Page 1

CC300 Operator Panel

» User Guide «

User Guide (Preliminary Version 0.2)

P/N: XXXX-XXXX

Page 2

Page 3

1. Table of Contents CC300 Operator Panel – User Guide

1. Table of Contents

1. Table of Contents ............................................................................................................................... 3

1.1. Table of Figures ........................................................................................................................................... 5

2. Introduction ....................................................................................................................................... 6

2.1. Symbols used in this User Guide ................................................................................................................. 7

3. Important Instructions ........................................................................................................................ 8

3.1. Note on the Warranty ................................................................................................................................. 8

3.2. Exclusion of Accident Liability Obligation ................................................................................................... 8

3.3. Liability Limitation / Exemption from the Warranty Obligation ................................................................ 8

4. General Safety Instructions for IT Equipment ...................................................................................... 9

4.1. Electrostatic Discharge (ESD) .................................................................................................................... 11

4.1.1. Grounding Methods ........................................................................................................................... 11

4.2. Instructions for the Lithium Battery ......................................................................................................... 12

5. Electromagnetic Compatibility .......................................................................................................... 13

5.1. Electromagnetic Compatibility (EU) ......................................................................................................... 13

5.2. FCC Statement (USA) ................................................................................................................................ 13

5.3. Nameplate of the CC300 Operator Panel ................................................................................................. 14

6. Scope of Delivery and optional Parts ................................................................................................. 15

7. Product Description .......................................................................................................................... 16

7.1. Front Side View ......................................................................................................................................... 19

7.1.1. On/Off Button .................................................................................................................................... 20

7.1.2. ............................................................................................................................................................ 20

7.1.3. RFID Read/Write Zone ....................................................................................................................... 20

7.1.4. Emergency Stop Switch ..................................................................................................................... 21

7.1.5. Buttons for Tilting the CC300 Operator Panel ................................................................................... 21

7.1.6. Touch Display ..................................................................................................................................... 22

7.1.7. Touch Display Care and Cleaning ....................................................................................................... 22

7.1.8. Traversing Buttons ............................................................................................................................. 23

7.1.9. Markings for the USB Ports ............................................................................................................... 23

7.1.10. Permissive Button and Program Interrupt Button .......................................................................... 23

7.1.11. Rotary/Push Button with Display .................................................................................................... 24

7.2. Rear View .................................................................................................................................................. 25

7.2.1. Harting Connector ............................................................................................................................. 26

7.2.2. Connection Cables for the Linear Actuator ....................................................................................... 26

7.2.3. Grounding Cable (PE) ......................................................................................................................... 27

7.2.4. LAN Cable ........................................................................................................................................... 27

Preliminary Version 0.2 3

Page 4

1. Table of Contents CC300 Operator Panel – User Guide

7.3. Left and Right Side View ............................................................................................................................ 28

7.3.1. USB Ports ............................................................................................................................................ 29

7.4. Top and Bottom View ................................................................................................................................ 30

7.5. Accessing internal Components ................................................................................................................ 31

7.5.1. Opening the CC300 Operator Panel ................................................................................................... 31

7.5.2. Closing the CC300 Operator Panel ..................................................................................................... 34

8. Maintenance and Prevention ........................................................................................................... 35

8.1. Replacing the Lithium Battery ................................................................................................................... 35

8.2. Replacing the Emergency Stop Switch ...................................................................................................... 36

8.3. Replacing the Rotary/Push Button ............................................................................................................ 36

8.4. Replacing the mSATA Module ................................................................................................................... 36

8.5. Replacing the Cable Gland ......................................................................................................................... 36

8.6. Firmware Updates ..................................................................................................................................... 37

8.6.1. System BIOS Update Procedure ......................................................................................................... 37

8.6.2. Firmware Update of the IO Board ...................................................................................................... 37

8.6.3. Firmware Update of the Rotary/Push Button .................................................................................... 37

8.6.4. Firmware Update of the RFID Module ............................................................................................... 37

8.6.5. Firmware Update of the capacitive Touch ......................................................................................... 37

9. Technical Data ................................................................................................................................. 38

9.1. External Connectors and Interfaces .......................................................................................................... 39

9.2. Electrical Specifications ............................................................................................................................. 40

9.3. Environmental Specifications .................................................................................................................... 41

9.4. Mechanical Specifications ......................................................................................................................... 41

9.5. International Compliance, Approvals and Certificates ............................................................................. 44

10. Interfaces – Pin Assignments .......................................................................................................... 45

10.1.1. Harting Connector ............................................................................................................................ 45

10.1.2. LAN 0 cable ....................................................................................................................................... 46

10.1.3. LAN 1-Kabel ...................................................................................................................................... 46

10.1.4. RS485 Cable ...................................................................................................................................... 47

10.1.5. Power Cable for Expansion Panel .................................................................................................... 47

10.1.6. DP Connector (Standard: DisplayPort 1.2) ....................................................................................... 48

10.1.7. USB Ports .......................................................................................................................................... 49

10.1.8. Grounding Cable (PE) ....................................................................................................................... 49

4 Preliminary Version 0.2

Page 5

1. Table of Contents CC300 Operator Panel – User Guide

1.1. Table of Figures

Fig. 1: CC300 Operator Panel - Nameplate ..................................................................................................... 14

Fig. 2: Bottom view ......................................................................................................................................... 18

Fig. 3: Right view ............................................................................................................................................. 18

Fig. 4: Front view ............................................................................................................................................. 18

Fig. 5: Rear view .............................................................................................................................................. 18

Fig. 6: Left view ............................................................................................................................................... 18

Fig. 7: Top view ............................................................................................................................................... 18

Fig. 8: Front view of the CC300 operator panel ............................................................................................. 19

Fig. 9: On/Off button....................................................................................................................................... 20

Fig. 10: RFID-read/write zone ......................................................................................................................... 20

Fig. 11: Emergency stop switch ...................................................................................................................... 21

Fig. 12: Buttons for tilting out and in the CC300 operator panel ................................................................... 21

Fig. 13: Traversing buttons below the touch display ...................................................................................... 23

Fig. 14: Markings for laterally mounted USB 2.0 ports .................................................................................. 23

Fig. 15: Permissive button and program interrupt button ............................................................................. 23

Fig. 16: Rotary/push button with illumination and display ............................................................................ 24

Fig. 17: Rear side of the CC300 operator panel .............................................................................................. 25

Fig. 18: Harting connector .............................................................................................................................. 26

Fig. 19: Grounding cable ................................................................................................................................. 27

Fig. 20: LAN cables .......................................................................................................................................... 27

Fig. 21: Right side of the CC300 operator panel ............................................................................................. 28

Fig. 22: Left side of the CC300 operator panel ............................................................................................... 28

Fig. 23: USB ports ............................................................................................................................................ 29

Fig. 24: Top view of the CC300 operator panel .............................................................................................. 30

Fig. 25: Bottom view of the CC300 operator panel ........................................................................................ 30

Fig. 26: Carefully open the CC300 a few inches.............................................................................................. 32

Fig. 27: Unlocking and removing the auxiliary switch block ........................................................................... 32

Fig. 28: CC300 operator panel, fully opened .................................................................................................. 33

Fig. 29: Removong the lithium battery from the battery holder ................................................................... 35

