Page 1

OPERATION AND MAINTENANCE MANUAL

Backpressure Monitor & Logger

Revision: 7.0 June 2011 Part Number: M18-0017

Page 2

Table of Contents

Symbols used in this Manual ..................................................................................................... 3

Introduction ................................................................................................................................ 4

Parts List .................................................................................................................................... 5

Understanding the BPM Connections ........................................................................................ 6

Understanding the Remote Driver Display ................................................................................ 7

Installation Procedure ................................................................................................................ 8

Using the DPF Utilities Software .............................................................................................. 14

Maintenance............................................................................................................................. 17

BPM Troubleshooting Guide .................................................................................................... 18

2

Page 3

Symbols Used in this Manual

This symbol emphasizes non-compliance with instructions or procedures can re-

WARNING

CAUTION

sult in serious injuries or death to personnel.

This symbol emphasizes non-compliance with instructions or procedures may

cause damage to equipment.

ATTENTION

TECH TIP

This symbol highlights and draws specific attention to important information

This symbol indicates that in this situation, the technician would suggest this

course of action to be done.

3

Page 4

Introduction

A diesel particulate filter (DPF) is used to reduce the exhaust particulate matter emitted by an engine. By

definition, the DPF accumulates the particulate matter (soot) and oxidizes it with a passive, active, or combined

strategy.

Diesel engines are sensitive to backpressure created by any restriction in the exhaust flow. When a DPF

is used, the backpressure varies depending on the soot loading in the filter. The filter will fill up with soot and ash

over time and periodically require cleaning. As a result, a backpressure monitor is used to inform the vehicle operator that the filter needs cleaning.

Monitoring exhaust backpressure is also a useful way to identify the condition of the engine. Increased

soot levels from the engine will cause the filter to load faster. Identifying this trend allows the service technician

to correct engine problems before they become severe. Backpressure monitoring can also indicate DPF overloading and/or slow soot combustion.

Engine Control Systems is pleased to offer a DPF Backpressure Monitor & Logger with features to protect both your engine and your DPF. The Backpressure Monitor & Logger will be referred to as the BPM throughout this manual.

4

Please completely read this manual.

