of oxygen throughout the body;

the victim suffers from oxygen deficiency, and may die from asphyxiation. The symptoms and degree of danger

resulting from exposure to CO depend upon the concentration of the gas and the length of exposure; this is shown in

Figure 8. The M

assessment of the degree of danger that he or she is exposed to.

Based upon knowledge of the effects of CO, the Occupational Safety and Health Authority (OSHA) has set limits on

exposure to CO in the workplace. These are 35 ppm (parts CO per million parts air) as an time weighted average for

an eight hour day, and a maximum exposure of 200 ppm. For compressed air line applications, OSHA requires Grade

D breathing air supplied, using a Compressed Gas Association (CGA) definition (G-7.1). Depending on interpretation

of the OSHA respiratory standard, 10 ppm and 20 ppm CO have been used as maximum limits and standard

instrument alarm points.

The M

ED AIR 2000 has two preset alarm set points, at 10 ppm and 20 ppm CO, which are adjustable, but cannot be set

below 5 ppm or above 100 ppm.

The curves below are for percent carboxalhemoglobin with 50% being the top curve, 5% the bottom. %COHb is a

measure of the amount of hemoglobin occupied by CO rather than oxygen. CO effects upon children, adults engaging

in physical activity, and smokers, are ore pronounced.

ED AIR 2000 instrument is employed to warn the user of the presence of CO, and to facilitate the

Figure 11: Carbon Monoxide Concentration

21

Page 26

ENMET Corporation MED AIR 2000

Notes:

22

Page 27

PO Box 979

680 Fairfield Court

Ann Arbor, Michigan 48106-0979

734.761.1270 Fax 734.761.3220

Returning an Instrument for Repair

ENMET instruments may be returned to the factory or any one of our Field Service Centers for regular

repair service or calibration. The ENMET Repair Department and Field Service Centers also perform

warranty service work.

When returning an instrument to the factory or service center for service, paperwork must be included

which contains the following information:

¾ A purchase order number or reference number.

¾ A contact name with return address, telephone and fax numbers

¾ Specific instructions regarding desired service or description

of the problems being encountered.

¾ Date of original purchase and copy of packing slip or invoice

for warranty consideration.

¾ If a price estimate is required, please note it accordingly and be

sure to include a fax number.

Providing the above information assists in the expedient repair and return of your unit.

Failure to provide this information can result in processing delays.

ENMET charges a one hour minimum billing for all approved repairs with additional time billed to the

closest tenth of an hour. All instruments sent to ENMET are subject to a minimum $30 evaluation fee,

even if returned unrepaired. Unclaimed instruments that ENMET has received without appropriate

paperwork or attempts to advise repair costs that have been unanswered, after a period of 60 days,

may be disposed of or returned unrepaired COD with the evaluation fee.

Service centers may have different rates or terms. Be sure to contact them for this information.

Repaired instruments are returned by UPS/RPS surface and are not insured unless

otherwise specified. If expedited shipping methods or insurance is required, it must be

stated in your paperwork.

Note: Warranty of customer installed components.

If a component is purchased and installed in the field, and fails within the warranty term, it can

be returned to ENMET and will be replaced, free of charge, per ENMET’s returned goods

procedure.

If the entire instrument is returned to ENMET Corporation with the defective item installed, the

item will be replaced at no cost, but the instrument will be subject to labor charges at half of the

standard rate.

Page 28

Page 29

Repair Return Form

Mailing Address:

ENMET Corporation

PO Box 979

Ann Arbor, Michigan 48106

Phone Number: 734.761.1270

FAX Number: 734.761.3220

Your Mailing Address:

Contact Name: __________________________ Your Phone: _______________________

Your PO/Reference Number: _______________ Your FAX: _______________________

Shipping Address:

ENMET Corporation

Attn: Repair Department

680 Fairfield Court

Ann Arbor, Michigan 48108

Your Shipping Address:

Payment Terms: T COD

(Check one) T VISA / MasterCard______________________ ________

Card number Expiration

Return Shipping Method:

T UPS/RPS Surface: T 3 day T 2nd Day Air T Next Day Air

T Federal Express: T Next Day Morning T Next Day AfternoonT Standard

T FedEx Account number: ________________________

Would you like ENMET to insure the return shipment?

T No T Yes Insurance Amount: $_________________

Page 30

Loading...

Loading...