VER. A 09 / 24 / 2009

Page 1 of 31

COMPANY PROFILE

Engler Engineering Corporation has been in business since 1964 and occupies an 8000 square

foot facility in Hialeah, Florida (USA). We manufacture ultrasonic dental scalers, polishers and

combination units including electro surgery equipment and ultrasonic instruments for the veterinary

market as well as a microprocessor controlled anesthesia delivery system and a respiratory monitor

for veterinary use only.

We also manufacture dental equipment for the human market. Please visit our website

www.englerusa.com for more detailed information or call us at the numbers shown below.

Engler Engineering Corp. acquired the exclusive manufacturing and marketing rights of Dynax

products, including stretchers, animal restraint devices, comfort cots, and other products. We also

acquired the Alpha-Sonic, Ora-Sonic, and Pro-Sonic line of piezo scalers.

Engler Engineering Corporation’s brand name products proudly include: Sonus II dental ultrasonic

scaler, Poli-x variable speed polisher, Scale-Aire High speed veterinary dental air unit with

ultrasonic scaler / Low speed/ high speed/ air/water syringe, Excelsior high speed veterinary dental

air unit with vacuum/ Electrosurgery/ ultrasonic scaler / Low speed/ high speed/ air/water syringe,

Tri- Mate scaler / polisher / electro surge (for veterinary use only), and A.D.S. 2000 Anesthesia

delivery system / Ventilator (for veterinary use only)

We manufacture all of the inserts and tips used in the Engler products as well as many others on

the market today in the 18K, 25K, and 30K frequency range.

Our repair department has the technical knowledge to repair and maintain a number of dental

devices manufactured by other companies including Shorline.

Engler Engineering Corporation’s foreign sales are handled through a large and growing network of

dental and veterinary distributors. At the present time we are represented throughout the Middle

East, Europe, Central and South America, Canada, Asia, New Zealand, Australia, and most other

countries.

If you have any questions or comments, please contact:

Engler Engineering Corporation

1099 East 47th Street, Hialeah, Florida 33013

800-445-8581 – 305-688-8581 – FAX 305-685-7671

Web site: www.englerusa.com Help site: www.engler411.com

Page 2 of 31

INTRODUCTION

Thank you for purchasing an Engler Son-Mate II Scaler Polisher combination.

The design of the Engler Engineering Corporation, Son-Mate II scaler circuitry uses integrated

computer technology along with our time remote feedback circuitry. This combination produces a

powerful and potent tool against periodontal disease. A reinforced solid aluminum chassis surrounds

the internal circuit board, providing a very durable and reliable unit.

The dental scaler utilizes an ultrasonic principle of operation. The internal circuitry converts ordinary

line voltage to an operating frequency of approximately 18,000 Hz. This frequency is then amplified

and delivered to the scaling tip. As a result, the tip vibrates at this ultrasonic frequency with an amplitude

of 0.001 to 0.004 in. (25.4 um to 102 um).

In designing our unique Engler tips, water flows internally through the tip as it vibrates. As the bubbles

in the lavage are bactericidal, the energy released collapses and destroys the bacterial cell walls. The water

flowing internally through the tip, effectively cools the area and assists in removing any debris from the

operative site.

This device is equipped with a digital readout that provides an indication of the power that the unit is set

at.

IMPORTANT:

We recommend that ultrasonic scalers should not be used by or in close proximity to anyone who has any

electronic implant device (pacemaker, defibrillator, or has any neurological problems).

PLEASE READ VERY CAREFULLY

Engler Engineering Corporation makes every effort to verify that all parts for the device along

with any optional accessories ordered were shipped from our facility in Hialeah, Florida and are

included in this shipment. It is imperative that you inspect the contents and if you find any

pieces missing or damaged, you must notify us immediately. All claims submitted after fifteen

days of receipt will not be valid.

All devices manufactured and/or sold by Engler Engineering Corporation are built and tested to

approved standards. Any modification to the device, cables or hoses, initiated by others

nullifies all warranty statements. Engler Engineering Corporation will not be held liable for any

injury, death or damage of any type, due to non-authorized service and / or improper installation

and / or improper use of the device.

This manual is not intended to teach dentistry. The information contained herein is intended only as

a guide. Individuals not properly trained in dentistry should not use this equipment. It is intended for

professional use only.

If you have any questions or comments, please contact:

Engler Engineering Corporation

1099 East 47th Street

Hialeah, Florida 33013 800-445-8581 – 305-688-8581 – FAX 305-685-7671

Web site: www.englerusa.com Help site: www.engler411.com

Page 3 of 31

TABLE OF CONTENTS

COMPANY PROFILE...........................................................................................................................2

INTRODUCTION..................................................................................................................................3

TECHNICAL DATA..............................................................................................................................5

INSTALLATION INSTRUCTIONS.......................................................................................................7

SCALER OPERATING INSTRUCTIONS............................................................................................9

SCALER MAINTENANCE..................................................................................................................12

STACK (TRANSDUCER) INSTALLATION / REMOVAL INSTRUCTIONS.......................................13

POLISHER INSTALLATION..............................................................................................................15

POLISHER OPERATION...................................................................................................................16

POLISHER MAINTENANCE: PROPHY ANGLE ..............................................................................16

STRAIGHT HANDPIECE MAINTENANCE........................................................................................17

MICROMOTOR MAINTENANCE:.....................................................................................................18

SCALER TROUBLESHOOTING.......................................................................................................19

POLISHER TROUBLESHOOTING....................................................................................................20

WATER FILTER CLEANING INSTRUCTIONS.................................................................................21

SADDLE VALVE ASSEMBLY ...........................................................................................................22

WATER TANK INSTRUCTIONS.......................................................................................................25

CARE AND MAINTENANCE OF YOUR PORTABLE WATER TANK...............................................26

OPTIONAL SON-MATE II ACCESSORIES.......................................................................................27

WARRANTY INFORMATION............................................................................................................29

RETURN FOR EVALUATION / REPAIR FORM...............................................................................30

SON-MATE II LOANER REQUEST FORM ...............................................................................31

Page 4 of 31

I. SCALER:

TECHNICAL DATA

Input Voltage:

Input Frequency:

Current (Amperes)

Transducer Style: Magnetostrictive

Operating Frequency: 17,500 -19,000 Hz.