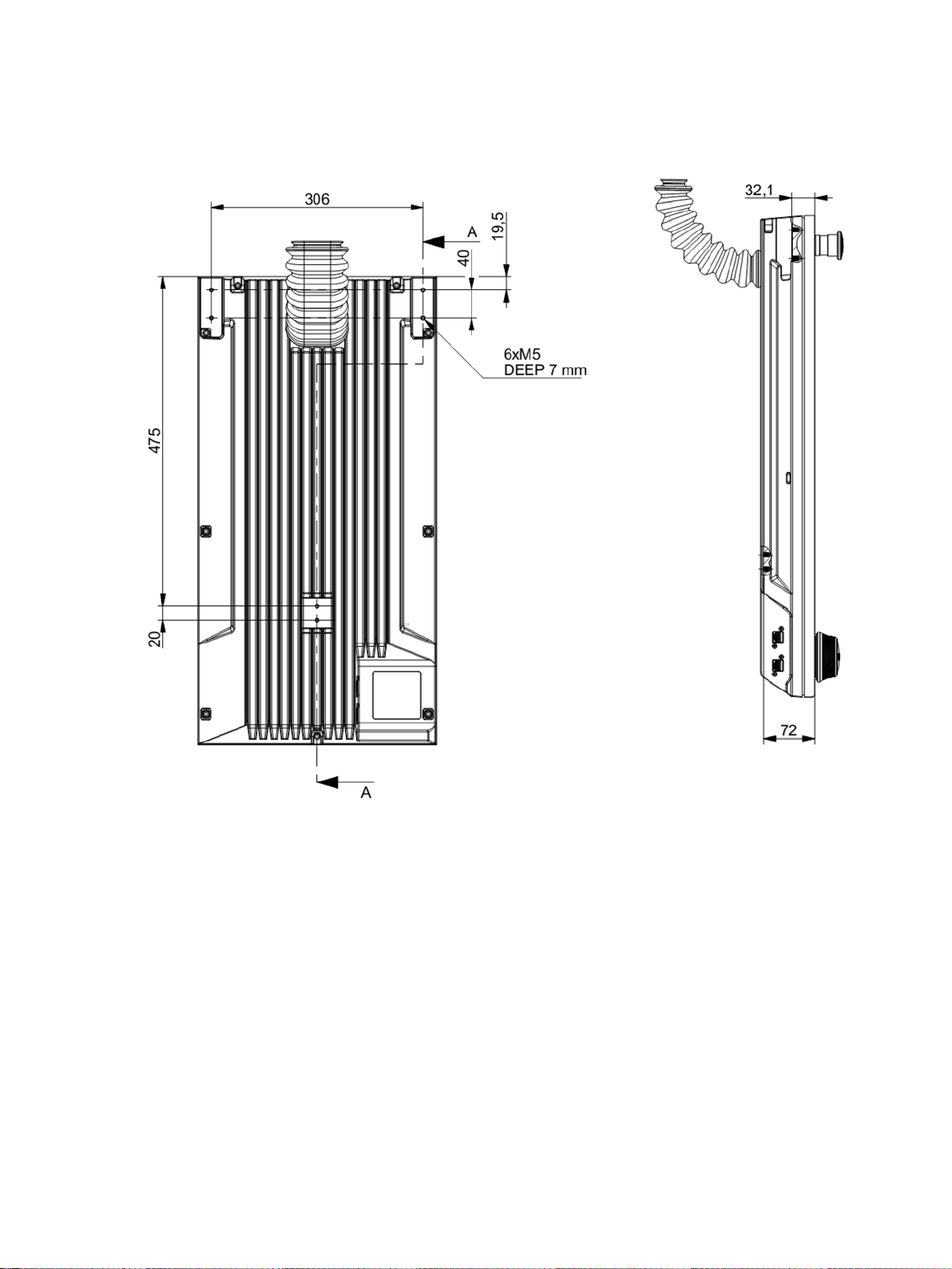

Fig. 30: Dimensioned view of the CC300 glass front (print side - reversed image) ....................................... 42

Fig. 31: Dimensioned rear and side view of the CC300 operator panel ......................................................... 43

Preliminary Version 0.2 5

Page 6

2. Introduction CC300 Operator Panel – User Guide

2. Introduction

Kontron Europe GmbH would like to point out that the information contained in this manual may be

subject to technical alteration, particularly as a result of the constant upgrading of Kontron Europe GmbH

products. The attached documentation does not entail any guarantee on the part of Kontron Europe

GmbH with respect to technical processes described in the manual or any product characteristics set out in

the manual. Kontron Europe GmbH does not accept any liability for any printing errors or other

inaccuracies in the manual unless it can be proven that Kontron Europe GmbH is aware of such errors or

inaccuracies or that Kontron Europe GmbH is unaware of these as a result of gross negligence and Kontron

Europe GmbH has failed to eliminate these errors or inaccuracies for this reason. Kontron Europe GmbH

expressly informs the user that this manual only contains a general description of technical processes and

instructions which may not be applicable in every individual case. In cases of doubt, please contact

Kontron Europe.

This manual is protected by copyright. All rights are reserved by Kontron Europe. Copies of all or part of

this manual or translations into a different language may only be made with the prior written consent of

Kontron Europe GmbH. Kontron Europe GmbH points out that the information contained in this manual is

constantly being updated in line with the technical alterations and improvements made by Kontron Europe

GmbH to the products and thus this manual only reflects the technical status of the products by Kontron

Europe GmbH at the time of printing.

© 2013 by Kontron Europe GmbH

Printing and duplication, even of sections, is only permissible with the express approval of

Kontron Europe GmbH

Sudetenstr. 7

87600 Kaufbeuren

Germany

6 Preliminary Version 0.2

Page 7

2. Introduction CC300 Operator Panel – User Guide

2.1. Symbols used in this User Guide

Symbol Meaning

This symbol indicates the danger of injury to the user or the risk of damage to the product

if the corresponding warning notices are not observed.

This symbol indicates that the product or parts thereof may be damaged if the

corresponding warning notices are not observed.

This symbol indicates general information about the product and the user guide.

This symbol indicates detail information about the specific product configuration.

This symbol precedes helpful hints and tips for daily use.

Preliminary Version 0.2 7

Page 8

3. Important Instructions CC300 Operator Panel – User Guide

3. Important Instructions

This chapter contains instructions which must be observed when using the CC300 Operator Panel. The

manufacturer’s instructions provide useful information on your device.

3.1. Note on the Warranty

Due to their limited service life, parts which by their nature are subject to a particularly high degree of

wear (wearing parts) are excluded from the warranty beyond that provided by law. This applies to

batteries, for example.

3.2. Exclusion of Accident Liability Obligation

Kontron Europe GmbH shall be exempted from the statutory accident liability obligation if the user fails to

observe the included document: “General Safety Instructions for IT Equipment” the hints in this manual or

eventually the warning signs label on the device.

3.3. Liability Limitation / Exemption from the Warranty Obligation

In the event of damage to the device caused by failure to observe the included document “General Safety

Instructions for IT Equipment”, the hints in this manual or eventually the warning signs label on the device,

Kontron Europe GmbH shall not be required to honor the warranty even during the warranty period and

shall be exempted from the statutory accident liability obligation.

8 Preliminary Version 0.2

Page 9

4. General Safety Instructions for IT Equipment CC300 Operator Panel – User Guide

4. General Safety Instructions for IT Equipment

Please read this section carefully and observe the instructions for your own safety and correct use of the

device.

Observe the warnings and instructions on the device and in the manual.

The CC300 Operator Panel has been built and tested by Kontron Europe in accordance to

IEC/EN/UL/CSA 60950-1 (EN60950/VDE0805) and left the company in a perfectly safe condition.

In order to maintain this condition and ensure safe operation, the user must observe the instructions and

warnings contained in this manual.

This product shall be supplied by 60950-1 LPS or NEC Class 2 power supply.

The device must be used in accordance with the instructions for use.

The electrical installations in the room must correspond to the requirements of the local (country-

specific) regulations.

For DC power connection:

The DC power source should be able to be switched off and on via an isolating switch.

The unit is only completely disconnected from the DC main power source, when the DC power cord is

disconnected either from the power source or the unit. Therefore, the DC power cord and its

connectors must always remain easily accessible.

Do not place the device in direct sunlight, near heat sources or in a damp place. Make sure the device

has adequate ventilation.

Only devices and components which fulfill the requirements of an SELV circuit (safety extra low voltage)

in accordance with EN60950 may be connected to the interfaces of the system.

The device is designed to be used in vertical (diagonal) position.

