Page 1

ENMETENMET Corporation

PO Box 979

Ann Arbor, MI 48106-0979

ISA-RAL-M

ISA-RAH-M

Operation and Maintenance

80002-030

04/10/95

MCN 149, 10/31/95

MCN 162, 03/25/97

MCN 164, 04/02/97

MCN 179, 10/06/97

MCN 204, 10/20/98

MCN 205, 01/19/99

MCN 214, 03/16/99

MCN 220, 09/17/99

MCN 241, 09/22/00

MCN-304, 10/17/03

Manual

Page 2

Page 3

Table of Contents

1.0 INTRODUCTION............................................................................................................................................................................1

1.1 OPERATION PRINCIPLE.........................................................................................................................................................................1

1.2 ISA-RAH-M HIGH PRESSURE MONITOR..........................................................................................................................................1

1.3 HYDROCARBON FILTER........................................................................................................................................................................1

2.0 UPON RECEIPT.....................................................................................................................................................................................1

3.0 FEATURES, DEFINITION OF PARTS ..........................................................................................................................................2

3.1 ELECTRONICS CONTROL UNIT ............................................................................................................................................................2

3.2 INTERNAL ELECTRONIC CIRCUITRY...................................................................................................................................................3

3.3 SAMPLE HEAD ASSEMBLY...................................................................................................................................................................4

4.0 INSTALLATION....................................................................................................................................................................................5

5.0 INITIAL WARM-UP AND OPERATION......................................................................................................................................7

5.1 QUICK FIELD TESTS..............................................................................................................................................................................8

6.0 CALIBRATION......................................................................................................................................................................................9

7.0 MAINTENANCE...................................................................................................................................................................................10

7.1 ROUTINE MAINTENANCE ...................................................................................................................................................................10

7.2 SENSOR CABLE REPLACEMENT.........................................................................................................................................................10

7.3 HYDROCARBON FILTER REPLACEMENT ..........................................................................................................................................10

7.4 REPLACEMENT PARTS.........................................................................................................................................................................11

8.0 SPECIFICATIONS ..............................................................................................................................................................................12

8.1 TYPICAL CALIBRATIONS .....................................................................................................................................................................12

8.2 OPTIONS AND V ARIATIONS................................................................................................................................................................12

9.0 WARRANTY ..........................................................................................................................................................................................13

9.1REPAIR OF CERTAIN UNITS.................................................................................................................................................................13

List of Illustrations

Figure 1: Electronics Control Unit................................................................................................................................................................2

Figure 2: High Pressure Regulator................................................................................................................................................................2

Figure 3: Utilizing the Relay Contacts.........................................................................................................................................................3

Figure 5: Internal Electronic Circuitry .........................................................................................................................................................3

Figure 4: Sample Head Assembly ................................................................................................................................................................. 4

Figure 6: Connecting to Compressed Air Line ........................................................................................................................................... 6

Figure 7: Calibration Adapter and Gas ........................................................................................................................................................8

Page 4

Page 5

ISA-RAL-M, ISA-RAH-M ENMET Corporation

1.01.0 IntroductionIntroduction

Sandblasting, welding, and spray painting are examples of activities that create potentially hazardous environments.

Such environments contain toxic gases, dust and fumes. An air compressor system with hoods or masks supplies clean

breathing air to workers and minimizes the risk of injury or death; however, carbon monoxide (CO) can contaminate

the air in a compressor system. Carbon monoxide contamination can occur either when the intake air itself is

contaminated, or when the compressor breaks down and overheats. Because of this hazard, Federal OSHA regulations

(Sec. 1910.134) require monitoring of CO in compressed air systems. In addition, the Compressed Gas Association

has set up guidelines governing maximum tolerable levels of CO and other contaminants (Spec. G-7.1) to ensure the

health and safety of persons who use respiratory air lines.

The ENMET ISA-RAL-M (See Figure 1) monitors the carbon monoxide in compressed air used for human breathing.

If the CO concentration exceeds any predetermined levels, the ISA-RAL-M will triggers audio-visual alarms and

activates any associated equipment to alert personnel in potential danger.

NOTE: All specifications stated in this manual may change without notice.

1.1 Operation Principle

The ISA-RAL-M is an all-solid state electronic gas-detecting instrument designed to continuously monitor the carbon

monoxide level in compressed air. The sensing element is a gas-sensitive metallic-oxide semiconductor (MOS). A

regulator-humidifier assembly collects and humidifies a small air sample from the respiratory air line and passes it

over the sensor. When the level of CO in the air passing over the sensor increases to preset values, the instrument

alarms with audio (horn) and visual (light) signals.

The ISA-RAL-M operates from single-phase 110 Vac, single-phase 220 Vac and/or 12 Vdc power and is equipped

with relay contacts to provide additional alarm signals.

1.2 ISA-RAH-M High Pressure Monitor

The ISA-RAH-M is designed to monitor breathing air from cylinders at pressures up to 5000 psi. The equipment

consists of an ISA-RAL-M with the addition of a high-pressure regulator at the sample air input as shown in Figure 2.

The high pressure regulator must be plumbed into the high pressure line with an appropriate fitting; the output is

connected to the ISA-RAL-M by means of a quick release pneumatic fitting. The operation of the ISA-RAH-M is

identical with that of the ISA-RAL-M, and calibration is also identical; the high pressure regulator is removed from the

sample input and the calibration procedures given in this manual are employed.