Ultrasonic Generator Data:

Auto-Tuned Feedback Oscillator

Variable pulse width Power Control

Pulse width Modulation Output II.

WATER:

Input Pressure: 30 PSI (min.) 60 PSI (max)

III. POLISHER:

Power Control: Variable Voltage Style

Output Voltage: 24 VDC

Output Current:5 Amperes (max)

IV. MICROMOTOR:

Velocity Range: 300 - 30,000 RPM

Style: Sealed Bearing “E” type

Brush Design: Fully Replaceable

V. STRAIGHT HANDPIECE:

Maximum Drive Velocity: 30,000 RPM

Style: Sealed Bearing “E” type

100-250VAC (UNIVERSAL POWER SUPPY)

50/60 Hz.

2.3 Amps

VI: PROPHY ANGLE:

Recommended Drive Velocity: 3,000 - 5,000 RPM

Type: Sealed Bearing/Open Bushing

IMPORTANT: Since the gears and bushings of the Prophy Angle are of an open design they

MUST be kept clean and lubricated daily to insure long life.

Page 5 of 31

VII. DIMENSIONS:

VIII. NET WEIGHT 3 Lbs. (1.36 Kg.)

IX. CHASSIS DIMMESION:

Length: 9 in. (23 cm)

Width: 8 in. (20 cm)

Height: 3.3 in. (8.4 cm)

X. CABLE LENGTHS

Handpiece

Footswitch

Power Cord

Water Line

96 in. (244 cm)

96 in. (244 cm)

72 in. (183 cm)

96 in. (244 cm)

XI. WEIGHT:

Net

Shipping

3 Lbs. (1.36 Kg.)

7 Lbs. (3.17 Kg.)

Page 6 of 31

INSTALLATION INSTRUCTIONS

Before installing or operating your new Son-Mate II, carefully read and follow all of the instructions.

IMPORTANT: This device must be connected to a clean, filtered, water supply, capable of delivering 30

to 60 psi (2.0 to 4.2 kg/cm2) of water input pressure. This unit comes with an In-Line water filter (P/N:

A52030). When kept clean and free of foreign matter, it will assist in proper water flow to the unit.

If the water pressure in your office is above 60 psi, we recommend you install a water pressure

regulator on the supply line to your scaler.

CONNECTING WATER SUPPLY:

We strongly recommend that a manual shut off valve be

placed prior to the Female Quick Disconnect, so that the water

can be completely shut-off, and line pressure relieved, when

the unit is not in use.

This device comes equipped with an 8 foot (244 cm)

water line, a male Poly-Quick disconnect fitting, a water filter

and a coupling body.

The water line must be connected to the white fitting located

on the back of the device before a connection is made to the

water source. To connect the water line, slide the white (male)

insert into the coupling body until the metal latch locks it in

place making a clicking sound. The water line can now be

connected to your water source.

We suggest that you use one of the four methods as shown

on the next two pages.

** Please note, male quick disconnects is

supplied as a standard item with all

Engler scalers.

PLEASE REMEMBER -

It is recommended that you disconnect the device from the

water supply when it is not in operation.