The device generates heat during operation. Make sure it is adequately ventilated. Do not cover the

cooling fins on the rear side of the device.

Maintenance or repair on the open device may only be carried out by qualified personnel authorized by

Kontron Europe GmbH which is aware of with the associated dangers.

The device may only be opened in accordance with the description in this user guide for replacing the

Lithium battery. The device must be switched off and disconnected from the power source.

Only approved original accessories (optional parts) approved by Kontron Europe GmbH may be used.

The DC-input must fulfill SELV requirements of EN60950-1 standard.

The chassis of the CC300 Operator Panel must be protective earthed by establishing a large-area

contact between the grounding cable and an appropriate grounding connection point.

Preliminary Version 0.2 9

Page 10

4. General Safety Instructions for IT Equipment CC300 Operator Panel – User Guide

It must be assumed that safe operation is no longer possible,

• if the device has visible damage or

• if the device no longer functions.

In these cases the device must be shut down and secured against unintentional operation.

10 Preliminary Version 0.2

Page 11

4. General Safety Instructions for IT Equipment CC300 Operator Panel – User Guide

4.1. Electrostatic Discharge (ESD)

A sudden discharge of electrostatic electricity can destroy static-sensitive devices or micro-circuitry.

Therefore proper packaging and grounding techniques are necessary precautions to prevent damage.

Always take the following precautions:

1. Transport boards in ESD-safe containers such as boxes or bags.

2. Keep electrostatic sensitive parts in their containers until they arrive at the ESD-safe workplace.

3. Always be properly grounded when touching a sensitive board, component, or assembly.

4. Store electrostatic-sensitive boards in protective packaging or on antistatic mats.

4.1.1. Grounding Methods

The following measures help to avoid electrostatic damages to the device:

1. Cover workstations with approved antistatic material. Always wear a wrist strap connected to

workplace as well as properly grounded tools and equipment.

2. Use antistatic mats, heel straps, or air ionizers for more protection.

3. Always handle electrostatic sensitive components by their edge or by their casing.

4. Avoid contact with pins, leads, or circuitry.

5. Turn off power and input signals before inserting and removing connectors or connecting test

equipment.

6. Keep work area free of non-conductive materials such as ordinary plastic assembly aids and styrofoam.

7. Use field service tools such as cutters, screwdrivers, and vacuum cleaners which are conductive.

8. Always place drives and boards PCB-assembly-side down on the foam.

Preliminary Version 0.2 11

Page 12

4. General Safety Instructions for IT Equipment CC300 Operator Panel – User Guide

4.2. Instructions for the Lithium Battery

The installed mainboard is equipped with a lithium battery.

For the replacing of this battery please observe the instructions described in the “Replacing the Lithium

Battery” chapter.

Warning

Danger of explosion when replacing with wrong type of battery. Replace only with the

same or equivalent type recommended by the manufacturer. The lithium battery type

must be UL listed.

Do not dispose of lithium batteries in general trash collection. Dispose of the battery

according to the local regulations dealing with the disposal of these special materials,

(e.g. to the collecting points for dispose of batteries).

12 Preliminary Version 0.2

Page 13

5. Electromagnetic Compatibility CC300 Operator Panel – User Guide

5. Electromagnetic Compatibility

5.1. Electromagnetic Compatibility (EU)

This product is intended only for use in industrial areas. The most recent version of the EMC guidelines

(EMC Directive 2004/108/EC) and/or the German EMC laws apply. If the user modifies and/or adds to the

equipment (e.g. installation of expansion cards) the prerequisites for the CE conformity declaration (safety

requirements) may no longer apply.

Warning!

This is a class A product. In domestic environment this product may cause radio interference in which

case the user may be required to take adequate measures.

5.2. FCC Statement (USA)

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in residential area is likely to cause harmful interference in which case the user will be required

to correct the interference at his own expense.

This device complies with Part 15 of the FCC Rules and with Industry Canada license-exempt RSS

standard(s). Operation is subject to the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received, including interference that may

cause undesired operation.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de

licence. L'exploitation est autorisée aux deux conditions suivantes : (1) l'appareil ne doit pas produire de

brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d'en compromettre le fonctionnement.

Changes or modifications not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

(English): This Class A digital apparatus complies with the Canadian ICES-003.

(French): Cet appareil numérique de la class A est conforme à la norme NMB-003 du Canada.

Preliminary Version 0.2 13

Page 14

5. Electromagnetic Compatibility CC300 Operator Panel – User Guide

5.3. Nameplate of the CC300 Operator Panel

The nameplate is located at the bottom rear side of the cabinet (see also Fig. 17, Pos. 8)

Fig. 1: CC300 Operator Panel - Nameplate

14 Preliminary Version 0.2

Page 15

6. Scope of Delivery and optional Parts CC300 Operator Panel – User Guide

6. Scope of Delivery and optional Parts

Scope of Delivery: CC300 Operator Panel

Optional Parts: DP cable

Blind panel

Add-on panel

Expansion panel

Expansion panel 2F

Preliminary Version 0.2 15

Page 16

The CC300 operator panel will not meet any safety functions!

7. Product Description CC300 Operator Panel – User Guide

7. Product Description

The CC300 operator panel is a Human Machine Interface (HMI) system designed for demanding industrial

applications. As a workstation system with integrated touch screen display it is designed for installation in

an instrument panel or other cabinets. For better handling and readability the operator panel can be tilt

continuously out of its vertical position up to a maximum tilt angle of 45 degrees by a linear actuator

(outwards, with the lower edge ahead).

Das CC300 operator panel consists of two main parts, the front plate and the rear cover.

The front of the CC300 operator panel is designed in glass; between the glass and the 21.5"display a PCAP

touch (capacitive touch with multi-touch capability) is laminated on the glass. In addition, the glass front

supports an emergency stop switch, an RFID antenna, capacitive buttons with LED backlight and a

rotary/push button with LED backlight.

The rear cover consists of die cast aluminum and serves the following functions: Heat sink of the system,

chassis for assembling of electronic modules, holder of the linear actuator (of the external tilting

mechanism) and cable gland for all outgoing cables.

The CC300 operator panel accommodates an INTEL processor architecture board that will host the “LINUX

64 Bit” operating system. All components, hardware and hardware drivers are designed to support 100%

the “ENGEL LINUX x86 64 Bit” operating system. An mSATA drive is installed as storage device. Optionally,

the CC300 operator panel can be equipped with a 2.5" SSD or HDD drive.

The CC300 operator panel has two externally accessible USB 2.0 ports located at the left side of the

chassis. The position of the USB ports is marked on the front plate with backlit symbols.

The CC300 operator panel provides two external LAN ports. Thus, it can be connected simultaneously e.g.

to the corporate LAN and to a stored program control (SPC).

Via the RFID read/write zone at the glass front of the CC300 operator panel e.g. smart cards can be read or

written contactless.

The CC300 operator panel is designed for 24V DC operation.

Monitoring of all safety-related components (emergency stop, protective covers etc.) will

be performed by particular safety modules of the terminal equipment.

16 Preliminary Version 0.2

Page 17

The CC300 operator panel complies with IP54 protection class.

When powering on the CC300 operator panel, make sure that the cooling fins are not

7. Product Description CC300 Operator Panel – User Guide

The CC300 operator panel is a fanless system. The cooling of the unit is performed by the surface and the

cooling fins of the aluminum cover on the rear side of the chassis.

The CC300 operator panel can be extended with an add-on panel and one or several expansion panels. The

add-on/expansion panels will be connected to the CC300 operator panel via an RS485 cable.

obstructed.

Preliminary Version 0.2 17

Page 18

Fig. 2: Bottom view

Fig. 3: Right view

Fig. 4: Front view

Fig. 5: Rear view

Fig. 6: Left view

Fig. 7: Top view

7. Product Description CC300 Operator Panel – User Guide

Views of the CC300 operator panel (Fig. 2 to Fig. 7) with cable gland, without tilting mechanism.

