SSI

EPS2U

Power Supply Design Guide

A Server System Infrastructure (SSI) Specification

For Entry Chassis Power Supplies

Version 1. 2

SSI

EPS2U Power Supply Design Guide, V1.2

Disclaimer:

THIS SPECIFICATION IS PROVIDED "AS IS" WITH NO WARRANTIES

WHATSOEVER, INCLUDING ANY WARRANTY OF MERCHANTABILITY,

NONINFRINGEMENT, FITNESS FOR ANY PARTICULAR PURPOSE, OR ANY

WARRANTY OTHERWISE ARISING OUT OF ANY PROPOSAL, SPECIFICATION OR

SAMPLE. WITHOUT LIMITATION, THE PROMOTERS (Intel Corporation, NEC

Corporation, Dell Computer Corporation, Data General a division of EMC Corporation,

Compaq Computer Corporation, Silicon Graphics Inc., and International Business

Machines Corporation) DISCLAIM ALL LIABILITY FOR COST OF PROCUREMENT OF

SUBSTITUTE GOODS OR SERVICES, LOST PROFITS, LOSS OF USE, LOSS OF

DATA OR ANY INCIDENTAL, CONSEQUENTIAL, DIRECT, INDIRECT, OR SPECIAL

AMAGES, WHETHER UNDER CONTRACT, TORT, WARRANTY OR OTHERWISE,

ARISING IN ANY WAY OUT OF USE OR RELIANCE UPON THIS SPECIFICATION OR

ANY INFORMATION HEREIN.

The Promoters disclaim all liability, including liability for infringement of any proprietary

rights, relating to use of information in this specification. No license, express or implied,

by estoppel or otherwise, to any intellectual property rights is granted herein.

This specification and the information herein is the confidential and trade secret

information of the Promoters. Use, reproduction and disclosure of this specification and

the information herein is subject to the terms of the S.S.I. Specification Adopter's

Agreement.

Copyright Intel Corporation, Dell Computer Corporation, Compaq Computer Corporation, Silicon Graphics

Inc., International Business Machines Corporation, 2000.

- 2 -

SSI

EPS2U Power Supply Design Guide, V1.2

Contents

1 Purpose ..............................................................................................................................................5

2 Conceptual Overview..........................................................................................................................5

3 Definitions/Terms/Acronyms ..............................................................................................................6

4 Mechanical Overview ..........................................................................................................................7

4.1 Airflow Requirements .........................................................................................................................8

4.2 Temperature Requirements................................................................................................................8

5 AC Input Requirements.......................................................................................................................9

5.1 AC Inlet Connector............................................................................................................................9

5.2 AC Input Voltage Specification ...........................................................................................................9

5.3 Efficiency..........................................................................................................................................9

5.4 AC Line Dropout.............................................................................................................................. 10

5.5 AC Line Fuse.................................................................................................................................. 10

5.6 AC Inrush........................................................................................................................................ 10

5.7 AC Line Transient Specification........................................................................................................ 11

5.8 AC Line Fast Transient Specification ................................................................................................ 11

6 DC Output Specification ................................................................................................................... 12

6.1 Output Connectors .......................................................................................................................... 12

6.1.1 Required Baseboard power connector ....................................................................................... 12

6.1.2 Required Processor Power Connector ....................................................................................... 12

6.1.3 Required Peripheral Power Connectors...................................................................................... 13

6.1.4 Required Floppy Power Connector ............................................................................................ 13

6.1.5 Optional Server Signal Connector.............................................................................................. 13

6.2 Grounding....................................................................................................................................... 14

6.3 Remote Sense ................................................................................................................................ 14

6.4 Output Power/Currents .................................................................................................................... 15

6.4.1 Standby Outputs .......................................................................................................................15

6.5 Voltage Regulation ..........................................................................................................................16

6.6 Dynamic Loading .............................................................................................................................17

6.7 Capacitive Loading .......................................................................................................................... 18

6.8 Ripple / Noise.................................................................................................................................. 18

6.9 Timing Requirements .......................................................................................................................19

7 Protection Circuits............................................................................................................................ 22

7.1 Current Limit ................................................................................................................................... 22

7.2 240VA Protection ............................................................................................................................ 22

7.3 Over Voltage Protection ...................................................................................................................23

7.4 Over Temperature Protec tion ........................................................................................................... 23

8 Control and Indicator Functions .......................................................................................................24

8.1 PSON# ........................................................................................................................................... 24

8.2 PWOK (Power OK) ..........................................................................................................................25

8.3 Field Replacement Unit (FRU) Signals.............................................................................................. 26

8.3.1 FRU Data .................................................................................................................................26

8.3.2 FRU Data Format ..................................................................................................................... 26

- 3 -

SSI

EPS2U Power Supply Design Guide, V1.2

9 MTBF ................................................................................................................................................ 28

10 Agency Requirements ...................................................................................................................... 28