Page 7 of 31

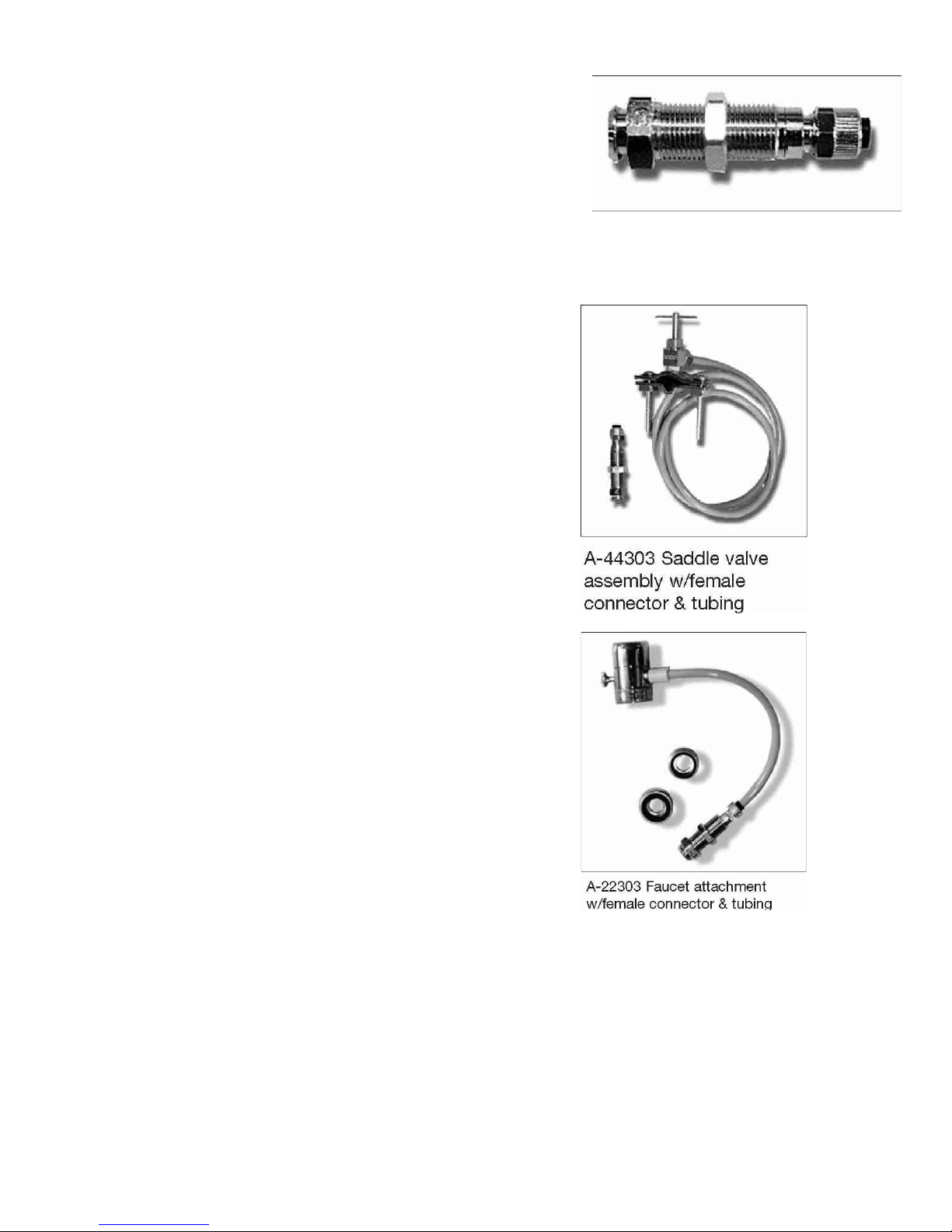

1. Female Quick Disconnect (P/N: 44300) - This is the female

mating connector to the male quick disconnect supplied with

the Son-Mate II . Use this to create a custom water

installation.

2. Saddle Valve Assembly (P/N: A44303) - This kit

contains all parts to quickly and easily connects

your unit to an existing cold water supply line.

44300 Female quick disconnect

3. Faucet Adapter Assembly (P/N: A22303) This

screws on the faucet and has a female mating

connector.

Page 8 of 31

4. Portable Water Tank (P/N: PT-1) - This is a self-

contained water source, which is ideally suited

for portable operation. We suggest you use

bottled water and fill the tank to the water fill line

(approximately 2/3). Tighten the cap, insert the

male quick disconnect on the water line into the

female on top of the tank, pressurize by

pumping the handle until you have resistance in

pushing down on the handle, and locking the

handle in place.

IMPORTANT: If you do not feel comfortable doing the water installation yourself, we recommend the

services of a professional plumber. Engler Engineering Corporation will not be held liable for any

damage including, but not limited to leakage caused by improper installation of our products.

PLEASE NOTE: Minerals and foreign particles in the water may cause a buildup or blockage of internal

hoses and parts.

The water filter supplied with this device must be opened and inspected quarterly and we suggest that

the filter disc and O ring be changed out at least once a year. See page 17 for instructions.

CONNECTING THE FOOT SWITCH:

To connect the footswitch to the unit, insert the male quick disconnect into the female quick disconnect

on the rear of the device and then tighten the securing nut by turning it clockwise.

CONNECTING POWER SUPPLY:

First plug the power cord into the unit and then plug the male end of the power cord into a grounded power

outlet. DO NOT remove or bypass the ground pin from the power cord of this device. Doing so will void the

warranty.

IMPORTANT: Your Son-Mate II has been equipped with a universal switching power supply and will not

require adjustments in this regard.

SCALER OPERATING INSTRUCTIONS

Initial procedures at the start of every day.

1. Make sure the water is turned on and flowing to the Device. Rotate the Selector Switch to the

“SCALER” position, the red LED indicator should light up, showing that you have power to the unit.

2. Adjust the power control knob to the minimum power setting fully counter-clockwise. The

Page 9 of 31

digital readout will read 1.

NOTE: The transducer (stack) has already been installed into the handpiece, please do not

remove it at this time.

3. With only the transducer (stack) in the handpiece (no tip installed), set the water control to its

maximum setting by rotating it counterclockwise, (knob will rotate up to 3 and a half turns for

maximum water) hold the handpiece over a sink and depress the footswitch until water comes

out in a stream. This should take a few seconds. This step is done to insure proper operation of

the delay cavitation feature by removing air that may be trapped in the water lines.

4. Insert a sterile tip into the nosecone, and rotate the nosecone in a clockwise direction. Then firmly

tighten by hand.

IMPORTANT: It is important that you DO NOT over-tighten the tips, as this will damage the Stack

and / or tip.

5. Always keep the power control at the lowest setting and the water control to a level where you

have a fine mist at the tip. Higher power settings will result in hotter water.

NOTE: Tips sent from our facility are not pre-sterilized.

IMPORTANT: If you find that tightening the nosecone by hand is not successful, you may lightly

tighten the nosecone with the tip wrench. Since the tip wrench is designed to remove the tips, it

is important that you DO NOT over-tighten the tips with the tip wrench, as this will damage the

Stack and / or the tip.

IMPORTANT: Keep in mind that higher power levels tend to heat the out-flowing water.

Temperature control can be achieved by balancing the power with water flow volume. Thus,

high power settings require high water flow rates and conversely low power requires low water

flow rates.

5. The scaler is now ready for use.

IMPORTANT: Operating this device with hot water may cause damage to gums, lips and

tongue. If the handpiece begins to get warm, stop and check water temperature. If it is hot,

make sure that the power is at the lowest setting and the water is set at a high setting to

provide a lukewarm mist.

Page 10 of 31

ULTRASONIC SCALING PROCEDURES:

1. Before placing tip into patient’s mouth, activate the scaler over a sink by depressing the

footswitch. A fine mist, with the temperature between cool to lukewarm to the touch is

recommended. This should be accomplished with minimal power and proper water flow.