18 Preliminary Version 0.2

Page 19

1 On/Off button

7 Program interrupt button

1

11 3 5

6 7 8

9 4 2

10

7. Product Description CC300 Operator Panel – User Guide

7.1. Front Side View

Legend for Fig. 8:

2 RFID read/write zone

3 21.5" TFT display with multi-touch

4 Traversing buttons

5 Markings for the two USB 2.0 ports

(laterally mounted)

6 Permissive button

Fig. 8: Front view of the CC300 operator panel

8 Rotary/push button (backlit)

9 Display of the rotary/push button

10 Emergency stop switch

11 Buttons for tilting out and in the

operator panel (up to 45 degrees

max.)

Preliminary Version 0.2 19

Page 20

On/Off button

RFID read/write zone

7. Product Description CC300 Operator Panel – User Guide

7.1.1. On/Off Button

Fig. 9: On/Off button

The On/Off button allows to boot up/shut down the system. It is a capacitive button with white LED

backlight, located top left on the front plate (see also Fig. 8, Pos. 1). The button responds to light touch of

a finger or but for safety reasons it has to be pressed for 10 seconds (e.g. to initiate a shutdown of the

system).

Even when the system is turned off via the On/Off button there is still a standby-voltage

on the mainboard. The system is not completely disconnected from the main power

supply (DC) by switching off via the On/Off button.

The unit is only completely disconnected from the DC main power supply, when the DC

power is cut off by an isolating switch or when the power cord is disconnected either

from the DC main power or the unit. Therefore, the DC power cord and its connectors

must always remain easily accessible.

To avoid the risk of data loss, always shut down the system before you cut off the

power using an isolating switch!

7.1.2.

7.1.3. RFID Read/Write Zone

Fig. 10: RFID-read/write zone

On the right side of the On/Off button the RFID read/write zone is located (see also Fig. 8, Pos. 2). At this

position the RFID antenna is mounted to the rear side of the front glass. RFID-equipped objects (e.g. ID

cards, smart cards, RFID labels) can be read or written by the CC300 operator panel, when held against the

front glass within the read/write zone. The RFID data will be processed by the installed software (e.g. user

login with different authorizations for different user accounts).

20 Preliminary Version 0.2

Page 21

Tilt out button

Tilt in button

7. Product Description CC300 Operator Panel – User Guide

7.1.4. Emergency Stop Switch

Fig. 11: Emergency stop switch

The emergency stop switch is located centered above the display on the glass front (see also Fig. 8, Pos.

10). Machines and processes connected to the contacts of the emergency stop switch (and, where

required, also monitored by the CC300 operator panel) can be halted immediately according to EN ISO

13850. For this, the emergency stop button has to be pressed firmly. The switch locks in place and can only

be released by turning the knob clockwise.

The emergency stop switch has four (optional: six) switching contacts that cut off the connected 24 V

circuits when being pressed.

The emergency stop switch is installed in the CC300 operator panel for the purpose of easy

and quick accessibility but it has an entirely independent function.

When the emergency stop switch is pressed, the CC300 operator panel will not be halted or

switched off.

7.1.5. Buttons for Tilting the CC300 Operator Panel

Fig. 12: Buttons for tilting out and in the CC300 operator panel

For better handling and readability the operator panel can be tilt continuously out of its vertical position

up to a maximum tilt angle of 45 degrees by a linear actuator.

By pressing the “Tilt out” button, the CC300 operator panel tilts outwards (with the lower edge ahead)

until the button is released. When the maximum tilt angle of 45 degrees is reached, the tilt-out process

will also be stopped.

Preliminary Version 0.2 21

Page 22

7. Product Description CC300 Operator Panel – User Guide

By pressing the “Tilt in” button, the CC300 operator panel tilts back (with the lower edge ahead) in the

direction of the vertical mounting position until the button is released. When the vertical mounting

position is reached, the tilt-in process will also be stopped.

The “Tilt out” and “Tilt in” buttons, as well as their symbols, are backlit white. During being pressed, the

particular button and the corresponding symbol are backlit blue.

7.1.6. Touch Display

The CC300 operator panel is equipped with a 21.5” TFT display and a capacitive touch (PCAP) with multitouch capability (see also Fig. 8, Pos. 3). The surface of the display and the touch is protected by the front

glass. The touch display responds to the light touch of a finger or glove (the touch display is factorycalibrated for operation with the PU-coated glove types Solidstar 1327 and Camapur Cut 620) and offers

the same degree of user comfort as a computer mouse.

For technical specification of the touch display refer to the chapter 9 “Technical Data”.

7.1.7. Touch Display Care and Cleaning

Use a lint-free cloth with mild detergent (e.g. glass cleaner) and water for cleaning the glass front. Do not

use strong or abrasive detergents or solvents, which could attack plastic parts (e.g. the rotary/push button)

or scratch the front glass.

Do not use a hard or a pointed object (like a screw driver) to operate the touch screen or

the capacitive buttons, since it can scratch or damage the front glass.

The front panel and the touch screen are protected by a continuous glass plate that should

be handled with care and cleaned regularly.

The capacitive touch screen is factory-calibrated and needs no recalibration.

22 Preliminary Version 0.2

Page 23

Permissive button

USB Port

USB Port

Program interrupt button

7. Product Description CC300 Operator Panel – User Guide

7.1.8. Traversing Buttons

Fig. 13: Traversing buttons below the touch display

Directly below the touch display, arranged in pairs, six traversing buttons are located, (see also Fig. 8, Pos.

4), which are processed by the capacitive touch of the display. The function of the buttons may be changed

by the software; the current function will be displayed on the display directly above the corresponding

buttons.

7.1.9. Markings for the USB Ports

Fig. 14: Markings for laterally mounted USB 2.0 ports

At the bottom left of the front plate, an USB symbol and two markings for the positions of the laterally

(behind the front plate) mounted USB 2.0 ports are located (see also Fig. 8, Pos. 5 and Fig. 23). The USB

symbol and the markings are backlit white.

7.1.10. Permissive Button and Program Interrupt Button

Fig. 15: Permissive button and program interrupt button

Below the traverse buttons, on the right of the USB markings, the permissive button (see also Fig. 8,

Pos. 6) and the program interrupt button (see also Fig. 8, Pos. 7) are located.

The capacitive permissive button will be used in certain situations in addition to a traverse button or a

button displayed on the display. In idle mode, the permissive button and its related symbol are backlit

white. The backlight changes to blue when the permissive button is pressed.

Preliminary Version 0.2 23

Page 24

Rotary/push button

Illumination of the rotary/push button

Display of the rotary/push

7. Product Description CC300 Operator Panel – User Guide

By pressing the capacitive program interrupt button (error acknowledgement button), all upcoming error

messages will be acknowledged an a running automatic cycle will be interrupted. In idle mode, the

program interrupt button and its related symbol are backlit white. The backlight changes to orange when

the program interrupt button is pressed.

7.1.11. Rotary/Push Button with Display

Fig. 16: Rotary/push button with illumination and display

At the bottom right of the front plate, below the touch display, the rotary/push button with display is

located (see also Fig. 8, Pos. 8 and Pos. 9). The rotary/push button can be adjusted to the left and to the

right to a maximum of 30 degrees and is self-resetting when released. Furthermore, the rotary/push

button provides a push button function. Around the rotary/push button a white backlit ring is mounted

that can change its color to red, green and orange by software.

The display of the rotary/push button is part of the touch display and visualizes the set values.