1.3 Hydrocarbon Filter

There are two versions of the ISA-RAL-M:

P/N 04526-001 is supplied with a hydrocarbon filter

P/N 04526-003 is supplied without a hydrocarbon filter

2.0 Upon Receipt2.0 Upon Receipt

1. Unpack and inspect your new ISA-RAL-M for damage, which might have occurred during shipment.

2. Make sure the instrument is calibrated according to your order.

3. Do not use damaged or incorrect equipment. If there is a problem, contact your distributor or ENMET personnel

immediately.

4. Read this manual thoroughly to assure proper handling, operation, and maintenance of your ISA-RAL-M.

1

Page 6

ENMET Corporation ISA-RAL-M, ISA-RAH-M

Alarm Light

Switch Indicator Light

4 holes, .31 Dia.

3.0 Features, Definition of Parts3.0 Features, Definition of Parts

3.1 Electronics Control Unit

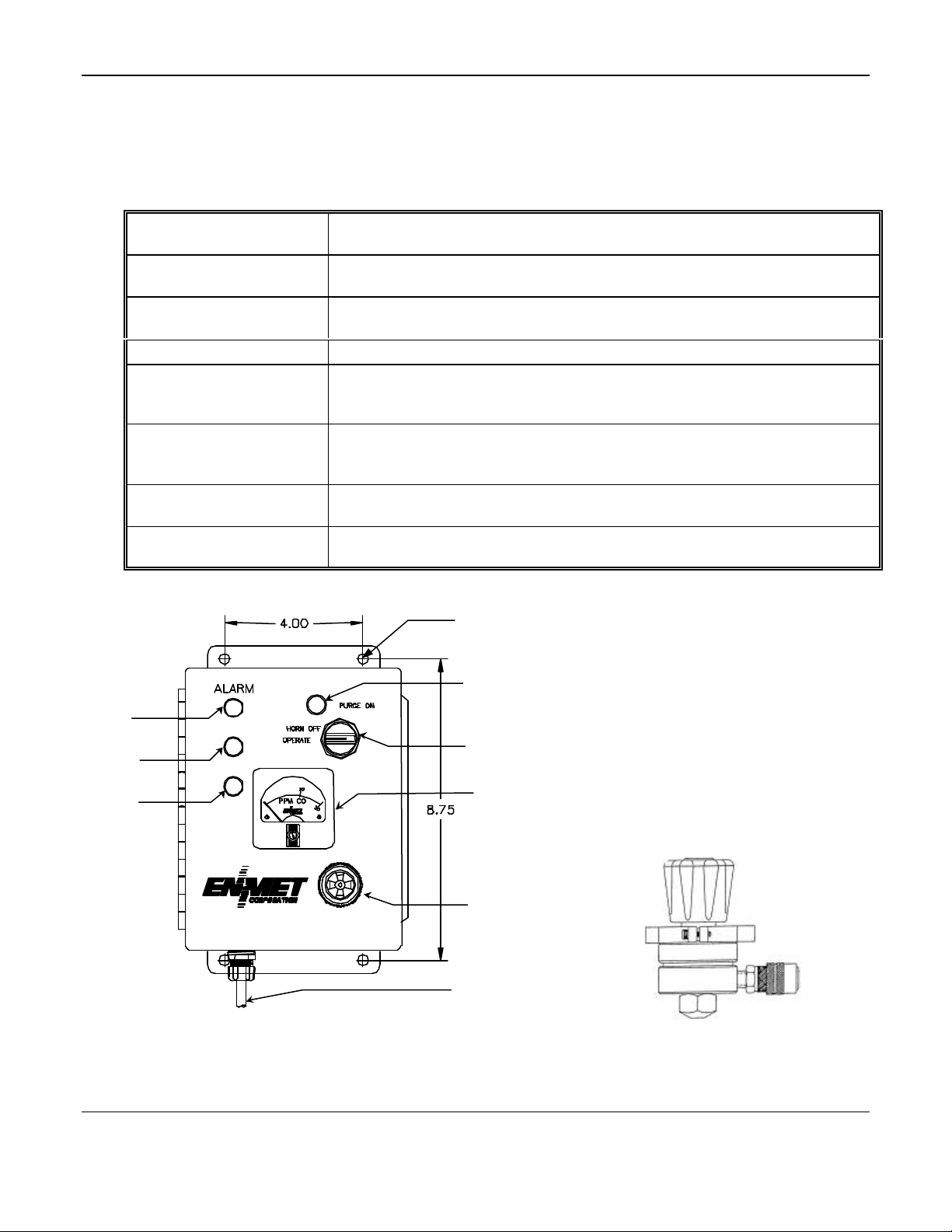

Figure 1 shows the control unit which contains the electronics circuitry and controls. Main features are listed below.

Power Light

(Green)

Alarm Light

(Amber)

Alarm Light

(Red)

Audio Alarm Audio alarm (2900 Hz,95 dB at 2 ft.). The audio alarm is on when the unit is in alarm.

Meter

Operation Switch A rotary switch, for OPERATE (normal operation), HORN OFF (disengage audio

Switch Indicator Light

(Red)

Sensor Cable Oiltight cable. Connects the sample head assembly to the control unit

When this light is on, the unit is operating and is not in alarm. When this light is off,

the unit is in alarm OR power to the unit has been interrupted.

