Engineered Comfort 35FH Series, 37FH Series Installation Instructions Manual

INSTALLATION INSTRUCTIONS

HORIZONTAL FAN COIL UNITS

MODEL SERIES: 35FH AND 37FH

Safety Considerations

The equipment covered by this manual is designed for safe and

reliable operation within its design specification limits. To avoid

personal injury or damage to equipment or property while installing

or operating this equipment, it is essential that qualified, experienced

personnel perform these functions using good judgment and safe

practices. See the following cautionary statements.

Danger

ELECTRICAL SHOCK HAZARDS. All power must be disconnected

prior to installation and servicing this equipment. There may be

more than one power source present. Insure that all power sources

have been disconnected to avoid electrocution or shock injuries.

MOVING PARTS HAZARD. Motor and blower must be disconnected

prior to opening access panels. Motors can start automatically;

disconnect all power and control circuits prior to servicing to avoid

serious crushing or dismemberment injuries.

BURN HAZARD. Electrical resistance heating elements must

be disconnected prior to servicing. Electric heaters may start

automatically; disconnect all power and control circuits prior to

servicing to avoid burns.

Caution

The equipment covered by this manual is available with a variety

of options and accessories. Consult the approved unit submittal,

order acknowledgment and other manuals for details on the options

and accessories provided with the equipment on each project. Safe

practices regarding mechanical equipment must be followed at

all times when handling, installing or servicing any unit. All power

must be disconnected before any installation or service should

be attempted. More than one power source may be supplied to

the unit. Power to remote mounted control devices may not be

supplied through the unit. Never wear bulky or loose fitting clothing

when working with mechanical equipment. Gloves should only

be worn when required for proper protection from heat or other

possible injury. Safety glasses or goggles should always be worn

when drilling, cutting or working with chemicals such as lubricants.

Never pressurize any equipment beyond specified test pressures.

The manufacturer assumes no responsibility for personal injury or

property damage resulting from improper or unsafe practices during

handling service or operation of any equipment.

Preface

Nailor Industries fan coils represent an investment, which can, when

installed and operated properly, give long and trouble free service.

Your equipment is initially protected under the manufacturer’s

standard warranty. However, this warranty is provided under the

condition that the steps outlined in this manual for initial inspection,

proper installation, periodic maintenance and everyday operation

of the equipment be followed in detail. This manual should be

fully reviewed in advance of any actual work being done on the

equipment. Should any questions arise, please contact your local

Sales Representative or the factory before proceeding.

Unpacking and Inspection

All units have been carefully inspected, tested and packaged at

Nailor’s manufacturing facility. It is the responsibility of the receiving

party to inspect the equipment upon arrival. Any obvious damage

to the packaging and/or its contents should be recorded on the

bill of lading and a claim should be filed with the freight carrier.

After determining the condition of the unit’s exterior, including all

piping, each unit should be carefully removed from the package

and inspected for hidden damage. Any hidden damage should be

recorded and immediately reported to the carrier and a claim filed.

Should a claim for shipping damage be filed, the unit, the shipping

package and all packing must be retained for inspection by the

freight carrier. All equipment should be stored in the factory shipping

package until installation. At the time of receipt, the equipment type

and arrangement should be verified against the order documents.

Should any discrepancy be found the local sales rep should be

notified immediately so that the proper action may be instituted. The

factory must be notified about any questions concerning warranty

repairs BEFORE any corrective action is taken. Should equipment

require factory operations a Return Authorization Number will be

issued. Any returns not marked with an authorization number will

be refused. The manufacturer will not accept claims for expenses

not authorized.

Receiving Inspection

After unpacking the fan coil unit, check it for shipping damage. If

any shipping damage is found, report it immediately to the delivering

carrier. Store units in a clean, dry location.

CAUTION: Do not use copper coil connections, drain pan

connections, outside air inlet collar, damper shaft, airflow sensor,

electrical conduit, or valve packages as a handle to lift or move

assembly. Damage to the fan coil unit or controls may result.

Ship Loose Items

Items may often be shipped loose for field installation. These items

are shipped loose to offer protection against shipping and job site

damage or by customer request. Refer to packing slip. These items

require the same inspection as the unit.

Minimum Access

Make appropriate accommodations for access panel removal. The

35FH units have access panels on the top, bottom and sides. Some

access may be limited depending on options. The 37FH units have

top and bottom access panels. Electrical enclosures have access

panels that are equipped with hinges. Blowers, motors, coils and

drain pans can be accessed and inspected from the bottom access

panel. For clearances for full opening of hinged access doors, refer

to project specifications, submittal sheets and NEC.

IMPORTANT: These recommendations do not preclude NEC or

local codes that may be in effect, which are the responsibility of the

installing contractor.

For units including valve package enclosures ensure that the access

door to the valve package is not obstructed. Optional universal filter

10/18 EC-35FH-37FH-INST

Engineered Comfort reserves the right to change any information concerning product or specification without notice or obligation.

Dimensions are in inches (mm).

Page 1 of 4

racks if selected provide access for filter replacement from the side

or bottom of the rack. Consult relevant submittals and/or project

plans detailing the location of these items.