24 Preliminary Version 0.2

Page 25

1 Screws that secure the rear cover at the front

7 2x USB 2.0 ports

2

2 1 12 3 1 1 1

1

1

7 9 4 5 6

11

10

8

7. Product Description CC300 Operator Panel – User Guide

7.2. Rear View

Legend for Fig. 17 :

plate

2 Threaded holes for mounting the CC300

3 Aluminum rear cover of the CC300

4 Cooling fins of the aluminum rear cover

5 Harting connector (24-pole)

6 2x LAN cables (Ethernet 10/100/1000; 1x male,

1x female)

Preliminary Version 0.2 25

Fig. 17: Rear side of the CC300 operator panel

8 Nameplate

9 Threaded holes for mounting the linear actuator

10 Connection cables for the linear actuator

11 Grounding cable

12 Cable gland (flexible cable inlet)

Page 26

7. Product Description CC300 Operator Panel – User Guide

Optionally, an additional DP cable (DisplayPort cable) can be connected to the mainboard

and led out through the cable gland. A digital display can be connected to the DP cable.

7.2.1. Harting Connector

Fig. 18: Harting connector

All outgoing cables of the CC300 operator panel are routed through the cable gland at the rear side of the

cabinet (see also Fig. 17, Pos. 12). Except for the cables for the linear actuator and the grounding cable, all

single wires are combined in the 24-pole Harting connector (Fig. 18). For the pin assignment of the Harting

connector, refer to chapter 10.1.1 “Harting Connector”.

7.2.1.1. Power Supply via the Harting Connector

The power supply of the CC300 operator panel will be provided via pin 7 (24 Volts; cable No. 6) and pin 19

(0 Volts; cable No. 5) of the Harting connector.

7.2.1.2. Control and Signal Lines

The power supply of the linear actuator, the interrupt circuits 1 to 4 (optional: 1 to 6) of the emergency

stop switch and other control lines (power transformer switch-off, Dig In 1) are also routed through the

24-pin Harting connector. For the pin assignment of the Harting connector, refer to chapter 10.1.1

“Harting Connector”.

7.2.2. Connection Cables for the Linear Actuator

The two single cables marked “1” and “2” (see Fig. 17, Pos. 10) will be connected to the linear actuator of

the tilting mechanism.

26 Preliminary Version 0.2

Page 27

Grounding cable (yellow/green)

“LAN 0”cable

“LAN 1”cable

7. Product Description CC300 Operator Panel – User Guide

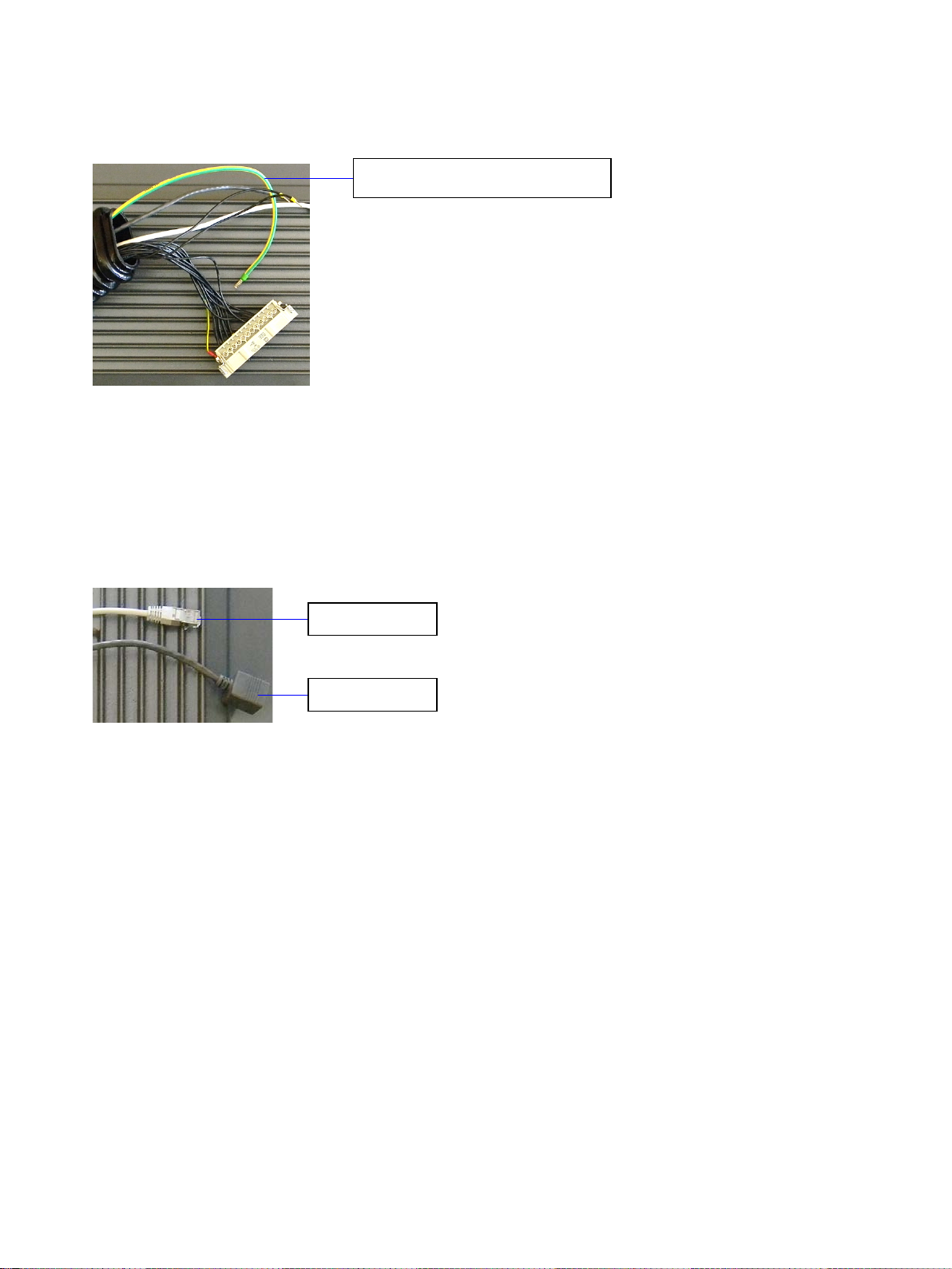

7.2.3. Grounding Cable (PE)

Fig. 19: Grounding cable

The CC300 operator panel must be grounded by establishing a large-area contact between the grounding

cable (see also Fig. 17, Pos. 11) and an appropriate grounding contact. The cross section of the grounding

cable is 6 mm

2

.

7.2.4. LAN Cable

Fig. 20: LAN cables

The „LAN 0“ LAN cable is equipped with a male RJ 45 connector (Ethernet 10/100/100 Base-T) and

provides the connection between the CC300 operator panel and the company network.

The “LAN 1” LAN cable is equipped with a female RJ45 connector (Ethernet 10/100/100 Base-T) and can be

connected e.g. to a stored program control (SPC) for controlling an injection molding machine.

Preliminary Version 0.2 27

Page 28

Fig. 21: Right side of the CC300 operator panel

Fig. 22: Left side of the CC300 operator panel

1 Emergency stop switch

5 Screws that secure the rear cover at the front

1

2 3 4 6 1

2 3 4 5 6

5

7

7. Product Description CC300 Operator Panel – User Guide

7.3. Left and Right Side View

Legend for Fig. 21 and Fig. 22:

2 Front plate of the CC300

3 Aluminum rear cover of the CC300

4 Rotary/push button

28 Preliminary Version 0.2

plate

6 Cable gland

7 Cavity with 2x USB 2.0 ports

Page 29

7. Product Description CC300 Operator Panel – User Guide

7.3.1. USB Ports

Fig. 23: USB ports

In a cavity at the left side of the aluminum cover, two USB 2.0 ports (see also Fig. 22, Pos. 7) are located.

The cavity is deep enough that plugged-in USB sticks will not restrain the tilting mechanism of the CC300

operator panel.