ATTENTION

Page 5

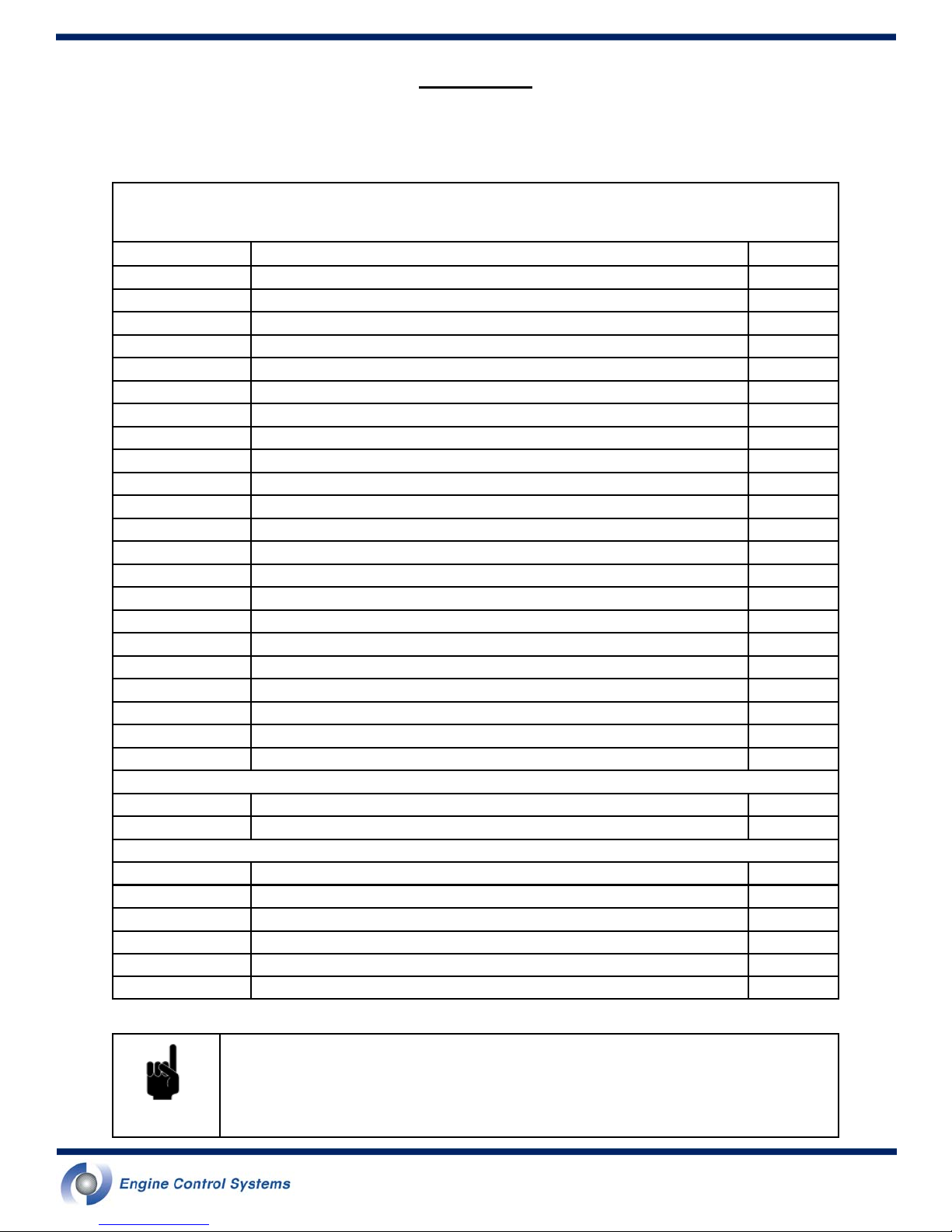

Parts List

The following parts are included in the BPM kit. Please take time to read all installation instructions and setup procedure carefully to ensure proper installation and use of the provided software. Spare parts for older BPM models are

listed at the bottom of this page.

Backpressure Monitor & Logger Part List

(Complete kit - A56-0067)

PART # DESCRIPTION QTY

A56-0066 Backpressure Monitor - Watlow thermocouple & Deutsch connector 1

J35-0269 Remote Driver Display 1

C25-0232 Condensation Trap 1

J16-0021 Fitting – ¼ NPT male - ¼ hose barb 1

J16-0126 Clear plastic tube — 10 ft 1

J16-0313 ¼“ swage to ¼“ swage brass 1

J16-0314 ¼” swage to ¼” NPT brass 2

J16-0316 Synflex tube - 1/4” OD, 6 ft 1

J16-0322 Brass tube insert 2

J19-0161 Stainless steel backpressure tube—1/4” OD 1

J35-0333 Watlow K-Type Thermocouple 1

J35-0334 K-Type thermocouple extension wire 1

J16-0340 Coupling—M14 x 1.5 1

J35-0270 Power cable — 20 ft 1

J35-0271 Remote Driver display cable—20 ft 1

J35-0272 Data cable—3 ft 1

J35-0277 2 amp fuse 1

J35-0278 Fuse holder 1

J16-0005 Coupling-NPT-SS 1/4 - 3/4” OD 1

M18-0017 Backpressure Monitor & Logger Installation & Setup Manual 1

M16-0019 Utility CD 1

M18-0026 BPM Driver’s Display Visor Card 1

Optional Accessories

J35-0273 Remote Driver Display Extension cable—20 ft. 1

J35-0336 Remote Driver Display Extension cable—40 ft. 1

Spare Parts for Old Style BPM with Omega thermocouple

A56-0063 Backpressure Monitor - Omega thermocouple & yellow connector 1

J35-0275 Omega Thermoco uple — 6” K-type 1

J35-0226 Thermocouple wire—15 ft 1

J35-0276 Thermocouple wire strain relief - #PCLM-SMP 1

J16-0285 Thermocouple plug — male 1

J16-0315 1/8” swage to ¼” NPT brass 1

If you are missing any components, contact your ECS representative before continuing

the installation.