Visual alarm (steady light). When this light is on, power to the unit is on and the unit

is in low alarm.

Visual alarm (steady light). When this light is on, power to the unit is on and the unit

is in high alarm.

A carbon monoxide (CO) concentration meter. The scale is marked in parts per

million (ppm) CO. This is a non-linear device. Do not infer exact readings from

unmarked regions of the meter scale.

alarm) or PURGE ON (sensor temperature control).

PURGE ON to clean (purge) sensor surface of adsorbed contaminants (sensor hot).

Indicates OPERATION SWITCH is not in OPERATE position.

(length 8-10 feet). See Caution in section 4.0 Installation step 5.

(Red)

Alarm Light

(Amber)

Power Light

(Green)

Figure 1: Electronics Control Unit

(Red)

Operation Switch

Meter

Audio Alarm

Sensor Cable

Figure 2: High Pressure Regulator

2

Page 7

ISA-RAL-M, ISA-RAH-M ENMET Corporation

Normally

Common

110 Vac

Manual On/Off

Suggested wiring configuration for Utilizing Relay Contacts

Low Level Set

High Level Set

Meter Adjust

110 / 115

12 VDC

Internal Relay

TB3

TB2

TB1

K1

K2

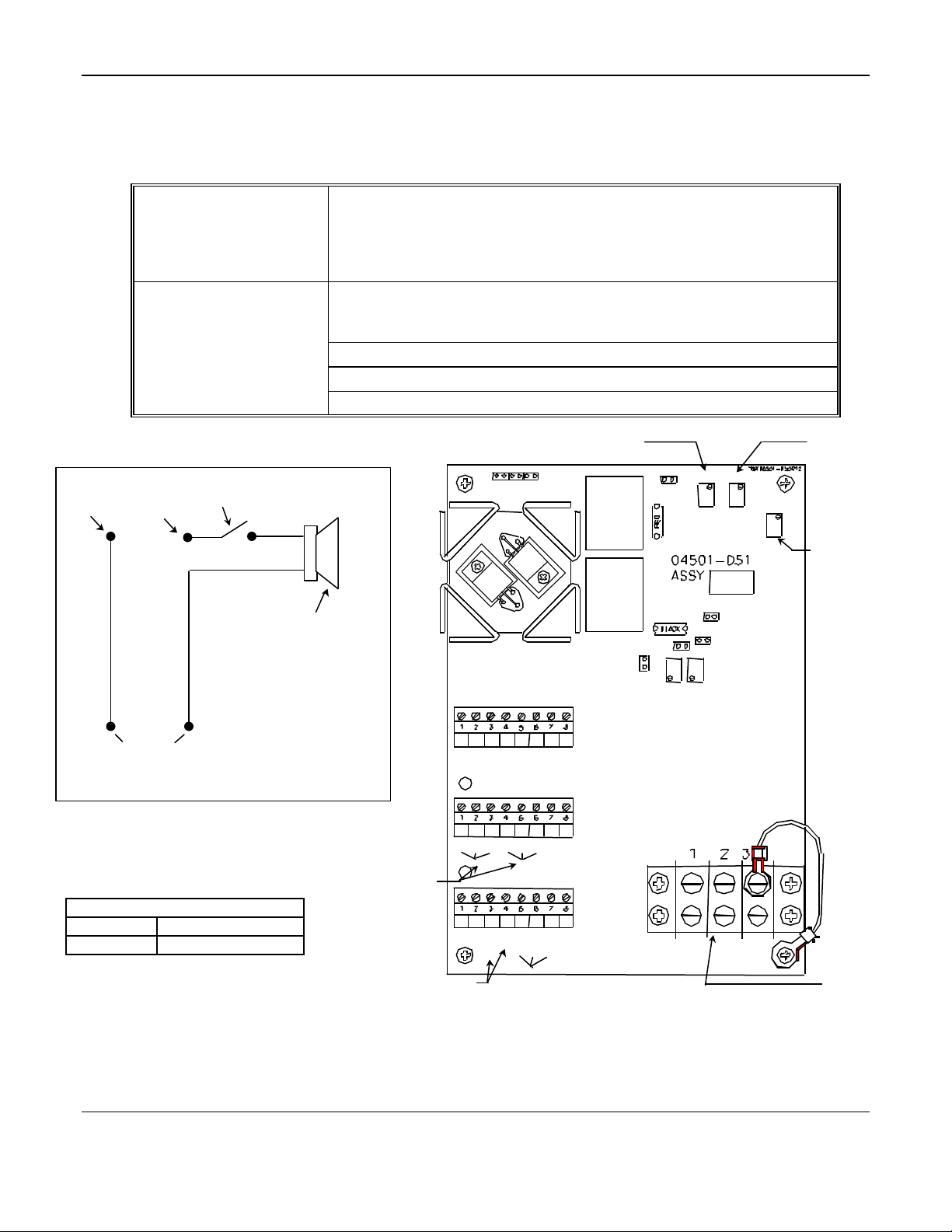

3.2 Internal Electronic Circuitry

Figure 5 shows the circuit board and terminal blocks housed inside the hinged oiltight control unit. Specific relays and

adjustments are defined:

Internal Relay Contacts Relays can be used to activate an external remote alarm signal when a

hazardous CO level is detected, or when the ac or dc power is interrupted.