Figures

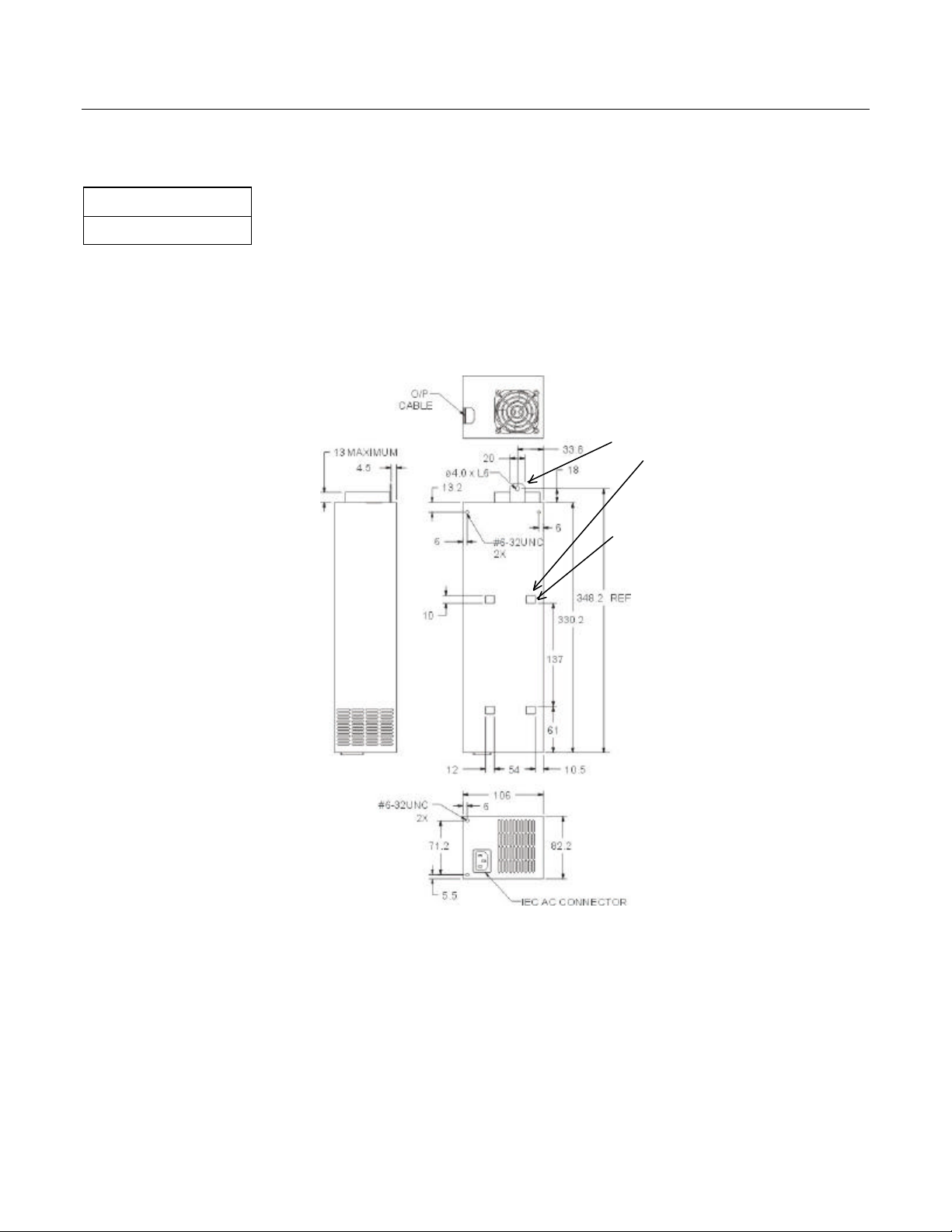

Figure 1: Enclosure Drawing ...........................................................................................................................7

Figure 2: Output Voltage Timing ................................................................................................................... 19

Figure 3: Turn On/Off Timing (Single Power Supply)...................................................................................... 21

Figure 4: PSON# Signal Characteristics........................................................................................................ 24

Tables

Table 1: Thermal Requirements ......................................................................................................................8

Table 2: AC Input Rating................................................................................................................................9

Table 3: AC Line Sag Transient Performance................................................................................................ 11

Table 4: AC Line Surge Transient Performance............................................................................................. 11

Table 5: P1 Baseboard Power Connector...................................................................................................... 12

Table 6: Processor Power Connector ............................................................................................................ 12

Table 7: Peripheral Power Connectors .......................................................................................................... 13

Table 8: P9 Floppy Power Connector ............................................................................................................ 13

Table 9: Server Signal Connector ................................................................................................................. 13

Table 10: 480 W Load Ratings...................................................................................................................... 15

Table 11: Voltage Regulation Limits.............................................................................................................. 16

Table 12: Optional +5V Regulation Limits...................................................................................................... 16

Table 13: Transient Load Requirements........................................................................................................ 17

Table 14: Capacitve Loading Conditions ........................................................................................................18

Table 15: Ripple and Noise .......................................................................................................................... 18

Table 16: Output Voltage Timing................................................................................................................... 19

Table 17: Turn On/Off Timing ....................................................................................................................... 20

Table 18: Over Current Protection .................................................................................................................22

Table 19: Over Current Protection .................................................................................................................23

Table 20: Over Voltage Limits .......................................................................................................................23

Table 21: PSON# Signal Characteristic.......................................................................................................... 24

Table 22: PWOK Signal Characteristics ........................................................................................................ 25

Table 23: FRU Device Information ................................................................................................................ 26

Table 24: FRU Device Product Information Area............................................................................................ 26

Table 25: FRU Device Product Information Area............................................................................................ 27

- 4 -

SSI

EPS2U Power Supply Design Guide, V1.2

1 Purpose

This 2U Rack Power Supply Specification defines a common power supply used in entry -level servers. This

supply may range typically from 400 to 700 watts and is used in a non-redundant configuration. The scope of this

document defines the requirement s for one supply in this power range. The parameters of this supply are defined

in this specification for open industry use.

This specification defines a 480 W power supply with 6 outputs; 3.3 V, 5 V, 12V1, 12V2, -12 V, and 5 VSB.

Because of its connector leads, the power supply is not intended to be a hot swap type of power supply.

2 Conceptual Overview

In the Entry server market, the bulk power system must source power on several output rails.

These rails are typically as follows:

• +3.3 V

• +5 V

• +12 V

• –12 V

• 5 V standby

NOTE

Local DC-DC converters shall be utilized for processor power, and will ideally convert power from the +12 V

rail, however, they may also convert power from other rails.

The bulk power system may be a n+1 redundant power system or a non-redundant power system.

- 5 -

SSI

EPS2U Power Supply Design Guide, V1.2

3 Definitions/Terms/Acronyms

Required The status given to items within this design guide, which are required to

meet SSI guidelines and a large majority of system applications.

Recommended The status given to items within this design guide which are not required to

meet SSI guidelines, however, are required by many system applications.

Optional The status given to items within this design guide, which are not required to

Autoranging A power supply that automatically senses and adjusts itself to the proper

CFM Cubic Feet per Minute (airflow).