Preliminary Version 0.2 29

Page 30

Fig. 24: Top view of the CC300 operator panel

Fig. 25: Bottom view of the CC300 operator panel

1 Cable gland

5 Emergency stop switch

4

1

5 6 4 3 7

2

1

3

2 6 5 7 8

4

7. Product Description CC300 Operator Panel – User Guide

7.4. Top and Bottom View

Legend for Fig. 23 and Fig.24:

2 Cooling fins of the aluminum rear cover

3 Aluminum rear cover of the CC300

4 Screws that secure the rear cover at the front

plate

6 Rotary/push button

7 Front plate of the CC300

8 2x USB 2.0 Ports

30 Preliminary Version 0.2

Page 31

The screws (M5 x 10) and the bonded seals must be replaced after 3 to 5 times of

7. Product Description CC300 Operator Panel – User Guide

7.5. Accessing internal Components

This section contains important information that you must read before accessing internal components.

Follow these procedures properly when handling any internal components of the system.

The replacement of the lithium battery (optional: the installation and removal of memory

modules, drives or cables) should only be carried out by qualified specialists, in

accordance with the description contained in this manual.

Before removing the cover of the CC300 operator panel in order to gain access to the

internal components, the system must be powered down and the power cord has to be

disconnected from the power source.

It is not allowed to operate the system without installed cover.

Please observe the safety instruction for handling assemblies with static sensitive device.

Disregarding of this warning instruction can result in damage to the device.

7.5.1. Opening the CC300 Operator Panel

To open the CC300 operator panel, perform the following steps:

1. Place the device on a soft underlayment (e.g. a thick PE foam sheet) with the front plate facing down

(see Fig. 26). Make sure that the underlayment is dimensioned so that only the glass plate rests on the

underlayment and the emergency stop switch and the rotary/push button do not rest on the

underlayment or table.

2. Remove the 10x screws (M5 x 10) and the bonded seals that fix the rear cover to the front plate (see

Fig. 17, Pos. 1).

tightening and loosening for continuing compliance with IP54 protection class!

3. Lift the rear cover on the left side (seen from behind, with the emergency stop switch at the top!)

carefully a few inches (see Fig. 26).

Preliminary Version 0.2 31

Page 32

Attention: The device can only be opened fully after the auxiliary switch block (of the

Rear cover

Front plate

Auxiliary

switch block

Soft

underlayment

Unlock the auxiliary

7. Product Description CC300 Operator Panel – User Guide

Fig. 26: Carefully open the CC300 a few inches

emergency stop switch) has been removed!

(It is recommended that the rear cover is held by a second person while the auxiliary

switch block is removed!)

4. Unlock the auxiliary switch block with a screwdriver and pull it out of its mounting (see Fig. 27).

switch block and

remove it

Fig. 27: Unlocking and removing the auxiliary switch block

32 Preliminary Version 0.2

Page 33

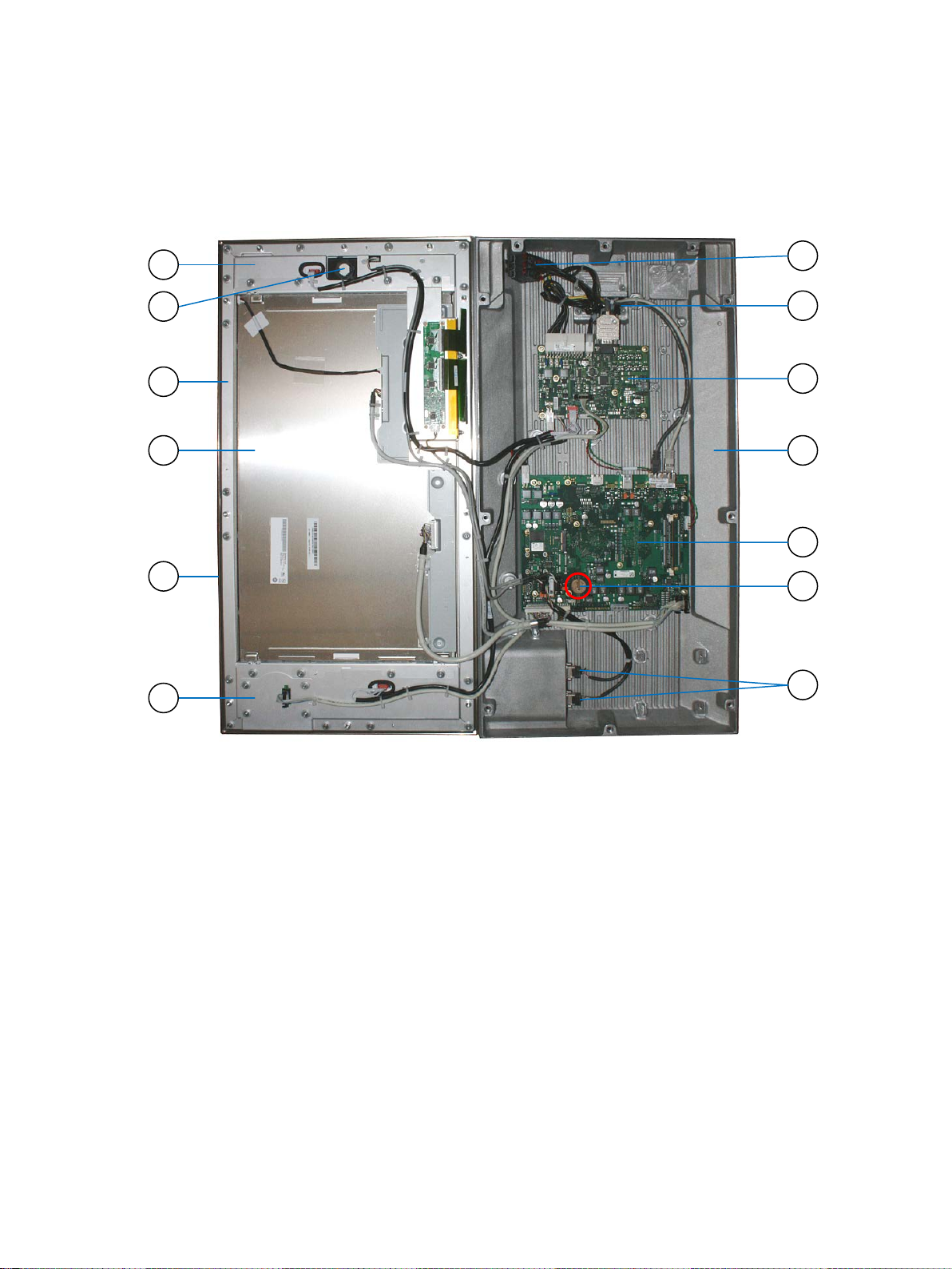

1 Circuit area above the display

8 Position of the lithium battery on the CPU

1

3

6

12

11

9

7 4 13

5 2 10

8

7. Product Description CC300 Operator Panel – User Guide

5. Now the CC300 operator panel can be folded apart carefully.

Legend for Fig. 27:

2 Mounting of the auxiliary switch block

(of the emergency stop switch)

3 Front plate with aluminum frame

4 Display with capacitive touch

5 Surrounding seal

6 Circuit area below the display

7 2x USB ports (externally accessible)

Fig. 28: CC300 operator panel, fully opened

board

9 CPU board (mainboard)

10 Aluminum rear cover

11 I/O board

12 Mounting and opening of the cable gland

13 Auxiliary switch block (detached)

Preliminary Version 0.2 33

Page 34

Do not exceed the maximum torque of x Nm when fastening the cabinet screws!

7. Product Description CC300 Operator Panel – User Guide

7.5.2. Closing the CC300 Operator Panel

Closing the CC300 operator panel will be performed in reverse order:

1. Carefully fold the aluminum rear cover back onto the front plate, but leave the rear cover open a few

inches (see Fig. 26).

It is recommended that the rear cover is held by a second person while the auxiliary switch block is

inserted into its mounting!

2. Press the auxiliary switch block of the emergency stop switch (see Fig. 28, Pos.13) into its mounting so

that it clicks into place (see Fig. 28, Pos.2 and Fig. 27).