These are double-pole relays with terminals normally open, normally closed

and common (see Figure 3 for relay contact hook-up). There is one relay for

each alarm level.

Potentiometers: The unit has five potentiometers. Only 3 are used by the customer. These vary

critical circuit resistances and are essential to calibration procedures. These

potentiometers are described below.

Meter Adjust To adjust and set the meter for appropriate gas response during calibration.

Low Level Set To adjust the trip level of the amber gas alarm light and the audio alarm.

High Level Set To adjust the trip level of the red gas alarm light and the audio alarm.

(manual on/off switch is suggested; user supplied component)

Contact

Closed

Contact

Switch

Horn

Black

White

Power supply Outside

of Control Unit

Non-Latching Relay contacts:

Identified below is the non-powered

(power to unit is off), alarm positions of

the non-latching relay contacts.

Contacts

Terminal Block 2 see Figure 5

Relay 1 High Alarm

Relay 2 Low Alarm

NOTE: N.C.= normally closed

N.O.= normally open

Red Lamp ----

INPUT

Jumper Holder

Green Lamp

N.O.

COM.

Relay 1

Battery

Purge

Amber Lamp

N.C.

COM.

Relay 2

GND

Backup

Sensor

GND

N.O.

Signal

Meter+

N.C.

Heater

Meter–

GND

Potentiometer

Jumper 2

GND

GND

Jumper 3

Jumper 5

RV38

TP1

TP2

RV35

RV32

110 VAC

Jumper 4

Jumper 1

TB4

RV33

110 VAC

Potentiometer

RV34

Potentiometer

GND

OR

210 / 230*

*See Section 4.0

Figure 3: Utilizing the Relay Contacts

Figure 5: Internal Electronic Circuitry

3

Page 8

ENMET Corporation ISA-RAL-M, ISA-RAH-M

3.3 Sample Head Assembly

The sample head connects to a compressed air line. This unit continuously monitors the respiratory lines for carbon

monoxide levels. Figure 4 illustrates this unit. Assembly parts are listed and defined below.

Pressure Regulator Reduces the pressure of a small sample of air from the compressed air line

before passing over the sensor. It includes a meter to measure the pressure in

pounds per square inch (psi) at the regulator exit.

Quick Release For quick connect/disconnect; fits into the port of an air line.

Pneumatic Fitting Air line filter unit and ENMET calibration adapter (03605-001). Air inlet

fitting is a Milton 727, compatible with Hansen 1000 series. If you substitute

other fittings, the calibration fixture must also be changed.

Humidifier Plastic bottle. This adds moisture to the air sample that passes over the sensor.

Metallic Oxide

Semiconductor

Sensor

Metering Orifice

Hydrocarbon Filter To enhance low level calibrations by removal of hydrocarbon vapors from the

Solid-state gas sensing element contained in sensor housing. When the

amount of CO in the air passing over the sensor increases to a preset level, the

equipment alarms and relays activate.

This replaceable assembly has a tiny orifice to ensure constant flow of air

between the humidifier and pressure regulator.

air sample. Supplied on ISA-RAL-M P/N 04526-001.

Quick Release

Fitting

See Cautions noted in

Metering Orifice

Hydrocarbon Filter

Pressure

Regulator

Humidifier

(Fill to Upper Water Level Mark)

Metallic Oxide

Semiconductor

Sensor

Sensor Cable

Section 4 Step 5

Figure 4: Sample Head Assembly

4

Page 9

ISA-RAL-M, ISA-RAH-M ENMET Corporation

4.0 Installation4.0 Installation

After becoming familiar with the main parts and their functions, follow the installation procedure as outlined below.

CAUTION: Neither the ISA-RAL-M control unit nor its sensor are rated for explosionproof environments. Take

caution that neither one is installed in an explosionproof-rated area.

1. Choose an appropriate location for mounting the electronics control unit and sample head assembly. The

mounting dimensions are given in Figure 1. Locate the sampling point upstream from the workers such that the

respiratory air reaches the carbon monoxide sensor before it reaches the workers. Locate the control unit, or an

auxiliary visual alarm actuated by the instrument's relay contacts, in an area where it can easily be seen by

workers using the breathing air.

NOTE: That the flow rate of the sample air to the sensor head is approximately 1 SCFH (Standard Cubic Feet per Hour).

2. A 110 Vac line cord is supplied, plug this into an appropriate outlet.

3. If conduit is preferred, remove the terminal strip cover from TB4 inside the control unit (simply pull the cover off

its holding prongs). Apply 110 Vac power to the appropriate terminals. Refer to Figure 5.

NOTE: Utilizing 220 Vac power requires a change in the transformer hook-up by a competent electrician or

electronics technician; but this change is best done at ENMET. 12 Vdc may be used as a primary source (refer

to Figure 5) or as an emergency back-up power source, both ac and dc power can be applied at the same time.

Current flows from the ac source; dc current will flow only when the ac power is interrupted.

4. Run the relay contact leads through the same oiltight fitting as the power supply leads or out through a second fitting.

NOTE: When the power supply is interrupted, the relays switch to the same position as for a true gas alarm condition,

and the power light goes off. Do not connect the unit to other voltage supply lines.

The ISA-RAL-M is completely oiltight. Use the correct oiltight fitting for the cord or conduit when supplying

power to the unit.