Dropout A condition that allows the line voltage input to the power supply to drop to

Latch Off A power supply, after detecting a fault condition, shuts itself off. Even if the

Monotonically A waveform changes from one level to another in a steady fashion, without

Noise The periodic or random signals over frequency band of 0 Hz to 20 MHz.

Overcurrent A condition in which a supply attempts to provide more output current than

PFC Power Factor Corrected.

Ripple The periodic or random signals over a frequency band of 0 Hz to 20 MHz.

meet SSI guidelines, however, some system applications may optionally

use these features.

input voltage range (110 VAC or 220 VAC). No manual switches or

manual adjustments are needed.

below the minimum operating voltage.

fault condition disappears, the supply does not restart unless manual or

electronic intervention occurs. Manual intervention commonly includes

briefly removing and then reconnecting the supply, or it could be done

through a switch. Electronic intervention could be done by electronic

signals in the Server System.

intermediate retracement or oscillation.

the amount for which it is rated. This commonly occurs if there is a "short

circuit" condition in the load attached to the supply.

Rise Time Rise time is defined as the time it takes any output voltage to rise from

Sag The condition where the AC line voltage drops below the nominal voltage

Surge The condition where the AC line voltage rises above nominal voltage.

VSB or Standby Voltage An output voltage that is present whenever AC power is applied to the AC

MTBF Mean time between failure.

PWOK A typical logic level output signal provided by the supply that signals the

10% to 95% of its nominal voltage.

conditions.

inputs of the supply.

Server System that all DC output voltages are within their specified range.

- 6 -

SSI

top access

EPS2U Power Supply Design Guide, V1.2

4 Mechanical Overview

STATUS

Required (Optional)

Note: Some features are noted as optional in the enclosure drawing figure below. These features may be use in

some chassis designs where only top access is allowed for the cage mounting.

The EPS2U is a power supply enclosure intended to handle a power range of 400W to 700W. A mechanical

drawing of the power supply cage is shown below in .

Optional mounting features for

mounting of the power supply.

Allow for 1.2mm

protrusion (x4)

Figure 1: Enclosure Drawing

- 7 -

SSI

EPS2U Power Supply Design Guide, V1.2

4.1 Airflow Requirements

STATUS

Recommended

The power supply shall have a two-speed fan(s) and provide cooling to both the supply and the system. , During

low-speed fan operation, the power supply must not exceed a noise level of 43 dBa measured at one meter on all

faces. At low fan speed, the power supply shall provide a minimum of 12 CFM of airflow with 0.003 inH2O of

system backpressure. At high fan speed, the power supply shall provide a minimum of 20 CFM with 0.006 inH2O

of system backpressure.

4.2 Temperature Requirements

STATUS

Recommended

The power supply shall operate within all specified limits over the Top temperature range. The average air

temperature difference (∆Tps ) from the inlet to the outlet of the power supply shall not exceed the values shown

below in Table 1. All airflow shall pass through the power supply and not over the exterior surfaces of the power

supply.

Table 1: Thermal Requirements

ITEM DESCRIPTION MIN MAX UNITS

Top

∆Tps

T

non-op

The power supply must meet UL enclosure requirements for temperature rise limits. All sides of the power supply

with exception to the air exhaust side, must be classified as “Handle, knobs, grips, etc. held for short periods of

time only”.

Operating temperature range. 0 45

Temperature rise from inlet air to outlet air of power supply.

480 W output power, 20 CFM, Sea level, 25 °C inlet air

480 W output power, 12 CFM, Sea level, 25 °C inlet air

Non-operating temperature range. -40 70

21

35

°C

°C

°C

°C

- 8 -

SSI

EPS2U Power Supply Design Guide, V1.2

5 AC Input Requirements

STATUS

Required

The power supply shall incorporate universal power input with active power factor correction, which shall reduce

line harmonics in accordance with the EN61000-3-2 and JEIDA MITI standards.

5.1 AC Inlet Connector

STATUS

Required

The AC input connector shall be an IEC 320 C-14 power inlet. This inlet is rated for 15 A/250 VAC.

5.2 AC Input Voltage Specification

STATUS

Required

The power supply must operate within all specified limits over the following input voltage range. Harmonic

distortion of up to 10% THD must not cause the power supply to go out of specified limits. The power supply shall

operate properly at 85 VAC input voltage to guarantee proper design margins.

Table 2: AC Input Rating

PARAMETER MIN RATED MAX Max Input

Current

Voltage (110) 90 V

Voltage (220) 180 V

Frequency 47 Hz 63 Hz

1 Maximum input current at low input voltage range shall be measured at 90VAC. A 480 W output load shall be applied.

2 Maximum input current at high input voltage range shall be measured at 180 VAC. A 480 W output load shall be applied.

3 This is not intended to be used for determining agency input current markings.

4 Maximum rated input current is measured at 100 VAC and 200 VAC.

100-127 V

rms

200-240 V

rms

140 V

rms

264 V

rms

8.4 A

rms

4.2 A

rms

1,3

7.6 A

rms

2,3

rms

Max Rated Input

Current

4

rms

4

3.8 A

rms

5.3 Efficiency

STATUS

Required

The power supply shall have a minimum efficiency of 65% at maximum load and over the specified AC voltage.

- 9 -

SSI

EPS2U Power Supply Design Guide, V1.2

5.4 AC Line Dropout

STATUS

Required

An AC line dropout is defined to be when the AC input drops to 0 VAC at any phase of the AC line for any length

of time. During an AC dropout of one cycle or less the power supply must meet dynamic voltage regulation

requirements over the rated load. An AC line dropout of one cycle or less shall not cause any tripping of control

signals or protection circuits. If the AC dropout lasts longer than one cycle, the power supply should recover and

meet all turn on requirements. The power supply must meet the AC dropout requirement over rated AC voltages,

frequencies, and output loading conditions. Any dropout of the AC line shall not cause damage to the power

supply.