2. It is recommended that when a tip is placed into a patient’s mouth, the lips, cheek and tongue

3. be retracted to prevent accidental contact.

4. Place the tip into the patient’s mouth and depress the footswitch in order to activate the scaler.

5. Bring the tip lightly up to the tooth and gently move it over the surface of the tooth with an

erasing motion.

IMPORTANT DO NOT allow the tip to stay in one spot for an extended period of time.

6. A saliva ejector or HVE is recommended.

Note: To avoid internal contamination by back flow this device forces clean water through the lines

causing droplets to form and fall from the tip when unit is disengaged.

IMPORTANT: Pressure on the tip is not necessary to remove calculus or tartar. Enamel on the teeth

may be damaged or removed when using excessive pressure. It can also be damaged if the scaling tip

is left to rest in one spot for even a few seconds. Using the tip as a pry to remove calculus or tartar

may change the shape of the tip, which in-turn, changes the frequency. The normal power setting for

most procedures should be LOW range. Since every operator has a different technique and some

patient’s are more sensitive than others, the power may be adjusted to satisfy specific requirements

CAUTION: Contact with Soft Tissue May Cause Burns.

The use of a facemask is recommended when operating the scaler, to avoid inhalation of bacterially

contaminated aerosol (water mist) by the operator.

FINAL PROCEDURES AT THE END OF EACH DAY:

1. Make sure the unit is turned off. .

2. Detach the tip and nose cone and sterilize.

3. Disconnect the unit from its water source or turn off the water supply.

4. Clean and disinfect all surfaces.

Page 11 of 31

SCALER MAINTENANCE

Instrument Tips:

IMPORTANT: The scaling tips should be thoroughly cleaned and free of blood, tissue, or any

other debris before sterilization.

The scaling tips, nosecone and stack may be sterilized by Autoclave or Chemiclave, always

following the manufacturer’s instructions and recommendations. Do not autoclave over 270

degrees F or more than twenty (20) minutes..

It is recommended that you do not leave tips screwed into the handpiece for several days,

as water and sediment may make it difficult to remove, causing possible damage to the

stack.

Transducer / Stack:

The stack may be sterilized using the same methods as listed above. Do not sterilize the entire

Stack, Tip and Nosecone assembly as one piece. Separate the tip from the stack before

sterilization.

To re-install stack into handpiece, follow correct procedures on page 10.

Note: To achieve optimum performance of your equipment, we recommend that the stack, tip

and nosecone be replaced every 6 months to a year.

Chassis:

The chassis of your unit should be cleaned at the end of every operating day with a chemical

sterilization solution. This procedure could be done by spraying a fine mist of sterilization solution

on the unit, allowing it to remain on the chassis for the length of time recommended by the

manufacturer. The surface should be wiped with a clean damp cloth or as suggested by the

Chemiclave manufacturer. Dry completely.

IMPORTANT: In using any chemical sterilization solution please follow the manufacturer’s

suggested procedures.

HANDPIECE, FOOTSWITCH AND POWER CABLES:

After each procedure, or at least once a day, it is suggested that the handpiece and its cable be

thoroughly cleaned and sterilized. The recommended procedure is as follows:

1. Remove Tip, and Nosecone - Sterilize these items as listed above.

2. Clean the outer surface of the handpiece and its cable with an antiseptic soap, rinse off with

water and sterilize with a chemical sterilization solution.

Note: If any chemicals are allowed to get into the handpiece you must flush it out with clean water.

3. Place cleaned Tip and Nosecone into handpiece for next patient.

4. The footswitch and power cables should be cleaned periodically by spraying a fine mist of

sterilization or cleaning solution on the cables. It should remain on the cables for the length of

time recommended by the manufacturer. Wipe the surface with a damp cloth and dry the cables

completely.

Page 12 of 31

STACK (TRANSDUCER) INSTALLATION / REMOVAL INSTRUCTIONS

You have purchased a precision instrument. Please handle gently - It is easily damaged

TO REMOVE THE STACK: Unscrew the scaling tip by turning the plastic nosecone counterclockwise.

a. Remove tip.

b. Pull off plastic nosecone. Pull stack straight up. DO NOT USE PLIERS! If you have difficulty pulling

up, insert the scaling tip and pull from tip.

IF YOU STILL CANNOT REMOVE IT CALL US AT 800-445-8581.

Do not twist or rotate stack while it is in the handpiece, as it will damage the stack and / or handpiece.

TO INSTALL THE STACK:

Carefully remove the new stack from the clear shipping tube.

A. Locate the hole (see photo above) on the side of the stack. Align it

with the white dot on the top of the handpiece and let the stack slide down

into the handpiece.

B. Gently push the stack down until it stops. There should be

approximately ½ inch showing above the handpiece.

DO NOT force the stack into the Handpiece.

D. Push plastic nosecone onto scaler handpiece.

E. Place Scaling Tip into nosecone and turn nose-cone clockwise.

Note: Tighten securely by hand. DO NOT USE TIP WRENCH.

NOTE: Twisting the nosecone or tip with excessive force will damage the stack.

FOR FURTHER ASSISTANCE CALL CUSTOMER SERVICE

800-445-8581 OR 305-688-8581

Page 13 of 31

Page 14 of 31

POLISHER INSTALLATION

1. Plug the Micromotor into the front of the control box. This is done by inserting the male connector

at the end of the Micromotor cable, into the female receptacle on the front panel of the unit and

rotating the locking collar clockwise.

2. Slide the Straight Handpiece down over the top of the Micromotor.

3. Line up the notch of the Prophy Angle with the Aligning Pin on the Straight Handpiece, and then

push the shaft of the Prophy Angle into the chuck of the Straight Handpiece.

4. Rotate the Lock Ring clockwise, until it clicks and locks the prophy angle in place.

5. Place a disposable rubber-polishing cup on the end of the prophy angle by snapping it on. The

Prophy Angle is now secured and ready for operation.