5

Page 10

ENMET Corporation ISA-RAL-M, ISA-RAH-M

Locate the Sample

Metallic Oxide

Humidifier

Pressure

Regulator

Quick Release

Fittings

Top Mount to Avoid

Locate near compressor

Plant Air

5. Connect regulator/humidifier and hydrocarbon filter (if supplied) to the sensor head assembly. Attach this

assembly to a 50 – 250 psi compressed air line (see Figure 6).

CAUTION: •DO NOT use a rubber hose to connect regulator to air line. This may cause inaccurate meter readings

and false alarms.

•DO NOT locate the sample point on a low spot in the line. Water condensation may clog or damage the

regulator or sensor assembly.

•DO NOT modify or extend the sensor cable without first contacting ENMET customer service personnel

for instructions regarding heater voltage and adjustment.

The instrument can be installed directly on an ENMET AFP-82 or AFP-40 air filtration panel if the work location is

suitable. In the event that the work environment is unsuitable for the installation of the ISA-RAL-M, it should be

installed in a suitable location in the air line, upstream of the work environment.

6. Add tap water to the upper Water Level mark. Replace bowl, ensure water does not go higher then the upper edge

of the bowl.

7. Adjust the pressure regulator to between 7 and 12 psi.

8. Replace terminal strip cover on TB4 inside the control unit.

9. Proceed to Section 5.0 for initial warm-up and operating procedures.

Water Trap

Point after Purification

Regulator Panel.

holding tank so sample air

reaches the sensor before

the same respiratory air

reaches the workers.

Cut-Off Valve (optional)

50 – 250 PSIG

(Fill to Upper Water Level mark)

Metering Orifice

Hydrocarbon Filter

Semiconductor

Sensor

Figure 6: Connecting to Compressed Air Line

6

Page 11

ISA-RAL-M, ISA-RAH-M ENMET Corporation

5.0 Initial 5.0 Initial Warm-Up and OperationWarm-Up and Operation

The ISA-RAL-M incorporates a Metallic Oxide Semiconductor (MOS) sensor to detect carbon monoxide. During

periods of inactivity, contaminants may build up on the sensor element that need to be cleaned off. It is normal for the

instrument to go into an alarm condition when first powered up after a time of storage or after power has been

disconnected for some time.

CAUTION: Do NOT operate the ISA-RAL-M without air passing over the sensor. The absence of air flow over

the sensor when the instrument is in operation can permanently damage the sensor!!!

You need a voltmeter for this procedure.

1. Mount and install the ISA-RAL-M as outlined in section 4.0.

NOTE: This unit has no ON/OFF switch for the power; this safety monitoring device is designed to operate

continuously. Turn the Operation Switch to HORN OFF to silence the audio alarm during warm-up.

2. Turn the operation switch to PURGE ON. The alarm light will go on; don't worry, this is normal.

3. Open the control unit. With a voltmeter, check the voltage across terminals 6 and 7 on TB1 (terminal 6 is positive,

terminal 7 is negative). The voltage must be 1.60 Vdc within a 0.07 Vdc range. This voltage is not adjustable, if it

is not within this range, contact your local distributor.

4. Let clean air pass over the sensor for at least one hour to purge (clear) the sensor of contaminants. CLEAN AIR

MUST PASS OVER THE SENSOR. If you suspect contaminated air (or really dirty conditions) in your

compressor, use bottled clean air. Do not operate the unit without air passing over the sensor. If you do, you are

likely to contaminate the sensor.

NOTE: After long periods of storage (several days or more), extend the purge operation to several hours; or operation

switch may be left set to PURGE ON overnight.

5. Purging is complete when the red alarm light goes out, and the meter stabilizes at a low reading.

6. Turn the operation switch to HORN OFF. Some meter drift is normal. Open the control unit and measure the

voltage across terminals 6 and 7 of TB1 (terminal 6 is positive, terminal 7 is negative). The voltage must be 0.86

Vdc within a 0.07 Vdc range. This voltage is not adjustable, if it is not within this range, contact your local

distributor.

7. Turn the operation switch to OPERATE.

Reference: State of Operation of ISA-RAL-M, ISA-RAH-M

Normal Operation:

If pressure is applied to the regulator input, and air is not bubbling through the humidifier, check to see that the

regulator is adjusted to between 7 and 12 PSI. If this is not the problem, then the metering orifice is probably plugged;

you must replace it. See section 7.1 for part number.

Important: When replacing the orifice, use teflon thread to seal the connections.

No alarms. Green light is off.

Green light is on. Amber light or red light/audio alarm on.

Enclosure feels warm to the touch.

Do Not use joint sealing compound.

Alarm State:

Relay contacts in alarm position.

7

Page 12

ENMET Corporation ISA-RAL-M, ISA-RAH-M

Metallic Oxide

Humidifier

Pressure

Quick Release

ENMET Calibration Gas

5.1 Quick Field Tests

To verify the instrument's response capability:

Use a cylinder of high-level CO/air mixture (i.e., 200 ppm CO for a 20 ppm calibrated unit) with a quick-disconnect

gas fixture.

1a. Remove the compressed air line and insert the test gas.

2a. Let a little gas flow over the sensor. You may need to adjust the regulator.

3a. Meter should move up-scale in less than 20 seconds and read full-scale within one minute.

OR

1b. Unscrew the sensor head assembly.