Handling & Installation

Even though the Nailor fan coil unit is a sturdily constructed unit,

great care should be taken when handling it. Care should be taken

to protect the blower assembly, coil, piping, and drain stub outs

during handling. The piping and blower assemblies should not be

used as handles for lifting or moving the unit. Units may also have

delicate internal components that could be damaged by improper

handling. Care should be taken to prevent impact forces on the unit

that may cause internal damage.

The units covered in this manual are not suitable for outdoor

installation and should never be used for that purpose. The units

should never be stored or installed where they may be subjected to

a harsh environment such as rain, snow, or extreme temperatures.

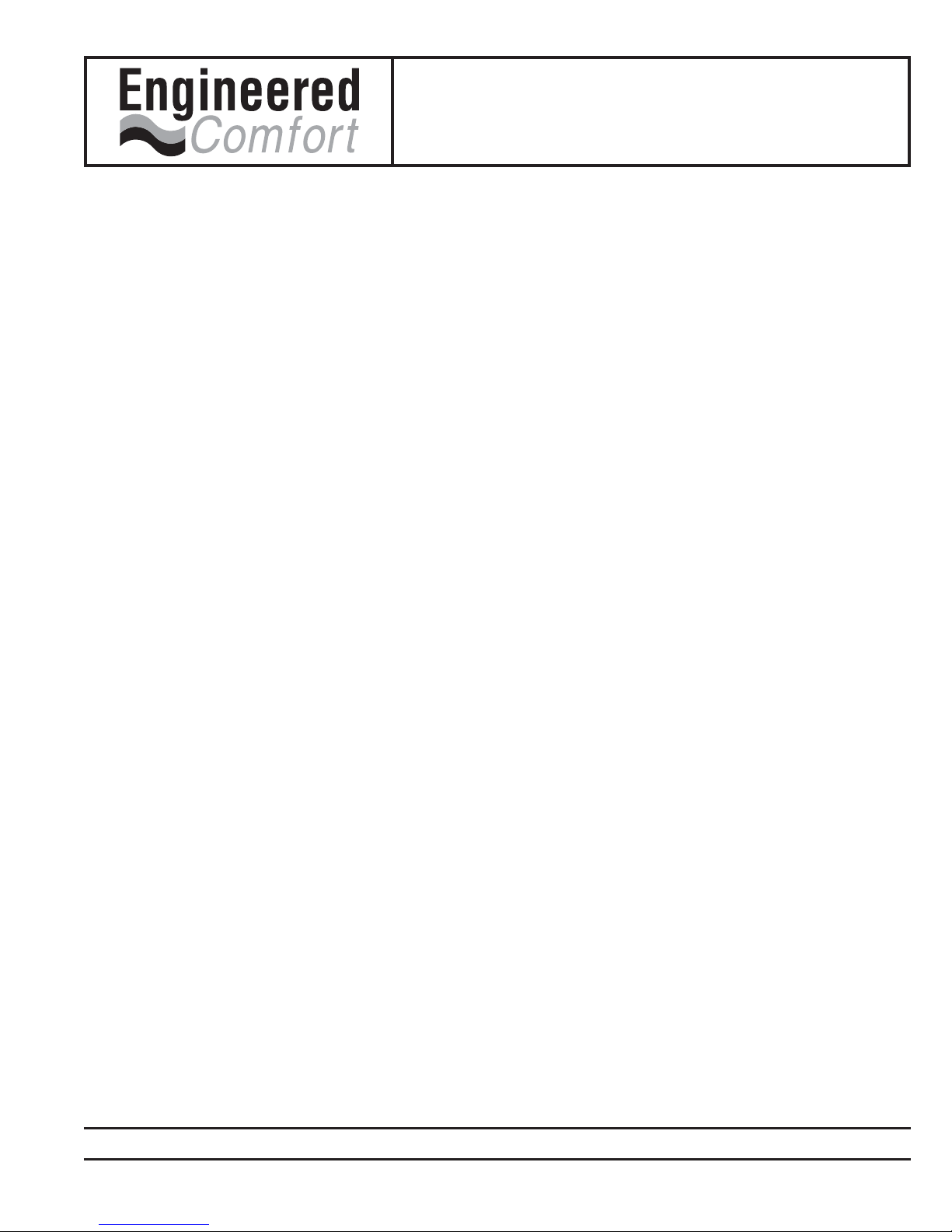

Fan Coil Unit Support Using Trapeze Suspension.

Care should be taken to prevent any materials such as paint,

plaster, drywall dust, and other construction materials from being

deposited in the drain pan, heater, coils, or on the motor or blower

wheels. Failure to do so may have negative effects on unit operation

and may result in premature failure. To prevent contamination, the

units should have some form of temporary covering placed over

them during construction.