6. Rotate the selector knob on the front of unit to either forward or reverse operation.

NOTE: When using the polisher the GREEN LED indicator should be on.

NOTE: It is suggested to use a low to mid range speed setting for polishing. High speed will

damage the gears in the Prophy angle.

SAFETY INFORMATION:

Never turn the Lock Ring while the handpiece is in operation.

1. Never reverse the direction of the micromotor while it is in operation. Possible damage to the

unit may occur.

2. Do not drop the Micromotor, Handpiece or Prophy Angle on the floor or other hard surface as

the shock may cause malfunction.

3. Do Not lock or run the Micromotor / Straight Handpiece Assembly without a Prophy Angle,

Cutting Disc, Contra Angle, or test shaft installed. Doing so could damage the Straight Handpiece

and / or Micromotor.

4. Never oil the micromotor.

5. When installing the Prophy Angle or other accessory, make sure that the Lock Ring is rotated

fully in the unlock position, otherwise the accessory can not be installed and the Straight

Handpiece will not operate.

6. Do Not rotate the selector switch on the front of the control box between Forward and Reverse

rapidly. Always allow a second between the two selections.

7. As this is a precision instrument, always return it to Engler Engineering Corporation for repair.

Page 15 of 31

POLISHER OPERATION

1. Dampen the rubber cup and place a small amount of polishing paste on it.

2. Rotate the POWER control to the minimum setting in the Prophy Range.

3. Depress the footswitch and the rubber cup will begin to rotate. The speed of rotation may be

adjusted to your desired level by readjusting the POWER control.

4. To keep the paste from flying off the cup, maintain a low speed and gently bring the cup up

to the tooth before depressing the footswitch.

IMPORTANT: The prophy angle is only rated to rotational speeds of 5,000 RPM - therefore, in

order to prevent premature failure of the angle keep the unit set in the prophy range whenever the

prophy angle is attached to the straight handpiece.

5. High-speed settings may throw the polishing paste off of the rubber cup. Always start with a

low speed and then adjust to a higher speed as required.

6. Place the end of the angle into the patients’ mouth and gently apply the rubber cup to the

surface of the tooth with a circular motion. Do not allow the rubber cup to remain stationary

on one area for an extended period of time.

POLISHER MAINTENANCE: PROPHY ANGLE

The Prophy Angle is a precision engineered dental device. All of the gears and shaft assemblies

are made of high-grade stainless steel, which if cleaned and lubricate correctly will provide long,

trouble-free service.

Daily Cleaning and Lubrication:

1. Remove prophy angle from straight handpiece.

2. Remove used rubber cup.

3. Follow the cleaning instructions that were supplied with the Prophy angle.

4. Place a new rubber cup onto the angle.

5. Slide the prophy angle down over the straight handpiece and lock it in place

IMPORTANT: For a long dependable life, the prophy angle should be lubricated daily, if possible

after each use. Keep hair away from prophy cup and head cap.

SUGGESTION: To keep hair from being tangled in the angle, we recommend using a gentle

adhesive tape around the lips, keeping hair in place away from treatment area.

This device is shipped with

Snap on rubber cups

P-MM-E 35,000 RPM

Micromotor W/Cord

P-SH-A1:1 Straight

handpiece

Page 16 of 31

P-A1-B Prophy

Angle (Sealed

Bearings)

Polishing

paste

STRAIGHT HANDPIECE MAINTENANCE

LUBRICATION

The spray nozzle oiling method is optional but highly recommended because it cleans as well as

lubricates. The alternate method is to place 1 drop of approved oil in the chuck hole. Do not lubricate

the handpiece while it is on the Micromotor.

Lubrication of the straight handpiece is required at least once a week.

Lubrication by spray lubricant:

1. Make sure that the straight handpiece is in the unlocked position prior to lubricating.

2. Install the E-Type nozzle by pushing it onto the top of the spray can. To lubricate, insert the

E-Type nozzle into the bottom of the handpiece. Holding the two together tightly, with can in the

upright position, push spray button for 2 to 3 seconds.

NOTE: If spray time is too short oil may not be propelled into all areas of the handpiece.

CLEANING and STERILIZATION OF HANDPIECE.

Cleaning:

1. Wipe the handpiece clean with an alcohol-soaked soft tissue.

2. Never clean the handpiece with boiling water, chemical solutions, ultrasonic cleaner, or with

wire brushes.

Sterilization:

1. Autoclaving is recommended for the Engler Straight Handpiece.

2. Clean the Handpiece as described above.

3. Lubricate the Handpiece as described in the lubrication section of this manual.

4. Place the Handpiece in an autoclaving pouch and seal it in accordance with the instructions on

the pouch.

Page 17 of 31

5. Autoclave the Handpiece for no longer than 20 minutes at 121 C (250 F), or 15 min. at 132 C

(270 F).

Keep the straight Handpiece away from water vapor or mist that may settle and cause premature

damage to the bearings.

IMPORTANT: If you experience problems during operation, call our repair department. DO NOT

attempt to repair the straight Handpiece. Doing so may shift the internal springs, causing

permanent damage to the unit and will void warranty.

MICROMOTOR MAINTENANCE:

The Micromotor is capable of rotational speeds up to 35,000 RPM for use in cutting, sectioning and

drilling. It contains sealed bearings and does not require any lubrication. The Micromotor has

cooling vents located at the back of its body, DO NOT allow water, oil, or any other substance to

enter these vents. Failure to keep debris out of the Micromotor will shorten the lifespan of the unit

and cause permanent damage.

IMPORTANT:

1. NEVER change the direction of the Micromotor while it is in operation. ALWAYS wait until

it has come to a full stop.