2b. Give the sensor a quick exposure to a bottle cap from an alcohol solution.

NOTE: Alcohol is heavier than air. Hold the cap over the sensor so vapors float down over it. Purge the sensor

after this test.

Whenever you use a test gas containing a level of gas greater than the high alarm level, the meter swings up-scale,

green power light goes out, amber and red alarm lights go on and relay contacts close to trigger remote alarms.

This test is to verify response capability. If it does not bring the unit into alarm, contact ENMET personnel.

CAUTION: Do not repeatedly blow smoke on the exposed sensor heat. Do not squirt pure gases or liquid

hydrocarbons (butane, propane, gasoline etc.) directly on the sensor.

Calibration Adapter

(CO in Air)

Metering Orifice

Fittings

Hydrocarbon Filter

Regulator

(Fill to Upper Water Level mark)

Semiconductor

Sensor

Figure 7: Calibration Adapter and Gas

8

Page 13

ISA-RAL-M, ISA-RAH-M ENMET Corporation

6.0 Calibration6.0 Calibration

The following procedure is for checking the calibration level and for recalibrating the ISA-RAL-M.

Perform A Complete Recalibration Periodically (At Least Every 90 Days) And:

• When you replace the sensor.

• When the sensor encounters severe conditions (i.e. gross exposure to smoke or liquid hydrocarbons).

MATERIALS:

• Cylinders of calibration gas of known CO concentration in air corresponding with the alarm level of the unit, for

example, 20 ppm CO in air.

CAUTION: Do not use CO in a pure inert carrier gas, such as nitrogen or argon.

• Calibration adapter, ENMET part no. 03605-001.

• Small screwdriver for potentiometer adjustment.

PROCEDURE:

1. Turn the switch to PURGE ON. The alarm lights go on; this is normal.

2. Leave switch in the PURGE ON position for at least one hour. Air must be flowing through the humidifier and

over the sensor during this time. Remember, if you suspect contaminated air in your compressor system, use clean

bottled air.

3. After at least one hour, turn the switch to HORN OFF. Allow the sensor to stabilize for 30 minutes before

continuing.

NOTE: Some compressor installations produce very clean air during normal operations. A medical air system is an

example of such an installation. In such situations, the purge operation before calibration can usually be

eliminated. The sensor requires purging only when the meter needle does not return to the normal “zero” area

within 30 minutes after the calibration gas is removed. If this occurs, purge and stabilize the sensor as

described above, then recalibrate. Of course, always purge the sensor after sensor replacement or heavy sensor

contamination due to severe conditions.

4. Be sure the humidifier bottle is filled with tap water to the Upper Water Level mark.

5. Remove the compressed air line and insert the calibration adapter (Figure 7).

6. Open the regulator on the top of the calibration gas cylinder. This brings the gas into the sampling asse mbly.

7. Regulate the flow of calibration gas to between 7 and 12 psi on the pressure regulator dial. Adjust flow using only

the valve on the calibration adapter.

8. Let the calibration gas flow into the system for 5 minutes. This assures a full and balanced response from the

sensor.

9. With the gas still flowing, adjust the Meter Adjust potentiometer (Ref figure 5 RV33; ccw to increase, cw to

decrease meter reading) with a small screwdriver. You want to have the meter pass through the low level alarm

point, verify that the alarm light triggers at the 10 ppm point. If it does not, set the meter to the 10 ppm mark and

adjust RV35 (low level alarm pot) turn the switch to OPERATE for a second to verify the horn is operational.

Then adjust the meter gain pot to pass through the 20 ppm point, verify that the alarm light triggers at the 20 ppm

point. If it does not, set the meter gain to the 20 ppm adjust RV34 to trigger the alarm light. Turn the switch to

OPERATE for a second to verify the horn is operational. This sets the alarm points (Refer to Figure 5). Do Not

adjust for instantaneous alarm when test gas is first released. If you do, the calibration is inaccurate, and the sensor

is overly sensitive.

10. Shut off the calibration gas flow at the valve on the gas cylinder.

11. Allow pressure to equalize - wait until the pressure meter on the humidifier-regulator assembly reads zero, then

remove the calibration adapter from the input of the sample head.

CAUTION: If you disassemble the calibration unit before the pressure is equalized, you may cause a back flow of

water from the humidifier. This damages the regulator valve.

12. Remove the calibration gas, reconnect the unit to the air line, the flow of clean air should clear the unit from its

gas alarm state in less than one minute. After the alarms have cleared, turn the switch to OPERATE

13. Clean compressed air results in a meter reading from 0 - 1/3 full scale, Green power light indicates a clean

condition.

9

Page 14

ENMET Corporation ISA-RAL-M, ISA-RAH-M

7.0 Maintenance7.0 Maintenance

Since the ISA-RAL-M carbon monoxide monitor is a safety instrument, it requires periodic testing and recalibration.

Refer to Operation (Section 5.0) and Calibration (Section 6.0) sections of this manual for testing and recalibration

procedures. In addition, perform the following:

7.1 Routine Maintenance

1. Check the unit for mechanical damage or simple malfunctions, such as burned out lamps.

2. Periodically check the water level inside the humidifier and add water to the high WATER LEVEL mark.

3. With the unit operating, make sure that the regulated air pressure is between 7 and 12 PSI on the gauge.

4. When power to the unit has been disconnected for more than a few hours, purge the sensor upon reapplication of

power. It may be necessary to periodically purge the sensor of a unit monitoring an airline that has a high level of

contamination. The interval between purges depends on the level of contamination. With the unit operation, turn

the switch to PURGE ON and leave for half-hour, then return the switch to OPERATE.