3. Carefully close the housing completely. Make sure that no cables are jammed and that the surrounding

seal is in correct position and will not be damaged (see Fig. 28, Pos. 5).

4. Fix the rear cover to the front plate with the 10x screws (M5 x 10) and bonded seals removed in

chapter 7.5.1 “Opening the CC300 Operator Panel”, step 2 (see Fig. 17, Pos. 1).

(Value not yet defined!)

34 Preliminary Version 0.2

Page 35

Holder (socket) of

Open the retaining

Lithium battery

8. Maintenance and Prevention CC300 Operator Panel – User Guide

8. Maintenance and Prevention

Kontron Europe systems require minimal maintenance and care to keep them operating correctly.

Occasionally wipe the system with a soft dry cloth.

You should only remove persistent dirt by use of a soft, slightly damp cloth (use only a mild detergent).

For the touch screen cleaning refer to the chapter 7.1.7. “Touch Display Care and Cleaning”.

8.1. Replacing the Lithium Battery

The mainboard of the CC300 operator panel is equipped with a lithium battery. To replace the lithium

battery, proceed as follows:

1. Open the CC300 operator panel, as described in chapter 7.5.1 “Opening the CC300 Operator Panel”.

2. The lithium CMOS battery is located in a holder on the CPU board (mainboard) of the CC300 operator

panel (see Fig. 28, Pos. 8 and Fig. 29).

3. Open the retaining spring by pushing it to the side with a screwdriver and remove the lithium battery

(see Fig. 29).

spring and remove

the Lithium battery

the Lithium battery

Fig. 29: Removong the lithium battery from the battery holder

4. Insert a new lithium battery into the battery holder.

5. Pay attention to the polarity of the battery (the positive pole marked “+” is connected to the retaining

spring) and make sure that the retaining spring is locked (see Fig. 29).

Preliminary Version 0.2 35

Page 36

8. Maintenance and Prevention CC300 Operator Panel – User Guide

6. The lithium battery must only be replaced with the same type of battery or with a type of battery

recommended by Kontron Europe GmbH. The type of the lithium battery must be UL listed.

7. Close the CC300 operator panel as described in chapter 7.5.2 “Closing the CC300 Operator Panel”.

Do not dispose of lithium batteries in general trash collection. Dispose of the battery

according to the local regulations dealing with the disposal of these special materials, (e.g.

to the collecting points for dispose of batteries).

8.2. Replacing the Emergency Stop Switch

- to be completed -

8.3. Replacing the Rotary/Push Button

-to be completed-

8.4. Replacing the mSATA Module

-to be completed-

8.5. Replacing the Cable Gland

-to be completed-

36 Preliminary Version 0.2

Page 37

8. Maintenance and Prevention CC300 Operator Panel – User Guide

8.6. Firmware Updates

8.6.1. System BIOS Update Procedure

To update the System BIOS the BIOS ROM File and the update tools shall be copied onto a bootable DOS

USB Stick (no EMM386 or himem driver installed).

The USB Stick shall be the first Boot Device and must have following files:

1B754003.bin BIOS Image (current BIOS; this file may change!)

AFUDOS.exe Flash Tool

pr_bios.bat Batch file

To start the update process, run the included batch file.

After BIOS flash update is finished, perform a power cycle to restart the system.

On the next boot the BIOS will enter Setup automatically.

8.6.2. Firmware Update of the IO Board

-to be completed-

8.6.3. Firmware Update of the Rotary/Push Button

-to be completed-

8.6.4. Firmware Update of the RFID Module

-to be completed-

8.6.5. Firmware Update of the capacitive Touch

-to be completed-

Preliminary Version 0.2 37

Page 38

9. Technical Data CC300 Operator Panel – User Guide

9. Technical Data

CC300 Operator Panel Technical Data

System Customer-specific HMI panel PC with glass front

Operating System ENGEL LINUX x86 64bit

Cooling Concept Fanless system

Cabinet Front: glass front with aluminum frame, Rear: die cast aluminum cover

Protection Class IP 54 (entire system)

Power Supply 24 V DC (see also chater 9.2 “Electrical Specifications”)

External Interfaces See chapter 9.1 “External Connectors and Interfaces”

Display TFT LCD Display, 21.5", 1920x1080, 16:9 portrait format, multi-touch,

contrast: 400:1, 16 million colors, brightness: 250 cd minimum, LED

backlight, view angle: 85x85x85x85 minimum

Optionally, an additional external display can be connected via DP cable

Touch Screen Capacitive PCAP multi-touch

RFID EM65 (Euromap Standard RFID ISO15693), 13.56 Mhz, read and write

functionality, implementation for user login

Emergency Stop Switch Four (optional: six) emergency stop circuits (24V break circuits), switch is

self-locking and can only be unlocked by turning the button

Front Glass Clear glass, thermally tempered, thickness: 5mm (+/- 0.2 mm), printed on

the rear side, 5 capacitive buttons integrated in the glass, LED backlight for

buttons and symbols

Buttons in the Glass Front Capacitive buttons (milled in the front glass) with LED backlight, partly with

software-controlled color change when pressed

Rotary/Push Button Can be adjusted to the left/right to a maximum of 30 degrees, self-resetting

when released, push button function, white backlit ring that can change its

color to red, green and orange by software

Mainboard Kontron SBC-754

CPU Intel Celeron 847E

Memory 2GB (1 socket, SO DIMM, DDR3, 1.066 MHz)

Drives 1x mSata, 8GB (optional: 2.5" HDD/SSD via SATA, drive bay available)

LAN 2x Ethernet 10/100/1000

IO Board B750 IO board, reverse voltage protection and short circuit protection

38 Preliminary Version 0.2

Page 39

DP cable

9. Technical Data CC300 Operator Panel – User Guide

9.1. External Connectors and Interfaces

Interface Amount Position Data

Type: 10/100/1000 Mbit

LAN cable

optional

Power cable

2 external

1 external

1 external

Connector: RJ45

Source: CPU board

Type: Display port

Connector: DP (DisplayPort)

Source: CPU board

Type: Power Connector Main

Connector: Harting 24-pin

Source: I/O board

Expansion Panel cable

Expansion Panel cable

Emergency Stop circuits

USB Port

Grounding (PE) cable

1 external

1 external

1 external

2 external

1 external

Type: Control RS485

Connector: DSUB

Source: I/O board

Type: Power

Connector: 4-Pin

Source: I/O board

Type: Control

Connector: 8 wires in Harting connector

Source: Emergency Stop switch

Type: USB 2.0

Connector: USB A

Source: CPU board

Type: PE

Connector: End-sleeve

Source: Chassis internal PEN

Preliminary Version 0.2 39

Page 40

9. Technical Data CC300 Operator Panel – User Guide

9.2. Electrical Specifications

CC300 Operator Panel Electrical Data

Power Supply 24VDC (+/- 20%), 3.5A max.

Component Theoretical Value (Measured Value)

CPU Board B754

(including CPU 847E) 27 W

LCD Panel 23 (16) W

SSD 2x 3 W

I/O-Board 2 W

RFID 1 W

Rotary/push button 2 W

USB external 2x - power 0.5 W

Total dissipated internal 58.5 (51.5) W

USB external 2x 5 W

Linear actuator CAHB 44 (36) W

Total input power

(including all possible loads)

107.5 (92.5) W

40 Preliminary Version 0.2

Page 41

9. Technical Data CC300 Operator Panel – User Guide

9.3. Environmental Specifications

Thermal Management Passive Cooling (CPU and entire system)

Operating Temperature +5 °C to +50 °C (41 °F to 122 °F)

Storage/Transit Temperature -30 °C to +80 °C (-22 °F to 176 °F)

Operating Rel. Humidity 5% to 95%, non-condensing

Storage/Transit Rel. Humidity 5% to 95%, non-condensing

Operating Altitude 0 m to 2000 m (0 ft. to 6560 ft.)

Storage/Transit Altitude 0 m to 10000 m (0 ft. to 32800 ft.)