5.5 AC Line Fuse

STATUS

Required

The power supply shall incorporate one input fuse on the LINE side for input over-current protection to prevent

damage to the power supply and meet product safety requirements. Fuses should be slow blow type or

equivalent to prevent nuisance trips. AC inrush current shall not cause the AC line fuse to blow under any

conditions. All protection circuits in the power supply shall not cause the AC fuse to blow unless a component in

the power supply has failed. This includes DC output load short conditions.

5.6 AC Inrush

STATUS

Required

The power supply must meet inrush requirements for any rated AC voltage, during turn on at any phase of AC

voltage, during a single cycle AC dropout condition, during repetitive ON/OFF cycling of AC, and over the

specified temperature range (Top). The peak inrush current shall be less than the ratings of its critical components

(including input fuse, bulk rectifiers, and surge limiting device).

STATUS

Recommended

An additional inrush current limit is recommended for some system applications that require multiple systems on a

single AC circuit. AC line inrush current shall not exceed 40 A peak for one-quarter of the AC cycle, after which,

the input current should be no more than the specified maximum input current from Table 2.

- 10 -

SSI

EPS2U Power Supply Design Guide, V1.2

5.7 AC Line Transient Specification

STATUS

Recommended

AC line transient conditions shall be defined as “sag” and “surge” conditions. Sag conditions (also referred to as

“brownout” conditions) will be defined as the AC line voltage dropping below nominal voltage. Surge conditions

will be defined as the AC line voltage rising above nominal voltage.

The power supply shall meet the requirements under the following AC line sag and surge conditions.

Table 3: AC Line Sag Transient Performance

AC Line Sag

Duration Sag Operating AC Voltage Line Frequency Performance Criteria

Continuous 10% Nominal AC Voltage ranges 50/60 Hz No loss of function or performance

0 to 1 AC

cycle

>1 AC cycle >10% Nominal AC Voltage ranges 50/60 Hz Loss of function acceptable, self

Duration Surge Operating AC Voltage Line Frequency Performance Criteria

Continuous 10% Nominal AC Voltages 50/60 Hz No loss of function or performance

0 to ½ AC

cycle

100% Nominal AC Voltage ranges 50/60 Hz No loss of function or performance

recoverable

Table 4: AC Line Surge Transient Performance

AC Line Surge

30% Mid-point of nominal AC

Voltages

50/60 Hz No loss of function or performance

5.8 AC Line Fast Transient Specification

STATUS

Recommended

The power supply shall meet the EN61000-4-5 directive and any additional requirements in IEC1000-4-5:1995

and the Level 3 requirements for surge-withstand capability, with the following conditions and exceptions:

• These input transients must not cause any out -of-regulation conditions, such as overshoot and

undershoot, nor must it cause any nuisance trips of any of the power supply protection circuits.

• The surge-withstand test must not produce damage to the power supply.

• The supply must meet surge-withstand test conditions under maximum and minimum DC-output load

conditions.

- 11 -

SSI

EPS2U Power Supply Design Guide, V1.2

6 DC Output Specification

6.1 Output Connectors

The power supply shall have the following output connectors and wire harness configuration.

6.1.1 Required Baseboard power connector

Connector housing: 24-Pin Molex 39-01-2240 or equivalent

Contact: Molex 44476-1111 or equivalent

Table 5: P1 Baseboard Power Connector

Pin Signal 18 AWG Color Pin Signal 18 AWG Color

1 +3.3 VDC Orange 13 +3.3 VDC Orange

2 +3.3 VDC Orange 14 -12 VDC Blue

3 COM Black 15 COM Black

4 +5 VDC Red 16 PS_ON Green

5 COM Black 17 COM Black

6 +5 VDC Red 18 COM Black

7 COM Black 19 COM Black

8 PWR OK Gray 20 Reserved (-5 V in

9 5 VSB Purple 21 +5 VDC Red

10 +12 V2 Yellow/Blue Stripe 22 +5 VDC Red

11 +12 V2 Yellow/Blue Stripe 23 +5 VDC Red

12 +3.3 VDC Orange 24 COM Black

6.1.2 Required Processor Power Connector

Connector housing: 8-Pin Molex 39-01-2080 or equivalent

Contact: Molex 44476-1111 or equivalent

Table 6: Processor Power Connector

Pin Signal 18 AWG color Pin Signal 18 AWG Color

1 COM Black 5 +12 V1 Yellow/Black Stripe

2 COM Black 6 +12 V1 Yellow/Black Stripe

3 COM Black 7 +12 V1 Yellow/Black Stripe

4 COM Black 8 +12 V1 Yellow/Black Stripe

ATX)

N.C.

- 12 -

SSI

EPS2U Power Supply Design Guide, V1.2

6.1.3 Required Peripheral Power Connectors

Connector housing: Amp 1-480424-0 or equivalent

Contact: Amp 61314-1 contact or equivalent

Table 7: Peripheral Power Connectors

Pin Signal 18 AWG Color

1 +12V2 Yellow

2 COM Black

3 COM Black

4 +5 VDC Red

6.1.4 Required Floppy Power Connector

Connector housing: Amp 171822-4 or equivalent

Table 8: P9 Floppy Power Connector

Pin Signal 22 AWG Color

1 +5 VDC Red

2 COM Black

3 COM Black

4 +12 V2 Yellow

6.1.5 Optional Server Signal Connector

Connector housing: 5-pin Molex 50-57-9405 or equivalent

Contacts: Molex 16-02-0088 or equivalent (gold plated)

Notes:

It is recommended to use gold plated signal contacts on both the power supply connector and the baseboard

header.

If the optional server signal connector is not used on the power supply the 3.3V RS and ReturnS lines shall be

crimped into the contacts in the baseboard power connector.

If the server signal connector is unplugged, the power supply shall not shutdown or go into an over voltage

condition.

Table 9: Server Signal Connector

Pin Signal 24 AWG Color

1 I2C Clock White/Green Stripe

2 I2C Data White/Yellow Stripe

3 Reserved NA

4 ReturnS Black/White Stripe

5 3.3RS Orange/White Stripe

- 13 -

SSI

EPS2U Power Supply Design Guide, V1.2

6.2 Grounding

STATUS

Required

The ground of the pins of the power supply wire harness provides the power return path. The wire harness

ground pins shall be connected to safety ground (power supply enclosure).