7.2 Sensor Cable Replacement

If the sensor no longer responds properly to calibration gases (see section 6.0, Calibration), the entire sensor cable

assembly must be replaced.

Materials Needed:

• ISA-RAL-M sensor cable assembly, ENMET part no. 03035-109

• Flat-headed screwdriver

• Two adjustable wrenches (adjust to approx. 1")

Procedure:

1. Disconnect power to the control unit to prevent electrical shock.

2. Unscrew the two front panel latches on the right side of the control unit. Open up the control unit front panel.

3. Locate TB1-5, TB1-6 and TB1-7 inside the control unit (see Figure 5). Unscrew the sensor cable leads from

these terminals.

4. Unscrew the rounded housing of the strain relief fitting in the bottom of the control unit, and draw the sensor

cable and terminal leads out through the fitting.

5. Empty the water from the humidifier bottle of the sample head assembly.

6. Using the adjustable wrenches, unscrew the brass bushing which connects the sensor cable to either the

regulator/humidifier or the hydrocarbon filter. Insert the bushing of the new sensor cable and tighten with

wrenches using hand pressure only.

7. Insert leads of new cable assembly through strain relief fitting located at bottom of enclosure. Tighten rounded

housing of fitting.

8. Attach colored leads of cable to TB1-5 (green), TB1-6 (white) and TB1-7 (black). Tighten terminal screws

gently but securely.

9. Close front panel of control unit, and replace and tighten latches.

10. Fill humidifier bottle of sample head assembly halfway with clean water and replace.

11. Apply power to instrument and allow to operate overnight with air flowing through bubbler and over sensor.

Then calibrate the instrument (see section 6.0).

7.3 Hydrocarbon Filter Replacement

The charcoal absorption filter for hydrocarbons will need periodic replacement. The length of time between

replacement depends on the instrument usage and VOC (Volatile Organic Compounds) level in the breathing air supply.

For ISA-RAL monitors that are in continuos air streams, 24 hours, 7 days a week 365 days a year it is recommended

that the filter be replaced when any of these conditions occur:

• At least annually

• Any time fluid is found inside the filter

• Any time the filter is damaged

• If any odor is detected in the breathing mask

10

Page 15

ISA-RAL-M, ISA-RAH-M ENMET Corporation

7.4 Replacement Parts

Description of Part Part Number

Metering orifice assembly 03415-000

Metering orifice* 03415-001

3-wire RAL cable assembly (with sensor) 03035-109

Pressure regulator 73089-057

Hydrocarbon filter assembly 73089-060

Hydrocarbon Filter Element* 73089-061

Humidifier assembly 03406-000

Male coupler plug (quick release fitting) 73061-000

Gauge (0 - 30 psi) 73089-058

Meter 03411-000

Lamp body 62012-010

Lens, red 62012-011

Lens, green 62012-012

Lens, amber 62012-013

Control unit light bulb 63001-002

Calibration kit 03414-000

Cylinder of 20 ppm CO in Air 03219-020

Calibration adapter 03605-001

*NOTE: For instruments S/N 634 and above, only the element needs to be replaced. For instruments with serial

numbers below S/N 634, the replacement assembly (73089-060) should be used to obtain the proper fitting.

Contact ENMET customer service for additional information.

11

Page 16

ENMET Corporation ISA-RAL-M, ISA-RAH-M

8.0 Specifications8.0 Specifications

ENCLOSURE: NEMA-12 enclosure

SIZE: Approximately 6" h x 8" w x 4" d

WEIGHT: Approximately 10 lbs.

CABLE LENGTH: Between box and air inlet: 8 - 10 ft.

AUDIO ALARM: 2900 Hz, 95 decibels at 2 ft.

MAXIMUM POWER: 117 Vac - 60 Hz - 25 watts 12 Vdc - 25 watts

RELAY CURRENT: 2 amp steady, 5 amp surge

SENSOR LIFE: Up to 3 years in clean air (no oil)

RESPONSE TIME: Up to 5 minutes for low-level carbon monoxide

gas calibrations

MAXIMUM AIR LINE PRESSURE: 250 psi

SAMPLE FLOW RATE: Approximately one cubic foot per hour

NOTE: All specifications stated in this manual may change without notice.

8.1 Typical Calibrations

Hazardous Gas Low Alarm High Alarm

Carbon monoxide 10 ppm 20 ppm

8.2 Options and Variations

Options:

• 220 Vac power input connection

• NEMA-4X fiberglass enclosure

Variations:

a)Available in an explosion-proof instrument housing, Models ISA-44RALE and ISA-44-R AHE. With this, the

equipment is suitable for operation in Class I, Division I, Groups C and D atmosphere, as defined in the National

Electrical Code. Units for Group B are available upon special order. Do not use the standard ISA-RAL-M where

you are required by the National Electrical Code or local codes to use an explosionproof variety.

b)ENMET Filtration Panels filter oil, water and solid particles from compressed air. AFP-40: equipped to

distribute air to three respirators. AFP-82: equipped to distribute air to six respirators.

c) Units that also monitor for oxygen deficiency in breathing air are available; consult a distributor or the factory.