Operating Shock 15 G, 11 ms duration, half-sine

Storage/Transit Shock 30 G, 11 ms duration, half-sine

Operating Vibration 5 Hz to 150 Hz, 0.5 G

Storage/Transit Vibration 5 Hz to 150 Hz, 1.0 G

Protection Class IP54 (entire system)

9.4. Mechanical Specifications

Dimensions CC300 Operator Panel

Height

Width

Depth

Weight

675 mm (26.57")

346 mm (13.62")

76 mm (2.99")

13 kg (28.66 lbs)

Preliminary Version 0.2 41

Page 42

9. Technical Data CC300 Operator Panel – User Guide

Fig. 30: Dimensioned view of the CC300 glass front (print side - reversed image)

42 Preliminary Version 0.2

Page 43

CC300 – Rear side

CC300 – left Side

9. Technical Data CC300 Operator Panel – User Guide

Fig. 31: Dimensioned rear and side view of the CC300 operator panel

Preliminary Version 0.2 43

Page 44

9. Technical Data CC300 Operator Panel – User Guide

9.5. International Compliance, Approvals and Certificates

CE Directives

Low Voltage Directive (Electrical Safety) 2006/95/EC

EMC Directive 2004/108/EC

RoHS II Directives 2011/65/EU

Electrical Safety Standards

EUROPE EN 60950-1

USA

CB Scheme

EMC Standards

EUROPE

Electromagnetic compatibility - Part 6-4: Generic standards – Emission standard for industrial

environments: EN 61000-6-4

Industrial, scientific and medical (ISM) radio-frequency equipment – Radio disturbance

characteristics - Limits and methods of measurement: EN 55011

Electromagnetic compatibility - Part 6-3: Generic standards – Emission standard for

residential, commercial and light industrial environments:

EN 61000-6-2

Limitation of human exposure to electromagnetic fields from devices operating in the

frequency range 0 Hz to 10 GHz, used in Electronic Article Surveillance (EAS), Radio Frequency

Identification (RFID) and similar Applications: EN 50 364

Electromagnetic compatibility and Radio spectrum Matters (ERM); Electromagnetic

Compatibility (EMC) standard for radio equipment and services: EN 301 489-1 /-3

UL 60950-1

IEC 60950-1

Electromagnetic compatibility and Radio spectrum Matters (ERM) - Short Range Devices (SRD)

- Radio equipment in the frequency range 9 kHz to 25 MHz and inductive loop systems in the

frequency range 9 kHz to 30 MHz: EN 300 330-1 /-2

U.S.A.

Canada

44 Preliminary Version 0.2

FCC 47 CFR Part 15, Class A

FCC Part 15.225

ICES-003 class A

RSS210 A2.6

Page 45

Pin 1

8

Emergency Stop channel 1 - 1

Pin 13

12

Emergency Stop channel 1 - 2

Pin 2

9

Emergency Stop channel 2 - 1

Pin 14

13

Emergency Stop channel 2 - 2

Pin 3

10

Emergency Stop channel 3 - 1

Pin 15

14

Emergency Stop channel 3 - 2

Pin 4

11

Emergency Stop channel 4 - 1

Pin 16

15

Emergency Stop channel 4 - 2

Emergency Stop channel 5 - 1

Emergency Stop channel 5 - 2

Emergency Stop channel 6 - 1

Emergency Stop channel 6 - 2

Pin 7

6

24V panel power supply

Pin 19

5

0V panel power supply

Pin 8

4

24V power transformer (linear actuator)

Pin 20

3

0V power transformer (linear actuator)

Pin 9

7

Power transformer switch-off

Pin 21

16

Dig In 1

Pin 10

free

Pin 22

free

Pin 11

free

Pin 23

free

Pin 12

free

Pin 24

free

Connector grounding (lateral)

10. Interfaces – Pin Assignments CC300 Operator Panel – User Guide

10. Interfaces – Pin Assignments

Low-active signals are indicated by a minus sign.

10.1.1. Harting Connector

24-pole Harting connector (Type Harting HAN 24 E, wire cross section: AWG 18)

Pin

No.

Pin 5

Pin 6

Wire

No.

Signal Name Pin

Wire

(not implemented) Pin 17

(not implemented) Pin 18

Signal Name

No.

(not implemented)

(not implemented)

Preliminary Version 0.2 45

Page 46

(RJ45)

(RJ45)

10. Interfaces – Pin Assignments CC300 Operator Panel – User Guide

10.1.2. LAN 0 cable

Pin Signal Name Standard Modular Plug

1 MDI0+

2 MDI0-

3 MDI1+

4 MDI2+

5 MDI2-

6 MDI1-

7 MDI33+

8 MDI3-

(The LAN cable is connected to the LAN 0 port of the mainboard and led out of the cabinet.)

10.1.3. LAN 1-Kabel

Pin Signal Name Standard Modular Plug/Socket

1 MDI0+

2 MDI0-

3 MDI1+

4 MDI2+

5 MDI2-

6 MDI1-

7 MDI33+

8 MDI3-

(The LAN extension cable is connected to the LAN 1 port of the mainboard and led out of the cabinet.)

46 Preliminary Version 0.2

Page 47

1 5

6 9

10. Interfaces – Pin Assignments CC300 Operator Panel – User Guide

10.1.4. RS485 Cable

This cable is required for connecting an expansion panel.

Pin Signal Name Direction 9-pin D-SUB Connector (female)

1 IDENT#

2 RxD+ (Receive Data)

3 TxD+ (Transmit Data++)

4 NUM_IDENT#

5 GND (Signal Ground)

6 TERM#

7 RXD- (Receive Data)

8 TXD- (Transmit Data)

9 n.c.

Out-

In

Out

In-

Power

In

In

Out

-

(The RS485 extension cable is connected to the RS485 port on the mainboard and led out of the cabinet.)

10.1.5. Power Cable for Expansion Panel

This cable is required for connecting an expansion panel.

Pin Signal Name 4-pin, 2.54mm, Mini-Fit Connector

(with Latch and Polarization, Cross Section: AWG17)

1 +24V

2 GND

3 +24V

4 GND

(The power cable is connected to the IO board and led out of the cabinet.)

Preliminary Version 0.2 47

Page 48

10. Interfaces – Pin Assignments CC300 Operator Panel – User Guide

10.1.6. DP Connector (Standard: DisplayPort 1.2)

Pin Signal Name 20-pin DP Connector

1 ML LANE 0+

2 GND (ML LANE 0)

3 ML LANE 0-

4 ML LANE 1+

5 GND (ML LANE 1)

6 ML LANE 1-

7 ML LANE 2+

8 GND (ML LANE 2)

9 ML LANE 2-

10 ML LANE 3+

11 GND (ML LANE 3)

12 ML LANE 3-

13 AUX_SEL#

14 Pull-down to GND

15 AUX CH+

16 GND (AUX CH)

17 AUX CH-

18 Hotplug

19 GND (GND_DDC)

20 +3.3V (DDC EEPROM power)

750mA fused

(The DisplayPort is located on the mainboard and can be optionally led out of the cabinet via DP cable or

DP extension cable.)

48 Preliminary Version 0.2

Page 49

10. Interfaces – Pin Assignments CC300 Operator Panel – User Guide

10.1.7. USB Ports

Pin Signal Name 4-pin USB Connector

Type A Version 2.0

1 +5V USB-A output (500mA max.)

2 USB-A Data -

3 USB-A Data +

4 Ground

The two externally accessible USB 2.0 ports are connected to the mainboard via cable. The 5V outputs are

separately, electronically fused to 500mA each. Another two USB 2.0 ports are located on the mainboard.

10.1.8. Grounding Cable (PE)

Grounding Cable (PE)

Cross section: 6mm2

Cable color: Yellow/green

Connector: End sleeve

2

6.0mm

/12mm

Preliminary Version 0.2 49

Loading...

Loading...