6.3 Remote Sense

STATUS

Optional

The power supply may have remote sense for the +3.3V (3.3VS) and return (ReturnS) if the Optional Server

Signal connector is implemented. The remote sense return (ReturnS) is used to regulate out ground drops for all

output voltages; +3.3V, +5 V, +12V1, +12V2, +12V3, -12 V, and 5 VSB. The 3.3V remote sense (3.3VS) is used

to regulate out drops in the system for the +3.3 V output. The remote sense input impedance to the power supply

must be greater than 200 W on 3.3 VS and ReturnS. This is the value of the resistor connecting the remote

sense to the output voltage internal to the power supply. Remote sense must be able to regulate out a minimum

of 200 mV drop on the +3.3 V output. The remote sense return (ReturnS) must be able to regulate out a minimum

of 200 mV drop in the power ground return. The current in any remote sense line shall be less than 5 mA to

prevent voltage sensing errors. The power supply must operate within specification over the full range of voltage

drops from the power supply’s output connector to the remote sense points.

- 14 -

SSI

EPS2U Power Supply Design Guide, V1.2

6.4 Output Power/Currents

STATUS

Recommended

The following table defines the power and current ratings for a 480 W power supply. The combined output power

of all outputs shall not exceed the rated output power. Below are load ranges for each of the two power supply

power levels. The power supply must meet both static and dynamic voltage regulation requirements for the

minimum loading conditions.

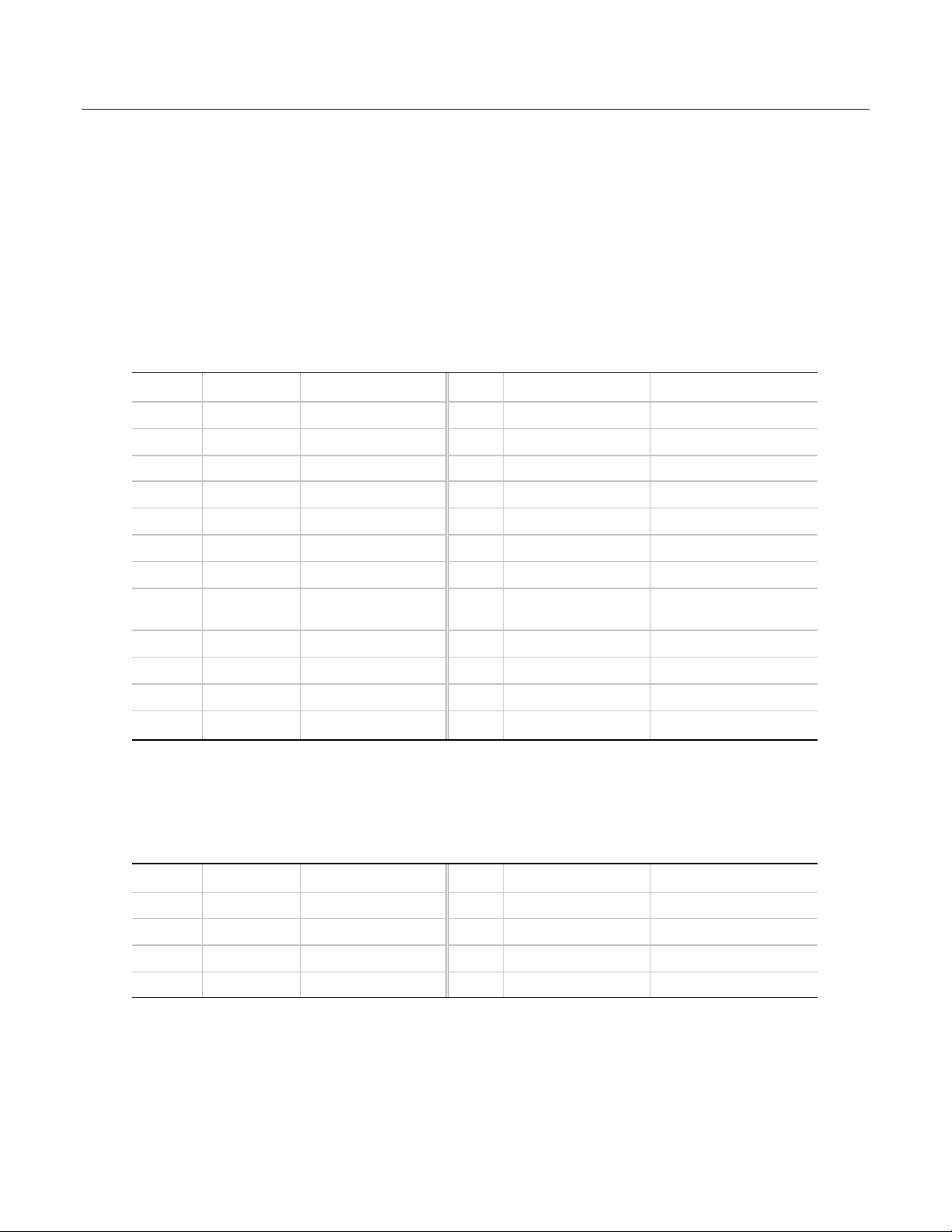

Table 10: 480 W Load Ratings

Load Range 1

Voltage Minimum Continuous Maximum Continuous Peak

+3.3 V 0.5 A 24 A

+5 V 5.0 A 20 A

+12V1 (Processors ) 2.0 A 16 A 18 A

+12V2 (Baseboard) 2.0 A 12 A

+12V3 (Peripherals) 1.0 A 7 A 16 A

-12 V 0 A 0.5 A

+5 VSB 0.1 A 2.0 A

Voltage Minimum Continuous Maximum Continuous Peak

+3.3 V 0.5 A 9 A

+5 V 2.0 A 7 A

+12V1 (Processors ) 0.5 A 7 A 9 A

+12V2 (Baseboard) 0 A 2 A

+12V3 (Peripherals) 0.5 A 7 A 14 A

-12 V 0 A 0.5 A

+5 VSB 0.1 A 2.0 A

1 Maximum continuous total DC output power should not exceed 480 W.

2 Maximum continuous combined load on +3.3 VDC and +5 VDC outputs shall not exceed 115 W.

3 Maximum Peak total DC output power should not exceed 550 W.

4 Peak power and current loading shall be supported for a minimum of 1 second.

5 Maximum combined current for the 12 V outputs shall be 32 A.

6 Maximum 12V combined peak current shall be 44A.

6.4.1 Standby Outputs

STATUS

Load Range 2

Required

The 5 VSB output shall be present when an AC input greater than the power supply turn on voltage is applied.