12

Page 17

ISA-RAL-M, ISA-RAH-M ENMET Corporation

9.0 Warranty9.0 Warranty

ENMET warrants new instruments to be free from defects in workmanship and material under normal use for a period

of one year from date of shipment from ENMET. The warranty covers both parts and labor. Equipment believed to be

defective should be returned to ENMET within the warranty period (transportation prepaid) for inspection. If the

evaluation by ENMET confirms that the product is defective, it will be repaired or replaced at no charge, within the

stated limitations, and returned prepaid to any location in the United States. ENMET shall not be liable for any loss or

damage caused by the improper use of the product. The purchaser indemnifies and saves harmless the company with

respect to any loss or damages that may arise through the use by the purchaser or others of this equipment.

This warranty is expressly given in lieu of all other warranties, either expressed or implied, including that of

merchantability, and all other obligations or liabilities of ENMET which may arise in connection with this equipment.

ENMET neither assumes nor authorizes any representative or other person to assume for it any obligation or liability

other than that which is set forth herein.

9.1Repair of Certain Units

The warranty does not apply to equipment returned in either of the conditions defined below. These are not the result

of defective workmanship or material. We will renovate and return at owner's expense.

a)Gross Recalibration: We calibrate all ISA-RAL-M's according to the customer order before shipping. Changing the

potentiometers voids the warranty, except when following the calibration procedures (Sec. 6.0). When we receive

such a unit for repair, and no defects exist, we will diagnose the problem and recalibrate the unit according to the

original order.

b)Gross Sensor Contamination: The MOS sensor is durable. It can be purged of normal contaminants by operating

the unit in the PURGE mode for a sufficient length of time. Gross contamination usually occurs during misuse.

Here are three examples of gross sensor contamination:

Close exposure to an open gas flame.

Dipping the sensor in lacquer.

Continuous exposure to heavy concentrations of industrial vapors.

A grossly contaminated sensor must be replaced. If we receive such a unit, we will diagnose the problem, replace the

sensor and recalibrate the unit.

WHEN YOU RETURN A UNIT TO THE FACTORY FOR SERVICE:

Warranty or otherwise:

• Be sure to include paperwork.

• A purchase order, return address and telephone number will assist in the expedient repair and return of your unit.

• Include any specific instructions.

• For warranty service, include date of purchase.

• If you require an estimate, please contact ENMET Corporation.

13

Page 18

ENMET Corporation ISA-RAL-M, ISA-RAH-M

Notes:

14

Page 19

PO Box 979

680 Fairfield Court

Ann Arbor, Michigan 48106-0979

734.761.1270 Fax 734.761.3220

Returning an Instrument for Repair

ENMET instruments may be returned to the factory or any one of our Field Service Centers for

regular repair service or calibration. The ENMET Repair Department and Field Service Centers

also perform warranty service work.

When returning an instrument to the factory or service center for service, paperwork must be

included which contains the following information:

Ø A purchase order number or reference number.

Ø A contact name with return address, telephone and fax numbers

Ø Specific instructions regarding desired service or description

of the problems being encountered.

Ø Date of original purchase and copy of packing slip or invoice

for warranty consideration.

Ø If a price estimate is required, please note it accordingly and be

sure to include a fax number .

Providing the above information assists in the expedient repair and return of your unit.

Failure to provide this information can result in processing delays.

ENMET charges a one hour minimum billing for all approved repairs with additional time billed

to the closest tenth of an hour. All instruments sent to ENMET are subject to a minimum $30

evaluation fee, even if returned unrepaired. Unclaimed instruments that ENMET has received

without appropriate paperwork or attempts to advise repair costs that have been unanswered,

after a period of 60 days, may be disposed of or returned unrepaired COD with the evaluation

fee.

Service centers may have different rates or terms. Be sure to contact them for this information.

Repaired instruments are returned by UPS/FedEx Ground and are not insured unless

otherwise specified. If expedited shipping methods or insurance is required , it must be

stated in your paperwork.

Note: Warranty of customer installed components.

If a component is purchased and installed in the field, and fails within the warranty term,

it can be returned to ENMET and will be replaced, free of charge, per ENMET’s returned

goods procedure.

If the entire instrument is returned to ENMET Corporation with the defective item

installed, the item will be replaced at no cost, but the instrument will be subject to labor

charges at half of the standard rate.

Page 20

Page 21

Repair Return Form

Mailing Address:

ENMET Corporation

PO Box 979

Ann Arbor, Michigan 48106

Phone Number: 734.761.1270

FAX Number: 734.761.3220

Your Mailing Address: Your Shipping Address:

Contact Name: __________________________ Your Phone: _______________________

Your PO/Reference Number: _______________ Your FAX: _______________________

Shipping Address:

ENMET Corporation

Attn: Repair Department

680 Fairfield Court

Ann Arbor, Michigan 48108

Payment Terms: q COD

(Check one) q VISA / MasterCard______________________ ________

Card number Expiration

Return Shipping Method:

q UPS: q Ground q 3 Day Select q Next Day Air q ND Air Saver q 2-Day Air

q Federal Express: q Ground q Express Saver q P-1 q Standard q 2-Day Air

q FedEx Account number: ________________________

Would you like ENMET to insure the return shipment?

q No q Yes Insurance Amount: $_________________

Page 22

Loading...

Loading...