2. NEVER oil, or allow oil to get into the micromotor.

Page 18 of 31

SCALER TROUBLESHOOTING

I “ON” LED INDICATOR DOES NOT LIGHT UP:

A. The unit is not plugged in to a power outlet: verify that the unit is plugged in.

B. Power Outlet not active: try another outlet.

C. The power cord is not connected to the device.

D. Contact Engler Engineering Corporation.

ll “ON” LED INDICATOR LIGHTS UP, NO WATER FLOW:

A. Verify that the selector switch is in scaling mode.

B. Verify water line is connected and water is flowing to unit.

C. Verify that the coupling insert is connected to the coupling insert.

D. Check if water line is kinked or twisted.

E. Check Water Filter and disk: clean disk with plain water and a toothbrush. If clogged,

replace “O” ring and disc.

F. If using Portable Water Tank: verify you have sufficient pressure in the tank.

G. Water blockage in tip: replace the tip. (Clean with # 5 piano wire)

H. Contact Engler Engineering Corporation.

lll “ON” LED INDICATOR LIGHTS UP, LITTLE OR NO VIBRATION / CAVITATION ON TIP:

A. Tip loose: tighten the tip.

B. Tip damaged: replace the tip.

C. Old or damaged stack: replace the stack.

D. Contact Engler Engineering Corporation.

HOT WATER AND / OR SCALING HANDPIECE:

The Stack requires a constant cool water flow in order to maintain tip water temperature below

100 degrees F. You may correct the problem by:

A. Adjusting water flow knob higher (counter clockwise).

B. Tip clogged. Replace tip.

C. Check and / or replace “O” ring and disc.

D. Water restriction in unit: contact Engler Engineering Corporation repair department.

E. If using Portable Water Bottle, pump up to pressurize the bottle.

INTERMITTENT OPERATION:

I. Tip vibrates/cavitates and then stops:

A. Tip loose: tighten tip.

B. Footswitch damaged: Contact Engler Engineering Corporation.

C. Handpiece / cable damaged: Contact Engler Engineering Corporation.

II Tip action ceases abruptly during operating procedure.

A. Tip not tightened: tighten tip.

B. Transducer broken: replace.

C. Handpiece / cable damaged: Contact Engler Engineering Corporation.

Page 19 of 31

POLISHER TROUBLESHOOTING

NO POWER:

I.“ON” LED indicator does not light up:

A. The unit is not plugged in to a power outlet: verify that the unit is plugged in.

B. Power Outlet not active: try another outlet. Also check the electrical panel to verify

circuit is on.

C. Contact Engler Engineering Corporation.

II. “ON” LED indicator lights up polisher not functioning:

A. Switch unit to Polisher mode.

B. Micromotor not plugged in: plug micromotor in.

C. Short in Micromotor or its cord: Contact Engler Engineering Corporation for instructions.

HOT HANDPIECE:

I. Handpiece not lubricated properly: Lubricate as shown on page 17.

II. Bearings in straight handpiece are becoming worn, causing drag. Contact Engler Engineering

Corporation.

POLISHER TROUBLESHOOTING:

HOT MICROMOTOR:

I. Straight handpiece causing drag, lubricate correctly.

II. Worn brushes in micromotor, Contact Engler Engineering Corporation.

III. Oil inside micromotor, return to Engler Engineering Corporation.

INTERMITTENT OPERATION:

I. Unit polishes and then stops:

a. Damaged micromotor cord: contact Engler Engineering Corporation.

b. Damaged footswitch: contact Engler Engineering Corporation.

MISCELLANEOUS:

I. If the micromotor speed does not vary (runs high speed only): Return the complete Son-Mate

with micromotor to Engler Engineering Corporation.

II. If the prophy cup “flies off” the prophy angle: Micromotor is rotating in the wrong direction,

change direction by rotating the selector on the front of the unit to the opposite direction.

III. Straight handpiece rotates on the micromotor: straight handpiece not properly locked, or Prophy

angle gears worn or binding. (Refer to Page 13-14)

Page 20 of 31

WATER FILTER CLEANING INSTRUCTIONS

SHOULD BE DONE AT LEAST QUARTERLY

1. Turn off water supply to unit or disconnect the male from the female water connector

2. Unscrew filter by firmly holding Point “A” in your left hand and Point “B” in your right hand.

(Refer to Figure) Next, unscrew by simultaneously rotating your left hand away from you and

rotating your right hand toward you. Continue this process until the filter unscrews into two

separate pieces.

3. The filter body consists of two sides, one with an outer male thread and another with an inner

female thread. Take the side with the inner female thread and look into it, should see an O-RING

and under it a FILTER DISC (Refer to Figure below).

4. Remove the O-RING by carefully prying it out of the inner wall with a fingernail or other dull object.

NOTE: Be careful not to rip or break this O-RING, a water leak could result.

1. Next, remove the FILTER DISC by turning the female side over and tapping it gently into the

palm of your hand.

2. Replace with new disc part # A-52031 and “O” ring part # A-52032.

3. Reassemble the filter in the reverse order as you disassembled it.

4. Turn on the main water supply and check for leaks.

Point A Point B

Page 21 of 31

SADDLE VALVE ASSEMBLY

Installation Instructions:

1. To assemble the saddle valve to existing water source: Place the saddle valve over and around

your existing 3/8” copper tubing. Evenly tighten the securing screws so that the saddle valve is

securely fastened onto the copper tubing.

DO NOT OVERTIGHTEN, THIS MAY CAUSE THE COPPER TUBING TO CRIMP AND

REDUCE FLOW.

2. To Mount the Female Quick Disconnect: YOU HAVE TWO OPTIONS.

Page 22 of 31

Page 23 of 31

Option “A”

Take the other end of the 1/4” water tubing that comes from the saddle valve and connect it to the

female quick disconnect. This is done by placing the hose coupling nut over the water tubing and

placing the hose into the back of the female quick disconnect, then tightening the coupling nut.