ATTENTION

5

Page 6

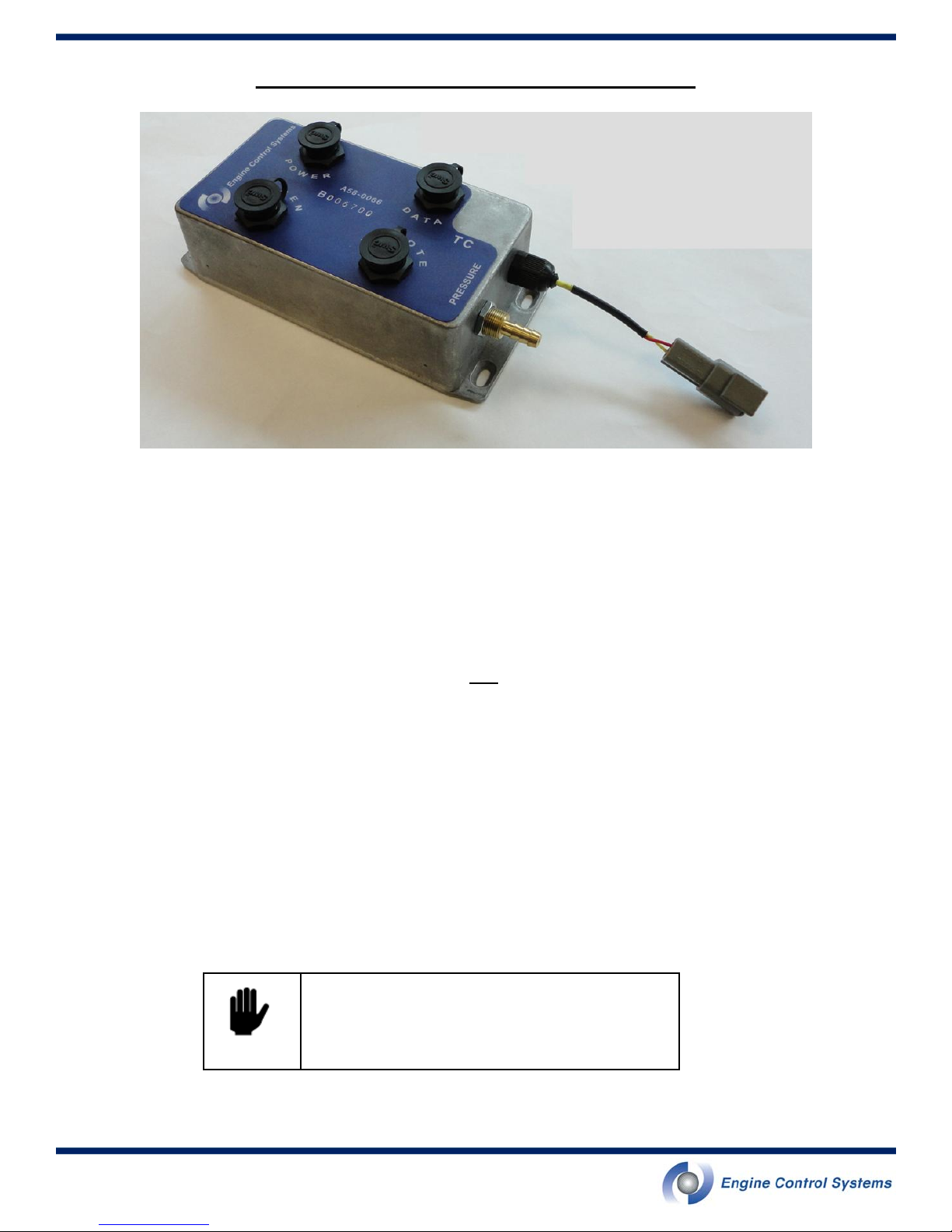

Understanding the BPM Connections

Figure 1 - Backpressure Monitor & logger (BPM)

POWER

Connects to continuous vehicle battery power. The BPM will operate with a 12V or 24V power source.

DATA

Connects to the PC for setup and data downloading.

REGEN

Connects to the junction box on Purifilter Plus systems only. The BPM can monitor the regeneration status when

connected.

REMOTE

Connects to the Remote Driver Display.

TC

Connects to the K-Type thermocouple that measures the exhaust temperature.

PRESSURE

Connects to the pressure line that samples the exhaust stream backpressure

Use caution when plugging in the cables. Make sure

the pins are aligned properly before pushing in the

connector.

CAUTION

6

Page 7

Understanding the Remote Driver Display

Figure 2 - Remote Driver Display

Pink light - SYSTEM ERROR

This pink light flashes when there is a BPM system error. It has two modes of operation: flashing and off.

FLASHING

soon as possible. If the error light stays on in combination with the red alarm light, the BPM and DPF should be

inspected as soon as possible. Refer to the troubleshooting guide for error light causes and m ore information.

OFF:

: A flashing error light indicates that there is a system error and the BPM should be inspected as

The unit is working properly.

Red light - SERVICE DPF NOW

This red light indicates that very high exhaust backpressure exists and the DPF is in need of immediate attention. There are two modes of operation: ON (solidly illuminated) and off.

ON

: When the light is illuminated for longer than 45 seconds, the operator should service the DPF within 24hrs.