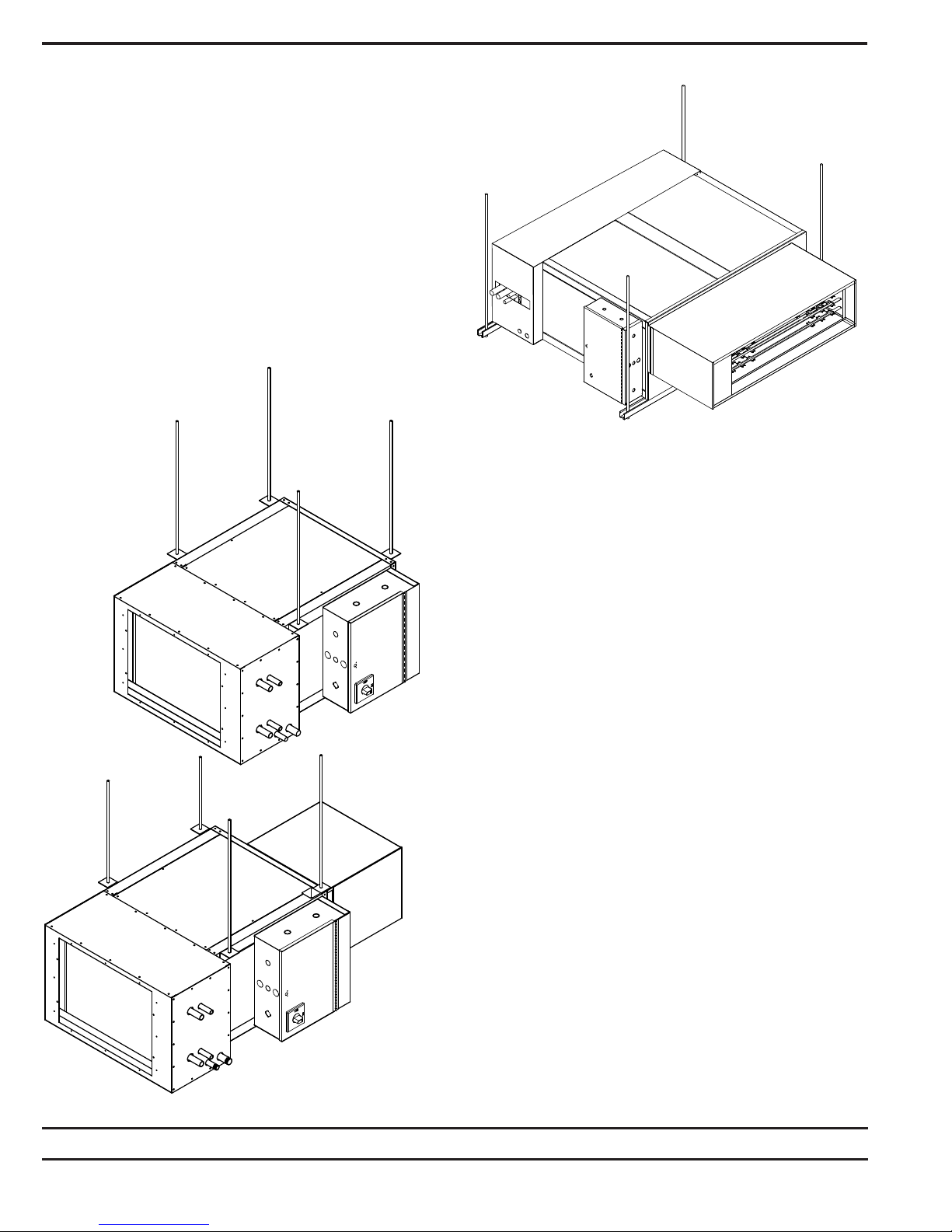

For model series 35FH & 37FH; suspend the unit from the building

structure in a horizontal plane. Be careful not to obstruct the bottom

access panels with support channels or straps. When requested,

unit is supplied with field mounted hanger brackets for use with

hanger rod up to 3/8" (9.5) diameter. Hanger brackets or straps

should be screwed to the top corner posts, unit casing sides, or

alternatively onto the inlet and outlet ends of the unit. Fan coil

units are too heavy to suspend with the ductwork they must be

independently supported. For the 35FH Size 30 & 40 it is advised

that these units are mounted by a trapeze suspension. The unit

must be mounted level. The drain pan has a built-in slope to ensure

proper drainage. Field-furnished and installed accessories such

as ductwork, mixing boxes, economizers, dampers, and valve

packages must be independently supported and must not rely on

the unit for support.

After unit is mounted, the service connections such as water, drain

and electrical can be made. At this time it should be confirmed that

the proper types of service have been provided to the unit. The

water connections should be checked for line size, temperature,

and location. Electrical service to the unit should be compared to

the unit nameplate to verify compatibility. The routing, and sizing

of all piping, the type and sizing of all wiring and other electrical

components such as circuit breakers, disconnects switches, etc.

should be determined by the individual job requirements and should

not be based on the size or type connections provided with the

equipment. All installations should be made in compliance with all

governing codes and ordinances. This compliance to all codes is

the responsibility of the installing contractor.

Fan Coil Unit Support Using Hanger Brackets and Rods.

Engineered Comfort reserves the right to change any information concerning product or specification without notice or obligation.

Dimensions are in inches (mm).

Page 2 of 410/18 EC-35FH-37FH-INST

Loading...

Loading...