- 15 -

SSI

EPS2U Power Supply Design Guide, V1.2

6.5 Voltage Regulation

STATUS

Required

The power supply output voltages must stay within the following voltage limits when operating at steady state and

dynamic loading conditions. These limits include the peak -peak ripple/noise specified in Section 5.8. All outputs

are meas ured with reference to the return remote sense (ReturnS) signal. The 5 V, 12V1, 12V2, 12V3, –12 V and

5 VSB outputs are measured at the power supply connectors referenced to ReturnS. The +3.3 V is measured at

its remote sense signal (3.3VS) located at the signal connector.

Table 11: Voltage Regulation Limits

Parameter MIN NOM MAX Units Tolerance

+3.3 V +3.20 +3.30 +3.46 V

+5 V +4.80 +5.00 +5.25 V

+12V1 +11.52 +12.00 +12.60 V

+12V2 +11.52 +12.00 +12.60 V

+12V3 +11.52 +12.00 +12.60 V

-12 V -11.40 -12.20 -13.08 V

+5 VSB +4.85 +5.00 +5.25 V

+5/-3%

rms

+5/-4%

rms

+5/-4%

rms

+5/-4%

rms

+5/-4%

rms

+9/-5%

rms

+5/-3%

rms

STATUS

Optional

Some system applications may require tighter regulation limits on the +5 V output. The optional regulation limits

are shown below.

Table 12: Optional +5V Regulation Limits

Parameter MIN NOM MAX Units Tolerance

+5 V +5.85 +5.00 +5.25 V

+5/-3%

rms

- 16 -

SSI

EPS2U Power Supply Design Guide, V1.2

6.6 Dynamic Loading

STATUS

Required

The output voltages shall remain within the limits specified in Table 11 for the step loading and within the limits

specified in Table 13 for the capacitive loading. The load transient repetition rate shall be tested between 50 Hz

and 5 kHz at duty cycles ranging from 10% -90%. The load transient repetition rate is only a test specification.

The ∆ step load may occur anywhere within the MIN load to the MAX load shown in Table 10.

Table 13: Transient Load Requirements

Output ∆ Step Load Size Load Slew

Rate

+3.3 V 30% of max load

+5 V 30% of max load

12V1+12V2+12V3 65% of max load

+5 VSB 25% of max load

0.5 A/µs 1,000 µF

0.5 A/µs 1,000 µF

0.5 A/µs 1,000 µF

0.5 A/µs 1 µF

Capacitive Load

- 17 -

SSI

EPS2U Power Supply Design Guide, V1.2

6.7 Capacitive Loading

STATUS

Required

The power supply shall be stable and meet all requirements with the following capacitive loading ranges.

Note: Up to 10,000 µF of the +12V capacitive loading may be on the +12V1 output.

Table 14: Capacitve Loading Conditions

Output MIN MAX Units

+3.3 V 10 12,000

+5 V 10 12,000

µF

µF

+12 V 10 11,000

-12 V 1 350

+5 VSB 1 350

µF

µF

µF

6.8 Ripple / Noise

STATUS

Required

The maximum allowed ripple/noise out put of the power supply is defined in Table 15. This is measured over a

bandwidth of 0 Hz to 20 MHz at the power supply output connectors. A 10 µF tantalum capacitor in parallel with a

0.1 µF ceramic capacitor are placed at the point of measurement.

Table 15: Ripple and Noise

+3.3 V +5 V +12 V -12 V +5 VSB

50 mVp-p 50 mVp-p 120 mVp-p 120 mVp-p 50 mVp-p

- 18 -

SSI

Vout

V2 V3

V4

EPS2U Power Supply Design Guide, V1.2

6.9 Timing Requirements

STATUS

Required

These are the timing requirements for the power supply operation. The output voltages must rise from 10% to

within regulation limits (T

rise at about the same time. All outputs must rise monotonically. The +5 V output needs to be greater than the

+3.3 V output during any point of the voltage rise. The +5V output must never be greater than the +3.3V output

by more than 2.25 V. Each output voltage shall reach regulation within 50 ms (T

on of the power supply. Each output voltage shall fall out of regulation within 400 ms (T

during turn off. Figure 3 and Figure 4 show the turn ON and turn OFF timing requirements. In Figure 4, the

timing is shown with both AC and PSON# controlling the ON/OFF of the power supply.

Item Description MIN MAX Units

T

Output voltage rise time from each main output. 5 70 ms

vout_rise

T

All main outputs must be within regulation of each

vout_on

T

All main outputs must leave regulation within this

vout_off

other within this time.

time.

) within 5 to 70 ms. The +3.3 V, +5 V and +12 V output voltages should start to

vout_rise

) of each other during turn

vout_on

) of each other

vout_off

Table 16: Output Voltage Timing

50 ms

400 ms

V1

10% Vout

T

vout_rise

T

vout_on

T

vout_off

Figure 3: Output Voltage Timing

- 19 -

SSI

EPS2U Power Supply Design Guide, V1.2

Table 17: Turn On/Off Timing

Item Description MIN MAX UNITS

T

sb_on_delay

T

T

vout_holdup

Delay from AC being applied to 5 VSB being

within regulation.

ac_on_delay

Delay from AC being applied to all output v oltages

being within regulation.

Time all output voltages stay within regulation

after loss of AC.