If the red light is on in combination with the system error light, the vehicle should be parked in a safe location

immediately. If when parked, the red light and pink light remain on with the vehicle at idle and/or with engine

turned off, do not continue to operate the vehicle. Engine damage may result. Product warranty may be void.

Refer to the troubleshooting guide for more information.

OFF:

The unit is working properly.

Yellow light - SCHEDULE DPF SERVICE

This yellow light indicates that higher than normal exhaust backpressure exists and that there is a need to

schedule the DPF for service. The light has two modes of operation: ON (solidly illuminated) and off.

ON

: It is normal that this light may briefly illuminate when pulling heavy loads up grades. When the light illuminates for periods longer than 45 seconds

should schedule the DPF for service. Delays in servicing may raise the alarm level to “SERVICE DPF NOW”.

Refer to the troubleshooting guide for more information.

OFF:

The DPF is not in need of service

Green light - POWER

This green light indicates that the system is powered and is operational. There are two modes of operation for

this light: ON and OFF.

ON:

When the light is illuminated the system is powered properly. This light remains illuminated even when the

engine is shut off.

OFF

: The system is either not powered or there is a problem with the system. Refer to the troubleshooting guide

for more information..

while the vehicle is in normal use on a level roadway, the operator

7

Page 8

Installation Procedure

Tools and Accessories Required

Power drill with 3/8” drill bit.

Self tapping 3/16” screws

Welding Tools for couplings

Zip ties for fastening cabling to the vehicle

Electrical Connectors

Laptop

Step 1 - Installing the thermocouple and stainless steel backpressure sampling tube

a. Drill two 3/8” holes in the exhaust pipe for the couplings. The couplings should be installed on a

straight section of pipe and not on bends or flex pipe. They should also be located upstream of the

DPF and as close as possible to the DPF inlet.

b. Find the 1/4” NPT coupling and the M14 coupling and weld to the exhaust pipe so that they align with

the drilled holes. The M14 coupling is the larger coupling. The NPT coupling should be upstream of the

M14 coupling.

c. Locate the thermocouple, apply anti-sieve to the threads, and tighten into the M14 coupling as shown

in Figure 3. Keep thermocouple wire away from hot surfaces.

d. Locate the 1/4” swage to 1/4” NPT brass fitting, apply anti-seize to the NPT threads, and tighten into

the NPT coupling.

e. Insert the stainless steel sampling tube into the 1/4” swage hole until it stops. Tighten the compression

nut finger tight and then turn one full turn further with a wrench. The backpressure sampling tube is

shown in Figure 4.

Figure 3 - Installation of the thermocouple sensor at the DPF inlet (pressure tube not installed

yet). Keep thermocouple wire away from hot

surfaces.

If the exhaust inlet diameter is less than 3 inches, an NPT coupling and a ther-

mocouple adaptor will be required to center the thermocouple tip within the

ATTENTION

8

pipe. Please call technical services.

Figure 4 - Installation of the backpressure

sampling tube

Page 9

Installation Procedure (cont’d)

Step 2 - Mounting the BPM

Mount the BPM in a location that is protected from direct water spray, excess heat, and moving parts. Some recommended locations include a battery box or engine compartment. Figure 5 shows recommended locations. If

the BPM cannot be installed in the recommended locations, cover the BPM with a shield or a box to protect it.

Ensure that the BPM is exposed to atmospheric pressure. The following page illustrates acce ptable orientations.

a

Figure 5 - Examples of properly mounted

BPMs; a) in an electrical panel; b) in the engine

compartment; c) in a battery box. BPM shown

may differ from the one supplied.

Do not install the BPM in direct exposure to water spray or rain. Do not

CAUTION

pressure wash the BPM.

Do not install the BPM inside the driver’s compartment. A leak could expose

the driver to exhaust gas.

CAUTION

If the BPM cannot be installed in the recommended locations, cover the BPM

b

c

with a shield or a box to protect it. Ensure that the BPM is exposed to atmos-

ATTENTION

pheric pressure.

The BPM will operate properly up to a maximum temperature of 70°C. Make

sure the BPM is installed in a location that does not exceed this temperature.

ATTENTION

9

Page 10

Installation Procedure (cont’d)

ACCEPTABLE BPM orientations:

a. Vertical surface with tube to the right

b. Vertical surface with tube to the left

c. Vertical surface with tube downward

d. Hanging from a horizontal surface with face downward (not

shown)

a

b

c

UNACCEPTABLE BPM orientations:

a. Vertical surface with tube upward

b. Sitting on a horizontal surface with the face upward

b

a

UNCCEPTABLE mounting locations or orientations will VOID the warranty!