A-44303 Saddle valve assembly w/female connector & tubing

Option “B”

If you wish, the female quick disconnect may be mounted directly through the sink top or vanity

counter. If you choose this way, you must first drill a 1/2” diameter hole through the surface in the

space desired. (see next page) Then mount the female quick disconnect and tighten the mounting

nut to securely hold it in place. Then proceed to place the hose coupling nut over the 1/4” water

tubing. Place this tubing into the back of the female quick disconnect and tighten the hose coupling

nut securely.

1. To Pierce Existing Water Tube: You are now ready to pierce the copper tube. Turn the handle

of the saddle valve in a CLOCKWISE direction until it will go no further. The Saddle valve is now

installed and in the OFF position. Turn the handle of the Saddle valve counter-clockwise until

resistance is felt. Water is ready to flow into the dental unit. Check for leaks.

2. To Connect the Scaler to the Quick Disconnect: Push the male quick disconnect from the scaler

into the female quick disconnect until they lock and installation is complete.

Engler Engineering Corporation will not be held liable for any damage including, but not limited to

leakage caused by improper installation of our products.

Page 24 of 31

WATER TANK INSTRUCTIONS

PT-1 Water Tank

DIRECTIONS:

1. Remove pump and cap assembly.

2. Fill tank with water or medicated solution up to the

“FILL LINE” mark. Do NOT fill beyond this line.

3. Replace pump and cap assembly and tighten

securely.

4. Pressurize tank by pumping it approximately 10-20

times (depending on the amount of liquid used). If

a hissing sound is detected, tank is overpressurized. Stop pumping. Leave tank on a level

surface until hissing stops. Insert the male quick

disconnect on the end of the waterline from scaler

into female quick disconnect provided on tank.

WATER TANK CARE & MAINTENANCE:

NOTE: A small amount of care will repay in long life and efficient operation.

1. RELEASE AIR PRESSURE by turning knob of pressure relief valve. Pull out fully and allow

air to escape.

2. Loosen cap slowly. Remove pump & cap assembly. Pour out any remaining liquid & rinse all

parts thoroughly with clean water.

3. Always store tank empty and with tank cap loose, upside down.

TROUBLESHOOTING:

PROBLEM: TANK FAILS TO PRESSURIZE.

1. Be sure cap is tight.

2. Check to see if pressure relief valve is in safety position.

3. Remove the pump from the tank. Turn pump handle counterclockwise and lift handle to unlock.

On top of the pump cap there is an opening that says “oil here”. Place 2 or 3 drops of oil (20 weight,

household vegetable oil, etc.) into the opening. Pump several times to work the oil into the walls

of the pump until it moves freely. Repeat if necessary. Screw the pump back into the tank and

resume normal operations. This process should be repeated often depending on usage, or

when pump starts to work harder.

4. Black particles found in water, the pump assembly is deteriorating. Order new pump assembly

from Engler Engineering.

Page 25 of 31

Pump assembly has been pre-lubricated...DO NOT TAKE THIS ASSEMBLY APART TO CLEAN

INSIDE PUMP.

WARNING:

READ AND FOLLOW ALL INSTRUCTIONS.

ALWAYS INSPECT your pump before each use.

ALWAYS RELEASE AIR pressure before removing pump or servicing tank, by pulling

pressure relief valve knob out fully.

ALWAYS TIGHTEN CAP securely, a loose cap could be forcibly ejected & cause injury.

DO NOT use mechanical devices to pressurize the tank .They can create excessive and

dangerous pressure which could cause the tank to explode.

DO NOT STAND over pressurized tank while using it or pumping it

DO NOT USE solutions hotter than 105¡F.

D0 NOT damage or alter the functions of the pressure relief valve or plug the pressure relief

valve hole, as this could cause the tank to explode

DO NOT pressurize the tank until ready for use.

DO NOT lift or carry the tank by waterline, extension rod or pump handle unless it is securely

locked in place.

CARE AND MAINTENANCE OF YOUR PORTABLE WATER TANK

To keep slime from forming inside the tank and eventually getting into the dental unit:

Every two weeks dispose of water in tank. Pour 1/2 cup of bleach and one quart of hot water into tank

and swirl the liquid thoroughly inside the tank.

DO NOT PLACE pump assembly in tank with Clorox solution as lubrication inside the assembly

may react with the mixture.

Dispose of the bleach mixture and rinse the tank out. You can allow the tank to dry overnight or fill it

again with distilled water.

Clean the outside of the pump assembly with paper towels and alcohol.

The pump assembly has been pre-lubricated. DO NOT TAKE THIS ASSEMBLY APART.

Page 26 of 31

OPTIONAL SON-MATE II ACCESSORIES

P-MF Maintenance free prophy angle

P-106 screw on rubber cups 144/pkt

CARE FOR YOUR MAINTENANCE-FREE ANGLE STERILIZATION PROCEDURES:

After each prophy...

A. Remove rubber cup.

B. Rinse abrasive paste from head area with water.

C. Thoroughly clean the outside of angle with disinfectant.

D. Autoclave angle - not more than 275 ºF (135 ºC) over 20 minutes.

E. After sterilization cycle is complete, install a new disposable rubber cup and attach

angle to handpiece. You are now ready for your next prophy.

CAUTIONS AND WARNINGS:

A. Do not attempt to disassemble.

B. DO NOT SUBMERGE IN LIQUIDS, INCLUDING ULTRASONIC SOLUTIONS.

C. Do not heat over 275 ºF (135 ºC).

D. Use only Engler Care Free Prophy Rubber Cups. Other brands will not properly seal the

angle, causing premature wear and voiding the warranty.