1500 ms

2500 ms

18 ms

T

pwok_holdup

T

pson_on_delay

Delay from loss of AC to deassertion of PWOK. 17 ms

Delay from PSON# active to output voltages within

5 400 ms

regulation limits.

T

Delay from PSON# deactive to PWOK being

pson_pwok

50 ms

deasserted.

T

Delay from output voltages within regulation limits

pwok_on

200 1000 ms

to PWOK asserted at turn on.

T

Delay from PWOK deasserted to output voltages

pwok_off

1 ms

(3.3 V, 5 V, 12 V, -12 V) dropping out of regulation

limits.

T

Duration of PWOK being in the deasserted state

pwok_low

100 ms

during an off/on cycle using AC or the PSON#

signal.

T

Delay from 5 VSB being in regulation to O/Ps

sb_vout

50 1000 ms

being in regulation at AC turn on.

STATUS

Recommended

Item Description MIN MAX UNITS

T

T

T

Time all output voltages stay within regulation

vout_holdup

after loss of AC.

pwok_holdup

sb_holdup

Delay from loss of AC to deassertion of PWOK. 20 ms

Time 5VSB output voltage stays within regulation

after loss of AC.

21 ms

70 ms

- 20 -

SSI

AC Input

Vout

T

EPS2U Power Supply Design Guide, V1.2

PWOK

5VSB

PSON#

T

sb_on_delay

T

AC_on_delay

T

pwok_on

T

sb_vout

AC turn on/off cycle

T

pwok_holdup

T

Tsb_holdup

vout_holdup

T

pwok_off

T

pwok_low

T

T

T

pson_on_delay

pwok_on

sb_on_delay

PSON turn on/off cycle

pwok_off

T

pson_pwok

Figure 4: Turn On/Off Timing (Single Power Supply)

- 21 -

SSI

EPS2U Power Supply Design Guide, V1.2

7 Protection Circuits

STATUS

Required

Protection circuits inside the power supply shall cause only the power supply’s main outputs to shutdown. If the

power supply latches off due to a protection circuit tripping, an AC cycle OFF for 15 s and a PSON# cycle HIGH

for 1 s must be able to reset the power supply.

7.1 Current Limit

STATUS

Required

The power supply shall have current limit to prevent the +3.3 V, +5 V, and +12 V outputs from exceeding the

values shown in Table 18. If the current limits are exceeded, the power supply shall shutdown and latch off. The

latch will be cleared by toggling the PSON# signal or by an AC power interruption. The power supply shall not be

damaged from repeated power cycling in this condition. -12 V and 5 VSB shall be protected under over current or

shorted conditions so that no damage can occur to the power supply.

Table 18: Over Current Protection

Voltage Over Current Limit (Iout limit)

+3.3 V 110% minimum; 150% maximum

+5 V 110% minimum; 150% maximum

+12V 110% minimum; 150% maximum

7.2 240VA Protection

STATUS

Recommended

System designs may require user access to energized areas of the system. In these cases the power supply may

be required to meet regulatory 240VA limits for any power rail. Since the +12V rail combined power exceeds

240VA it must be divided into separate channels to meet this requirement. Each separate rail needs to be limited

to less than 20A for each +12V rail. The separate +12V rails do not necessarily need to be independently

regulated outputs. They can share a common power conversion stage. The +12V rail is divided into two rails for

the 450W power level and three rails for the 550W power level. +12V1 is dedicated for providing power to the

input of the processor voltage regulator(s). The +12V2 rail is used to power the rest of the main board +12V

power needs and peripherals devices. The +12V3 on the 550W power supply is used to power peripheral devices

only.

- 22 -

SSI

EPS2U Power Supply Design Guide, V1.2

Table 19: Over Current Protection

Voltage Over Current Limit (Iout limit)

+3.3 V 110% minimum; 150% maximum

+5 V 110% minimum; 150% maximum

+12V1 18A minimum; 20A maximum

+12V2 12A minimum; 20A maximum

+12V3 16A minimum; 20A maximum

7.3 Over Voltage Protection

STATUS

Required

The power supply over voltage protection shall be locally sensed. The power supply shall shutdown and latch off

after an over voltage condition occurs. This latch shall be cleared by toggling the PSON# signal or by an AC

power interruption. Table 20 contains the over voltage limits. The values are measured at the output of the

power supply’s connectors. The voltage shall never exceed the maximum levels when measured at the power

pins of the power supply connector during any single point of fail. The vo ltage shall never trip any lower than the

minimum levels when measured at the power pins of the power supply connector.

Table 20: Over Voltage Limits

Output Voltage MIN (V) MAX (V)

+3.3 V 3.9 4.5

+5 V 5.7 6.5

+12V1,+12V2, +12V3 13.3 14.5

-12 V -13.3 -14.5

+5 VSB 5.7 6.5

7.4 Over Temperature Protection

STATUS

Recommended

The power supply will be protected against over temperature conditions caused by loss of fan cooling or

excessive ambient temperature. In an OTP condition the PSU will shutdown. When the power supply

temperature drops to within specified limits, the power supply shall restore power automatically. The OTP circuit

must have built in hysteresis such that the power supply will not oscillate on and off due to temperature recovering

condition. The OTP trip level shall have a minimum of 4 °C of ambient temperature hysteresis.

- 23 -

SSI

EPS2U Power Supply Design Guide, V1.2

8 Control and Indicator Functions

The following sections define the input and output signals from the power supply.

Signals that can be defined as low true use the following convention:

signal# = low true

8.1 PSON#

STATUS

Required

The PSON# signal is required to remotely turn on/off the power supply. PSON# is an active low signal that turns

on the +3.3 V, +5 V, +12 V, and -12 V power rails. When this signal is not pulled low by the system, or left open,

the outputs (except the +5 VSB and Vbias) turn off. This signal is pulled to a standby voltage by a pull-up resistor

internal to the power supply. Refer to Figure 4 for timing diagram.

Table 21: PSON# Signal Characteristic

Signal Type

PSON# = Low

PSON# = Open or High

Accepts an open collector/drain input from the system.

Pull-up to VSB located in power supply.