ATTENTION

10

Page 11

Installation Procedure (cont’d)

Step 3 - Assemble the Condensation Trap

Locate the condensation trap, 1/4” NPT to 1/4” barbed fitting, and 1/4” swage to 1/4” NPT brass fitting.

a. Apply anti-seize compound to the NPT threads of each fitting

b. Remove the condensation trap from the box. Be careful not to lose the two small crews in the box that

fasten the bracket to the trap.

c. Thread the barbed fitting into the outlet

d. Thread the swage fitting into the inlet

Step 4 - Mount the Condensation Trap

Mount the condensation trap at a location higher than the exhaust system so that excess condensation drains to

the exhaust. The condensation trap should be installed below the BPM to prevent any moisture from entering the

BPM. Make sure it is away from all moving parts and excessive heat. The flow direction will be marked by an

arrow or small triangle pointing in the direction of flow. The exhaust sample should flow from the exhaust stream

towards the BPM.

a. Remove the condensation trap bracket from the box and use it to mark the holes

b. Drill two mounting holes on the vehicle for the bracket

c. Fasten the bracket to the condensation trap using the two screws provided. Make sure the outlet is

facing the correct direction.

d. Mount the condensation trap to the vehicle using the drilled holes.

e. Measure and cut the appropriate length of clear plastic tube

f. Push the clear plastic tube onto the barbed fittings at the condensation trap and BPM

marked with a square and tighten.

marked with a triangle and tighten.

Figure 6 - Two examples of condensation trap mounting.

The flow direction is marked on the condensation trap by an arrow or small triangle pointing in the

direction of flow. The exhaust sample should flow from the exhaust stream towards the BPM.

ATTENTION

11

Page 12

Installation Procedure (cont’d)

Step 5 - Assemble and route the Synflex backpressure sampling tube

a. Measure and cut the appropriate length of Synflex tube to go from the end of the stainless steel tube to

the condensation trap. Cut the ends square and clean to ensure proper sealing when assembled.

b. Locate the brass tube inserts and press into each end of the synflex tube

c. Locate the 1/4” swage to 1/4” swage fitting

d. Connect one end of the fitting to the stainless steel tube. Tighten compression nut finger tight and then

tighten one full turn with a wrench

e. Slide one end of the synflex tube into the fitting. Tighten compression nut finger tight and then tighten

one full turn with a wrench.

f. Route the synflex tube to the condensation trap and slide the tube into the inlet fitting. Tighten com-

pression nut finger tight and then tighten one full turn with a wrench.

Be careful not to lose the small brass tube inserts.

CAUTION

Step 6 - Route the thermocouple wire

a. Plug the thermocouple extension wire into the thermocouple and route to the BPM. Do not cut the ther-

mocouple extension wire. Plug the thermocouple extension into the BPM.

Do not cut or shorten the thermocouple extension wire.

ATTENTION

ATTENTION

Route wires with existing wire harnesses and keep away from hot surfaces. Wire

loom is recommended but not provided.

12

Page 13

Installation Procedure (cont’d)

Step 7 - Mount the Remote Driver Display

Mount the Remote Driver Display in clear view of the driver as shown in Figure 7. Do not interfere with any driving mechanisms, instruments, or gages. Plug the six pin Remote Driver Display cable into the Remote Driver

Display and route to the BPM. Plug the other end into the “Remote” plug on the BPM.

ARB Verification requires that

the Remote Driver Display is

visible when sitting in the

ATTENTION

driver’s seat.

Use caution when plugging in the cables. Make sure the pins are aligned

properly before pushing in the con-

CAUTION

nector.

Figure 7 - Remote Driver Display mounted to instrument panel

Step 8 - Install the Power Cable

The BPM must be connected to a continuous and unswitched power supply of 12V or 24V. It is strongly recommended to wire directly to ONE

a. Locate the power cable, measure, and cut to the desired length.

b. Strip the outer gray wire to expose 6” of the black and white wire.

c. Connect the provided the fuse holder to the WHITE (positive) wire. Do not insert the fuse yet.

d. Connect the red wire to the positive terminal of the battery

e. Connect the black wire to the negative terminal of the battery. Connect wires to a single battery.

f. Route the power cable to the BPM and plug it into the “Power” connector.

g. Insert the 2 amp fuse into the fuse holder.

battery.

ATTENTION

ATTENTION

In the event of jump starting the

vehicle, remove the BPM fuse.

Failure to do so could result in

BPM damage.

In the event of welding on the

vehicle, remove the BPM fuse.

Failure to do so could result in

BPM damage.