E. Use 1 year and dispose of properly.

YOUR CARE-FREE ANGLE IS WARRANTED AGAINST DEFECTS IN MATERIAL AND

WORKMANSHIP FOR 6 MONTHS. A COPY OF OUR INVOICE OR PICKING TICKET WILL

BE REQUIRED AS PROOF OF PURCHASE.

WARRANTY IS VOID IF:

A. Engler Care-Free rubber cups are not used exclusively.

B. Sterilization procedure is not followed properly.

C. The angle has been submerged in any liquid.

D. The angle has been damaged or abused.

E. Damaged due to use at high speed.

Page 27 of 31

If you have any questions or concerns, please contact us.

ENGLER ENGINEERING CORP

800-445-8581

To co nt a c t us by int er n et ple a s e us e:

info@englerusa.com

To help troubleshoot problems, download manuals and see our products,

Visit us at:

www.engler411.com

Page 28 of 31

WARRANTY INFORMATION

It is imperative that when calling Engler Engineering regarding the operation of your

unit, that you have the serial number available for quick reference.

The Son-Mate II, scaler polisher combination, with attachments, is warranted to be free

from material and manufacturing defects to the original consumer / purchaser for a period as

specified below.

The Son-Mate II control box is warranted for a period of six (6) years from date of purchase.

The scaler handpiece is warranted for a period of two (2) years from date of purchase.

The Micromotor is warranted for a period of one (1) year from date of purchase.

The polishing straight handpiece is warranted for a period of one year from date of purchase.

Stacks (transducer) are warranted for a period of six (6) months from date of purchase.

Scaling tips are warranted for a period of thirty (30) days from date of purchase.

Prophy warranted for a period of thirty (30)

days from date of purchase.

All warranties are void if the items have been damaged due to negligence, improper use,

failure to lubricate, removed parts, or opening the control unit.

PLEASE NOTE:

Whenever returning any products for evaluation and / or repair, we strongly suggest you send

in the complete unit with all attachments so that a correct evaluation can be made.

Engler Engineering Corp, has been in business since 1964, in Hialeah, Florida, building and

maintaining dental units and parts for our ultrasonic scalers, polishers, and anesthesia machines

as well as manufacturing inserts and other items for many devices on the market today. As a

leader in the field, we would appreciate a minute of your time to let us know how we can better

serve you.

You can mail all comments, suggestions and questions to us at the following address and number:

Engler Engineering Corp. 1099 East 47 Street Hialeah, FL 33013

If you wish to fax to us, please use 305-685-7671.

Page 29 of 31

RETURN FOR EVALUATION / REPAIR FORM

PLEASE PHOTOCOPY AND INCLUDE A COMPLETED COPY WHENEVER SENDING UNITS IN TO US

FOR EVALUATION AND / OR REPAIR.

CLINIC PHONE NUMBER: ___________________________FAX #___________________________

CLINIC NAME: _____________________________________________________________________

Contact person: ____________________________________________________________________

Shipping Address: __________________________________________________________________

City: __________________ State: ___________________ Zip:

_______________________________

ITEM BEING SENT: _________________________________ SERIAL # _______________________________

Please describe what is happening or why you are sending in this unit:

When returning items to us, we would prefer you send the complete unit so that a proper evaluation can

be made.

It is suggested that you ship all returns to us by Federal Express or UPS. If using US Mail, it is

suggested that you track and insure the package.

Address all returns as follows:

ENGLER ENGINEERING CORP.

REPAIR DEPARTMENT

1099 EAST 47 STREET

HIALEAH, FL 33013

If you have any questions or concerns, please call us.

ENGLER ENGINEERING CORP 800-445-8581.

Page 30 of 31

SON-MATE II LOANER REQUEST FORM

Please review and complete this form and FAX it back to us at 305-681-3831 or 305-688-0018 so we can

ship a unit out to you.

CONDITIONS of the Engler Engineering Corporation loaner program:

1. We must receive this completed and signed form before a loaner is shipped out.

2. A Credit Card is required – the information must be shown on the form below.

3. It is understood that if Engler Engineering does not receive your unit for repair within five (5) business

days of you receiving the loaner, your credit card will automatically be charged $50.00 per week for

rental of the loaner.

4. You have five (5) business days after we send your estimate of repairs to send us your reply;

otherwise a weekly rental charge of $50.00 will be applied to your credit card.

5. Our loaner must be shipped back to us by Federal Express or UPS (NOT GROUND), to be received

within five (5) days of the date you receive your unit. You need to insure it and keep record of the

tracking number for reference if needed. If the loaner is not received, Engler Engineering will

automatically charge your card for the full value of the loaner.

6. You are responsible for all shipping charges.

7. All parts are double checked at shipping to verify that they are included with the loaner. It is your

responsibility to notify Engler Engineering at 800-445-8581 on the day the loaner is received if any

items are missing.

8. All loaner items must be returned in good working condition. We include a copy of our check list for

you to use to verify all parts are being returned. Missing and/or damaged items will be charged to

your credit card.

NOTE: Loaner requests received after 11:00 AM Eastern time will be shipped out the next business day.

Unless specified, all loaners will be shipped Federal Express - Express Saver with a 3 to 4 business day

delivery time.

Check box if OVERNIGHT or SECOND DAY is requested at additional cost.

Please fill in the information below authorizing the transaction to accommodate your request.

Contact Name: _________________________________________________________________

Clinic Name: __________________________________________________________________

Phone ______________________________ FAX ___________________________________

Address: _____________________________________________________________________

City: __________________________________ State:______ Zip _______________________

The serial number(s) of the device being sent in is _____________________________________________

Credit card number (Amex) (Visa) (MC) _____________________________________________

Expiration:________________ Zip Code of billing address: ______________

I understand and agree to the terms and conditions stated above. Date:__________________

____________________________________________________________________________

Signature Print Name

E03-08-00 C

Page 31 of 31

Loading...

Loading...