ON

OFF

MIN MAX

Logic level low (power supply ON)

Logic level high (power supply OFF)

Source current, Vpson = low

Power up delay: T

PWOK delay: T

pson_on_delay

pson_pwok

0 V 1.0 V

2.0 V 5.25 V

4 mA

5 ms 400 ms

50 ms

Disabled

Hysteresis ≥ 0.3V and/or other de-bounce method

≤ 1.0 V

PS is

enabled

≥ 2.0 V

PS is

disabled

Enabled

0V

1.0V

2.0V

5.25V

Figure 5: PSON# Signal Characteristics

- 24 -

SSI

EPS2U Power Supply Design Guide, V1.2

8.2 PWOK (Power OK)

STATUS

Required

PWOK is a power OK signal and will be pulled HIGH by the power supply to indicate that all the outputs are within

the regulation limits of the power supply. When any output voltage falls below regulation limits or when AC power

has been removed for a time sufficiently long so that power supply operation is no longer guaranteed, PWOK will

be deasserted to a LOW state. See Figure 4 for a representation of the timing characteristics of PWOK. The

start of the PWOK delay time shall be inhibited as long as any power supply output is in current limit.

Table 22: PWOK Signal Characteristics

Signal Type

PWOK = High

PWOK = Low

MIN MAX

Logic level low voltage, Isink = 4 mA

Logic level high voltage, Isource=200 µA

Sink current, PWOK = low

Source current, PWOK = high

PWOK delay: T

PWOK rise and fall time

Power down delay: T

pwok_on

pwok_off

Open collector/drain output from power supply. Pull-up

to VSB located in power supply.

Power OK

Power Not OK

0 V 0.4 V

2.4 V 5.25 V

4 mA

2 mA

200 ms 1000 ms

1 ms 200 ms

100 µs

- 25 -

SSI

EPS2U Power Supply Design Guide, V1.2

8.3 Field Replacement Unit (FRU) Signals

STATUS

Optional

Two pins will be allocated for the FRU information on the power supply connector. One pin is the Serial Clock

(SCL). The second pin is used for Serial Data (SDA). Both pins are bi-directional and are used to form a serial

bus. The FRU circuits inside the power supply must be powered off of 5 VSB output and grounded to ReturnS

(remote sense return). The Write Control (or Write protect) pin should be tied to ReturnS inside the power supply

so that information can be written to the EEPROM.

8.3.1 FRU Data

FRU data shall be stored starting in address location 8000h through 80FFh. The FRU data format shall be

compliant with the IPMI specifications. The current version of these specifications are available at:

http:\\developer.intel.com/design/servers/ipmi/spec.htm.

8.3.2 FRU Data Format

The information to be contained in the FRU device is shown in the following table.

Table 23: FRU Device Information

Area Type Description

Common Header As defined by the FRU document

Internal Use Area Not required, do not reserve

Chassis Info Area Not applicable, do not reserve

Board Info Area Not applicable, do not reserve

8.3.2.1 Product Info Area

As defined by the IPMI FRU document. Product information shall be defined as follows:

Table 24: FRU Device Product Information Area

Field Name Field Description

Manufacturer Name {Formal name of manufacturer}

Product Name {Manufacturer’s model number}

Product part/model number Customer part number

Product Version Customer current revision

Product Serial Number {Defined at time of manufacture}

Asset Tag {Not used, code is zero length byte}

FRU File ID {Not required}

PAD Bytes {Added as necessary to allow for 8-byte offset to next area}

- 26 -

SSI

EPS2U Power Supply Design Guide, V1.2

8.3.2.2 MultiRecord Area

As defined by the IPMI FRU document. The following record types shall be used on this power supply:

• Power Supply Information (Record Type 0x00)

• DC Output (Record Type 0x01)

• No other record types are required for the power supply.

MultiRecord information shall be defined as follows:

Table 25: FRU Device Product Information Area

Field Name (PS Info) Field Information Definition

Overall Capacity (watts) 480

Peak VA 550

Inrush current (A) 50

Inrush interval (ms) 5

Low end input voltage range 1 90

High end input voltage range 1 140

Low end input voltage range 2 180

High end input voltage range 2 264

A/C dropout tol. (ms) 20

Binary flags Set for: Hot Swap support, Autoswitch, and PFC

Peak Wattage

Combined wattage Set for 5 V & 3.3V combined wattage of 115 W

Predictive fail tach support Not supported, 00h value

Field Name (Output) Field Description:

Output Information Set for: Standby on +5 VSB, No Standby on all others.

All other output fields Format per IPMI specification, using parameters in the EPS12V

Set for: 10 s, 550 W

Five outputs are to be defined from #1 to #5, as follows: +3.3 V, +5

V, +12 V, -12V, and +5 VSB.

specification.

- 27 -

SSI

EPS2U Power Supply Design Guide, V1.2

9 MTBF

STATUS

Recommended

The power supply shall have a minimum MTBF at continuous operation of 1) 50,000 hours at 100% load and

45 °C, as calculated by Bellcore RPP, or 2) 100,000 hours demonstrated at 100% load and 50 °C.

10 Agency Requirements

STATUS

Recommended

The power supply must comply with all regulatory requirements for its intended geographical market. Depending

on the chosen market, regulatory requirements may vary. Although a power supply can be designed for

worldwide compliance, there may be cost factors that drive different versions of supplies for different

geographically targeted markets.

This specification requires that the power supply meet all regulatory requirements for the intended market at the

time of manufacturing. Typically this includes:

• UL

• CSA

• A Nordic CENELEC

• TUV

• VDE

• CISPR Class B

• FCC Class B

The power supply, when installed in the system, shall meet immunity requirements specified in EN55024.

Specific tests are to be EN61000-4-2 ,-3, -4, -5, -6, -8, -11, EN61000-3-2, -3, and JEIDI MITI standard. The

power supply must maintain normal performance within specified limits. This testing must be completed by the

system EMI engineer. Conformance must be designated with the European Union CE Marking. Specific

immunity level requirements are left to customer requirements.

- 28 -

Loading...

Loading...