Figure 8 - Installing the power cable

TECH TIP

Connect the BPM directly to only

ONE

battery

13

Page 14

Using the DPF Utilities Software

STEP 1 - Install the DPF Utilities Software

The software required to view and retrieve data from the BPM is provided with your kit.

Computer Requirements

The software requires the minimum system requirements:

Windows XP/2000 System

Pentium 3 Class System or newer

At least 64 MB of RAM

RS-232 Serial port

Serial port to USB adaptor if no serial port is available

Software Installation

Insert the CD containing the ECS Backpressure Monitor & Logger Software into your computer’s CD-ROM drive.

Click install and follow the procedures on screen.

STEP 2: Making the Connection

a. Connect your computer to the BPM using the data cable provided.

b. Double click on the ECS_DPF_Utilites shortcut located on the desktop. This will launch the DPF Alarm

Logger Utilities window shown in Figure 9.

c. Enter the Comm port number and select “OK.”

Figure 9 - Select the Comm port that the data

cable is plugged in to.

TECH TIP

14

Comm port 1 will work for most users. However, if you are

using a USB to serial port adaptor, you may have to change

this number

Page 15

Using the DPF Utilities Software (cont’d)

STEP 3: Viewing Real-time data from the BPM

After clicking “OK,” the Parameter View tab will open as shown in Figure 10. From this tab, you can see real-time

data from the BPM. The flashing blue light next to the word “Update” indicates that the computer is connected to

the BPM. Check to make sure that the thermocouple reading is reasonable. For example, if the thermocouple is

exposed to room temperature, it will read around 20

o

C.

Figure 10 - “Parameter View” tab showing real-time data from the BPM.

TECH TIP

Ensure that you have a good connection by checking the temperature readings. For a cold engine, the thermocouple temperature should read ambient temperature. It is possible to

have a flashing blue light, but and bad connection. If you have

a thermocouple reading of 0.0, you are not connected properly. Try a different Comm port setting.

15

Page 16

Using the DPF Utilities Software (cont’d)

STEP 4: Accessing the data stored in the BPM

Selecting the “Log View” tab will bring up the data transfer area of the utilities program. This is shown in Figure

11. This is where all communications and information can be controlled by the user.

On the right hand side are buttons used for downloading and saving the data stored in the BPM. The “Parameter

Logs” contains the temperature, pressure, regeneration status, and alarm status taken every 12 seconds over

the past 24 hours. The “Histogram Logs” contain frequency data in the form of a histogram from the last 365

days.

Select the desired radio button and click on “Get data.” The data will show up in the white viewing pane on the

left.

When you have selected to read one type of data (Histogram or Parameters) you must clear the screen before

displaying the next time to ensure accurate data display. This can be done with the “Clear Log Display” button in

the upper right hand section of this tab.

Figure 11 - The Log View tab is where the data

transfer takes place.

STEP 5: Saving the BPM data

Once the desired data is shown in the viewing pane, it can be saved to your computer.

Clicking on the “Save for Excel” button will save the data in the viewing pane to a CSV file that can be opened by

most viewing programs.

It is recommended to save all data log files, both Parameter logs and both Histogram logs, at every de-ashing for

future reference. Each log must be brought into the viewing pane individually and saved individually.

TECH TIP

16

Include the date and vehicle information in the filename when saving

the data.

Page 17

Maintenance

Proper maintenance of the BPM system is important for reliable operation. Lack of BPM maintenance may void

DPF warranty. The following service items should be performed:

At every oil change

Empty any water that has collected in the condensation trap. To do this, twist off the metal bowl protec-

tor and remove the bowl. Empty water out of the bowl and reinstall.

Inspect the clear tube that goes from the condensation trap to the BPM. There should be no visible

soot. If there is soot, see troubleshooting guide for further instruction.

Inspect the pressure line going from the DPF to the condensation trap. Make sure that this line is clear.

To clean the line, remove line at the condensation trap and use compressed air to blow out the line.

Serve items as defined by the appropriate Purifilter or Purifilter Plus product manual.

At every Filter de-ashing

All the service items outlined to be performed at every oil change above

Service items as defined by appropriate Purifilter or Purifilter Plus manual

Engine-Out Opacity should be measured. If opacity indicates engine maintenance is required, this

maintenance should be performed prior to re-installation of the filter.

:

:

Download histogram data and parameter data from the BPM and save it. Refer to page 16 for

downloading and saving instructions.

17

Page 18

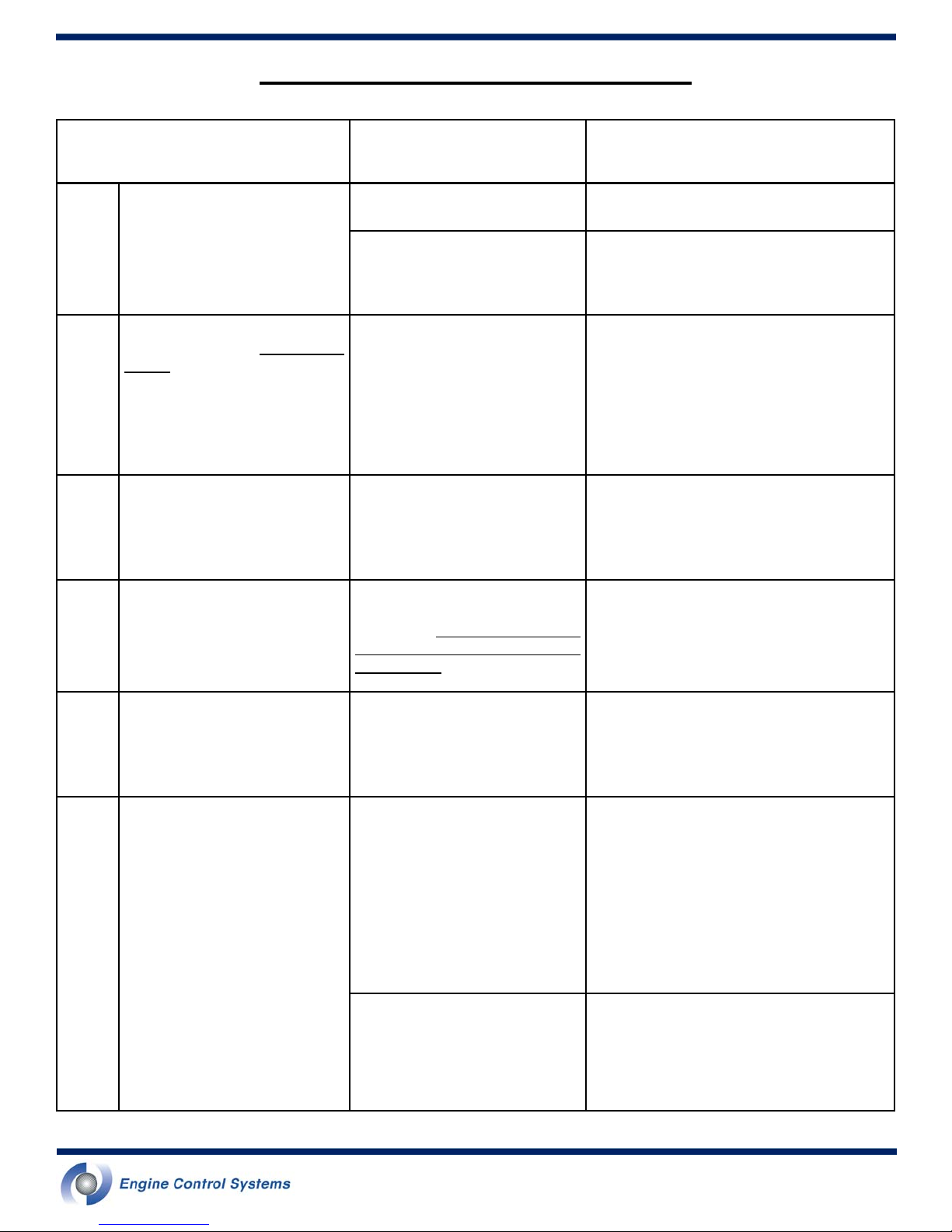

BPM Troubleshooting Guide

Note: Refer to Purifilter or Purifilter Plus Product Manuals for Additional Troubleshooting information

Event Probable Cause(s) Action

1 Yellow light illuminates continu-

ously for periods longer than 45

seconds in duration

2 Red light illuminates continu-

ously for periods longer than 45

seconds in duration OR red

light stays illuminated at all

times.

Engine exhaust backpressure is

increasing and the DPF should be

scheduled for service within the

next 72 hours.

Engine exhaust backpressure is at

a level where the DPF should be

cleaned within the next 24 hours.

Purifilter systems - download BPM histogram

and parameter files and confirm reported

Yellow Alarm

Confirm duty cycle is acceptable for pas-

sive regeneration.

Remove DPF and clean

Perform all service items defined in the

Maintenance section under this service

Purifilter Plus systems - perform on-board

regeneration.

Purifilter systems - download BPM histogram

and parameter files and confirm reported

Red Alarm

Confirm duty cycle is acceptable for pas-

sive regeneration

Remove DPF and clean

3 Pink system error light flashes

continuously

Backpressure Sensor problem

* The logged parameter data and

user interface will show “-3276.8” in

the pressure column when there is

an abnormal pressure condition.

Thermocouple connection problem

* The logged parameter data will

show “SAT” in the temperature

column and user interface when

the thermocouple is disconnected

High backpressure Error. Backpressure greater than 500 mbar.

This will latch the system error

light.

Perform all service items defined in the

Maintenance section under this service

If red light remains illuminated, contact

your ECS distributor to reset the red light

Purifilter Plus systems - perform on-board

regeneration.

Refer to Purifilter Plus manual if problem is

apparent.

Check the backpressure sensor line for any

breaks or leaks . Check the tubing between the

water trap and exhaust pipe for any blockage

and clear with compressed air blowing toward

the exhaust pipe. Service the condensation

trap and condensation trap filter.

Check thermocouple connections. Check

thermocouple sensor. Make sure the thermocouple polarity is correct. Refer to installation

instructions.

Follow the actions required in item 2 above.

Contact your ECS distributor to reset the

system error light.

4 All lights on the remote driver

display are on continuously

18

Internal problem with the BPM Contact your ECS distributor.

Power supply voltage has been

out of the normal operating range.

The BPM will operate with a supply voltage between 9V and 30V.

Disconnect power to the BPM for 20 seconds

and then reconnect power. This can be done

by removing the fuse or the power connector, whichever is more convenient.

Page 19

BPM Troubleshooting Guide (cont’d)

Event Probable Cause(s) Action

5

DPF requires more frequent

cleanings than usual

6 System Error Light flashes in

combination with Red and/or

Yellow alarm illumination when

vehicle is driven or at idle.

7

System Error Light flashes

shortly after engine shut down

8 When the engine is warming

up, the thermocouple temperature decreases.

Filter is not completely clean Clean filter again with reference to the ap-

plicable ECS product manual.

Engine requires servicing Measure the opacity of the engine out ex-

haust. If it is out of the manufacturers

specification, service engine immediately.

Severe system backpressure

due to engine malfunction or

failure to service filter.

Remove, inspect and clean the DPF on

appropriate cleaning machine. Perform

engine inspection and correct faults found.

Confirm engine opacity prior to reinstallation of cleaned filter. Service BPM

Logger condensation trap and clean sensor line. Contact your ECS distributor to

rest lights.

Engine shut down while excessively hot

The yellow and red wires are

crossed in the thermocouple

connector. This only applies to

the old (yellow) Omega thermo-

Start engine and operate. After two minutes

the System Error light should turn off. If this

error persists, contact your ECS distributor.

Check the connector and ensure that the

YELLOW is connected to the positive terminal and the RED is connected to the

negative terminal.

couple style.

9 Soot in the clear tube between

the condensation trap and the

BPM

10

Remote driver display shows no

lights

High backpressure occurred at

some point.

Download data from the BPM and check

for signs of high backpressure. Service

condensation trap. Clean DPF or regenerate as required.

No power getting to the remote

driver display

Check that power is getting to the Remote

Driver Display. Locate the “Remote” connection at the BPM. Pull out the connector

and check that 5 volts is available at the

center pin. If there is power, the Remote

Driver Display is faulty. If there is no

power, the remote driver display is not getting power from the BPM. See next item for

troubleshooting.

No power getting to the BPM. Inspect BPM fuse and connectors first. If

no troubles found, disconnect the power

connector at the BPM and check for power

from the battery. If there is vehicle battery

voltage, then the BPM could be faulty.

19

Page 20

Engine Control Systems Limited

World Headquarters

83 Commerce Valley Drive East

Thornhill, ON, L3T 7T3

Phone: 905-707-7746

Toll Free: 1-800-661-9963

Fax: 905-707-7686

Engine Control Systems Ltd.

North America—Western

4910 Longley Lane, Suite 103

Reno, Nevada, 89502

Phone: 1-775-827-3400

Fax: 1-775-827-1670

Engine Control Systems Europe AB

European Headquarters

Box 9015, Agnesfridsvagen, 184

SE-200 39 Malmo, Sweden

Phone: 46 (40) 670 1550

Fax: 46 (40) 210 335

Website: www.enginecontrolsystems.com

Email: ecs@enginecontrolsystems.com

Contact Information

20

Loading...

Loading...